Novel electro-hydraulic hybrid drive crawler-type chassis

A hybrid drive and crawler-type technology, which is applied to the arrangement of multiple prime movers of power plants, pneumatic power plants, and general power plants, can solve the problems of flow and pressure loss, energy loss, and power shortage, etc., and achieve Reduce overflow loss and throttling loss, reduce system pressure and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

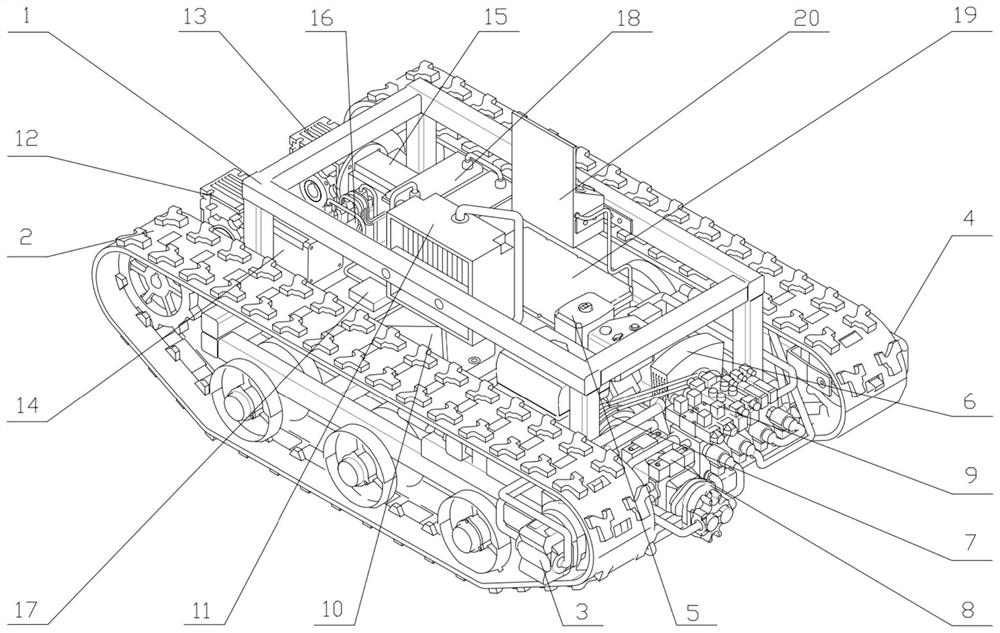

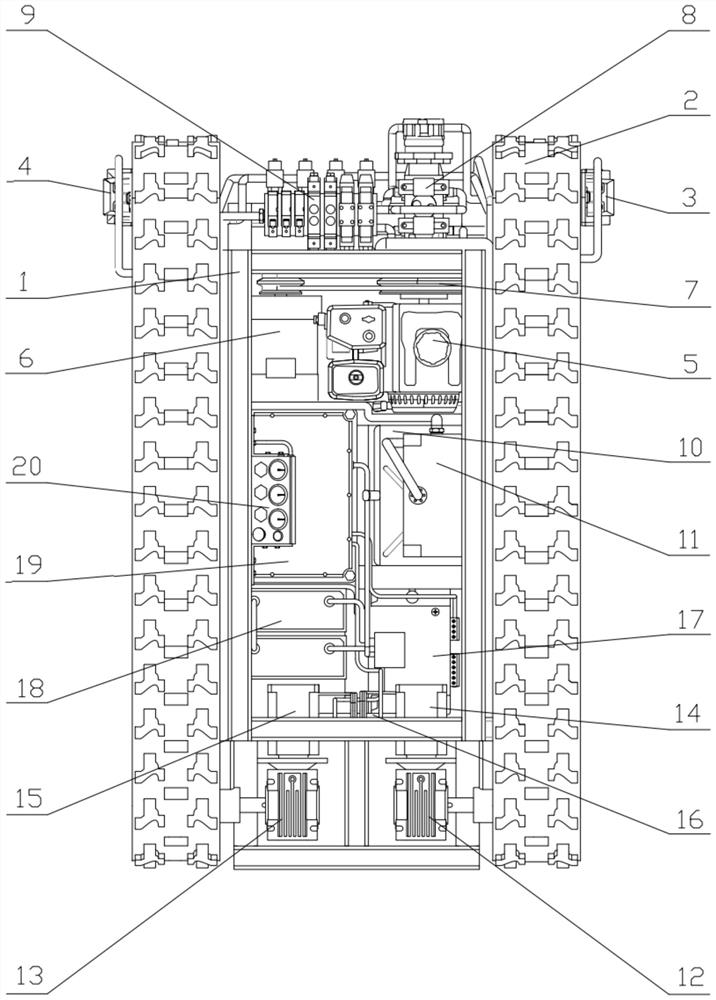

[0027] like Figure 1 to Figure 6As shown in the figure, the present invention discloses a new type of hydraulic-electric hybrid drive crawler chassis. , pulley 7, hydraulic pump group 8, hydraulic control valve group 9, hydraulic oil tank 10, radiator 11, left reducer 12, right reducer 13, left drive motor 14, right drive motor 15, motor driver 16, battery management module 17. The battery pack 18, the controller 19, and the operating table 20. The traveling crawler mechanism 2 is symmetrically arranged on both sides of the frame 1; the left hydraulic motor 3 and the right hydraulic motor 4 are both connected to the traveling crawler. The mechanism 2 is fixedly connected; the engine 5 is fixedly connected to the frame 1, the generator 6 is fixedly connected to one side of the engine 5 and is connected to the engine 5 through the pulley 7, and the hydraulic The control valve group 9 is arranged on the side of the hydraulic pump group 8 and is fixedly connected with the frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com