Flywheelless Diesel Engine Generator/Motor System Control Method

A diesel engine and electric motor technology, applied in electronic commutation motor control, engine control, motor generator control and other directions, can solve the problems of complex energy management of the whole machine, low fuel utilization rate of diesel engine, poor endurance, etc., to avoid endurance poor, eliminate safety problems, improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

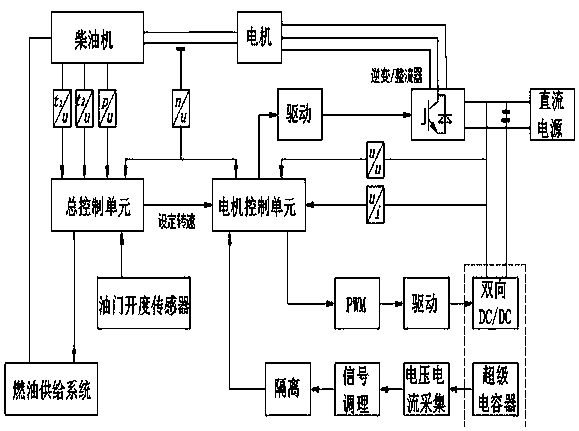

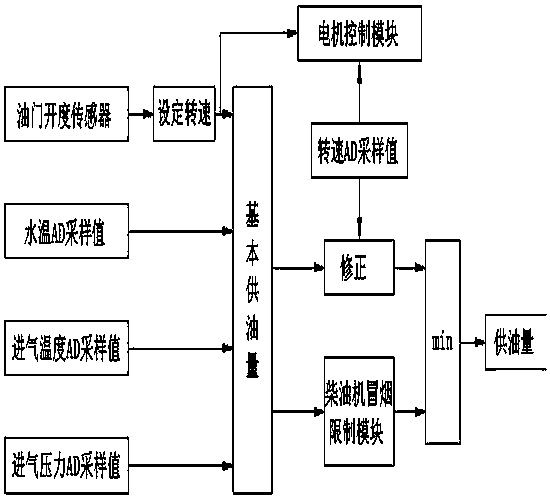

[0025] In the present invention, the energy storage and re-release process of the four-quadrant operation of the generator / motor is used to replace the energy storage function of the flywheel of the diesel engine, to "shave the peak and fill the valley" of the output torque of the diesel engine, reduce the moment of inertia of the crankshaft, and speed up the speed adjustment response of the diesel engine .

[0026] figure 1 The crankshaft of the diesel engine without flywheel 1 is connected with the generator / motor 4 through the overrunning clutch 2 (with ring gear), and the output shaft of the motor drives the hydraulic pump 5 of the hydraulic transmission system to control the operation of the excavator under different working conditions.

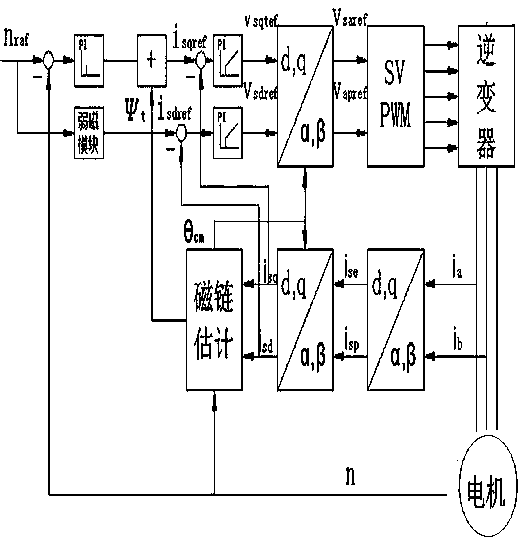

[0027] when , the generator / motor is in generator mode, and the speed n is the target speed n 1 , to charge the battery;

[0028] when When , it is powered by the battery, the generator / motor is in the motor working mode, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com