Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Easy rotary cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

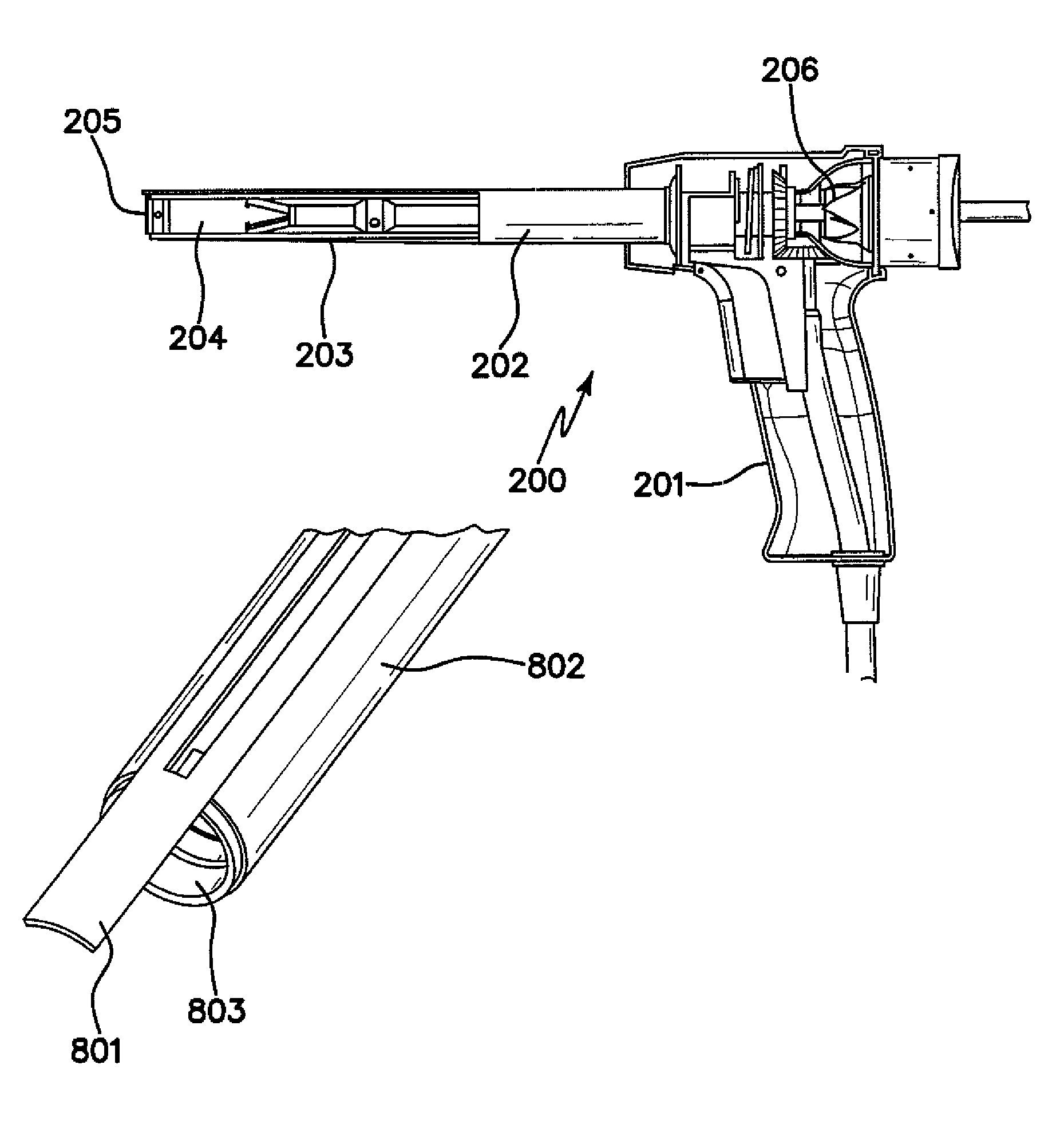

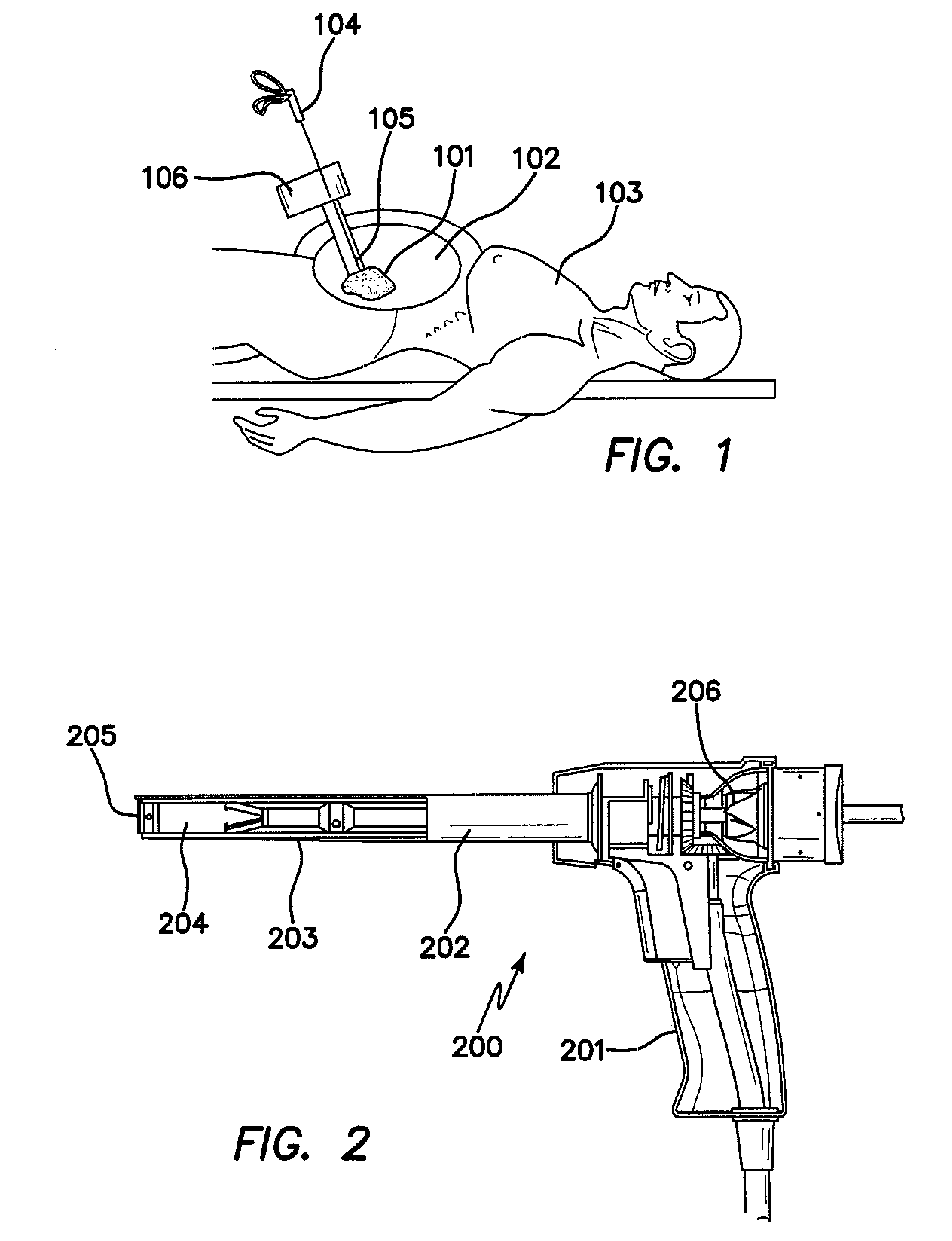

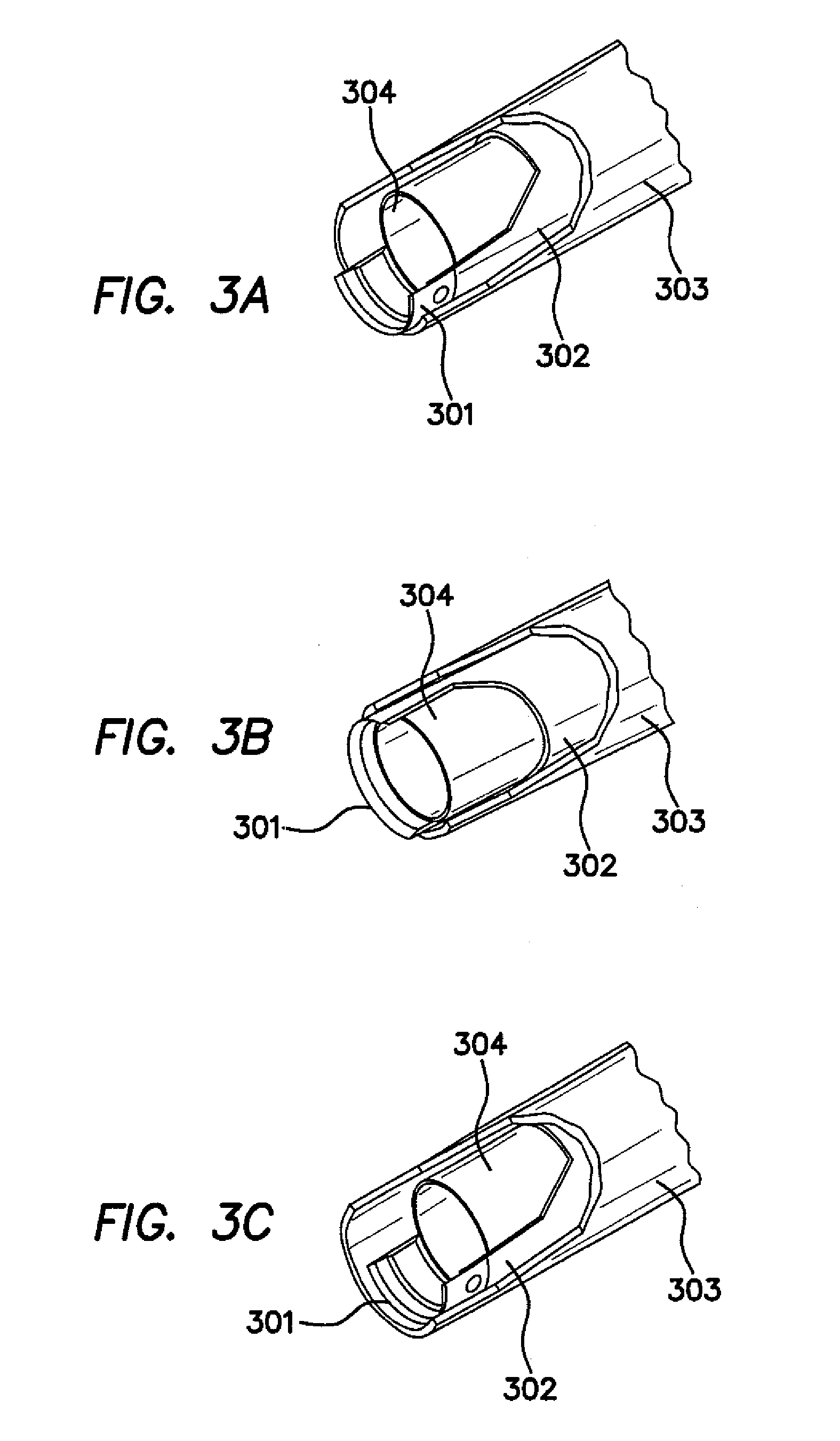

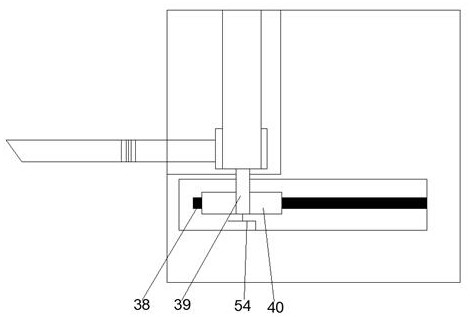

Method and apparatus for tissue morcellation

InactiveUS8308746B2Easy rotary cuttingFacilitate tissue cuttingDiagnosticsExcision instrumentsCoringSurgical department

