Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Fast response to speed regulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

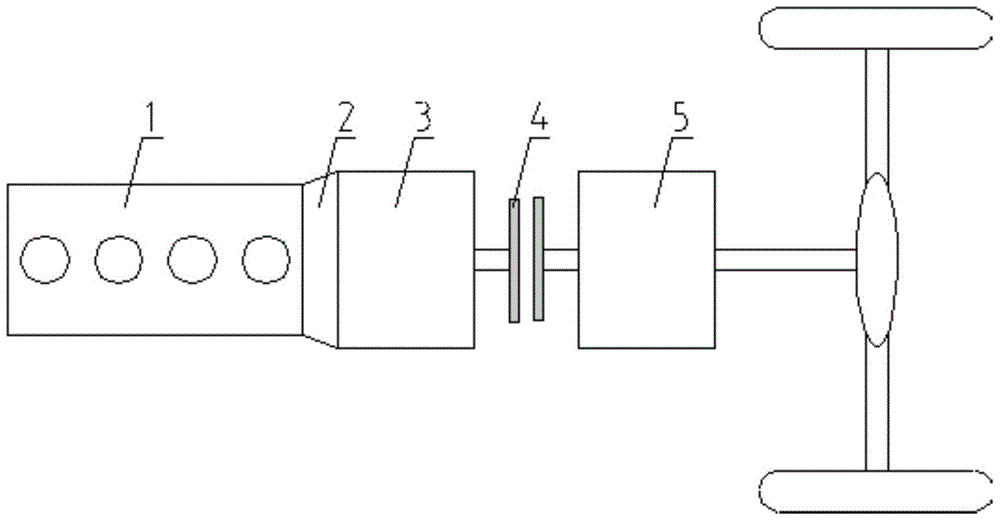

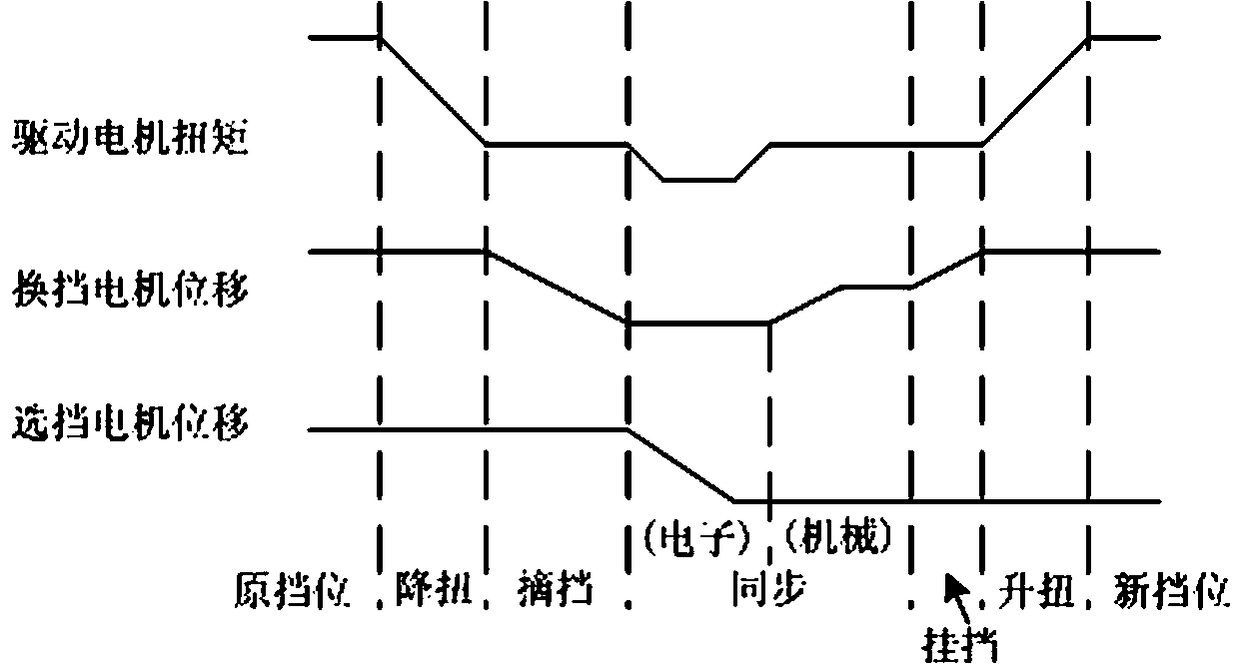

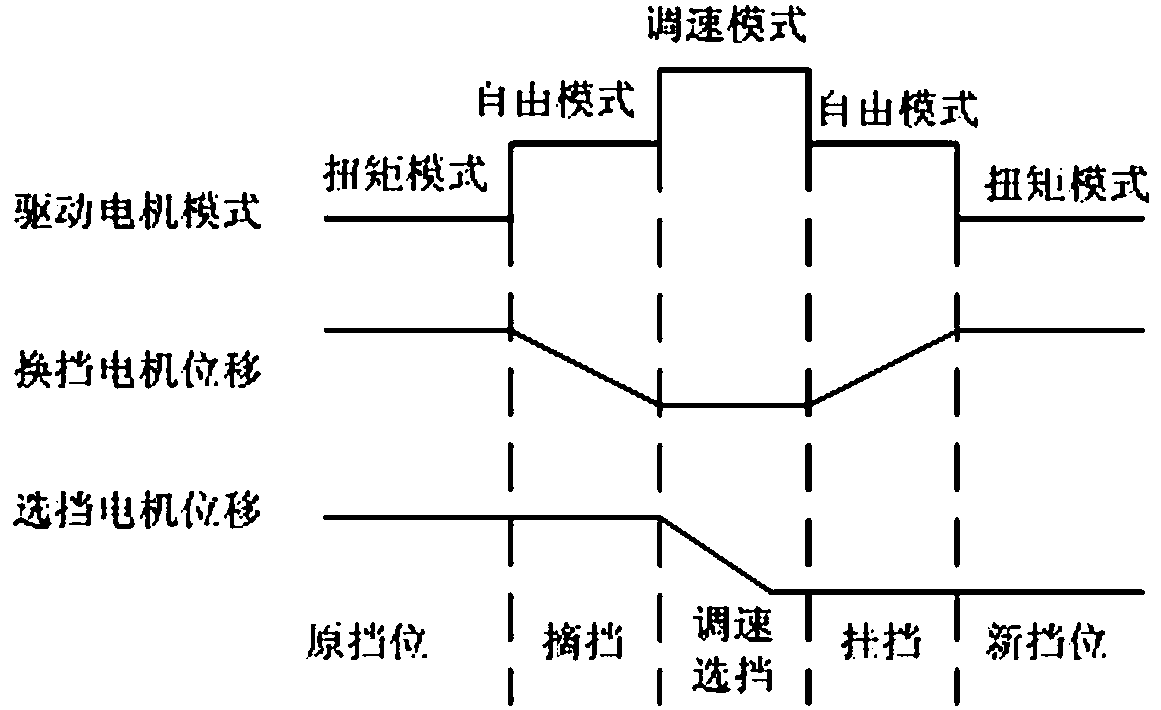

Non-clutch AMT (Automatic Manual Transmission) control system and method

ActiveCN105972199AImprove shift qualityImproved shift stabilityGearing controlControl systemElectric machine

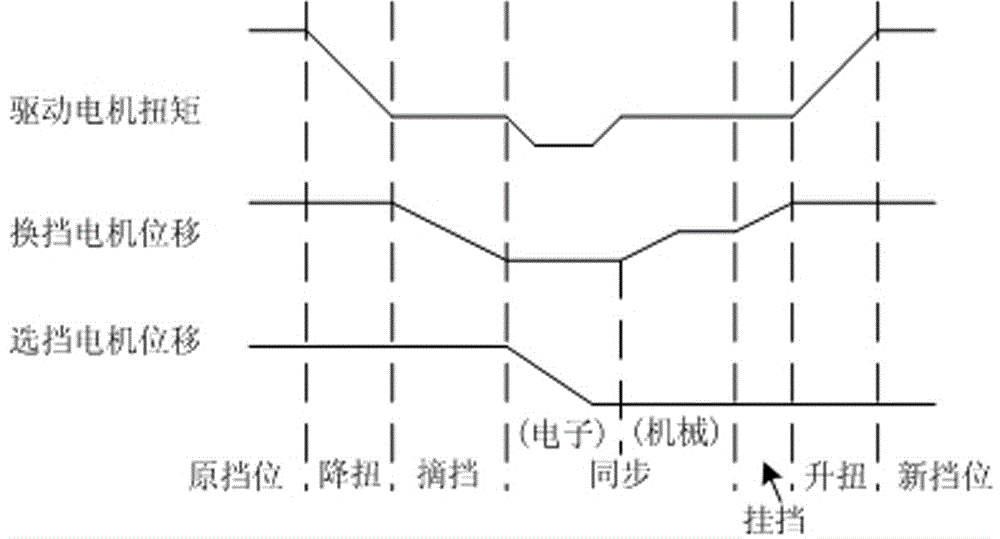

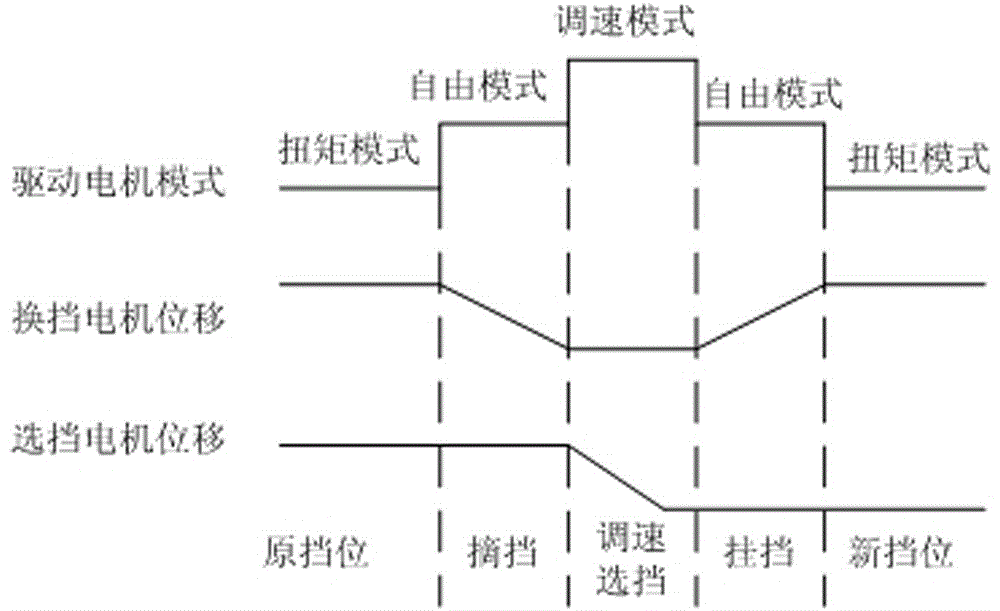

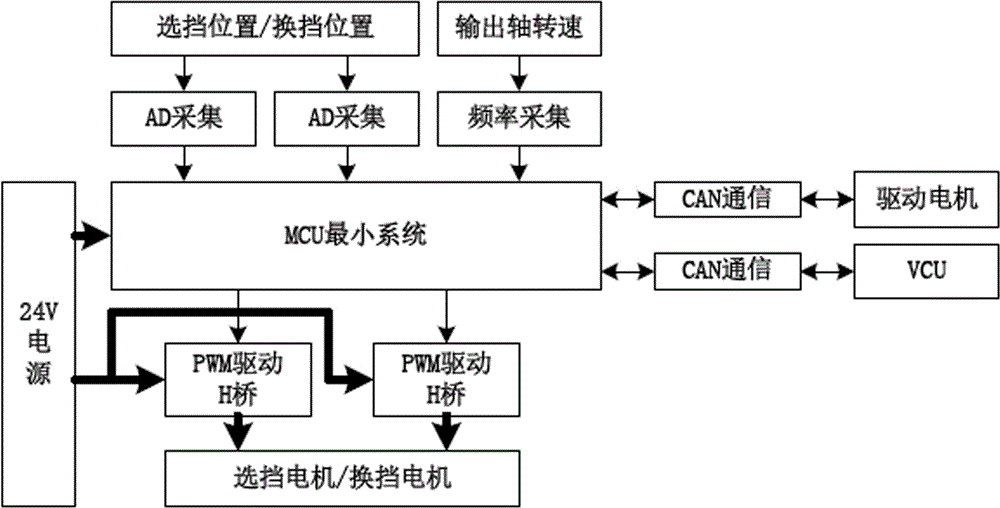

The invention relates to a non-clutch AMT (Automatic Manual Transmission) control system. The non-clutch AMT control system comprises an MCU (Microprogrammed Control Unit) and a TCU (Transmission Control Unit) which are interconnected. Compared with the prior art, the non-clutch AMT control system has the beneficial effects that after the system enters a shifting process, the TCU can take over the control right of a driving motor, so that the technical effects of optimizing the shifting quality, reducing the shifting time and improving the shifting stability can be achieved. The invention also relates to a non-clutch AMT control method. The non-clutch AMT control method comprises a speed regulating stage; the motor in the shifting process of the method is in a torque mode; the speed regulating stage comprises a motor synchronous speed regulating stage and a mechanical synchronous speed regulating stage. Compared with the prior art, the non-clutch AMT control method has the beneficial effects that the shifting process is divided into six stages through the control method, namely, an unloading stage, an idling stage, an electronic synchronizing stage, a mechanical synchronizing stage, a gear engaging stage and a loading stage, and thus the technical effects of greatly reducing the overall shifting time, reducing the impact in gear engaging, and prolonging the service lives of mechanical parts such as a synchronizer can be achieved.

