Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

283results about How to "Avoid direct rays" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automatic control method, device and system for sun shield

InactiveCN105818650ASolve the problem of manually adjusting the sun visorGuaranteed visionAntiglare equipmentAutomatic controlDriver/operator

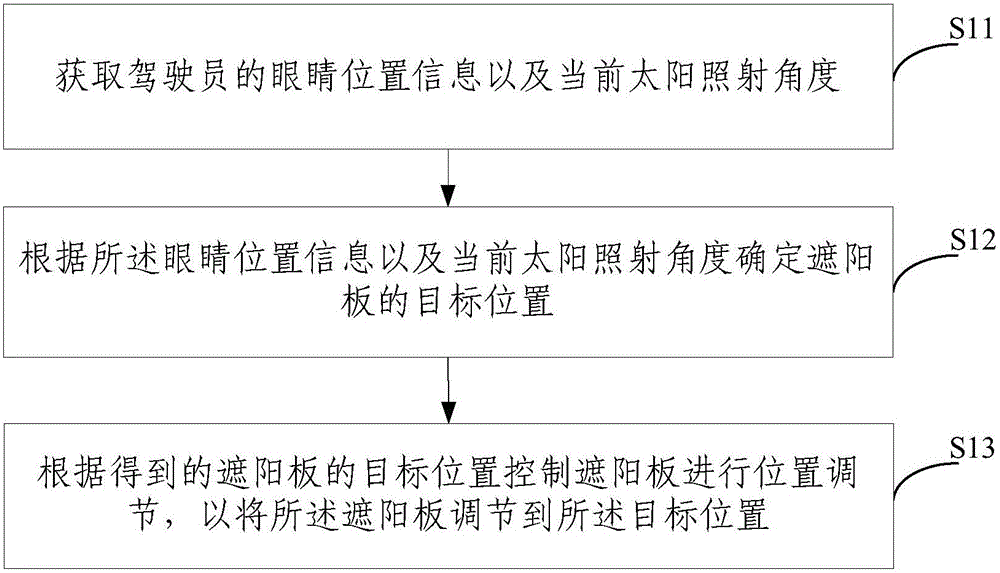

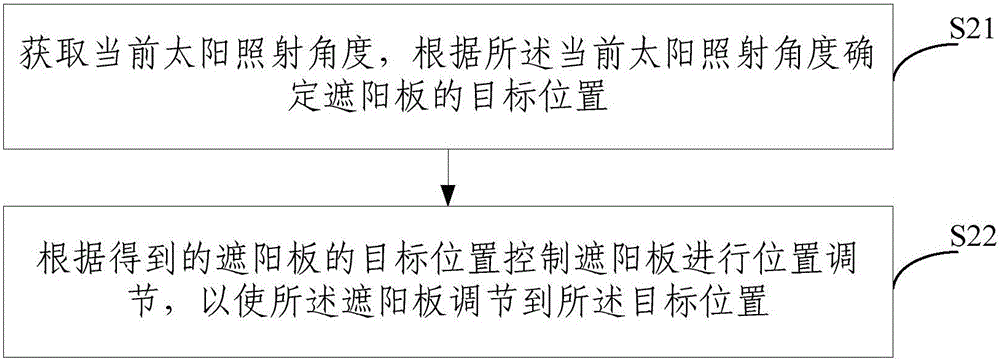

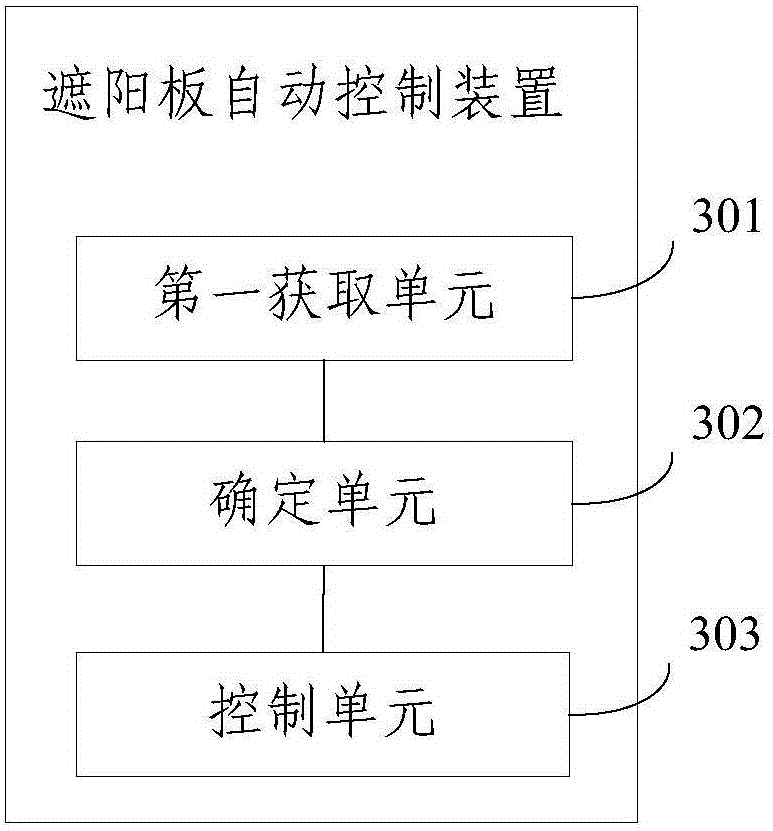

The invention provides an automatic control method, device and system for a sun shield. The automatic control method for the sun shield includes the steps that eye position information of a driver and the current sun irradiation angle are obtained; the target position of the sun shield is determined according to the eye position information and the current sun irradiation angle; and the position of the sun shield is controlled to be adjusted according to the obtained target position of the sun shield, so that the sun shield is adjusted to the target position. By the adoption of the method, device and system, the irradiation angle of the sun is analyzed, so that the position of the sun shield of an automobile is controlled to be automatically adjusted, the eyes of the driver are prevented from being directly irradiated by the sunlight, meanwhile, the maximum view of the driver is kept, and the user experience is improved.

Owner:LEAUTO INTELLIGENT TECH (BEIJING) CO LTD

Method for cultivating dendrobe

InactiveCN1748455AGuaranteed healthy growthPromote reproductionHorticulture methodsLiving treeNutrient solution

The dendrobe cultivating method is to fix live dendrobe on plant of live tree stem and bamboo or stump with bark, irrigate, apply nutritious liquid and provide shady and cool environment for dendrobe to grow. The said method provides moist growth environment, reduce disease and ensure healthy growth of dendrobe. In addition, the present invention can utilize space fully to lower the dendrobe cultivating cost.

Owner:刘俊

Method for winter protection of trees by utilizing aluminum plating reflective membrane

InactiveCN101584290AMitigates drastic changes in local temperatureLocal temperature drastic changes can be adjustedPlant protective coveringsFrost crackYoung tree

The invention relates to a method for winter protection of trees by utilizing an aluminum plating reflective membrane. For the winter protection of gardening shrubs such as highbush blueberries and the like and arbor young trees, the aluminum plating reflective membrane used as a winter protection material is made into a tubular bag with proper length; during end-autumn and early-winter, tubular bags are sleeved outside tree bodies of which branches are bound into fasciculation by nylon cords in advance, and then are tightly bounded and sealed; for the winter protection of shrub-like trees such as lowbush blueberries and the like, vine plants such as grape vines and the like, and nursery-grown plants, the aluminum plating reflective membranes are directly covered above the plants, the planted row and a seed bed with necessary winter protection, of which branches are bound in advance, and the aluminum plating reflective membranes are compacted around by soil; and for the prevention of frost crack of trunks of planting tree species, the aluminum plating reflective membrane covers 1 to 2m from the bottom of the trunk. The method has the advantages that: 1, damage to trees caused by overhigh local temperature and overlarge temperature difference between day and night of the trunk due to direct solar irradiation to the day side of the tree is avoided; and 2, the bag covering mode has the effects of heat insulation and moisture resistance, and the method is low in cost and can be easily operated.

