Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Avoid mutual obstruction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

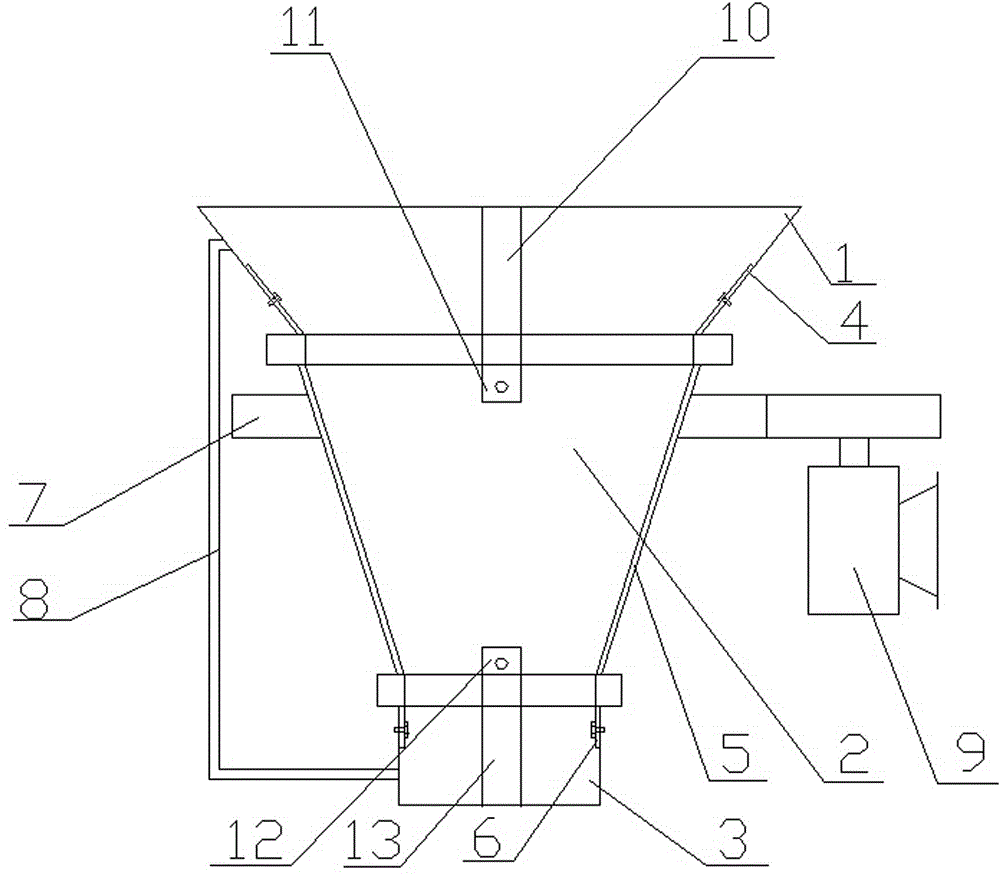

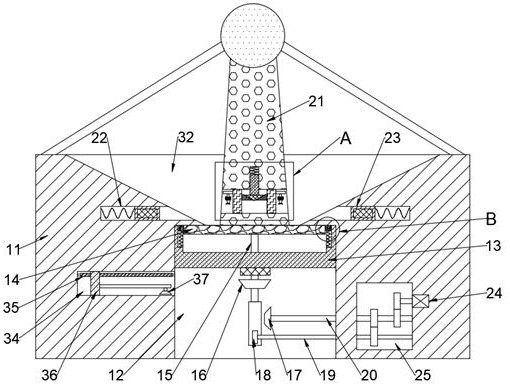

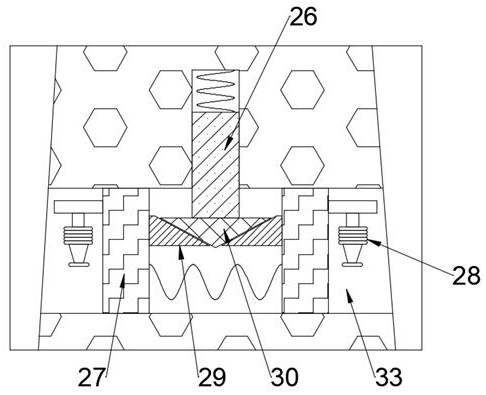

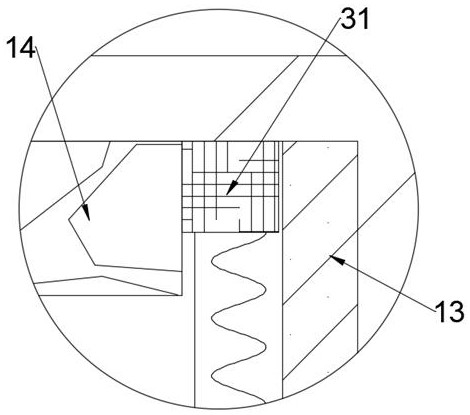

Upward moving type movable formwork for continuous box girder construction

InactiveCN105155423ALow costSpeed up the construction progressBridge erection/assemblyStructural stabilityEngineering

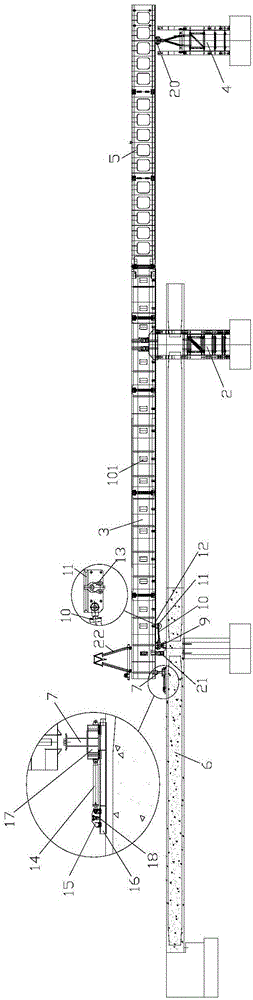

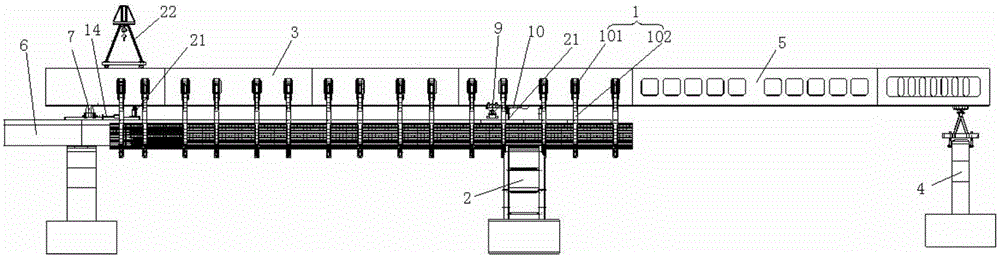

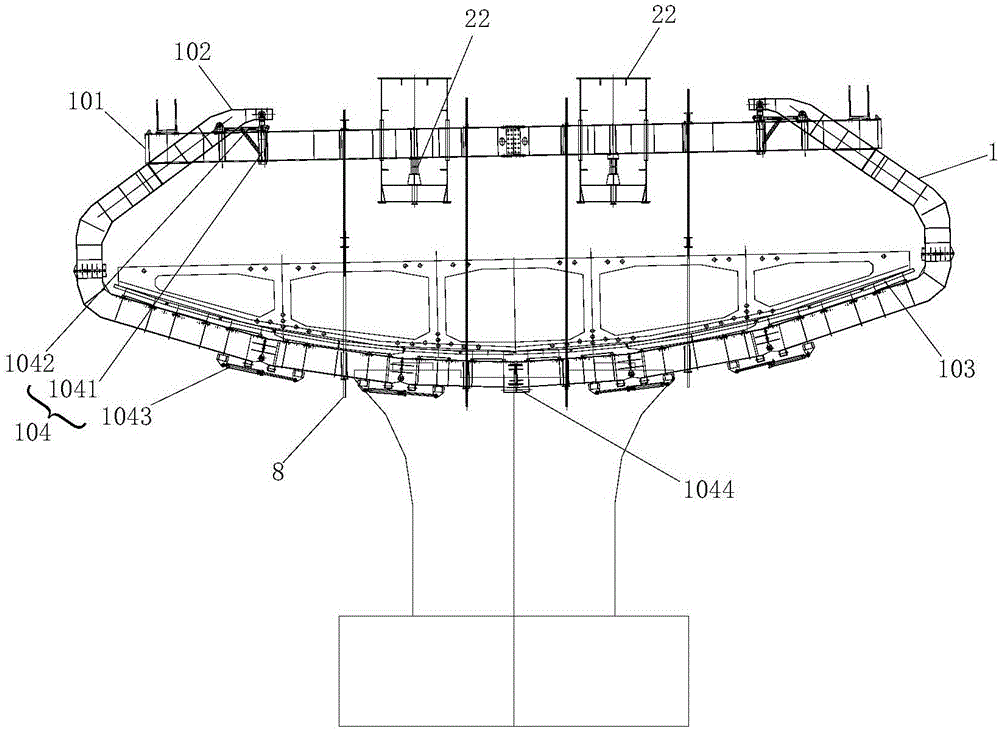

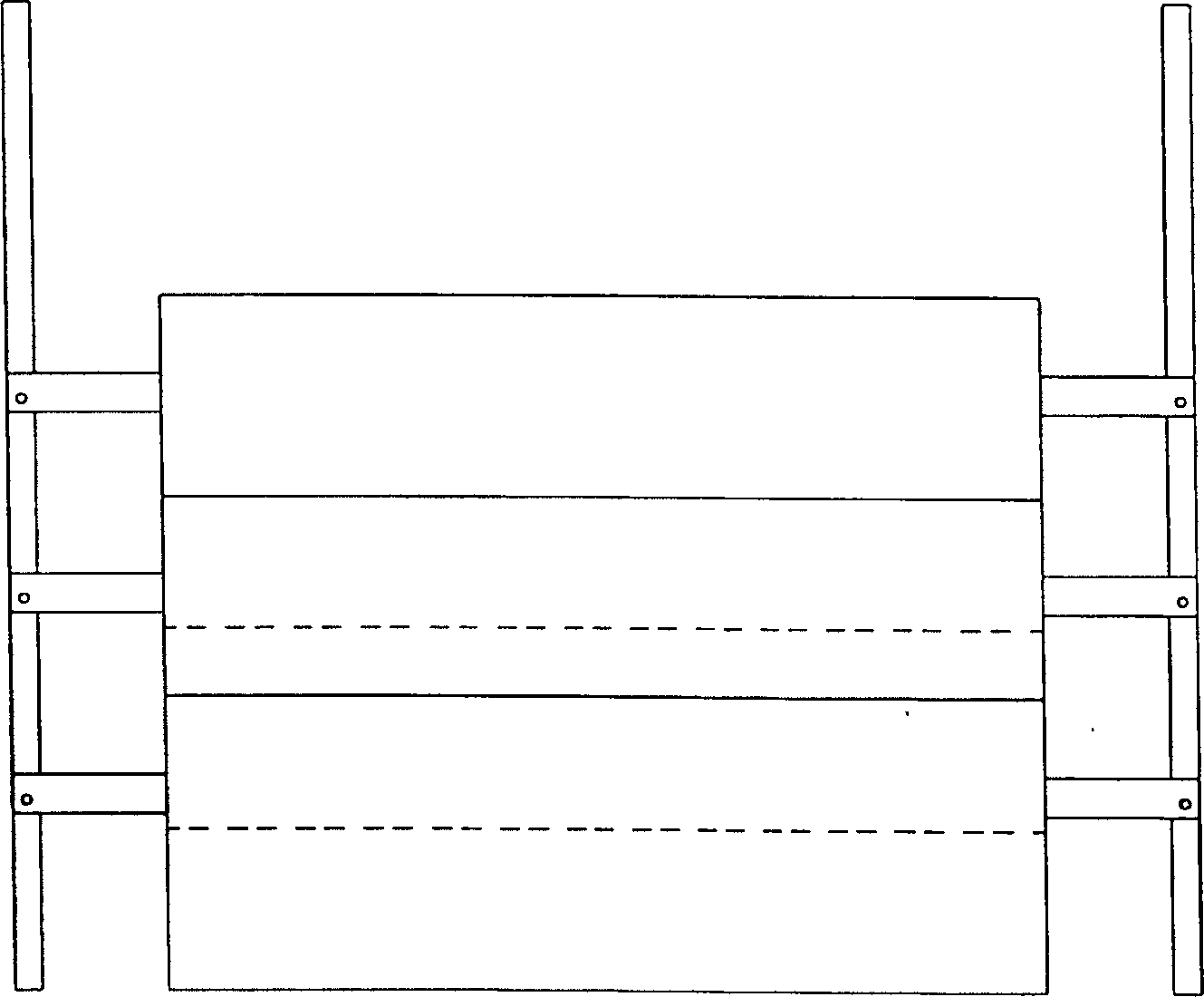

The invention discloses an upward moving type movable formwork for continuous box girder construction. The upward moving type movable formwork comprises a box girder body construction mold, a main beam, a nose beam and a rear sliding beam. The bottom of the box girder body construction mold is unfolded for box girder form removal or the bottom of the box girder body construction mold is closed so that a box girder can be poured. The main beam is supported on a middle supporting leg of the box girder and used for bearing the box girder body construction mold and driving the box girder body construction mold to move in the longitudinal direction of the box girder. The nose beam is supported on a front supporting leg of the box girder and used for guiding the main beam moving in the longitudinal direction of the box girder. The rear sliding beam is supported on the poured molded box girder and used for assisting the main beam in moving in the longitudinal direction of the box girder and being adjusted to be bent in the transverse direction of the box girder. The box girder body construction mold is suspended on the main beam, the nose beam is arranged at the advancing end of the main beam, and the rear sliding beam is arranged at the rear end of the main beam. Whole box girder pouring construction and mold movement are finished on the supporting legs and the poured molded box girder, the box girder body construction mold is opened from the bottom to form a folding span-crossing structure, and therefore the structural stability and safety of the whole formwork are guaranteed.

Owner:CCFEB CIVIL ENG

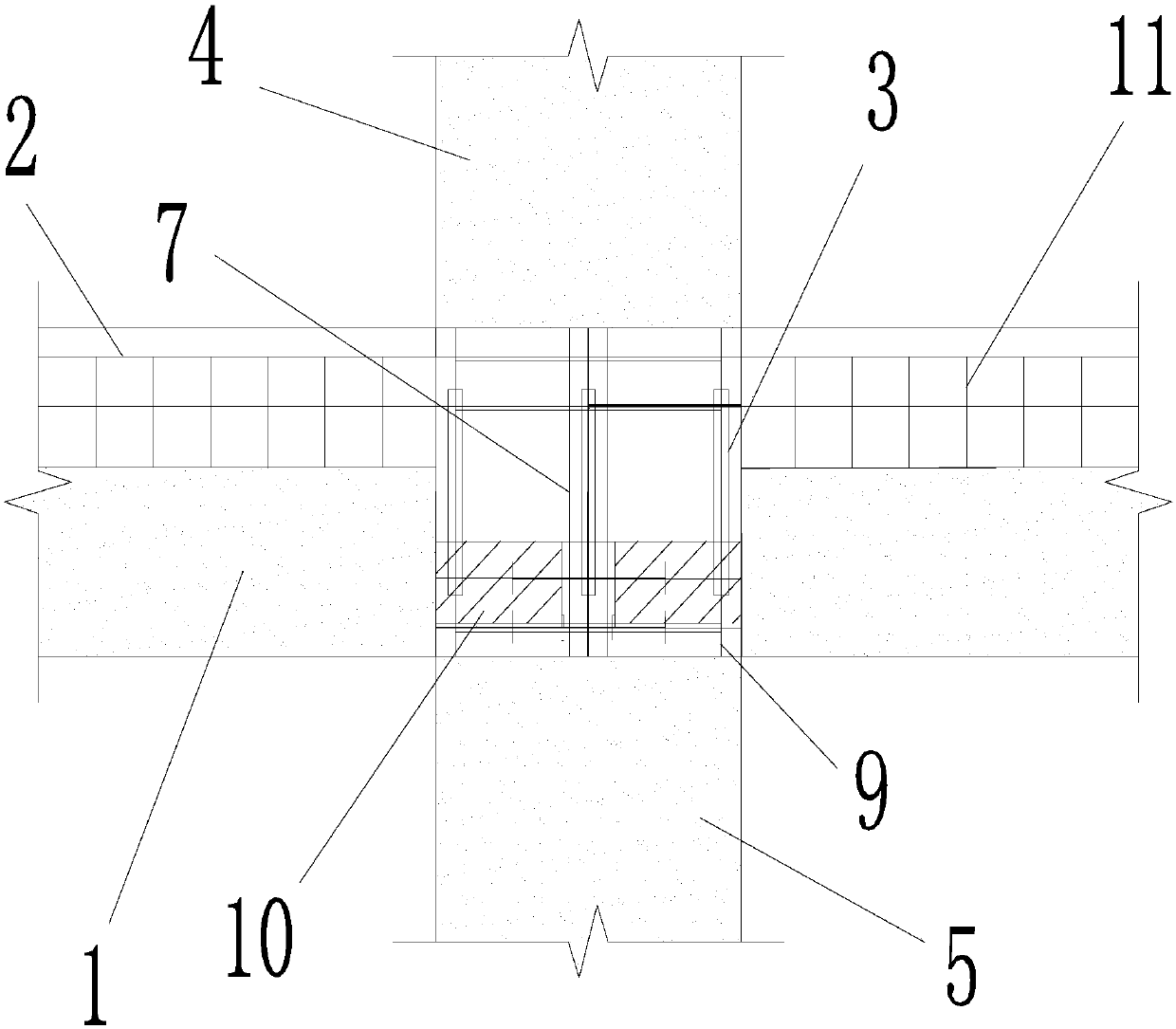

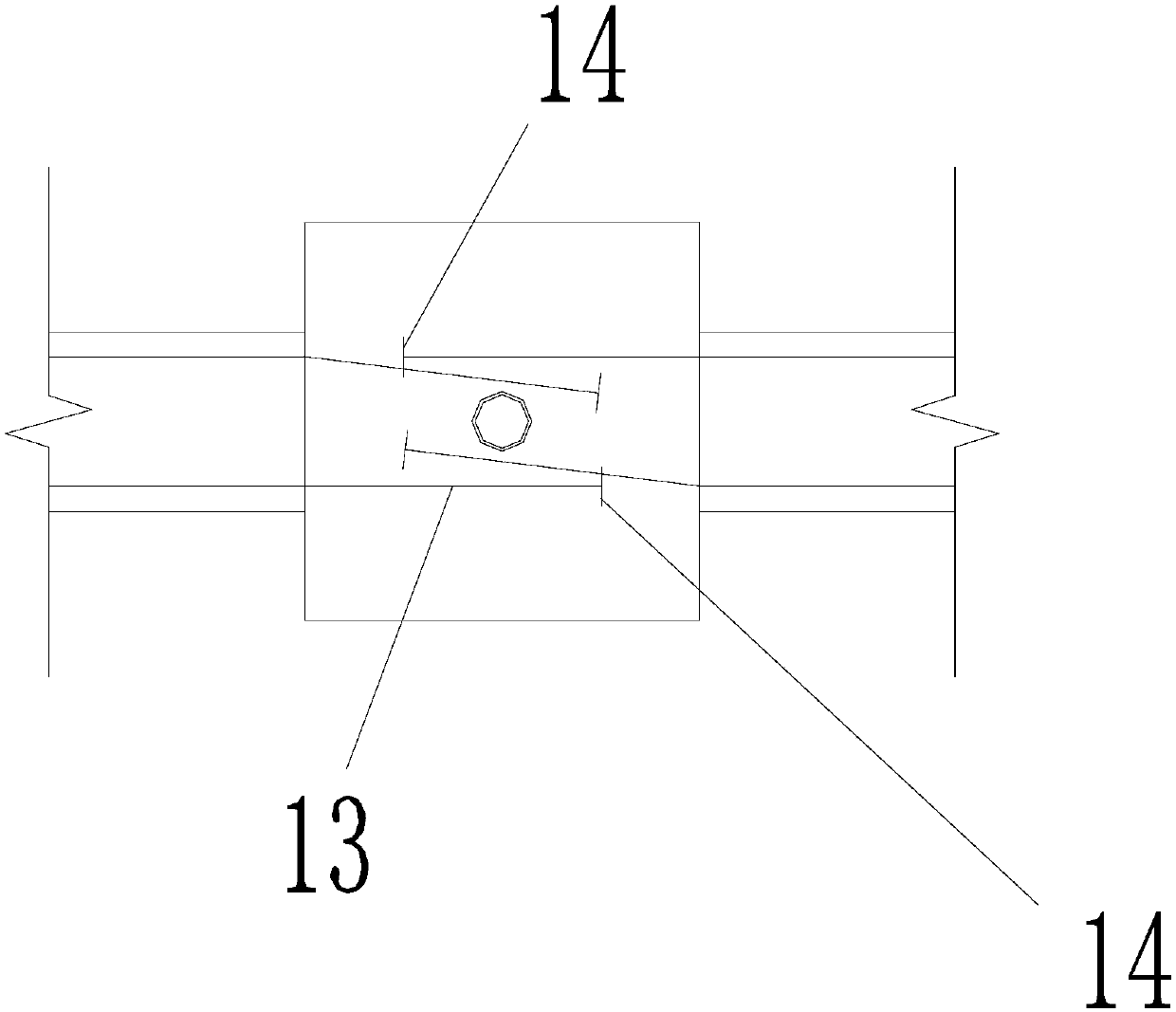

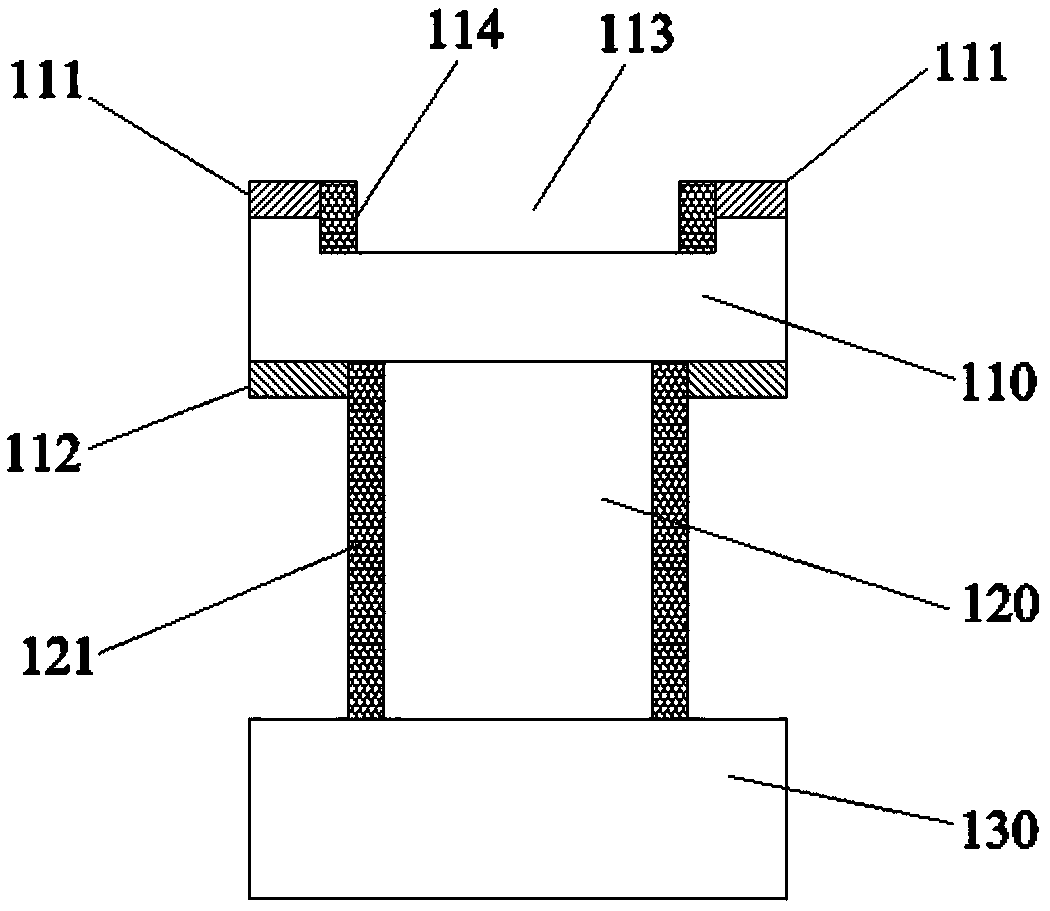

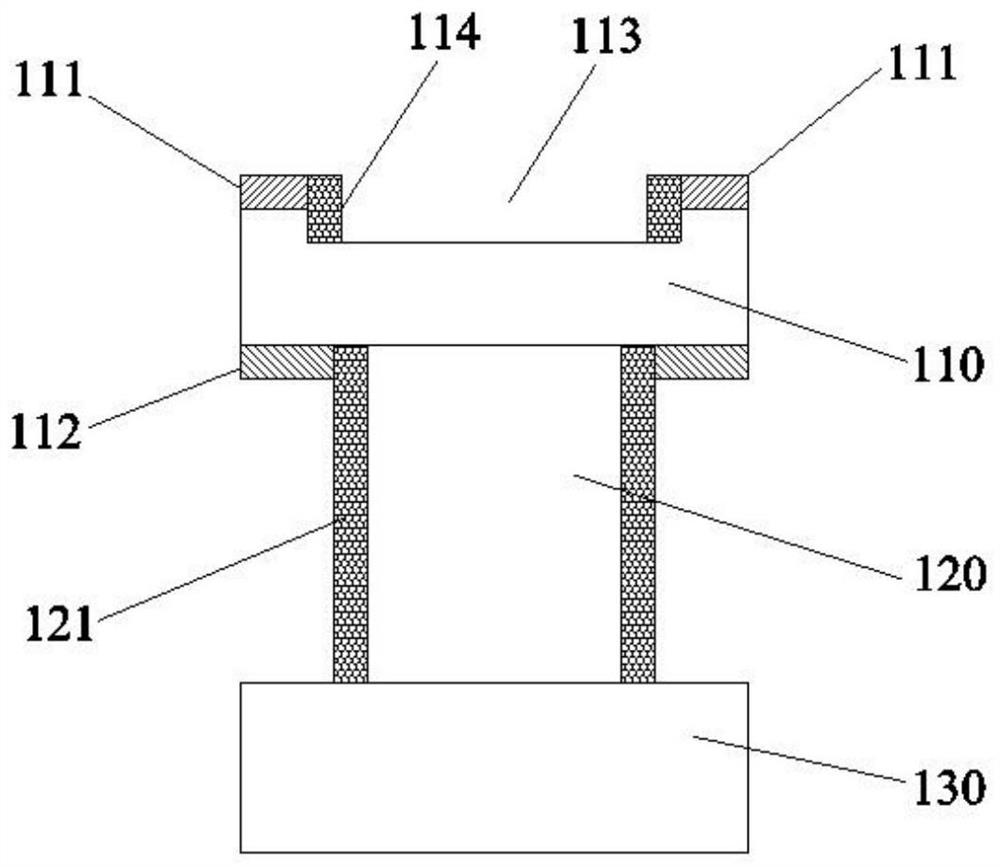

Prefabricated beam-column joint and construction method thereof

PendingCN107795010AHigh speedSimplify the construction processBuilding constructionsArchitectural engineeringRebar

