Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

149results about How to "Guaranteed winding effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Control method for electronic expansion valve during sudden indoor load change of air conditioner

ActiveCN106322640AAvoid the risk of overheating or even shutdownGuaranteed winding effectSpace heating and ventilation safety systemsSpace heating and ventilation control systemsEngineeringControl theory

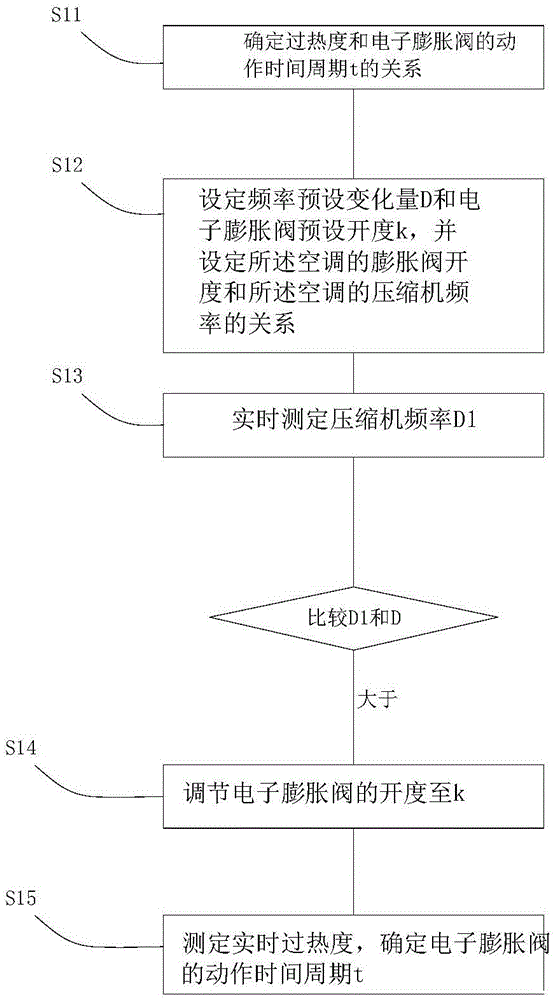

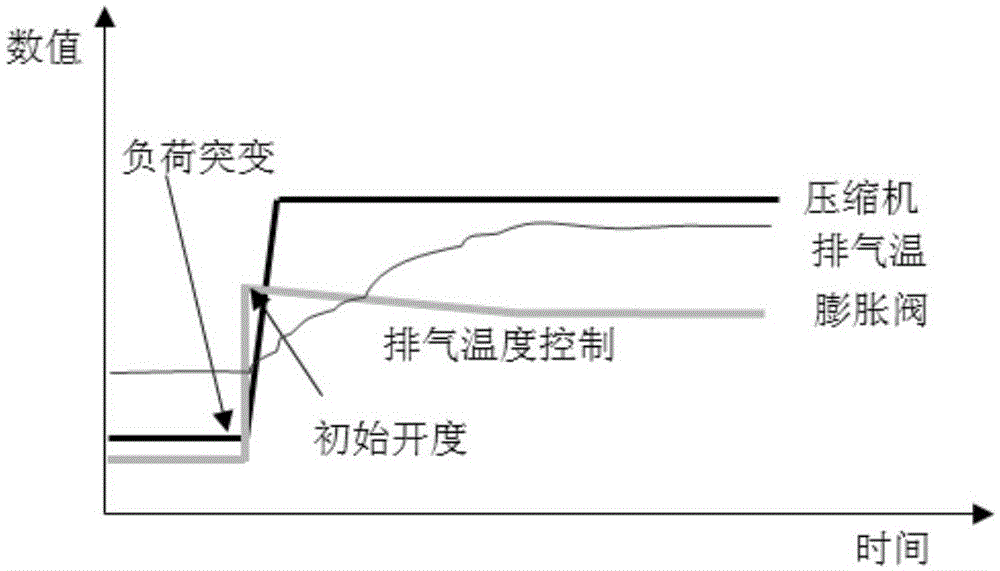

The invention provides a control method for an electronic expansion valve during sudden indoor load change of an air conditioner. The control method comprises the steps that preset frequency variation and preset opening of the electronic expansion valve are set, and the relationship between the expansion valve opening of the air conditioner and the compressor frequency of the air conditioner is set; the compressor frequency of the air conditioner is measured in real time; if the variation of the compressor frequency of the air conditioner is greater than the preset frequency variation, the compressor opening is adjusted to the preset opening of the electronic expansion valve; and the real-time superheat degree of the air conditioner is measured, and the action time cycle of the expansion valve is determined according to the real-time superheat degree. According to the control method, by setting the preset opening of the electronic expansion valve, when sudden load change happens, the compressor frequency and the opening of the electronic expansion valve are changed simultaneously, so that the risk of overheating or even halting caused by circulation volume insufficiency caused by sudden change of revolutions of the compressor can be effectively avoided, so that air outlet performance is ensured, and the compressor is also protected.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

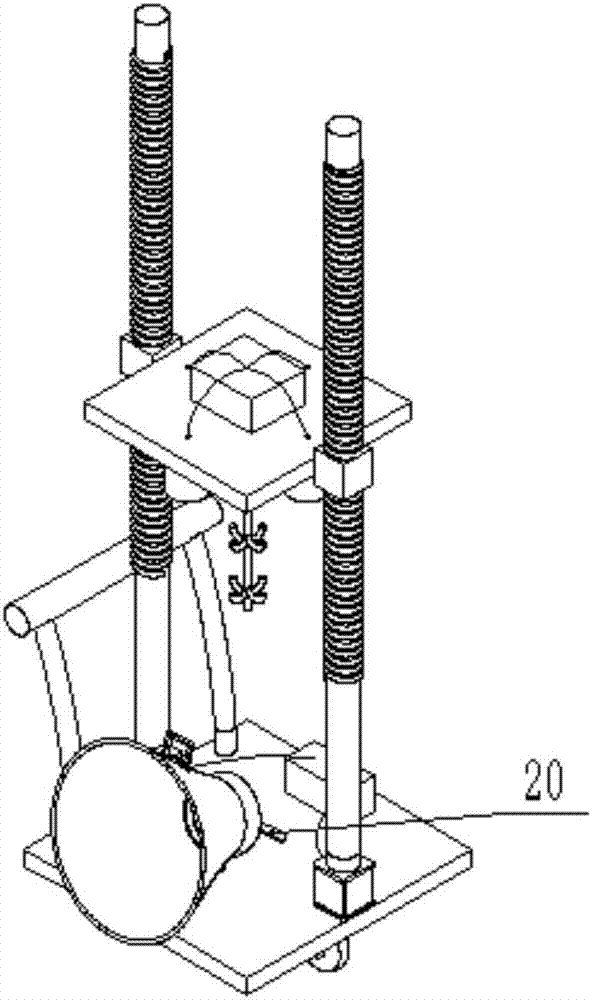

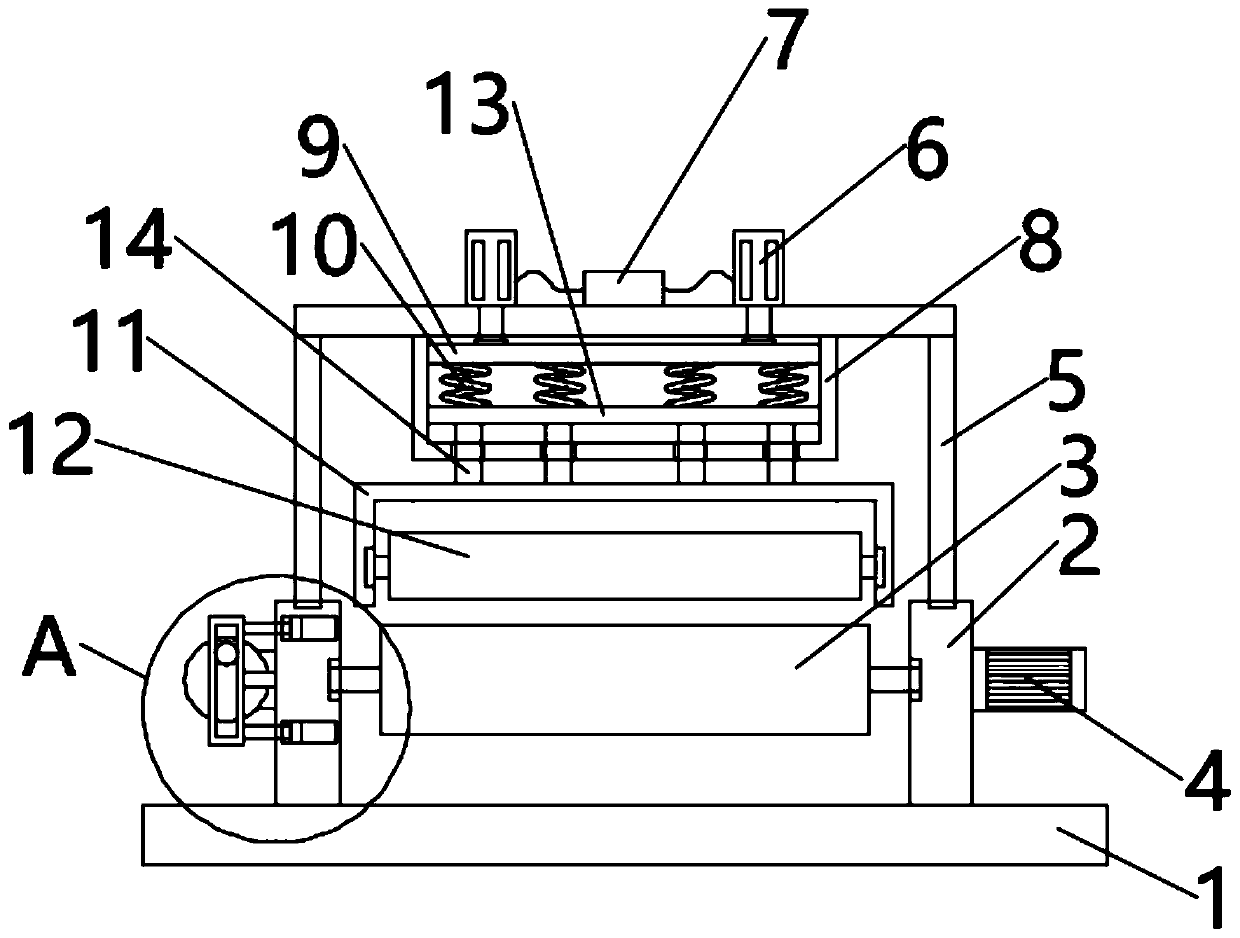

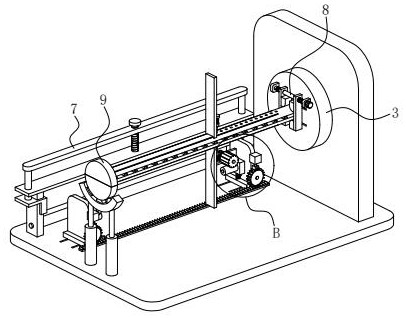

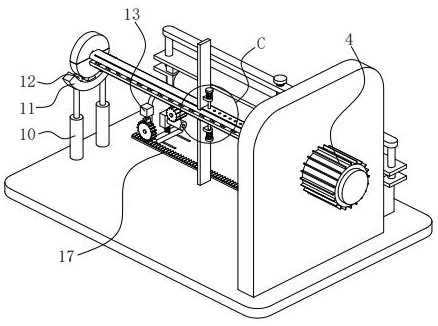

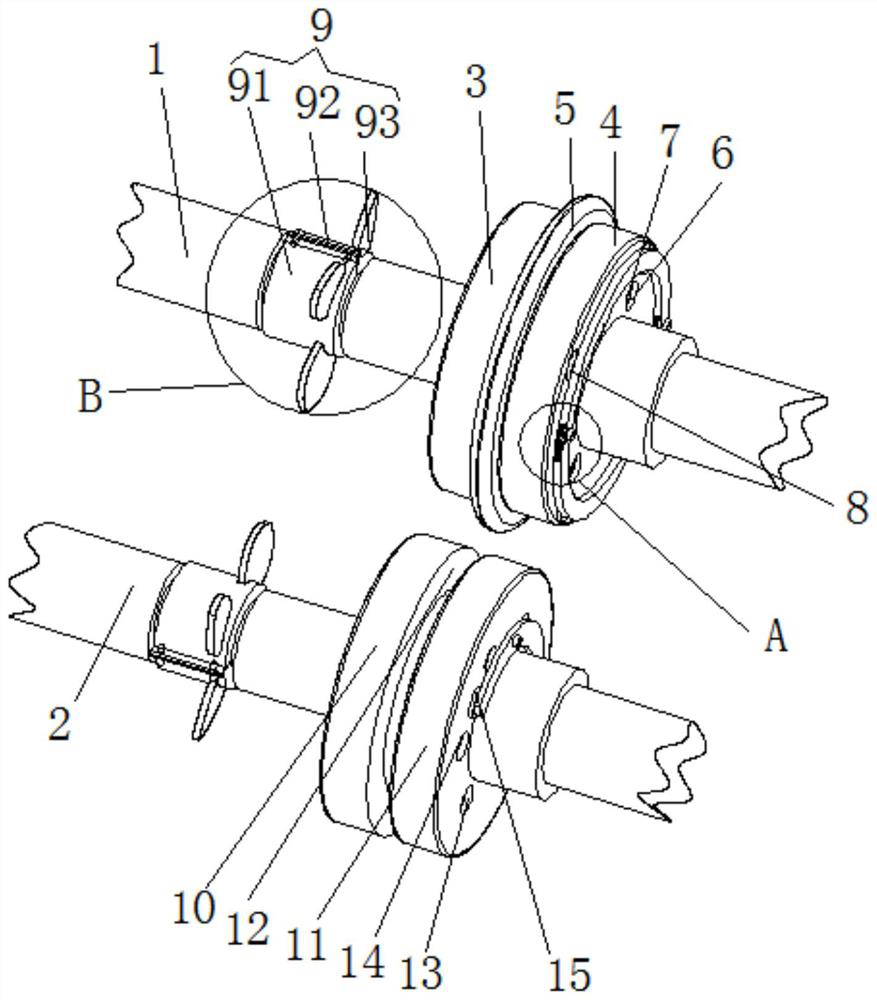

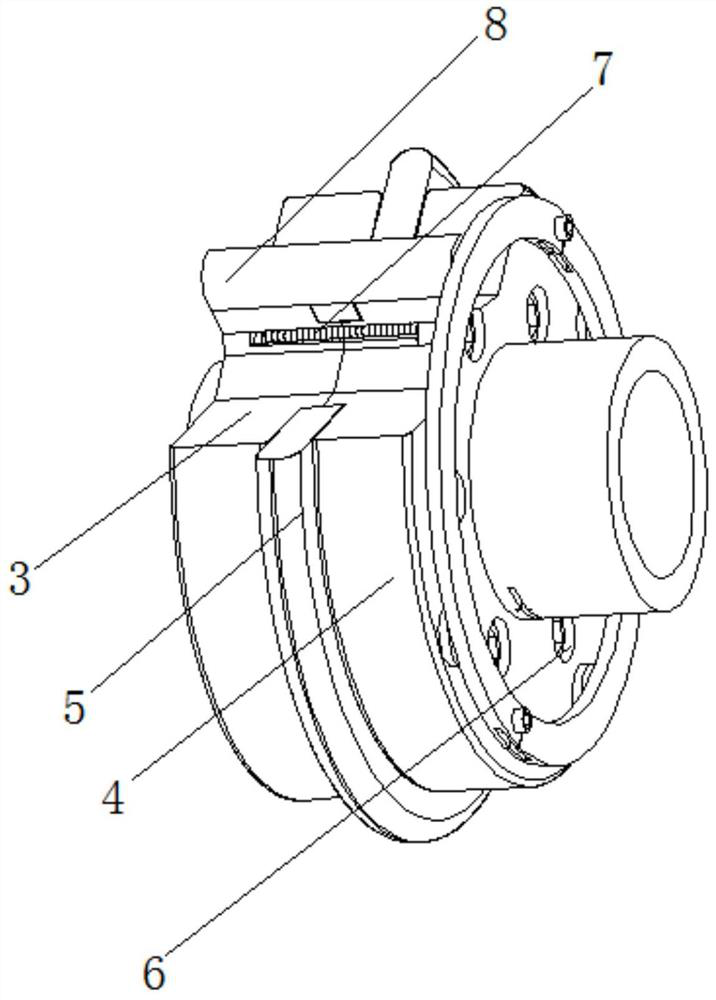

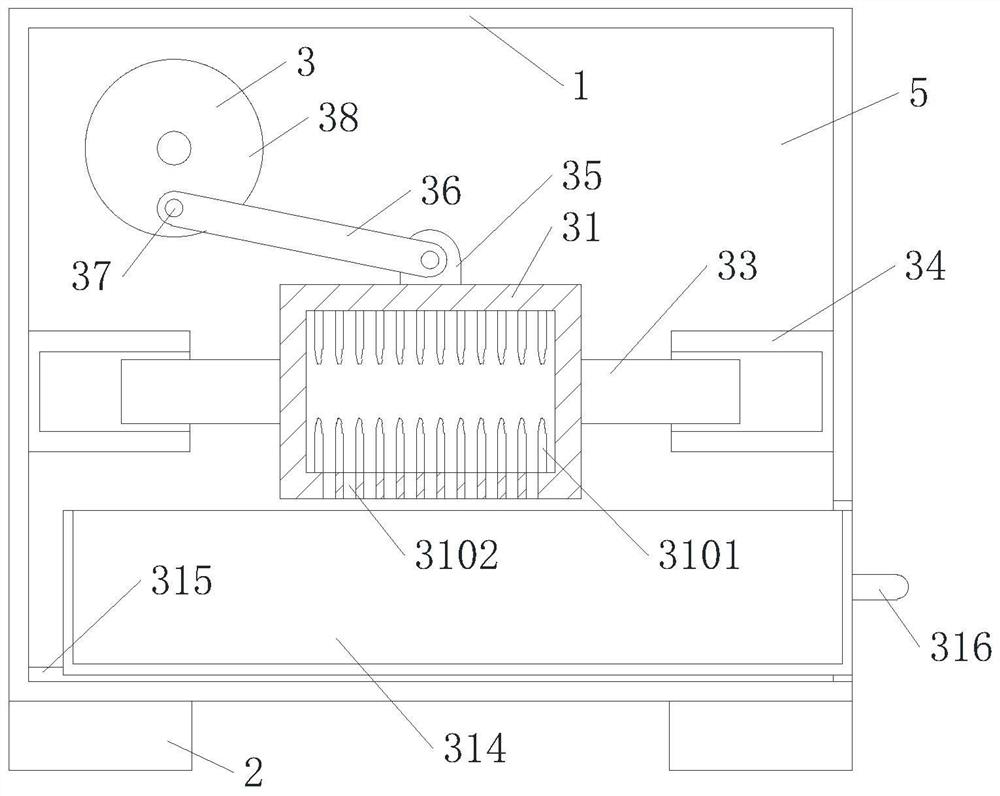

Small-scale copper wire winding mechanism capable of moving leftwards and rightwards

