Foam forming die for soft sealing of parting surfaces

A foam molding and parting surface technology, which is applied to household appliances, other household appliances, household components, etc., to achieve good sealing effect, beautiful appearance, and improve product qualification rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

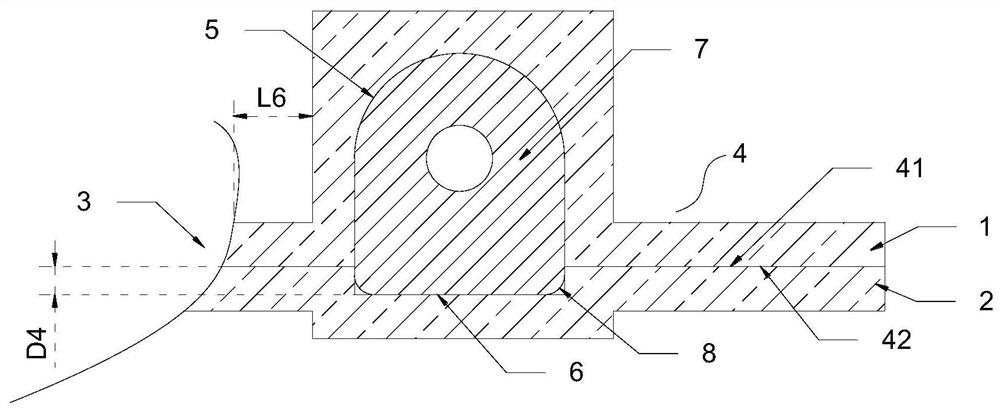

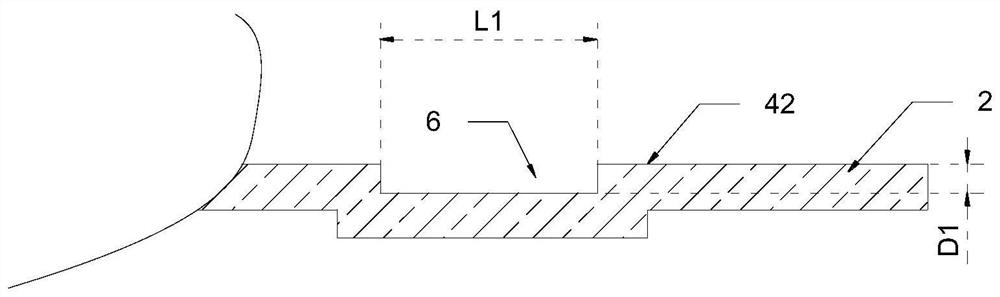

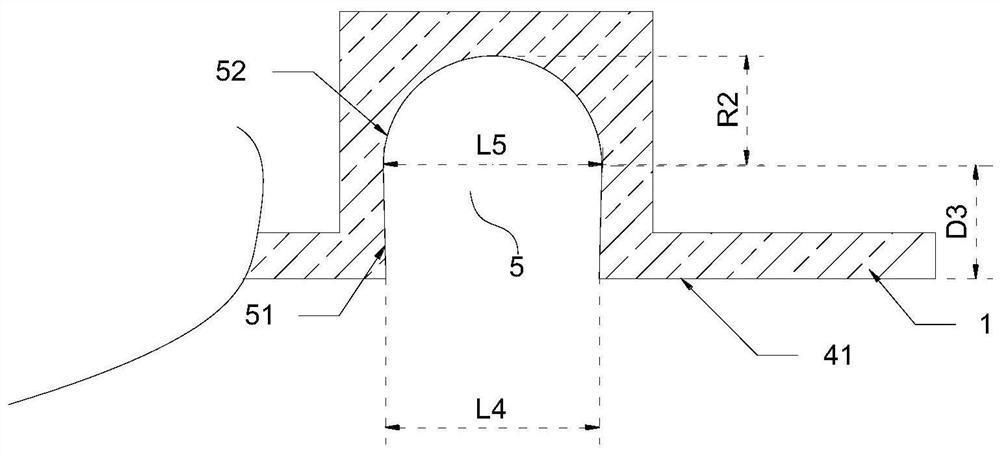

[0036] A foam molding mold with 4 soft seals on the parting surface, see Figure 1~4, comprising an upper mold 1 and a lower mold 2, the upper mold 1 and the lower mold 2 are closed to form a mold, the mold is provided with a cavity 3 and a parting surface 4 to be processed, and the parting surface 4 is arranged on Around the cavity 3, the parting surface 4 includes the parting surface 4 of the upper mold 1 and the parting surface 4 of the lower mold 2, and the parting surface 4 of the upper mold 1 is bonded to the parting surface 4 of the lower mold 2 The cavity formed inside the rear mold is the cavity 3, and a U is set at a position 3 to 5 mm (L6) preset from the boundary line between the parting surface 4 and the cavity 3 on one of the parting surfaces 4. type groove 5, another said parting surface 4 is provided with an air groove 6, the position of said air groove 6 corresponds to said U-shaped groove 5, and said air groove 6 and said U-shaped groove 5 are combined to for...

Embodiment 2

[0041] Embodiment 2 parameter optimization

[0042] According to the previous analysis, the depth of the air groove, the pressure of the air bag and the sealing method of the parting surface are potentially important factors affecting the length of the flash. More detailed parameter optimization was carried out through further univariate analysis and DOE (DESIGN OF EXPERIMENT) experiments, and the data were analyzed by 2sample t test. The flash length is measured using a vernier caliper.

[0043] 1. Depth of air groove

[0044] The depth of the air groove determines the size of the passage where the foaming material overflows the mold to form flash. If the passage is too large, the foaming raw material may overflow a large amount of raw materials through the air groove, resulting in abnormal product quality; lead to product shortage. Therefore, comparative experiments were carried out using 0.5mm air grooves and 1mm air grooves respectively. Each produces 30 pieces of auto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com