Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53results about How to "Improve cleaning and drying efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

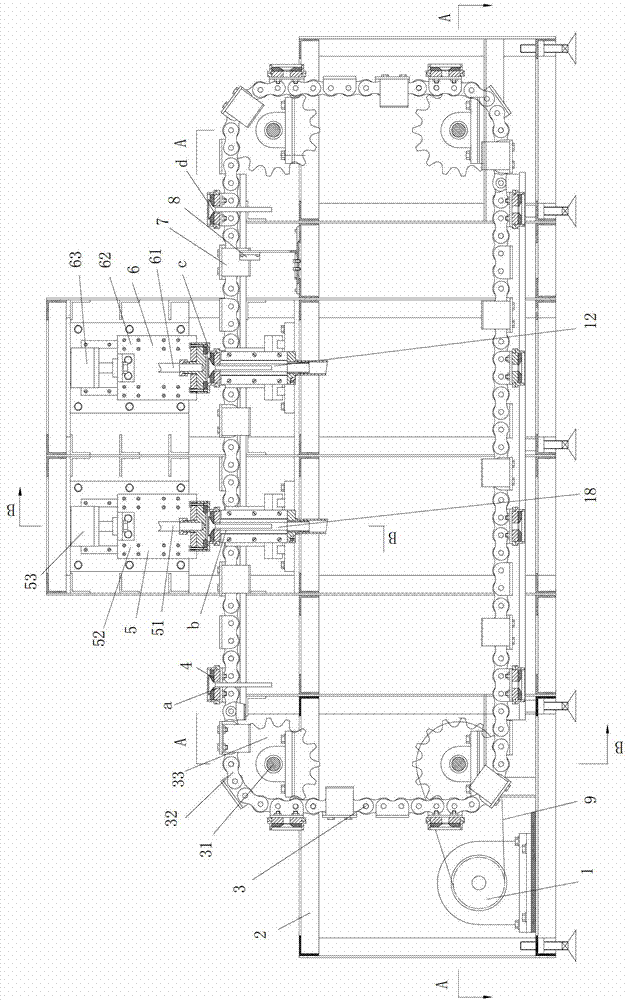

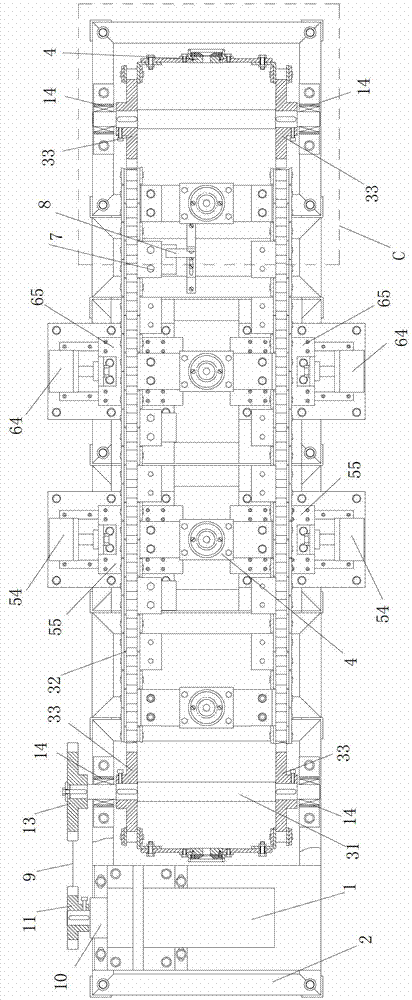

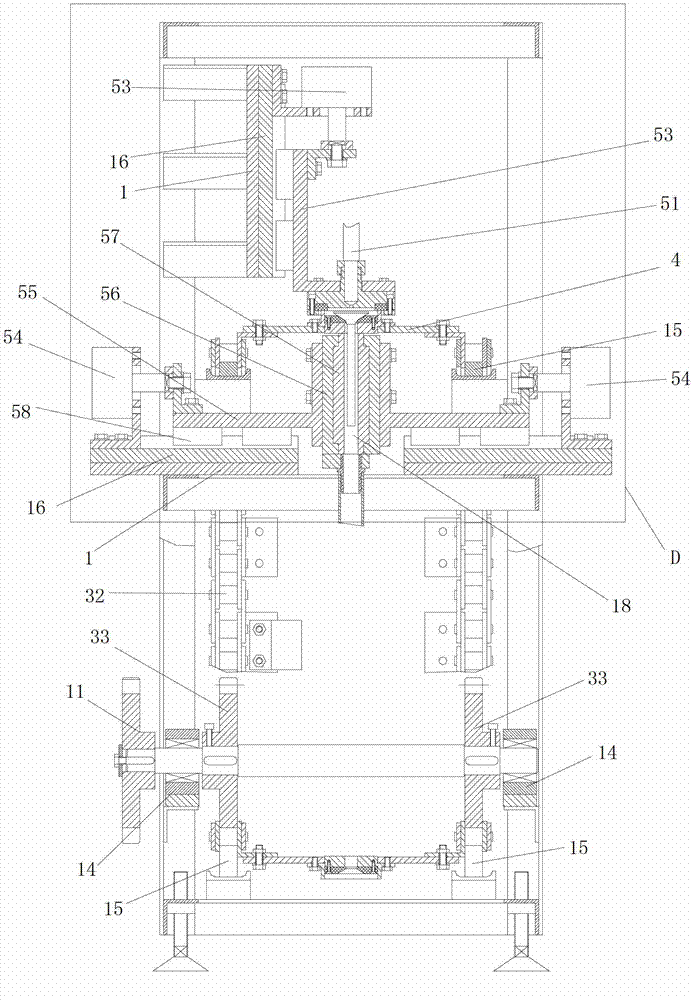

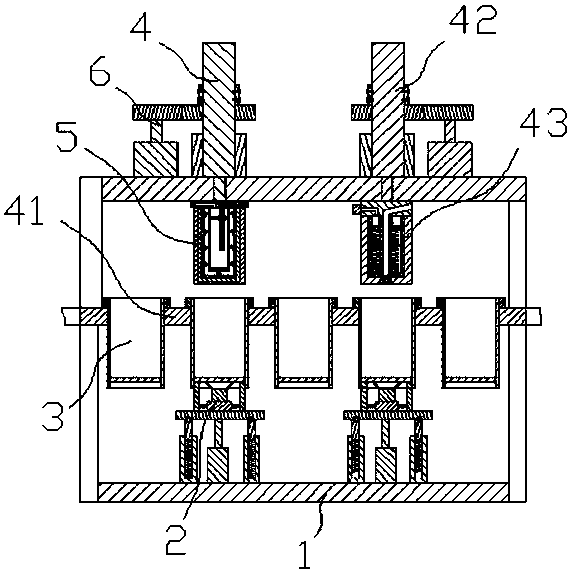

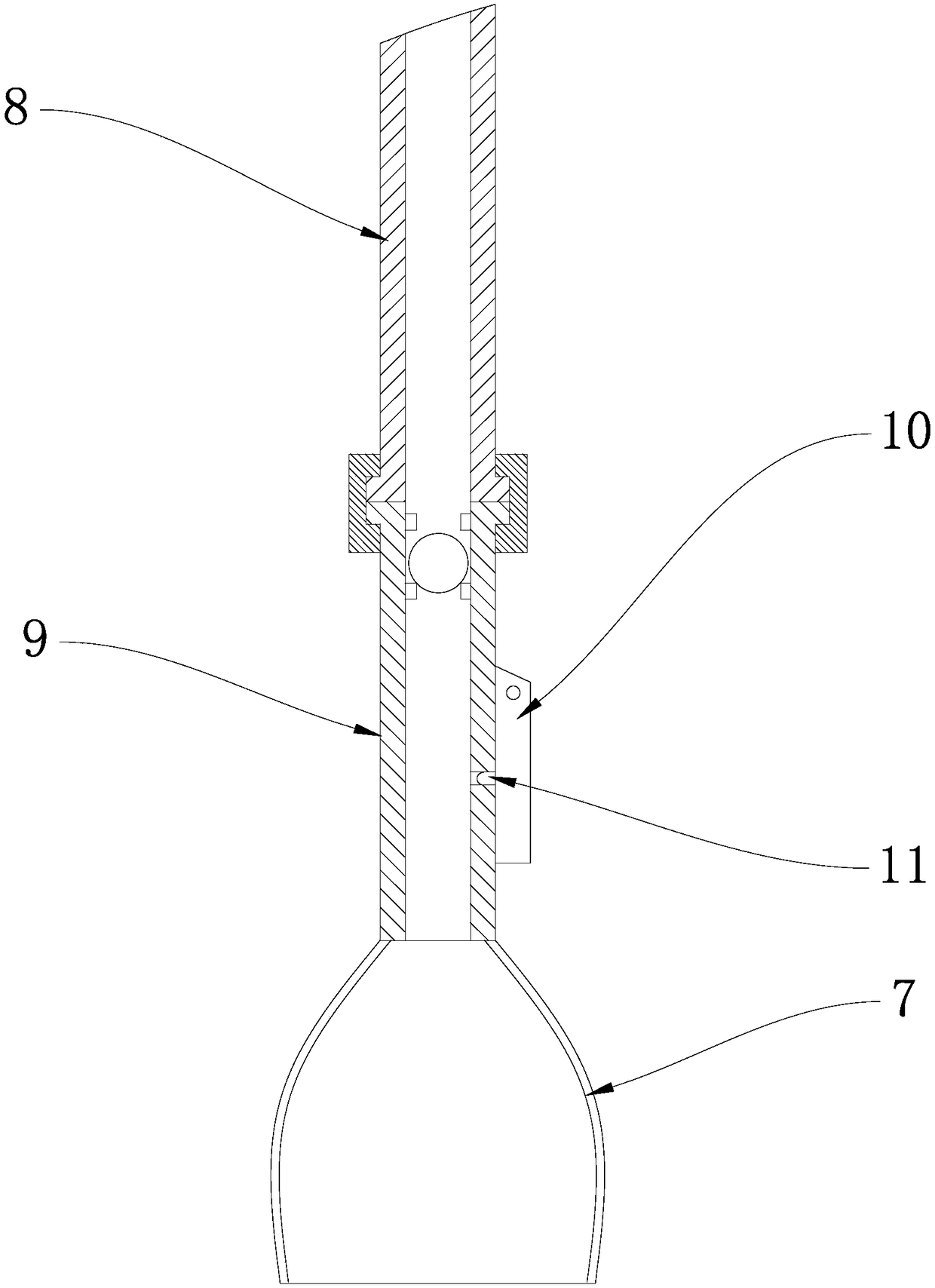

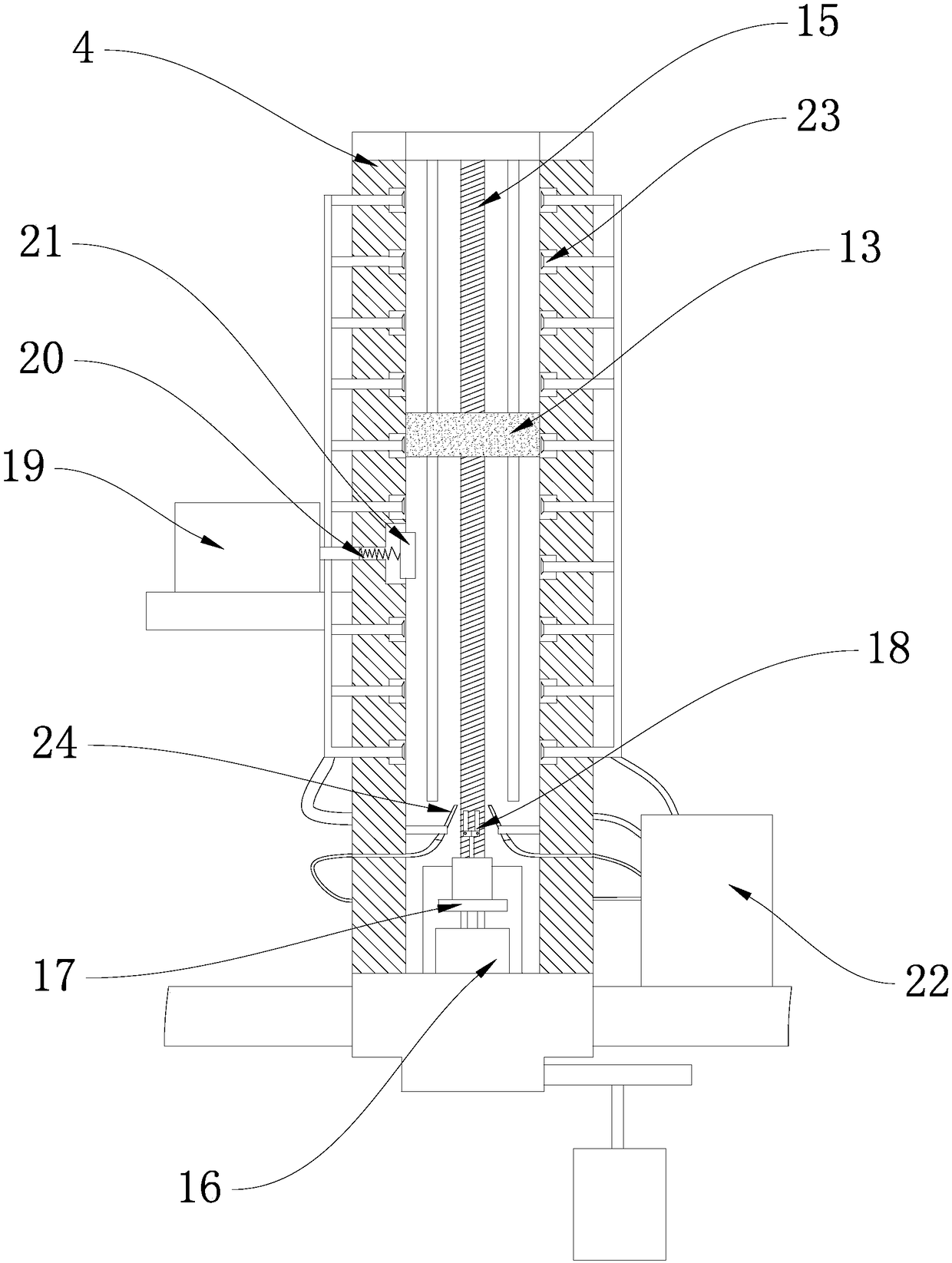

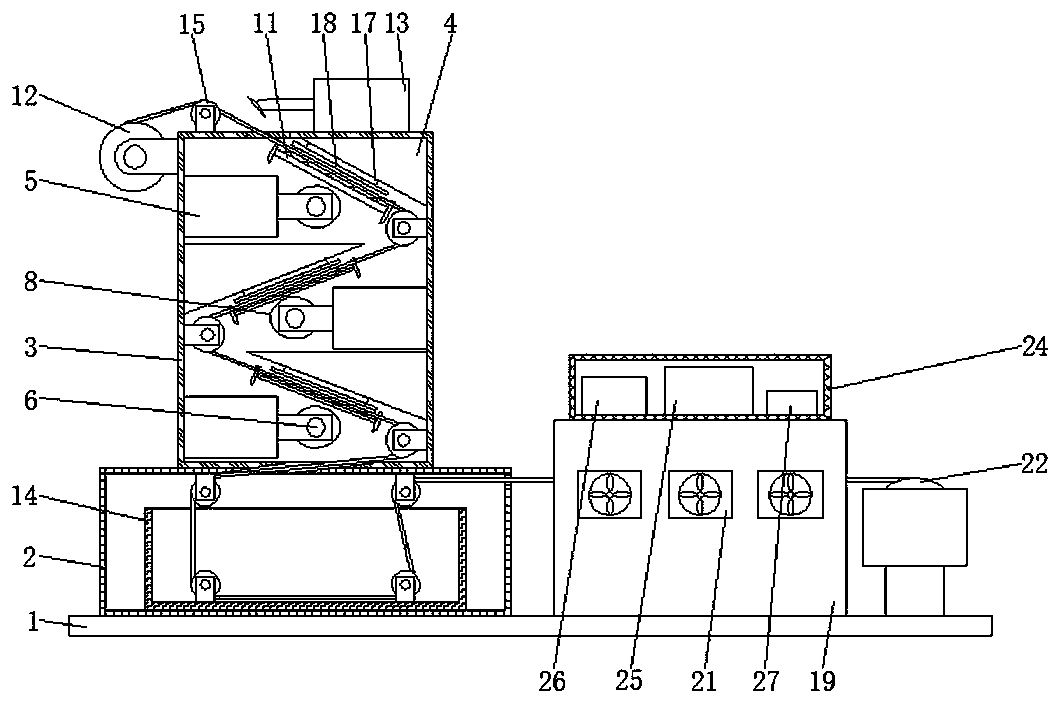

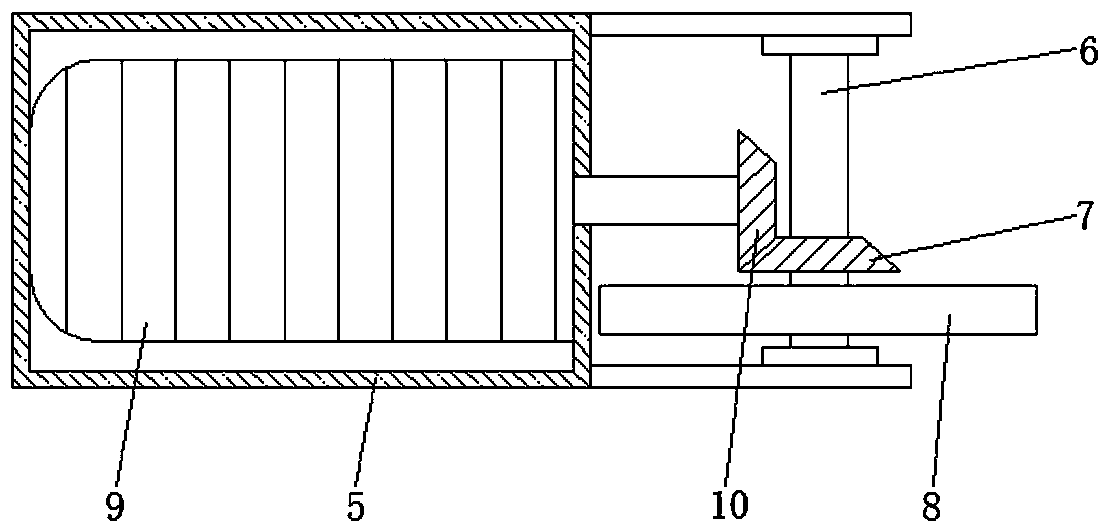

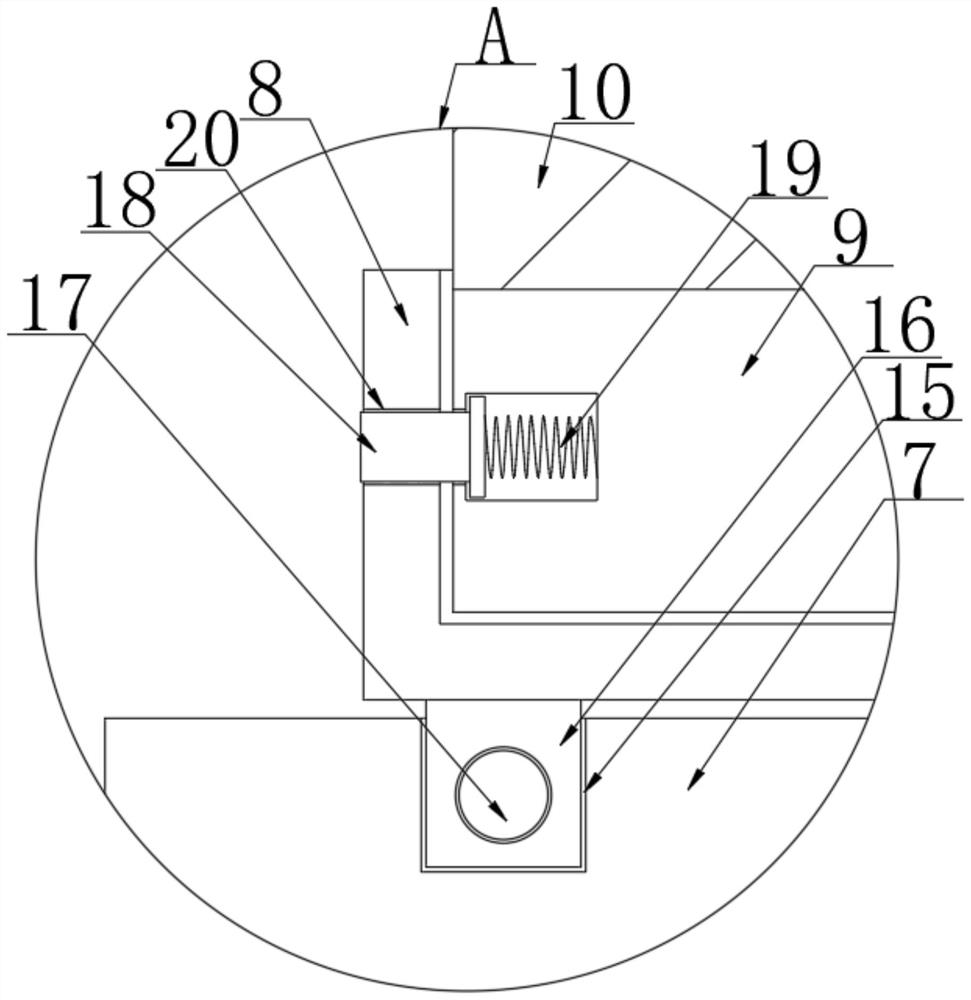

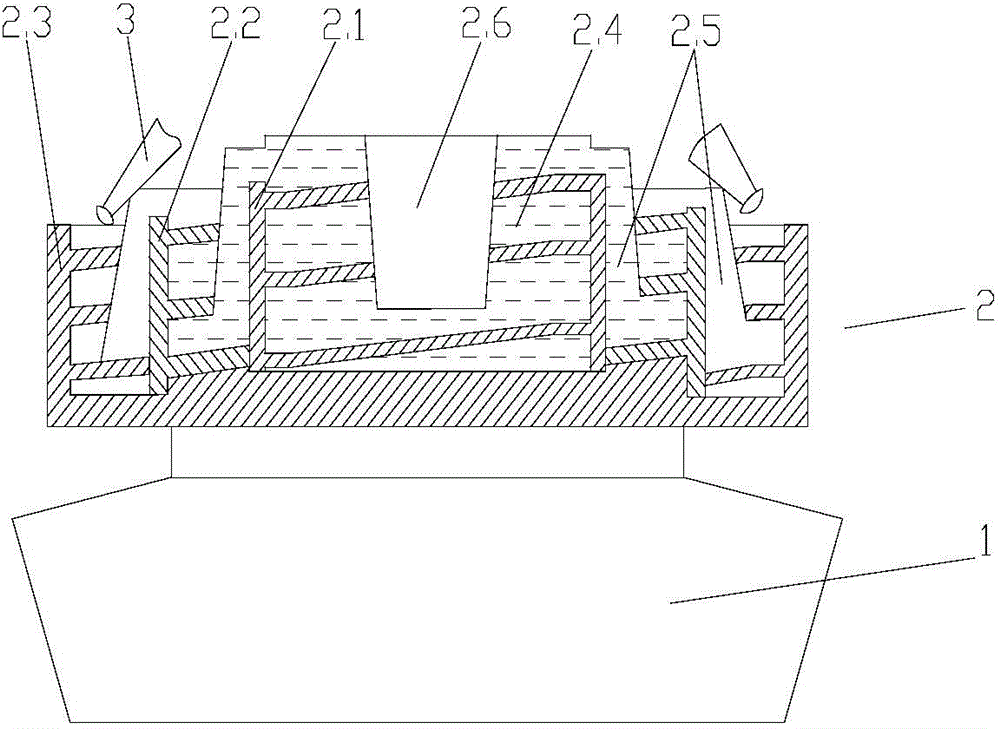

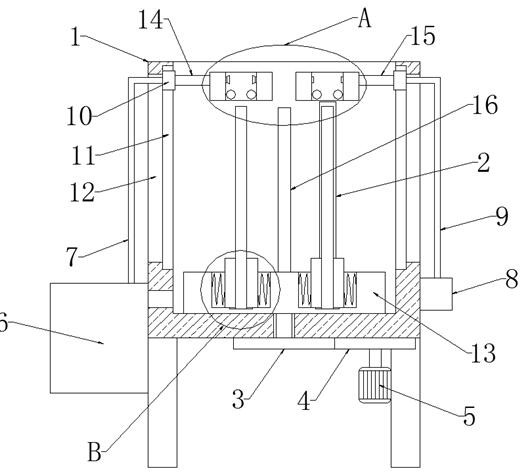

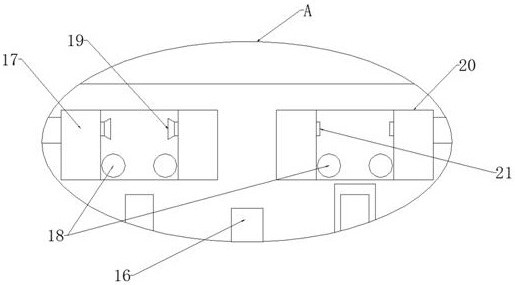

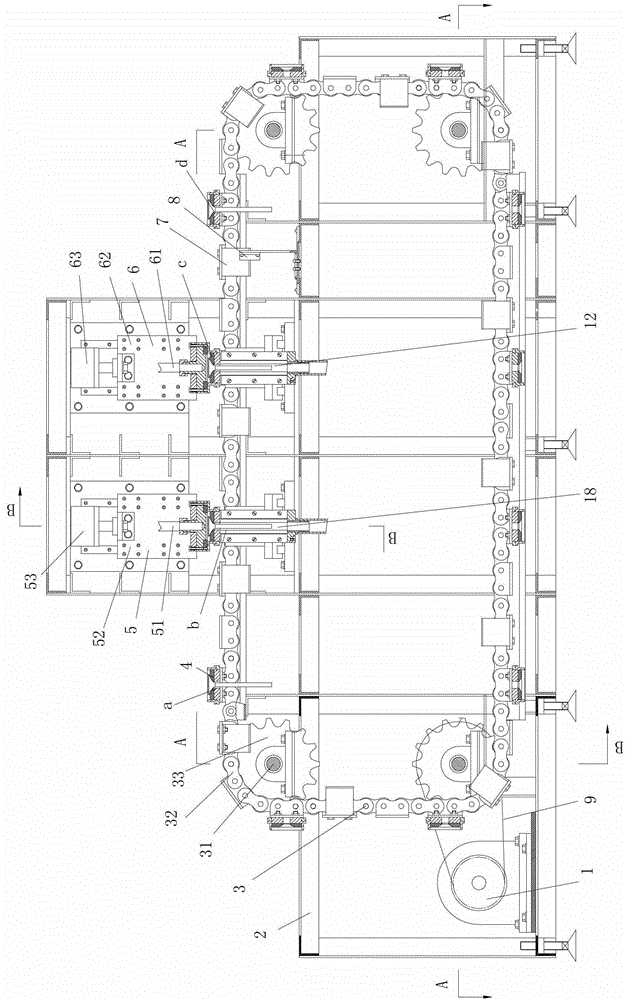

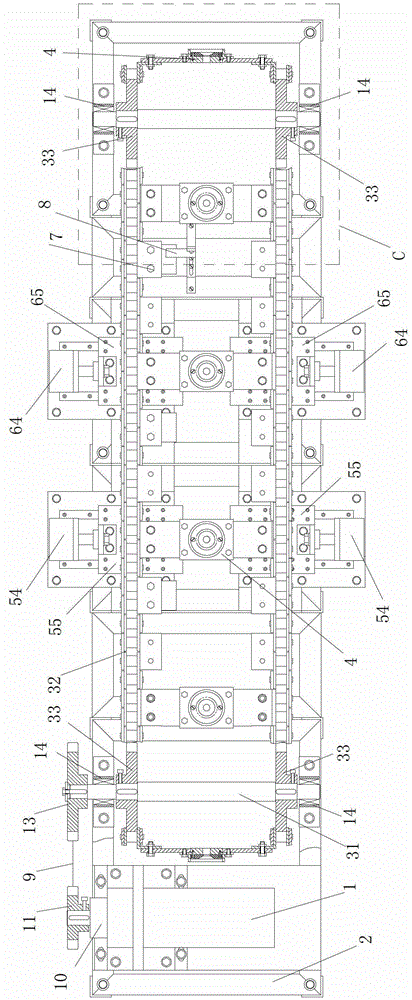

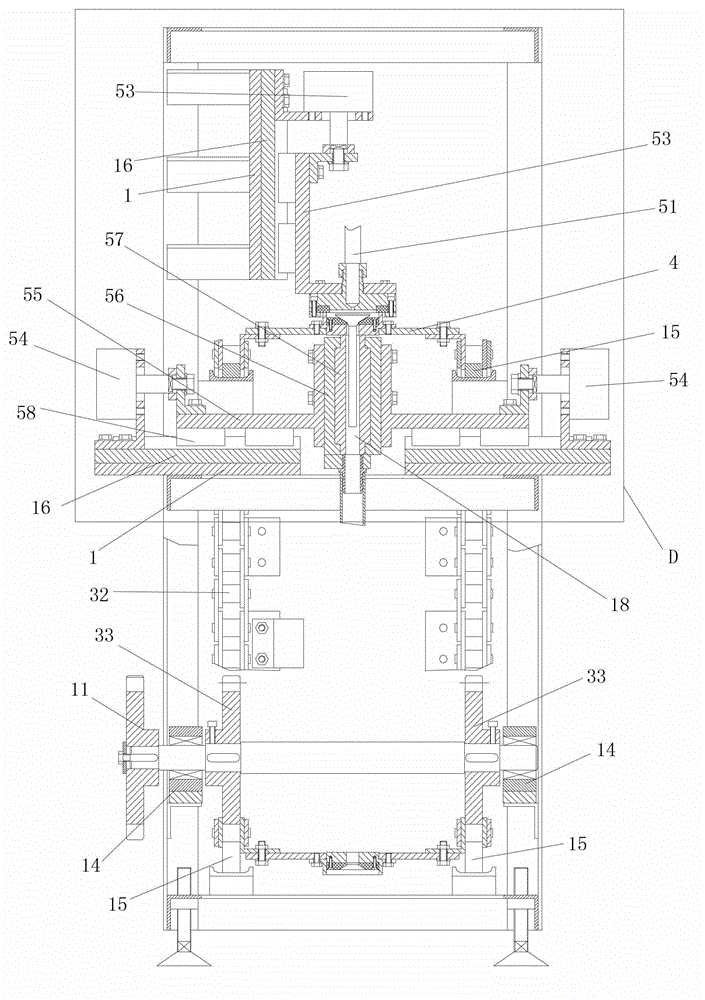

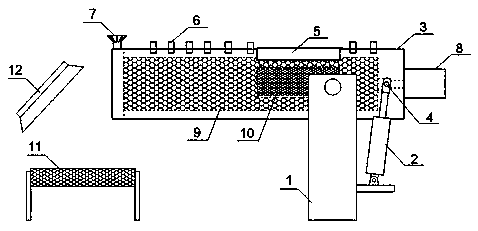

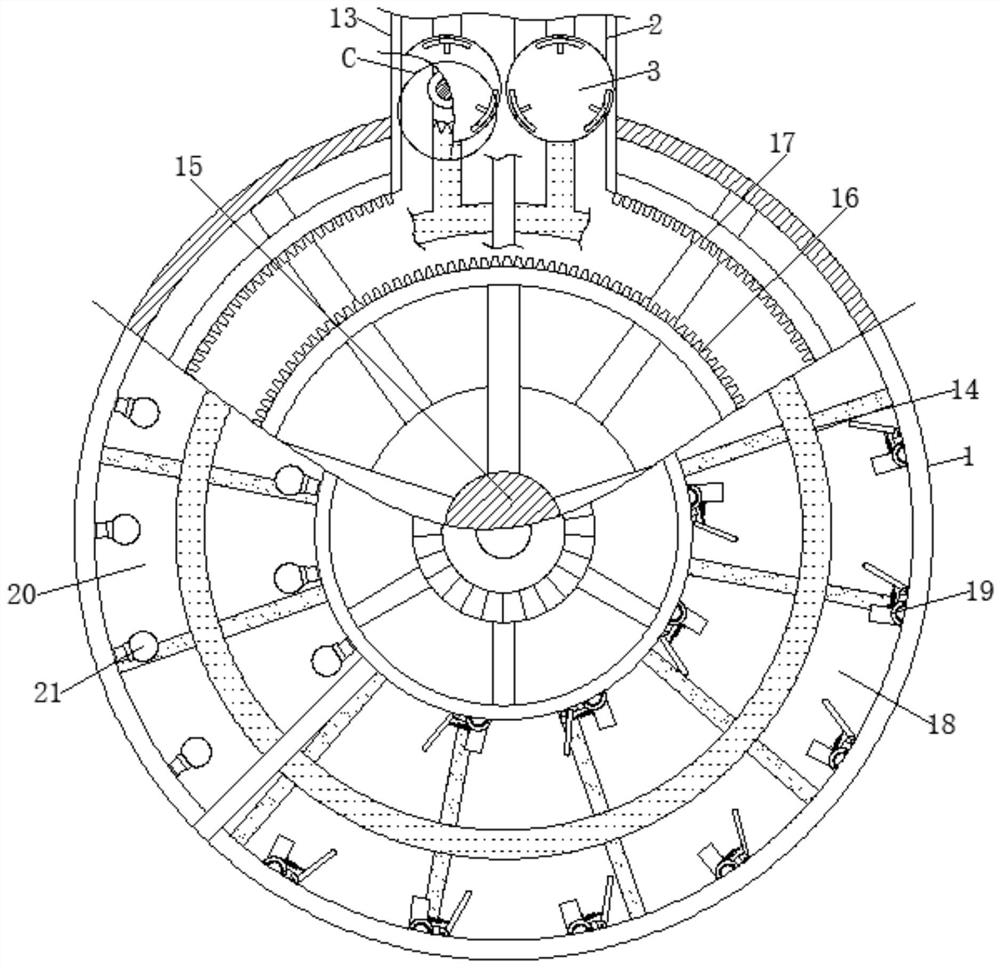

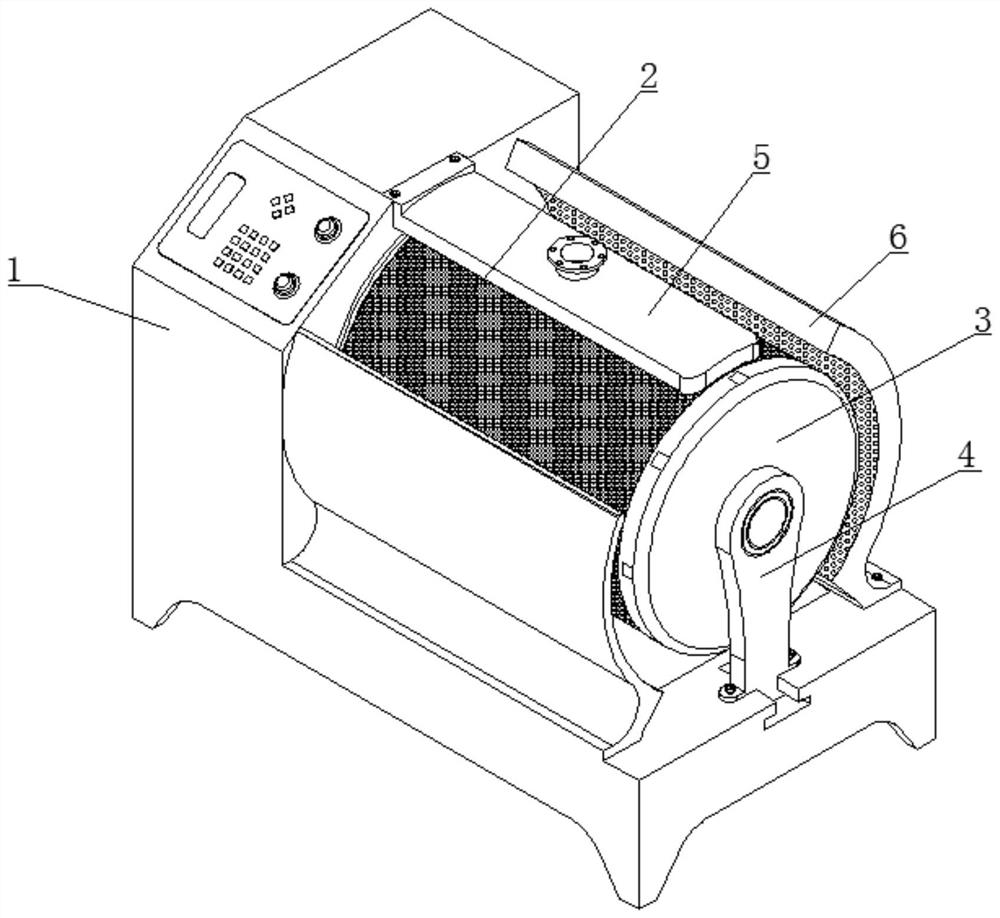

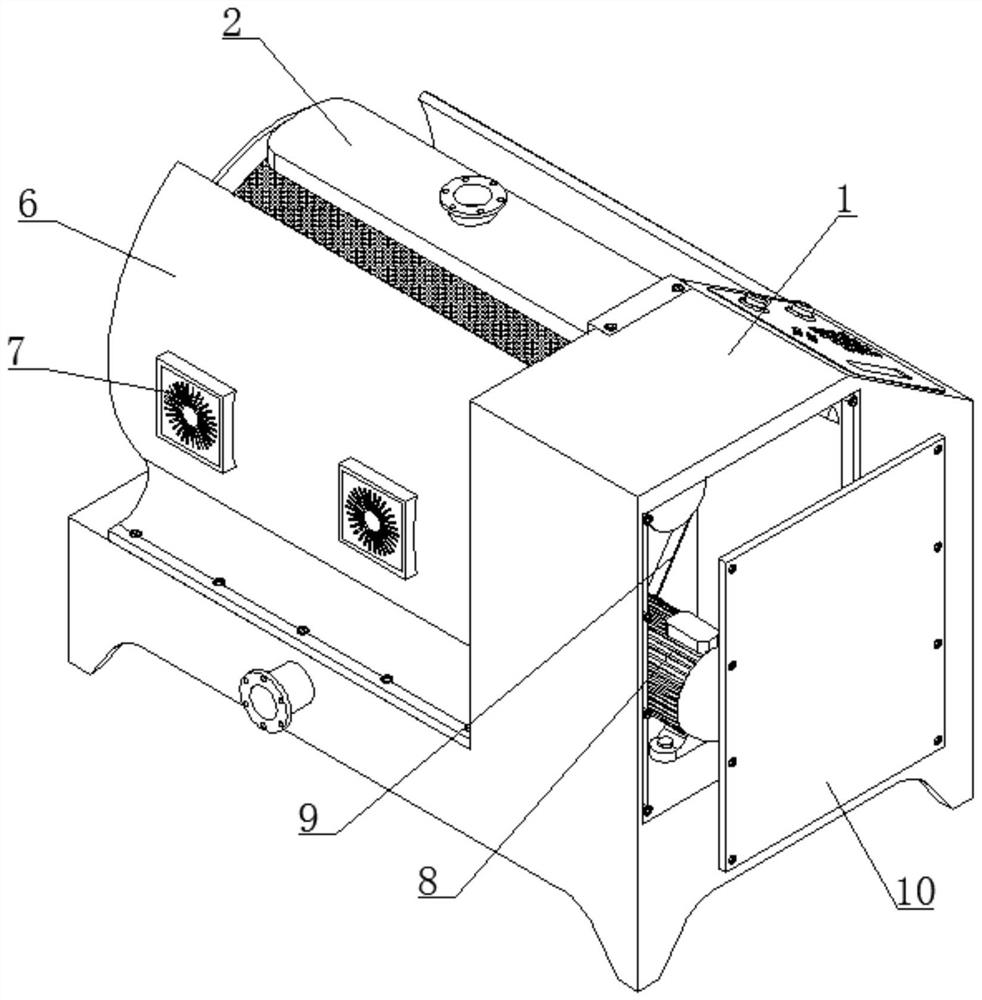

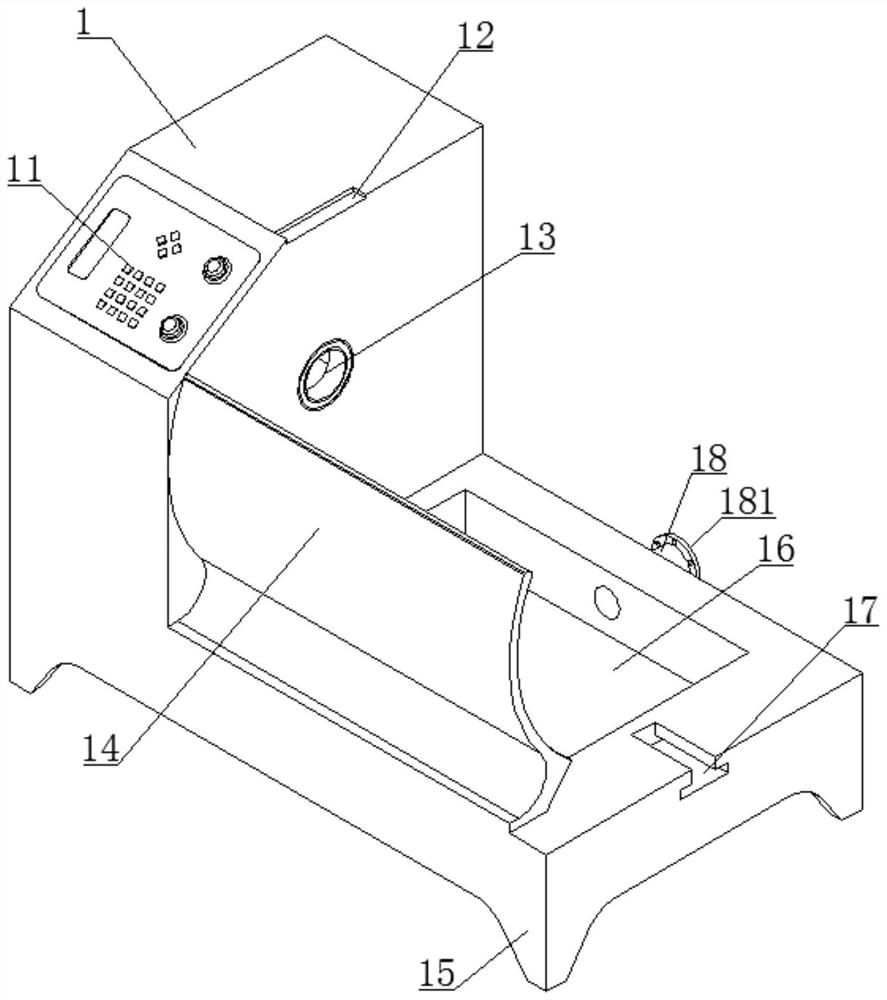

Automatic cleaning and drying device for air valve

InactiveCN102886358AEasy to cleanThere will be no dirty cleaningDrying gas arrangementsDrying machines with local agitationEngineeringMechanical engineering

