Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Control drilling depth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for drilling deep hole and PCB product obtained by same method

InactiveCN1787726AControl drilling depthReduce the impactConductive material mechanical removalEngineeringControl software

This invention discloses a new method for deep drilling and PCB products got from it, which sets the platform control loop on the POWER layer in the board and begins computing the designed depth from the place contacting the POWER by the drilling pin or drills the test holes of Z1,Z2 and Z3 on the necessary drilled regions of the upper surface, the upper target layer and the lower target layer then adds G87, G88 and G89 functional instructions on the control software of the platform to detect the depth values of Z1 and Z2 and judges the drilled depth value based on their positions, finally the platform adds a compensation value of a drill point to the depth of (Z2+Z3) / 2 to drill.

Owner:WUS PRINTED CIRCUIT (KUNSHAN) CO LTD

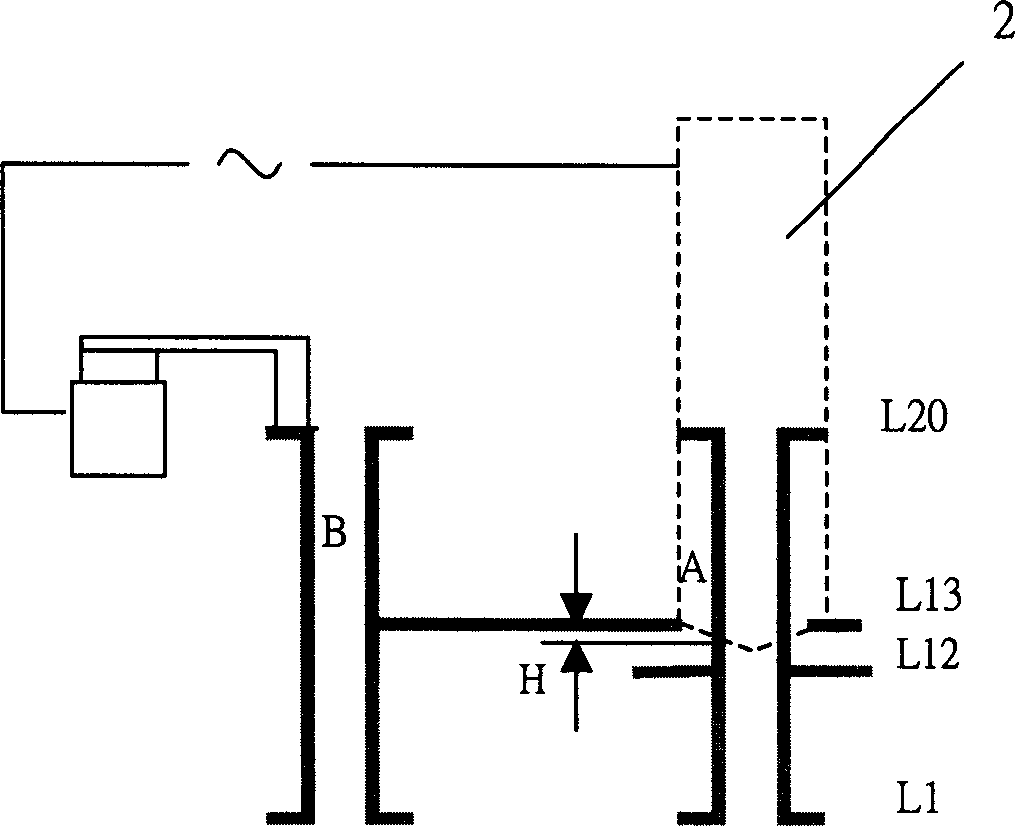

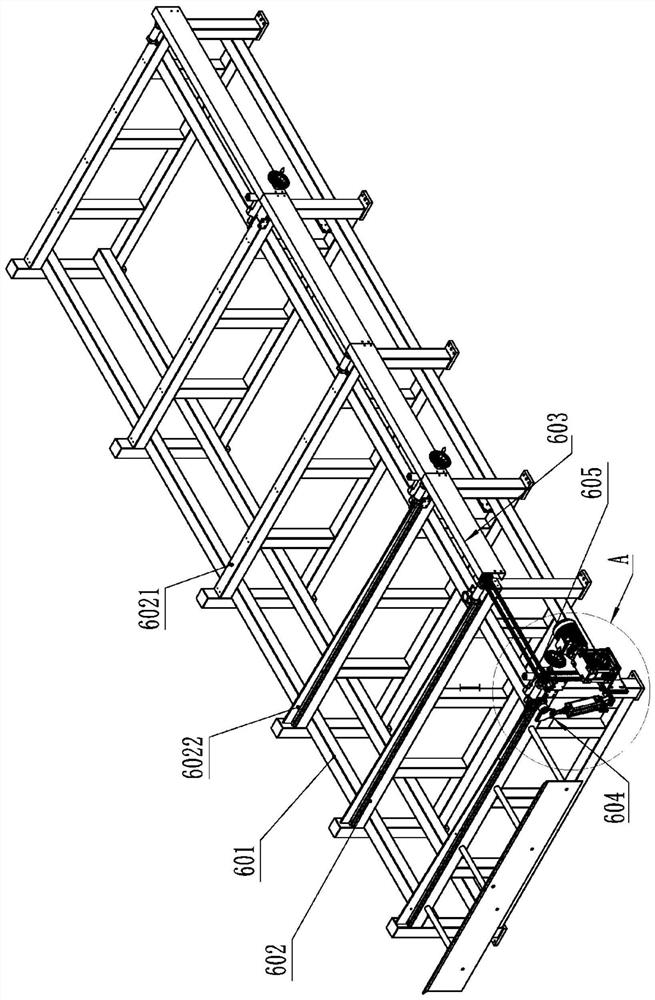

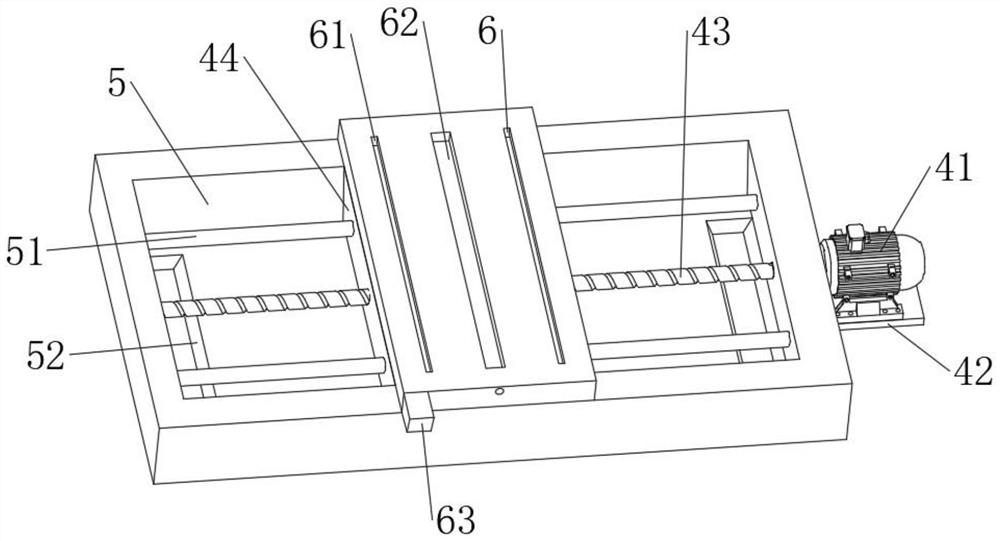

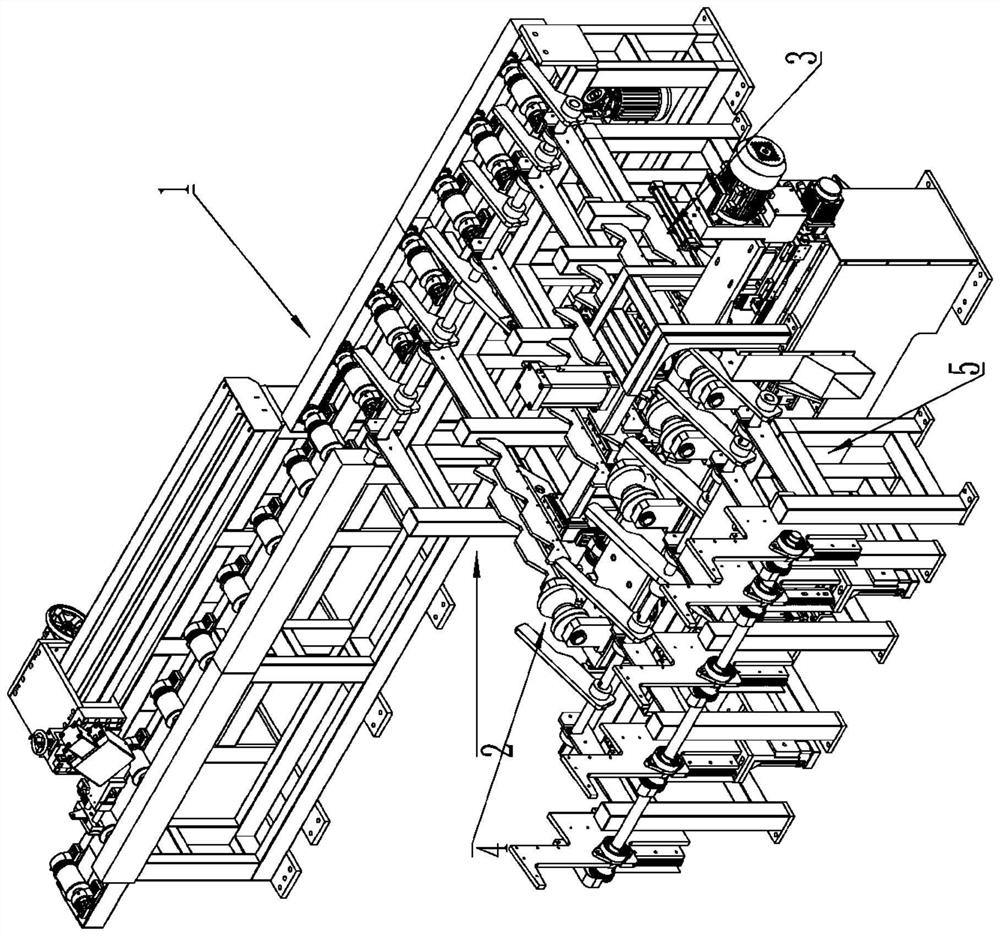

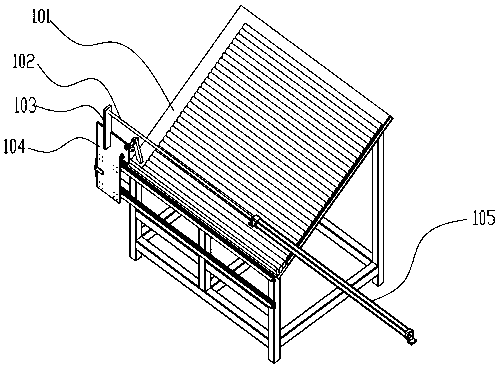

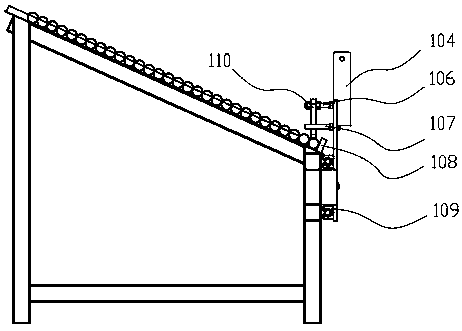

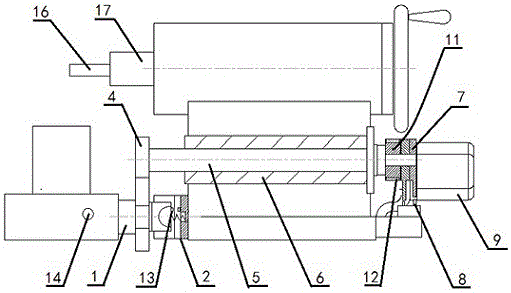

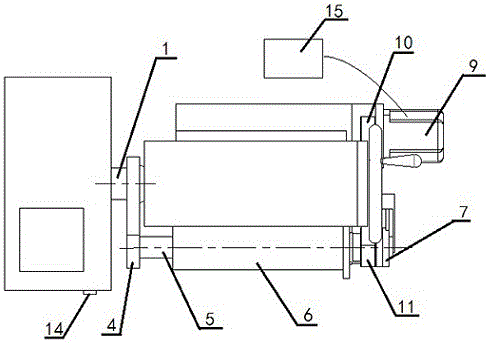

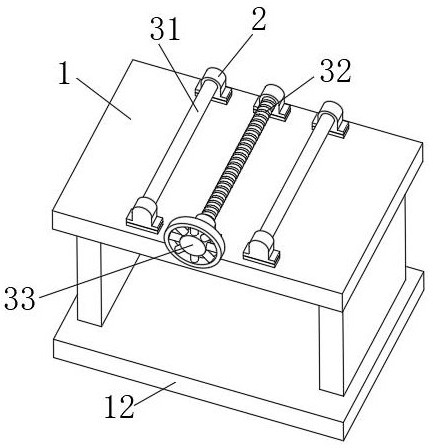

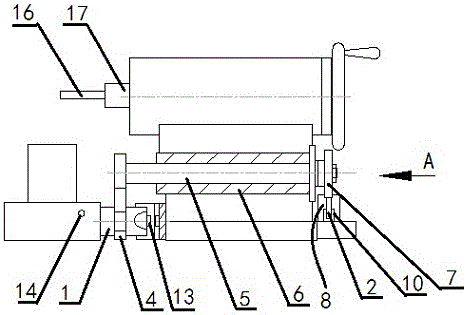

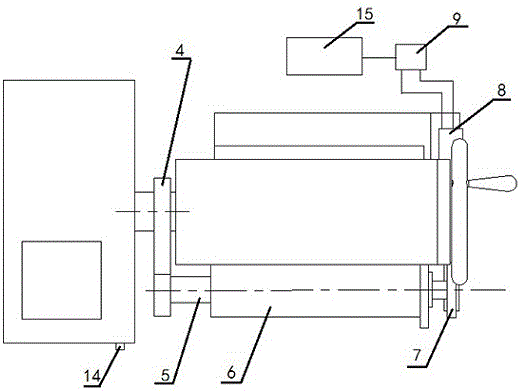

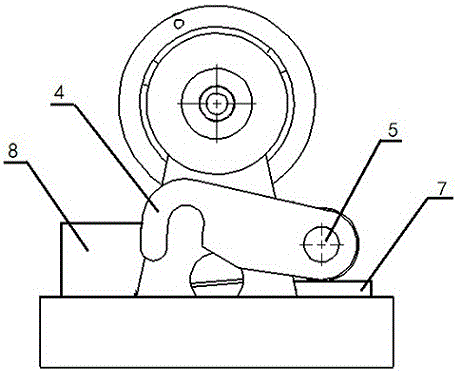

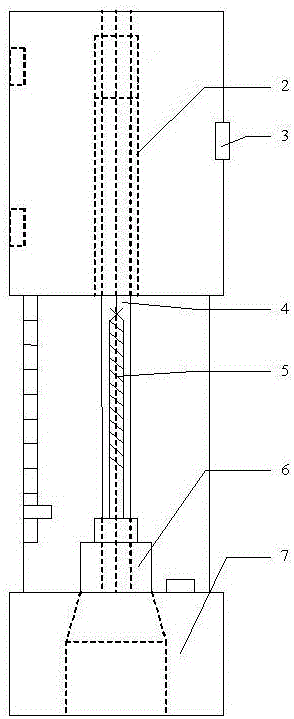

Short material sawing and drilling integrated production line

PendingCN112676840AEasy to sendRealize automatic feeding processOther manufacturing equipments/toolsStructural engineeringManufacturing line

The invention discloses a short material sawing and drilling integrated production line. The short material sawing and drilling integrated production line involves an upstream material overturning and conveying device, a sawing device, a sawing discharging conveying device, a transverse material overturning and temporary storage device, a transverse stepping feeding device, a drilling device and a drilling discharging device; the sawing device is used for sawing long material bars conveyed by the upstream material overturning and conveying device, and the sawing discharging conveying device is used for longitudinally conveying the sawn bars; the transverse material overturning and temporary storage device is used for transversely overturning and conveying the longitudinally-placed bars to a temporary storage material frame, and the transverse stepping feeding device is used for conveying the bars on a material taking station to a drilling supporting station in a stepping mode; the drilling device comprises a drilling machine base and a drilling supporting device, the drilling supporting device is used for supporting the bars, and a drill bit assembly and a drilling clamping device are longitudinally arranged on the drilling machine base in a sliding mode; and the drilling discharging device is used for sending out the bars on the drilling supporting device. According to the short material sawing and drilling integrated production line, the long material bars are automatically fed and supplied to the sawing device to be sawn, and then the long material bars are automatically conveyed to the drilling device to be subjected to end face drilling, so that continuous automation of sawing and drilling of the metal bars is completed, and the efficiency is improved.