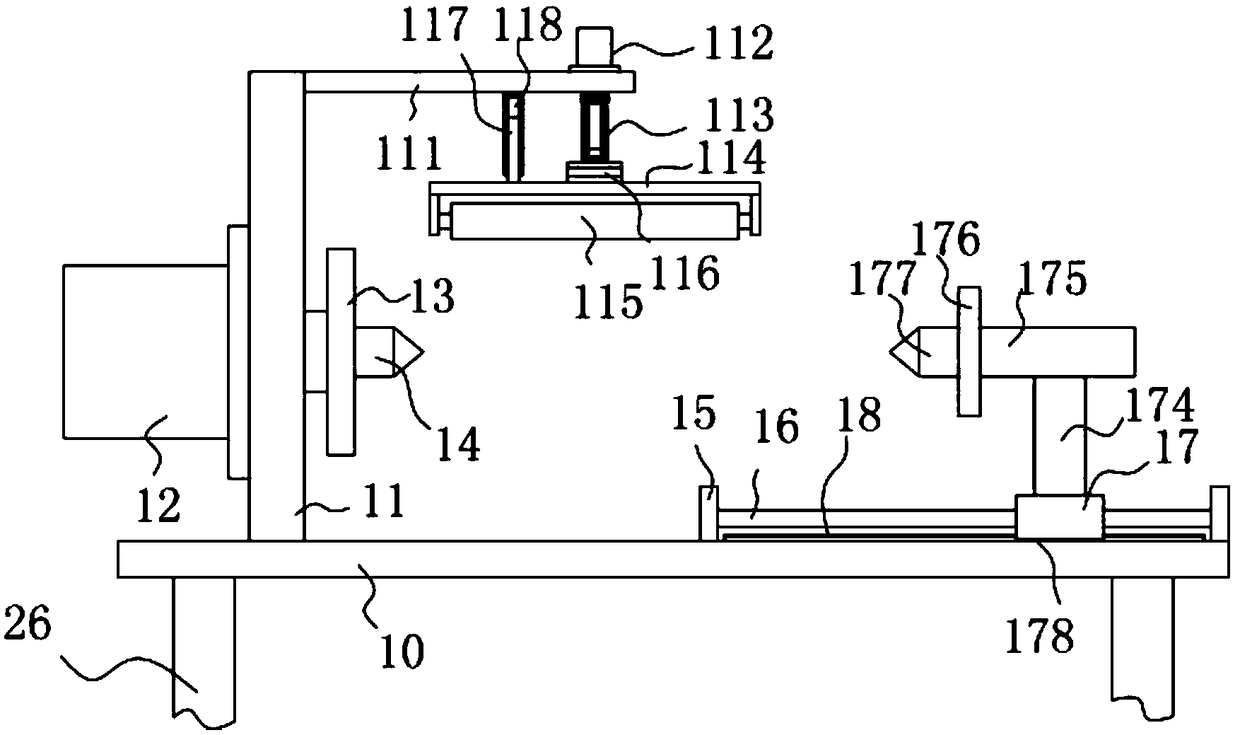

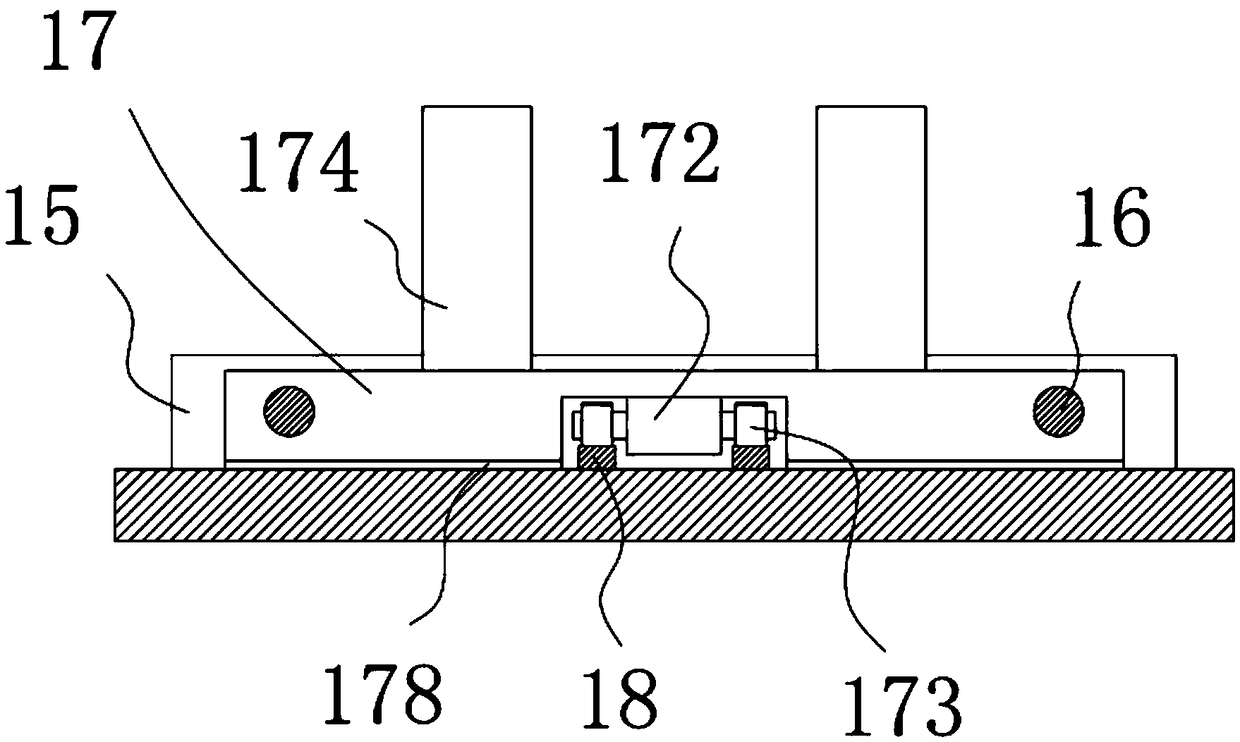

The invention discloses a small-scale copper wire winding mechanism capable of moving leftwards and rightwards. The small-scale copper wire winding mechanism capable of moving leftwards and rightwardscomprises a main base plate and a supporting and fixing frame. Side supporting plates are fixed to the top faces of the left side and the right side of the base plate of the supporting and fixing frame. The two ends of a main transverse screw are hinged to the two side supporting plates through bearings. A movable transmission gear is fixed to one end of the main transverse screw. A main movablemotor is fixed to the outer side wall of one side supporting plate. The output shaft of the main movable motor penetrates through the corresponding side supporting plate, and a movable driving gear isfixed to the output shaft of the main movable motor. The movable driving gear is meshed with the movable transmission gear. Two lower vertical plates are fixed to the bottom face of the main base plate. The two lower vertical plates are in threaded connection with the main transverse screw. A vertical supporting plate is fixed to the top face of the left side of the main base plate. A rotary servo motor is fixed to the left side wall of the vertical supporting plate. A movable block in the position of a right ejector pin of the winding mechanism can move leftwards and rightwards automatically, and thus a small barrel body for winding is mounted and disassembled conveniently. Besides, positions of two limiting plates can be adjusted automatically, and thus positions of two proximity switches are adjusted.

Owner:FOSHAN XUNTUOAO TECH CO LTD

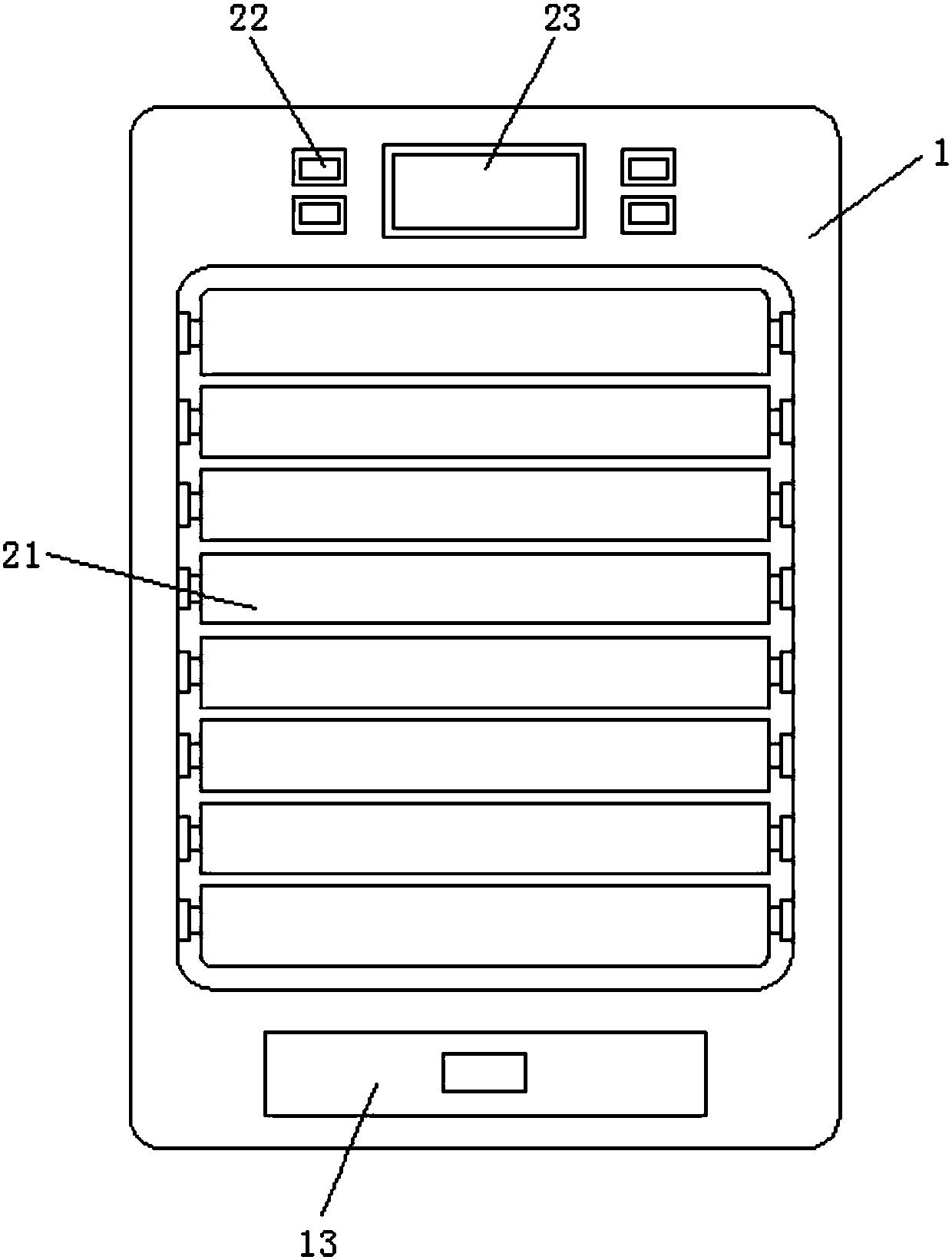

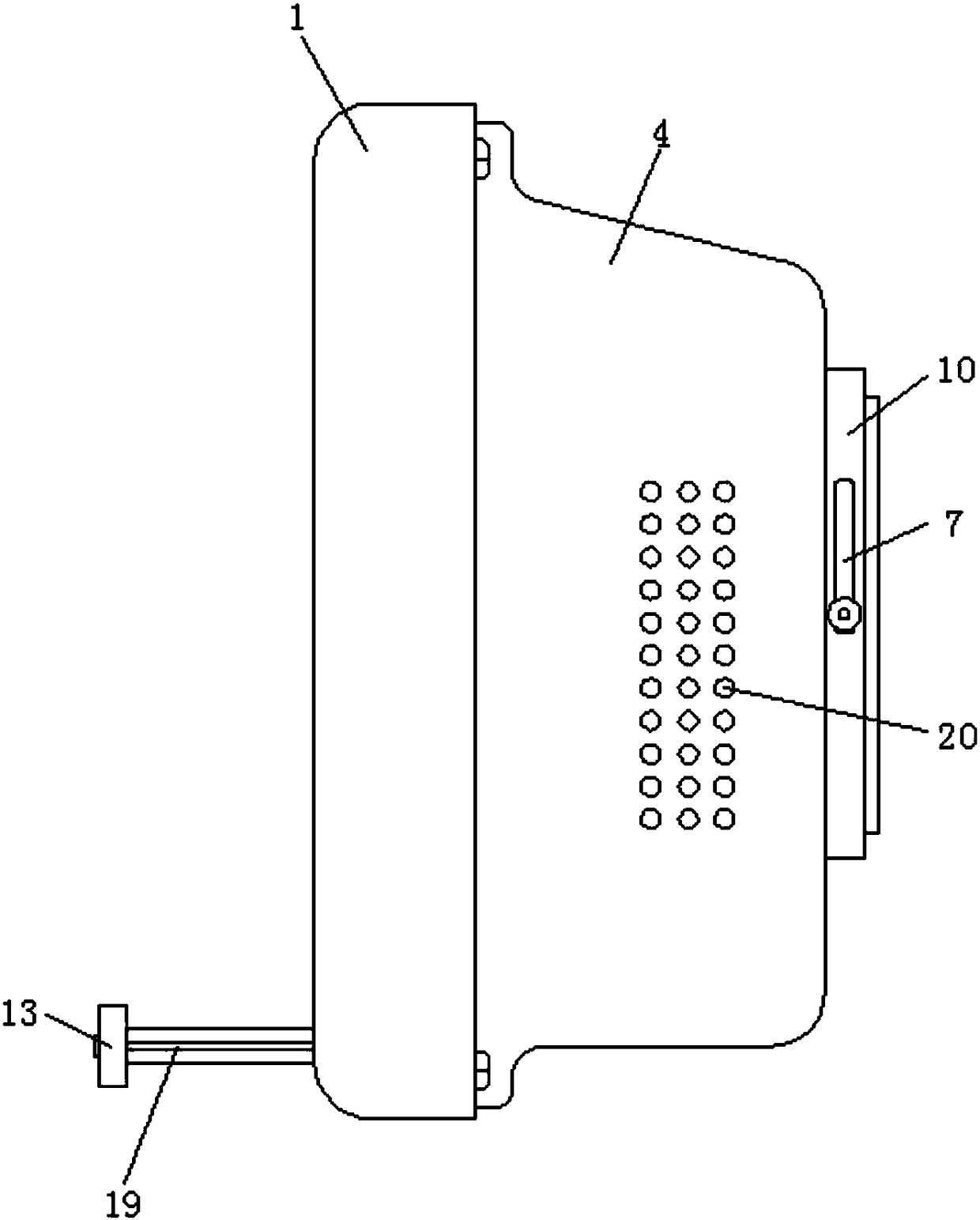

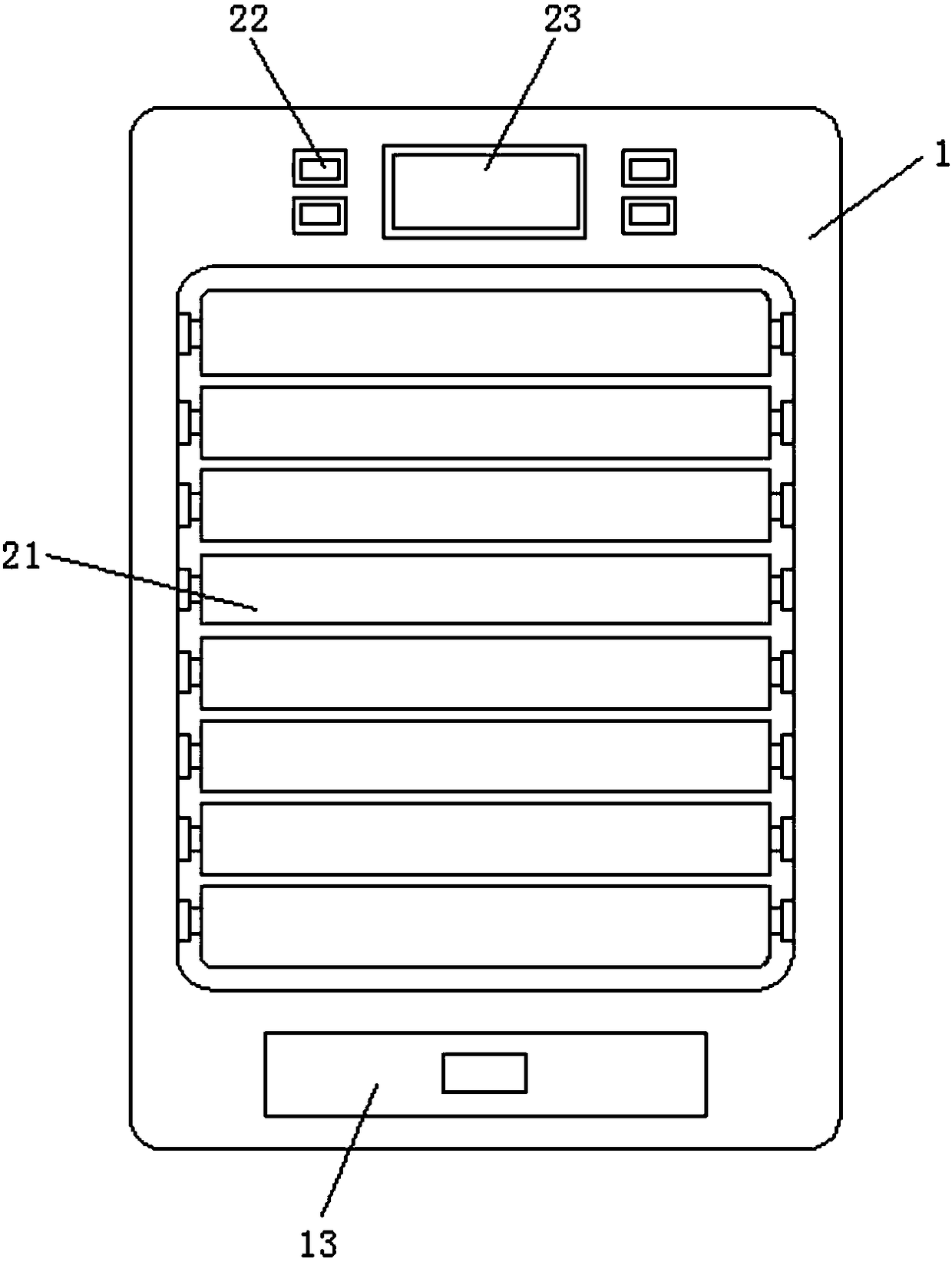

Medical gauze winder

InactiveCN109850649ATo prevent positional deviationEnsure hygieneChemicalsArticle deliveryEngineeringMedical treatment

The invention discloses a medical gauze winder comprising a box. A first rectangular opening is formed in the outer surface of the left side of the box. A second rectangular opening is formed in the outer surface of the front side of the box. A motor is fixedly connected with the inner surface of the box. The outer surface of an output shaft of the motor is fixedly connected with a rotating shaft.According to the medical gauze winder, after gauze is wound to a certain thickness, the medical gauze winder can automatically stop and cut off the gauze, so that the work efficiency is effectively improved; in the winding process, a first circular ring shell, a second circular ring and a shell limit the winding position of the gauze, it is avoided that the gauze deviates, and the winding effectis guaranteed; the distance between the first circular ring and the second circular ring can be adjusted according to the width of the gauze, and the whole winding process is conducted in the box; andbefore winding, an atomizing sprayer sprays sterilizing mist to the gauze to sterilize the gauze, and therefore the sanitary conditions of the gauze are guaranteed.

Owner:YANTAI POWER SUPPLY COMPANY OF STATE GRID SHANDONG ELECTRIC POWER +2

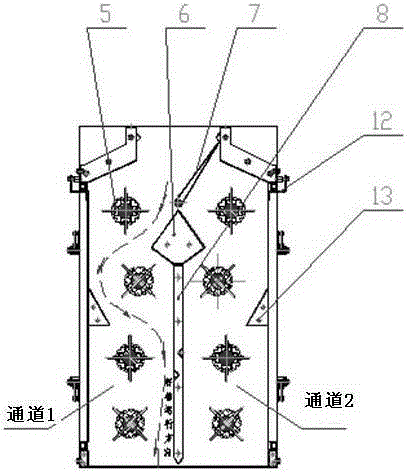

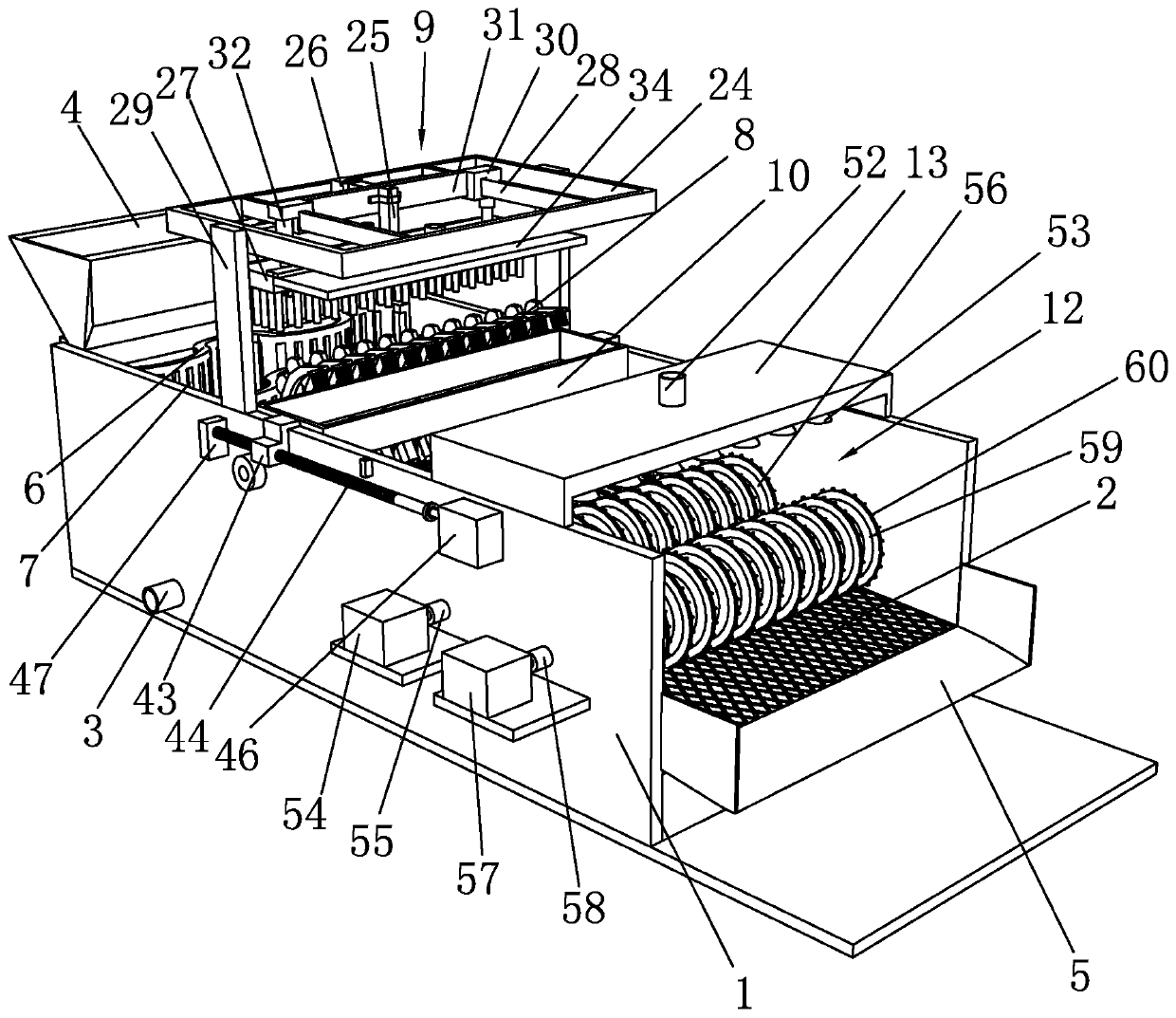

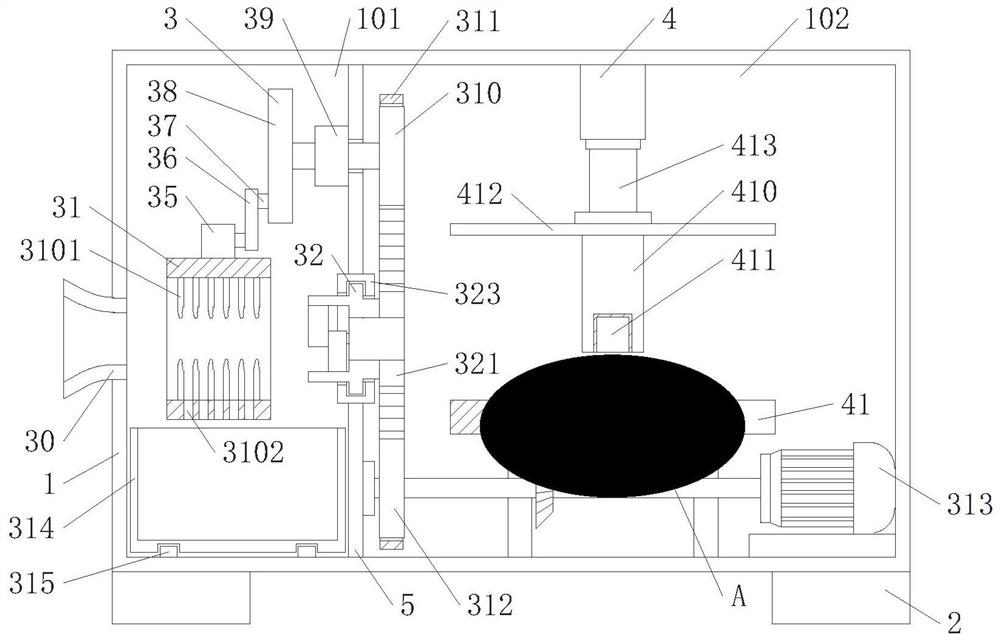

Seed cotton foreign fiber treatment system

The present invention relates to a cotton processing technique device, and concretely discloses a seed cotton foreign fiber treatment system. The system comprises foreign fiber treatment assemblies which are disposed at left and right sides and separated by a middle separating plate, lower parts of the two foreign fiber treatment assemblies are communicated with discharge ports, an upper part of the middle separating plate is provided with a flip plate which can turn left and right, each foreign fiber treatment assembly comprises a wall board support and at least two winding rolls fixed on the wall board support, and the winding rolls are in S-shaped up-down arrangement. The beneficial effects of the system are that normal production is not impacted while cleaning the winding rolls; the cleaning efficiency is high, the cleaning strength is adjustable, and with safety protection measures, a cleaning system which can ensure personal safety of operators during cleaning is realized.