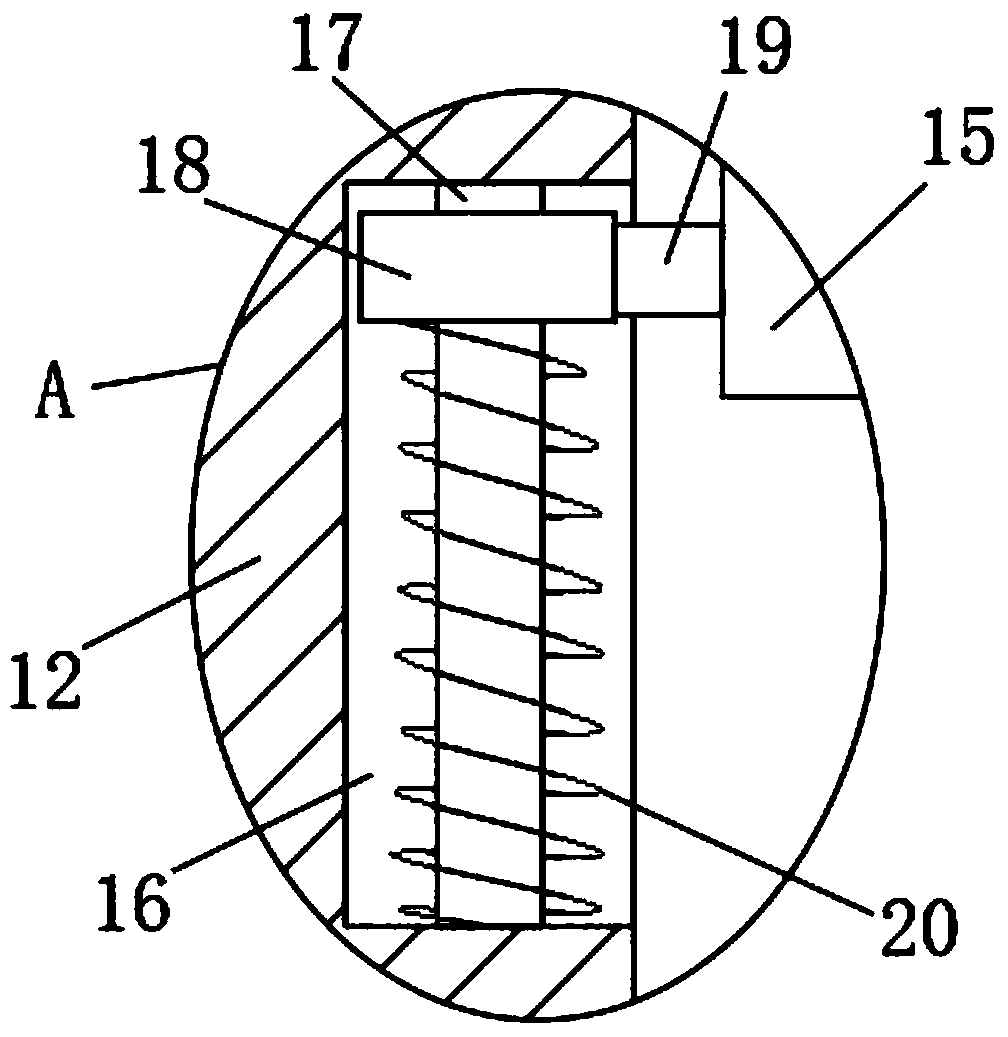

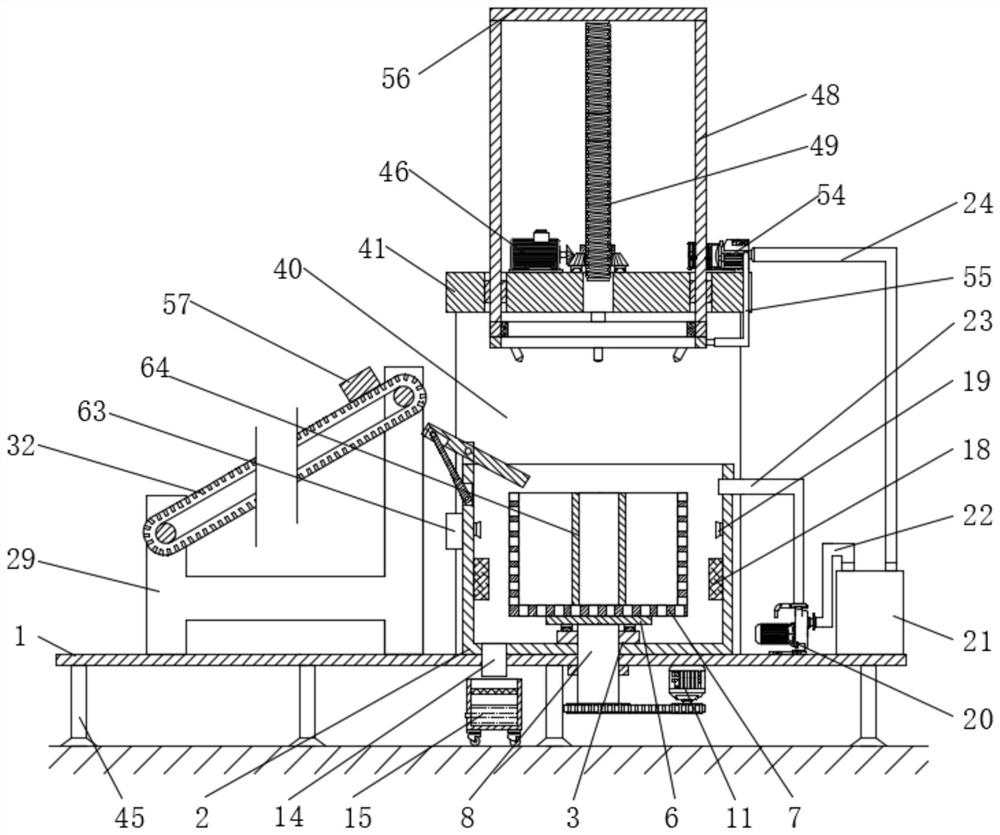

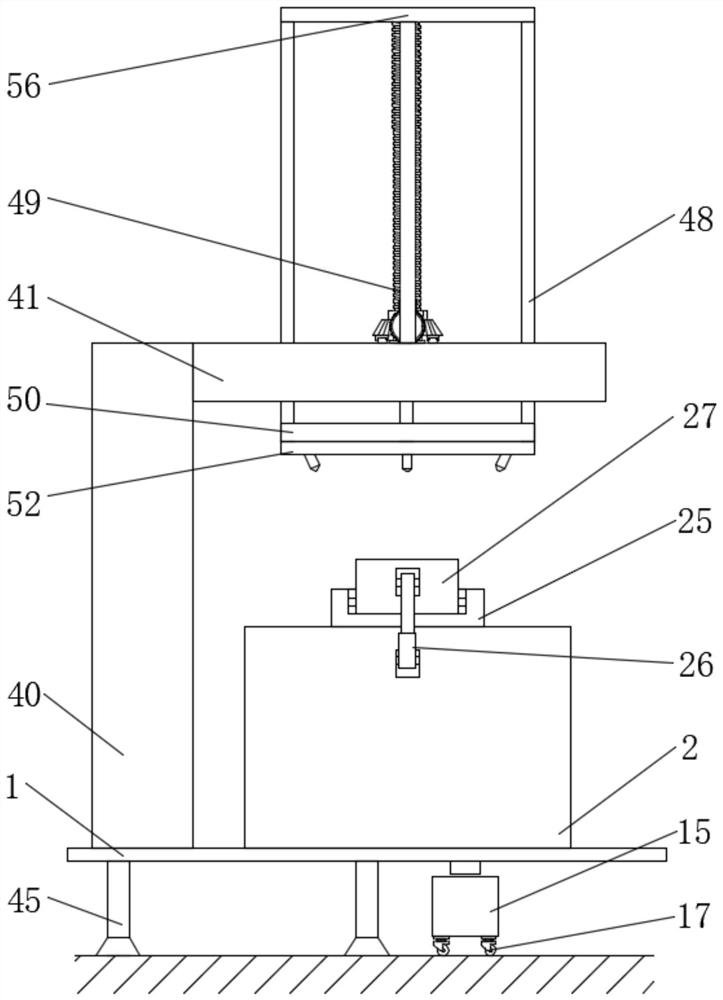

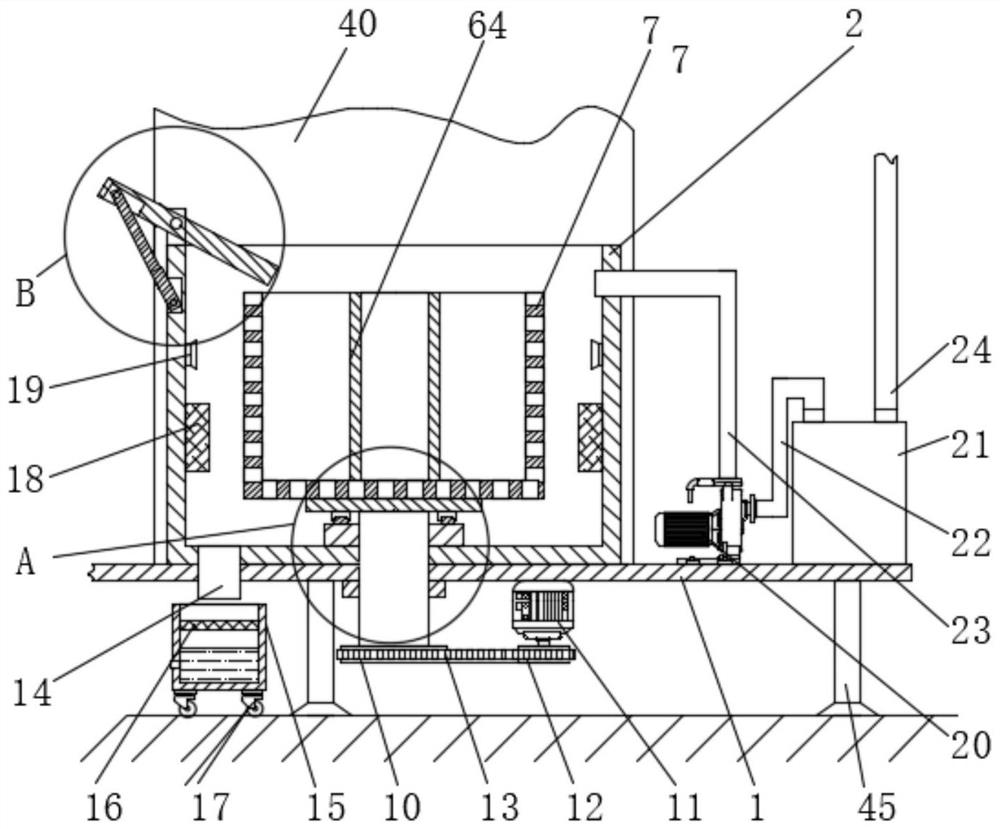

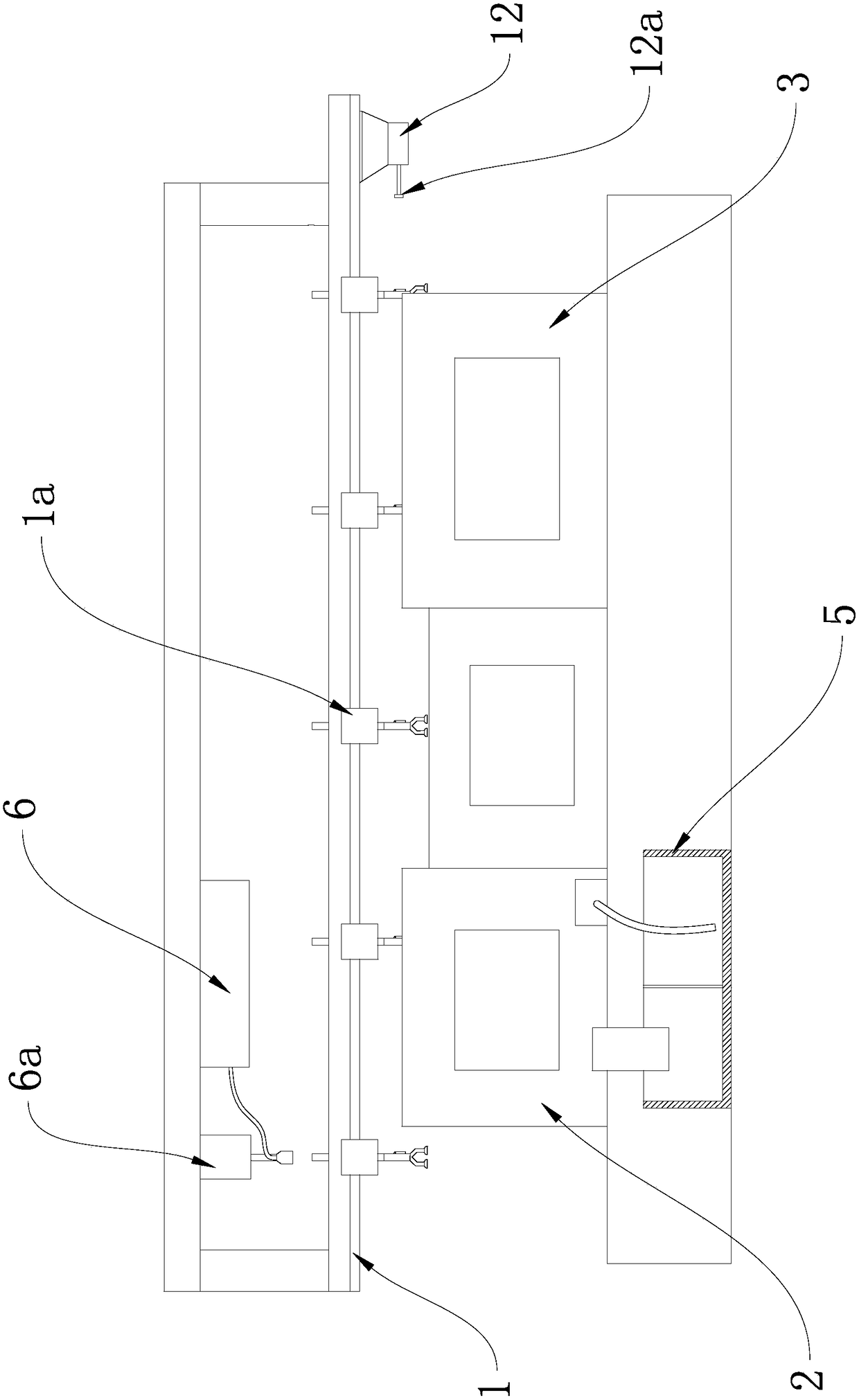

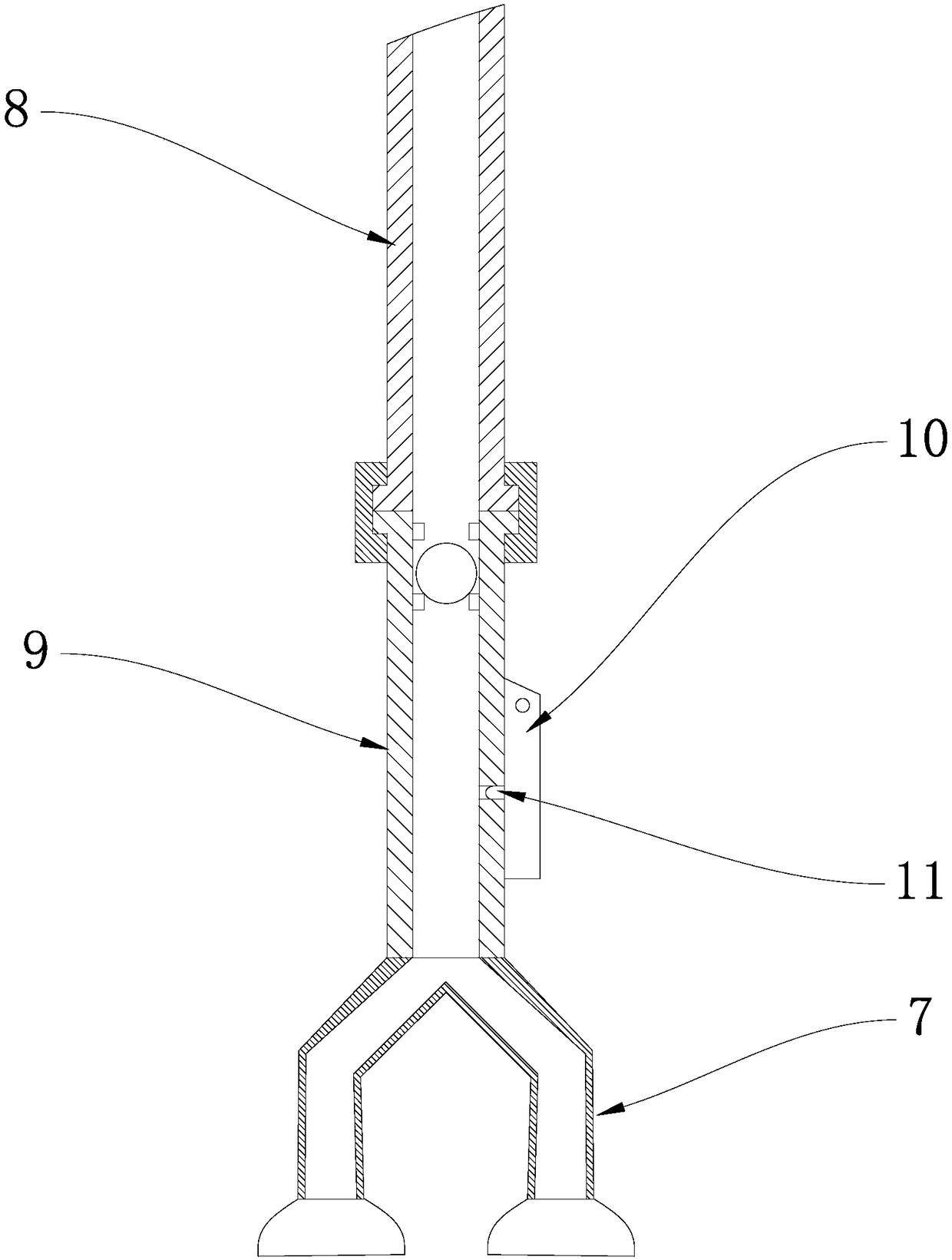

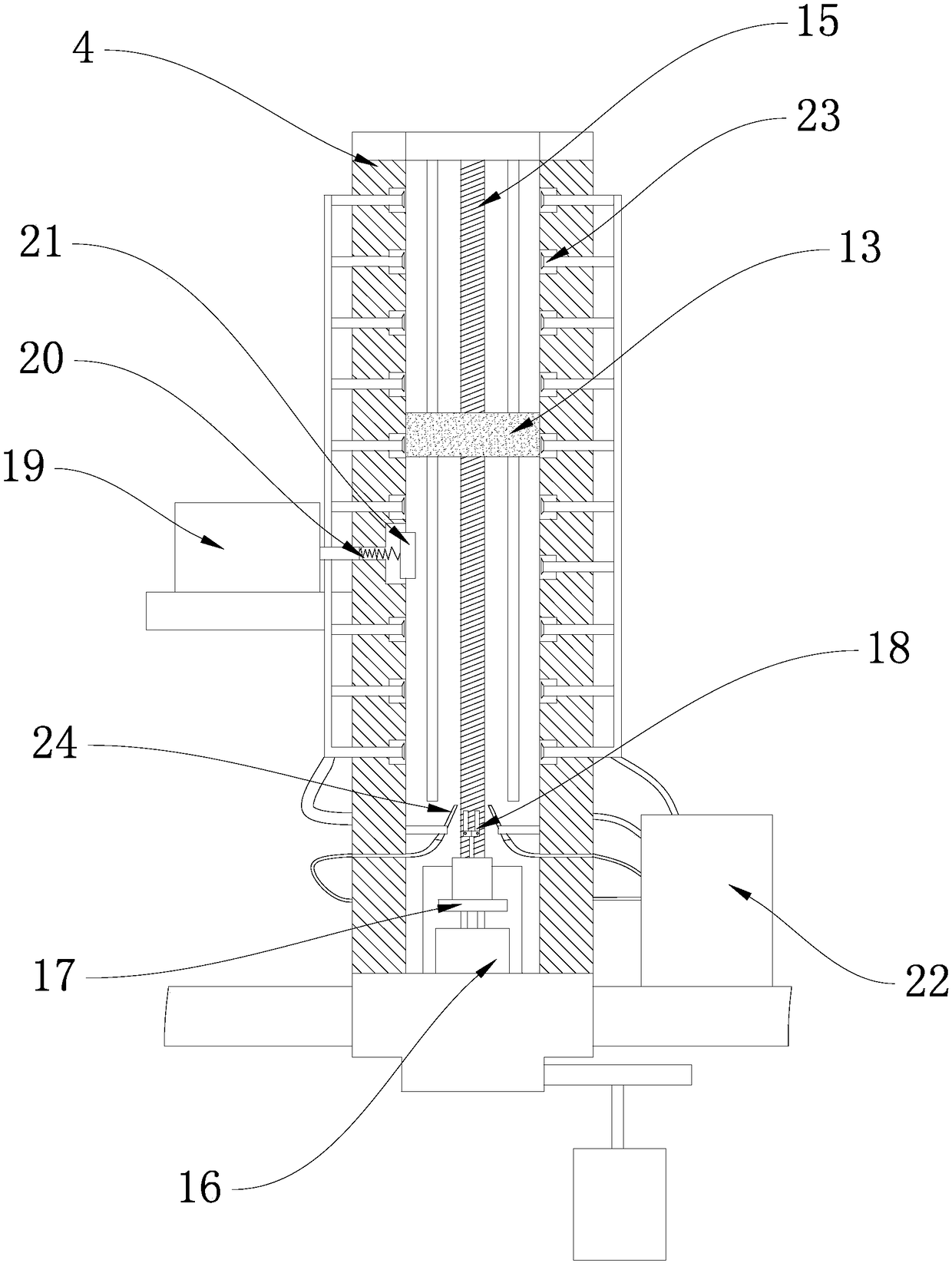

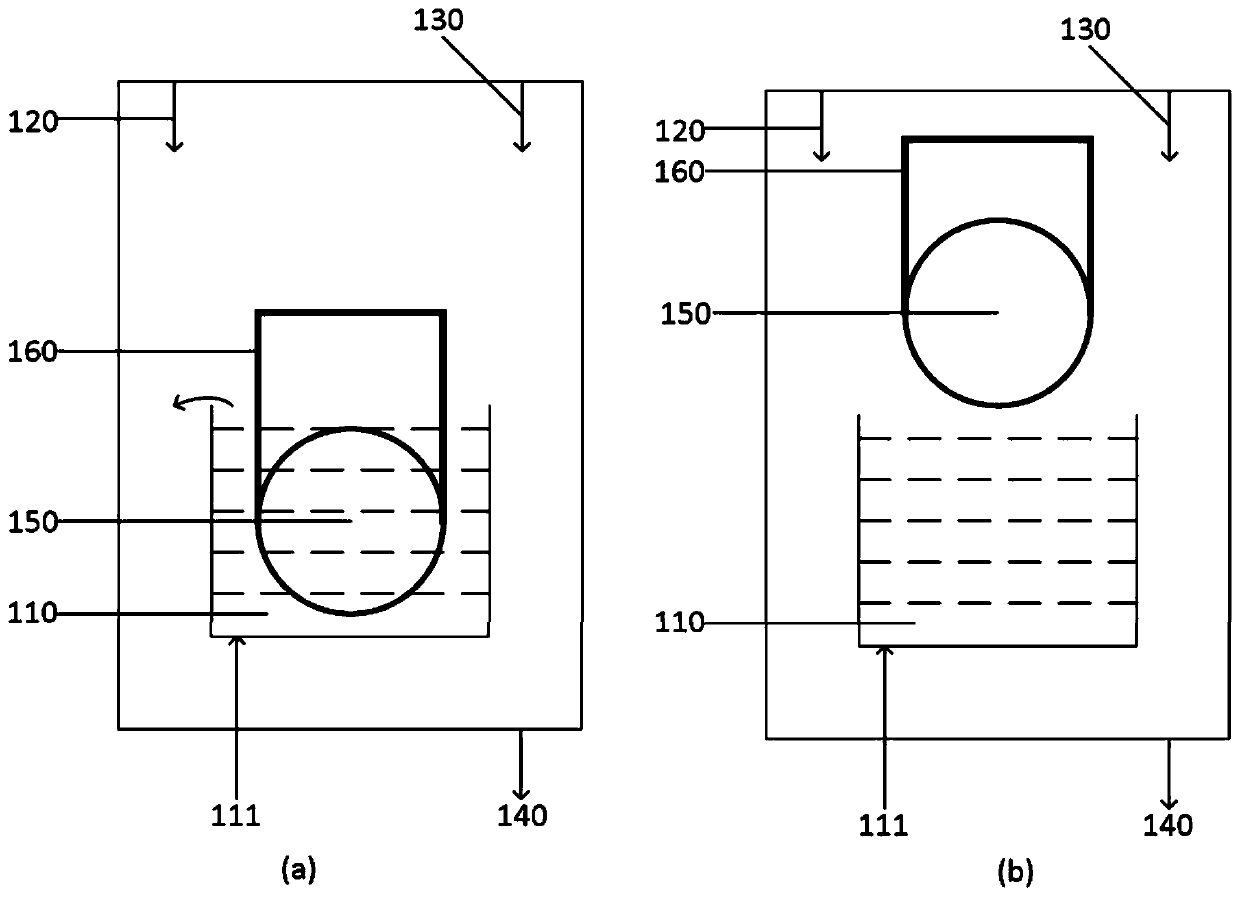

The invention discloses an automatic cleaning and drying device for an air valve. The automatic cleaning and drying device comprises a motor, a stander, a transmission mechanism, at least one air valve conveying seat, a cleaning mechanism, a drying mechanism and a control device. According to the automatic cleaning and drying device, the air valve is arranged in the air valve conveying seat; the air valve conveying seat with the air valve is sequentially conveyed to a cleaning position and a drying position through the transmission mechanism; then the control device controls the cleaning mechanism and the drying mechanism to act; and therefore, the air valve is automatically cleaned and dried. By the automatic cleaning and drying device, the labor intensity is reduced and the efficiency of cleaning and drying the air valve is improved. Furthermore, by the automatic cleaning and drying device, the intelligent degree is improved, so that a batch of air valves can be cleaned and dried efficiently, and the accuracy of an air valve detection result is guaranteed.

Owner:SOUTH CHINA UNIV OF TECH

Cleaning equipment for agricultural product processing

InactiveCN108499970AImprove cleaning efficiencyImprove filtering effectDrying gas arrangementsCleaning using liquidsEngineeringProduct processing

The invention discloses cleaning equipment for agricultural product processing, and relates to the field of agriculture. The cleaning equipment comprises supporting legs, a box body is welded on the surfaces of the supporting legs, first bead grooves are formed in the inner wall of the box body, and round beads are slidably connected to the inner walls of the first bead grooves; limiting grooves are formed in the inner wall of the box body, connecting blocks are slidably connected to the inner walls of the limiting grooves, and first threaded rods are welded to the surfaces of the connecting blocks; and a water tank cleaning mechanism is arranged on the box body in a penetrating mode, a lifting and rotating mechanism is arranged on the box body in a penetrating mode, and a drying mechanismis arranged on the box body in a penetrating mode. According to the cleaning and drying equipment for agricultural product processing, the water tank cleaning mechanism and the drying mechanism are arranged on the same machine, and furthermore, the lifting and rotating mechanism is used for assisting in lifting and rotating, so that the effect of improving the efficiency of cleaning and drying agricultural products is achieved, and then the problems that a common mechanical device is relatively single in function, the processing time is relatively long, and the working efficiency is influenced to a certain extent are effectively solved.

Owner:雷秀泗

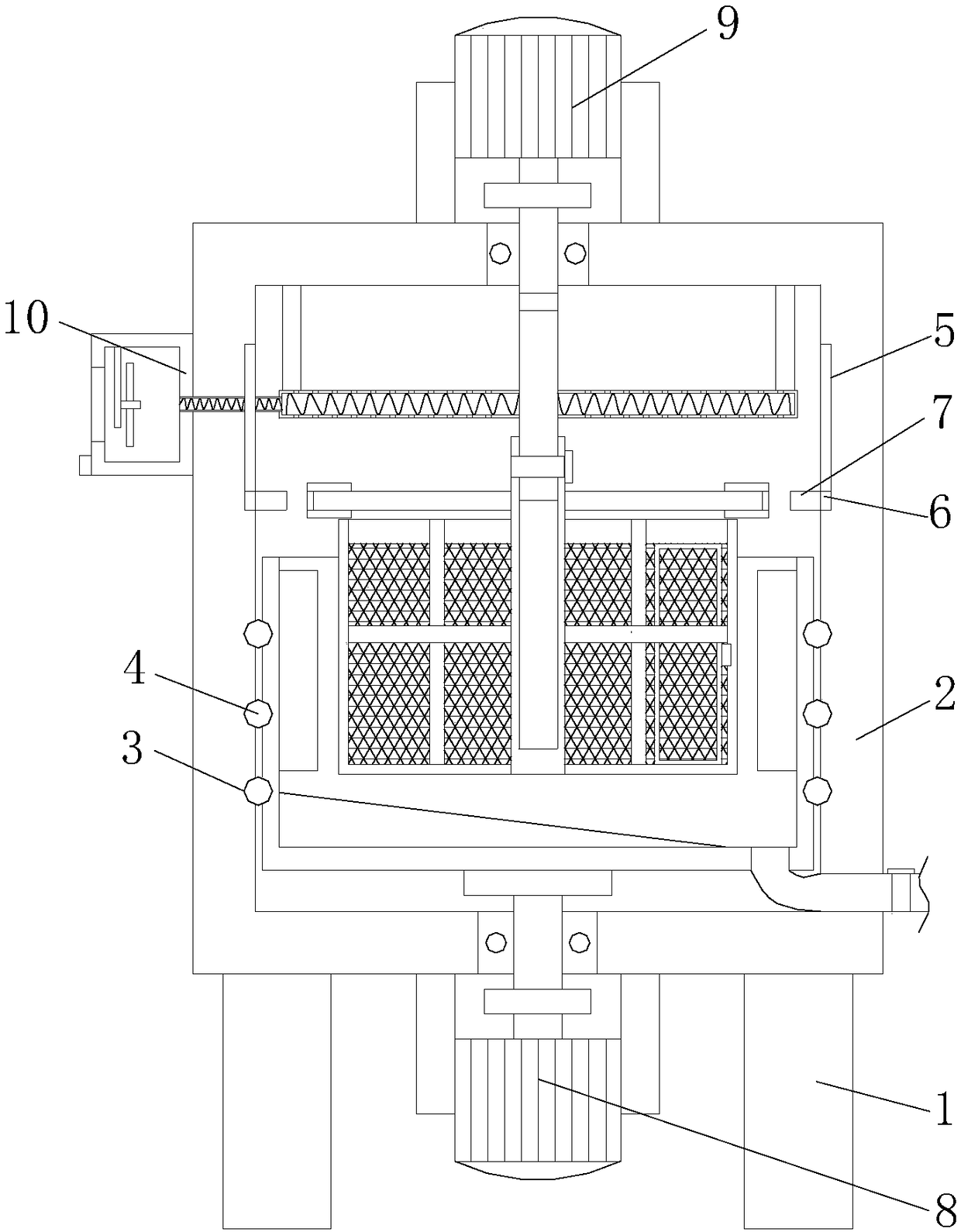

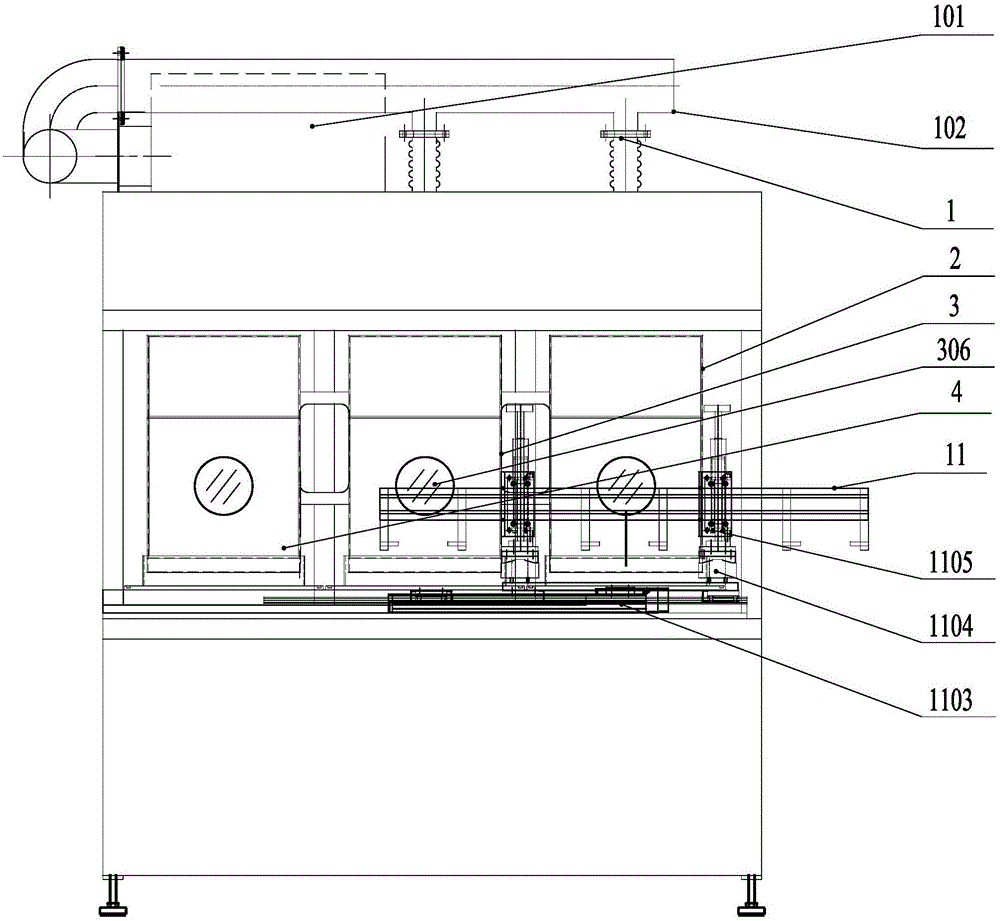

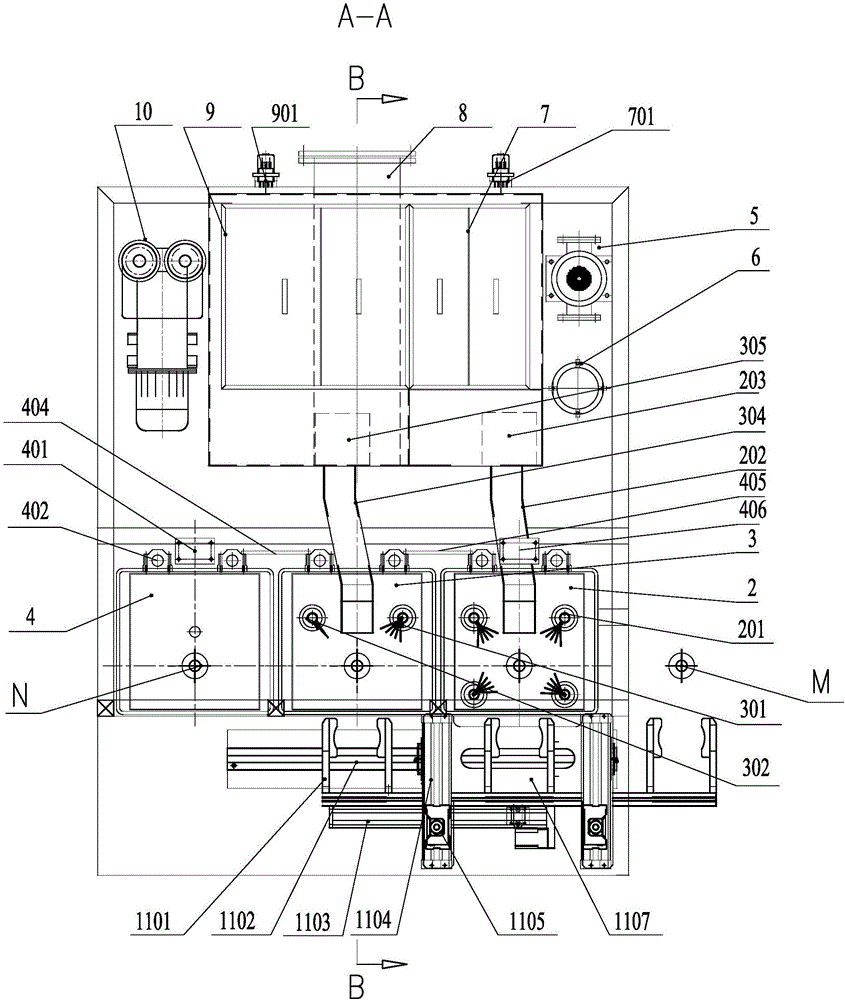

Multi-station spraying cleaning and drying machine

InactiveCN106429410AImprove cleaning and drying efficiencyGood cleaning and drying efficiencyDrying solid materials without heatCleaning using liquidsEngineeringCleaning station

