Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

62results about How to "Eliminate partial wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

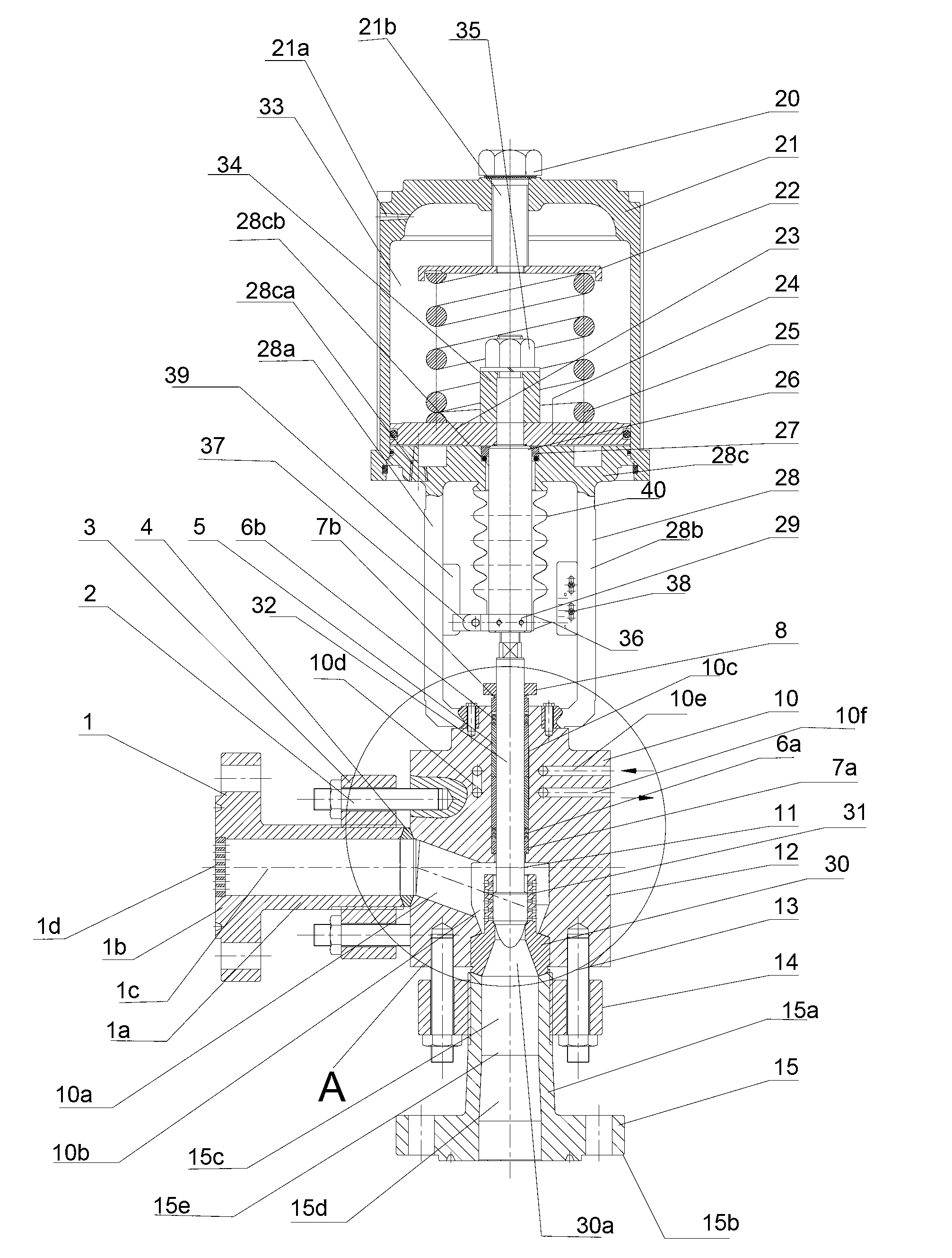

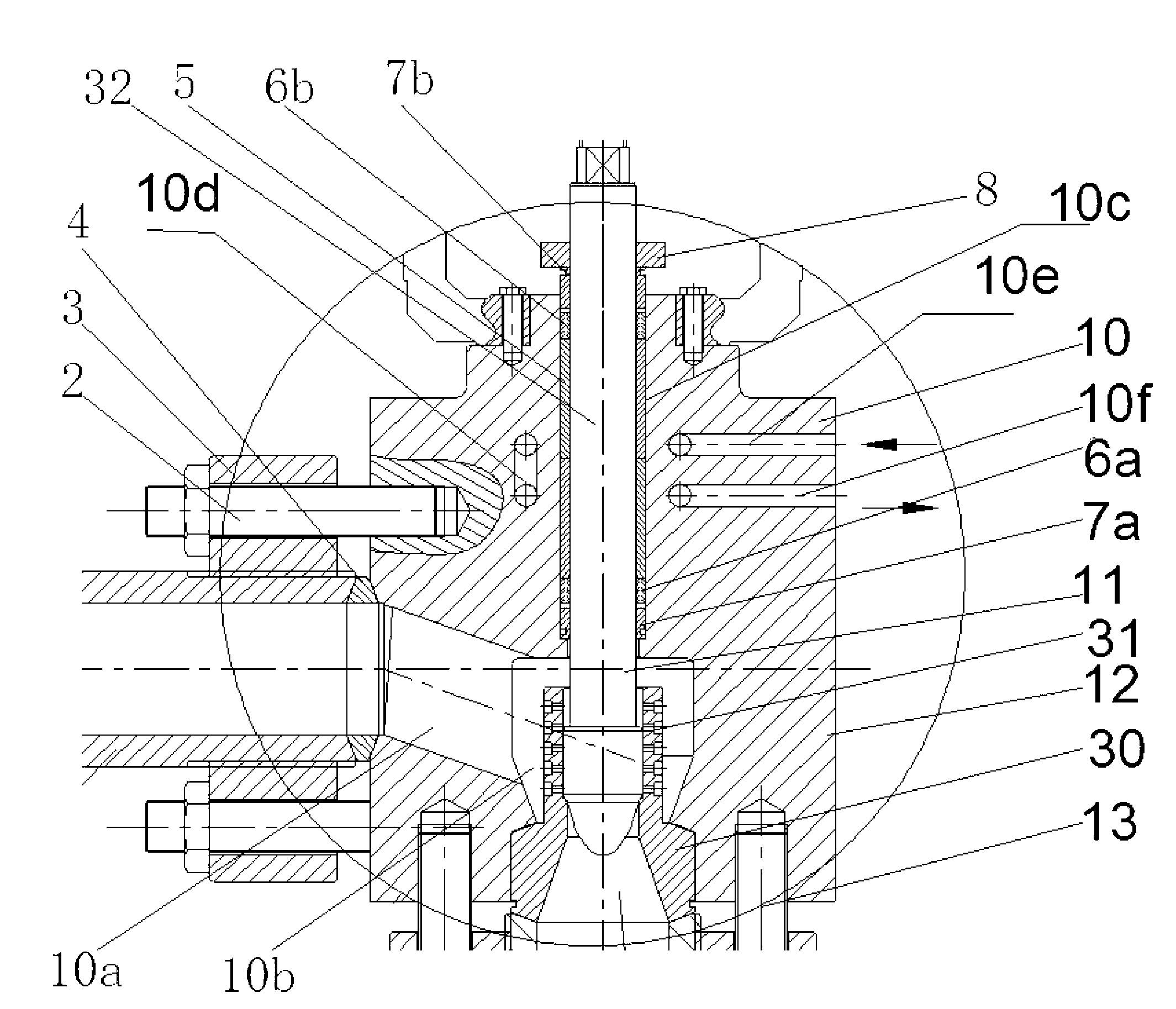

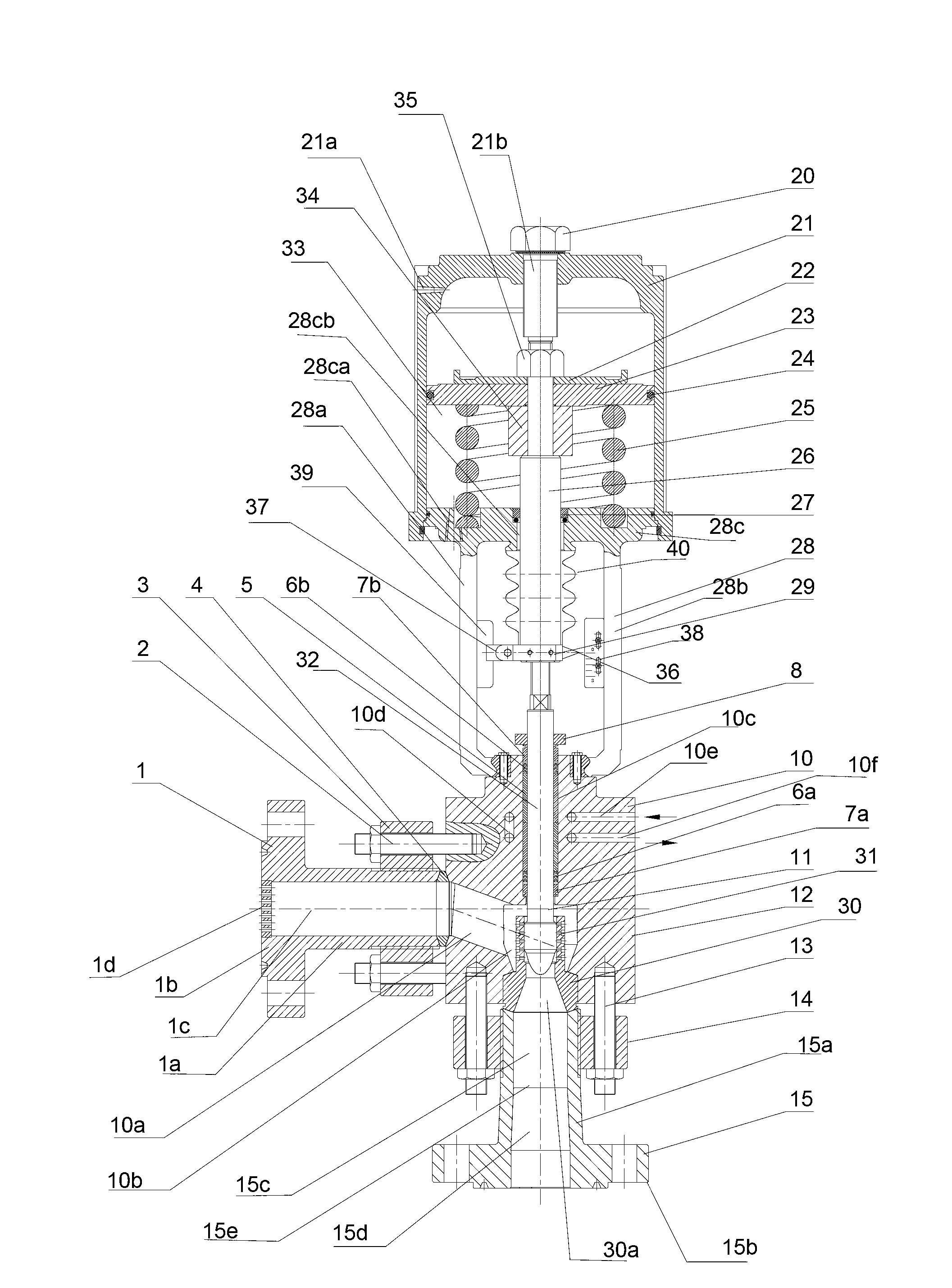

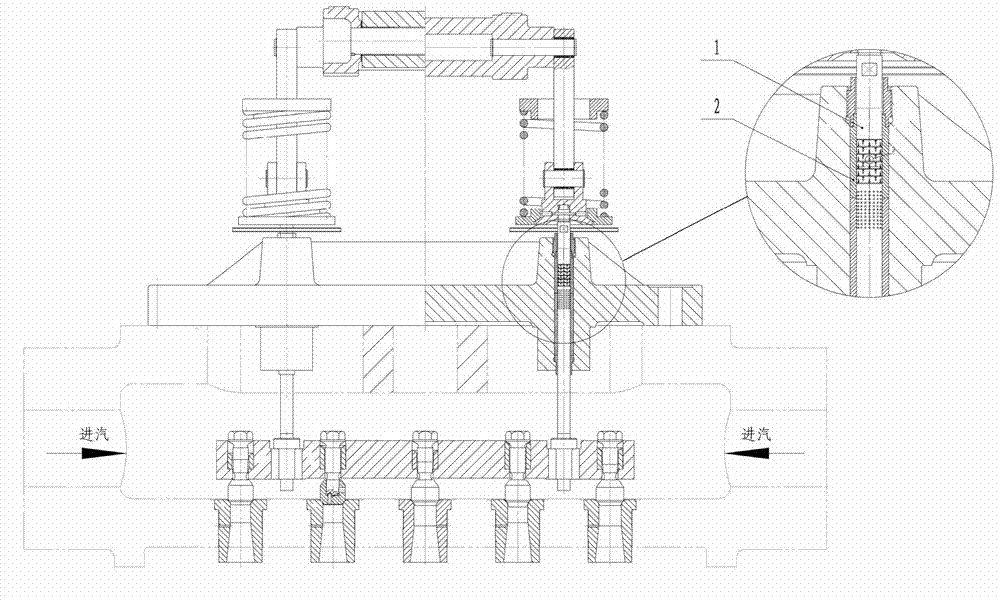

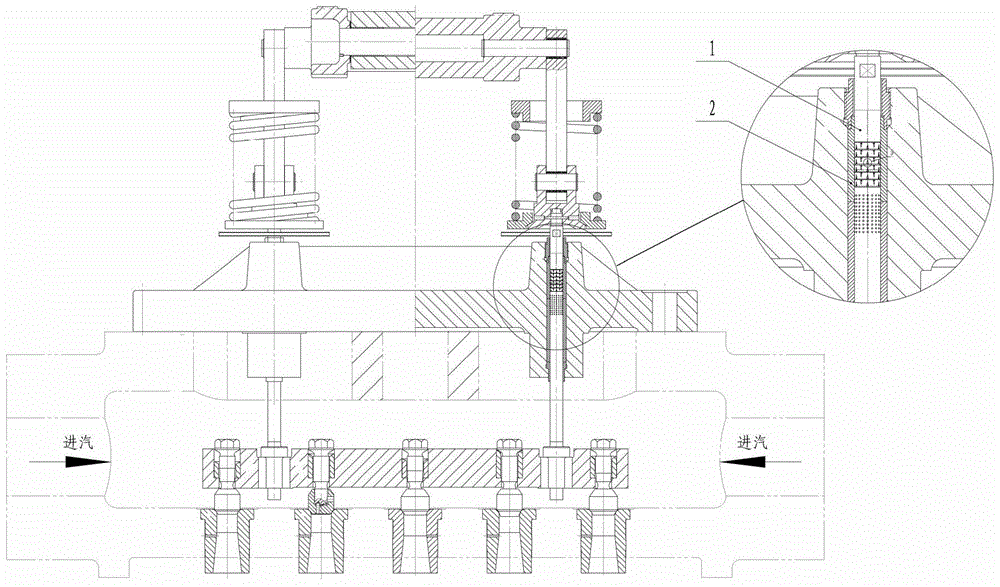

Pneumatic high pressure regulating valve

ActiveCN103016754AReasonable runner designShorten speedSpindle sealingsOperating means/releasing devices for valvesCavitationAutomatic control

The invention discloses a pneumatic high pressure regulating valve. The pneumatic high pressure regulating valve comprises an executing mechanism and a valve part which is arranged under the executing mechanism, wherein the valve part comprises a valve body; an inlet runner and an outlet runner are arranged in the valve body; and an angle formed between the inlet runner and the outlet runner is 120 degrees. The pneumatic high pressure regulating valve disclosed by the invention has the advantages as follows: as the plurality of special structural designs are adopted, applicable pressure difference of the valve is very high and cavitation phenomenon is completely eliminated; sensitive action and high response speed are obtained and the pneumatic high pressure regulating valve can be freely closed and opened and can be tightly closed when meeting very high fluid pressure difference; a side flange and a valve cage of the specially designed valve body can be also used for guiding fluid, buffering fluid pressure and protecting a valve core against being damaged by fluid ablation, flash evaporation and cavitation; meanwhile, noises can be also reduced; simple and rapid maintenance and low cost are also obtained; the service life is obviously prolonged; and the pneumatic high pressure regulating valve is especially suitable for automatically controlling high temperature and high pressure mediums with high pressure differences and is safe and reliable in use. The pneumatic high pressure regulating valve disclosed by the invention is especially incomparable with other valves in advantages when being used for places with high pressure urea and other easily crystallized mediums.