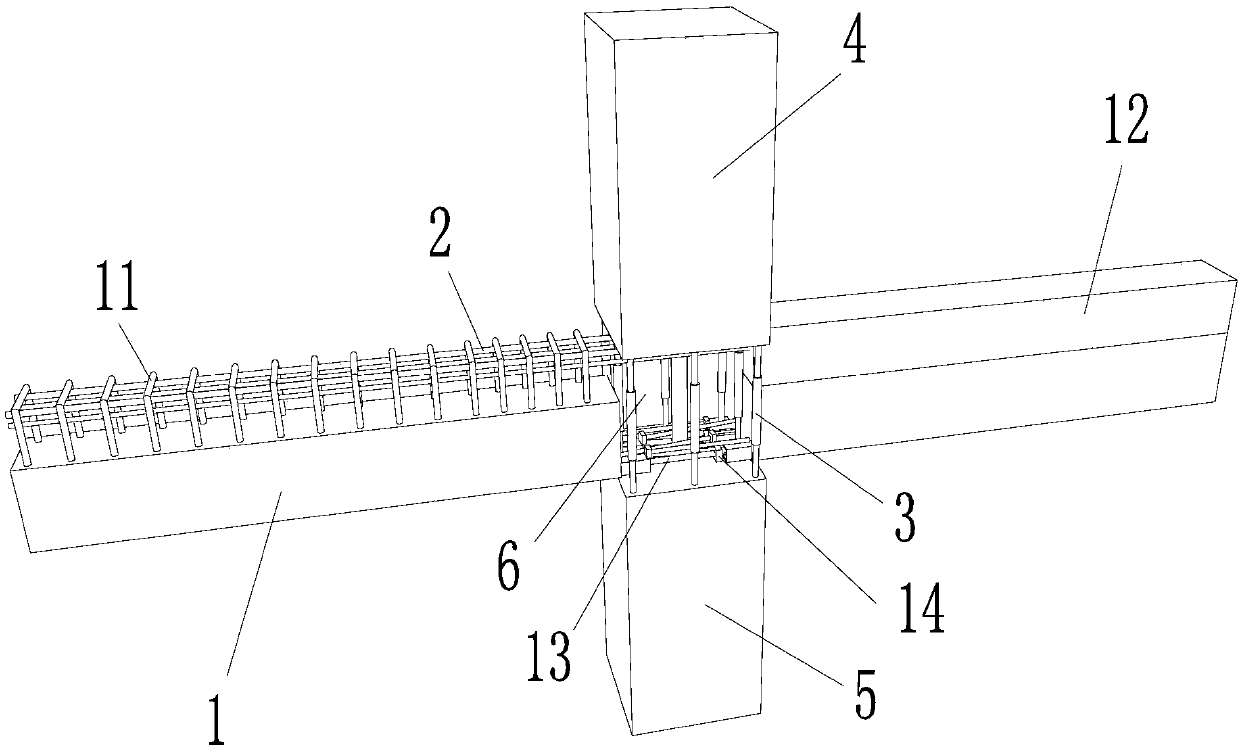

The invention discloses a prefabricated beam-column joint and a construction method thereof. The prefabricated beam-column joint comprises a prefabricated beam, a prefabricated column, a beam connecting rib and a joint rebar sleeve; the prefabricated column comprises a prefabricated upper column and a prefabricated lower column; the prefabricated beam is divided into two sections, and one ends ofthe two sections of prefabricated beam bodies are correspondingly arranged between the prefabricated upper column and the prefabricated lower column; and a joint area is formed between the prefabricated upper column, the prefabricated lower column and the two sections of prefabricated beam bodies, and the joint area is filled with concrete to form a joint section. According to the prefabricated beam-column joint and the construction method thereof, pre-embedded U-steel is arranged in the prefabricated beam so that the prefabricated beam can be directly erected on the prefabricated lower columnduring construction, and the construction speed of the structure is increased; and brackets or other structures are not required to be manufactured at the edge of the column to conveniently erect theprefabricated beam on the prefabricated lower column, so that the construction process is simplified.

Owner:广东精宏建设有限公司 +1

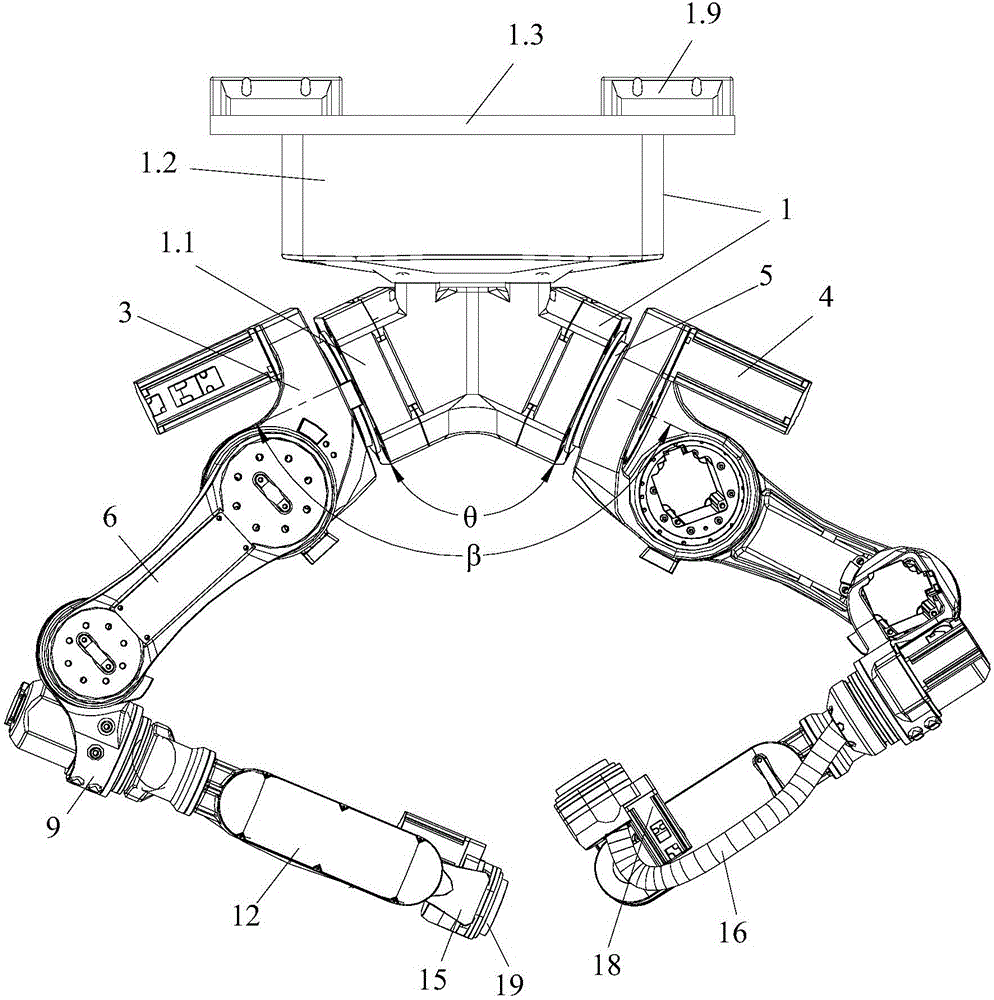

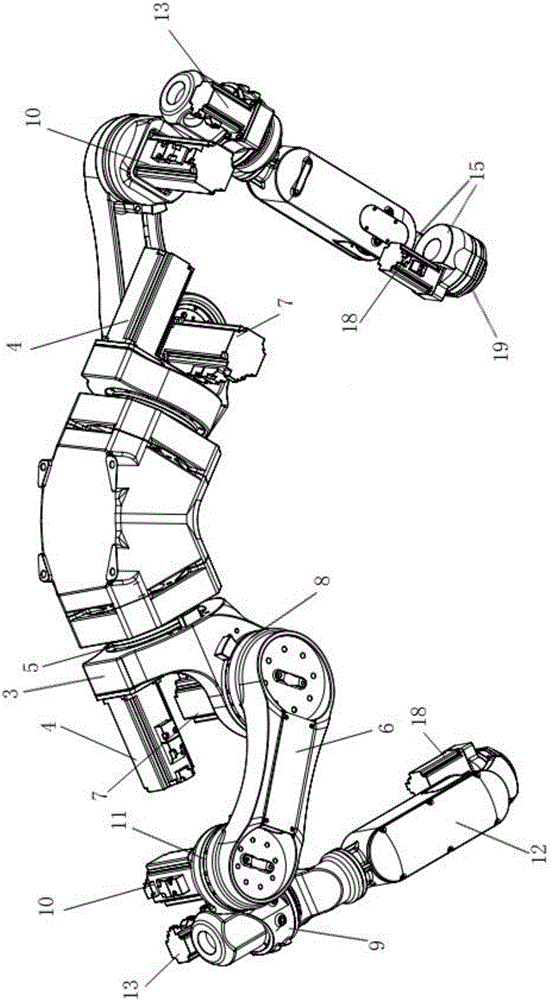

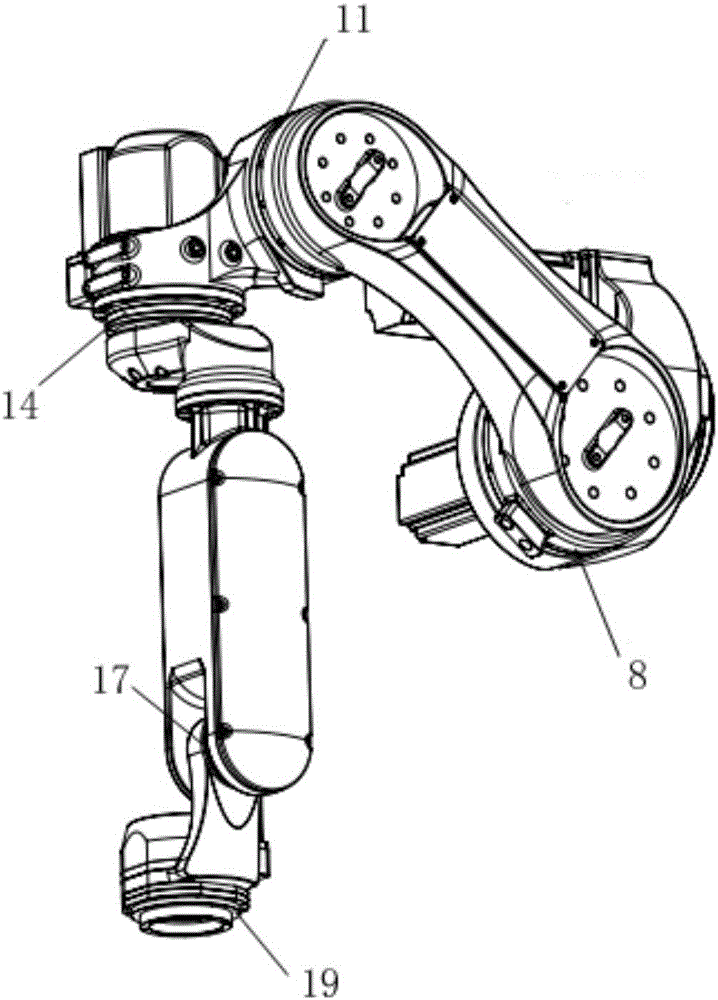

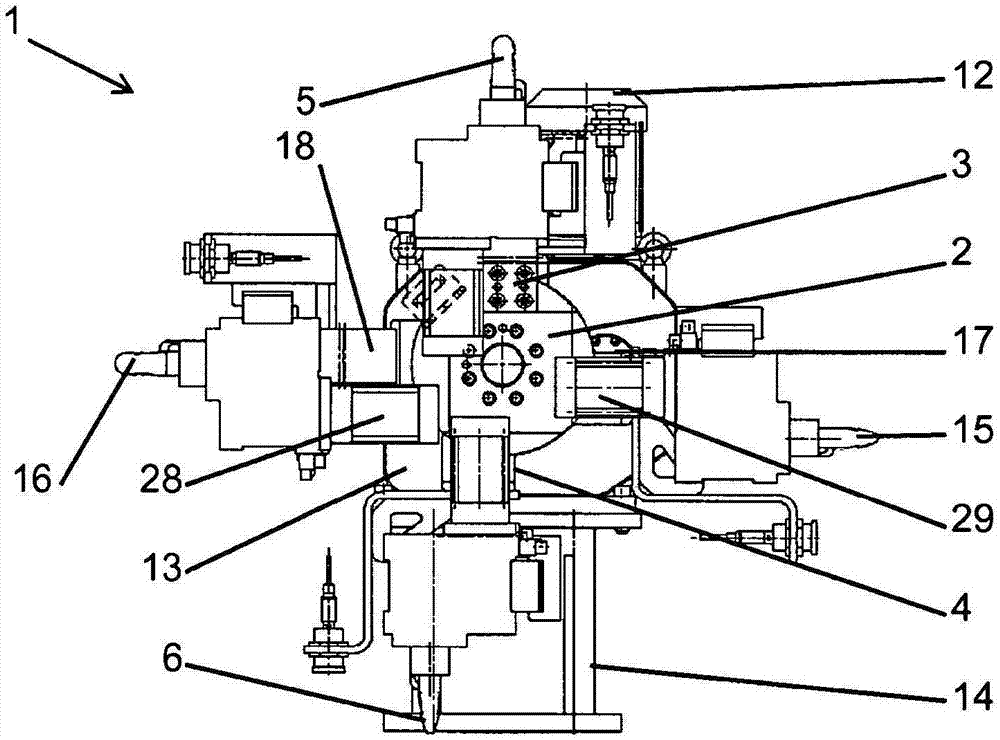

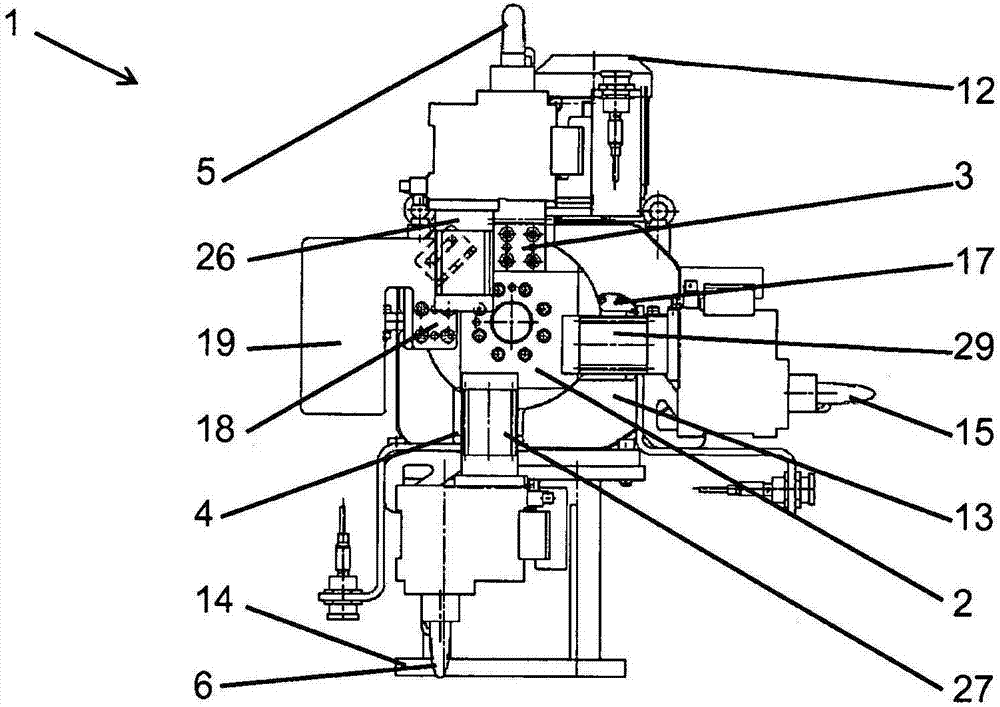

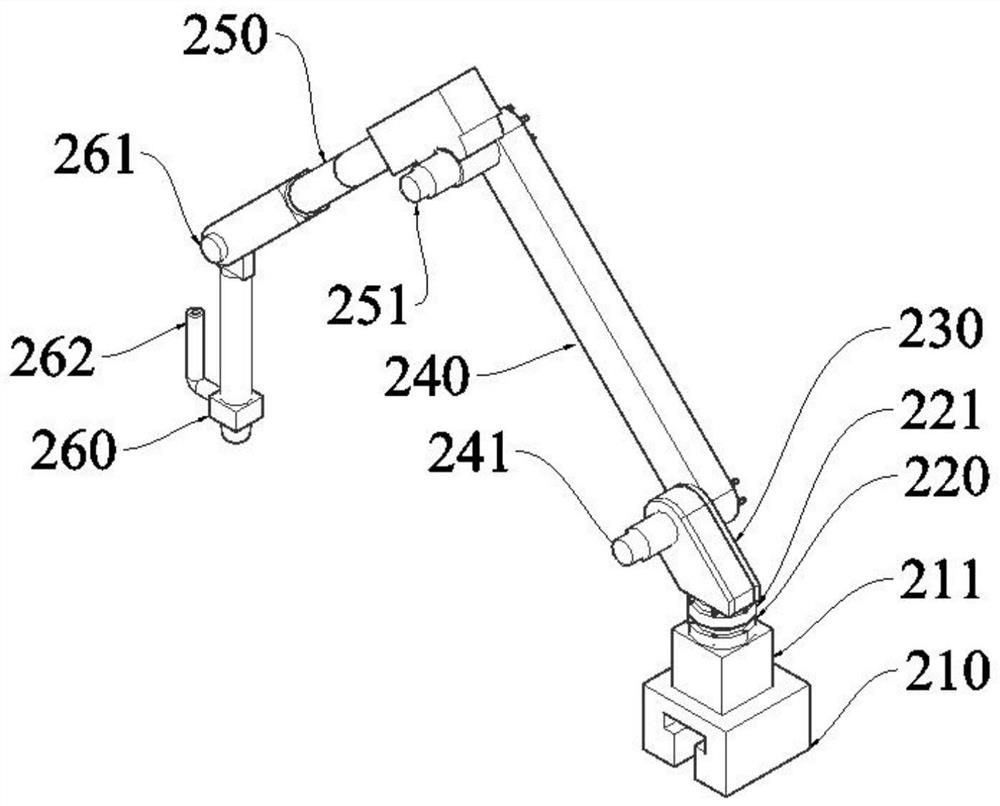

Intelligent cooperation dual-arm robot

ActiveCN106041897AGood mechanical structure rigidityReduce sizeProgramme-controlled manipulatorJointsEngineeringStructural rigidity

The invention provides an intelligent cooperation dual-arm robot. The robot comprises a mounting base and two arms, the two arms are arranged on the two sides of the mounting base in a mirror symmetry manner, and each arm comprises a shoulder arm assembly, a rear end arm assembly, a toggle arm assembly, a front end arm assembly and a wrist arm assembly connected with a tail end execution component, all of which are sequentially connected; one end of each shoulder arm assembly is connected with the mounting base, each shoulder arm assembly can rotate around the mounting base, one end of each rear end arm assembly is rotatably connected with the side wall of the other end of the corresponding shoulder arm assembly, the side face of one end of each toggle arm assembly is rotatably connected with the other end of the corresponding rear end arm assembly, one end of each front end arm assembly is connected with the other end of the corresponding toggle arm assembly, and each front end arm assembly can rotate around the axial direction; and one end of each wrist arm assembly is connected with the other end of the corresponding front end arm assembly, each wrist arm assembly can swing in the length direction of the corresponding front end arm assembly, and the other end of each wrist arm assembly is connected with the corresponding tail end execution component. The robot is compact in structure and reasonable in design, and the intelligent cooperation dual-arm robot is good in mechanical structural rigidity, small in size and small in weight.