Owner:DALIAN UNIV +1

Adaptive curtain for living room

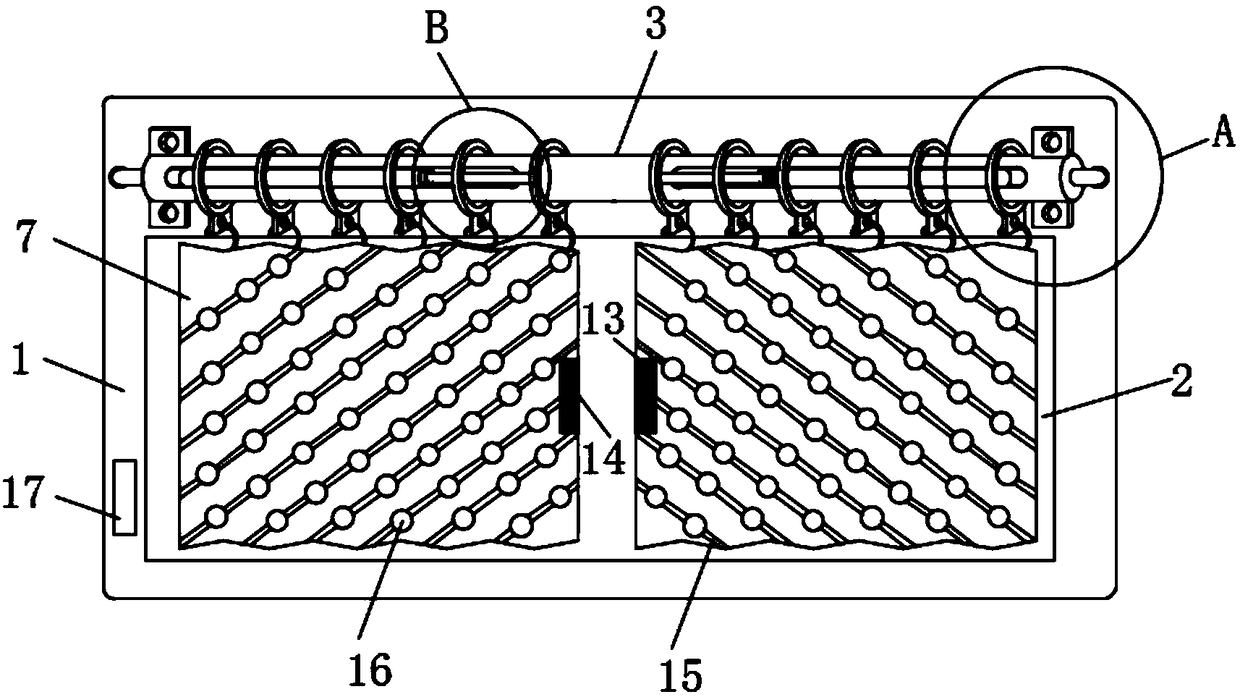

InactiveCN109090975AAvoid direct raysAdaptableBatteries circuit arrangementsElectric powerLiving roomLight beam

The invention discloses an adaptive curtain for a living room. The curtain includes a window frame installed on a wall, a sliding rod is arranged on the inner wall body of the wall, two fixing platesare welded to the outer walls of the two ends of the sliding rod respectively, threaded ports are formed in the two fixing plates respectively, multiple sliding rings slide on the outer wall of the sliding rod, the lower side walls of the sliding rings are fixedly connected with connecting plates respectively, and a hanging port is formed in each connecting plate. The curtain has the advantages that when external sunlight gets stronger in summer and the temperature rises, the volume of gas in gasbags is increased, correspondingly pistons and connecting rods are driven to move, the sliding rings thus drive curtain bodies to move oppositely and be unfolded, and therefore light beams cast into the living room is weakened. Meanwhile, based on the characteristic that an EVA resin material is softened and extends when heated under the sunlight, foam bodies extend to further weaken the cast light beams; after the sunlight is weakened, the gasbags, the curtain bodies and the foam bodies recover to the original states, and the curtain is high in self-adaptability and can adaptively change according to the intensity of the sunlight.