Owner:SHANDONG SWAN COTTON INDAL MACHINERY STOCK

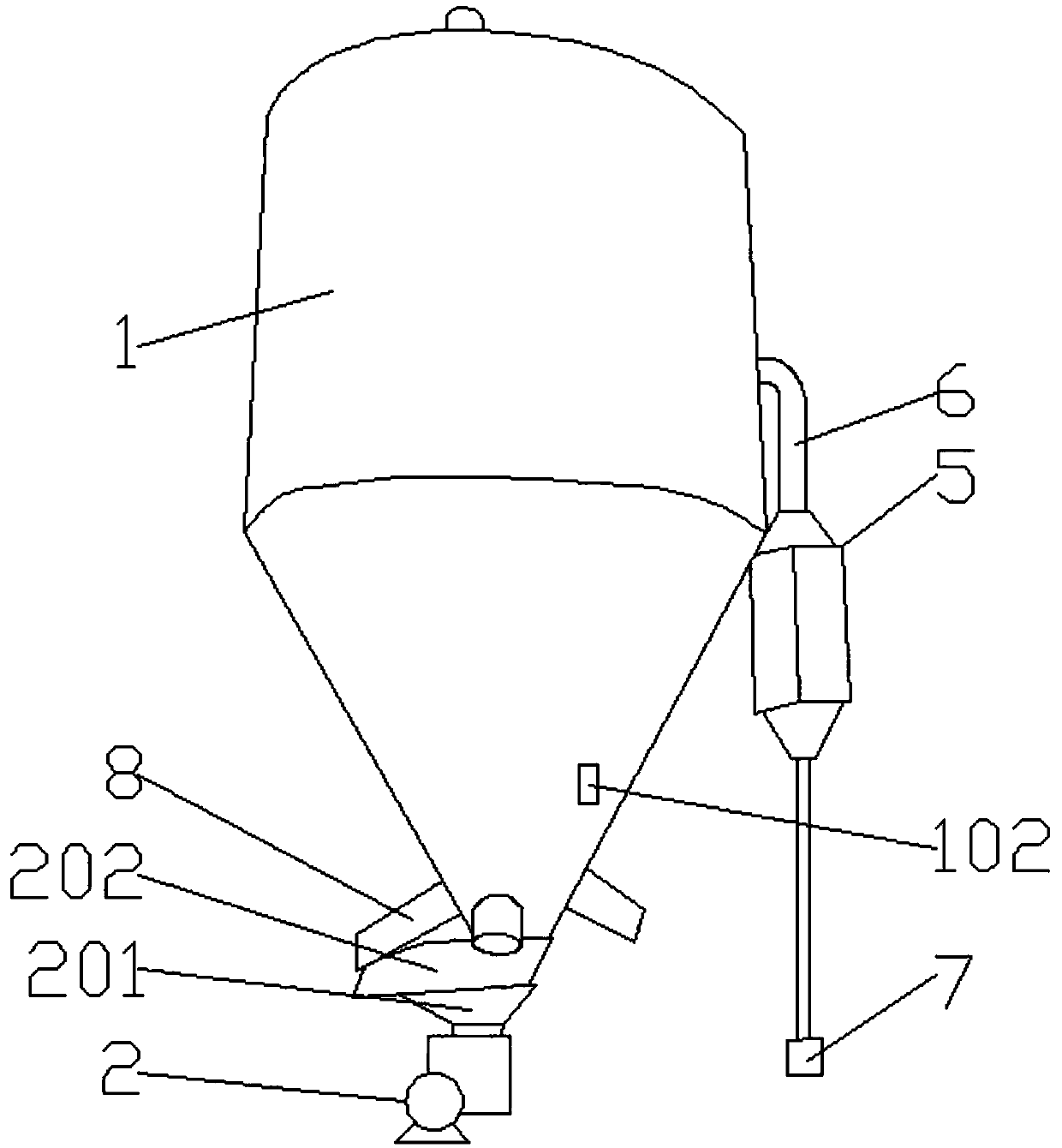

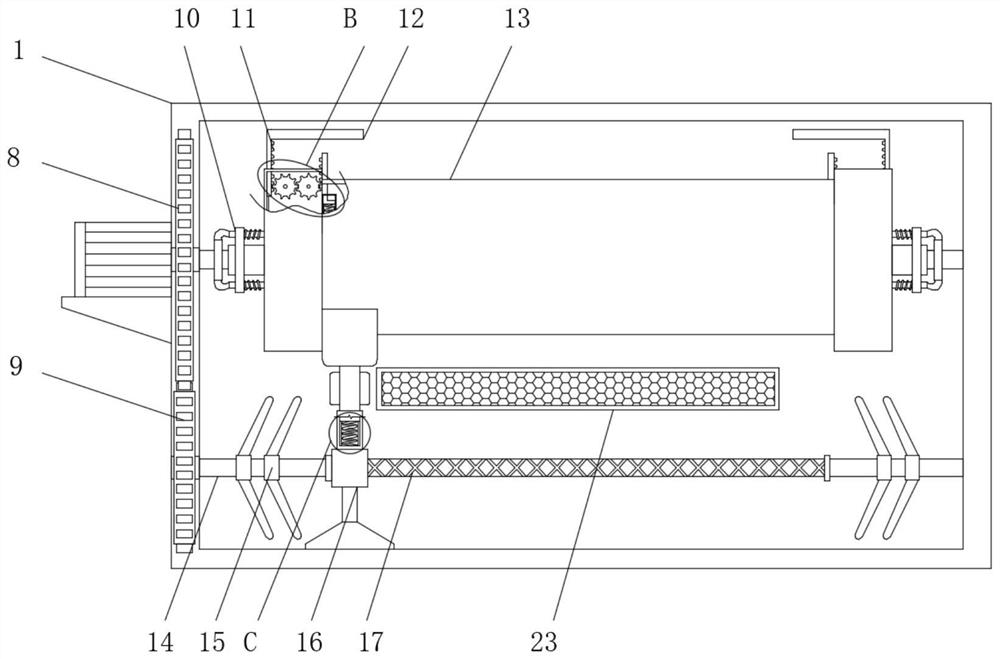

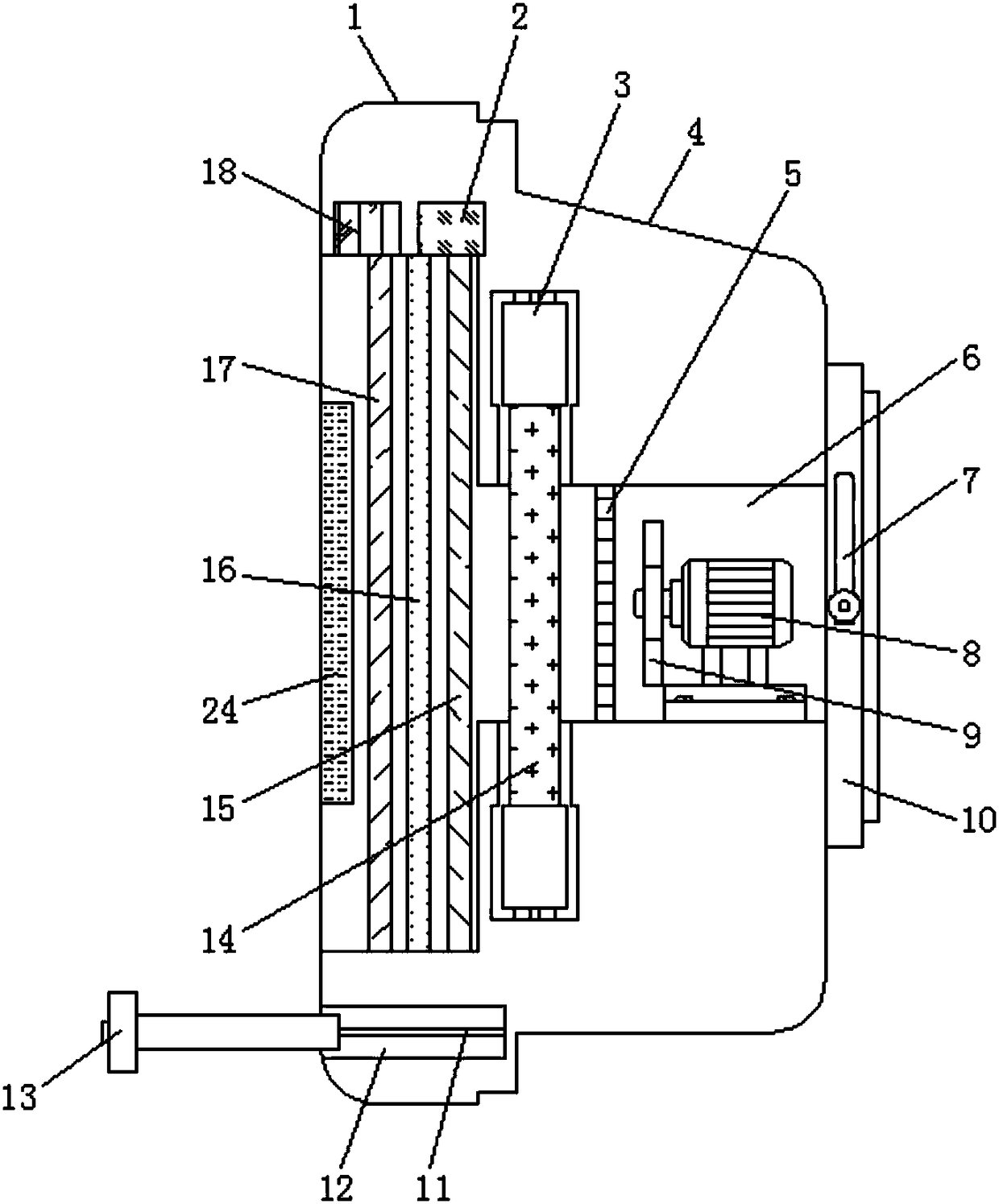

Urban ecological river sediment pre-treatment system and treatment method

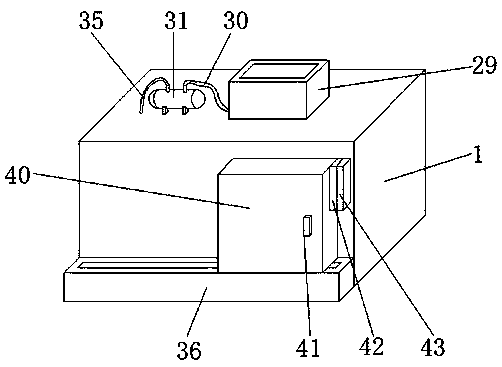

InactiveCN110372161AGuaranteed winding effectEasy to handleSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesFlocculationSewage

The invention discloses an urban ecological river sediment pre-treatment system. The urban ecological river sediment pre-treatment system comprises a treatment box, the treatment box is internally provided with a water strainer plate arranged in an inclined mode, the water strainer plate separates the inner part of the treatment box into a treatment cavity and an accumulated water cavity which arearranged up and down, the treatment cavity is divided into a filtering cavity, a winding cavity, an adsorption cavity and a flocculation cavity from left to right, the winding cavity is internally provided with a winding assembly, a sewage cleaning assembly is arranged on the upper part of the winding assembly, a sewage accumulating box is arranged on the right side of the winding assembly, and the adsorption cavity is internally provided with an adsorption assembly. A treatment method comprises the following steps of (1) filtering treatment, (2) winding and impurity removing treatment, (3) adsorption treatment, (4) flocculation dehydration treatment, and (5) cleaning and maintenance. According to the urban ecological river sediment pre-treatment system and the treatment method, stone, impurities and the like in sediment are removed through the filtering cavity, suspended impurities in the sediment are removed in a winding mode through design of the winding cavity, magnetic materialsin the sediment are adsorbed through the absorption cavity, and finally flocculation is conducted on the sediment through the flocculation cavity, and follow-up dehydration and drying treatment is conveniently conducted on the sediment.

Owner:浙江永安工程咨询集团有限公司

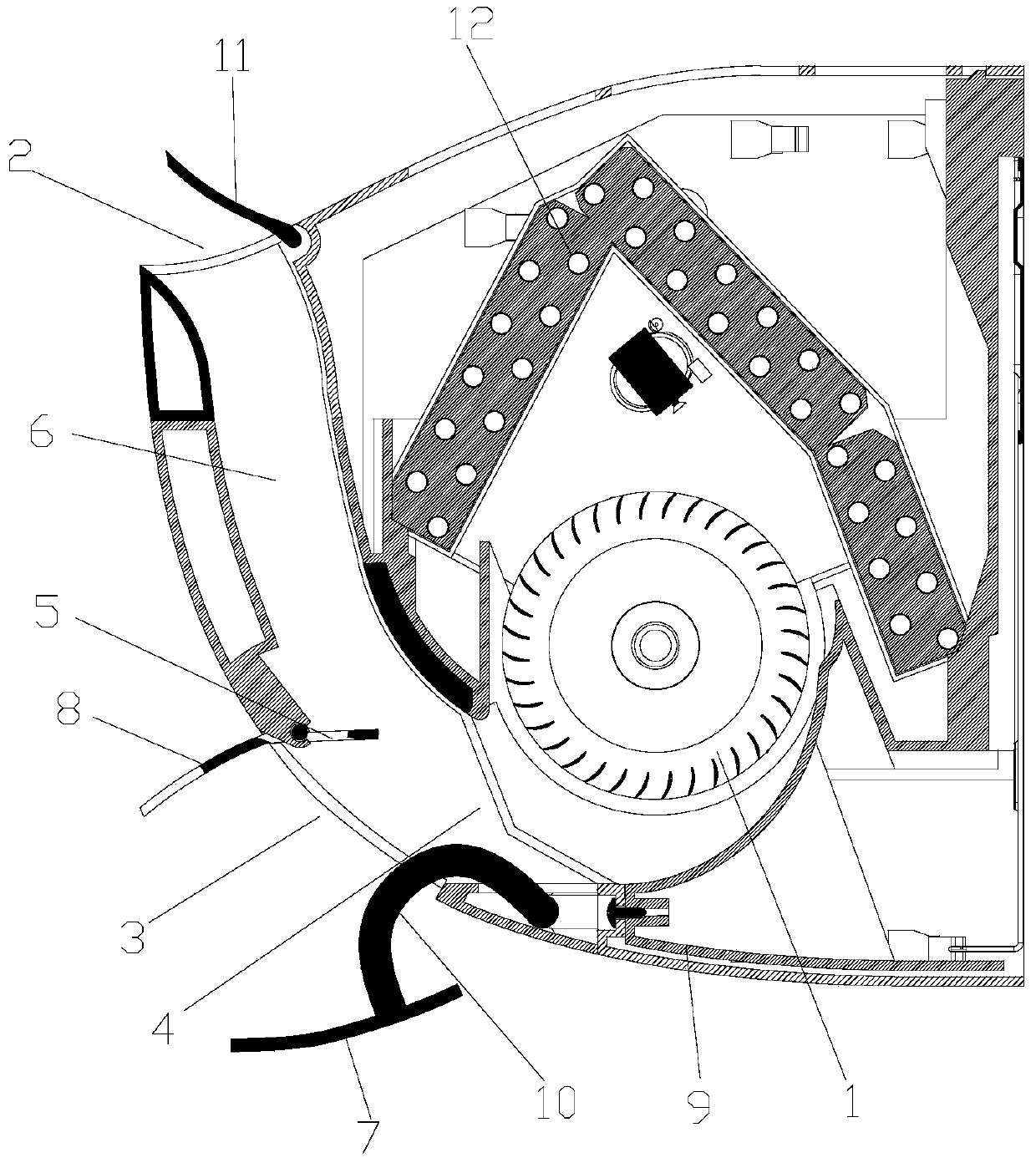

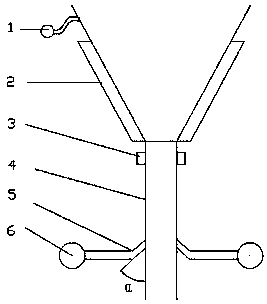

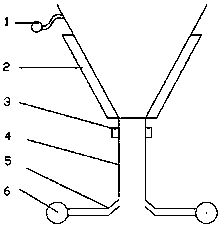

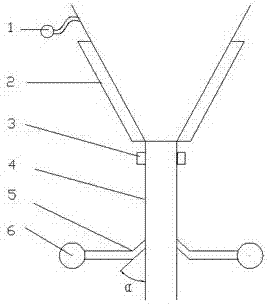

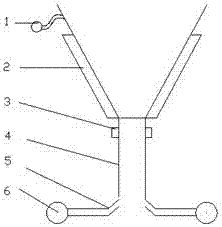

Air conditioner indoor unit, air outlet control method thereof and air conditioner

InactiveCN110056957ABest wind conditionGuaranteed winding effectMechanical apparatusLighting and heating apparatusAir volumeFlue

The invention provides an air conditioner indoor unit, an air outlet control method thereof and an air conditioner. The air conditioner indoor unit comprises a cross-flow fan (1), a first air outlet (2) and a second air outlet (3). The cross-flow fan (1) comprises a draught fan outlet (4), the first air outlet (2) and the second air outlet (3) are jointly connected to the draught fan outlet (4), and a flow dividing structure (5) for adjusting the flow dividing proportion of the first air outlet (2) and the second air outlet (3) is arranged between the first air outlet (2) and the second air outlet (3). The first air outlet (2) is located in the upper side of the center axis of the cross-flow fan (1), and the second air outlet (3) is located in the lower side of the center axis of the cross-flow fan (1). According to the air conditioner indoor unit, the flow dividing proportion of an upper air outlet air flue and a lower air outlet air flue can be adjusted according to the air outlet mode, accordingly, the air volume of the upper air outlet air flue and the lower air outlet air flue is dynamically controlled, and the air outlet effect is guaranteed.

Owner:GREE ELECTRIC APPLIANCES INC

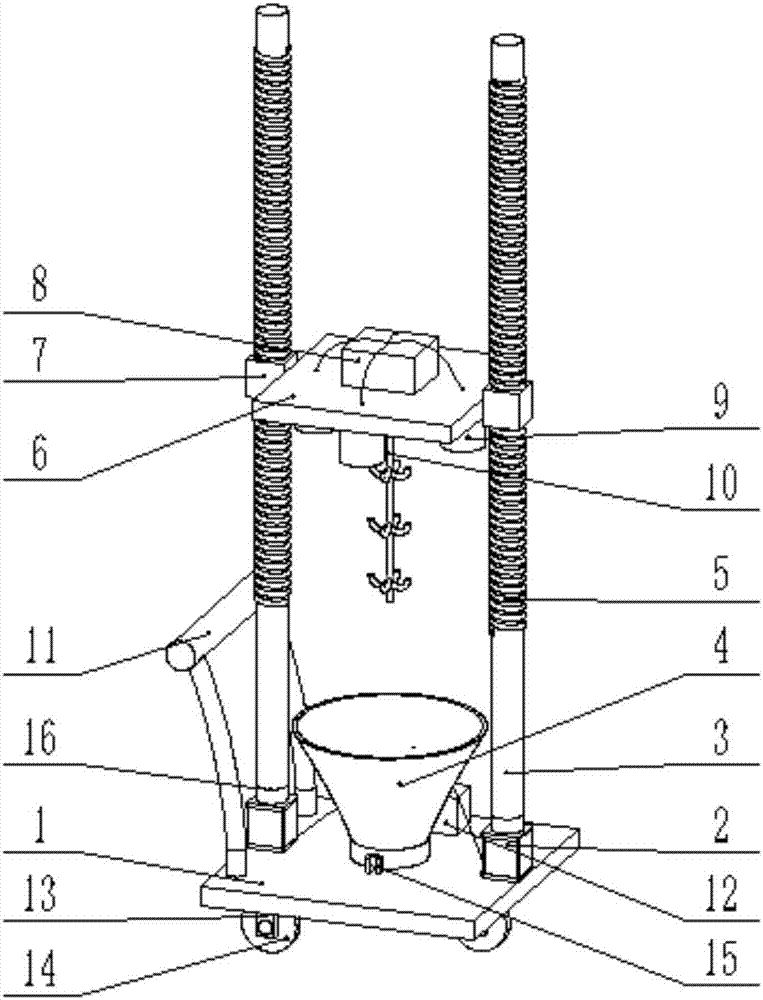

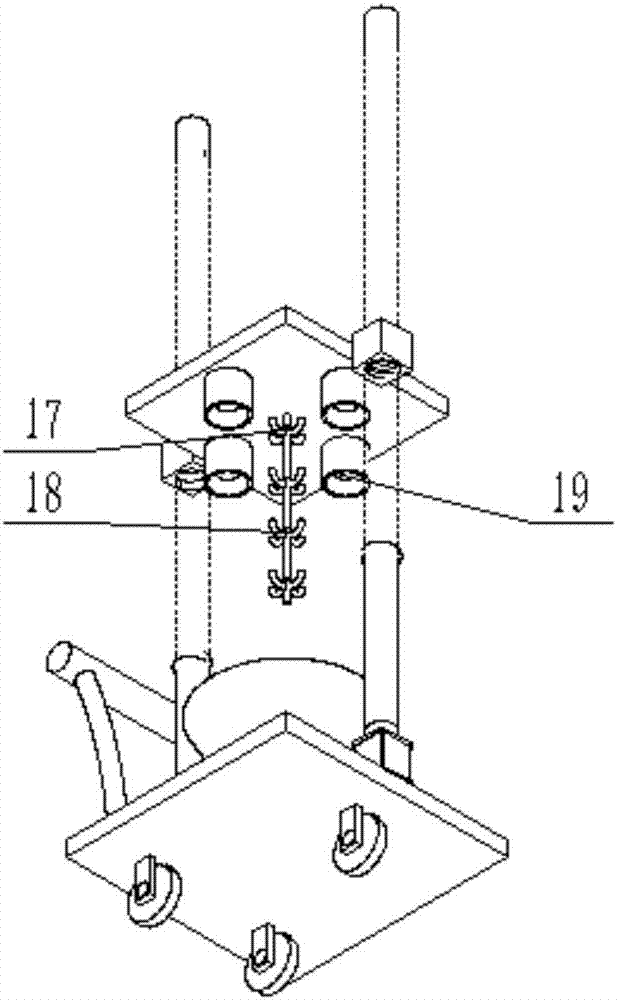

Firecracker firing and recovering device

ActiveCN106895748APrevent the phenomenon that cannot be ignitedAggregation is achievedFirecrackersFirecrackerFireworks

The invention discloses a firecracker firing and recovering device, and belongs to the field of firework and firecracker firing equipment. A firing barrel is arranged at the upper end of a bottom plate; a light concentration disc is arranged at the lower end in the firing barrel; two stepping motors are mounted on two sides of the firing barrel at the upper end of the bottom plate; an output shaft of each stepping motor is connected with an upright column; outside threads are formed in the circumference of each upright column; a connecting block sleeves the outside threads of each upright column and is fixedly connected with a lifting plate; the lower end of the lifting plate is fixedly connected with a hanging device; an incandescent lamp is mounted at the lower end of the lifting plate; and a lampshade is mounted at the periphery of the incandescent lamp; the upper end of the lifting plate is fixedly connected with a battery box which supplies power for the incandescent lamp; and a control cabinet is arranged on the bottom plate and is connected with the stepping motors. The firecracker firing and recovering device fires a firecracker by generating heat through light concentration and has the recovering function to firecracker skin generated after the firecracker is fired.