Owner:MAXCO IND TECH (SHANGHAI) CO LTD

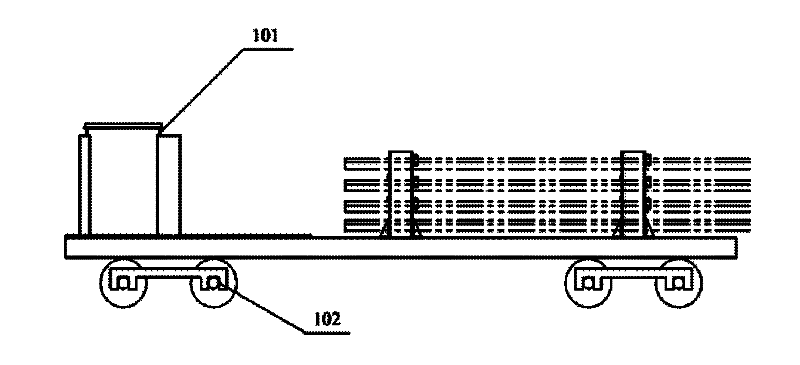

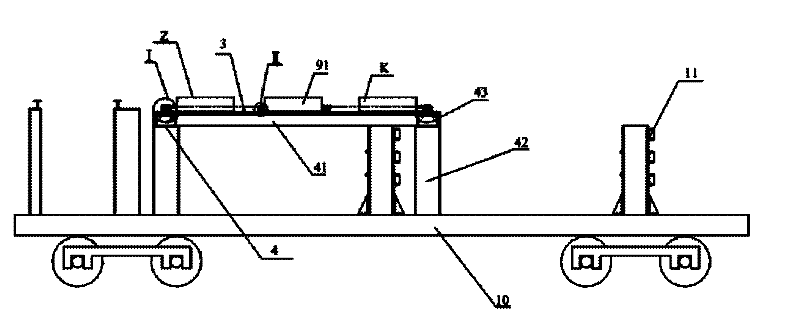

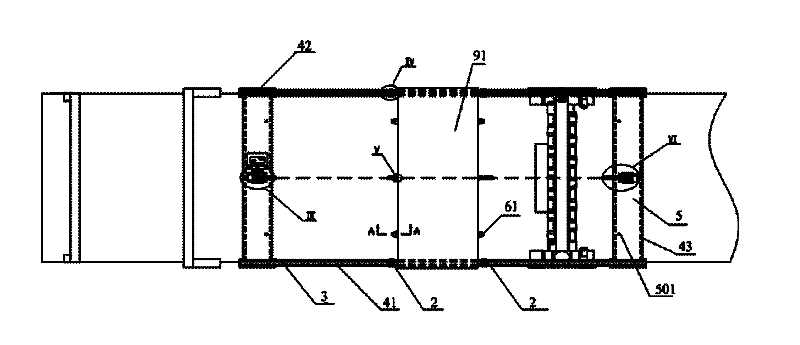

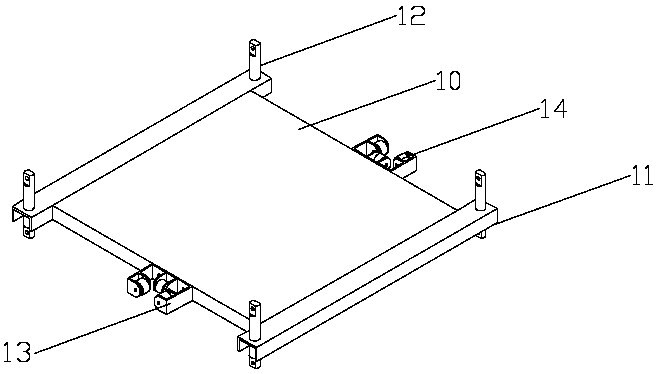

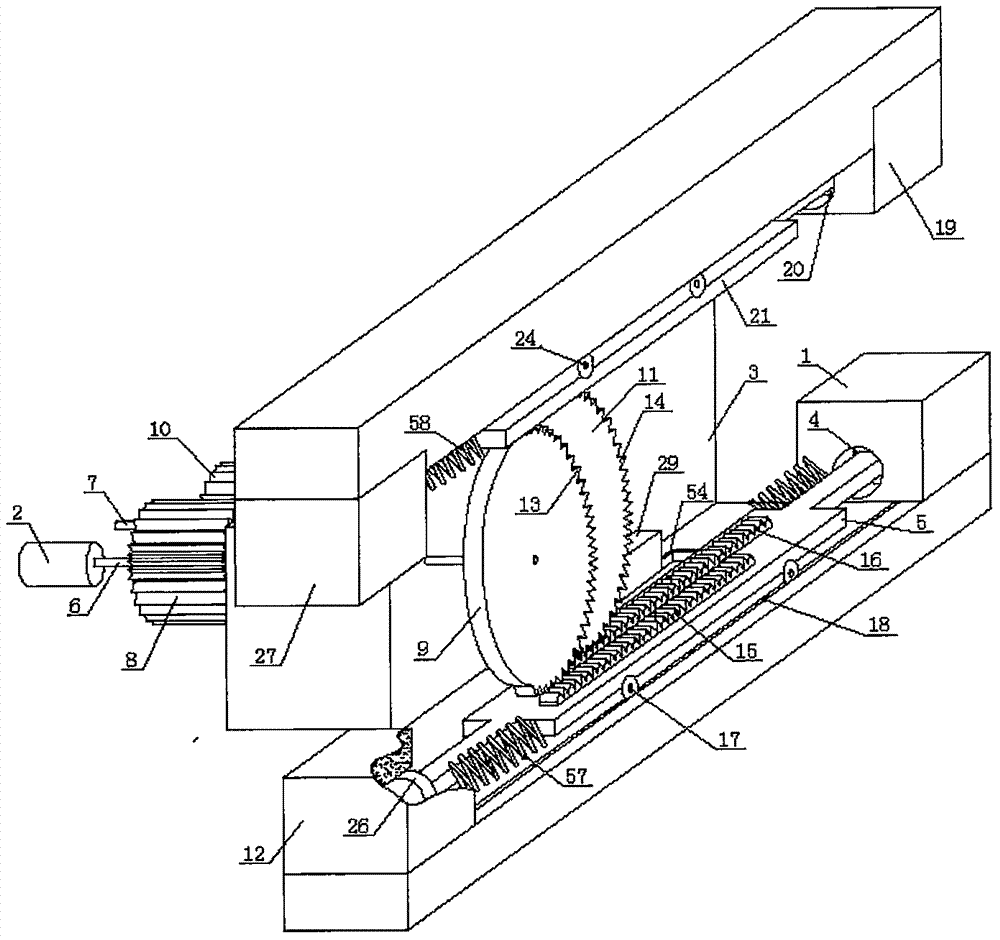

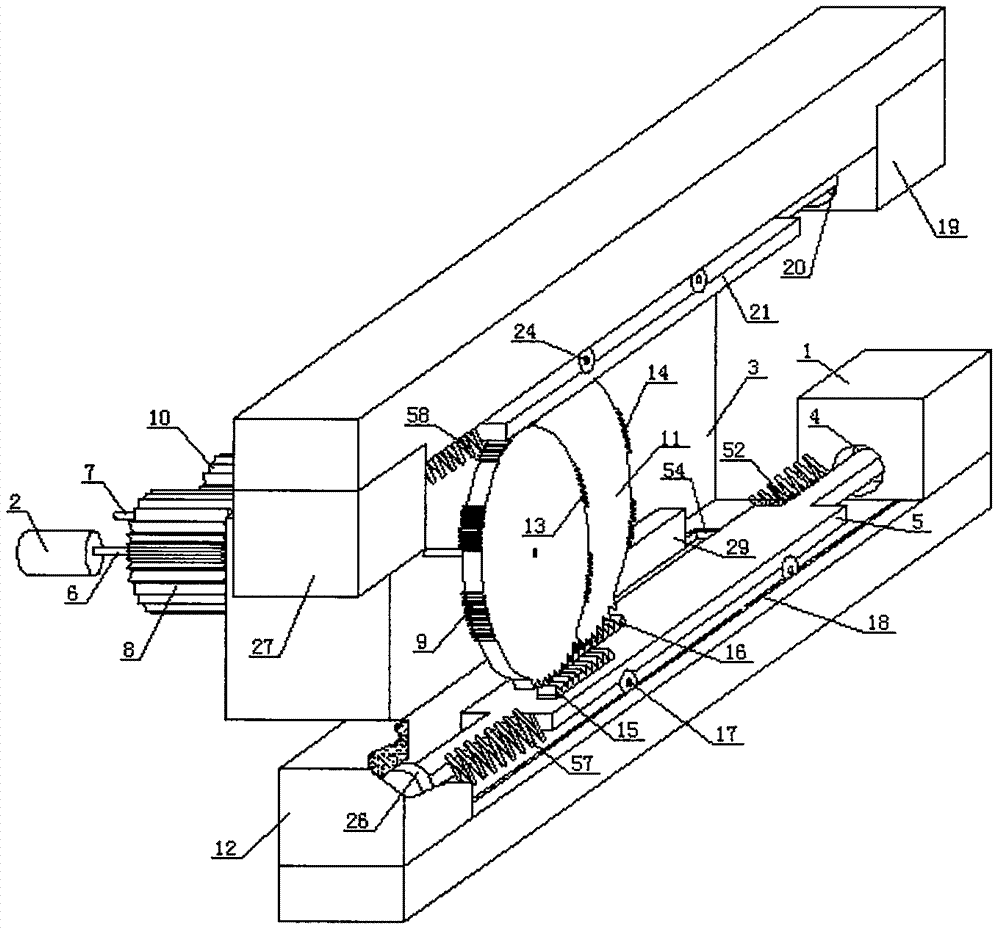

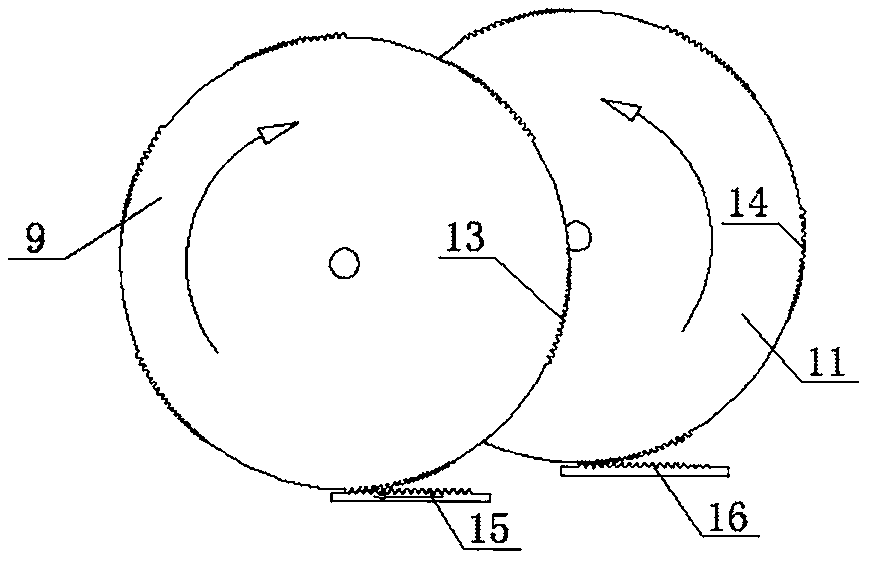

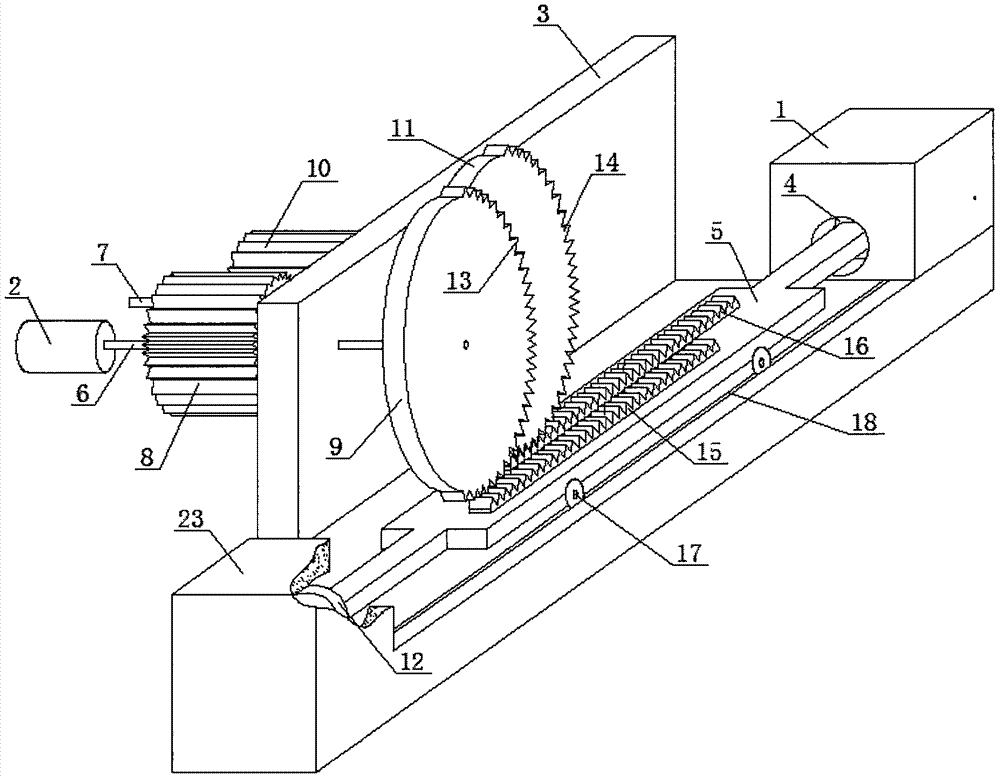

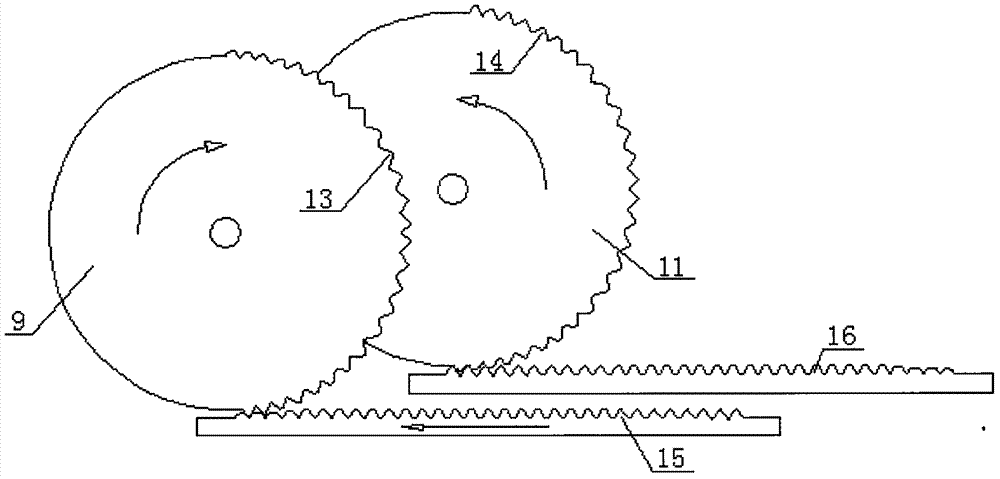

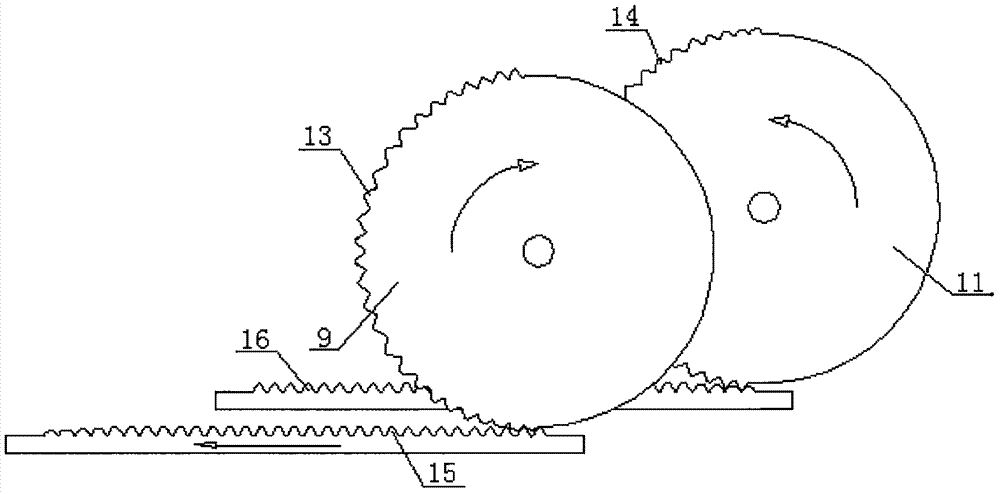

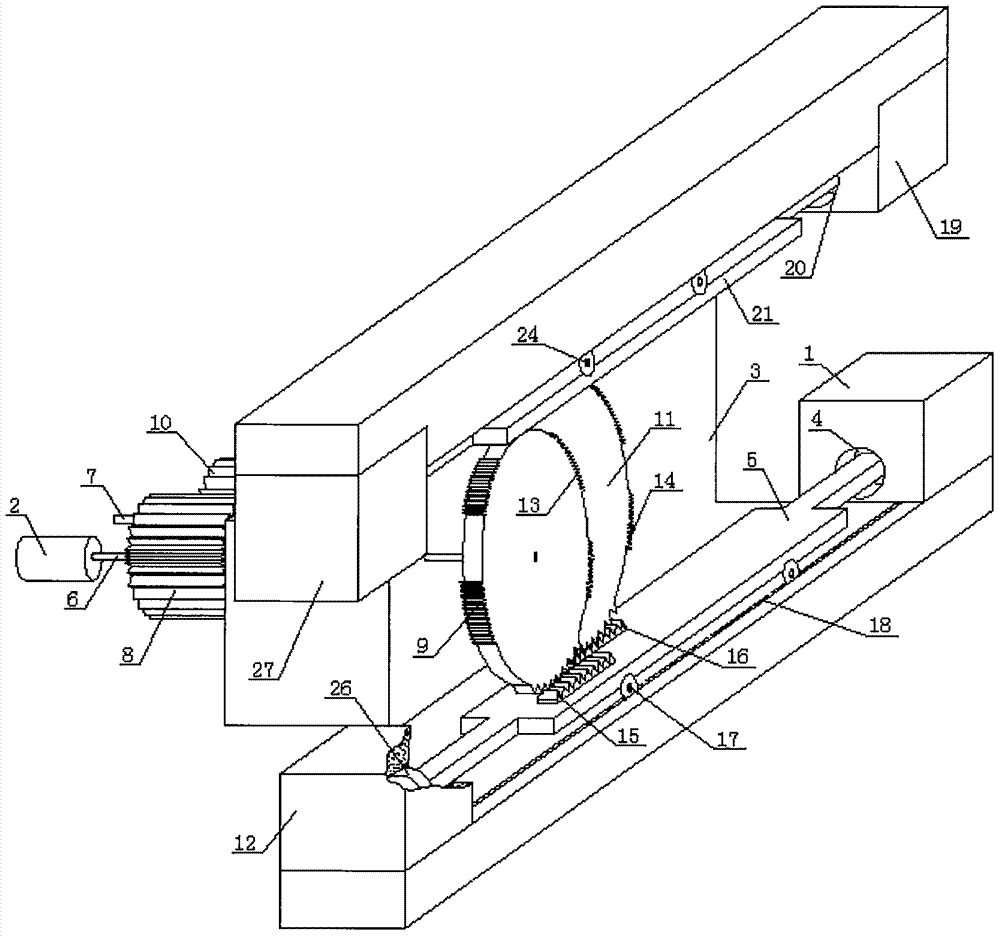

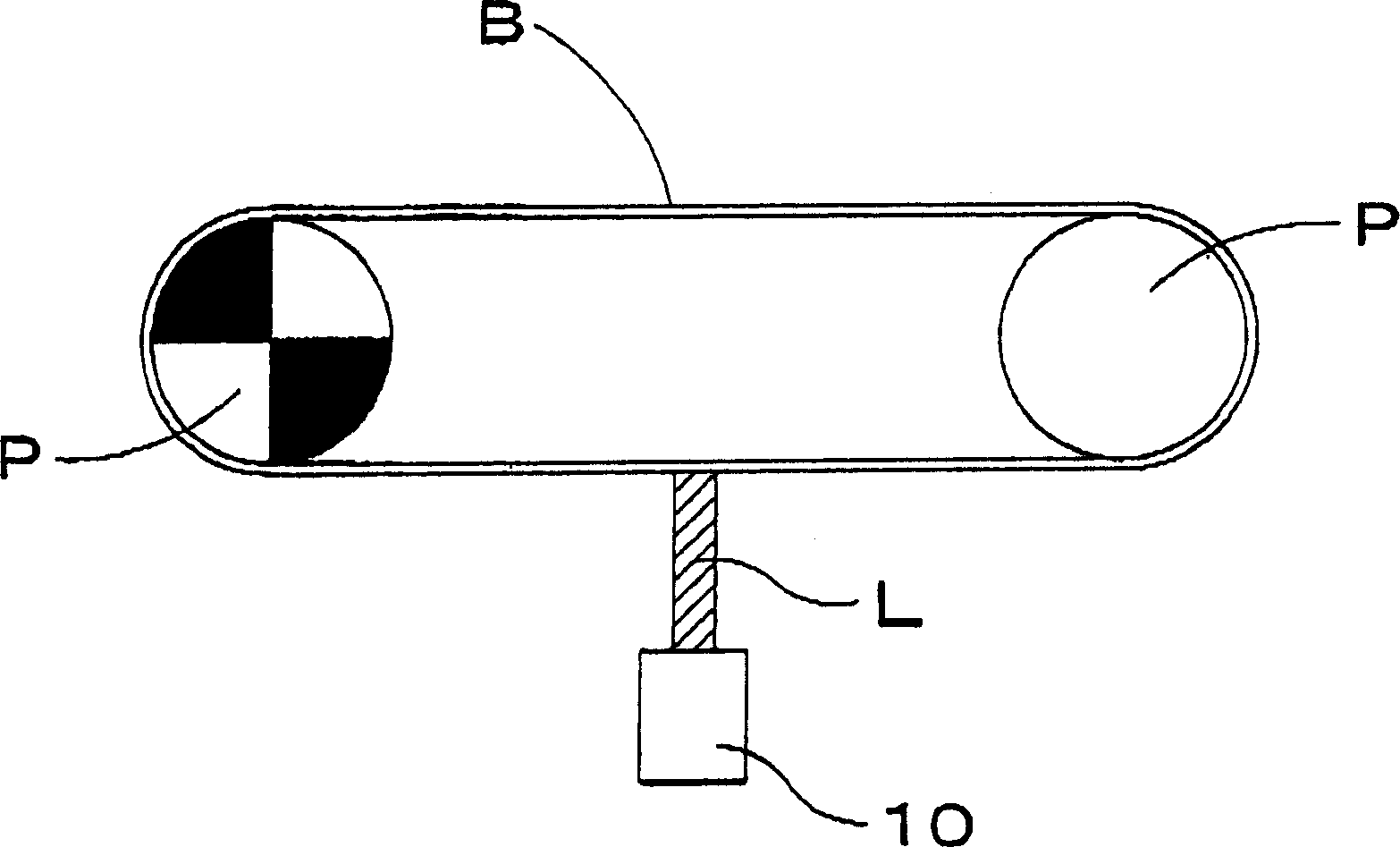

Security vehicle for long rail train set and long rail train set

ActiveCN102529989AEliminate partial wearExtended service lifeWagons/vansCargo supporting/securing componentsBogieDerailment

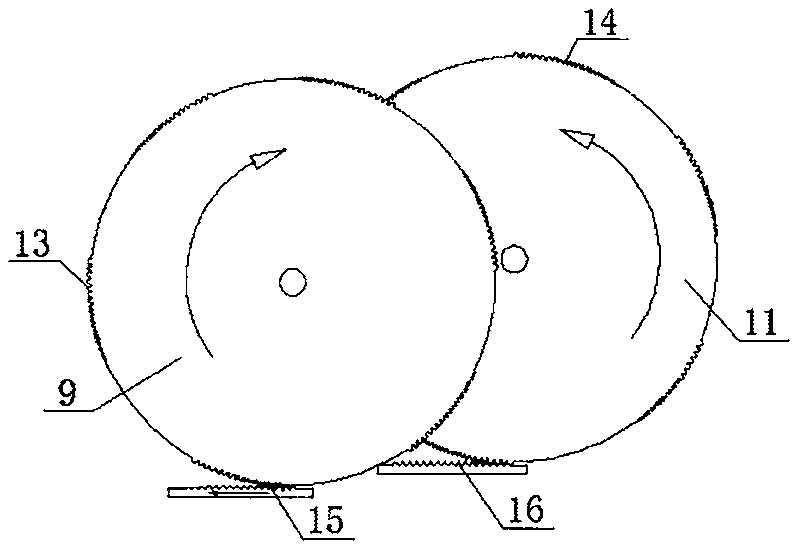

The invention provides a security vehicle for a long rail train set and the long rail train set. The security vehicle comprises a security vehicle body. A mounting rack is fixedly arranged on the upper surface of the security vehicle body. A longitudinally extended guide rail is fixedly arranged on each of the two sides of the security vehicle body above the security vehicle body. An iron balancing weight is arranged on each of the guide rails in a sliding way. A guide component is arranged on each of the iron balancing weights. Two longitudinally arranged sprocket wheel devices are fixedly arranged between the two guide rails. Each sprocket wheel device comprises two support parts arranged oppositely. A wheel shaft is transversely arranged on each of the support parts. A sprocket is fixedly sleeved on each of the wheel spindles. The two sprockets are driven by a haulage chain wound on the two sprockets. The haulage chains are fixedly connected with the iron balancing weights to drive the iron balancing weights to longitudinally slide. According to the security vehicle for the long rail train set and the long rail train set, the eccentric wear phenomenon of a steering rack of the security vehicle body in no-load running is avoided, so that the service life of the steering rack is prolonged; and the probability of derailment in running is reduced.