Owner:SUZHOU KINKALTECK MACHINERY TECH

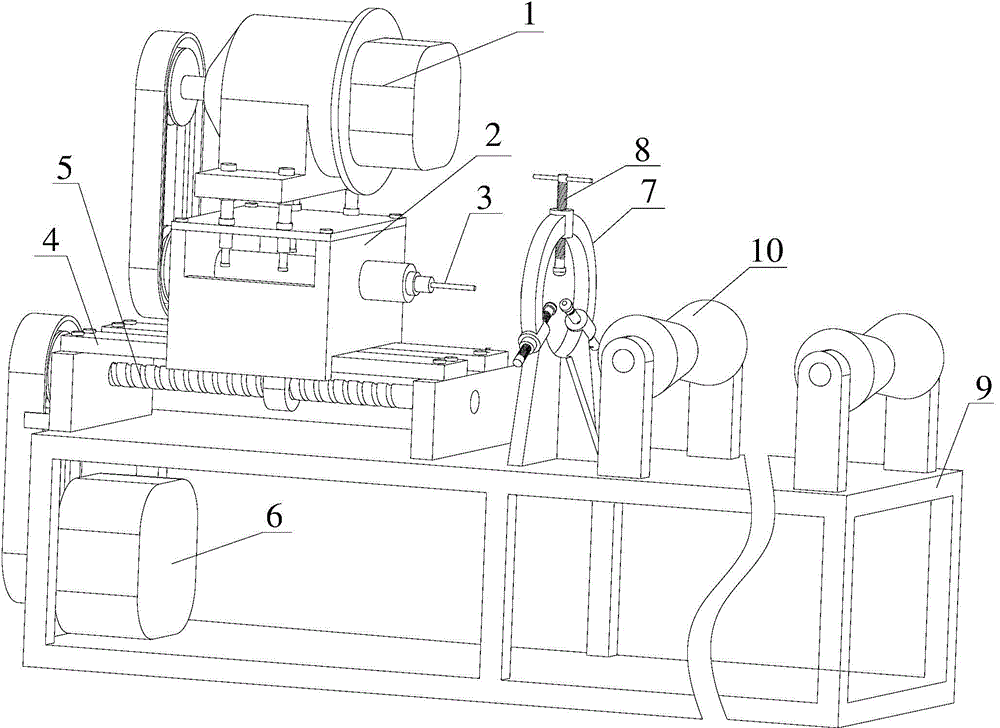

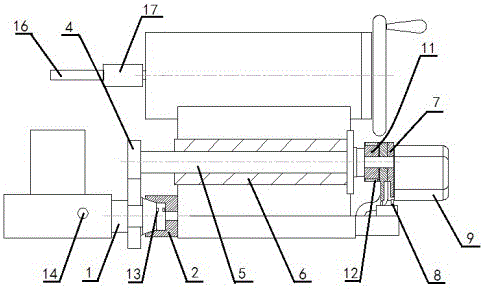

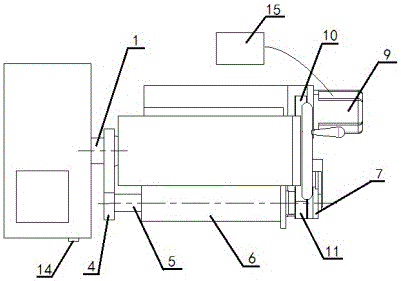

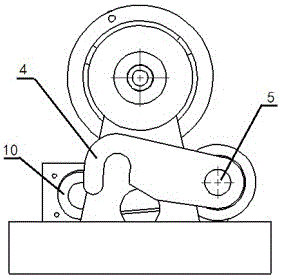

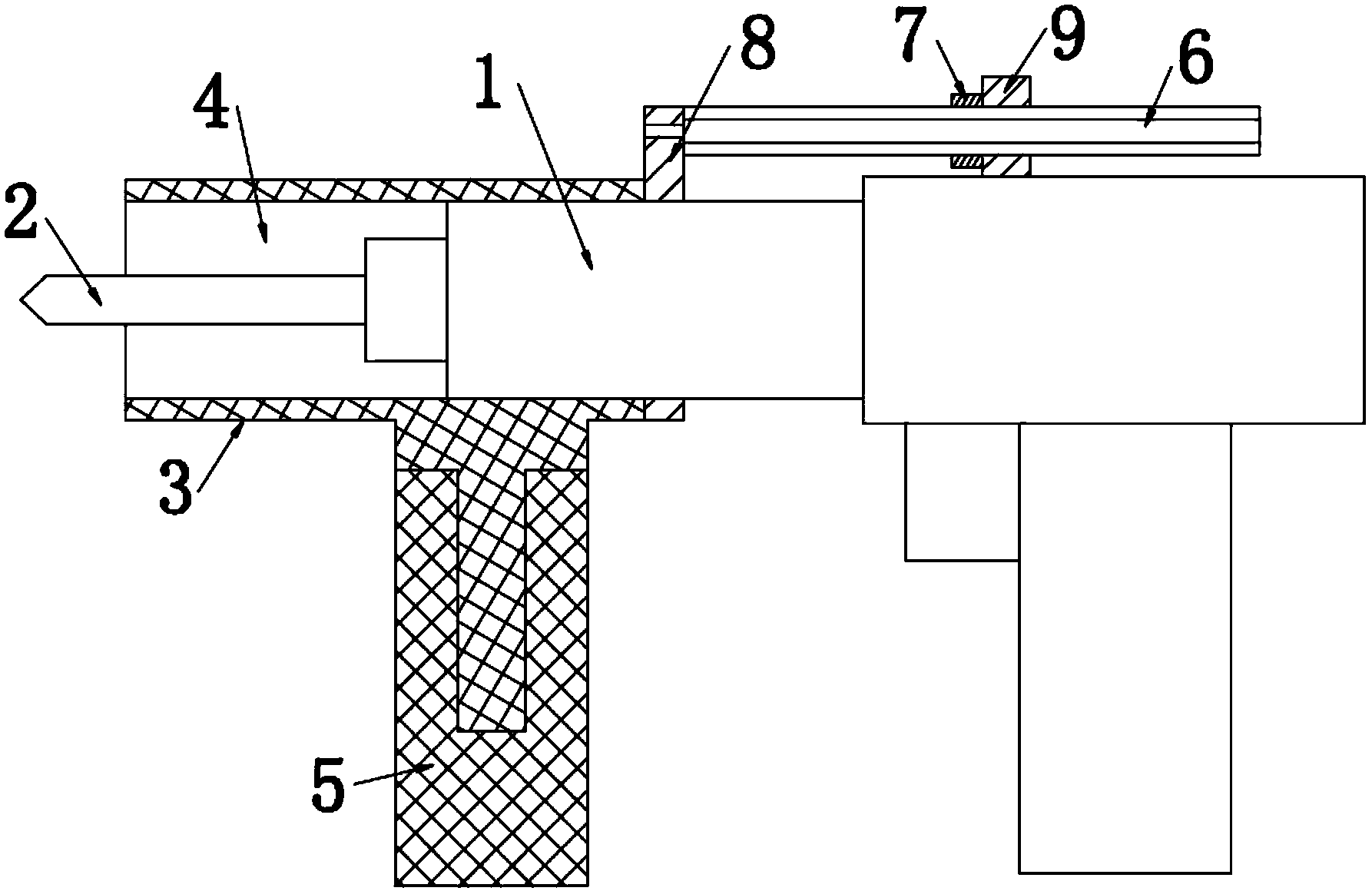

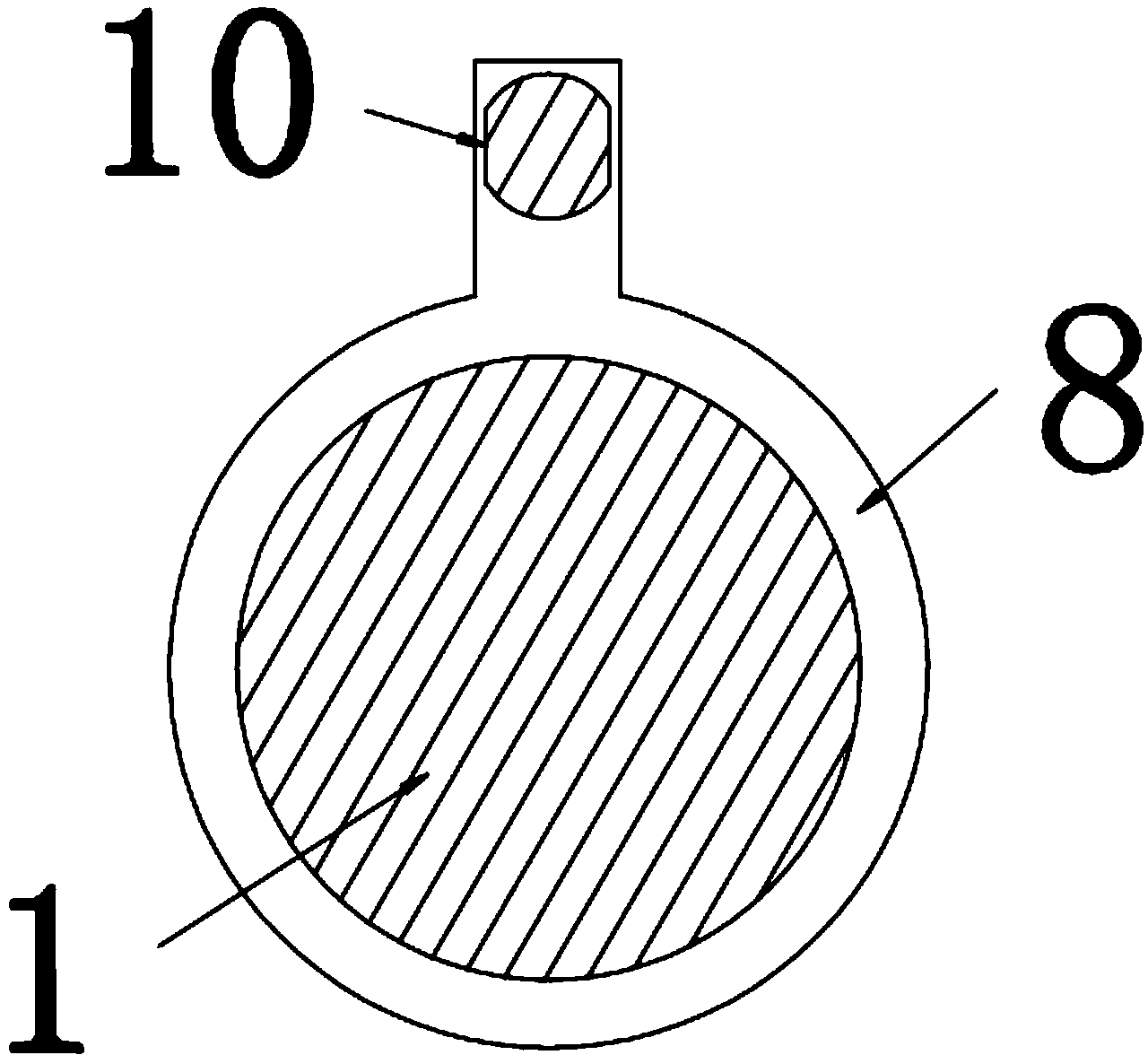

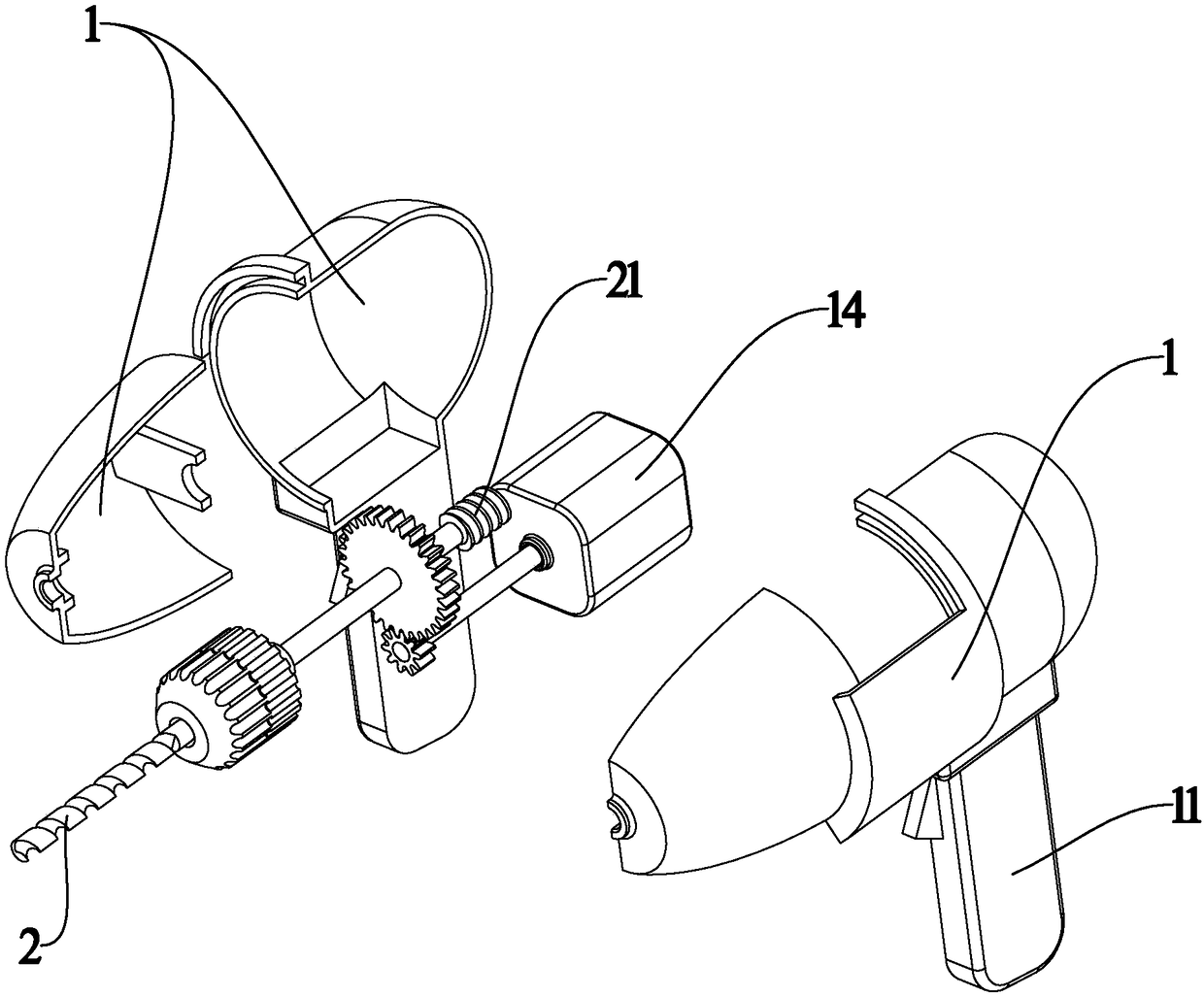

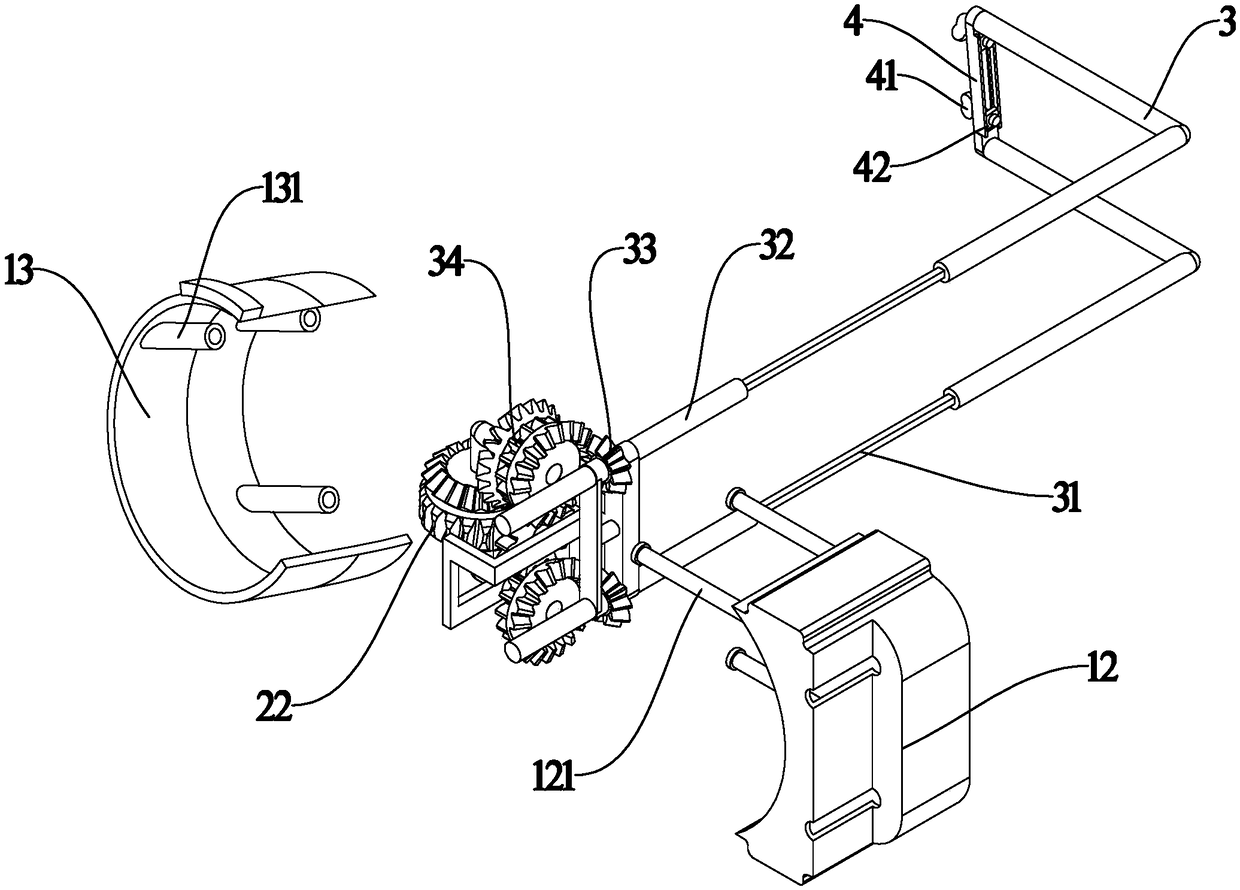

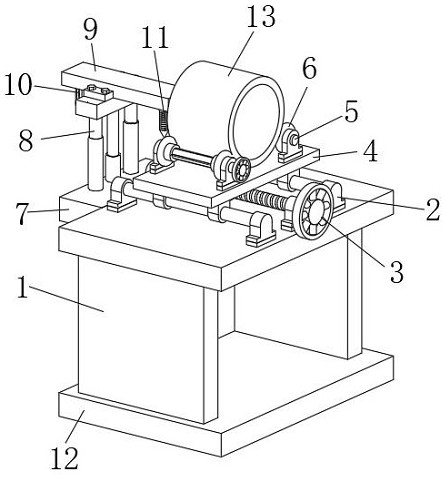

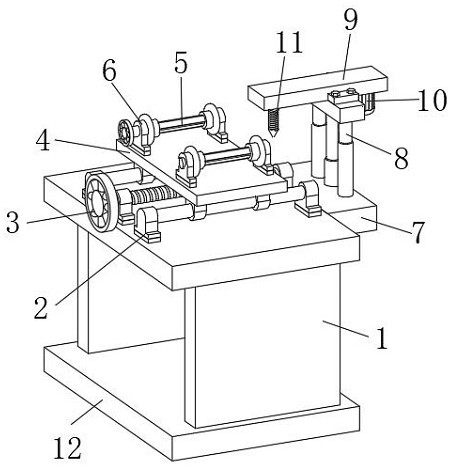

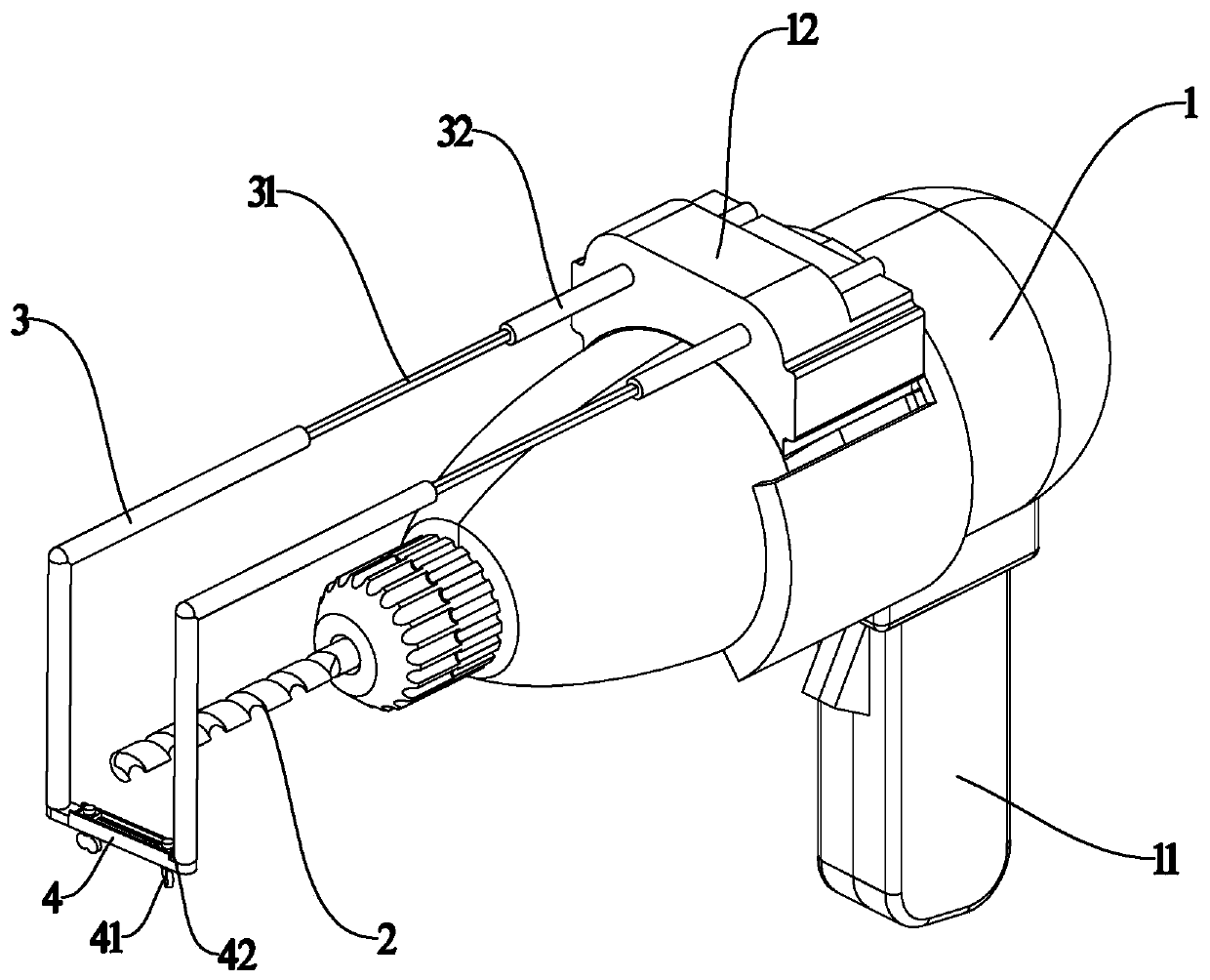

Bar material drill

InactiveCN104439394AAchieve feedAvoid breakingFeeding apparatusPositioning apparatusEngineeringDrilling machines

The invention provides a bar material drill and adopts the technical scheme that the bar material drill comprises a drilling mechanism, a propelling mechanism for pushing the drilling mechanism to advance, a support mechanism for supporting a bar material, and a positioning device for positioning the bar material, wherein the drilling mechanism comprises a motor I, a reduction gearbox and a drill bit, the reduction gearbox is in transmission connection with the motor I, the drill bit is fixedly connected with the output end of the reduction gearbox, the positioning device is positioned at one end of the drill bit, and the drilling mechanism can be pushed by the propelling mechanism to move towards the positioning device. The bar material drill has the benefits that the motor I is fixedly mounted on the reduction gearbox, so that the drilling mechanism can move forwards and backwards without affecting the transmission of the motor; besides, a screw is driven by the motor to push the drilling mechanism to advance, the feeding of the drill bit is realized, the drilling depth is effectively controlled, deviating phenomena cannot occur in the feeding process, drill bit breaking problems are effectively avoided, the structure is simple, and the operation is convenient.

