Guide structure for blanking die

A technology of guiding structure and blanking die, which is applied in the direction of metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of poor stability of the guiding structure, achieve the effect of stable guiding, uniform radial force, and avoid easy wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below by means of specific embodiments:

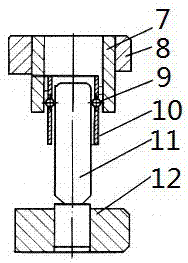

[0013] The reference signs in the accompanying drawings of the description include: blanking punch 1, first fixing plate 2, side edge 3, punching punch 4, material guide plate 5, second fixing plate 6, guide sleeve 7, upper die seat 8. Ball 9, cage 10, guide post 11, lower mold seat 12.

[0014] as attached figure 1 Shown: this embodiment is used for the guiding structure of punching die, comprises the vertical guide sleeve 7 that is arranged on the lower part of the upper die base 8 and the vertical guide post 11 that is arranged on the upper part of the lower die base 12, the diameter of the guide sleeve 7 Greater than the diameter of the guide post 11, the upper part of the guide post 11 is penetrated into the guide sleeve 7, and evenly arranged balls 9 are arranged between the guide post 11 and the inner wall of the guide sleeve 7, and are specifically fixed on the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com