Owner:CRRC SHENYANG CO LTD

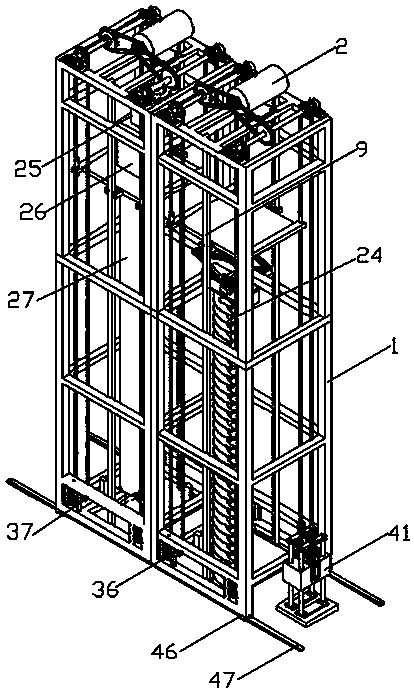

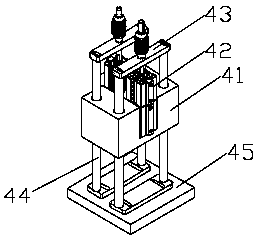

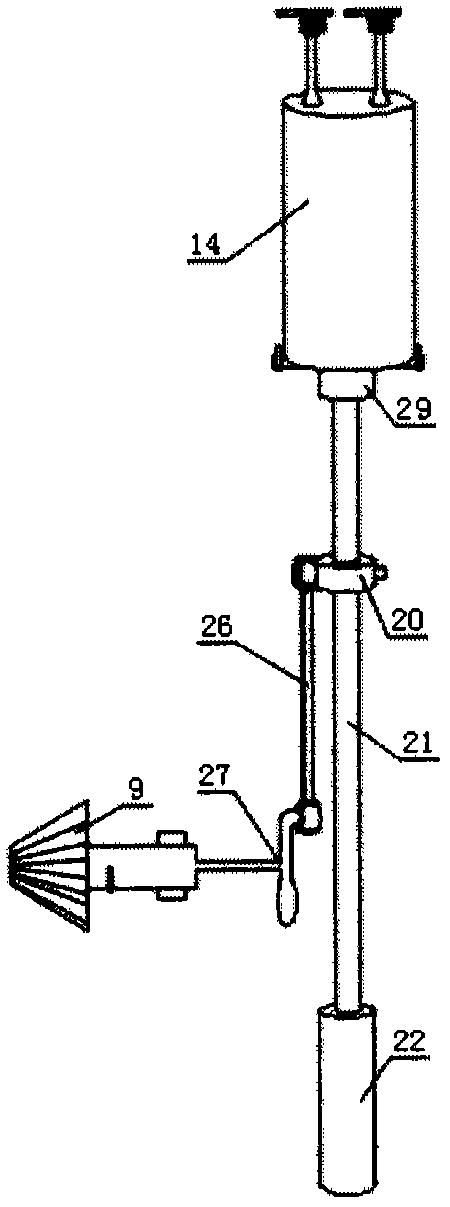

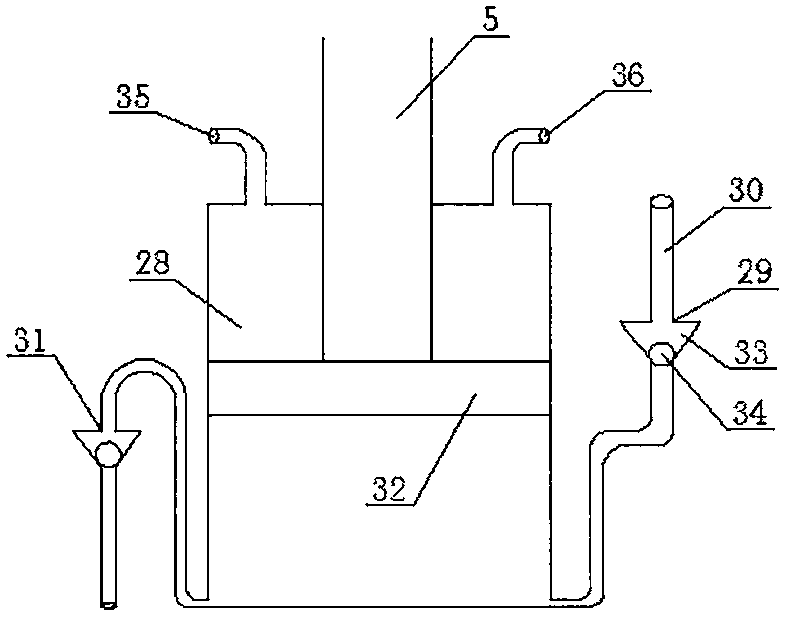

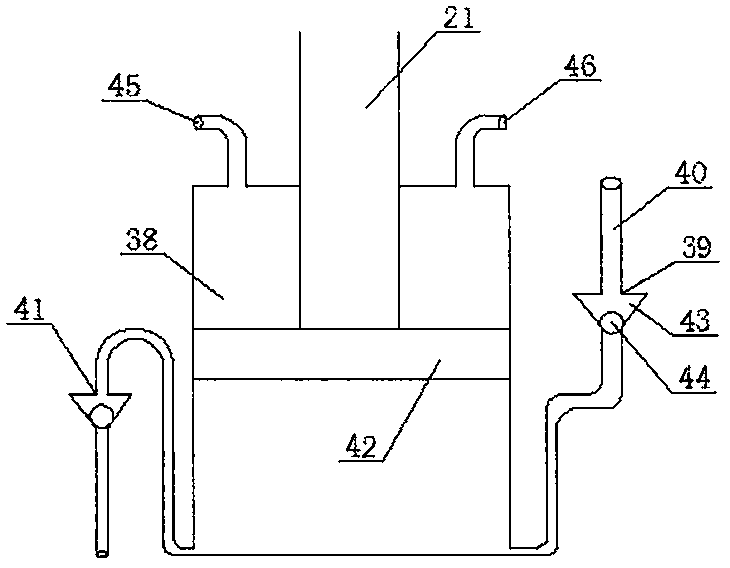

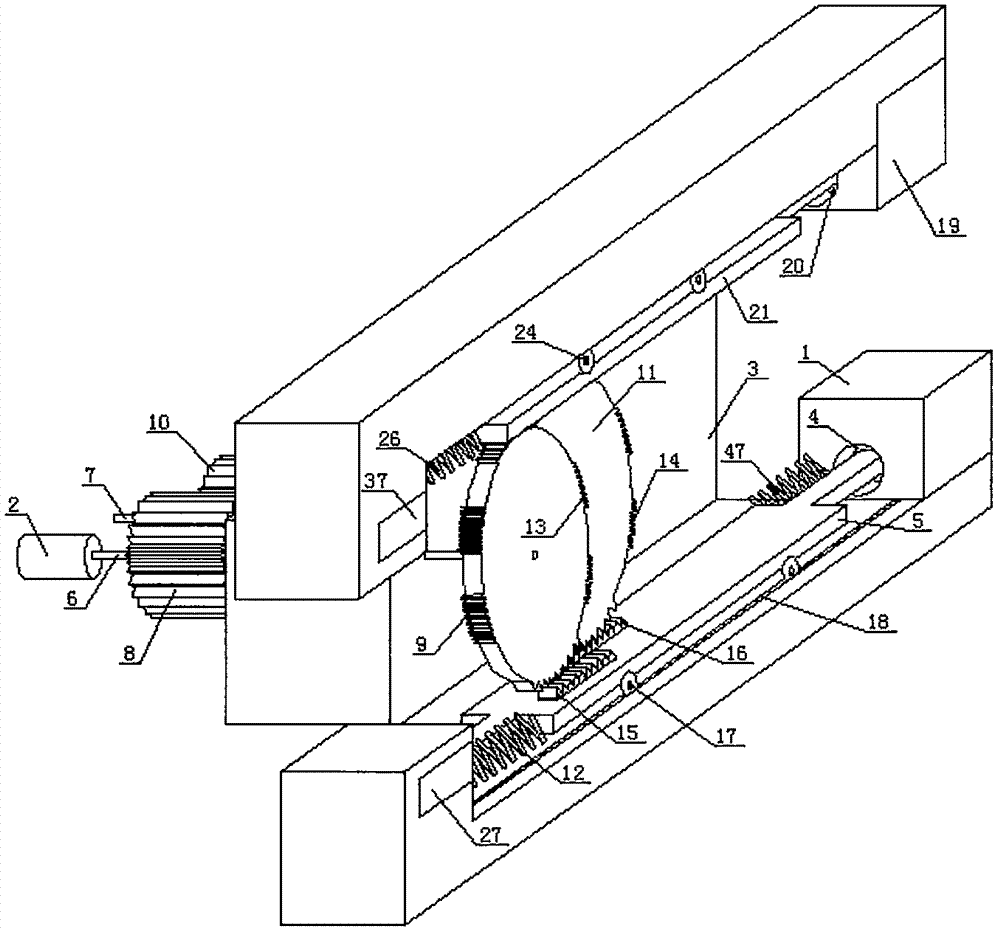

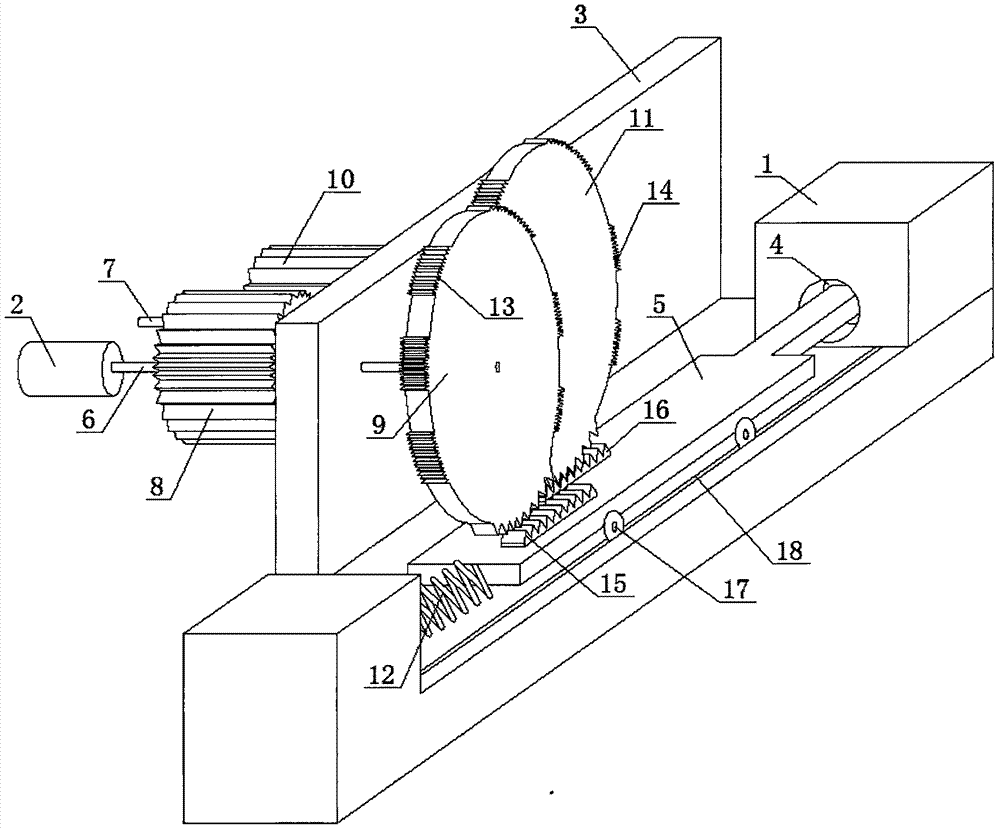

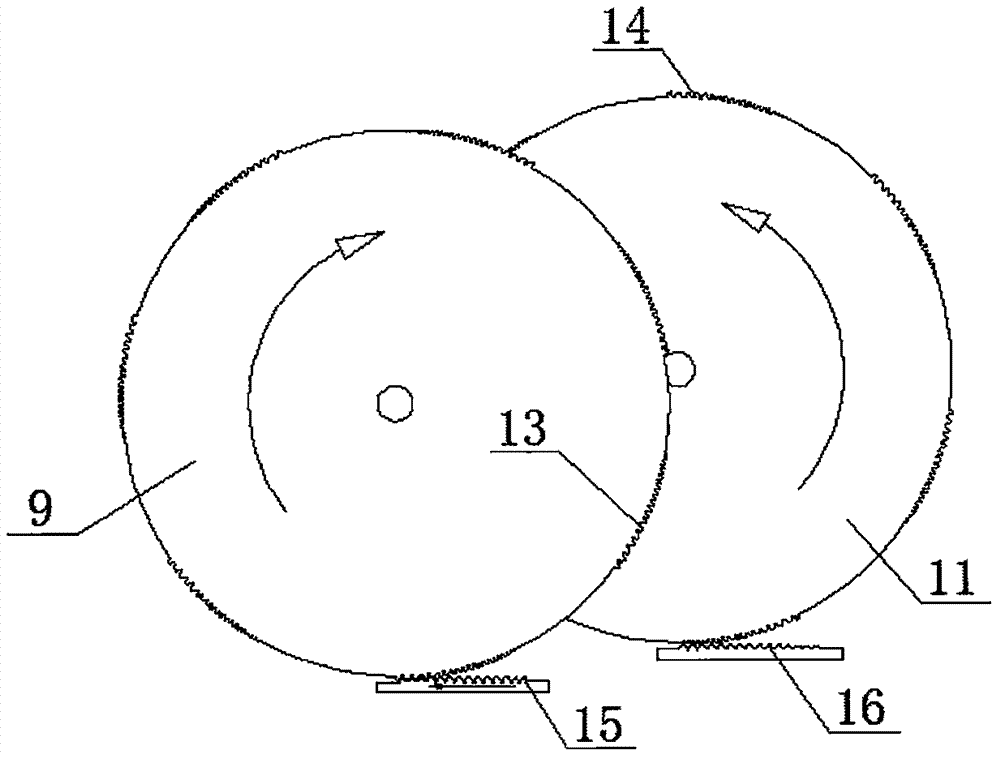

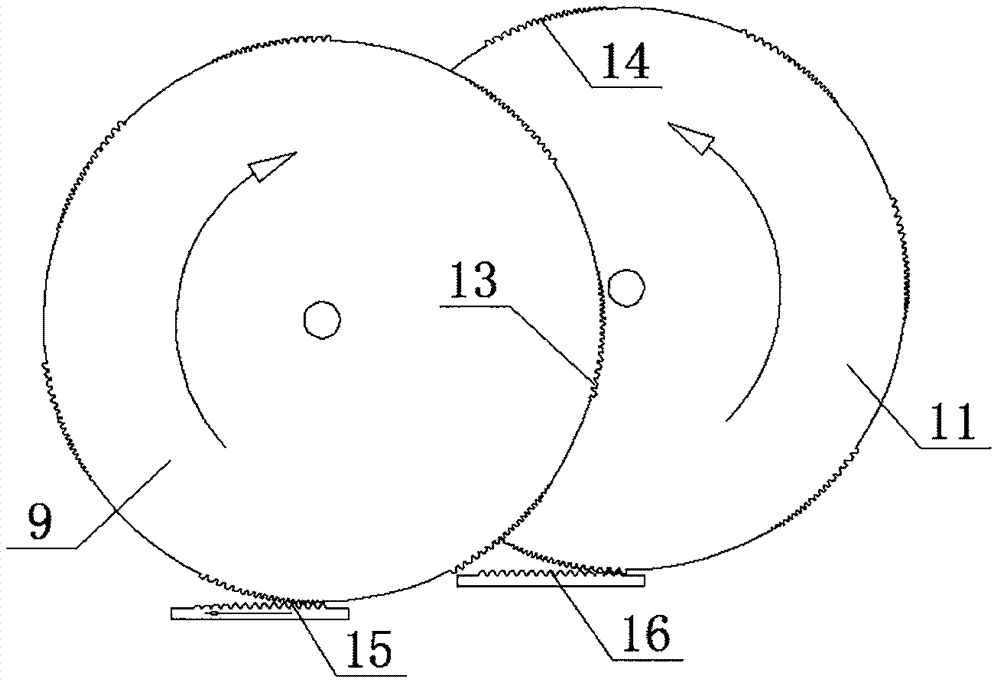

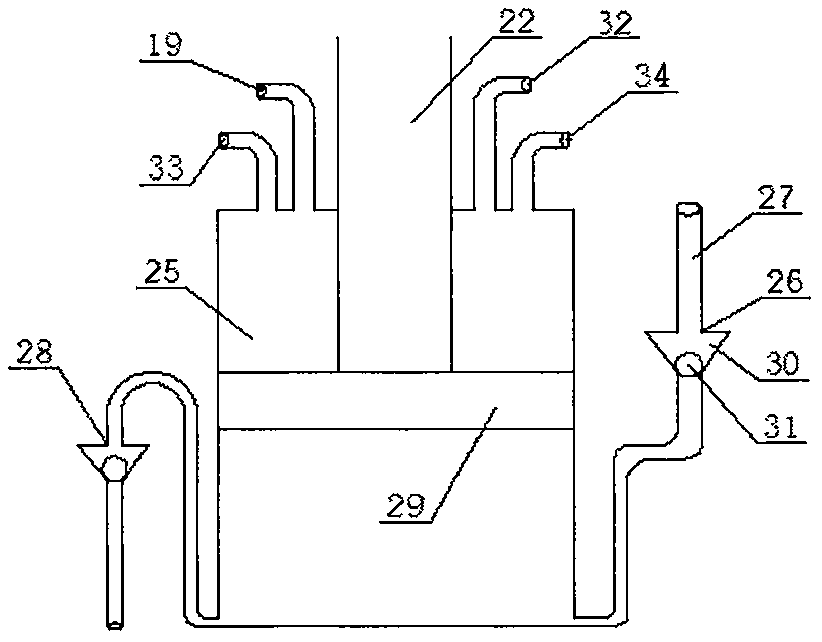

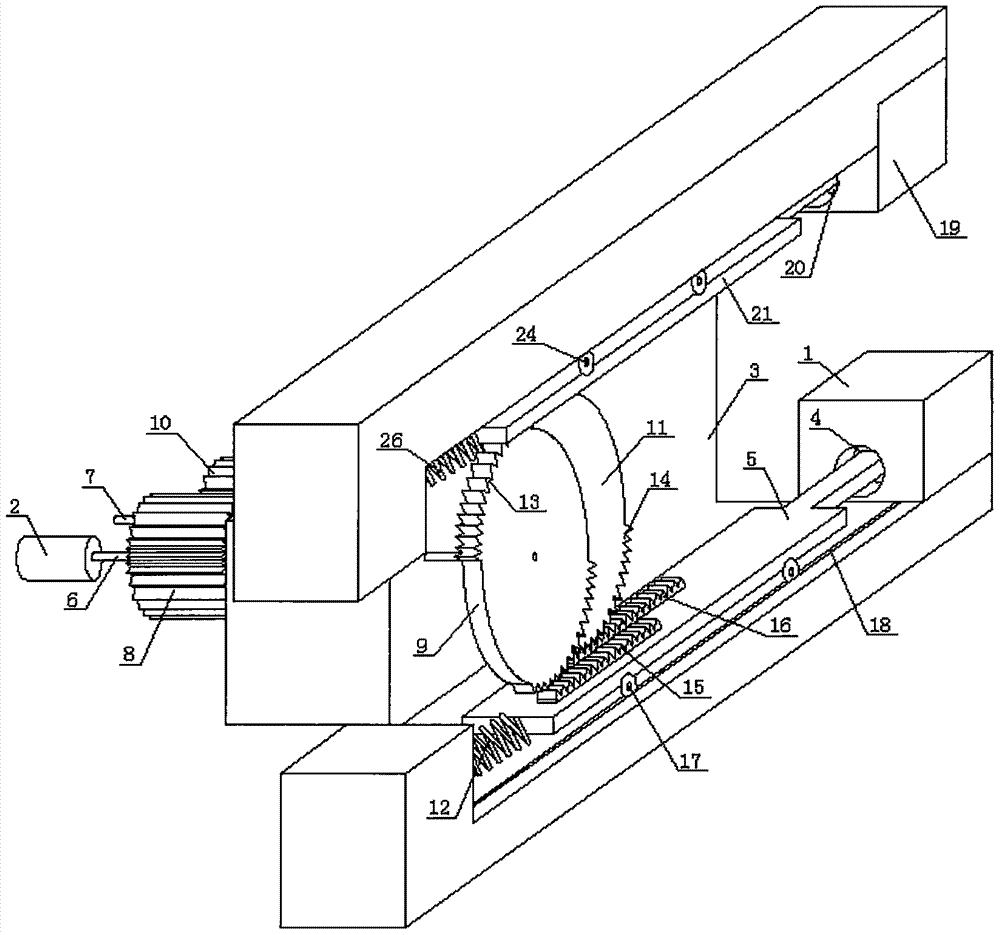

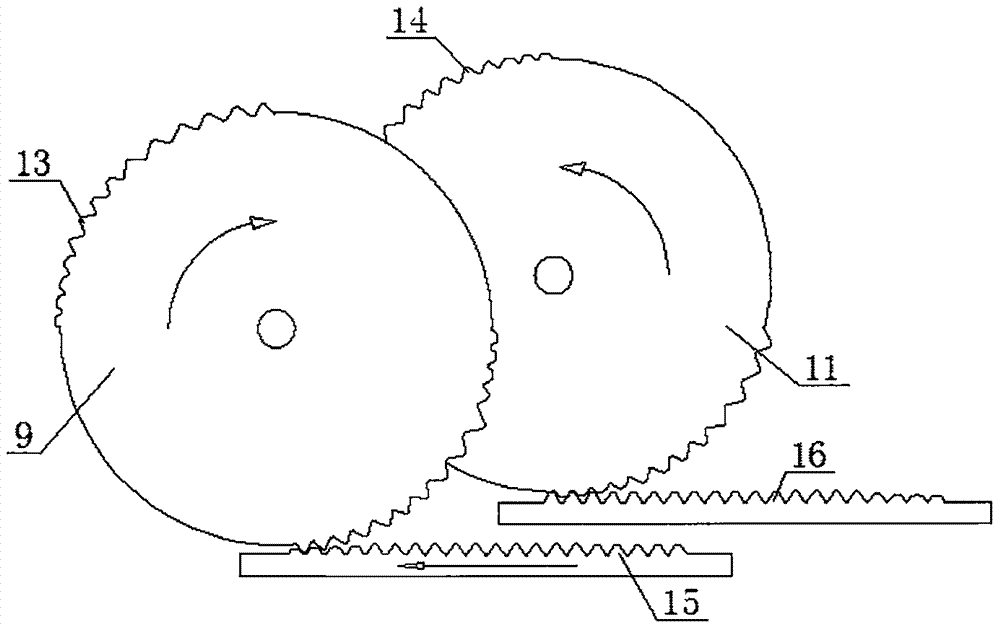

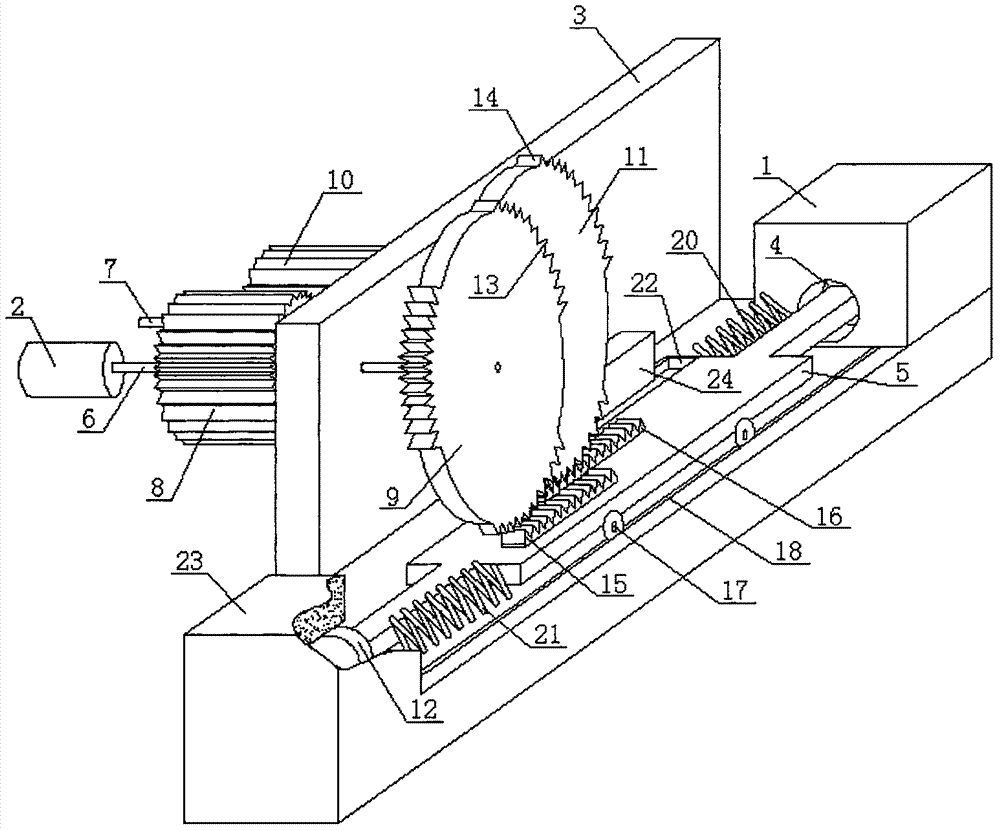

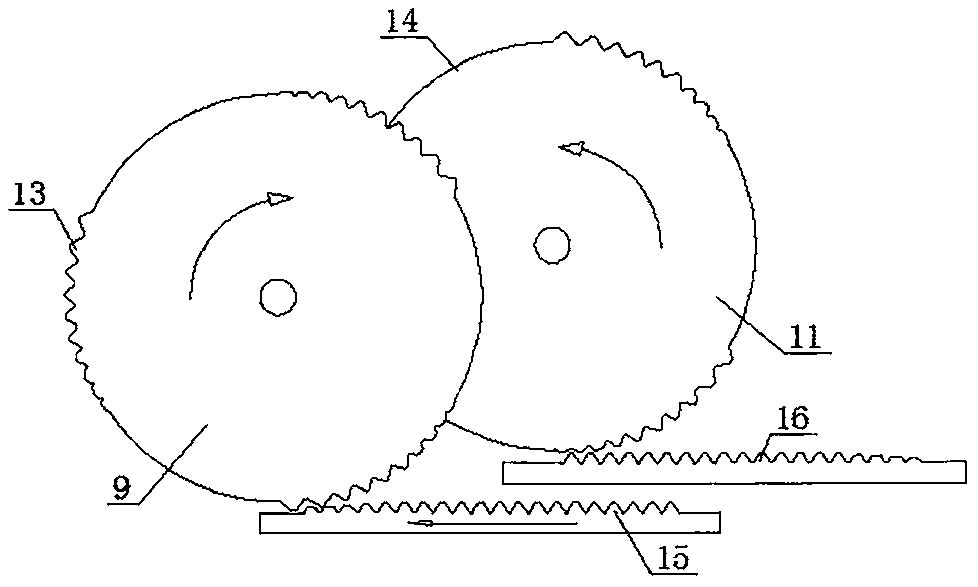

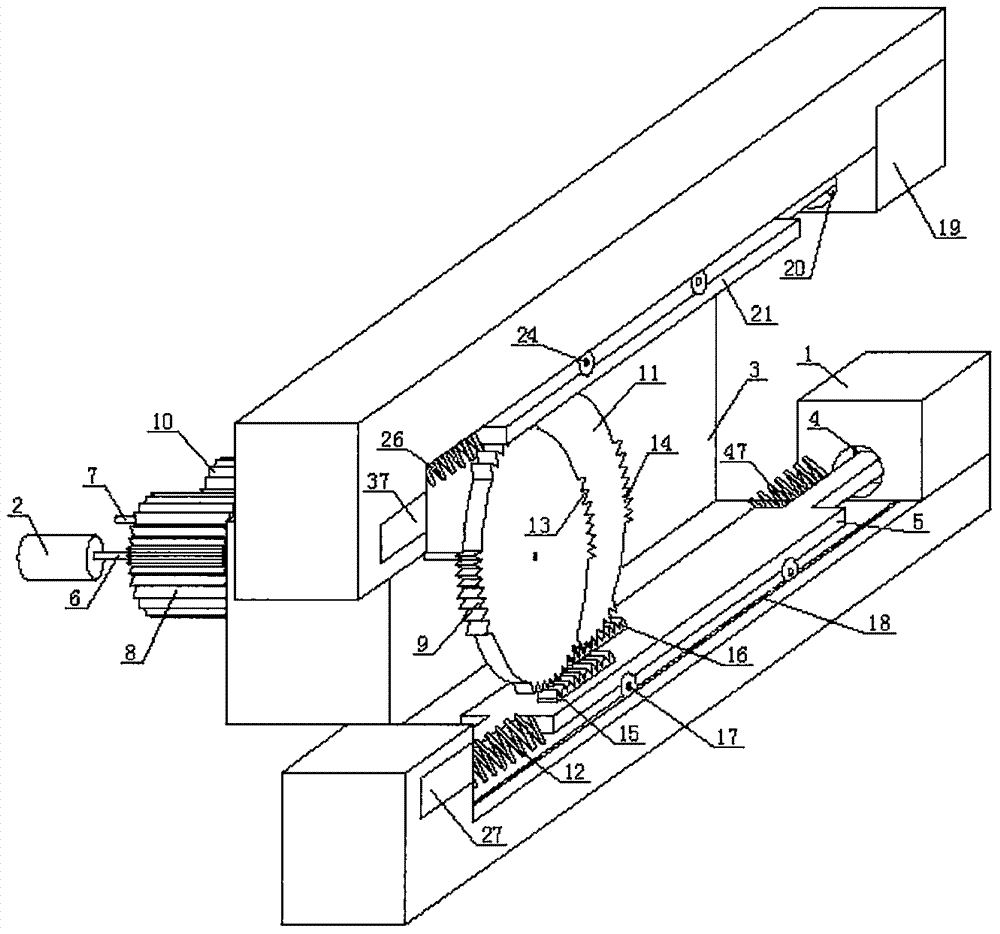

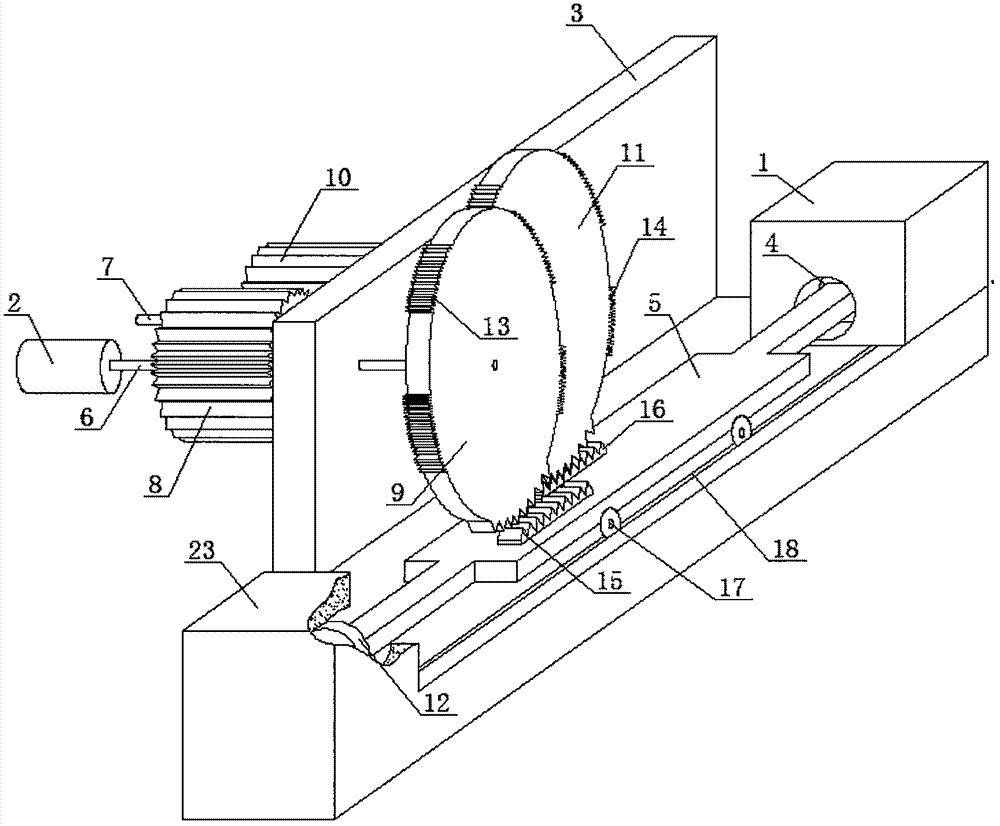

Direct-drive type ground screw pump oil production device and operating method thereof

The invention discloses a direct-drive type ground screw pump oil production device and an operating method thereof. The direct-drive type ground screw pump oil production device comprises two supporting frames which are of the same structure and are welded to each other. A first motor is installed on the top of each supporting frame. A dual-row toothed chain wheel is installed at one end of an output shaft of each first motor. The dual-row toothed chain wheels are in transmission connection with a first chain wheel and a second chain wheel through chains. The first chain wheel sleeves a firstchain wheel shaft, and the second chain wheel sleeves a second chain wheel shaft. The two ends of the first chain wheel shaft and the two ends of the second chain wheel shaft are each sleeved with anupper chain wheel. Through foundation supporting plates on the two sides of the two supporting frames, during well mouth excavation and oil production, the two supporting frames can be fixed to the ground, the shaking situation of the supporting frames caused by the vibration generated by a spiral auger during well mouth excavation and the vibration generated by shell oil pumping during oil production is effectively avoided, and the technical problems that an oil production device cannot meet the excavation requirement of an oil well and meanwhile the shaking of the supporting frames can be caused during oil production in the prior art are solved.