Owner:喻正江

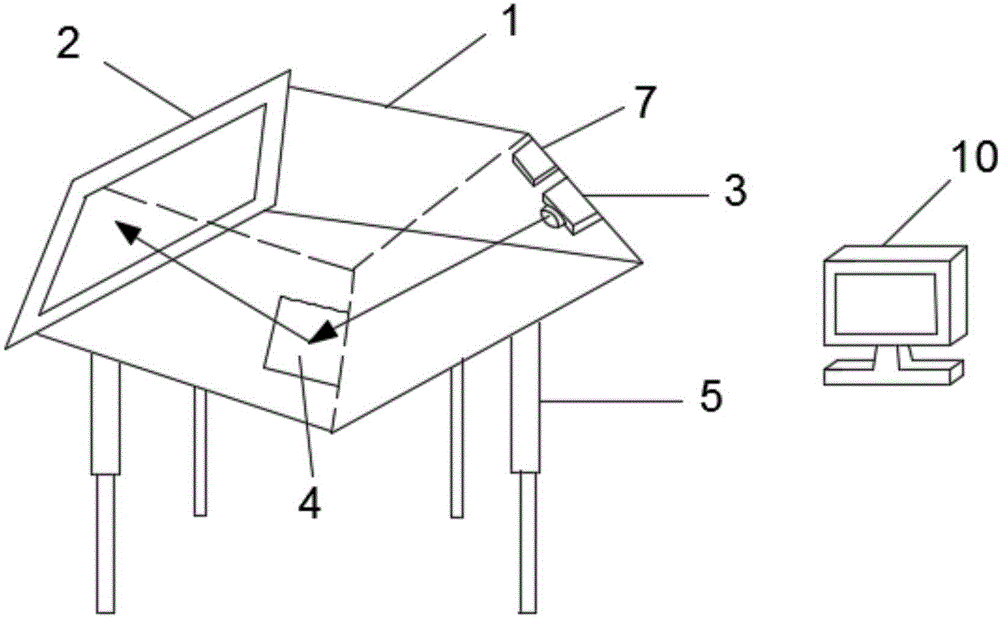

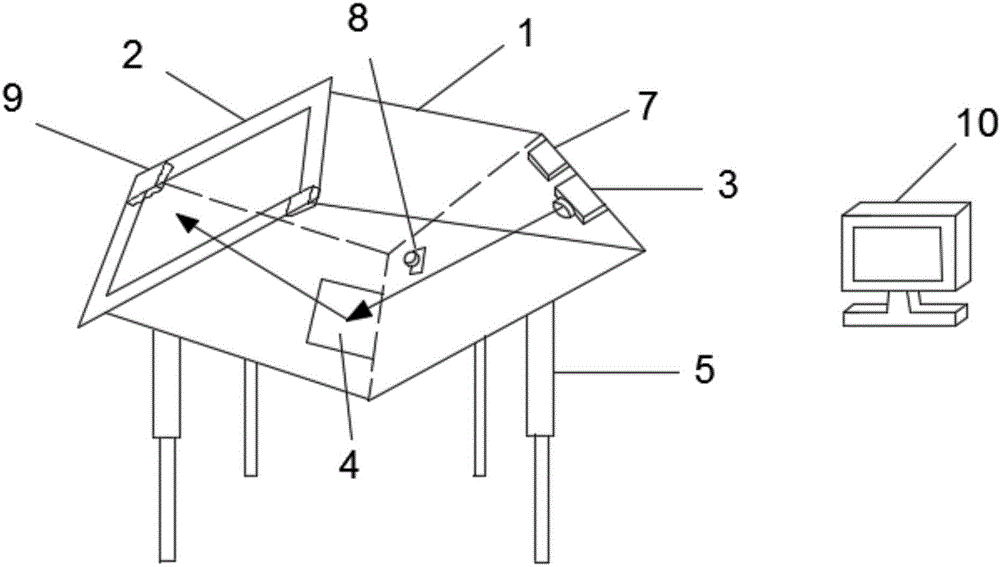

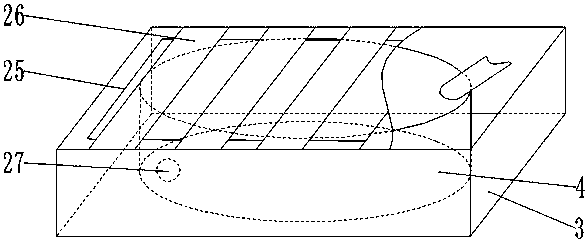

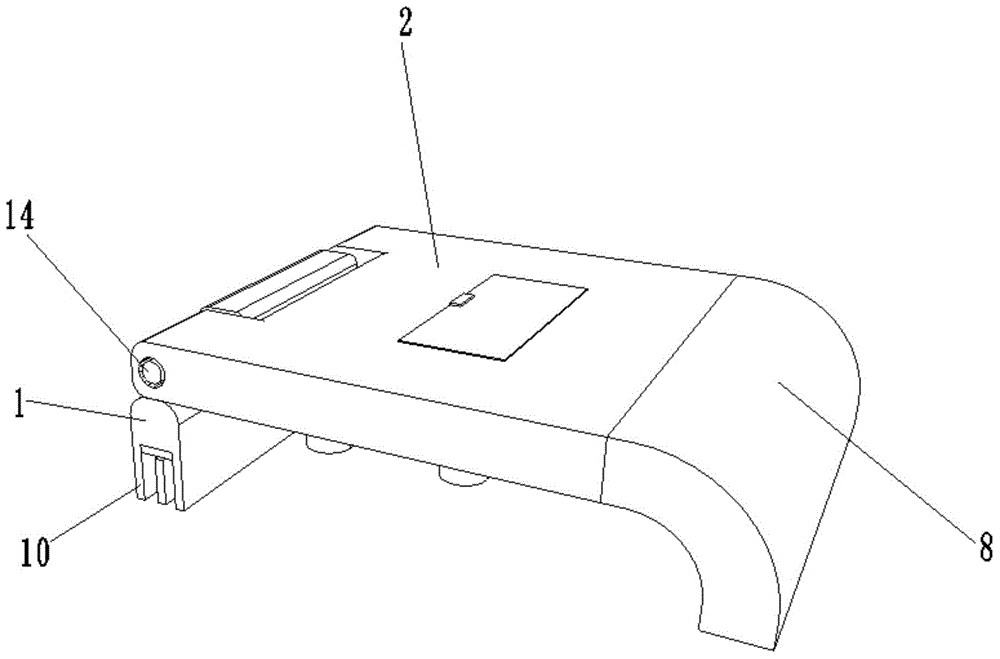

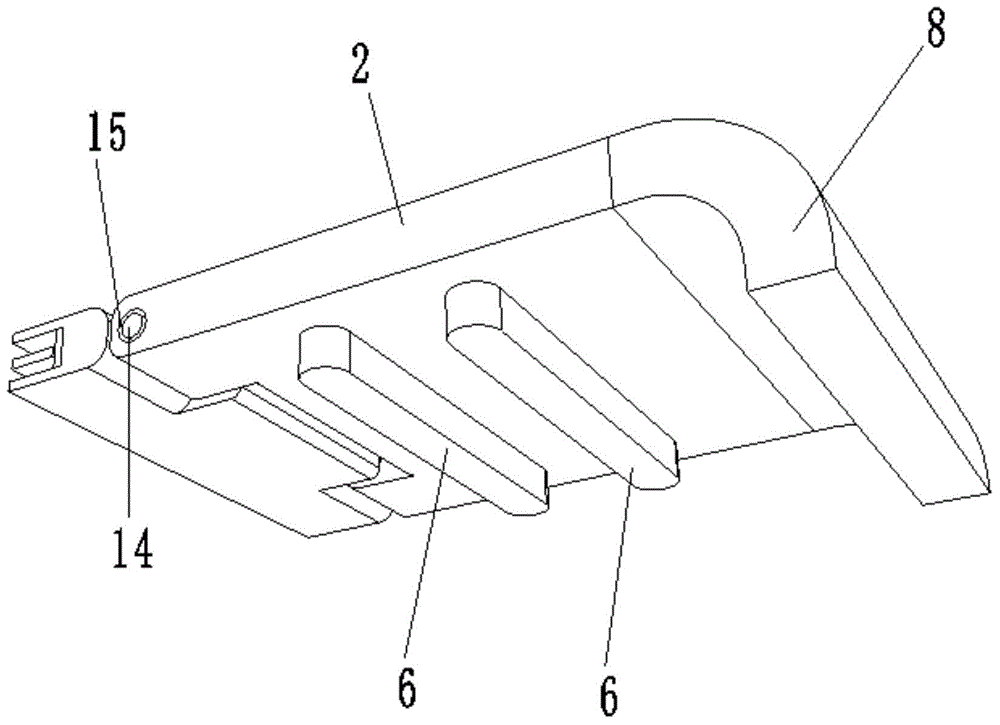

Micro projection imitation display apparatus and display method

ActiveCN106373455ASolve the problem that only static copying can be achievedAvoid direct raysTeaching apparatusHolographic screenComputer graphics (images)

The invention brings forward an imitation display apparatus capable of dynamically performing calligraphy or painting imitation, and a display method thereof. A holographic screen and a micro projection technology are employed, dynamic imitation of calligraphy or paintings can be realized through dynamic demonstration of projection, the problem that an imitation learning apparatus can only realize static imitation in the prior art is solved, holographic screen imaging is employed, the sharpness, the contrast and the color reduction degree are quite high, and the display effect is quite good. Besides, a desk body is different from the shape of a conventional desk body, the desk body employs a structure with a rhombus-shaped side surface, projection light is enabled to maintain a certain angle with the visual angle of a user, direct light is avoided, and human eyes are protected. Besides, the invention also brings forward an imitation projection display method. User imitation learning information is compared with preset standard information. A learning result of a user is evaluated by use of an intelligent apparatus, and learning and improvement of the user can be facilitated.

Owner:陈新德

Automobile cab sunshade device

ActiveCN104149579AAvoid direct raysRaise the room temperatureWindowsAntiglare equipmentEngineeringElectrical and Electronics engineering