The invention relates to a tissue morcellator for minimally invasive surgery. The morcellator has a metallic cutting ring mounted on a visually transparent hollow cylinder, which in combination with a visually transparent outer morcellator tube enables a surgeon to visualize the inside of the morcellator shaft for detection of loose tissue fragments in the device. A tenaculum used with the morcellation device has a spacer for preventing contact with the blade. The cutting tube can oscillate, rather than rotate, along the longitudinal axis of the cutting tube. The morcellator utilizes an extendable tissue guide on the outer tube of the morcellator shaft for preventing the tissue from rotating along the longitudinal axis of the morcellator tube. This allows the tissue to be continuously rotated into the morcellator device for continuous peel. The tissue guide can also be fully retracted to allow for coring of the bulk tissue.

Owner:APPL MEDICAL RESOURCES CORP

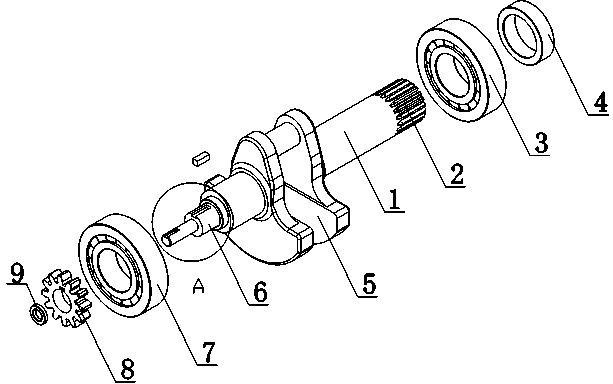

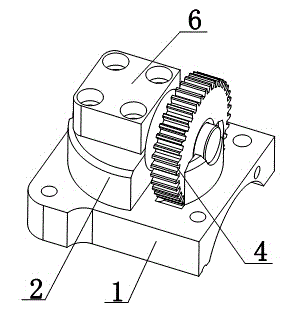

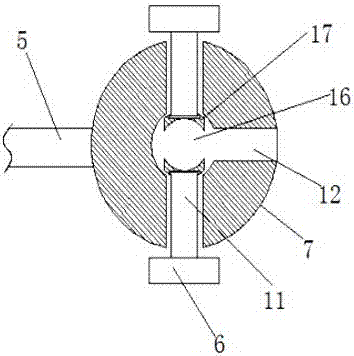

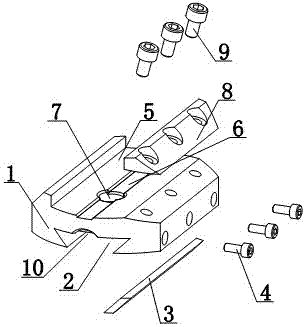

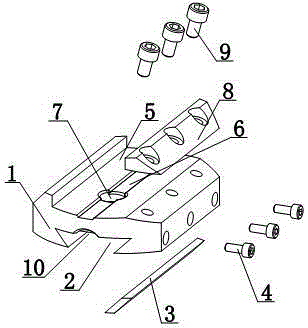

Rod-shaped material rotary cutting mechanism

The invention discloses a rod-shaped material rotary cutting mechanism. The rod-shaped material rotary cutting mechanism comprises a driving tube, wherein the driving tube is of a tubular structure, a driving cylinder is arranged at the end of the driving tube, a driving shaft is connected to the driving cylinder in an insertion mode, a first plane bearing and a second plane bearing are arranged between the driving shaft and the driving cylinder, a gear is arranged at the end of the driving shaft, and teeth are arranged on the outer surface of the gear. The rod-shaped material rotary cutting mechanism can be installed in a cylinder body, and is externally connected with a driving motor through the driving tube, the driving tube can be controlled to rotate through the driving motor, the driving shaft can be controlled to rotate through the driving tube, and therefore the gear is driven to rotate, and rotary cutting processing can be conveniently conducted on a rod-shaped material.

Owner:朱德金

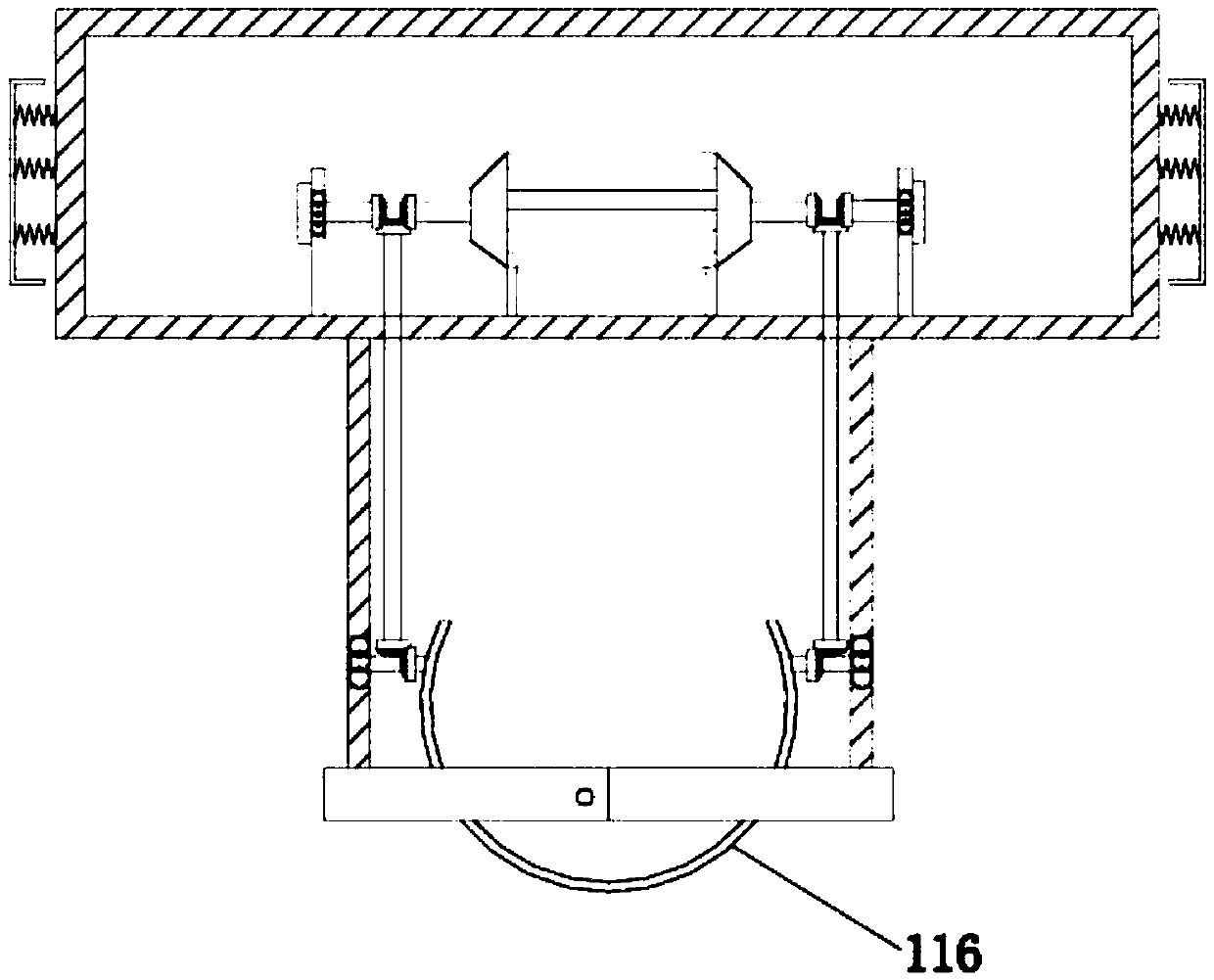

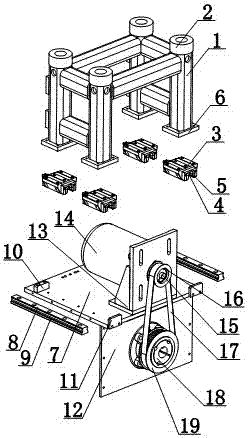

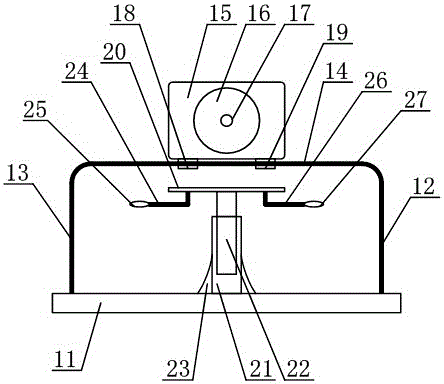

Progressive aluminum pipe rotary-cutting device

InactiveCN105081442AEasy to transportEasy rotary cuttingFeeding apparatusTube shearing machinesEngineeringDrive shaft

The invention discloses a progressive aluminum pipe rotary-cutting device. The device comprises a base plate. Supporting pillars are arranged on the base plate, and a conveyance pipeline is arranged between the ends of the supporting pillars. A guiding pipe is arranged on the base plate, and a lifting control pipe is sleeved with the guiding pipe. A rotary-cutting motor is arranged at one end of the lifting control pipe and connected with a driving shaft. The driving shaft is sleeved with a driving pipe, and the driving pipe is connected with the driving shaft through threads. A rotary-cutting wheel is arranged at one end of the driving pipe and located in front of the conveyance pipeline. By the adoption of the device, aluminum pipe conveyance is facilitated; the rotary-cutting motor can control the rotary-cutting wheel to rotate through the driving shaft and the driving pipe, so that rotary-cutting of aluminum pipes is facilitated.