Owner:北理华创(佛山)新能源汽车科技有限公司

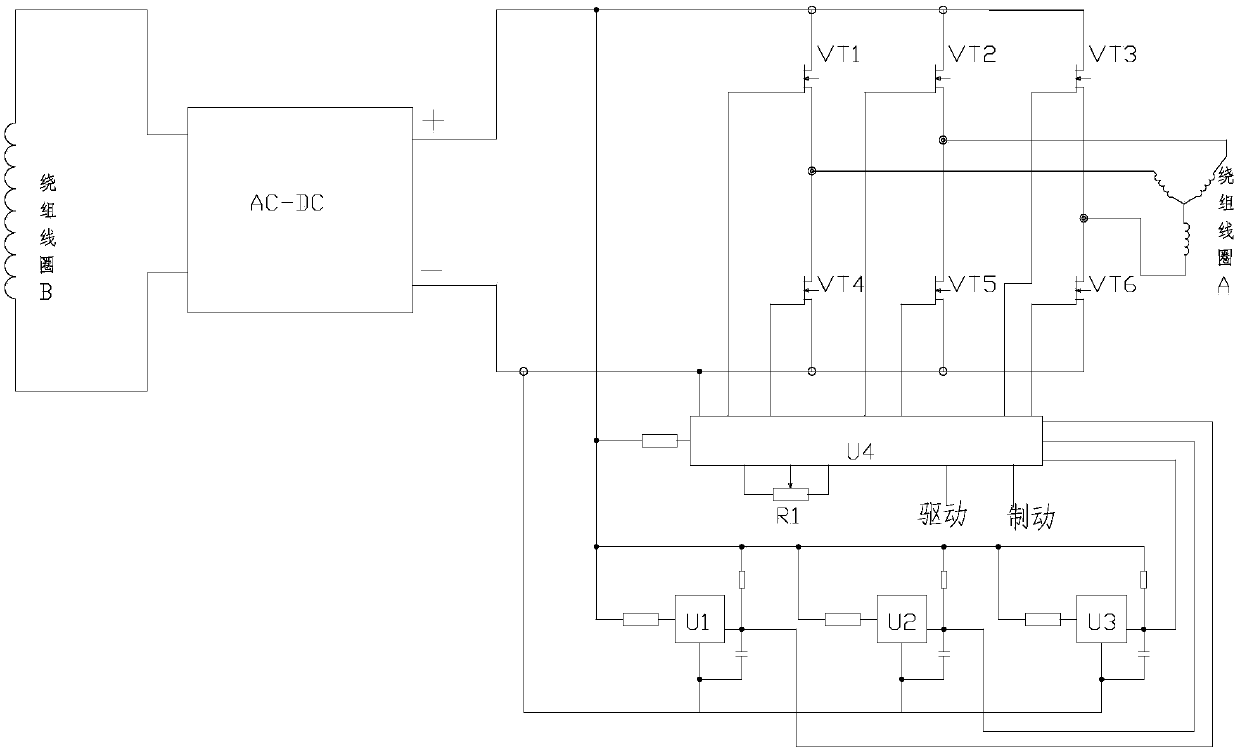

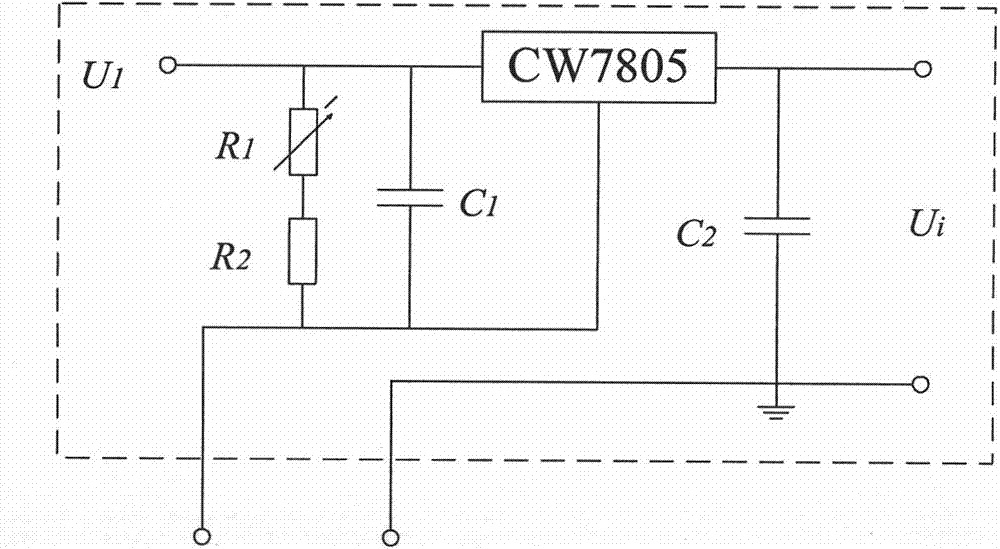

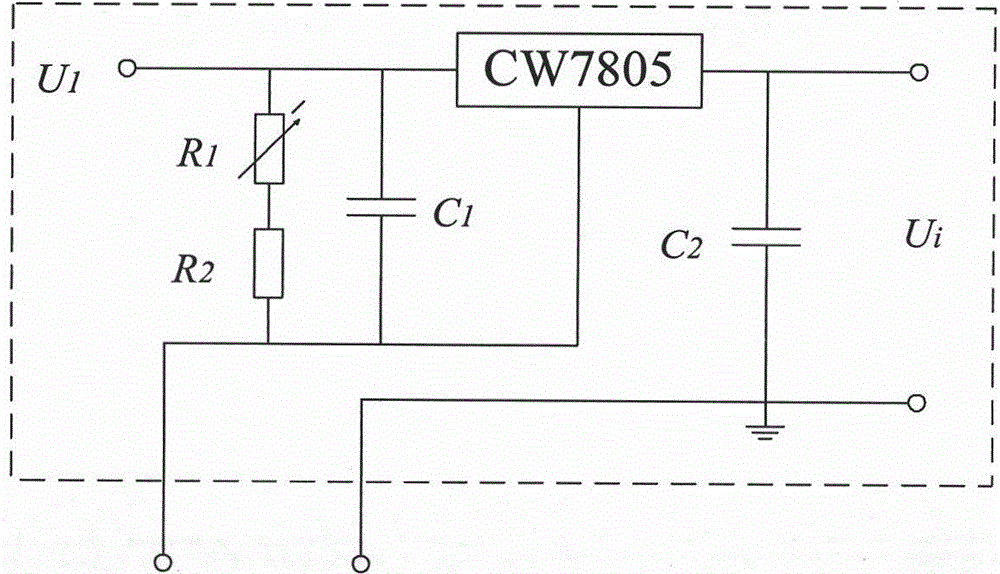

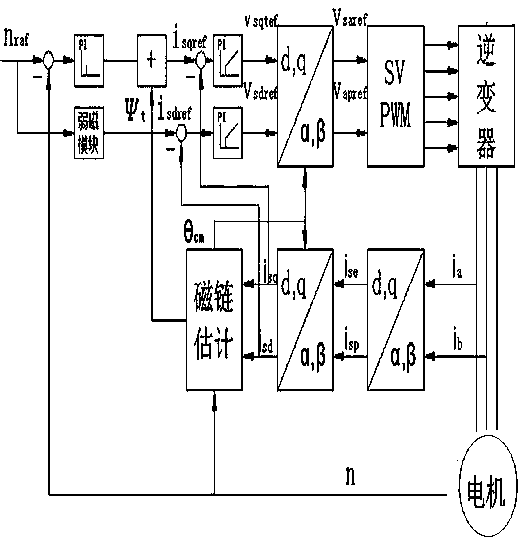

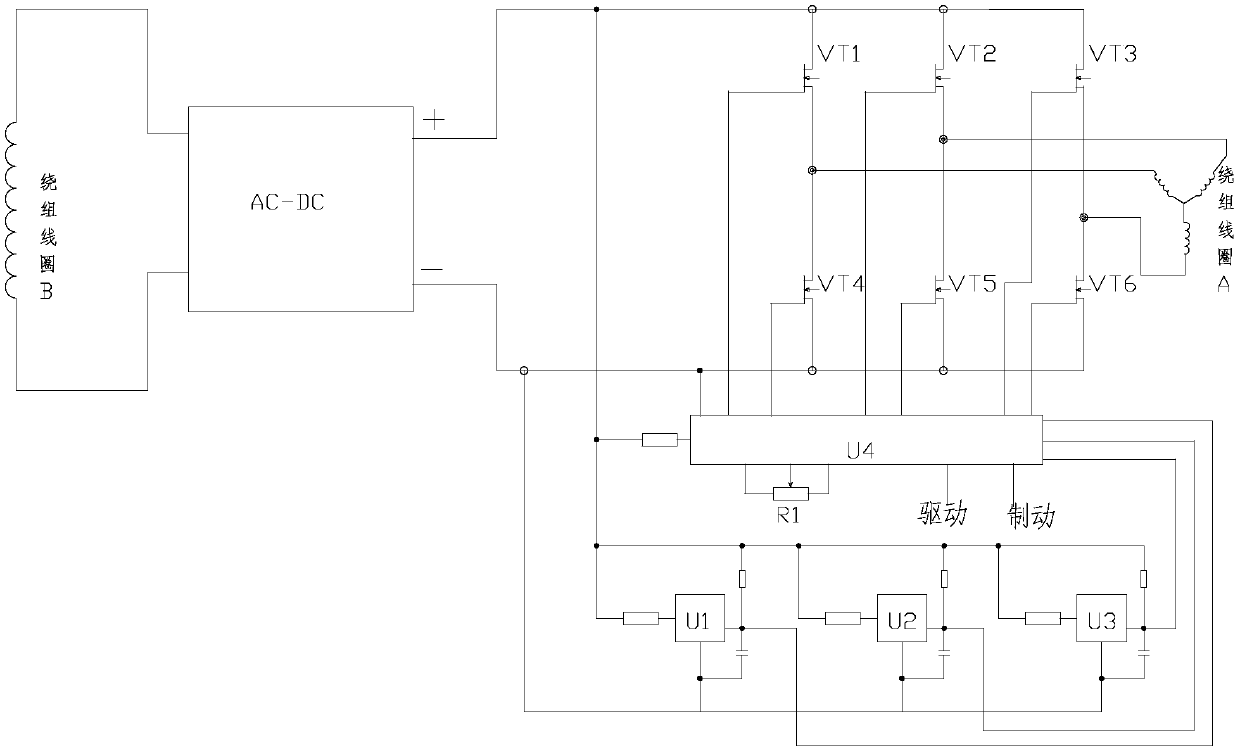

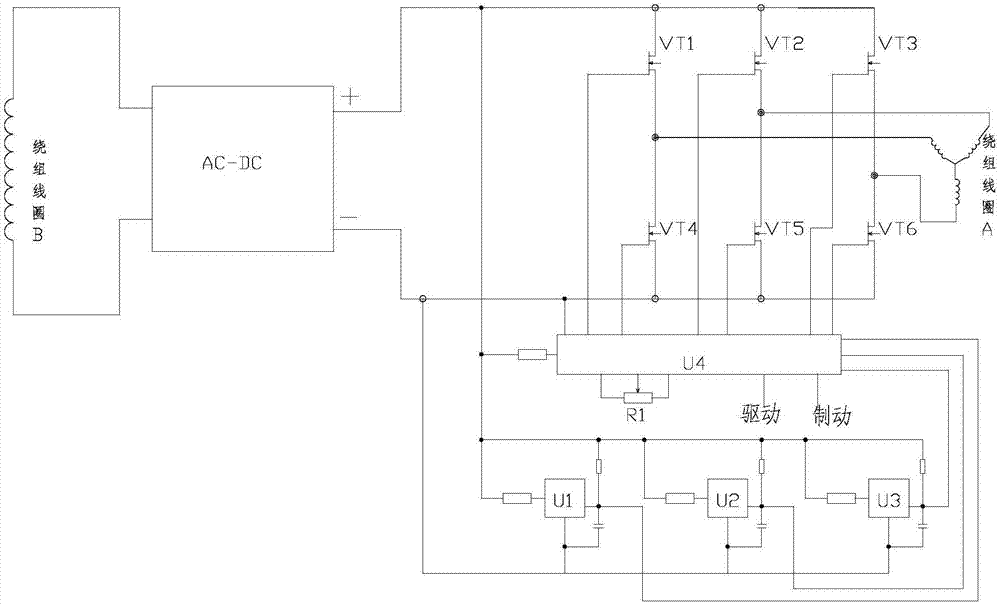

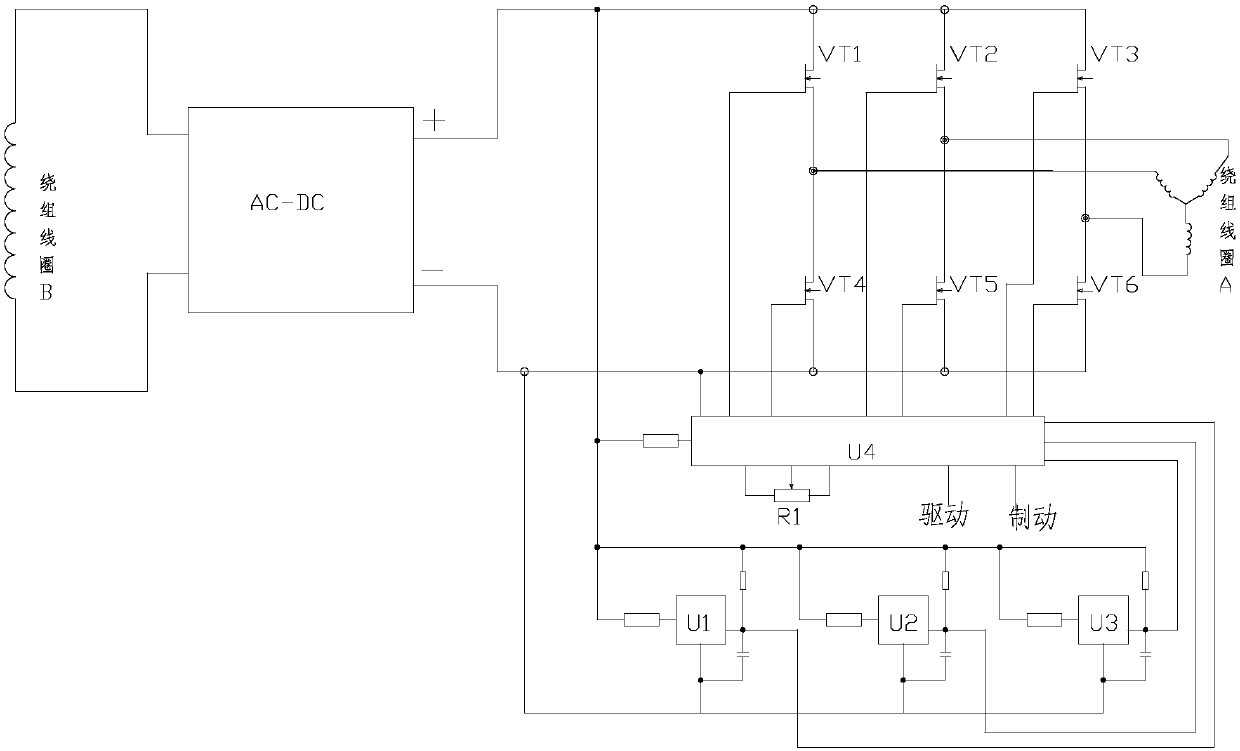

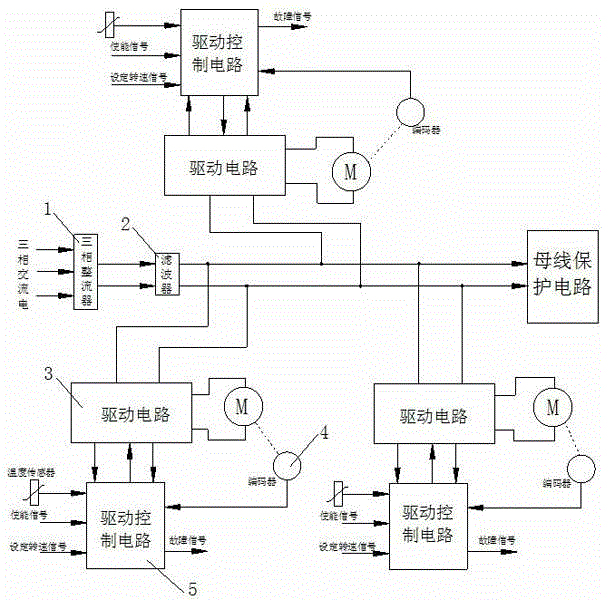

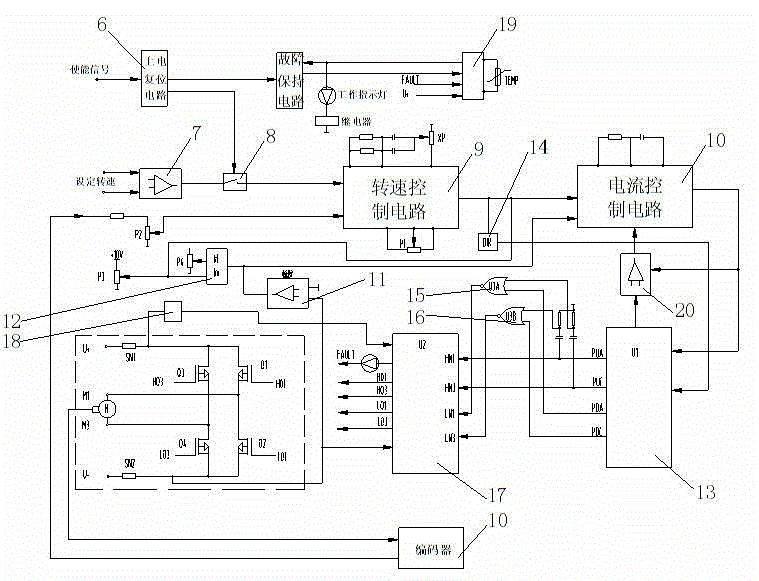

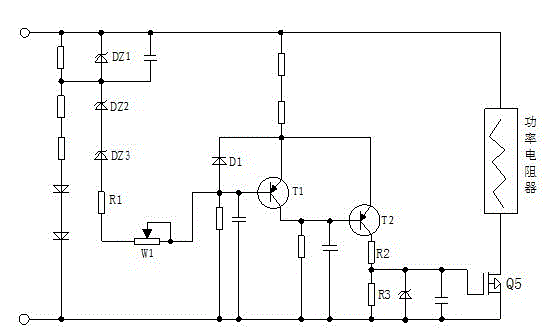

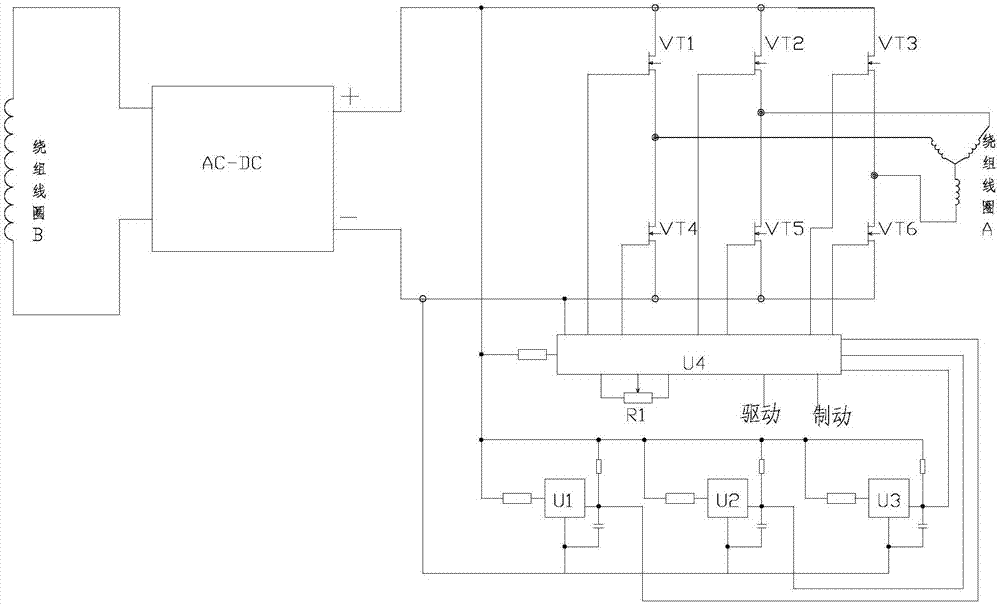

DC (direct current) motor driver

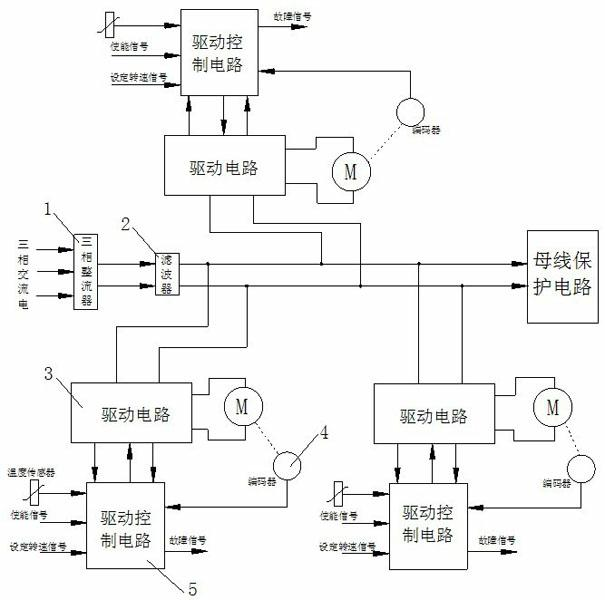

InactiveCN102097989AEasy to controlLarge starting torqueEmergency protective circuit arrangementsField or armature current controlControl systemClosed loop

The invention discloses a DC (direct current) motor driver which is designed by using a full-analog electronic circuit, a PWM (pulse width modulation) pulse width control chip and a high voltage driving chip. The motor is precisely controlled by using a DC bus protection circuit, a rotary speed feedback and current feedback dual closed-loop PI (Proportional Integral) adjusting circuit, a DC motor back discharging controllable circuit and a pulse width limit controlling circuit. The invention has the following obvious effects: the DC motor driver is reliable in operation, fast in speed regulation response, and strong in anti-interference performance; the motor is exactly controlled by using current feedback dual closed-loop PI adjusting circuit, DC motor back discharging and pulse width limit controlling; and the DC motor driver is perfect in protection function, suitable for a wind power variable paddle system, large in starting torque and is frequently adjusted.

