Fixed-magnetic gap permanent-magnet speed regulator

A technology of permanent magnet governor and fixed magnet, which is applied in the direction of permanent magnet clutch/brake, control electromechanical brake, electric brake/clutch, etc. It can solve the problems of low torque transmission capacity, inability to achieve synchronization, consumption, etc., and achieve Fast response to speed regulation, saving transmission energy, and improving energy-saving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

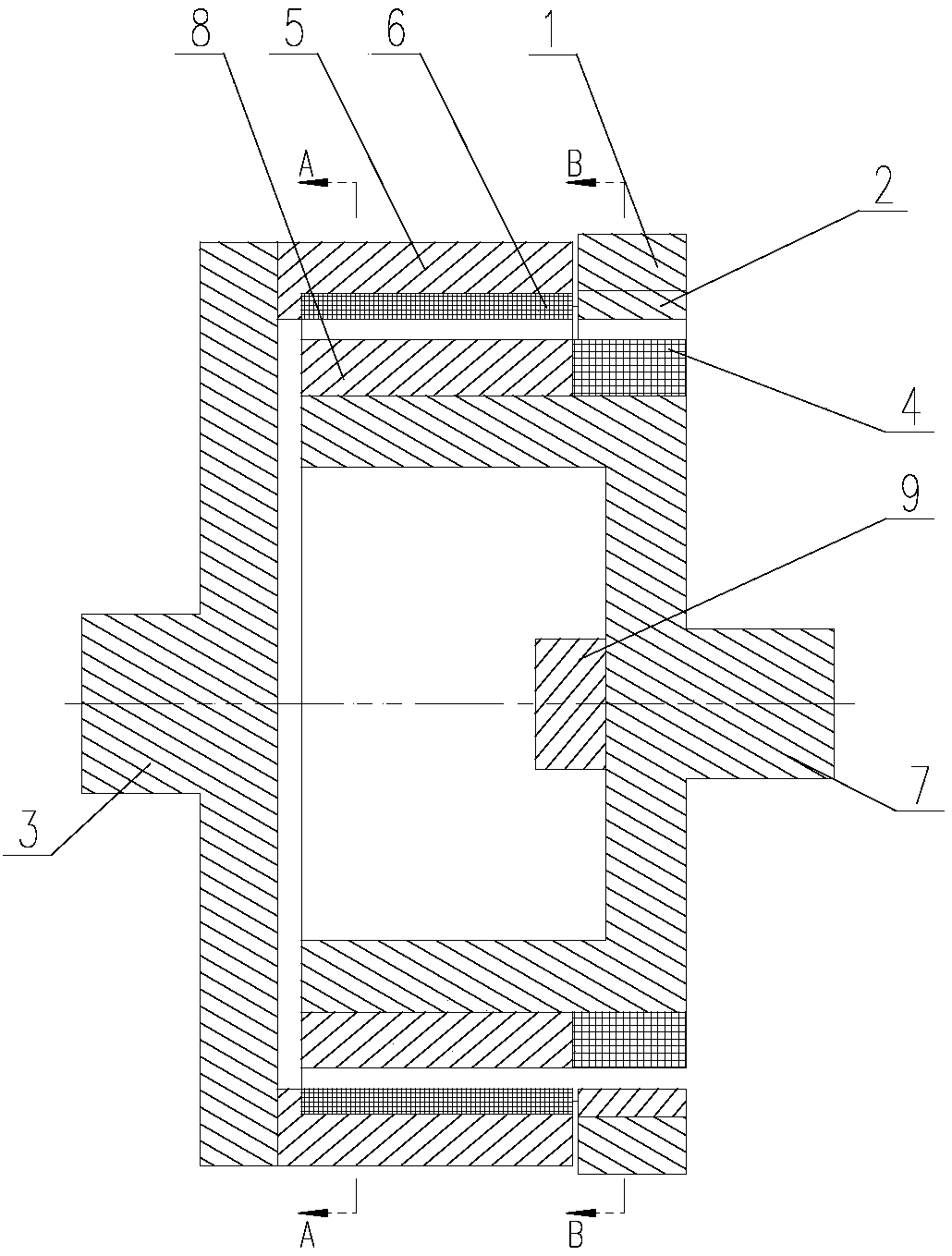

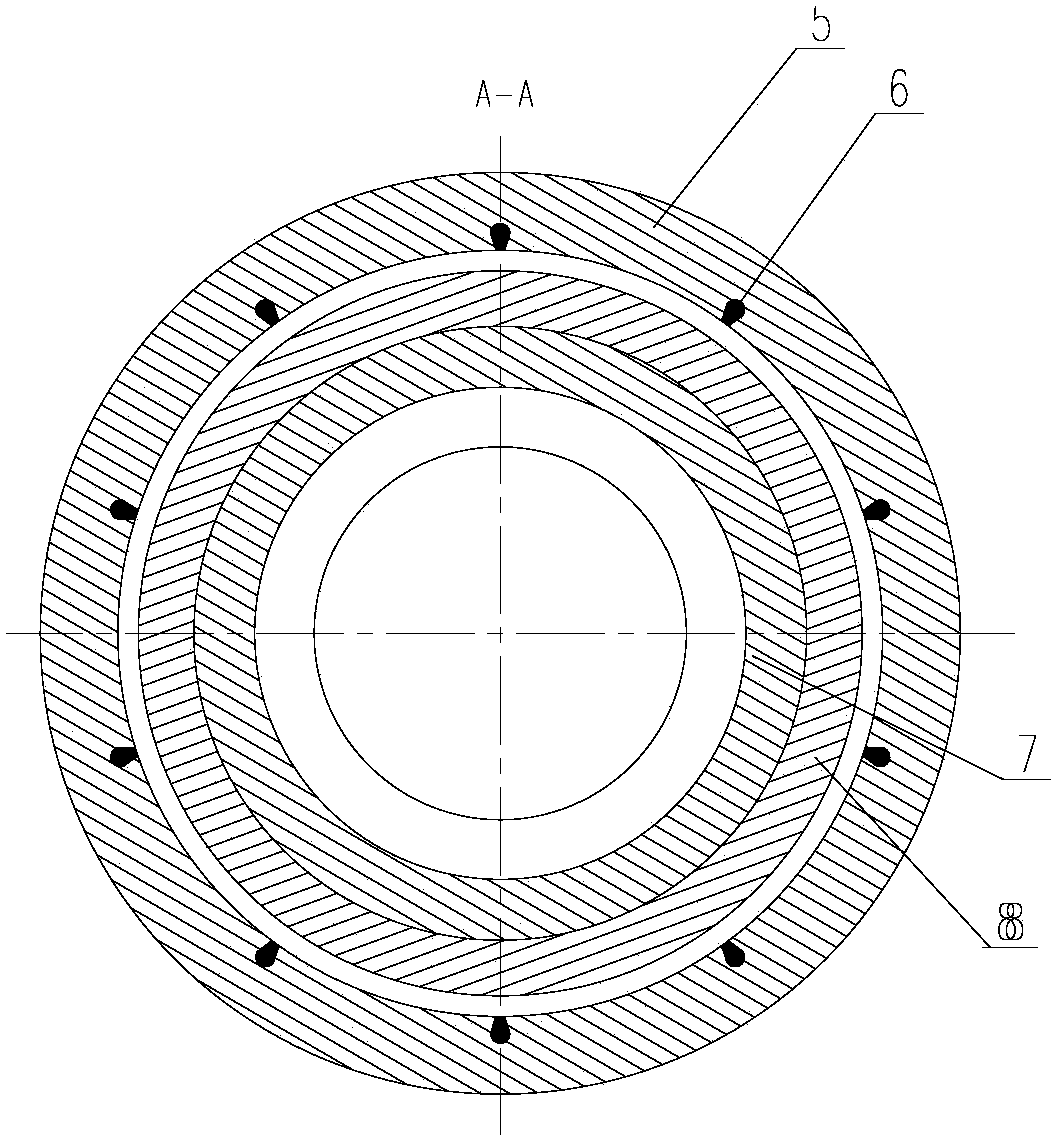

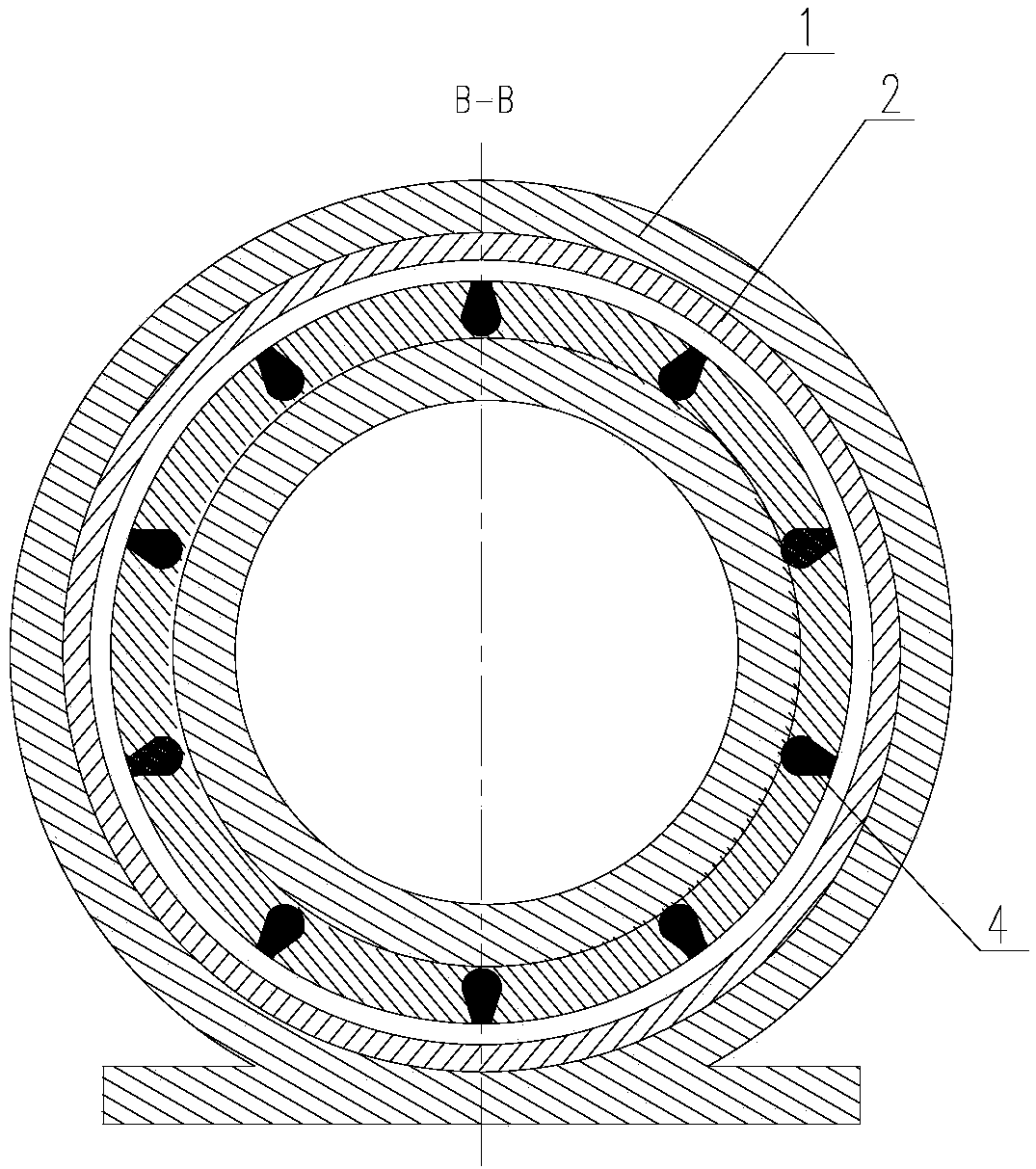

[0024] A permanent magnet governor with a fixed magnetic gap, including an armature rotor connected to the input shaft 3, a magnetic stator located at the end of the armature rotor and arranged in parallel with the armature rotor, and a magnetic stator