Owner:陈忠

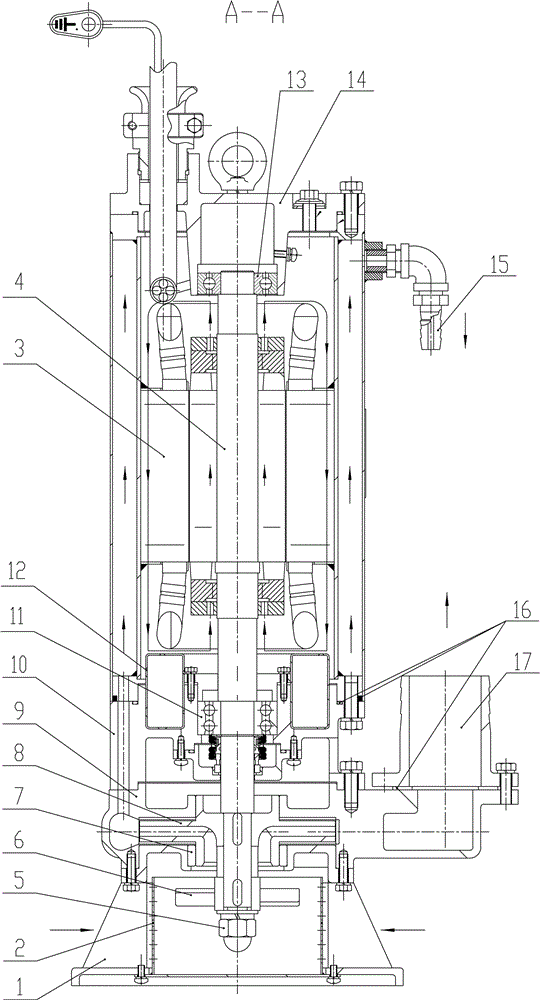

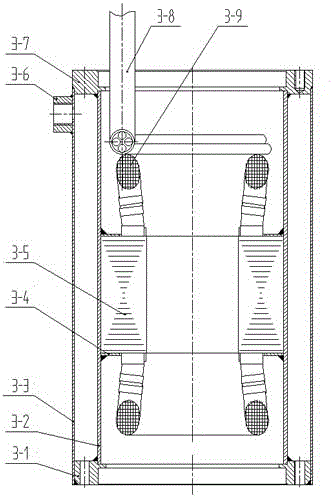

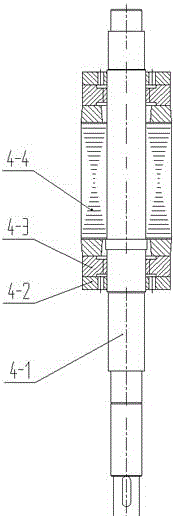

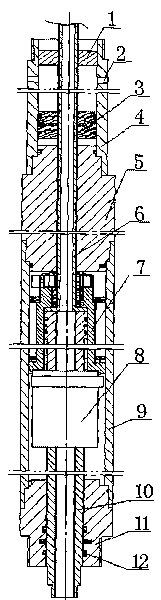

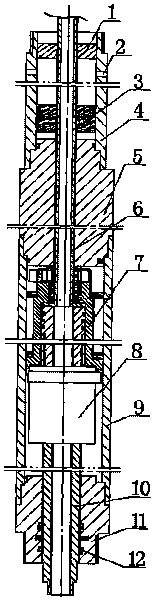

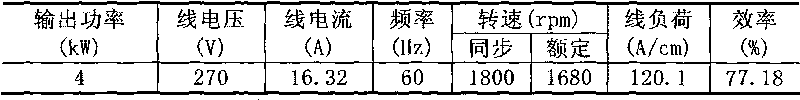

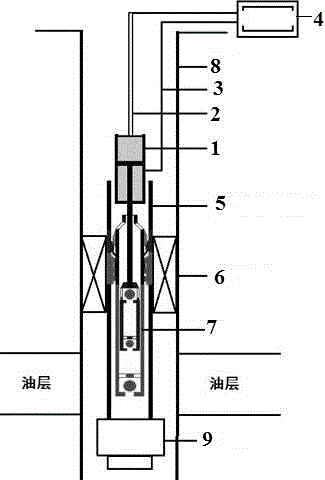

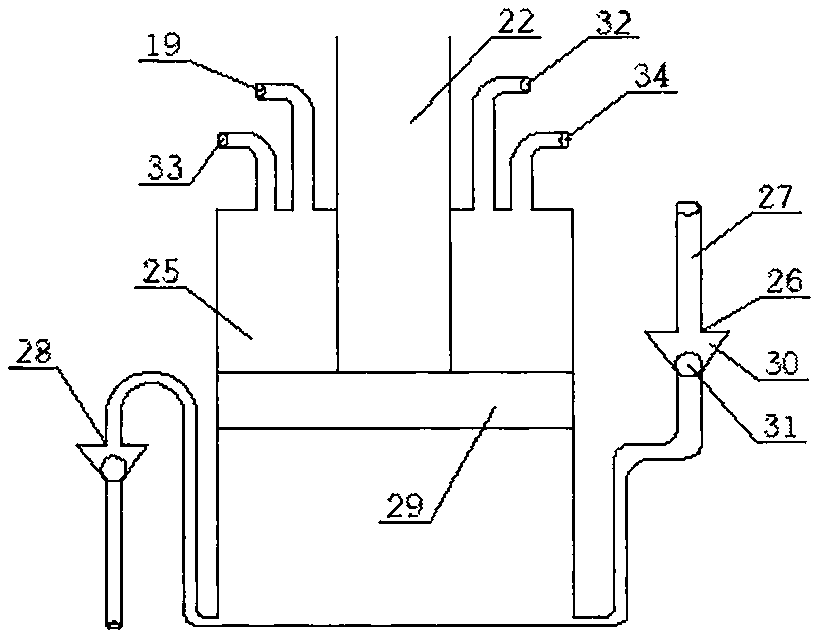

Flameproof submersible electric pump for dual-cooling efficient mining

ActiveCN105736399AImprove reliabilityExtended service lifePump componentsPump installationsElectricityImpeller

The invention relates to a flameproof submersible electric pump for dual-cooling efficient mining. According to the flameproof submersible electric pump, an oil-immersed motor as well as a water and oil resistant winding wire are adopted; a closed ring-shaped pressure regulating capsule is arranged in the inner cavity of the motor; a dual-cooling structure that strong water cooling in the outer cavity of the motor and self-circulation oil cooling in the inner cavity of the motor are combined is adopted for motor cooling; a mixed flow blade structure is arranged in front of the inlet of an impeller, a turbulent-flow-free balancing axial thrust technology is adopted for the inlet of the impeller, and no axial thrust balancing hole is formed, so as to solve the problem of liquid flow turbulence at the inlet of the impeller as well as effectively improve the axial thrust balancing effect and the pumping efficiency; and an electric pump shaft is in rolling bearing connection with an upper bearing seat and a lower bearing seat, so as to eliminate the phenomenon of eccentric abrasion caused by an improper electric pump mounting position. The flameproof submersible electric pump provided by the invention has the beneficial effects of being simple in structure, high in reliability, strong in practicability, efficient, and good in heat dissipation performance; furthermore, the flameproof submersible electric pump is simple to mount and wide in using range, and can be operated under various working conditions; and wastewater is pumped thoroughly, the total head is prevented from overloading, and the service life of the flameproof submersible electric pump is long.

Owner:河北省机械科学研究设计院有限公司

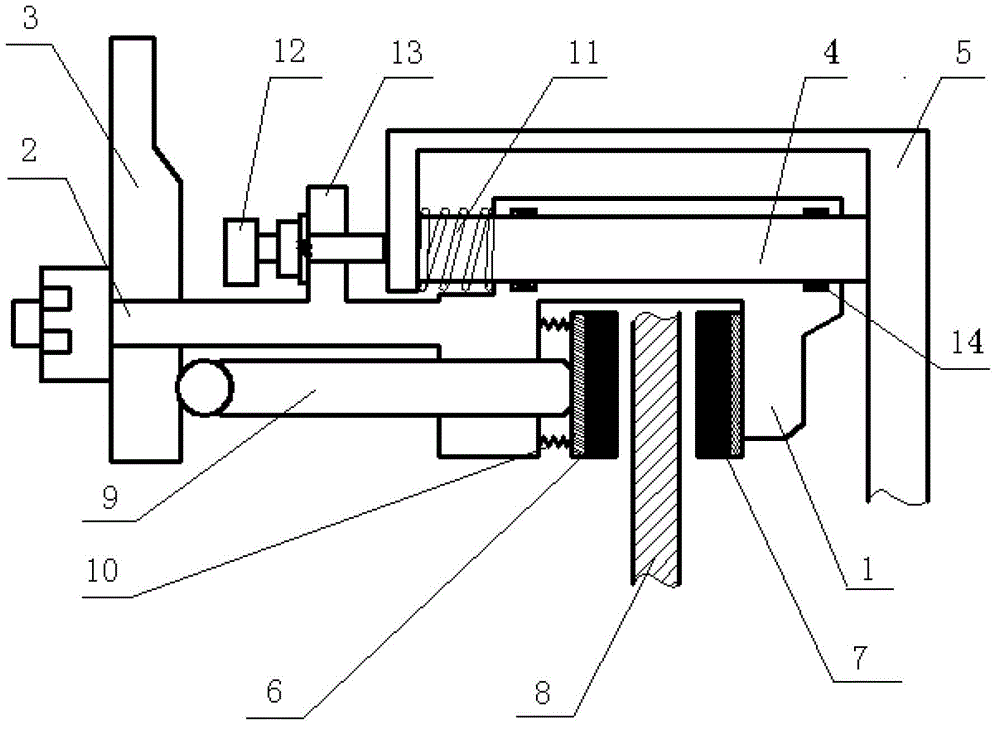

Floating caliper disc center brake with automatic return mechanism

The invention provides a floating caliper disc center brake with an automatic return mechanism, which comprises a center brake caliper body, a rocker arm shaft, a rocker arm, a sliding pin, a sliding pin bracket, a front brake shoe, a rear brake shoe, a center brake disc, a brake lifting pin assembly and a front friction block return spring, wherein the rocker arm shaft and the rocker arm are connected with the center brake caliper body; the sliding pin passes through the center brake caliper body; the front brake shoe and the rear brake shoe are arranged on the center brake caliper body; the center brake disc is positioned between the front brake shoe and the rear brake shoe; a compression spring is sleeved on the sliding pin between the rear end of the center brake caliper body and the sliding pin bracket; a limit plate extends out of the center brake caliper body; a gap adjustable stop screw is arranged on the limit plate; the rod end of the gap adjustable stop screw corresponds to the sliding pin bracket at the position of the compression spring; rectangular sealing rings are arranged at both ends of the sliding pin in the center brake caliper body; in an initial state, the gap adjustable stop screw is attached to the sliding pin bracket; and the gap adjustable stop screw and the sliding pin are coaxially arranged.

Owner:DONGFENG OFF ROAD VEHICLE CO LTD

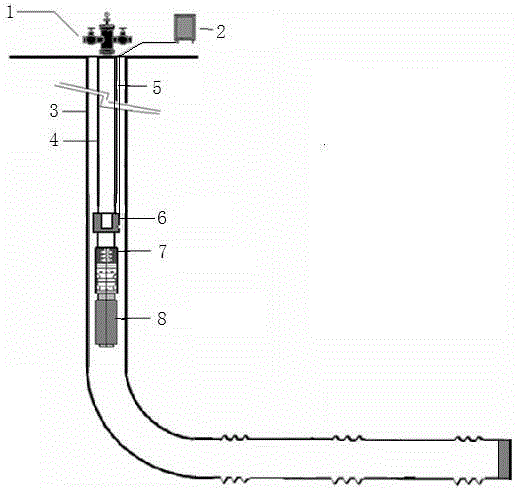

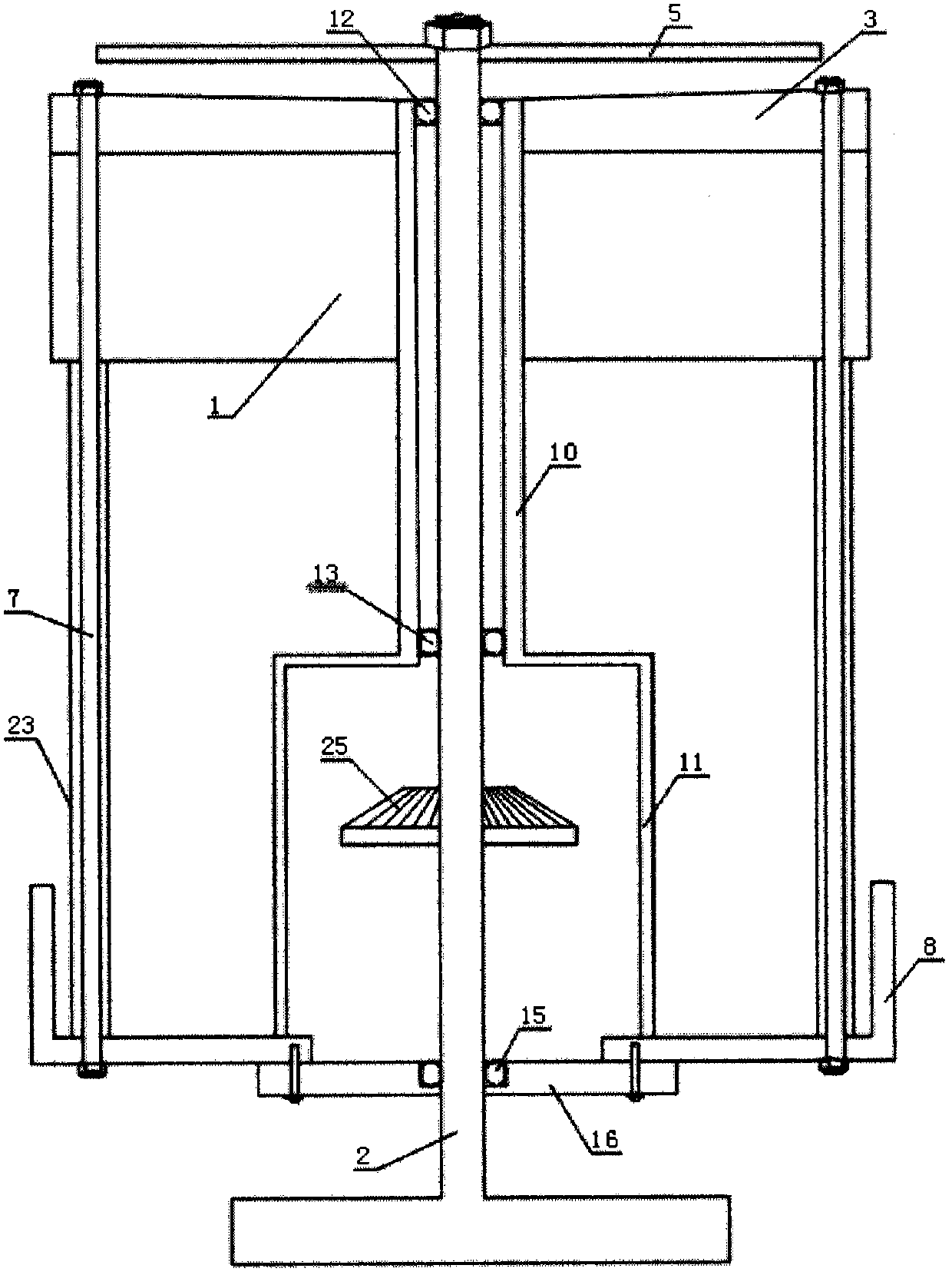

Rodless oil extraction system driven by underground rotation motor

ActiveCN101701515AImprove pump efficiencyImprove system efficiencyFluid removalMechanical energy handlingDirectional wellReciprocating motion

The invention relates to a rodless oil extraction system driven by an underground rotation motor and applied to the technical field of oil extraction in oil fields. The rodless oil extraction system comprises a pressure balance device, a three-phase asynchronous rotation motor, a mechanical transformation mechanism, a lower cylinder tube and a lower stopper. A balance piston and an upper spacing ring are arranged in an upper cylinder tube, a ventilation hole is arranged on the wall of the upper cylinder tube, the lower end of the upper cylinder tube is fixedly provided with the three-phase asynchronous rotation motor, the center of a motor shaft is provided with an axial through hole, the lower end of the three-phase asynchronous rotation motor is fixedly provided with the lower cylinder tube and the lower stopper, the mechanical transformation mechanism is arranged in the lower cylinder tube and comprises a shaft coupling, a lead screw and a nut, the upper end of the shaft coupling is connected with the motor shaft, the lower end of the shaft coupling is connected with the nut, and the lower end of the lead screw penetrates through a center hole of the lower stopper. The motor shaft drives the nut to rotate by the shaft coupling, the lead screw makes a linear reciprocating motion under the drive of the nut, and an oil pumping pump is driven to realize lifting oil pumping. The rodless oil extraction system driven by the underground rotation motor solves the problem of lopsided wear of a rod pipe existing in a directional well, enhances the efficiency of the oil pumping pump and lowers the energy consumption.

Owner:PETROCHINA CO LTD

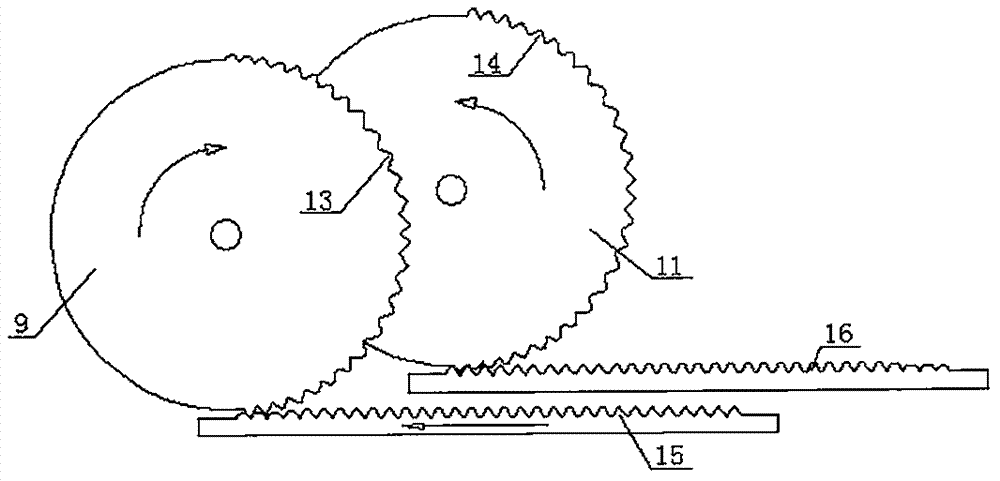

Pushing-rod single-movable-tooth efficient lubricant transmission four-cylinder internal combustion engine

InactiveCN107420197ASimple structureReasonable designMachines/enginesLubrication pressure controlEffective powerExternal combustion engine

The invention discloses a pushing-rod single-movable-tooth efficient lubricant transmission four-cylinder internal combustion engine, and relates to the field of internal combustion engine transmission. The problems that a current crankshaft connecting rod internal combustion engine is large in volume, prone to eccentrically being worn, high in energy consumption, low in power, high in manufacturing precision and the like are solved. A engine body of the pushing-rod single-movable-tooth efficient lubricant transmission four-cylinder internal combustion engine is fixedly provided with a driving rotating shaft and a driven rotating shaft through a bearing. A driving movable tooth and a driven movable tooth are half of a driving movable tooth disc and a driven movable tooth disc. A first air cylinder and a third air cylinder are corresponding arranged on the side, where the driving movable tooth disc is located on, of the driving movable tooth disc, a second air cylinder and a fourth air cylinder are corresponding arranged on the side, where the driven movable tooth disc is located on, of the driven movable tooth disc. A first pushing rod and a second pushing rod are correspondingly connected with a first lubricating oil conveying device and a second lubricating oil conveying device. The pushing-rod single-movable-tooth efficient lubricant transmission four-cylinder internal combustion engine is simple in structure and small in volume, eccentric wear prevention is achieved, the energy consumption is low, and the effective power is greatly improved.

Owner:邱秀芳

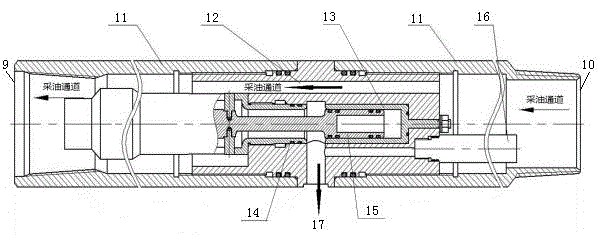

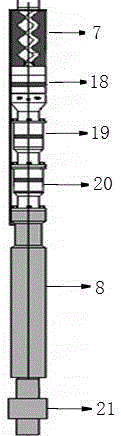

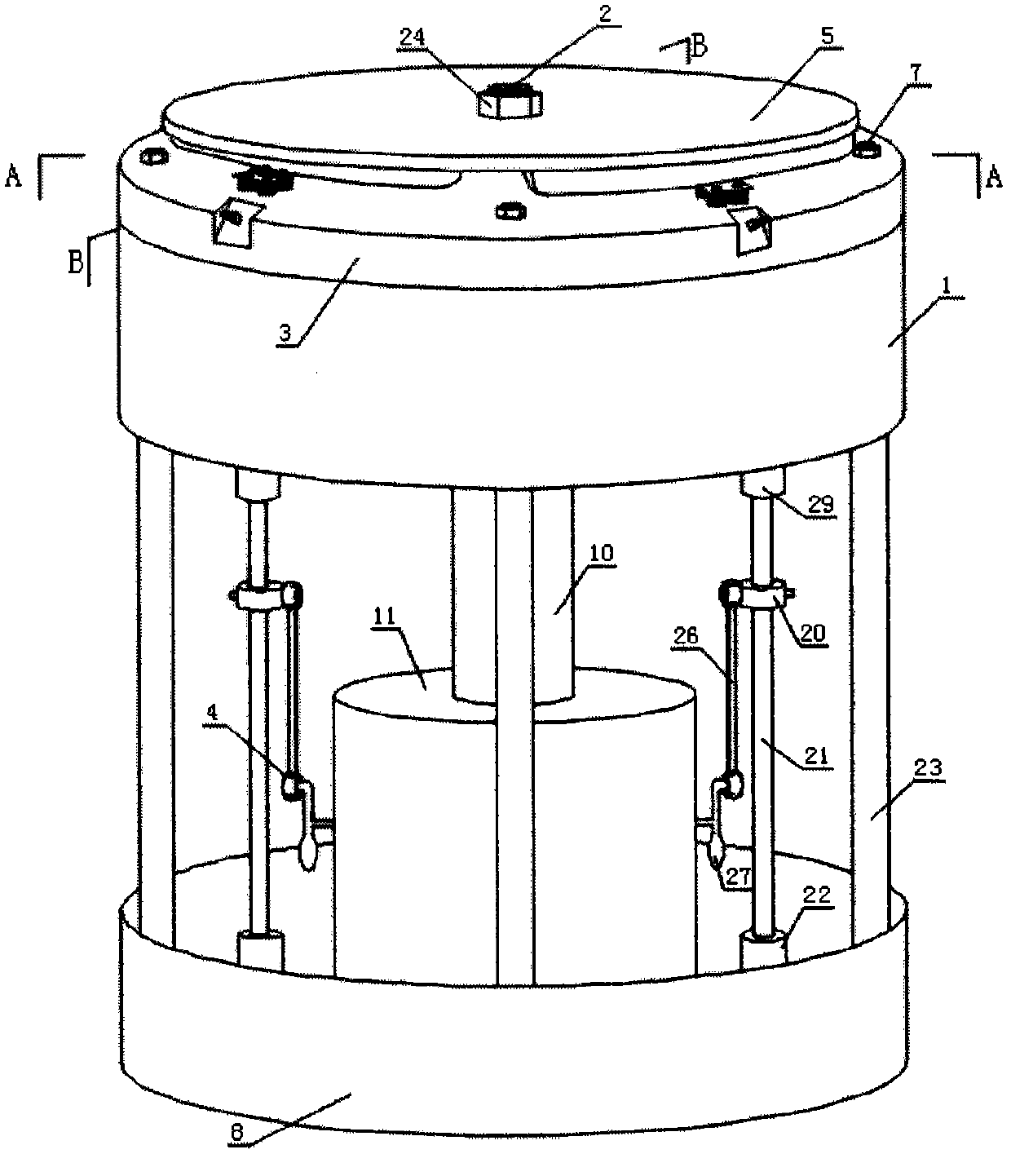

Huff-and-puff oil production device with submersible directly-driven screw pump

ActiveCN105422053AOptimize work processImprove construction efficiencyFluid removalWell/borehole valve arrangementsMarine engineeringElectric machinery

The invention provides a huff-and-puff oil production device with a submersible directly-driven screw pump. The huff-and-puff oil production device comprises an underground automatic water injection switch for realizing water injection and oil production channel switching and a submersible directly-driven screw pump, wherein a liquid outlet in the upper end of the underground automatic water injection switch is connected with an oil pipe, and a liquid inlet in the lower end of the underground automatic water injection switch is connected with an oil outlet in the upper end of the submersible directly-driven screw pump through the oil pipe; the submersible directly-driven screw pump comprises a screw pump, a flexible shaft, an upper protect tor, a lower protector, a submersible motor and a centralizer which are non-coaxially connected from top to bottom; the upper end of the screw pump is connected with the lower end of the underground automatic water injection switch; and the screw pump and the submersible motor are respectively electrically connected to a submersible cable outside a wellhead. The huff-and-puff oil production device is free of repeatedly tripping and has the characteristics of simple and convenient operation flow, high construction efficiency, safety, environment friendliness, low risk and the like; and due to the adoption of the lifting way, the huff-and-puff oil production device has the characteristics of low rotating speed and large torque and is suitable for a well with low liquid quantity, the eccentric wear of pipe poles is eliminated, the maintenance-free period of an oil well is prolonged, and the economic benefit can be effectively increased.

Owner:PETROCHINA CO LTD

Suspension type underground hydraulic rod type pumping production device

InactiveCN105464628AEliminate partial wearExtension of Advanced Standing PeriodFluid removalHydraulic cylinderHydraulic pump

The invention provides a suspension type underground hydraulic rod type pumping production device which comprises a hydraulic cylinder, a hydraulic pipe communicated with the hydraulic cylinder, a hydraulic control cabinet and a rod type oil-well pump. A hollow sucker rod is communicated to the upper end of the hydraulic cylinder. The hollow sucker rod and the other end of the hydraulic pipe are connected with the hydraulic control cabinet. The rod type oil-well pump is connected with the hydraulic cylinder. The rod type oil-well pump is arranged in an oil pipe. The hydraulic cylinder is arranged above the oil pipe. The lower portion of the oil pipe is provided with a supporting slip. The oil pipe is sleeved with a packer. Pipe rod eccentric wear is eliminated, and the oil well maintenance-free period can be prolonged; the hollow sucker rod is adopted as a hydraulic transmission pipe, the heat of high-temperature hydraulic oil can be transferred to a well shaft, and paraffinning is effectively prevented. The device adopts a casing pipe oil extraction mode, only one or two oil pipes are needed, the operation process is simplified, and the operation cost is reduced.

