Pressing die for continuous pattern on surface of thin-walled metal shell of cup or kettle

A metal shell, pressing mold technology, applied in decorative arts, embossed ornaments and other directions, can solve the problems of immature technology, inability to mass production, metal shell out of round, etc., to achieve high product qualification rate, long service life, ensure the overall sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

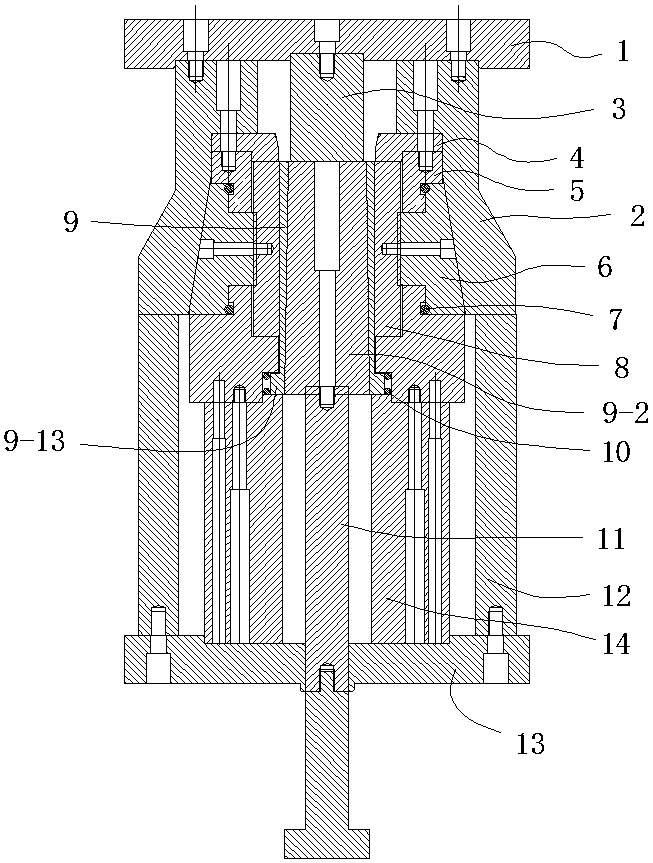

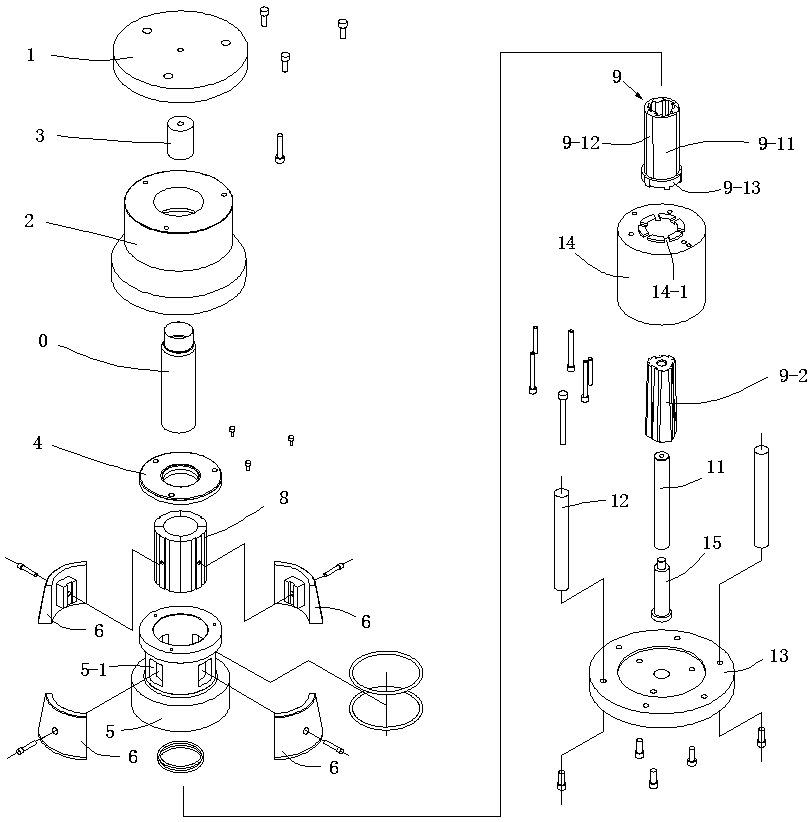

[0043] In order to make the technical solution of the present invention clearer, the following in conjunction with the attached Figures 1 to 24 , the present invention will be described in detail. It should be understood that the specific implementations described in this specification are only for explaining the present invention, and are not intended to limit the protection scope of the present invention.

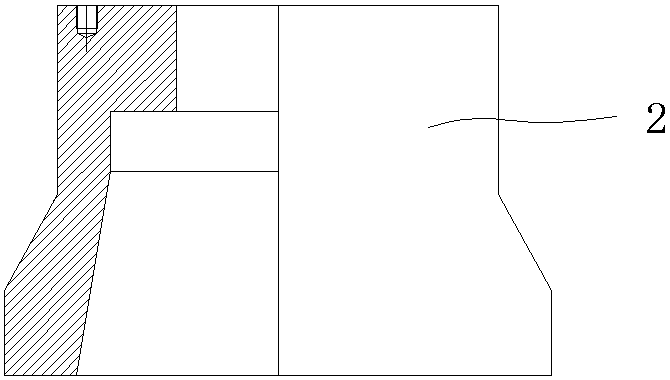

[0044]The present invention is a pressing mold with continuous patterns on the surface of a thin-walled metal shell of a cup or pot, comprising an upper mold force positioning assembly, a lower mold positioning assembly, and a force positioning assembly located between the upper mold force positioning assembly and the lower mold positioning assembly The die assembly and punch assembly for pressing continuous patterns on the surface of a thin-walled metal shell, the upper die force positioning assembly includes a clamping ring 2 fixed under the upper bottom plate 1; the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com