Owner:JIANGSU WUJIN STAINLESS STEEL PIPE GRP

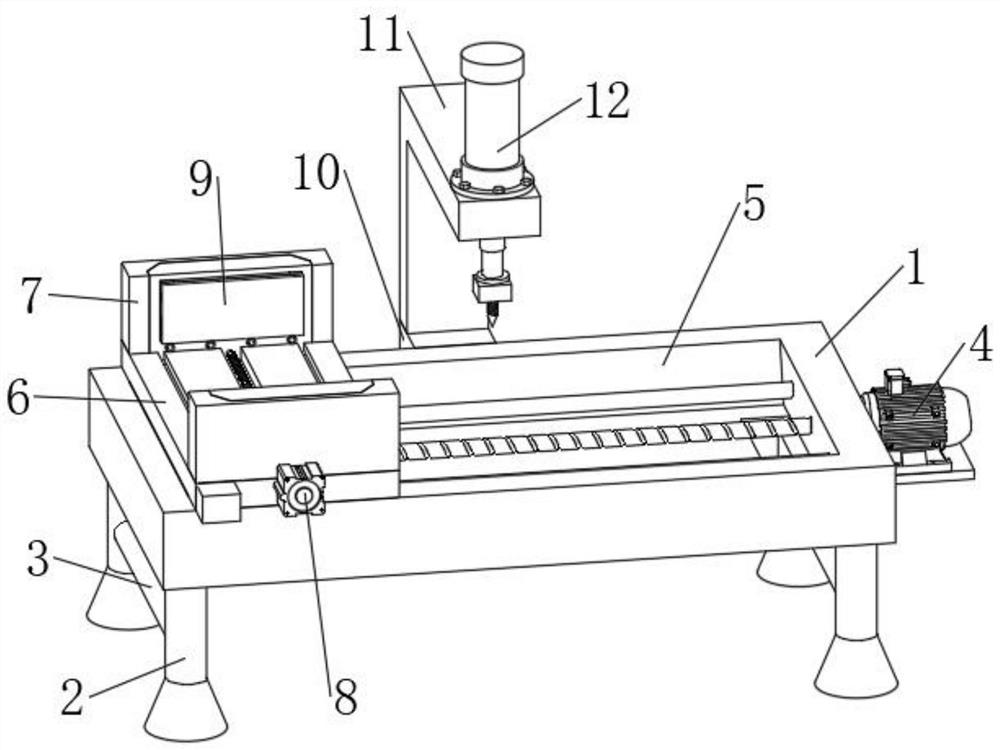

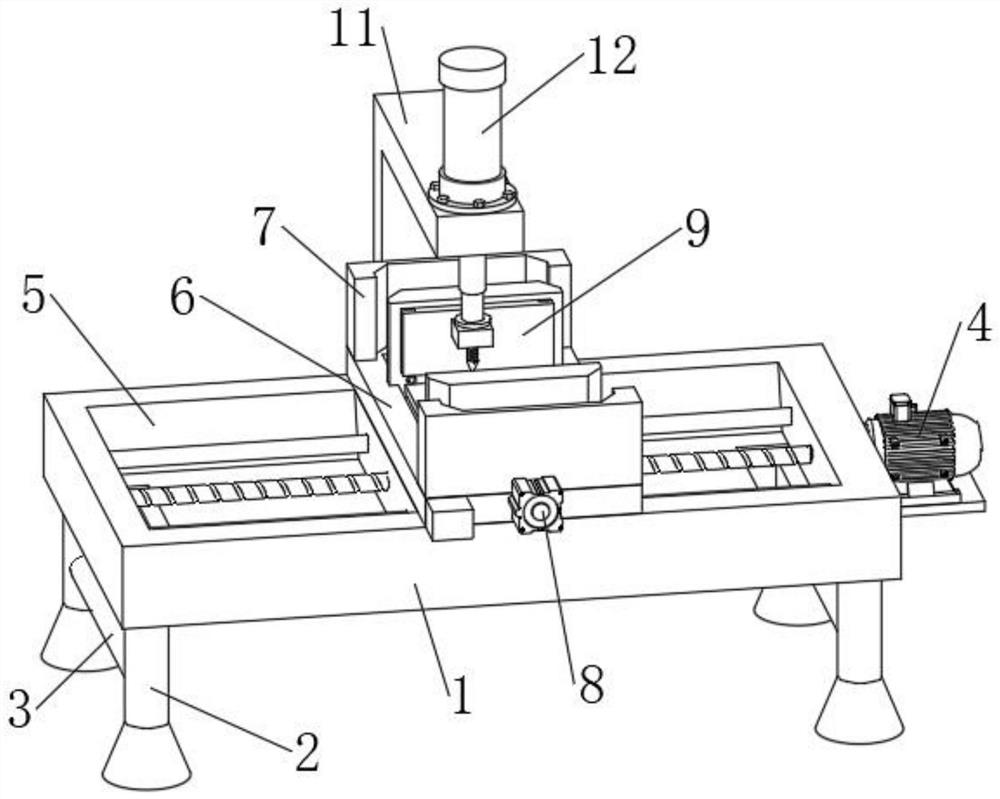

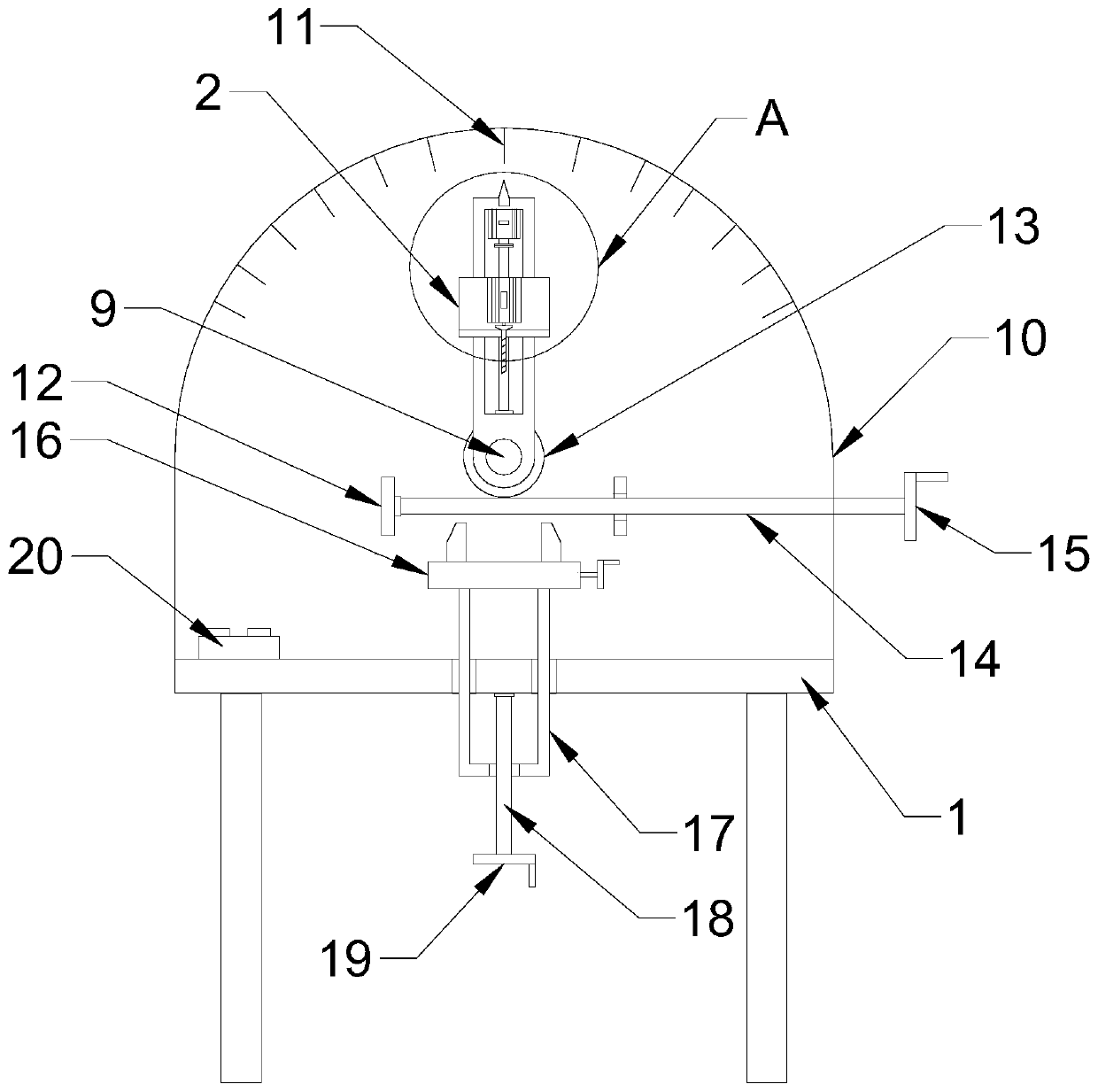

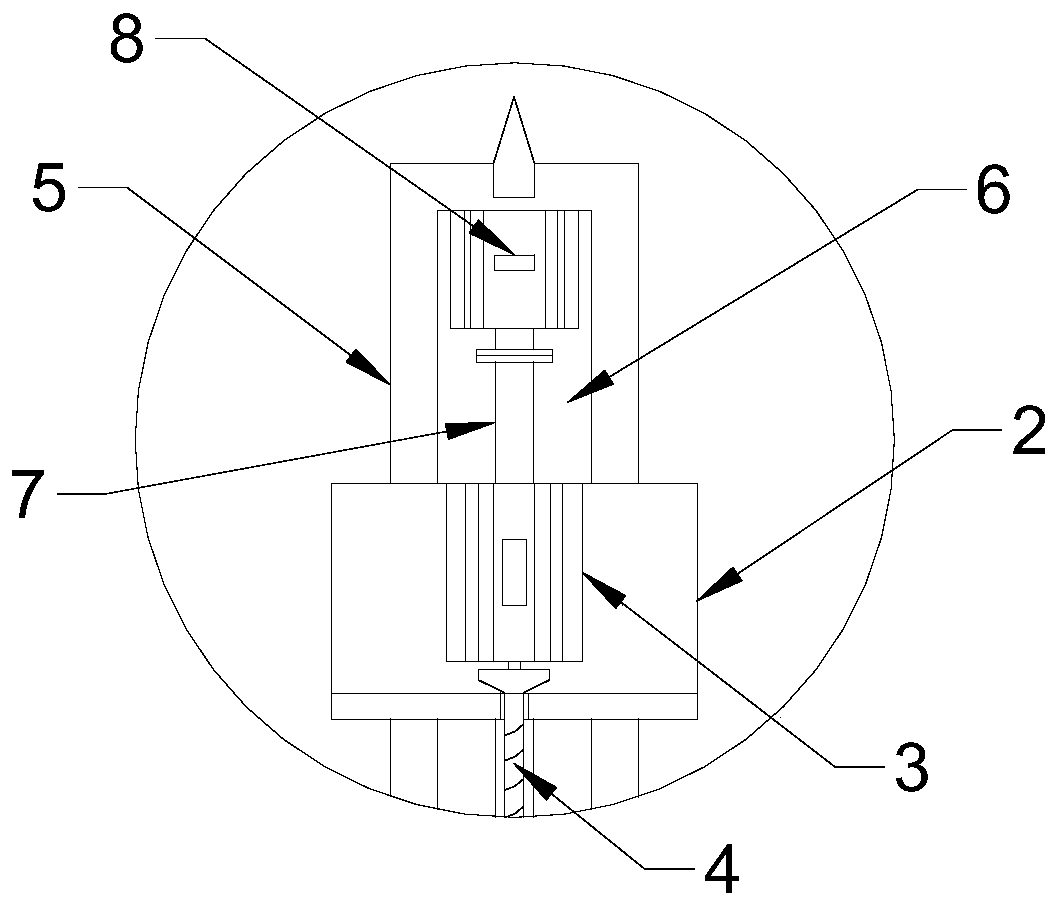

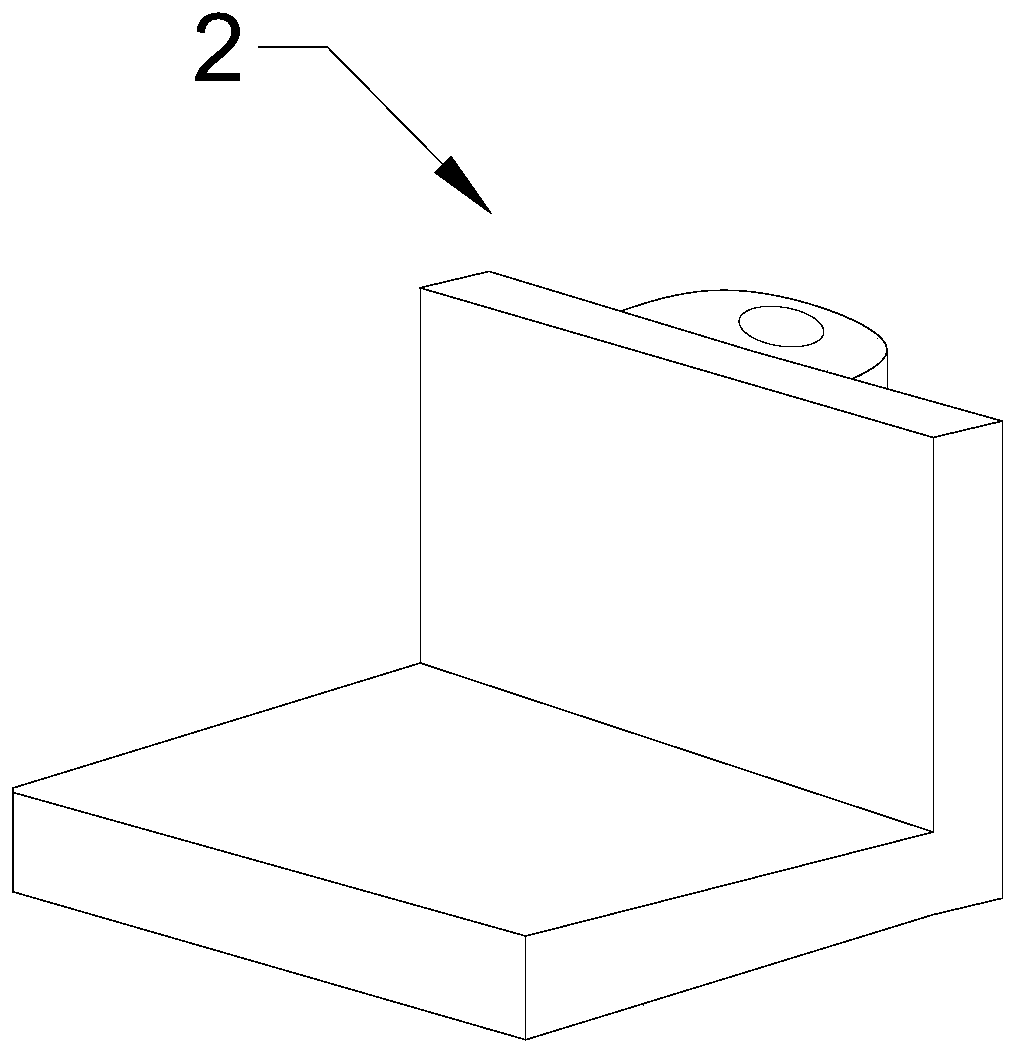

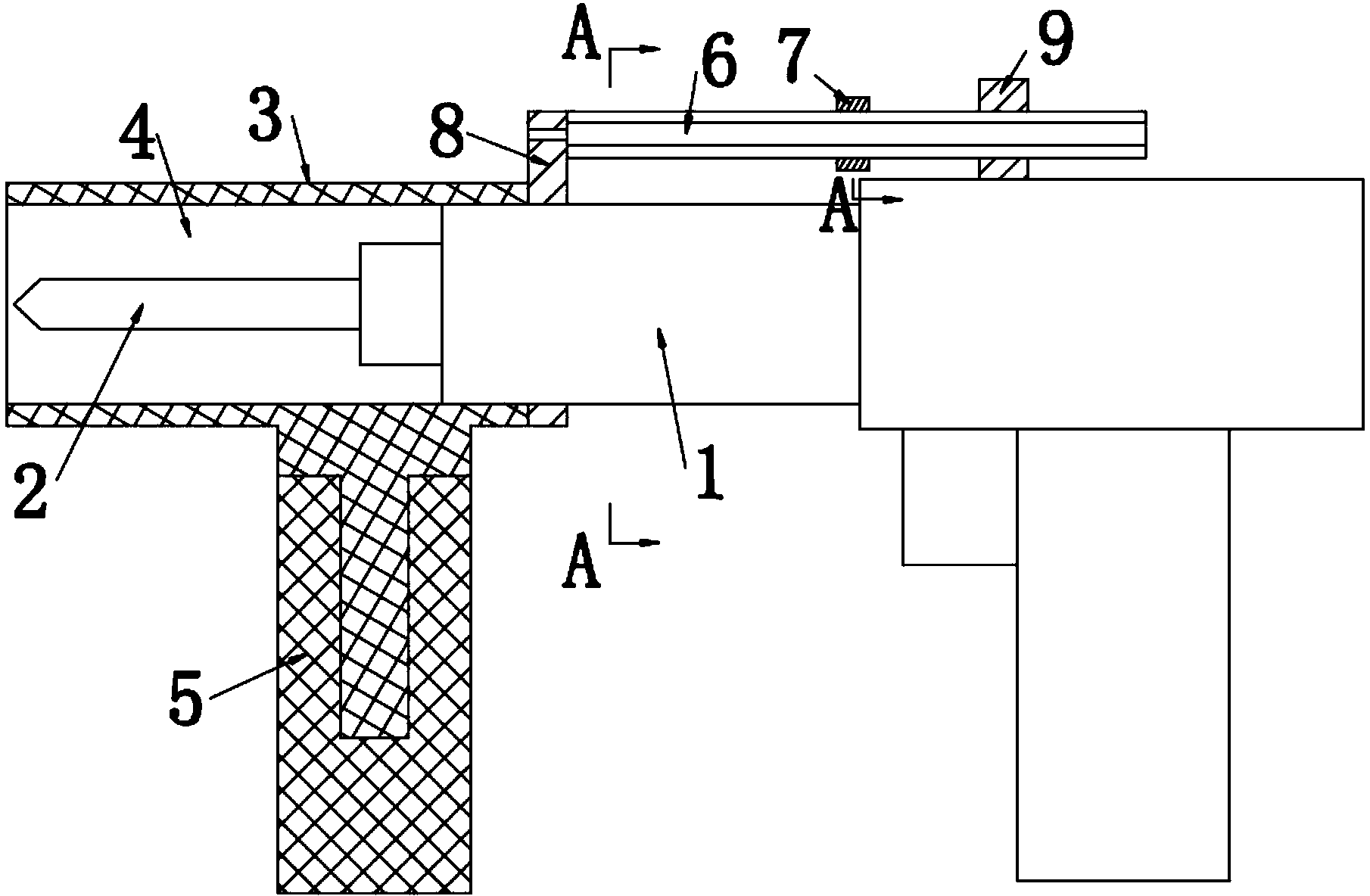

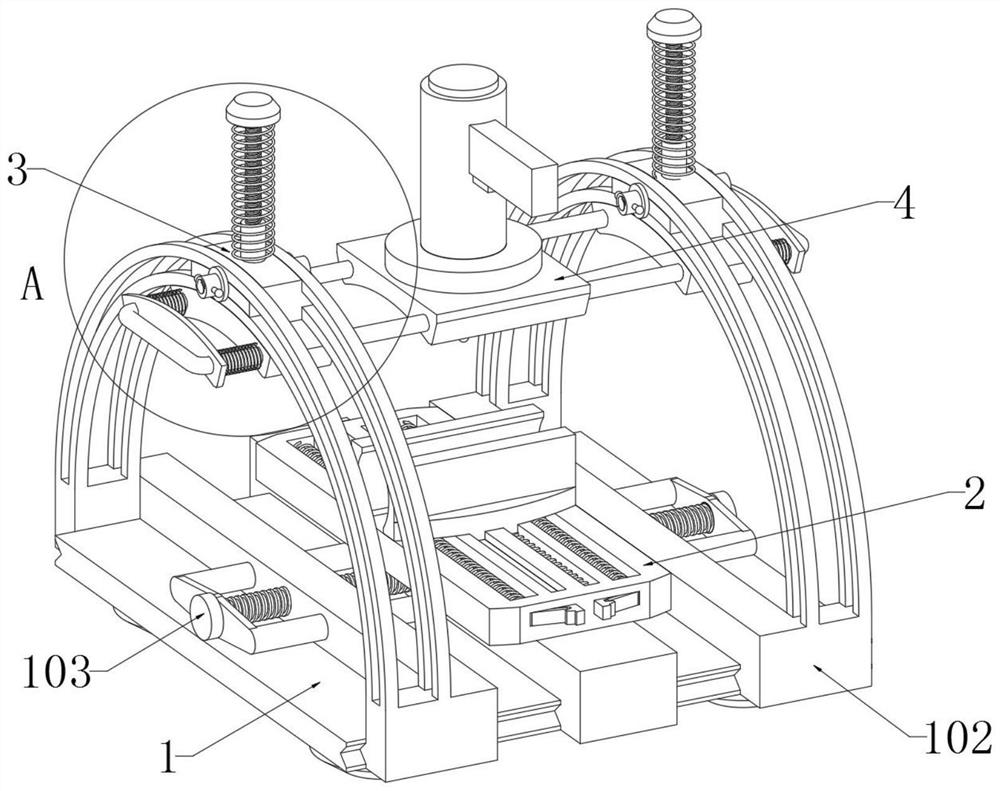

Automatic bidirectional clamping drilling machine

PendingCN112247626ARealize automatic clampingRealize automatic fixationMeasurement/indication equipmentsFeeding apparatusEngineeringWorkbench

The invention discloses an automatic bidirectional clamping drilling machine. The automatic bidirectional clamping drilling machine comprises a workbench. Two supporting legs are fixedly installed oneach the left portion of the lower end of the workbench and the right portion of the lower end of the workbench, a reinforcing rod is fixedly connected between the every two corresponding supporting legs jointly, a first installing groove is formed in the upper end of the workbench, and a moving mechanism is arranged at the right end of the workbench. A containing table is arranged at the upper end of the workbench, vertical plates are fixedly installed at the front portion and the rear portion of the upper end of the containing table, a clamping mechanism is arranged at the front end of the containing table, automatic stopping mechanisms are arranged at the ends, close to each other, of the two vertical plates, and a connecting block is fixedly installed in the middle of the rear end of the workbench. An L-shaped arm is fixedly installed at the rear portion of the upper end of the connecting block, a drilling mechanism is arranged at the upper end of the L-shaped arm, and the drillingmechanism extends to the position above the first installing groove. The automatic bidirectional clamping drilling machine is compact in structure, capable of automatically clamping and fixing a workpiece, high in drilling precision, high in practicability and convenient to use.

Owner:谢东

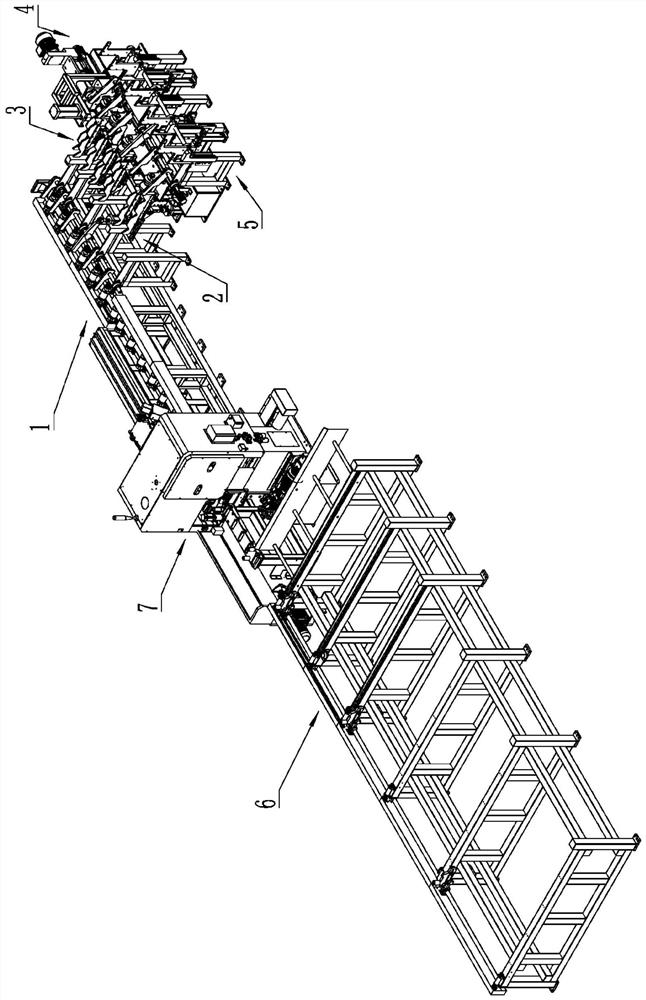

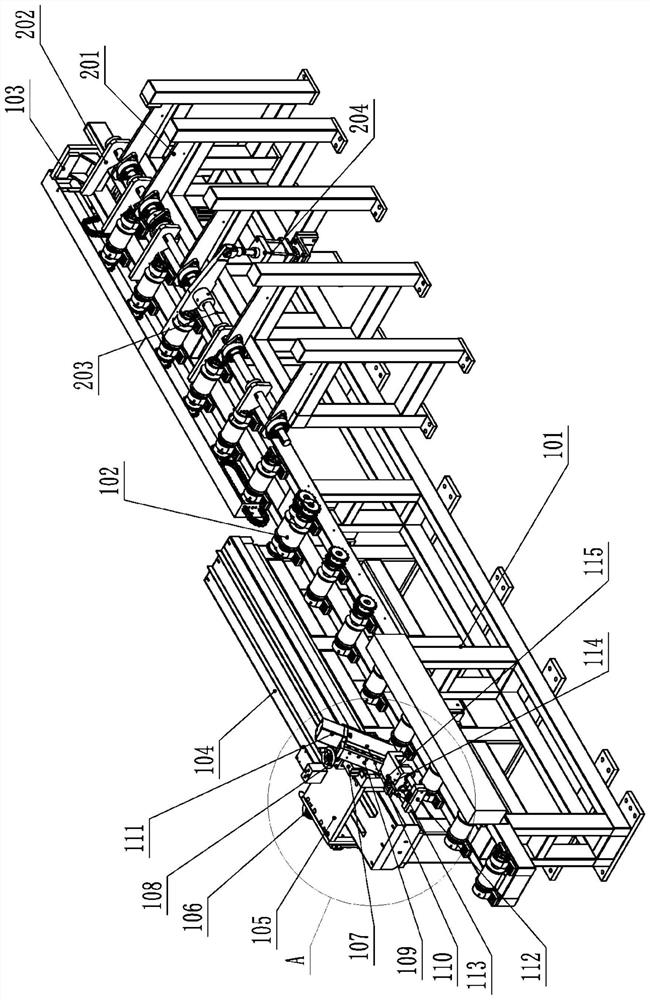

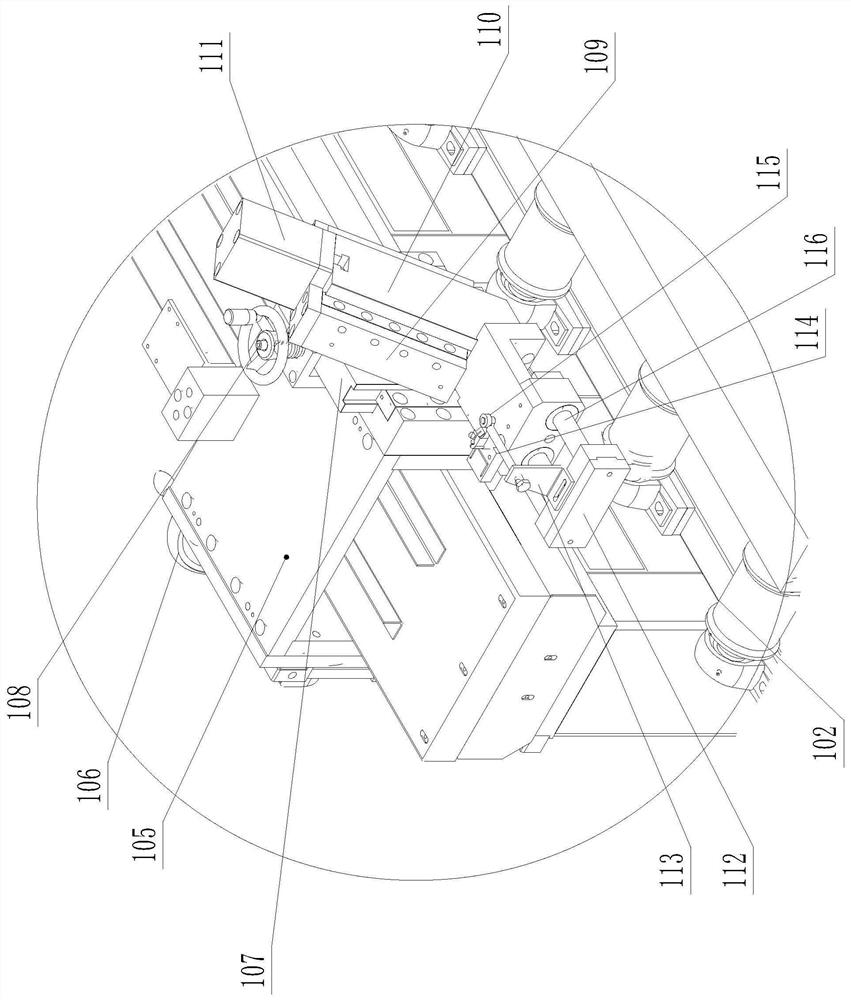

Automatic drilling device of short material sawing and drilling all-in-one machine

PendingCN112676841AEasy to sendAchieving lateral transferMeasurement/indication equipmentsOther manufacturing equipments/toolsStructural engineeringMechanical engineering

The invention discloses an automatic drilling device of a short material sawing and drilling all-in-one machine. The automatic drilling device comprises a sawing, discharging and conveying device, a transverse material turning and temporary storage device, a transverse stepping feeding device, a drilling device and a drilling discharging device, wherein the sawing, discharging and conveying device is used for longitudinally conveying sawn bars; the transverse material turning and temporary storage device is used for transversely turning and conveying the longitudinally-placed bars to a temporary storage material frame; the transverse stepping feeding device is used for feeding the bars on a material taking station to a drilling supporting station in a stepping mode; the drilling device comprises a drilling machine base and a drilling supporting device, the drilling supporting device is used for supporting the bars conveyed by the transverse stepping mechanism, and a drill bit component and a drilling clamping device are longitudinally arranged on the drilling machine base in a sliding mode; and the drilling discharging device is used for discharging the bars on the drilling supporting device. According to the automatic drilling device, the bars can be automatically conveyed to the drilling device one by one to be drilled after the bars are sawn, so that the production efficiency is improved, and meanwhile, the occupied area of the whole equipment is smaller.