Owner:PETROCHINA CO LTD

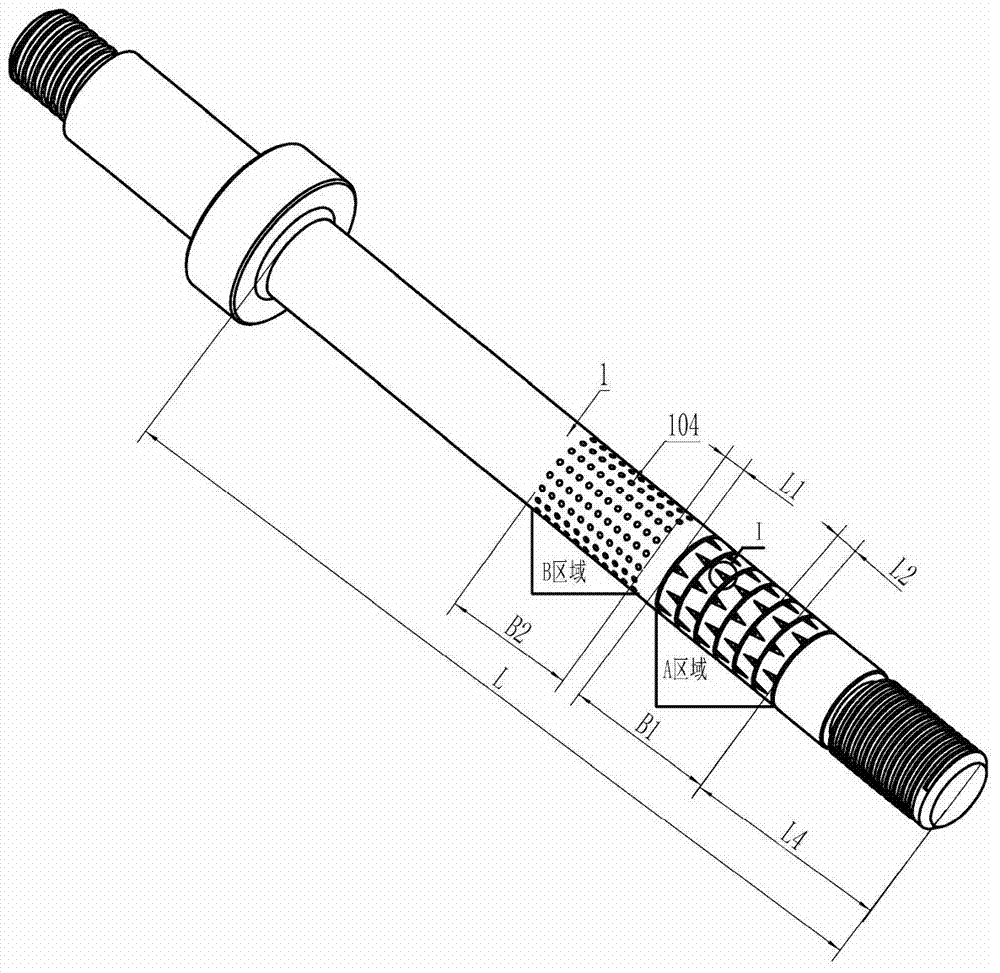

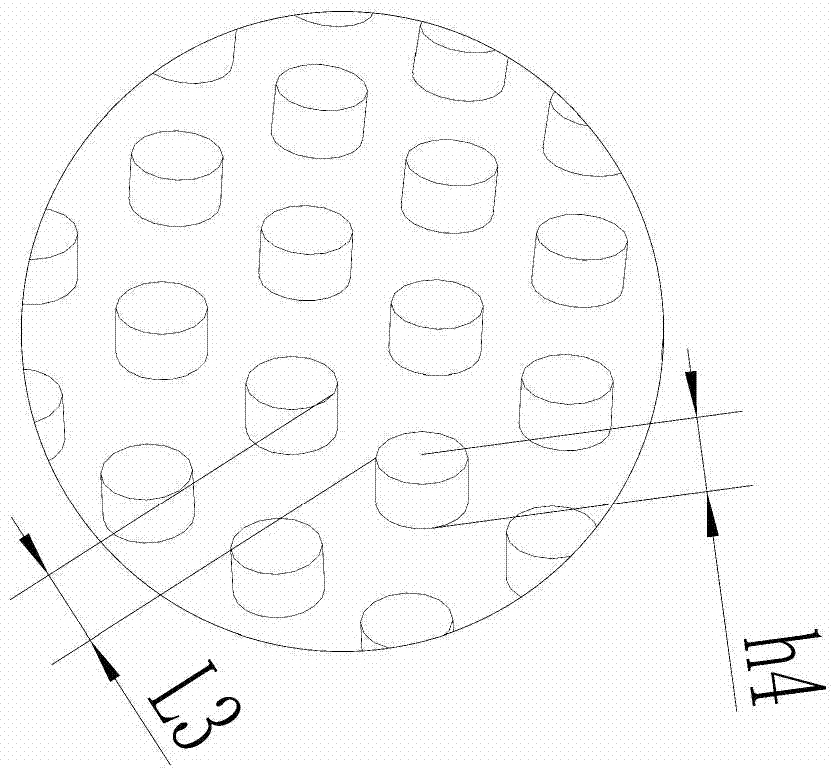

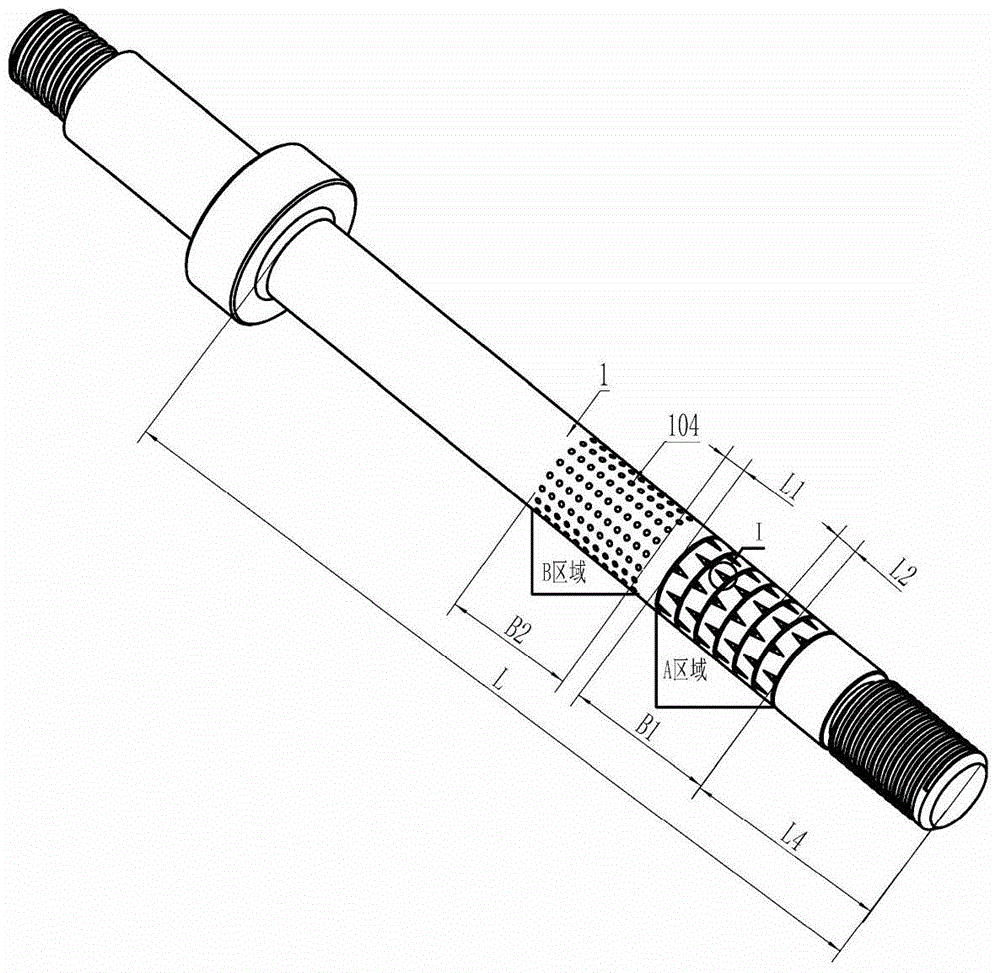

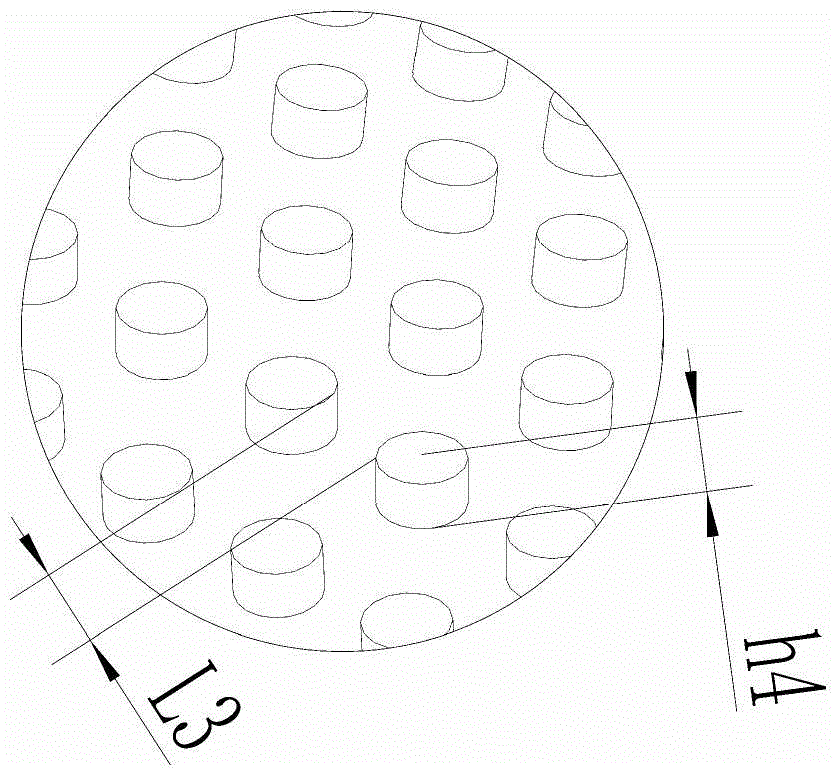

Valve rod and valve bush of turbine regulating valve

InactiveCN104747796AReduce frictionImprove wear resistanceOperating means/releasing devices for valvesEngineeringDynamic pressure

The invention discloses a valve rod and a valve bush of a turbine regulating valve. The area segment, matched with the valve bush, of the valve rod is provided with an area A and an area B, and the area B is located at the lower end of the area A. The area A is a dynamic pressure balancing area, the area B is a hydrophobic area, and the area A is arranged at the position, 1 / 8 to 1 / 6 of the total length of the valve rod away from the outlet end, of the valve rod. The distance between the area A and the area B is 10 mm to 20 mm. The width of the area A accounts for 1 / 6 to 1 / 5 of the total length of the valve rod, and the width of the area B accounts for 1 / 6 to 1 / 5 of the total length of the valve rod. The valve bush is of a split structure, and micro-convex or micro-concave areas C of a superhydrophilic surface texture are arranged in the valve bush and the matched area segment of the area A. According to the valve rod and the valve bush, friction can be reduced, the abrasion resisting performance can be increased, the stability of the valve rod can be improved so that the multi-stage sealing function can be achieved, and based on the flow resistance effect, steam leakage is further reduced.

Owner:HANGZHOU DIANZI UNIV

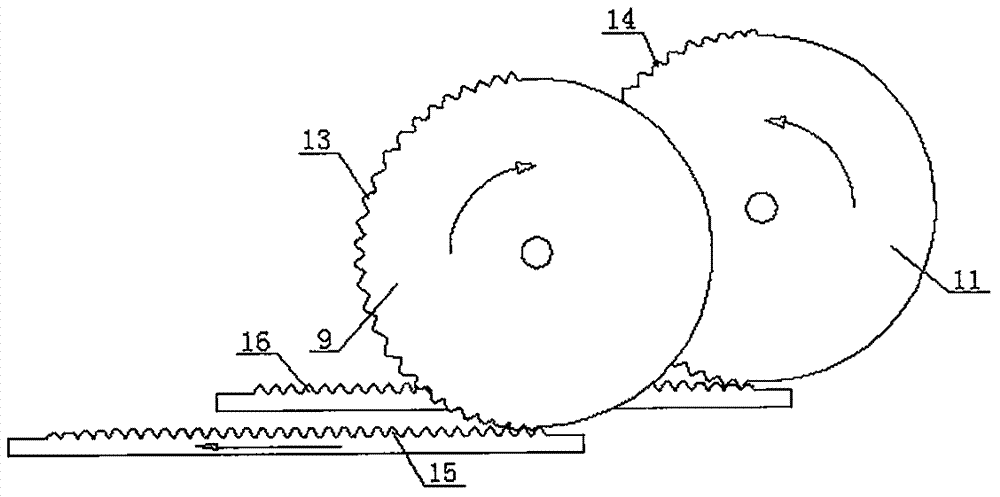

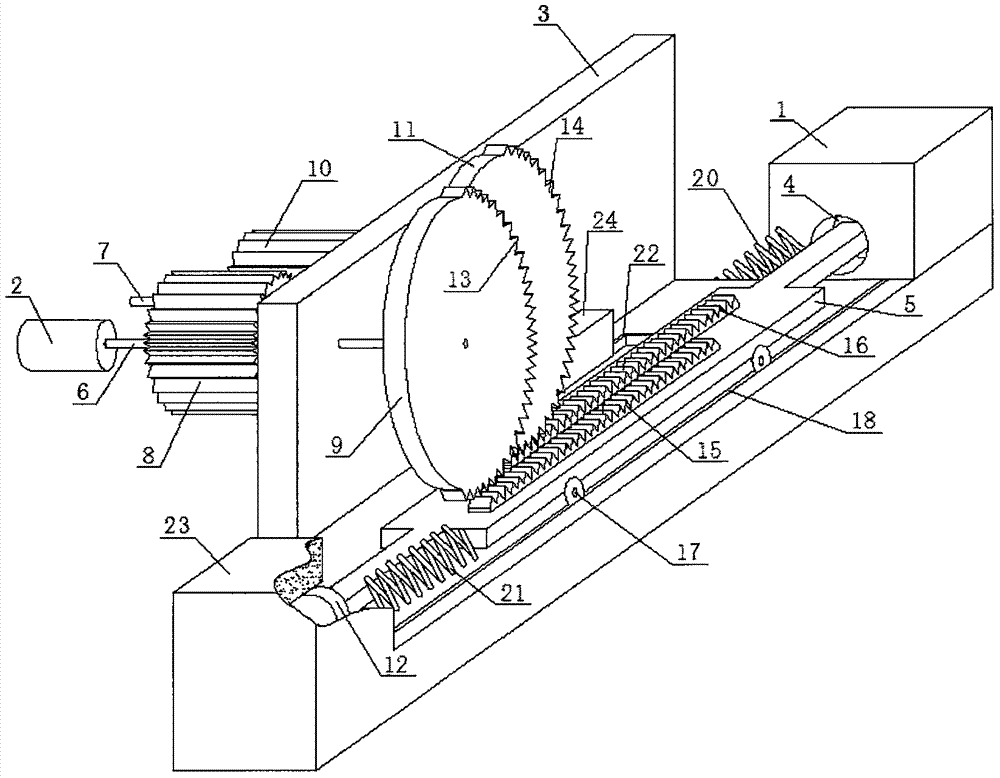

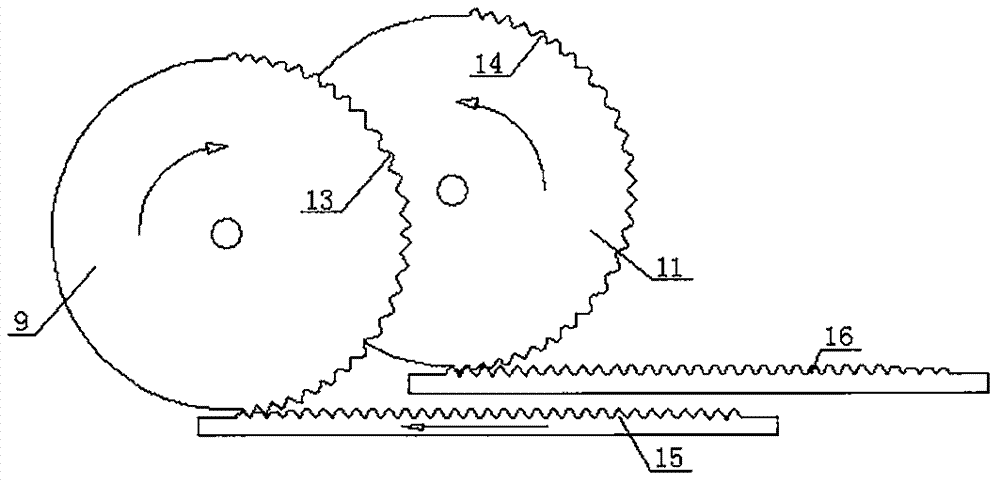

Push rod six-oscillating-tooth efficient lubrication transmission four-cylinder internal combustion engine

InactiveCN107061005ASimple structureReasonable designGearingMachines/enginesEffective powerExternal combustion engine

The invention discloses a push rod six-oscillating-tooth efficient lubrication transmission four-cylinder internal combustion engine, and relates to the field of internal combustion engine transmission. The push rod six-oscillating-tooth efficient lubrication transmission four-cylinder internal combustion engine solves the problem that an existing crankshaft connecting rod internal combustion engine is large in size, prone to generating eccentric wearing, high in energy consumption, low in power, high in manufacturing accuracy and the like. A driving rotating shaft and a driven rotating shaft are fixed to an engine body of the push rod six-oscillating-tooth efficient lubrication transmission four-cylinder internal combustion engine through bearings; driving oscillating teeth are one twelfth of the perimeter of a driving oscillating tooth disc, and driven oscillating teeth are one twelfth of the perimeter of a driven oscillating tooth disc; a first air cylinder and a third air cylinder are arranged on one side of the driving oscillating tooth disc, a second air cylinder and a fourth air cylinder are arranged on one side of the driven oscillating tooth disc, and a first push rod and a second push rod are connected with a first lubricating oil conveying device and a second lubricating oil conveying device correspondingly. The push rod six-oscillating-tooth efficient lubrication transmission four-cylinder internal combustion engine is simple in structure, small in size, resistant to eccentric wearing and low in energy consumption, and greatly improves the effective power.