The invention relates to industrial cleaning equipment, in particular to a multi-station spraying cleaning and drying machine. The multi-station spraying cleaning and drying machine comprises a cleaning station arranged on a rack worktable. The cleaning station comprises a fixed-point positioning spraying cleaning cavity, a rotary spraying rinsing wind shear cavity and a vacuum drying cavity, wherein the fixed-point positioning spraying cleaning cavity, the rotary spraying rinsing wind shear cavity and the vacuum drying cavity are arranged in a simultaneous vertical opening or closing manner. A mechanical arm is arranged at the position, corresponds to the cleaning station, of the front portion of the rack worktable. The mechanical arm is used for simultaneously carrying workpieces in a feeding position, the fixed-point positioning spraying cleaning cavity and the rotary spraying rinsing wind shear cavity to the next corresponding station. A vacuum pump, a rinsing liquid storage box, a cleaning liquid storage box, a spraying pump and a pressure tank are arranged at the rear portion of the rack worktable. The cleaning liquid storage box is connected with a first spraying pipeline in the spraying cleaning cavity through the spraying pump. According to the cleaning and drying machine, space can be effectively saved, the problems about cleaning, rinsing, drying and the like are solved in the limited space, and high-efficiency cleaning is achieved.

Owner:无锡新弘田环保技术有限公司

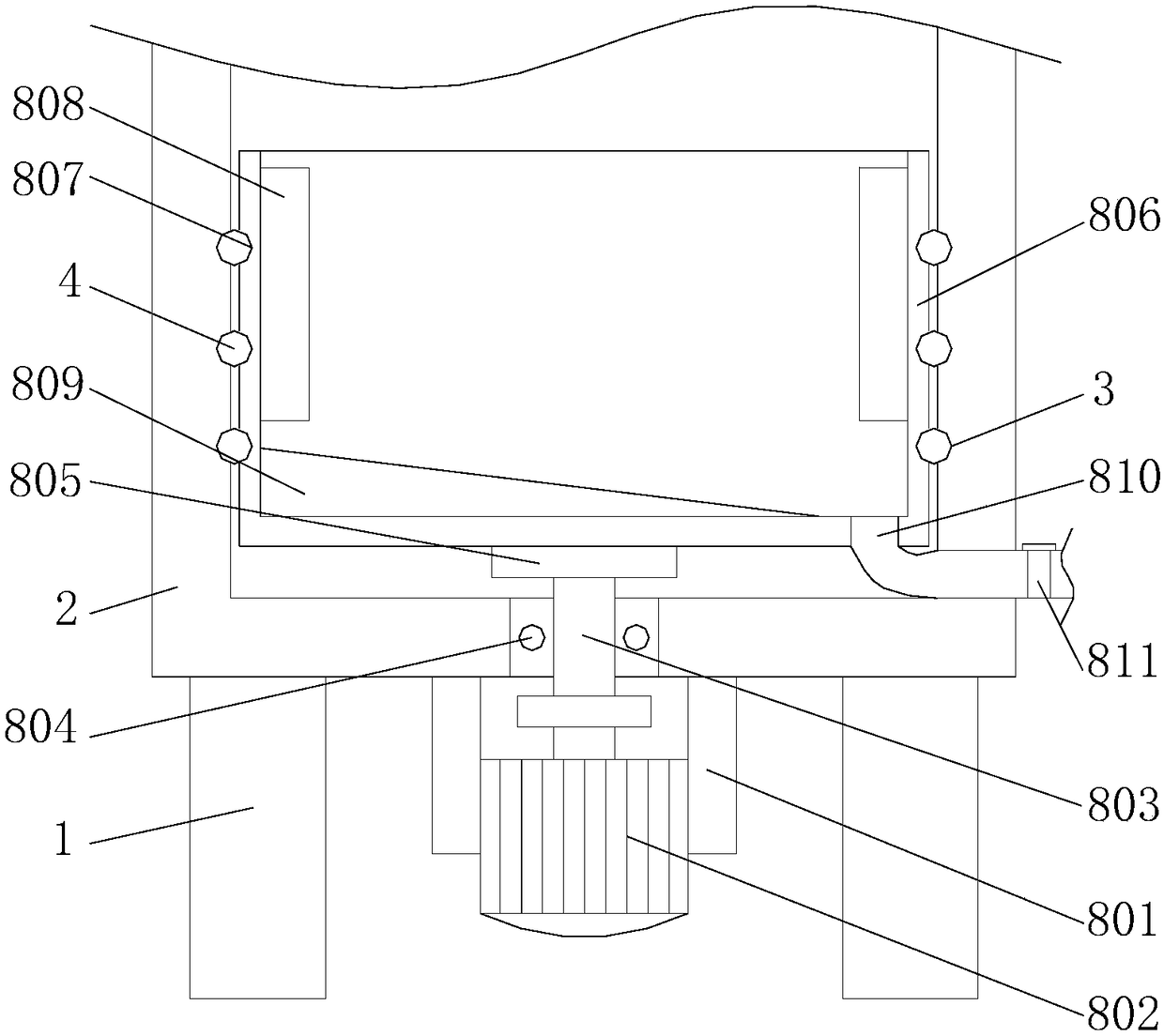

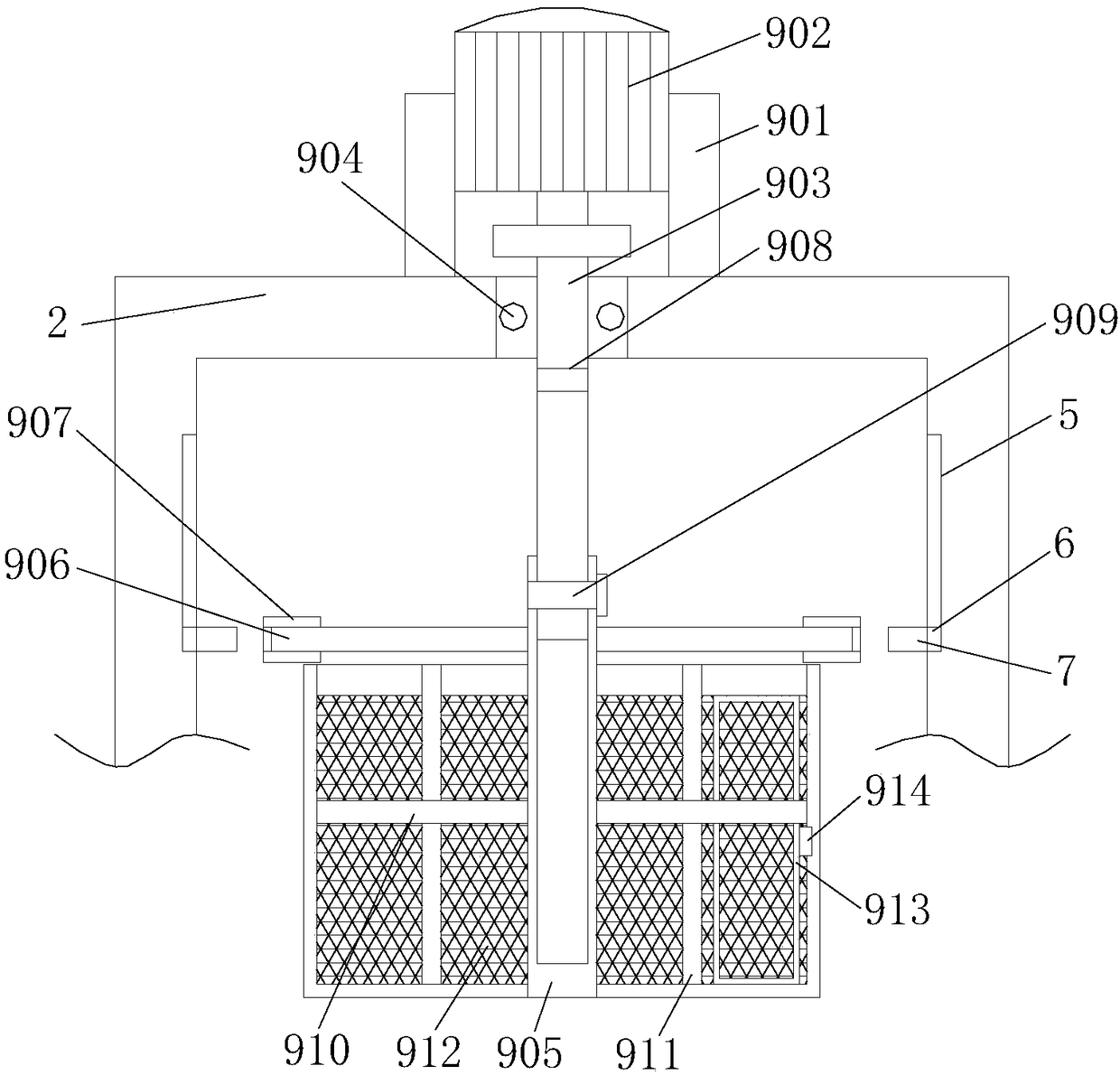

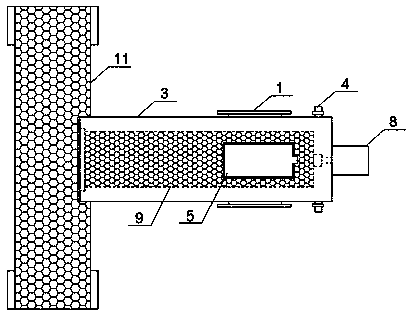

Washing and wipe dry integrated machine for coating barrel

InactiveCN108746126AImprove cleaning and drying efficiencySimple structureDrying solid materials without heatHollow article cleaningEngineeringMechanical engineering

The invention relates to a washing and wipe dry integrated machine for a coating barrel. The washing and wipe dry integrated machine comprises a rack and a conveying carrier band, the conveying carrier band is provided with a carrying opening matched with the coating barrel, the upper portion of the rack is sequentially provided with a washing mechanism and a wipe dry mechanism, and clamping devices are arranged at the positions, at the lower portions of the washing mechanism and the wipe dry mechanism, of the rack; the washing mechanism comprises a washing lifting air cylinder arranged on therack, the lower portion of the washing lifting air cylinder is connected with a washing device matched with the coating barrel, and the washing lifting air cylinder is matched with an air cylinder rotating device arranged on the rack; and the wipe dry mechanism comprises a wipe dry lifting air cylinder arranged on the rack, the lower portion of the wipe dry lifting air cylinder is connected witha wipe dry device matched with the coating barrel, and the wipe dry lifting air cylinder is matched with the air cylinder rotating device on the rack. According to the washing and wipe dry integratedmachine, the conveying carrier band tightened for conveying is used as a carrier of continuous movement of the coating barrel, the washing mechanism and the wipe dry mechanism are used in cooperationto achieve continuous and automatic washing and wipe dry, and the washing and wipe dry efficiency of the coating barrel is greatly improved.