Owner:ZHENJIANG COLLEGE

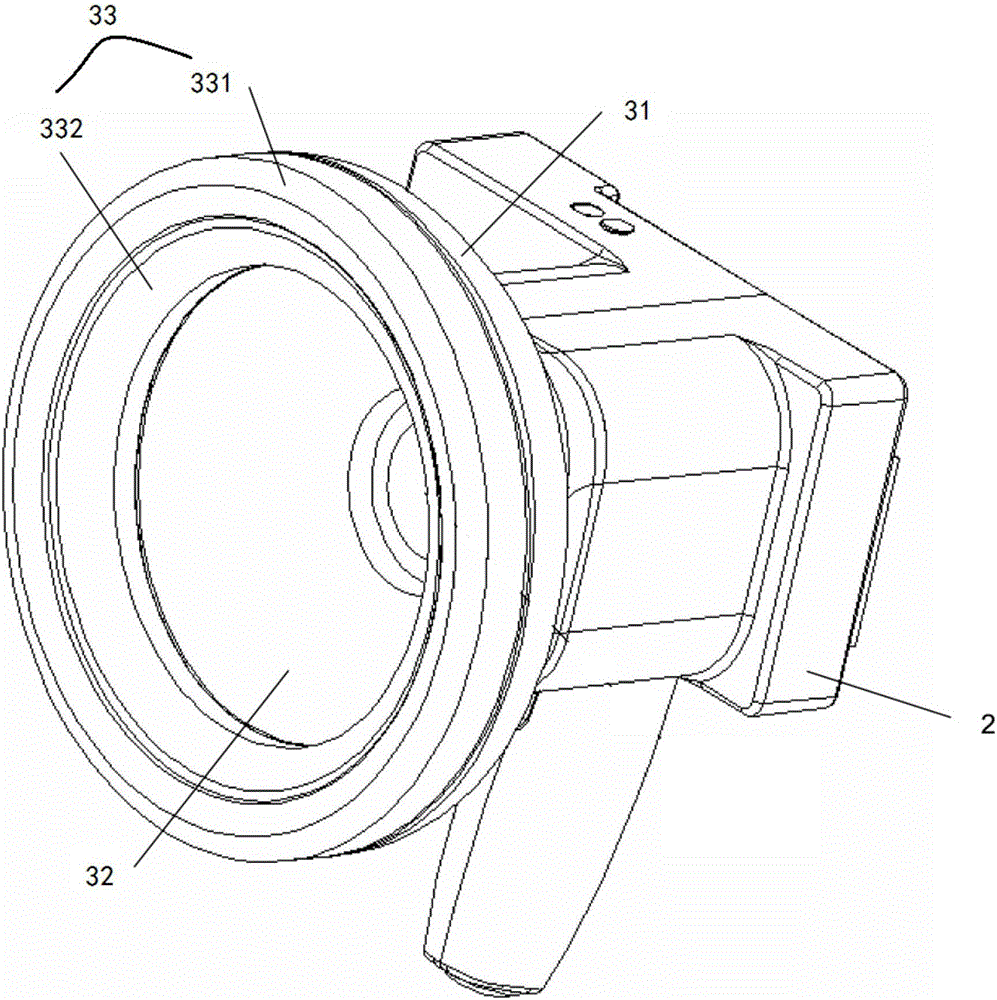

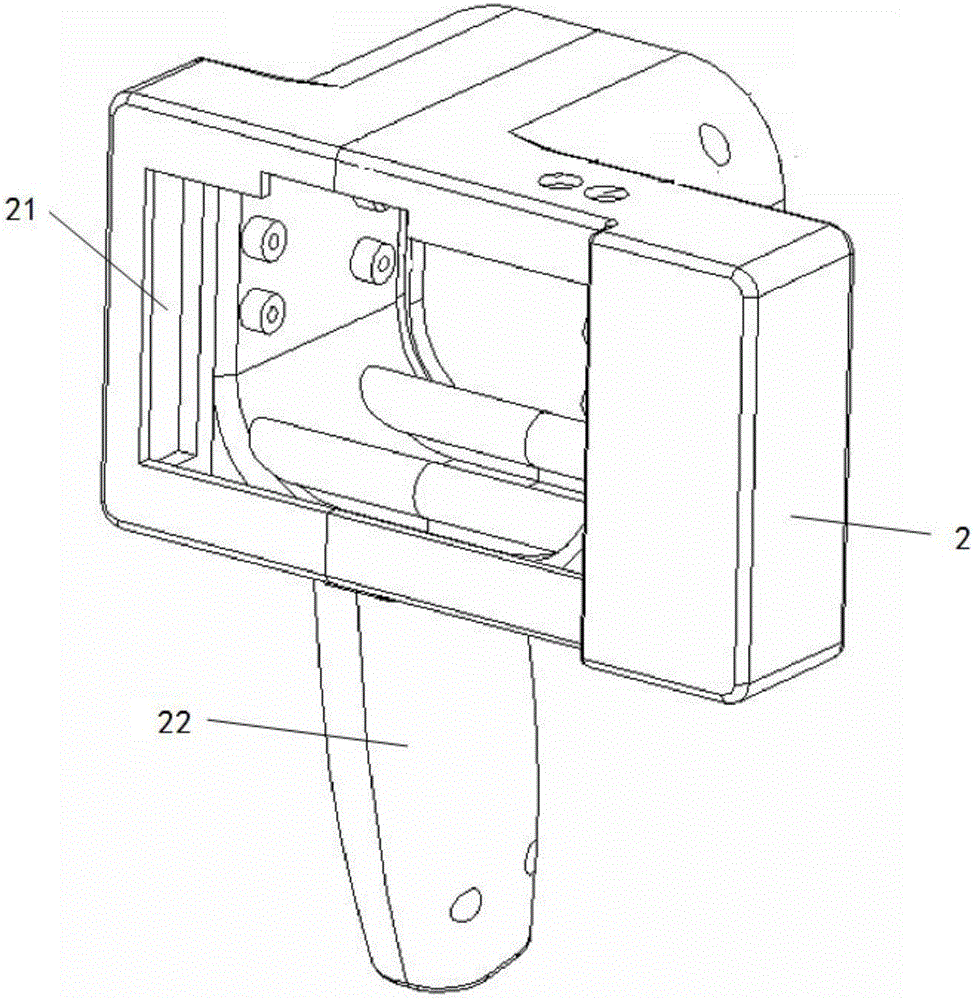

Novel rainproof monitoring camera device

InactiveCN104683662AAvoid direct raysAvoid enteringTelevision system detailsColor television detailsEngineeringMoisture sensor

The invention discloses a piece of monitoring camera equipment, and particularly relates to a novel rainproof monitoring camera device. According to the novel rainproof monitoring camera device of the invention, sunlight can be effectively blocked in all directions, rainwater can be prevented from directly beating against the lens of a camera, and that the sharpness is not reduced after long-term use is effectively ensured. A fixed cover sleeves a lens of a camera. A rotary cover coaxially sleeves the fixed cover, and rotates relatively. The inner end of the rotary cover is provided with teeth, a first motor is fixedly arranged on the fixed cover, and the first motor is in transmission connection with the teeth. The outer end of the rotary cover is connected with a rain shielding plate through a rotating shaft, and the rain shielding plate is a half-side light-transmitting glass rain shielding plate. A second motor is fixedly arranged on the rotary cover, a gear is connected to the rotating shaft, and the second motor is in transmission connection with the gear. A control mechanism is fixedly arranged on the fixed cover, and the control mechanism comprises a control chip, a humidity sensor, a photoreceptor, and a timer.

