Push rod single-oscillating-tooth efficient lubrication transmission opposite-column double-cylinder internal combustion engine

A technology for internal combustion engines and movable teeth, which is applied in the field of dual-cylinder internal combustion engines with high-efficiency lubrication and transmission of push rod single movable teeth, which can solve the problem of low thermal energy utilization rate of internal combustion engines, excessive power transmission, damage to the inner wall of the cylinder or piston, etc. problem, to achieve the effect of eliminating eccentric wear, simple structure, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

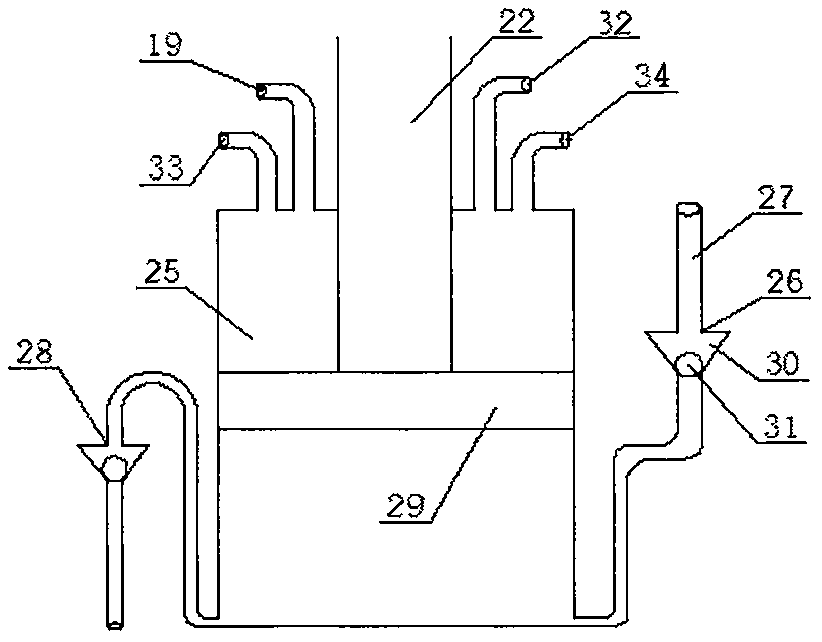

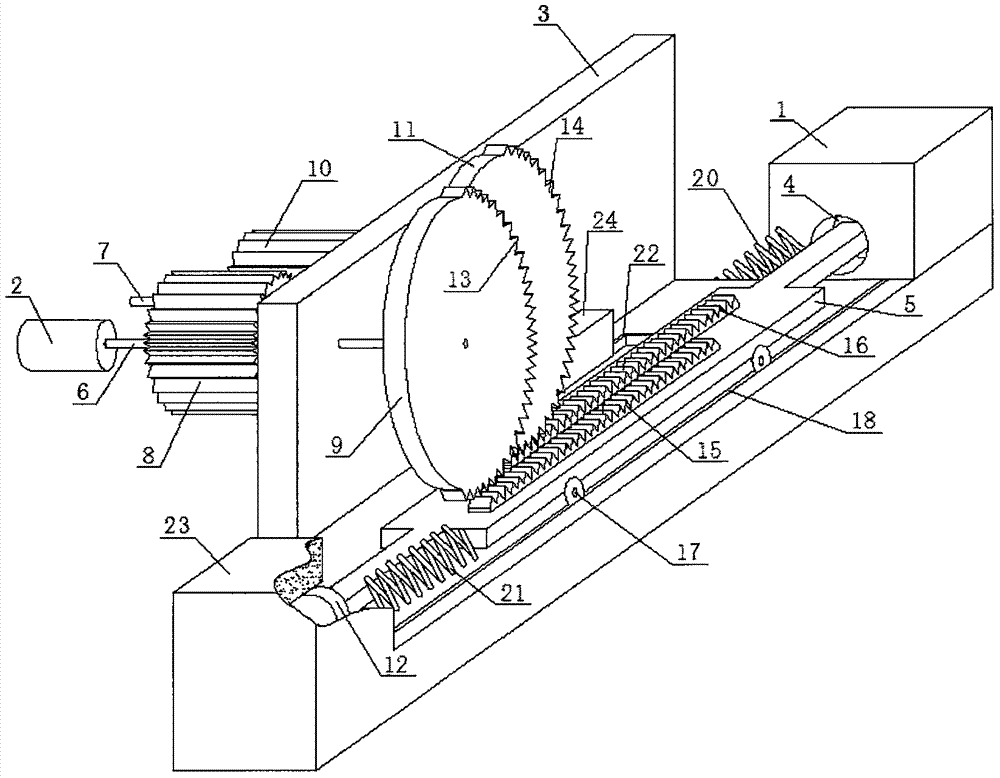

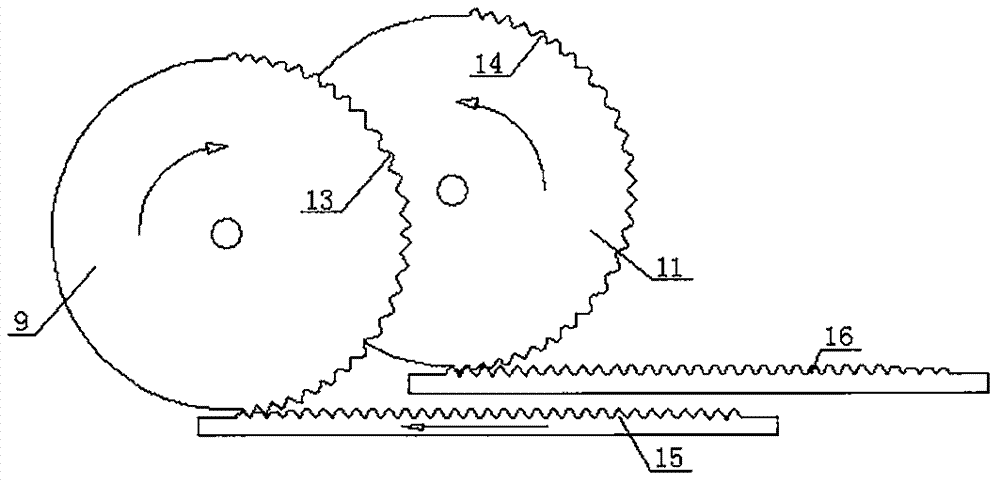

[0020] Such as figure 1As shown, the push rod single-movable tooth high-efficiency lubrication transmission dual-cylinder internal combustion engine of the present embodiment includes a cylinder, a transmission shaft 2, a lubricating oil tank, a lubricating oil delivery device 24 and an internal combustion engine body 3, and a piston is arranged in the cylinder. The internal combustion engine body 3 is fixed with a driving shaft 6 and a driven shaft 7 by bearings, and the outer end of the driving shaft 6 fixed on the internal combustion engine body 3 is a transmission shaft 2 . The active rotating shaft 6 is provided with an active toothed disc 8 and an active movable toothed disc 9, and the active rotating shaft 6 between the active toothed disc 8 and the active movable toothed disc 9 is provided with a bearing and is fixed with the internal combustion engine body 3. The driven shaft 7 is provided with a driven toothed disc 10 meshing with the active toothed disc 8 on the act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com