connected to the output shaft 7 located at the armature rotor and The inner rotor inside the circumference of the magnetic stator; the armature rotor includes an iron core 5 and winding coils B 6 distributed along the inner circumference of the iron core 5; Permanent magnets A 2 distributed circumferentially on the circumferential surface; permanent magnets B 8 and winding coils A 4 are distributed side by side along the outer circumferential surface of the inner rotor; the permanent magnets B8 and winding coils A4 are respectively connected with winding coils B 6 Corresponding to the permanent magnet A2; the control system 9 for electric energy conversion is connected between the winding coil B6 and the winding coil A4; the arma...

Embodiment 2

[0029]A permanent magnet governor with a fixed magnetic gap, including an armature rotor connected to the input shaft 3, a magnetic stator located at the end of the armature rotor and arranged in parallel with the armature rotor, and a magnetic stator connected to the output shaft 7 located at the armature rotor and The inner rotor inside the circumference of the magnetic stator; the armature rotor includes an iron core 5 and winding coils B 6 distributed along the inner circumference of the iron core 5; Permanent magnets A 2 distributed circumferentially on the circumferential surface; permanent magnets B 8 and winding coils A 4 are distributed side by side along the outer circumferential surface of the inner rotor; the permanent magnets B8 and winding coils A4 are respectively connected with winding coils B 6 Corresponding to the permanent magnet A2; the control system 9 for electric energy conversion is connected between the winding coil B6 and the winding coil A4; the armat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com