Owner:TIANJIN WORLD DIGITAL VIDEO

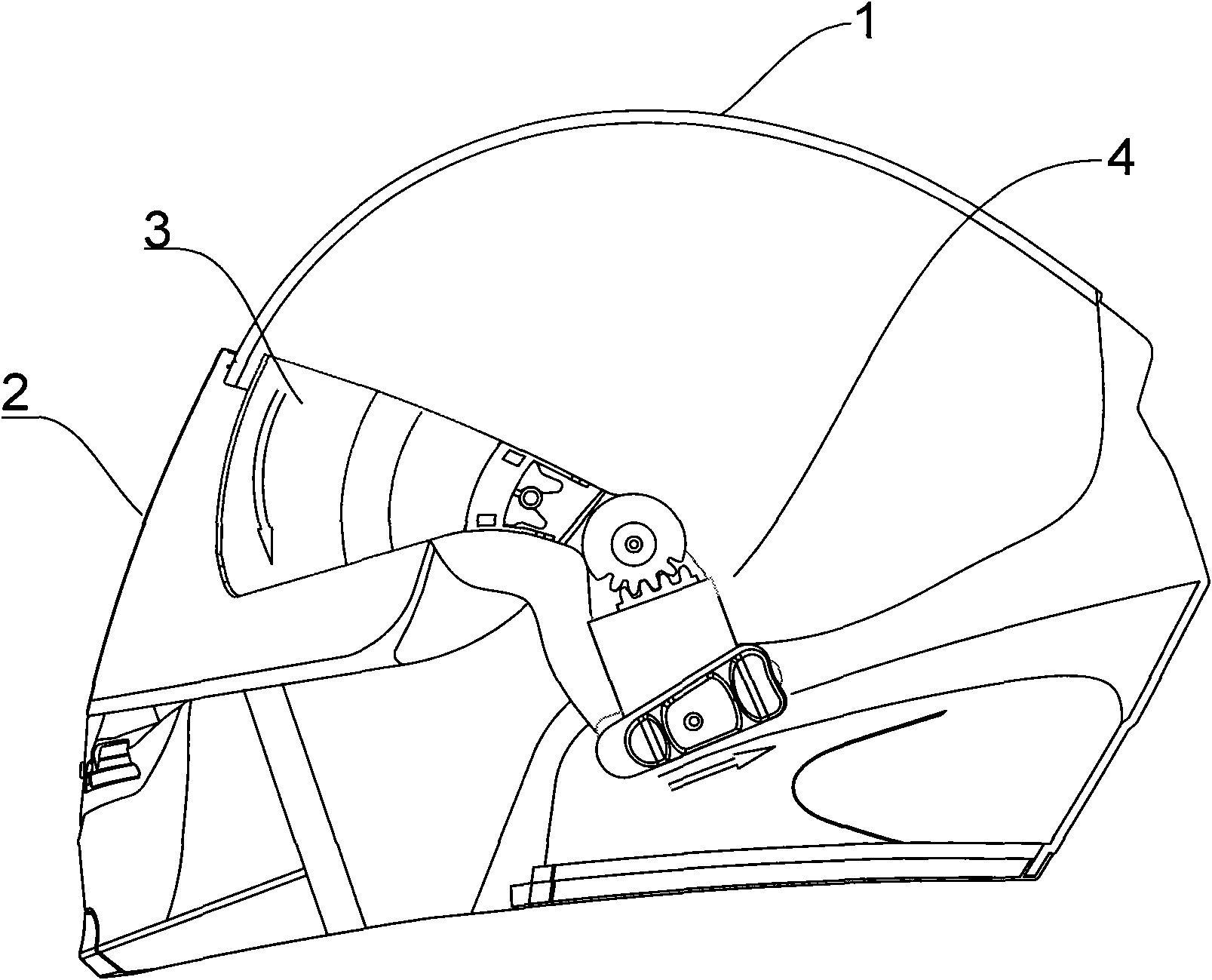

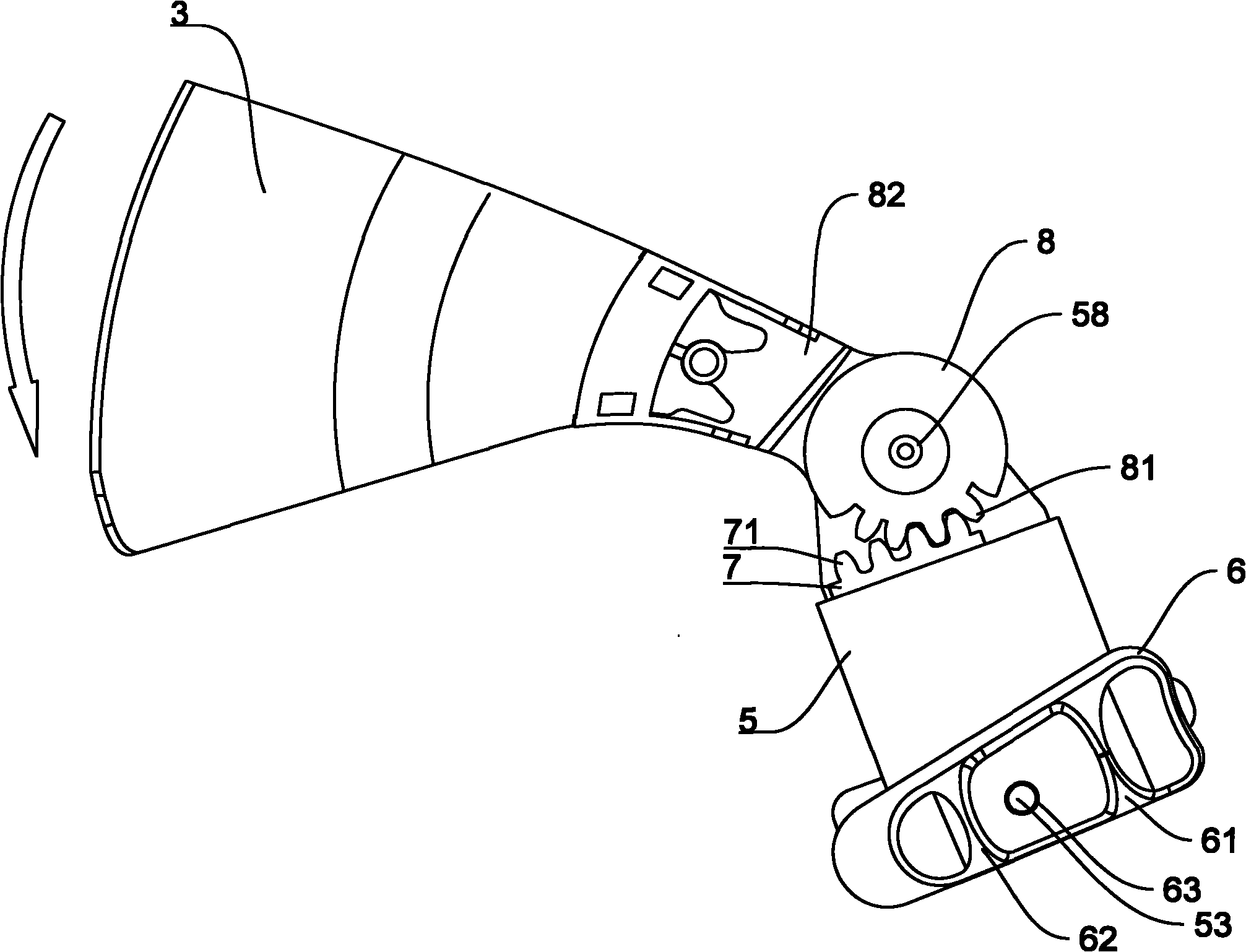

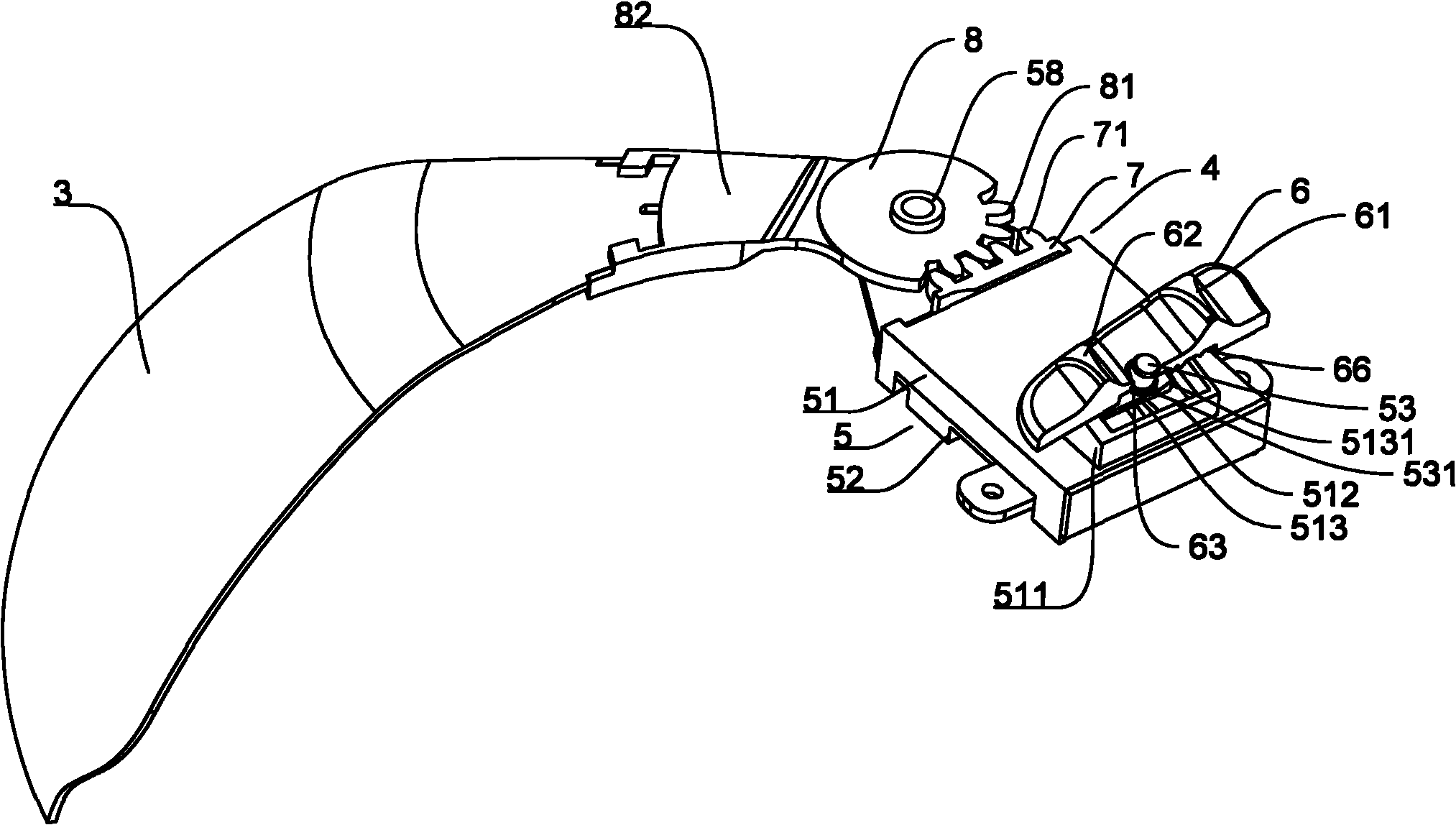

Helmet lens position adjustment device and helmet

ActiveCN101940378AEasy to useAvoid direct sunlight in the eyesMountingsHelmetsSight lineCovering eye