Owner:广东省智行机器人科技有限公司

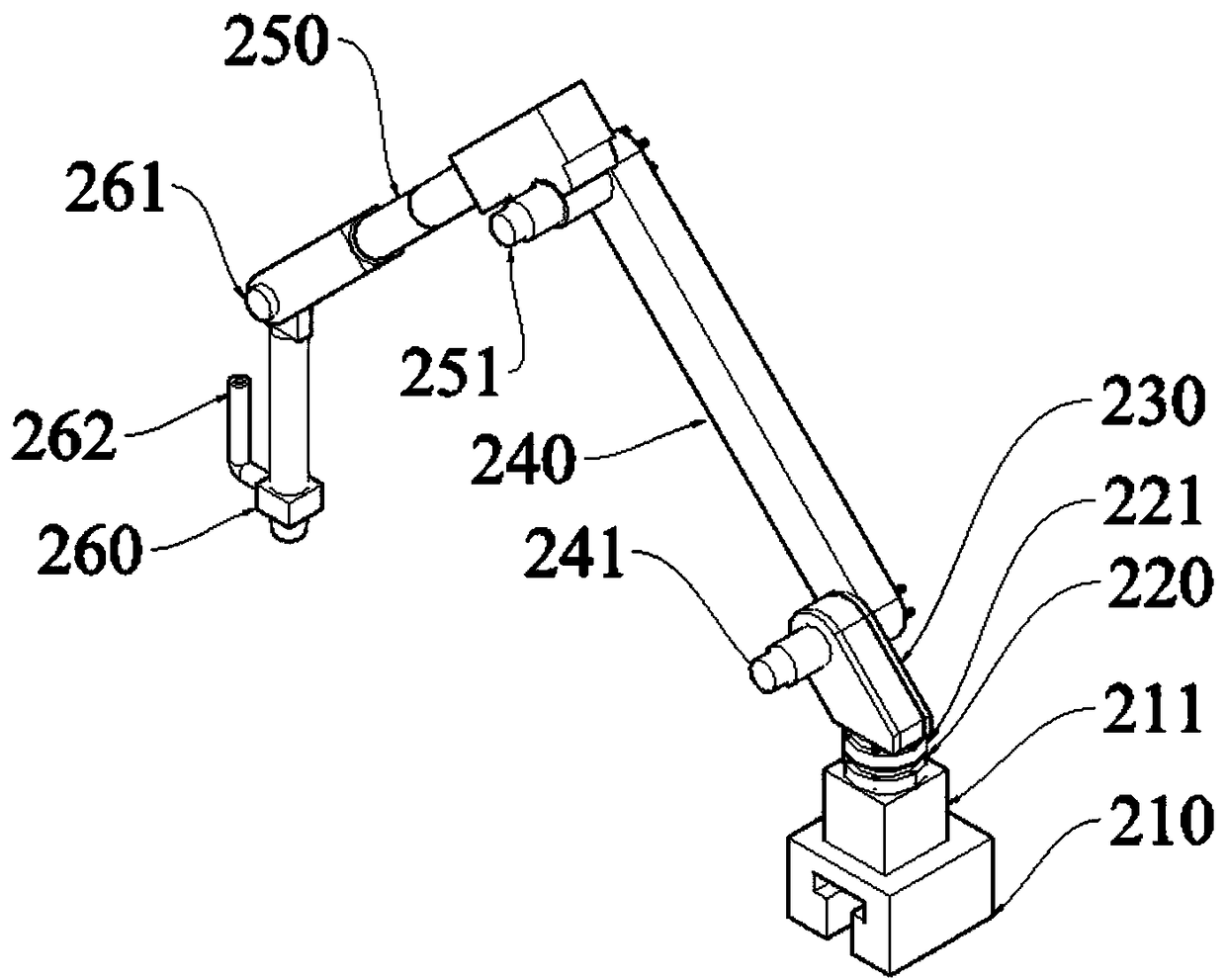

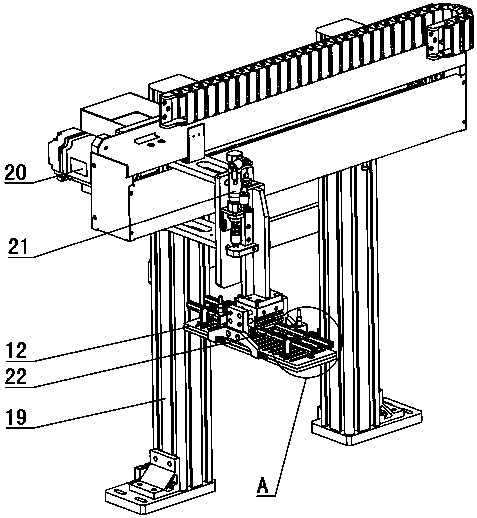

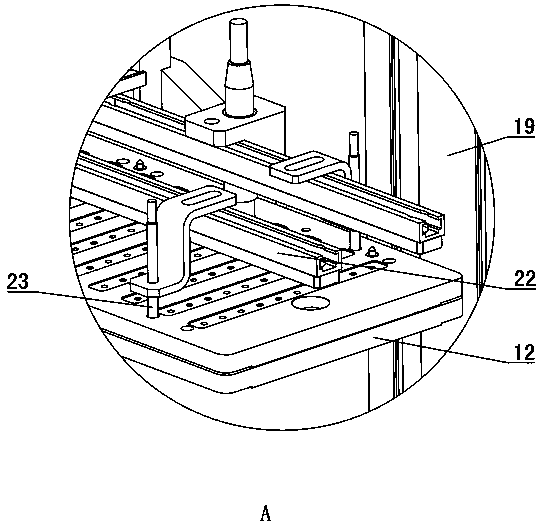

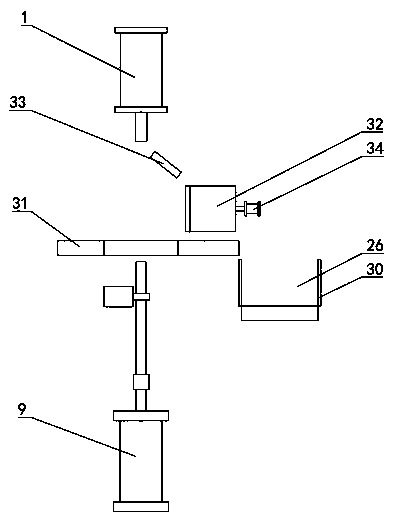

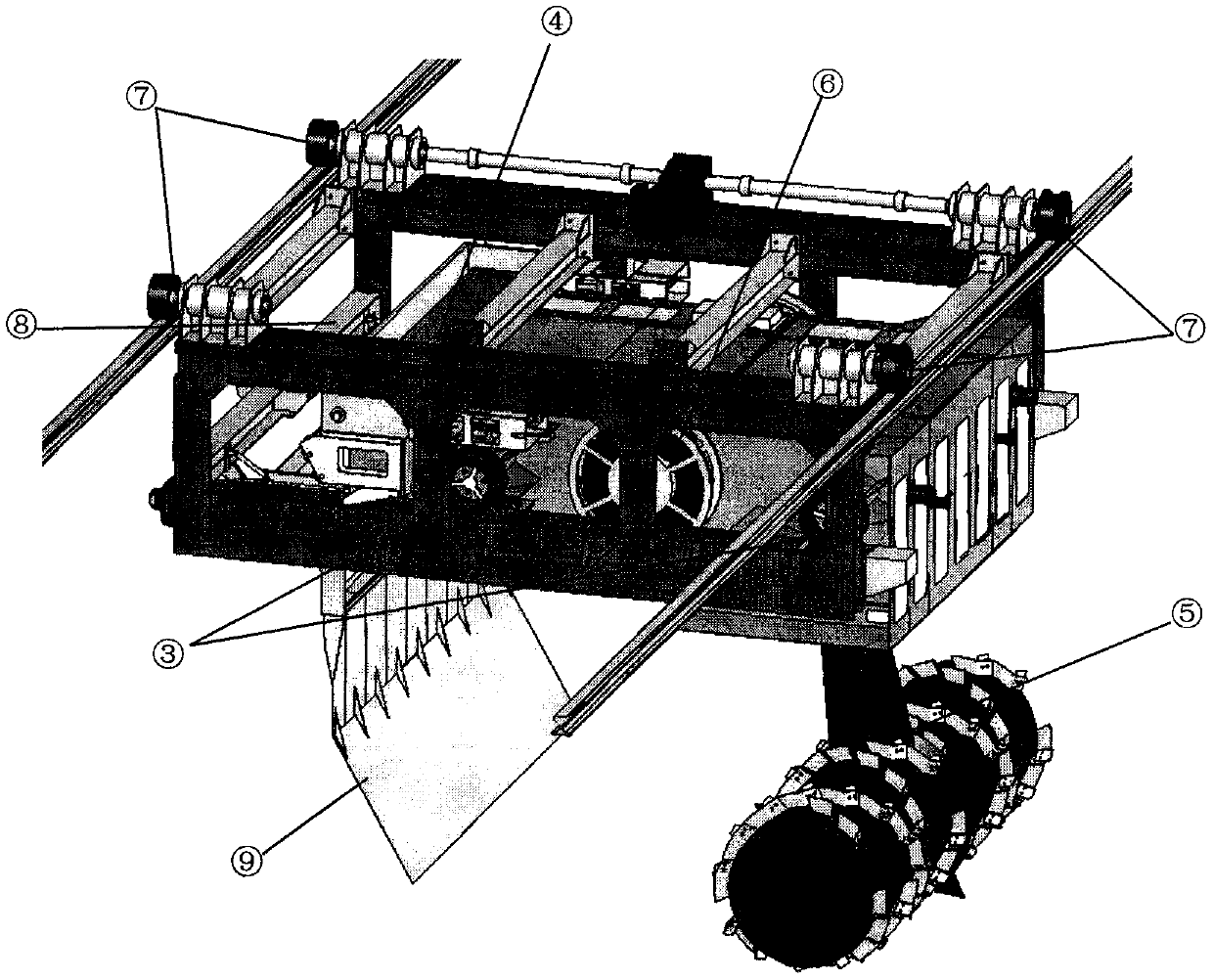

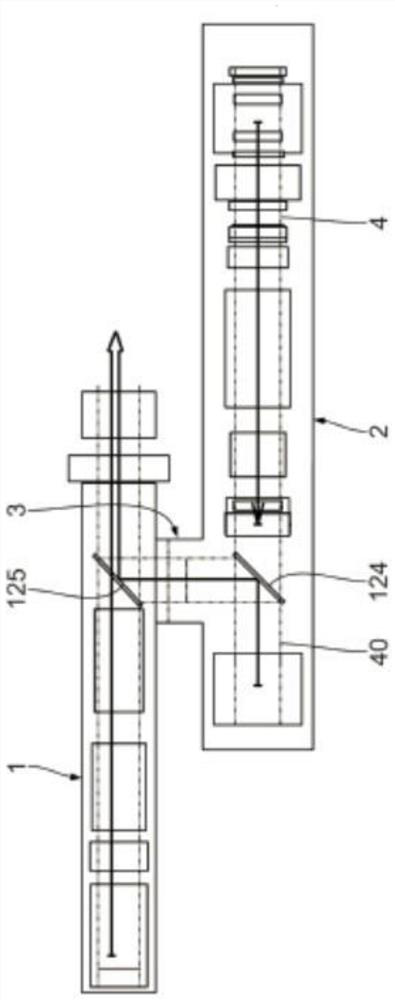

Hybrid 3D printing device and method used for building components

ActiveCN109079955ARealize simultaneous 3D printingFully automatedAdditive manufacturing apparatusCeramic shaping apparatus3d printerStructural material

The invention discloses a hybrid 3D printing device and method used for building components. The hybrid 3D printing device comprises a guide rail, a main structure 3D printing mechanism and a reinforcing structure 3D printing mechanism. The guide rail comprises an upper rail body, a middle rail body and a rail base. First rack guide rails are arranged on the two sides of the middle rail body. An upper sliding rail and a lower sliding rail are separately arranged on the upper surface and the lower surface of the upper rail body. Second rack guide rails are arranged on the two side faces of a rectangular groove of the upper rail body. The main structure 3D printing mechanism and the reinforcing structure 3D printing mechanism are fixed to the guide rail through a first sliding base and a second sliding base. According to the hybrid 3D printing device and method, synchronous 3D printing of main structures and reinforcing structural materials of building components is achieved, and the technical problems that existing 3D-printed building components are poor in strength and the printing efficiency is low are solved.

Owner:SHANGHAI CONSTRUCTION GROUP

Wall-scrapping type rotary hopper device

Owner:PUYANG CITY HONGYU PRESSURE VESSEL

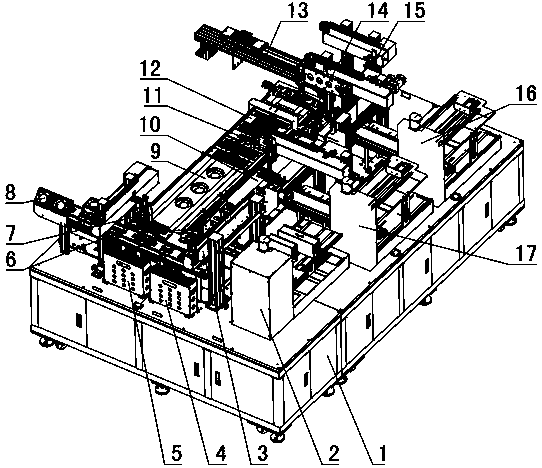

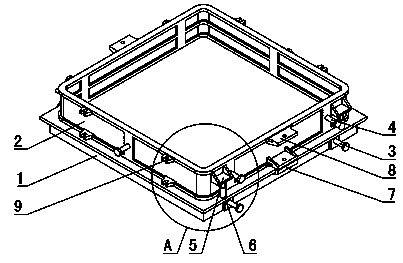

Laminating mechanism with recyclable welding die

PendingCN108155129AReduce in quantityInhibit sheddingSemiconductor/solid-state device manufacturingAssembly lineManipulator

The invention discloses a laminating mechanism with a recyclable welding die, and belongs to the technical field of automatic devices. The laminating mechanism is characterized by comprising a weldingdie input module (6), a top cover conveying module (9) and a bottom plate conveying module (10), the top cover conveying module (9) and the bottom plate conveying module (10) are arranged on one sideof the welding die input module (6), a die opening mechanical hand (7) is arranged between the input end of the top cover conveying module (9) and the welding die input module (6), a die closing mechanical hand (14) is arranged between the output end of the top cover conveying module (9) and the bottom plate conveying module (10), and a blanked piece transferring mechanical hand (11) is arrangedon one side of the bottom plate conveying module (10). By means of the laminating mechanism, a welding die bottom plate and a welding die top cover are recycled, assembly line type production can be realized without preparing too many welding dies, and production cost is reduced.