Owner:牟浩语

Optical polyester film and preparation method thereof

ActiveCN101866023AOvercome the phenomenon of sandy fogOvercoming the technical problem of sandy foggingFlat articlesCoatingsPolyesterDisplay device

The invention relates to an optical polyester film and a preparation method thereof; the film comprises base material prepared from two-way stretched polyester and a crosslinkable resin layer coated on at least one surface of the base material; the concentration of solid in the coating liquid of the crosslinkable resin is 10 to 100 percent; and the film does not contain any additive particle, andis characterized by high total light transmission, low haze, high surface smoothness and good anti-scratch effect. The preparation method solves the complicated production process that the film is wound after corona treatment and then unwound and applied after arriving at the factory of a user, has simple process, solves the problems that the film is easy to produce protruding points, adhesion and the like after being wound and stored, and simultaneously reduces the film manufacturing cost. The optical polyester film can be widely applied in producing touch screens, and effectively protects the surface of display devices.

Owner:CHINA LUCKY FILM CORP +2

Broken plastic stirring device

The invention relates to the technical field of waste plastic reprocessing equipment and particularly discloses a broken plastic stirring device. The broken plastic stirring device comprises a material cylinder, a feeding device, a stirring device body, an air uniformizing device and a temperature increasing device. The feeding device comprises a feeding bin, feeding hoppers, a first screw rod, asecond screw rod, a first spiral blade and a second spiral blade, and the spiral direction of the second spiral blade is opposite to the spiral direction of the first spiral blade. The stirring devicebody comprises a stirring motor, a stirring shaft, a spiral stirring blade and a spreading disk, and the spiral stirring blade is of a structure gradually becoming larger from bottom to top on the stirring shaft. The air uniformizing device comprises a main air pipe, annular air uniformizing pipes and gourd-shaped air uniformizing nozzles. The temperature increasing device comprises a shell, twosupporting plates, insulating rings and heating pipes. The broken plastic stirring device has the characteristics that stirring is uniform, the manpower cost and the material resource cost are both low, and dust and moisture are easy to discharge.

Owner:德清意欣塑料制品有限公司

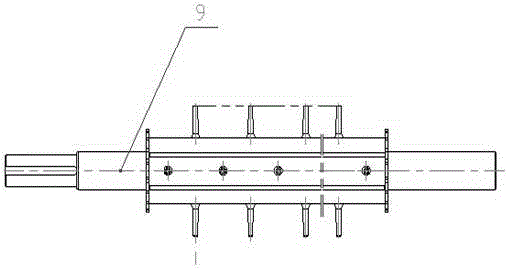

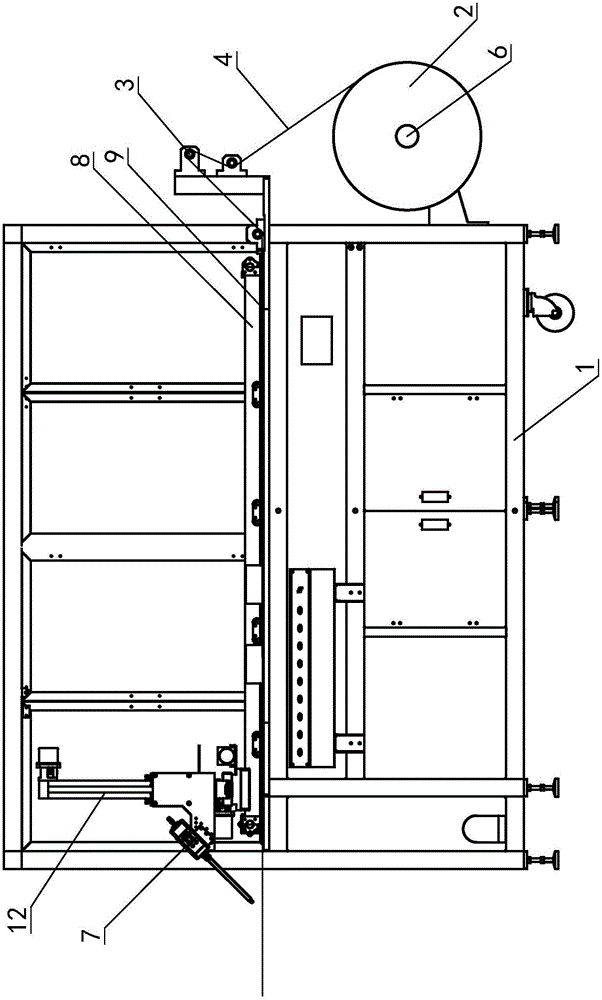

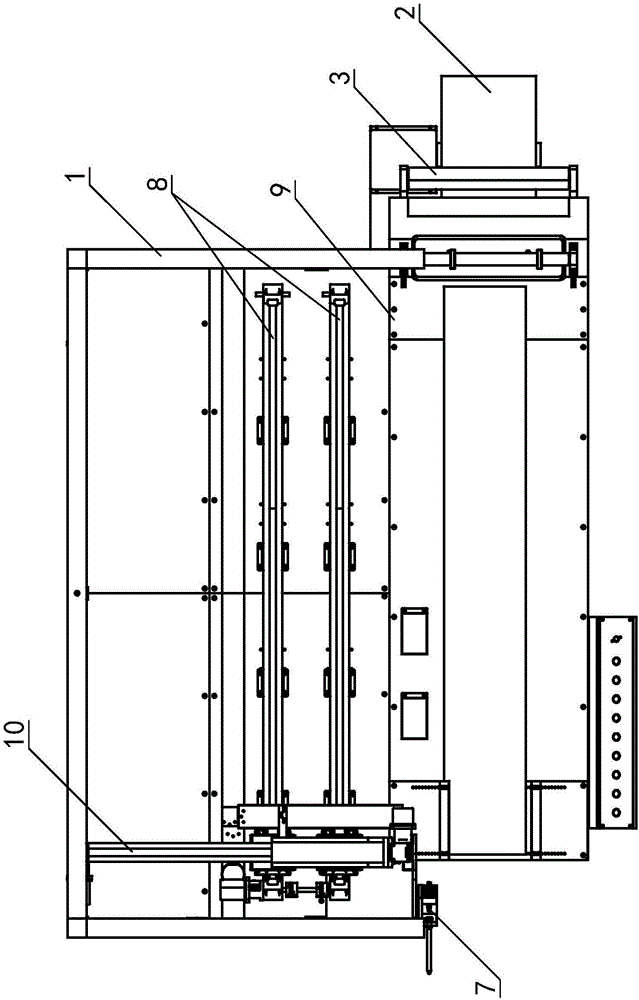

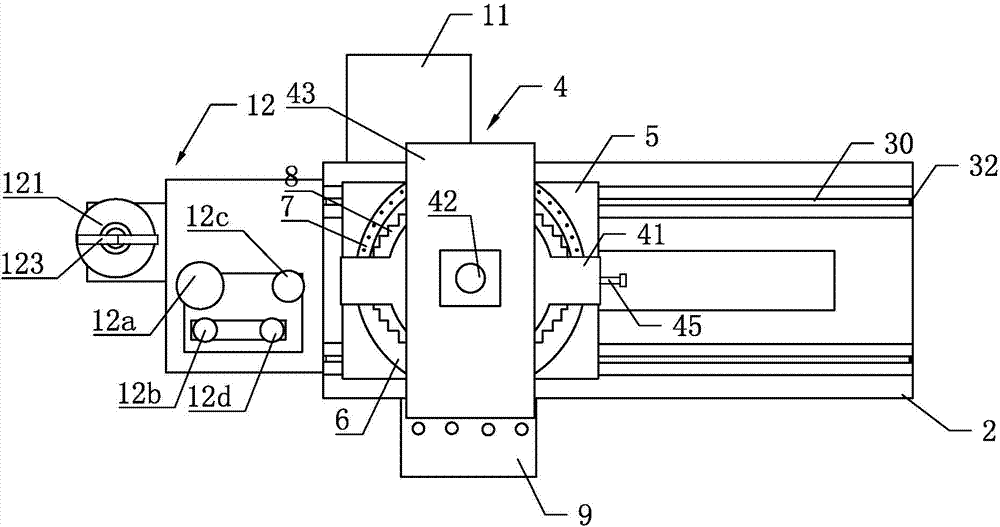

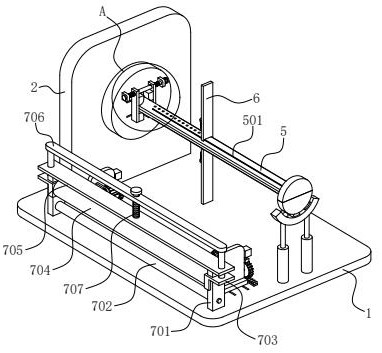

Film putting-on and glue filling unit of automatic RO film winding machine

ActiveCN106219278AImprove quality and consistencySmooth linesLiquid surface applicatorsCoatingsWinding machineManipulator

A film putting-on and glue filling unit of an automatic RO film winding machine comprises an automatic flow guide cloth roll putting-on mechanism and an automatic glue filling mechanism; the automatic flow guide cloth roll putting-on mechanism comprises a flow guide cloth roll and a tension drum; flow guide cloth pulled out of the flow guide cloth roll is tensioned and supported through the tension drum; a first sensor is arranged on the tension drum; a magnetic powder clutch is in transmission connection with a flow guide cloth roll rotating shaft; a second sensor is arranged on the flow guide cloth roll, and the two sensors are electrically connected with the magnetic powder clutch; the automatic glue filling mechanism comprises a three-axis mechanical arm and a glue dispensing valve; the three-axis mechanical arm comprises an X-axis guide rail, a Y-axis guide rail and a Z-axis guide rail; the glue dispensing valve is arranged on the Z-axis guide rail in a sliding manner; the unit is high in automation degree, and many defects of manual operation are completely eradicated; during RO film winding, stable tension can be obtained, and therefore the winding effect is ensured, quality and consistency of products are improved, and the rejection rate is greatly reduced; during glue filling, it can be ensured that U-shaped glue lines are smooth, well-balanced and flat, the glue breaking phenomenon is avoided, and the use amount of glue can be saved.

Owner:苏州迈硕自动化设备有限公司

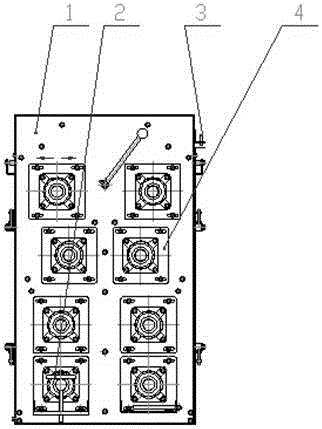

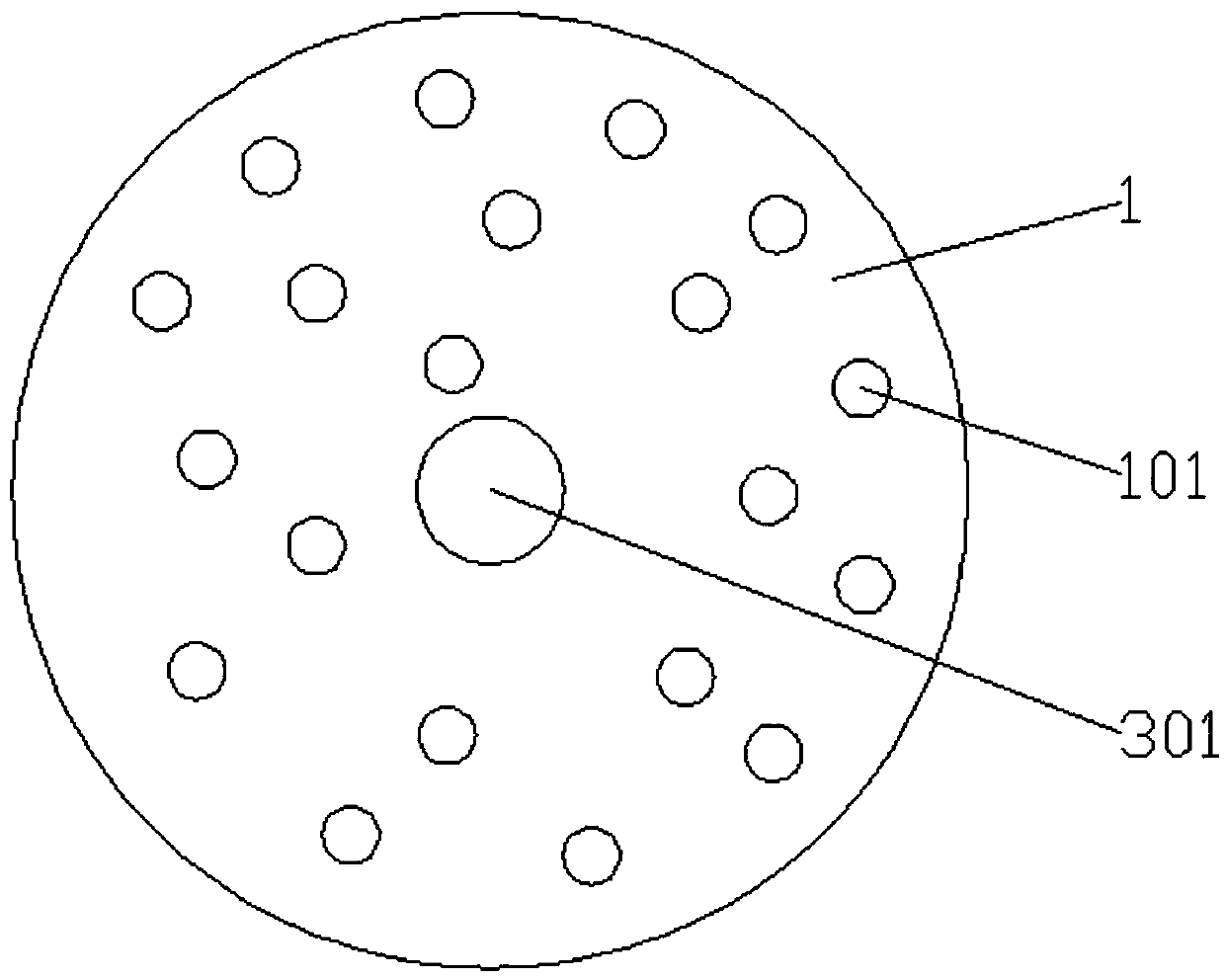

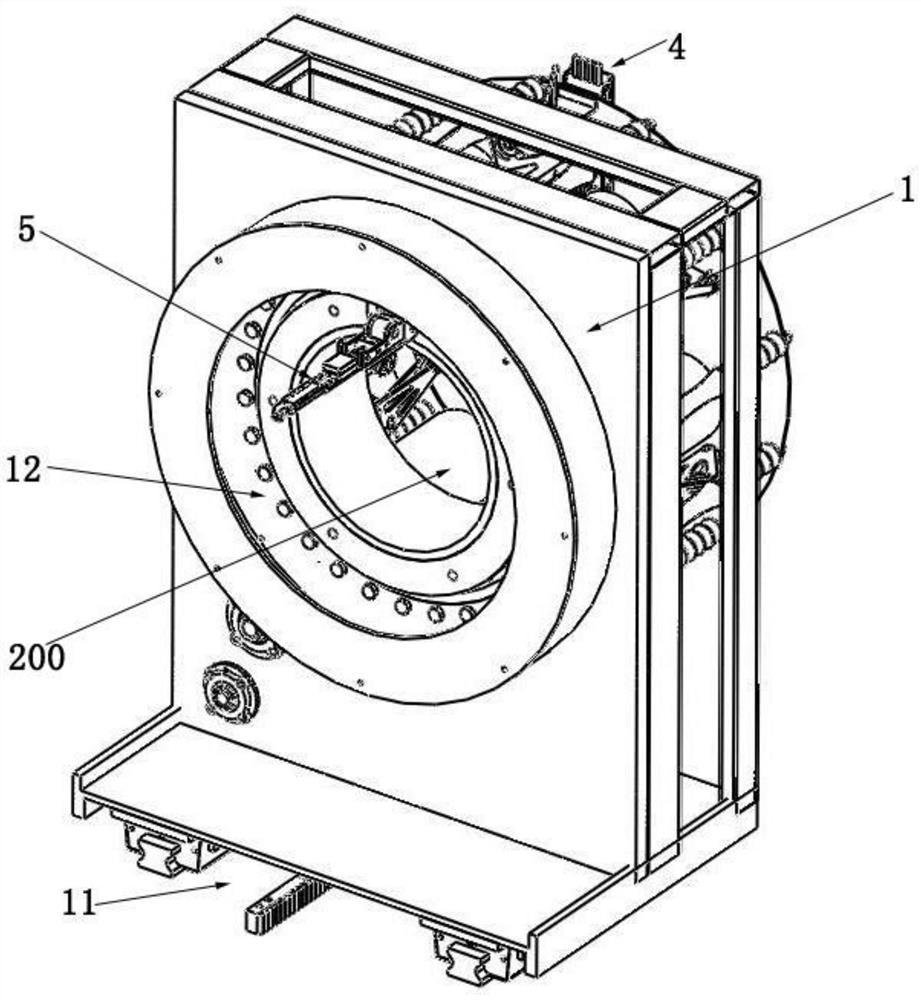

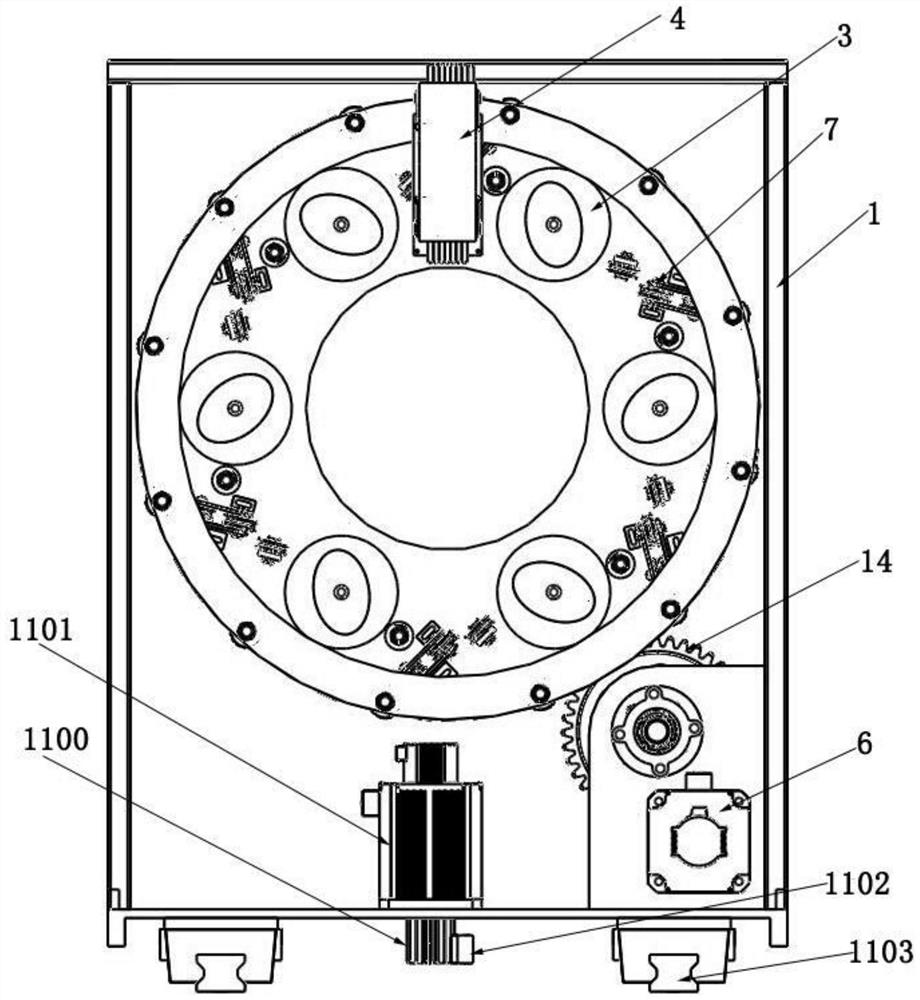

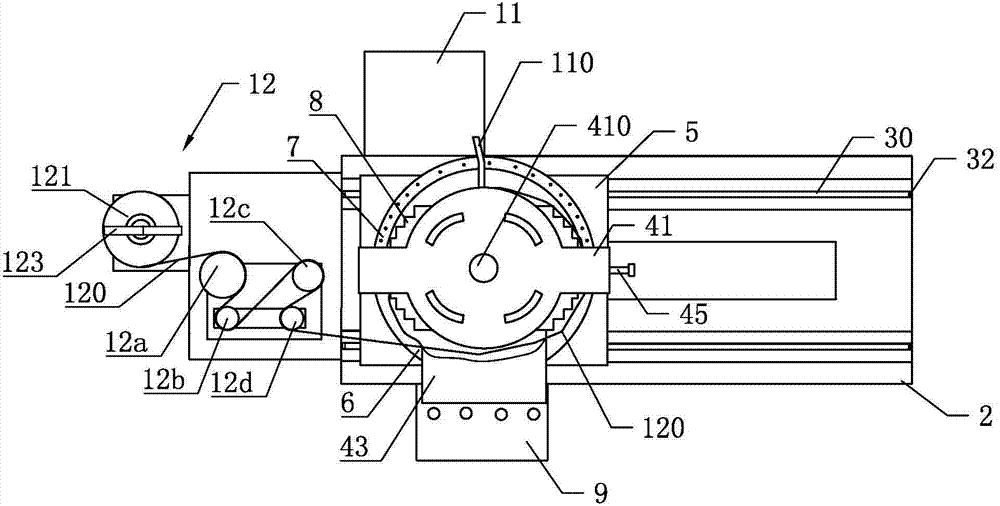

Multi-fiber circumferential winding device and control system thereof

ActiveCN113371528AHoop windingIncrease productivityLiquid surface applicatorsFilament handlingAuto industryFiber bundle