Owner:CHONGQING HUAYU HEAVY IND ELECTROMECHANICAL CO LTD

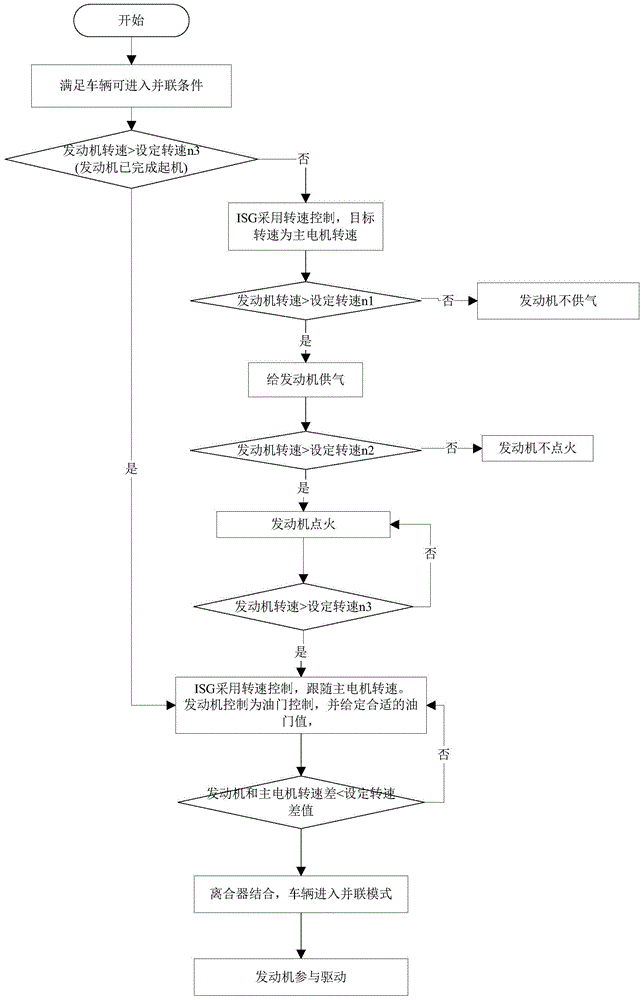

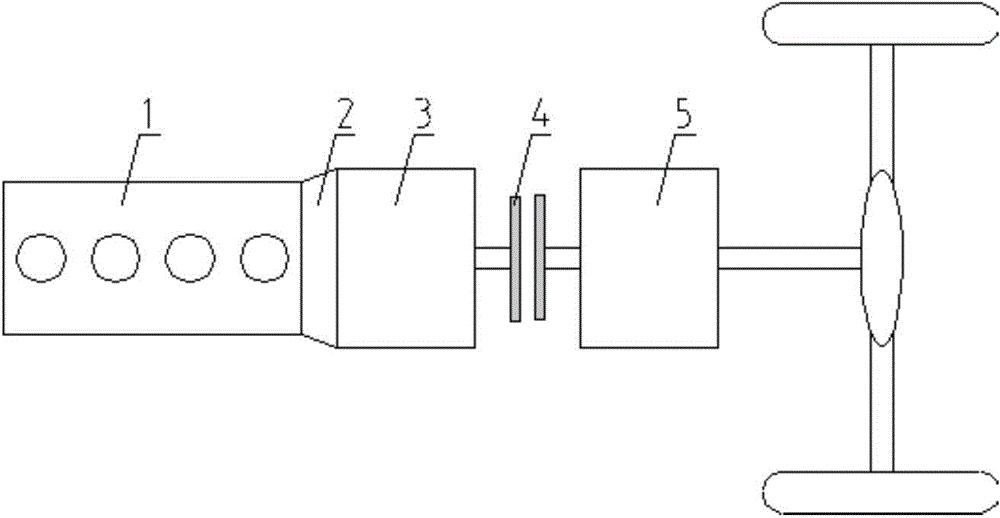

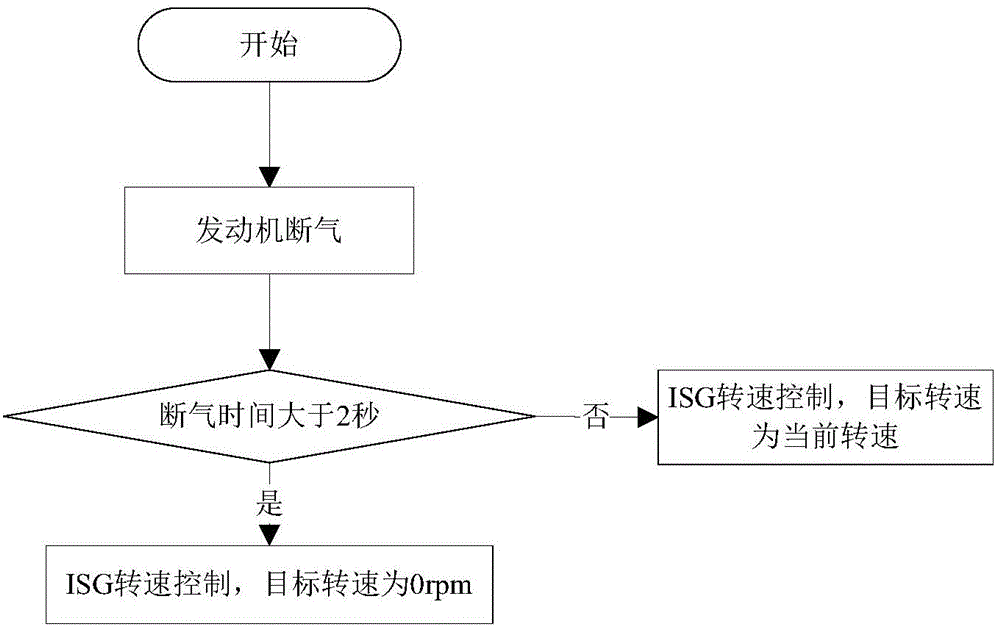

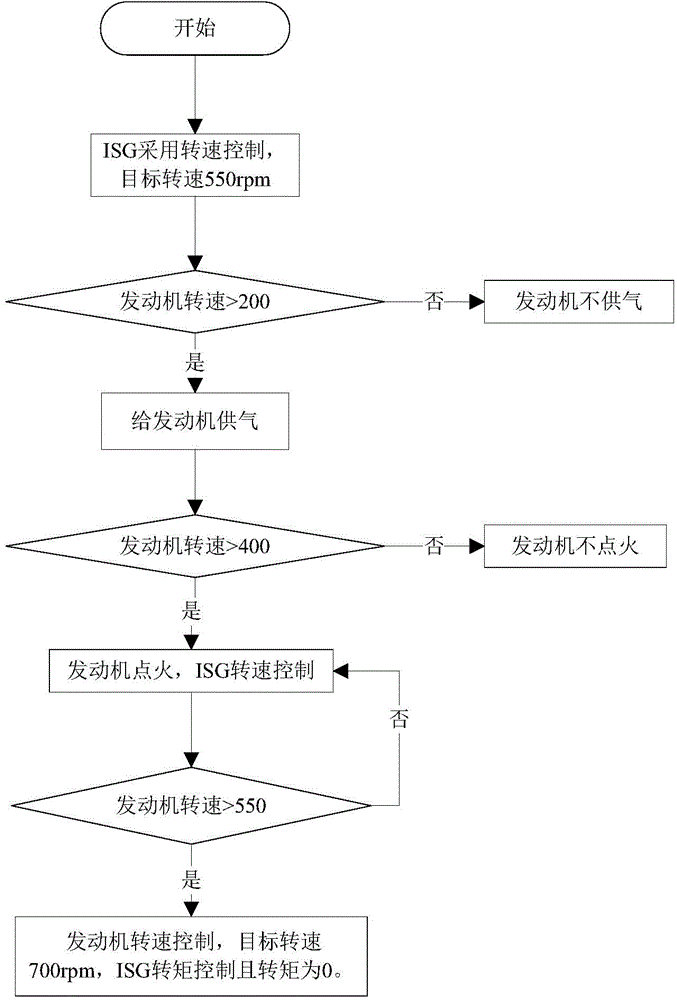

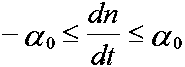

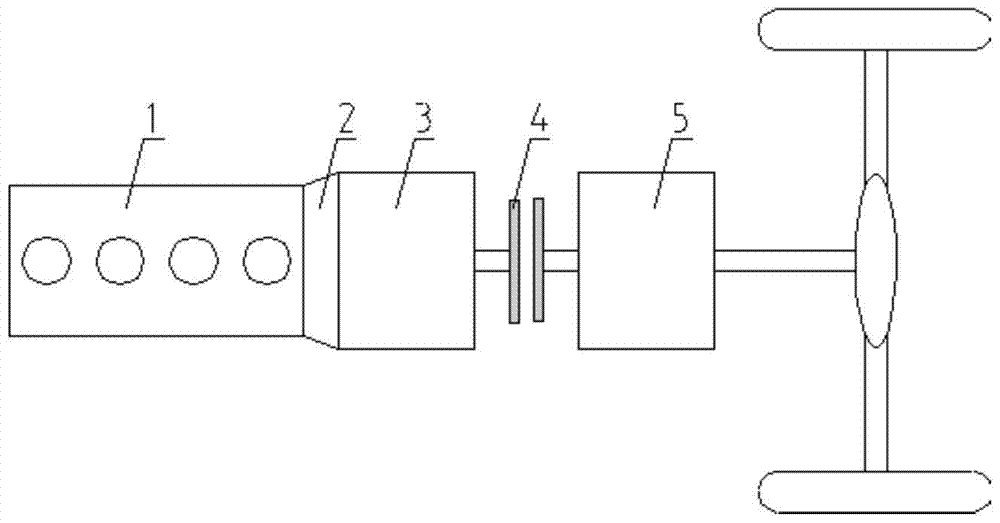

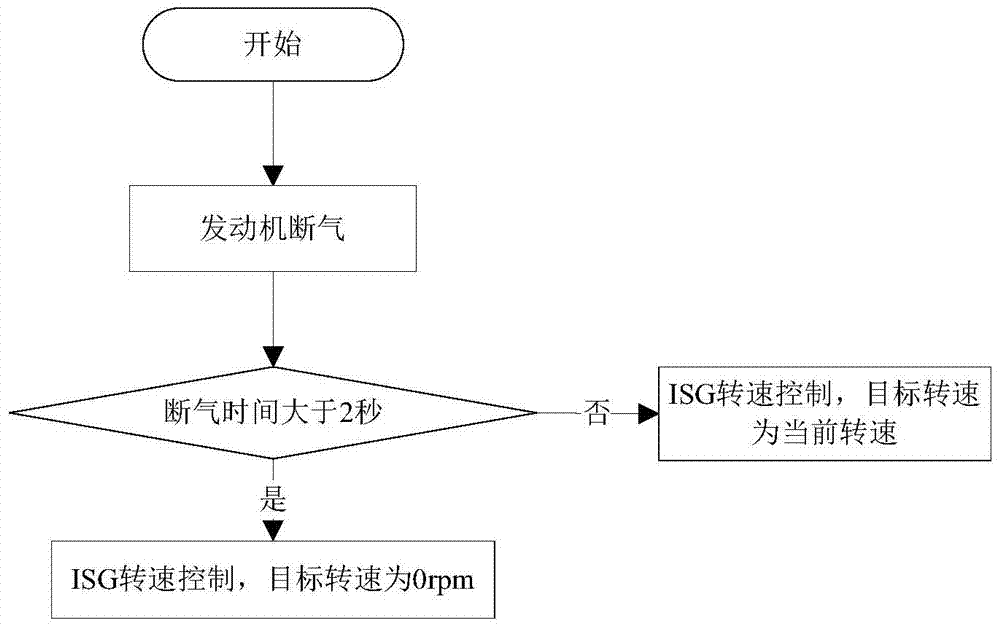

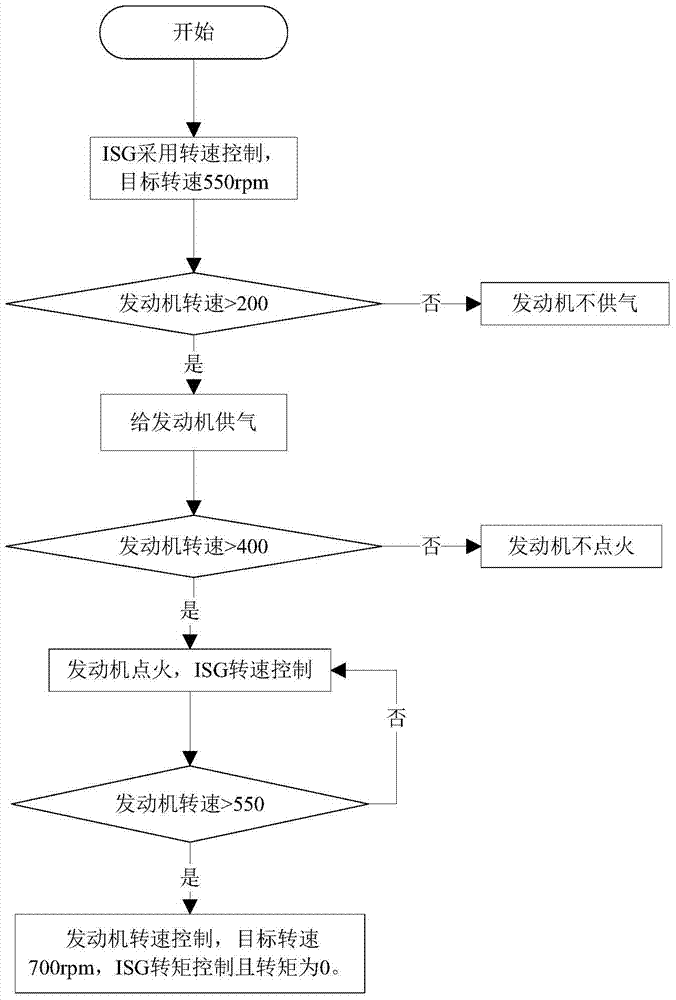

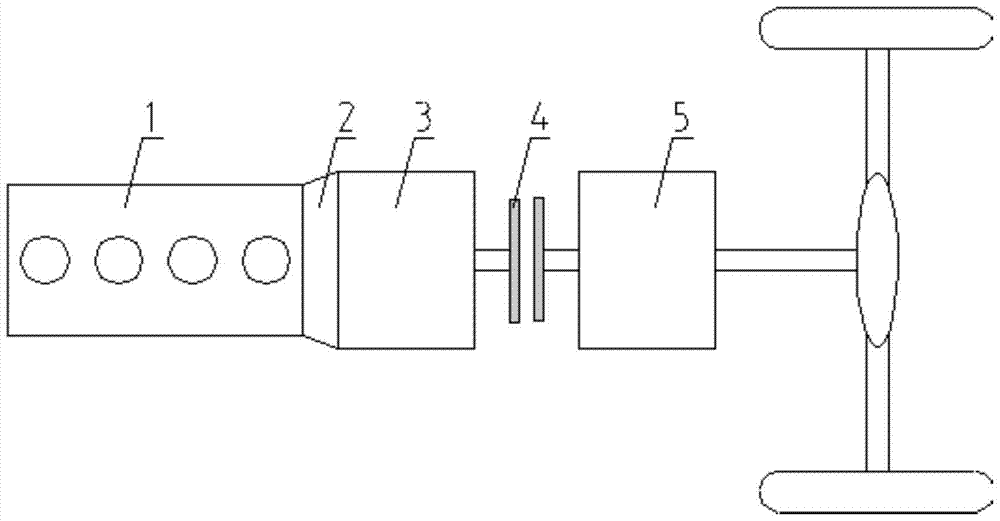

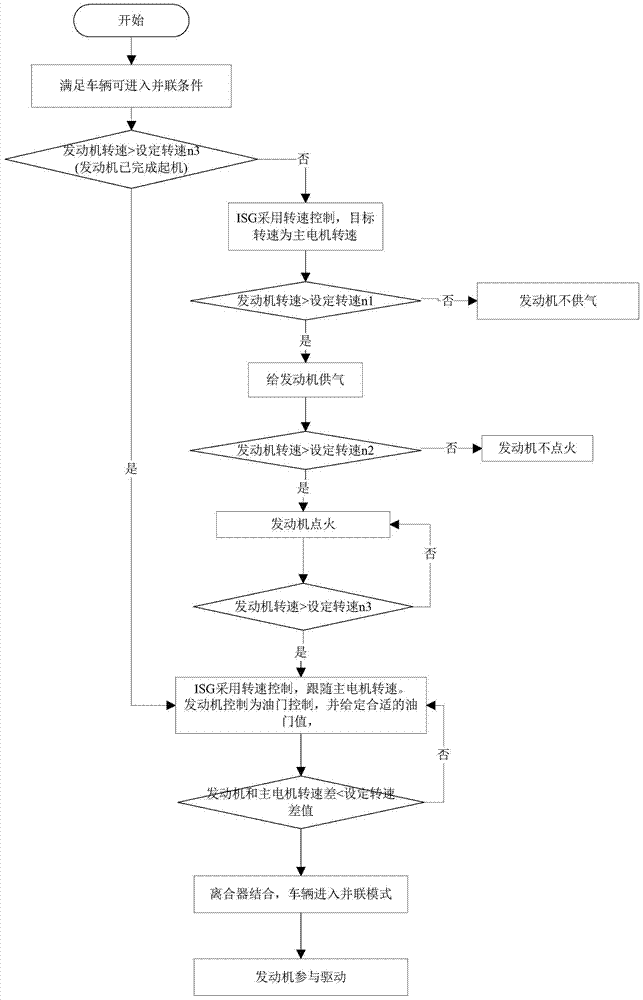

Serial-to-parallel control method of electrical-electric connecting type hybrid power system

ActiveCN104554240AFast response to speed regulationHybrid vehiclesDriver input parametersStarter generatorElectric machinery

The invention discloses a serial-to-parallel control method of an electrical-electric connecting type hybrid power system. The method is that when a vehicle meets the condition of entering parallel connection and an engine is failed to be started, ISG (Integrated Starter Generator) is subjected to rotating speed control, namely, the target rotating speed is the rotating speed of a main motor; the engine supplies air when reaching the set rotating speed n1, and is ignited when reaching the set rotating speed n2; when starting successfully, the ISG remains the rotating speed control; on the basis of the rotating speed of the main motor, the engine control is replaced by accelerator control, and a proper accelerator value is provided; when the rotating speed difference between the engine and the main motor is less than the set rotating speed difference value, a clutch is connected, and the vehicle enters the parallel connection mode. The method has the outstanding characteristics that the ISG is subjected to rotating speed control under a serial-to-parallel mode; the engine is subjected to accelerator control and the proper accelerator value is provided on the basis of the rotating speed of the main motor, so that the speed regulating can be responded fast; in addition, the response of the engine in the parallel connection mode is faster than that of the mode that the engine control is performed and the accelerator value is 0 during speed adjustment; the hybrid power system is free of power cut-off after the clutch is connected.

Owner:ZHENGZHOU YUTONG BUS CO LTD

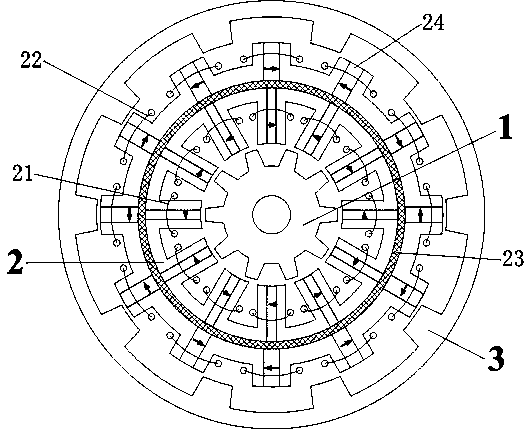

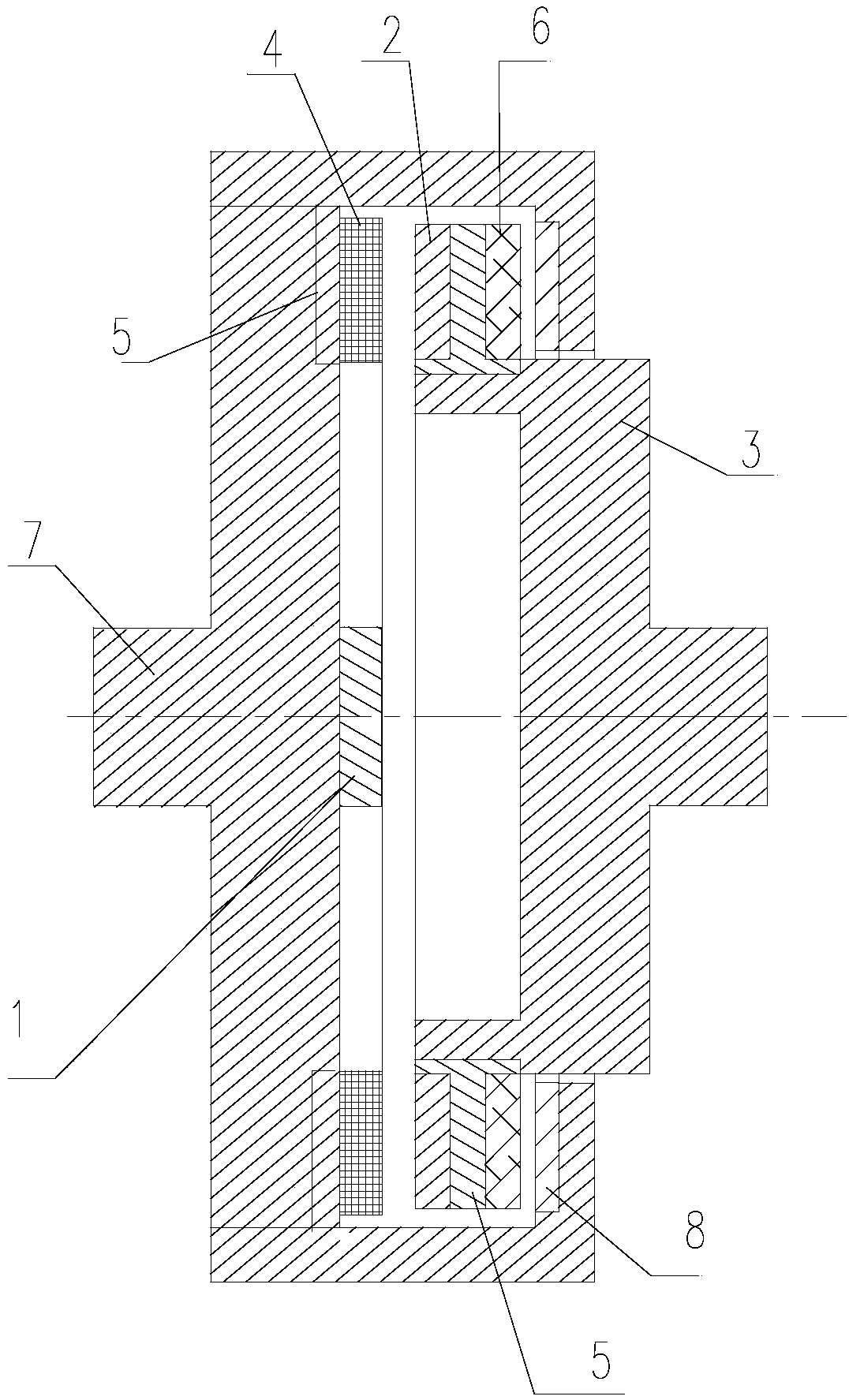

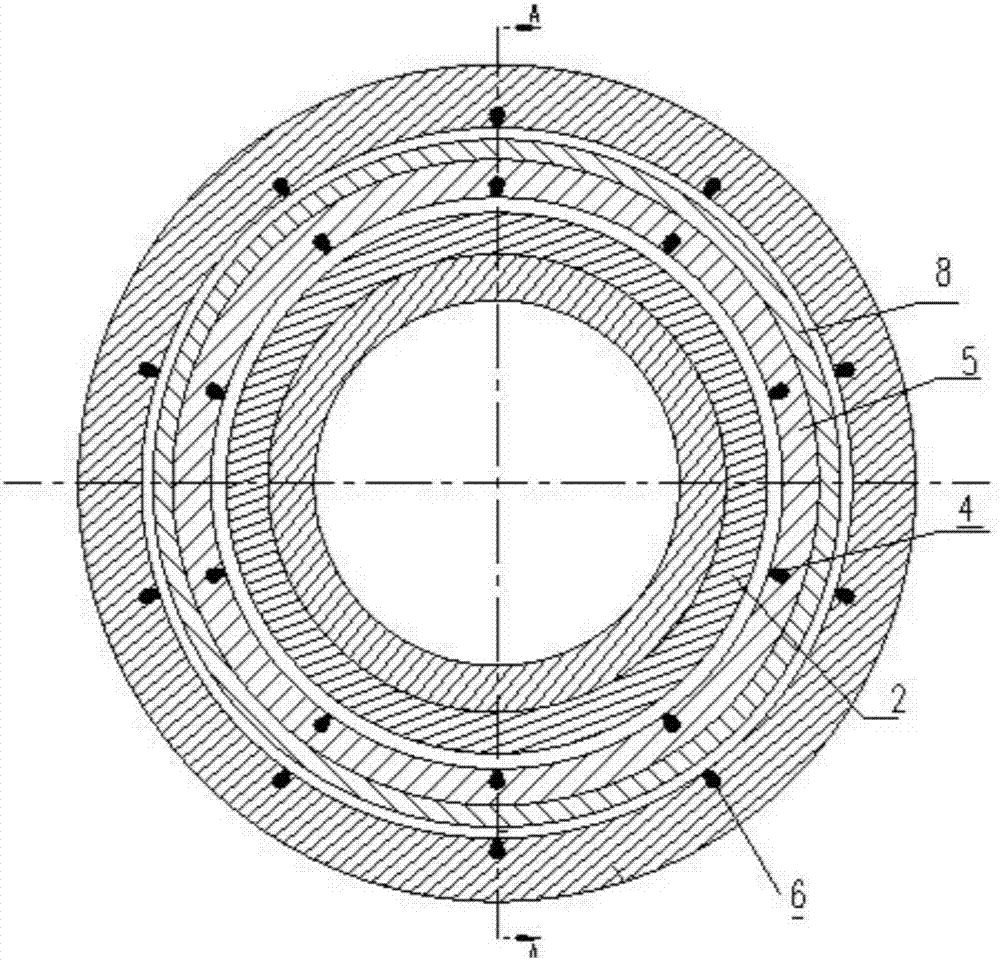

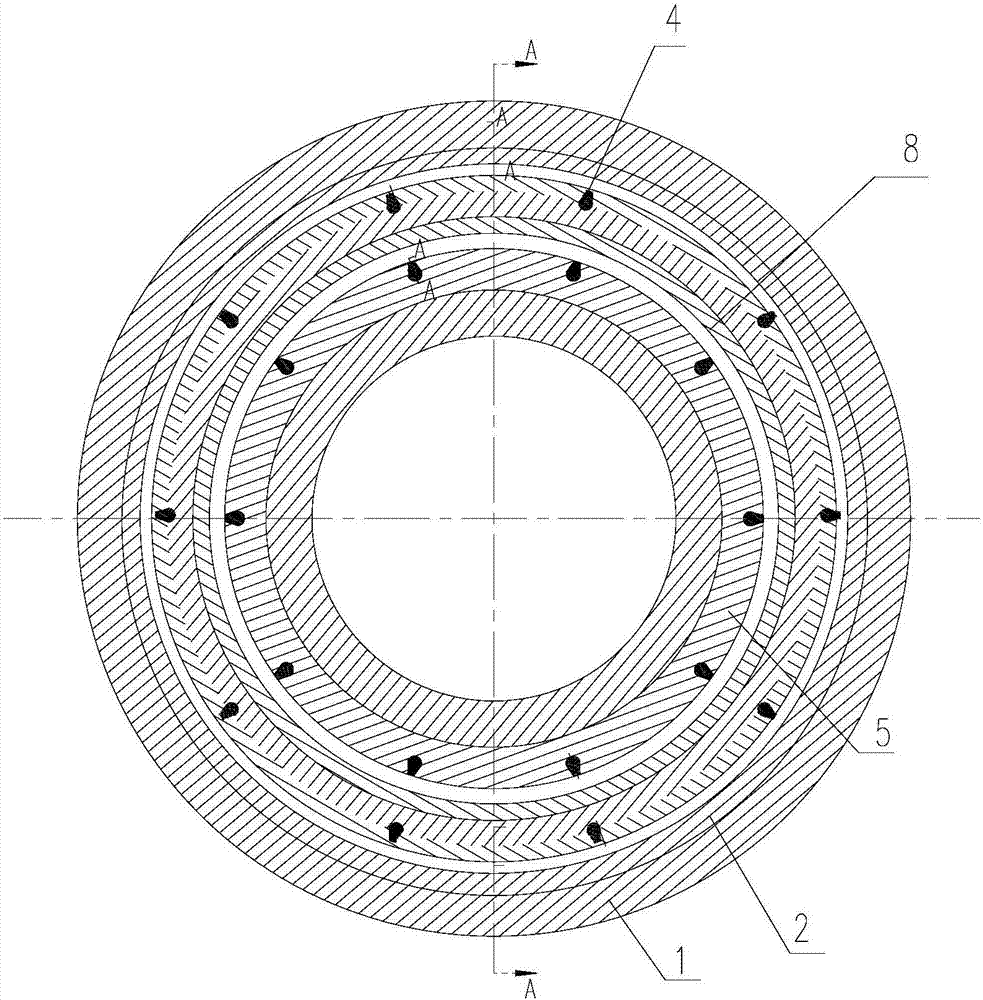

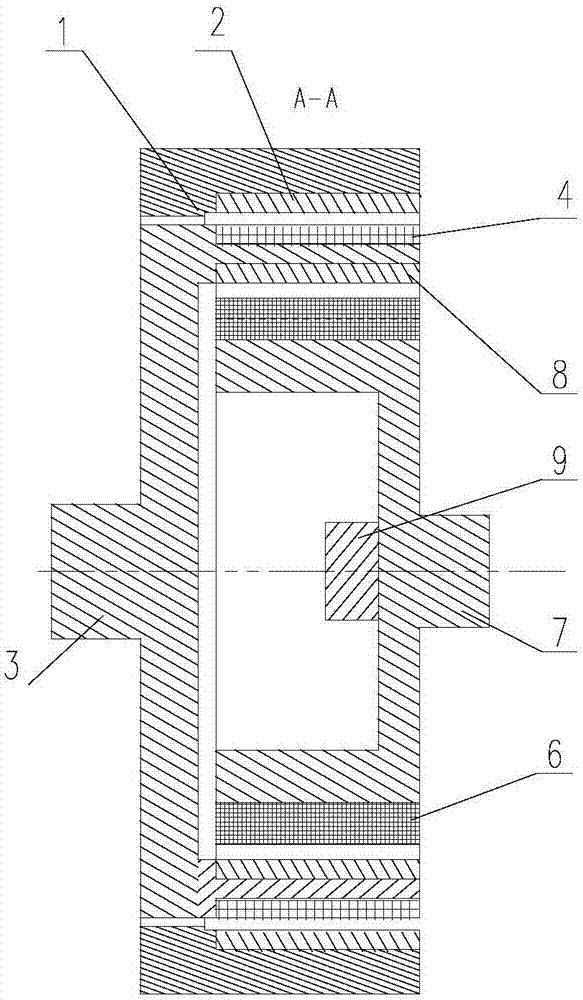

Combined-type flux switching permanent magnet motor

ActiveCN102832771BImprove reliabilityAvoid serious temperature riseMagnetic circuit rotating partsMagnetic circuit stationary partsPermanent magnet motorPhysics

The invention discloses a combined-type flux switching permanent magnet motor which comprises an inner rotor, a stator and an outer rotor,wherein the stator surrounds the inner rotor; the outer rotor surrounds the stator; air clearances are arranged between the two rotors and the stator; salient pole gears without windings are arranged at one sides, which are towards the stator, of the inner rotor and the outer rotor; salient pole gears are arranged on the inner side and outer side of the stator; an inner side winding and an outer side winding which are sleeved on the salient pole gears are respectively arranged on the inner side and the outer side of the stator; an insulation magnetic ring is embedded on the yoke part of the stator; the salient pole gears at the inner side and outer side of the stator are internally provided with excitation devices; the magnetizing directions of the excitation devices are the circumferential tangency direction of the stator, and are at the same side of the stator; and the magnetizing directions of the excitation devices in the two adjacent salient pole gears are opposite.

Owner:SUZHOU KAIBO YIKONG DRIVE TECH CO LTD

A clutchless amt control system and method

ActiveCN105972199BImprove shift qualityImproved shift stabilityGearing controlControl systemElectric machine

The invention relates to a non-clutch AMT (Automatic Manual Transmission) control system. The non-clutch AMT control system comprises an MCU (Microprogrammed Control Unit) and a TCU (Transmission Control Unit) which are interconnected. Compared with the prior art, the non-clutch AMT control system has the beneficial effects that after the system enters a shifting process, the TCU can take over the control right of a driving motor, so that the technical effects of optimizing the shifting quality, reducing the shifting time and improving the shifting stability can be achieved. The invention also relates to a non-clutch AMT control method. The non-clutch AMT control method comprises a speed regulating stage; the motor in the shifting process of the method is in a torque mode; the speed regulating stage comprises a motor synchronous speed regulating stage and a mechanical synchronous speed regulating stage. Compared with the prior art, the non-clutch AMT control method has the beneficial effects that the shifting process is divided into six stages through the control method, namely, an unloading stage, an idling stage, an electronic synchronizing stage, a mechanical synchronizing stage, a gear engaging stage and a loading stage, and thus the technical effects of greatly reducing the overall shifting time, reducing the impact in gear engaging, and prolonging the service lives of mechanical parts such as a synchronizer can be achieved.