Owner:SHANDONG CAIJU ELECTRONICS TECH CO LTD

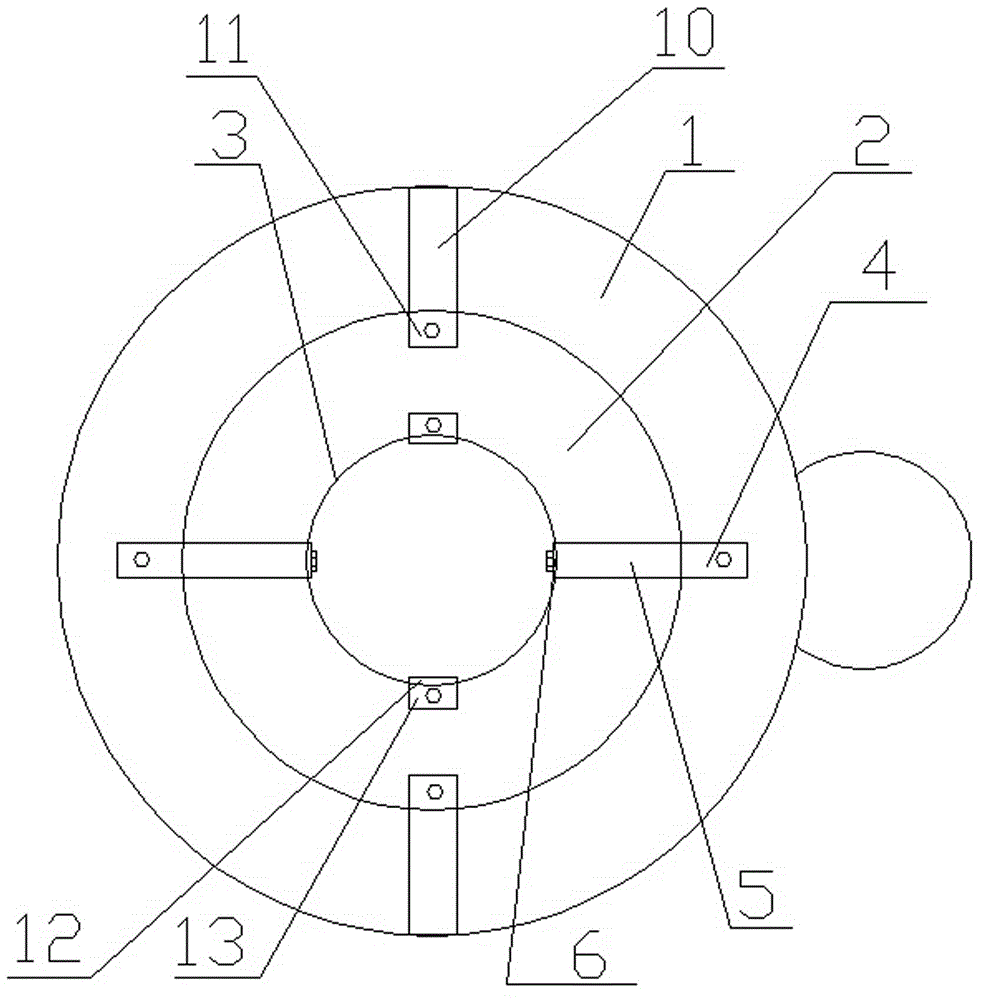

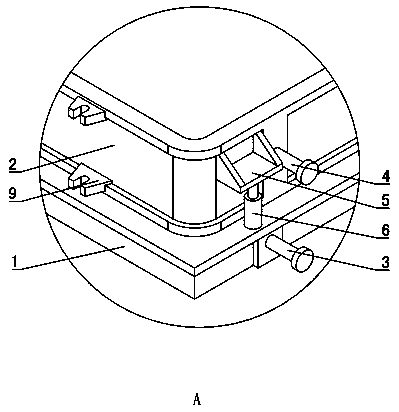

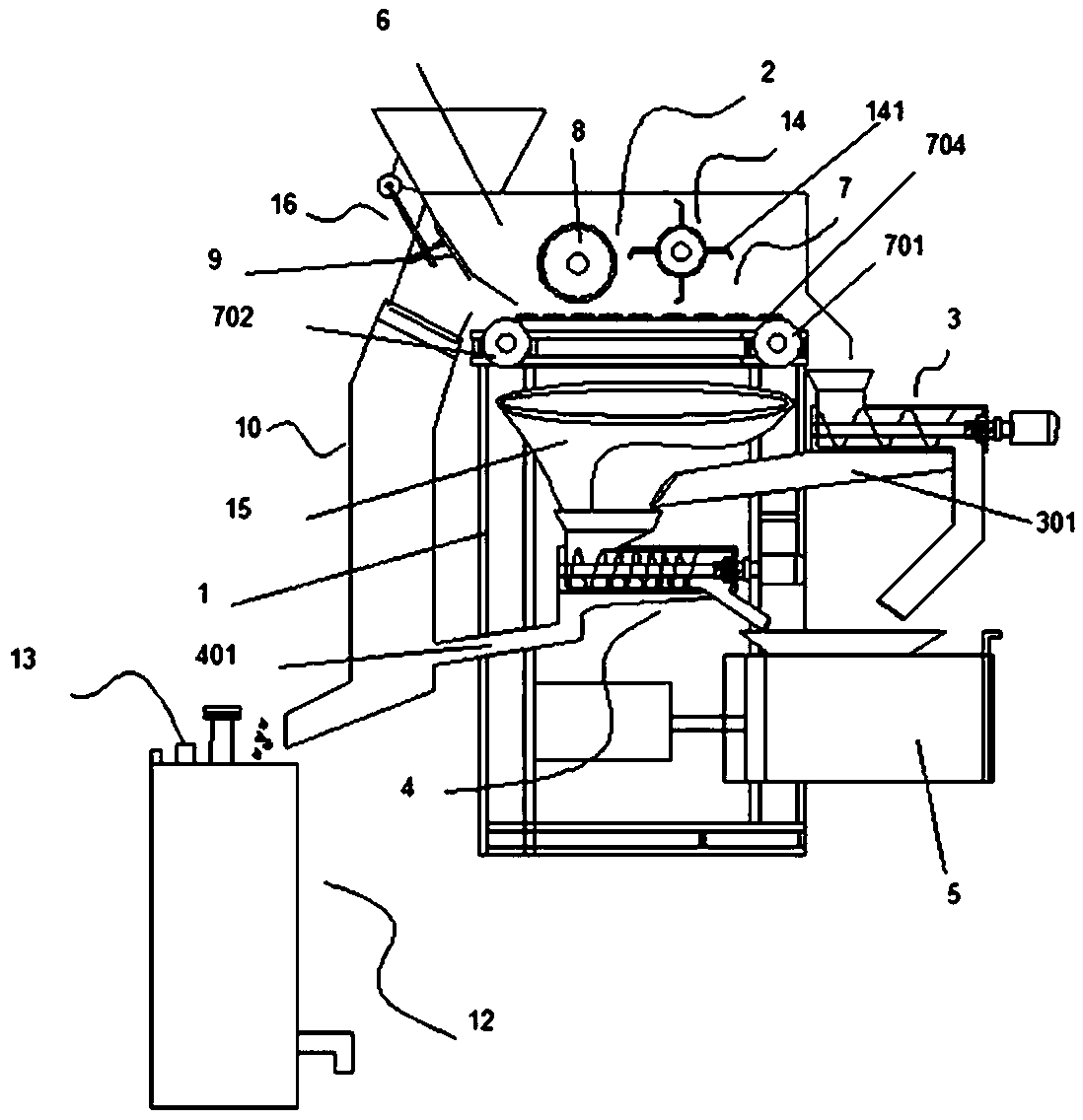

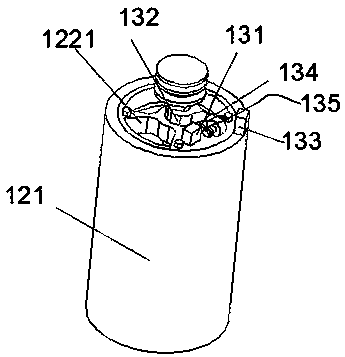

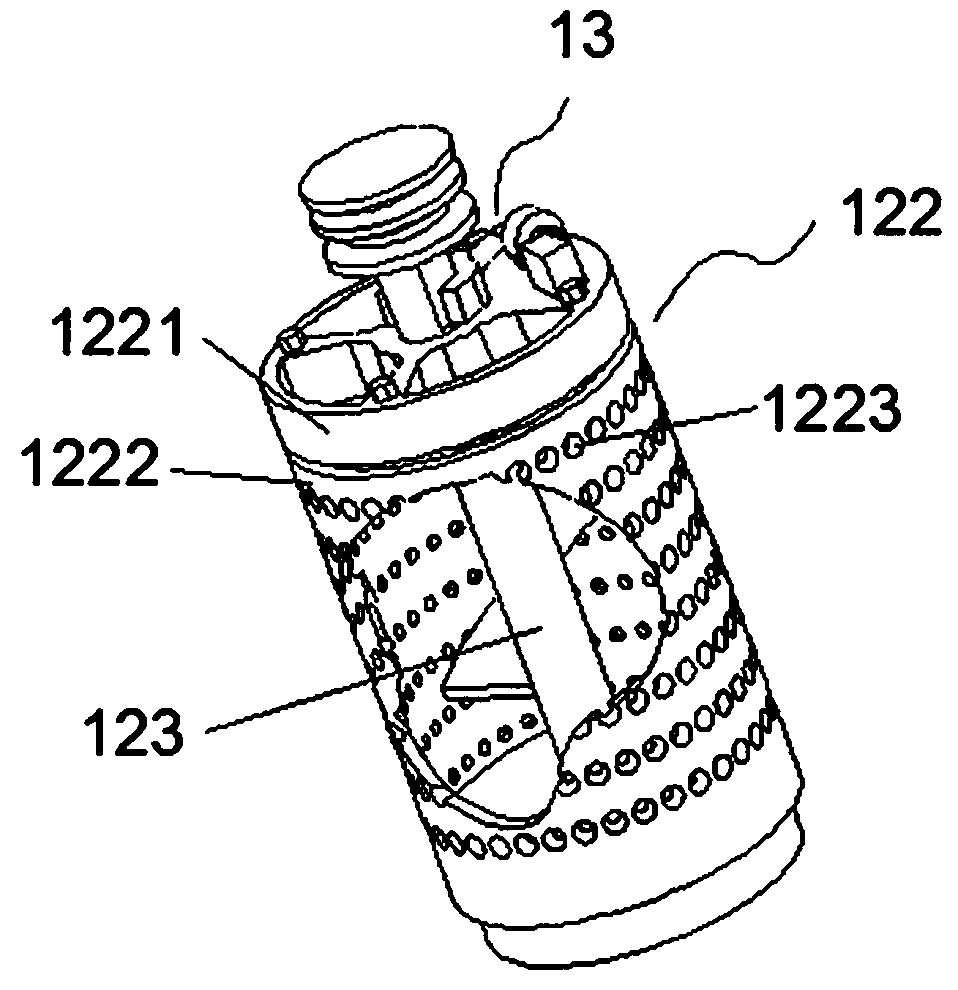

Broken shot blasting shot sorting device

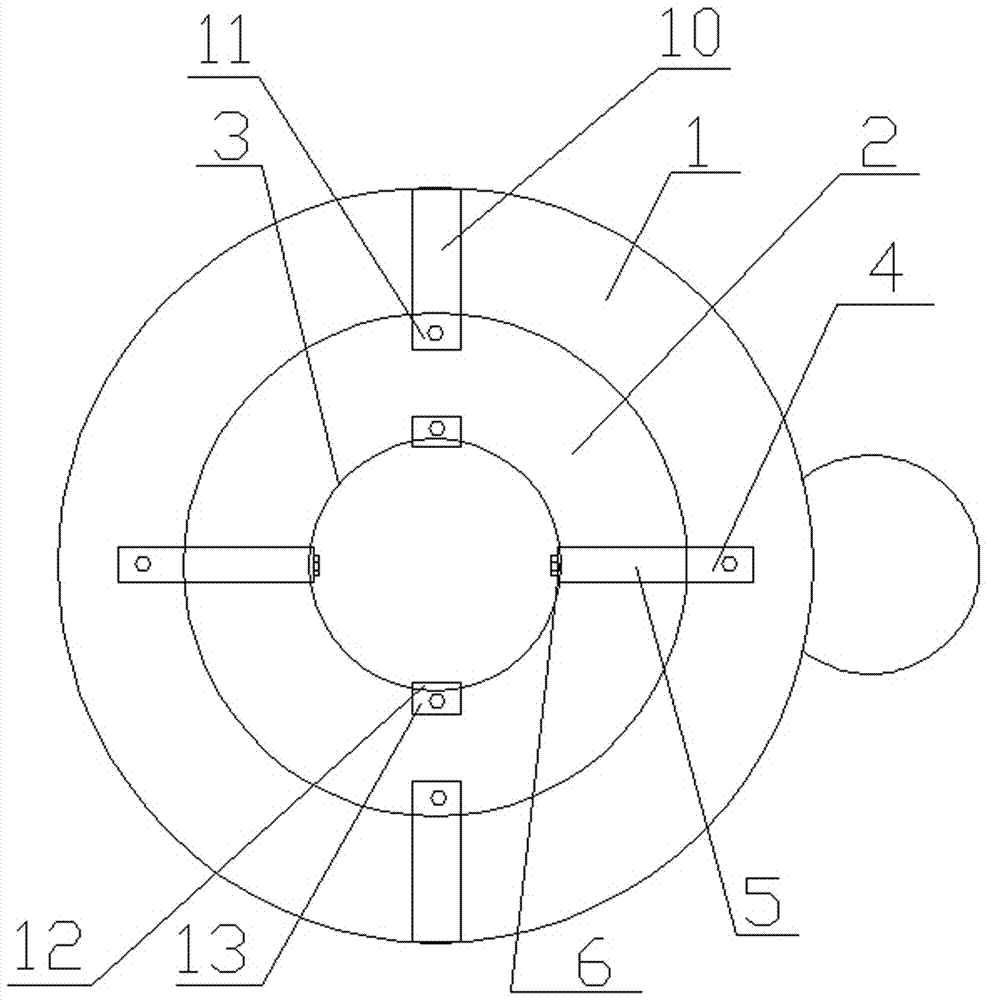

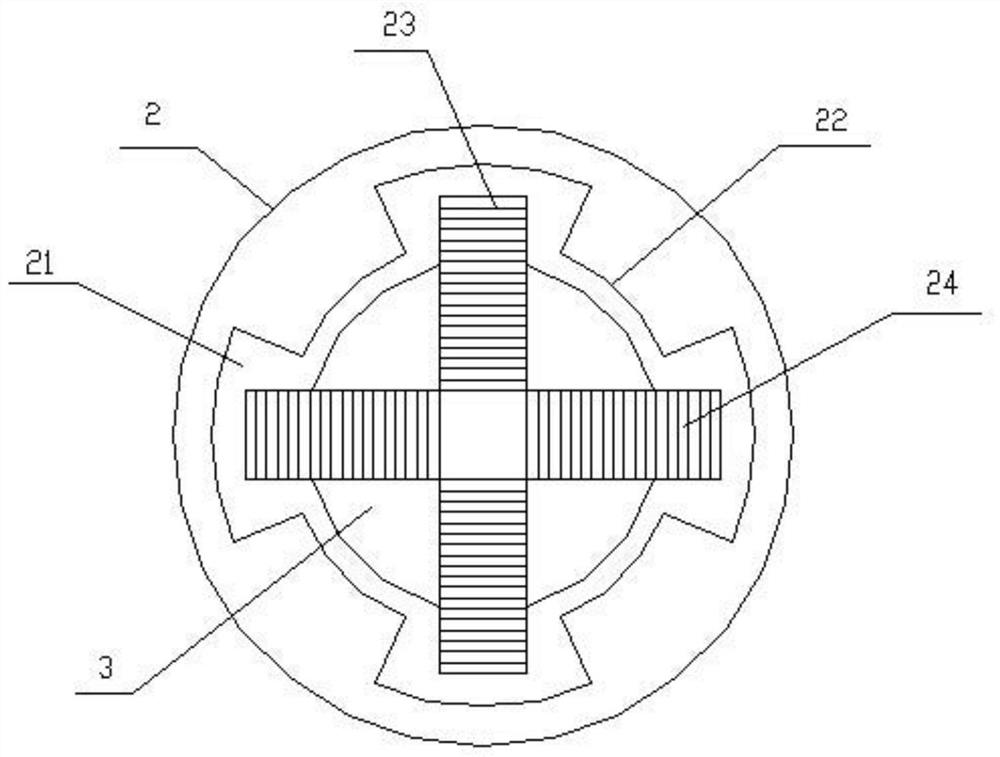

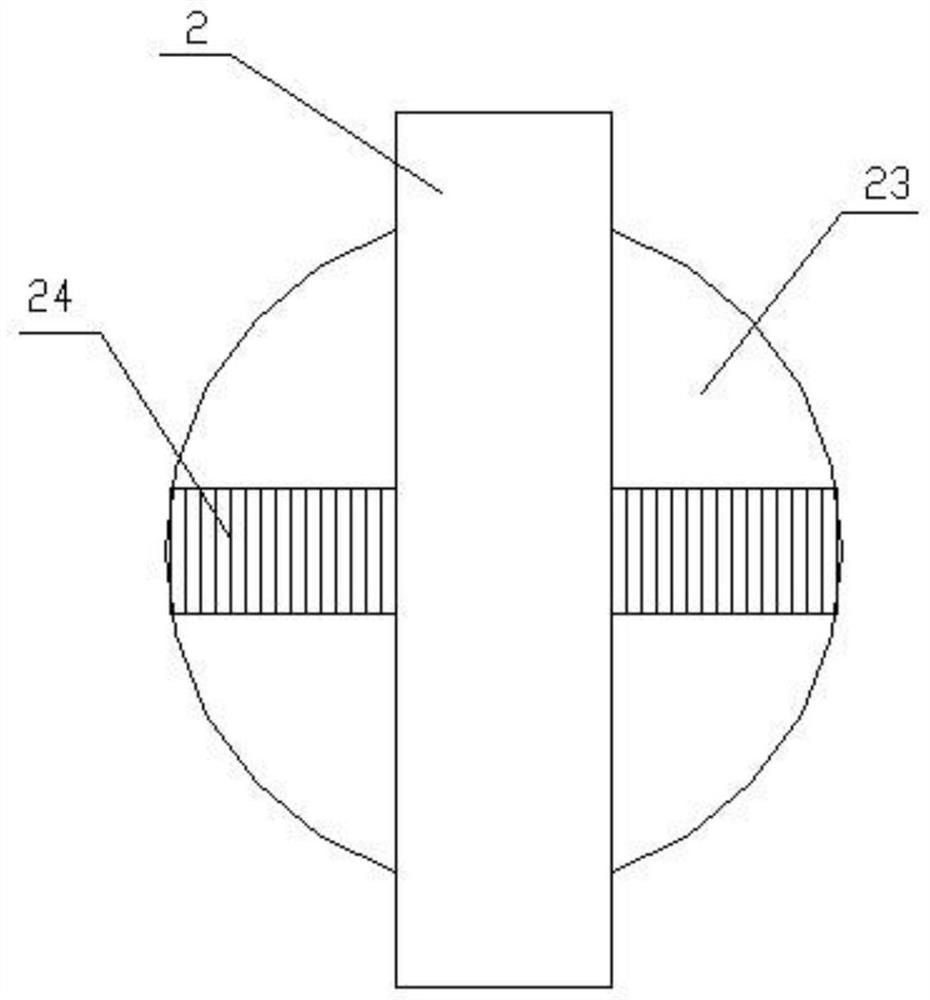

InactiveCN113083690AAvoid mutual obstructionProcessing quality is not affectedAbrasive machine appurtenancesGradingCentrifugationStructural engineering

The invention discloses a broken shot blasting shot sorting device. The broken shot blasting shot sorting device comprises a machine body, centrifugal space is arranged in the machine body, an outer centrifugal disc is slidably arranged between the inner side walls of the centrifugal space, the outer centrifugal disc can rotate in the centrifugal space, and an inner centrifugal disc is slidably arranged in a cavity in the centrifugal space. By means of different contact areas between a high-viscosity glue solution and complete shots and between the high-viscosity glue solution and broken shots, the complete shots and the broken shots can be distinguished in batches and recycled respectively through different resistances borne by the complete shots and the broken shots during centrifugation, it is guaranteed that the machining quality is not affected when the shots are repeatedly used, and meanwhile efficient distinguishing is achieved; and the device can arrange the shots into a single-layer ring during centrifugation, mutual obstruction between the shots during centrifugation is avoided as much as possible, and the sorting precision is improved.

Owner:义乌市韩狐贸易有限公司

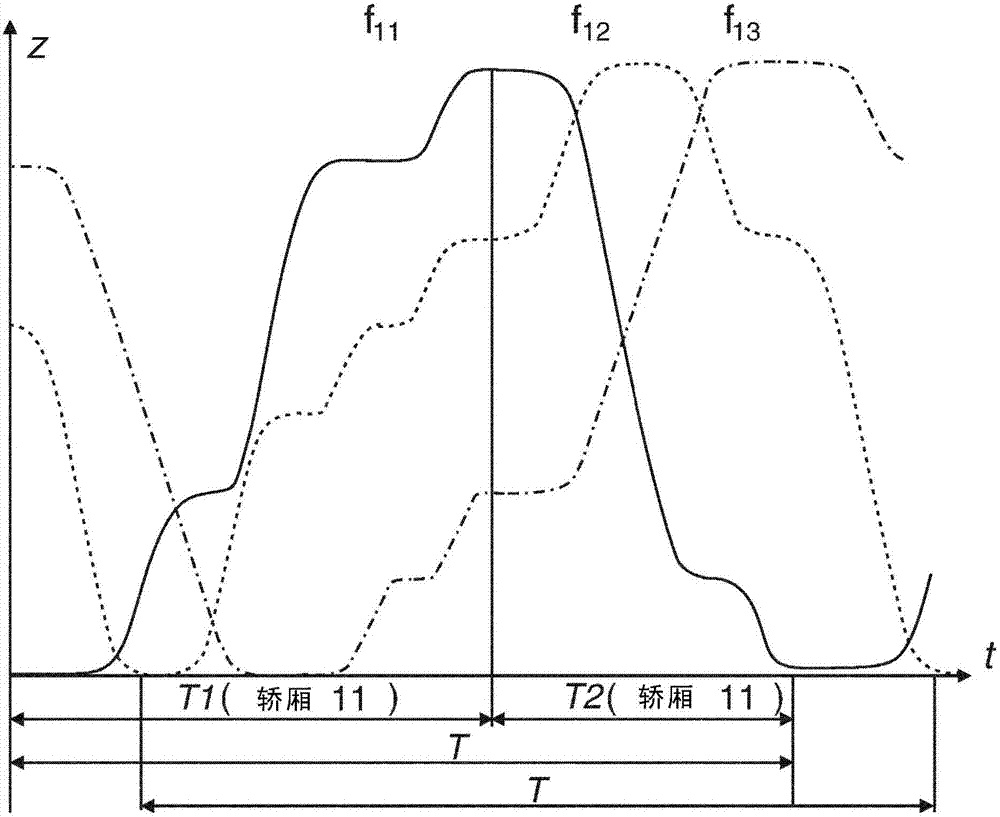

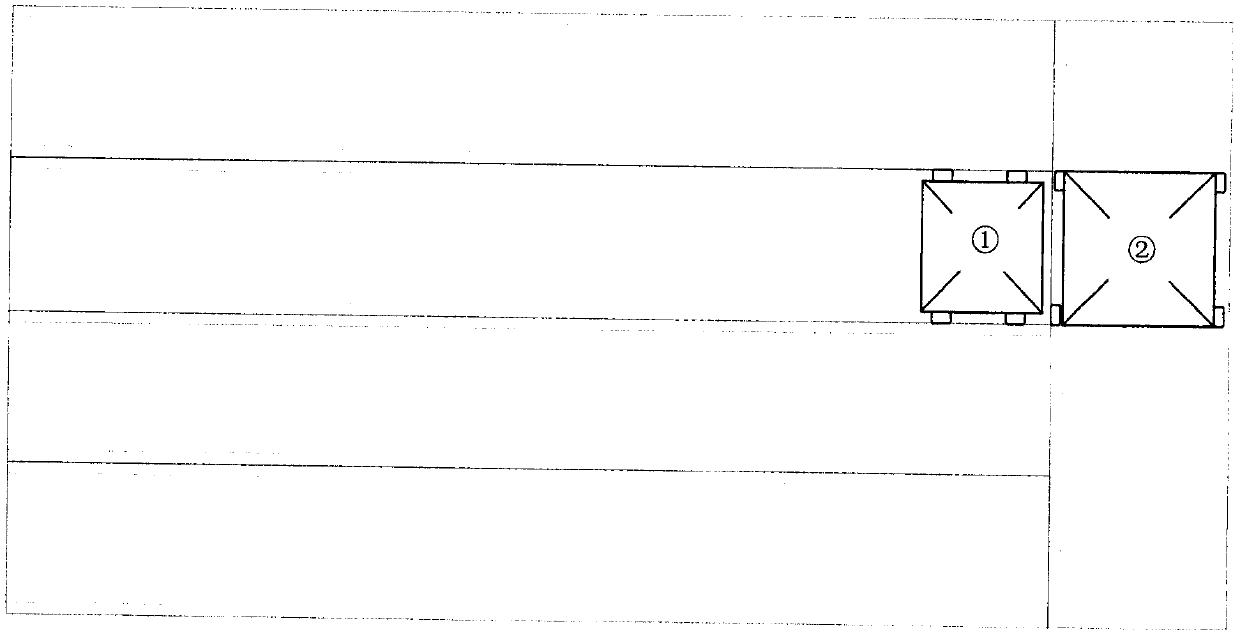

Method for operating a transport system and corresponding transport system

ActiveCN107074482AAvoid mutual obstructionAvoid getting in the wayElevatorsTransport systemEngineering

The invention relates to a method for controlling a transport system (1) and a transport system (1) of this type comprising at least two conveyor sections (2, 3) and at least three cars (11, 12, 13, 14, 15, 16) that are moved individually in the cyclical operation, wherein, starting from a first start position, every car passes through a first conveyor section (2) and subsequently a second conveyor section (3) back to the first start position, wherein at least one stop is provided at least along a conveyor section (2, 3), and one or more consecutive stops are assigned to a respective block (21, 22, 23), and wherein the travelling of the cars is controlled in such a way that the cars approach a respective predetermined block one at a time, and an equal cycle time (T) is specified for every car to pass through the first and the second conveyor section.

Owner:TK ELEVATOR INNOVATION & OPERATIONS GMBH

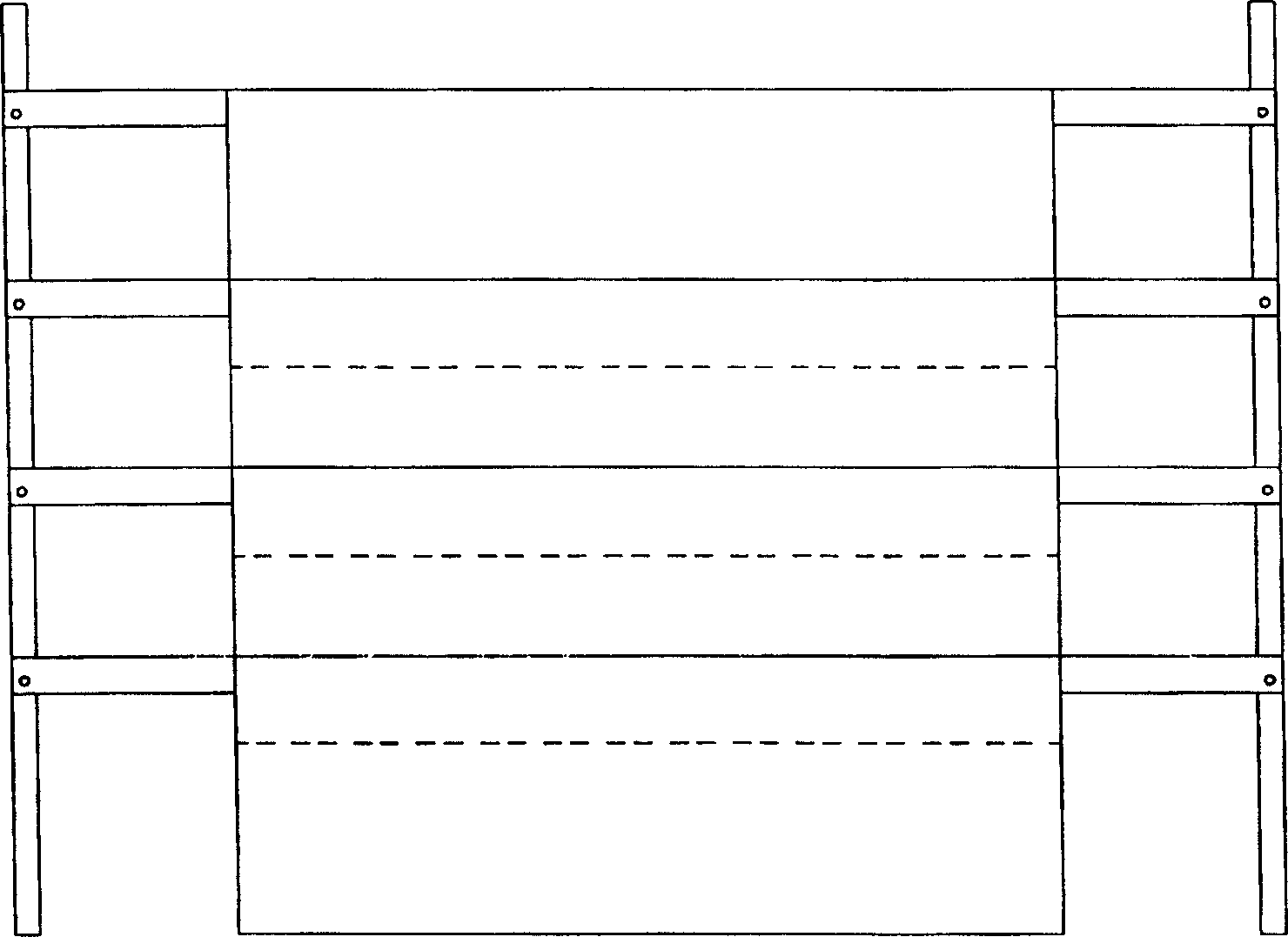

Large vacuum pump impeller casting method

The invention relates to a large vacuum pump impeller casting method and belongs to the technical field of production of a vacuum pump impeller. The large vacuum pump impeller casting method is characterized by comprising the following steps: 1) mounting a mold in a sand box; 2) filling a sand box main body (2) with molding sand, tamping, scraping the redundant molding sand, and arranging a casting head and a vent hole; 3) drawing the sand box main bodies (2) one by one from top to bottom, lifting the corresponding sand box main body (2) by a lifting device, lifting the sand box main body (2)through a travelling crane, and synchronously lifting by the lifting device corresponding to the same layer of sand box main body (2); 4) taking out the mold and sequentially performing mold closing on the sand box main body (2) through the travelling crane; and 5) fixedly connecting a pedestal (1) with the adjacent sand box main body (2) as well as each adjacent two layers of sand box main bodies(2). By the large vacuum pump impeller casting method, the operation of lifting the sand box main bodies by the travelling crane, rapidly lifting the mold and separating from the mold is facilitated.

Owner:ZIBO WATER RING VACUUM PUMP FACTORY +2

Full-automatic coconut cutting device

PendingCN111436625AFast cutting speedReduce labor intensityHuskingHullingAgricultural engineeringStructural engineering

The invention discloses a full-automatic coconut cutting device, and belongs to the technical field of coconut cutting equipment. The device is characterized by comprising clamping devices and a cutting device, the at least two clamping devices are arranged side by side, the cutting device is correspondingly arranged in the middle of each clamping device, the clamping devices are connected with apower device for driving the clamping devices to rotate, and a side cutting part and an upper cutting part are arranged on the side portion and the upper portion of each cutting device respectively. The full-automatic coconut cutting device is provided with at least two cutting stations, multiple coconuts can be automatically cut at the same time, automatic cutting is achieved, the cutting speed is high, the labor intensity of workers is greatly reduced, potential safety hazards are eliminated, the upper cutting part and the side cutting part cut the upper portions and the side portions of thecoconuts correspondingly. The coconut cutting device guarantees attractive appearance of cut coconuts, is accurate in cutting, cannot damage the coconuts, and can also guarantee removal of coconut peels.