Owner:上海和汇安全用品有限公司

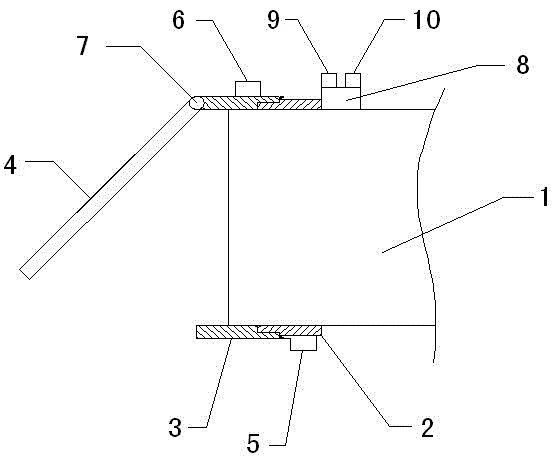

Chemical storage tank

InactiveCN105620954AImprove energy saving effectAvoid direct raysLarge containersTank wagonsSunlightWater supply

The invention provides a chemical storage tank. The chemical storage tank comprises a tank body, a tank cover body and a shielding cover, wherein the tank cover body is arranged on the top of the tank body, and the shielding cover is arranged on the top of the tank cover body. The tank cover body is provided with a shielding edge extending out of the tank body. The tank cover body further comprises a plurality of first spraying pipes arranged on the shielding edge in a surrounded mode. A second spraying pipe is arranged at the center of the shielding cover. A water receiving groove is formed in the bottom of the tank body and internally provided with a water supplying pipe. A condensing device is connected to the water supplying pipe. A water supplying pump is connected to a water outlet of the condensing device and connected with the first spraying pipes and the second spraying pipe. The chemical storage tank has the beneficial effects that direct sunlight to the tank body is avoided through the arranged shielding cover, and the tank body is cooled through the arranged spraying pipes; in addition, cyclic utilization of water is achieved through the arranged condensing device and the water supplying device, so that the energy-saving effect is improved.

