Sheet feeding device in a printing machine

A printing press and paper feeding technology, applied in printing presses, general parts of printing machinery, printing, etc., can solve problems such as unstable paper running, and achieve the effect of reducing the risk of sliding and smooth running of paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

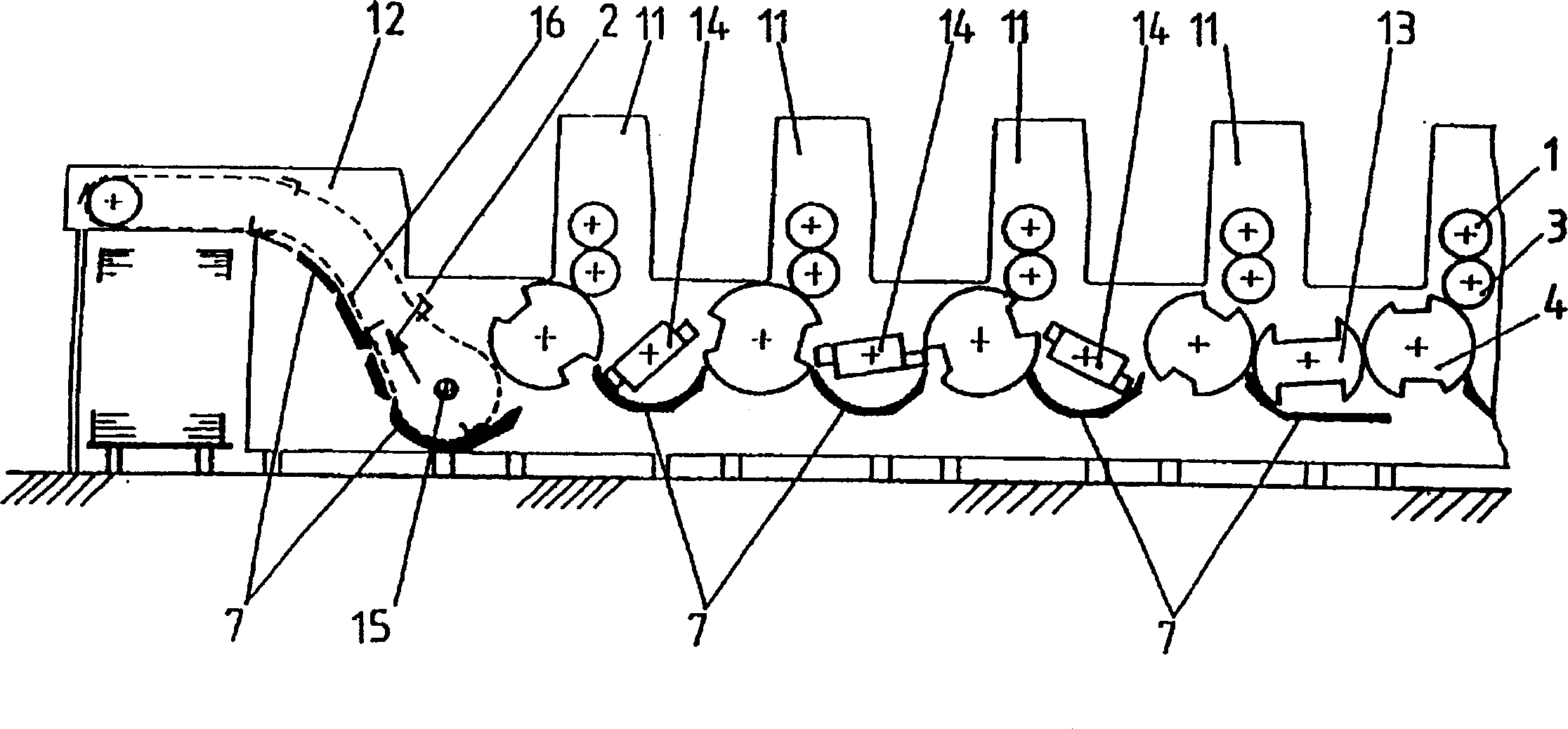

[0019] The tandem rotary printing press has a plurality of printing units 11 for multicolor offset printing. In addition, at least one varnishing unit or a usual processing station can be arranged downstream of the printing unit 11 . Each printing unit 11 consists of a leveling roll 1 , a blanket roll 3 and a guide roll, shown here as printing roll 4 . Each smoothing roller 1 is provided with an inking unit and optionally a dampening unit. One or more deflection systems 13 (for example single-drum deflection or three-drum deflection) as well as transport rollers 14 are arranged between the printing units 11 as guide rollers.

[0020] In the conveying direction 2 , the carriage 12 is arranged after the last printing unit 11 (or a varnishing unit). The carriage 12 has a continuous endless conveyor system 16 , for example a sprocket system with a sprocket shaft 15 . The paper guide rollers (contact cylinder, deflection system 13 , delivery roller 14 , printing roller 4 ) as we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com