Owner:淄博天型食品机械有限公司

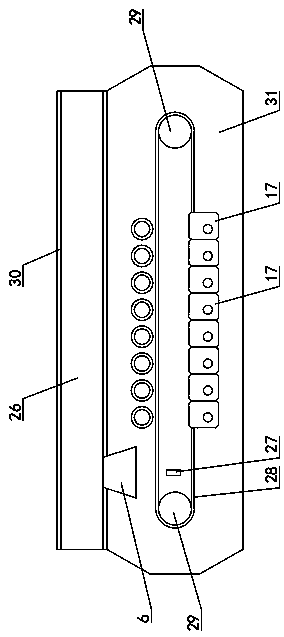

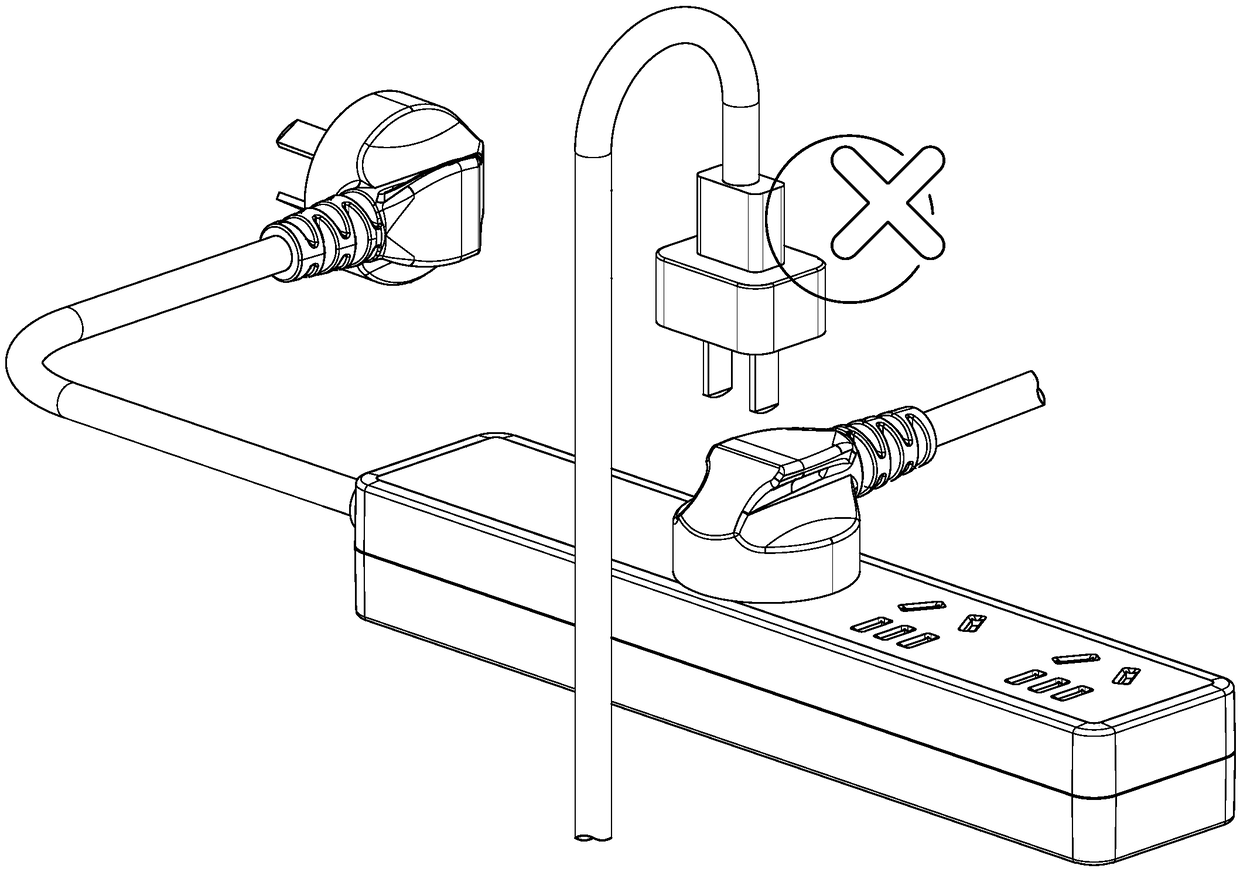

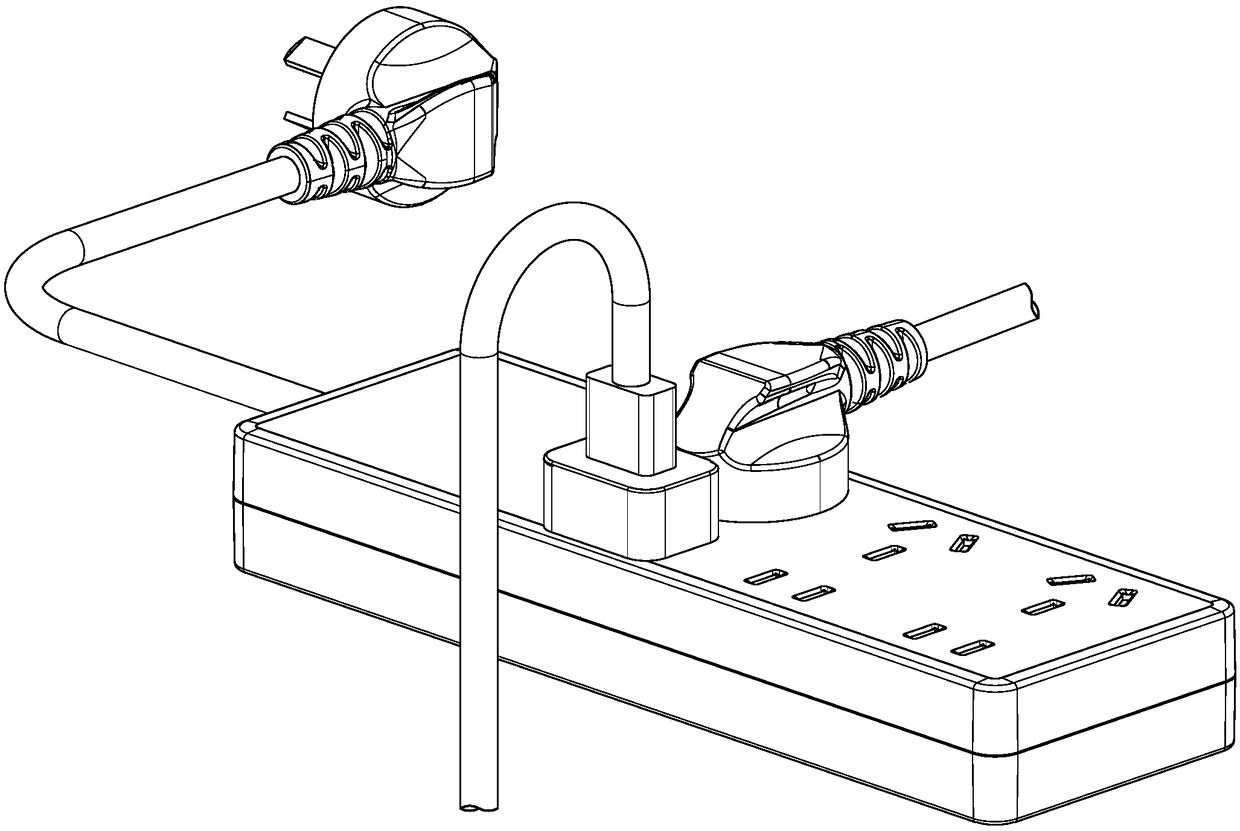

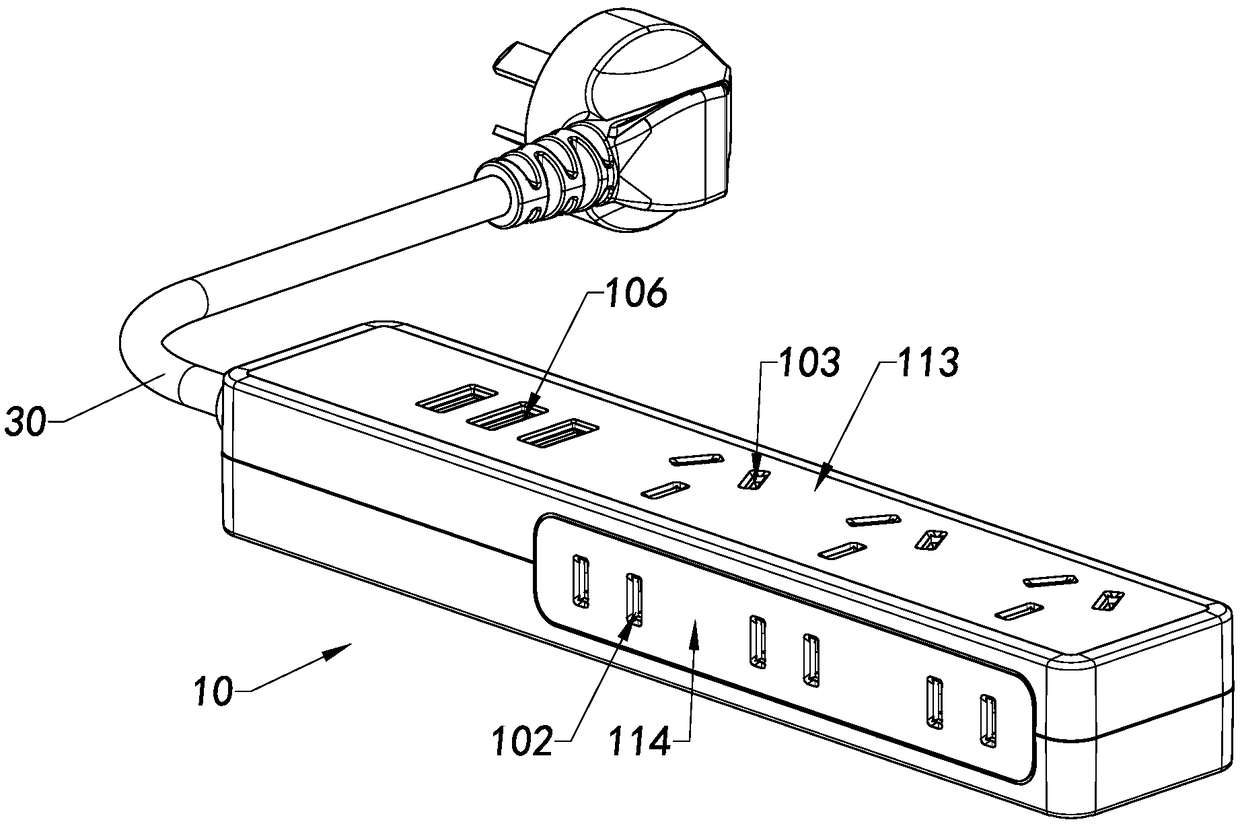

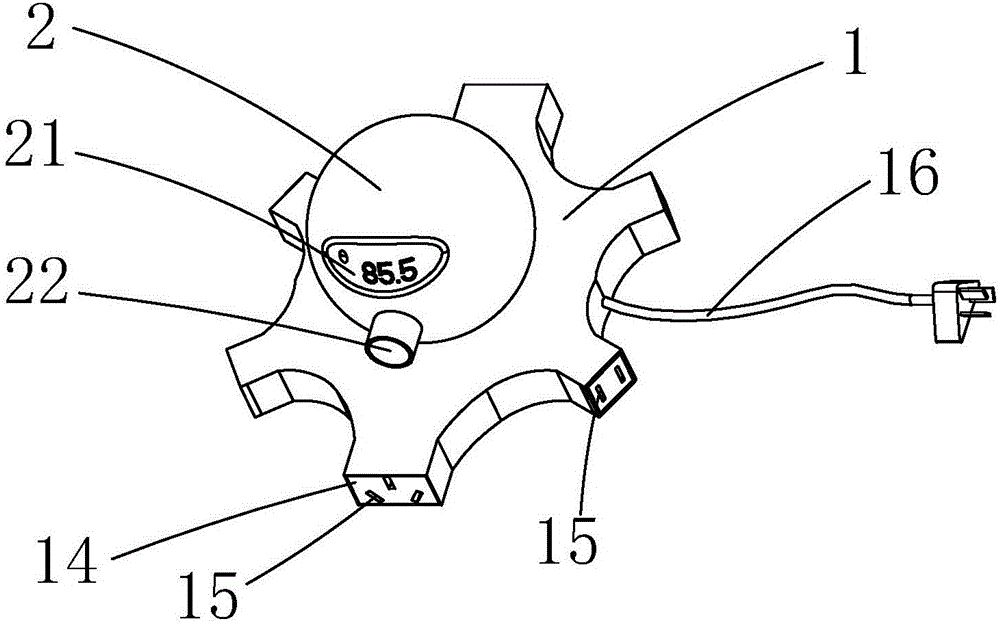

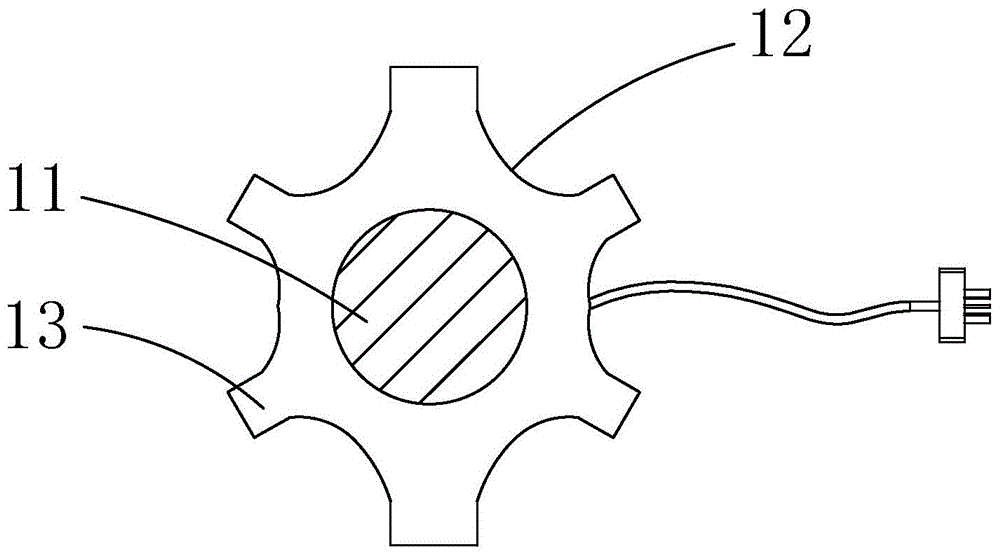

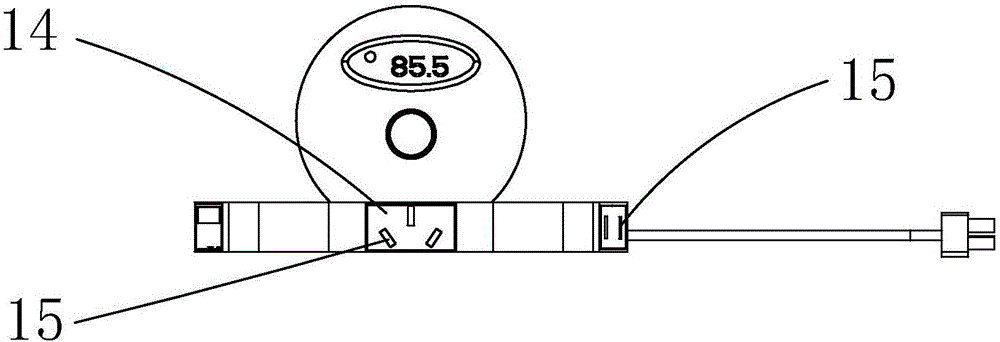

Socket

PendingCN109473802ASolve the problem that two-pin plugs cannot be inserted at the same timeSolve the problem of three-pin plugCoupling contact membersPower cableEngineering

The invention provides a socket, which comprises a housing, at least a socket main body and a power cable. The socket main body is arranged on the housing, the socket main body comprises a main body base and at least two insertion devices, the insertion devices are disposed on the main body base, and the insertion devices are fixedly supported by the main body base. The main body base is further provided with at least two base upper openings and at least two base side openings to allow plug pins of a plug to be connected from the base upper openings to the insertion devices from top to bottomor to be connected from the base side openings to the insertion devices from outside to inside.

Owner:江西普拉格电子制品有限公司

Multi-stage spiral water removal machine used in garbage classifying resource recycling device

PendingCN110271217AAvoid interactionAvoid mutual obstructionPressesMoving filtering element filtersWater filterSewage

The invention discloses a multi-stage spiral water removal machine used in a garbage classifying resource recycling device. The machine comprises a rack, a supply device, a first-stage water removal device, a second-stage water removal device and a cake pressing machine. The supply device is arranged on the upper end of the rack and comprises a material inlet box, a half type filter conveying belt assembly arranged in the material inlet box and a pressing roller used for pressing water removal. The pressing roller is arranged above the half type filter conveying belt assembly, a water filter opening is formed in an inlet of the material inlet box in an inclined manner, a filter net and a sewage pipeline I are arranged on the water filter opening, and the first-stage water removal device and the second-stage water removal device are used for treating garbage separated out of the upper and the lower of the half type filter conveying belt assembly. Peels and fluid cooked wheaten food garbage are separated to be subjected to independent water removal, the mutual influences or obstruction is removed, and the water removal efficiency and water removal sufficiency are improved.