Owner:DONGGUAN UNIV OF TECH

Machining technology for vacuum pipe inner pipes

InactiveCN108278886AIncrease productivityImprove cleaning and drying efficiencyHollow article cleaningDrying gas arrangementsEngineeringGlass manufacturing

The invention provides a machining technology for vacuum pipe inner pipes, and belongs to the technical field of glass manufacturing. The machining technology solves the technical problem that the existing vacuum pipe inner pipe production efficiency is low. According to the machining technology for the vacuum pipe inner pipes, the machining technology comprises the first step of raw material out-purchasing, the second step of inner pipe manufacturing, the third step of round head firing, the fourth step of annealing and the fifth step of drying cleaning. The machining technology has the beneficial effect that the production efficiency is improved.

Owner:浙江海光能源有限公司

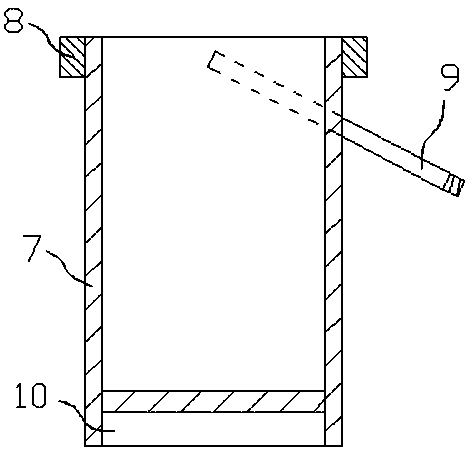

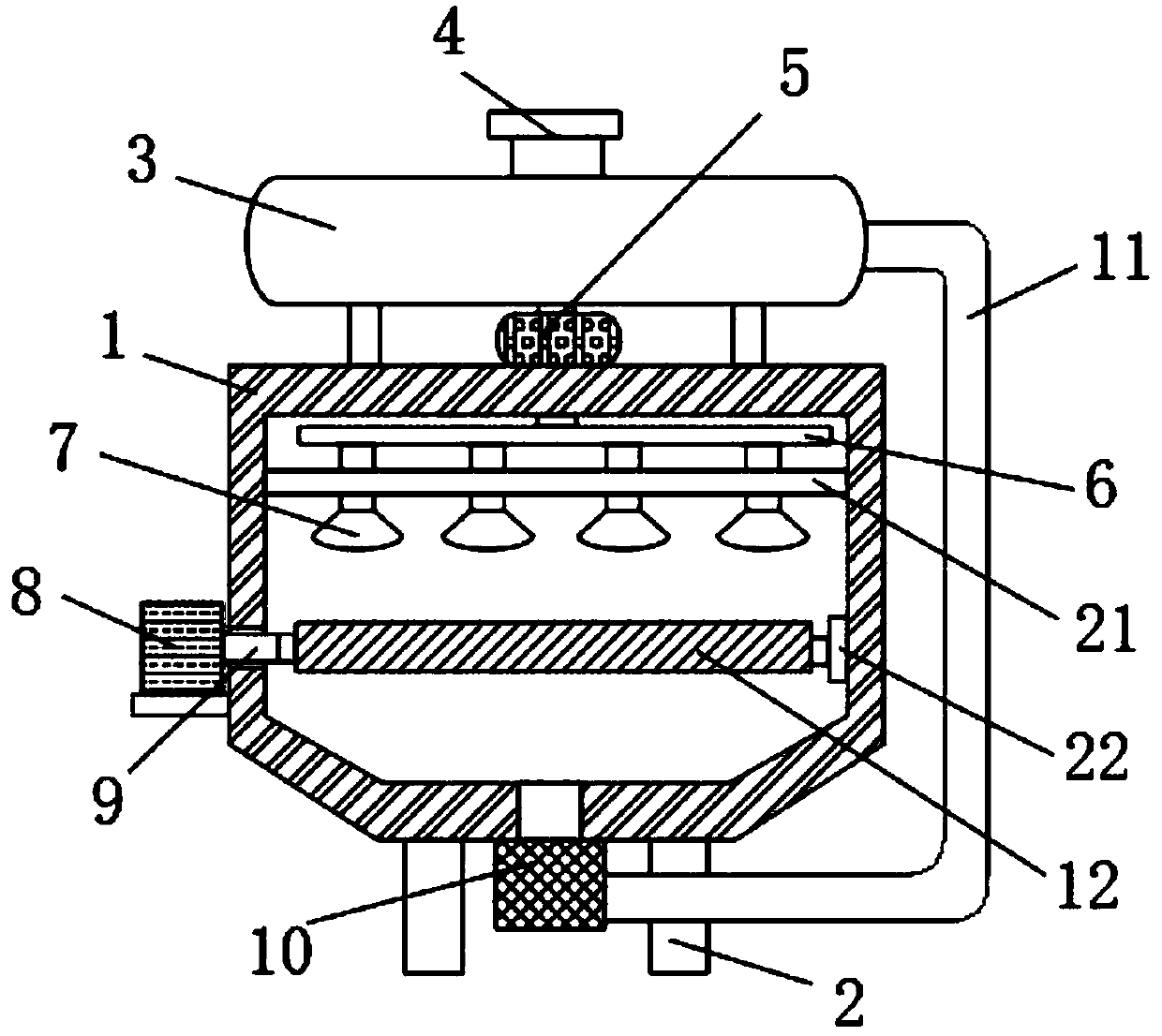

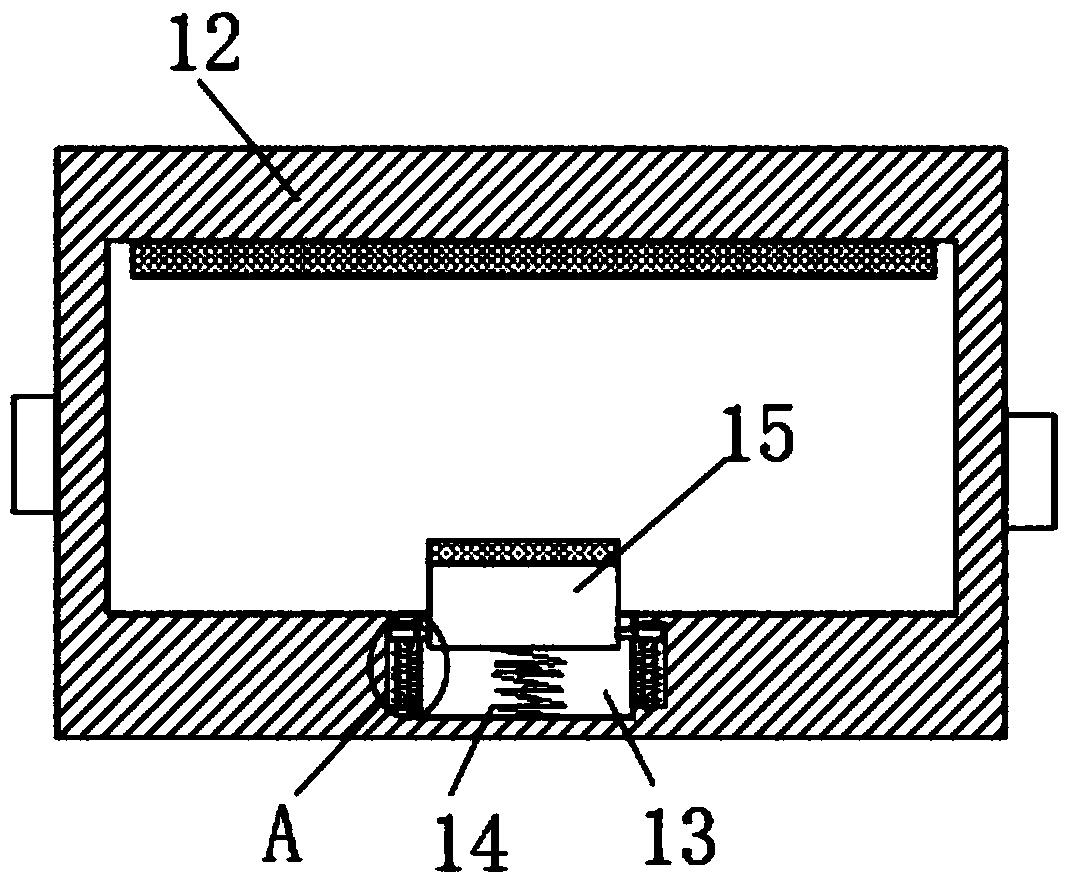

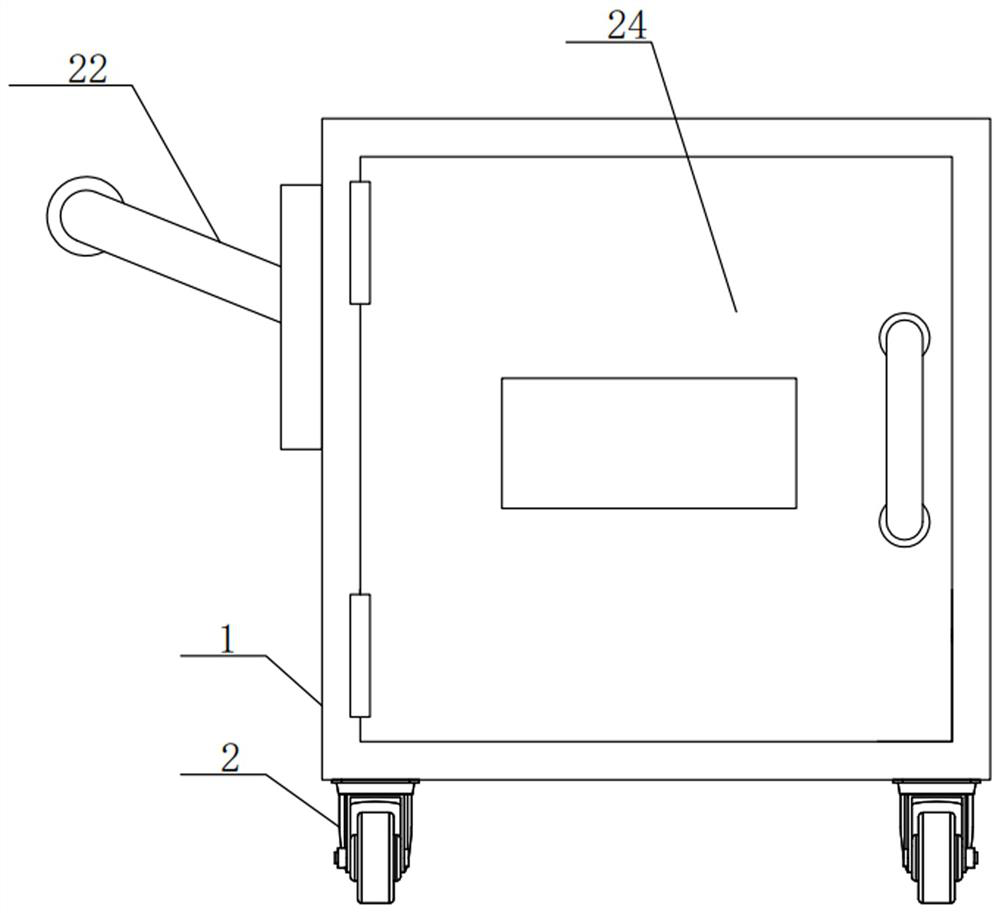

Aluminum alloy door and window machining, cleaning and drying device

InactiveCN109647772AAvoid damageSave waterDrying solid materials without heatCleaning using liquidsWater vaporEngineering

The invention discloses an aluminum alloy door and window machining, cleaning and drying device. The aluminum alloy door and window machining, cleaning and drying device comprises a box body, and multiple supporting blocks are fixedly connected to the bottom of the box body; a water tank is fixedly connected to the side wall of the upper end of the box body, the side wall of the upper end of the water tank is provided with a water inlet in a communicating mode, a high-pressure water pump is arranged on the water tank, a main water pipe which is transversely arranged and communicates with the high-pressure water pump is arranged in the box body, and multiple high-pressure spray guns which are arranged at equal distance are arranged on the main water pipe in a communicating pipe; and a motoris fixedly connected to the side wall of one side of the box body, a rotation shaft which is transversely arranged is rotatably connected to the driving end of the motor, and the side wall of the end, far away from the motor, of the rotation shaft extends into the box body in a penetrating mode and is fixedly connected with a door and window fixing device which is transversely arranged. Accordingto the aluminum alloy door and window machining, cleaning and drying device, doors and windows are driven by a starting motor to rotate, water on the doors and windows is thrown away through the centrifugal force, drying is accelerated, therefore, the drying efficiency is improved, and damage of high temperature on the doors and windows and water vapor generation are avoided.

Owner:安徽思睿门窗有限公司

Cleaning equipment for refractory material production and using method thereof

ActiveCN111940381AReduce labor intensitySimple structureCleaning using liquidsHeating arrangementSewageWorkbench

The invention discloses cleaning equipment for refractory material production. The cleaning equipment for the refractory material production comprises a workbench, a cleaning barrel is fixedly connected to the top of the workbench, a fixed plate is fixedly connected to the inner wall of the bottom of the cleaning barrel, a rotating plate is slidably connected to the top of the fixed plate, a hollowed-out metal frame is fixedly connected to the top of the rotating plate, a circular barrel is fixedly connected to the inner wall of the bottom of the hollowed-out metal frame, a rotating shaft is rotationally connected to the inner wall of the bottom of the cleaning barrel, and the top end of the rotating shaft penetrates through the fixed plate and fixedly connected with the bottom of the rotating plate. The cleaning equipment is simple in structure, capable of integrating first-stage simple cleaning, second-stage fine cleaning, flushing, water throwing and drying, simple, practical, a machine being used for multiple purposes is achieved, in addition, a waste water collecting box and a waste water filtering net are further arranged, the waste water can be collected after being filtered, the effects of waste water collecting and recycling can be achieved, the cleaning and drying efficiency is improved, water resources can be further saved, and the cleaning cost is reduced.

Owner:山东嘉岳新材料有限公司

Cleaning and drying device for surgical medical tool

InactiveCN110762952AWash thoroughlyImprove cleaning and drying efficiencyDrying gas arrangementsDrying machines with local agitationEngineeringSewage

The invention discloses a cleaning and drying device for a surgical medical tool. The device comprises a drying box with a box door, wherein one side of the drying box is provided with a sewage tank,a fan is fixed on one side of the top end of the drying box, a heating box is fixed on one side of the inner top wall of the drying box, a plurality of uniformly distributed heating wires are arrangedin the heating box, an air outlet of the fan is connected with an air guide pipe, the other end of the air guide pipe extends into the heating box, a cleaning cylinder is fixed in the center of the top of the drying box, a horizontally arranged first grid is arranged inside the drying box, the first grid is located below the cleaning cylinder, a discharging port is formed in the side wall of thebottom end of the cleaning cylinder, a cylinder is fixed on the inner wall of the side, away from the heating box, of the drying box, and the cylinder is located above the first grid. The cleaning anddrying device is reasonable in structure, ingenious in concept, continuous and automatic in cleaning and drying, good in cleaning effect, capable of saving manpower, and improving the cleaning and drying efficiency, high in practicability and suitable for popularization.

Owner:天津阿斯科雷生物科技有限公司

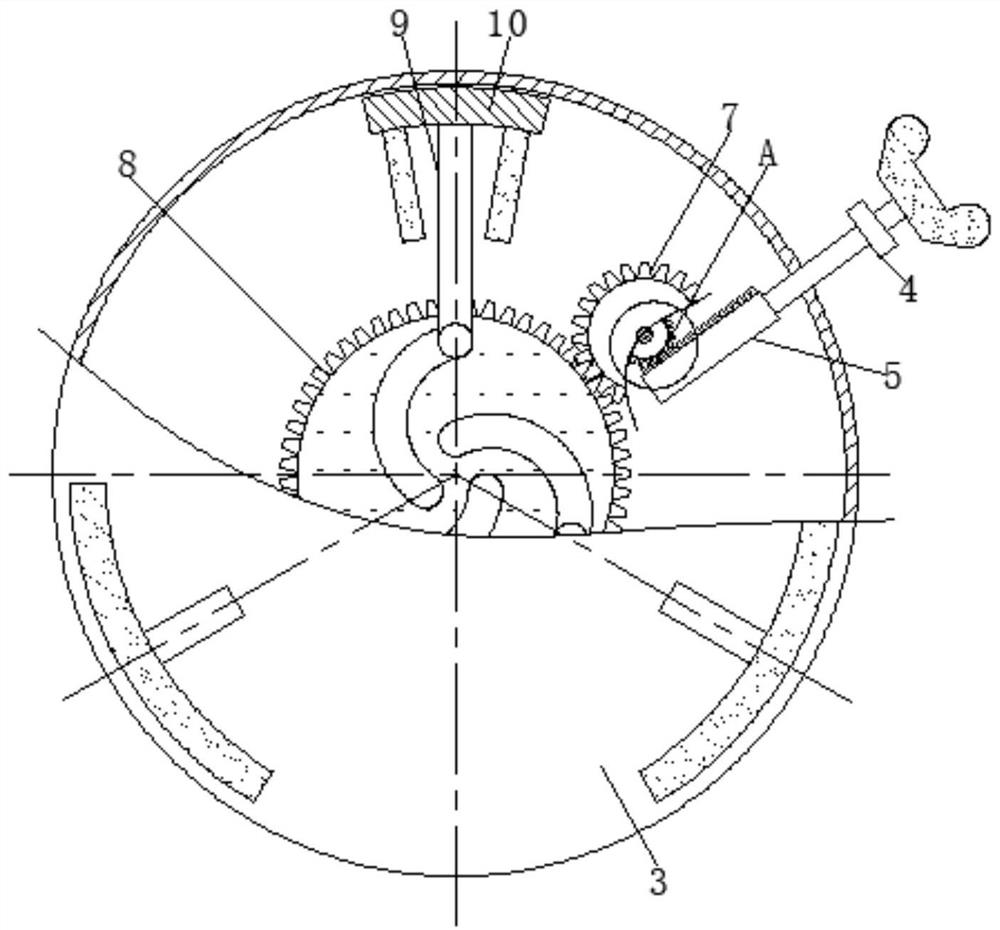

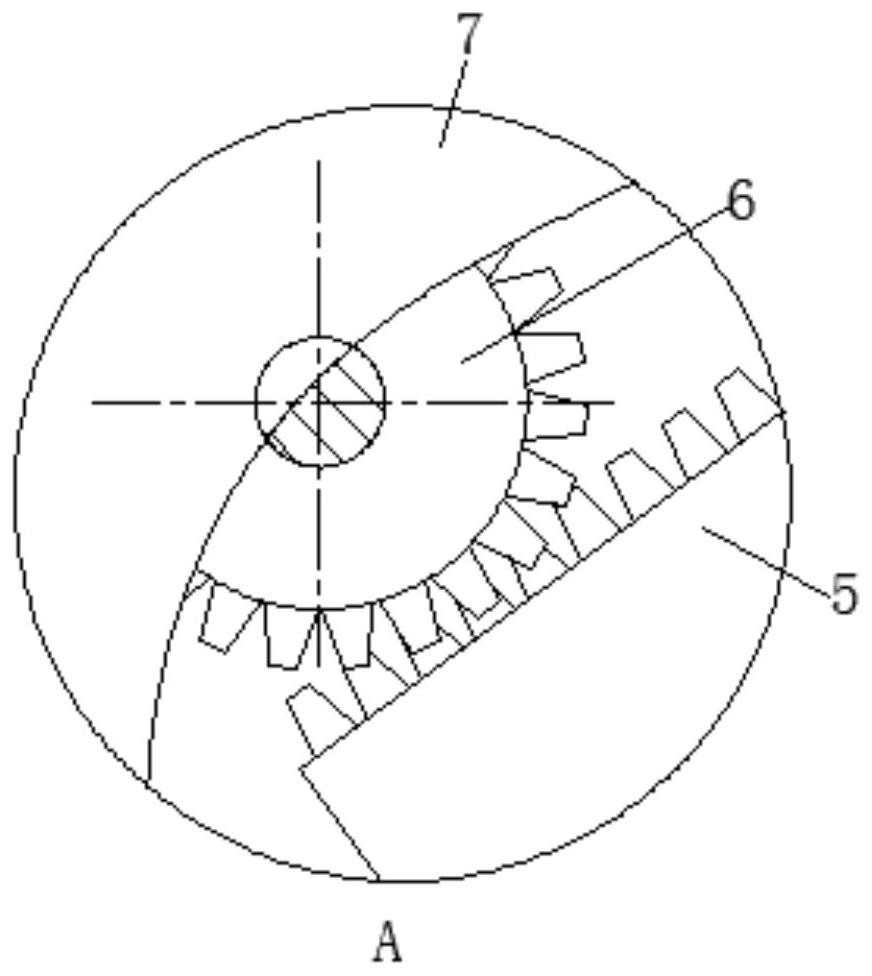

Automatic drying device for bamboo and wood toy processing

InactiveCN108151475AAchieve cleaningAchieve dryingDrying machines with non-progressive movementsDrying solid materialsMechanical engineeringGas pressure

The invention discloses an automatic drying device for bamboo and wood toy processing. The automatic drying device is characterized by structurally comprising a cleaning equipment outer shell, a transfer slide bottom plate, a rotary cleaning device, a rotary device drive mechanism, a protective cover telescopic device and a drying equipment trigger device, wherein the protective cover telescopic device is equipped with an air pressure telescopic main rod, an air pressure telescopic branch rod, a cleaning protective cover, an inner heating and drying layer and a protective cover pressure rod; and the drying equipment trigger device is equipped with a transmission gear set, a drying equipment traction device and a drying equipment circuit connecting mechanism. While used, the automatic drying device can be in a sealed space to perform comprehensive cleaning work through the rotary cleaning device and toys are dried through the drying equipment trigger device, so that the problem that manual drying is needed is avoided, batch cleaning and drying of the toys is realized, toy cleaning and drying efficiency is greatly improved, time and labor are saved, and energy conservation and environmental protection are achieved.

Owner:惠安闽神石材加工设备开发有限公司

Integrated cleaning and drying equipment for textile cloth and working process thereof

ActiveCN108277600AImprove bindingFast and efficient cleaningSucessive textile treatmentsLiquid/gas/vapor removal by gas jetsElectric machineryEngineering

The invention discloses integrated cleaning and drying equipment for textile cloth and relates to the technical field of production processing equipment for textile cloth. The equipment comprises a baseplate, a cleaning box is fixedly connected to the top of the baseplate, and a beat pounding box is fixedly connected to the top of the cleaning box; a wedge block and a motor box are fixedly connected to the inner wall of the beat pounding box separately, rotation shafts are rotatably connected to one side of the motor box through a supporting rack, and first bevel gears and rotation cams sleevethe rotation shafts from top to bottom in sequence; a motor is fixedly connected to the interior of the motor box. According to the integrated cleaning and drying equipment for the textile cloth anda working process thereof, the cleaning and drying effect is greatly improved, the cleaning and drying efficiency is well improved, production personnel do not need to spend a large amount of time incleaning and drying the textile cloth, the textile cloth is quickly and efficiently subjected to cleaning and drying integrated treatment, and great convenience is provided for production personnel toconduct production work of the textile cloth.

Owner:泉州台商投资区国进信息技术有限公司

Cleaning and drying integrated equipment for textile fabric production

PendingCN114657720ARinse clean and efficientImprove drying effectMechanical cleaningPressure cleaningMechanical engineeringIndustrial engineering

The cleaning and drying integrated equipment comprises a machine body and a partition plate, the partition plate is fixedly connected to the inner groove wall of the machine body, an inner groove of the machine body is divided into a cleaning bin and a drying bin through the partition plate, a through groove is formed in the partition plate, and guide rollers are rotationally arranged on the inner walls of the cleaning bin and the drying bin of the inner groove of the machine body; cleaning channels are welded to the portion, close to the inner groove wall and the side wall of one side of the cleaning bin, of the machine body, nozzles are arranged on the inner walls of the upper sides and the lower sides of inner grooves of the two cleaning channels, water inlet pipes are connected to the tops of the two cleaning channels in an inserted mode, and the other ends of the water inlet pipes penetrate through the top of the machine body and are inserted into a water conveying device; the cloth washing device has the beneficial effects that after cloth is washed, dust and fine attachments which are not washed off on the cloth are adsorbed or rubbed into a non-attachment state by the brush head through the reciprocating slow-speed rubbing structure, and then washing is carried out again, so that the cloth is washed more cleanly and efficiently.