Owner:北理华创(佛山)新能源汽车科技有限公司

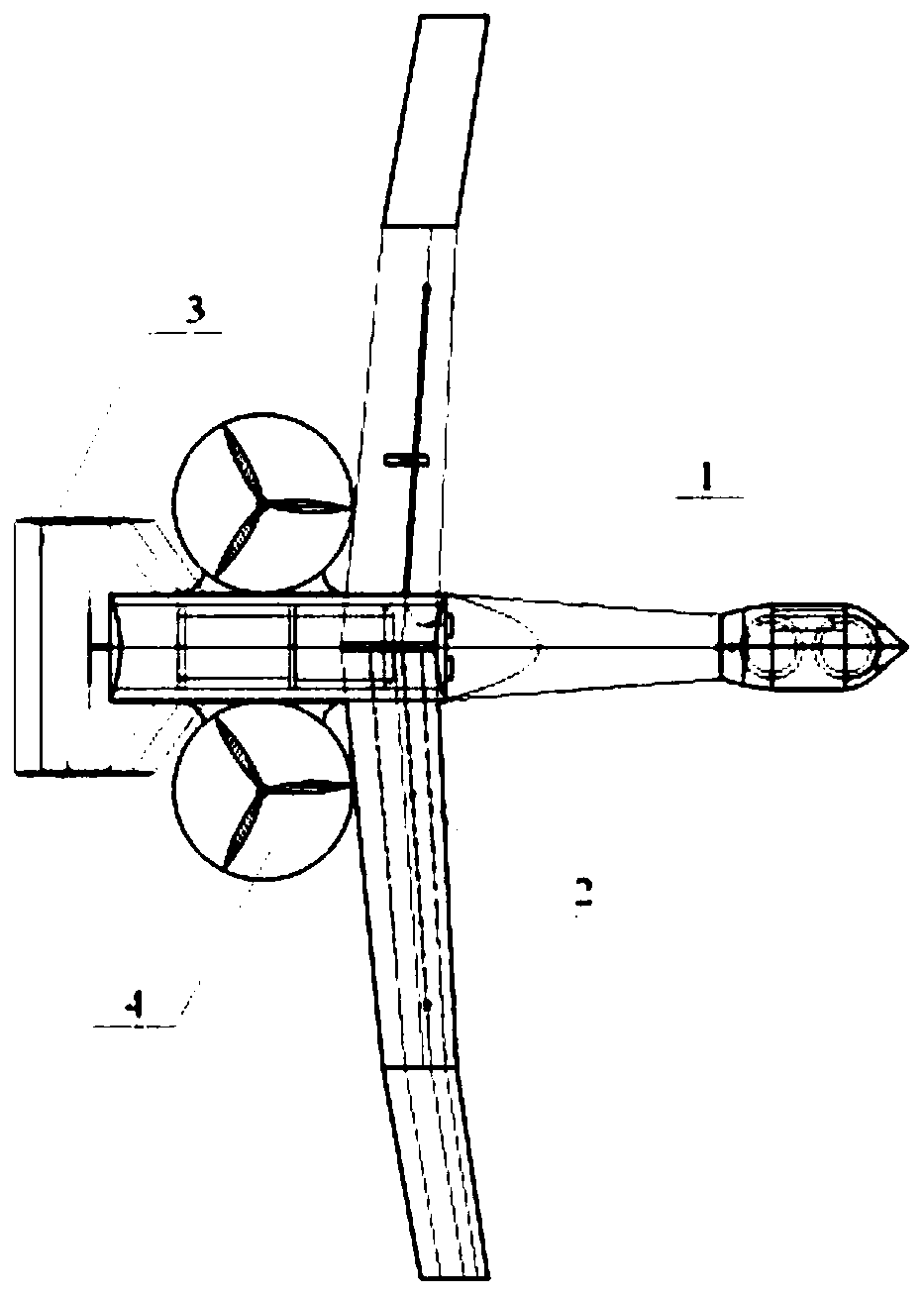

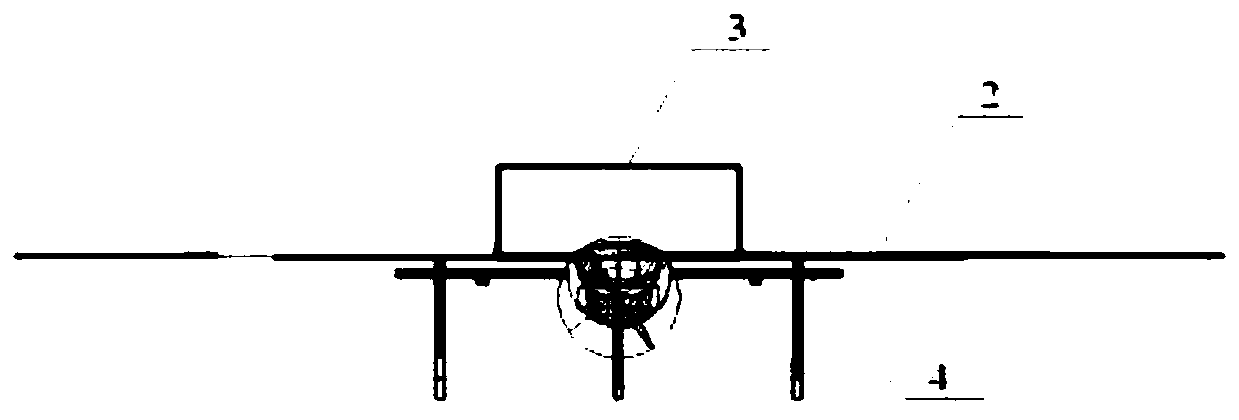

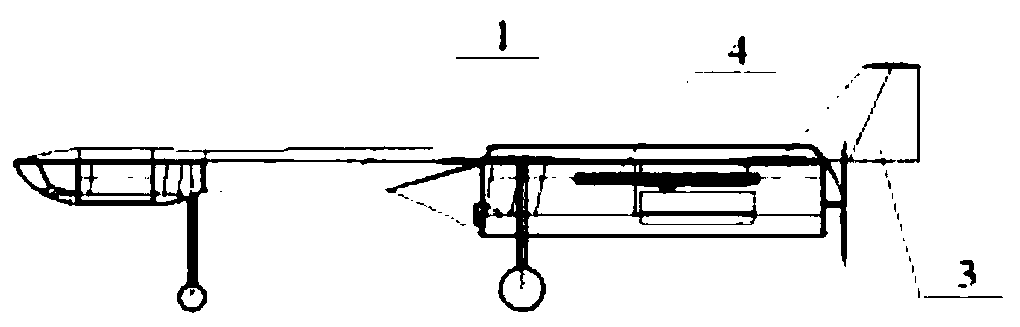

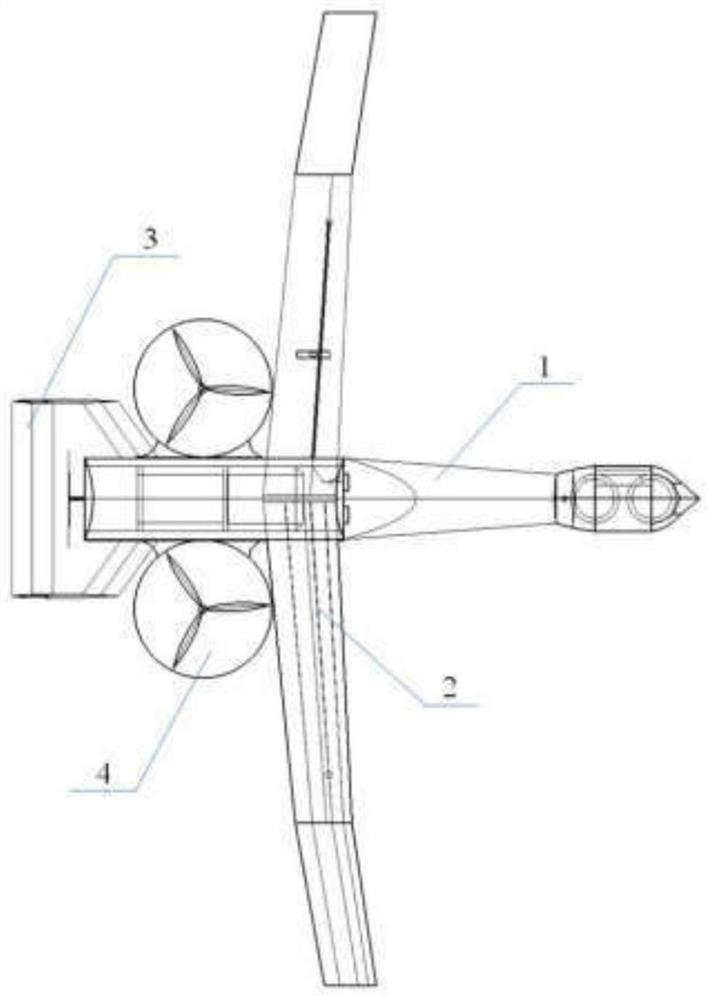

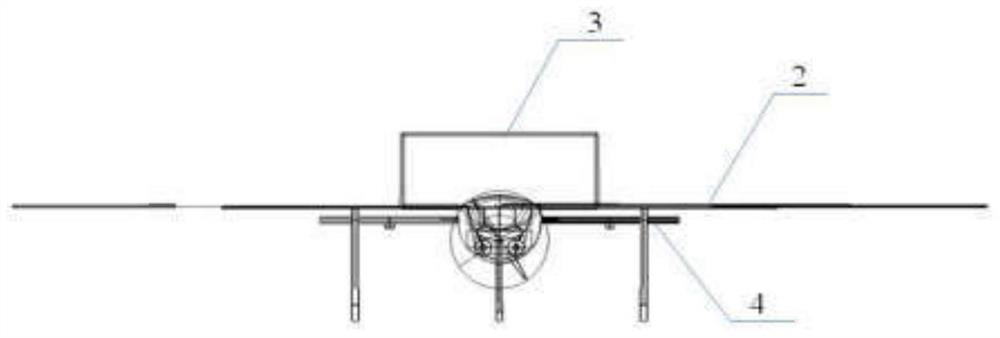

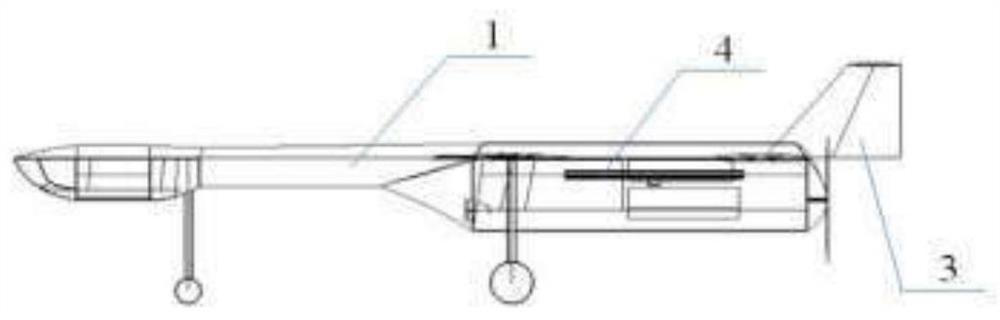

Petrol-electric hybrid vertical take-off and landing sweepforward fixed wing unmanned aerial vehicle

ActiveCN110217391ALarge laminar flow areaImproved aerodynamic pressure distributionWingsPower plant typeElectricityLevel flight

The invention relates to the technical field of unmanned aerial vehicles, and provides a petrol-electric hybrid vertical take-off and landing sweepforward fixed wing unmanned aerial vehicle. A fuselage assembly comprises a handpiece front cabin, a front fuselage and a rear fuselage which are sequentially connected from front to back, and at least one electric ducted fan engine is internally arranged in the handpiece front cabin; energy assembly and a load cabin are internally arranged in the rear fuselage, a propelling propeller assembly is arranged at the tail of the rear fuselage, and the propelling propeller assembly is used for proving front thrust to overcome aerodynamic resistance of the unmanned aerial vehicle during flying; and wing assemblies are installed on the two sides of therear fuselage in a sweepforward mode; an empennage assembly is installed on the tail segment of the rear fuselage; vertical lift force devices are of an electric fan mode, and the two vertical lift force devices are symmetrically installed on the left side and the right side of the middle fuselage. The petrol-electric hybrid vertical take-off and landing sweepforward fixed wing unmanned aerial vehicle has the characteristics of vertical take-off and landing and remote navigation, large lift force vertical take-off and efficient horizontal flight integration, vertical lift force system and fixed wing layout integrated design and rotary wing vertical lift force and fixed wing lift force integrated control are realized.

Owner:沈阳迪智科技有限公司

Auxiliary power unit (APU) controlling method for gas-electric hybrid system

ActiveCN104554239AReduce up and down fluctuationsImprove powerHybrid vehiclesStarter generatorHybrid system

The invention discloses an auxiliary power unit (APU) controlling method for a gas-electric hybrid system. In a series-connection high-speed generation mode and in a rotating speed tracking mode of a vehicle, an integrated starter generator (ISG) is controlled by rotating speed, and an engine is controlled by a throttle; in the series-connection high-speed generation mode, the target rotating speed of the ISG is the rotating speed for generation, and the throttle valve of the engine is preset; in the rotating speed tracking mode, the target rotating speed of the ISG is the current rotating speed of a main motor, and the throttle valve of the engine is zero. According to the APU controlling method for the gas-electric hybrid system, in the series-connection high-speed generation mode and in the rotating speed tracking mode, the ISG is controlled by rotating speed, speed adjusting response is quick especially during climbing, the hybrid system can quickly switch into the series-connection mode, then the engine and the main motor provide power at the same time, and the dynamic property of the vehicle is excellent; and during high-speed generation at the preset rotating speed, the ISG is controlled by rotating speed, and the engine is controlled by the preset throttle, so that up-down fluctuation of the rotating speed of the engine can be reduced, and generation efficiency is improved.

Owner:ZHENGZHOU YUTONG BUS CO LTD

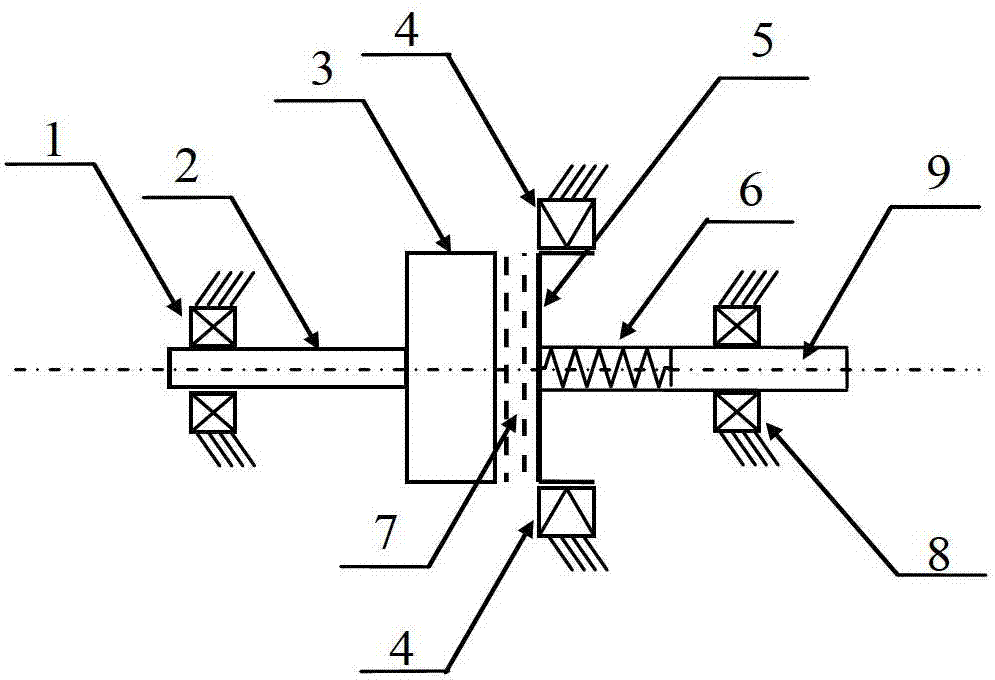

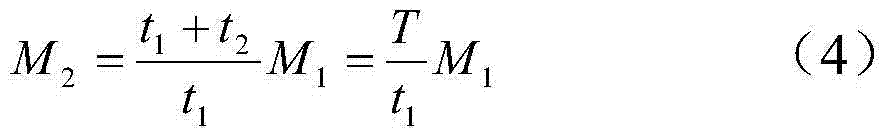

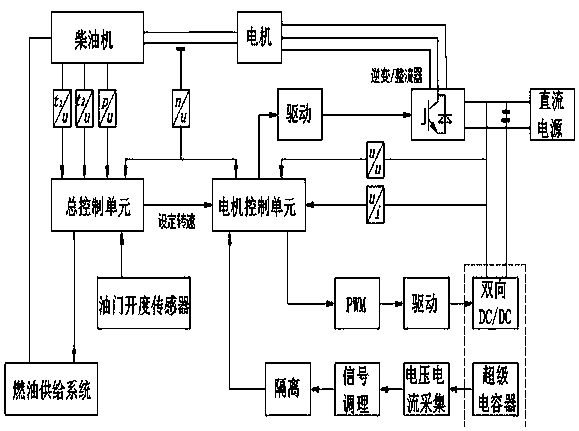

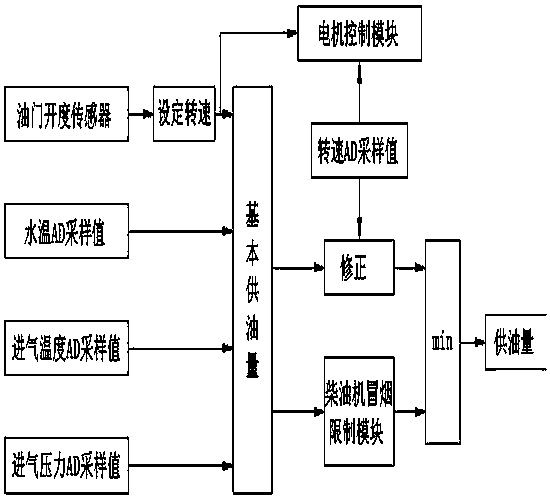

Flywheel-free diesel engine generator/motor system control method

ActiveCN107701318AFast response to speed regulationFast dynamic responseElectronic commutation motor controlPower operated startersFlywheelDynamo

The invention provides a flywheel-free diesel engine generator / motor system control method and belongs to the field of machines. According to the flywheel-free diesel engine generator / motor system control method, an energy storage function of a diesel engine flywheel is replaced with a generator / motor four-quadrant working mode, peak load shifting is performed on the output torque of a diesel engine, uniform fluctuation torque is achieved, and uniform output of the rotating speed of a crankshaft is represented. Meanwhile the rotational inertia of the crankshaft can be lowered greatly, the adjusting response of the rotating speed of the diesel engine is accelerated, and therefore the speed adjusting performance of the diesel engine is improved.