Owner:河南中成环保科技股份有限公司

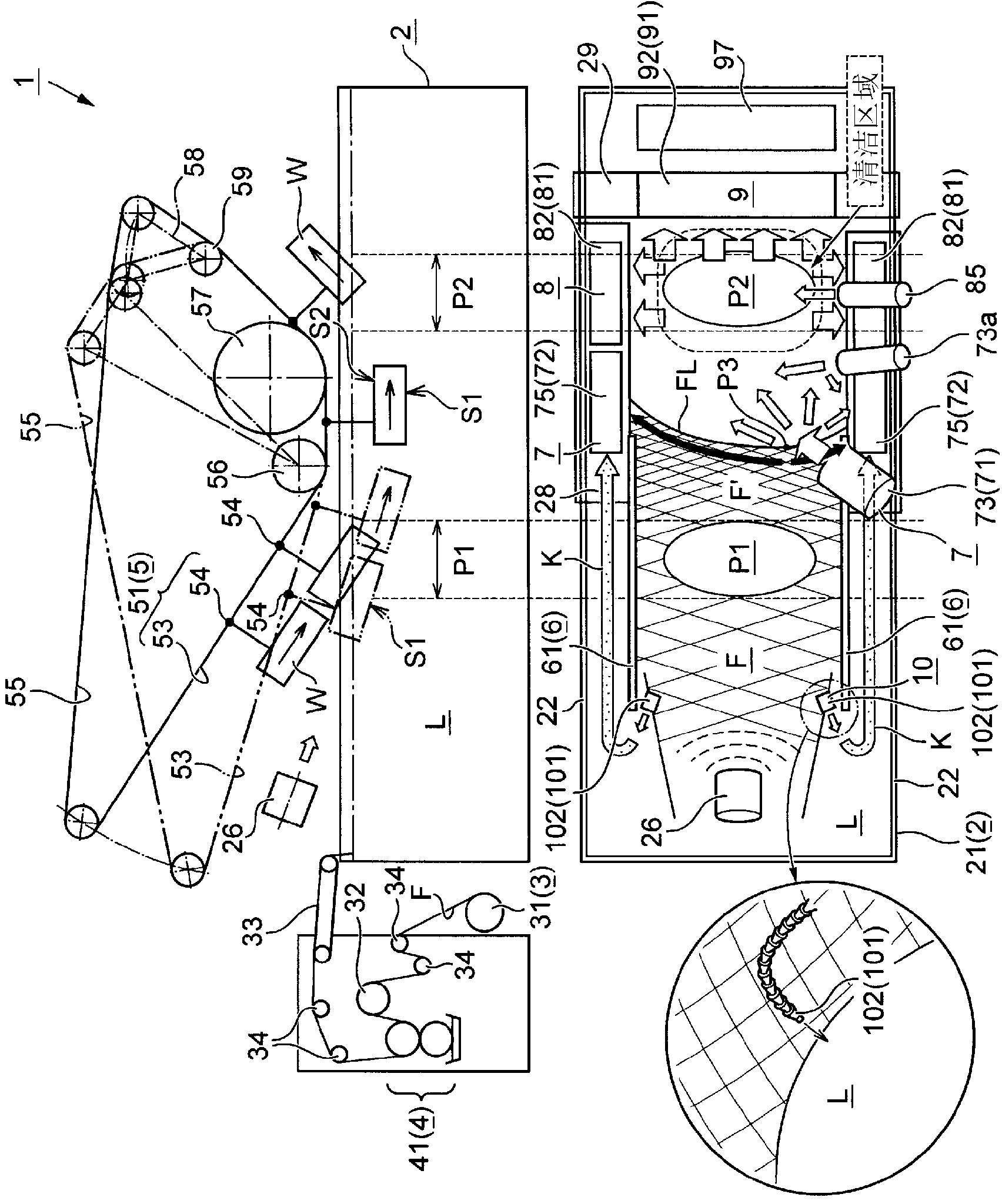

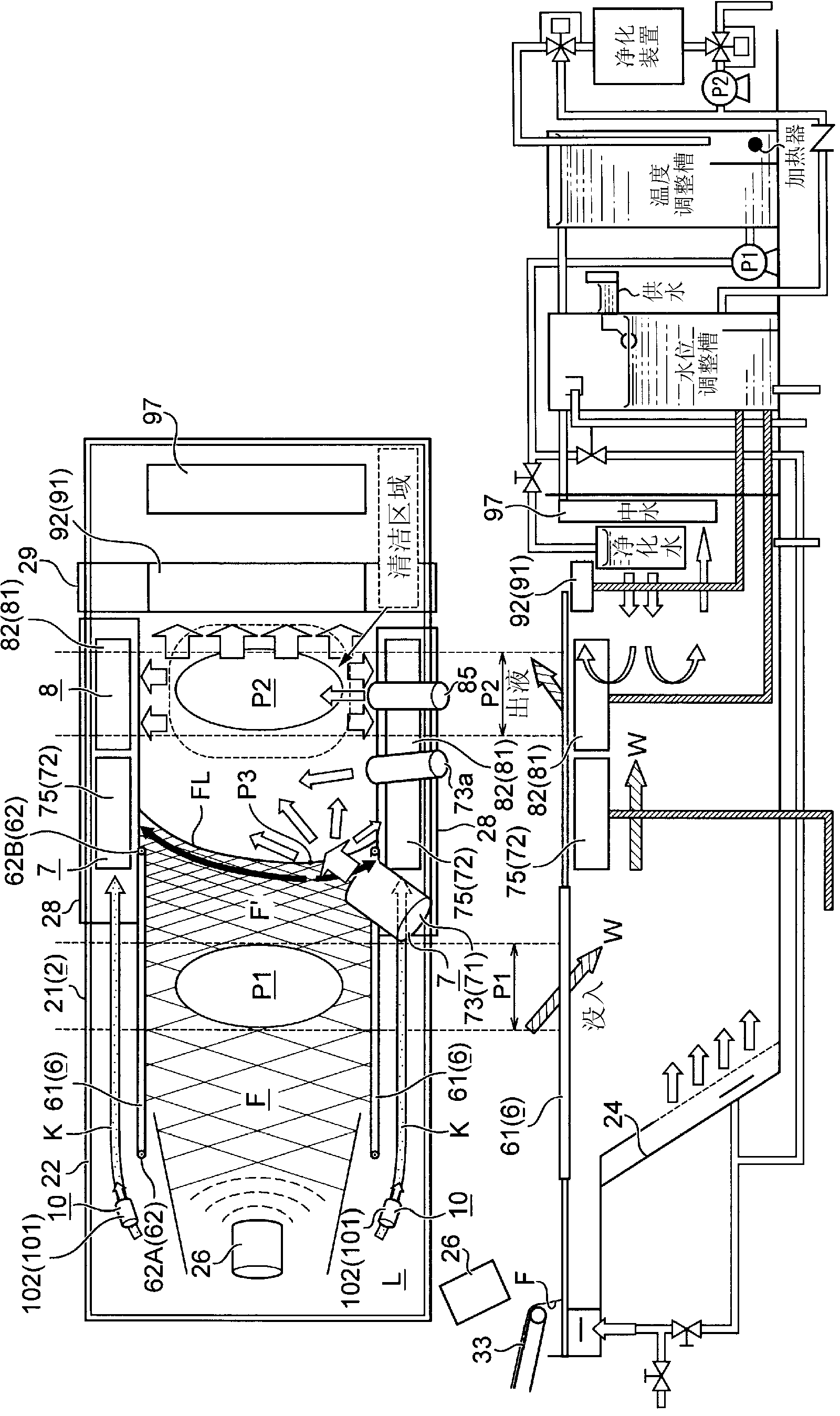

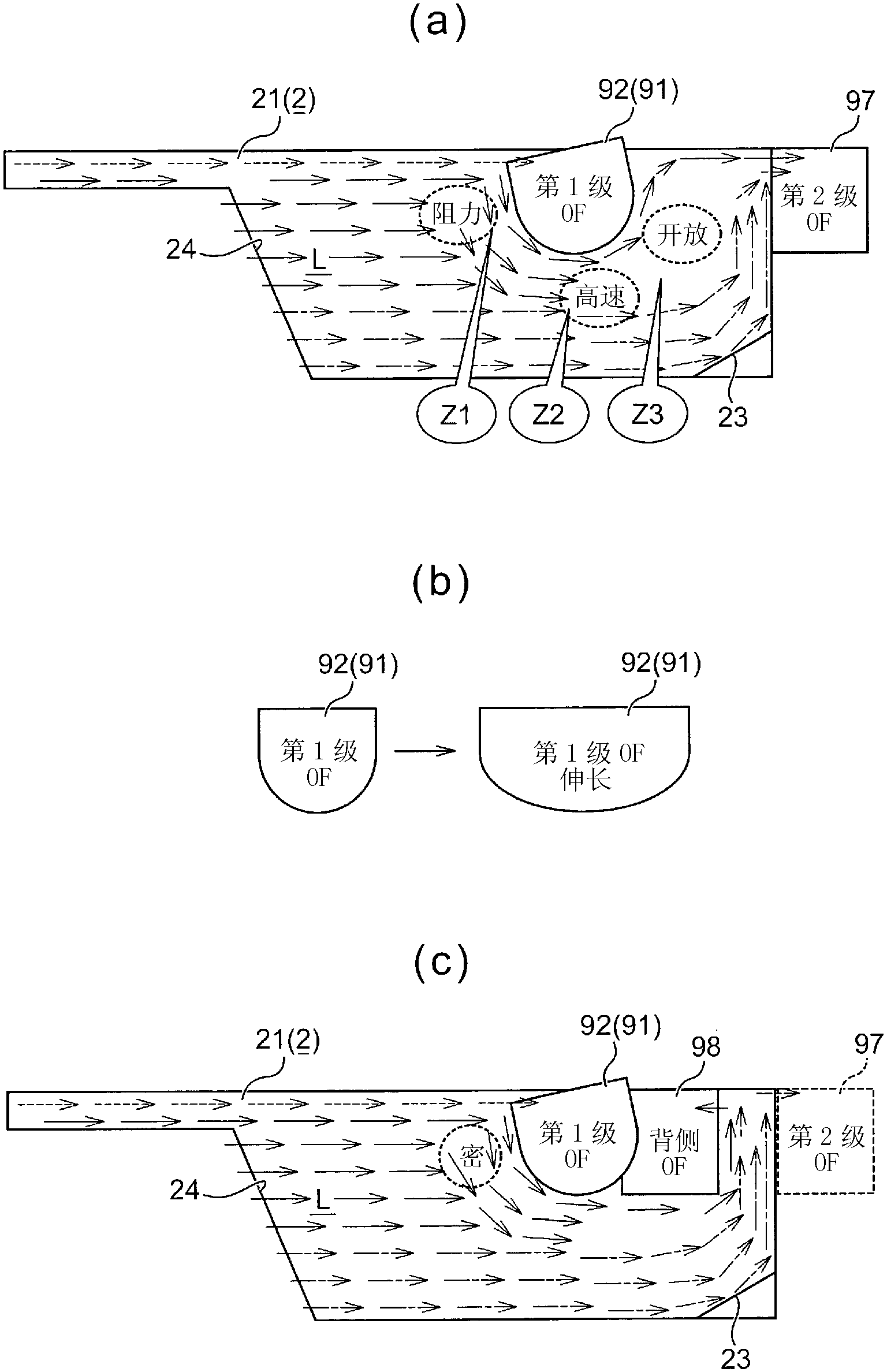

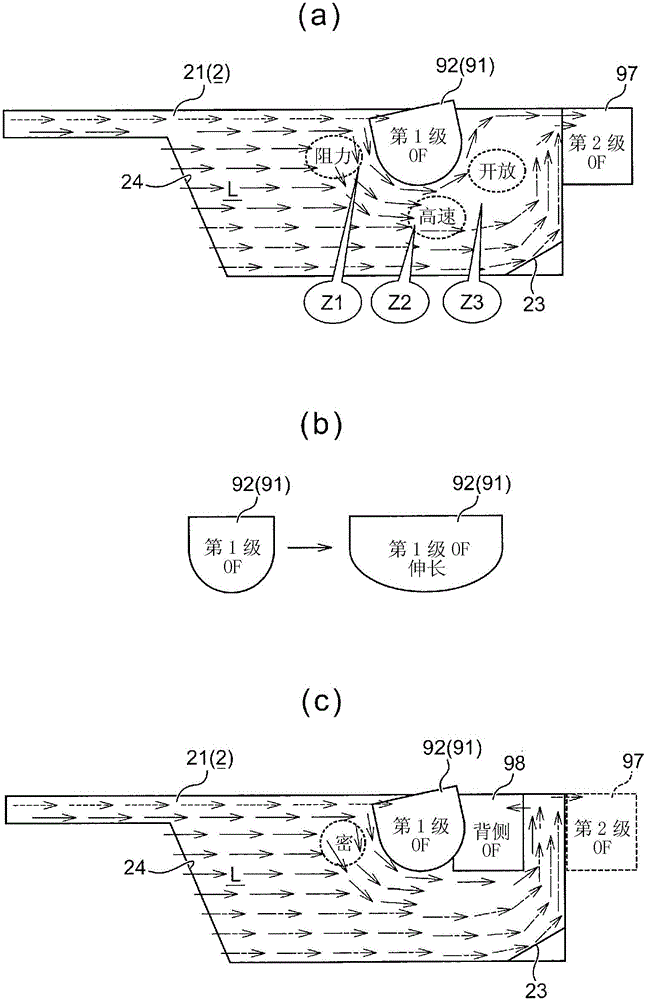

Hydraulic transfer method provided with design surface purification mechanism, and hydraulic transfer device therefor

ActiveCN103260898ASpeed up the flowEfficient recyclingTransfer printingDecorative surface effectsThin membraneEngineering

Owner:TAICA

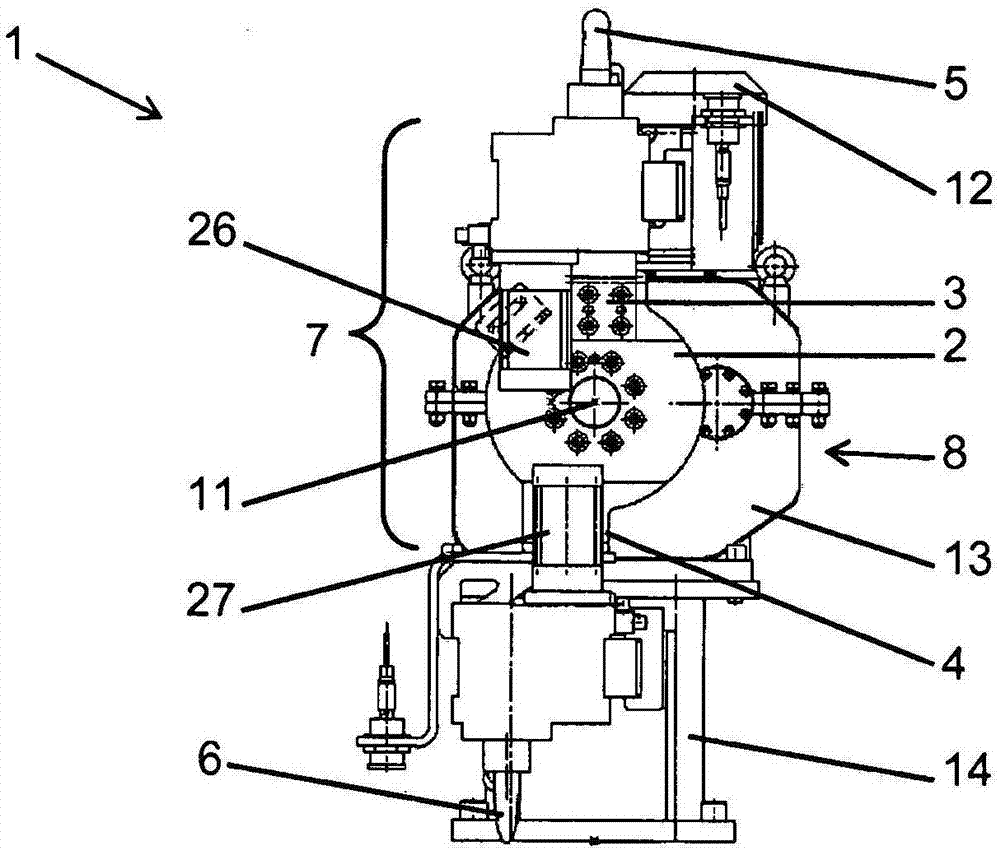

Replacement device for clamping and/or centering subassemblies

InactiveCN107074311AAvoid mutual obstructionProper weight distributionPrecision positioning equipmentMachine tool componentsEngineeringTool holder

Owner:TMS TURNKEY MFG SOLUTIONS

Workpiece distributing device

The invention discloses a workpiece distributing device, and belongs to the technical field of column head machining devices. The distributing device is characterized by comprising positioning devices(2) and a conveying device, wherein at least two positioning devices (2) are arranged along the conveying device, the conveying device is provided with a containing part used for containing workpieces (4), and the positioning devices (2) are provided with positioning parts used for positioning the workpieces (4). According to the distributing device, at least two positioning devices are arrangedalong the conveying device so that the workpieces can be distributed for at least two production lines at the same time; the positioning devices position the conveyed workpieces through the positioning parts so that manipulators can accurately clamp the workpieces, and then accurate feeding of the manipulators is achieved; and the manipulators only need to transfer the workpieces on the corresponding positioning devices to corresponding machine tools, so that the actions of the manipulators are reduced, the mutual interference among the manipulators is avoided, and accurate and stable feedingof the manipulators is ensured.

Owner:SHANDONG HANYE MACHINERY CO LTD +1

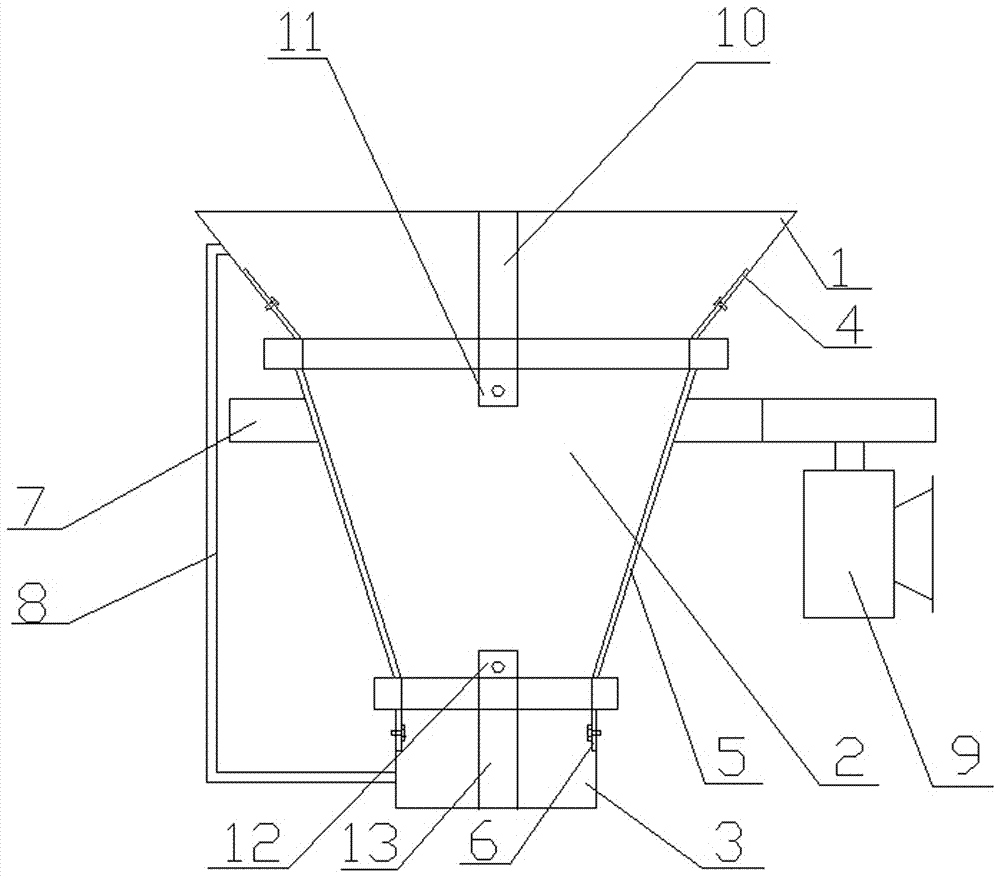

Pile-turning and bin-transferring device for multi-connected dynamic tunnel type fermentation bin

PendingCN111548211ASmall footprintImprove closureBio-organic fraction processingOrganic fertiliser preparationAgricultural engineeringEngineering

The invention discloses a pile-turning and bin-transferring device for a multi-connected dynamic tunnel type fermentation bin. The pile-turning and bin-transferring device comprises a pile-turning machine and a bin-transferring machine; the bin-transferring machine walking on an overhead rail carries the pile-turning machine to reach the tail of the dynamic tunnel type fermentation bin; the walking tread of the pile-turning machine is aligned with a corbel beam; the pile-turning machine walks into the dynamic tunnel type fermentation bin, and meanwhile, the pile-turning machine drives the mudblocking mechanism of the bin-transferring machine to reach a bin opening to form a shielding state; a roller pile-turning mechanism is laid down, and starts to perform pile turning and moves to the head of the dynamic tunnel type fermentation bin; materials are crushed under the action of the roller pile-turning mechanism and move towards the tail of the bin; after the pile-turning machine reaches the head of the bin, the roller pile-turning mechanism is lifted, the pile-turning machine runs towards the tail of the bin, leaves the bin and runs on the bin-transferring machine, meanwhile, the drives the mud blocking mechanism of the bin-transferring machine to return to the bin-transferring machine; the bin transferring machine loads the pile-turning machine to run towards the next dynamictunnel type fermentation bin, and one pile turning and bin transferring process is completed.

Owner:BEIJING BRANCH JIKE DEV SCI & TECH

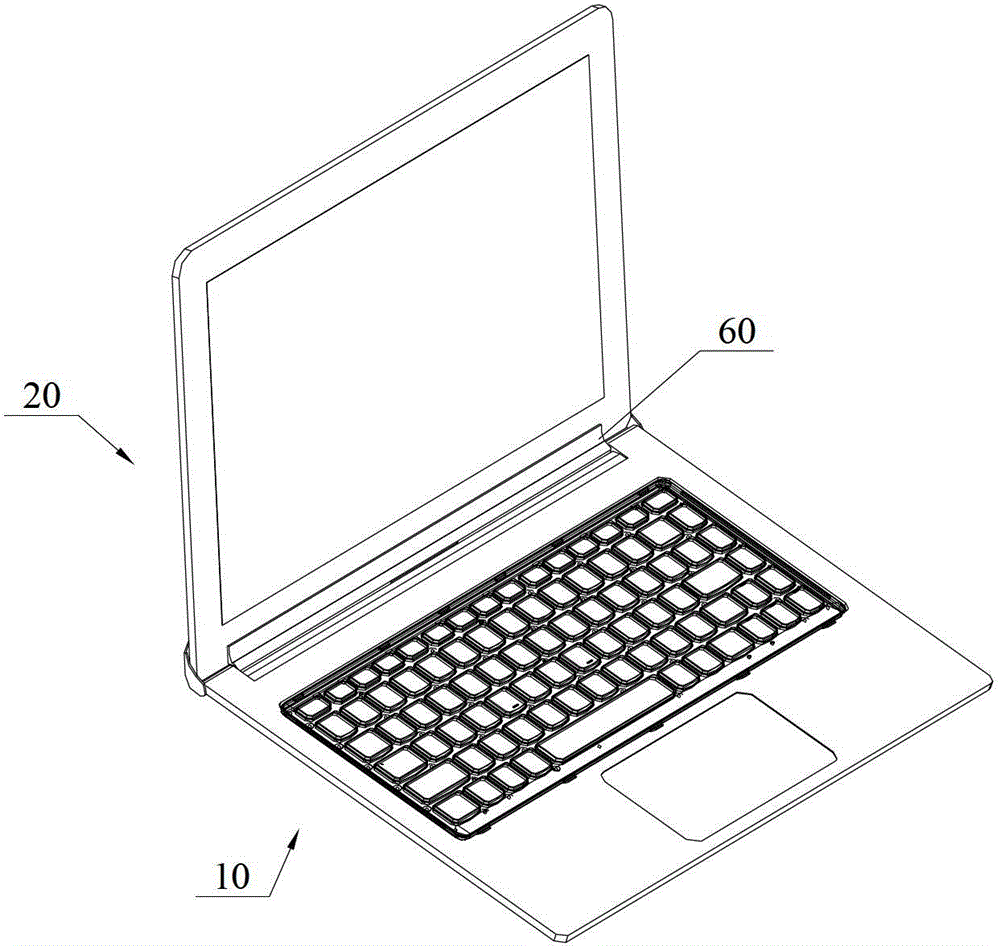

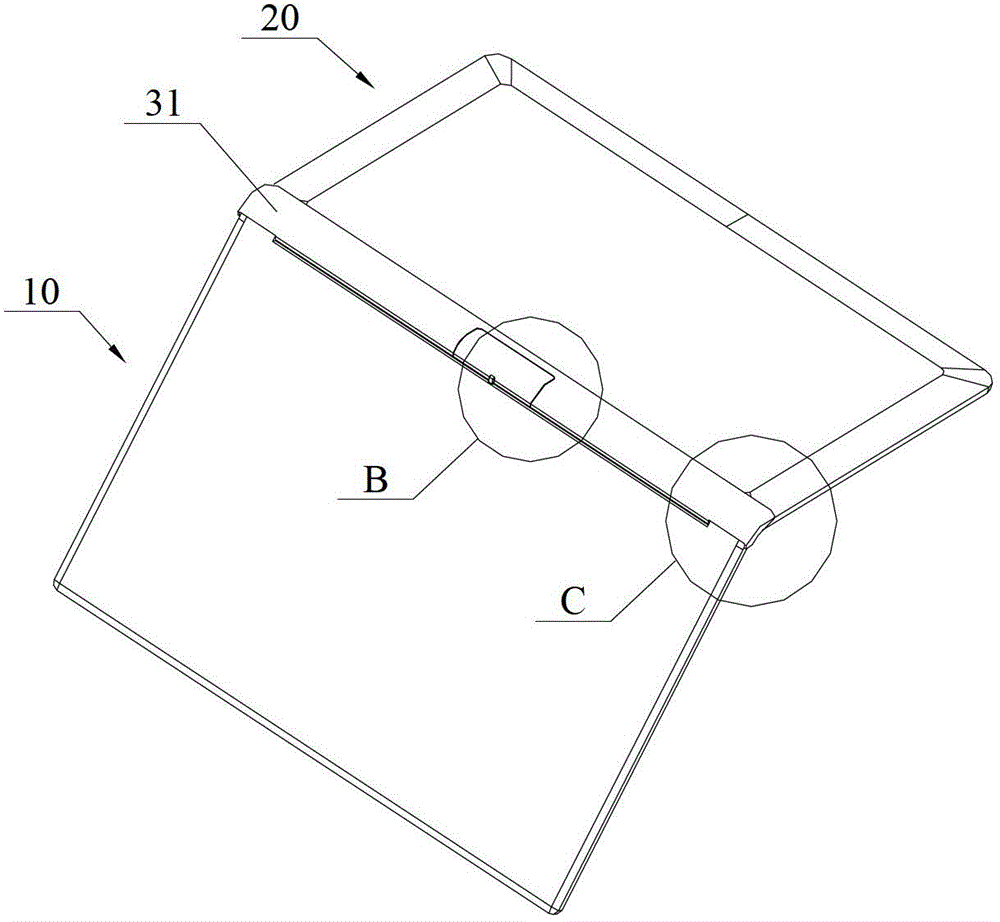

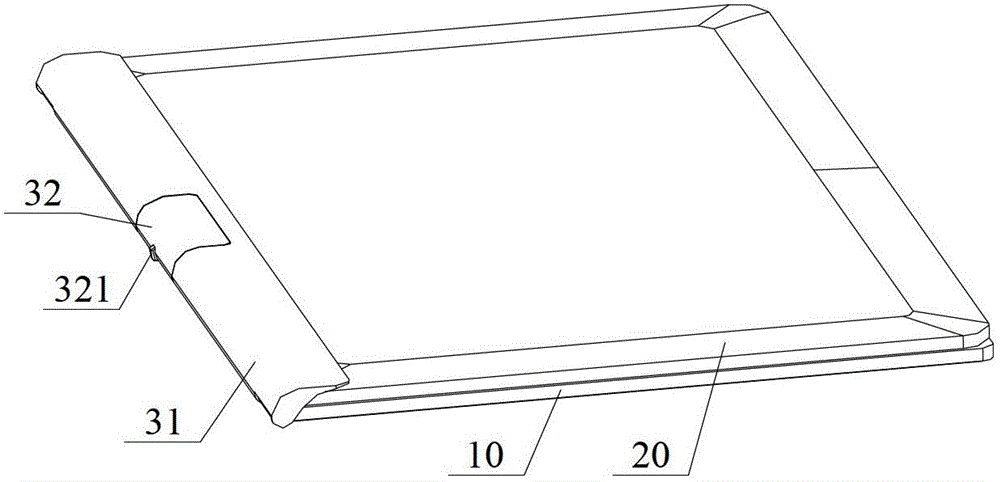

Electronic equipment and docking station

ActiveCN104035482AReasonable structural designImprove operational reliabilityDigital data processing detailsDocking stationElectric equipment

The invention discloses electronic equipment and a docking station used for flat electronic equipments. A first body is detachably connected with a second body through a connecting mechanism, a first connecting piece of the connecting mechanism is hinged to the first body, a plug-in mounting part is arranged between the first connecting piece and the hinged side of the first body, and a second connecting piece of the connecting mechanism is hinged to the first connecting piece and is capable of switching between an unlocking work position and a locking work position in a rotating mode relative to the first connecting piece; the connected second body is plugged in the plug-in mounting part, and the second connecting piece at the locking work position is fixed with the second body in a fit clamping mode; the second connecting piece is provided with an unlocking bump, the unlocking bump synchronously rotates to arrive at a preset opening / closing angle along with the second body, the first connecting piece and the second connecting piece, the unlocking bump is propped against the first body to form a torque for enabling the second connecting piece to rotate to the unlocking working position, and the second connecting piece at the unlocking work position is separated from the second body.