Owner:TIANJIN SHENGFA IND & TRADE

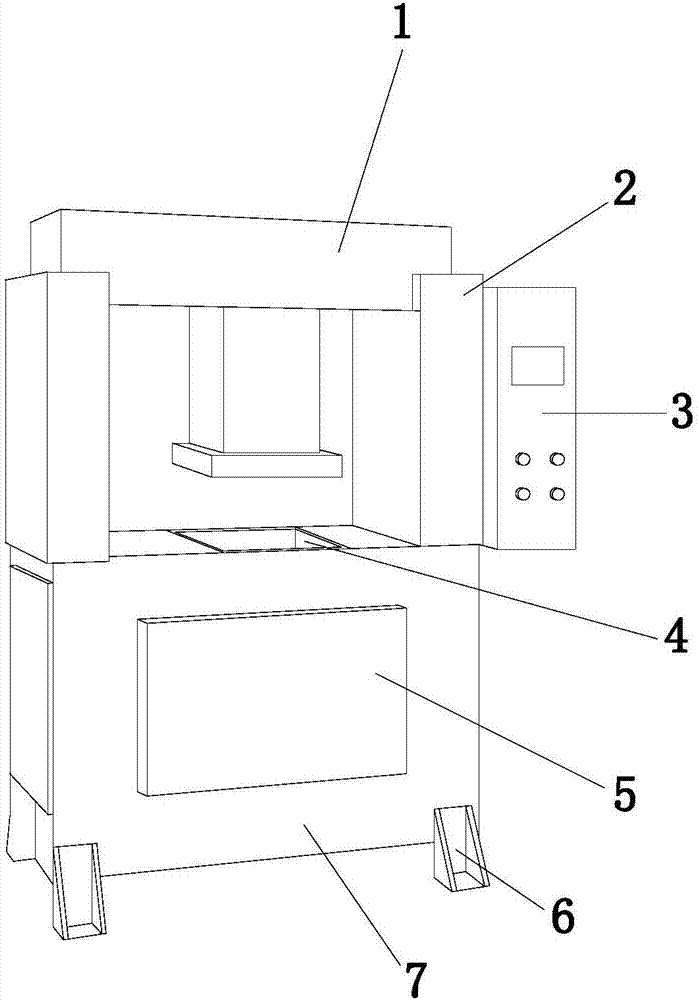

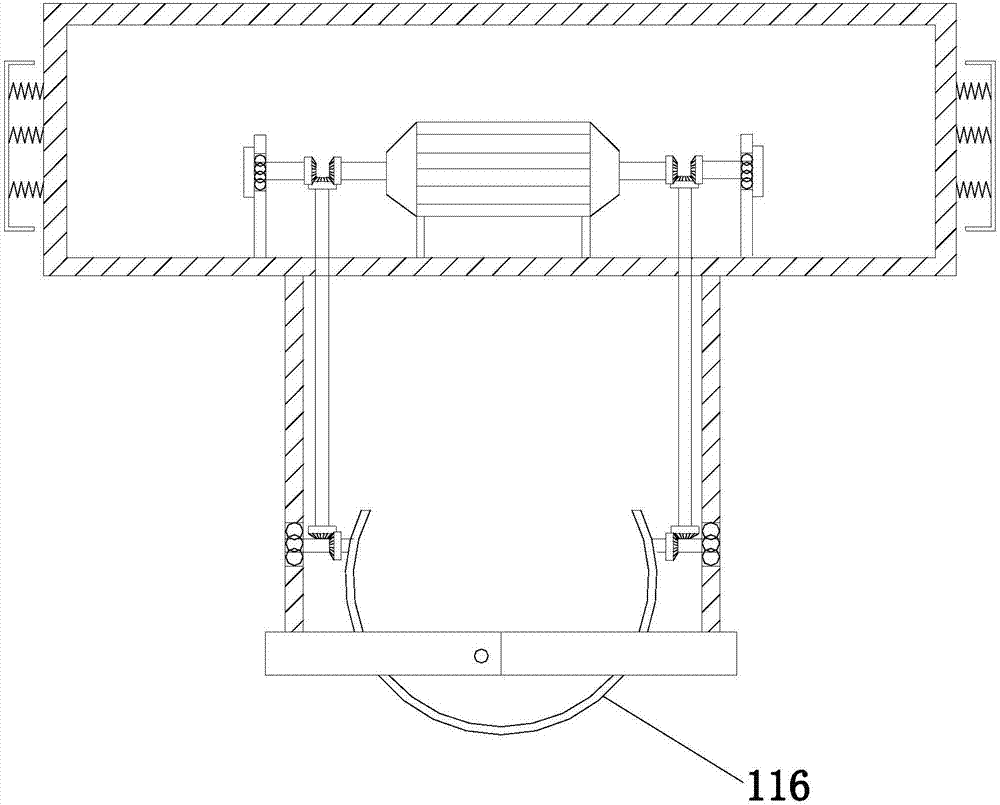

Outer rubber die cutting machine for sporting goods

The invention discloses an outer rubber die cutting machine for sporting goods. The outer rubber die cutting machine structurally comprises a die cutting machine, fixed supporting columns, a controller, a waste material inlet, a cleaning door cabinet, bottom supporting feet and a waste material collecting box. According to the outer rubber die cutting machine for the sporting goods, a double-shaftmotor is arranged in a machine body of the die cutting machine, the double-shaft motor meshes with driven gears arranged at the top ends of transmission shafts through driving gears arranged on a rotating shaft, the transmission shafts mesh with gears arranged on shafts through the driven gears arranged at the bottom ends, and therefore the shafts can be rotated; the left side and the right sideof an arc-shaped laminating die cutter are fixed on the shafts respectively in a buckling mode, and therefore rotary cutting can be carried out on the finished rubber ball-shaped sporting goods, andthe texture of the sporting goods during use is improved; and the materials which are processed automatically fall off from a clamp, and therefore the processing efficiency is improved.

Owner:聊城约取知识产权运营有限公司

Tool changing device for machine tool

InactiveCN106078304AHigh hardnessImprove toughnessPositioning apparatusMetal-working holdersDrive motorDrill bit

The invention discloses a tool changing device for a machine tool. The tool changing device comprises a main shaft, a driving motor and a driving box, wherein the main shaft is positioned on the left side of the driving box and is fixed to the driving box, a connecting head is arranged on the lower end of the main shaft, clamping jaws are arranged on both ends of the connecting head, a standby tool is arranged on the left clamping jaw, a tool is arranged on the right clamping jaw, the driving motor is positioned above the driving box, a connecting seat is arranged on the lower end of the driving motor, the connecting seat is fixed to the driving box, a movable rod is arranged on the connecting seat, a driving shaft is arranged on the lower end of the connecting seat, the driving shaft is positioned in the driving box, a speed reduction wheel is arranged in the driving box, a meshing gear is arranged in the speed reduction wheel, and a drill is arranged on the lower end of the driving box. The tool changing device for the machine tool has the advantages of convenience and rapidity in tool changing, high efficiency and convenience in control, and the main shaft has the advantages of high hardness and good toughness.

Owner:NINGBO JINKAI MASCH TOOL CO LTD

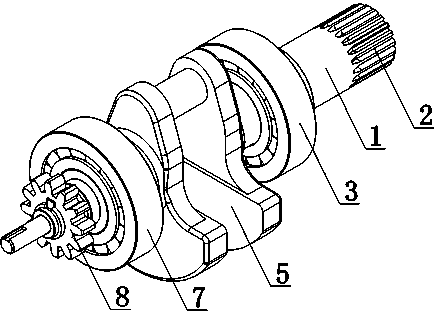

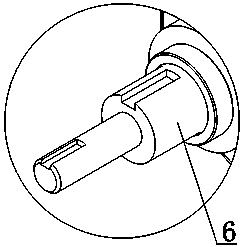

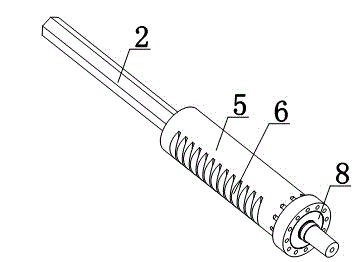

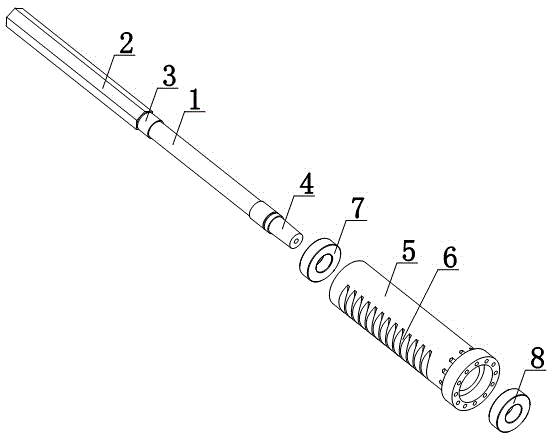

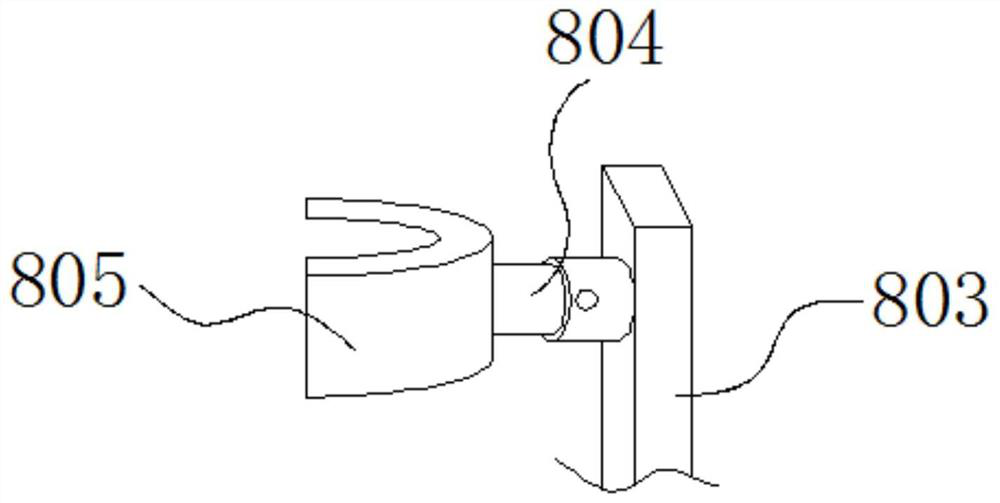

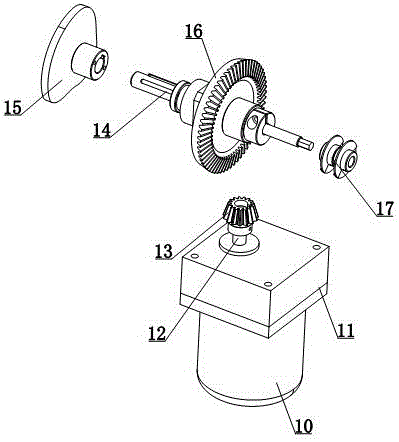

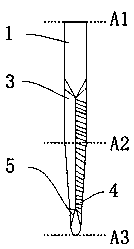

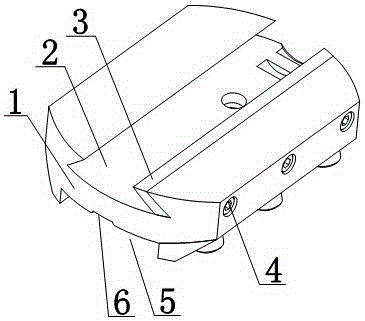

Simple rotary cutting mechanism

InactiveCN104760104AImplement rotation controlEasy rotary cuttingVeneer manufactureDrive motorEngineering

The invention discloses a simple rotary cutting mechanism. The mechanism comprises a driving pipe; a rotary cutting groove is formed in one end of the driving pipe; the driving pipe is provided with an oscillating block and sleeved with a first plane bearing, wherein the first plane bearing is in contact with the oscillating block; a sleeve ring is arranged at the part in which the plane bearing is connected with the driving pipe; the oscillating block is provided with a driving end which is sleeved with a second plane bearing and a driving gear. According to the mechanism, the driving end is externally connected with a driving motor; the driving motor can directly control the driving gear to rotate so as to achieve the rotating control of the driving pipe; the rotary cutting groove in the end part of the driving pipe can achieve the rotary cutting function, so that an article can be conveniently treated by rotary cutting.