Owner:CHANGLE HUADA TEXTILE CO LTD

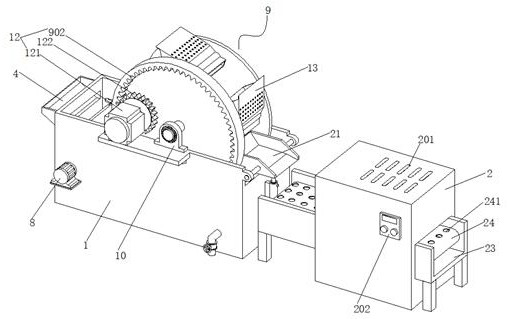

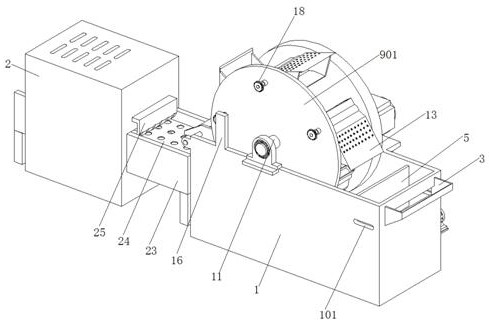

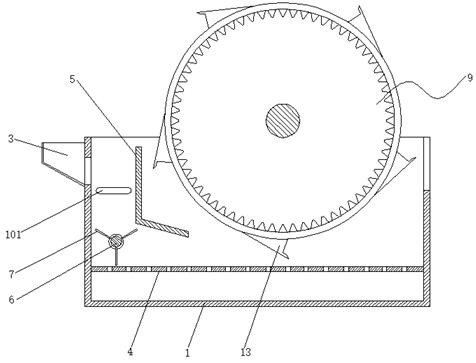

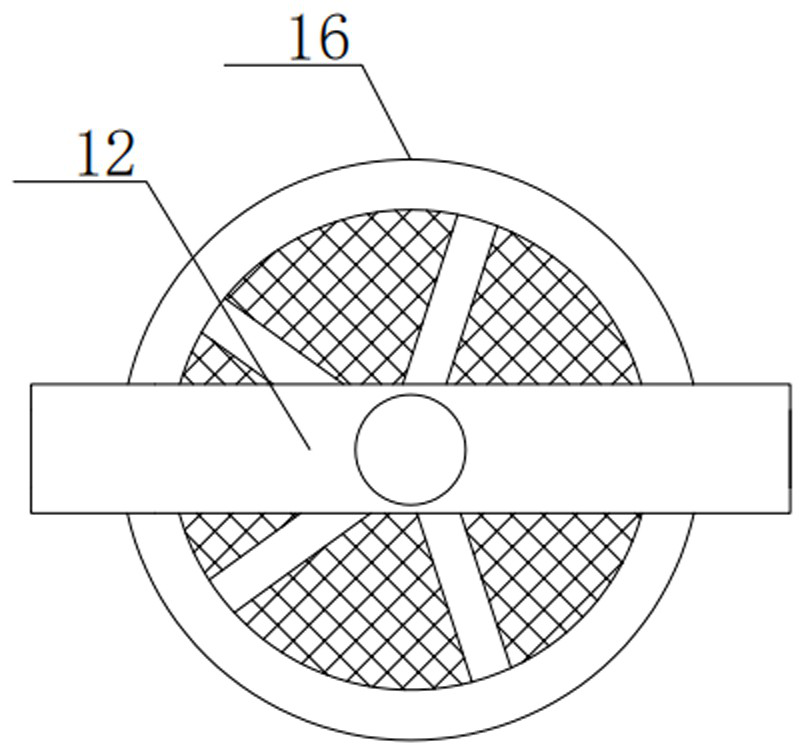

Wheat cleaning and drying integrated equipment

ActiveCN112221553AEasy to cleanImprove cleaning efficiencyDrying gas arrangementsGrain millingAgricultural scienceAgricultural engineering

The invention relates to the technical field of flour processing, and particularly discloses wheat cleaning and drying integrated equipment. The equipment comprises a cleaning pool and a drying machine, a feeding hopper is arranged on the left side face of the cleaning pool, a filtering plate is arranged at the lower end in the cleaning pool, a folding plate is fixedly arranged at the left end inthe cleaning pool, and a dross discharging opening is formed at the position, located at the left side of the folding plate, of the rear side face of the cleaning pool; and a wheel type material fishing mechanism is arranged at the position, located at the right side of the folding plate, of the cleaning pool, and a power device for driving the wheel type material fishing mechanism to rotate is arranged on the cleaning pool. According to the wheat cleaning and drying integrated equipment, the steps of continuously cleaning, fishing up and drying wheat are achieved, the whole operation processis continuous, the cleaning effect on the wheat before processing is excellent, and meanwhile the cleaning and drying efficiency is higher.

Owner:安徽康美达面业有限责任公司

Machining process of vacuum pipe outer pipe

InactiveCN108266975AIncrease productivityImprove cleaning and drying efficiencyDrying solid materials without heatHollow article cleaningMachining processGlass manufacturing

The invention provides a machining process of a vacuum pipe outer pipe, and belongs to the technical field of glass manufacturing. The technical problem that the production efficiency of an existing vacuum pipe outer pipe is low is solved. The machining process of the vacuum pipe outer pipe includes the following steps of a, raw material outsourcing; b, outer pipe manufacturing; c, round head firing; d, deflator connecting; e, annealing; and f, drying and cleaning. The machining process has the beneficial effect that the production efficiency is improved.

Owner:浙江海光能源有限公司

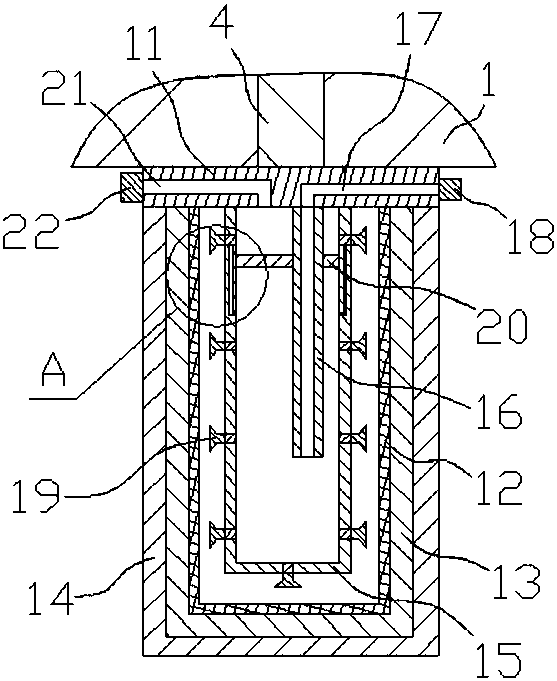

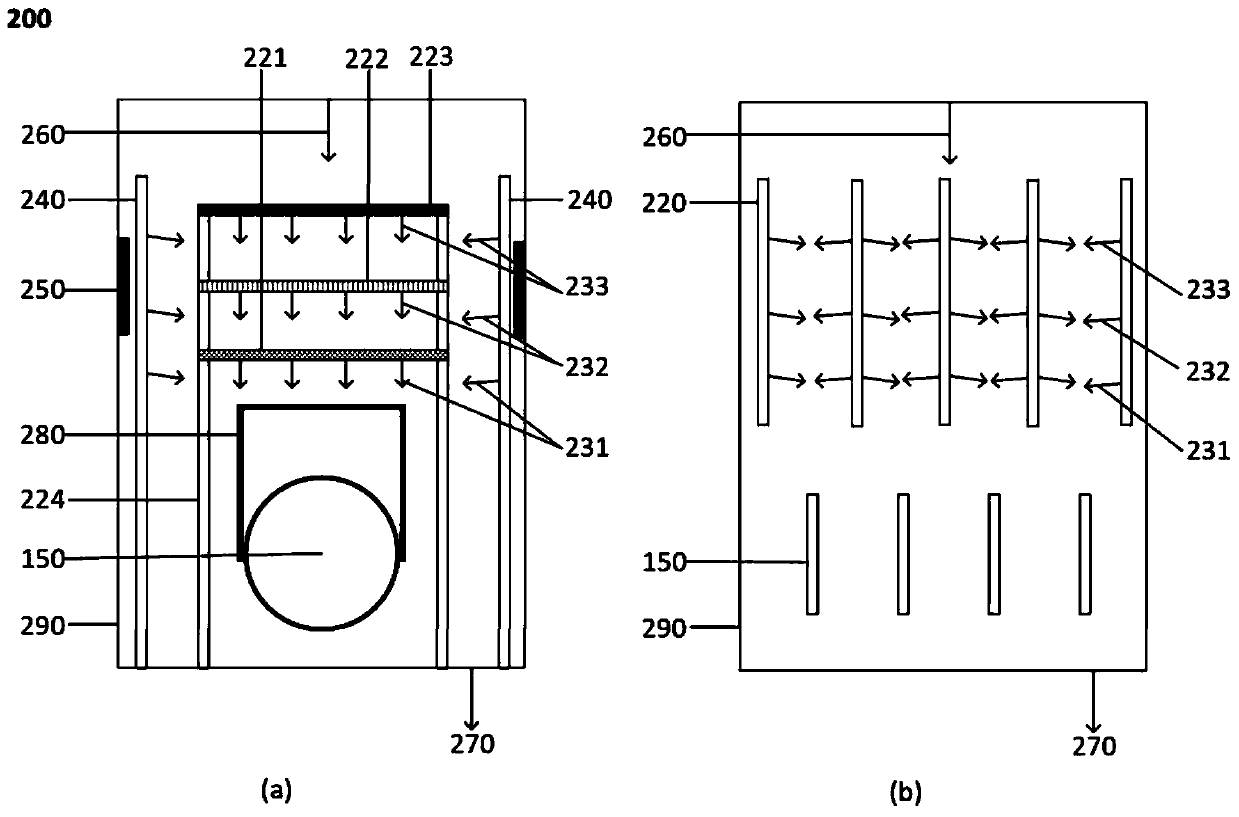

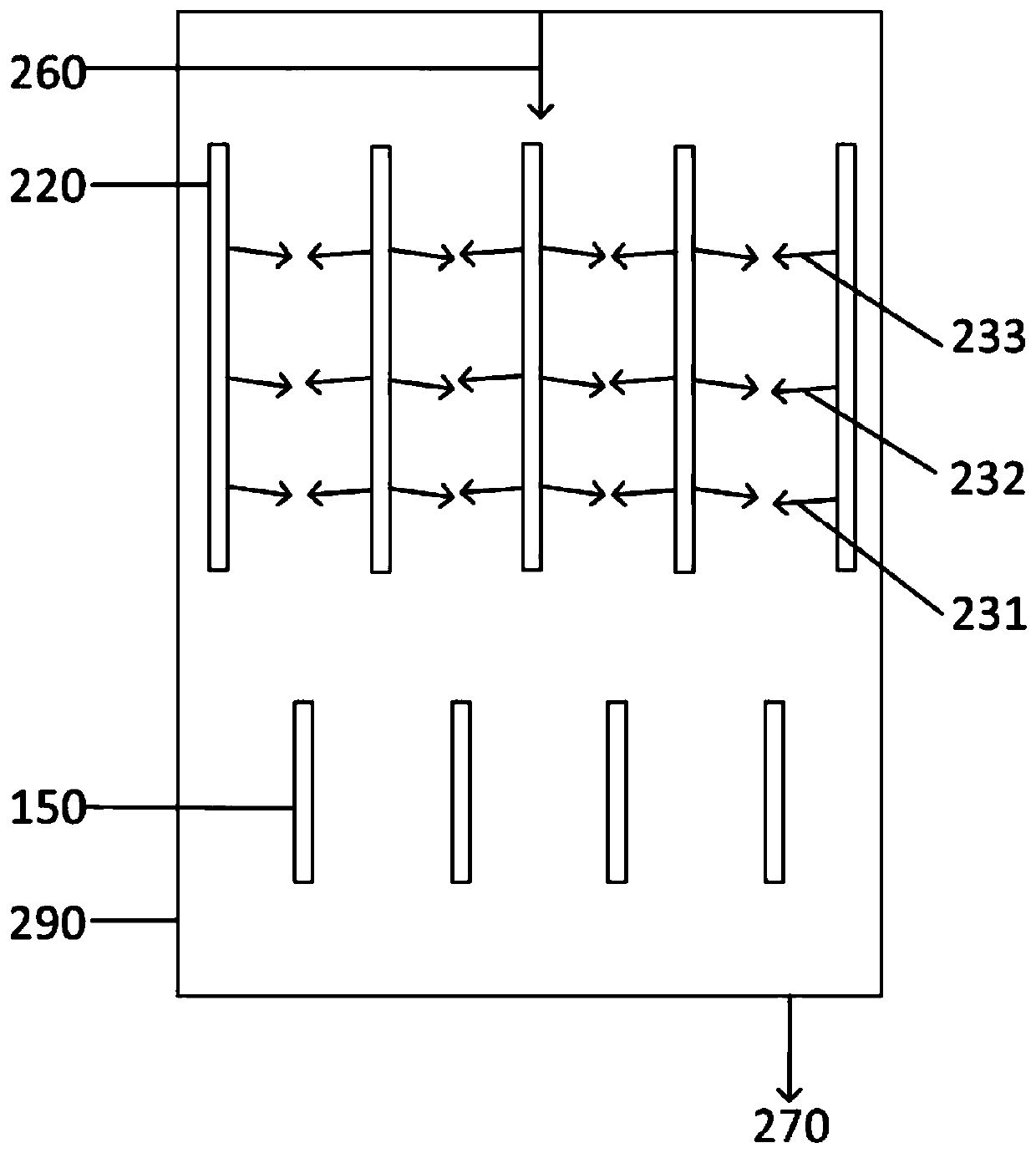

Wafer cleaning and drying device and method

InactiveCN110299311AImprove cleaning and drying efficiencyReduce processing timeSemiconductor/solid-state device manufacturingNozzleDrying tube

The invention relates to the technical field of wafer processing and particularly relates to a wafer cleaning and drying device and method. The wafer cleaning and drying device comprises a cavity, andat least two sets of main nozzle tubes disposed in the cavity. Each set of the main nozzle tubes comprises at least one cleaning tube for spraying cleaning liquid to the surface of a wafer, at leastone auxiliary drying tube for spraying auxiliary drying liquid, and at least one drying tube for spraying drying gas. The wafer sequentially passes through cleaning nozzles, auxiliary drying nozzles and drying nozzles of the wafer cleaning and drying device to be cleaned and dried, the cleaning and drying processes can be performed in one step, the wafer cleaning and drying efficiency can be improved, the processing time is reduced, materials are saved, energies are saved, and the emission is reduced.

Owner:HUAIAN IMAGING DEVICE MFGR CORP

Cleaning and drying device for anti-smog textile cloth

InactiveCN107475954AAvoid adsorptionAvoid affecting the drying effectLiquid/gas/vapor removalTextile treatment carriersEngineeringAutomation

The invention discloses a cleaning and drying device for anti-fog and haze textile cloth, which comprises a cleaning tank and a drying plate. Cylinder and film release cylinder, the anti-fog and haze textile cloth of film release cylinder is connected with the film collection cylinder after passing through the cleaning tank and drying plate. One end of the film collection cylinder is provided with a drive mechanism to drive the film collection cylinder to rotate; the cleaning tank is equipped with Cloth guide rollers, the cloth guide rollers are set along the left and right direction of the cleaning tank and the distance between adjacent cloth guide rollers is equal, the cloth guide rollers are located in the cleaning liquid of the cleaning tank and above the anti-fog textile fabric, drying A heating cavity is arranged under the plate, and a heater is arranged in the heating cavity. The invention has a high degree of automation, saves manpower, reduces costs, and directly dries through a drying plate after cleaning to prevent dust adsorption and improve production efficiency.