Owner:邱秀芳

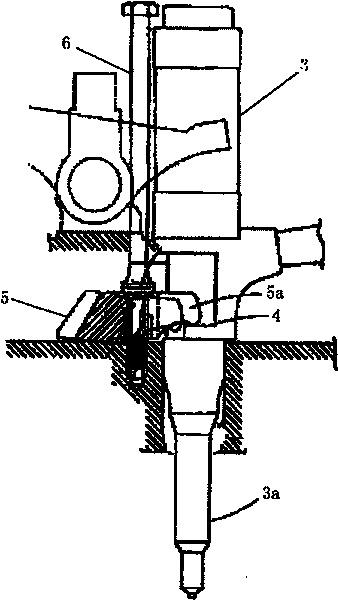

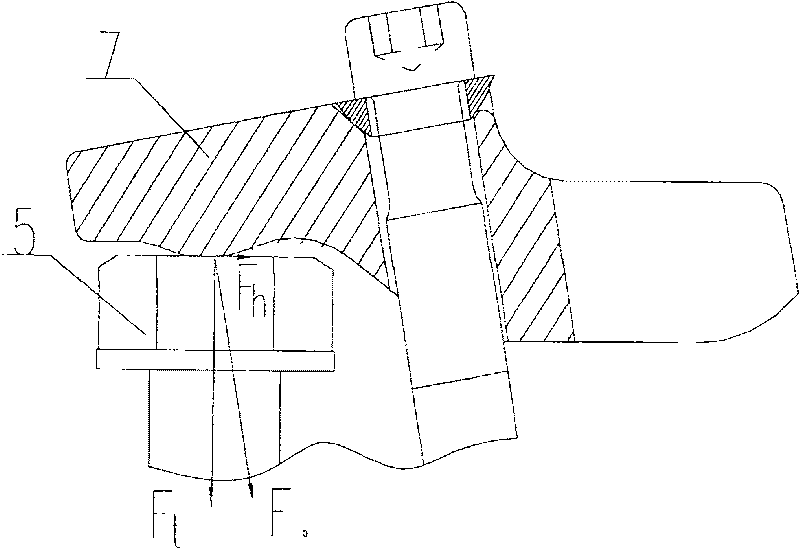

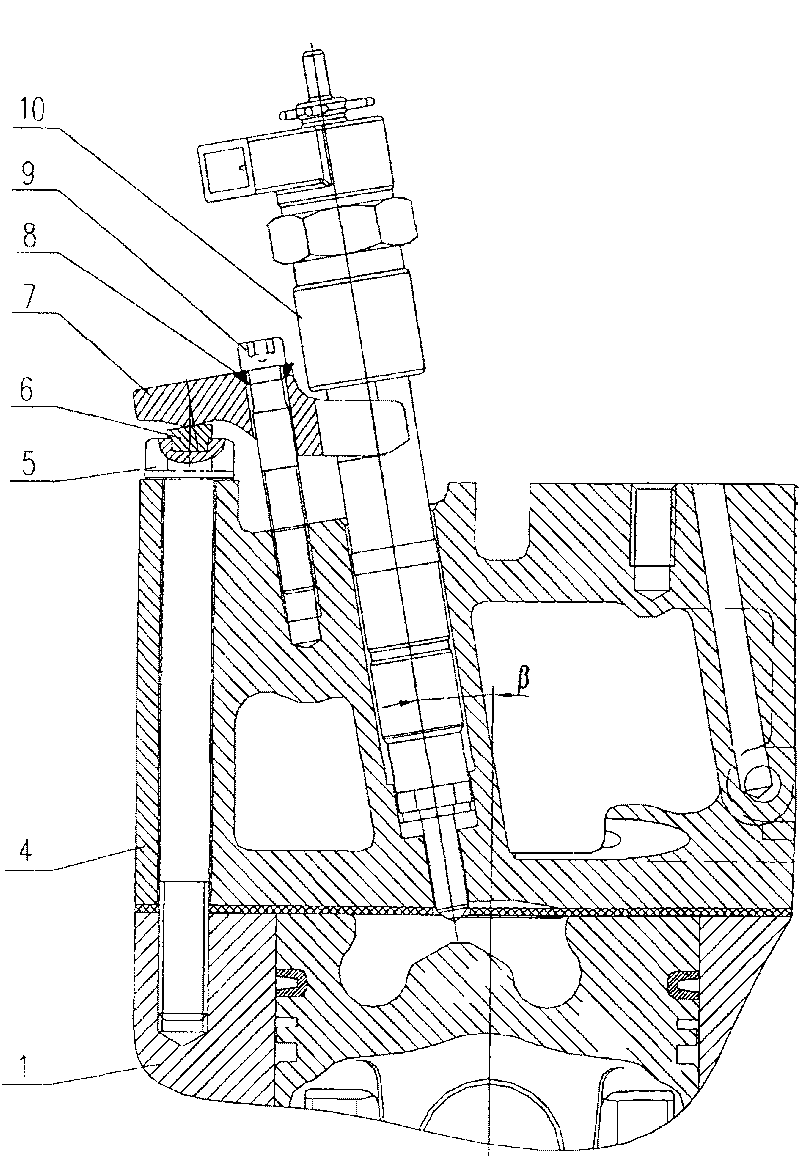

Fixed device of engine fuel oil injector and engines with same

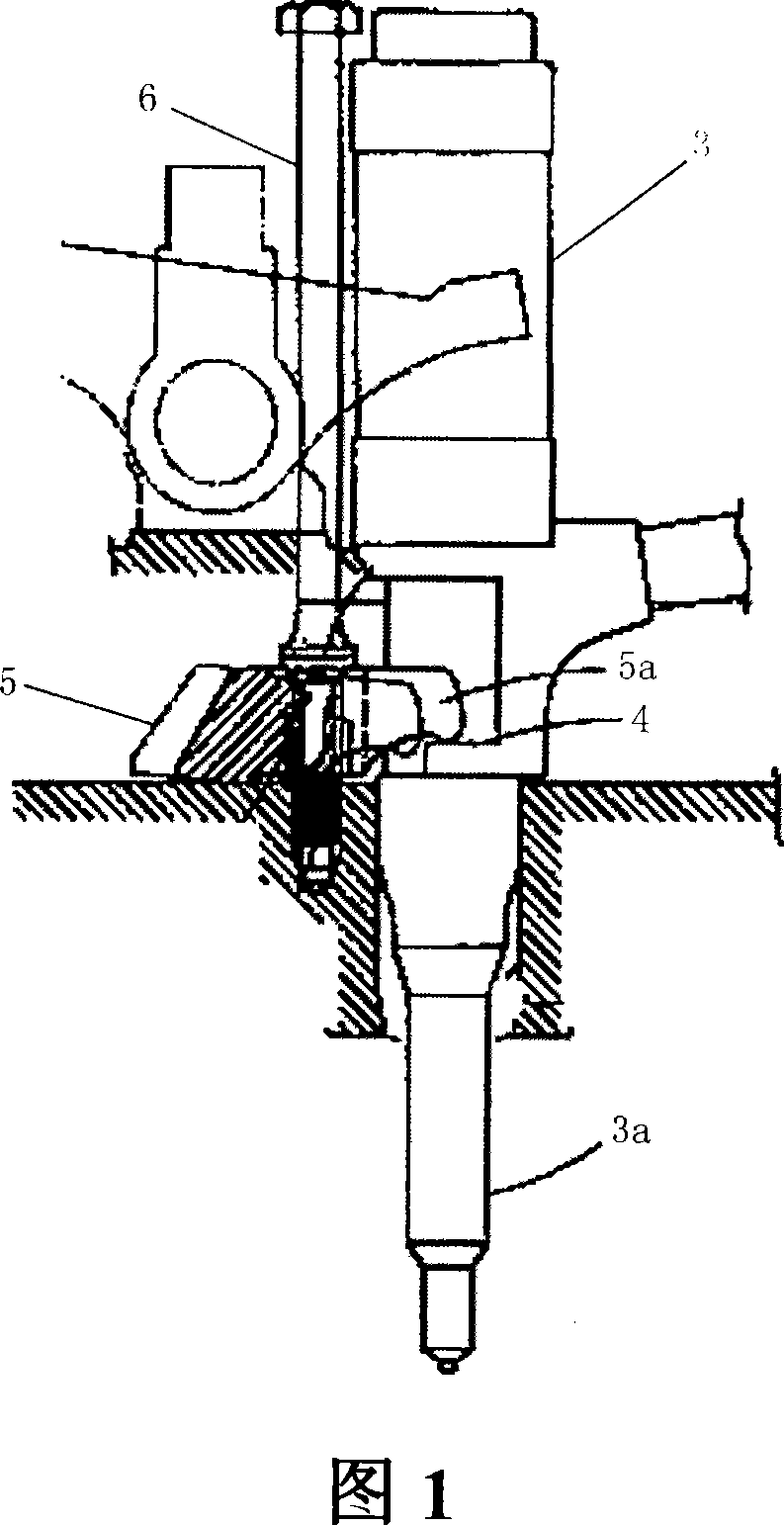

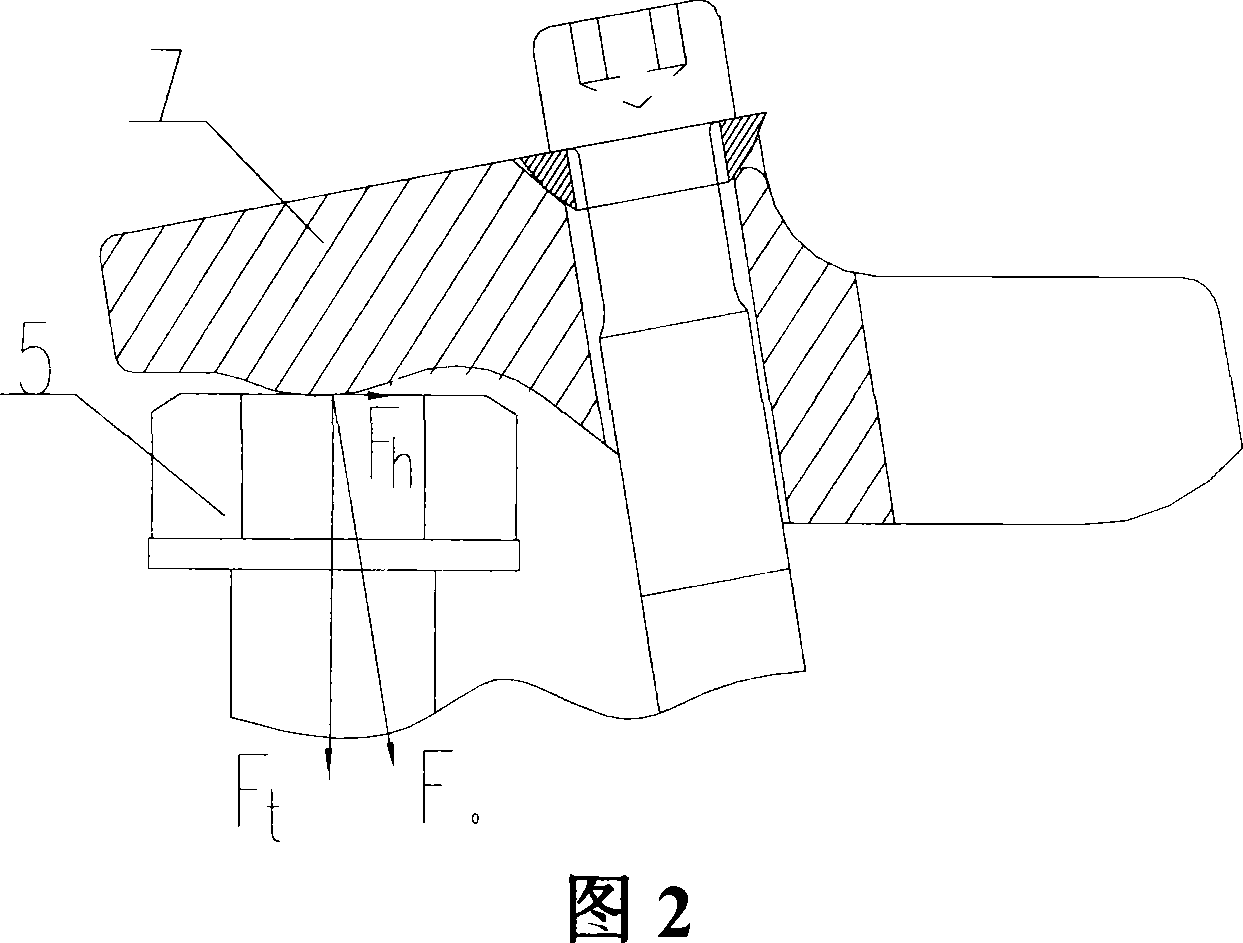

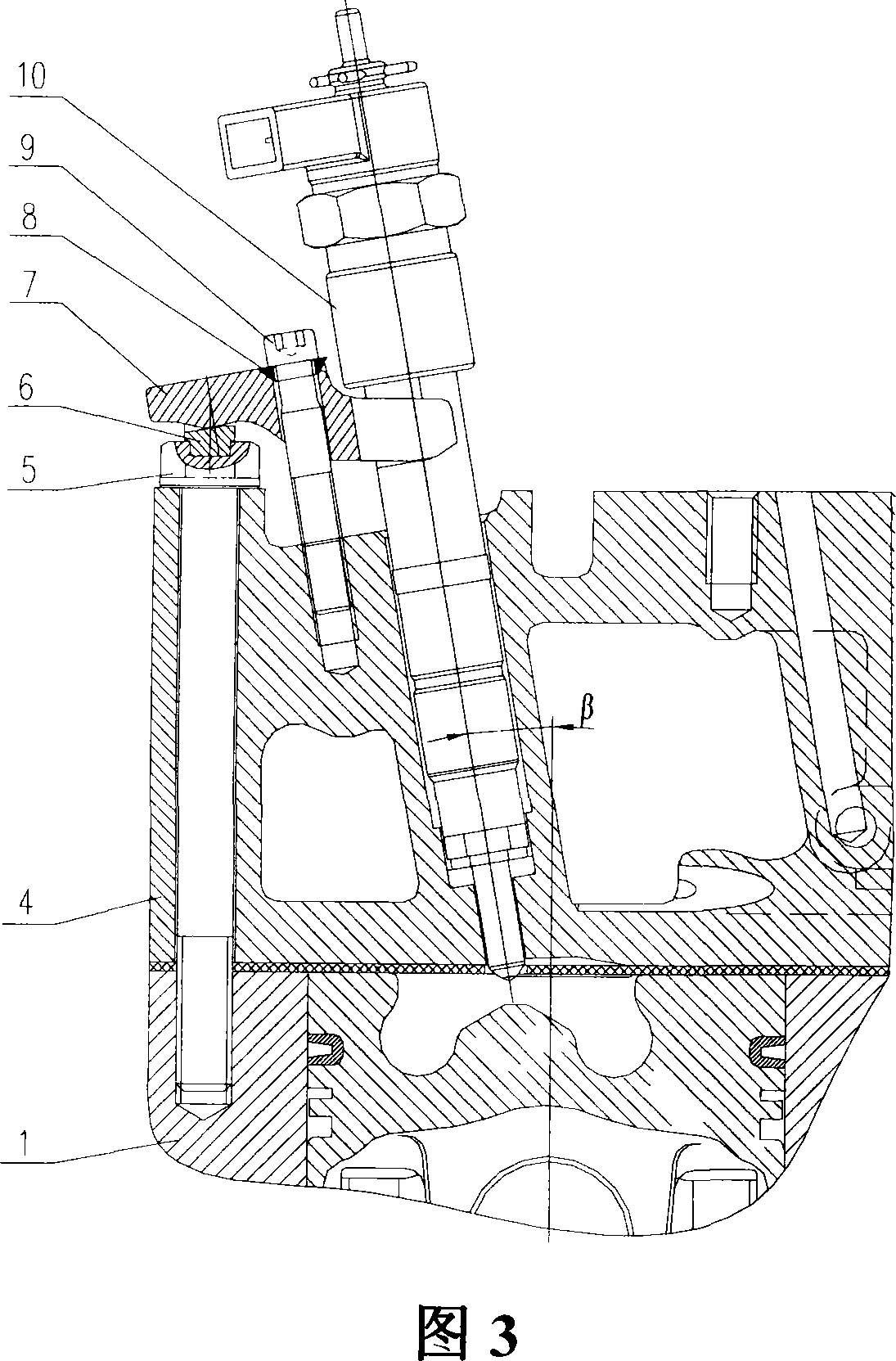

ActiveCN101063433AEliminate partial wearFuel injection apparatusMachines/enginesHorizontal forceFuel oil

The invention discloses a fixed device for a motor fuel injector and the motor with the device and the fixed device of the injector comprises an injector press plate and an injector fixed screw, wherein the injector fixed screw fixes the injector on a cylinder lid of the motor via the injector press plate, characterized in that the device also comprises a press plate heel block which is arranged below the injector press plate and on a cap of a cylinder screw, and the dip angle between the press plate heel block and the contact face of the injector press plate is same to the assembling angle of the injector. The invention delivers the horizontal force of the injector press plate as being pressed to the cylinder lid screw to make the cylinder lid screw bearing the force, therefore the injector only can bear the down packing force without any horizontal force, thereby eliminating grinder phenomenon of coupling parts in the injector.

Owner:BEIQI FOTON MOTOR CO LTD

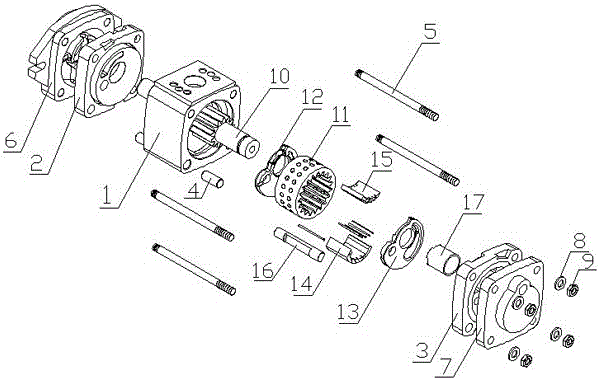

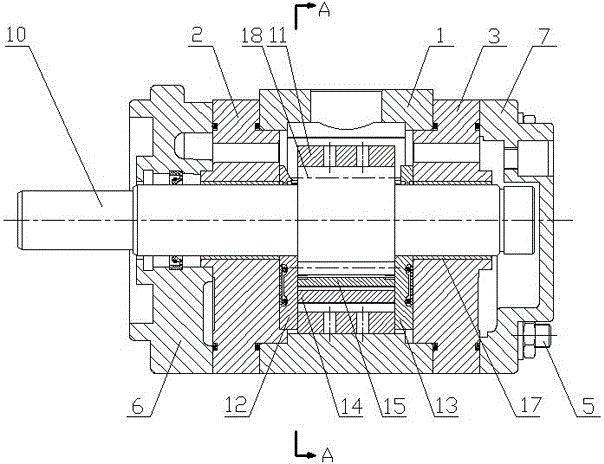

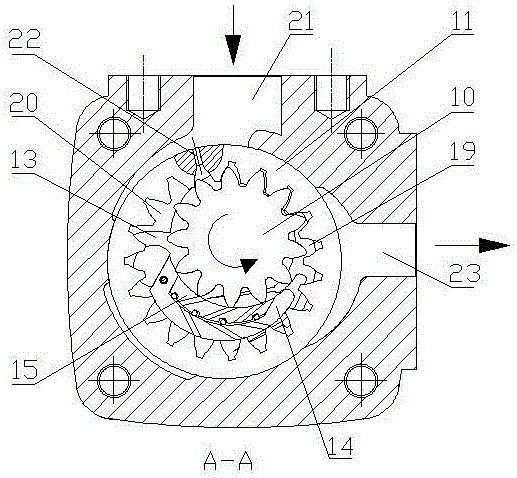

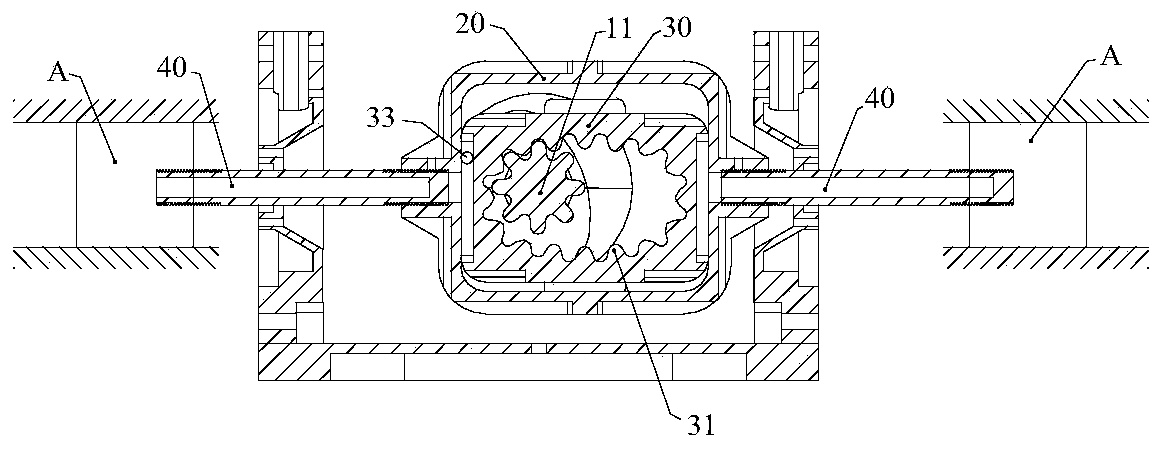

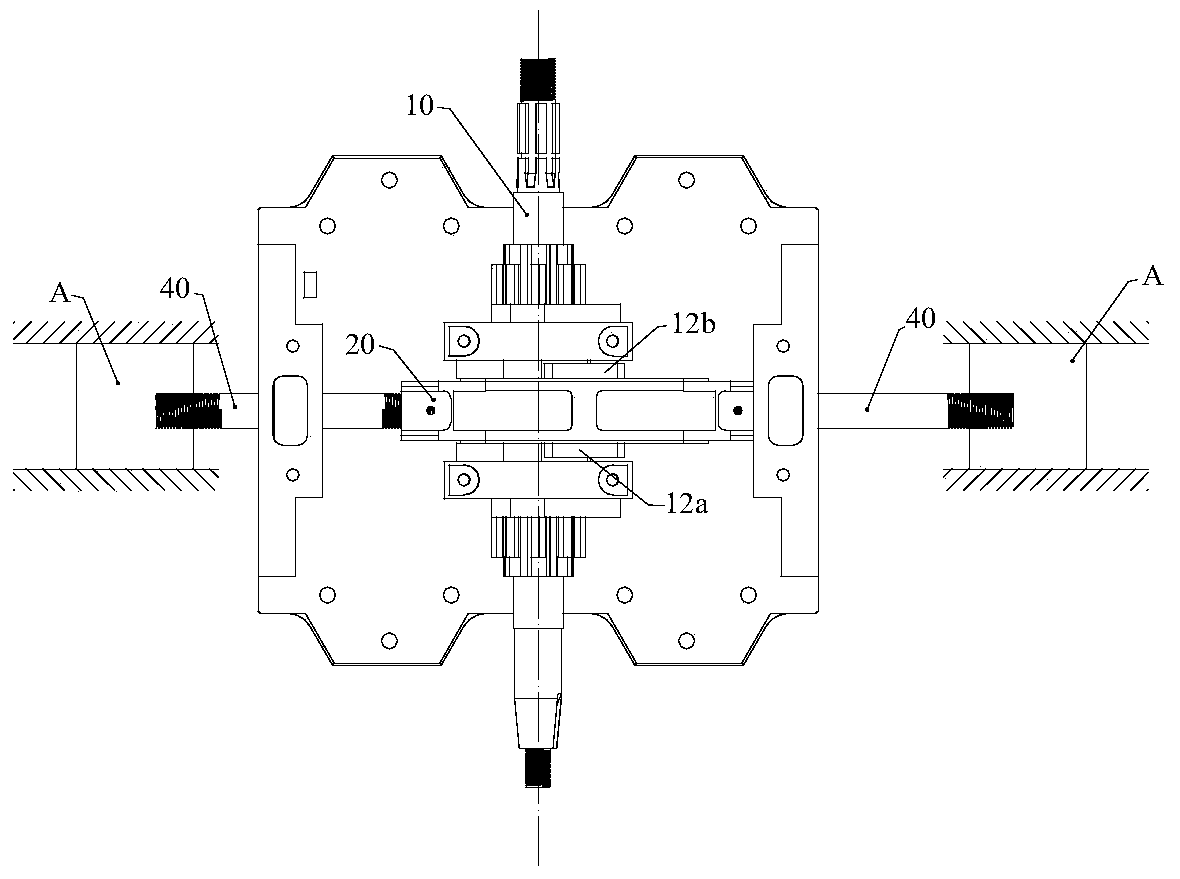

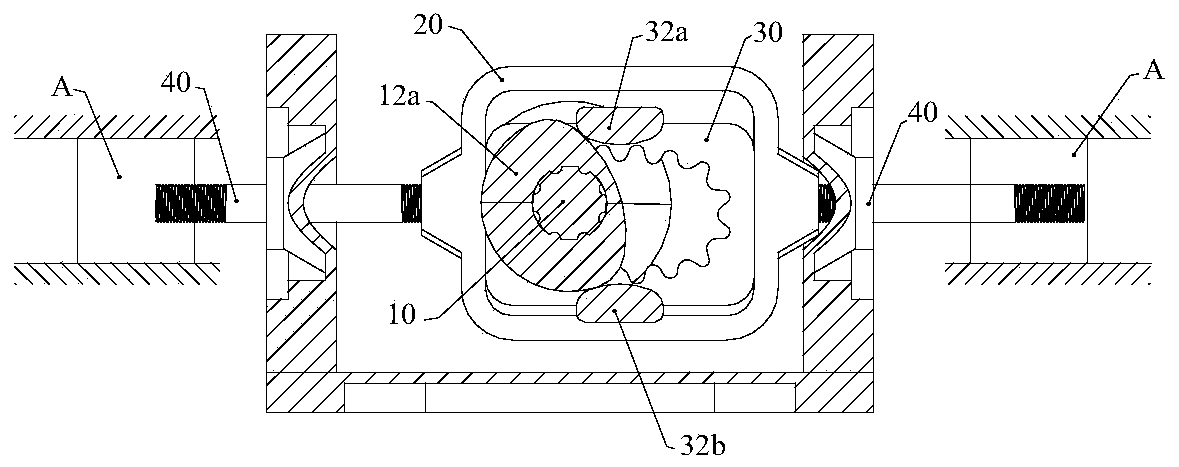

A kind of internal meshing gear pump capable of realizing partial axial compensation

InactiveCN104265623BReduce internal leakageImprove stress resistanceRotary piston pumpsRotary piston liquid enginesGear pumpEngineering

The invention relates to an internal gear pump capable of achieving partition axial compensation. The internal gear pump comprises a pump body, a gear pair and crescent blocks; a gear shaft is meshed with an internal gear ring to form the gear pair; the crescent blocks are arranged in the gear pair; a left axial compensation device and a right axial compensation device which are the same in structure are symmetrically arranged on the two end faces of the crescent blocks and the gear pair; each axial compensation device comprises a first-level side plate, a second-level side plate and a third-level side plate; a first compensation groove is formed in the outer end face of each first-level side plate; a second compensation groove is formed in the inner end face of each first-level side plate; elastic sealing rings and side plate gaskets are sequentially stacked in the first compensation grooves to form a first-level axial compensation system; springs and the second-level side plates are sequentially stacked in the second compensation grooves to form a second-level axial compensation system; sealing blocks and the third-level side plates are sequentially stacked on the second-level side plates to form a third-level axial compensation system. Partition self-adaption adjustment is carried out on abrasion positions and non-abrasion positions, internal leakage of the pump is effectively reduced, and large-area supporting of the side plates can be still achieved under the abrasion state.

Owner:FUZHOU UNIV

Valve stem and valve sleeve of a steam turbine control valve

InactiveCN104747796BReduce frictionImprove wear resistanceOperating means/releasing devices for valvesEngineeringTurbine

The invention discloses a valve rod and a valve bush of a turbine regulating valve. The area segment, matched with the valve bush, of the valve rod is provided with an area A and an area B, and the area B is located at the lower end of the area A. The area A is a dynamic pressure balancing area, the area B is a hydrophobic area, and the area A is arranged at the position, 1 / 8 to 1 / 6 of the total length of the valve rod away from the outlet end, of the valve rod. The distance between the area A and the area B is 10 mm to 20 mm. The width of the area A accounts for 1 / 6 to 1 / 5 of the total length of the valve rod, and the width of the area B accounts for 1 / 6 to 1 / 5 of the total length of the valve rod. The valve bush is of a split structure, and micro-convex or micro-concave areas C of a superhydrophilic surface texture are arranged in the valve bush and the matched area segment of the area A. According to the valve rod and the valve bush, friction can be reduced, the abrasion resisting performance can be increased, the stability of the valve rod can be improved so that the multi-stage sealing function can be achieved, and based on the flow resistance effect, steam leakage is further reduced.

Owner:HANGZHOU DIANZI UNIV

A shaft connecting rod transmission system and an opposed piston engine

ActiveCN105114179BEfficient use ofSimple structureGearingMachines/enginesReciprocating motionGear wheel

A shaft connecting rod transmission system and an opposed piston engine to convert reciprocating linear motion into rotary motion in the same direction, effectively improve the reliability of the transmission system, simplify the transmission system to make it more compact, and make the piston on the back of the internal combustion engine It is possible to effectively use the space between the cylinder and the cylinder. The shaft link transmission system includes a main shaft and at least one rectilinear reciprocating unit, and the rectilinear reciprocating unit includes at least one rectilinear reciprocating body. The linear reciprocating body is fixedly connected to one end of the corresponding shaft connecting rod, the other end of the shaft connecting rod is fixedly connected to one side of the corresponding push-pull frame, and the axes of the shaft connecting rod and the main shaft are perpendicular to each other. A sliding block is arranged in the push-pull frame, and the two lateral outer walls of the sliding block form a vertical sliding fit with the two lateral inner walls of the push-pull frame. The teeth are cyclically meshed with the gears correspondingly arranged on the main shaft. A reversing mechanism is arranged between the main shaft and the sliding block.

Owner:郑安庆

Internal combustion engine cylinder anti-eccentric wear device

ActiveCN105065131BLow running costSimple structureCylinder headsCylindersExternal combustion engineHigh energy

The invention discloses an anti-eccentric wearing device for a cylinder of an internal combustion engine and relates to the field of the internal combustion engine. The anti-eccentric wearing device solves the problems of high processing difficulty, easy wearing, high energy consumption and the like existing in the internal combustion engine at present. Upper shaft sleeves of the anti-eccentric wearing device for the cylinder of the internal combustion engine are fixed at the lower ends of cylinder holes of a cylinder block, and lower shaft sleeves of the anti-eccentric wearing device are fixed at the inner bottom of a lubricating oil tank; two ends of each piston guide rod are respectively connected to the corresponding upper shaft sleeve and the corresponding lower shaft sleeve in a sleeved manner; each connecting rod is connected to the corresponding piston guide rod through a piston guide rod retaining latch sleeve; the piston guide rod retaining latch sleeves and the piston guide rods are fixed by pin bolts; and the upper ends of the piston guide rods and pistons are fixed. The anti-eccentric wearing device is simple in structure, easy to process, and convenient to install, is energy-saving, and can greatly prolong the service life of the cylinder and the piston.