The invention belongs to the technical field of fiber winding devices, and particularly relates to a multi-fiber circumferential winding device and a control system thereof. The multi-fiber circumferential winding device comprises a rack, a fixing plate, a plurality of fiber bundle tubes, a bundling device and a wire guide head, wherein the fixing plate is rotationally connected with the rack, the fixing plate is connected with a driving element, and the driving element drives the fixing plate to rotate; the plurality of fiber bundle tubes are arranged, and each fiber bundle tube corresponds to one tension controller; a through hole is formed in the middle of the fixing plate; and the fiber bundle tubes are circumferentially distributed along the center of the through hole and rotationally connected with the fixing plate; a plurality of winding rollers are arranged on the fixed plate, are circumferentially distributed along the center of the through hole and are rotationally connected with the fixed plate; and the bundling device and the wire guide head are fixed on the fixing plate. According to the multi-fiber circumferential winding device, the multi-fiber synchronous winding technology is achieved, and the technology is high in winding efficiency, and small in gaps between fiber bundles, is suitable for winding processing of various rotary bodies and can be widely promoted to the fields of the automobile industry, the building industry and the aerospace industry.

Owner:TAIYUAN UNIV OF TECH

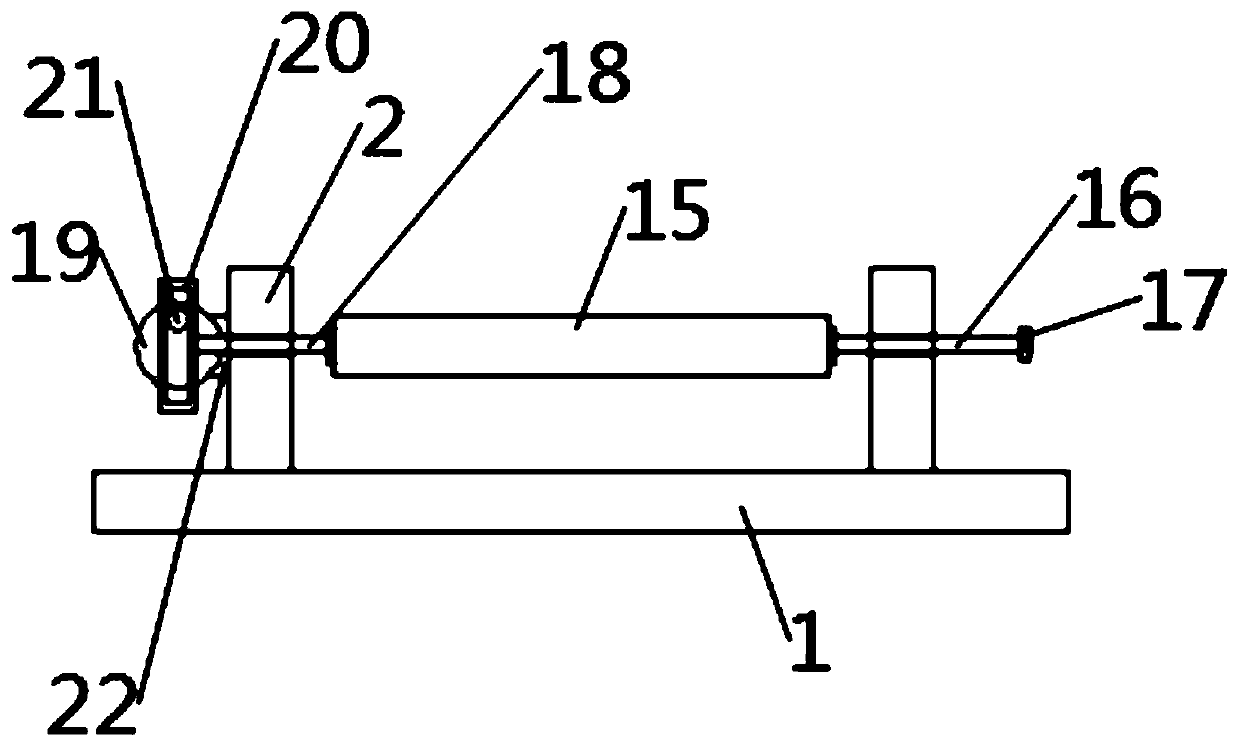

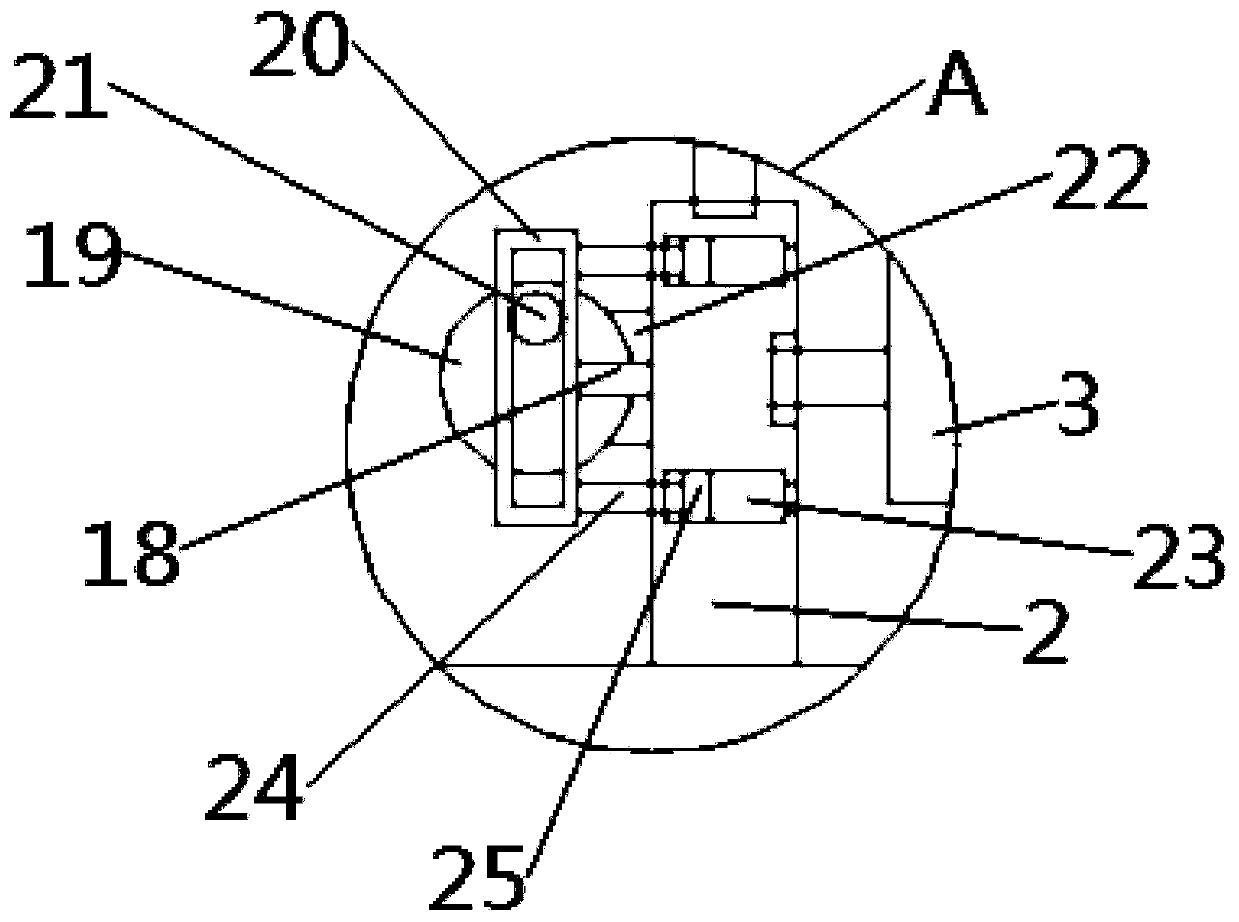

Cloth beam rotating machine

PendingCN111039055AGuaranteed winding effectImprove winding qualityWebs handlingTextileReciprocating motion

The invention relates to the technical field of textile machinery and particularly discloses a cloth beam rotating machine. The cloth beam rotating machine comprises a base, two vertical support plates are symmetrically and fixedly mounted on the base, and a winding roller is rotationally arranged between the two vertical support plates; an equalizing assembly is rotationally arranged between thetwo vertical support plates and comprises an equalizing roller; a left support cross bar is arranged on the other vertical support plate in a penetrating and sliding manner; a push-pull assembly is arranged on the vertical support plates through support plate support frames, and the push-pull assembly pushes the equalizing roller to reciprocate horizontally. The equalizing assembly can equalize cloth wound on the equalizing roller, and has the advantages of high cloth winding quality and good use effects. The pre-tightening force of a second lifting plate on the winding roller can be adjusted,so that the winding effect of the winding roller during cloth winding is guaranteed.

Owner:INTEGRATE BENEFICIAL TEXTILE CO LTD

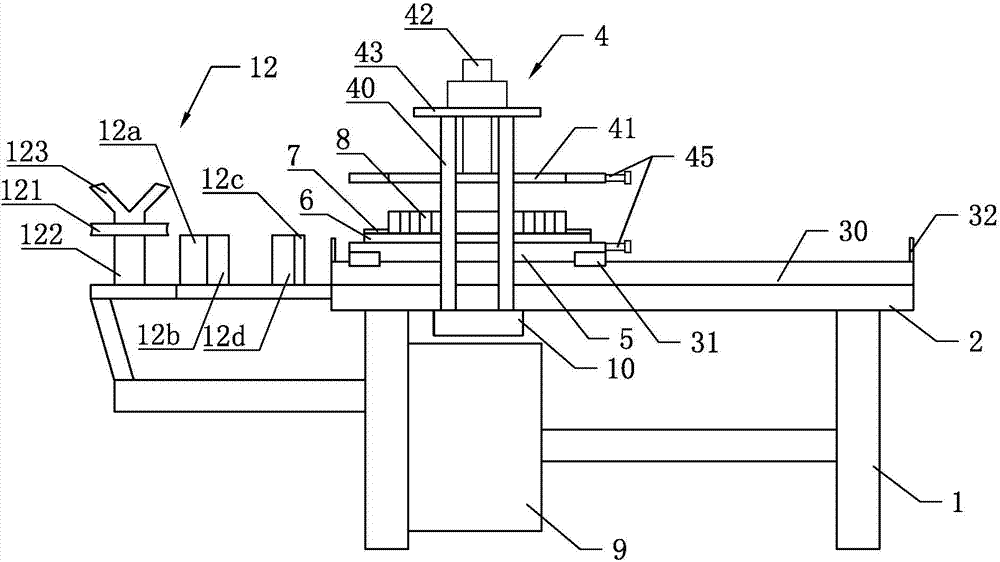

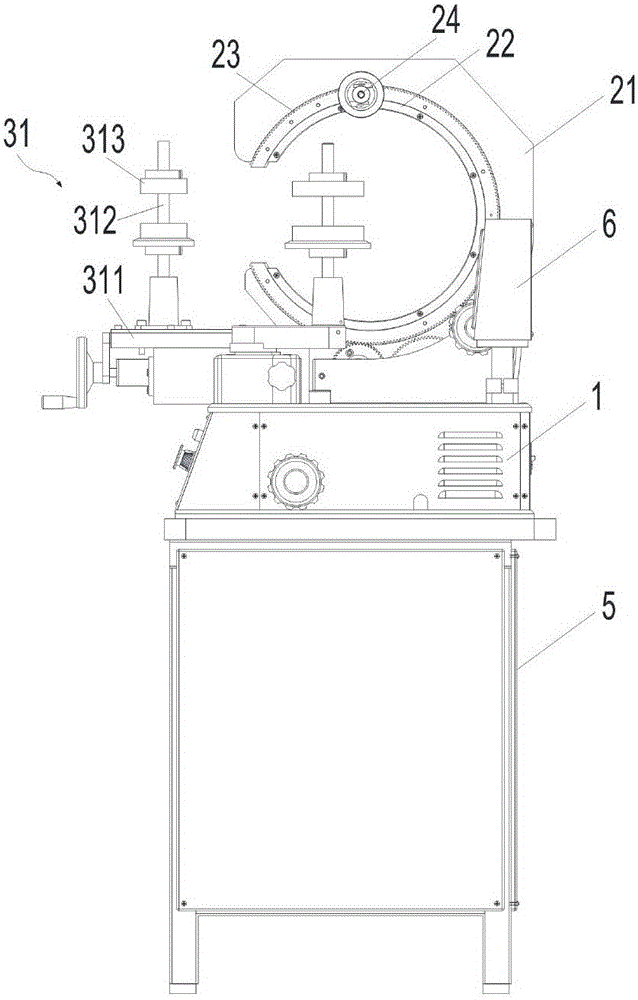

Automatic iron core column pie winding and binding machine

ActiveCN104733174AEasy to placeReduce laborTransformers/inductances detailsBinding material applicationEngineeringElectrical connection

The invention discloses an automatic iron core column pie winding and binding machine. The automatic iron core column pie winding and binding machine comprises a support, and a workbench is arranged on the support; the automatic iron core column pie winding and binding machine further comprises a chassis fixing device, an automatic rotating device and an adhesive tape part; the chassis fixing device comprises a base, a chassis is placed on the base, and the chassis is manufactured to a mould according to the level of a iron core column pie; the automatic rotating device comprises a distribution box and a motor which are in electrical connection, an output shaft of the motor penetrates through the base to be in transmission connection with the bottom of the chassis; the adhesive tape part comprises an adhesive tape which is wound on an adhesive tape reel, and the end of the outer side of the adhesive tape is detachably connected with a silicon steel sheet on the chassis; the adhesive tape reel is arranged on a support column in a sleeving mode, and the bottom of the support column is fixed on the workbench, and the adhesive tape reel rotate around the support column to release the adhesive tape. According to the automatic iron core column pie winding and binding machine, after the silicon steel sheet is installed on the moulded chassis, the end, exposed outside, of the adhesive tape is fixed on the silicon steel sheet, the chassis is driven to rotate after the motor is started to enable the adhesive tape to be wound on the silicon steel sheet, the motor is controlled to automatically rotate by the distribution box, therefore, automatic winding and binding of the adhesive tape are achieved, and labor is saved.

Owner:潍坊五洲浩特电气有限公司

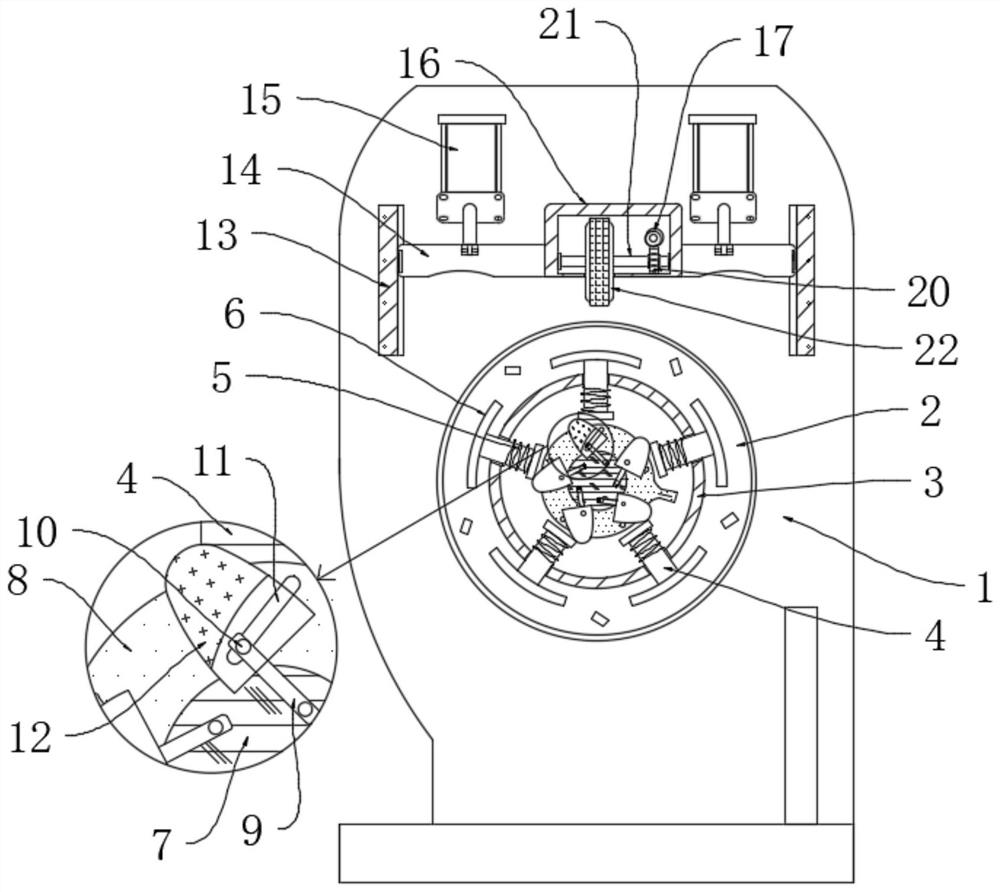

Winding device for fiber fabric processing

The invention relates to the technical field of textile processing, in particular to a winding device for fiber fabric processing. The winding device comprises a machine frame, a base plate is rotatably mounted on the machine frame, and a central cylinder is fixedly mounted on the base plate. Sliding rods are slidably mounted on the central cylinder, and springs sleeve the sliding rods. Winding plates are fixedly mounted on the sliding rods, a core shaft is fixedly mounted on the base plate, and a rotary disc is rotatably mounted on the core shaft. A push rod is rotatably mounted on the core shaft, and a guide column is fixedly mounted on the push rod. The guide column is movably mounted in a guide groove, and a push block is fixedly mounted on the push rod. Fabrics can be wound through acylindrical winding structure with a notch formed by the multiple winding plates, and the winding radius of the winding structure can be adjusted according to the texture of the fabrics, so that the winding effect is guaranteed; and meanwhile, the movement uniformity of the winding plates is good, the integrity of the winding structure is guaranteed, and the winding plates can be independently replaced after being abraded.

Owner:安福风起科技有限公司

Winding device for carbon fiber prepreg

InactiveCN113086704AIncrease tightnessGuaranteed stabilityCleaning using toolsWebs handlingFiberCarbon fibers

The invention discloses a winding device for carbon fiber prepreg, and belongs to the technical field of carbon fiber prepreg winding. The winding device comprises a machine shell, a driving gear, a driven gear, a positioning piece, a winding roller, a cleaning assembly and an extrusion assembly, a dust collector is fixedly installed on the outer wall of the rear side of the machine shell, and a shell is fixedly installed on the outer wall of the front face of the machine shell. According to the winding device for the carbon fiber prepreg, an L-shaped pressing plate and the extrusion assembly are installed on the winding roller, when the carbon fiber prepreg is wound, the carbon fiber prepreg can extrude an extrusion rack of the extrusion assembly, through the linkage process, the carbon fiber prepreg wound on the winding roller can be effectively and automatically pressed, the thickness can be increased along with increase of the number of turns of winding of the carbon fiber prepreg, the distance between the carbon fiber prepreg and the L-shaped pressing plate can be reduced, meanwhile, the compactness of pressing the carbon fiber prepreg can be effectively improved through descending of the L-shaped pressing plate, and the stability of the wound carbon fiber prepreg is guaranteed through the ingenious linkage design.