Owner:SUZHOU SISHAN NANO TECH CO LTD

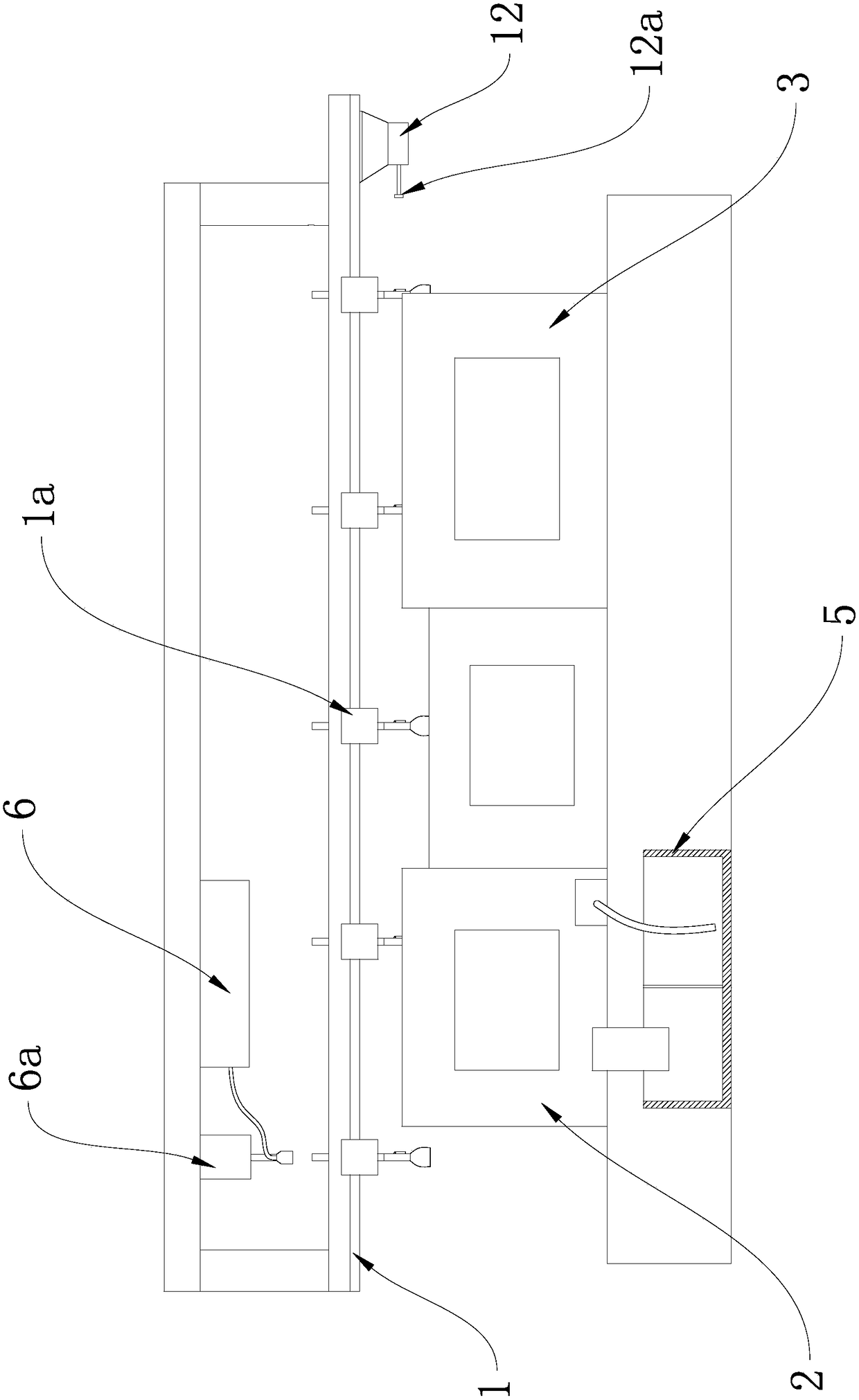

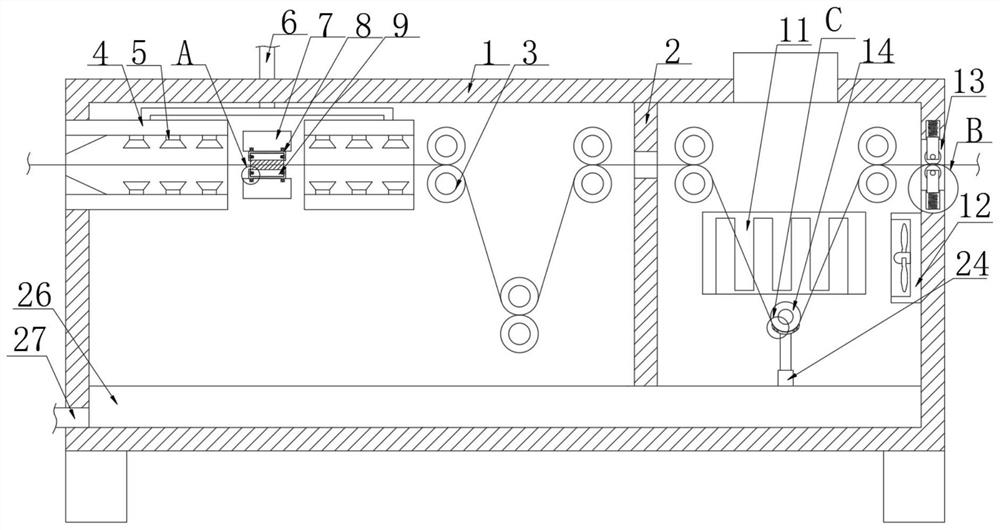

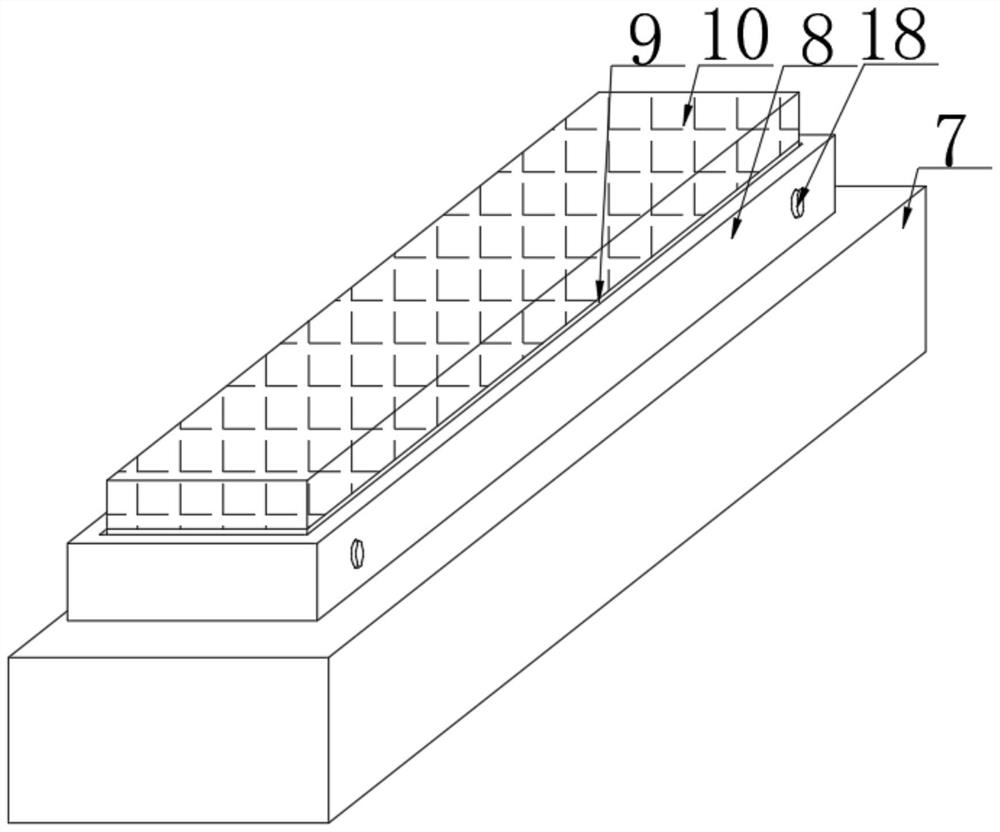

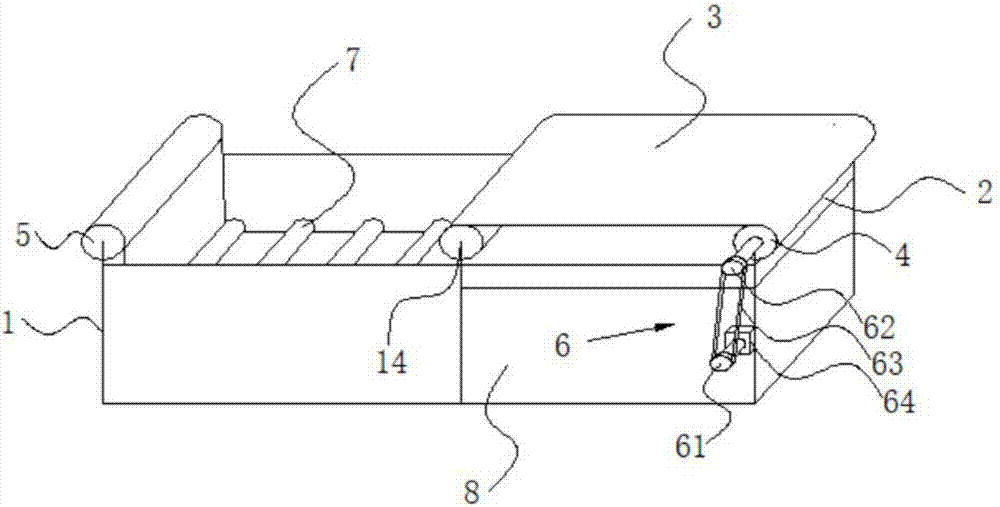

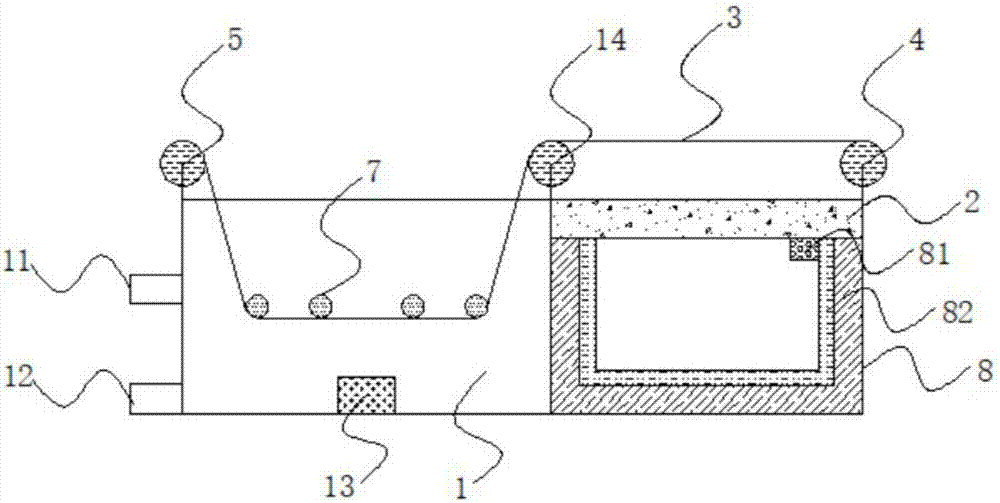

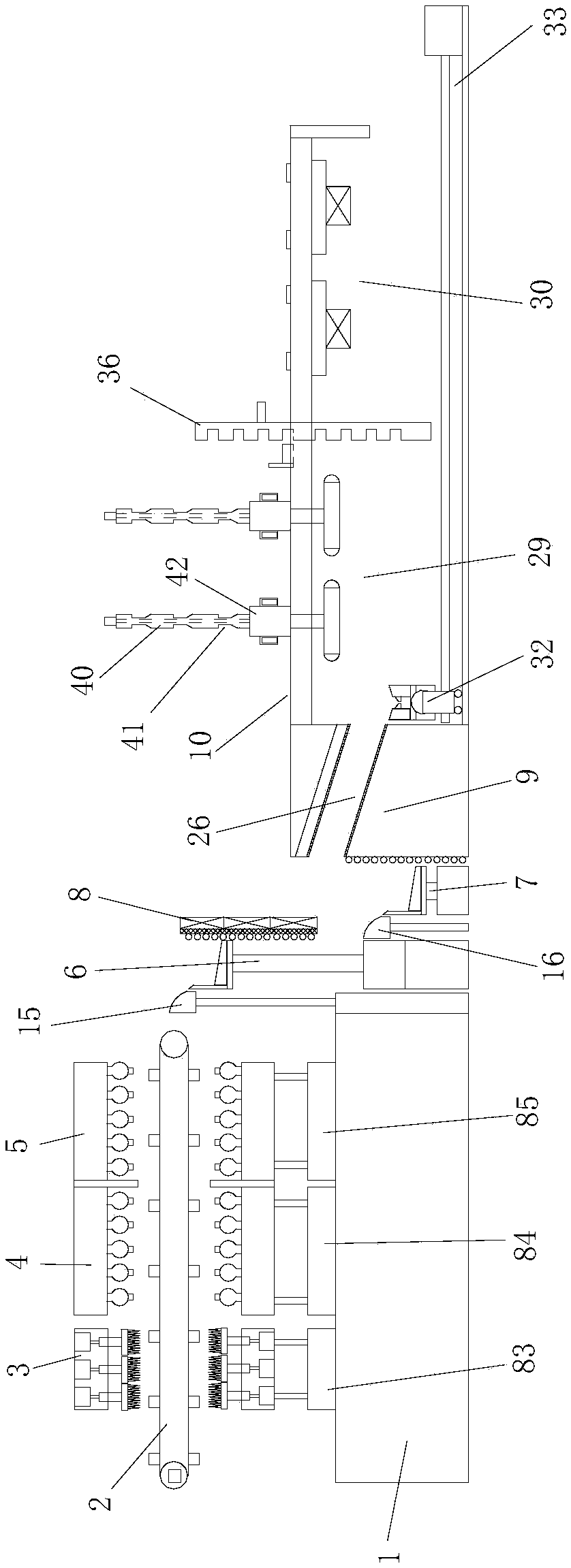

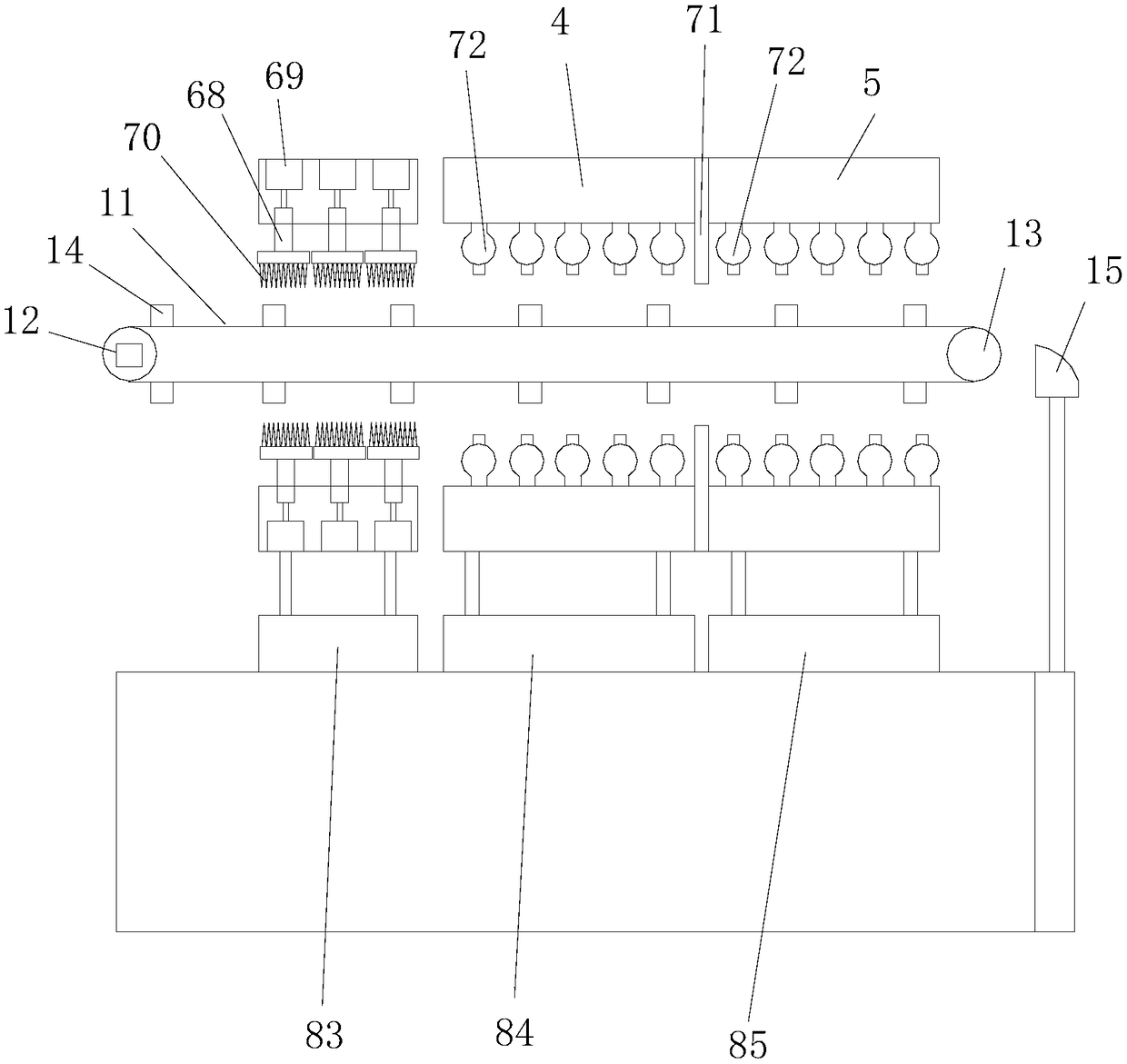

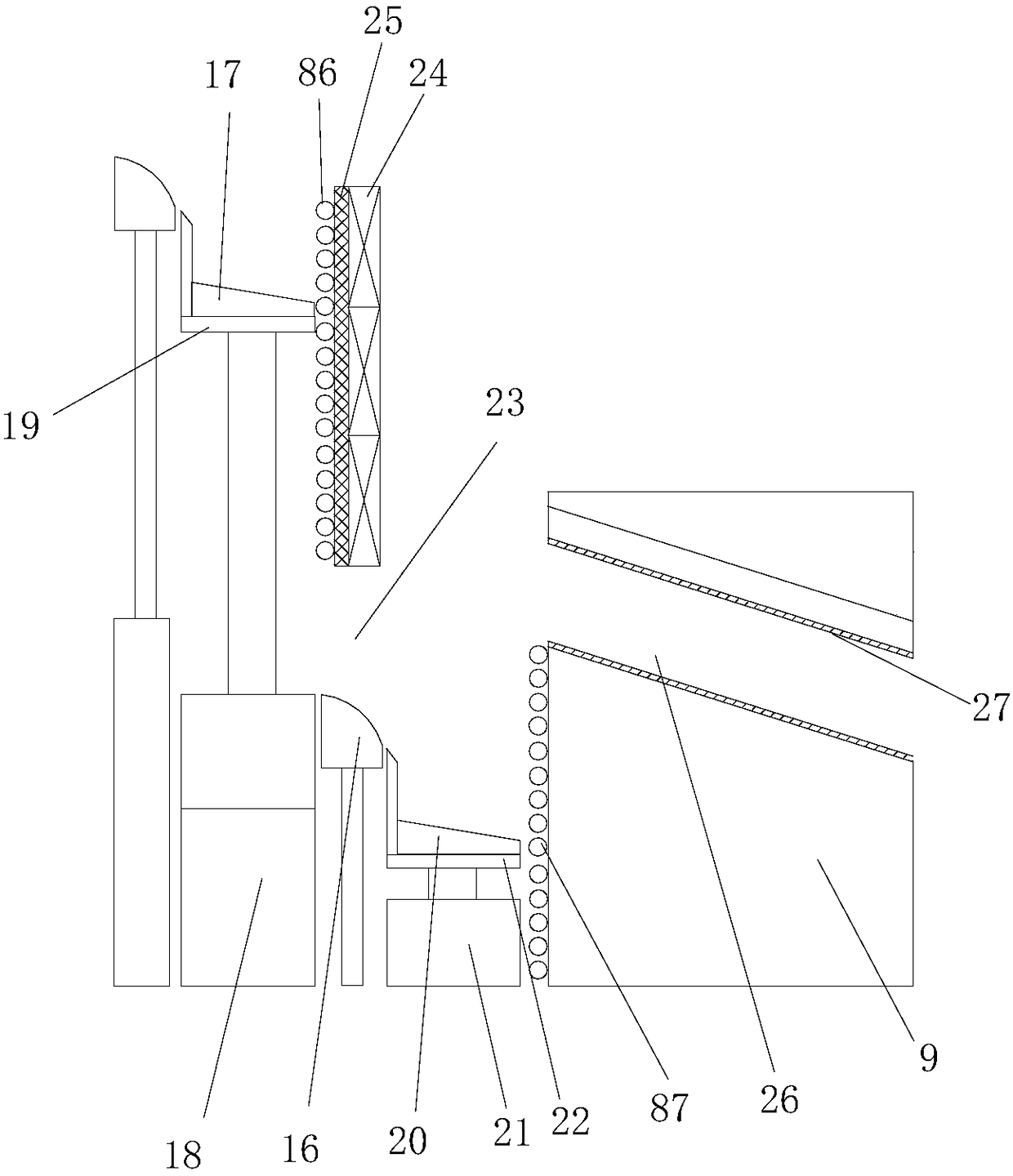

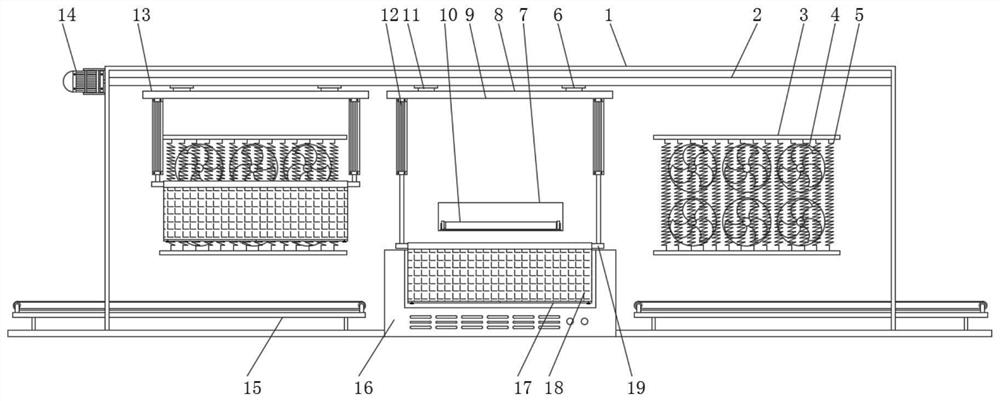

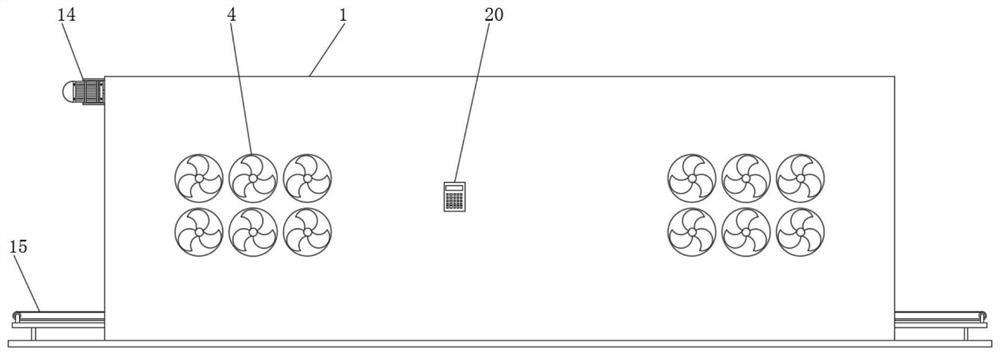

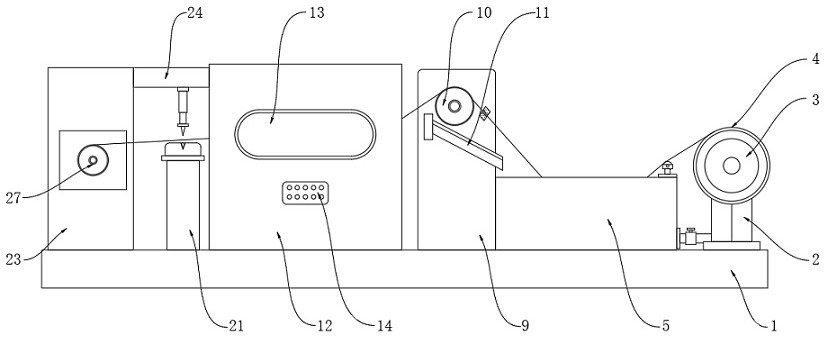

Automatic cleaning and drying machine for printing plate roller

PendingCN108177437AImprove cleaning and drying efficiencySimple structureDrying gas arrangementsPrinting press partsMechanical engineeringStatic electricity

The invention relates to the technical field of cleaning and drying equipment, in particular to an automatic cleaning and drying machine for a printing plate roller. The automatic cleaning and dryingmachine comprises a rack, a feeding mechanism is installed on the rack, and a material brushing mechanism, a first spray-wash mechanism and a second spray-wash mechanism are arranged above and under the feeding mechanism in sequence in the direction of the moving of materials; the tail end of the feeding mechanism is provided with a first material receiving mechanism and a second material receiving mechanism, a blowing mechanism used for blowing and drying the materials is arranged between the first material receiving mechanism and the second material receiving mechanism to blow and dry the materials, and one side of the second material receiving mechanism is sequentially provided with a static electricity eliminating mechanism for eliminating static electricity from the materials and a drying mechanism for drying the materials; the feeding mechanism comprises two transmission crawlers arranged in parallel and a driving wheel and a driven wheel for driving the transmission crawlers torotate, and the transmission crawlers are wound around the driving wheel and the driven wheel; and a plurality of spacing blocks for locating the materials are uniformly arranged on the transmission crawlers at intervals.

Owner:DONGGUAN SHANGYUN LASER PLATE MAKING CO LTD

Cleaning and drying device for agricultural product processing

ActiveCN108722990AImprove cleaning efficiencyImprove filtering effectDrying gas arrangementsCleaning using liquidsEngineeringProduct processing

The invention discloses a cleaning and drying device for agricultural product processing and relates to the field of agriculture. The cleaning and drying device comprises supporting legs; a box is welded to the surfaces of the supporting legs; a first ball groove is formed in the inner wall of the box; balls are slidably connected to the inner wall of the first ball groove; a limiting groove is formed in the inner wall of the box; connecting blocks are slidably connected to the inner wall of the limiting groove; first screw rods are welded to the surfaces of the connecting blocks; and a watertank cleaning mechanism, a lifting and rotating mechanism and a drying mechanism are arranged on the box in a penetrating mode. According to the cleaning and drying device for agricultural product processing, the water tank cleaning mechanism and the drying mechanism are located on the same machine, the lifting and rotating mechanism conducts auxiliary lifting and rotating, thus the effect of improving the agricultural product cleaning and drying efficiency is achieved, and the problems that a general mechanical device is simplex in function and long in processing consumed time, and the work efficiency is affected to a certain extent are effectively solved.

Owner:浙江豆豆宝中药研究有限公司

Cleaning device

InactiveCN104438203AEasy to cleanImprove air drying effectDrying gas arrangementsCleaning using liquidsEngineeringAir drying

The invention relates to the technical field of cleaning devices, in particular to a cleaning device which comprises an electromagnetic vibrator and a cleaning hopper on the electromagnetic vibrator, wherein the cleaning hopper comprises rotary cleaning chambers and a rotary air-drying chamber surrounding the rotary cleaning chambers; upward spiral laminates are arranged in the rotary cleaning chambers and the rotary air-drying chamber; spiral cleaning channels and a spiral air-drying channel are formed by the upward spiral laminates; the rotary cleaning chambers are higher than the rotary air-drying chamber; a material channel is arranged on the outermost wall of one rotary cleaning chamber and extends from the upper part of the rotary cleaning chamber to the bottom of the rotary air-drying chamber; a cleaning solution is arranged in the spiral cleaning channels; a blowing nozzle for blowing air into the air-drying chamber is arranged above the rotary air-drying chamber; a feed channel extending downwards to the bottom of one rotary cleaning chamber is arranged at the axle center of the rotary cleaning chamber. The cleaning device can clean a workpiece and has the advantages of high effect, simple structure and high efficiency.

Owner:CHANGZHOU YUJIA PACKAGING

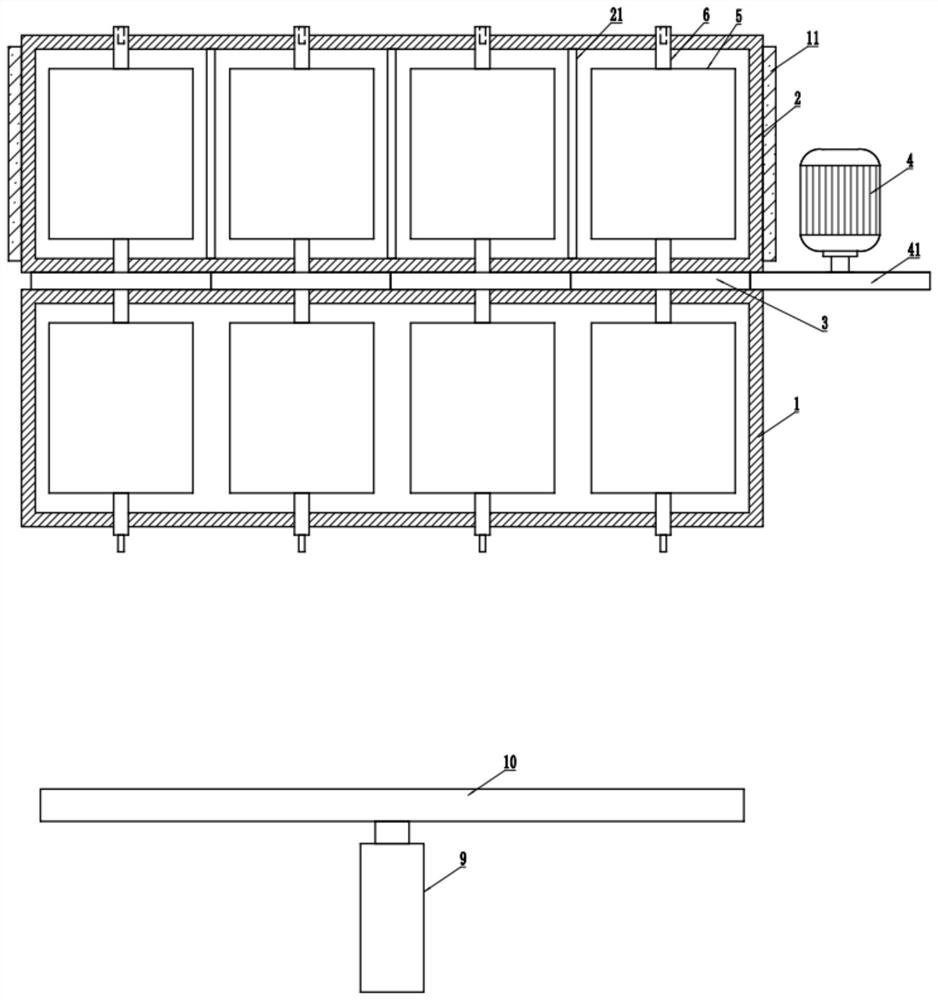

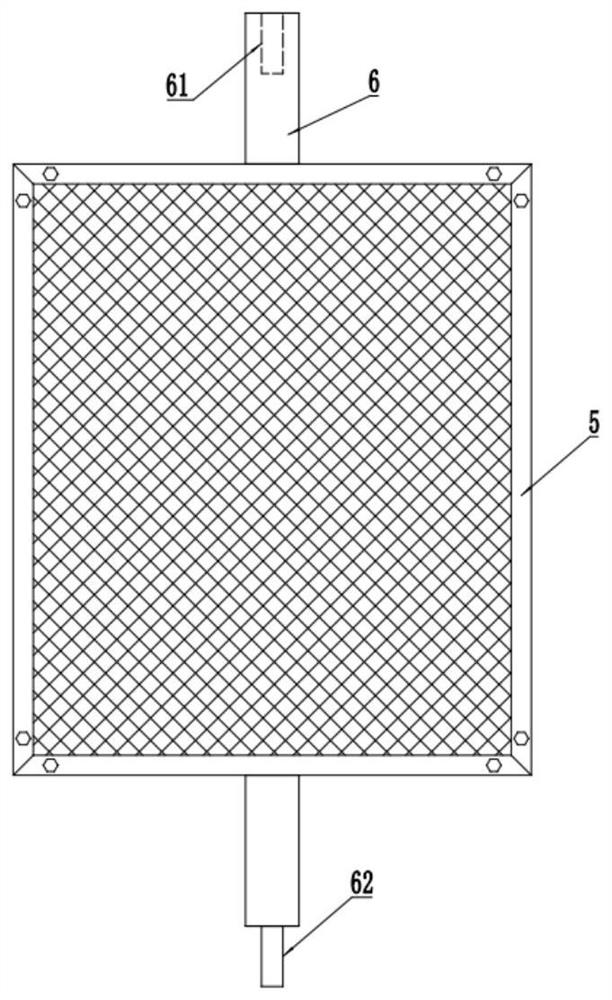

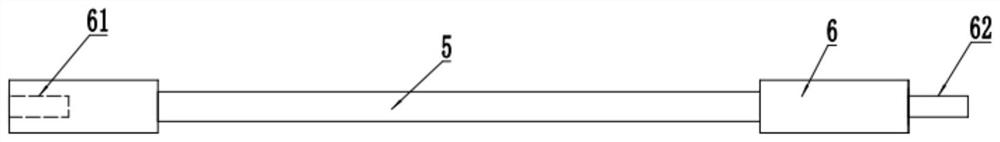

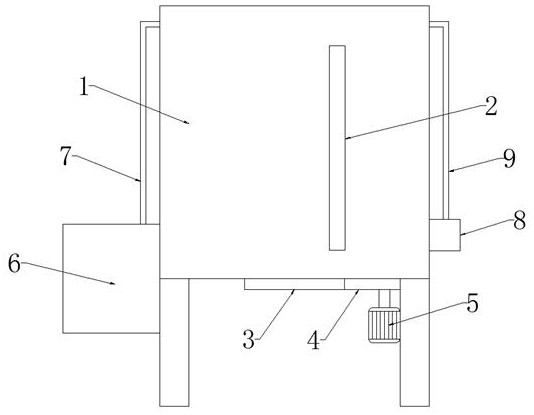

Cleaning device for screen production

InactiveCN112474574AEasy accessImprove cleaning efficiencyCentrifugesCleaning using liquidsGear wheelFixed frame

One or more embodiments of the specification provide a cleaning device for screen production. The cleaning device comprises a cleaning cavity, a drying cavity and a plurality of driven gears attachedto the adjacent middle positions of the cleaning cavity side by side, fixing frames are arranged in the cleaning cavity and the drying cavity side by side respectively to clamp and fix a screen, mainshafts are fixed to the two ends of each fixing frame, through openings are formed in the side walls of the two ends of the cleaning cavity and the side walls of the two ends of the drying cavity correspondingly, the through openings in the two ends of the cleaning cavity are sealed through movable sealing mechanisms, and a main gear is driven by a motor to rotate so as to drive the driven gears to rotate synchronously and correspondingly drive the main shafts connected in a matched mode to rotate so as to drive the fixing frames in the cleaning cavity and the drying cavity to rotate synchronously, the cleaning and drying efficiency is further improved, the fixed frames of the next batch are pushed by a telescopic cylinder to penetrate into the cleaning cavity to be cleaned, so that the fixed frames in the original cleaning cavity are conveyed into the drying cavity, the fixed frames in the original drying cavity are conveyed out to be discharged, and cyclic continuous operation is achieved.

Owner:利辛县亿隆筛网有限公司

Cleaning and drying device for production of electronic mainboard

ActiveCN111721090AEffective clamping and fixingSmooth feedingDrying solid materials without heatDrying gas arrangementsDrive wheelElectric machinery

The invention discloses a cleaning and drying device for production of an electronic mainboard, and relates to the field of production of the electronic mainboard. Aiming at solving the problem of reduction of production efficiency due to the fact that cleaning and drying cannot be operated continuously during production processing of the electronic mainboard conventionally, the following scheme is proposed: the cleaning and drying device comprises a processing box, wherein two symmetrically distributed supporting plates are fixedly mounted at the bottom end of the processing box, a driving motor is fixedly mounted on the side wall of one supporting plate, an output shaft of the driving motor is vertically upward and fixedly connected with a driving wheel, the driving wheel is rotationallyconnected with the bottom end of the processing box, a driven wheel is rotationally mounted in the middle position of the bottom end of the processing box, and a rotary disc is rotationally mounted on the inner wall of the bottom end of the processing box. The cleaning and drying device is novel in structure, can realize stable feeding of the to-be-processed electronic mainboard, and can realizecontinuous operation of cleaning and drying of the electronic mainboard, and the production efficiency of the electronic mainboard is improved.

Owner:广州润诚通信技术有限公司

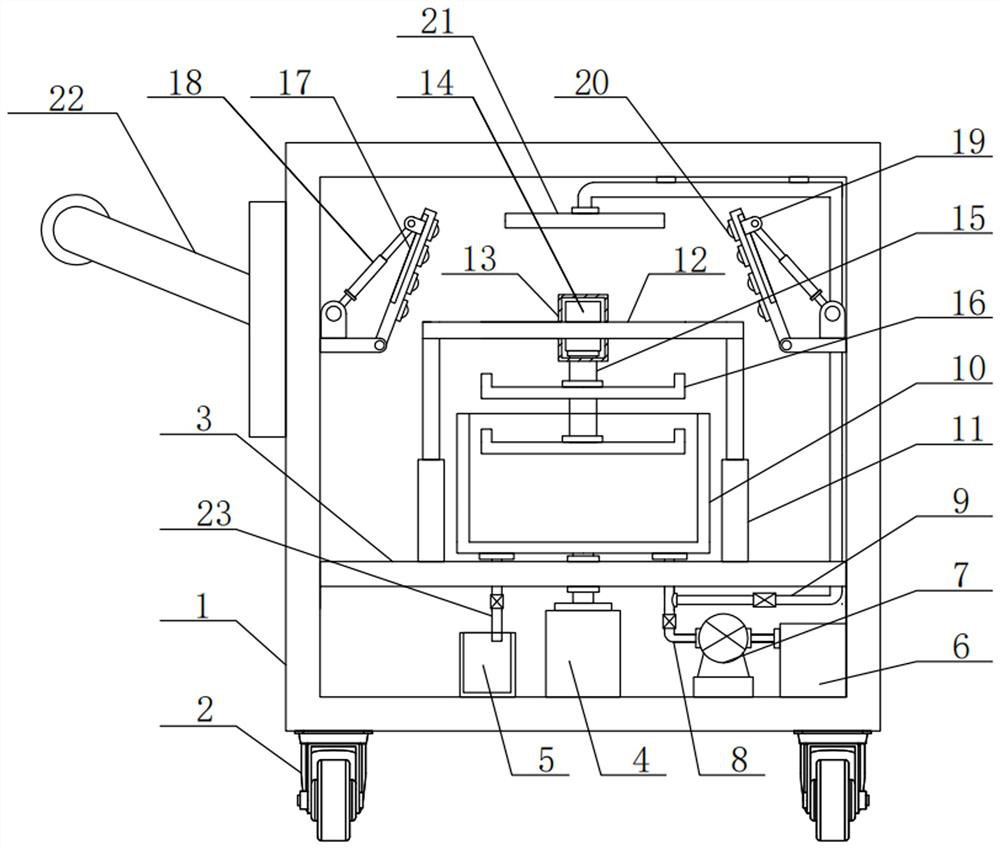

Efficient cleaning and drying integrated device for automobile parts

ActiveCN112923709AImprove cleaning and drying efficiencyImprove work efficiencyDrying machines with progressive movementsDrying solid materialsMegasonic cleaningElectric machinery

The invention discloses an efficient cleaning and drying integrated device for automobile parts. The efficient cleaning and drying integrated device comprises a working bin and an ultrasonic cleaning machine. The ultrasonic cleaning machine is fixedly installed in the center of the bottom face in the working bin, a sliding rail is fixedly installed on the top face in the working bin, and a sliding block is slidably connected into the sliding rail. A driving motor is fixedly installed at one end of the sliding rail and located on the outer wall of the working bin, a screw is installed at the output end of the driving motor, the screw penetrates through the sliding block and is rotationally connected with the inner wall of the other end of the working bin, and the bottom face of the sliding block is fixedly connected with a first transfer mechanism and a second transfer mechanism through connecting rods. The efficient cleaning and drying integrated device for automobile parts has the beneficial effects that automobile parts are transferred through the first transfer mechanism and the second transfer mechanism, the cleaned automobile parts can be conveniently and directly transferred to a fan to be dried, cleaning and drying are conducted in the same working bin, the cleaning and drying efficiency is improved, and therefore the working efficiency is improved.