Owner:周玉翔

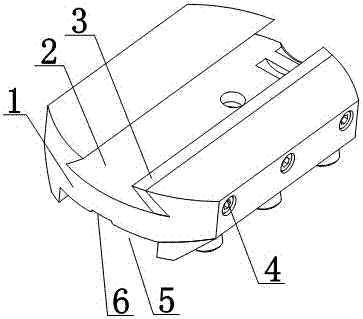

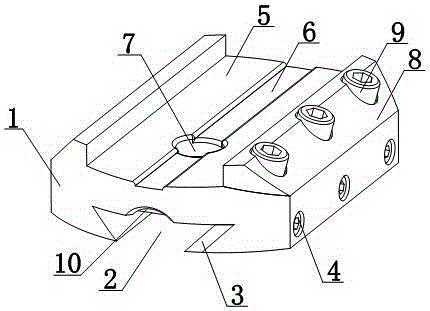

Gear-driven rotary cutting seat for boards

The invention discloses a gear-driven rotary cutting seat for boards. The gear-driving rotary cutting seat comprises a base plate, a base is arranged on the base plate, a mounting groove is formed in the base, a driving shaft is mounted on the mounting groove, a rotary cutting wheel is arranged at the end of the driving shaft, a rotary cutting groove is formed in the outer periphery of the rotary cutting wheel, a fastening seat is arranged on the base, the driving shaft is fastened by the fastening seat, and the fastening seat is provided with a fastening groove corresponding to the mounting groove. The gear-driven rotary cutting seat has the advantages that the driving shaft is connected with a driving motor externally, the driving motor can control the driving shaft to rotate, and accordingly, the rotary cutting wheel is rotated conveniently; the boards can be placed on the base plate and close to the rotary cutting wheel, thereby being subjected to rotary cutting conveniently.

Owner:李广连

Tabular material rotary-cut bar

InactiveCN104924405AEasy rotary cuttingGood rotary cutting efficiencyVeneer manufactureRotary cutting toolsDrive motorEngineering

The invention discloses a tabular material rotary-cut bar, which comprises a driving rod; the end part of the driving rod is provided with a mounting end; the mounting end is sleeved with a rotary-cut barrel; the outer surface of the rotary-cut barrel is provided with a plurality of rotary-cut grooves; the rotary-cut grooves are in equal interval arrangement; the rotary-cut barrel is internally provided with a connecting ring; and the rotary-cut barrel is externally provided with a buckling ring. The rotary-cut bar can be connected with a driving motor which can control the rotary-cut bar to rotate, so that the rotary-cut bar can conveniently carry out rotary-cut processing on tubular materials, and the rotary-cut efficiency is higher.

Owner:张立

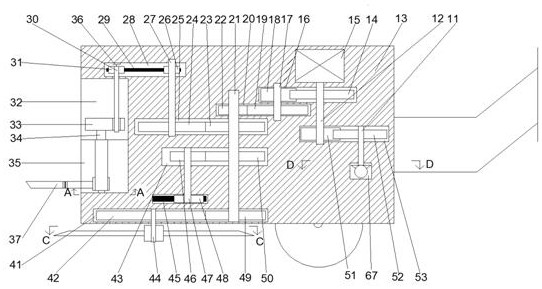

Cable breakpoint wiring device for electric power

ActiveCN111969504AEasy to fixEasy to separateLine/current collector detailsApparatus for removing/armouring cablesStructural engineeringInsulation layer

The invention discloses a cable breakpoint wiring device for electric power. The device comprises a body, a feeding mechanism is arranged in the middle of the upper surface of the body; a telescopic rod is mounted in the middle of the interior of the feeding mechanism; a material receiving opening is formed in the surface of the left side of the clamping mechanism; a second rack is arranged underthe right side surface of the clamping mechanism; a feeding hole is formed in the center of the left side surface of the body; a collecting box is mounted under the body; and the clamping mechanism and the cutting mechanism are arranged in the body. The body is arranged, so that the clamping mechanism and the cutting mechanism can be fixed conveniently, through arrangement of the cutting mechanism, body injuries caused by manual misoperation of a technician can be avoided conveniently through mechanical operation, meanwhile, through arrangement of the clamping mechanism, a cable insulation layer can be fixed conveniently, and therefore separation between the insulation layer and an electric wire is facilitated.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO PINGYUAN POWER SUPPLY CO

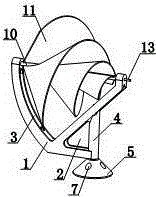

Seedling taking device for agricultural seedling cultivation

The invention discloses a seedling taking device for agricultural seedling cultivation. The seedling taking device structurally comprises a gripping handle, a hollow rod, a connection disc, thin connection rods, a seedling taking groove, a pedal, a U-shaped frame, a rotary rod and a soft sleeve, the gripping handle is perpendicularly welded to the left and right sides of the top of the hollow rod,and the tail end of the gripping handle is wrapped with the soft sleeve; the bottom of the hollow rod is perpendicularly welded to the top of the connection disc, and the left and right sides of theconnection disc are perpendicularly welded to the inner wall of the top of the seedling taking groove through the thin connection rods; the seedling raking device has the advantages that a rotary device is installed between the seedling taking groove and a seedling taking inner frame, and soil around seedlings is conveniently cut rotatably, so that the seedling roots are wrapped with the soil; oblique cutting edges are arranged at the tail ends of the seedling taking inner frame, and the seedling taking inner frame is conveniently inserted in the soil of the roots of the seedlings under the effect of external force; an arc rolling groove is formed in a second rotation groove, inward deformation can be caused to the tail end of the seedling taking inner frame, and a certain compaction effect on the soil is achieved, so that soil clumps are formed, and the soil does not easily fall off.

Owner:湖南界溪河生物科技有限公司

Shearing device for piston rubber ring machining

The invention discloses a shearing device for piston rubber ring machining, and relates to the technical field of piston rubber ring machining. The shearing device comprises a base, a clamping and fixing mechanism, a cutting mechanism and a movable positioning mechanism, a side plate is fixed to the outer side of the upper portion of the base, a hydraulic cylinder is installed above the middle ofthe base, and a piston rod is arranged above the hydraulic cylinder; and a supporting seat is fixed above the piston rod, a driving motor is installed above the supporting seat, a rotating shaft is arranged above the driving motor, an auxiliary steel core is arranged above the rotating shaft in a sleeving mode, and a rubber ring pipe blank is arranged on the outer side of the auxiliary steel core.The shearing device has the following beneficial effects that the auxiliary steel core and the rubber ring pipe blank on the outer side of the auxiliary steel core are conveniently driven to rotate through the arrangement of the driving motor and the rotating shaft, so that the cutting mechanism can rotate for a circle on the outer side of the auxiliary steel core and the rubber ring pipe blank to deepen the cutting effect; and through the arrangement of the hydraulic cylinder and the piston rod, the driving motor and the auxiliary steel core are conveniently driven to ascend and descend, andtherefore the shearing position is conveniently adjusted.

Owner:王水成

Portable numerical control cutting machine

InactiveCN107160003AEasy to reinforceUniform distanceGas flame welding apparatusNumerical controlQuality of work

The invention discloses a portable numerical control cutting machine, which comprises a cutting machine body, one side of the cutting machine body is slidably connected with a base, and the side of the cutting machine body close to the base is rotatably connected with a slider, and the base is provided with a There are through slots matching with the sliders, four sets of limit slide bars are provided on the cutting machine body, and chutes matching with the limit slide bars are provided on the base, and the limit slide bars are far away from the bottom of the base. One end is vertically provided with a lifting plate, and the lifting plate is connected to the cutting machine body through a spring. The cutting machine body is provided with a vertical beam, and one end of the beam is provided with a cutting torch. One side of the machine body is provided with two sets of rotating plates. The invention can keep the distance between the cutting torch and the steel plate uniform, and can avoid problems such as cutting tumors or incomplete cutting when cutting. At the same time, when changing the site, it does not need to be disassembled, and is easy to carry, ensuring the work quality.

Owner:张艳

A sporting goods skin die-cutting machine

The invention discloses an outer rubber die cutting machine for sporting goods. The outer rubber die cutting machine structurally comprises a die cutting machine, fixed supporting columns, a controller, a waste material inlet, a cleaning door cabinet, bottom supporting feet and a waste material collecting box. According to the outer rubber die cutting machine for the sporting goods, a double-shaftmotor is arranged in a machine body of the die cutting machine, the double-shaft motor meshes with driven gears arranged at the top ends of transmission shafts through driving gears arranged on a rotating shaft, the transmission shafts mesh with gears arranged on shafts through the driven gears arranged at the bottom ends, and therefore the shafts can be rotated; the left side and the right sideof an arc-shaped laminating die cutter are fixed on the shafts respectively in a buckling mode, and therefore rotary cutting can be carried out on the finished rubber ball-shaped sporting goods, andthe texture of the sporting goods during use is improved; and the materials which are processed automatically fall off from a clamp, and therefore the processing efficiency is improved.