Owner:武克学

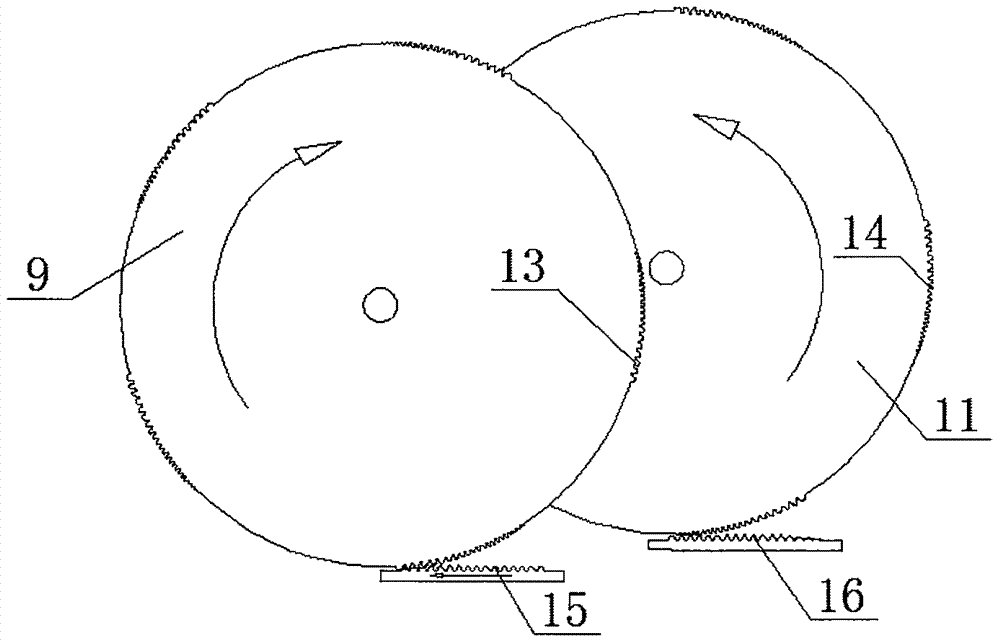

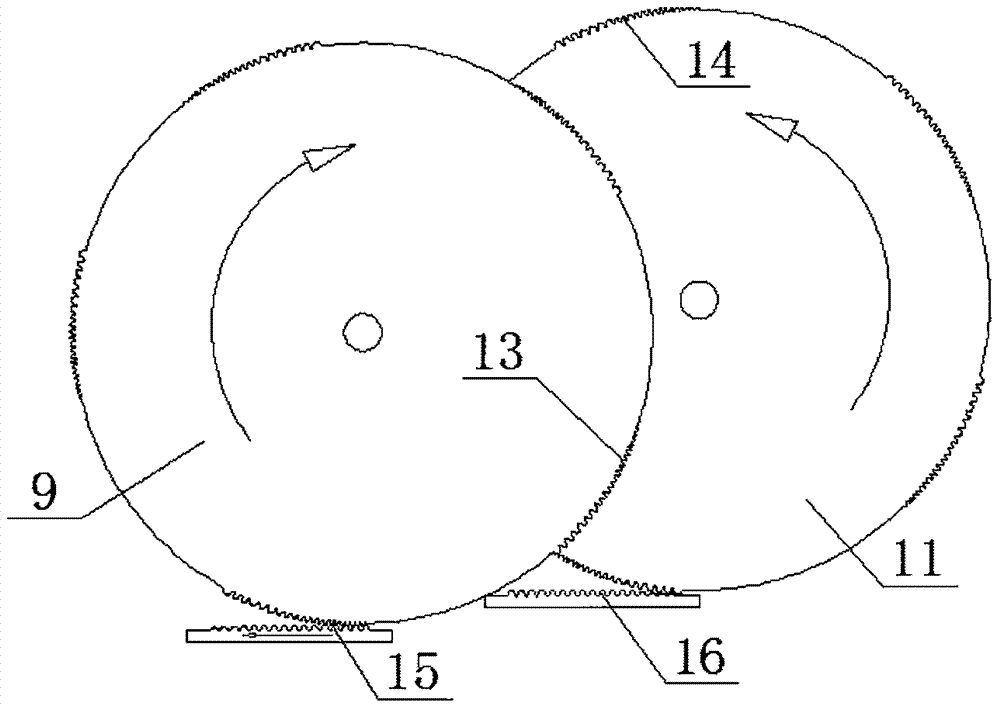

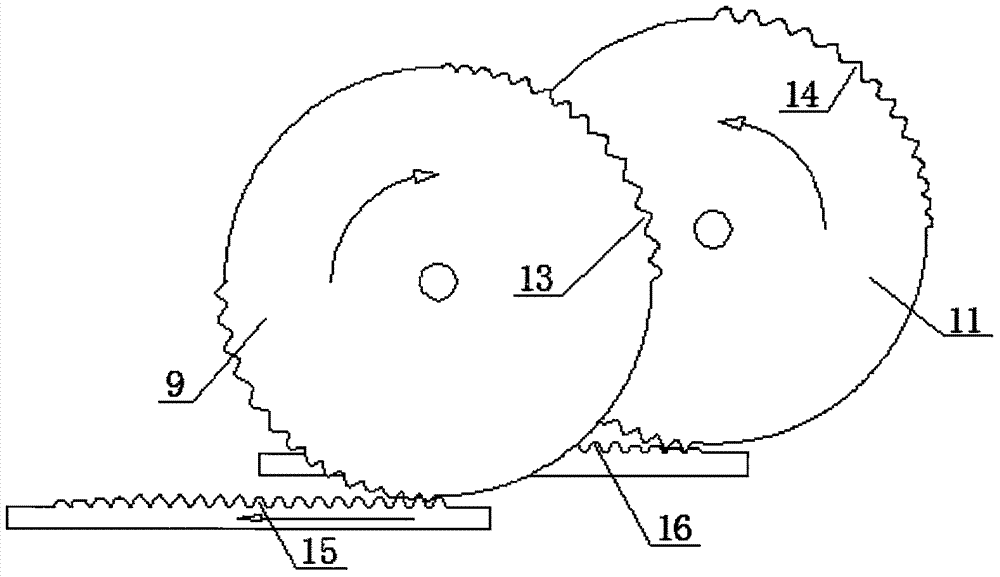

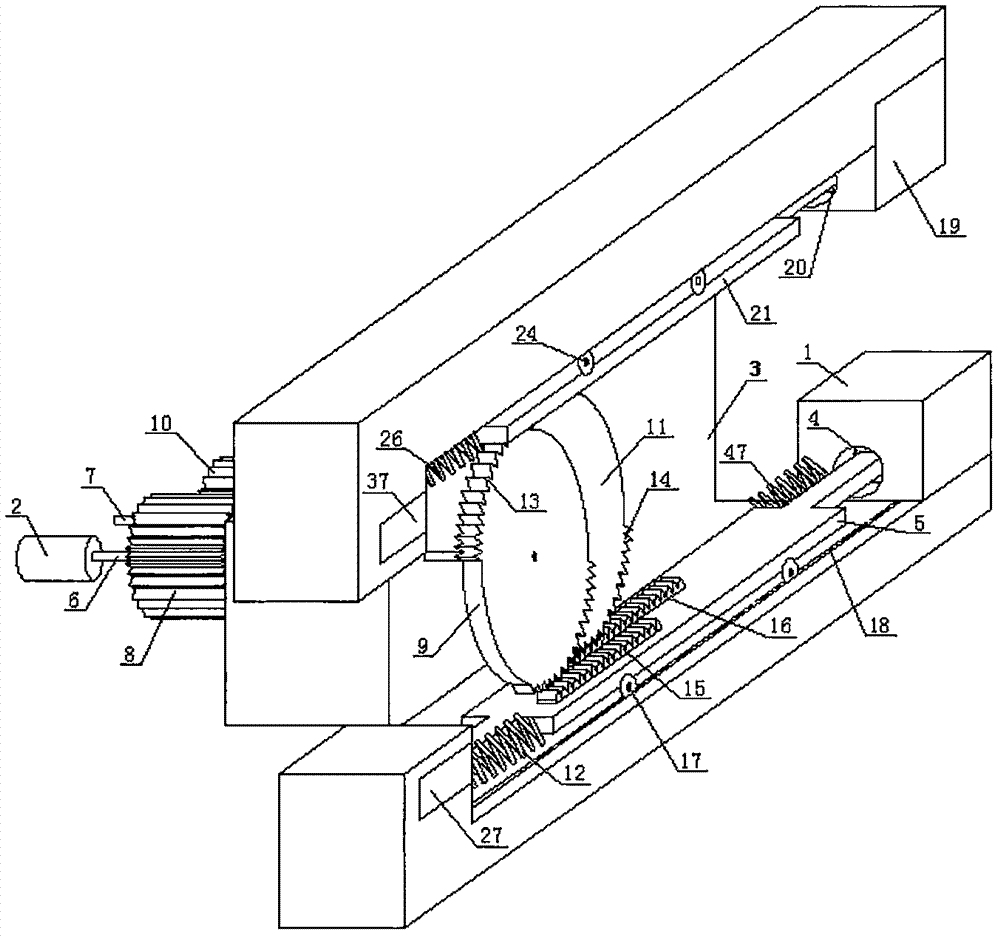

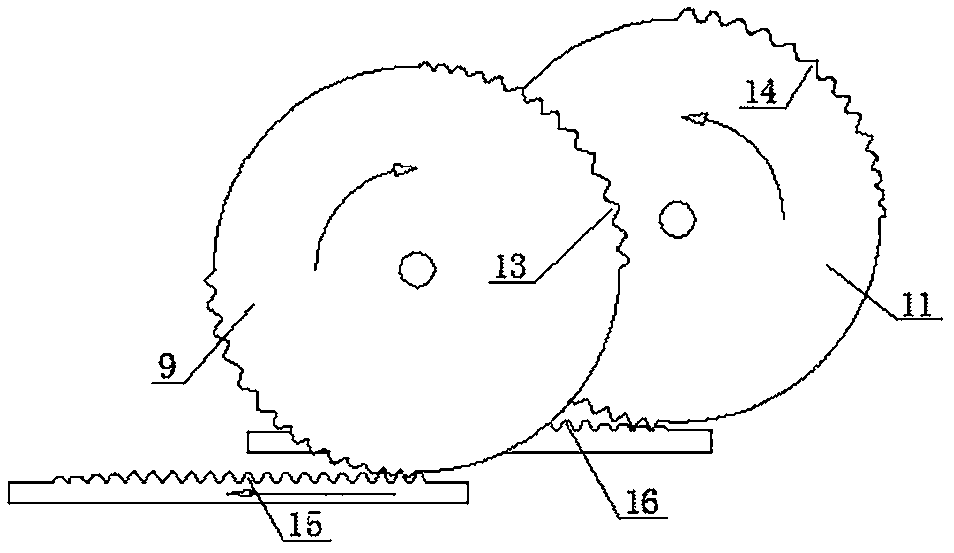

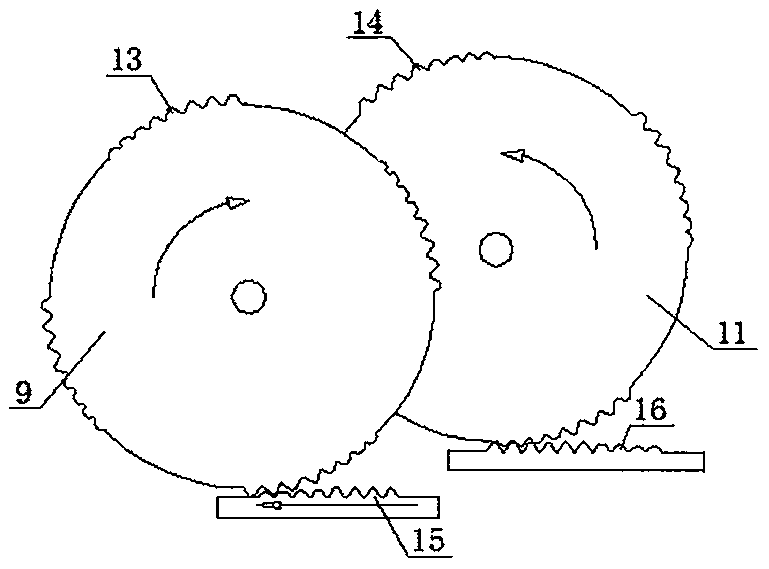

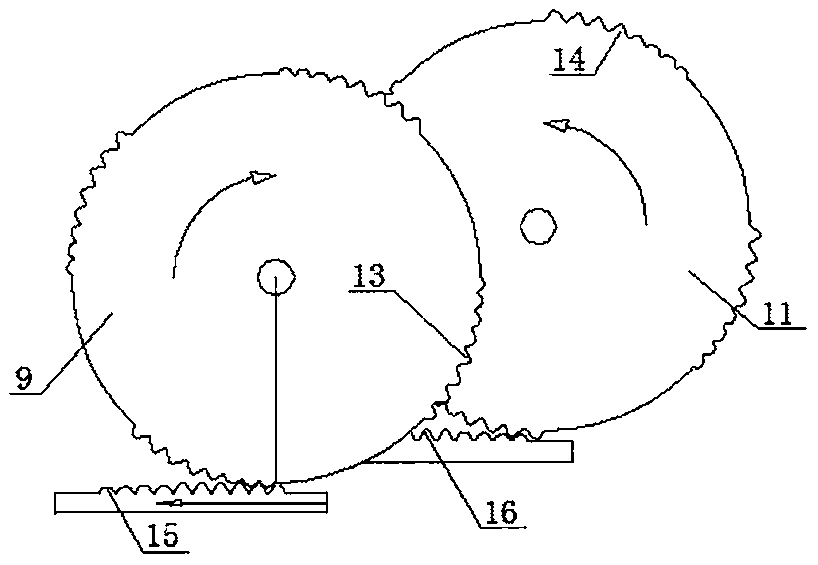

Push rod single-oscillating-tooth transmission opposite-column double-cylinder internal combustion engine

The invention discloses a push rod one-oscillating-tooth transmission opposite-column double-cylinder internal combustion engine and relates to the field of transmission of internal combustion engines. The push rod one-oscillating-tooth transmission opposite-column double-cylinder internal combustion engine solves the problems that an existing crankshaft connecting rod internal combustion engine is large in size, prone to eccentric wear, high in energy consumption, low in power, low in manufacturing precision and the like. A drive rotating shaft and a driven rotating shaft are fixed to an engine body of the push rod one-oscillating-tooth transmission opposite-column double-cylinder internal combustion engine through bearings, a driven oscillating-tooth disc is arranged on the driven rotating shaft, wherein the shape and the size of the driven oscillating-tooth disc are the same with those of a drive oscillating-tooth disc on the drive rotating shaft. The length of each of drive oscillating teeth is one second of the perimeter of the drive oscillating-tooth disc, and the length of each of driven oscillating teeth is one second of the perimeter of the driven oscillating-tooth disc. A first air cylinder and a second air cylinder are perpendicularly and fixedly arranged at the two ends of a push rod correspondingly. The push rod one-oscillating-tooth transmission opposite-column double-cylinder internal combustion engine is used and is simple in structure, convenient to manufacture, small in size, low in cost, capable of preventing eccentric wear, easy to maintain, low in energy consumption and capable of greatly improving effective power.

Owner:雷敬汉

Push rod five-sliding-teeth transmission four-cylinder internal combustion engine

InactiveCN106917677ASimple structureReasonable designMachines/enginesEffective powerExternal combustion engine

The invention discloses a push rod five-sliding-teeth transmission four-cylinder internal combustion engine, and relates to the field of transmission of an internal combustion engine. The internal combustion engine solves problems that an existing crankshaft connecting rod internal combustion engine is large in volume, easy in eccentric wearing, high in energy consumption, low in power, and high in manufacturing precision. A machine body of the push rod five-sliding-teeth transmission four-cylinder internal combustion engine is fixedly provided with an active rotating shaft and a driven rotating shaft through a bearing. The driven rotating shaft is provided with a driven sliding-teeth disk which has the same shape and size with an active sliding-teeth disk on the active rotating shaft. Active sliding-teeth and driven sliding-teeth are respectively one tenth of perimeters of the active sliding-teeth disk and the driven sliding-teeth disk. One side of the active sliding-teeth disk is provided with a first air cylinder and a third air cylinder, and one side of the driven sliding-teeth disk is provided with a second air cylinder and a fourth air cylinder. The four-cylinder internal combustion engine is simple in structure, small in volume, low in cost, easy in maintenance, and low in energy consumption, and the four-cylinder internal combustion engine prevents eccentric wearing and effective power is greatly improved.

Owner:雷敬汉

Push rod six-oscillating-tooth efficient lubricating driving parallel double-cylinder internal combustion engine

InactiveCN106884718ASimple structureReasonable designMachines/enginesLubrication pressure controlEffective powerCombustion

The invention discloses a push rod six-oscillating-tooth efficient lubricating driving parallel double-cylinder internal combustion engine, and relates to the field of internal combustion engines. The invention solves the problems that a crankshaft connecting rod internal combustion engine at present is large in size, is likely to be eccentrically worn, high in energy consumption, low in power and high in manufacturing accuracy. A driving rotating shaft and a driven rotating shaft are fixed on an engine body of the push rod six-oscillating-tooth efficient lubricating driving parallel double-cylinder internal combustion engine through bearings; the driven rotating shaft is provided with a driven oscillating tooth plate with an identical shape and size as a driving oscillating tooth plate on the driving rotating shaft, and the size of a driving oscillating tooth and the size of a driven oscillating tooth are one-twelfth of the perimeter of the driving oscillating tooth plate and the perimeter of the driven oscillating tooth plate respectively; and a push rod I and a push rod II are connected with a lubricating oil conveyor I and a lubricating oil conveyor II respectively. The push rod six-oscillating-tooth efficient lubricating driving parallel double-cylinder internal combustion engine provided by the invention is simple in structure, small in size, eccentric-wear-resistant, and low in energy consumption and is greatly improved in effective power.

Owner:邱秀芳

Fixed device of engine fuel oil injector and engines with same

ActiveCN101063433BEliminate partial wearFuel injection apparatusMachines/enginesHorizontal forceEngineering

The invention discloses a fixed device for a motor fuel injector and the motor with the device and the fixed device of the injector comprises an injector press plate and an injector fixed screw, wherein the injector fixed screw fixes the injector on a cylinder lid of the motor via the injector press plate, characterized in that the device also comprises a press plate heel block which is arranged below the injector press plate and on a cap of a cylinder screw, and the dip angle between the press plate heel block and the contact face of the injector press plate is same to the assembling angle ofthe injector. The invention delivers the horizontal force of the injector press plate as being pressed to the cylinder lid screw to make the cylinder lid screw bearing the force, therefore the injector only can bear the down packing force without any horizontal force, thereby eliminating grinder phenomenon of coupling parts in the injector.

Owner:BEIQI FOTON MOTOR CO LTD

Push rod seven-movable tooth driving internal combustion engine

InactiveCN106884717ASimple structureReasonable designGearingMachines/enginesEffective powerHigh energy

The invention discloses a push rod seven-movable tooth driving internal combustion engine, which relates to the field of internal combustion engine driving. The push rod seven-movable tooth driving internal combustion engine aims to solve the problems of large size, easiness in eccentric wear, high energy consumption, low power, high manufacturing accuracy and the like of an existing crankshaft connecting rod internal combustion engine. According to the push rod seven-movable tooth driving internal combustion engine, a driving rotating shaft and a driven rotating shaft are fixed to an engine body by virtue of bearings; a driven movable tooth disc of which the shape and size are the same as that of a driving movable tooth disc on the driving rotating shaft is arranged on the driven rotating shaft, and driving movable teeth and driven movable teeth are respectively one fourteenth of the perimeters of the driving movable tooth disc and the driven movable tooth disc; and driving push teeth and driven push teeth which are engaged with the driving movable tooth disc and the driven movable tooth disc are formed on push rods. The push rod seven-movable tooth driving internal combustion engine has the advantages of simple structure, convenience in manufacturing, small size, low cost, eccentric wear resistance, easiness in maintenance and low energy consumption, and the effective power is greatly increased.