Owner:瑞昌市人民冲压有限公司

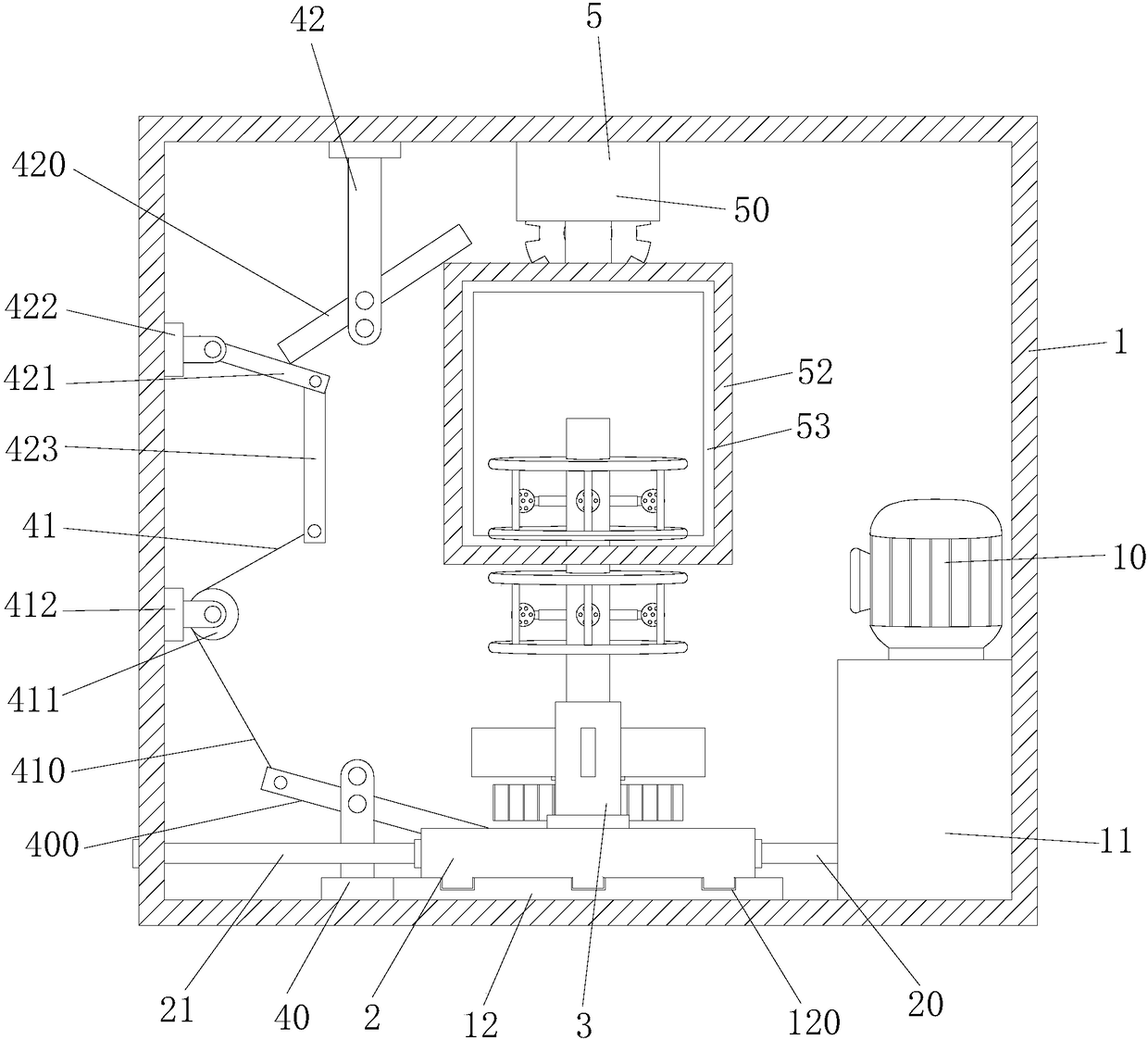

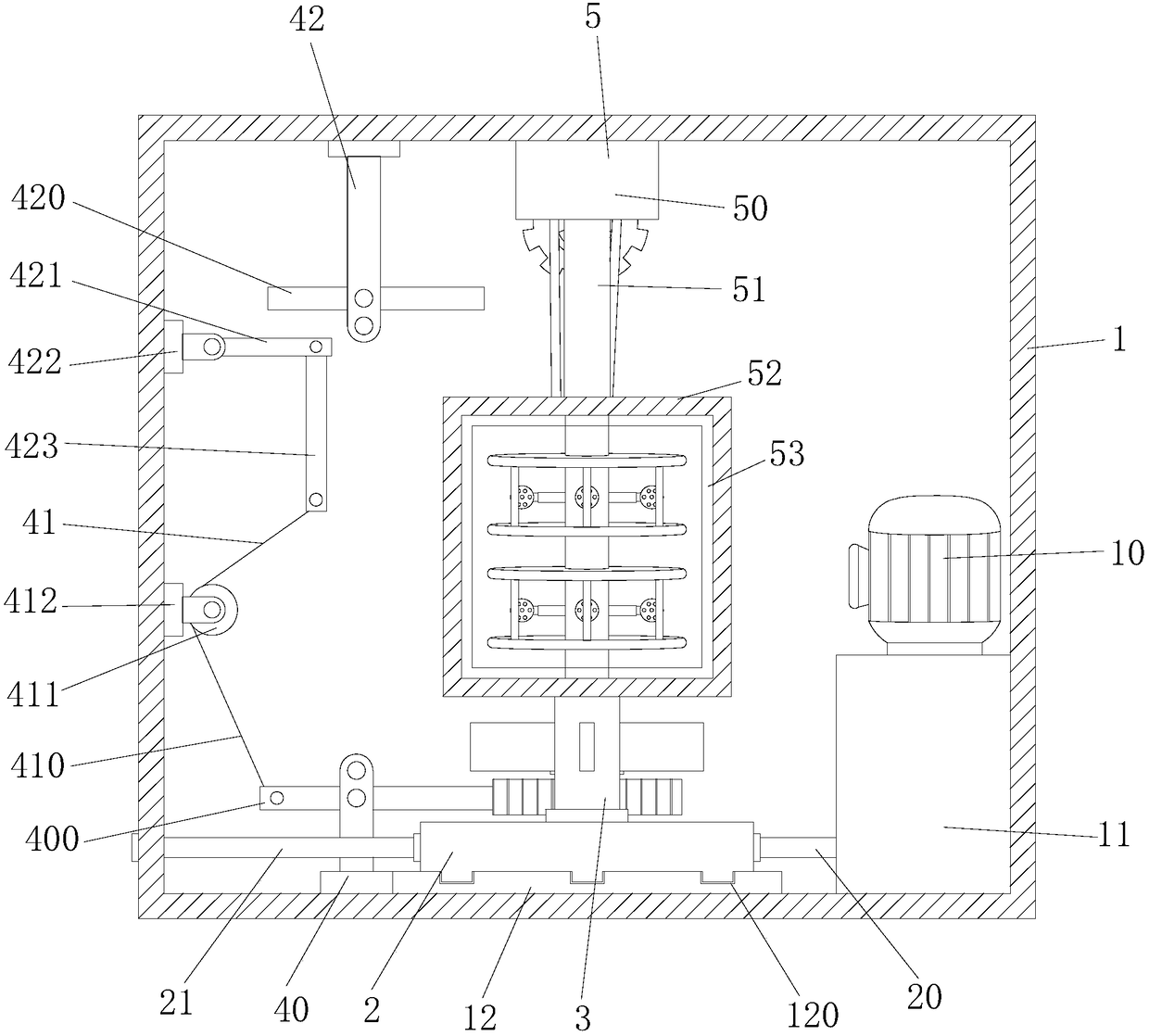

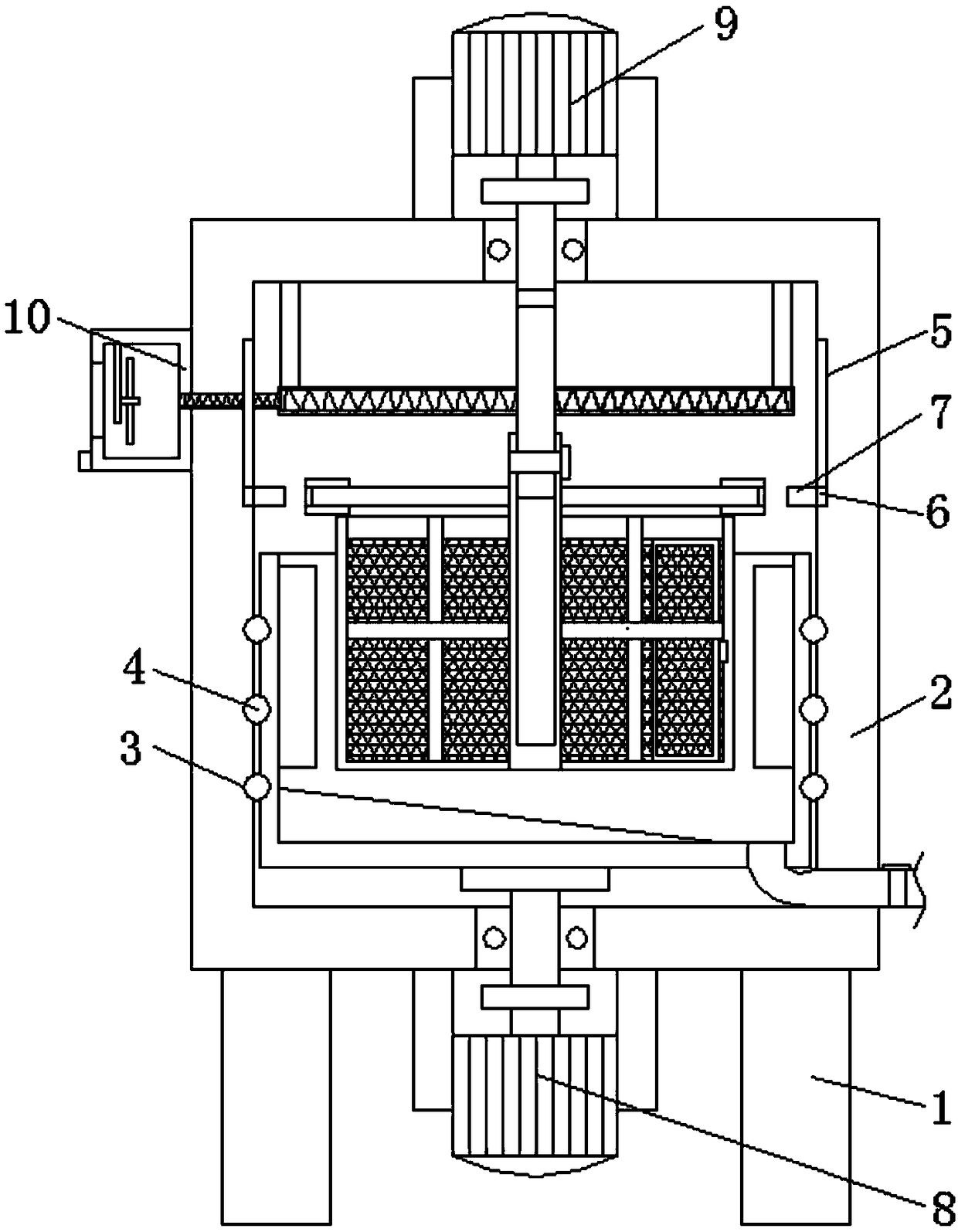

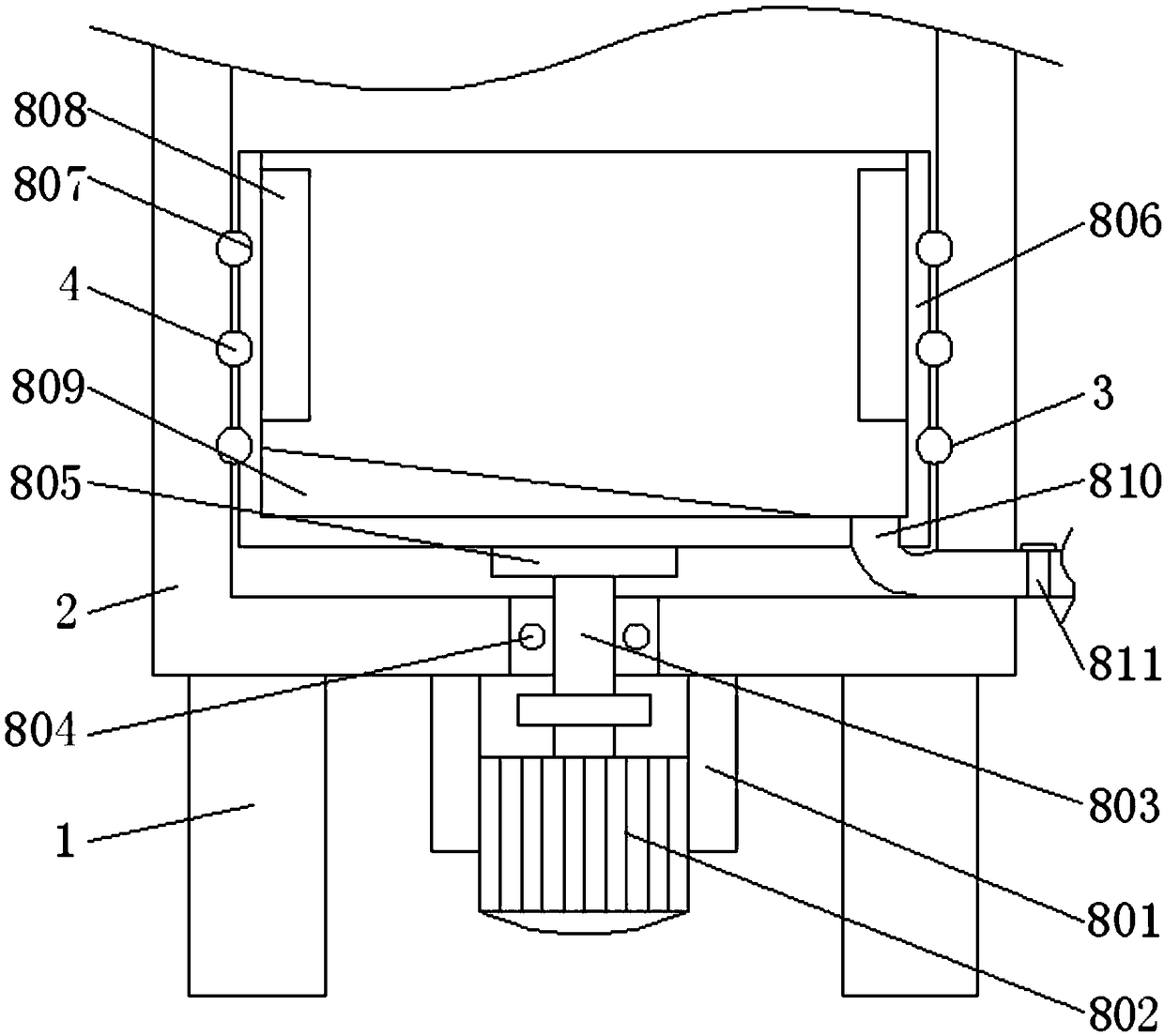

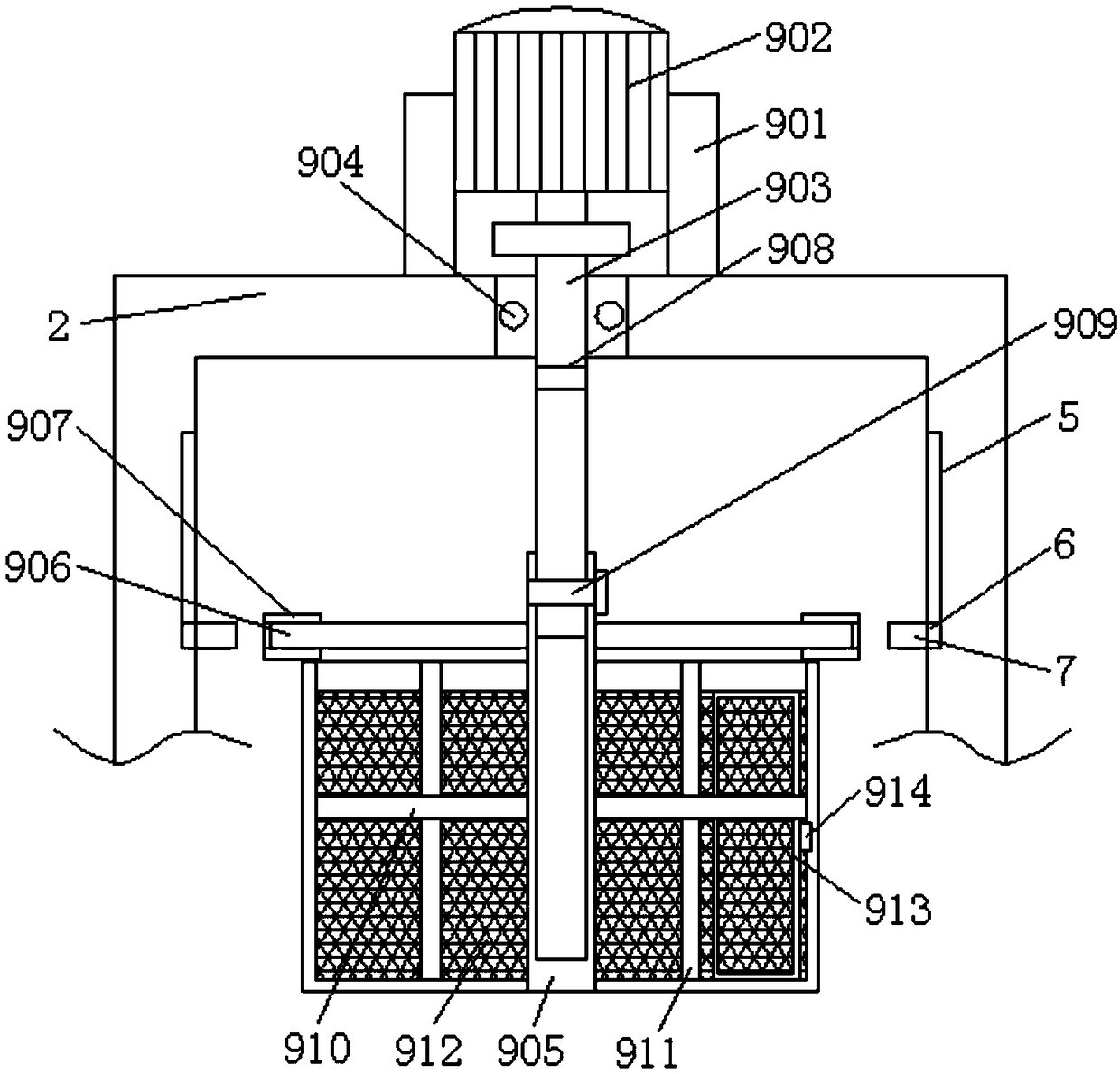

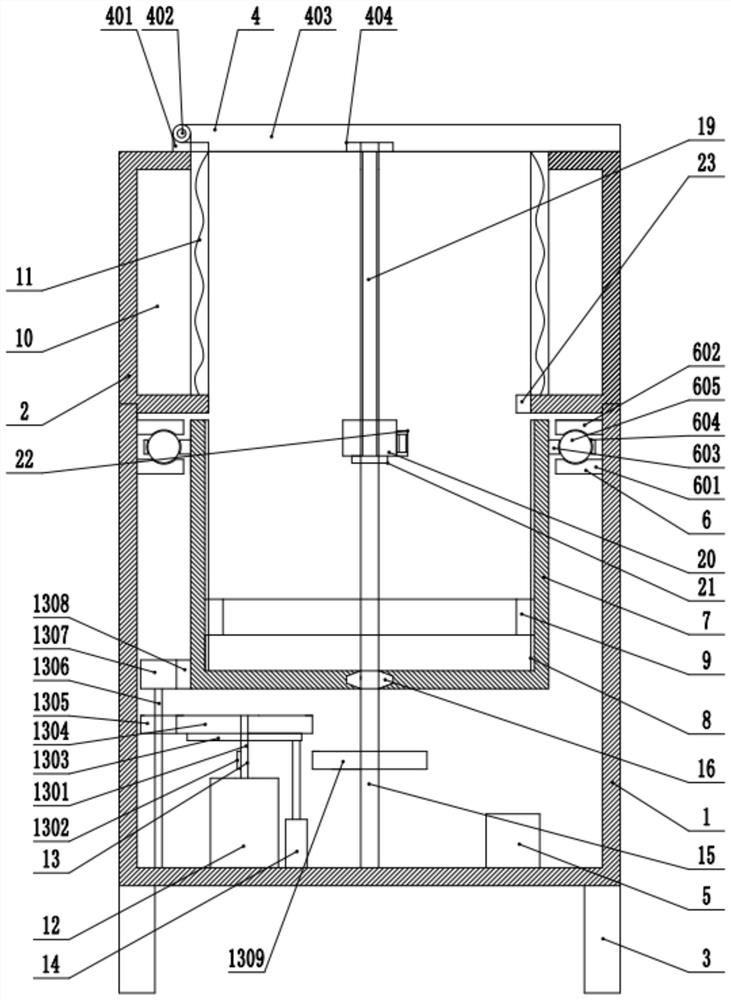

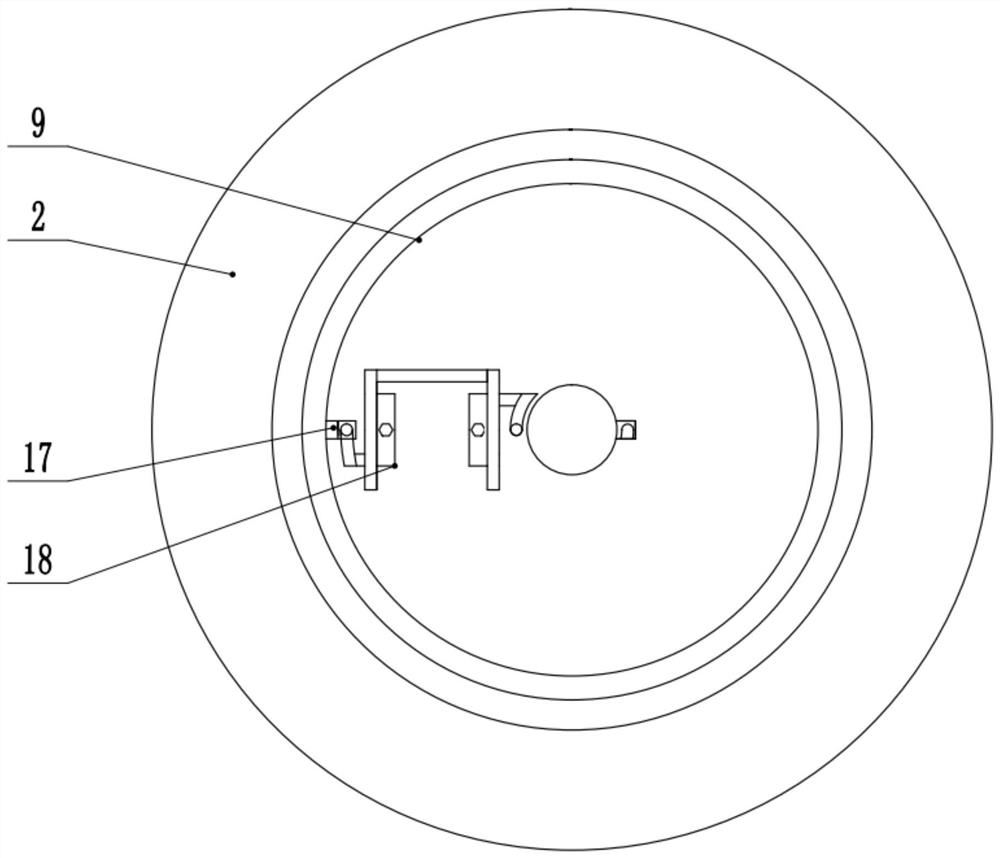

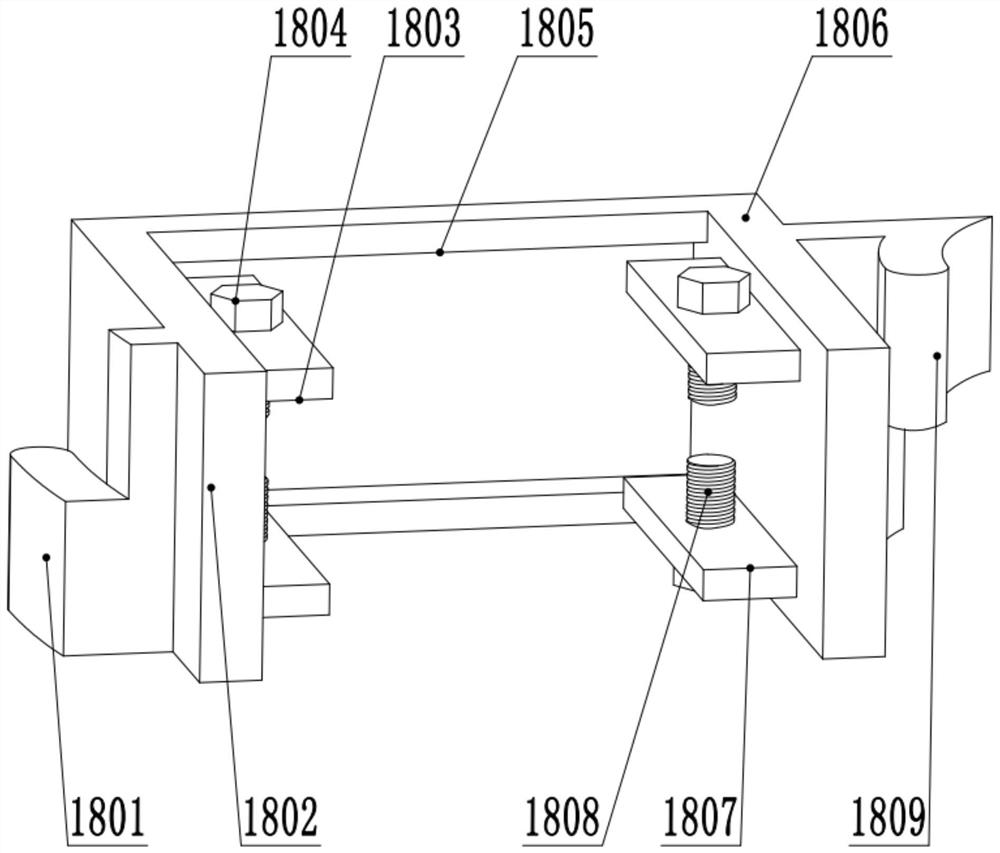

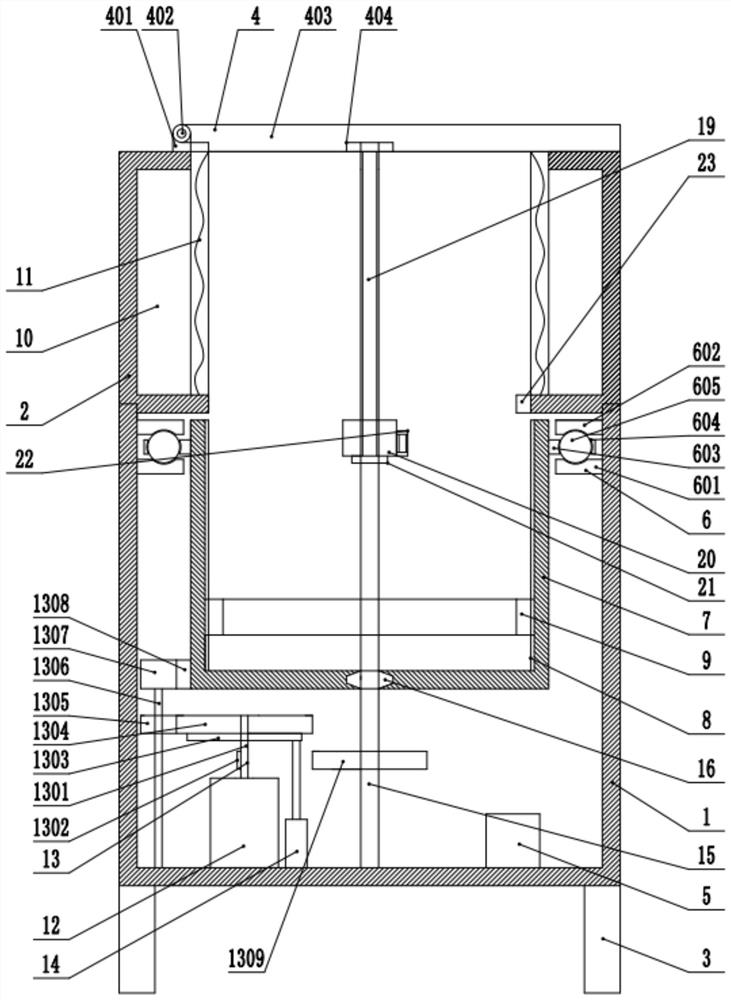

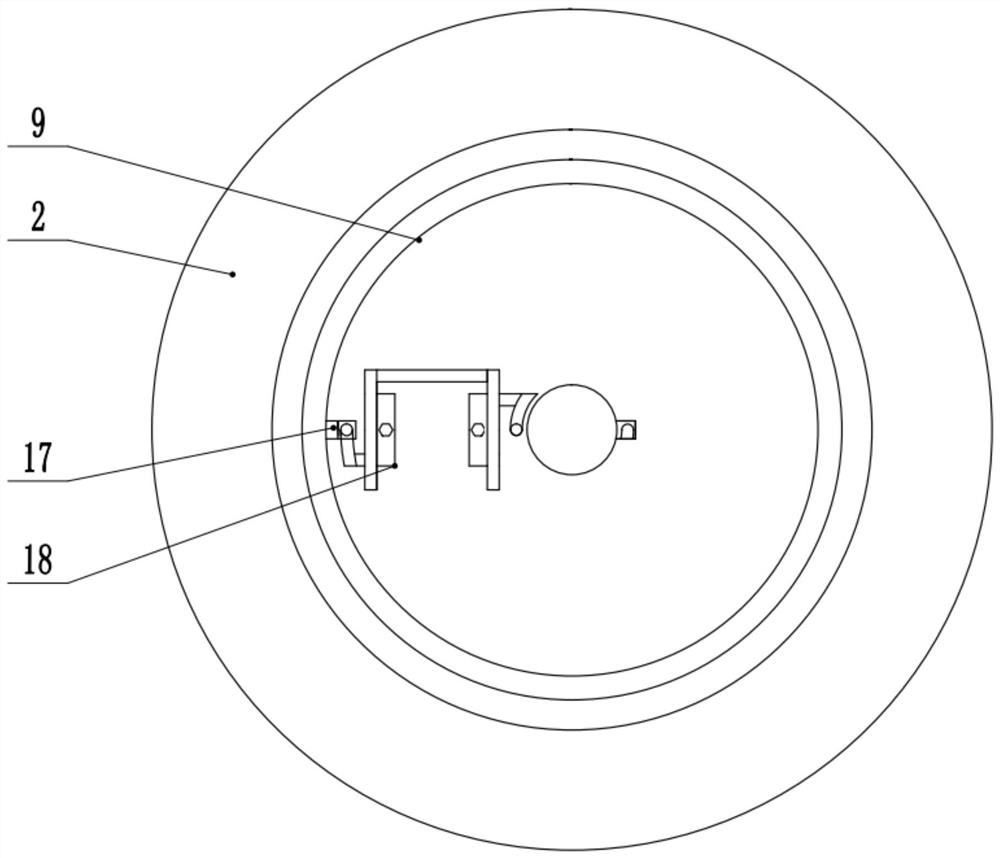

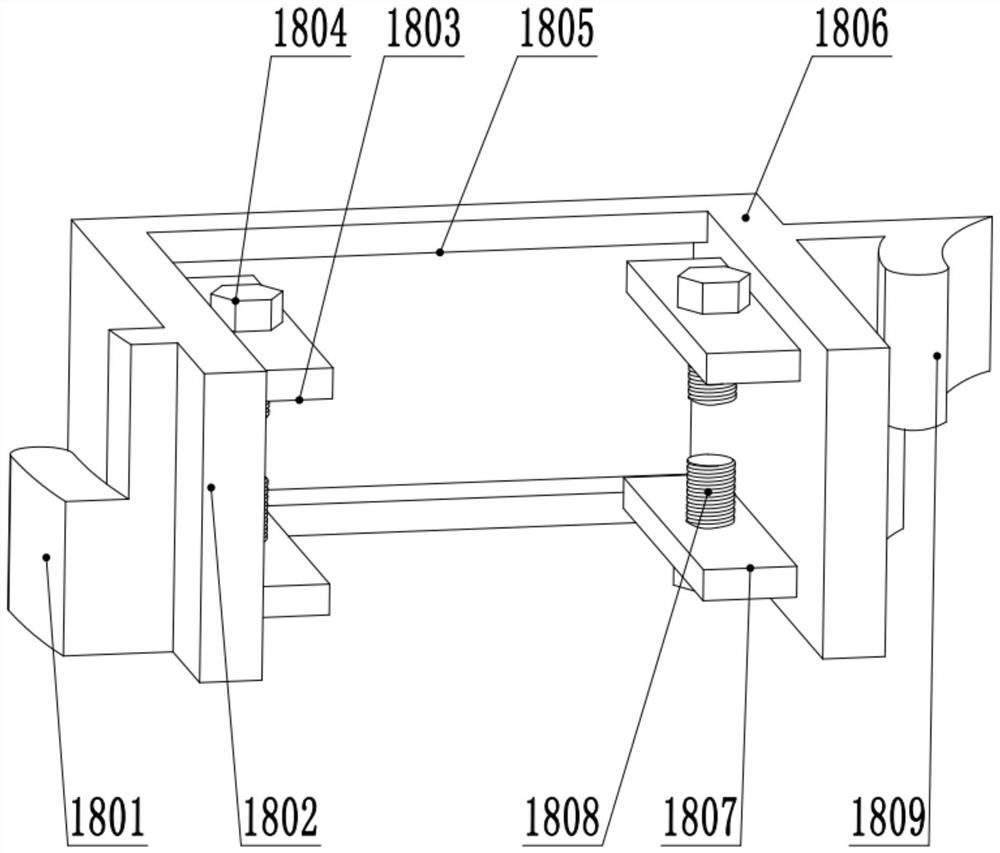

Automatic cleaning and drying device for air valve

InactiveCN102886358BEasy to cleanThere will be no dirty cleaningDrying gas arrangementsDrying machines with local agitationEngineeringMechanical engineering