Owner:WEIHAI BAOWEI NEW MATERIAL TECH CO LTD

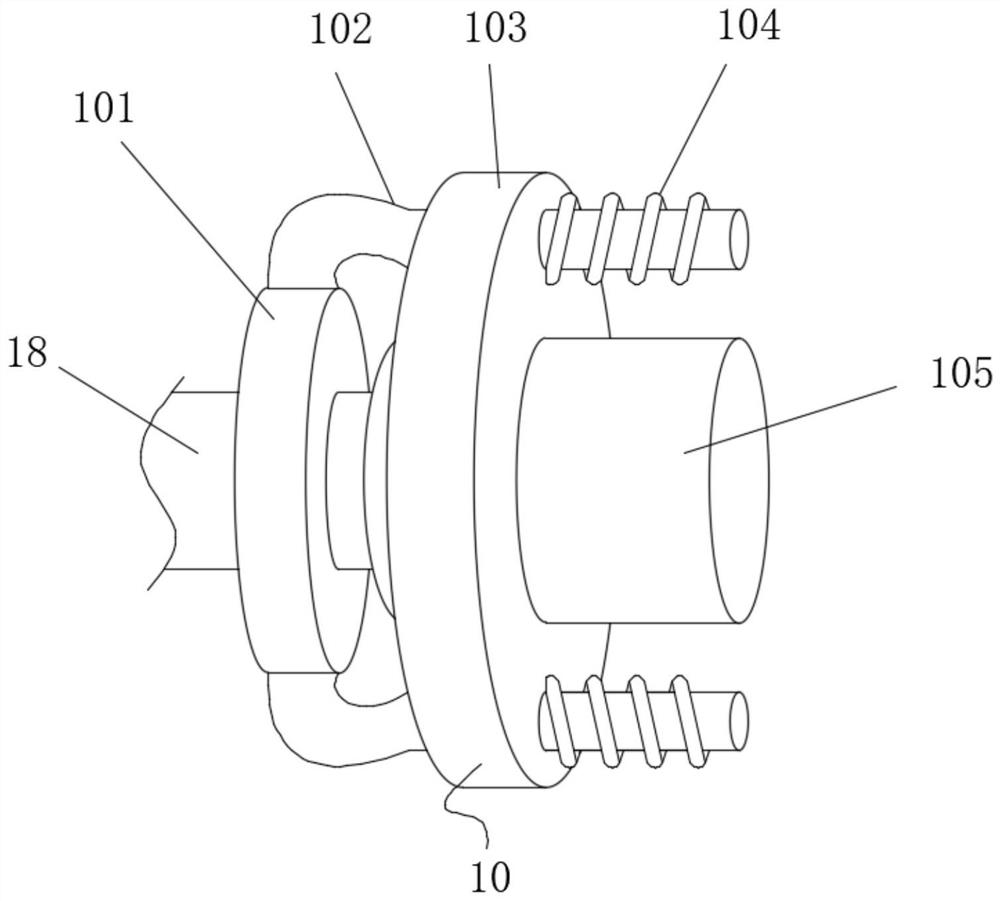

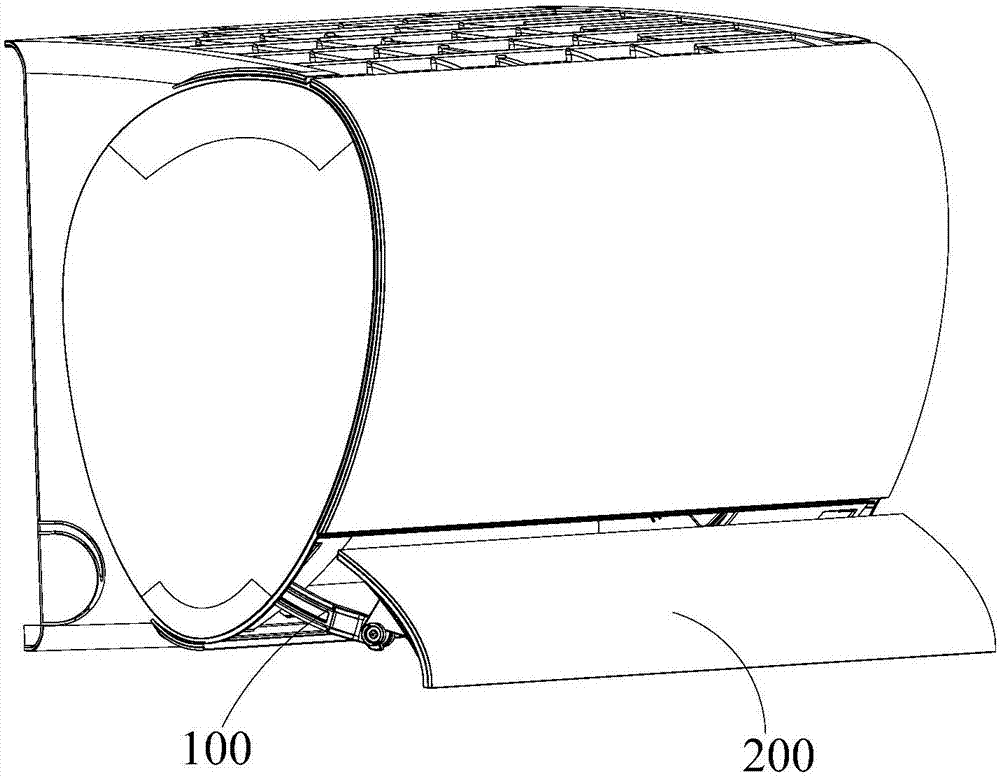

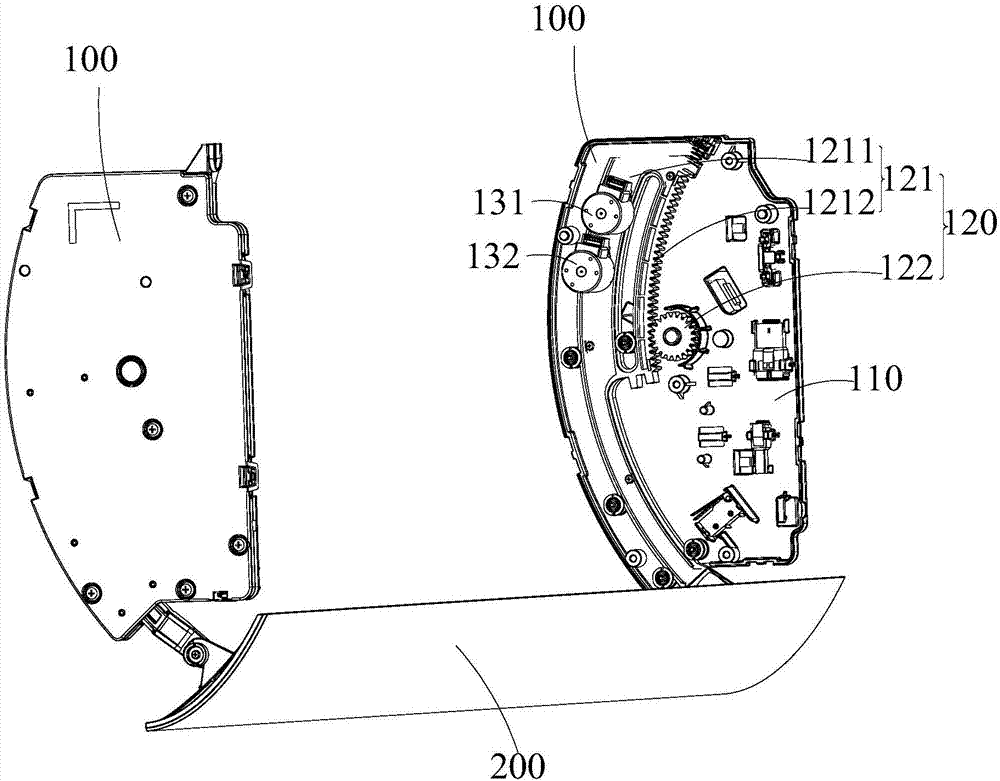

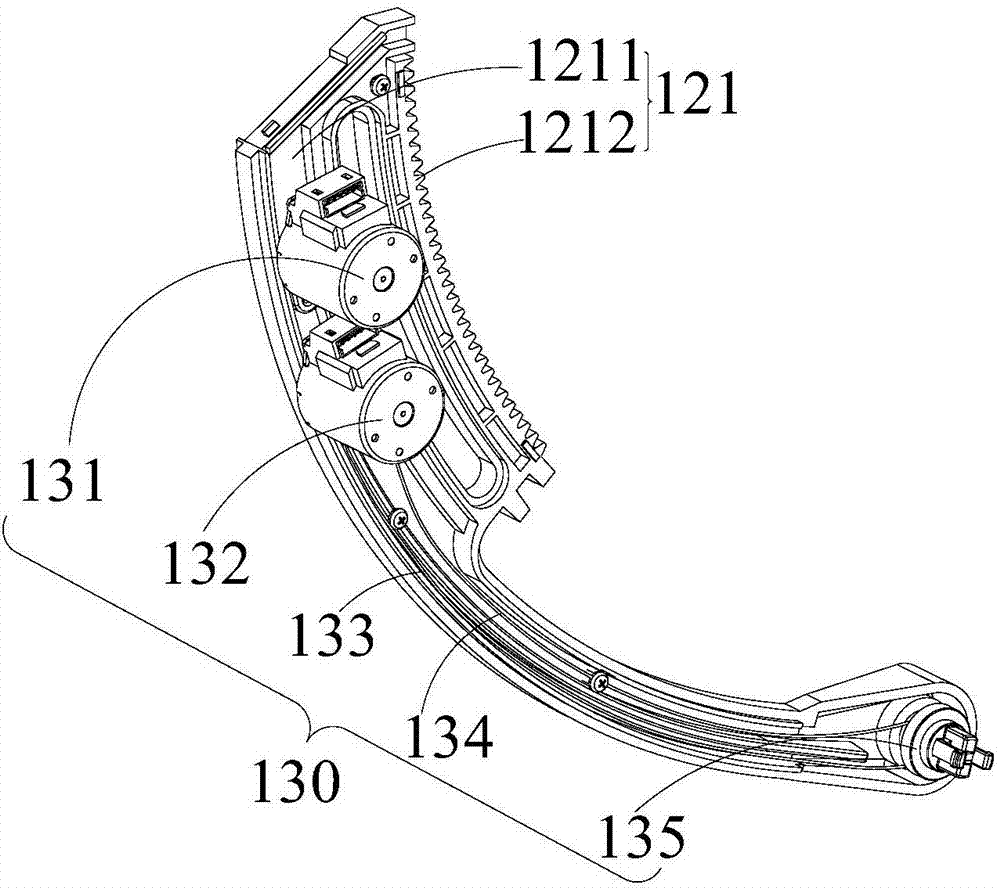

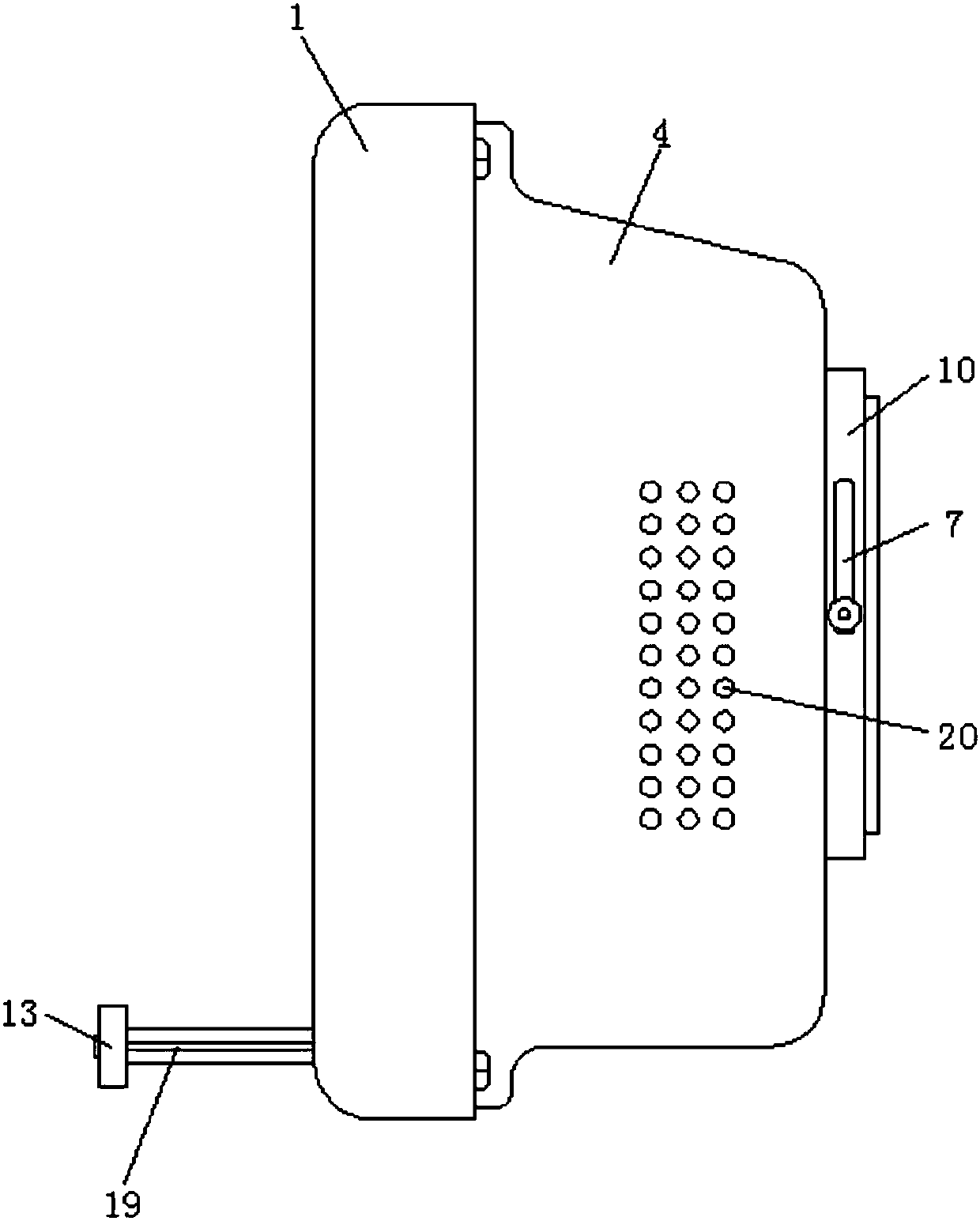

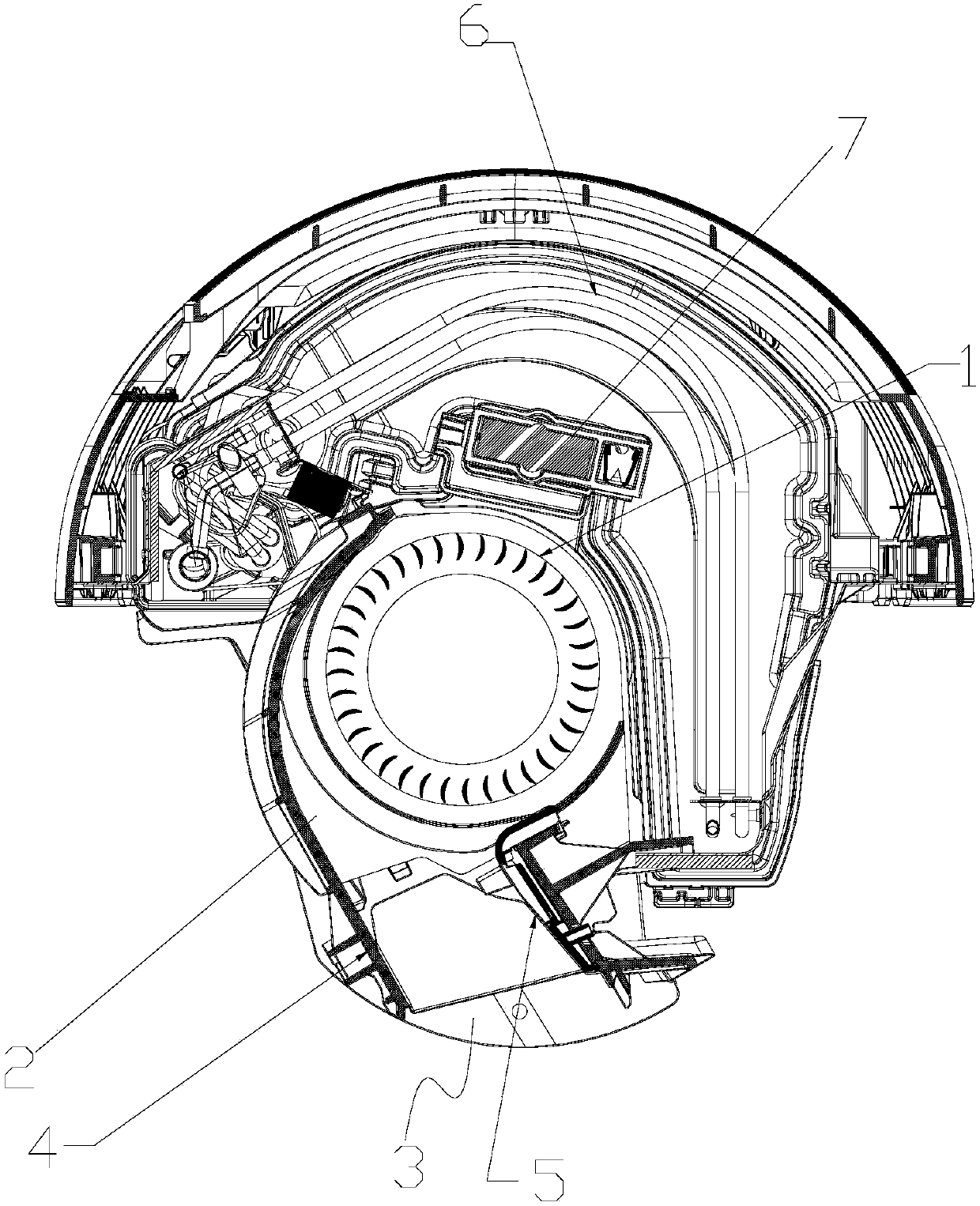

Air conditioner internal unit, air guiding plate drive device and control method of air guiding plate drive device

ActiveCN106918075ASmall sizeReduce volumeMechanical apparatusSpace heating and ventilation safety systemsHead sizeReliable transmission

The invention provides an air guiding plate drive device which comprises a drive box, a push-out mechanism and a air guiding mechanism; the push-out mechanism comprises a connection rod assembly; the air guiding mechanism comprises a first air guiding drive assembly, a second air guiding drive assembly, a first transmission component, a second transmission component and an output component, and the output component is arranged at the head of the connection rod assembly; the first air guiding drive assembly is connected with the output component through the first transmission component and can drive the output component to rotate in one direction; the second drive assembly is connected with the output component through the second transmission component and can drive the output component to rotate in one direction. By means of the air guiding plate drive device, the problem that a compact structure and a reliable transmission portion of an existing air guiding plate push-out structure cannot be compatible is solved, the head size of the connection rod assembly is reduced, it is guaranteed that an air guiding plate drive structure is compact, and inefficient transmission is avoided. The invention furthermore provides a control method of the air guiding plate drive device and an air conditioner internal unit.