Owner:YANGZHOU HUADONG POWER MACHINE

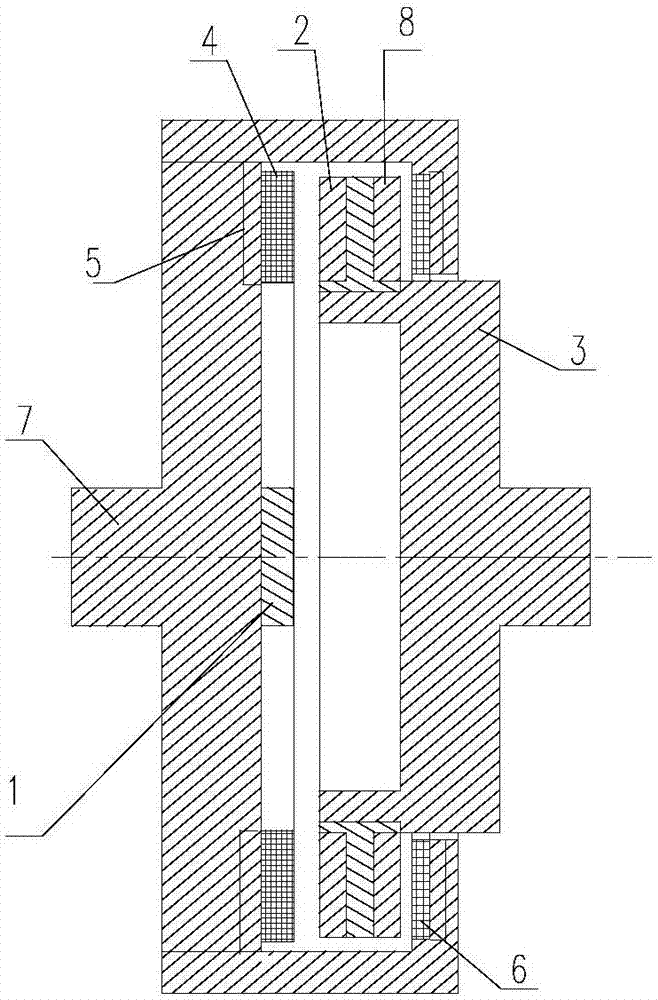

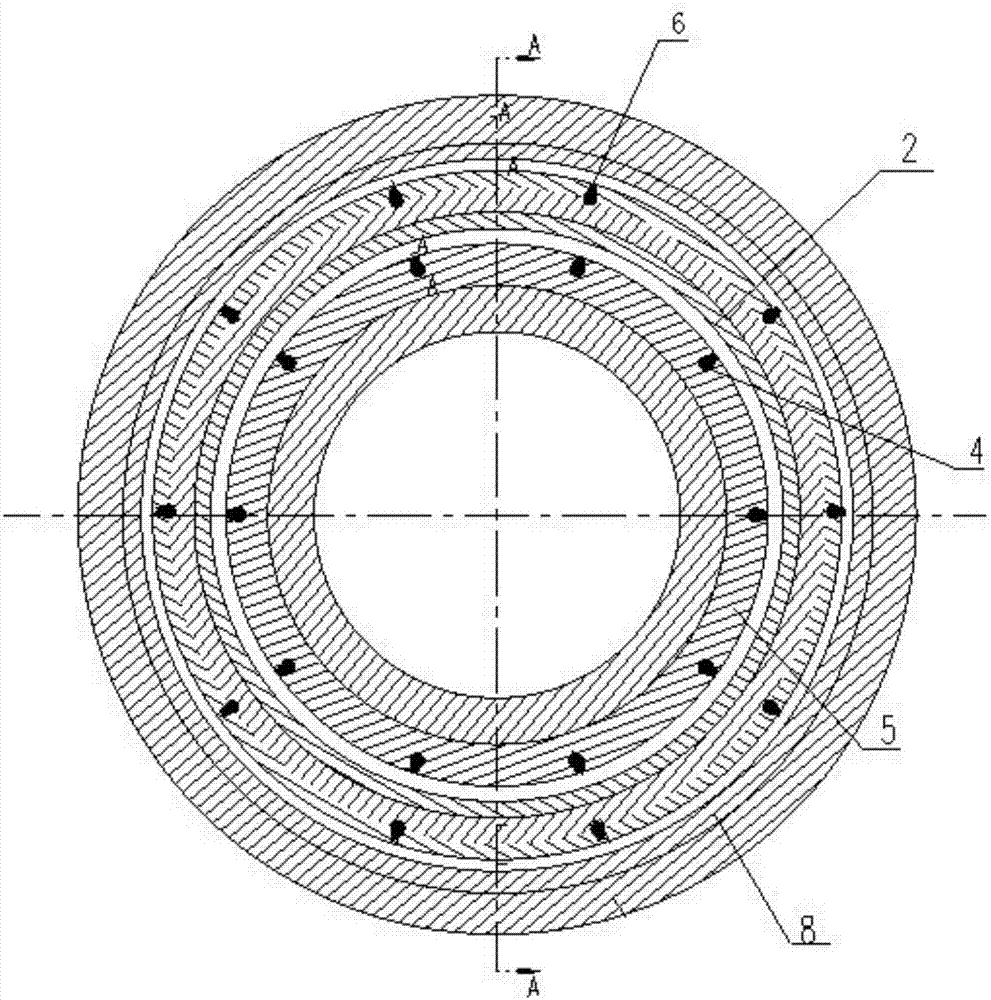

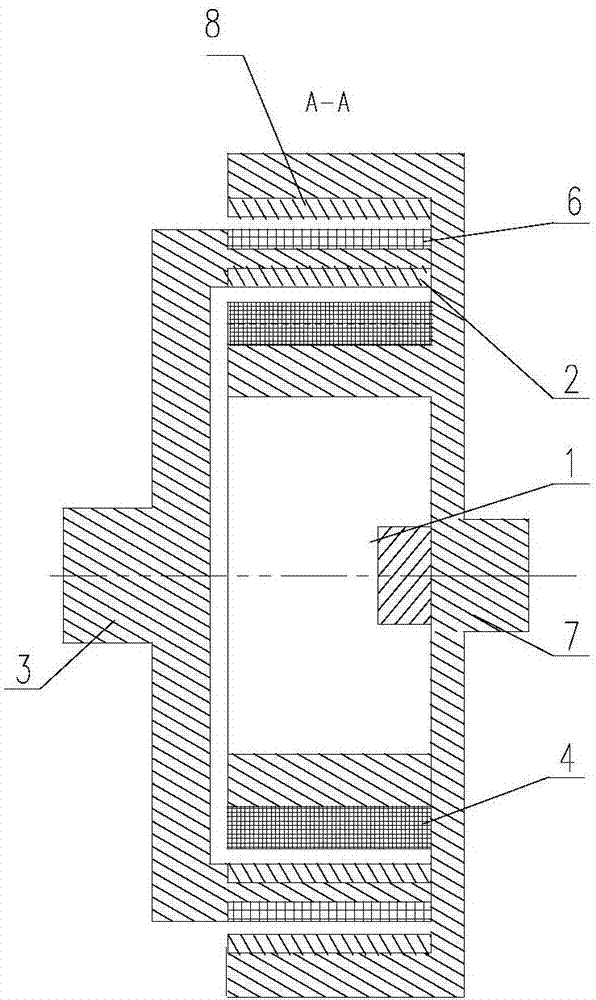

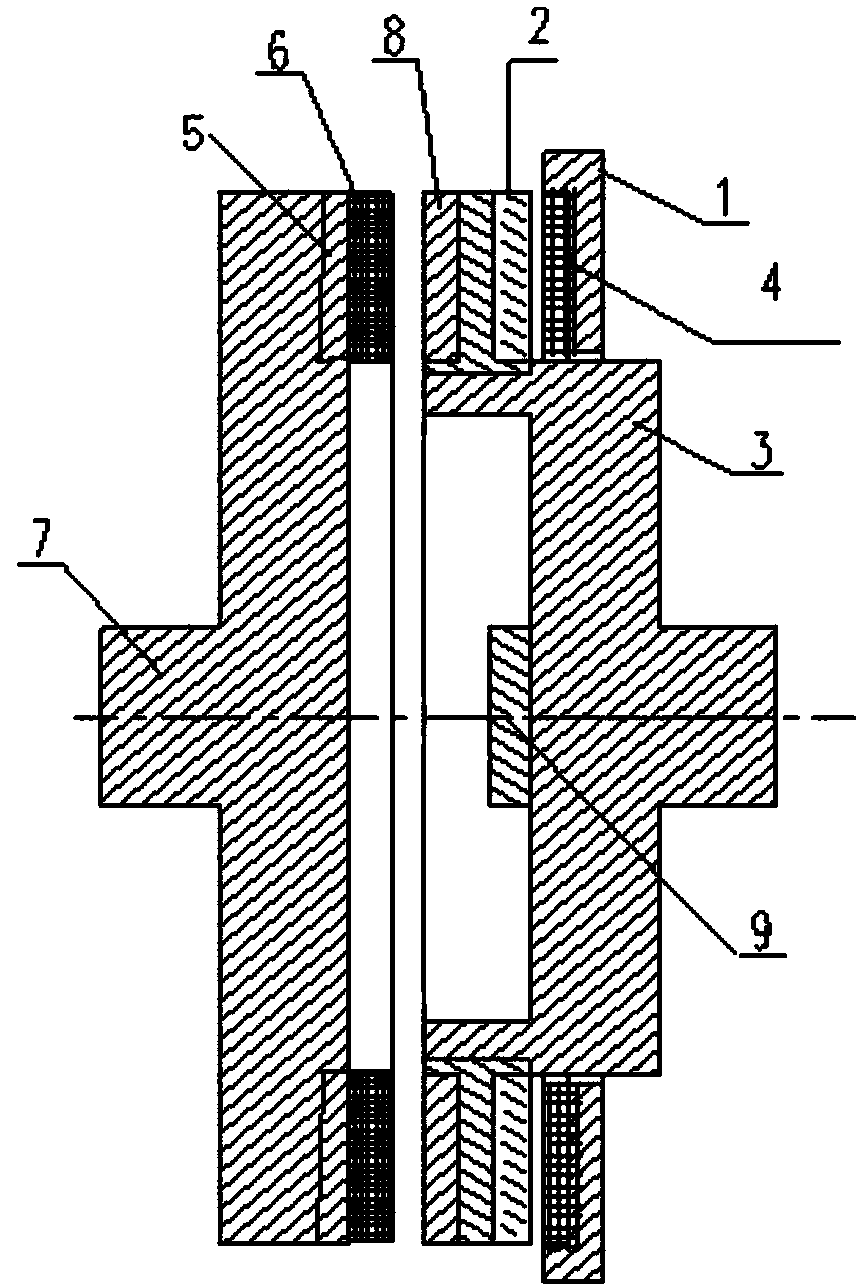

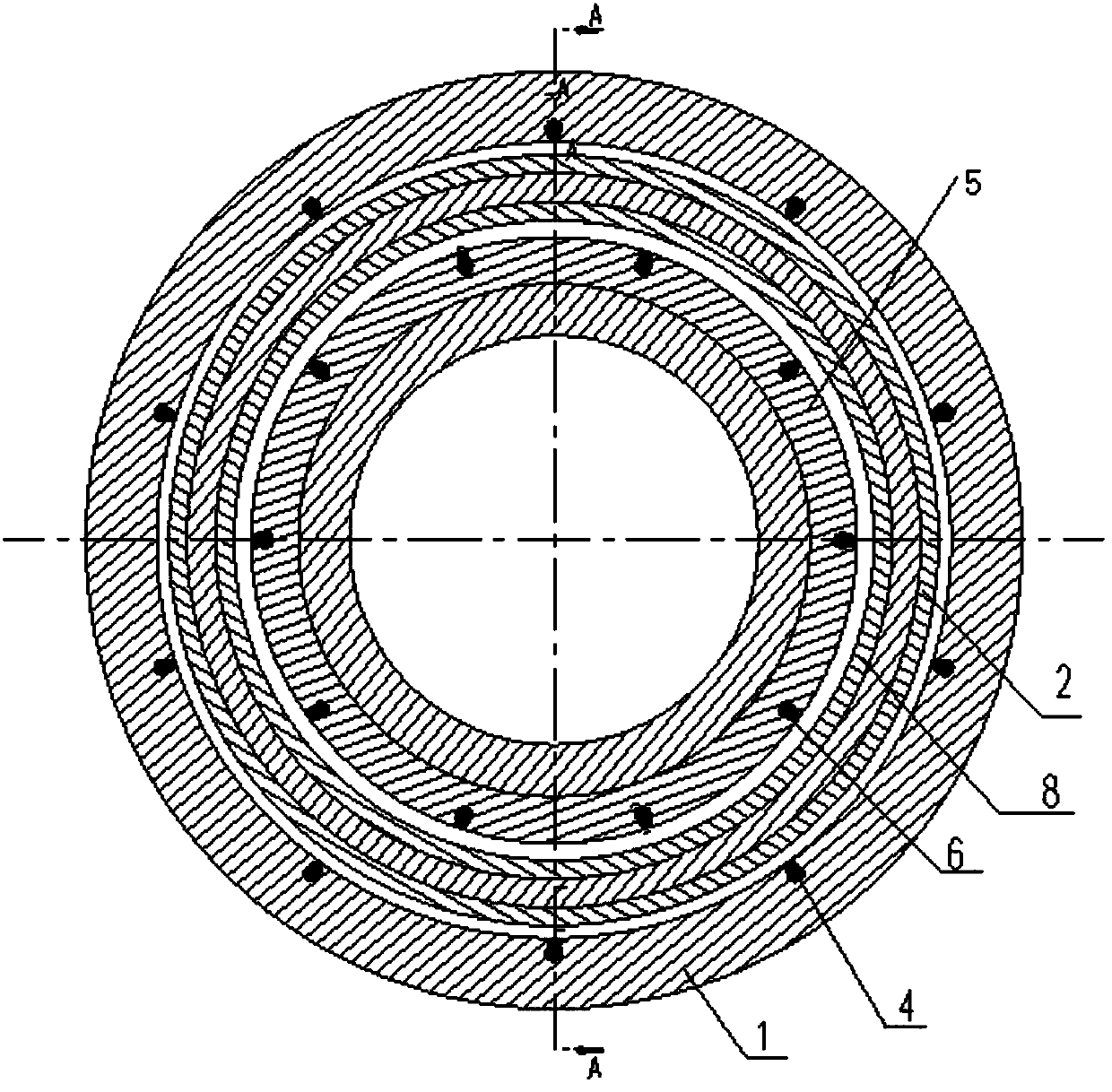

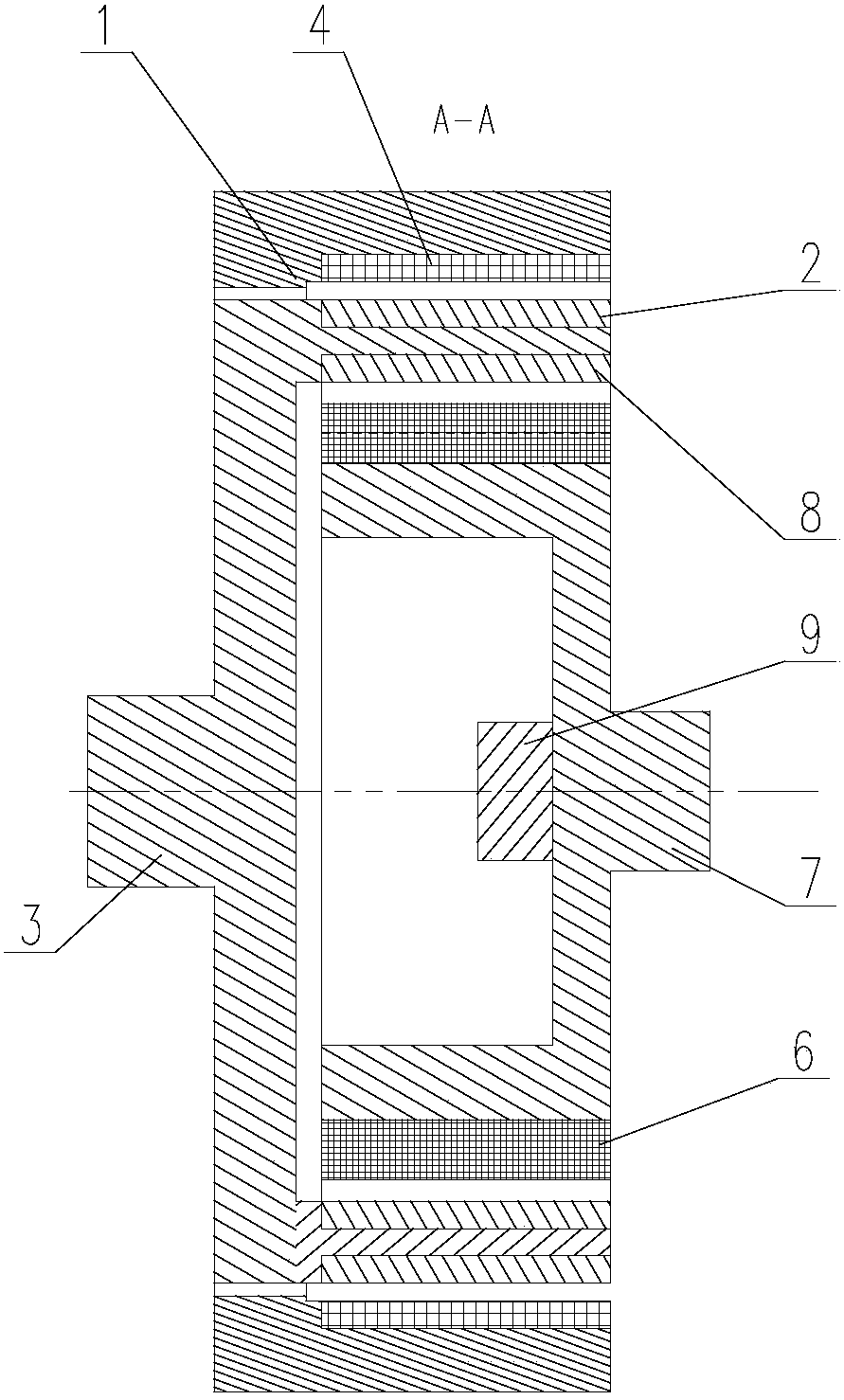

Magnetic gap-fixed permanent-magnet speed regulator

PendingCN107800266AFast response to speed regulationImprove energy efficiencyAsynchronous induction clutches/brakesPermanent-magnet clutches/brakesMagnetic disksPhysics

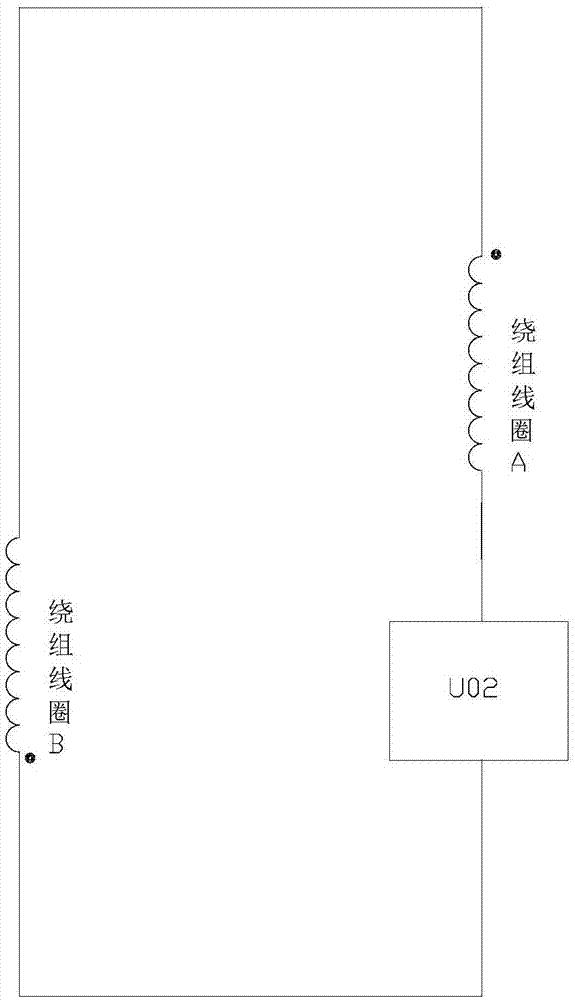

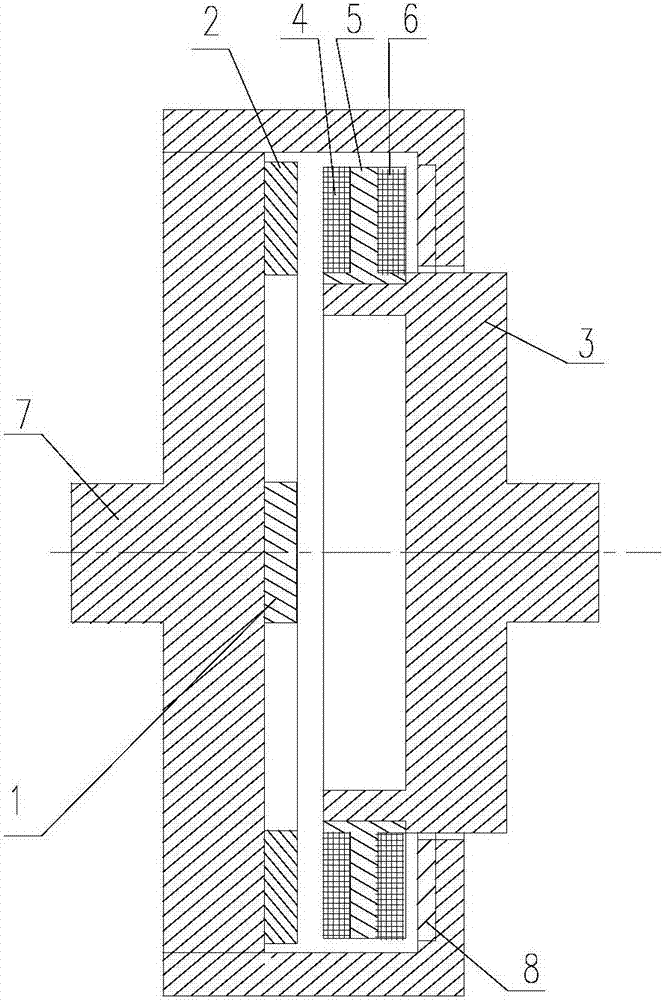

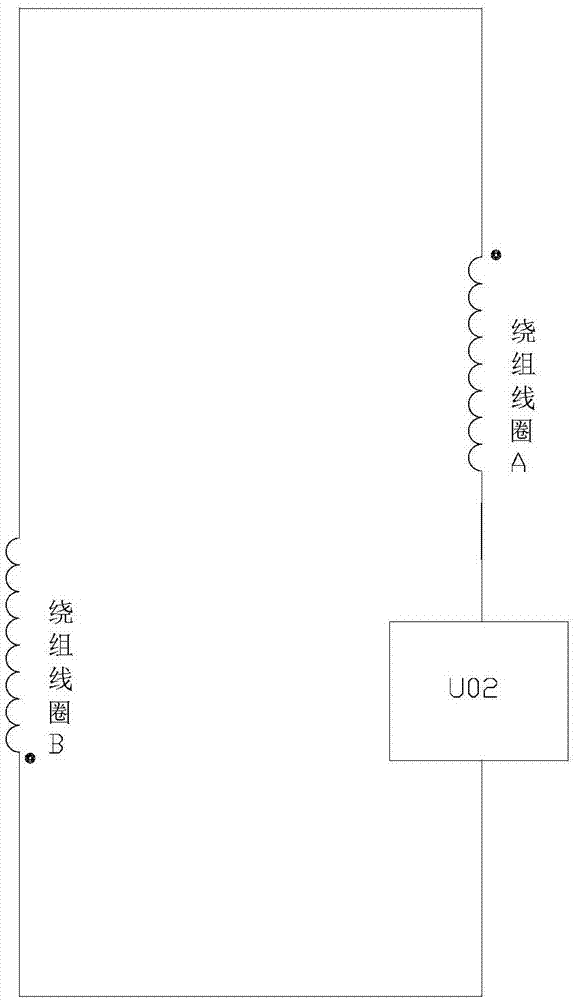

The invention relates to a magnetic gap-fixed permanent-magnet speed regulator. The magnetic gap-fixed permanent-magnet speed regulator comprises a rotor disc, a magnetic rotor disc and an armature stator, wherein the rotor disc is connected with an input shaft, the magnetic rotor disc is arranged on a surface opposite to the rotor disc and is connected with an output shaft, the armature stator isarranged on a back surface of the rotor disc, the rotor disc comprises a winding coil B, a permanent magnet A and an iron core, the winding coil B and the permanent magnet A are respectively arrangedin an outer circumference and on an outer side surface of the rotor disc, the iron core is arranged between the winding coil B and the permanent magnet A, a permanent magnet B is arranged on a side surface of an outer circumference of the magnetic rotor disc, the armature stator comprises a fixed seat and a winding coil A, the winding coil A is arranged along an inner side of the circumferentialsurface of the fixed seat, a control system is connected between the winding coil B and the winding coil A and is used for electric energy conversion, and a sliding ring is arranged on the rotor disc.A slip frequency energy rectification feedback technology is employed, rapid boosting or braking is achieved by the winding coil A, so that the magnetic gap-fixed speed regulator is rapid, flexible and stable in speed regulation response; and by a slip frequency energy rectification feedback boosting effect, maximum speed regulation efficiency is achieved.

