Magnetic gap-fixed permanent-magnet speed regulator

A permanent magnet speed governor, fixed magnetic technology, applied in the direction of permanent magnet clutch/brake, control electromechanical brake, electric brake/clutch, etc. The effect of speed regulation response is fast, transmission energy is saved, and energy saving efficiency is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

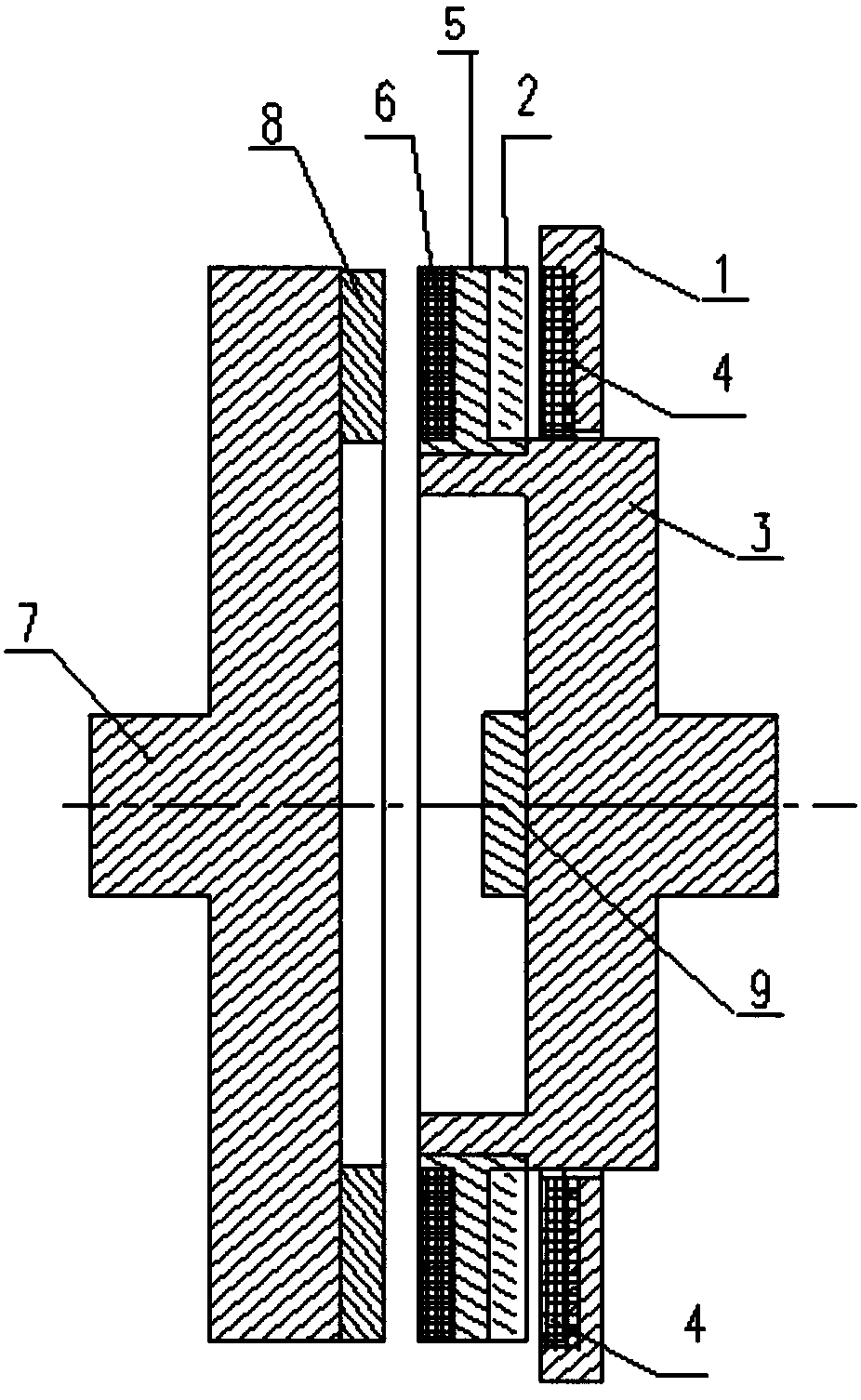

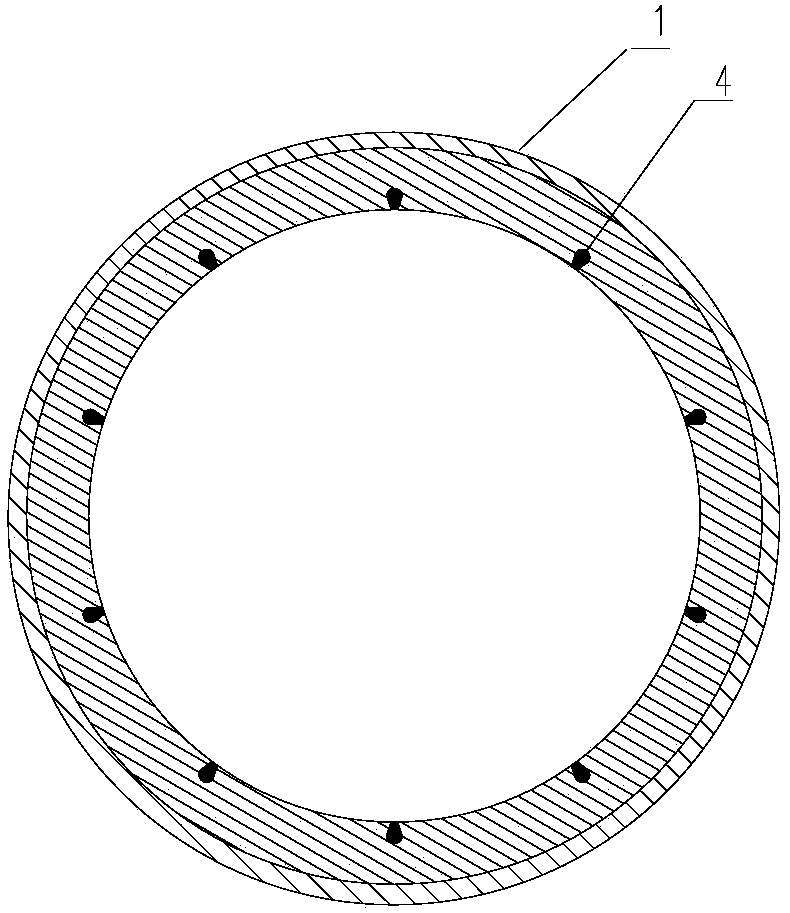

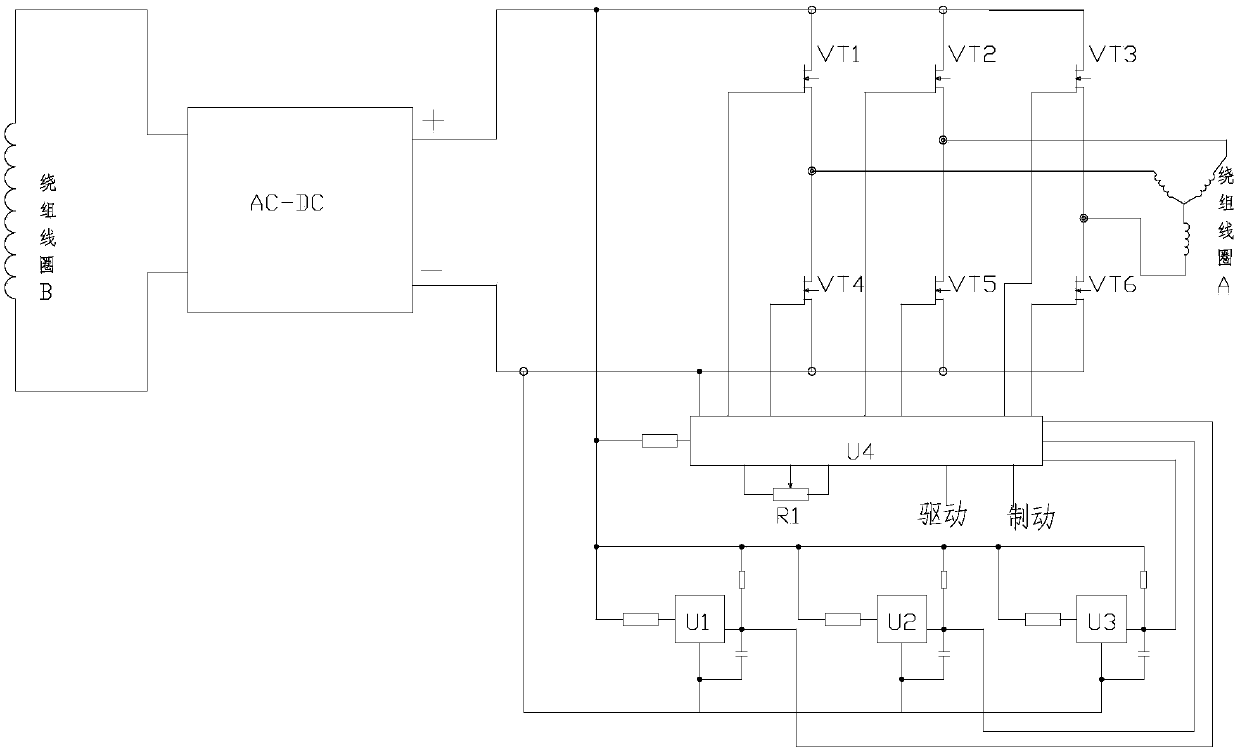

[0023] A permanent magnet governor with a fixed magnetic gap, including a rotor disk connected to the input shaft 3, a magnetic rotor disk connected to the output shaft 7 arranged on the opposite side of the rotor disk, and an armature stator arranged on the back of the rotor disk; The rotor disk includes a winding coil B6, a permanent magnet A2 and an iron core 5 between the two on the inner and outer sides of its outer circumference. The magnetic rotor disc is provided with a winding coil B6 on the inner side of its outer circumference. Corresponding to the permanent magnet B8, the armature stator includes a fixed seat 1 and a winding coil A4 that is distributed along the inner side of the circumferential surface of the fixed seat 1 and is arranged correspondingly to the permanent magnet A2; the described winding coil B6 is connected to the winding coil A4 There is a control system 9 for electric energy conversion, and a slip ring is installed on the rotor disk.

[0024] The...

Embodiment 2

[0029]A permanent magnet governor with a fixed magnetic gap, including a rotor disk connected to the input shaft 3, a magnetic rotor disk connected to the output shaft 7 arranged on the opposite side of the rotor disk, and an armature stator arranged on the back of the rotor disk; The rotor disk includes a winding coil B6, a permanent magnet A2 and an iron core 5 between the two on the inner and outer sides of its outer circumference. The magnetic rotor disc is provided with a winding coil B6 on the inner side of its outer circumference. Corresponding to the permanent magnet B8, the armature stator includes a fixed seat 1 and a winding coil A4 that is distributed along the inner side of the circumferential surface of the fixed seat 1 and is arranged correspondingly to the permanent magnet A2; the described winding coil B6 is connected to the winding coil A4 There is a control system 9 for electric energy conversion, and a slip ring is installed on the rotor disc.

[0030] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com