Broken shot blasting shot sorting device

A kind of sorting device and shot technology, which is applied to the used abrasive processing device, grading, solid separation, etc. It can solve the problems of no longer smooth surface, affecting the accuracy and quality of shot blasting, and damage, so as to improve the classification Picking accuracy, high-efficiency distinction, avoiding the effect of mutual obstruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

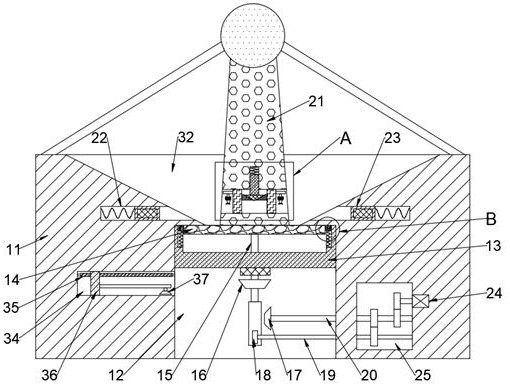

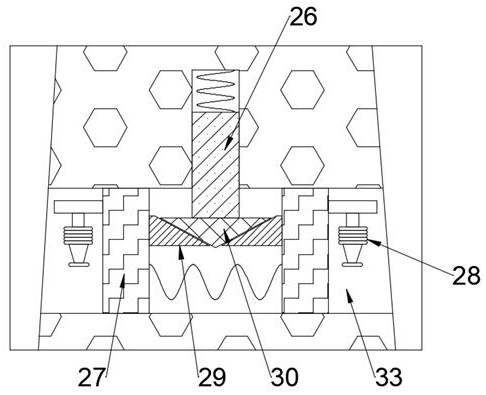

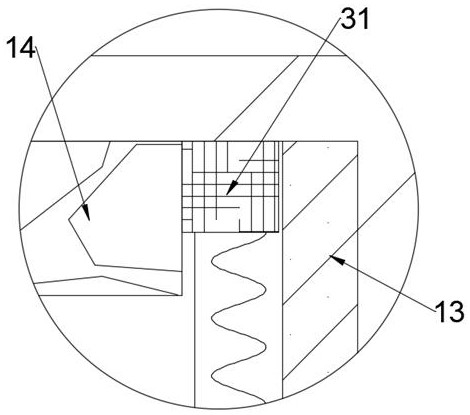

[0019] Combine below Figure 1-4 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0020] A shot blasting pellet damage sorting device described in conjunction with accompanying drawings 1-4 includes a body 11, a centrifugal space 12 is provided inside the body 11, and an outer centrifugal disc 13 is provided slidingly between the inner walls of the centrifugal space 12 , the outer centrifugal disc 13 can rotate in the centrifugal space 12, the inner centrifugal disc 14 is slid in the cavity in the centrifugal space 12, and the upper side of the inner centrifugal disc 14 is provided with a ring-shaped shallow concave Slot, the left and right side walls of the inner cavity of the outer centrifugal disc 13 are provided with chute, each of the chute of the inner cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com