Dyeing method of brocade and cotton blended fabric

A technology of blended fabrics and dyeing methods, applied in the field of fabric dyeing and finishing, can solve the problems of low fastness and color difference of nylon-cotton fabric dyeing, achieve deep dyeing, reduce the amount of dye, and shorten the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

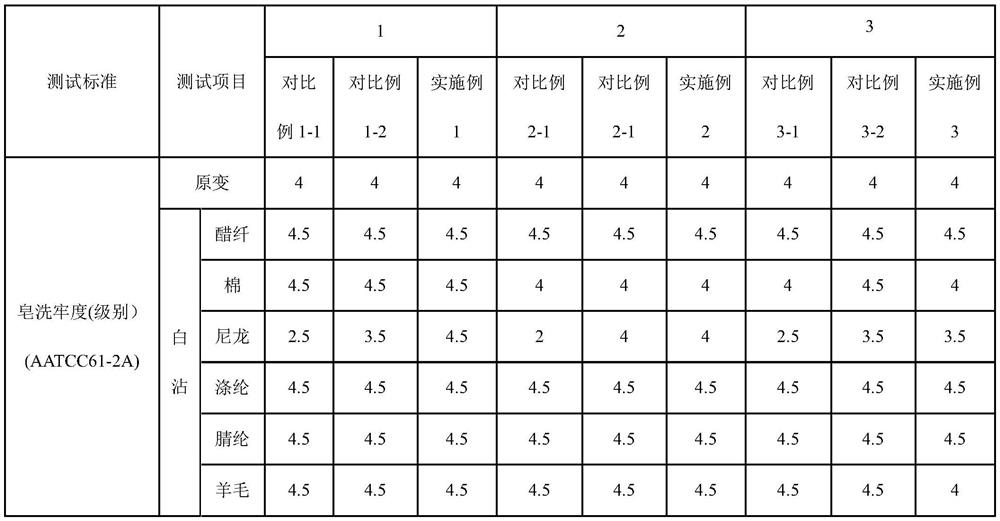

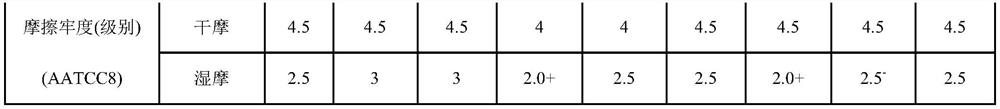

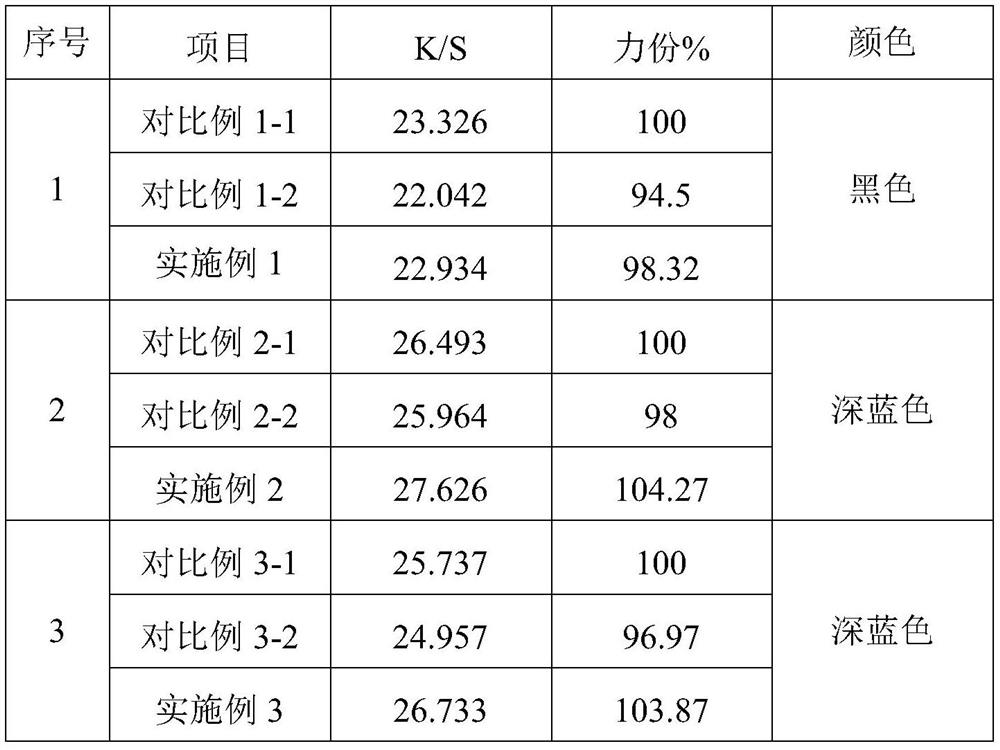

Embodiment 1

[0018] In the dyeing method for nylon-cotton blended fabric according to the present invention, the fabric is a nylon-cotton blended fabric, the specification is RSJC, 21XN100D+40D, 100×71, 52 / 53", the dyed fabric is black, and the dyeing process is as follows: Padding acid dyes) → pre-baking → padding acid vapor-solid liquid → steaming (100~102℃) → water washing → one soaping → water washing → ironing drying → rolling stock (padding reactive dyes) → pre-baking → padding Active vapor-solid solution (alkaline fixative)→steaming→water washing→secondary soaping→water washing→iron drying→finishing (padding solution)→drying.

[0019] The dyeing formula adopted in this embodiment is as follows:

[0020] Acid dye prescription: Lanner free and easy black B71.25g / L, PA yellow 3.75g / L, anti-migration agent TX5g / L;

[0021] Reactive dye prescription: reactive black GNB40g / L, reactive red SHE0.35g / L, reactive yellow SNE2.4g / L, anti-migration agent TX5g / L;

[0022] The formula of the soa...

Embodiment 2

[0031] In the dyeing method for nylon-cotton blended fabric according to the present invention, the fabric is a nylon-cotton blended fabric, the specification is RSJC, 21XN100D+40D100×71, 52 / 53", the dyed fabric is dark blue, and the dyeing process is as follows: Padding