Owner:SUZHOU KINKALTECK MACHINERY TECH

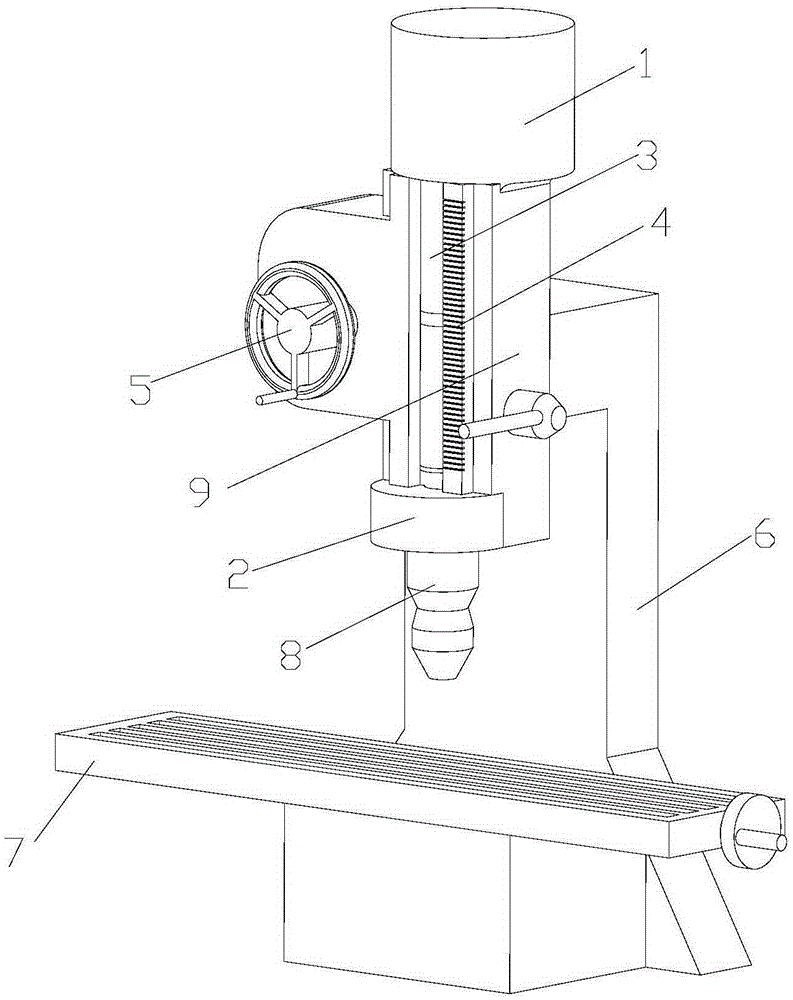

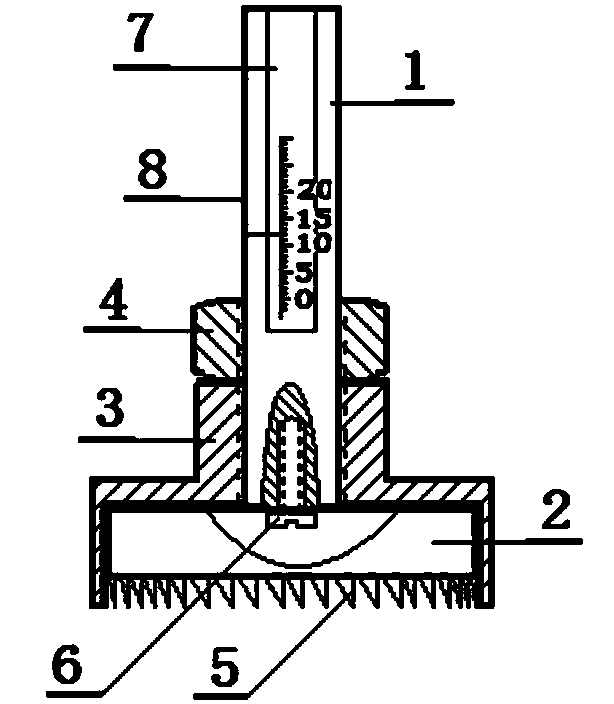

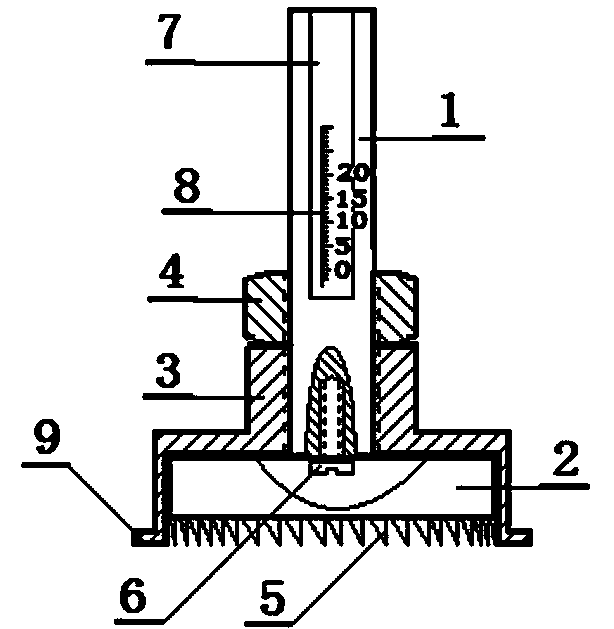

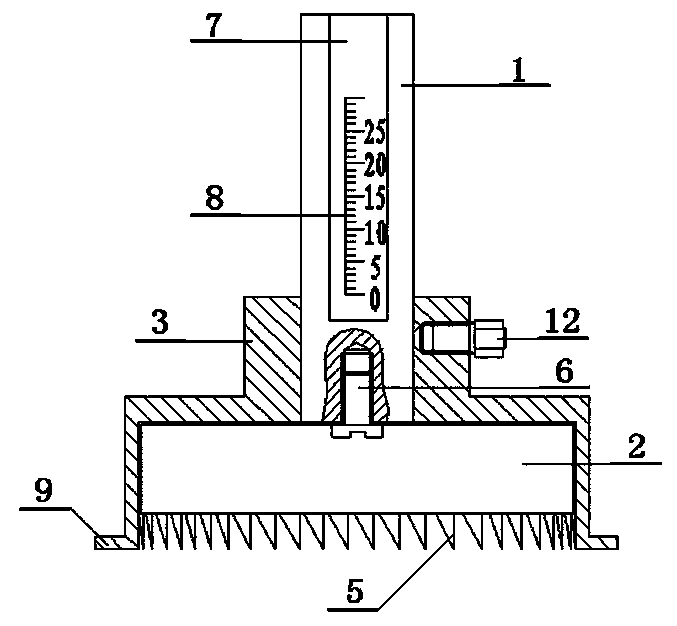

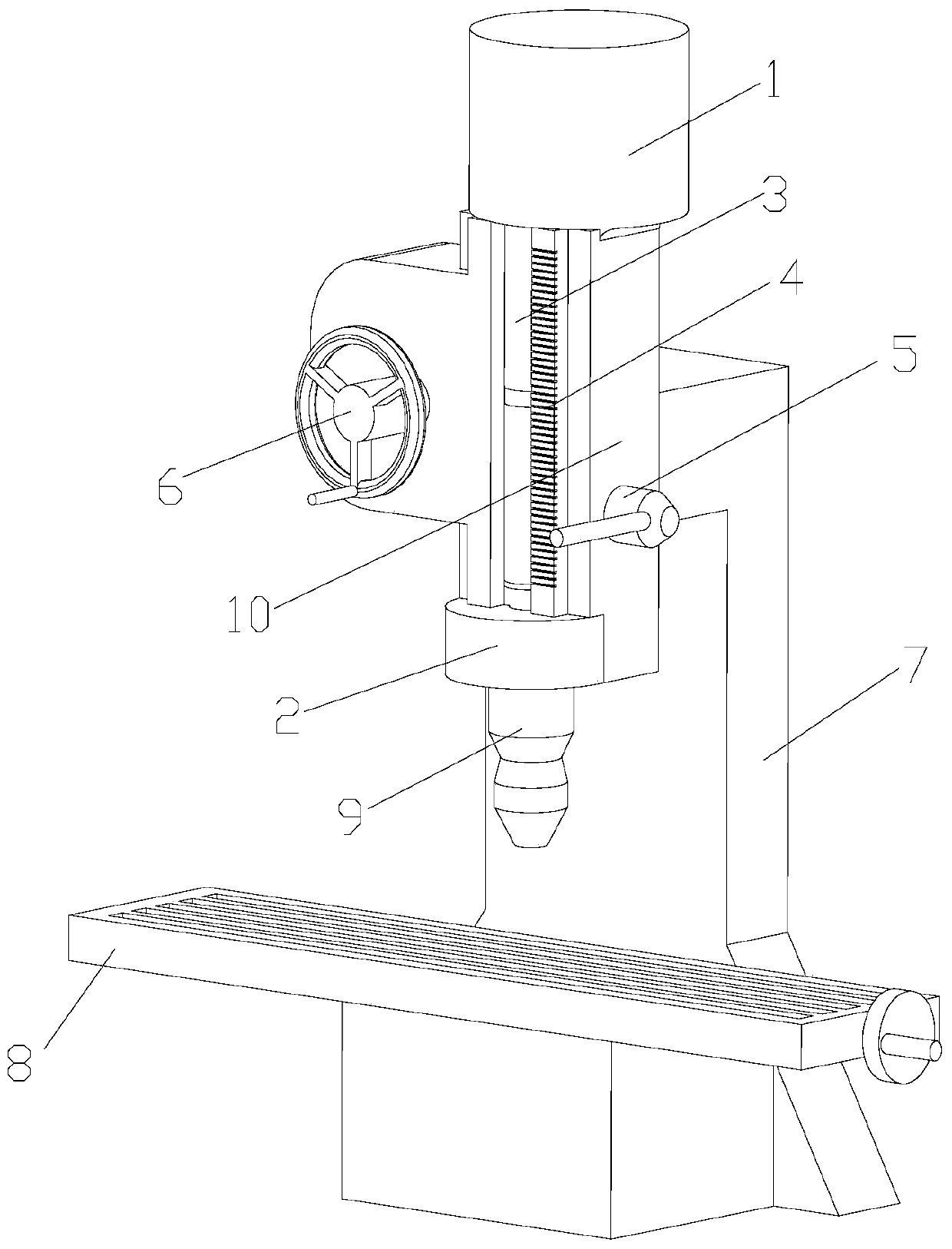

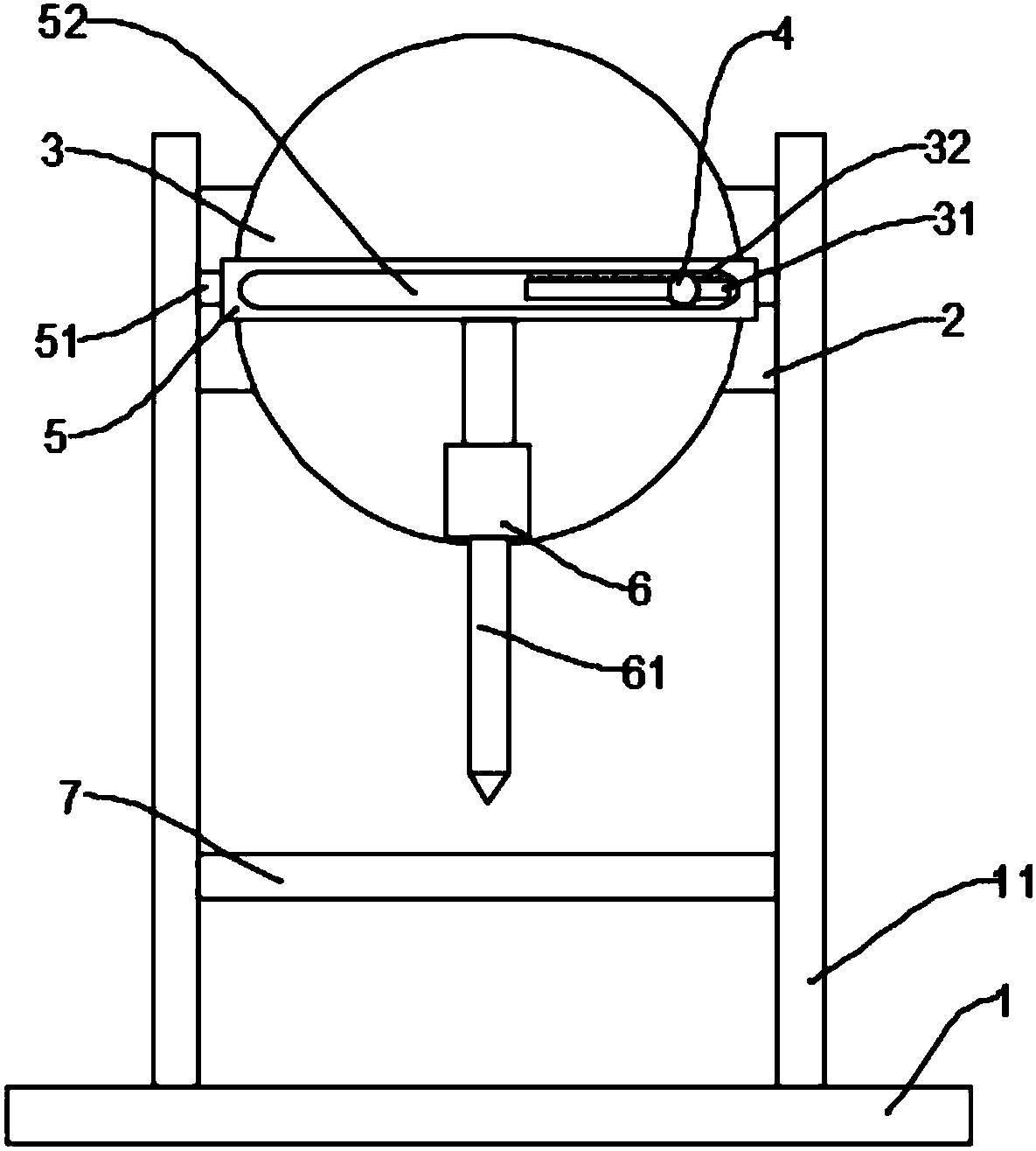

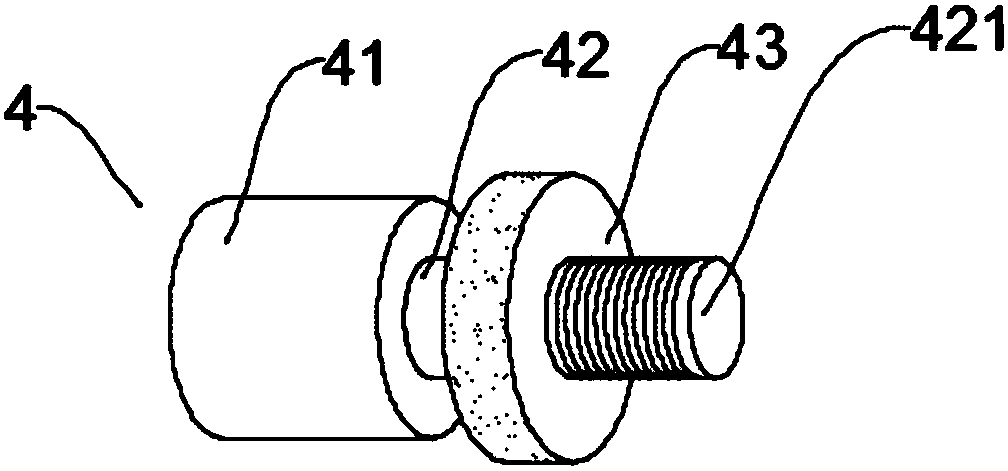

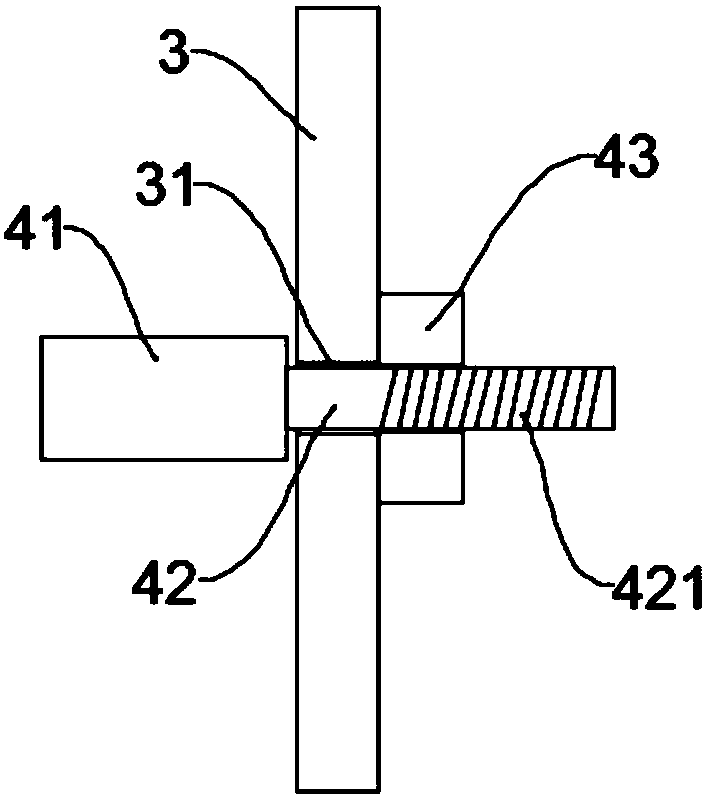

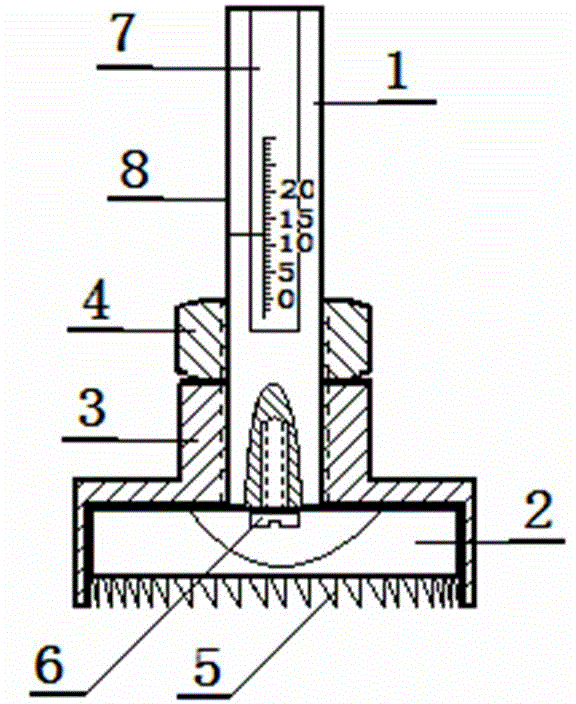

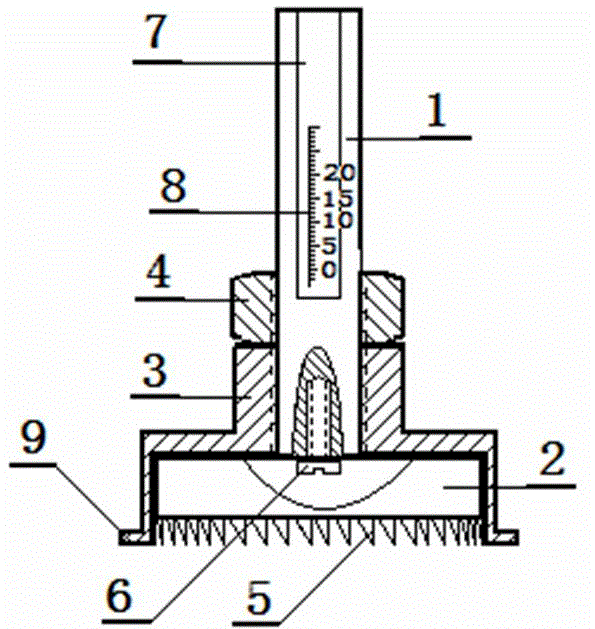

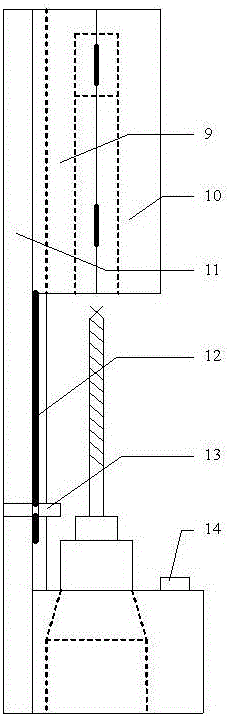

Drilling machine mechanism and drilling machine

ActiveCN105345076AControl drilling depthReduce defective rateMeasurement/indication equipmentsBoring/drilling machinesDrilling machinesDrill bit

The invention discloses a drilling machine mechanism and a drilling machine. The drilling machine mechanism comprises a scaleplate rod, a drill rod, a vertically arranged supporting frame, an upper supporting platform fixedly connected with the top end of the supporting frame and a lower supporting platform fixedly connected with the bottom end of the supporting frame; one end of the drill rod penetrates through the lower supporting platform and is detachably connected with a drill sleeve, the other end of the drill rod extends to the inside of the upper supporting platform, and the drill rod is vertically arranged; one end of the scaleplate rod is fixedly connected with the upper supporting platform, and the other end of the scaleplate rod is fixedly connected with the lower supporting platform; the scaleplate rod is parallel to the drill rod, so that when the drill rod moves vertically, an operator can observe the moving distance of the drill rod through the scaleplate rod. According to the drilling machine mechanism, when a drill bit is used for machining a part to be machined, the defective percentage of machined finished products is low.

Owner:盐城市国海精工机械有限公司

Automatic drilling machine

PendingCN108788222AImprove consistencyReduce biasAutomatic control devicesDrilling/boring measurement devicesMachiningDrilling machines

The invention relates to the technical field of pipe machining, in particular to an automatic drilling machine. The automatic drilling machine comprises a feeding device, a discharging device and a drilling device. The feeding device, the drilling device and the discharging device are sequentially connected. A series of working procedures of feeding, machining and discharging are achieved, drilling machining of a pipe is automatically completed, and the machining efficiency is high.

Owner:GUANGZHOU KINGHING CONSTR TECH

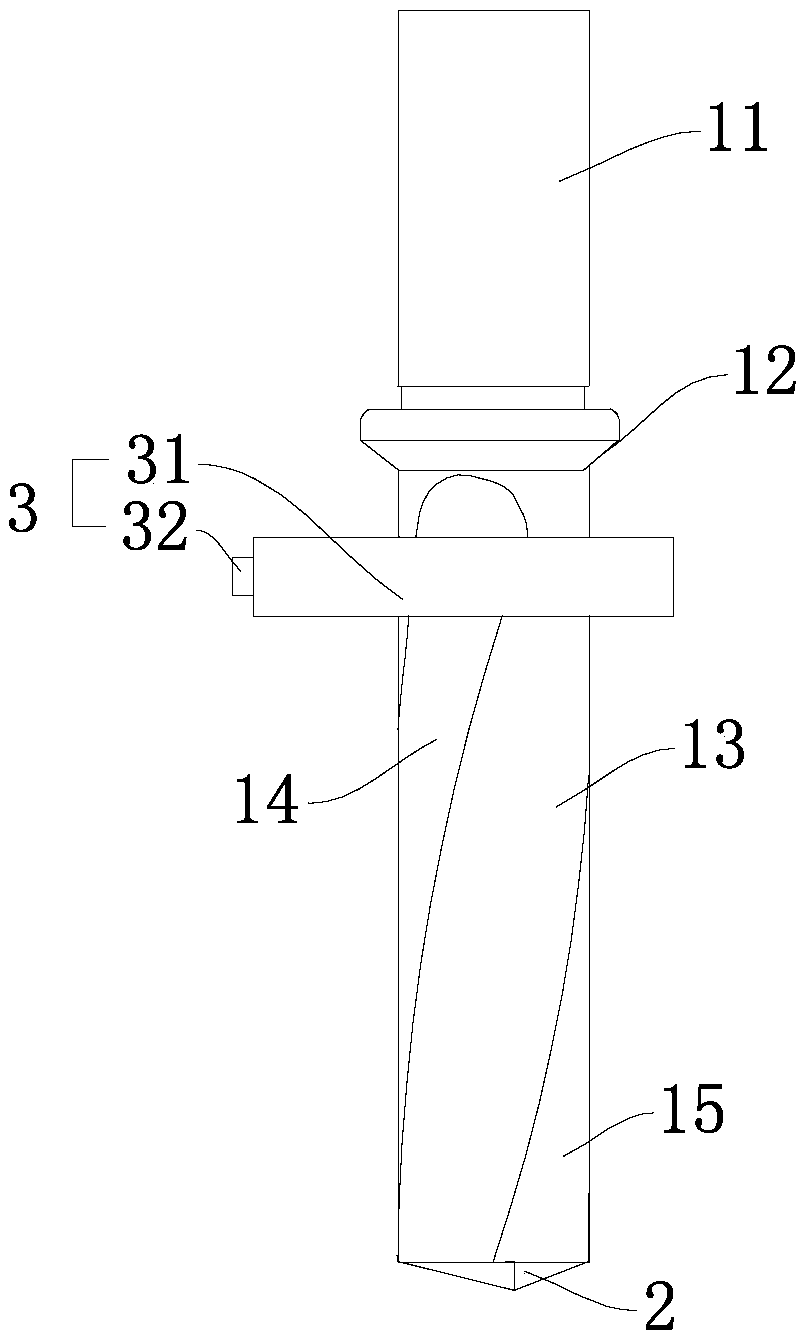

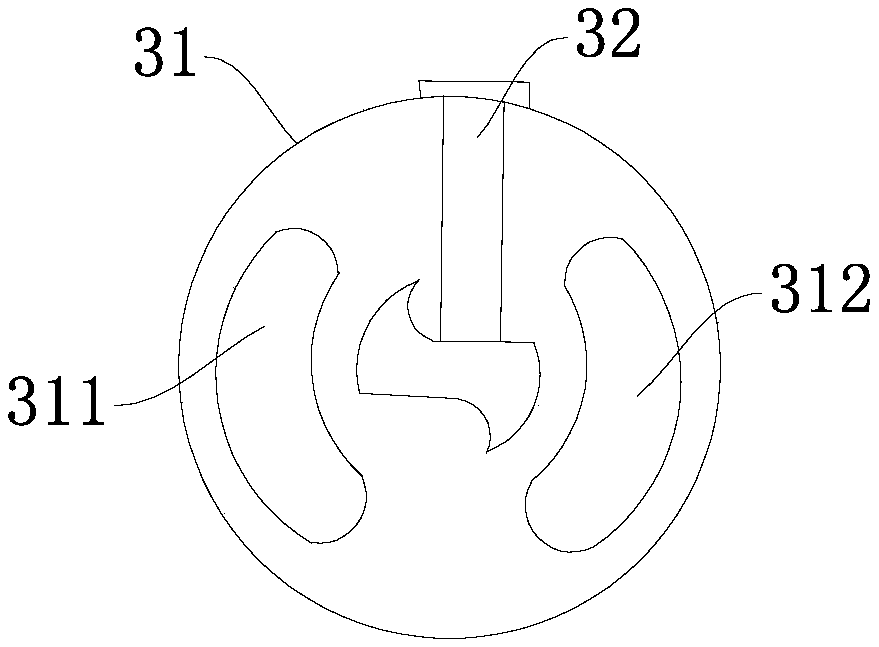

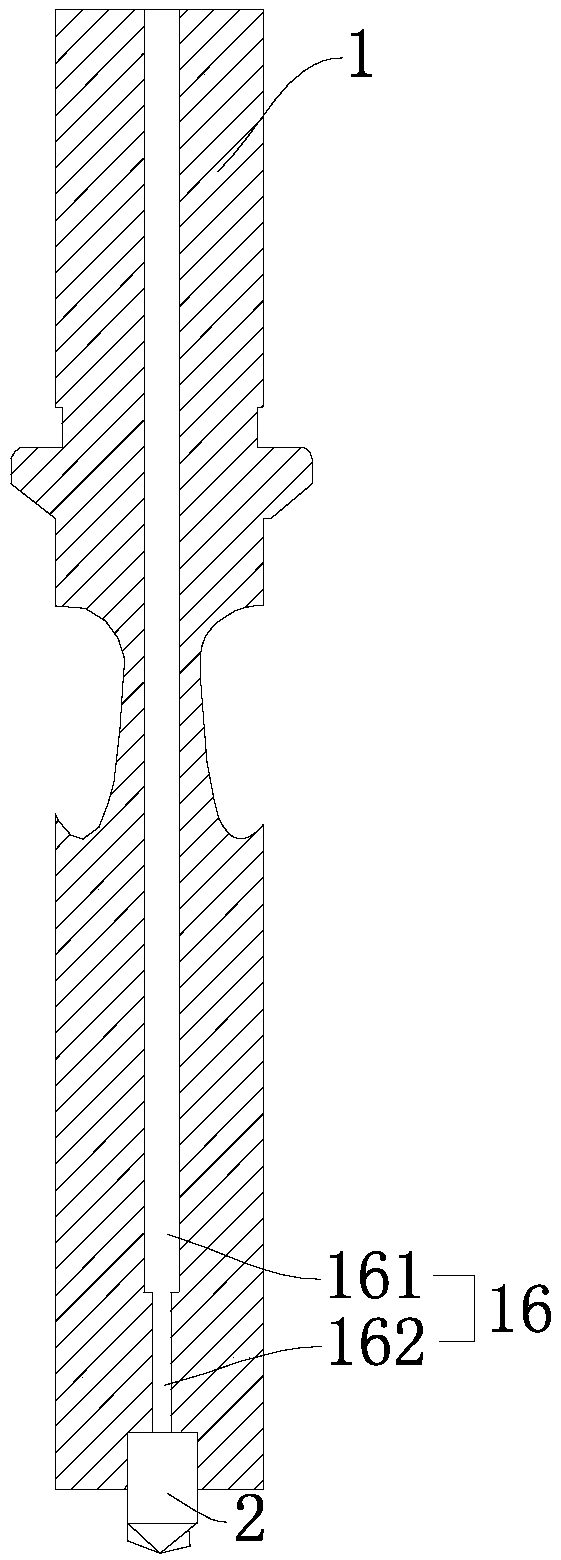

Efficient depth-keeping drilling device for resin gypsum for fixing limbs

InactiveCN103417341AControl drilling depthReduce usageBandagesStructural engineeringReoperative surgery

