Stepless tooth engagement control type high efficiency and high power clutch

A tooth meshing and clutch technology, applied in the field of controlled transmissions and mechanical clutches

Inactive Publication Date: 2005-06-22

王国斌

View PDF0 Cites 25 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The present invention innovates and improves the shortcomings of existing clutches, and provides a new type of control clutch and overrunning clutch on this basis to meet and adapt to the needs of modern industries, especially suitable for existing pulsating continuously variable transmissions, and patent: 03140569.X 032634

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

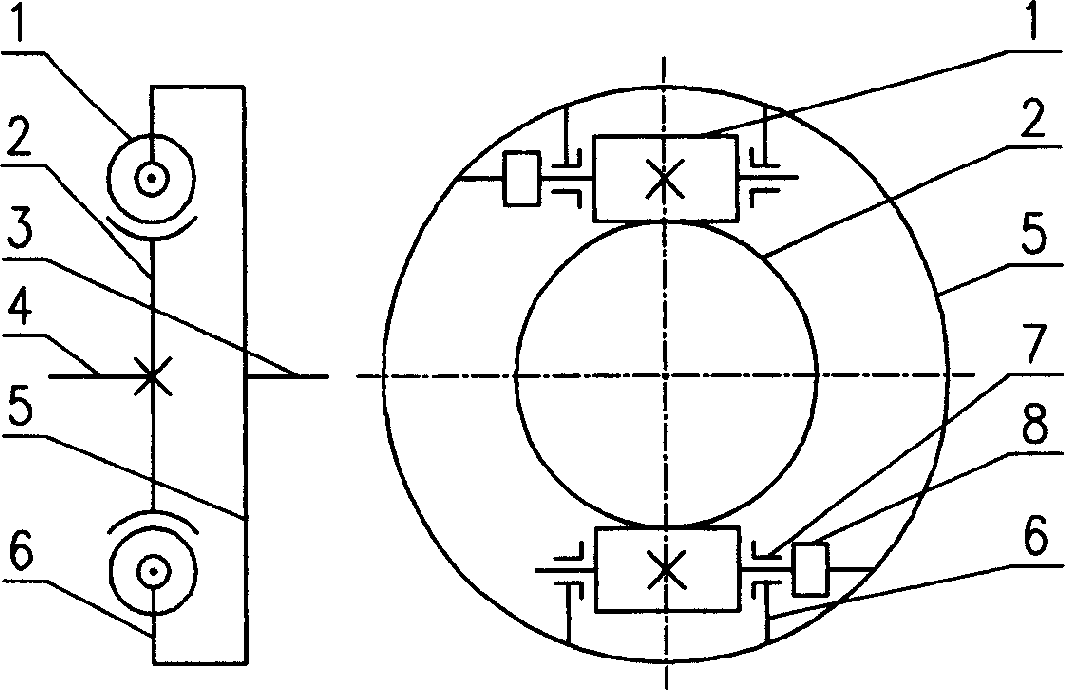

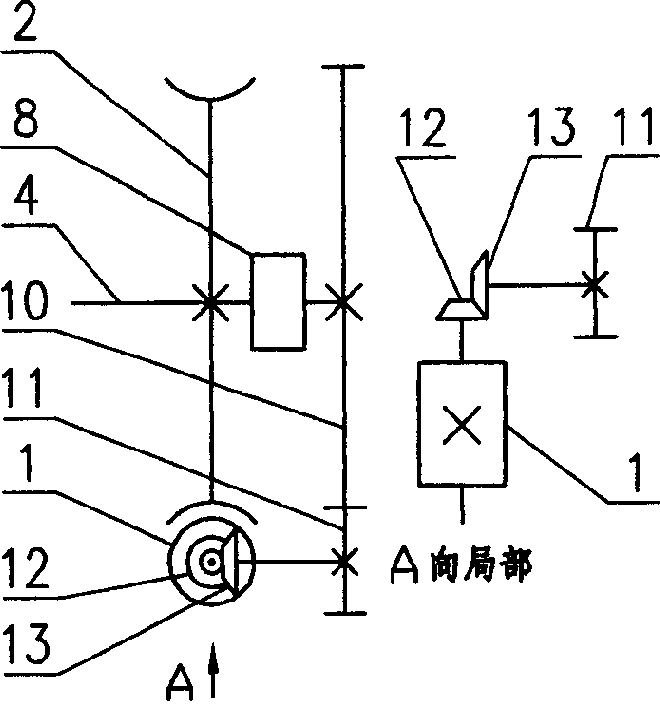

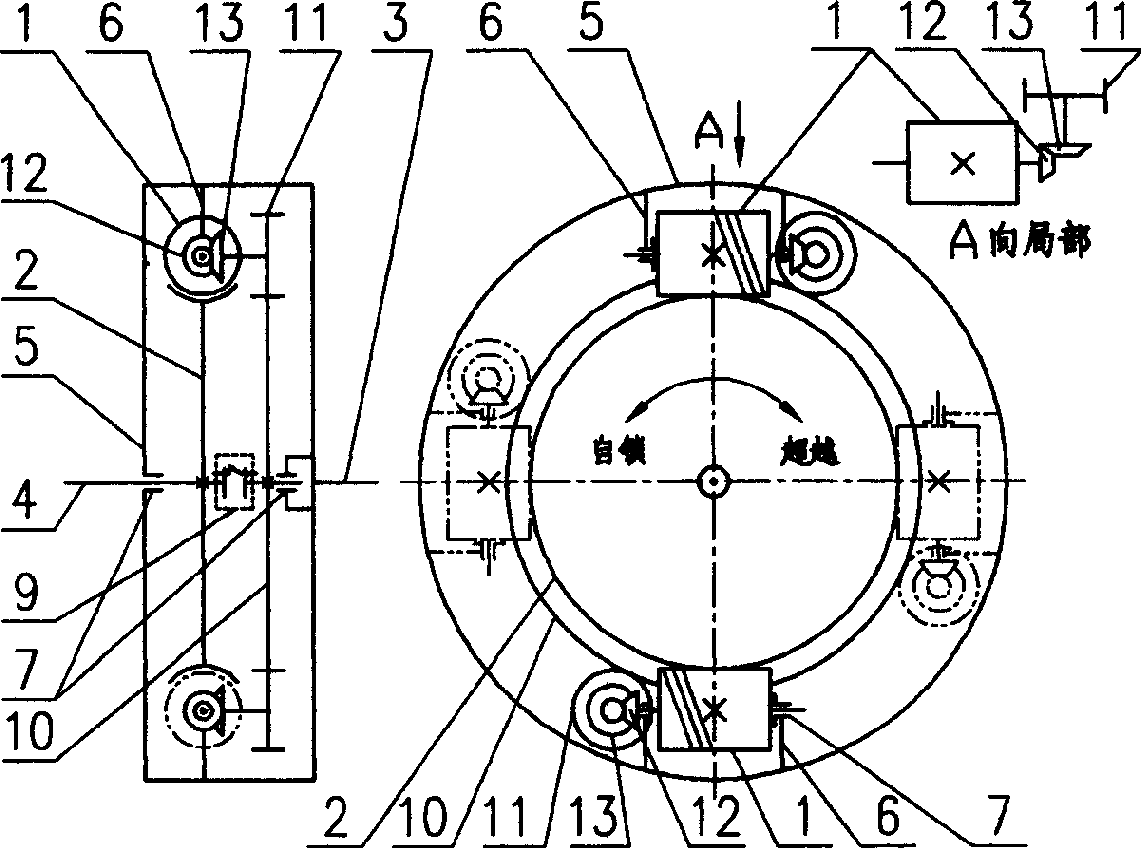

This invention relates to a stepless meshing control clutch with large power. The clutch, super clutch, control derailleur, line clutch, control strains drive device, which are designed by the principles of meshing stepless displacement and the continuous meshing stepless locking and control, which are suitable to automobile, derailleur, impulse derailleur, automatic derailleur, machine bed and other locations needing large power.

Description

technical field [0001] The invention belongs to the technical field of mechanical clutches and control transmissions, especially the design and manufacture of overrunning clutches. Background technique [0002] At present, mechanical stepless clutches generally use friction to transmit power. During operation, a large pressing force is required between the driving and driven discs, the phenomenon of wear and heat is serious, the volume is large, and the transmission power is limited. Overrunning clutch is a special kind of mechanical clutch. In mechanical transmission, automatic engagement or separation is achieved by changes in the relative movement speed or rotation direction of the main and driven elements, and the reciprocating torque is output as one-way torque, so it is also called single-way clutch. One-way clutch or one-way bearing; because its clutch state is related to the relative speed of the inner and outer rings, it is also called a differential clutch. The ex...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F16D41/02

Inventor 王国斌

Owner 王国斌

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com