Owner:聊城约取知识产权运营有限公司

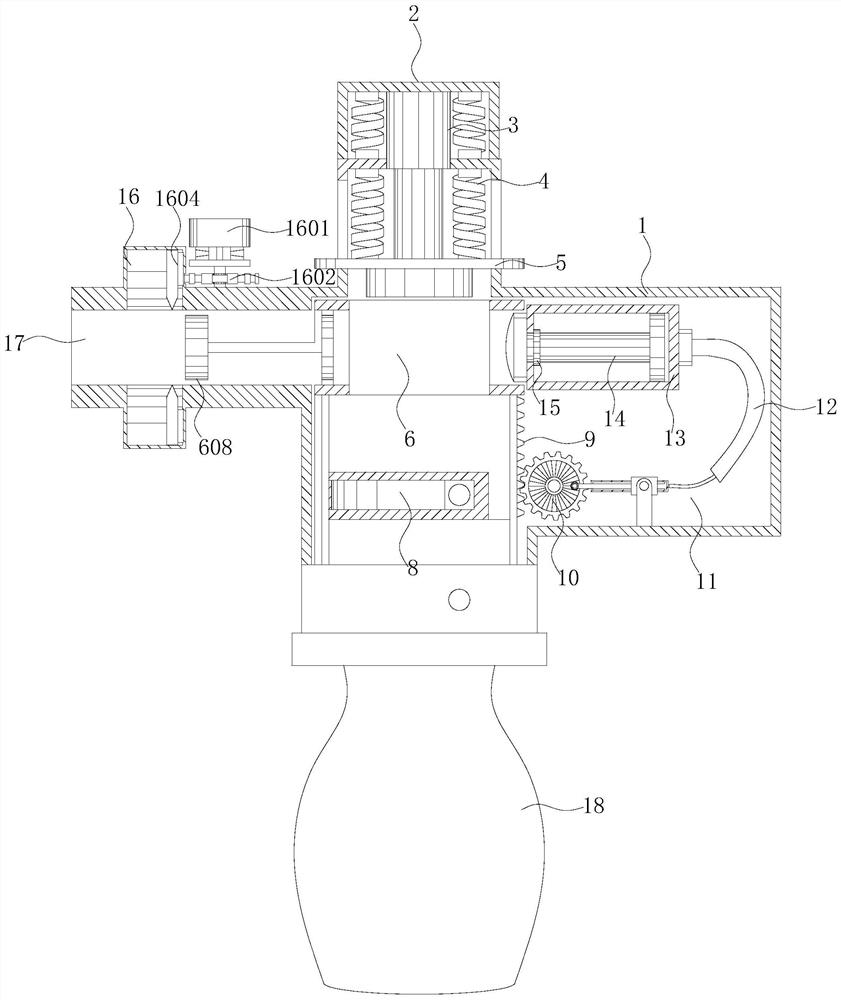

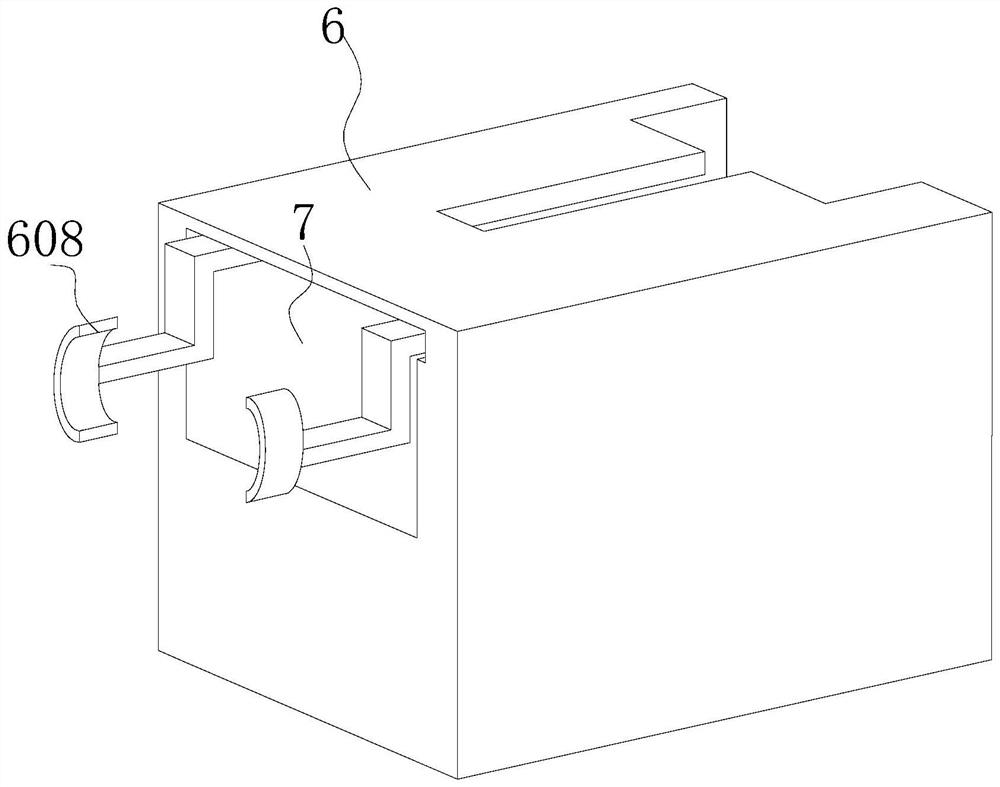

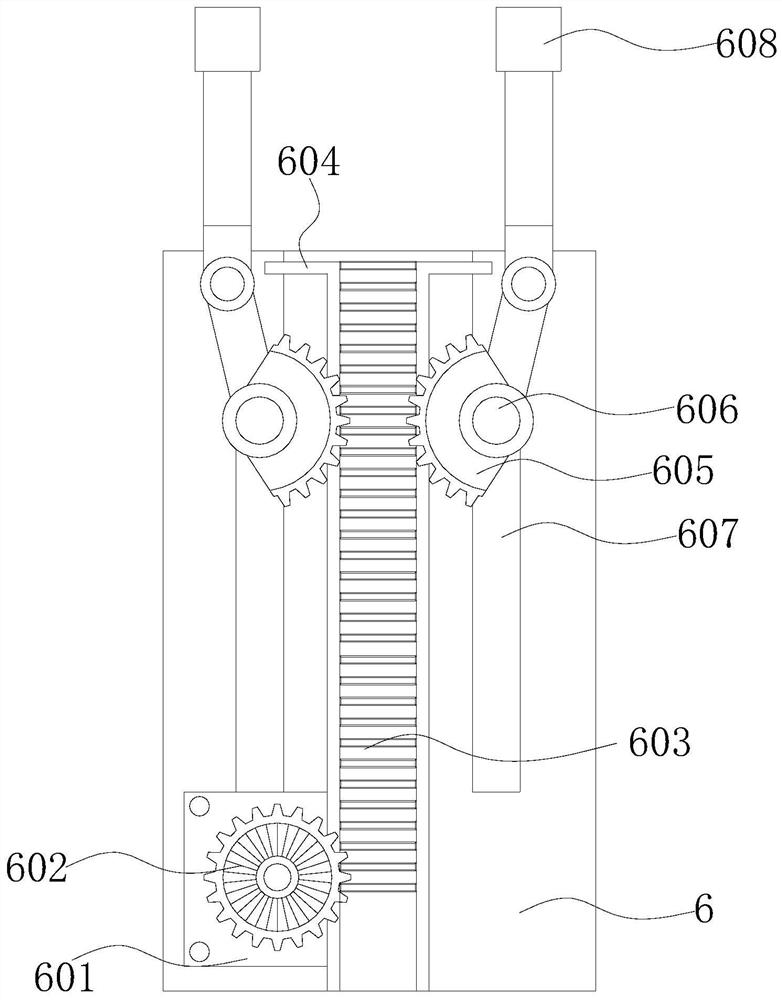

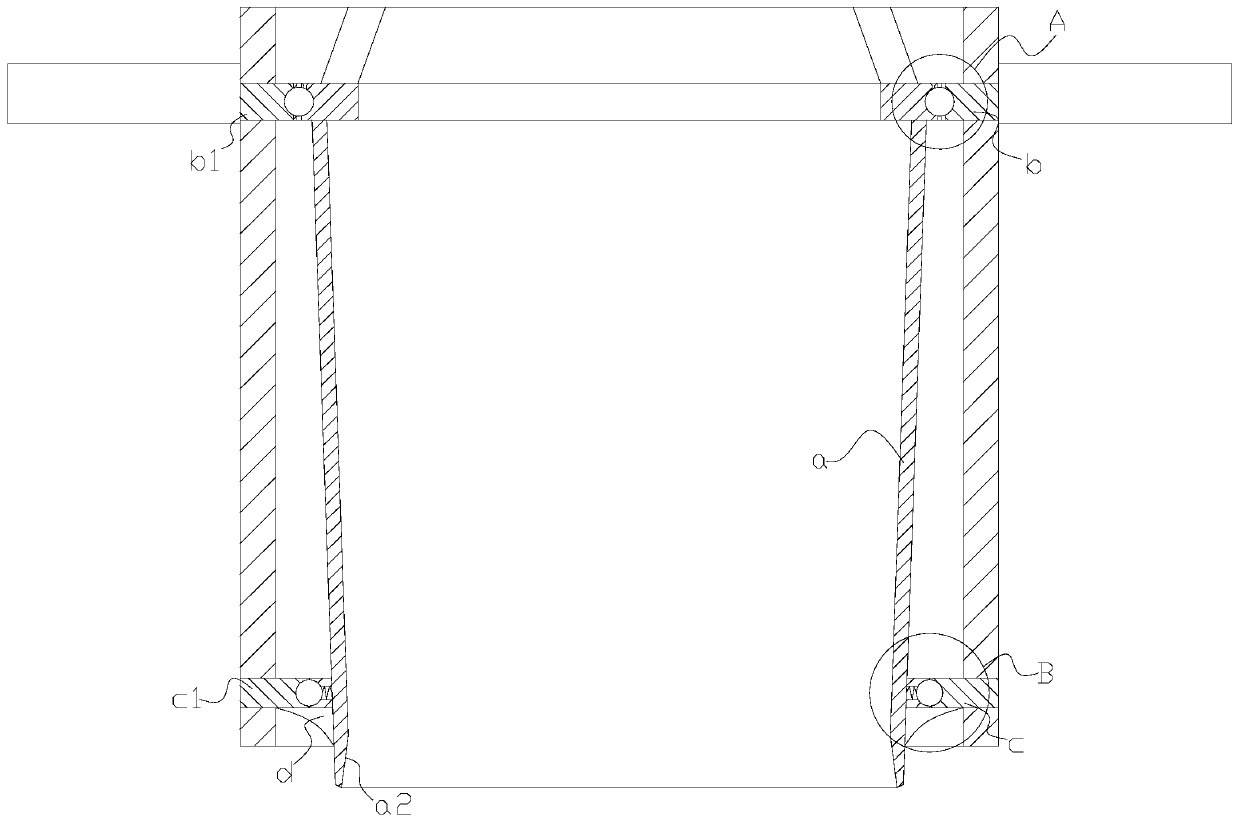

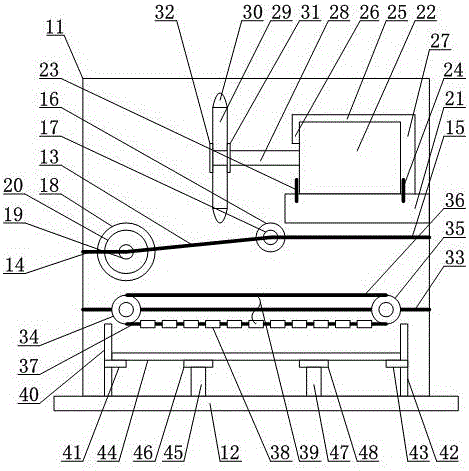

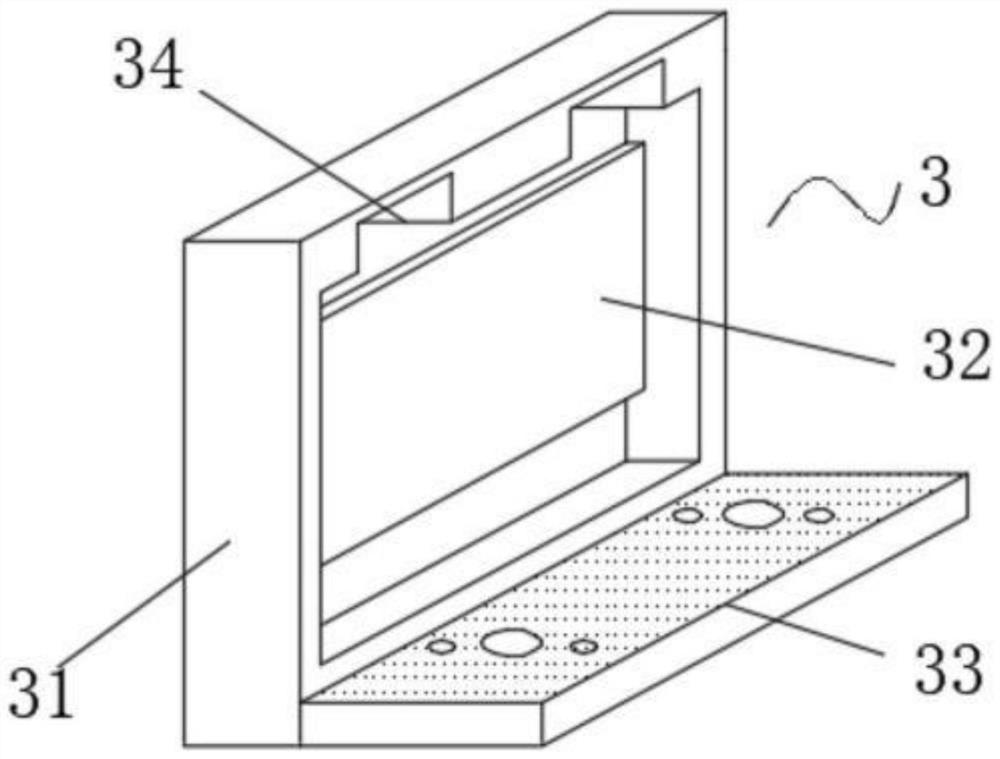

Suspended ceiling type wood rotary cutting device

The invention discloses a ceiling-type wood rotary cutting device, comprising a ceiling frame, the end of the ceiling frame is provided with a mounting end; the ceiling frame is arranged on a fixing plate, the fixing plate is provided with guide rails, and grooves are arranged on both sides of the guide rails , the bottom of the ceiling frame is provided with a sliding seat, the bottom of the sliding seat is provided with a sliding groove, the inward facing surface of the sliding groove is provided with a convex edge, the sliding seat is set on the guide rail, and the convex edge is set in the groove; The part is provided with a mounting plate, the fixed plate is provided with a fixed frame, the fixed frame is provided with a driving wheel, the fixed plate is provided with a driving motor, the driving motor is provided with a driving shaft, the driving shaft is connected with the driving wheel, and the mounting plate is provided with a rotary cutting wheel, The rotary cutting wheel is connected with the driving wheel through a belt, and the rotary cutting wheel is set with a rotary cutting knife ring. The driving wheel of the invention drives the rotary cutting wheel to rotate through the belt, so as to facilitate the rotation control of the rotary cutting wheel; the rotary cutting wheel facilitates the rotary control of the rotary cutting knife ring, and the rotary cutting knife ring facilitates the rotary cutting treatment of wood .

Owner:季晓鸣

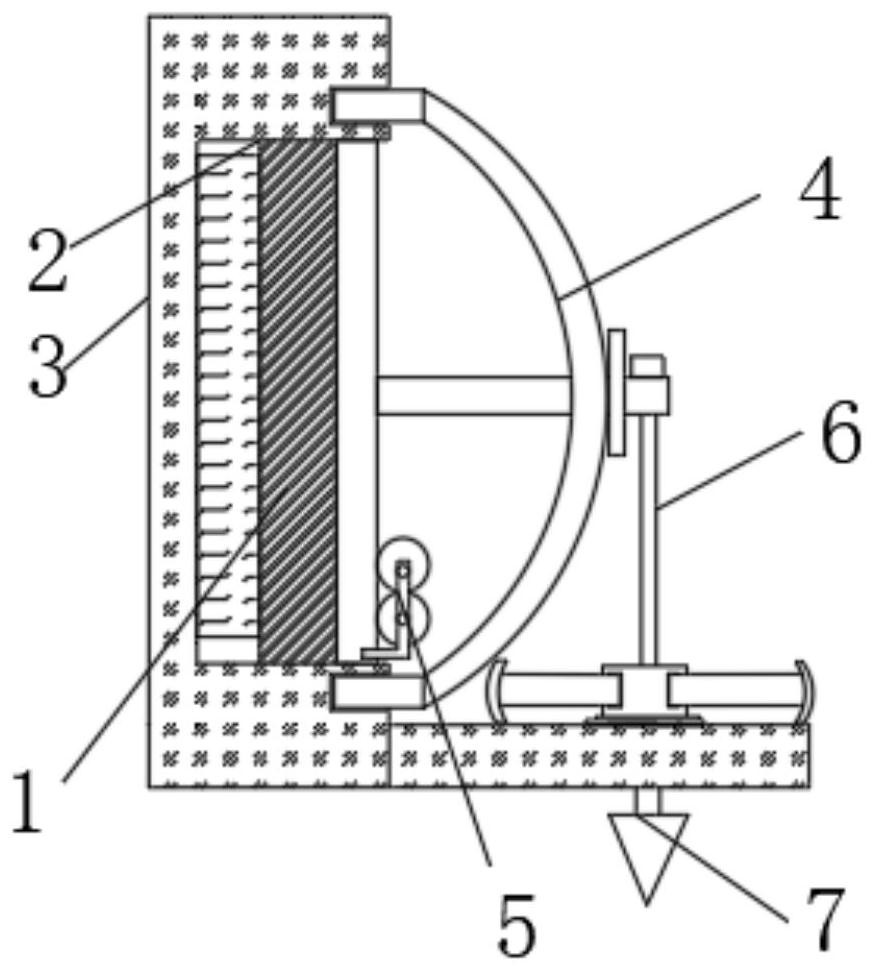

Spin cutting device for coaxial cable sampling

InactiveCN106486880AStable supportEasy to installLine/current collector detailsMilling equipment detailsCoaxial cableDrive shaft

The invention discloses a spin cutting device for coaxial cable sampling. The spin cutting device comprises a rack; the rack is arranged on a base; a mounting frame is arranged in the rack; one side of the mounting frame is provided with a first connecting frame; the other side of the mounting frame is provided with a second connecting frame; a traction mounting shaft is arranged between the mounting frame and the second connecting frame; the outer peripheral surface of the traction mounting shaft is sleeved with a traction wheel; an unreeling mounting shaft is arranged between the mounting frame and the first connecting frame; the outer peripheral surface of the unreeling mounting shaft is sleeved with an unreeling mounting wheel; the inner side wall of the rack is provided with a motor seat; the motor seat is provided with a driving motor; the front portion of the driving motor is provided with a driving shaft; an end portion of the driving shaft is provided with a spin cutting wheel; and the outer peripheral surface of the spin cutting wheel is provided with a spin cutting blade ring. Spin cutting processing can be performed on a coaxial cable conveniently through the spin cutting blade ring; and a user can be facilitated to observe a cut coaxial cable and to observe the coaxial cable.