Owner:GREE ELECTRIC APPLIANCES INC

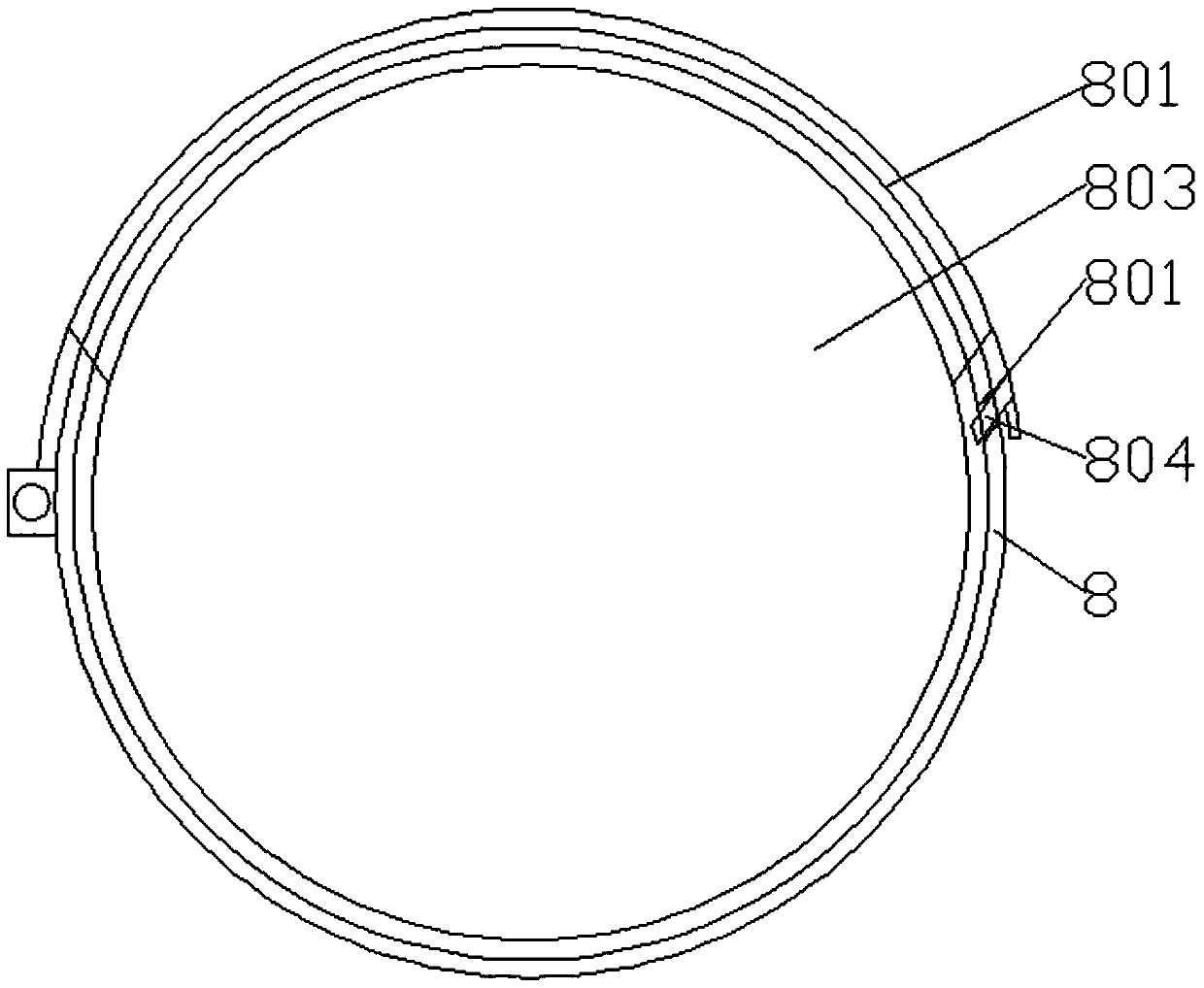

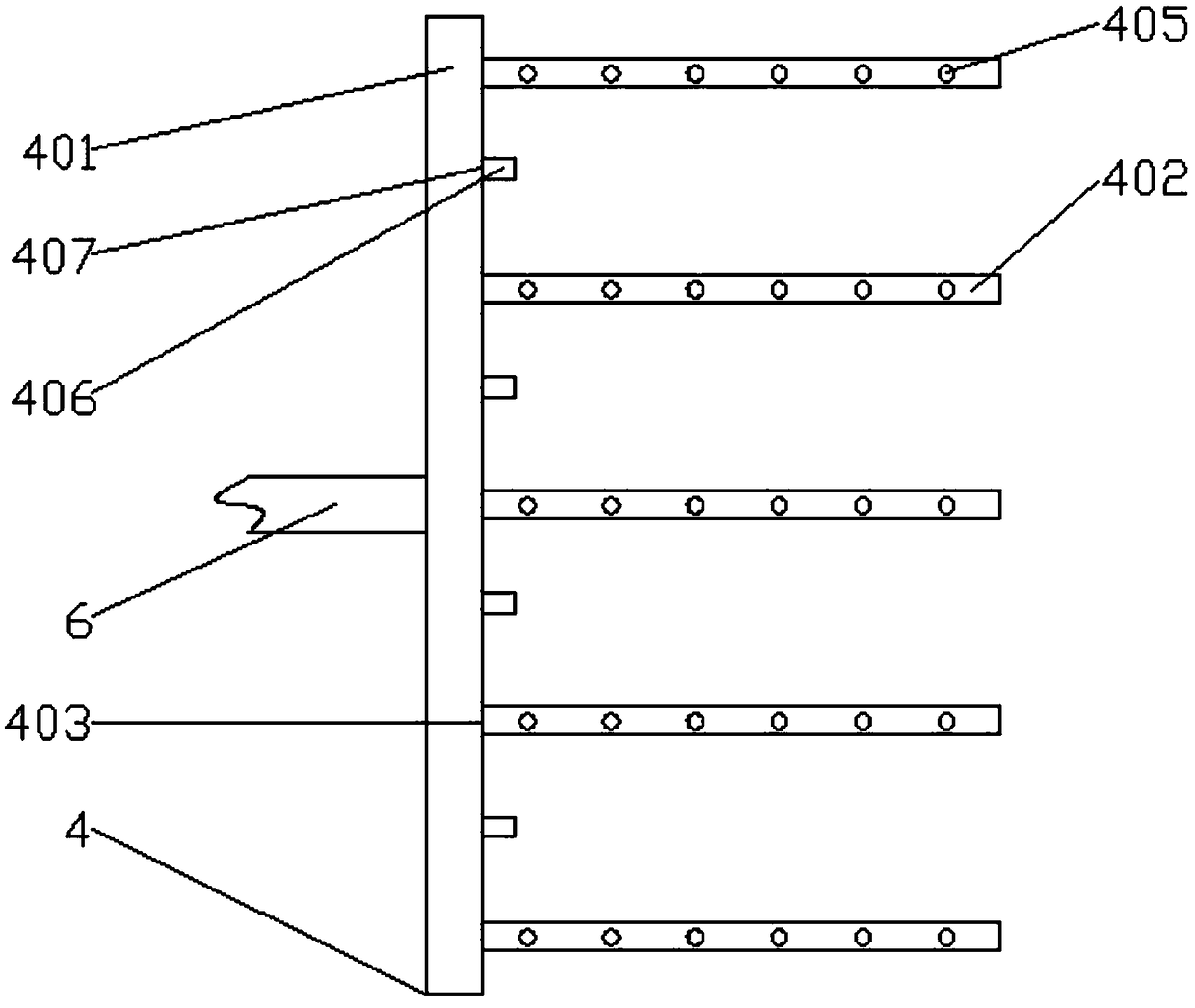

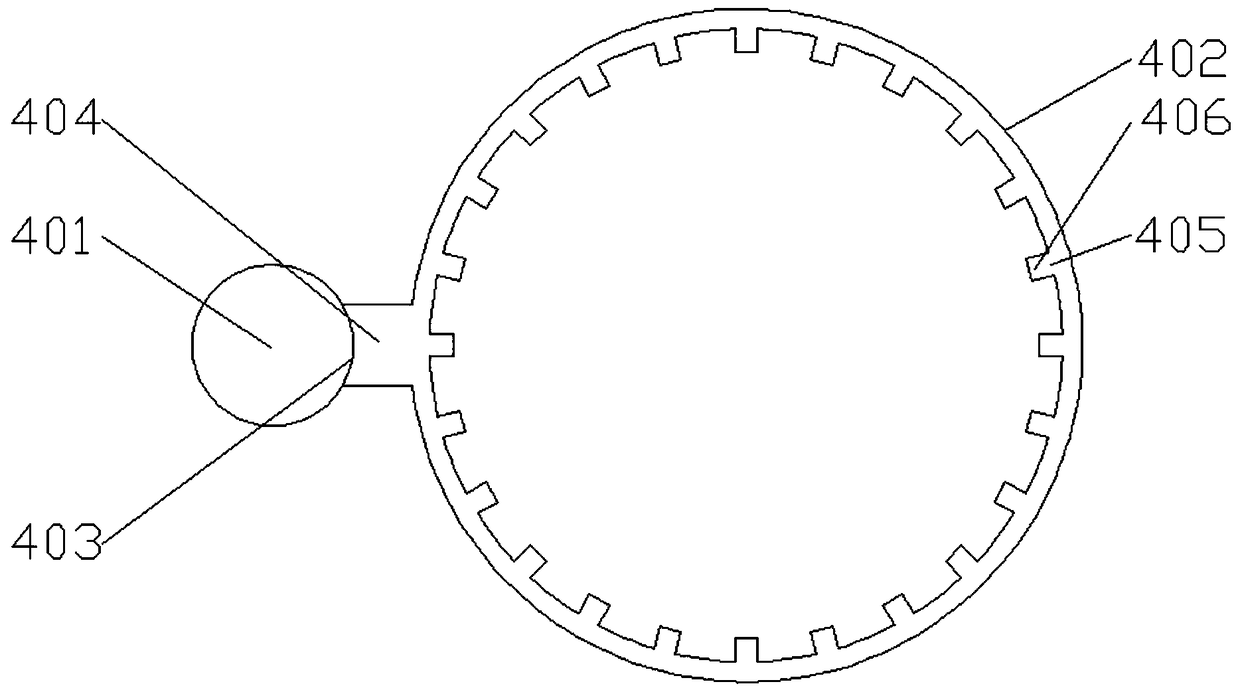

Annular surrounding device

InactiveCN105775195AWind evenlyGuaranteed winding effectWeb rotation wrappingEngineeringConductor Coil

Owner:BEIJING WDT MECHANICAL & ELECTRICAL TECH INST

Automatic printer cleaning method

The invention belongs to the field of ink-jet printers, and particularly relates to an automatic printer cleaning method. The automatic printer cleaning method comprises the following steps that a printer is assembled; a heating body is started and heats a runner and a telescopic spray head, wherein the heating temperature of the heating body is controlled to not exceed 50 DEG C; and a micro motoris started and drives the telescopic spray head to carry out repeated extension. With the adoption of the automatic printer cleaning method, spray head bonding can be prevented effectively and automatic cleaning can be realized.

Owner:江苏剑山包装科技有限公司

Textile fabric conveying and winding machine

The invention belongs to the technical field of textile, and particularly relates to a textile fabric conveying and winding machine which comprises a bottom plate. A vertical plate is mounted on the bottom plate; a disc is rotatably mounted on the surface of the vertical plate; a driving motor is fixedly mounted on the vertical plate; two strip-shaped clamping plates are mounted on the surface of the disc; strip-shaped grooves are formed in the strip-shaped clamping plates in the length directions of the strip-shaped clamping plates; strip-shaped baffles perpendicular to the strip-shaped clamping plates are slidably mounted on the strip-shaped clamping plates through the strip-shaped grooves; and a pressing mechanism is mounted on the bottom plate. According to the textile fabric conveying and winding machine provided by the invention, in the process of taking down cloth, adhesion force does not exist between the cloth on the innermost layer and the strip-shaped clamping plates, and the friction force between the cloth on the innermost layer and the strip-shaped clamping plates is reduced through rolling wheels on the strip-shaped clamping plates, so that the cloth on the innermost layer does not wrinkle or deviate, and the rolling effect of the cloth is guaranteed; the cloth is pressed through the pressing mechanism, so that the cloth is in a tensioned state; and the edges of the two sides of the cloth are reversely flattened through a flattening roller, so that the cloth is ensured to be flat.

Owner:徐州市佳宁纺织科技有限公司

Line pressing device of corrugated carton printing and slotting machine

ActiveCN113232363ARealize cooling protectionExtended service lifeBox making operationsPaper-makingCartonCooling fluid

The invention relates to the technical field of corrugated carton processing, and discloses a line pressing device of a corrugated carton printing and slotting machine. The line pressing device comprises a top pressing shaft rod, the bottom of the top pressing shaft rod is provided with a bottom pressing shaft rod, the surface of one end of the top pressing shaft rod is fixedly sleeved with a first line pressing wheel, one side of the first line pressing wheel is movably connected with a second line pressing wheel, and the interior of the middle of the second line pressing wheel is clamped to the surface of one end of the top pressing line shaft rod. According to the line pressing device of the corrugated carton printing and slotting machine, six sealed containers, namely four first hollow cylinders in the interior of a first liquid type cooling mechanism and two second hollow cylinders in the interior of a second liquid type cooling mechanism, are used for receiving cooling liquid, so that cooling protection of the first line pressing wheel, the second line pressing wheel, a line pressing convex disc, a third line pressing wheel and a fourth line pressing wheel is realized, the heat dissipation efficiency of the structure after heat production due to processing is improved, the service life of the line pressing convex disc is prolonged, and the processing quality of a corrugated board is improved.

Owner:石家庄图瑞包装制品有限公司

Intelligent anti-breakage fiber material winding device

The invention relates to the technical field of fiber processing, and discloses an intelligent anti-breakage fiber material winding device. The intelligent anti-breakage fiber material winding devicecomprises a machine shell, a wire guide wheel is movably connected into the machine shell, a pressure spring is fixedly connected into the machine shell, and a buffer rod is fixedly connected with thebottom of the pressure spring; and one electric contact block is fixedly connected with the top of the buffer rod, the top of the other electric contact block is fixedly connected with an adjusting rod, a bidirectional lead screw is movably connected into the machine shell, a lead screw sliding block is in threaded connection with the outer part of the bidirectional lead screw, a wire guide rod is hinged to the outer part of the lead screw sliding block, and the wire guide wheel is movably connected into the wire guide rod. Through cooperative use of a fixing roller, a threaded disc, worms and clamping rods, the effect of fixing a winding roller is achieved, the fixing operation of winding rollers of different diameters is met, different special clamps are not needed for fixing, thereforethe clamp cost is reduced, the use effect is improved, and the use range of the device is effectively widened.

Owner:余金斌

Self-adaptation cable rolling device

PendingCN108689225AReal-time monitoring of winding situationGuaranteed winding effectFilament handlingEngineeringElectric cables

The invention discloses a self-adaptation cable rolling device. The self-adaptation cable rolling device comprises a rack, an auxiliary conveying roller, a self-adaptation wheel, a spring telescopic column, a tension sensor, a displacement base, a displacement motor, a displacement guide rail, a rolling monitoring plate, a rolling shaft, a rolling motor, a rolling disc and a control center. According to the self-adaptation cable rolling device, a good rolling effect can be achieved during cable rolling, wire pressing is not likely to happen, the rolling effect is monitored in real time, the adaptive adjustment is made, the rolling quality is guaranteed, rolling losses are reduced, and the production efficiency is improved.