Owner:JIANGXI ACADEMY OF SCI

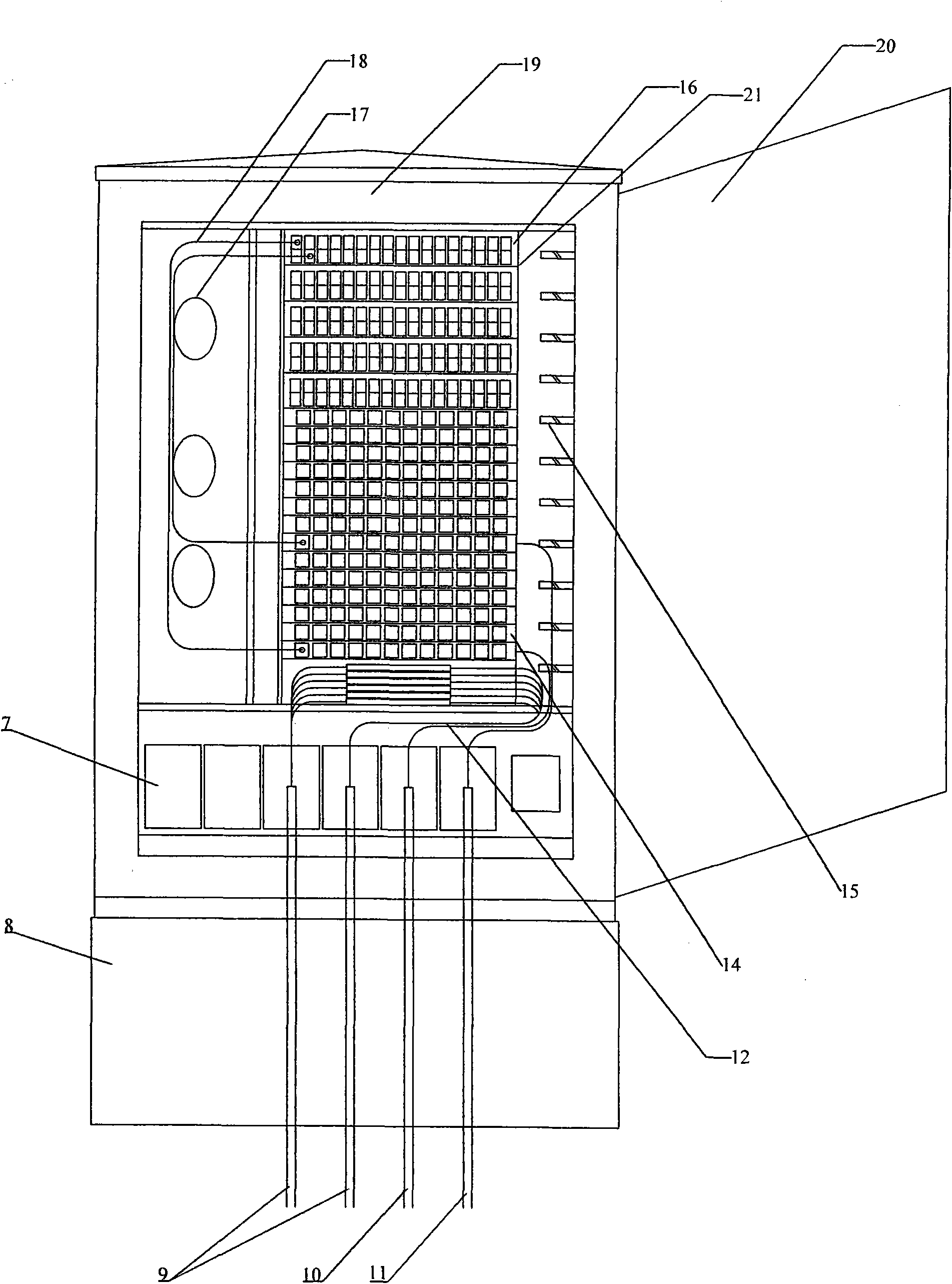

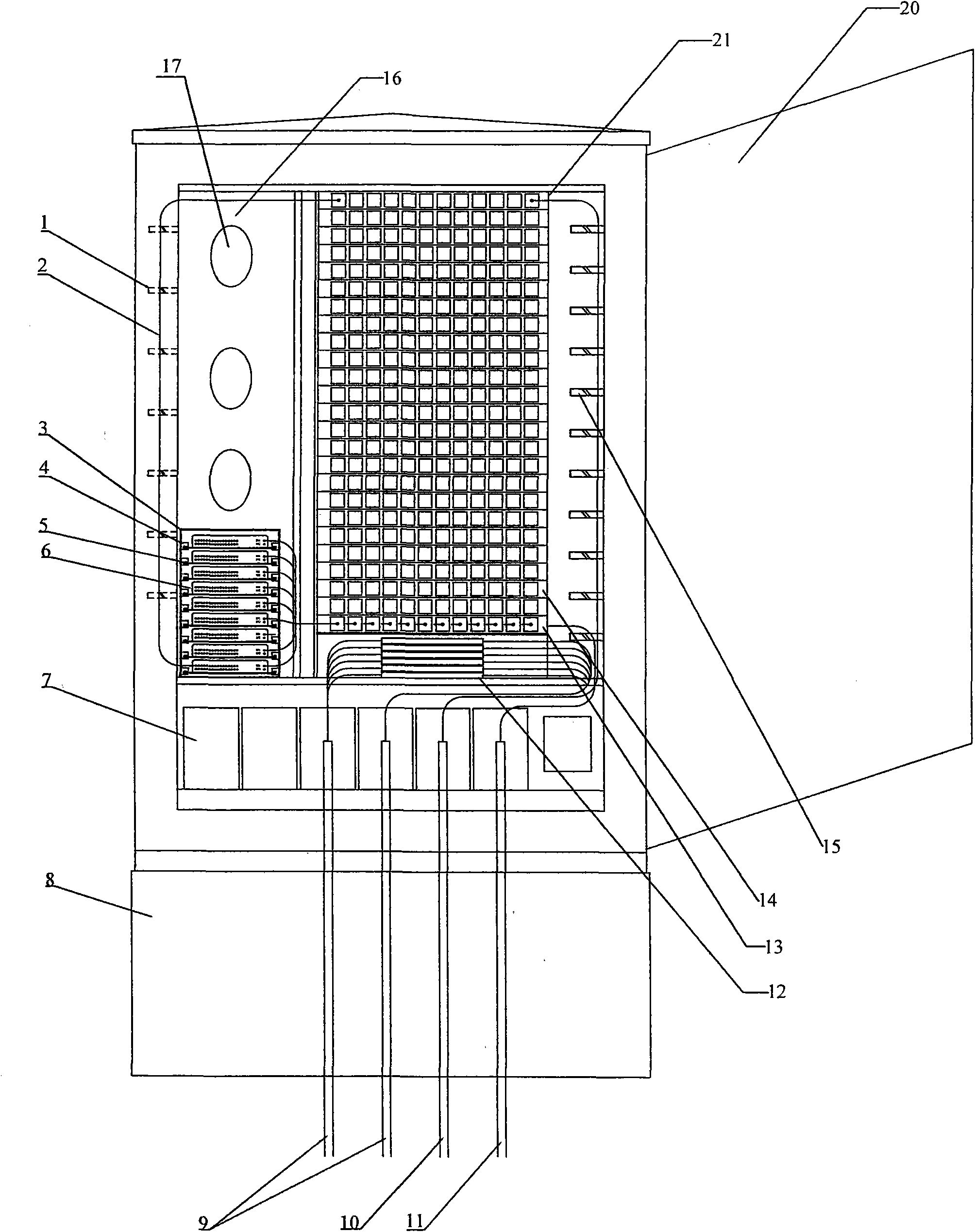

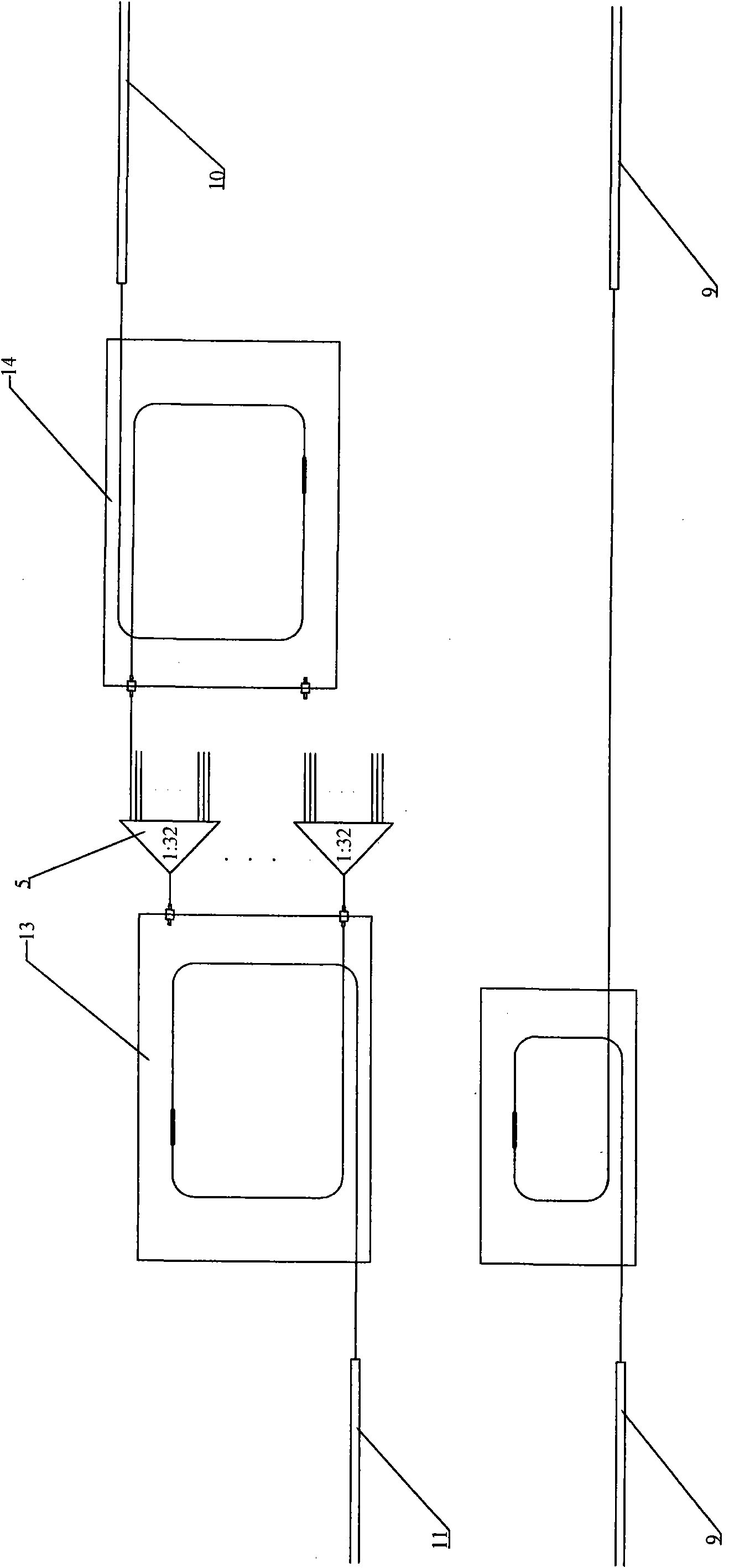

