Disperse dye composition as well as preparation method and application thereof

A technology of disperse dyes and compositions, applied in dyeing methods, organic dyes, textiles and papermaking, etc., can solve the problems of inability to remove polyester fiber oligomers, unsuitable for strong alkaline conditions, and high processing water consumption, and achieve sublimation fastness. Excellent temperature, good temperature dependence, and the effect of reducing water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

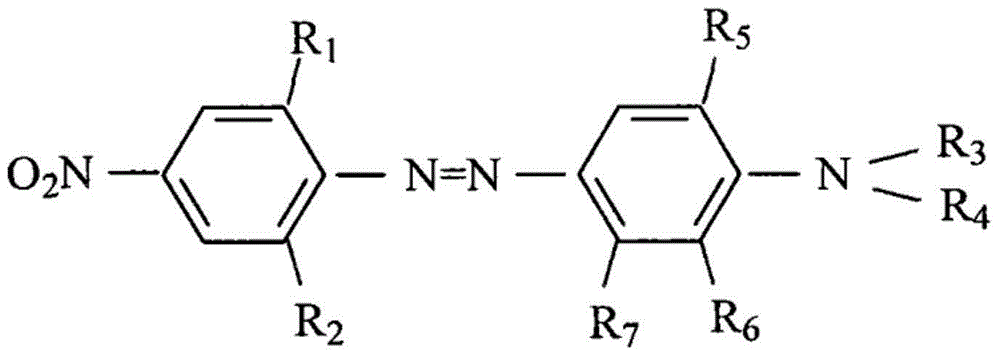

Method used

Image

Examples

Embodiment 1

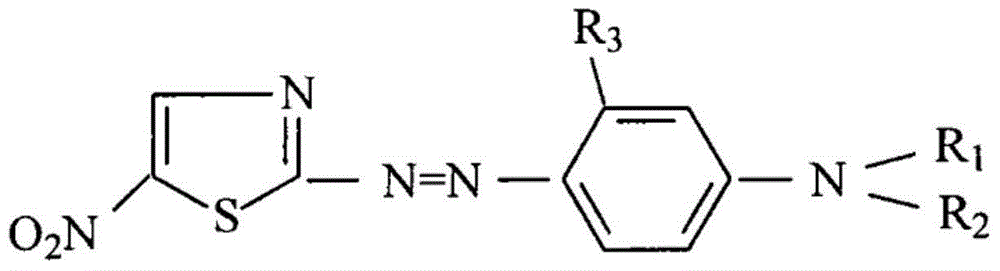

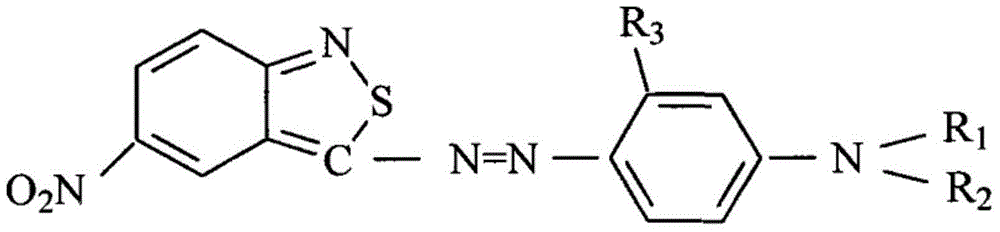

[0061] Add 100g of 98% concentrated sulfuric acid into a 500ml flask, control the temperature at 20°C, slowly add 0.128mol of 3-amino-5-nitrobenzoisothiazole, raise the temperature to 50°C and keep it for 60 minutes, then cool down to 5°C ~10°C, slowly add 0.128mol of nitrosyl sulfuric acid, keep the temperature at 5°C for 3 hours to obtain the diazo component. In another 2000ml flask, add 500ml of water, 10g of 2.5% sulfuric acid, a small amount of auxiliary agent and 0.128mol of N-ethyl-N-propylcyanide-m-methylaniline to obtain a coupling component. Add an appropriate amount of ice to the coupling component and lower it to 0°C, then add the diazo component, control the reaction at 0°C to 5°C until the diazo component disappears, and obtain component A.

[0062] Add 55 milliliters of sulfuric acid in the three-necked flask, dropwise add 13 grams (100%) of nitrosyl sulfuric acid, add 2-bromo-3-chloro-4,6-dinitroaniline 29.65 grams at room temperature, stir and react for 4 hour...

Embodiment 2

[0065] Take 80% of the component A obtained in Example 1, 20% of the component B obtained in Example 1, filter, wash with water, dry, and sand-mill together with the diffusing agent to obtain the disperse dye.

Embodiment 3

[0067] Take 60% of the component A obtained in Example 1, and 40% of the component B obtained in Example 1, filter, wash with water, dry, and sand with a dispersing agent to obtain a disperse dye.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com