Owner:SUZHOU HONGYE LAMP EQUIP CO LTD

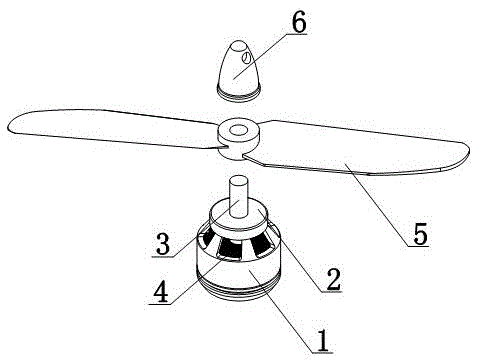

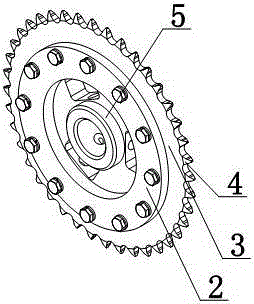

Weed straw cutting rotary blade

The invention discloses a weed straw cutting rotary blade which comprises a rotary base.A rotary shaft is arranged on the rotary base.A rotary ring is arranged between the rotary shaft and the rotary base.Several window holes are formed in the position, close to the rotary ring, of the rotary base.A rotary blade body is arranged at the end of the rotary shaft and connected with the rotary shaft through a lock cap.The rotary base can be connected with a driving motor in a butt joint mode.Rotary control over the rotary blade can be realized through the driving motor, then weed straw to be processed is close to the rotary blade, and rotary cutting of the weed straw is convenient.

Owner:夏云美

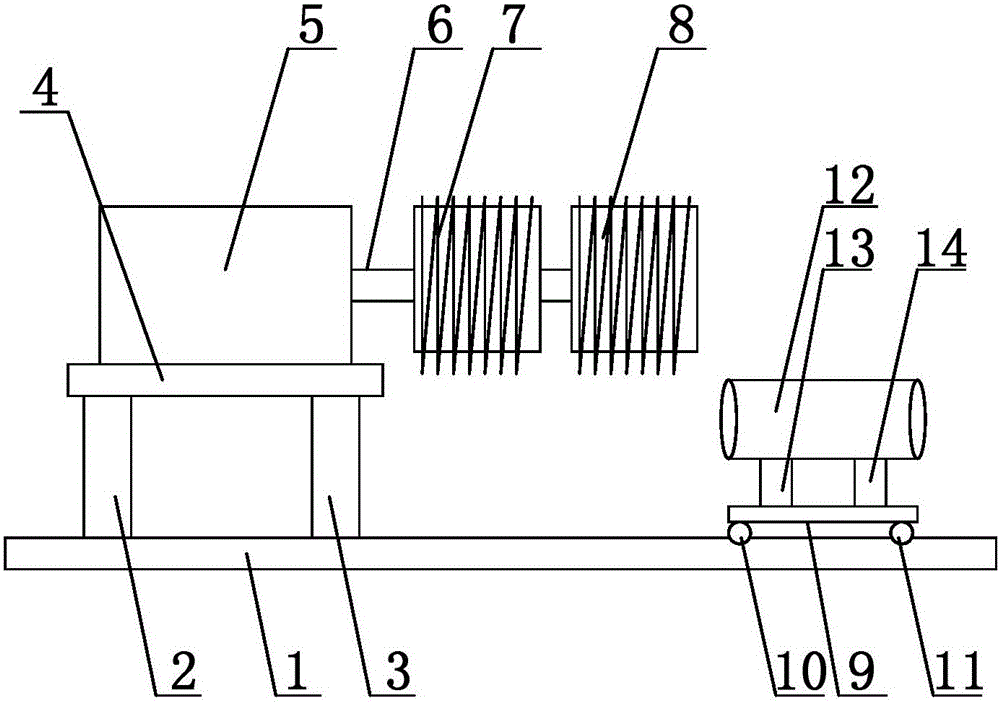

Rod material cutting machine

InactiveCN105965079AStable supportEasy rotary cuttingShearing machinesShearing machine accessoriesDrive shaftDrive motor

The invention discloses a rod material cutting machine. The rod material cutting machine comprises a base plate. The base plate is provided with a first supporting plate and a second supporting plate. A carrying plate is arranged between the end of the first supporting plate and the end of the second supporting plate. The carrying plate is provided with a driving motor, and the driving motor is connected with a driving shaft. One end of the driving shaft is connected with the driving motor, and a first rotary-cutting wheel and a second rotary-cutting wheel are arranged at the other end of the driving shaft. The first rotary-cutting wheel and the second rotary-cutting wheel are the same in shape and size, and rotary-cutting teeth are arranged on the outer circumferential face of the first rotary-cutting wheel and the outer circumferential face of the second rotary-cutting wheel. The base plate is provided with a movable base. First moving wheels and second moving wheels are arranged at the bottom of the movable base. The first moving wheels and the second moving wheels are arranged on the base plate. The base plate is provided with guide grooves, and the first moving wheels and the second moving wheels are arranged in the guide grooves. The movable base is provided with a guide pipe. By means of the rod material cutting machine, a rod material to be treated can be moved along the guide pipe, and therefore the rod material can be rotary-cut conveniently.

