Efficient cleaning and winding equipment for cable production

A cable and cleaning technology, which is applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., can solve the problems of low cable winding efficiency, inconvenient cable discharge, and inability to clean the cable, so as to ensure the winding quality , Improve the effect of discharging, improve the efficiency of discharging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

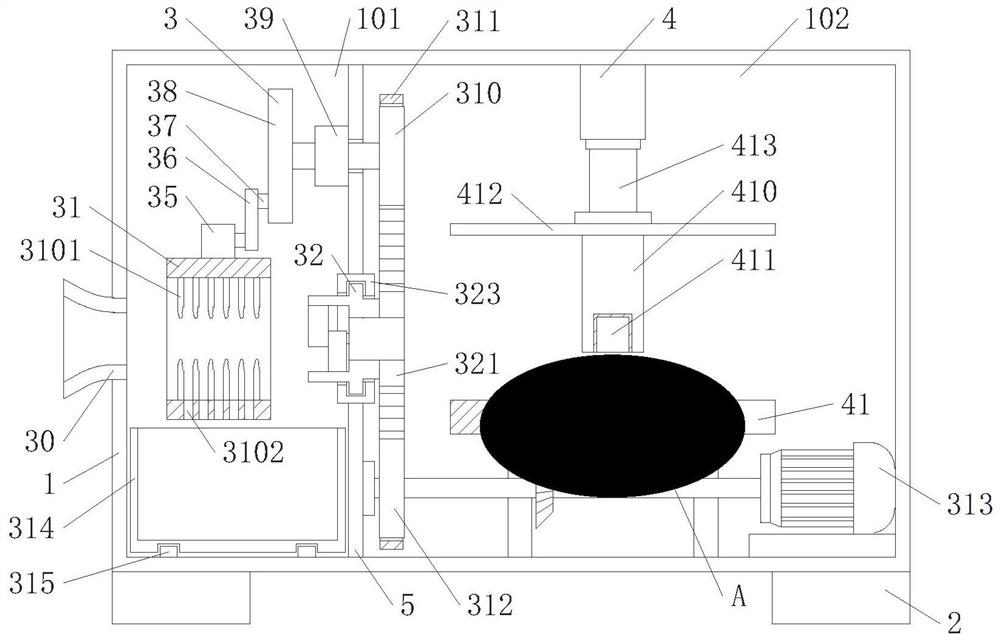

[0034] Refer Figure 1-5 A highly efficient cable production is used to clean the winding device, including a plurality of support pedicers 2 mounted in the lower end of the inner hollow chassis 1 and the lower end of the chassis 1, the cabinet 5 is vertically provided with a separator 5, and the chassis 1 The cavity is separated from the cleaning chamber 101 and the winding chamber 102, and the cleaning chamber 101 is provided with a cleaning mechanism 4, and the winding chamber 102 is provided.

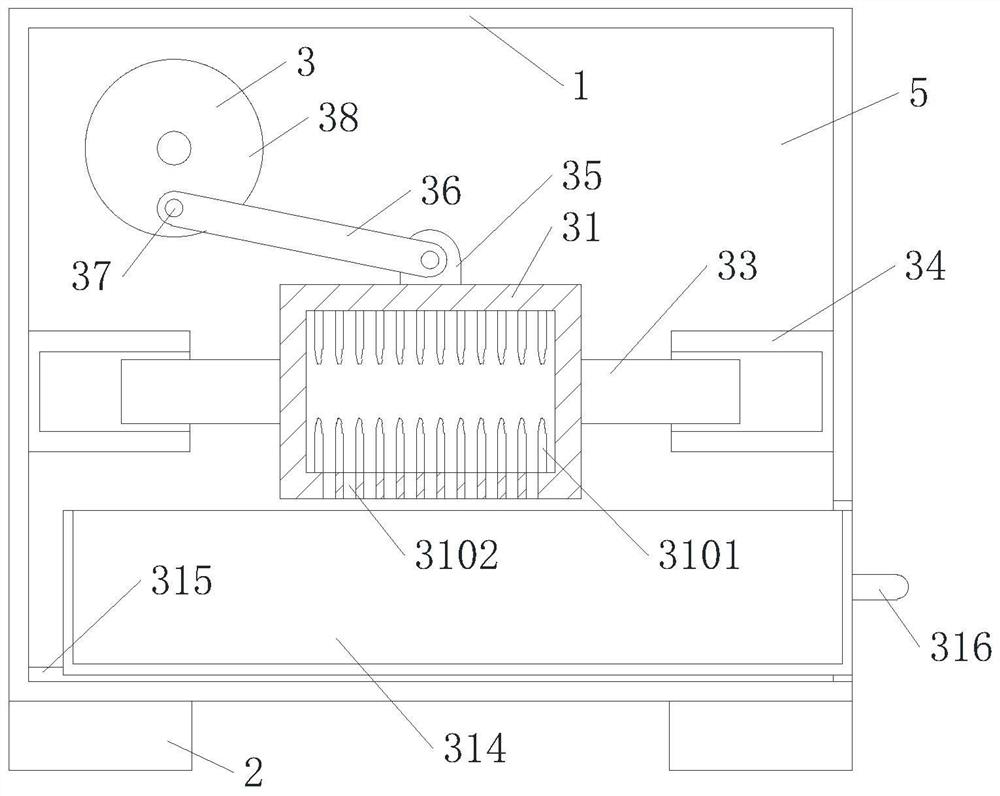

[0035] In this embodiment, if Figure 1-6 As shown, the cleaning mechanism 3 includes an inverse port 30 inserted through the sidewall of the cleaning chamber 101, and the cleaning chamber 101 slides in the inner chamber of the horizontal position of the inner port 30, and the cleaning cartridge 31 is provided, and two of the cleaning cartridges 31 The side is not closed, the inside of the cleaning cartridge 31 has a soft brush 3101, and the horizontally extends horizontally extends on th...

Embodiment 2

[0041] like figure 2 , 4 As shown in FIG. The synchronous wheel 310, the active synchronization wheel 312 is connected, the transport hole 324 extends towards one side close to the tray 41 and penetrates through the first homarch 321.

[0042] In this embodiment, the elastic wiping strip 326 is rotated by the synchronous belt 311, and the wiping effect of the cable is improved.

Embodiment 3

[0044] like figure 2 with 3 As shown, the present embodiment is substantially the same, preferably, and preferably, there is a plurality of lower gray holes 3102 on the bottom wall of the cleaning cartridge 31, which is convenient for dust-discharge, avoiding dust stacking to affect the cleaning effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com