Owner:山东洁盟节能环保技术有限公司

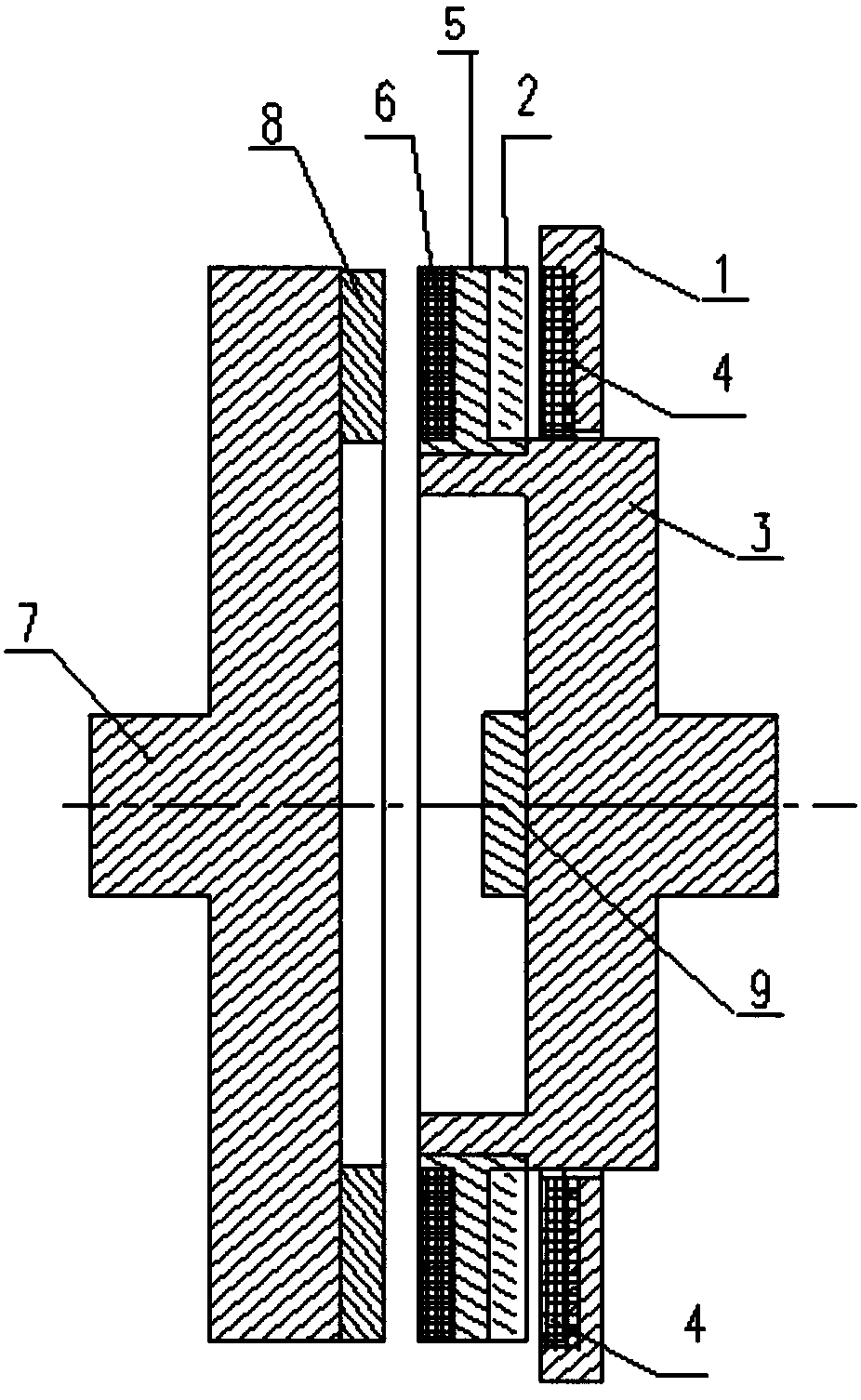

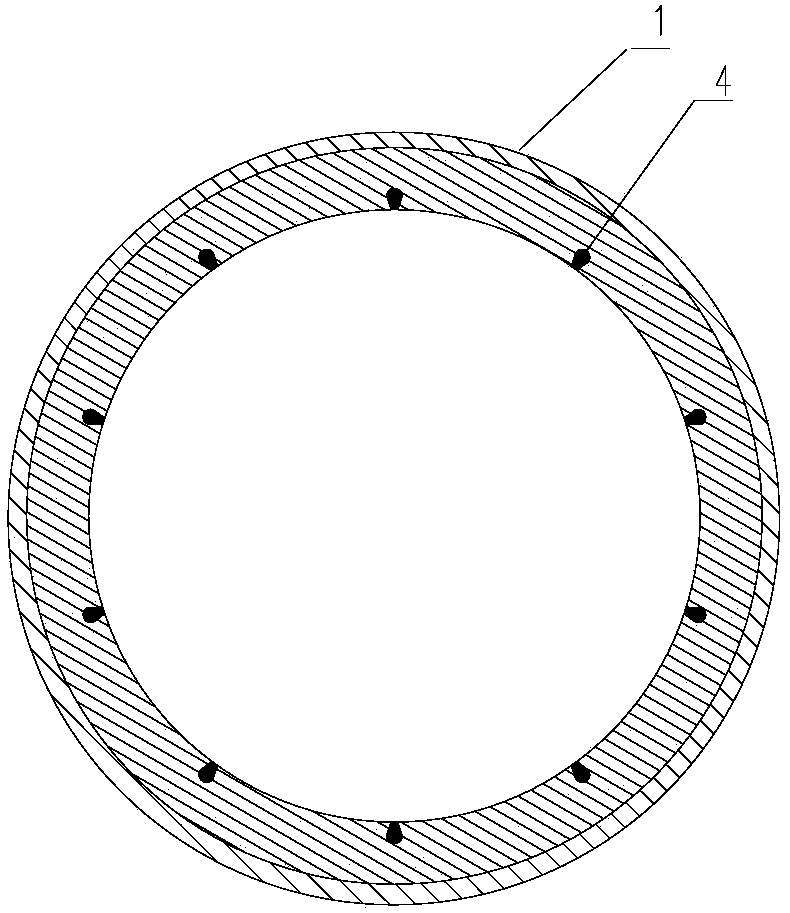

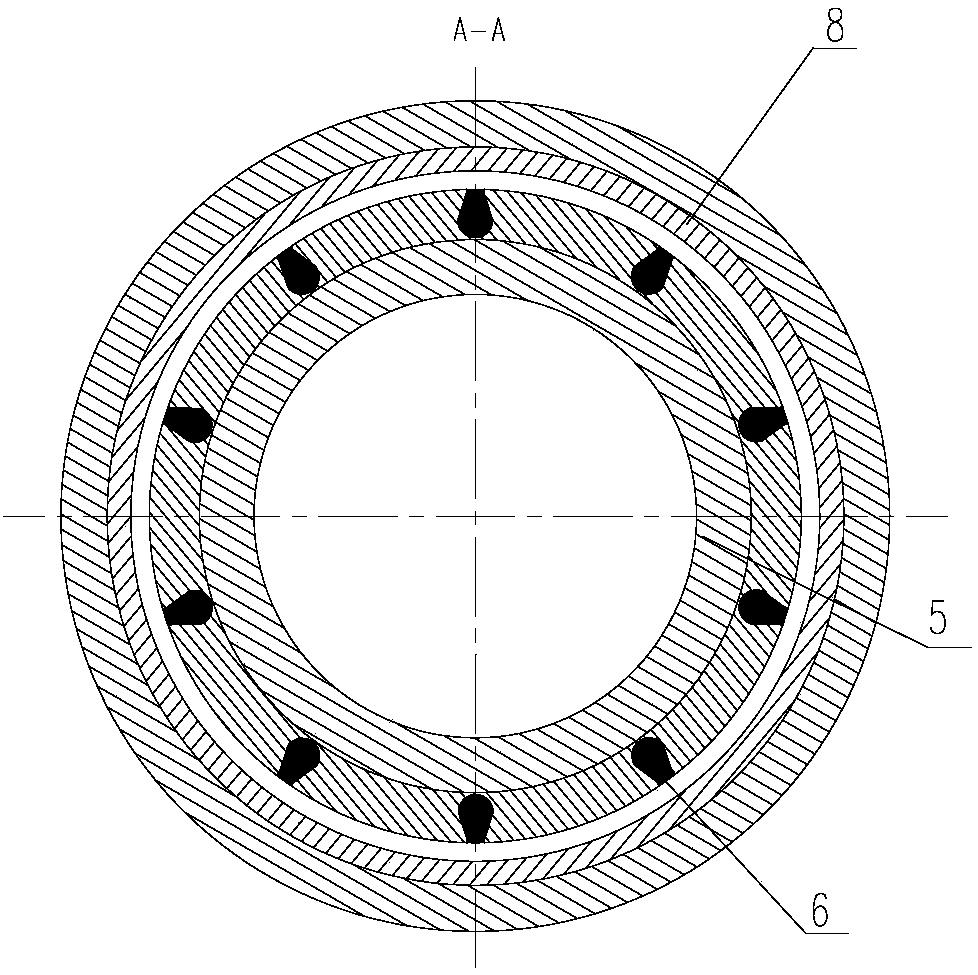

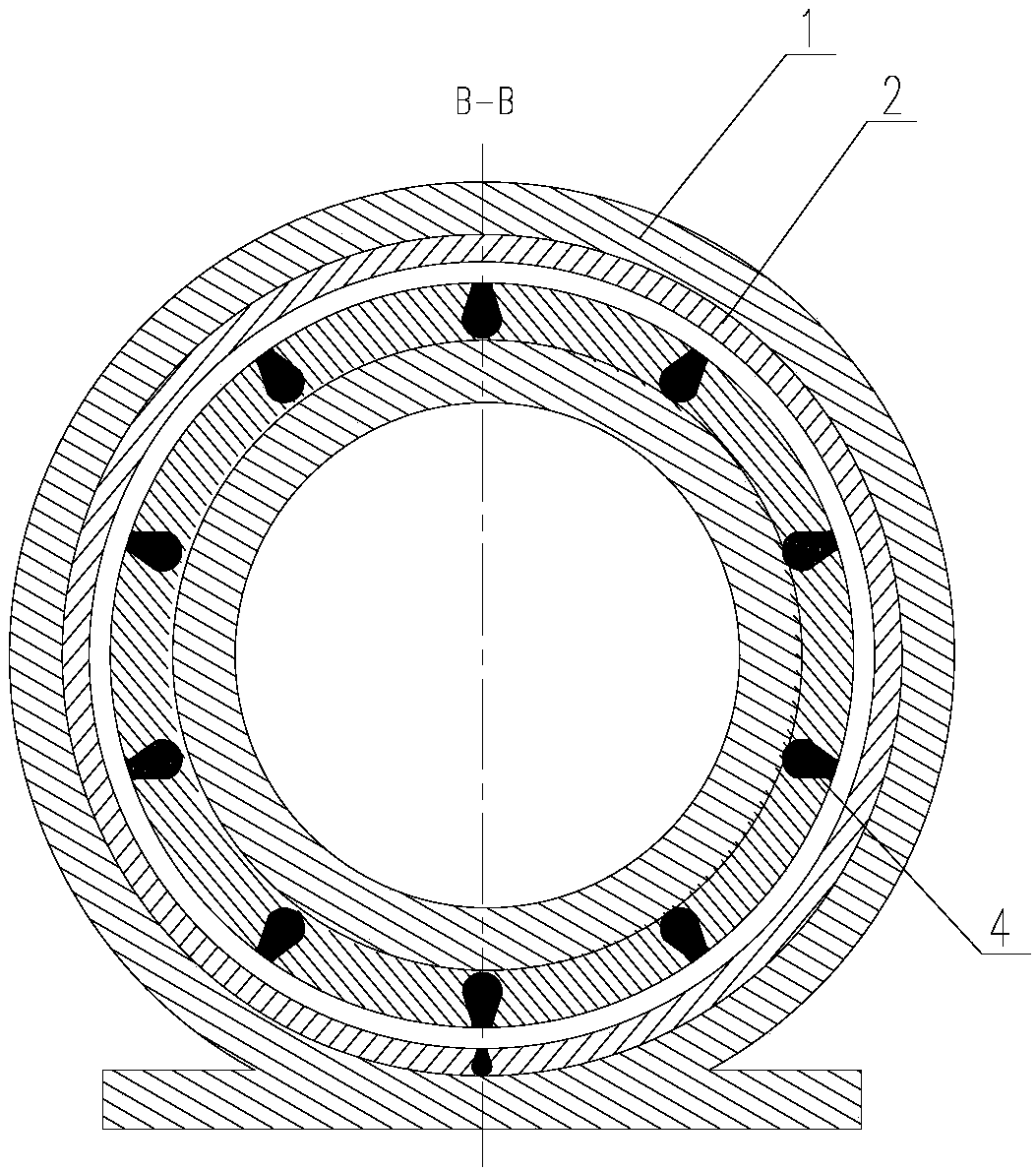

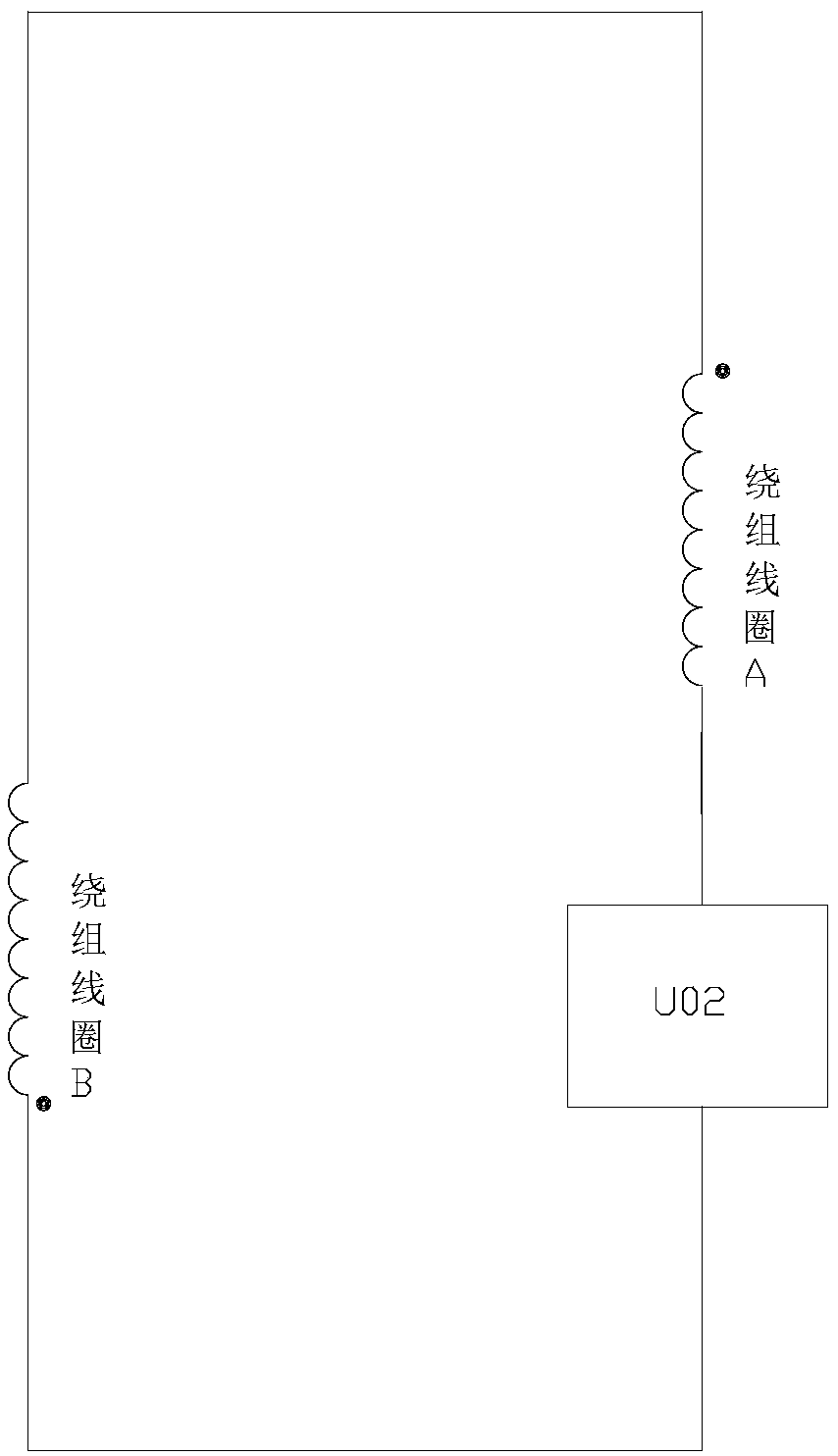

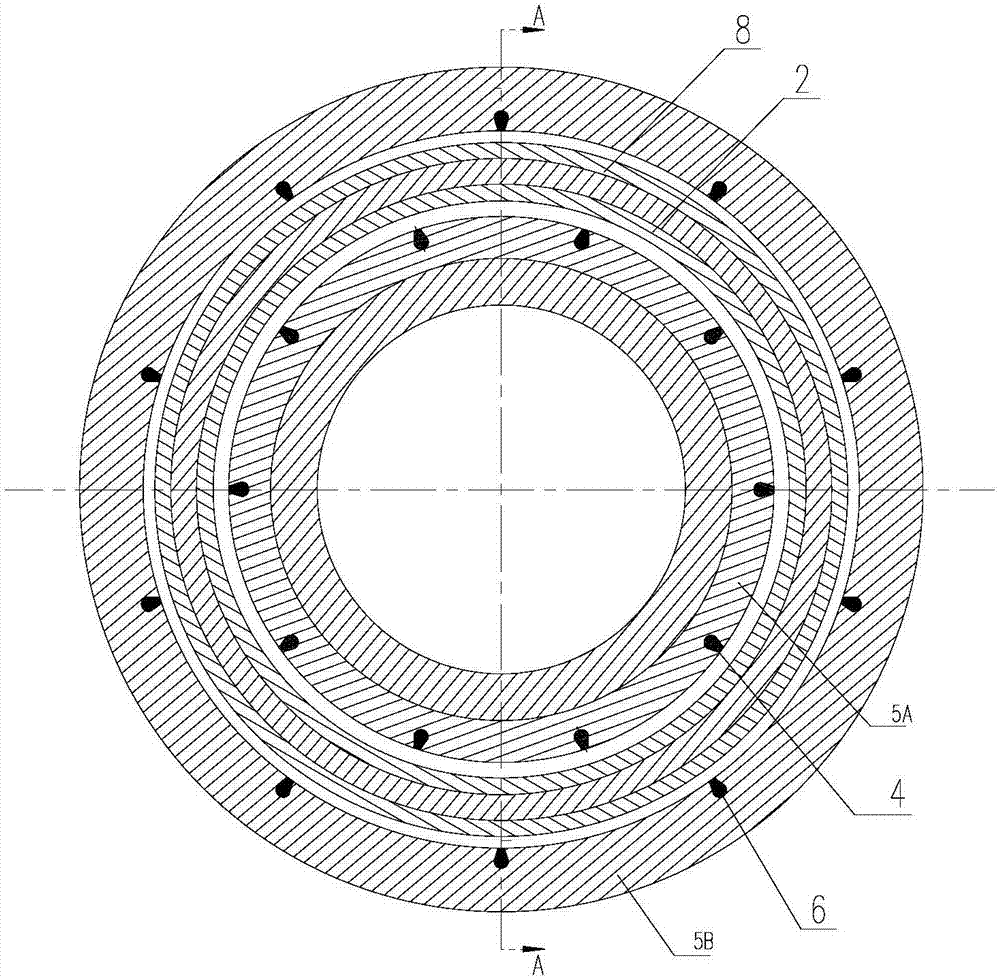

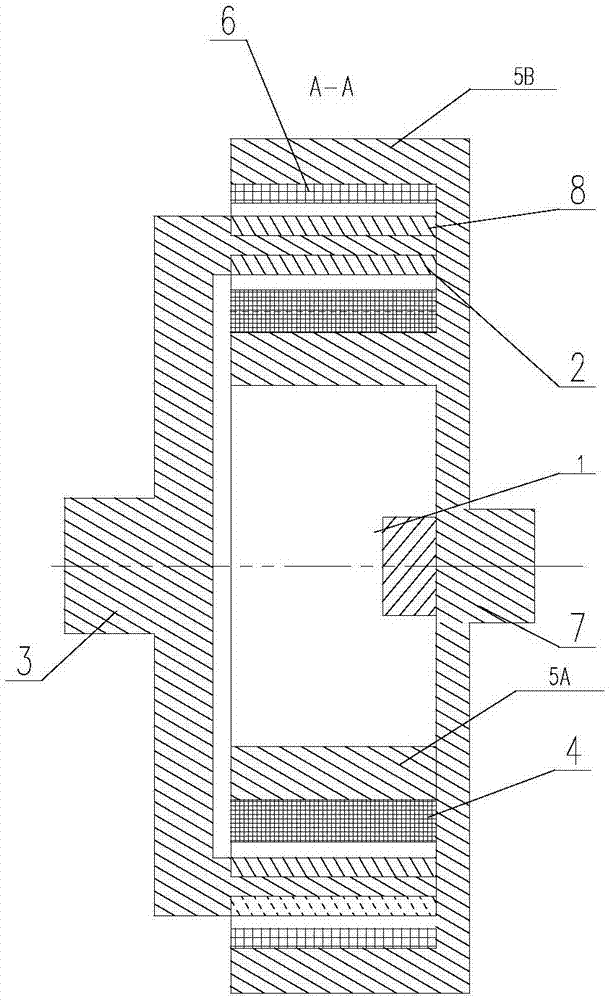

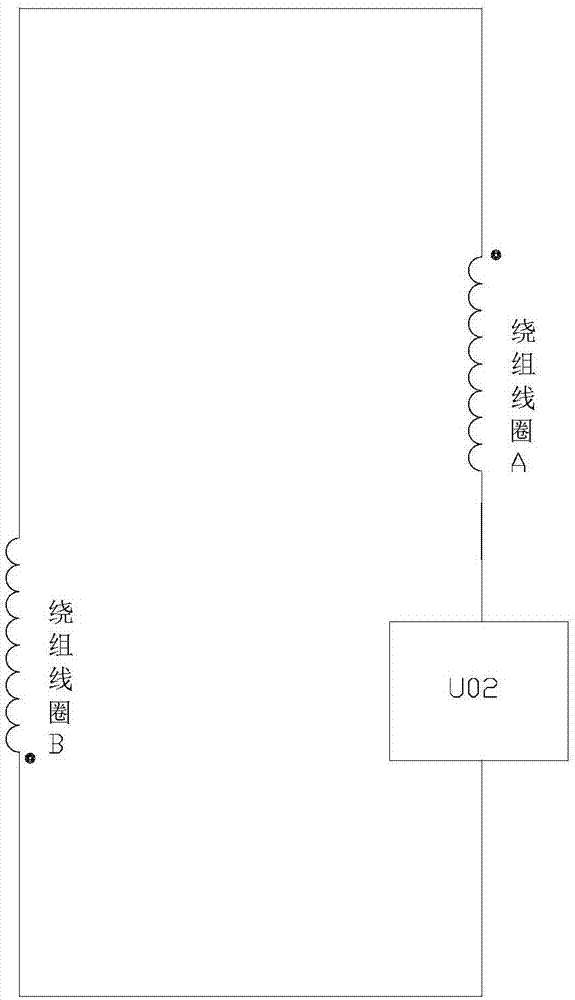

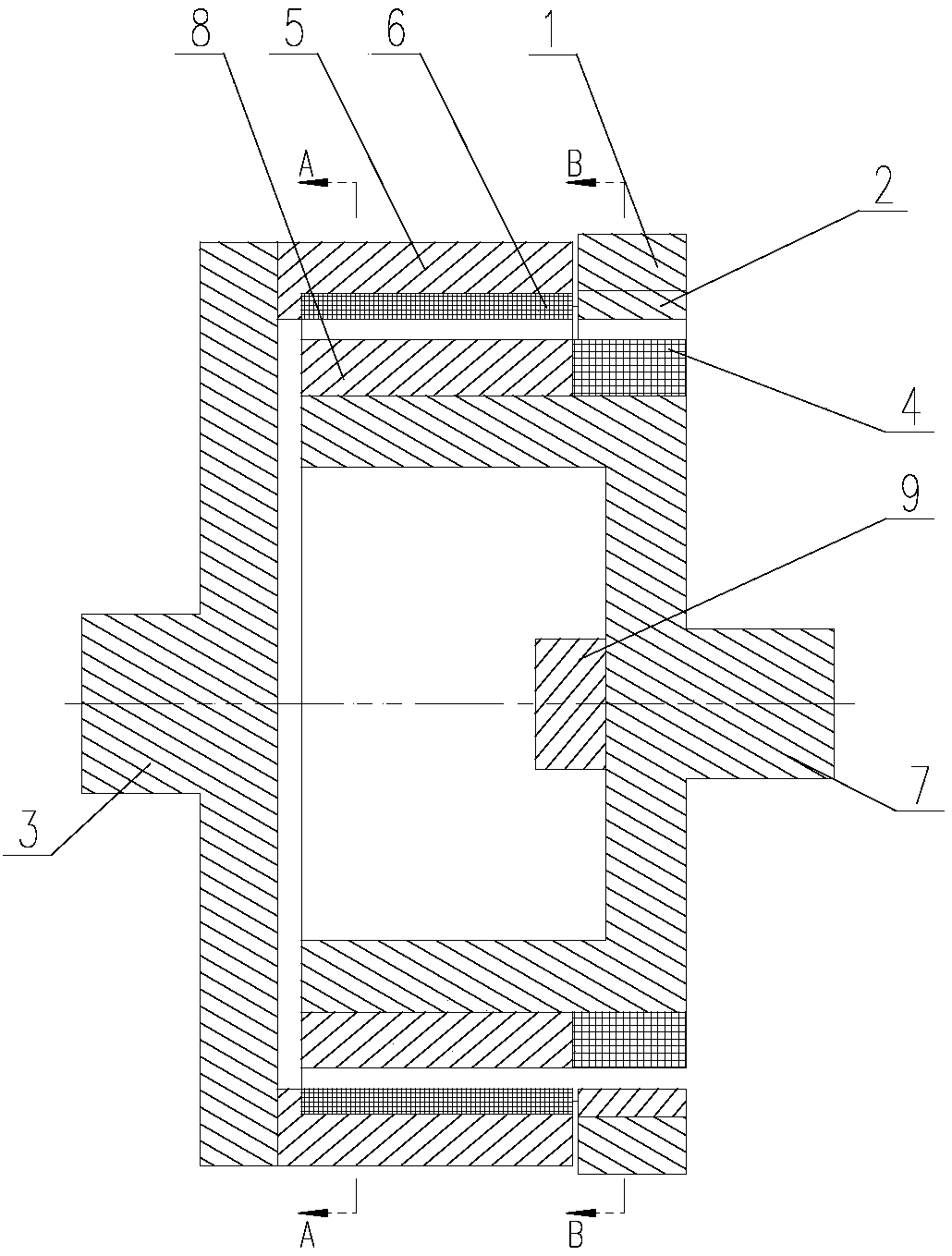

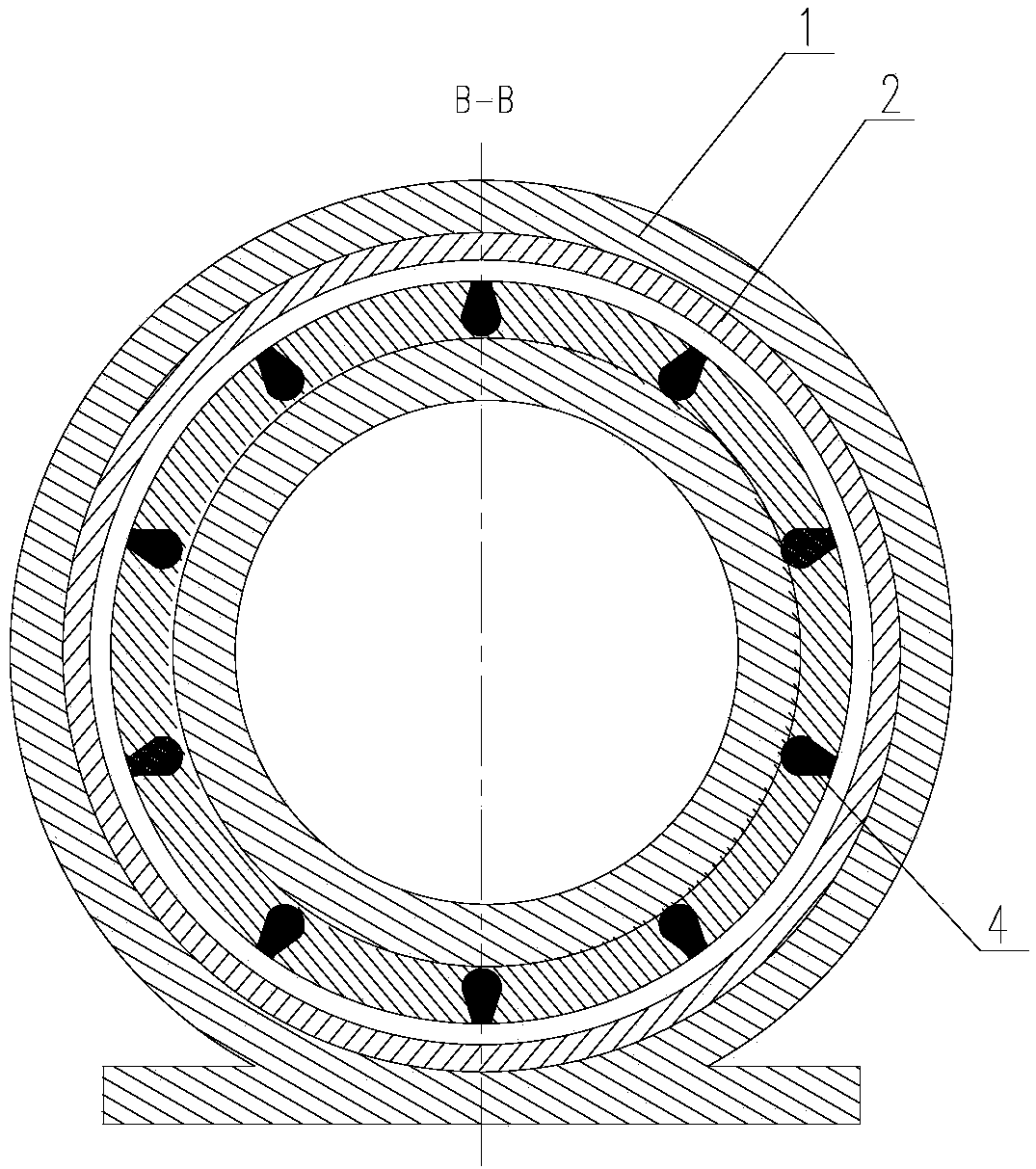

Permanent magnet speed regulator with fixed magnetic gap

PendingCN107863874AFast response to speed regulationImprove energy efficiencyAsynchronous induction clutches/brakesPermanent-magnet clutches/brakesPhysicsStator

The invention relates to a permanent magnet speed regulator with a fixed magnetic gap. The permanent magnet speed regulator comprises a magnetic rotor connected with the input shaft, a magnetic statorarranged at the tail end of the magnetic rotor and arranged parallel to the magnetic rotor, and an inner armature rotor connected with the output shaft and positioned on the circumferential inner sides of the magnetic rotor and the magnetic stator; permanent magnets B are distributed in the circumferential direction of the inner circumferential surface of the magnetic rotor; the magnetic stator comprises a fixed base and permanent magnets A distributed in the circumferential direction of the inner circumferential surface of the fixed base; the inner armature rotor comprises an iron core, anda winding coil B and a winding coil A which are distributed in parallel along the outer circumferential surface of the iron core; and a control system used for electric energy conversion is arranged between the winding coil B and the winding coil A. By adoption of a slip frequency energy rectifying and feedback technology, quick boosting or braking can be realized through the winding coil A, so that the permanent magnet speed regulator with the fixed magnetic gap is quick in response, flexible and stable; and by virtue of the slip frequency energy rectifying and feedback boosting effect, maximum of the speed regulating efficiency is realized consequently.

Owner:山东洁盟节能环保技术有限公司

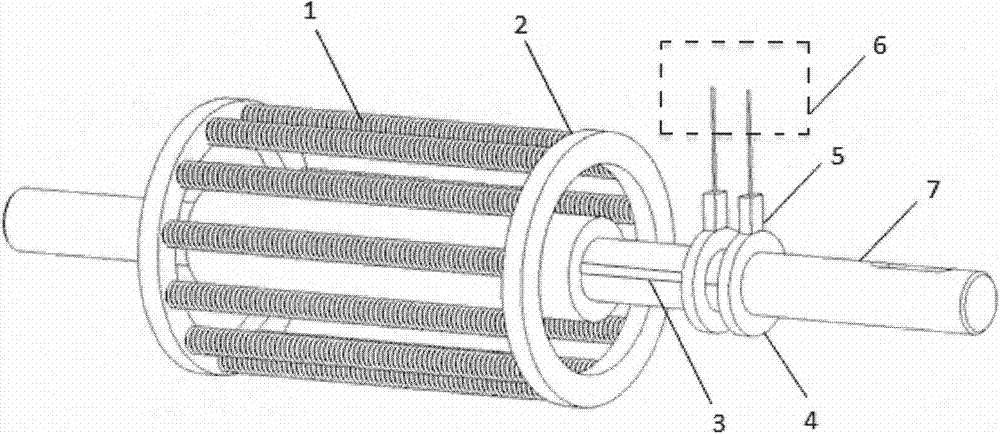

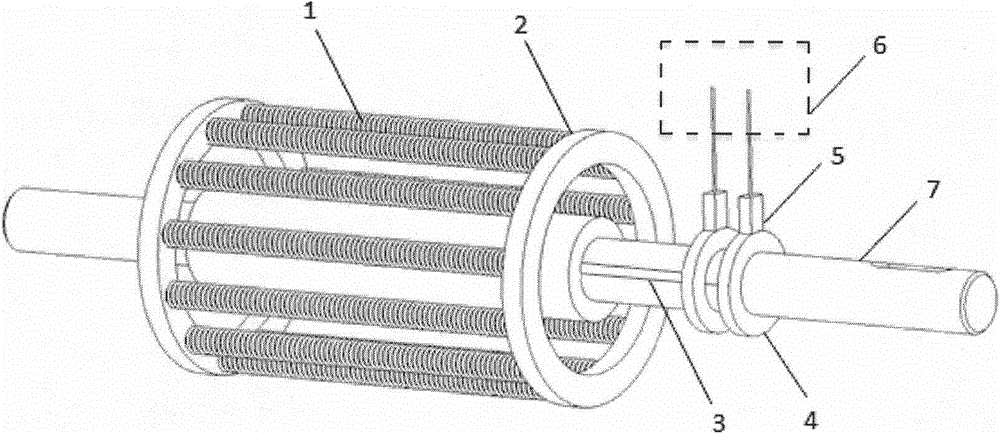

Cage type asynchronous motor speed regulating system based on magnetorheological fluid

ActiveCN104283389ASimple structureWide speed rangeAC motor controlAsynchronous induction motorsElectrical resistance and conductanceMotor speed

The invention provides a cage type asynchronous motor speed regulating system based on magnetorheological fluid. The cage type asynchronous motor speed regulating system comprises a cage type winding and a flow regulating control circuit. The cage type winding is composed of the magnetorheological fluid, an insulating tube, a magnet exciting coil and an end ring. The flow regulating control circuit is composed of a wire, a collecting ring, an electric brush and a constant flow source circuit capable of outputting adjustable currents. When a cage type asynchronous motor works, the magnet exciting coil on the cage type winding can generate corresponding strong or weak magnetic fields by changing the size of the current output by the constant flow source circuit, the resistance of the magnetorheological fluid is changed under the effect of the magnetic fields, induced current passing the cage type rotor winding changes along with the change of the resistance, so that the rotation speed of the a cage type rotor is changed, and finally the output rotation speed of the cage type asynchronous motor is changed. The cage type asynchronous motor speed regulating system is designed by utilizing the characteristic that the resistance of the magnetorheological fluid changes under the magnetic field environment and has the advantages of being wide in speed regulating range, quick in speed regulating response, capable of achieving stepless speed regulation and the like.

