Carrier Assembly with Fused Powder and Frame-Warp Aperture

a carrier assembly and fused powder technology, applied in the direction of knitting, thin material processing, textiles and papermaking, etc., can solve the problems of reducing the quality and performance of the resulting vehicular strip, affecting the performance of the vehicle, and affecting the quality of the vehicle strip, so as to improve the consistency and quality of the carrier assembly, the effect of improving consistency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

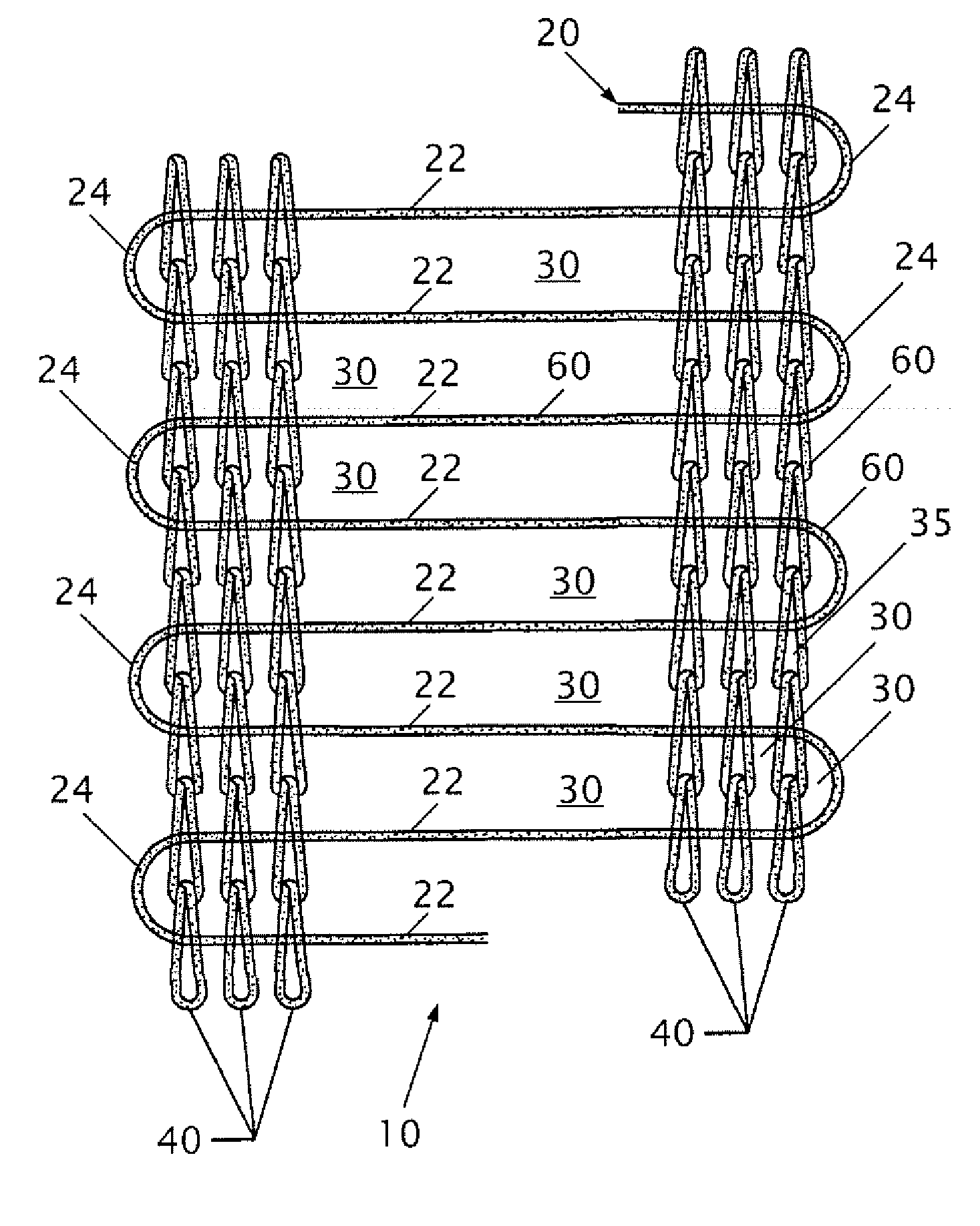

[0032] A carrier assembly 10 in accordance with the present invention is shown in FIG. 1. The carrier assembly 10 includes a serpentine frame 20, at least one warp 40 and a fused powder 60 on at least one of the frame and the warp to define at least one frame-warp aperture 30.

