Permanent magnet speed governor with fixed magnetic gap

A technology of permanent magnet speed governor and fixed magnet, which is applied in the direction of permanent magnet clutch/brake, control electromechanical brake, electric brake/clutch, etc. It can solve the problems of low energy conversion efficiency, slow adjustment speed and insensitive response, etc. Achieve the effects of fast speed regulation response, improved transmission efficiency, and reduced heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

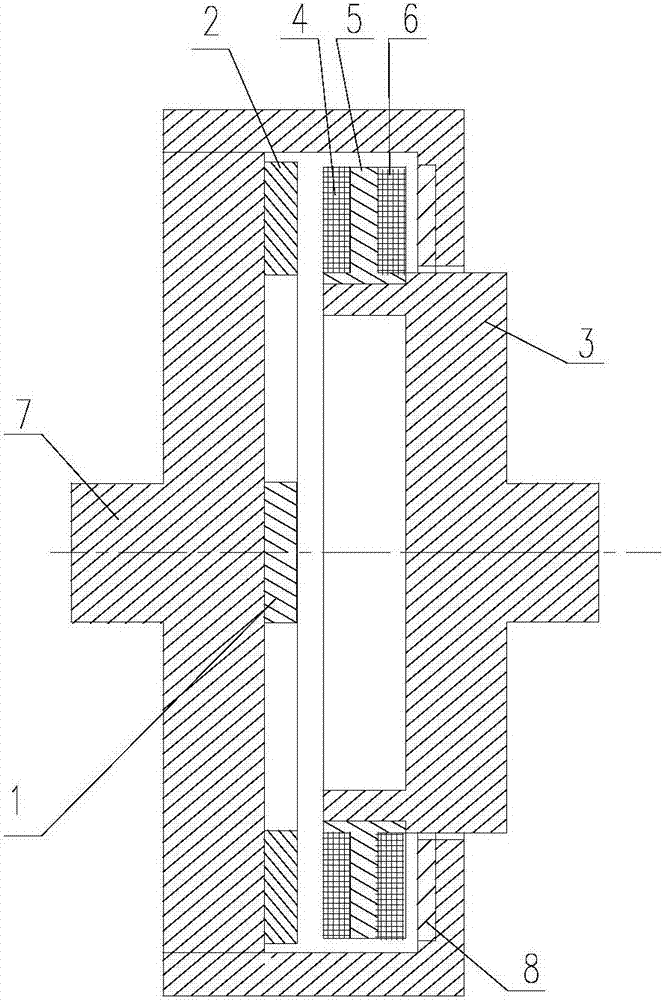

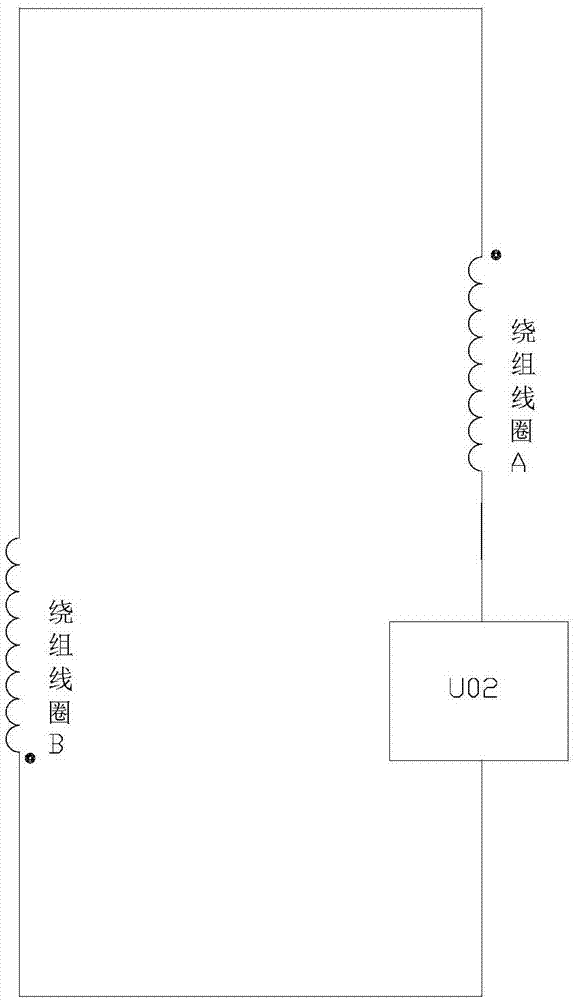

[0011] A permanent magnet governor with a fixed magnetic gap, comprising an armature rotor disc connected to an input shaft 3, a magnetic rotor disc A and a magnetic rotor disc B arranged on both sides of the armature rotor disc and connected to an output shaft 7; The armature rotor disc includes winding coil B6, winding coil A4 and iron core 5 arranged between winding coil B6 and winding coil A4 in its outer circumference and outer surface respectively. The magnetic rotor disc B is Its inner surface is provided with a permanent magnet B8 corresponding to the winding coil B6, and the magnetic rotor disk A is provided with a permanent magnet A2 corresponding to the winding coil A4 on its inner surface; the winding coil B6 and the winding coil A4 is connected in series with the same polarity, and a control system 1 for current regulation is connected in series between the two winding coils. The control system 1 is a thyristor or a MOS tube.

[0012] Preferably, the positions of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com