Owner:SHIHEZI UNIVERSITY

APU control method for gas-electric hybrid power system

ActiveCN104554239BReduce up and down fluctuationsImprove powerHybrid vehiclesStarter generatorHybrid system

The invention discloses an auxiliary power unit (APU) controlling method for a gas-electric hybrid system. In a series-connection high-speed generation mode and in a rotating speed tracking mode of a vehicle, an integrated starter generator (ISG) is controlled by rotating speed, and an engine is controlled by a throttle; in the series-connection high-speed generation mode, the target rotating speed of the ISG is the rotating speed for generation, and the throttle valve of the engine is preset; in the rotating speed tracking mode, the target rotating speed of the ISG is the current rotating speed of a main motor, and the throttle valve of the engine is zero. According to the APU controlling method for the gas-electric hybrid system, in the series-connection high-speed generation mode and in the rotating speed tracking mode, the ISG is controlled by rotating speed, speed adjusting response is quick especially during climbing, the hybrid system can quickly switch into the series-connection mode, then the engine and the main motor provide power at the same time, and the dynamic property of the vehicle is excellent; and during high-speed generation at the preset rotating speed, the ISG is controlled by rotating speed, and the engine is controlled by the preset throttle, so that up-down fluctuation of the rotating speed of the engine can be reduced, and generation efficiency is improved.

Owner:ZHENGZHOU YUTONG BUS CO LTD

Cage Asynchronous Motor Speed Control System Based on Magneto-rheological Fluid

ActiveCN104283389BSimple structureWide speed rangeAC motor controlAsynchronous induction motorsMotor speedInduction motor

The invention provides a cage type asynchronous motor speed regulating system based on magnetorheological fluid. The cage type asynchronous motor speed regulating system comprises a cage type winding and a flow regulating control circuit. The cage type winding is composed of the magnetorheological fluid, an insulating tube, a magnet exciting coil and an end ring. The flow regulating control circuit is composed of a wire, a collecting ring, an electric brush and a constant flow source circuit capable of outputting adjustable currents. When a cage type asynchronous motor works, the magnet exciting coil on the cage type winding can generate corresponding strong or weak magnetic fields by changing the size of the current output by the constant flow source circuit, the resistance of the magnetorheological fluid is changed under the effect of the magnetic fields, induced current passing the cage type rotor winding changes along with the change of the resistance, so that the rotation speed of the a cage type rotor is changed, and finally the output rotation speed of the cage type asynchronous motor is changed. The cage type asynchronous motor speed regulating system is designed by utilizing the characteristic that the resistance of the magnetorheological fluid changes under the magnetic field environment and has the advantages of being wide in speed regulating range, quick in speed regulating response, capable of achieving stepless speed regulation and the like.

Owner:SHIHEZI UNIVERSITY

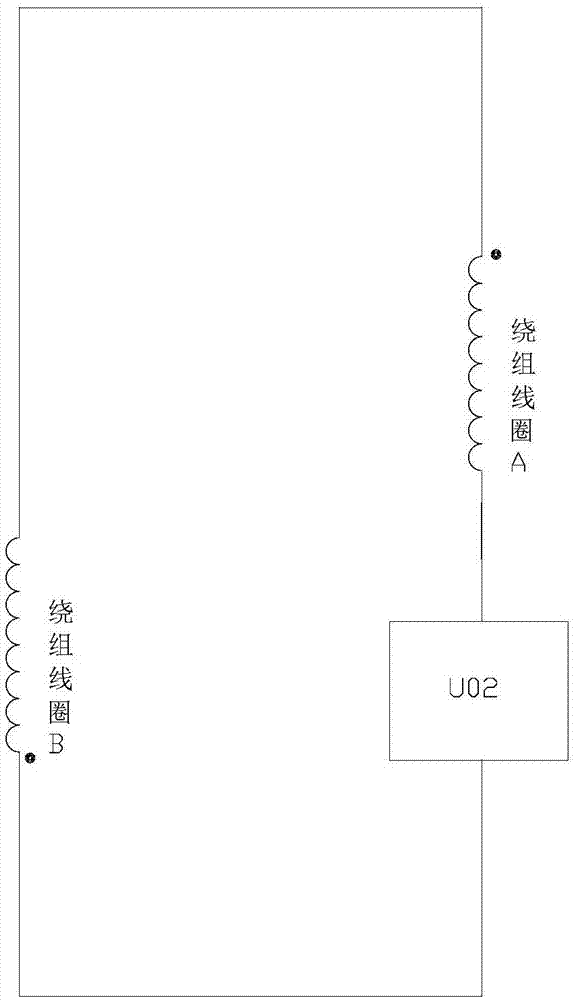

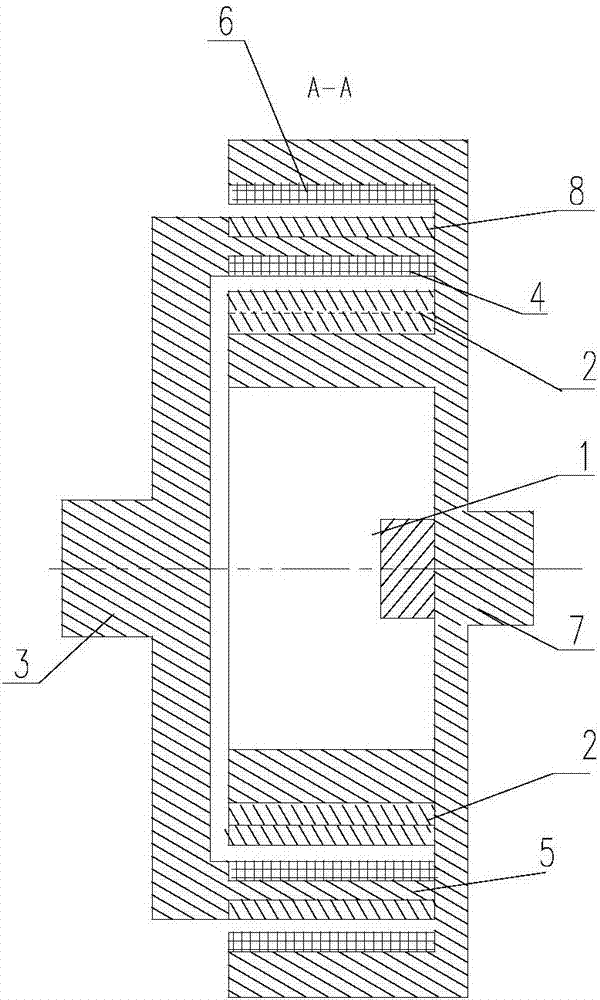

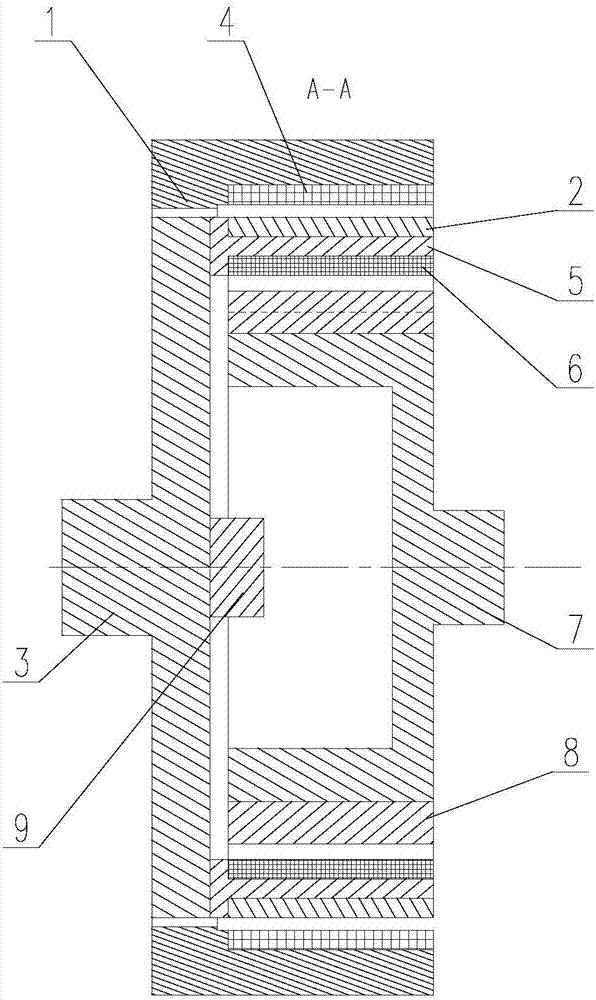

Magnetic-gap-fixed permanent magnet speed regulator

PendingCN108011494AReduce heat lossFast response to speed regulationPermanent-magnet clutches/brakesDynamo-electric brake controlControl systemElectrical polarity

The invention relates to a magnetic-gap-fixed permanent magnet speed regulator comprising a magnet rotor disc which is connected with an input shaft and an armature rotor disc A and an armature rotordisc B which are arranged on the two side surfaces of the magnet rotor disc and connected with an output shaft. The magnet rotor disc comprises permanent magnets B and permanent magnets A which are arranged on the internal and external side surfaces of the external circumference of the magnet rotor disc. The armature rotor disc B is provided with winding coils B which are arranged to be corresponding to the permanent magnets B on the internal side surface. The armature rotor disc A is provided with winding coils A which are arranged to be corresponding to the permanent magnets A on the internal side surface. The winding coils B and the winding coils A are connected in series in a homo-polar way, and a control system used for current regulation is connected in series between the two windingcoils. The armature windings are used so that the rotor heat loss can be greatly reduced, rapid, flexible and stable speed regulation response of the speed regulator can be realized by using the principle of current control and thus the transmission efficiency of the permanent magnet speed regulator having the structure can be greatly enhanced and the range of application is wider.

Owner:山东洁盟节能环保技术有限公司

Permanent magnet speed regulator with fixed magnetic gap

PendingCN107863871AReduce heat lossFast response to speed regulationAsynchronous induction clutches/brakesPermanent-magnet clutches/brakesEngineeringCurrent regulation

The invention relates to a permanent magnet speed regulator with a fixed magnetic gap. The permanent magnet speed regulator comprises an inner rotor disc connected with an input shaft, and an armaturerotor disc and a magnetic rotor disc arranged on the two side surfaces of the inner rotor disc and connected with an output shaft; the inner rotor disc comprises a winding coil B and a permanent magnet A arranged on the inner and outer side surfaces of the outer circumference thereof; a winding coil A is arranged on the inner side surface of the armature rotor disc; a permanent magnet B is arranged on the inner side surface of the magnetic rotor disc; the winding coil B and the winding coil A are connected in series at the same polarity, and a control system used for current regulation is connected in series between the two winding coils; and slip rings are mounted on the inner rotor disc and the armature rotor disc respectively. By adoption of the armature winding, rotor heating loss canbe greatly lowered; and by adopting a current control principle, quick response, flexibility and stability of the speed regulator can be realized, thereby greatly improving the transfer efficiency ofthe permanent magnet speed regulator with the structure and achieving a wider application range.

Owner:山东洁盟节能环保技术有限公司

Permanent magnetic speed regulator with fixed magnetic gap

PendingCN107979261AReduce heat lossFast response to speed regulationAsynchronous induction clutches/brakesPermanent-magnet clutches/brakesConductor CoilControl principle

The invention relates to a permanent magnetic speed regulator with a fixed magnetic gap. The speed regulator comprises a rotor connected with an input shaft, an armature rotor and a magnetic rotor. The armature rotor and the magnetic rotor are connected with an output shaft and arranged on the inner side and the outer side of the circumference of a rotor respectively. The rotor comprises permanentmagnets A which are circumferentially distributed along the inner circumferential face of the rotor, and winding coils B which are circumferentially distributed along the outer circumferential face of the rotor. The armature rotor comprises winding coils A which are circumferentially distributed along the outer circumferential face of the armature rotor. The winding coils B and the winding coilsA are serially connected in a same-polarity manner. A control system is serially connected between the winding coils B and the winding coils A. Sliding rings are installed on the rotor and the armature rotor. According to the invention, by use of the armature rotor, heating loss of the rotor can be greatly reduced; by use of the current control principle, rapid, flexible and stable speed regulation reactions of the speed regulator can be achieved; transmission efficiency of the speed regulator is greatly improved; and application range is quite wide.

Owner:山东洁盟节能环保技术有限公司

A stepless speed regulator

ActiveCN102937151BWide speed rangeFast response to speed regulationGearingFluid clutchesLiquid stateFlywheel

The invention discloses a stepless speed controlling method and a stepless speed controller. According to the method, a medium serves as a high-frequency transmission switch, conversion between the output revolving speed and the torque is achieved through a mechanical energy storage mechanism, the medium is subjected to solid and liquid transformation under the effect of voltage or a magnetic field, the mechanical energy storage mechanism is composed of a heavy energy storage flywheel and a light transmission disk, the medium is located between the energy storage flywheel and the transmission disk, when the voltage or the magnetic field is applied, the medium is solidified, the energy storage flywheel and the transmission disk are connected into a whole, when the voltage or the magnetic field disappears, the medium is liquefied, no mechanical connection exists between the energy storage flywheel and the transmission disk, the energy storage flywheel and the transmission disk rotate freely and separately, and the output revolving speed and the torque are controlled through controlling of the ratio of the solid state time of the medium to the liquid state time of the medium. The stepless speed controller which implements the method has the advantages of being wide in speed regulating time, fast in reaction, simple in structure, stable in output power and the like.

Owner:SOUTH CHINA AGRI UNIV

Flywheelless Diesel Engine Generator/Motor System Control Method

ActiveCN107701318BSmall moment of inertiaFast response to speed regulationElectronic commutation motor controlPower operated startersDiesel engine generatorDieseling

The invention provides a flywheel-free diesel engine generator / motor system control method and belongs to the field of machines. According to the flywheel-free diesel engine generator / motor system control method, an energy storage function of a diesel engine flywheel is replaced with a generator / motor four-quadrant working mode, peak load shifting is performed on the output torque of a diesel engine, uniform fluctuation torque is achieved, and uniform output of the rotating speed of a crankshaft is represented. Meanwhile the rotational inertia of the crankshaft can be lowered greatly, the adjusting response of the rotating speed of the diesel engine is accelerated, and therefore the speed adjusting performance of the diesel engine is improved.

Owner:YANGZHOU HUADONG POWER MACHINE

A series-to-parallel control method for a gas-electric hybrid hybrid power system

ActiveCN104554240BFast response to speed regulationHybrid vehiclesDriver input parametersStarter generatorHybrid system

Owner:ZHENGZHOU YUTONG BUS CO LTD

Magnetic-gap-fixed permanent magnet speed regulator

PendingCN108011495AReduce heat lossFast response to speed regulationPermanent-magnet clutches/brakesDynamo-electric brake controlCurrent regulationPhysics

The invention relates to a magnetic-gap-fixed permanent magnet speed regulator comprising a rotor which is connected with an input shaft and a magnet rotor and an armature rotor which are connected with an output shaft and respectively arranged on the internal side and the external side of the circumference of the rotor. The rotor comprises winding coils A which are circumferentially distributed along the internal circumferential surface of the rotor and permanent magnets B which are circumferentially distributed along the external circumferential surface of the rotor. The magnet rotor comprises permanent magnets A which are circumferentially distributed along the external circumferential surface of the magnet rotor. The armature rotor comprises winding coils B which are circumferentiallydistributed along the internal circumferential surface of the armature rotor. The winding coils B and the winding coils A are connected in series in a homo-polar way, and a control system used for current regulation is connected in series between the two winding coils. A slip ring is installed on the rotor and the armature rotor. The armature windings are used so that the rotor heat loss can be greatly reduced, rapid, flexible and stable speed regulation response of the speed regulator can be realized by using the principle of current control and thus the transmission efficiency of the permanent magnet speed regulator having the structure can be greatly enhanced and the range of application is wider.

Owner:山东洁盟节能环保技术有限公司

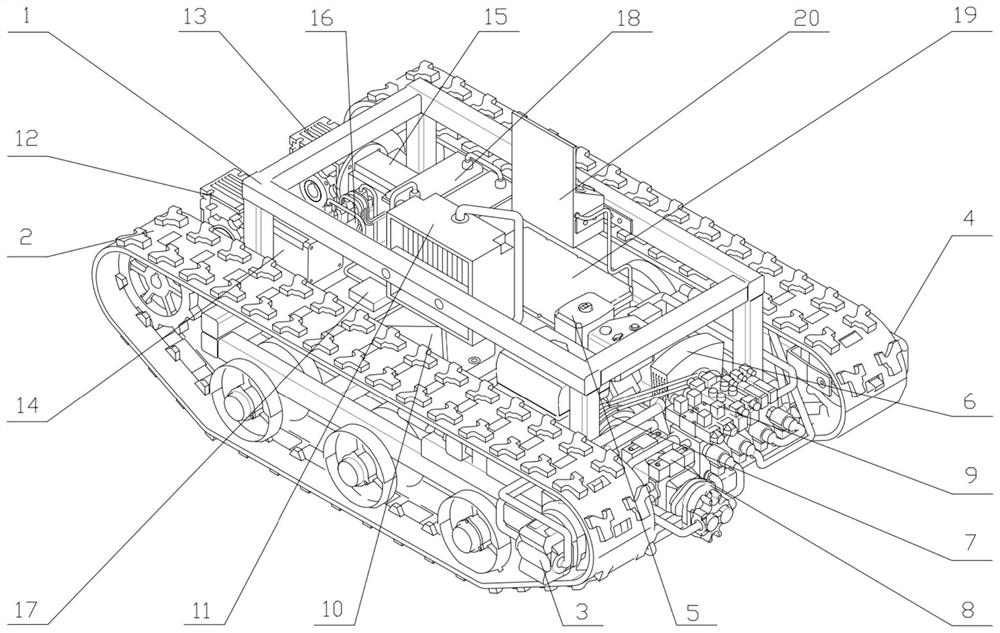

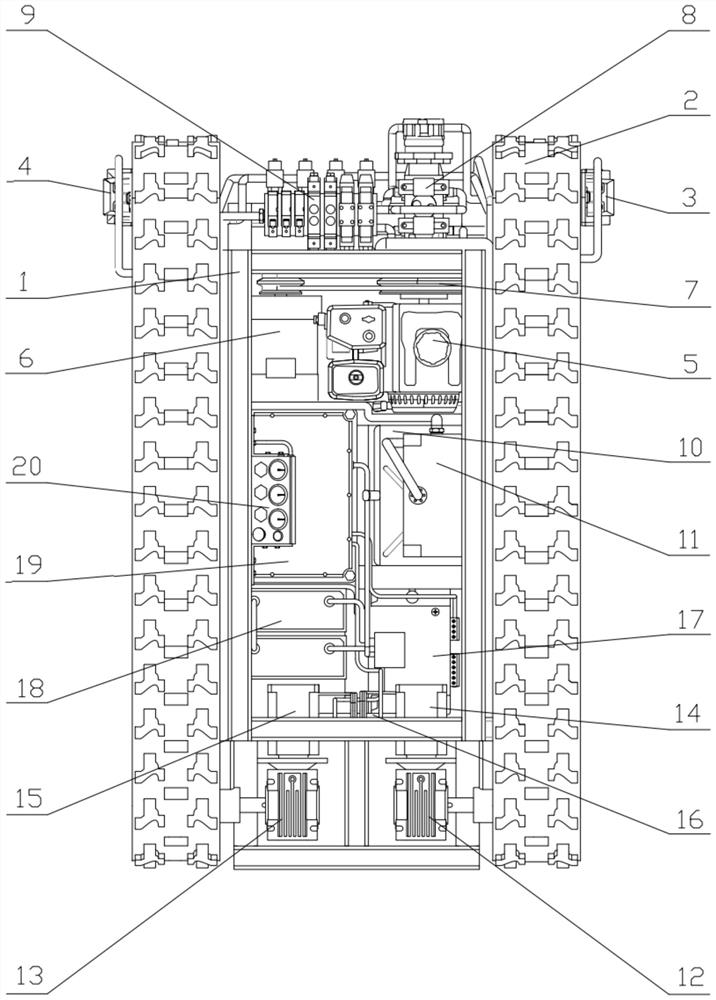

Novel electro-hydraulic hybrid drive crawler-type chassis

PendingCN114654993AFast response to speed regulationPowerfulGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingElectric driveHydraulic hybrid vehicle

The invention discloses a novel electro-hydraulic hybrid drive crawler-type chassis, relates to the field of crawler-type chassis, and aims to solve the problems that in the prior art, the speed regulation range is small, the response is slow, the energy loss is large, and the service life of a hydraulic system is shortened. The advantages of fast speed regulation response and sufficient power are taken into consideration, stable walking under complex road conditions is achieved, energy conservation and emission reduction are achieved, electric energy of an electric drive system is provided by a generator, compared with traditional single electric drive, long-time charging is not needed, long-distance work can be achieved, the system pressure of a hydraulic system during work is reduced through power distribution design, and the service life of the hydraulic system is prolonged. The service life of the hydraulic system is greatly prolonged, the hydraulic system adopts a variable pump and closed loop integrated cooling system, overflow loss and throttling loss are reduced, the utilization rate of energy is increased, and the purposes of environmental protection and energy conservation are achieved.