The invention discloses an efficient depth-keeping drilling device for resin gypsum for fixing limbs. The device comprises a connection rod (1), a rotary-cut saw (2) and an adjusting protective sleeve (3); the lower end of the connection rod (1) is provided with the rotary-cut saw; the upper part of the adjusting protective sleeve is in adjusting match with the lower part of the connection rod (1) in a locking mode; and the lower part of the adjusting protective sleeve (3) is in wrapping match with the rotary-cut saw (2). A structure of matching the rotary-cut saw, an adjusting mechanism and a connection device is adopted, so the drilling depth of the rotary-cut saw can be precisely controlled, and the connection device can be connected with a driving mechanism for supplying power for the rotary-cut saw. The resin gypsum efficient depth-keeping drilling device is simple in structure, simple and convenient to operate, stable and reliable in work, and capable of overcoming the labor-consuming, time-consuming and unsafe defects of the cutting drilling by common cutters in the prior art, the work efficiency of improving the removal rate of resin gypsum molds can be greatly improved by effectively reducing the use of a steel wire saw, the pain of a patient is reduced, the surgical effect is improved, and the rehabilitation of the wrist joint function of the patient is more facilitated. The drilling efficiency in the gypsum molds can be greatly improved by more than 5 times by using the efficient depth-keeping drilling device for the resin gypsum for fixing limbs.

Owner:中国人民解放军联勤保障部队第九二〇医院

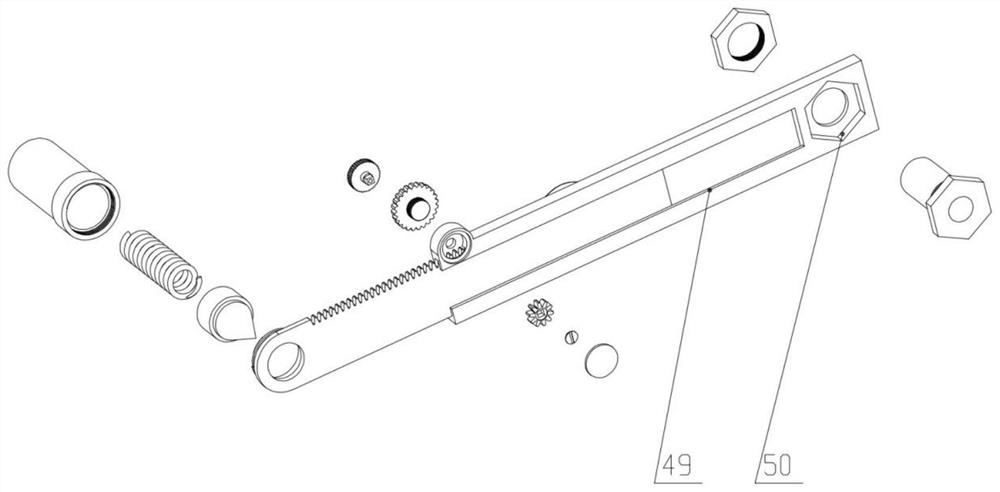

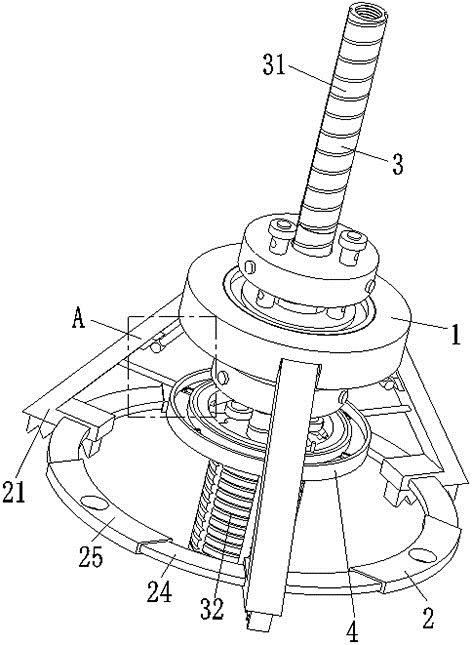

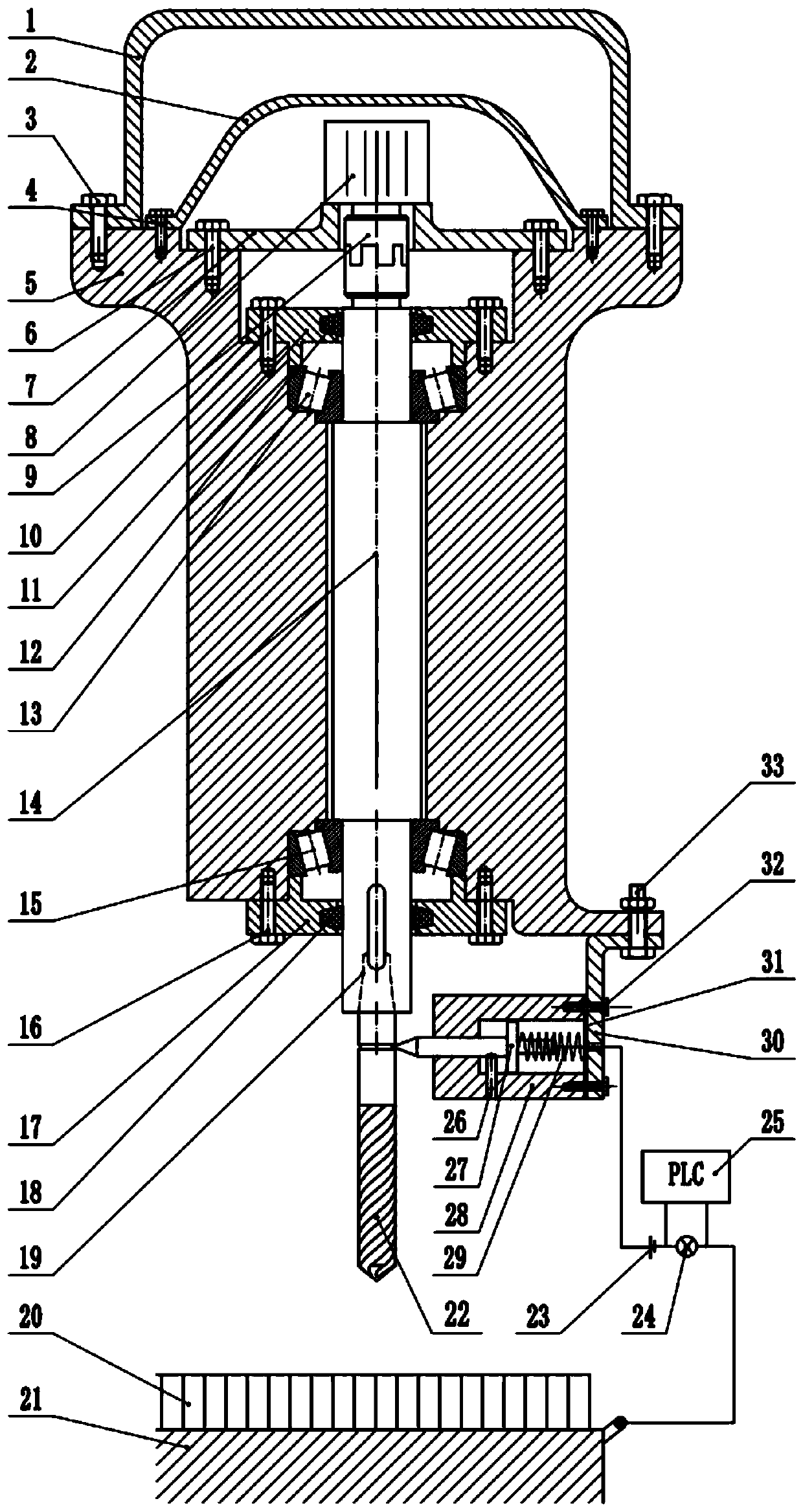

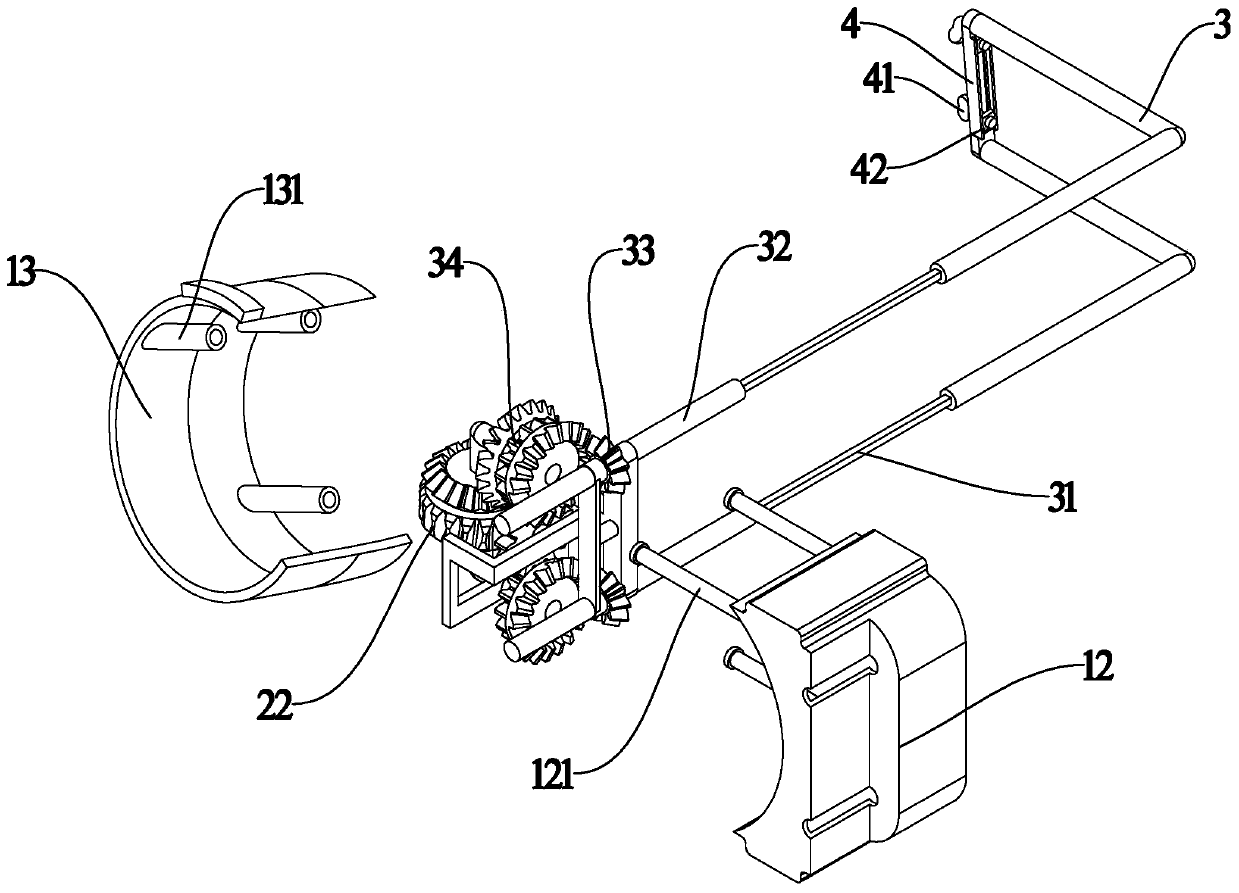

Numerical control lathe tailstock automatic control method capable of controlling drilling depth and finishing hole bottom

InactiveCN106001631ARealize synchronized movementRealize finishingTailstocks/centresAttachable boring/drilling devicesNumerical controlAutomatic control

The invention provides a numerical control lathe tailstock automatic control method capable of controlling the drilling depth and finishing a hole bottom. A connection device achieving connection and disconnection of a saddle and the tailstock of a numerical control lathe is adopted and comprises a centering assembly, a rotating arm assembly, a driving assembly and a drill bit assembly. The drill bit assembly is installed in a tube sleeve of the tailstock of the numerical control lathe. The centering assembly comprises a centering shaft and a centering sleeve with an inner cone hole. The shaft end of the centering shaft and the bottom of the cone hole of the centering sleeve are provided with a sensor. The rotating arm assembly comprises a rotating arm, a rotating shaft, a shaft sleeve and two limiting pressure blocks, the driving assembly comprises a pair of belt drivers, a driving motor, a reset switch and a controller, the controller is installed in a distribution cabinet of the lathe, the reset switch is installed on the front face of the saddle of the numerical control lathe, and the driving motor is fixedly connected with the tailstock of the numerical control lathe and electrically connected with the controller.

Owner:惠州市天力和丰精密五金有限公司

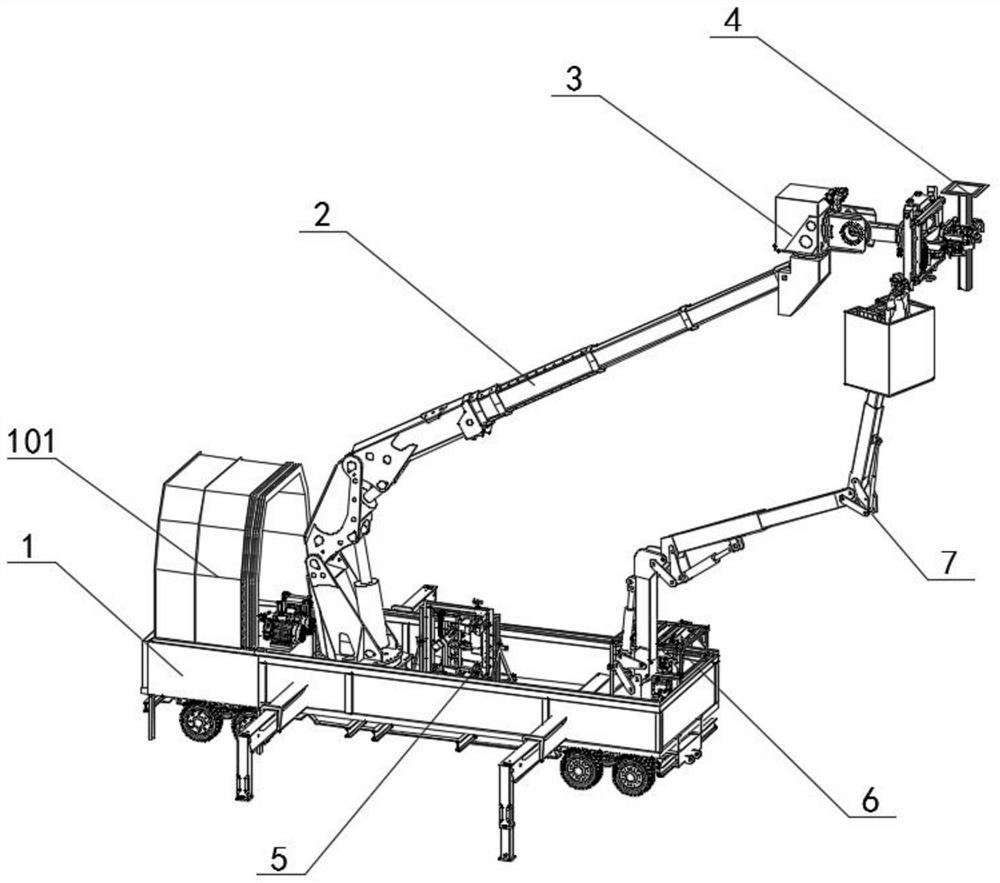

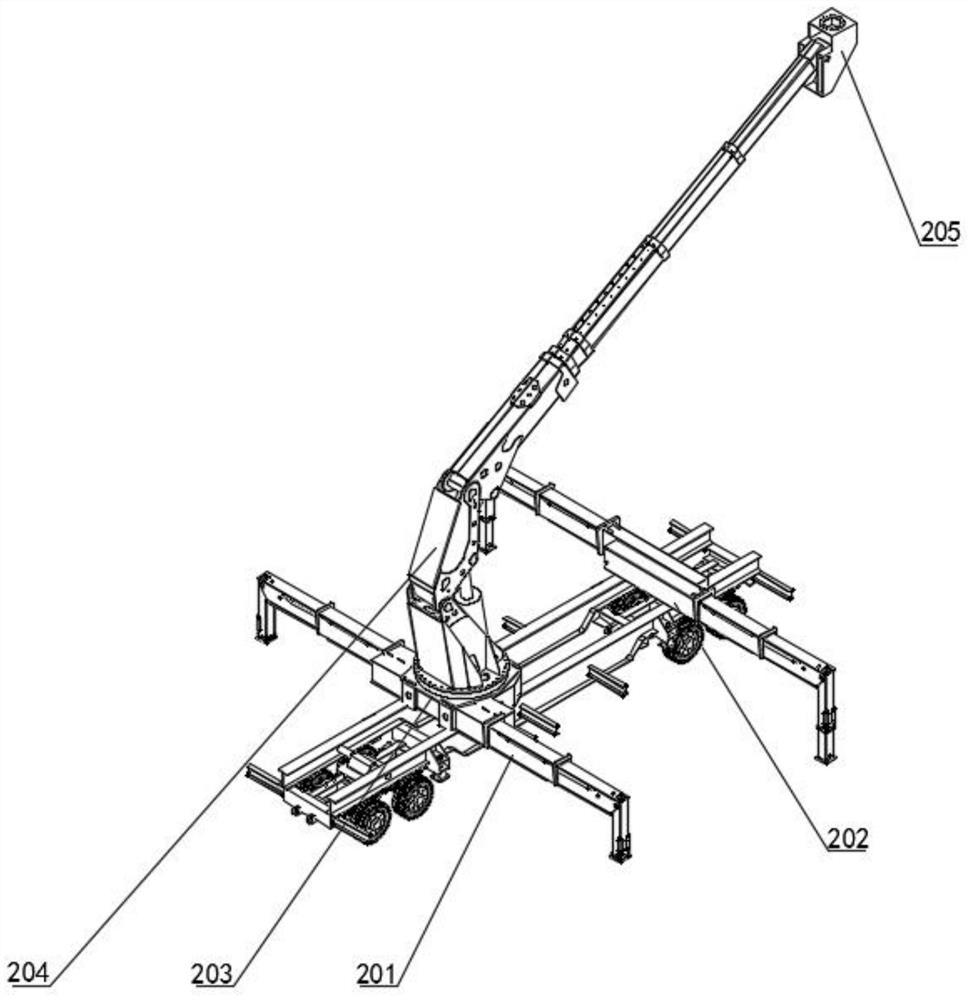

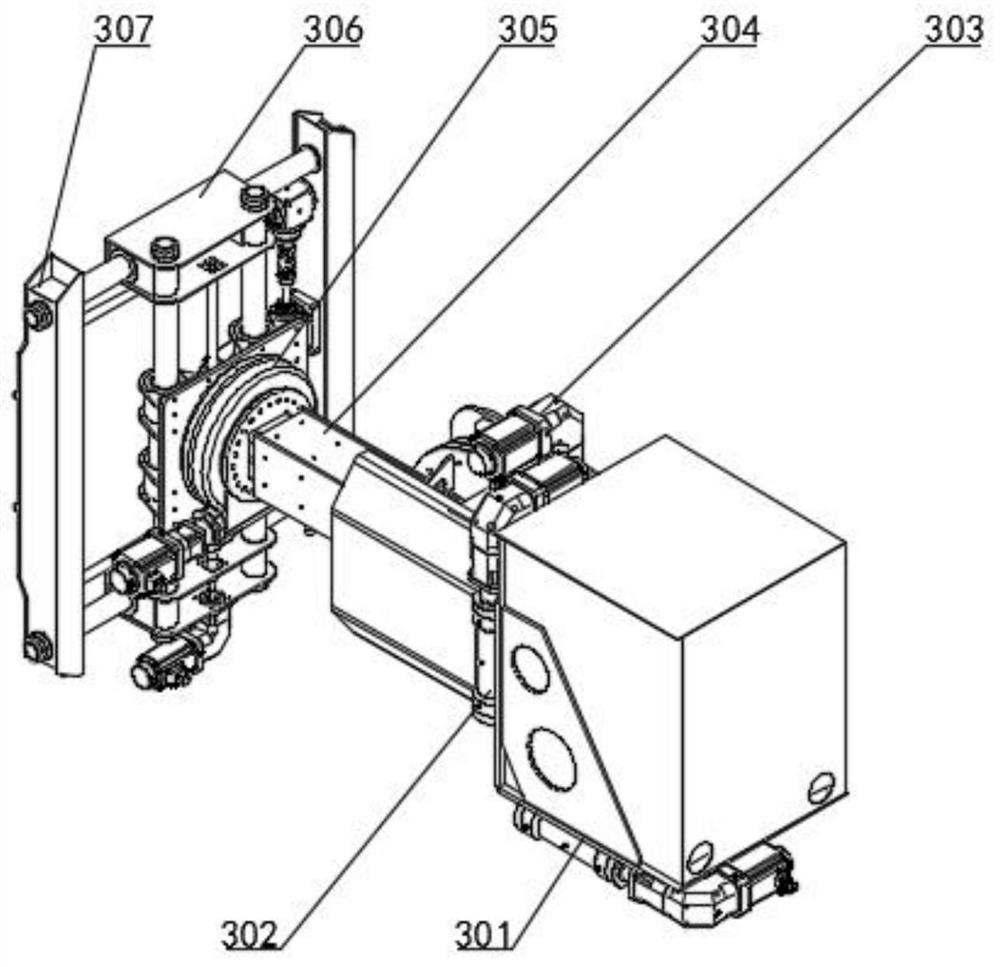

Multifunctional intelligent moving platform for tunnel operation

InactiveCN112777534AIncrease flexibilityProtection securityLifting devicesCranesDrill holeStructural engineering

The invention discloses a multifunctional intelligent moving platform for tunnel operation. The multifunctional intelligent moving platform for tunnel operation comprises an engineering vehicle body, a telescopic boom, an alignment correction mechanism and an ascending arm, wherein the telescopic boom comprises front supporting legs, rear supporting legs, a boom rotation part, a boom body and an installation platform, the front supporting legs and the rear supporting legs are installed on the engineering vehicle body, the boom body is installed on the front supporting legs, the installation platform is installed on the boom body, and the alignment correction mechanism is installed on the installation platform and comprises a first rotating shaft, a second rotating shaft, a third rotating shaft, a telescopic arm, a fourth rotating shaft, a horizontal movement shaft and vertical movement shafts. According to the multifunctional intelligent moving platform for tunnel operation, firstly, a double-mechanical-arm operation structure is arranged, and therefore the safety of personnel is protected to the maximum extent in the ascending operation process; secondly, a synchronous double-drilling structure is arranged, and therefore the drilling operation efficiency can be improved in a multiplied mode; and finally, an eight-shaft alignment structure is arranged, and therefore the vehicle body can be parked at any position in a tunnel to conduct operation.