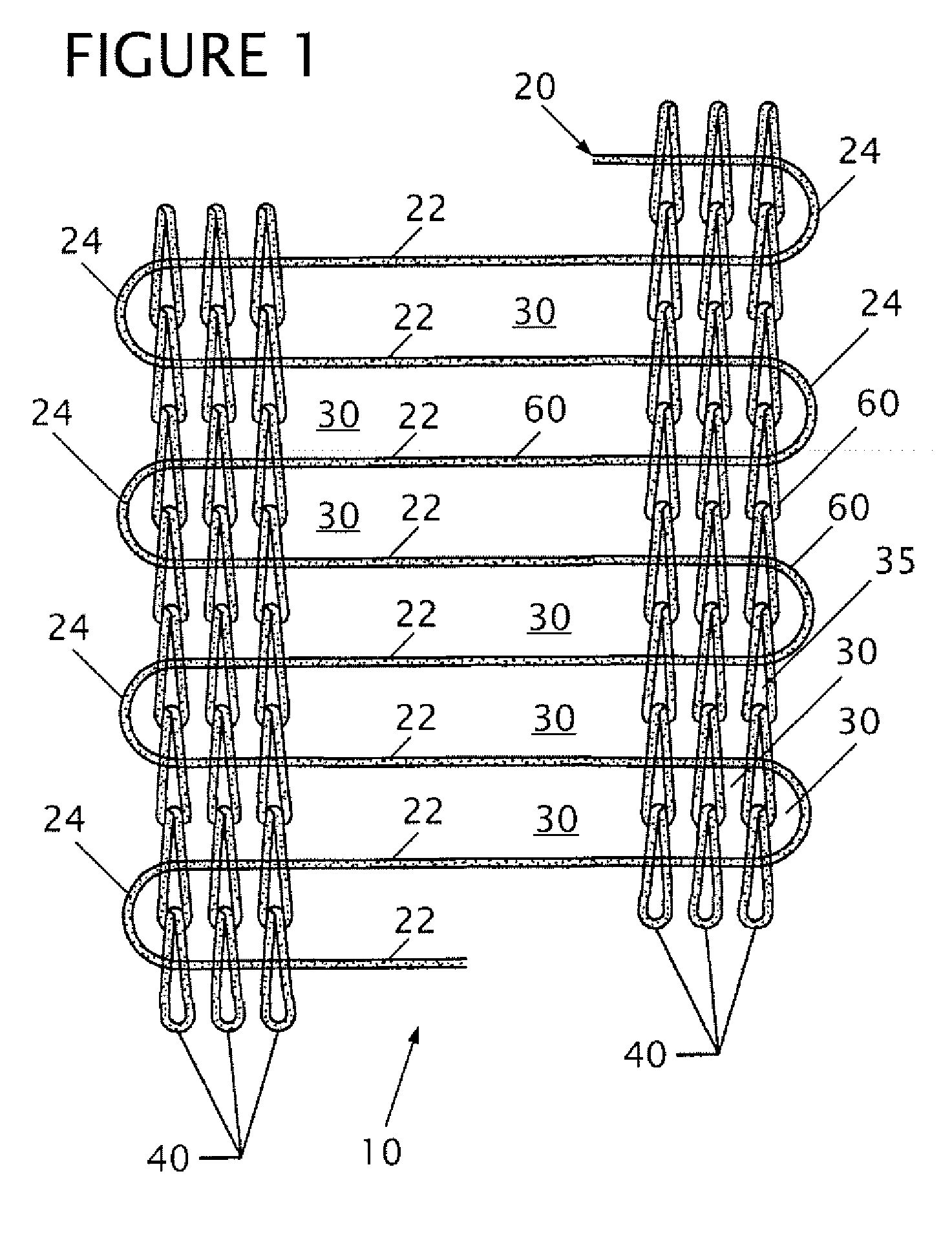

[0033] Referring to FIG. 2, the carrier assembly 10 can be incorporated into any of a variety of motor vehicle finishing strips, trim strips or weather strips. A vehicular weatherstrip 12 embedding the carrier assembly 10 is shown in FIG. 2. It is understood the vehicle strips can have any of a variety of configurations for engaging a vehicle, such as a flange engaging strip.