Owner:LENOVO (BEIJING) CO LTD

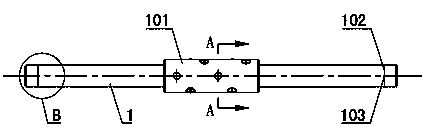

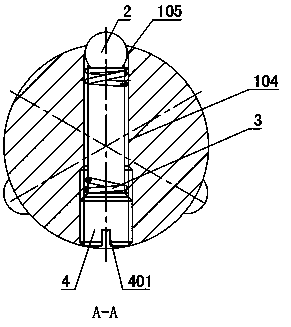

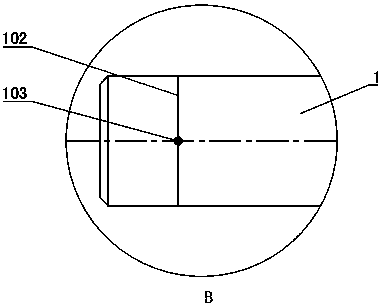

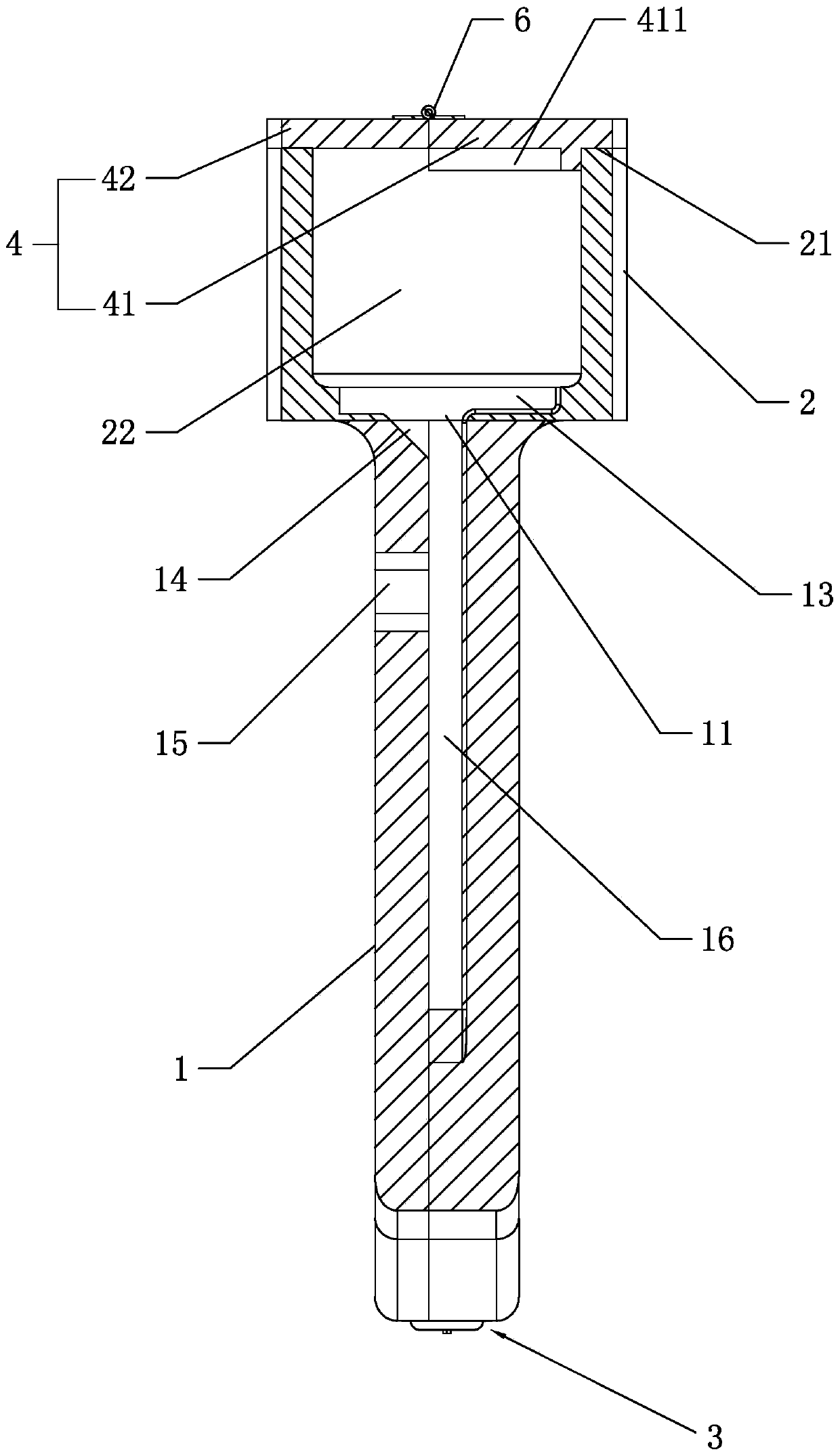

Multifunctional steel plate spring detection mandrel

The invention provides a multifunctional steel plate spring detection mandrel, and belongs to the technical field of steel plate spring detection equipment. The multifunctional steel plate spring detection mandrel is characterized by comprising a mandrel main body (1), a middle diameter of the mandrel main body (1) is greater than the diameters of both ends, a detection portion (101) is formed, atleast three radial mounting holes (104) are uniformly distributed around the detection portion (101) at intervals, a steel ball (2) is slidably installed at one end of each mounting hole (104), a spring (3) for pushing a steel ball to move outward is further arranged in each mounting hole (104), an outer side of the steel ball (2) is arranged to protrude from the detection portion (101), and oneend of the mounting hole (104) close to the steel ball (2) is provided with a limiting portion (105) having a diameter smaller than the diameter of the steel ball (2). The multifunctional steel platespring detection mandrel can detect lifting lugs of steel plate springs of various model numbers, the stress is uniform, after the lifting lugs of the steel plate springs are installed, the detectionmandrel is uniformly stressed and does not become loose, and the detection is accurate.

Owner:SHANDONG BEIQI HAIHUA AUTOMOBILE PARTS CORP LTD

A scraper-type rotary hopper device

Owner:PUYANG CITY HONGYU PRESSURE VESSEL

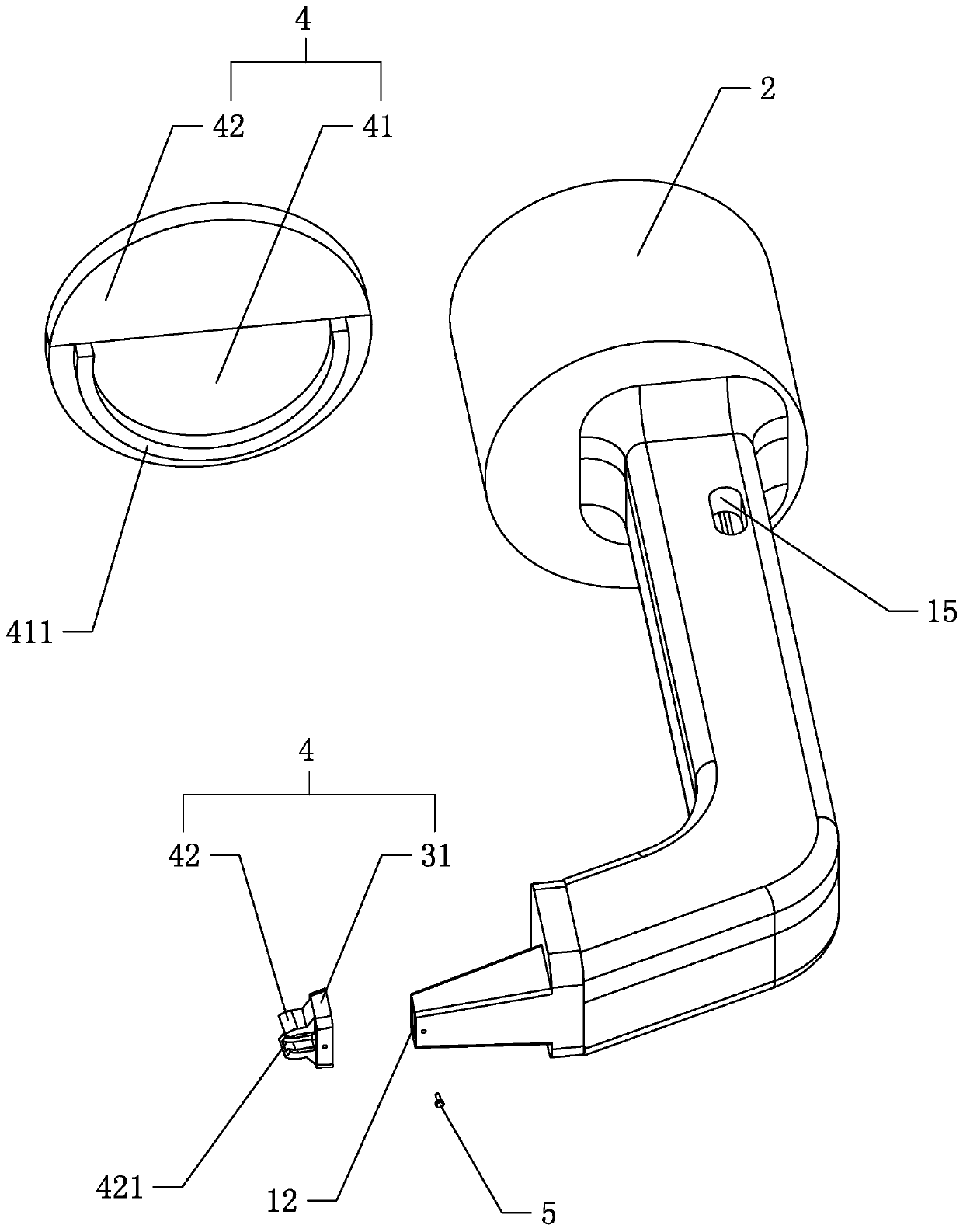

A device for adjusting the angle of led lights

Owner:YANYANG LAMP SET TIANCHANG CITY

Multipicture covering method and mobile hanging advertisement machine for implementing said method

InactiveCN1165025CSimple processing technologyReduce manufacturing costIdentification meansEngineeringStructural engineering

Owner:席延勃 +2

High voltage changeable resistor

InactiveCN1212624CAvoid mutual obstructionResistor terminals/electrodesResisitors with sliding contactMetal moldHigh voltage

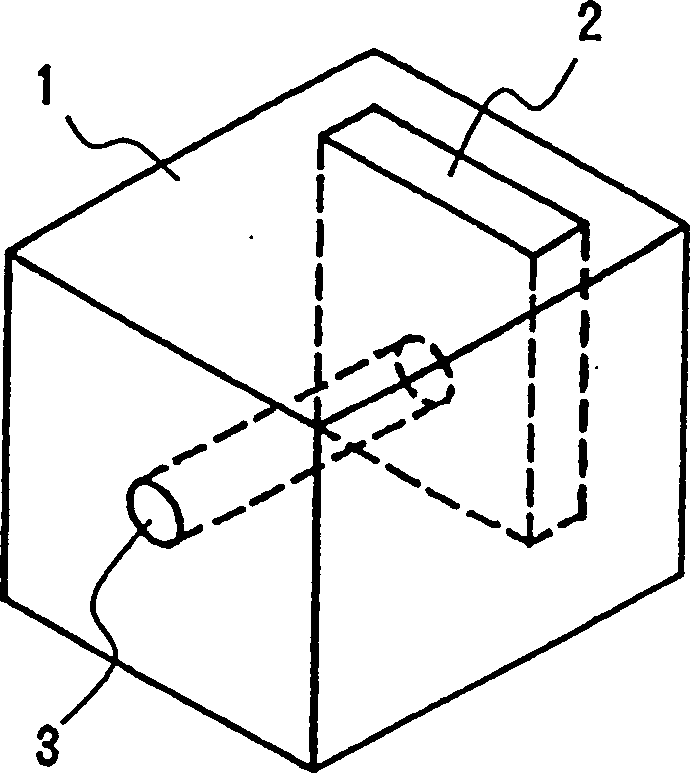

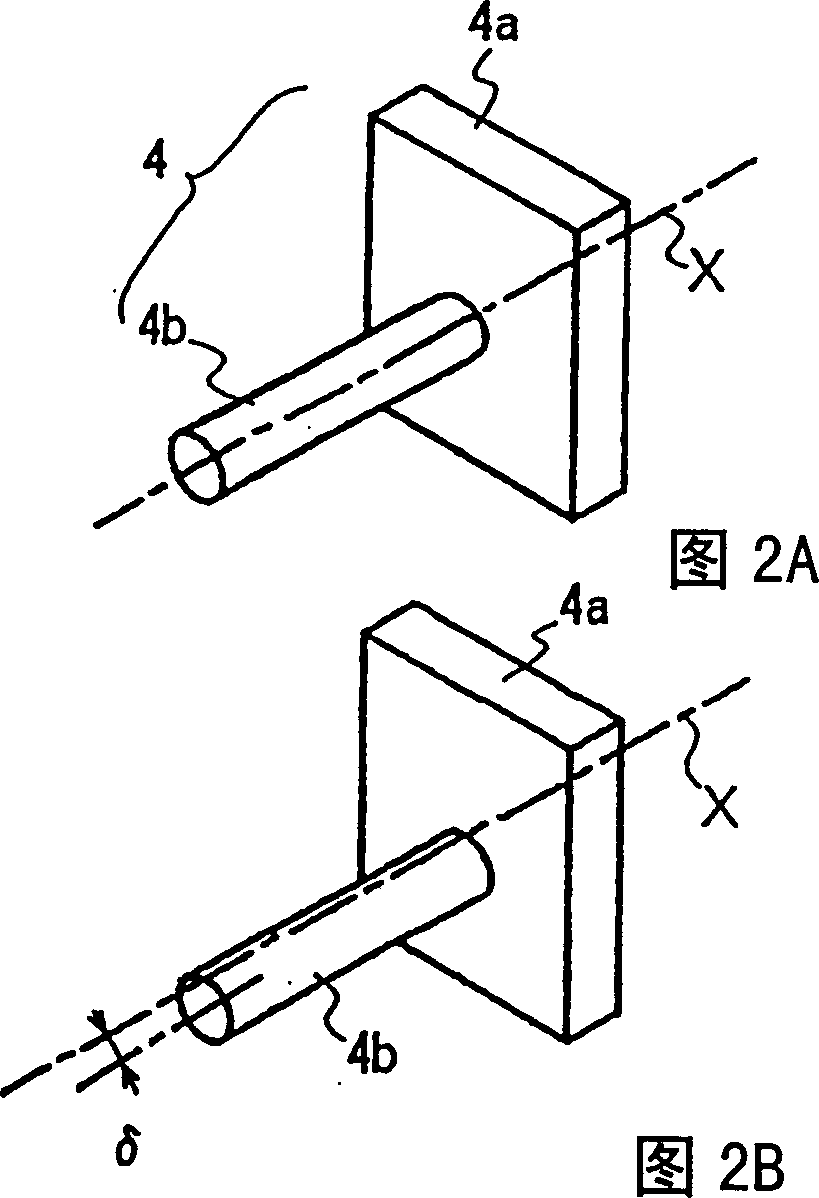

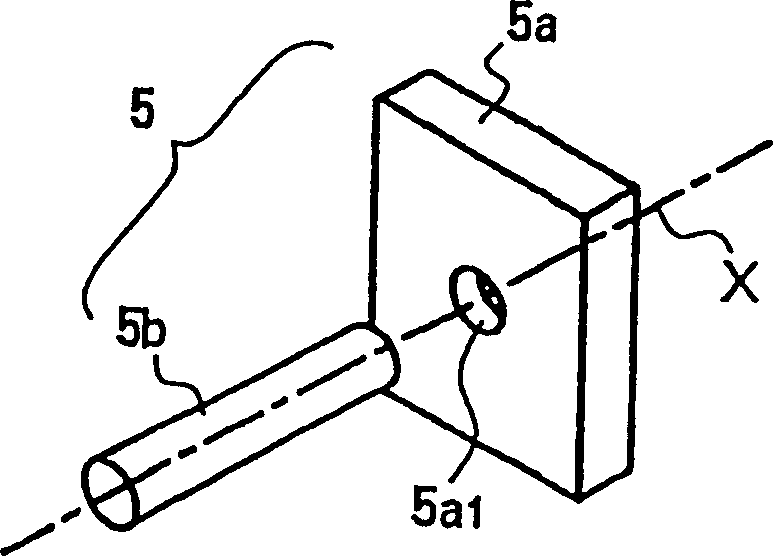

A high-voltage variable resistor includes a circuit section contained in an insulating casing, a snap-in terminal inserted in a terminal base portion of the casing and connected to an output portion of the circuit section, and an output connecting electrode inserted in the terminal base portion from a direction orthogonal to the snap-in terminal and press-fitted in and connected to the snap-in terminal. The terminal base portion of the casing has an insertion groove for guiding and inserting the snap-in terminal, an insertion hole for guiding and inserting the output connecting electrode, and a relief groove formed on a side face of the insertion groove intersecting the insertion hole. The insertion groove, the insertion hole, and the relief groove are simultaneously formed by a metal mold of the structure to be pierced.

Owner:MURATA MFG CO LTD

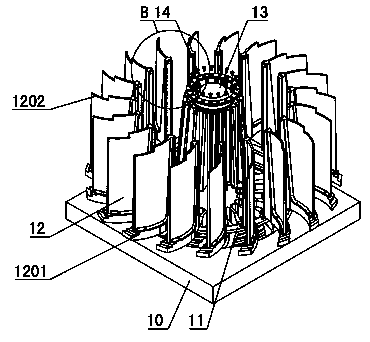

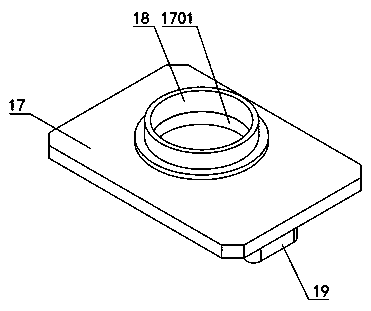

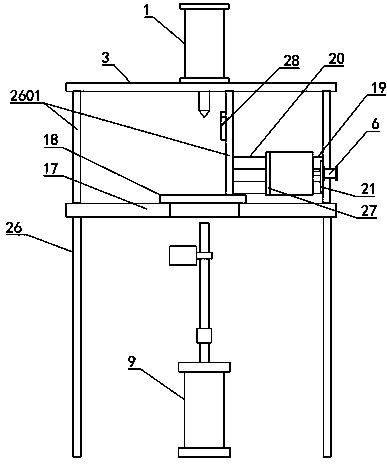

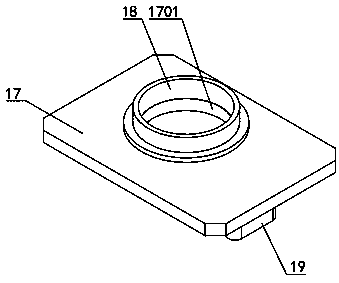

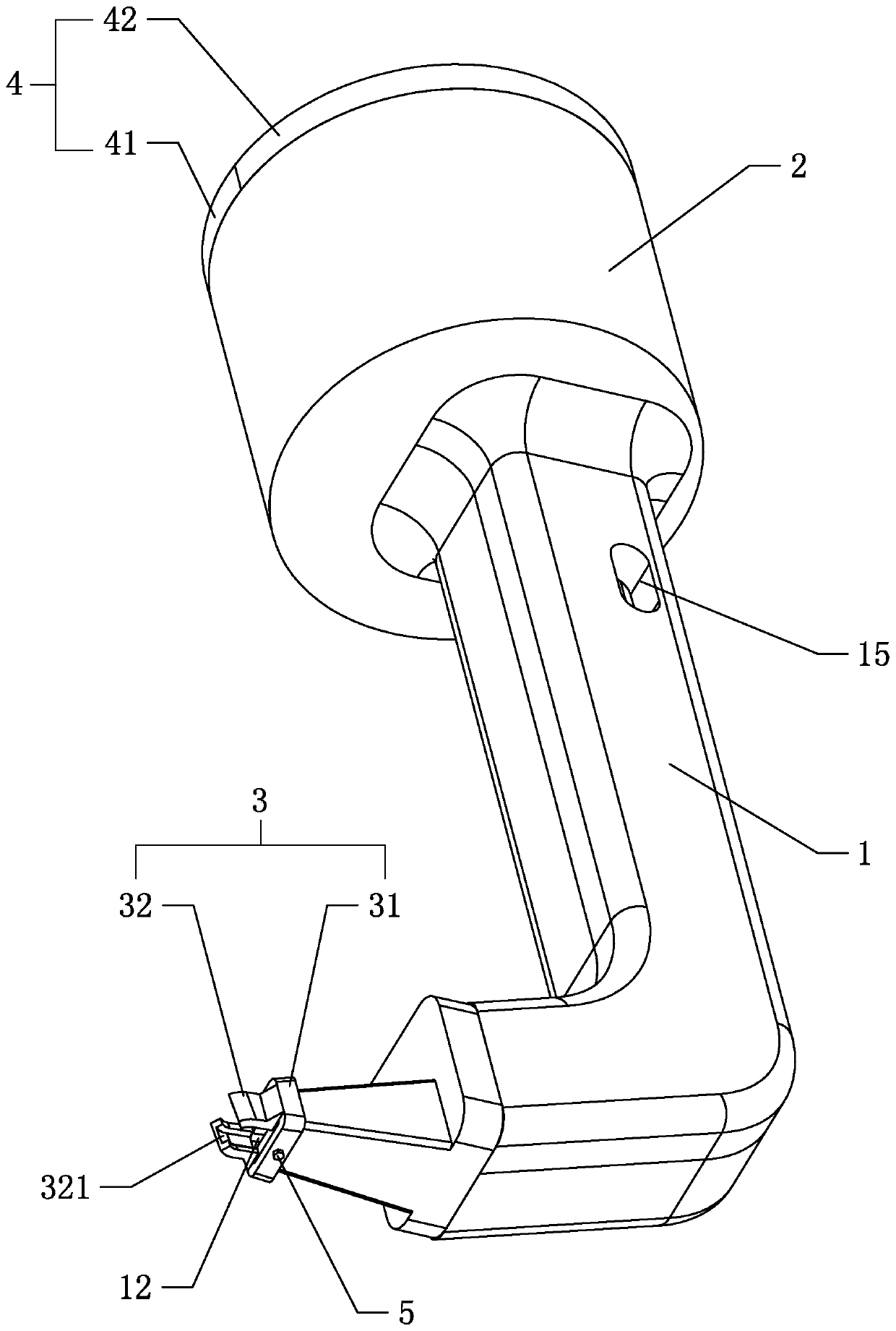

Full-automatic coconut peeling device

The invention provides a full-automatic coconut peeling device, and belongs to the technical field of coconut peeling equipment. The full-automatic coconut peeling device is characterized in that a horizontally arranged mounting beam (3) is arranged at the top of a machine frame (26), wherein a horizontally arranged bearing plate (17) is arranged in the middle of the machine frame (26); a vertically formed receding through hole (1701) is formed in the bearing plate (17); a cutting device is arranged on the machine frame (26) between the mounting beam (3) and the bearing plate (17); a clampingdevice comprises a loading device of which the output end is arranged upwards and a pressing device of which the output end is arranged downwards; a space for accommodating coconuts is formed betweenthe pressing device and the loading device; and a power device for driving the output end of the loading device to rotate is arranged at the output end of the loading device. According to the full-automatic coconut peeling device disclosed by the invention, automatic cutting is realized, the cutting speed is high, the labor intensity of workers is greatly reduced, potential safety hazards are eliminated, the situation that the cut coconuts are artistic in shape is guaranteed, cutting is accurate, the coconuts cannot be damaged, and the situation that coconut peels are removed can also be guaranteed.