Owner:武汉中安佳通装备技术有限公司

Semi-automatic multi-angle workpiece drilling device

InactiveCN110102796AEasy to adjustConvenient heightBoring/drilling componentsBoring/drilling machinesSemi automaticIndustrial engineering

The invention discloses a semi-automatic multi-angle workpiece drilling device, which comprises a working table and a drilling motor.The drilling motor is fixedly connected with a moving seat throughbolts, and the moving seat is nested with a swinging plate; the swinging plate is fixedly connected with a rotating shaft, and the rotating shaft is rotatably connected with a scale plate through a bearing seat; the upper part of the scale plate is in a circular arc shape,a scale line is formed in the surface ofthe scale plate, and a pointer is arranged at the upper end of the swinging plate; andthe rotating shaft sleeve is fixedly connected with a worm wheel in a sleeving mode, the worm wheel is meshed with a worm, and a first regulating wheel is fixedly connected with the tail end of the worm. According to the semi-automatic multi-angle workpiece drilling device,through the arrangements ofthe scale plate, the swinging plate,the worm wheel, and the worm, precise adjustment of the drilling angle of the drilling motor is facilitated, and the needs of the drilling angle are met; and through the arrangements of a lifting frame and a second screw rod, the adjustment of the height ofa clamping seat is facilitated so as to control the depth of drilling, and adjustability is good.

Owner:马单智

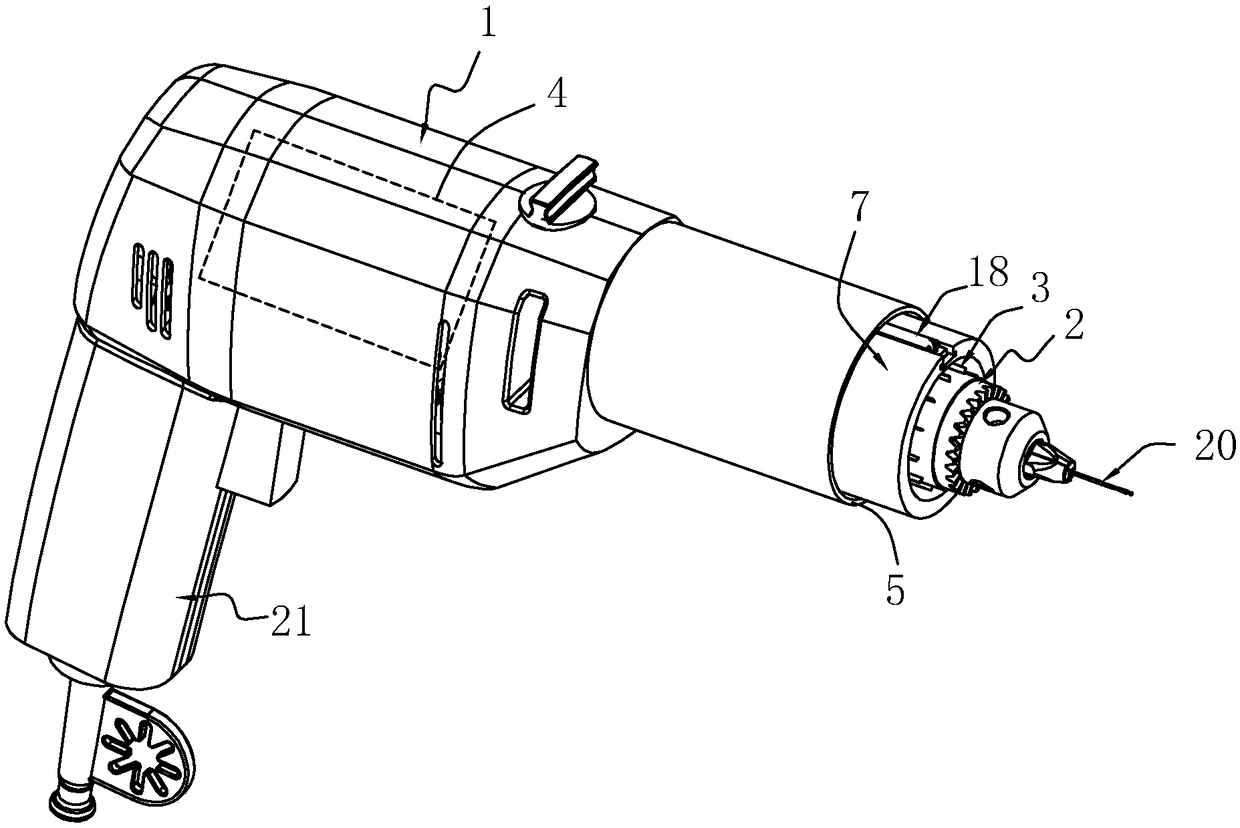

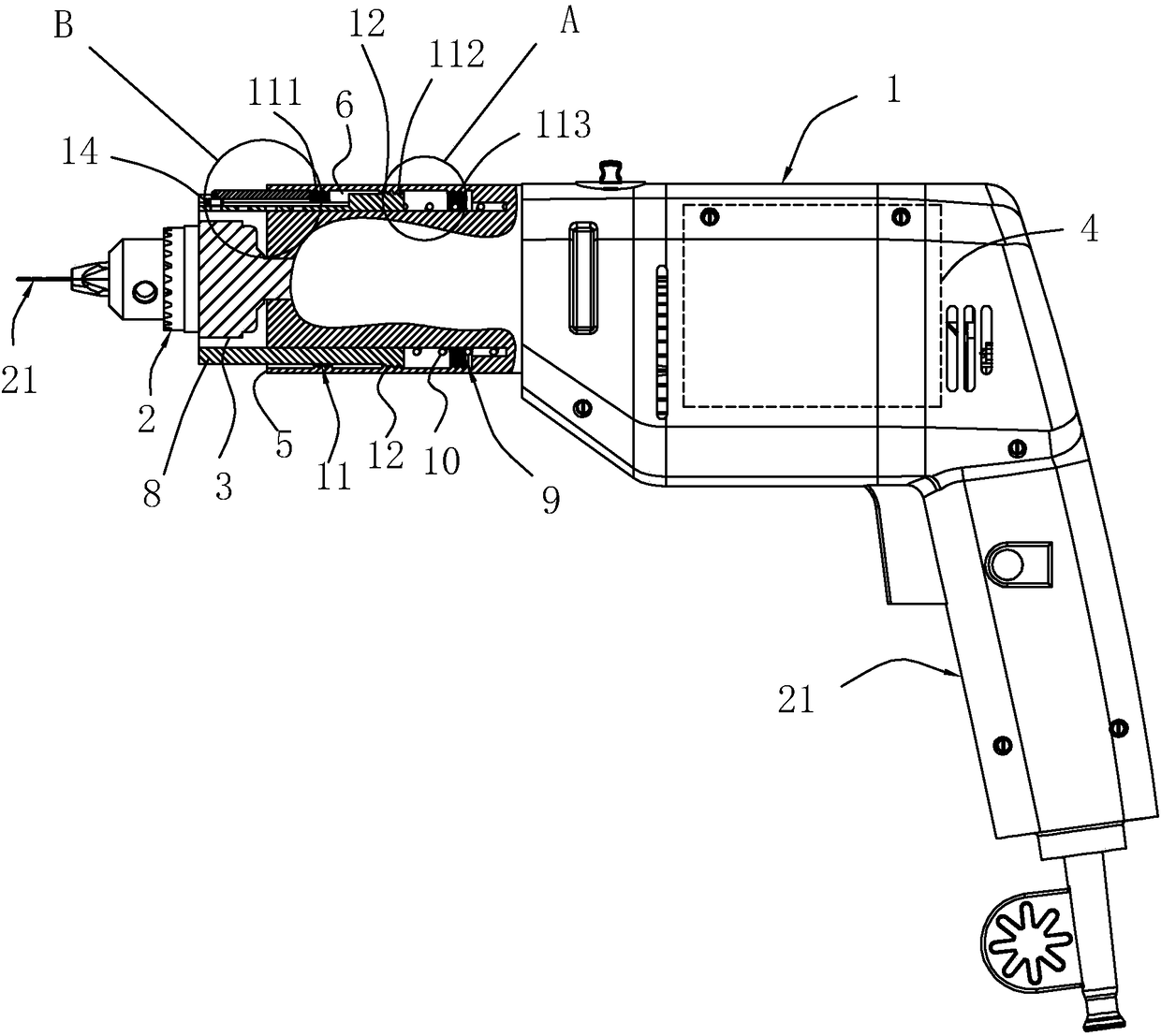

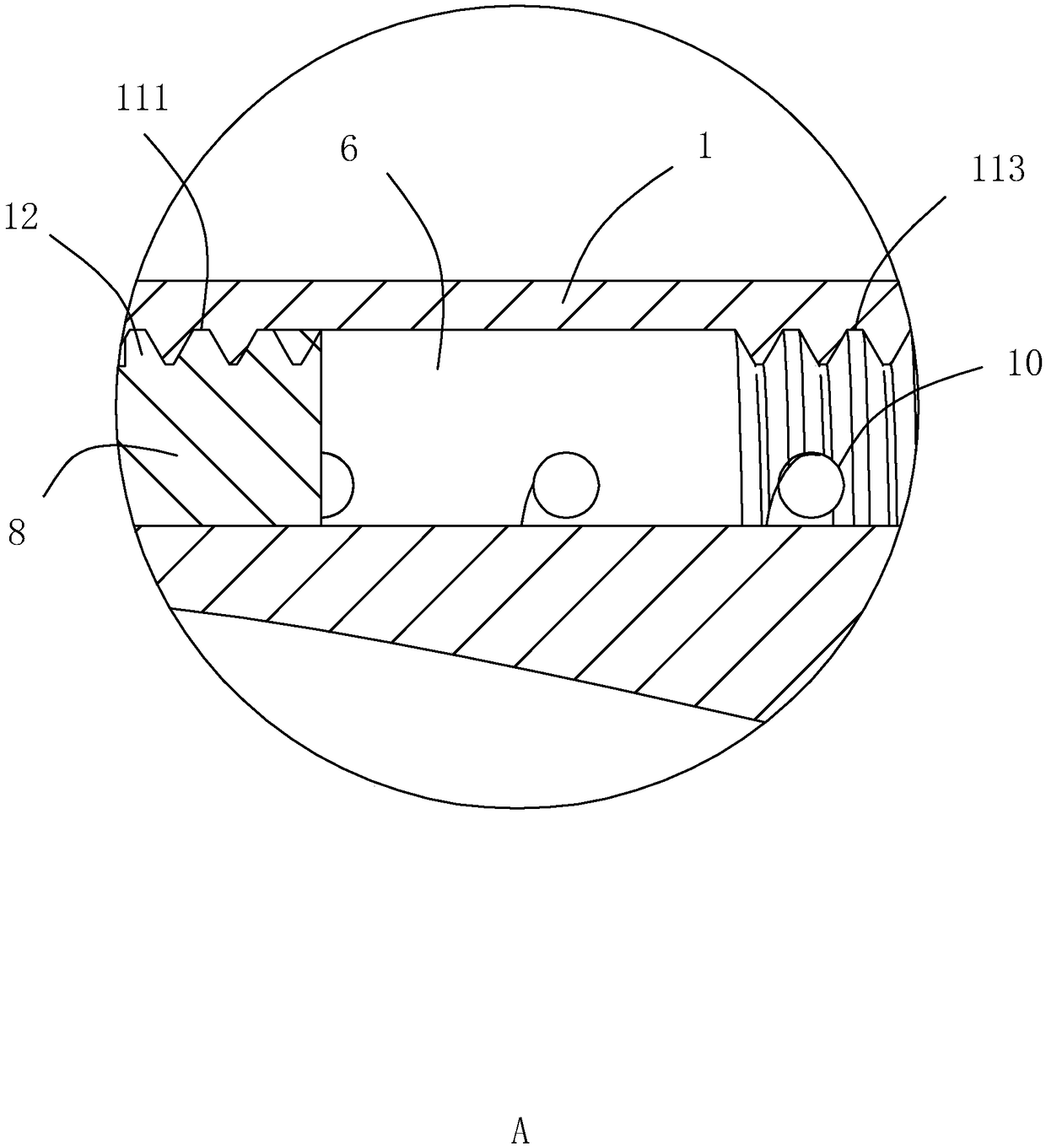

Electric drill safe in use

InactiveCN103978251AControl drilling depthAvoid injuryDrilling/boring measurement devicesPortable power-driven toolsRadial surfaceDrill bit

The invention discloses an electric drill safe in use. The electric drill comprises a shell, a drill bit and a protective cover, wherein the protective cover comprises a sleeve and a handle, the sleeve is connected to the shell and the drill bit in a sleeved mode in the axial direction and can rotate and move on the shell in the axial direction, the handle is installed on the radial surface of the sleeve, and the sleeve is made of a transparent material. The electric drill is quite safe in use.

Owner:NINGBO ZHENMING SHAFT

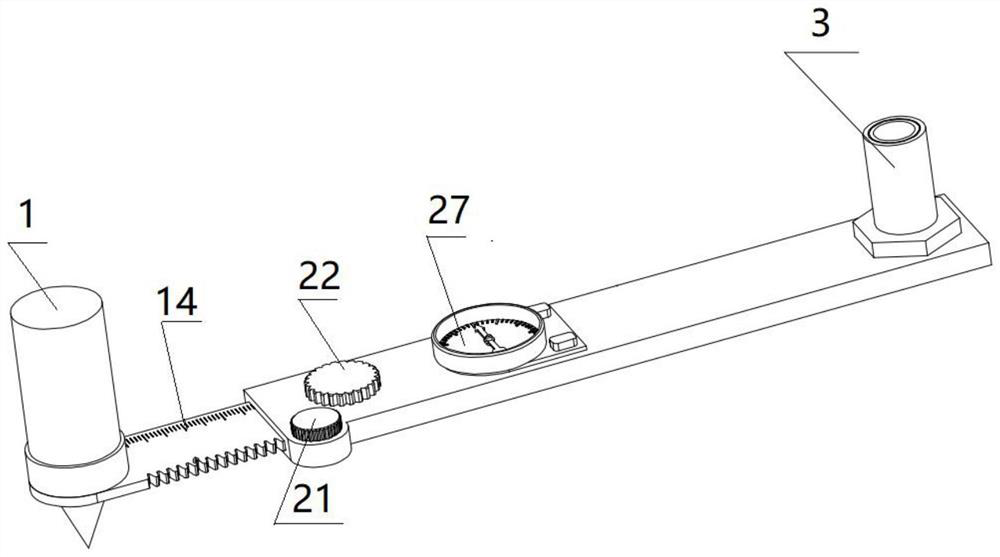

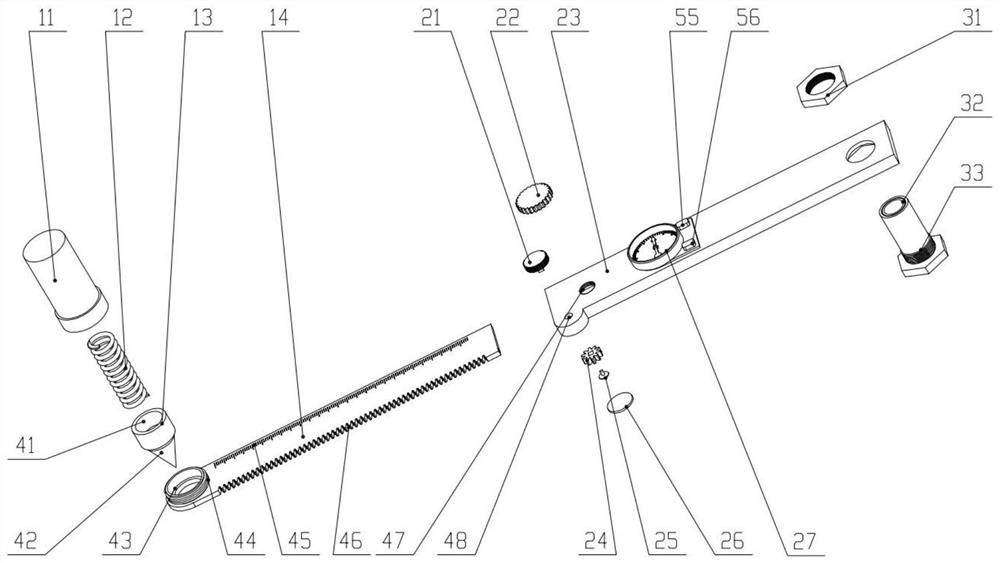

Drilling auxiliary tool

ActiveCN111958019AGuaranteed accuracyFast drillingMeasurement/indication equipmentsDrill jigsMeasuring rulerMechanical engineering

The invention discloses a drilling auxiliary tool. The drilling auxiliary tool comprises a measuring ruler body, a positioning device and a control sleeve, wherein the measuring ruler body comprises ascale body and a guide rail ruler body; one side, in the length direction, of the scale body is provided with a size scale; a mounting hole is reserved in the head of the scale body for mounting thepositioning device; the positioning device is used for positioning the auxiliary tool; the guide rail ruler body is provided with a guide rail clamping groove; the scale body is slidably mounted on the guide rail clamping groove; the guide rail ruler body is provided with a locking device; the locking device is used for locking the scale body so that the scale body cannot move, and the accuracy ofmeasuring size is effectively ensured; meanwhile, the guide rail ruler body is provided with an angle meter, and the angle meter is used for measuring the angle deflection information; and in addition, a through hole for mounting the control sleeve is reserved at the tail end of the guide rail ruler body, and the control sleeve is used for controlling the drilling depth. The auxiliary drilling tool can quickly and accurately obtain the hole spacing between a hole to be drilled and a positioning hole, as well as an angle of the connecting line of the two holes and the reference line, so that the position to be drilled is found and quickly drilled.

Owner:HUNAN LIANZHI BRIDGE & TUNNEL TECH

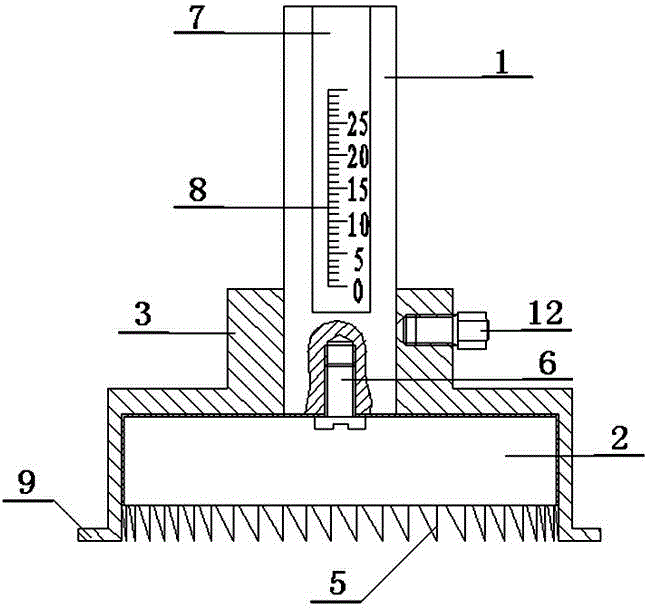

Drilling Units and Drilling Presses

ActiveCN105345095BControl drilling depthReduce defective rateDrilling/boring measurement devicesLarge fixed membersThreaded rodDrilling machines

The invention discloses a drill press device and a drill press. The drill press device comprises a scale rod, a drill rod, a supporting rack arranged vertically, an upper supporting platform fixedly connected to the top end of the supporting rack, a lower supporting platform fixedly connected to the bottom end of the supporting rack, and a limiting mechanism arranged on the supporting rack. When the drill rod moves in the vertical direction, an operator can observe the movement distance of the drill rod through the scale rod. The limiting mechanism comprises a threaded rod and a rotating piece. The threaded rod penetrates through the supporting rack, and the straight line where the threaded rod is located in the length direction is perpendicular to the straight line where the drill rod is located in the length direction. A round groove is formed in the drill rod in the circumferential direction so that the drill rod can be stopped when the threaded rod stretches into the round groove. The threaded rod is sleeved with the rotating piece. When the drill press device is used for machining pieces to be treated through a drill bit, the defective percentage of machined finished products is low.

Owner:上海天檀电子科技有限公司

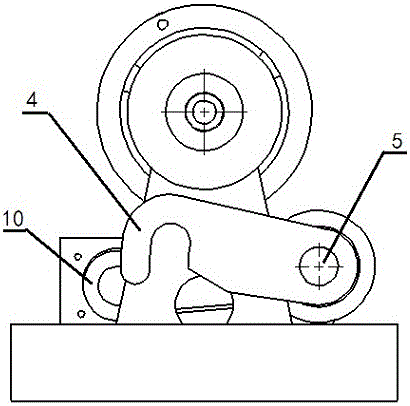

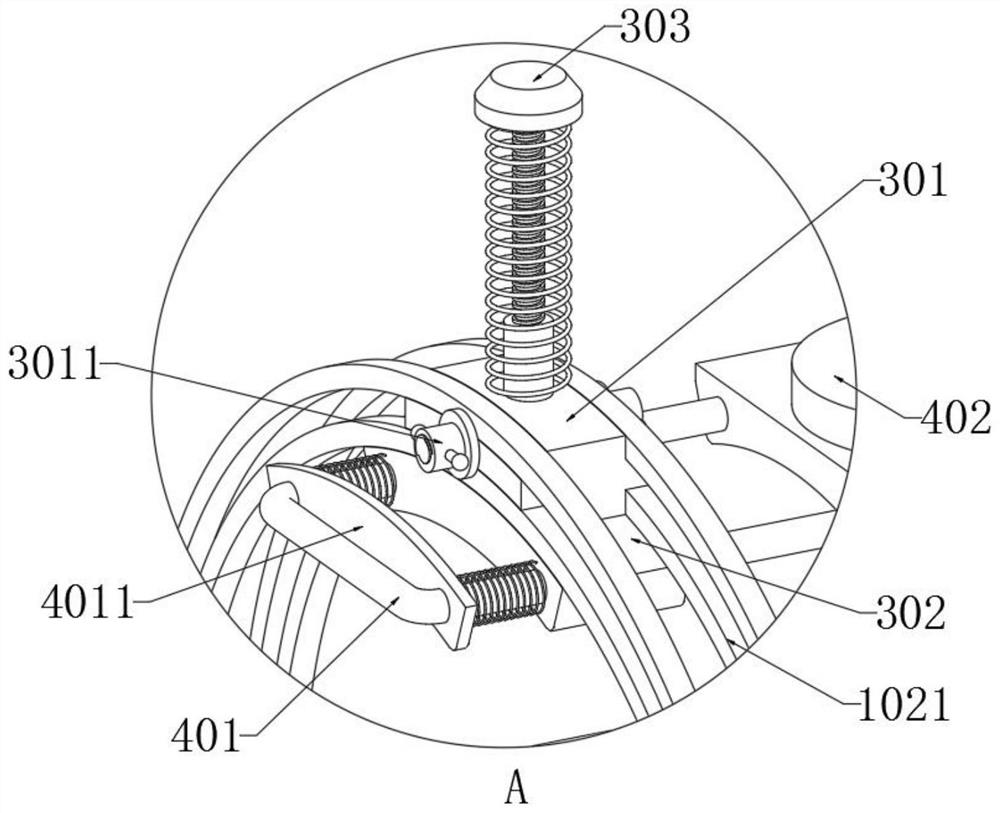

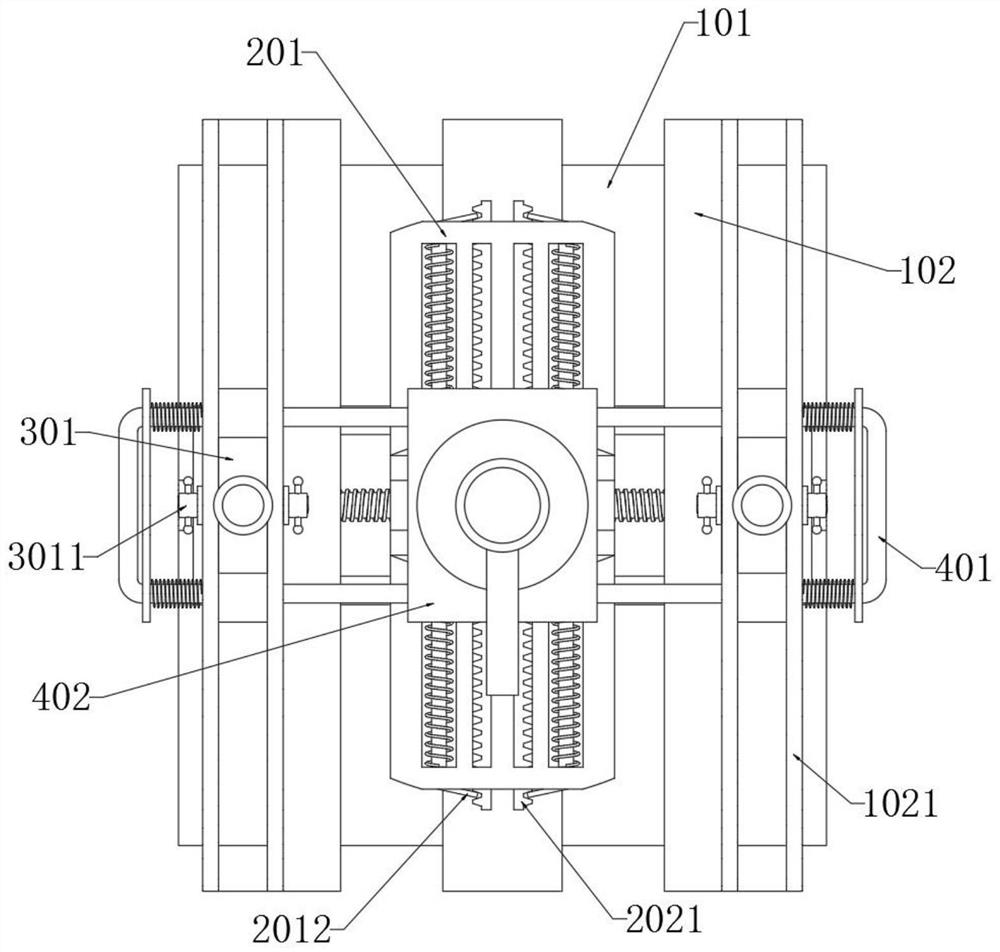

Automatic feeding control method used for numerical control lathe tailstock and capable of controlling drilling depth

ActiveCN106180765ARealize synchronized movementRealize finishingTailstocks/centresAttachable boring/drilling devicesNumerical controlDrive motor

The invention provides an automatic feeding control method used for a numerical control lathe tailstock and capable of controlling the drilling depth. A connecting device for automatic connection and separation of a saddle and the tailstock of a numerical control lathe is adopted. The connecting device comprises a centering assembly, a rotating arm assembly, a driving assembly and a drill bit assembly. The drill bit assembly is mounted in a barrel sleeve of the numerical control lathe tailstock. The centering assembly comprises a centering shaft and a V-shaped block. The rotating arm assembly comprises a rotating arm, a rotating shaft, a shaft sleeve and two limiting press blocks. The driving assembly comprises a pair of belt drive parts, a drive motor, a reset switch and a controller, wherein the controller is mounted in a distribution box of the lathe, the reset switch is mounted in front of the saddle of the numerical control lathe, and the drive motor is fixedly connected with the numerical control lathe tailstock and electrically connected with the controller.

