Film putting-on and glue filling unit of automatic RO film winding machine

An automatic, glue-filling technology, which is applied in the direction of winding strips, devices for coating liquid on the surface, thin material processing, etc., can solve the problems of glue breaking, increase labor intensity of workers, and can't control the amount of glue pouring, etc., to achieve improvement Quality and Consistency Results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

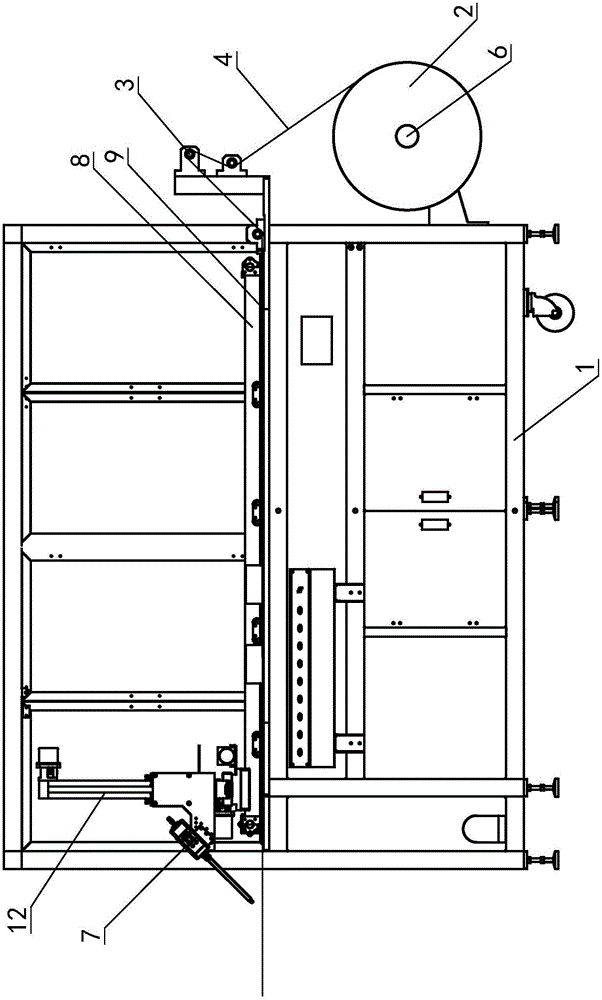

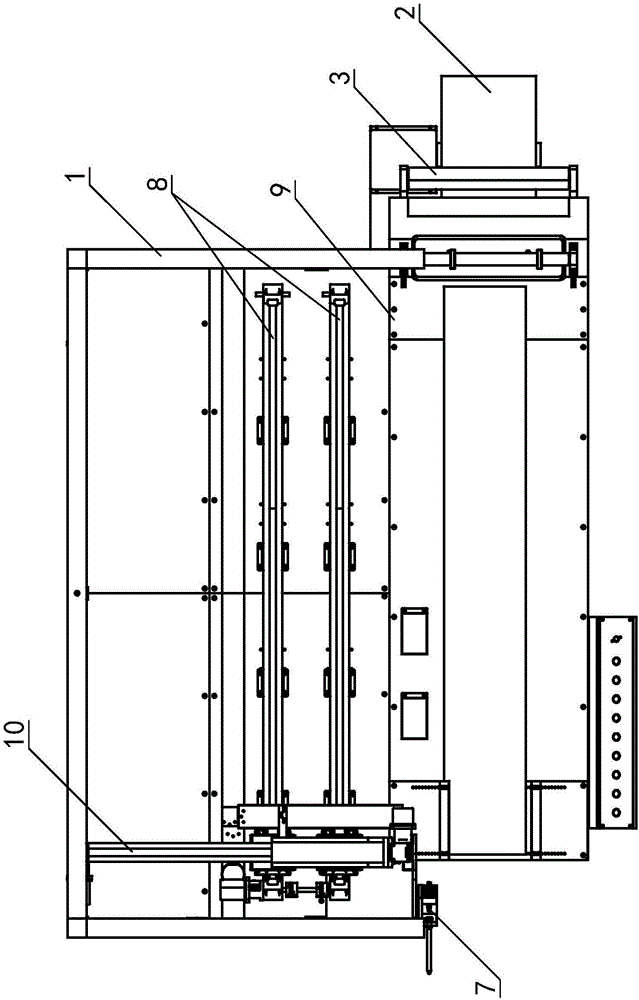

[0040] Example: see attached Figure 1~9 As shown, a film glue filling unit of an RO film automatic roll film machine includes a frame 1, and the frame 1 is provided with an automatic release guide cloth volume mechanism and an automatic glue filling mechanism; wherein,

[0041] The automatic release guide cloth roll mechanism includes a guide cloth roll 2 and a tension roller 3, and the guide cloth roll 2 and the tension roller 3 are all rotated and arranged on one side of the frame 1 along the height direction of the frame 1 , and the tension roller 3 is located above the guide cloth roll 2; the guide cloth 4 pulled out from the guide cloth roll 2 is tensioned and supported by the tension roller 3, and the guide cloth 4 is supported by one of the automatic film rolls Rotary mechanism pulls;

[0042] Also includes a magnetic powder clutch 5, the magnetic powder clutch 5 is arranged in the frame 1, and is connected with the rotating shaft of the guide cloth roll 2, and is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com