Owner:雷敬汉

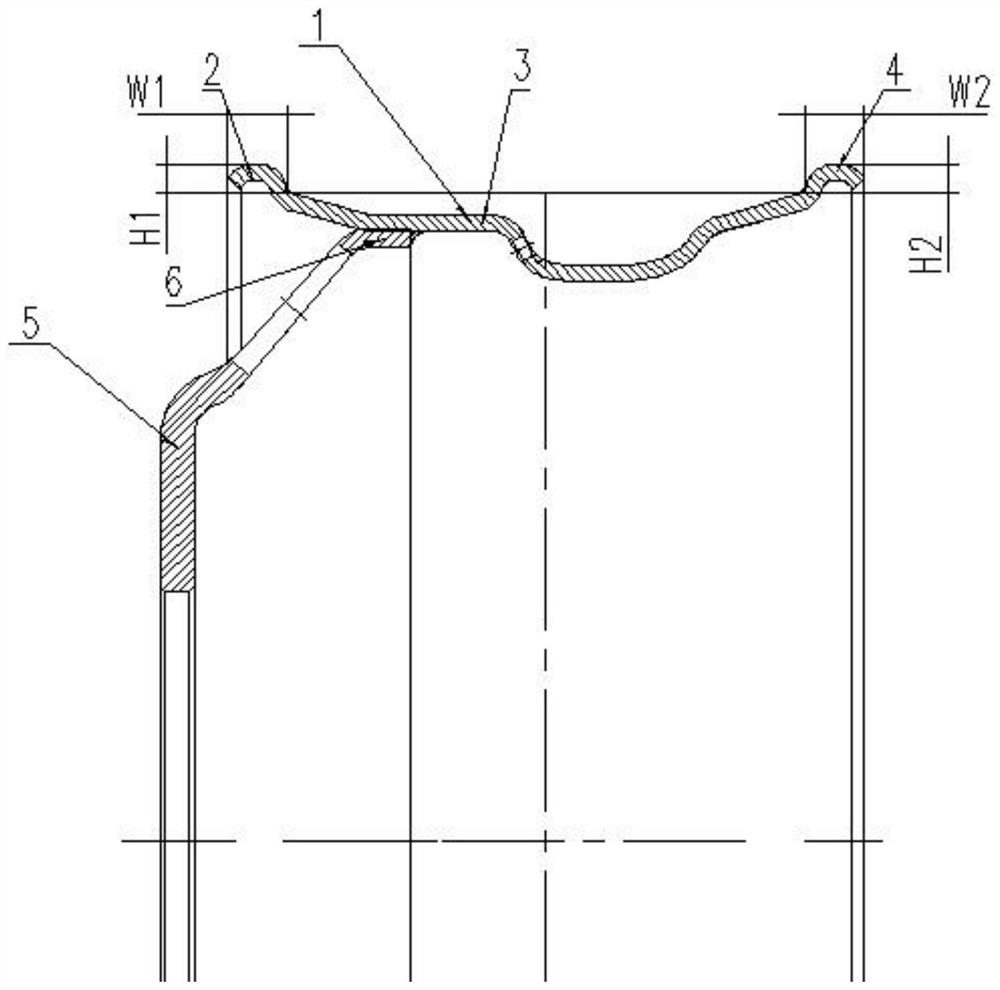

A rim and wheel with asymmetrical design of rims on both sides

Owner:东风汽车底盘系统有限公司

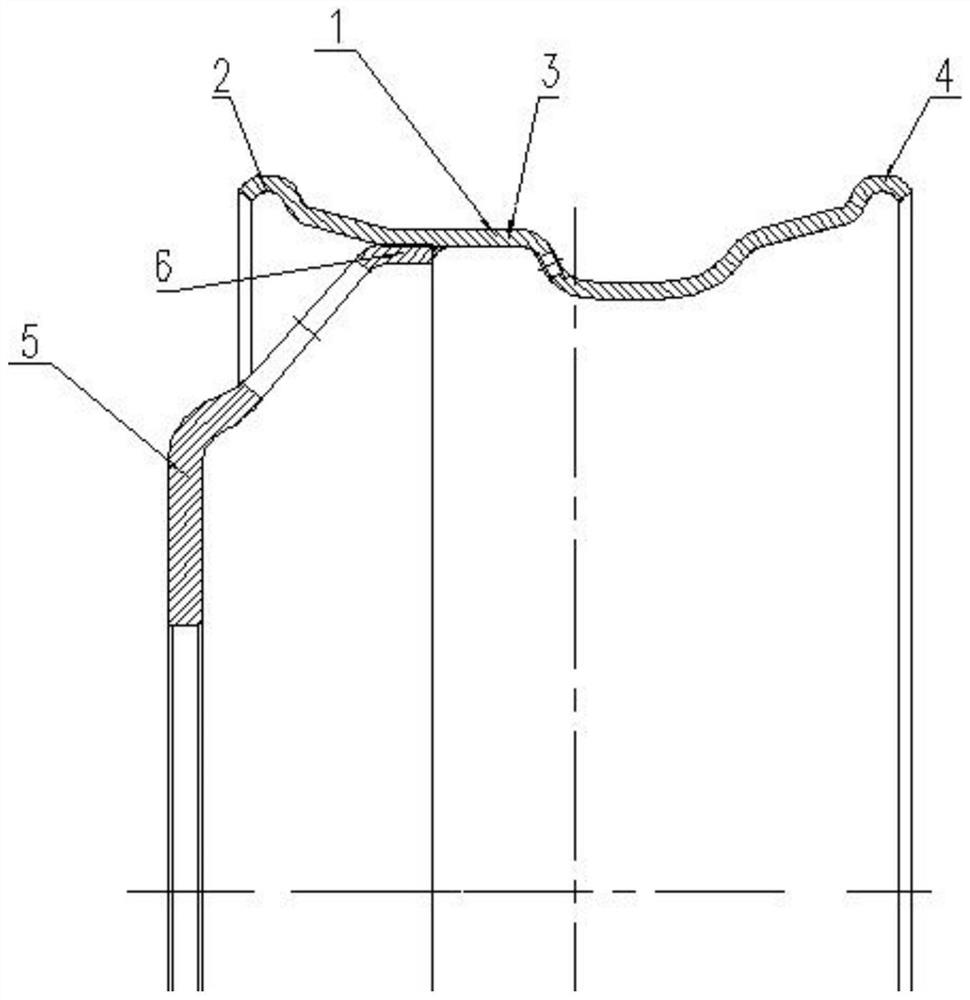

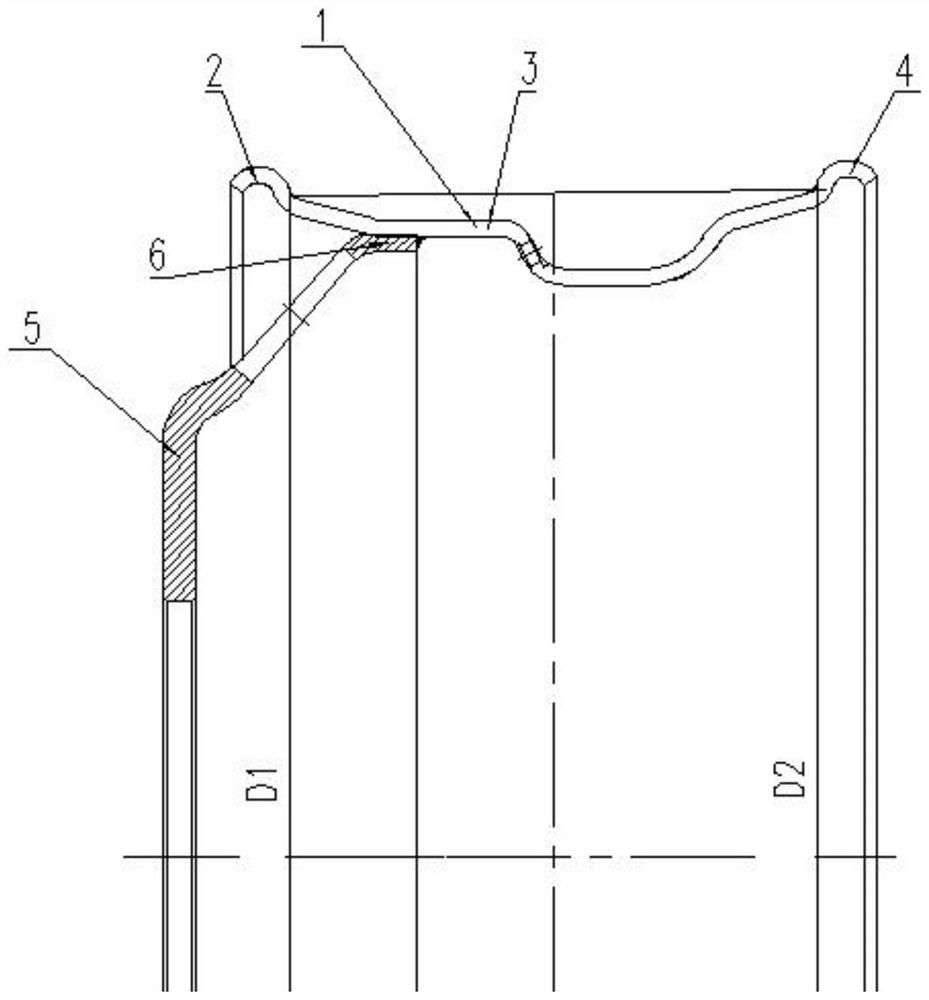

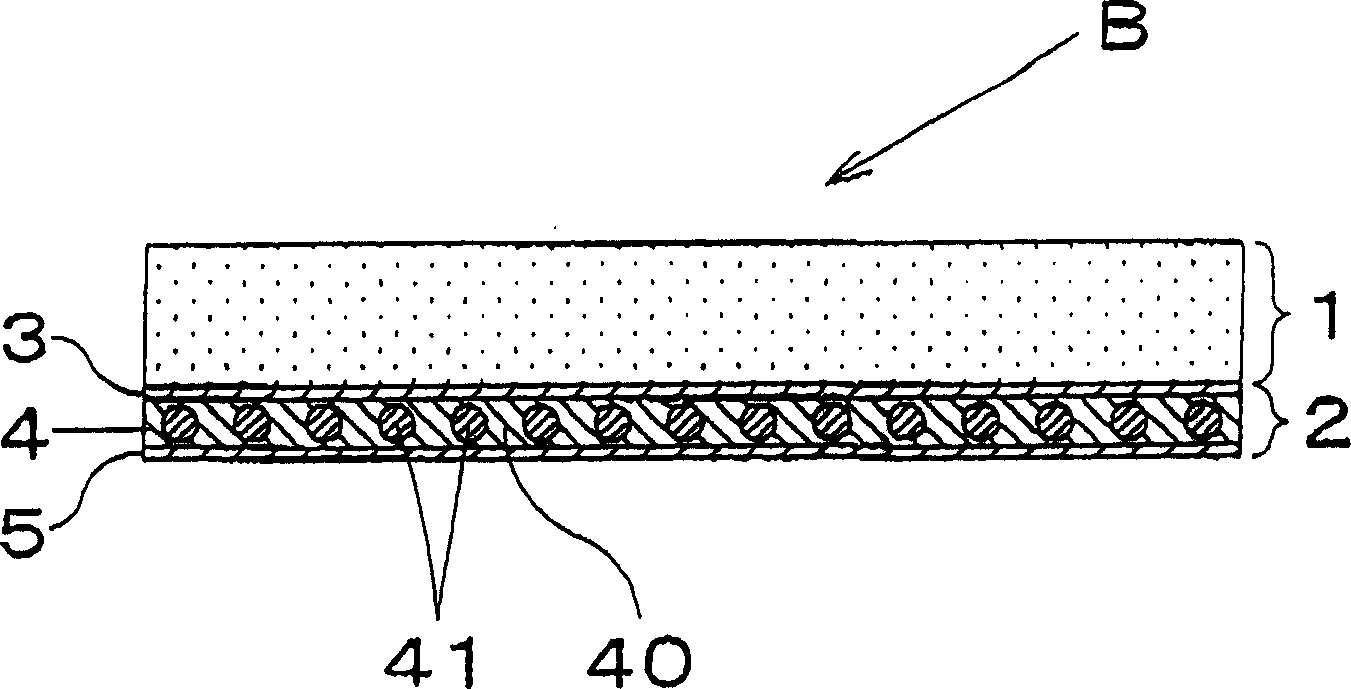

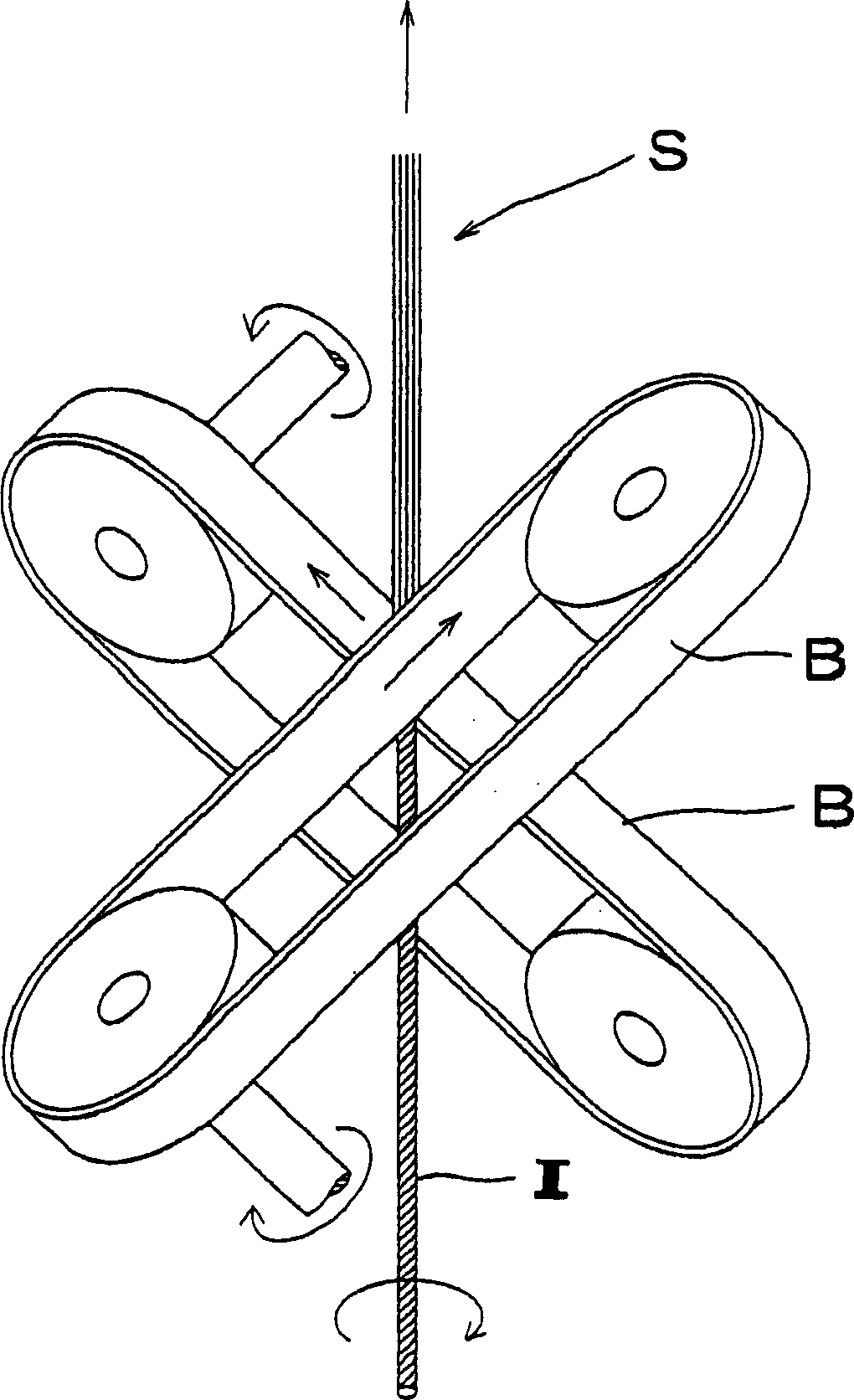

Belt for yarn twisting

InactiveCN1910311AQuality improvementReduce vibrationDriving beltsContinuous wound-up machinesYarnEngineering

A yarn twisting belt formed in an endless loop that ensures longer service life of the belt and stable quality of the yarn, comprising a surface rubber layer 1 that touches yarn to be twisted and a reinforcing layer 2 that is laminated on the surface rubber layer 1, having an intermediate woven fabric 3 provided on the surface rubber layer 1 side of the reinforcing layer 2 while a seamless woven fabric is used as the intermediate woven fabric 3. The seamless woven fabric is elastic in the direction of the belt circumference and rigid in the direction of the belt width. The reinforcing layer 2 comprises the intermediate woven fabric 3 that is constituted from the seamless woven fabric, a core layer 4 constituted from core yarns embedded in the longitudinal direction of the belt, and an external woven fabric 5 that is put on pulleys, while being integrated with the surface rubber layer.

Owner:NITTA CORP

Push rod single-oscillating-tooth efficient lubrication transmission opposite-column double-cylinder internal combustion engine

InactiveCN106988877ASimple structureReasonable designMachines/enginesPressure lubricationEffective powerHigh energy

The invention discloses a push rod single movable tooth high-efficiency lubricated transmission opposed row double-cylinder internal combustion engine, and relates to the field of internal combustion engine transmission. The invention solves the problems of large volume, easy partial wear, high energy consumption, low power and high manufacturing precision of the current crankshaft connecting rod internal combustion engine. The body of the push rod single movable tooth efficiently lubricates and drives the dual-cylinder internal combustion engine with bearings to fix the driving shaft and the driven shaft; The tooth plate, the active movable tooth and the driven movable tooth are all half of the circumference of the active movable tooth and the driven movable tooth; a lubricating oil delivery device is fixed between the active push tooth and the driven push tooth. The invention has the advantages of simple structure, small volume, partial wear prevention, low energy consumption and greatly improved effective power.

Owner:邱秀芳

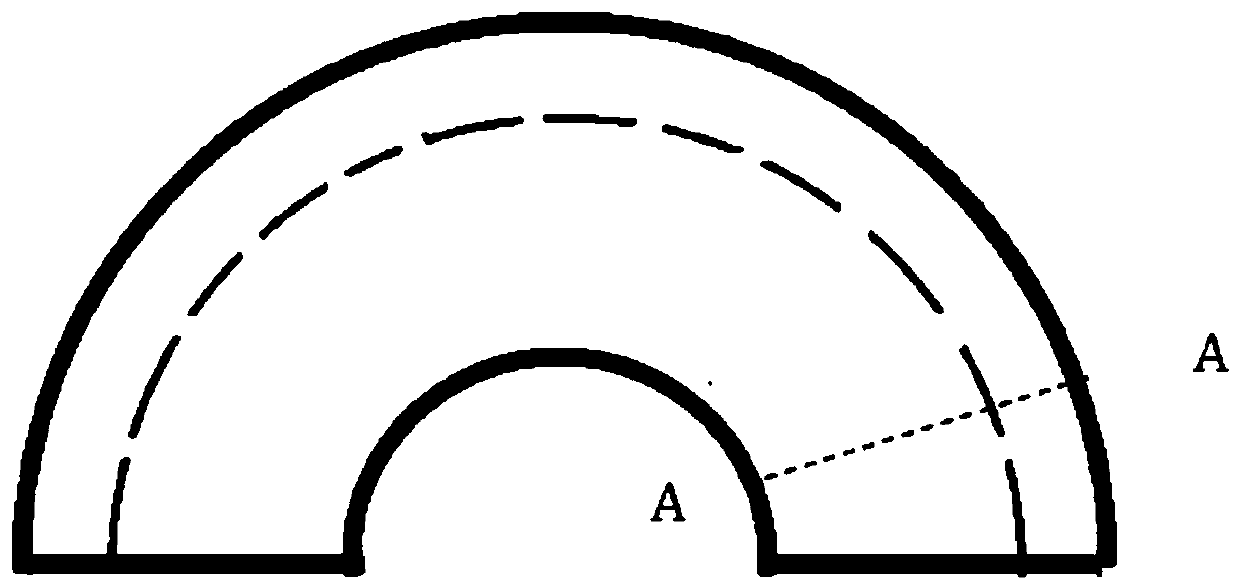

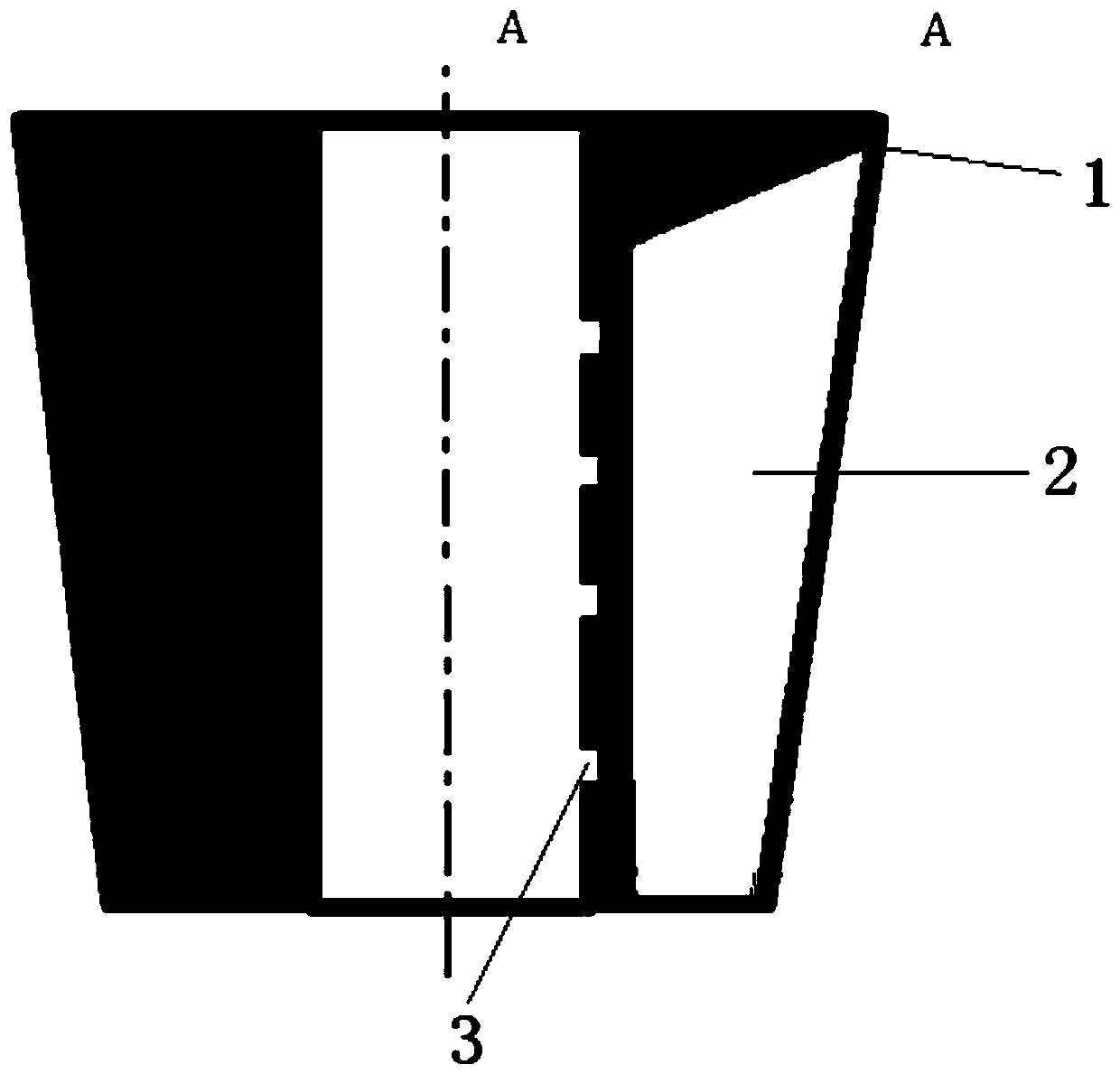

Eccentric-wear-preventing packing for oil extraction

PendingCN110630205AReduce the difficulty of replacementReduce the intensity of disassembly workDrilling rodsSealing/packingWellheadMetal

The invention relates to the technical field of polish rod sealing devices of oil pumping units in oil fields, in particular to an eccentric-wear-preventing packing for oil extraction. The packing comprises two semi-annular packing bodies; the packing bodies are internally provided with liquid cavities, and the liquid cavities are filled with filling liquid. The liquid cavities are formed in the packing, the packing replacement difficulty is reduced, the elasticity compensation capability of the packing is increased, the sealing effect of the packing is improved, the packing automatically adapts to the deviation degree of a polish rod and a wellhead, eccentric wear phenomena are eliminated, the use of parent metal is reduced, the service life of the packing is greatly prolonged, the structure is simple, and the use is convenient.

Owner:张程

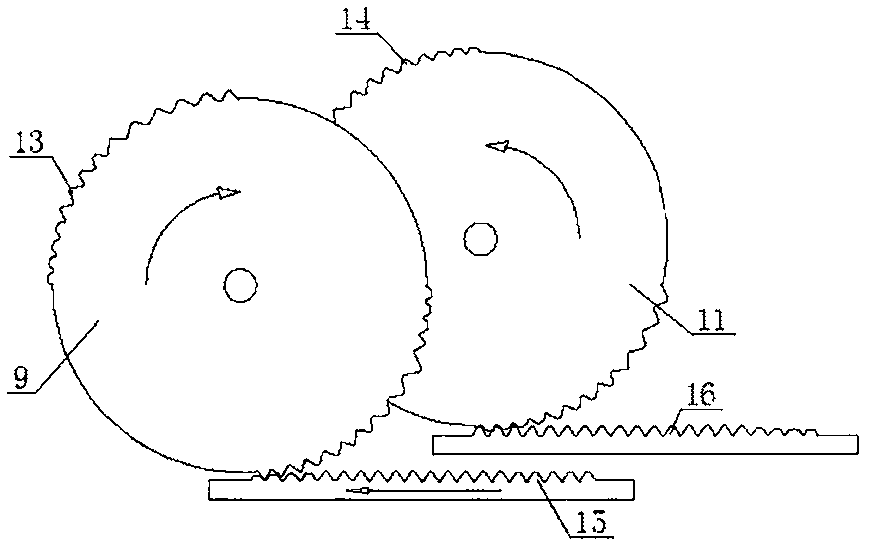

Push rod dual-oscillating-tooth drive parallel dual-cylinder internal combustion engine

InactiveCN107100731ASimple structureReasonable designMachines/enginesFriction gearingsEffective powerExternal combustion engine

The invention discloses a push rod dual-oscillating-tooth drive parallel dual-cylinder internal combustion engine, and relates to the field of internal combustion engine drive. The push rod dual-oscillating-tooth drive parallel dual-cylinder internal combustion engine solves the problems that a current crankshaft connecting rod internal combustion engine is large in size, prone to suffering from eccentric wear, high in energy consumption, low in power, high in manufacturing precision and the like. A driving rotary shaft and a driven rotary shaft are fixed to an engine body of the push rod dual-oscillating-tooth drive parallel dual-cylinder internal combustion engine through bearings; a driven oscillating tooth disc with the shape and size the same as those of a driving oscillating tooth disc on the driving rotary shaft is arranged on the driven rotary shaft, and driving oscillating teeth and driven oscillating teeth are 1 / 4 of the perimeter of the driving oscillating tooth disc and 1 / 4 of the perimeter of the driven oscillating tooth disc correspondingly; and a first push rod and a second push rod are arranged on the two sides of the driving oscillating tooth disc and the driven oscillating tooth disc correspondingly. The push rod dual-oscillating-tooth drive parallel dual-cylinder internal combustion engine is simple in structure, convenient to manufacture, small in size, low in cost, capable of preventing eccentric wear, easy to maintain and low in energy consumption, and effective power is greatly improved.

Owner:雷敬汉

Push-rod double-oscillating-tooth efficient lubricating transmission parallel double-cylinder internal combustion engine

InactiveCN106870148ASimple structureReasonable designMachines/enginesPressure lubricationEffective powerCombustion

The invention discloses a push-rod double-oscillating-tooth efficient lubricating transmission parallel double-cylinder internal combustion engine, relates to the field of internal combustion engines and solves the problems that a current crankshaft connecting rod internal combustion engine is large in size, prone to eccentric wear, high in energy consumption, low in power, high in manufacturing precision and the like. A driving rotating shaft and a driven rotating shaft are fixed to an engine body of the push-rod double oscillating-tooth efficient lubricating transmission parallel double-cylinder internal combustion engine through bearings; the driven rotating shaft is provided with a driven oscillating-tooth disc with the shape and size being the same as those of a driving oscillating-tooth disc on the driving rotating shaft, and driving oscillating teeth and driven oscillating teeth are both one quarter the perimeter of the driving oscillating-tooth disc and one quarter the perimeter of the driven oscillating-tooth disc; and a first push rod and a second push rod are connected with a first lubricating oil conveying device and a second lubricating oil conveying device correspondingly. The push-rod double oscillating-tooth efficient lubricating transmission parallel double-cylinder internal combustion engine is simple in structure, small in size, resistant to eccentric wear and low in energy consumption, and effective power is greatly improved.

Owner:邱秀芳

Push rod three-oscillating-teeth efficient lubrication transmission opposite-column double-cylinder internal combustion engine

InactiveCN106988876ASimple structureReasonable designMachines/enginesPressure lubricationEffective powerRAM drive

The invention discloses a push rod three movable teeth high-efficiency lubricated transmission opposed row double-cylinder internal combustion engine, and relates to the field of internal combustion engine transmission. The invention solves the problems of large volume, easy partial wear, high energy consumption, low power and high manufacturing precision of the current crankshaft connecting rod internal combustion engine. The three movable teeth of the push rod are efficiently lubricated and driven. The body of the dual-cylinder internal combustion engine is fixed with a driving shaft and a driven shaft through bearings; The tooth plate, the active movable tooth and the driven movable tooth are all one-sixth of the circumference of the active movable tooth and the driven movable tooth; a lubricating oil delivery device is fixed between the active push tooth and the driven push tooth. The invention has the advantages of simple structure, small volume, partial wear prevention, low energy consumption and greatly improved effective power.

Owner:邱秀芳

High-efficiency lubricating and transmitting type internal combustion engine with push rods, four sets of oscillating teeth double and parallel cylinders

InactiveCN106870149ASimple structureReasonable designMachines/enginesPressure lubricationEffective powerCombustion

The invention discloses a high-efficiency lubricating and transmitting type internal combustion engine with push rods, four sets of oscillating teeth double and parallel cylinders, and relates to the field of internal combustion engines. The internal combustion engine solves the problems that an existing crankshaft and connecting rod internal combustion engine is large in size, prone to eccentric wear, high in energy consumption, low in power, low in manufacturing precision and the like. According to the high-efficiency lubricating and transmitting type internal combustion engine with the push rods, the four sets of oscillating teeth double and the parallel cylinders, a driving rotating shaft and a driven rotating shaft are fixed on an internal combustion engine body through a bearing; a driven oscillating tooth disc is arranged on the driven rotating shaft, wherein the shape and the size of the driven oscillating tooth disc is the same as the shape and the size of a driving oscillating tooth disc on the driving rotating shaft; the edge arrangement length of each set of driving oscillating teeth is one eighth of the perimeter of the driving oscillating tooth disc, and the edge arrangement length of each set of driven oscillating teeth is one eighth of the perimeter of the driven oscillating tooth disc; and the first push rod and the second push rod are connected to a first lubricating oil conveying device and a second lubricating oil conveying device respectively. The high-efficiency lubricating and transmitting type internal combustion engine with the push rods, the four sets of oscillating teeth double and the parallel cylinders is simple in structure, small in size, capable of preventing eccentric wear and low in energy consumption, and the effective power is greatly improved.

Owner:邱秀芳

Push-rod five-oscillating-tooth transmission oppositely-arranged double-cylinder internal combustion engine

InactiveCN106988875ASimple structureReduce volumeMachines/enginesFriction gearingsEffective powerExternal combustion engine

The invention discloses a push-rod five-oscillating-tooth transmission oppositely-arranged double-cylinder internal combustion engine, relates to the field of internal combustion engine transmission and solves the problems that an existing crankshaft connecting rod internal combustion engine is large in size, prone to eccentric wear, high in energy consumption, low in power, high in manufacturing precision and the like. An engine body of the push-rod five-oscillating-tooth transmission oppositely-arranged double-cylinder internal combustion engine is fixedly provided with a driving rotating shaft and a driven rotating shaft through bearings; the driven rotating shaft is provided with a driven oscillating-tooth disc with the same shape and size as those of a driving oscillating-tooth disc on the driving rotating shaft, driving oscillating teeth and driven oscillating teeth are all one tenth of the perimeter of the driving oscillating-tooth disc and the perimeter of the driven oscillating-tooth disc, and the two ends of a push rod are vertically and fixedly provided with a first air cylinder and a second air cylinder correspondingly. The push-rod five-oscillating-tooth transmission oppositely-arranged double-cylinder internal combustion engine is simple in structure, convenient to manufacture, small in size, low in cost, prone to eccentric wear, easy to maintain and low in energy consumption, and effective power is greatly improved.

Owner:雷敬汉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com