Owner:HUAZHONG AGRI UNIV

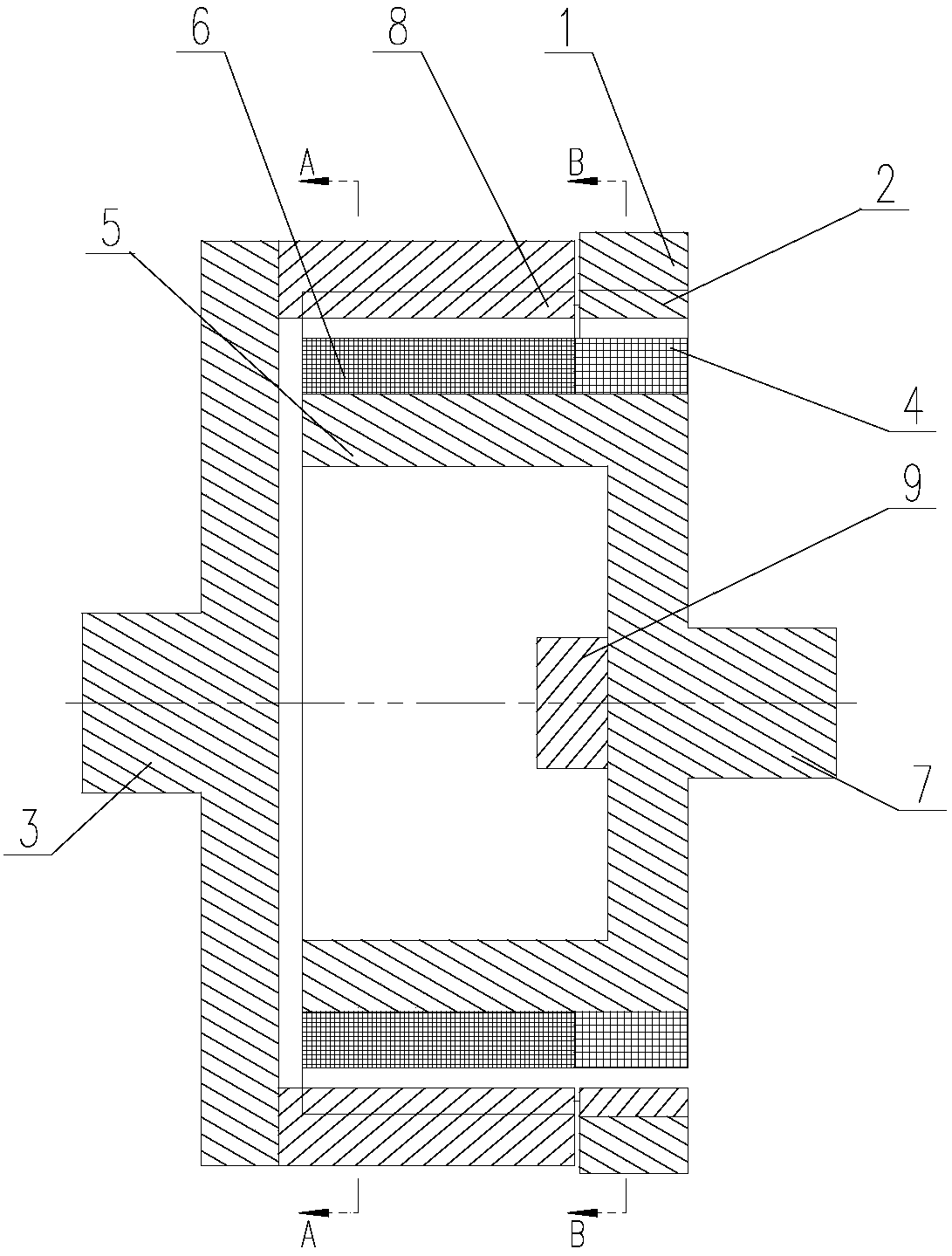

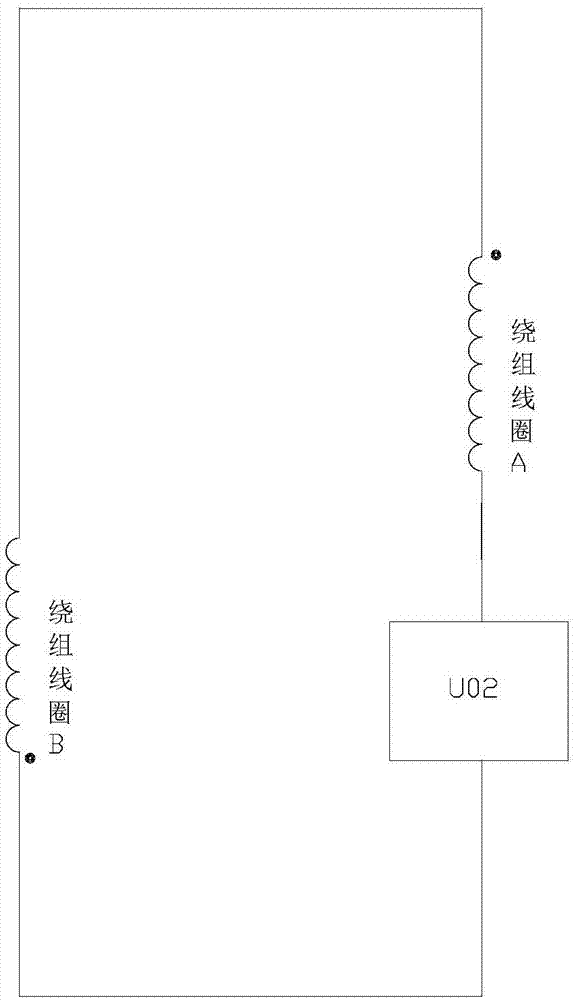

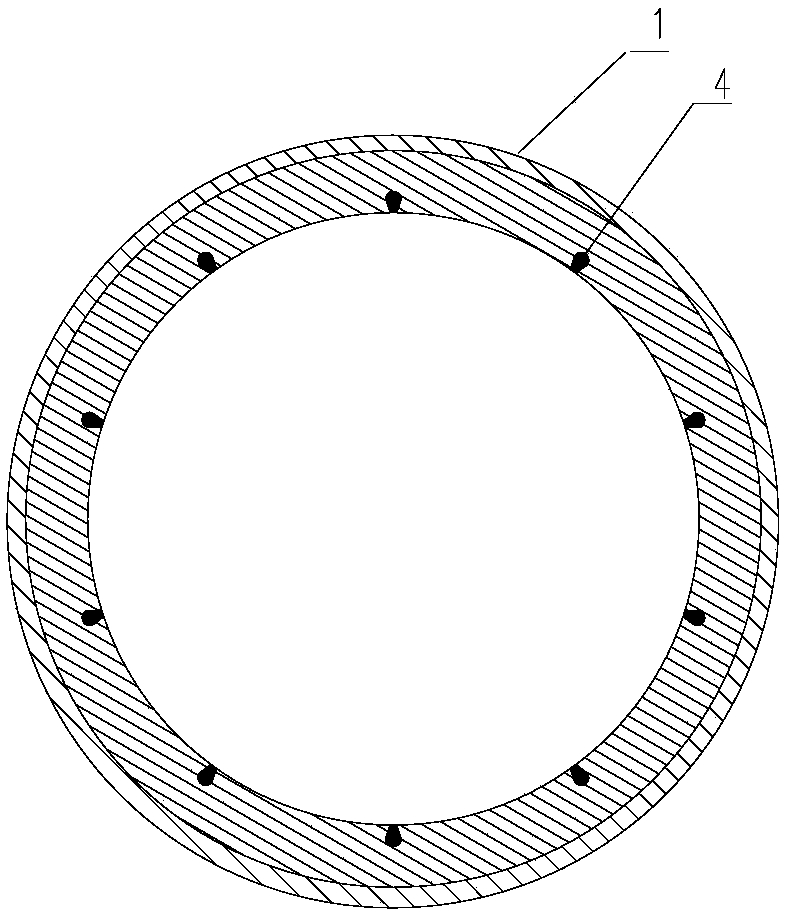

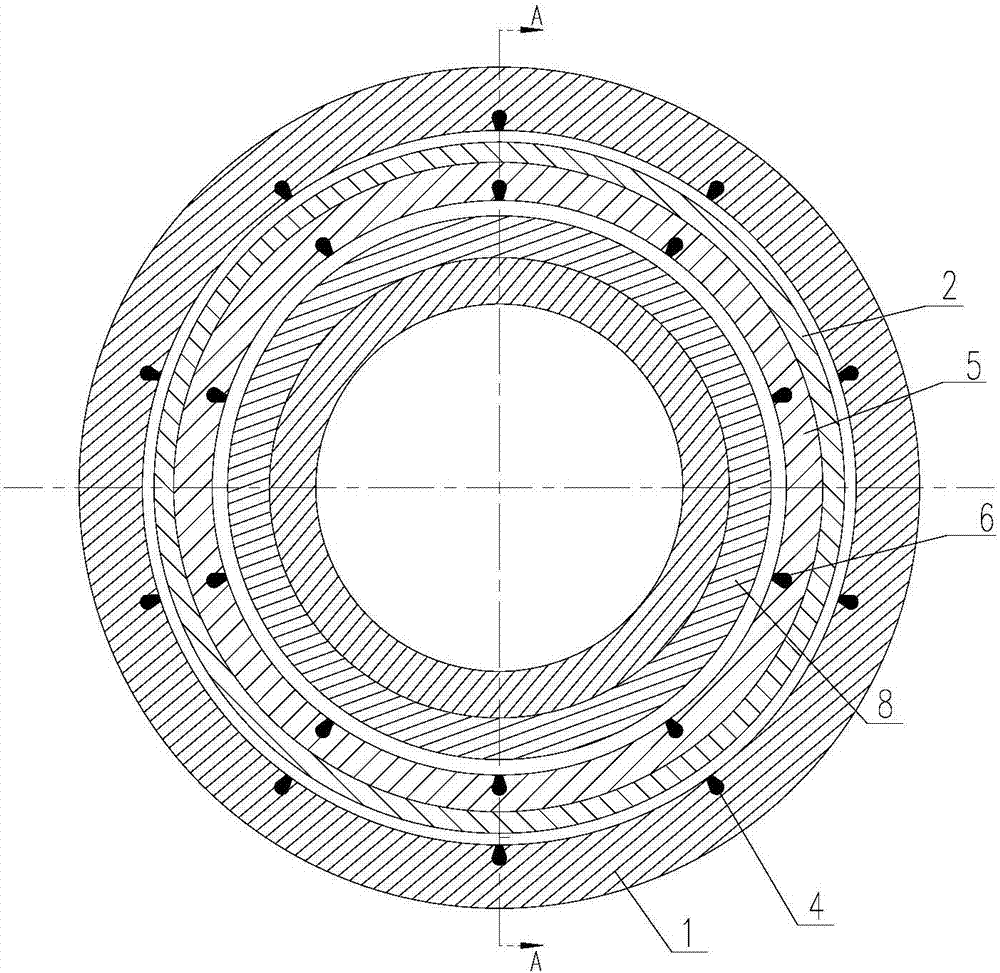

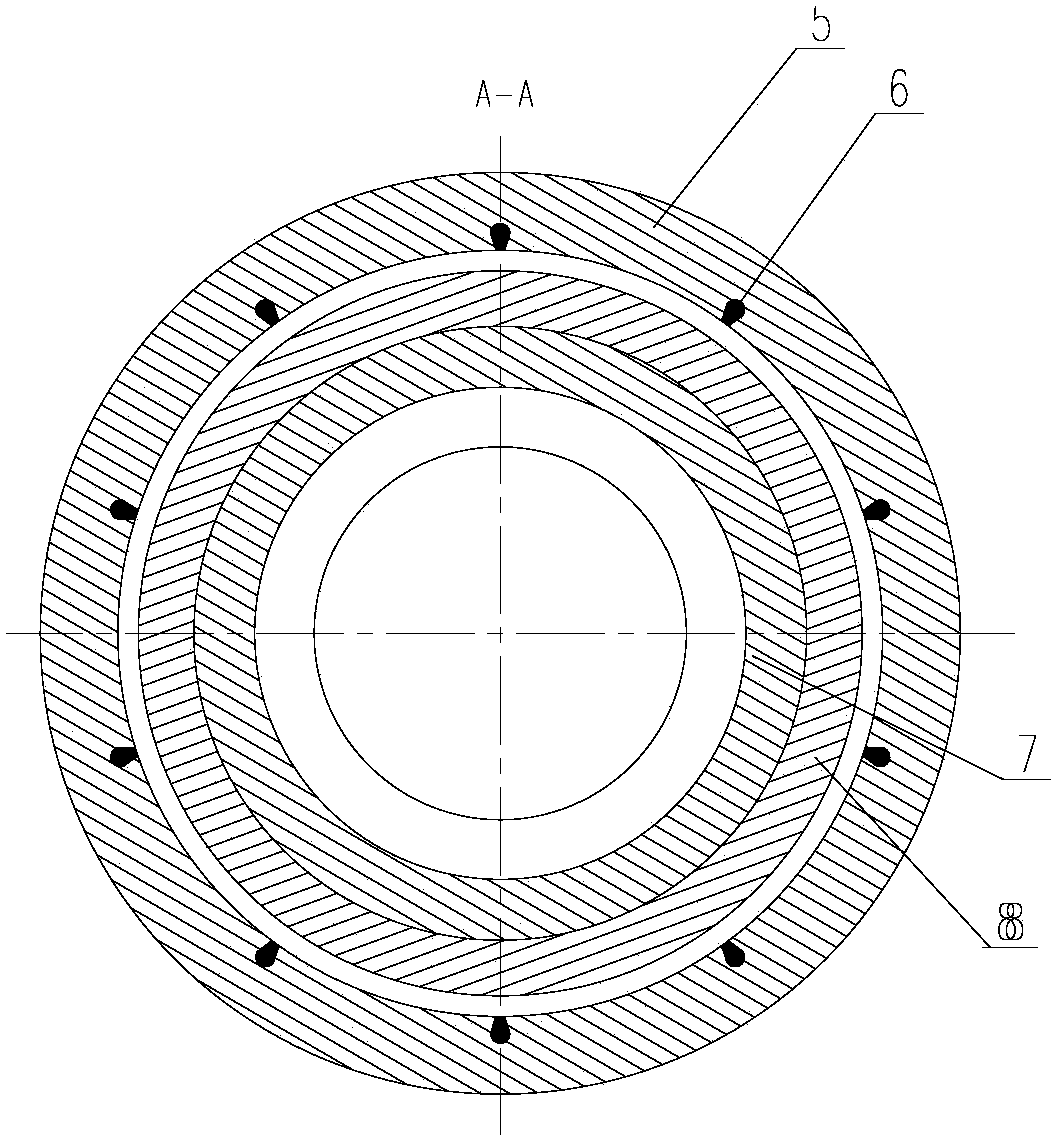

Permanent magnet speed regulator with fixed magnetic gap

PendingCN107863870AFast response to speed regulationFlexible speed responseAsynchronous induction clutches/brakesPermanent-magnet clutches/brakesControl systemEngineering

The invention relates to a permanent magnet speed regulator with a fixed magnetic gap. The permanent magnet speed regulator comprises a magnetic rotor disc connected with an input shaft, an armature rotor disc arranged on the opposite surface of the magnetic rotor disc and connected with an output shaft, and an armature stator arranged on the back surface of the magnetic rotor disc; the magnetic rotor disc comprises a permanent magnet B and a permanent magnet A arranged on the inner and outer side surfaces of the outer circumference thereof respectively; a winding coil B is arranged on the inner side surface of the outer circumference of the armature rotor disc; the armature stator comprises a fixed base and a winding coil A distributed in the inner side circumferential direction of the circumference of the fixed base; a control system is arranged between the winding coil B and the winding coil A; and a slip ring is mounted on the armature rotor disc. By adoption of a slip frequency energy rectifying and feedback technology, quick boosting or braking can be realized through the winding coil A, so that the permanent magnet speed regulator with the fixed magnetic gap is quick in response, flexible and stable; and by virtue of the slip frequency energy rectifying and feedback boosting effect, maximum of the speed regulating efficiency is realized consequently.

Owner:山东洁盟节能环保技术有限公司

Magnetic-gap-fixed permanent magnet speed regulator

PendingCN108011493AReduce heat lossFast response to speed regulationPermanent-magnet clutches/brakesDynamo-electric brake controlCurrent regulationPhysics

The invention relates to a magnetic-gap-fixed permanent magnet speed regulator comprising a magnet rotor which is connected with an input shaft and an armature rotor A and an armature rotor B which are connected with an output shaft and respectively arranged on the internal side and the external side of the circumference of the magnet rotor. Permanent magnets A and permanent magnets B are circumferentially distributed along the internal and external circumferential surfaces of the magnet rotor. The armature rotor A comprises winding coils A which are circumferentially distributed along the external circumferential surface of the armature rotor A. The armature rotor B comprises winding coils B which are circumferentially distributed along the internal circumferential surface of the armaturerotor B. The winding coils B and the winding coils A are connected in series in a homo-polar way, and a control system used for current regulation is connected in series between the two winding coils. The armature windings are used so that the rotor heat loss can be greatly reduced, rapid, flexible and stable speed regulation response of the speed regulator can be realized by using the principleof current control and thus the transmission efficiency of the permanent magnet speed regulator having the structure can be greatly enhanced and the range of application is wider.

Owner:山东洁盟节能环保技术有限公司

Magnetic-gap-fixed permanent magnet speed regulator

PendingCN108011492AFast response to speed regulationFlexible speed responsePermanent-magnet clutches/brakesDynamo-electric brake controlControl systemConductor Coil

The invention relates to a magnetic-gap-fixed permanent magnet speed regulator comprising an external rotor which is connected with an input shaft, an external armature stator which is arranged on theexternal side of the circumference of the external rotor and an internal magnet rotor which is connected with an output shaft and arranged on the internal side of the circumference of the external rotor. The external rotor comprises an iron core, winding coils B which are circumferentially distributed along the internal circumferential surface of the iron core and permanent magnets A which are circumferentially distributed along the external circumferential surface of the iron core. Permanent magnets B are circumferentially distributed along the external circumferential surface of the internal magnet rotor. The external armature stator comprises a fixing base which is arranged on the external side of the circumference of the external rotor and winding coils A which are circumferentially distributed along the internal circumferential surface of the fixing base. A control system used for electric energy conversion is connected between the winding coils B and the winding coils A. A slipring is installed on the external rotor. The slip energy rectification feedback technology is used, and rapid boosting or braking can be realized through the winding coils A so that the speed regulation response of the magnetic-gap-fixed speed regulator is enabled to be rapid, flexible and stable and maximization of the speed regulation efficiency can be realized through the effect of slip energyrectification feedback boosting.

Owner:山东洁盟节能环保技术有限公司

Permanent magnet speed regulator of fixed magnetic gap

PendingCN107834807AFast response to speed regulationFlexible speed responseAsynchronous induction clutches/brakesPermanent-magnet clutches/brakesControl systemCondensed matter physics

The invention relates to a permanent magnet speed regulator of a fixed magnetic gap. The speed regulator comprises a magnet rotor, an outer armature stator and an inner armature rotor, wherein the magnet rotor is connected to an input shaft; the outer armature stator is located in a circumferential outer side of the magnet rotor; and the inner armature rotor is connected to an output shaft and islocated in a circumferential inner side of the magnet rotor. The magnet rotor comprises permanent magnets B which are circumferentially distributed along an inner circular surface and permanent magnets A which are circumferentially distributed along an outer circular surface. Winding coils B are circumferentially distributed along an outer circular surface of the inner armature rotor. The outer armature stator comprises a fixed seat and winding coils A, wherein the fixed seat is located at an outer side of a circumference of the magnet rotor; and the winding coils A are circumferentially distributed along an inner circular surface of the fixed seat. A control system is connected between the winding coils B and the winding coils A. The inner armature rotor is equipped with a slip ring. In the invention, a slip energy rectification feedback technology is adopted; through the winding coils A, rapid boost or brake is realized so that speed regulation reaction of the speed regulator of thefixed magnetic gap is rapid, flexible and stable; and through a slip energy rectification feedback boost effect, maximization of speed regulation efficiency is realized.

Owner:山东洁盟节能环保技术有限公司

Fixed-magnetic gap permanent-magnet speed regulator

PendingCN107863867AFast response to speed regulationFlexible speed responseAsynchronous induction clutches/brakesPermanent-magnet clutches/brakesPhysicsElectric energy

The invention relates to a fixed-magnetic gap permanent-magnet speed regulator. The fixed-magnetic gap permanent-magnet speed regulator comprises an armature rotor, a magnetic stator and an inner rotor, wherein the armature rotor is connected with an input shaft, the magnetic stator is arranged at a tail end of the armature rotor, the magnetic stator and the armature rotor are arranged in parallel, the inner rotor is connected with an output shaft and is arranged at circumferential inner sides of the armature rotor and the magnetic stator, the armature rotor comprises an iron core and windingcoils B, the winding coils B are circumferentially arranged along an inner circumferential surface of the iron core, the magnetic stator comprises a fixed seat and permanent magnets A, the permanent magnets A are circumferentially arranged along an inner circumferential surface of the fixed seat, permanent magnets B and winding coils A are arranged in parallel along an outer circumferential surface of the inner rotor, a control system is connected between the winding coils B and the winding coils A and is used for converting electric energy, and sliding rings are arranged at the armature rotorand the inner rotor. A slip frequency energy rectification feedback technology is employed, rapid boosting or braking is achieved by the winding coil A, so that the fixed-magnetic gap speed regulatoris rapid, flexible and stable in speed regulation response; and by a slip frequency energy rectification feedback boosting effect, maximum speed regulation efficiency is achieved.

Owner:山东洁盟节能环保技术有限公司

DC (direct current) motor driver

InactiveCN102097989BEasy to controlLarge starting torqueEmergency protective circuit arrangementsField or armature current controlControl systemClosed loop

The invention discloses a DC (direct current) motor driver which is designed by using a full-analog electronic circuit, a PWM (pulse width modulation) pulse width control chip and a high voltage driving chip. The motor is precisely controlled by using a DC bus protection circuit, a rotary speed feedback and current feedback dual closed-loop PI (Proportional Integral) adjusting circuit, a DC motor back discharging controllable circuit and a pulse width limit controlling circuit. The invention has the following obvious effects: the DC motor driver is reliable in operation, fast in speed regulation response, and strong in anti-interference performance; the motor is exactly controlled by using current feedback dual closed-loop PI adjusting circuit, DC motor back discharging and pulse width limit controlling; and the DC motor driver is perfect in protection function, suitable for a wind power variable paddle system, large in starting torque and is frequently adjusted.

Owner:CHONGQING HUAYU HEAVY IND ELECTROMECHANICAL CO LTD

Permanent-magnet speed governor with fixed magnetic gap

PendingCN107888049AFast response to speed regulationFlexible speed responseAsynchronous induction clutches/brakesPermanent-magnet clutches/brakesControl systemCondensed matter physics

A permanent-magnet speed governor with a fixed magnetic gap includes an outer rotor connected to an input shaft; an outer magnetic stator disposed on the outer side of the circumference of the outer rotor; and an inner armature rotor connected to an output shaft and disposed on the inner side of the circumference of the outer rotor. The outer rotor includes an iron core, a permanent magnet B distributed circumferentially along the inner circumferential surface of the iron core, and a winding coil A distributed circumferentially along the outer circumferential surface of the iron core. A winding coil B is distributed circumferentially along the outer circumferential surface of the inner armature rotor. The outer magnetic stator includes a fixed seat on the outer side of the circumference ofthe outer rotor and a permanent magnet A distributed circumferentially along the inner circumferential surface of the fixed seat. A control system is connected between the winding coil B and the winding coil A. The outer rotor and the inner armature rotor are both equipped with slip rings. The permanent-magnet speed governor uses a slip energy rectification feedback technology and realizes rapidboosting or braking through the winding coil A so as to be fast, flexible and stable in speed regulation response. The slip energy rectification feedback boosting effect achieves maximum speed governing efficiency.

Owner:山东洁盟节能环保技术有限公司

A gasoline-electric hybrid vertical take-off and landing forward-swept fixed-wing unmanned aerial vehicle

ActiveCN110217391BLarge laminar flow areaImproved aerodynamic pressure distributionWingsPower plant typeLevel flightClassical mechanics

The present invention relates to the technical field of unmanned aerial vehicles, and relates to an oil-electric hybrid vertical take-off and landing forward-swept fixed-wing unmanned aerial vehicle. At least one electric ducted fan engine is built in the front compartment of the nose; the rear fuselage has a built-in energy component and a load compartment, and the rear fuselage tail is provided with a propulsion propeller assembly, which is used to provide forward thrust to overcome the UAV when it is flying. The aerodynamic resistance; the wing assembly is installed on both sides of the rear fuselage in the form of forward swept wing; the empennage assembly is installed on the tail section of the rear fuselage; the vertical lift device assembly is an electric fan type, and the two vertical lift device assemblies are installed symmetrically On the left and right sides of the middle section of the rear fuselage; the UAV has many characteristics such as vertical take-off and landing, long-distance navigation, etc., realizes the integration of high-lift vertical take-off and landing and efficient horizontal flight, the integrated design of vertical lift system and fixed-wing layout, And the integrated control of rotor vertical lift and fixed wing lift.

Owner:沈阳迪智科技有限公司

Permanent magnet speed governor with fixed magnetic gap

PendingCN107888050AReduce heat lossFast response to speed regulationAsynchronous induction clutches/brakesPermanent-magnet clutches/brakesPhysicsMagnetic disks

The invention relates to a permanent magnet speed governor with a fixed magnetic gap. The permanent magnet speed governor comprises an armature rotor disc connected to an input shaft; a magnetic rotordisc A and a magnetic rotor disc B that are disposed on both sides of the armature rotor disc and that are connected to an output shaft. The armature rotor disc includes a winding coil B and a winding coil A that are disposed inside the outer circumference thereof and the outer side surface thereof respectively, and a core disposed between the winding coil B and the winding coil A. The magnetic rotor disc B is provided with a permanent magnet B on the inner side surface thereof. The magnetic rotor disc A is provided with a permanent magnet A on the inner side surface thereof. The same polarity of the winding coil B and the winding coil A are connected in series. A control system for current regulation is connected in series between the two winding coils. Because of the armature winding, the fixed-gap permanent magnet speed governor can greatly reduce rotor heat loss, and can achieve quick, flexible and stable speed governing responses by using a current control principle so that the permanent magnet speed governor having such structure achieves greatly improved transmission efficiency and a wide application range.

Owner:山东洁盟节能环保技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com