Owner:盐城市力真佳机电有限公司

Novel adjustable drilling device

The invention discloses a novel adjustable drilling device. The novel adjustable drilling device comprises a pedestal, a rotary table, an adjusting slider, a T-shaped rod, a motor and a workbench. Vertical frames are symmetrically fixed to the left side and the right side of the top of the pedestal. A mounting plate is fixed between upper frame bodies of the vertical frames on the two sides. The rotary table is connected to the front side of the mounting plate in a rotating mode. The rotary table is provided with an adjusting hole in the radius direction, and the adjusting hole is connected with the adjusting slider in a matched mode. The T-shaped rod is arranged on the front side of the rotary table. The motor is installed at the tail end of a vertical rod body of the T-shaped rod. The workbench is fixed between the vertical frames on the two sides and is further located at the position below a rotating rod. The novel adjustable drilling device is novel in structure, the drilling depth can be adjusted by changing the position of the adjusting slider on the rotary table, and therefore different technological requirements are met, and the using flexibility of the device is improved;moreover, the adjusting slider can be operated conveniently and rapidly; and meanwhile, scale marks are arranged, and workers can accurately control the drilling depth.

Owner:孙梦思

Electric drill

ActiveCN108393515AImprove the quality of building constructionFast adjustmentDrilling/boring measurement devicesPortable power-driven toolsDrill bitMotor drive

The invention discloses an electric drill. According to the technical scheme, the electric drill is characterized by comprising a shell and a drill chuck, wherein a motor is arranged in the shell andis used for driving the drill chuck to rotate; the drill chuck can be used for clamping a drill bit; a side wall, close to the drill chuck, of the shell is an installation wall; a sliding chute is formed in the installation wall; a control piece is slidably connected into the sliding chute, and can slide toward one side of the drill chuck; a limiting piece is arranged in the sliding chute, and isused for limiting a sliding position of the control piece; after the control piece moves to an ideal position, the limiting piece can limit the sliding position of the control piece; during an actualelectric drill use process, the motor drives the drill chuck to rotate, and the drill bit further rotates so as to drill into a corresponding wall surface; and when the end part of the control piece abuts against the corresponding wall surface, the motor stops working, the electric drill stops working, and only the drill bit needs to be pulled out from the wall surface, so that the depth accuracyof a hole drilled by the drill bit can be accurately controlled, and the building construction quality can be further effectively improved.

Owner:TAIZHOU MINGTAI CONSTR ENG

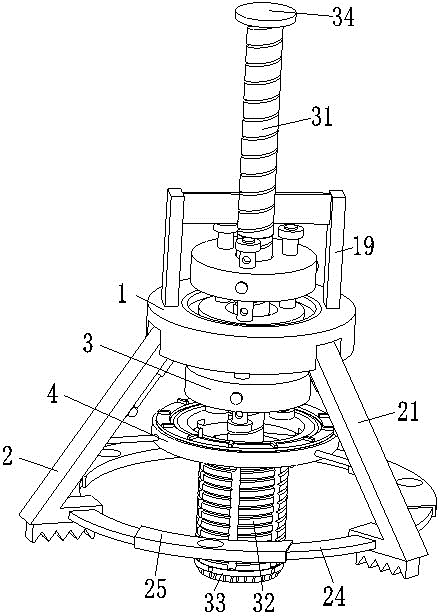

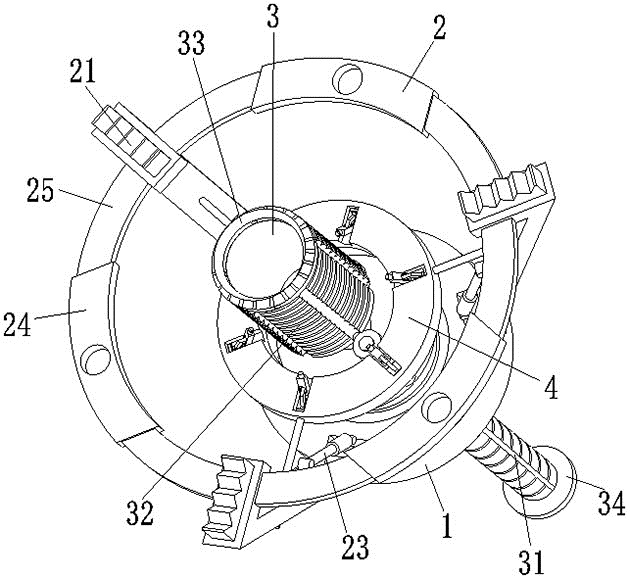

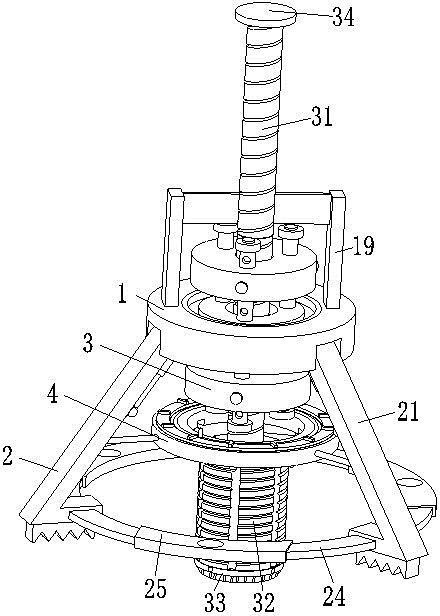

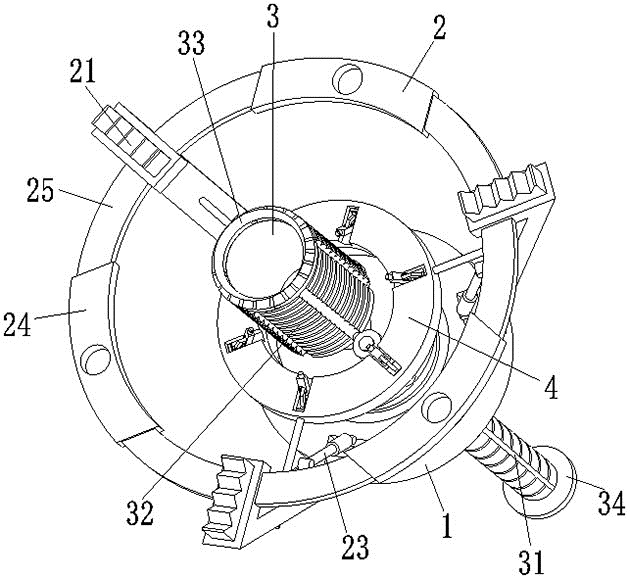

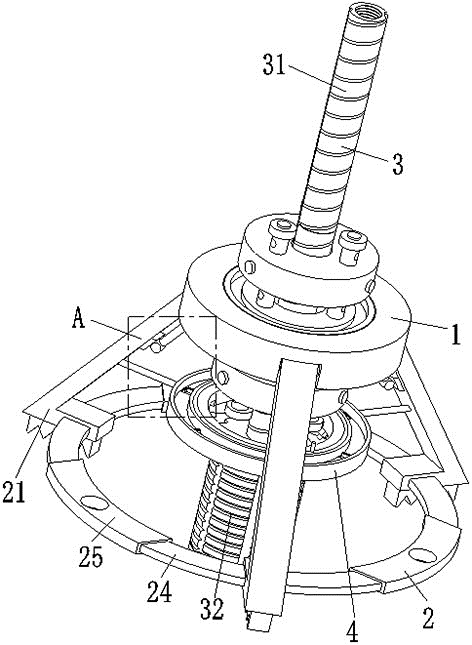

Vertical rock drilling device and drilling method

ActiveCN113250615AImprove stabilityEnsure drilling qualityDrilling rodsConstructionsDrill holeMechanical engineering

The invention relates to the technical field of drilling, and provides a vertical rock drilling device and a drilling method. The vertical rock drilling device comprises a driving device, supporting devices, drilling devices and spraying devices, wherein the supporting devices are uniformly arranged at the lower end of the driving device in a hinged mode, the drilling devices are installed in the driving device in a threaded connection mode, the spraying devices are arranged on the outer walls of the drilling devices in a sleeving mode, and the spraying devices are fixed to the supporting devices through air pressure rods in a hinged mode. According to the vertical rock drilling device and the drilling method, the main technical defects in the rock drilling process can be overcome by adopting a vertical mode, wherein the main technical defects are that a drilling machine is prone to shaking in the drilling process, so that the drilling quality is influenced; in addition, a drilling cylinder and an annular drilling tool can rub with rock to generate high temperature in the drilling process, so that the rigid strength of the annular drilling tool and the drilling cylinder is reduced, and continuous drilling work is influenced; and dust generated in the drilling process can be dispersed around a hole, so that the construction environment is influenced.

Owner:山东辛丁技术有限公司

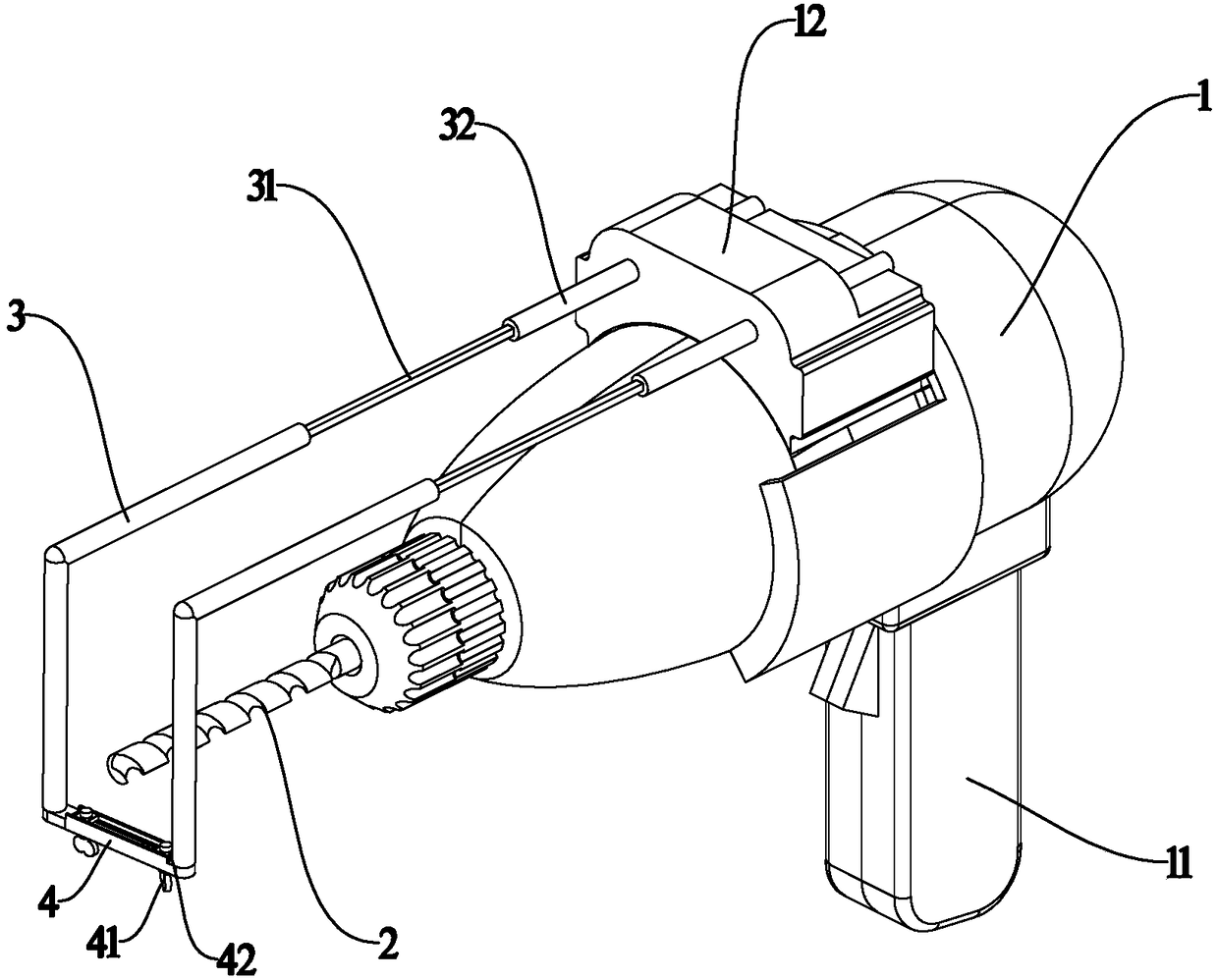

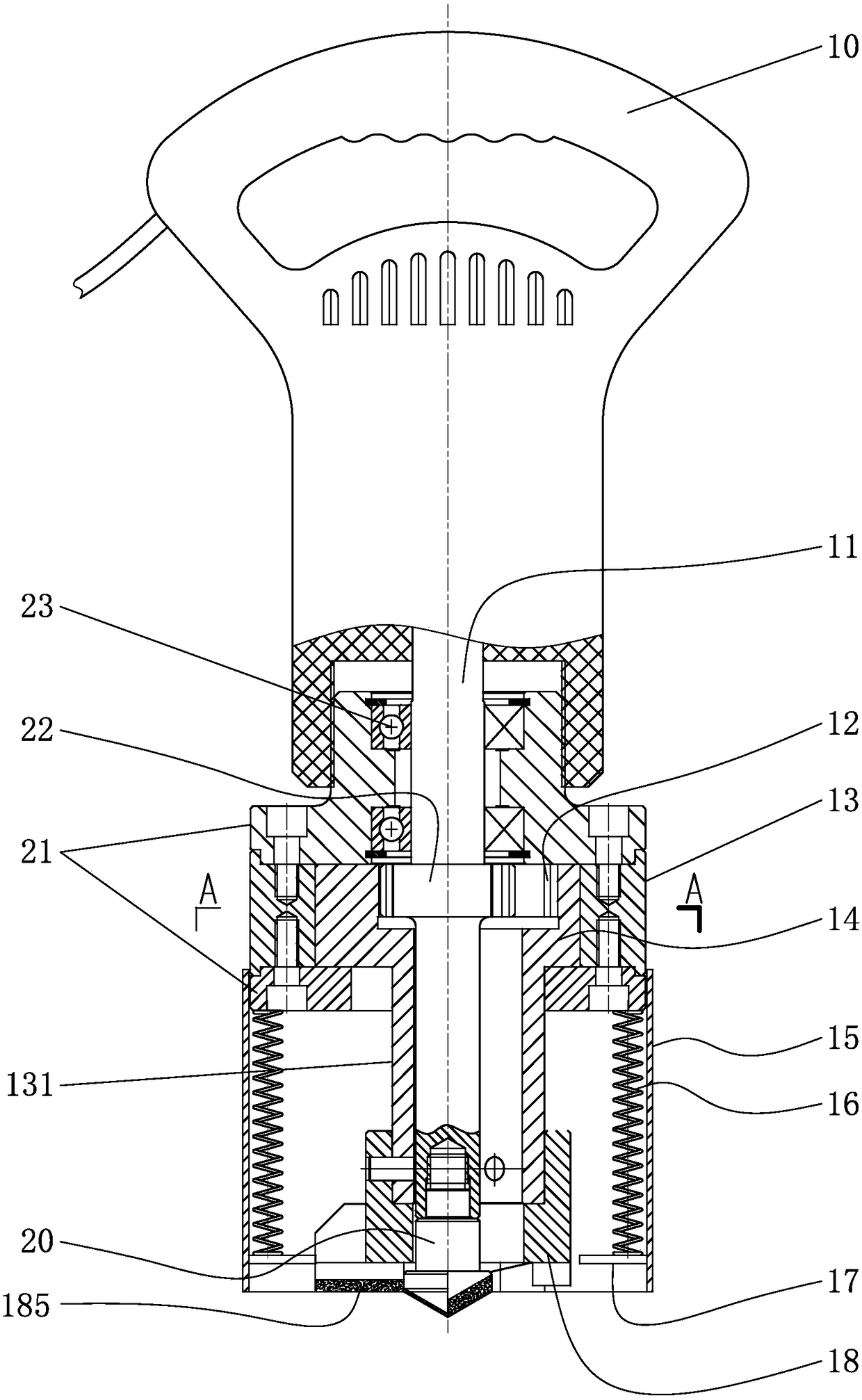

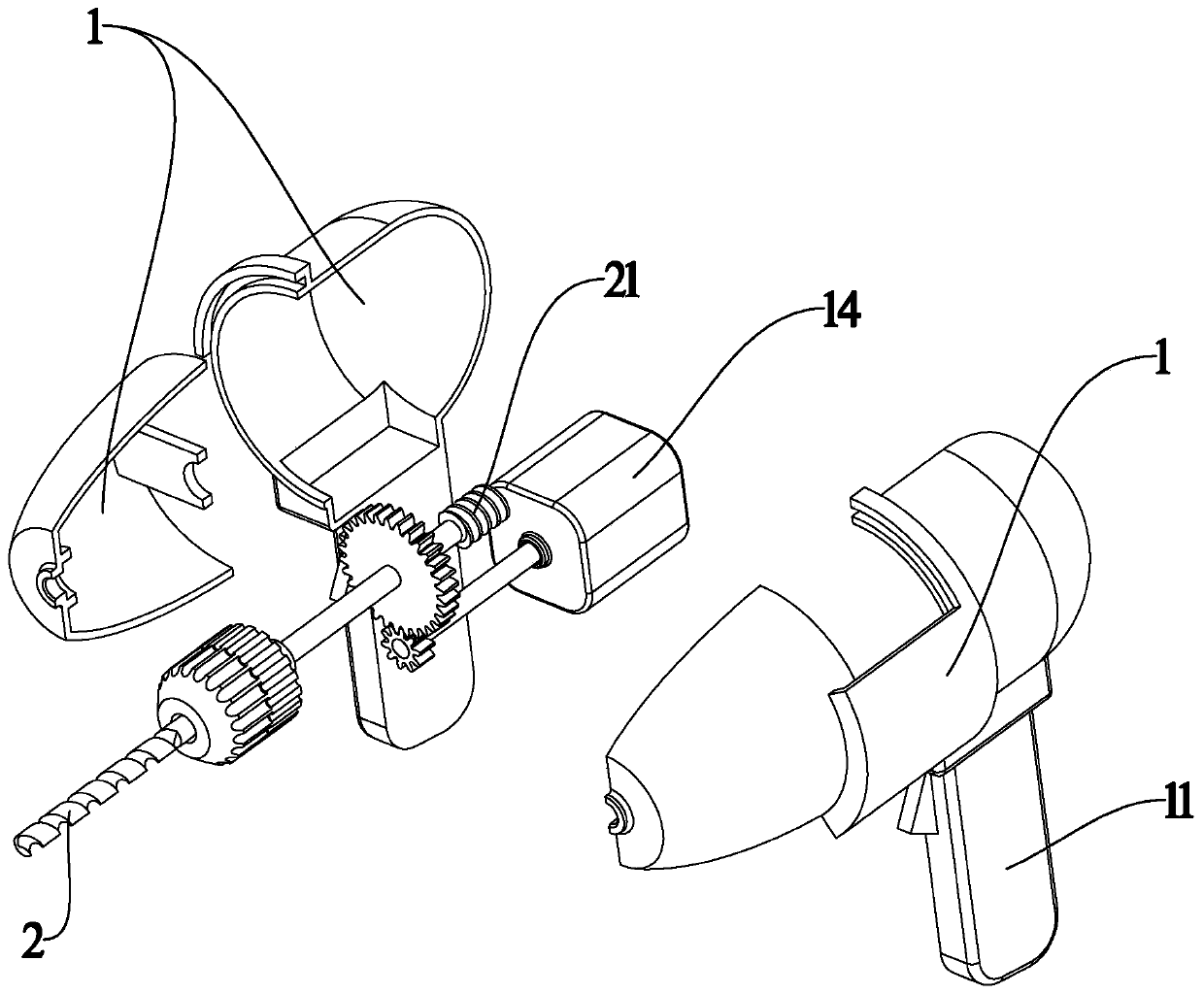

Electric drill drilling inclined holes at multiple angles

ActiveCN108556153AControl drilling depthSuitable for different job scenariosPortable percussive toolsPortable power-driven toolsDrill bitPetroleum engineering

The invention provides an electric drill drilling inclined holes at multiple angles. The electric drill drilling the inclined holes at multiple angles comprises an electric drill body and an angle adjuster module provided with folded rods. The electric drill body comprises a shell and a handle fixed to the shell. A motor and a drill bit driven by the motor are arranged in the shell. The angle adjuster module comprises a rotating block and an angle adjuster, wherein the rotating block rotates around the shell. A gear group and two angle adjusting gears meshed with the gear group are arranged between the rotating block and the angle adjuster. The angle adjusting gears are connected to two parallel lead screws in a sleeving manner correspondingly. The movement directions of the two lead screws are opposite. A straight rod extends from the end, close to the drill bit, of each lead screw. Each straight rod is connected to one end of the corresponding folded rod in a sliding manner. The other ends of the folded rods are mutually connected through a telescopic rod, and the folded rods are always in the parallel state. The electric drill drilling the inclined holes at multiple angles can solve the problem that an electric drill cannot control the hole drilling depth, and the electric drill can accurately drill inclined angles at various angles.

Owner:YONGKANG KAIBANG TOOLS

Medical orthopedics department perforating machine convenient to operate

ActiveCN113598870AQuick fixReduce the risk of injuryInstruments for stereotaxic surgeryOrthopedic departmentApparatus instruments

The invention provides a medical orthopedics department perforating machine convenient to operate, and relates to the technical field of medical apparatuses and instruments. The medical orthopedics department perforating machine aims to solve the problems that an existing orthopedics department perforating machine lacks a limiting structure, and when the existing orthopedics department perforating machine is used, due to the fact that the moving range of the perforating machine cannot be limited, the drilling precision is low, and the risk that a patient is injured is increased. The medical orthopedics department perforating machine comprises a mounting mechanism, wherein a fixing part is arranged on the mounting mechanism, and a fixing plate of the fixing part is arranged in the middle position of the upper end of a bottom plate; and two guide assemblies are arranged on the mounting mechanism, and sliding blocks of the guide assemblies are slidably arranged in guide rails. During use, an electric drill is inserted into a positioning hole in the middle of a contact plate to be fixed, the drilling depth is measured, a measuring range rod is screwed out of an insertion block by the corresponding height, after the height is set, an affected part of the patient can be drilled, through the design, the drilling depth of the affected part of the patient can be effectively controlled, and the risk that the patient is injured is reduced.