Owner:苏州市灵通玻璃制品有限公司

A rotary cutting device for wheat straw processing

InactiveCN106808535AEasy rotary cuttingPlay a supporting roleProfiling/shaping machinesMechanical engineering

The invention discloses a rotary cutting device for straw processing, which comprises a bracket, the bracket is provided with slots, the bracket is provided with a fixed pipe, the fixed pipe is vertically arranged, the fixed pipe is arranged on the base, and the lower end of the fixed pipe is provided with a fixed pipe. The fixed rod is arranged in the base; the lower end of the fixed rod is provided with a fixed piece and a fixed nut, and the fixed nut buckles the fixed piece, and both the fixed piece and the fixed nut are arranged at the bottom of the base; the end of the bracket is provided with a connecting pipe to connect The pipes are arranged horizontally, and the connecting pipe is set with a rotary cutting blade, which is in a spiral shape; one end of the connecting pipe is connected to the bracket through the first fixing pin, and the other end of the connecting pipe is connected to the bracket through the second fixing pin; the rotary cutting blade The edge position is equipped with a blade. In the present invention, the blade at the edge of the rotary cutting blade can quickly cut the wheat straw, thereby facilitating the rotary cutting process of the wheat straw.

Owner:SHANGHAI LANXUAN SOFTWARE TECH CO LTD

Mower device for mowing grassland after rain

The invention discloses a mower device for mowing grassland after rain. The mower device comprises a main body, wherein a belt wheel cavity is formed in the main body; a lifting cavity with a leftwardopening is formed in the lower side of the belt wheel cavity; a lifting shaft which extends downwards into the lifting cavity and extends upwards into the belt wheel cavity is connected in the lowerend wall of the belt wheel cavity in a rotating fit mode; a partition plate reset torsion spring is fixedly connected between the upper end surface of the lifting shaft and the upper wall surface of the belt wheel cavity; and a partition plate which is in threaded fit connection with the lifting shaft is connected in the lifting cavity in a sliding fit mode. A collecting and clamping device is additionally arranged on the mower, so that the mower falls to the ground and collapses after wind and rain, and the disordered mower is clamped and gathered together; a clamp lifting device is designedto lift the gathered grass, so that the height of the grass is higher than that of a cutter, and the cutter can rotate and cut conveniently; and the working steps of the mower are controlled through the design of a grooved wheel, so that a series of actions such as clamping, lifting, cutting and advancing are circularly carried out, the use is convenient, and the automation degree is higher.

Owner:福州市长乐区拓密斯电子科技有限公司

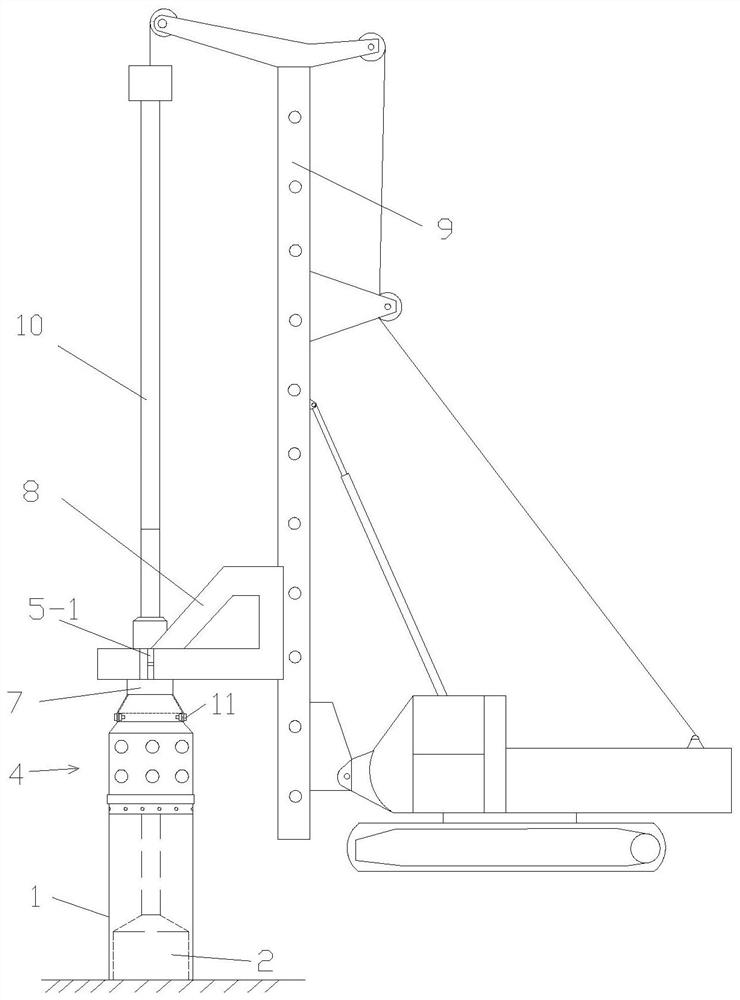

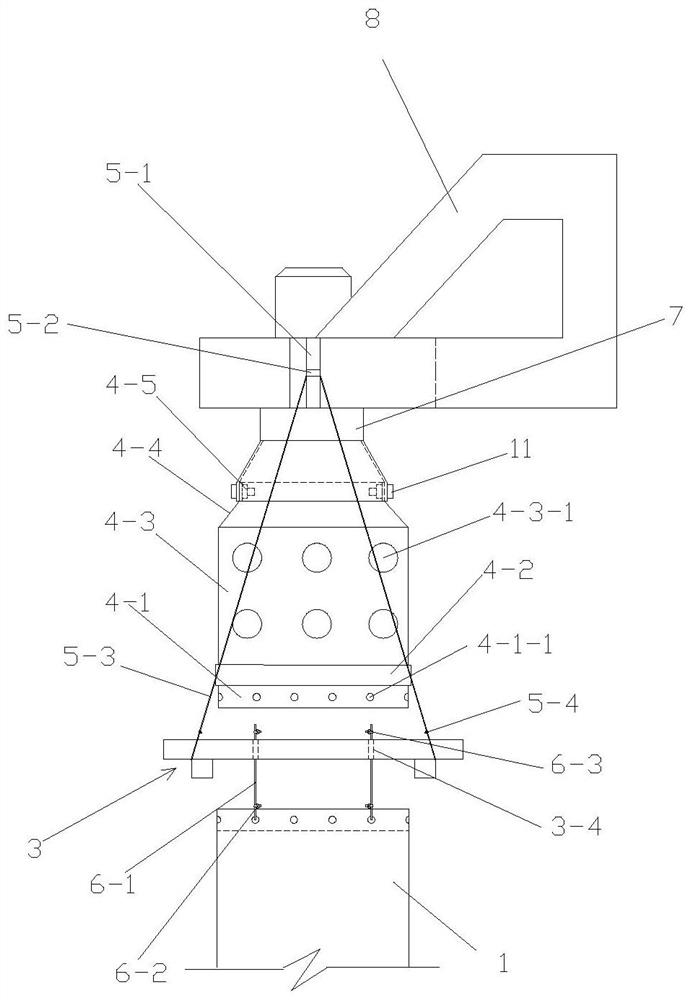

A Hole Forming Method Using Steel Casing Cooperating with Rotary Drilling in Complicated Strata

ActiveCN113090192BQuality improvementThe construction method steps are simpleConstructionsDrilling with mechanical conveyingMechanical engineeringDrill hole

The invention discloses a method for forming a hole in a complex stratum with rotary drilling and steel casing matching. The method comprises the following steps: 1. leveling the construction site and measuring and placing pile positions; Drilling of drilling rigs and subsequent release of steel casings; 4. Drilling of rotary drilling rigs in the lower karst formations and subsequent release of steel casings. The steps of the method of the present invention are simple and reasonable in design. By setting the casing lowering power part on the rotary drilling rig, the construction of the rotary drilling drill can be realized, and the follow-up and lowering of the steel casing can be realized through the casing lowering power part, effectively adapting to the Bored piles in complex strata form holes to prevent hole collapse. The required construction equipment is small, the equipment utilization rate is high, the hole forming speed is fast, the construction efficiency is high, and the cost is low.

Owner:CHINA RAILWAY FIRST GRP CO LTD

Foamed concrete heat insulation board

ActiveCN112627370ADecreased thermal insulationImprove protectionLivestock managementCuttersStructural engineeringMechanical engineering

The invention discloses a foamed concrete heat insulation board. The foamed concrete heat insulation board comprises two board bodies, wherein a clamping mechanism, a fixing mechanism and a protection mechanism are sequentially arranged outside each board body; and each fixing mechanism is composed of a concave frame, a rectangular plate and a long plate, wherein the rectangular plate is fixedly installed at the position, close to the middle, of the inner surface of the concave frame, and transverse grooves are formed in the front and back positions, close to the upper end, of the outer surface of the right side of the concave frame. The foamed concrete heat insulation board can serve as a shell of a wall to protect and install a heat insulation board body, and a shed body can be temporarily built conveniently; in addition, rainwater can conveniently slide down, the situation that the board bodies are wetted by the rainwater can be reduced, the waterproofness of the board bodies is improved, the probability that reptiles gnaw and damage equipment is reduced, the protection effect of the board bodies is effectively improved, the probability that boston ivy climbs on the wall is reduced, and the risk that the boston ivy hurts the wall is reduced; and sunlight can conveniently irradiate the wall, and therefore the heat insulation effect is better achieved.

