High efficiency filter

A high-efficiency filter and filter paper technology, which is applied in the direction of dispersed particle filtration, chemical instruments and methods, and dispersed particle separation, can solve the problems of short service life, high cost of use, and small dust holding capacity of filter paper, and achieve long service life. Large dust holding capacity, increase the effect of filtering air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

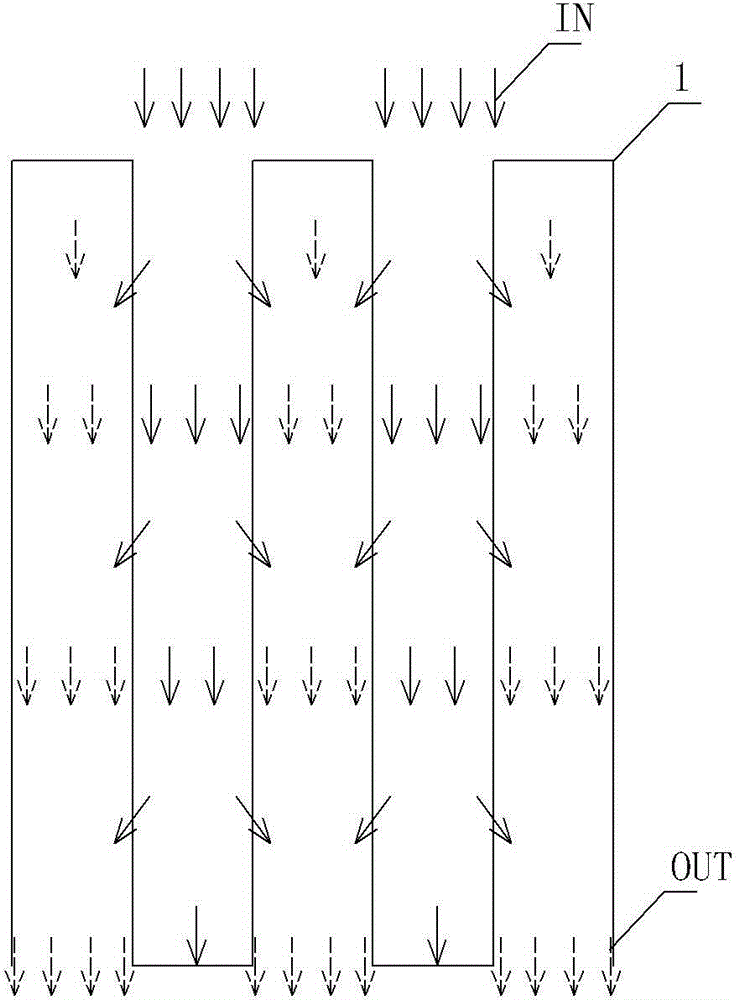

[0017] See Figure 4 , Figure 5 The high-efficiency filter of the present invention includes a box body 10, and a filter element 20 is arranged in the box body 10. The filter element 20 includes a filter paper 21 and a partition 22, and the filter paper 21 is repeatedly folded to form a plurality of concave grooves 23 with opposite opening directions, see Figure 7 Each concave groove is provided with a partition 22, and the concave groove 23 formed by repeated folding of the filter paper 21 is a tapered groove, the cone top 231 of the cone groove is closed, and the cone bottom 232 is open. image 3 and Figure 8 Among them, IN is the air supply before filter paper filtration; OUT is the exhaust air after filter paper filtration.

[0018] See Figure 5 and Figure 6 , the partition 22 is a zigzag folding structure, and the zigzag section of the partition 22 is perpendicular to the tapered groove section of the filter paper 21; The plate corresponds to the number of zigza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com