Owner:ANHUI YINUOQINGCHUN IND DESIGN CO LTD

Drilling machine drill bit

InactiveCN109454270AAvoid cloggingImprove work efficiencyTransportation and packagingTrepanning drillsMechanical equipmentDrilling machines

The invention discloses a drilling machine drill bit which comprises a tool body, a drilling tool and a limiting device. The tool body comprises a connecting part, an installation part and a tool rodpart in sequence from top to bottom. The drilling tool is connected to the lower end of the tool rod part. A first chip discharging groove and a second chip discharging groove which are spirally arranged and are opposite are formed in the tool rod part, and the first chip discharging groove and the second chip discharging groove extend to the installation part from the end portion of the tool rodpart. The limiting device comprises a limiting sleeve and a fixing screw, the limiting sleeve is rotationally connected to the tool rod part, the limiting sleeve is provided with a threaded hole, andthe limiting sleeve is fixed to the tool rod through the fixing screw. During drilling, the position of the limiting sleeve is adjusted, when drilling is conducted to the position of the limiting sleeve, continuous drilling is stopped, and therefore the purpose of controlling the drilling depth is achieved, and the phenomenon that a hole site is not in place or a hole is through is avoided. The drilling machine drill bit is applied to drilling mechanical equipment.

Owner:长沙新麓机床制造有限公司

Drilling machine for steel pipe machining

The invention discloses a drilling machine for steel pipe machining. The drilling machine comprises an operation table; six first fixing bases are fixedly installed at the upper end of the operation table; a pushing mechanism is jointly connected among the six first fixing bases; the upper part of the pushing mechanism is in threaded connection with a fixing frame; two transmission wheels are fixedly installed on each of the left side and the right side of an adjusting mechanism; a fixing plate is fixedly installed at the back end of the operation table; a lifting mechanism is fixedly installed at the upper end of the fixing plate; a protection box is fixedly installed at the upper end of the lifting mechanism; a drilling mechanism is connected to the back part of the lower end of the protection box in a penetrating mode; and the front part of the drilling mechanism penetrates through the lower box wall of the protection box and is detachably provided with a drill bit. The drilling machine for steel pipe machining is simple and compact in structure, capable of drilling holes in different positions of a main steel pipe body and completing row hole machining, labor-saving and convenient to operate, high in stability, capable of conveniently replacing the drill bit and low in maintenance cost.

Owner:东莞市龙飞数控科技有限公司

A vertical rock drilling device and drilling method

ActiveCN113250615BImprove stabilityEasy to adjust the angleDrilling rodsConstructionsThermodynamicsHole drilling method

The invention relates to the field of drilling technology, and provides a vertical rock drilling device and a drilling method, including a driving device, a supporting device, a drilling device and a spraying device; the lower end of the driving device is uniformly provided with a supporting The device is located inside the driving device and is equipped with a drilling device through a threaded connection. The spray device is sleeved on the outer wall of the drilling device, and the spray device is fixed on the support device in a hinged manner through an air pressure rod; the present invention adopts a vertical It can solve the main technical defects in the process of drilling rocks: the drilling machine is easy to shake during the drilling process, which affects the quality of the drilling, and the drill barrel and annular drill will rub against the rock during the drilling process The high temperature will lead to the reduction of the rigidity of the ring drill and the drill barrel, affecting the continuous drilling work, and the dust generated during the drilling process will be dispersed around the hole, thereby affecting the construction environment.

Owner:山东辛丁技术有限公司

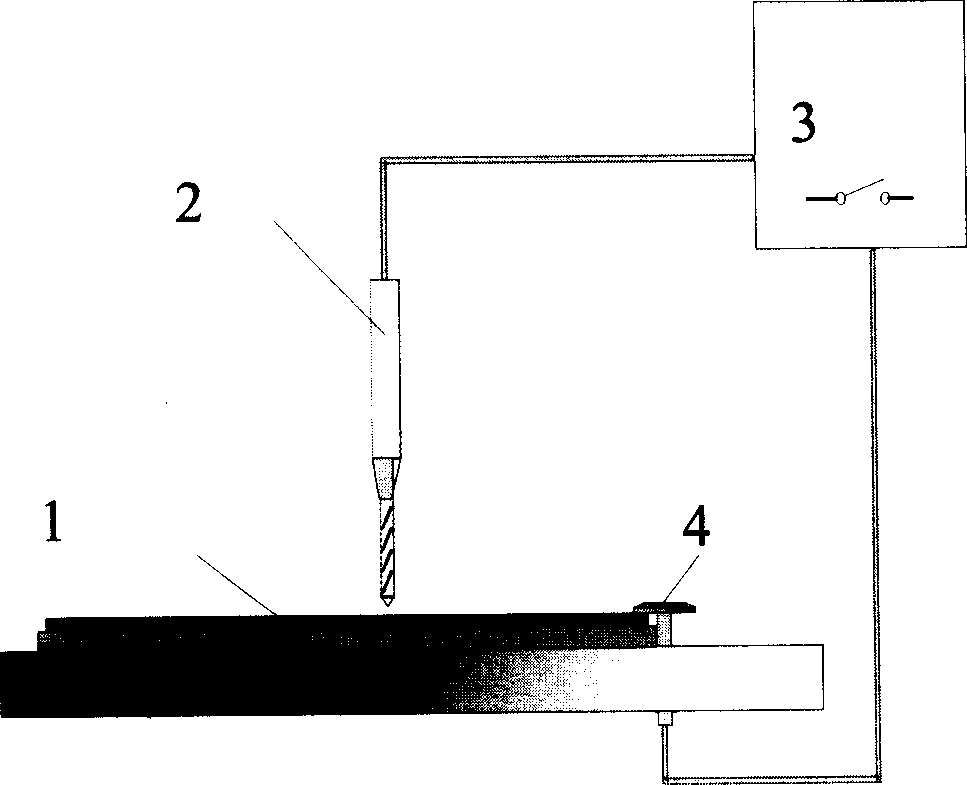

Rotary kiln residual refractory brick breaking device and method capable of accurately controlling breaking depth

The invention discloses a rotary kiln residual refractory brick breaking device and method capable of accurately controlling breaking depth, and belongs to the technical field of breaking equipment. The device comprises a rack system, a breaking system and a control system, and the device is characterized in that a spindle motor drives a drill bit to rotate, meanwhile, a handle is held by a hand to conduct feeding motion, when the drill bit penetrates through residual refractory bricks to make contact with a rotary kiln steel kiln body, a circuit in the control system forms a closed loop, an alarm lamp flickers to give an alarm, voltages generated at the two ends drive a controller to work to switch on the circuit direction of the spindle motor, and the motor rotates reversely, so that thedrill bit slowly retreats under the driving of external force. According to the device and the method, the feeding amount of the drill bit is accurately controlled through a weak current system, andthe drill bit is prevented from damaging the steel kiln body in the breaking process, so that the rotary kiln body is effectively protected against damage by the drill bit in the maintenance process,and the service life of the kiln body is greatly prolonged.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Numerically-controlled lathe tailstock automatic feeding control method capable of controlling finishing of hole bottoms

ActiveCN106112024ARealize synchronized movementRealize finishingTailstocks/centresAttachable boring/drilling devicesGear wheelEngineering

The invention provides a numerically-controlled lathe tailstock automatic feeding control method capable of controlling the finishing of hole bottoms. A connecting device for realizing the automatic connection and disconnection of a saddle and a tailstock of a numerically-controlled lathe by using a cylinder, used in the invention, comprises a centering assembly, a rotating arm assembly, a driving assembly and a drill bit assembly, wherein the centering assembly comprises a centering shaft and a V-shaped block, the rotating arm assembly comprises a rotating arm, a rotating shaft, a shaft bushing and a gear wheel, the shaft bushing is fixed to the front side surface of the tailstock of the numerically-controlled lathe, the rotating shaft penetrates through the shaft bushing, the front end of the rotating shaft is fixedly connected with the rotating arm, the other end of the rotating shaft is fixedly connected with the gear wheel, a hook part capable of being clamped in an annular groove is arranged at the front end of the rotating arm, the driving assembly comprises a rack, a cylinder, an electromagnetic directional valve, a rack guide groove, a reset switch and a controller, the controller is mounted in a lathe power distribution cabinet and electrically connected with a numerical control system and the electromagnetic directional valve, and the reset switch is mounted on the front side of the saddle of the numerically-controlled lathe and is electrically connected with the controller.

Owner:南京华艺酒店设备制造工程有限公司

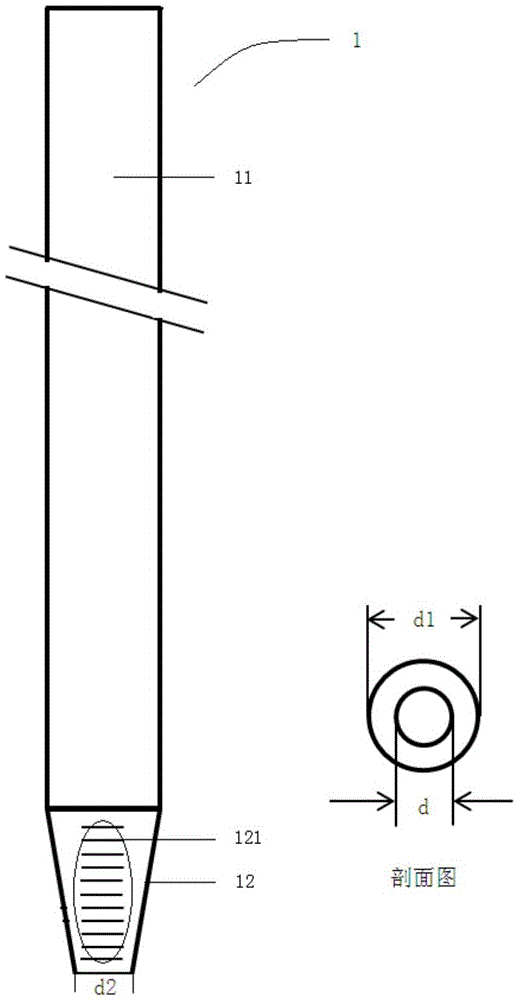

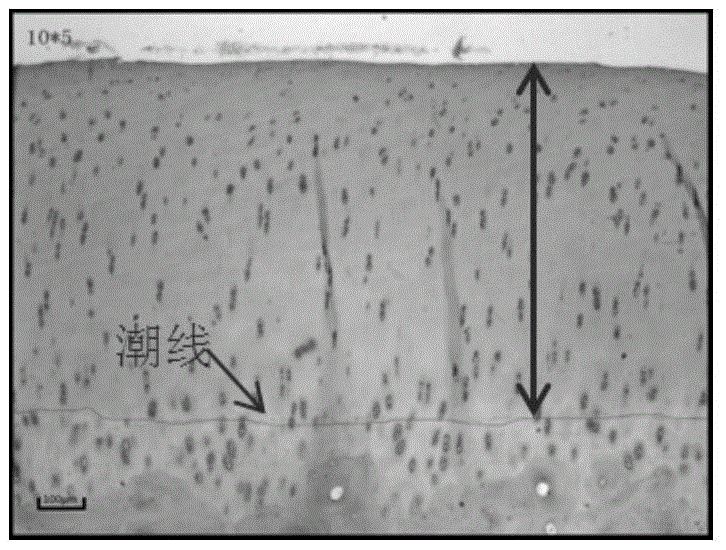

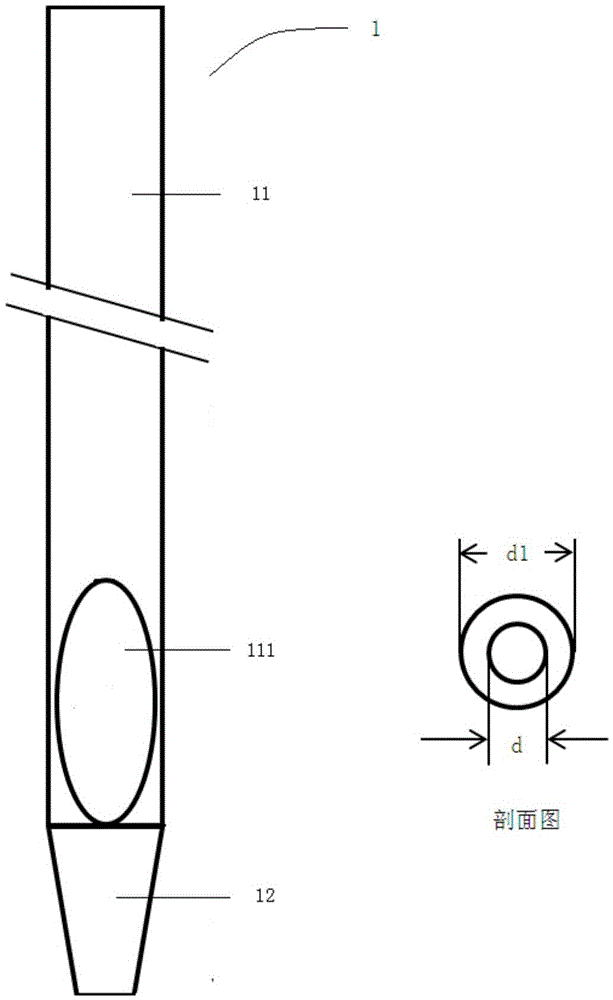

Appliance for molding of pig knee-joint cartilage coloboma and application thereof

InactiveCN105640664ANormative experimental researchPrecise structureDiagnostic recording/measuringSensorsPhysical medicine and rehabilitationKnee Joint

The invention is applicable to the field of biomedicines and provides an appliance for molding of pig knee-joint cartilage coloboma and application thereof. The appliance for molding of the pig knee-joint cartilage coloboma comprises a main body arranged in a tubular mode, wherein the main body comprises a handheld section for holding and a measurement section for measurement, and the handheld section and the measurement section are connected mutually. The measurement section is in a shape of a circular truncated cone, the outer diameter of the measurement section is gradually decreased in the direction deviating from the handheld section, a graduated scale for measuring the depth is arranged on the outer wall of the measurement section, and scales of the graduated scale are parallelly arranged in the axis direction perpendicular to the measurement section.

Owner:THE SECOND PEOPLES HOSPITAL OF SHENZHEN

Efficient depth-keeping drilling device for resin gypsum for fixing limbs

InactiveCN103417341BControl drilling depthReduce usageBandagesStructural engineeringReoperative surgery

The invention discloses an efficient depth-keeping drilling device for resin gypsum for fixing limbs. The device comprises a connection rod (1), a rotary-cut saw (2) and an adjusting protective sleeve (3); the lower end of the connection rod (1) is provided with the rotary-cut saw; the upper part of the adjusting protective sleeve is in adjusting match with the lower part of the connection rod (1) in a locking mode; and the lower part of the adjusting protective sleeve (3) is in wrapping match with the rotary-cut saw (2). A structure of matching the rotary-cut saw, an adjusting mechanism and a connection device is adopted, so the drilling depth of the rotary-cut saw can be precisely controlled, and the connection device can be connected with a driving mechanism for supplying power for the rotary-cut saw. The resin gypsum efficient depth-keeping drilling device is simple in structure, simple and convenient to operate, stable and reliable in work, and capable of overcoming the labor-consuming, time-consuming and unsafe defects of the cutting drilling by common cutters in the prior art, the work efficiency of improving the removal rate of resin gypsum molds can be greatly improved by effectively reducing the use of a steel wire saw, the pain of a patient is reduced, the surgical effect is improved, and the rehabilitation of the wrist joint function of the patient is more facilitated. The drilling efficiency in the gypsum molds can be greatly improved by more than 5 times by using the efficient depth-keeping drilling device for the resin gypsum for fixing limbs.

Owner:中国人民解放军联勤保障部队第九二〇医院

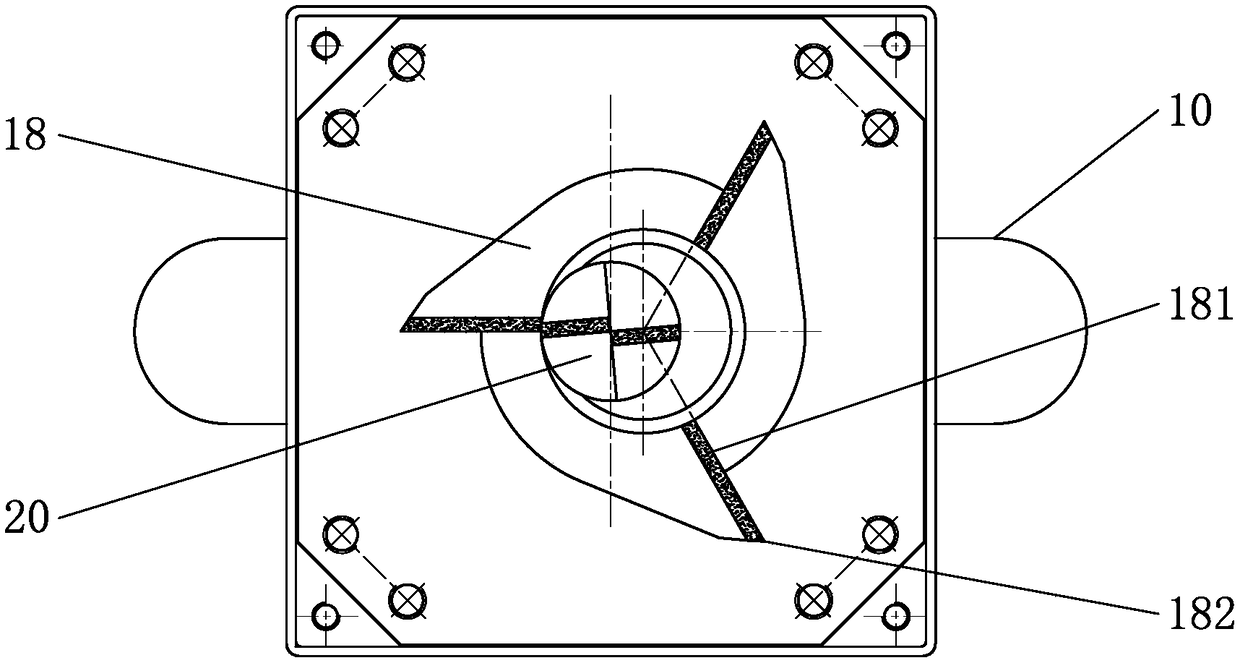

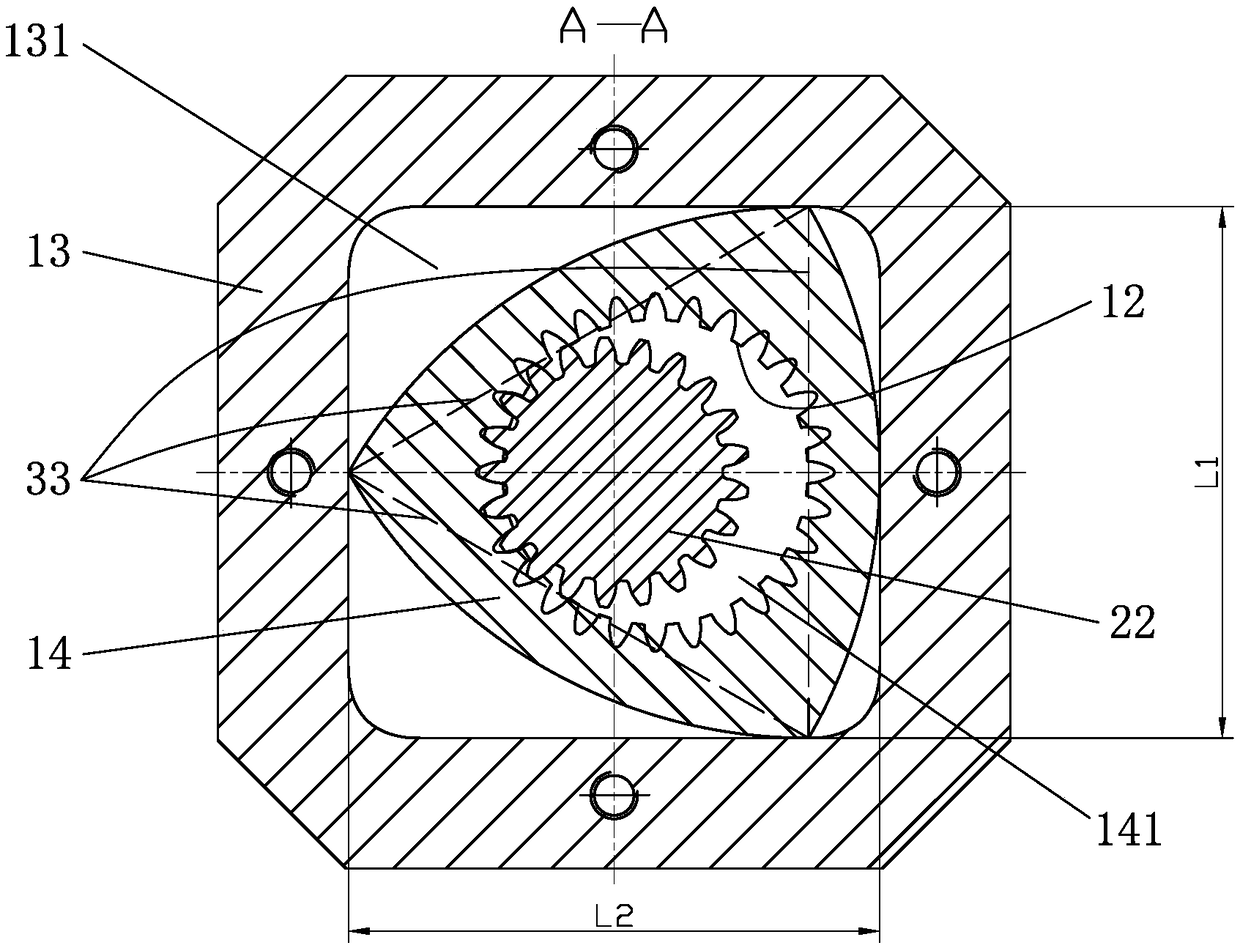

A square hole drilling rig

ActiveCN106424833BReduce cutting resistanceReduce mistakesTransportation and packagingPortable drilling machinesGear wheelMilling cutter

The invention belongs to the technical field of hole opening equipment and relates to a square hole drilling machine. The machine comprises a casing and a bit; a driving rod mounted in the middle of the casing is connected; a centering bit is fixed at the lower end of the driving rod; a pinion is arranged in the middle of the driving rod; the outer side of the pinion is sleeved with a Reuleaux triangle block; the Reuleaux triangle block is placed in a central square hole of a square guiding frame; the square guiding frame is fixed on the casing; the pinion is in meshed transmission with an inner gear; a hollow square hole milling cutter is arranged at the lower end of the Reuleaux triangle block; and the lower end of the centering bit is located below the lower end surface of the square hole milling cutter. The machine has the advantages as follows: the centering bit is adopted for direct hole drilling centering, labor-saving operation is realized, the centering accuracy is high, the rejection rate is low, by the aid of the guiding structure of the Reuleaux triangle and the square hole milling cutter, drilled square holes have the small error and the high quality and is standard, noise is low, and the machine is applicable to drilling of the square holes.

Owner:马文强

Preparation method of finished cigarette empty cylinder and preparation device thereof

ActiveCN104142260BAvoid damageSo as not to damagePreparing sample for investigationMining engineeringStructural engineering

The invention relates to a method for preparing an empty tube of finished cigarettes and a preparation device thereof, belonging to the technical field of cigarettes. The device for producing the empty cylinder of finished cigarettes includes a bracket, a clamping unit arranged on the bracket for clamping the finished cigarettes in a vertical state, and a drill set on the bracket and located directly below the clamping unit. The drilling tool unit for removing shredded tobacco in the finished cigarette, the center of the drilling tool of the drilling tool unit is directly facing the center of the clamping opening of the clamping unit cigarette, and the drilling tool of the clamping unit or the drilling tool unit can be moved along the vertical direction Moving toward the drilling tool or the clamping unit, the bracket is fixed with a limit block for limiting the drilling depth of the drill bit clamped on the drilling tool into the finished cigarette. When in use, use the clamping unit to clamp the finished cigarette first, and set the burning end of the cigarette downward. When the clamping unit or the drilling unit moves, control the rotation of the drill bit on the drilling tool so that the drill bit gradually draws the cigarette in the cigarette. Tobacco is drilled out, and the limit block can limit the drilling depth of the drill bit.

Owner:CHINA TOBACCO HENAN IND

An electric drill for drilling oblique holes at multiple angles

ActiveCN108556153BControl drilling depthSuitable for different job scenariosPortable percussive toolsPortable power-driven toolsDrill bitPetroleum engineering

The invention provides an electric drill drilling inclined holes at multiple angles. The electric drill drilling the inclined holes at multiple angles comprises an electric drill body and an angle adjuster module provided with folded rods. The electric drill body comprises a shell and a handle fixed to the shell. A motor and a drill bit driven by the motor are arranged in the shell. The angle adjuster module comprises a rotating block and an angle adjuster, wherein the rotating block rotates around the shell. A gear group and two angle adjusting gears meshed with the gear group are arranged between the rotating block and the angle adjuster. The angle adjusting gears are connected to two parallel lead screws in a sleeving manner correspondingly. The movement directions of the two lead screws are opposite. A straight rod extends from the end, close to the drill bit, of each lead screw. Each straight rod is connected to one end of the corresponding folded rod in a sliding manner. The other ends of the folded rods are mutually connected through a telescopic rod, and the folded rods are always in the parallel state. The electric drill drilling the inclined holes at multiple angles can solve the problem that an electric drill cannot control the hole drilling depth, and the electric drill can accurately drill inclined angles at various angles.

Owner:YONGKANG KAIBANG TOOLS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com