Owner:联海装配式建材有限公司

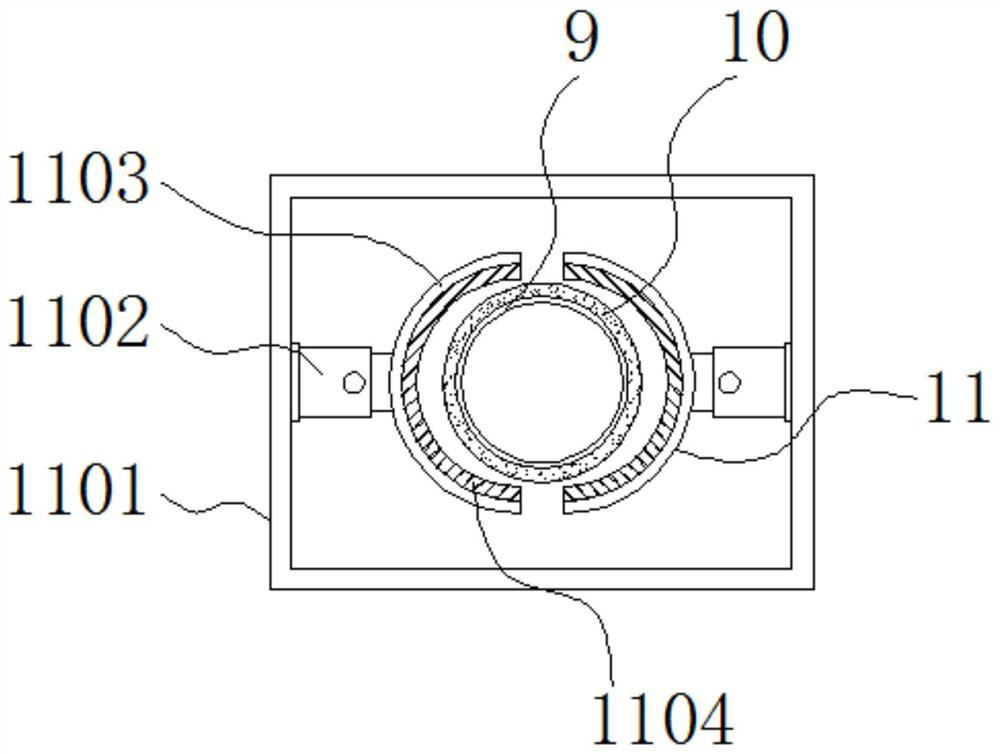

Motor drive type device for rotary-cut of pipe lined with plastics

The invention discloses a motor-driven plastic-lined pipe rotary cutting device, which comprises a fixed plate, a side plate is arranged on the side wall of the fixed plate, a fixed plate is arranged between the side plate and one side of the fixed plate, and the side plate is connected with the fixed plate. There is a partition between the boards, and a rotary cutting groove is provided on the fixed board; an operation frame is provided on the fixed board, an operation table is provided on the end of the operation frame, an operation slot is provided on the inner end of the operation table, and an operation slot is provided on the fixed board. There is a drive mechanism, the drive mechanism includes a drive motor, the drive motor is provided with a drive shaft, the drive motor is arranged at the bottom of the fixed plate, the drive shaft passes through the fixed plate, the upper end of the drive shaft is provided with a drive gear, the side wall of the side plate A driven shaft is provided, and the outer peripheral surface of the driven shaft is covered with a driving gear, and the driving gear and the driving gear are connected through meshing; the end of the driven shaft is provided with a rotary cutter ring, and the rotary cutter ring is arranged in the operation groove. The invention is a motor-driven plastic-lined pipe rotary-cutting device that can conveniently carry out rotary-cut processing on the plastic-lined pipe through the rotary-cut groove.

Owner:高佳

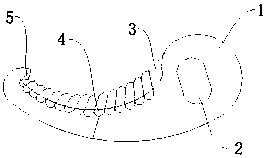

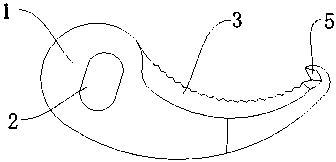

Poultry assembly line neck-cutting tooth cutter production technology

The invention discloses a poultry assembly line neck-cutting tooth cutter production technology. A cutting cutter body is included and is in a crescent shape. The production technology of the cuttingcutter body includes the following steps of raw material cutting, cutter blank surface treatment, heat treatment, deep cooling treatment, cutter body machining, polishing treatment and cutter body edging machining. According to the cutter body, an arc cutter blade and a hook-shaped left cutter head are adopted to hook poultry necks conveniently; single-face cutting edge type design is adopted so that the bearing force of a cutting edge can be dispersed to the cutter blade; wave-shaped cutting cutter teeth are formed at the positions of edge sharps of tooth grooves and the cutting edge, the sawtooth-shaped edge sharps can exert force for cutting continuously, and therefore the poultry necks can be conveniently cut rotationally, and the cutting force is strong; tempering treatment is conducted multiple times after quenching, the stress in a cutter blank is reduced, then the cutter body is wrapped by wax for preliminary deep cooling treatment, the phenomenon that the cutter blank is cracked when being suddenly cooled through liquid nitrogen is prevented, the wax is removed after deep cooling treatment is conducted for 1 hour, deep cooling treatment is conducted, the internal stress inthe cutter blank is completely eliminated, toughness is improved after the cutter body is finished, and the service life is prolonged.

Owner:马鞍山市松林刮刀锯有限公司

Metal pipe machining propeller

The invention discloses a metal pipe machining propeller which comprises a base. The base is provided with a push hole, installation blocks are arranged on the base, a push rod is connected with the installation blocks, a push column is connected with the push hole in an inserted mode, the front end of the push column is connected into the push hole in an inserted mode, and the rear end of the push column is connected with the lower end of the push rod. By means of the propeller, a metal pipe to be machined can be inserted in the push hole, the push rod can control the push column to horizontally move along the push hole, the metal pipe is conveniently controlled to be pushed along the push hole, and the metal pipe can be rotationally cut conveniently through a rotary cutter.

Owner:周玉翔

Slide base for aluminum plate sheet machining

The invention discloses a sliding seat for aluminum sheet processing, which comprises a loading seat, the bottom of the loading seat is provided with a chute, the inwardly facing surface of the chute is provided with a buckle, and the buckle is installed on the inwardly facing surface of the chute The position of the inner side wall of the surface, the buckle and the loading seat are connected by a number of fixed pins, the fixing pin and the buckle are connected by threads, and the fixing pin and the loading base are connected by threads; there is a conveying groove on the loading base, and the There is a clamping groove, which is set in the middle of the conveying tank; a limit hole is provided on the loading seat, and the limiting hole is connected with the clamping groove; the limiting hole and the clamping groove are vertically arranged; A limit block is provided, and the limit block is arranged on the side wall of the conveying trough. The invention facilitates rapid processing of the aluminum plate thin slices, and facilitates rotary cutting of the aluminum plate thin slices by a rotary cutter.

Owner:周如彬

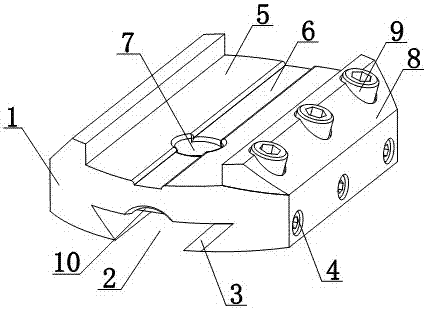

Rotary-cut processing device for racks

InactiveCN105834526AFlexible operationEasy rotary cuttingGear-cutting machinesGear teethDrive shaftEngineering

The invention relates to a rotary-cut processing device for racks. The rotary-cut processing device for racks comprises a base. Supporting boards are arranged on the base. A guide board is arranged between the ends of the supporting boards. A rotary-cut motor is arranged on the guide board and provided with a drive shaft. A rotary-cut wheel is arranged at the end of the drive shaft. The base is provided with a guide pipe, and a rotary adjusting column is sleeved with the guide pipe. An object table is arranged at the end of the rotary adjusting column. The object table can be adjusted horizontally and rotationally along the guide pipe through the rotary adjusting column, so that racks on the object table are operated conveniently and flexibly; and the rotary-cut motor can rotate the rotary-cut wheel conveniently through the drive shaft, and rotary-cut processing can be conducted on racks conveniently through the rotary-cut wheel.

Owner:TAICANG BAODA RACK

A foamed concrete insulation board

ActiveCN112627370BDecreased thermal insulationImprove protectionLivestock managementCuttersFoam concreteArchitectural engineering

Owner:联海装配式建材有限公司

Sliding seat used for processing thin sheet of aluminum plate

InactiveCN106466788AEasy to transportEasy to handleMetal working apparatusRapid processingEngineering

The invention discloses a sliding seat used for processing a thin sheet of an aluminum plate. The seat comprises an object-carrying seat, the bottom of which is provided with a sliding groove. The surface to which the sliding groove is inwardly opposite is provided with a buckle piece. The buckle piece is installed on the inner side wall inwardly facing the sliding groove. The buckle piece is connected with the object-carrying seat through multiple fixing pins in threaded connection with the buckle piece. The fixing pins are in threaded connection with the object-carrying seat, on which a conveying groove is arranged. A clamping groove is arranged in the object-carrying seat and arranged in the middle of the conveying groove. A limiting hole is arranged in the object-carrying seat and communicates with the clamping groove. The limiting hole and the clamping groove are vertically arranged. A limiting block is arranged on the object-carrying seat and arranged on the side wall of the conveying groove. The sliding seat used for processing the thin sheet of the aluminum plate has following beneficial effects: the thin sheet of the aluminum plate is conveniently and rapidly processed; and a rotary-cutting machine is capable of conveniently perform rotary-cutting operation on the thin sheet of the aluminum plate.

Owner:周如彬

Cutting device for preparation of automobile safety belt

InactiveCN105947765AEasy rotary cuttingEasy to turn and adjustArticle deliveryDrive shaftDrive motor

The invention discloses a cutting device for preparation of an automobile safety belt. The cutting device comprises a bottom plate, wherein a guide tube is arranged on the bottom plate; a rotating adjusting tube is mounted inside the guide tube in a sleeving manner; a releasing winding wheel is arranged at the end part of the rotating adjusting tube; an auxiliary wheel is arranged between the releasing winding wheel and the end part of the rotating adjusting tube; a support box is arranged on the bottom plate; an object carrying seat is arranged on the support box; a driving motor is arranged on the object carrying seat; the driving motor is provided with a driving shaft; the driving shaft is horizontally arranged; one end of the driving shaft is connected with the driving motor; the other end of the driving shaft is provided with a rotating cutting wheel; the rotating cutting wheel is arranged in front of the releasing winding wheel; a first limiting pin and a second limiting pin are arranged on the object carrying seat; the first limiting pin is arranged on one side of the driving motor; and the second limiting pin is arranged on the other side of the driving motor. According to the cutting device, the automobile safety belt can be conveniently released and wound through the releasing winding wheel, the driving motor can control the rotating cutting wheel to rotate through the driving shaft, and rotating cutting treatment can be conveniently carried out on the automobile safety belt through the rotating cutting wheel.

Owner:KUNSHAN HAOSHUO PRECISION MECHANISM CO LTD

Rotary cutting wheel for net rope

InactiveCN105291228AEasy rotary cuttingConvenient rotary controlVeneer manufactureDrive motorEngineering

The invention discloses a rotary cutting wheel for a net rope. The rotary cutting wheel for the net rope comprises a driving cylinder; a rotating ring is arranged on an external surface of the driving cylinder; the rotary cutting wheel is arranged on an external surface of the rotating ring; a toothed groove is formed in an external surface of the rotary cutting wheel; an inner barrel is arranged on an inner peripheral surface of the driving cylinder. According to the rotary cutting wheel for the net rope, the rotary cutting wheel can be connected with the driving motor and the driving motor is capable of controlling the rotary cutting wheel to rotate; as a result, a rotation control on the rotary cutting wheel can be realized conveniently, and further, a rotary cutting treatment on the net rope also can be realized conveniently.

Owner:王琳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com