acid dyes)→pre-baking→padding acid vapor-solid liquid→steaming (100~102℃)→water washing→one soaping→water washing→iron drying→rolling material (padding reactive dyes)→pre-baking→padding activity Steam-solid solution (alkaline fixative)→steaming→water washing→secondary soaping→water washing→iron drying→finishing (padding solution)→drying.

[0032] The dyeing formula adopted in this embodiment is as follows:

[0033] Acid dye prescription: Lanna Free Blue 2R76g / L, Lanna Free Black B 24g / L, Anti-migration agent TX5g / L;

[0034] Reactive dye prescription: reactive blue SNE 68g / L, reactive sea blue WNE 17g / L, anti-migration agent TX5g / L;

[0035] The formula of the soaping liquid during the first soaping of the p...

Embodiment 3

[0044] In the dyeing method for nylon-cotton blended fabric according to the present invention, the fabric is a nylon-cotton blended fabric, the specification is RSJC, 21XN100D+40D100×71, 52 / 53", the dyed fabric is dark blue, and the dyeing process is as follows: Padding acid dyes)→pre-baking→padding acid vapor-solid liquid→steaming (100~102℃)→water washing→one soaping→water washing→iron drying→rolling (padding reactive dyes)→pre-baking→padding activity Steam-solid solution (alkaline fixing agent)→steaming→water washing→secondary soaping→water washing→iron drying→finishing (padding solution)→drying.

[0045] The dyeing formula adopted in this embodiment is as follows:

[0046]Acid dye prescription: Lanner Free Blue 2R 53g / L, Navy Blue R 32g / L, PA Yellow 15g / L, Anti-migration agent TX5g / L;

[0047] Reactive dye prescription: reactive blue SNE 68g / L, reactive sea blue WNE 17g / L, anti-migration agent TX5g / L;

[0048] The formula of the soaping liquid during one soaping of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com