The invention discloses an automatic cleaning and drying device for an air valve. The automatic cleaning and drying device comprises a motor, a stander, a transmission mechanism, at least one air valve conveying seat, a cleaning mechanism, a drying mechanism and a control device. According to the automatic cleaning and drying device, the air valve is arranged in the air valve conveying seat; the air valve conveying seat with the air valve is sequentially conveyed to a cleaning position and a drying position through the transmission mechanism; then the control device controls the cleaning mechanism and the drying mechanism to act; and therefore, the air valve is automatically cleaned and dried. By the automatic cleaning and drying device, the labor intensity is reduced and the efficiency of cleaning and drying the air valve is improved. Furthermore, by the automatic cleaning and drying device, the intelligent degree is improved, so that a batch of air valves can be cleaned and dried efficiently, and the accuracy of an air valve detection result is guaranteed.

Owner:SOUTH CHINA UNIV OF TECH

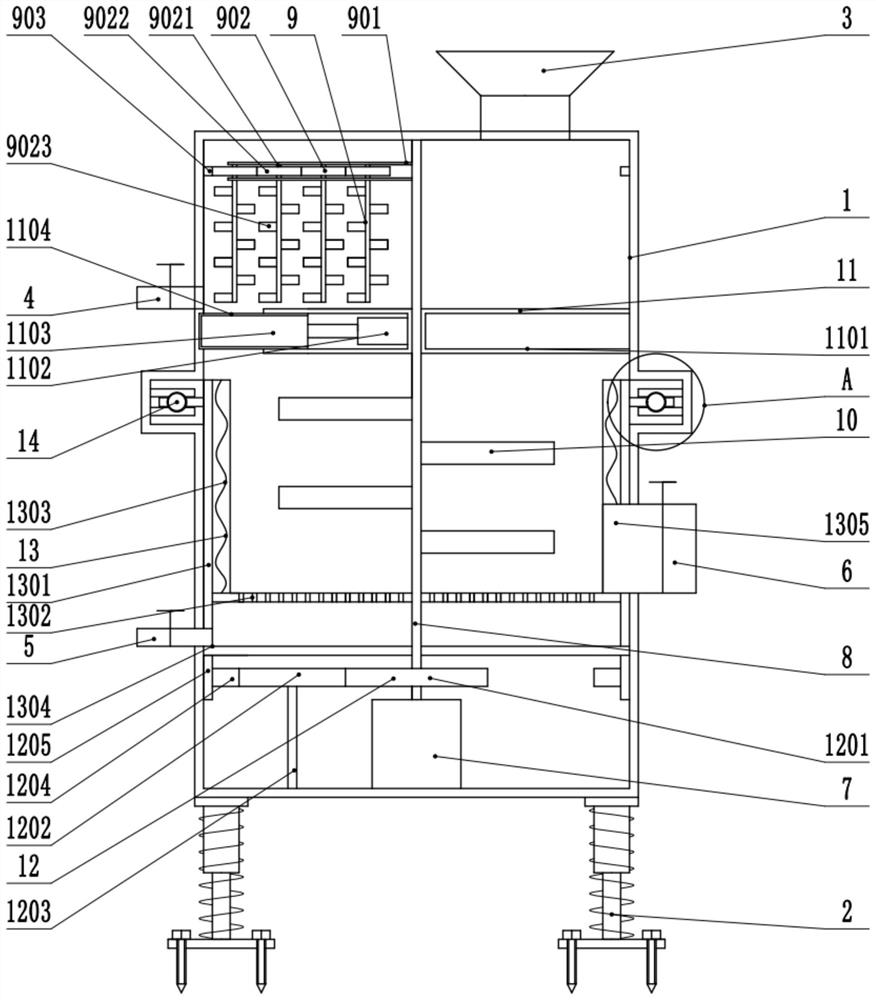

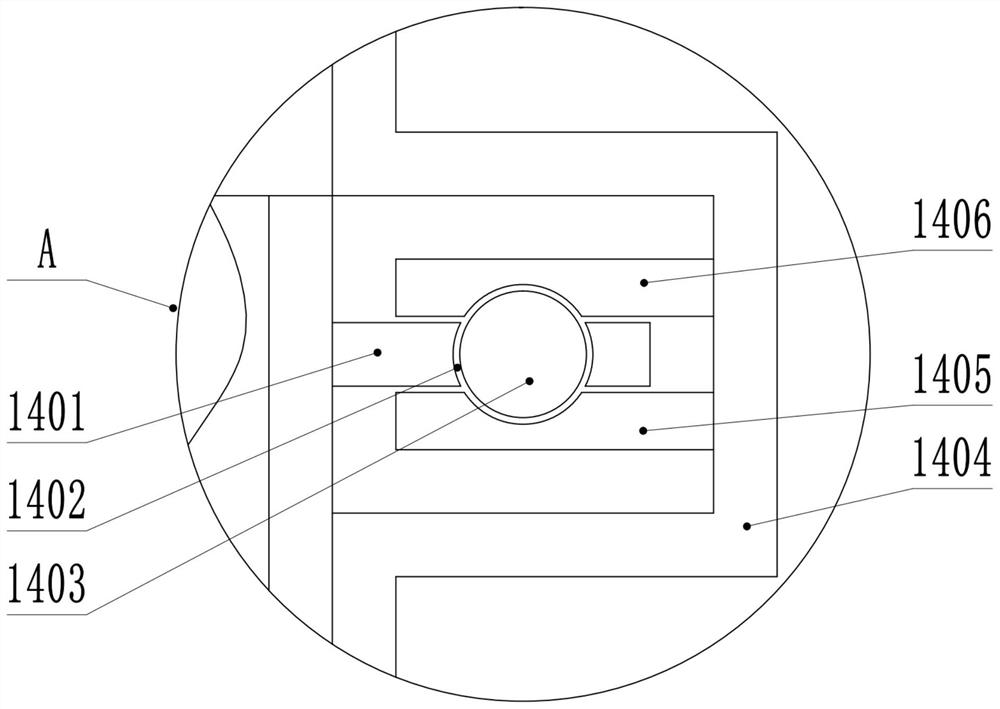

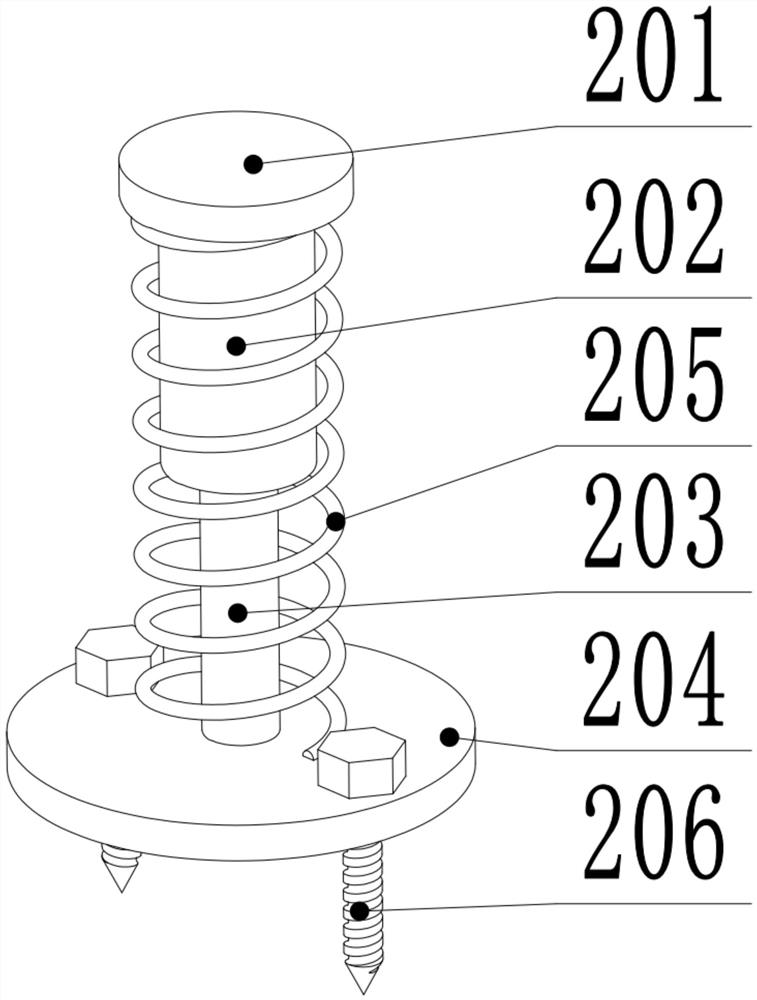

Wool cleaning and drying device for animal husbandry

InactiveCN112458546ARealize connection fixationAchieve rotationTextile treatment containersWool fibre washing/scouringRotational axisAnimal science

The invention discloses a wool cleaning and drying device for animal husbandry, and relates to the field of animal husbandry. The device comprises a box body; the lower surface of the box body is fixedly connected with a damping and fixing mechanism; the upper surface of the box body is fixedly connected with a feeding port; the side edge of the box body is fixedly connected with a first drainageport; the side edge of the box body is located under the first drainage port and fixedly connected with a second drainage port; the right side of the box body is fixedly connected with a discharging port; a motor is fixedly connected to the bottom of the inner side of the box body; a rotating shaft is fixedly connected to an output shaft of the motor; a cleaning mechanism and a plurality of stirring blades are fixedly connected to the rotating shaft; a sealing door mechanism is fixedly connected to the inner wall of the box body; a transmission mechanism is fixedly connected to the rotating shaft and fixedly connected with a drying box mechanism; and a rotary bearing mechanism is fixedly connected between the drying box mechanism and the box body. According to the wool cleaning and dryingdevice, the whole device can be fixedly connected with the ground by arranging the damping and fixing mechanism, and meanwhile, vibration generated when the device works can be buffered, so that the wool cleaning and drying efficiency is improved, and meanwhile the labor cost is reduced.

Owner:罗运敏

Gynecological speculum cleaning and disinfecting device

InactiveCN112058791ARealize vibration cleaningImprove cleaning efficiencyCleaning using liquidsRadiationWater storage tankElectric machinery

The invention particularly relates to a gynecological speculum cleaning and disinfecting device which comprises a cleaning box. A partition plate is horizontally arranged at the bottom end of the inner part of the cleaning box, a waste water tank is arranged on the right side, located at the bottom end of the inner part of the cleaning box, of the bottom end of the partition plate, and a vibrationmotor is arranged on the right side of the waste water tank; a rotating shaft of the vibration motor penetrates through and extends into the upper end of the partition plate to be fixedly connected with a cleaning frame, electric push rods are arranged at the positions, located at the upper end of the partition plate, of the two sides of the cleaning frame, a water pump is arranged on the right side of the vibration motor, and the output end of the water pump communicates with a first water outlet pipe; and the input end of the water pump communicates with a water storage tank through a connected water pipe, an arranged telescopic air cylinder pushes an adjusting plate and a high-temperature sterilization lamp to move by an inclined angle to be inclined to a corresponding position, then pushing is stopped, and the high-temperature sterilization lamp on the adjusting plate is used for conducting high-temperature drying and sterilization on a gynecological speculum on a cleaning frame.The cleaning and drying efficiency of the gynecological speculum by the device is improved.

Owner:王琳琳

Integrated production equipment for non-woven fabric

ActiveCN113388990AEasy to cleanEasy to importSevering textilesLiquid/gas/vapor removal by gas jetsNonwoven fabricMechanical engineering

The invention discloses integrated production equipment for a non-woven fabric. The equipment comprises a fixed base; a rotating disc frame is fixedly connected to the upper surface of the fixed base; a rotating disc is movably connected to the upper surface of the rotating disc frame; the non-woven fabric is connected to the surface of the rotating disc in a wound mode; a cleaning pool is fixedly connected to the upper surface of the fixed base; the inner wall of the cleaning pool is movably connected with a cleaning roller; the inner wall of the cleaning pool is fixedly connected with a cleaning brush; and the upper surface of the cleaning pool is fixedly connected with a guide roller. According to the integrated production equipment for the non-woven fabric, the rotating disc frame and the rotating disc are arranged, so that the non-woven fabric needing to be cleaned can be fixed; the cleaning pool and the cleaning brush are arranged, so that the non-woven fabric in the cleaning pool can be cleaned conveniently; a drying box, a fan heater, a ventilation pipe, an air outlet nozzle and a heater are arranged, so that the cleaned non-woven fabric can be quickly dried, and the non-woven fabric cleaning and drying efficiency is improved; and the equipment is reasonable in structure.

Owner:江苏聚源新材料科技有限公司

Traditional Chinese medicine washing and drying all-in-one machine

InactiveCN108816877AReduce labor intensityImprove cleaning and drying efficiencyDrying gas arrangementsCleaning using liquidsHydraulic cylinderEngineering

The invention discloses a traditional Chinese medicine washing and drying all-in-one machine. The traditional Chinese medicine washing and drying all-in-one machine comprises supporting frames, hydraulic cylinders, washing barrels, rotary shafts, barrel doors, water spraying pipes, valves, a servo motor, a washing cage, a cage door, a conveying belt and an air supply pipe; the hydraulic cylindersare rotationally arranged at the right ends of the supporting frames; the washing barrels are rotationally arranged on the two supporting frames; the rotary shafts are fixedly arranged at the symmetrical positions of the front and back faces of the washing barrels; the rotary shafts are rotationally connected with piston rods of the hydraulic cylinders; the valves are arranged at the left ends ofthe washing barrels; the conveying belt is arranged below the valves; and the air supply pipe opposite to the conveying belt is arranged above the left portion of the conveying belt. The traditional Chinese medicine washing and drying all-in-one machine has the advantages of being convenient to use, relieving the labor intensity of workers, improving the washing and drying efficiency and the like.

Owner:安徽俊祺生物科技有限公司

A handicraft cleaning and drying equipment based on new materials

ActiveCN112077071BQuick clampingQuick releaseCleaning using liquidsHeating arrangementGear wheelNew materials

Owner:邵阳市众兴工艺品有限公司

A rotary displacement type mechanical parts cleaning and drying device

ActiveCN111687119BImprove cleaning and drying efficiencyReduce labor costsDrying solid materials without heatDrying machines with non-progressive movementsVision sensorScrew thread

The invention discloses a rotary displacement type cleaning and drying device for mechanical accessories, which relates to the technical field of parts cleaning equipment, and comprises a lower box body, an upper box body is arranged on the upper part of the lower box body, and the lower surface of the lower box body is fixedly connected with support legs, and the upper box body The upper surface of the box body is fixedly connected to the cover plate mechanism, the bottom of the lower box body is fixedly connected to the controller, the inner wall of the lower box body is fixedly connected to the rotating mechanism, the rotating mechanism is fixedly connected to the cleaning box, and the inner wall of the cleaning box is fixedly connected to the inner threaded sleeve, the inner threaded sleeve The threaded ring is connected to the threaded ring, the inner wall of the threaded ring is fixedly connected to the outer mounting seat, the outer mounting seat is equipped with a clamping mechanism, the lower box is equipped with a servo motor, a transmission mechanism, an electric telescopic rod and a climbing shaft, and the upper box is fixedly connected to a visual sensor , the present invention can realize the station conversion of mechanical parts from cleaning to drying by setting the outer mounting seat, the inner mounting seat and the clamping mechanism, and the cleaning and drying efficiency of the mechanical parts is improved by setting the visual sensor to judge the completion of the cleaning of the parts.

Owner:诸暨市卓昂针织有限公司

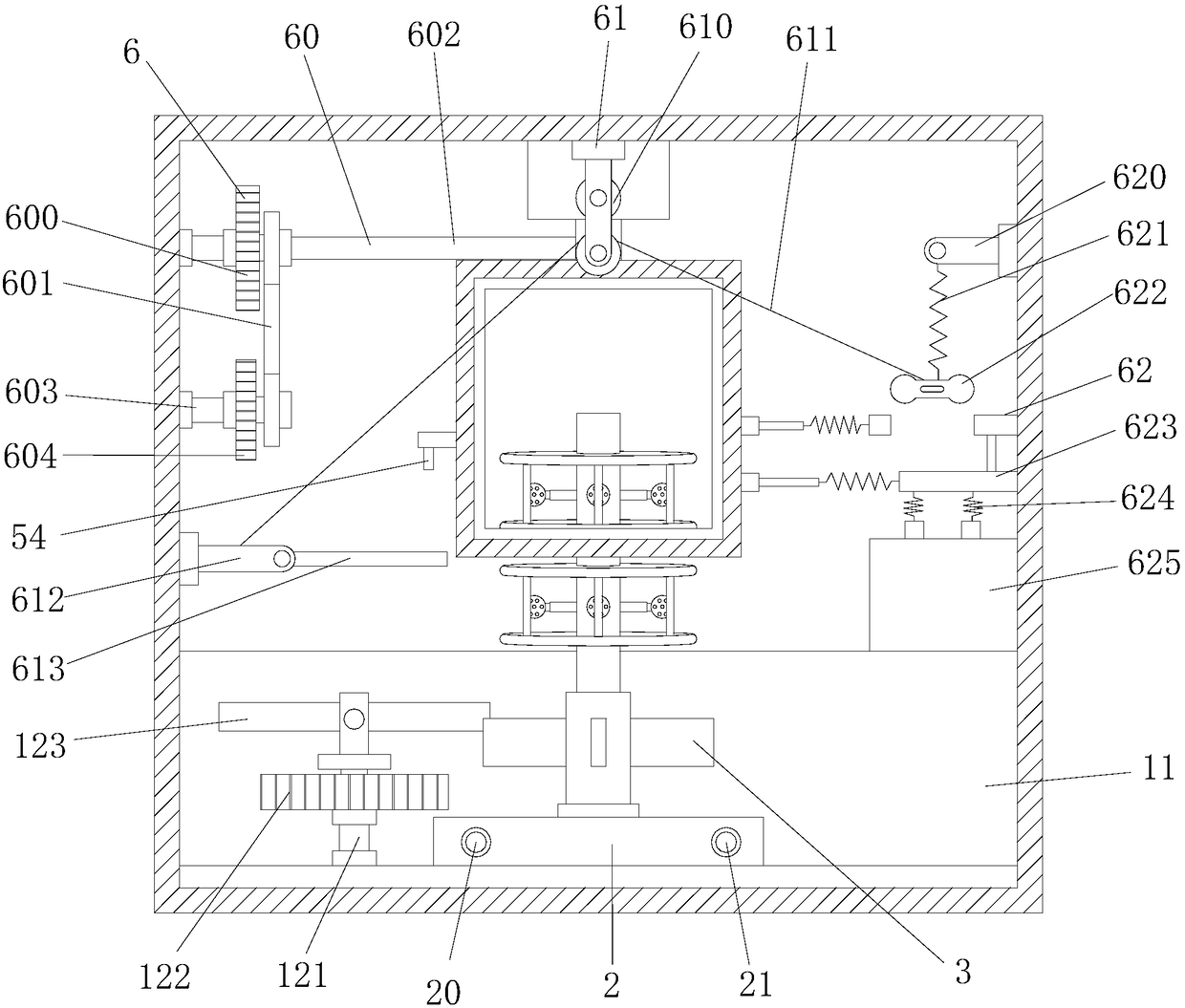

Rotary station-changing type mechanical part cleaning and drying device

ActiveCN111687119AImprove cleaning and drying efficiencyReduce labor costsDrying solid materials without heatDrying machines with non-progressive movementsEngineeringVision sensor

The invention discloses a rotary station-changing type mechanical part cleaning and drying device, and relates to the technical field of part cleaning equipment. The rotary station-changing type mechanical part cleaning and drying device comprises a lower box body, an upper box body is arranged on the upper portion of the lower box body, supporting legs are fixedly connected to the lower surface of the lower box body, a cover plate mechanism is fixedly connected to the upper surface of the upper box body, a controller is fixedly connected to the bottom of the lower box body, the inner wall ofthe lower box body is fixedly connected with a rotating mechanism, the rotating mechanism is fixedly connected with a cleaning box, the inner wall of the cleaning box is fixedly connected with an inner threaded sleeve, the inner threaded sleeve is in threaded connection with a threaded ring, the inner wall of the threaded ring is fixedly connected with an outer mounting seat, a clamping mechanismis arranged in the outer mounting seat, a servo motor, a transmission mechanism, an electric telescopic rod and a climbing shaft are arranged in the lower box body, and a visual sensor is fixedly connected to the interior of the upper box body. According to the rotary displacement type mechanical part cleaning and drying device, station changing from cleaning to drying of mechanical parts can be achieved by arranging the outer mounting seat, an inner mounting seat and the clamping mechanism, and the cleaning completion condition of the parts is judged by arranging the visual sensor, so that the cleaning and drying efficiency of the mechanical parts is improved.

Owner:诸暨市卓昂针织有限公司

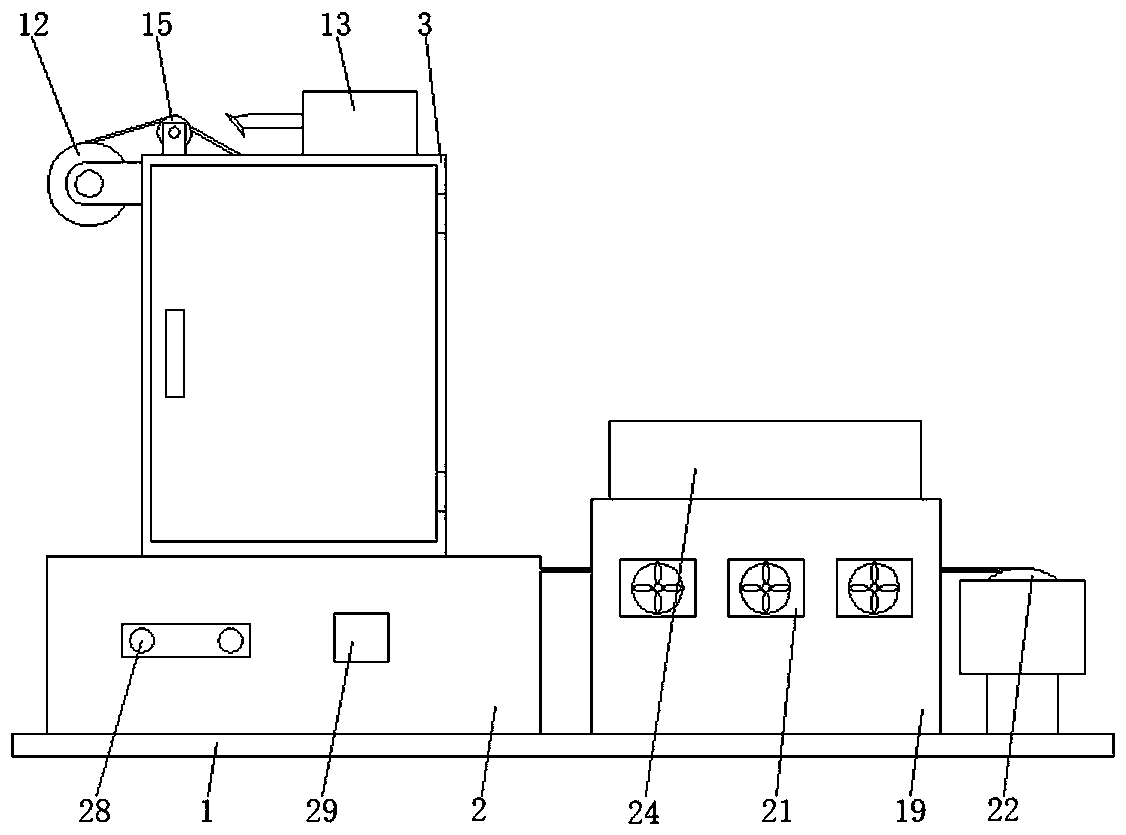

Rice processing, cleaning and drying integrated equipment

PendingCN114653647AImprove cleaning and drying efficiencyEasy to take outDrying gas arrangementsCleaning using liquidsAgricultural scienceAgricultural engineering

The rice processing, cleaning and drying integrated equipment comprises a machine body, a roller is arranged on one side of the machine body, a cover plate is arranged at the end, not connected with the machine body, of the roller, a supporting head is arranged at the end, facing the outside, of the cover plate, the cover plate and the supporting head are rotationally connected together, and a water guide plate is arranged at the top of the machine body along the position over the roller. A water guide plate is arranged on the machine body, the water guide plate and the machine body are connected together through a bolt, a dryer is arranged at the position, aligned to the rear end of the roller, of the machine body, and two fans are symmetrically arranged on the back face of the dryer. The problems that rice needs to be transferred into drying equipment to be dried after being washed, and accordingly the production and processing efficiency of the rice is affected are solved, the structure of washing equipment is improved and optimized, so that the rice is washed and dried in one equipment in the production and processing process of the rice, and the production and processing efficiency of the rice is improved. Therefore, the rice cleaning and drying efficiency is effectively improved.

Owner:颍上县锡安山米业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com