Owner:淄博天型食品机械有限公司

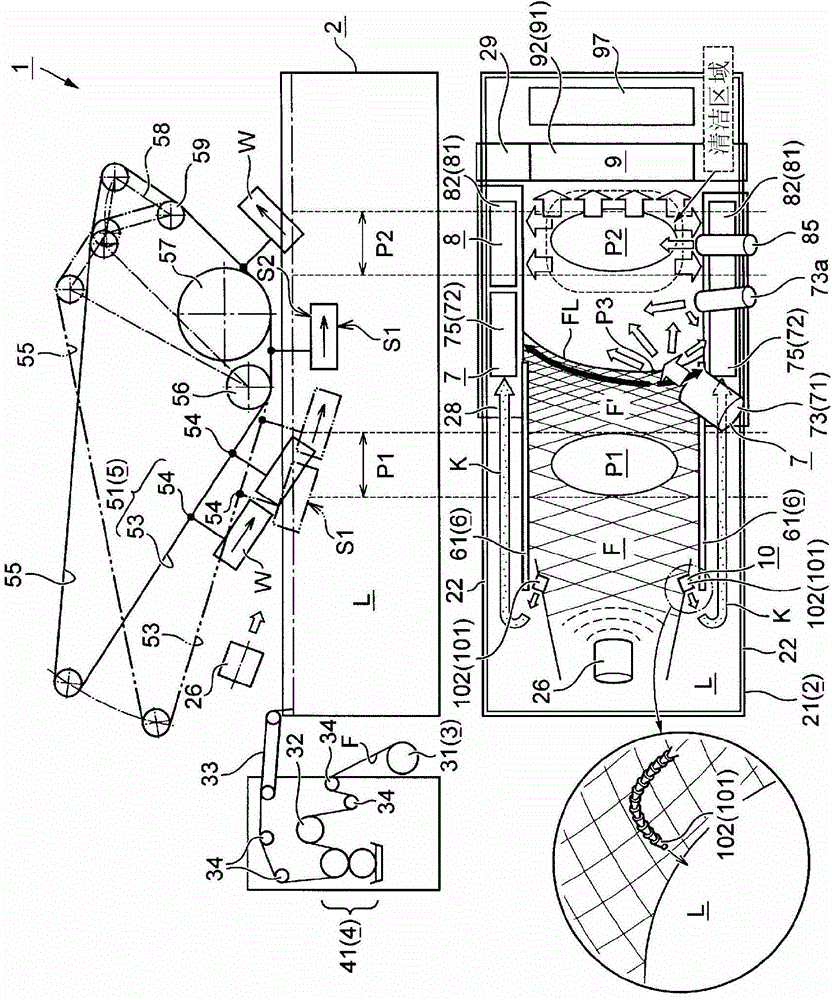

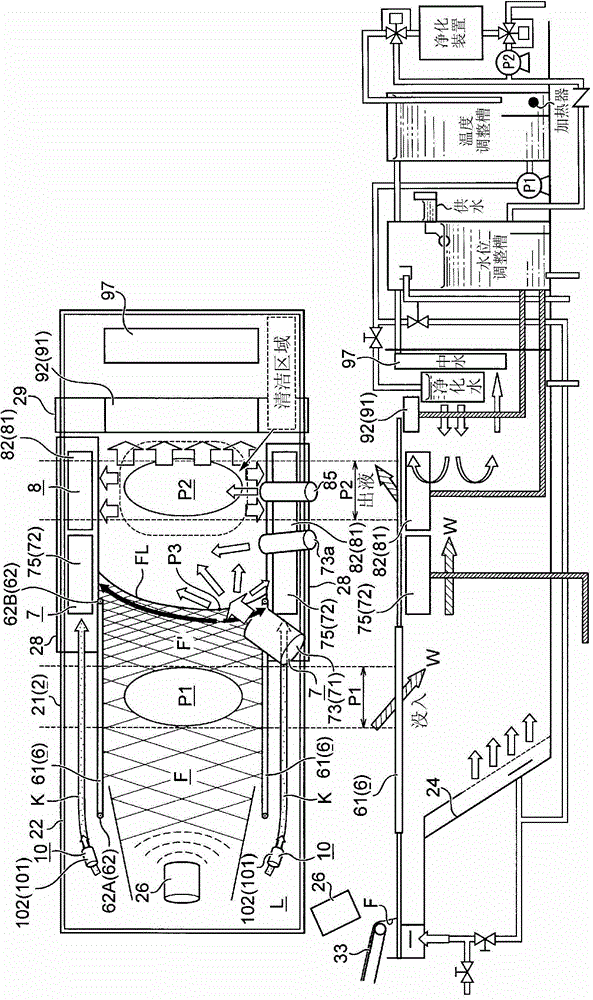

Hydraulic transfer printing method with appearance surface purification mechanism and hydraulic transfer printing device

InactiveCN103260898BEfficient recyclingNot easy to precipitateTransfer printingDecorative surface effectsSurface cleaningEngineering

It is an object to develop a novel liquid pressure transferring technique for not allowing film residuals, foam, and the like on a transfer liquid surface to approach a design surface of an object floating up from the transfer liquid with a relatively simple structure. The present invention relates to a liquid pressure transferring technique for forming an appropriate transfer pattern on the surface of an object by pressing the object from the upper side of a transfer tank, in a liquid-leaving area in which the object is pulled up from the transfer liquid in the transfer tank, a design surface oppositely-separating flow that is separated away from a design surface of the object that is in the process of getting out of a liquid is formed by using the design surface cleaning device such as an overflow tank, and foam on a surface of the transfer liquid and foreign substances staying in the liquid are separated away from the design surface of the object that is in the process of getting out of the liquid and are discharged outside the transfer tank.

Owner:TAICA

a socket

ActiveCN103915706BImprove securityAvoid direct contactCouplings bases/casesLive contact access preventionConvertersWireless internet access

Owner:钟浩凯

Mixed material 3D printing device and method for building components

ActiveCN109079955BRealize simultaneous 3D printingFully automatedAdditive manufacturing apparatusCeramic shaping apparatus3d printComputer printing

Owner:SHANGHAI CONSTRUCTION GROUP

Corrugator

ActiveCN112566777AReliable functionTrouble-free deliveryMechanical working/deformationWebs handlingPolymer scienceEngineering

The invention relates to a corrugator which has a corrugated-fiberboard production assembly (1) having at least one device (5) for producing at least one corrugated fiberboard web (6) laminated on oneside and having a joining device for producing a corrugated fiberboard web laminated on both sides, which comprises the at least one corrugated fiberboard web (6) laminated on one side. The corrugator also has a print-web / laminating-web production assembly (2), which comprises: a printing device (58) for printing on a print web (4); a print-web storage device (66); and a laminating-web unrollingdevice (70) for unrolling a laminating web (40). Furthermore, the corrugator has a coupling / uncoupling assembly (76) having a coupling device for coupling the printing device (58) to the corrugated-fiberboard production assembly (1), while the print web (4) is used as a laminating web in the corrugated-fiberboard production assembly (1), and / or having an uncoupling device for uncoupling the printing device (58) from the corrugated-fiberboard production assembly (1), while the laminating web (40) is used in the corrugated-fiberboard production assembly (1).

Owner:BHS CORRUGATED MASCHEN & ANLAGENBAU

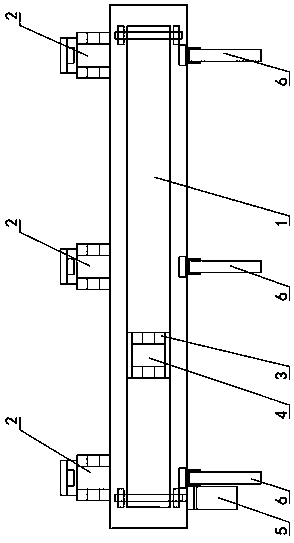

Auxiliary mounting tool for shaft sleeve ring and method for mounting shaft sleeve ring

InactiveCN111230437ANo falling phenomenonAvoid secondary cleaningMetal working apparatusEngineeringMechanical engineering

The invention relates to an auxiliary mounting tool for a shaft sleeve ring. The auxiliary mounting tool comprises an L-shaped pipe body convenient to handhold, a rail for allowing a ring body to passat a time is arranged in the pipe body, and a feeding port and a discharging port communicating with the rail are formed in the two ends of the pipe body correspondingly. A container which communicates with the rail and is used for storing the ring body is arranged on the feeding port, the side, away from the feeding port, of the container is open, and a clamping part which is elastic and is usedfor clamping the single ring body is arranged at one end of the discharging port. The auxiliary mounting tool has the effect that the shaft sleeve ring can be mounted on a shaft fast.

Owner:邱建忠

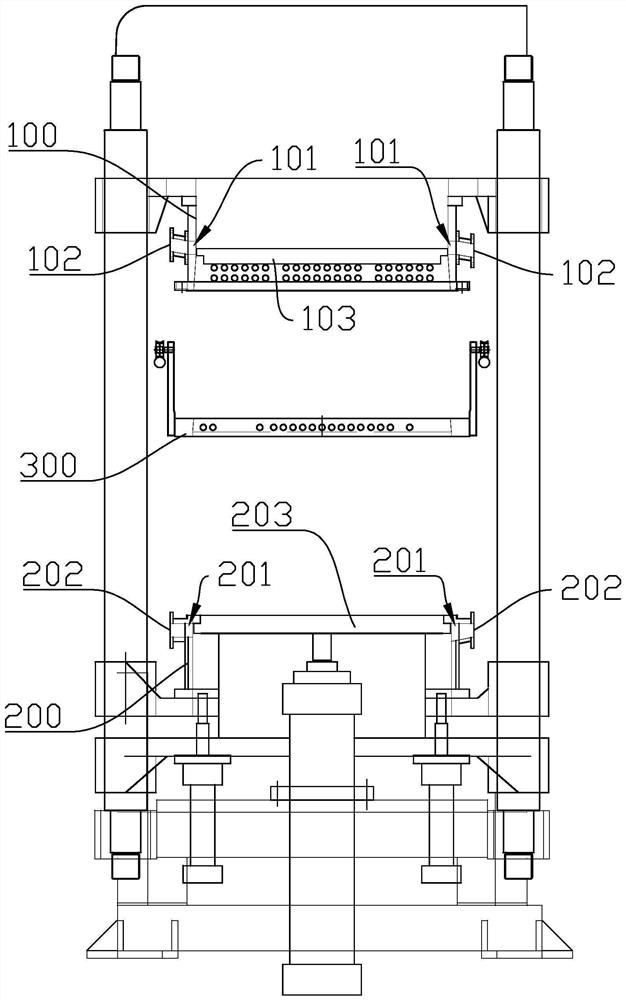

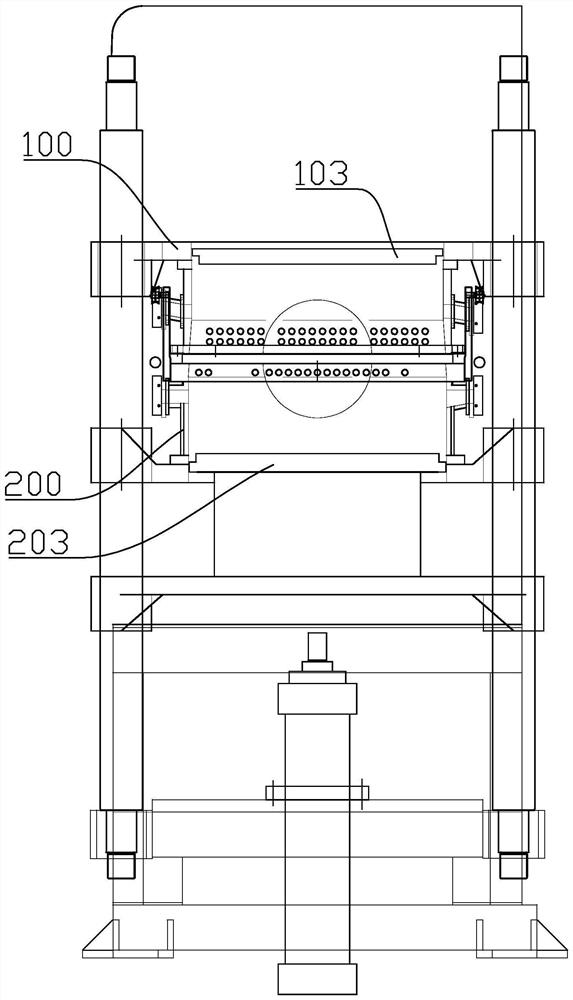

Molding machine

PendingCN114367640AImprove sand production efficiencyAvoid mutual obstructionMoulding machinesMoulding flasksMolding machineMechanical engineering

The molding machine comprises an upper sand box and a lower sand box, upper sand outlets are formed in the opposite side walls of the upper sand box correspondingly, and the sand outlet directions of the upper sand outlets located in the two opposite sides are staggered; lower sand outlets are formed in the opposite side walls of the lower sand box correspondingly, and the sand outlet directions of the lower sand outlets located in the two opposite sides are staggered. The sand outlet efficiency is improved, meanwhile, convection of shot sand can be avoided, mutual interference among multiple strands of shot sand is avoided, and the sand box can be filled with the discharged sand. The method can be widely applied to the technical field of casting.

Owner:广东中铸智能装备有限公司

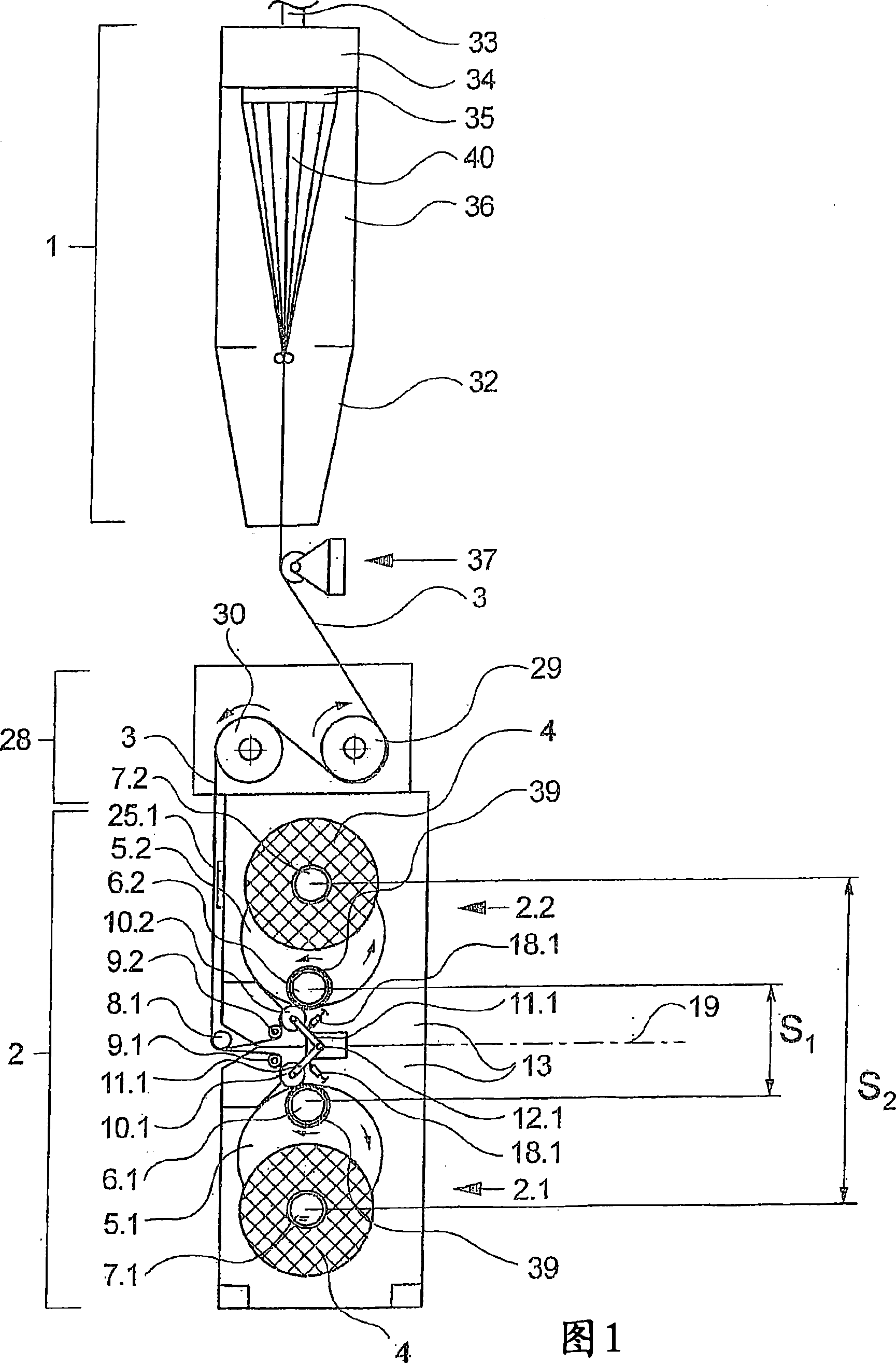

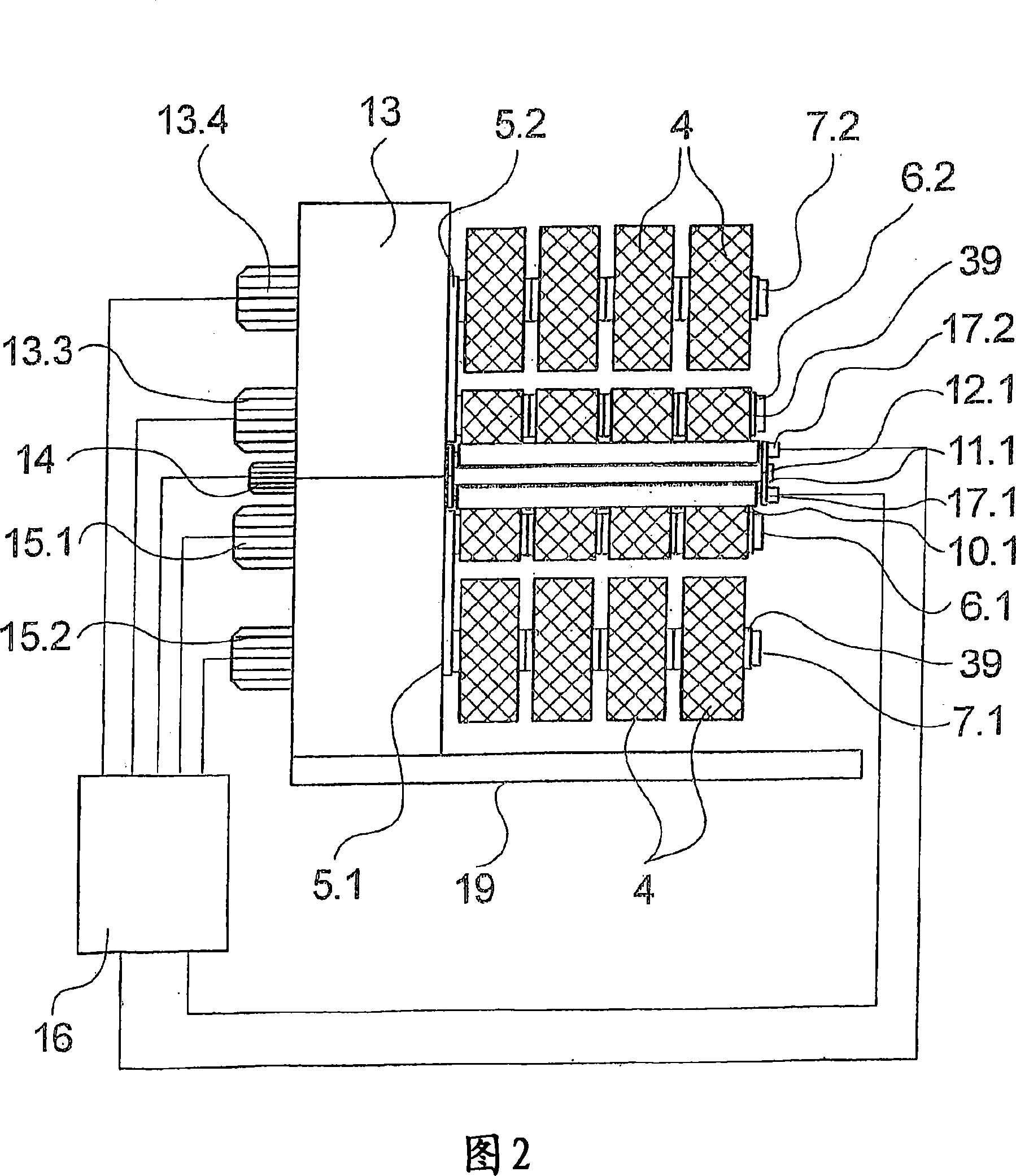

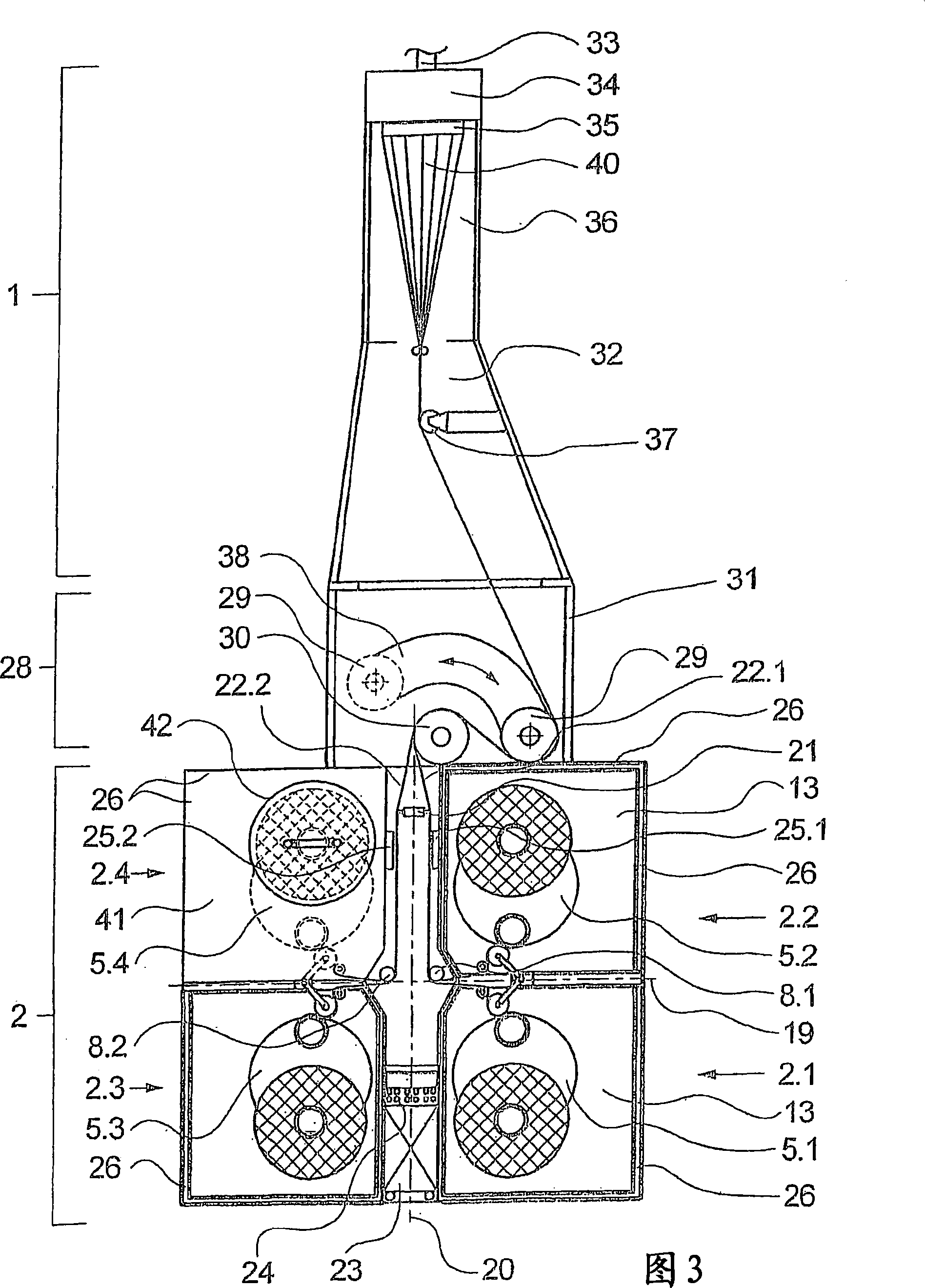

Apparatus for spinning and winding several synthetic threads

InactiveCN1957120BAvoid mutual obstructionUniform entry featureNew-spun product collectionFilament handlingBobbinEngineering

The invention relates to an apparatus for spinning and winding several synthetic threads. Said apparatus comprises a spinning device and a group of several winding units, which is located below the spinning device. Each of said winding devices is provided with a rotatably mounted winding revolver encompassing two saliently mounted winding spindles on which the threads are alternately wound so as to obtain bobbins. In order to do so, the winding spindles are alternately guided into an operating zone and a changing zone by the winding revolver. At least two winding units are disposed in a mirror-inverted manner. In order to be able to keep the separation width as narrow as possible by means of the group of winding units, the two winding units are arranged on top of each other such that the distance between the winding spindles retained in the operating zone is smaller than the distance between the winding spindles retained in the changing zone, thus allowing the threads to be advantageously separated from the plane of symmetry to the individual winding units.

Owner:SAURER GMBH & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com