Owner:JIAXING AOYIPU DATA CABLE

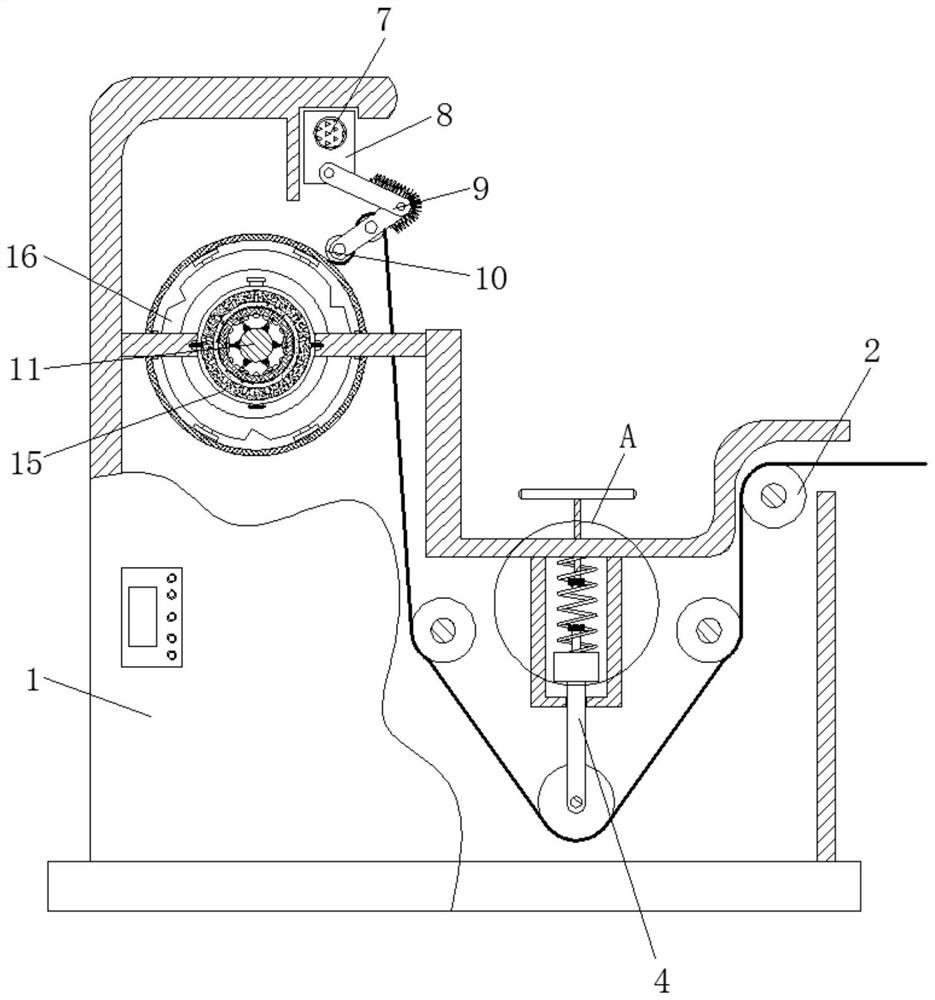

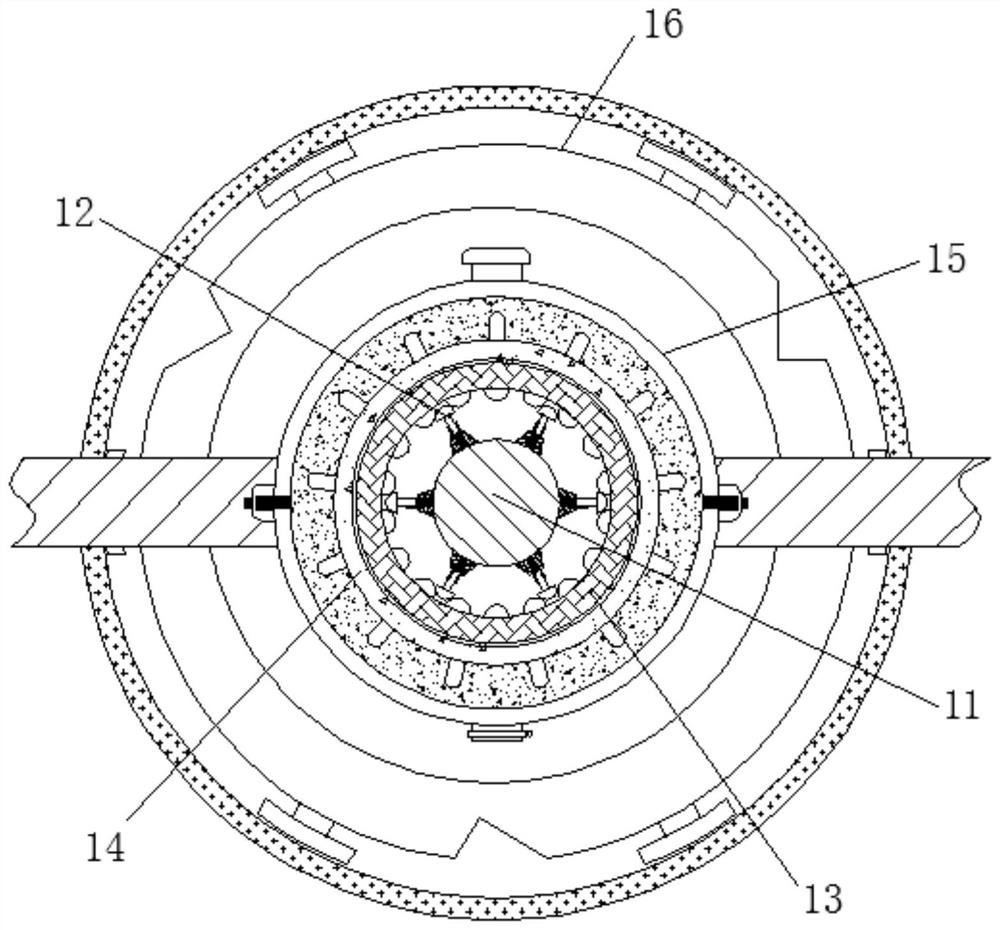

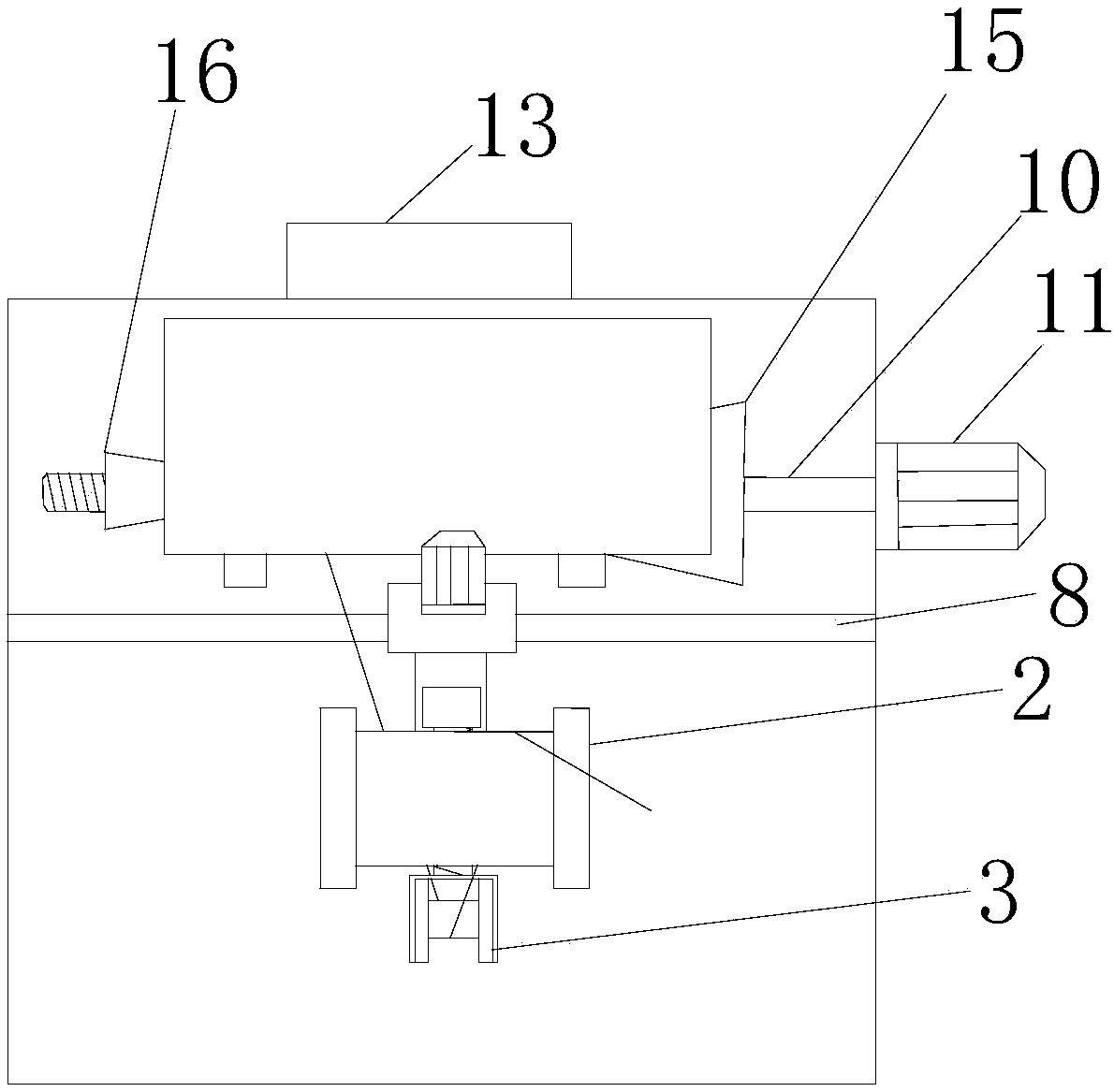

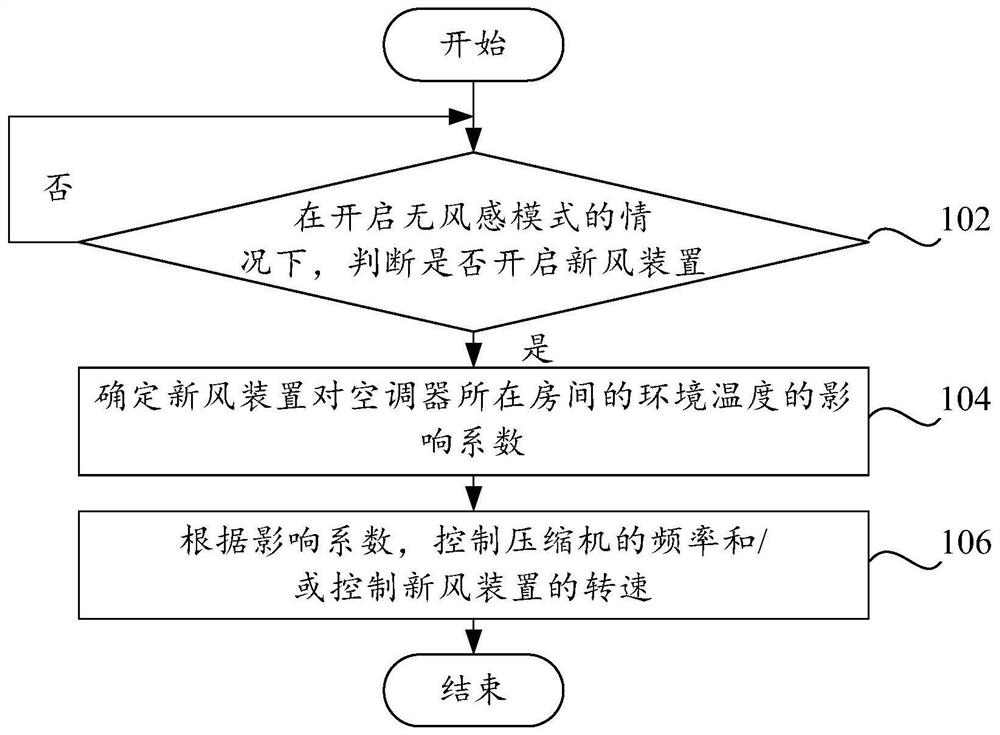

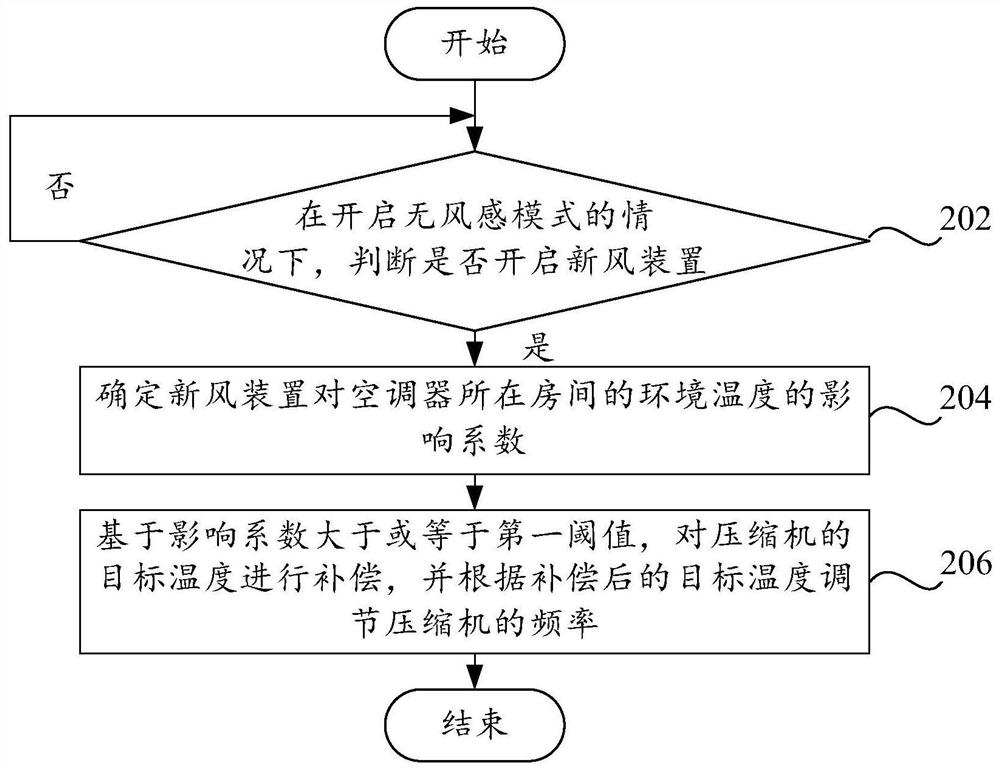

Control method and device of air conditioner, air conditioner and readable storage medium

ActiveCN113623836AReduce distractionsDoes not affect the windless effectMechanical apparatusSpace heating and ventilation safety systemsThermodynamicsFresh air

The invention provides a control method and device of an air conditioner, the air conditioner and a readable storage medium. The air conditioner comprises a compressor and a fresh air device used for introducing outdoor fresh air. The control method comprises the steps that under the condition that a wind-feeling-free mode is started, whether the fresh air device is started or not is judged; based on starting of the fresh air device, the influence coefficient of the fresh air device on the environment temperature of a room where the air conditioner is located is determined; and the frequency of the compressor and / or the rotating speed of the fresh air device are / is controlled according to the influence coefficient. When the air conditioner starts the wind-feeling-free mode and the fresh air mode, the rotating speed of the fresh air device and / or the operation frequency of a compressor are / is controlled according to the influence coefficient of the fresh air device on the environment temperature of the room where the air conditioner is located, so that the influence of the amount of fresh air introduced into the room by the fresh air device on the indoor environment temperature is reduced, the interference of starting the fresh air device on the wind-feeling-free mode is effectively reduced, and therefore the purposes that the indoor wind-feeling-free effect is not affected, and the fresh air effect can be guaranteed are achieved.

Owner:CHONGQING MIDEA REFRIGERATION EQUIP CO LTD +1

Printer with automatic cleaning mechanism

The invention belongs to the field of inkjet printer, and relates to a printer with automatic cleaning mechanism. The printer comprises an ink box, and further comprises a flow channel, a telescopic spray head, a micro motor, an air blower and an air duct, wherein the flow channel is communicated with the ink box; the telescopic spray head is communicated with the flow channel, and one end, capable of stretching out of the telescopic spray head, of the telescopic spray head is one end far away from the flow channel; the micro motor is arranged on the telescopic spray head and can drive the telescopic spray head to extend and contract; and one end of the air duct is close to the lowest end of the telescopic spray head when the telescopic spray head in a shortened state, the other end of theair duct is communicated with the air blower, and the air blower can provide reverse air to the telescopic spray head. According to the printer with automatic cleaning mechanism, the spray heads canbe effectively placed and adhesive materials can be automatically cleaned.

Owner:江苏剑山包装科技有限公司

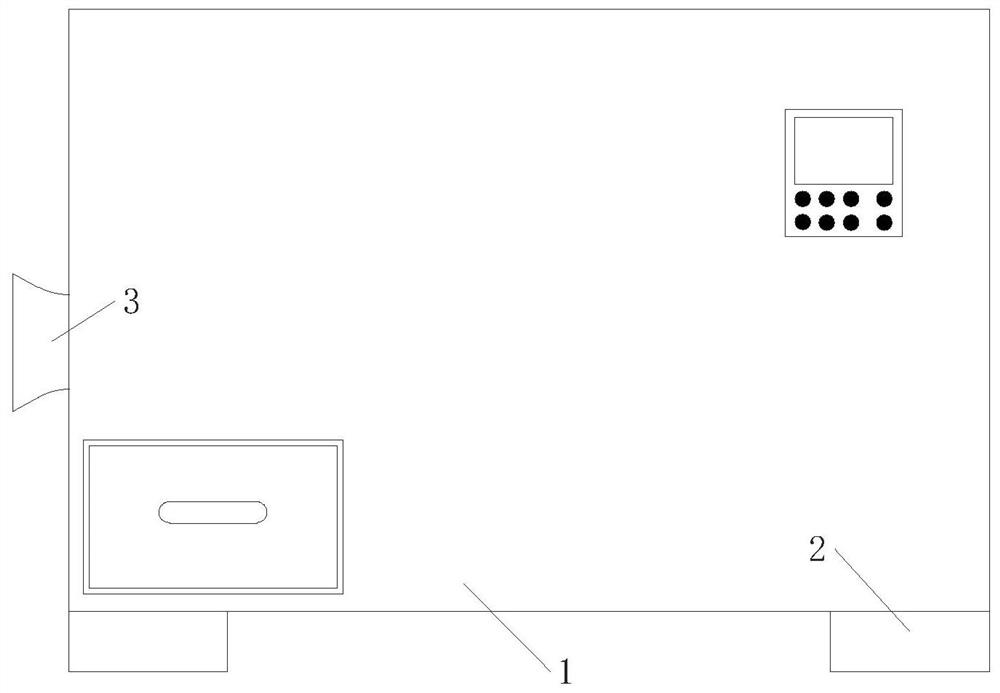

Public place peculiar smell cleaning device

InactiveCN107726470ARealize regular cleaningGuaranteed winding effectMechanical apparatusLighting and heating apparatusPublic placeLED display

The invention discloses a public place peculiar smell cleaning device. The public place peculiar smell cleaning device comprises a machine shell body, a front cover plate is arranged at one end of themachine shell body, a fixed suction cup is arranged at the end, opposite to the front cover plate, of the machine shell body, a water outlet blind window is arranged in the middle of the front coverplate, an LED display screen is arranged at the position, close to the top of the air outlet blind window, of the front cover plate, a dust collection box is arranged on the side, away from the LED display screen, of the front cover plate, a negative ion generator is arranged on the inner wall of the front cover plate, and two sliding blocks are symmetrically arranged on the two sides of the dustcollection box. The dust collection box is arranged, collection of dust in the cleaning device is achieved, the dust is prevented from being accumulated in the cleaning device, the air outlet effect of the cleaning device is ensured, the service life of the cleaning device is prolonged, the fixed suction cup is arranged, mounting and dismounting of the cleaning device are achieved, the device canbe used and dismantled at any time, and flexibility and practicability of the cleaning device are improved.

Owner:绍兴易浩家居有限公司

Indoor unit and air conditioning system

PendingCN107687671AImprove matchGuaranteed winding effectLighting and heating apparatusNoise suppressionEngineeringAir conditioning

The invention provides an indoor unit and an air conditioning system. The indoor unit comprises an air duct and a cross flow fan blade arranged in the air duct. The air duct comprises a first flow guide wall and a second flow guide wall arranged oppositely; the air duct is provided with an air outlet, the diameter of the cross flow fan blade is D, the length of the air outlet is L2, the width of the air outlet is a1, the width of the air outlet is the minimum distance from the inner wall surface of the first flow guide wall and the inner wall surface of the second flow guide wall, and the relationship between D and L2 meets the condition: D=a*L2-b*L2<^2>-c; and / or the relationship between D and L1 meets the condition: D=d*a1-e*a1<^2>+f*a1<^3>-g, wherein a is ranged from 2.85 to 2.95; b isranged from 1.51*10<^-3> to 1.61*10<^-3>; c is ranged from 1241.3 to 1261.3; d is ranged from 702.3 to 710.3; e is ranged from 6.05 to 6.15; f is ranged from 0.0171 to 0.0183; and g is ranged from 27100 to 27300. The indoor unit provided by the invention can guarantee the air out performance of an air conditioner and reduce the air out noise.

Owner:ZHUHAI LANDA COMPRESSOR +1

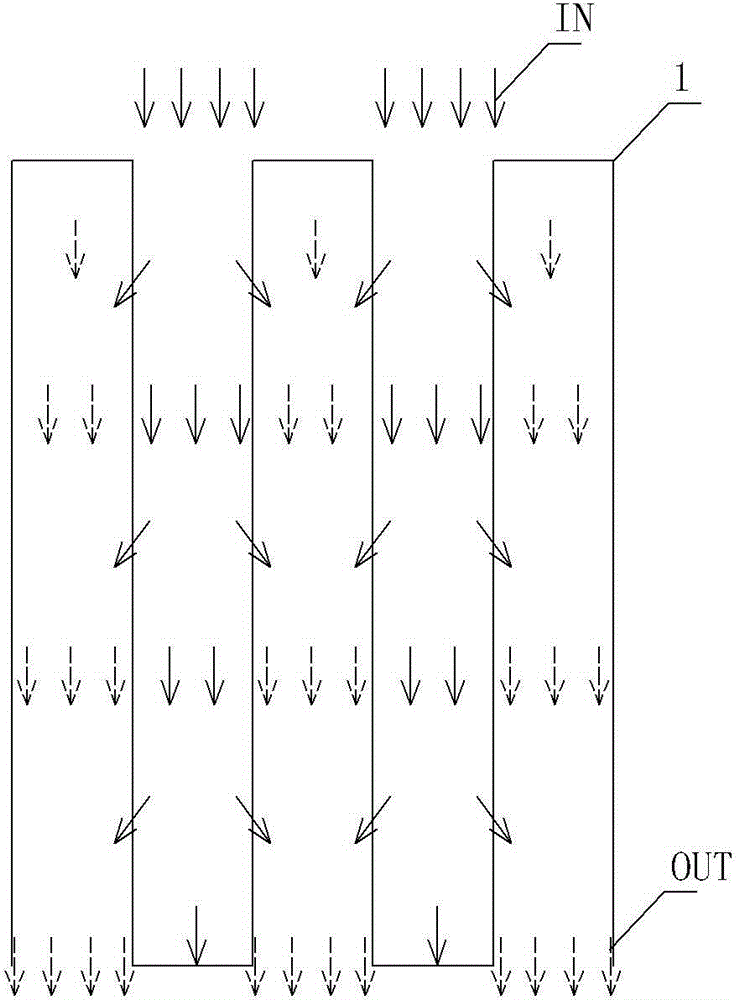

High efficiency filter

InactiveCN105169840AEvenly orientedIncrease the filtered air volumeDispersed particle filtrationAir velocityBiochemical engineering

The invention provides a high efficiency filter, which can solve the problems that air velocity is less, the dust holding capacity is small, the service life of filter paper is short, and the use cost is high in the existing high efficiency filter. The high efficiency filter comprises a box, wherein a filter element is arranged in the box, the filter element comprises filter paper and clapboards, the filter paper is repeatedly folded to be shaped, the filter is repeatedly folded and a plurality of concave grooves of which the directions of openings are opposite are formed, one clapboard is arranged in each concave groove, and the high efficiency filter is characterized in that the concave grooves forming by repeatedly folding to shape the filter paper are tapered grooves, and a conical roof of each tapered groove is closed, and a conical bottom of each tapered groove is open.

Owner:WUXI UNMIXED CLEANSE EQUIP

Efficient cleaning and winding equipment for cable production

The invention discloses efficient cleaning and winding equipment for cable production. The efficient cleaning and winding equipment comprises a hollow machine box and a plurality of supporting legs mounted at the lower end of the machine box, a partition plate is vertically arranged in an inner cavity of the machine box and divides the inner cavity of the machine box into a cleaning chamber and a winding chamber in sequence, a cleaning mechanism is arranged in the cleaning chamber, a winding mechanism is arranged in the winding chamber, the cleaning mechanism comprises a wire inlet penetrating through the side wall of the cleaning chamber in an inserted mode, a cleaning box is arranged in an inner cavity, corresponding to the horizontal position of the wire inlet, of the cleaning chamber in a sliding mode, the two sides of the cleaning box are not closed, banister brush wires are densely distributed in the cleaning box, sliding rods horizontally extend on the front side wall and the rear side wall of the cleaning box, the sliding rods are sleeved with sliding sleeves in a sliding mode, the sliding sleeves are horizontally and fixedly installed on the inner walls of the front side and the rear side of the cleaning chamber correspondingly, and a linkage rod is connected to the top wall of the cleaning box in a rotating mode through a linkage base. The efficient cleaning and winding equipment solves the problems that in the prior art, the cable winding efficiency is low, cable discharging is inconvenient, and the wound cables cannot be cleaned.

Owner:皖缆集团股份有限公司

Odor cleaning device for public place

InactiveCN108087988ARealize regular cleaningGuaranteed winding effectMechanical apparatusLighting and heating apparatusLED displayPublic place

The invention discloses an odor cleaning device for a public place. The odor cleaning device comprises a machine shell body, a front cover plate is mounted at one end of the machine shell body, and afixed sucking disc is mounted at the end, relative to the front cover plate, on the machine shell body; the middle of the front cover plate is provided with an air-out blind window, and an LED displayscreen is arranged at the position, close to the top of the air-out blind window, of the front cover plate; and a dust collecting box is mounted on the side, away from the LED display screen, of thefront cover plate, a negative ion generator is mounted on the inner wall of the front cover plate, and two sliding blocks are symmetrically mounted on the two sides of the dust collecting box. The odor cleaning device for the public place is provided with the dust collecting box, collecting of dust in the cleaning device is achieved, the dust is prevented from accumulating in the cleaning device,the air-out effect of the cleaning device is ensured, the service life of the cleaning device is prolonged, by arranging the fixed sucking disc, mounting and dismounting of the cleaning device are conveniently achieved, the cleaning device can be dismounted after using, and flexibility and practicability of the cleaning device are improved.

Owner:成都柒瑰科技有限公司

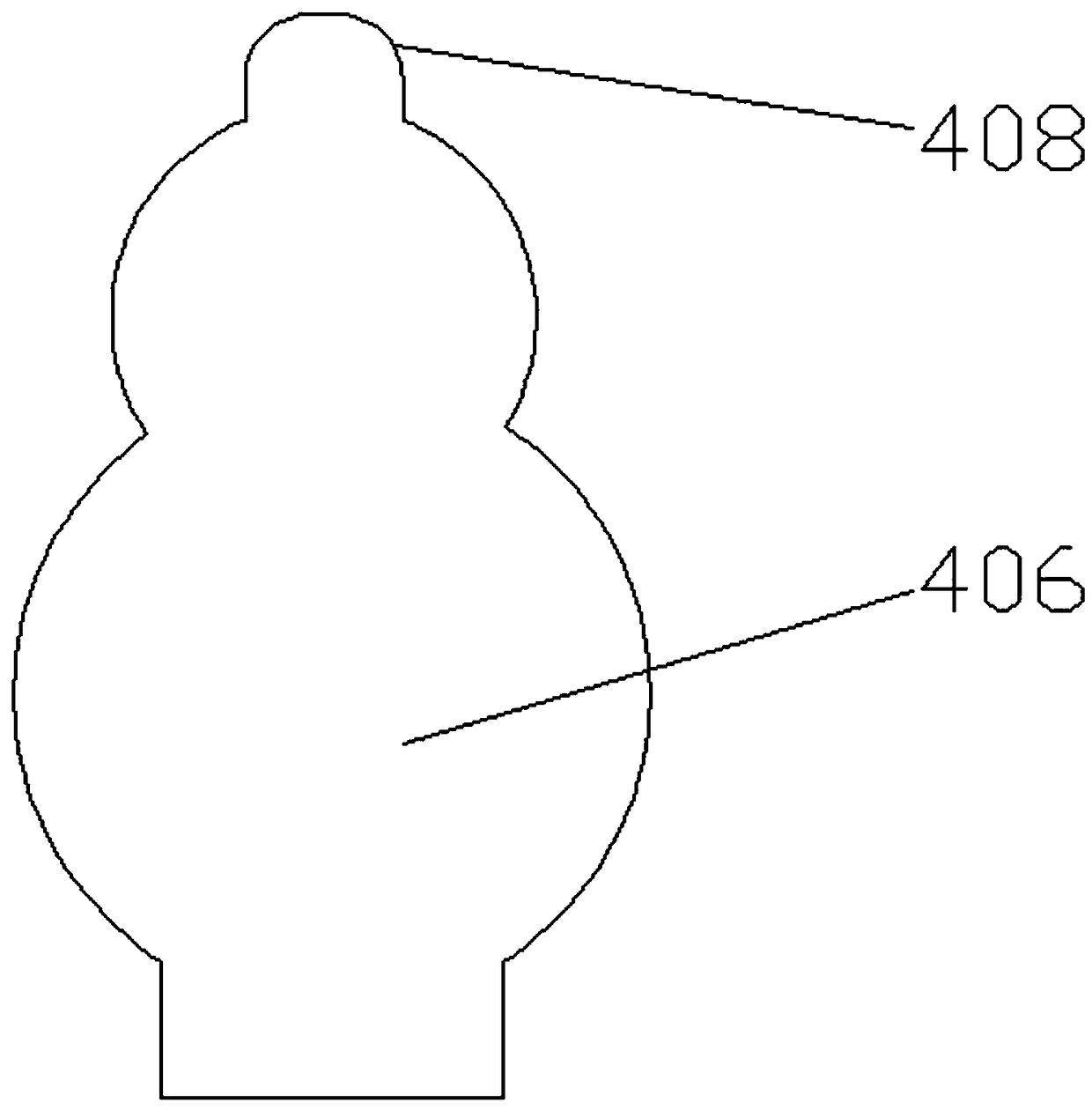

Crushed plastic stirring device good in air circulation effect

The invention relates to the technical field of waste plastic reprocessing equipment, and particularly discloses a crushed plastic stirring device good in air circulation effect. The crushed plastic stirring device comprises a material barrel, a feeding device, a mixing device and an air homogenizing device. The feeding device comprises a feeding bin and a feeding hopper. A feeding motor is arranged at the side portion of the feeding bin. A spiral feeding rod is arranged on an output shaft of the feeding motor. The mixing device comprises a stirring motor and a spiral stirring rod. The air homogenizing device comprises a main air pipe vertically arranged on the inner wall of the material barrel and a plurality of annular air homogenizing pipes, the annular air homogenizing pipes are attached to the inner wall face of the material barrel, the main air pipe is provided with a plurality of connecting holes, and air inlets of the annular air homogenizing pipes are connected with the connecting holes through outer threaded pipes. The annular air homogenizing pipes are provided with a plurality of air homogenizing holes pointing at the centers of the annular air homogenizing pipes. The positions of the air homogenizing holes are provided with calabash-shaped air homogenizing nozzles, and a ventilation pipeline is connected with an air inlet of the main air pipe. The crushed plastic stirring device has the beneficial effects that inner air circulation is smooth, and dust and moisture are likely to be discharged.

Owner:德清意欣塑料制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com