[0034] Serpentine Frame

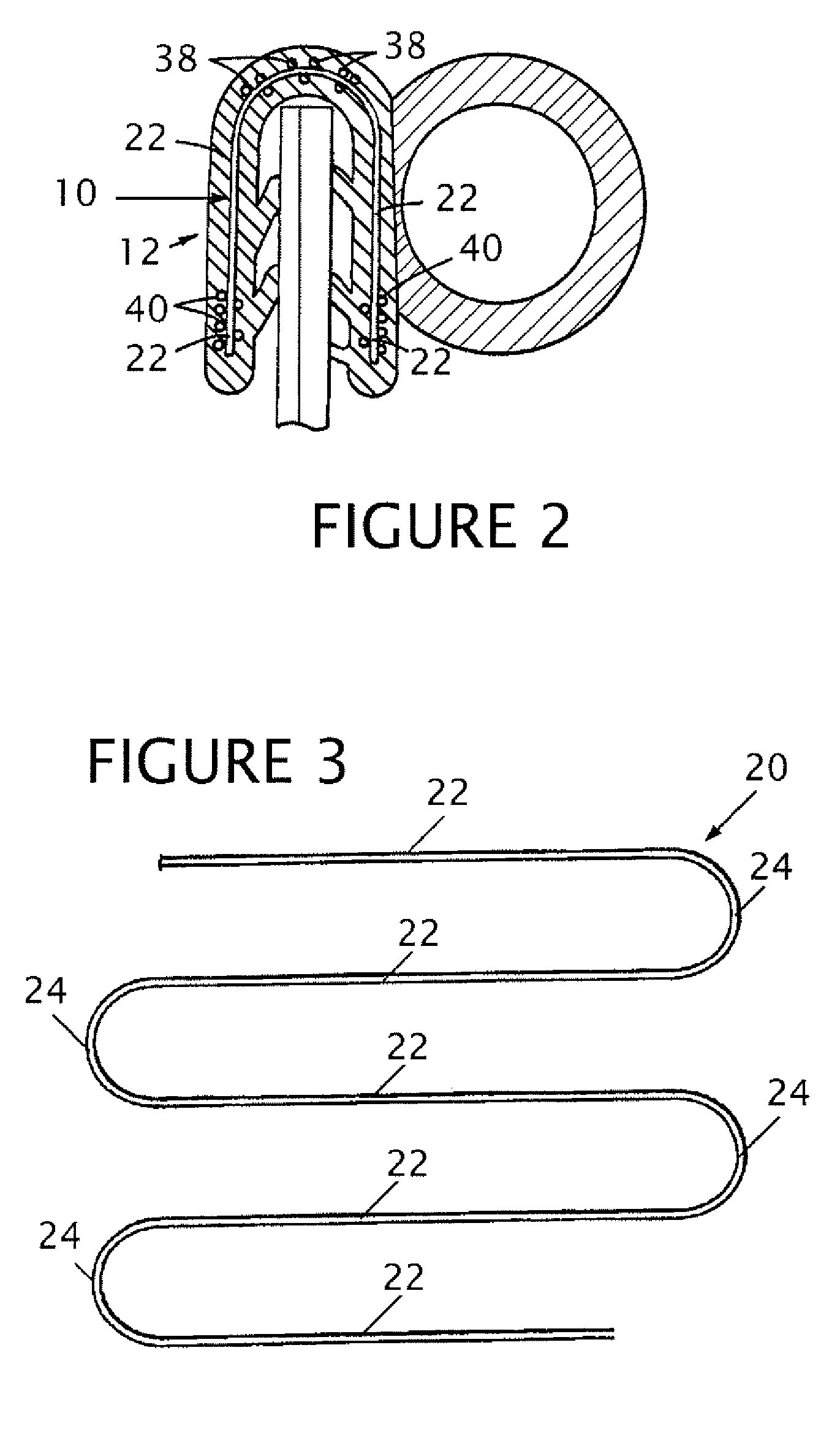

[0035] The serpentine frame 20 has a plurality of transversely extending limbs 22 interconnected at alternate ends by connecting regions 24. The limbs 22 can be straight or curvilinear, and can define sections that are linear, faceted, banana shaped, propeller shaped or any combination thereof. The limbs 22 are in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com