Vertical rock drilling device and drilling method

A drilling device and vertical technology, applied in drilling equipment and methods, supporting devices, impact drilling, etc., can solve problems such as affecting the construction environment, shaking of the drilling machine, and dust scattered around the hole, to ensure that the Drilling quality, preventing drilling deflection, and ensuring the effect of the use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be described below with reference to the drawings. In this process, in order to ensure the clearness and convenience of the description, we may exaggerate the size of the width or constituent elements of the middle line.

[0030]Further, the term hereinafter is defined based on the functions in the present invention, and can be different depending on the user, the user's intention or convention; therefore, these terms are defined based on the entire contents of the present specification.

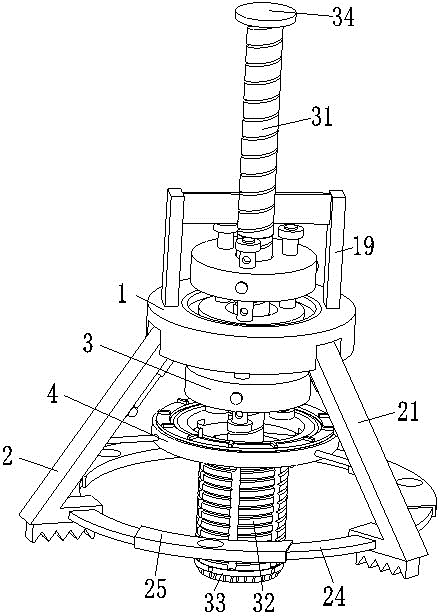

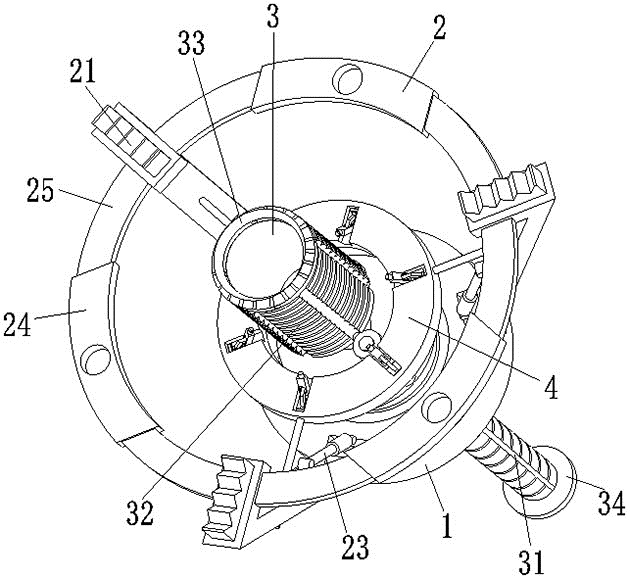

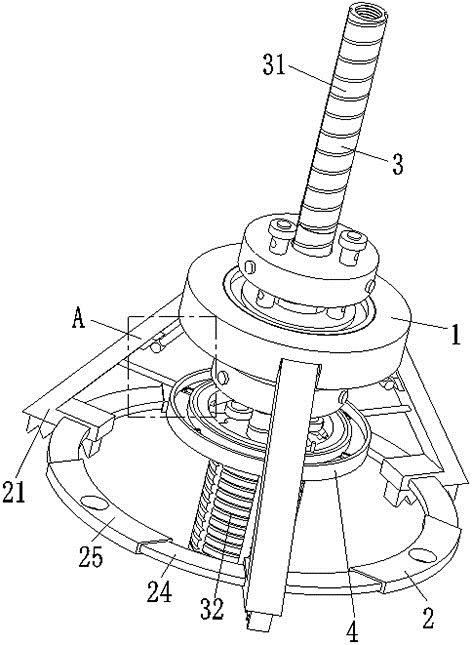

[0031] like Figure 1 to 6 As shown, a vertical rock drilling device comprising a drive device 1, a support device 2, a drilling device 3, and a spray device 4; the lower end of the driving device 1 is uniformly provided with a support device 2 in a hinge manner. The inside is attached to the outer wall of the drilling device 3 by a threaded connection, and the spray device 4 is fixed to the support device 2 by the air pressure rod.

[0032] The dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com