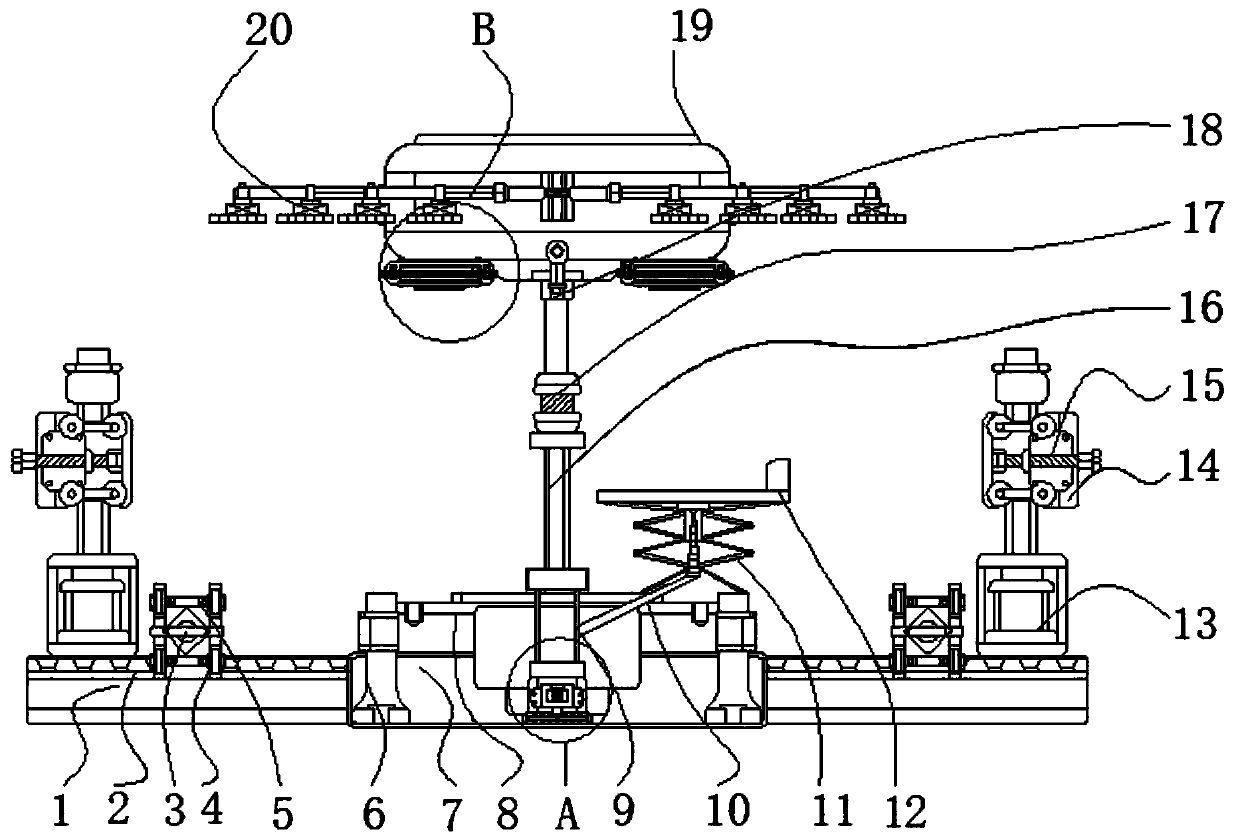

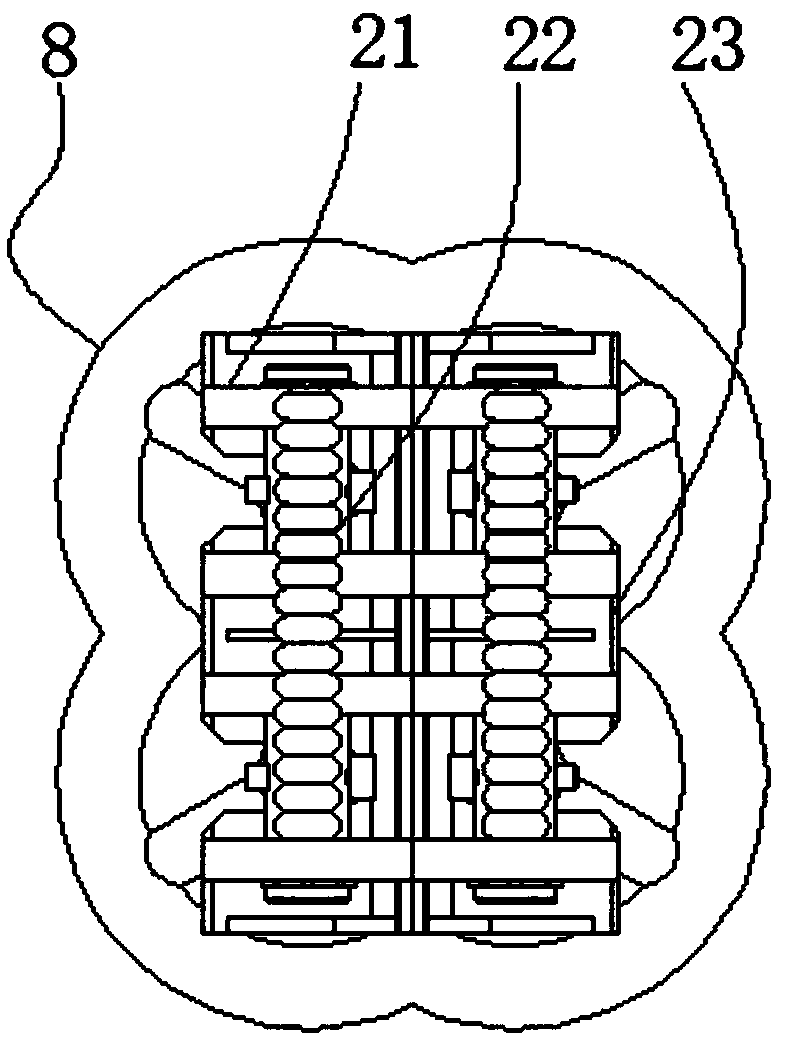

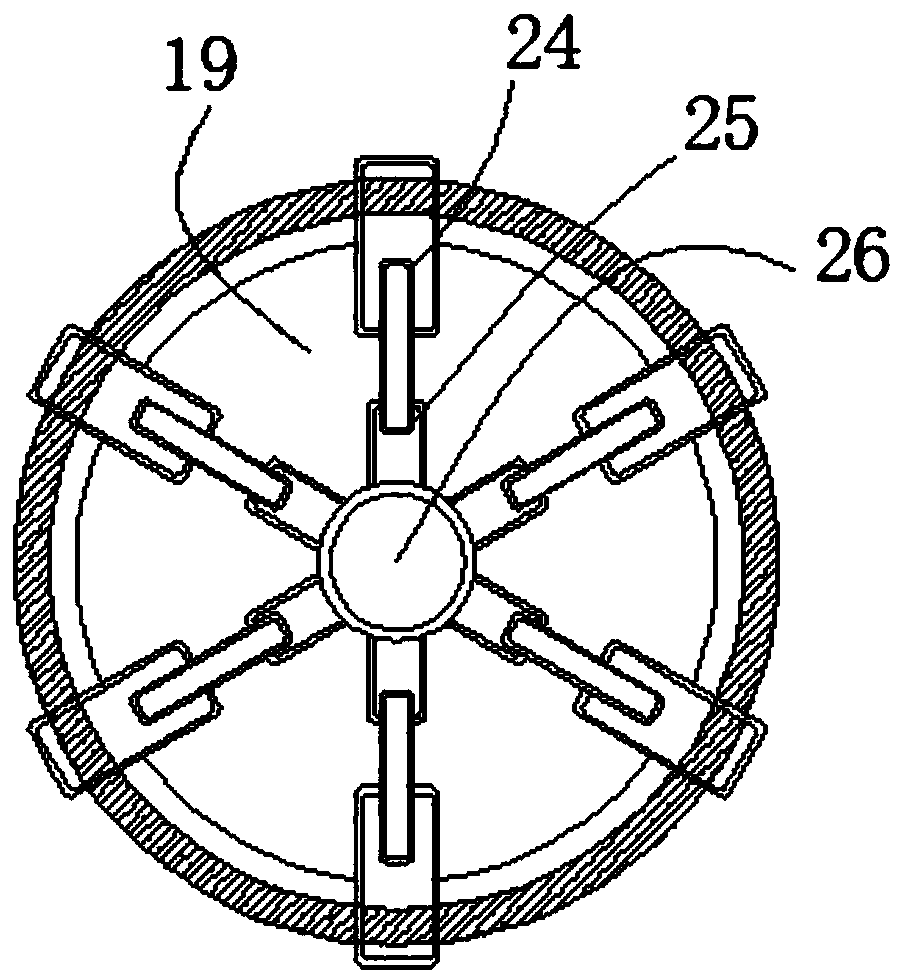

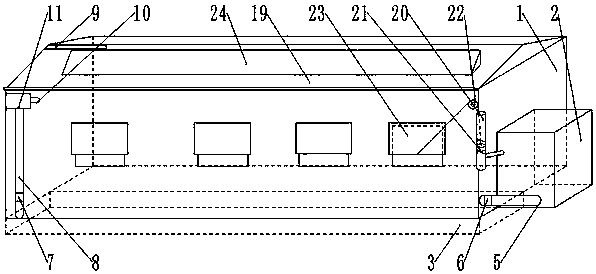

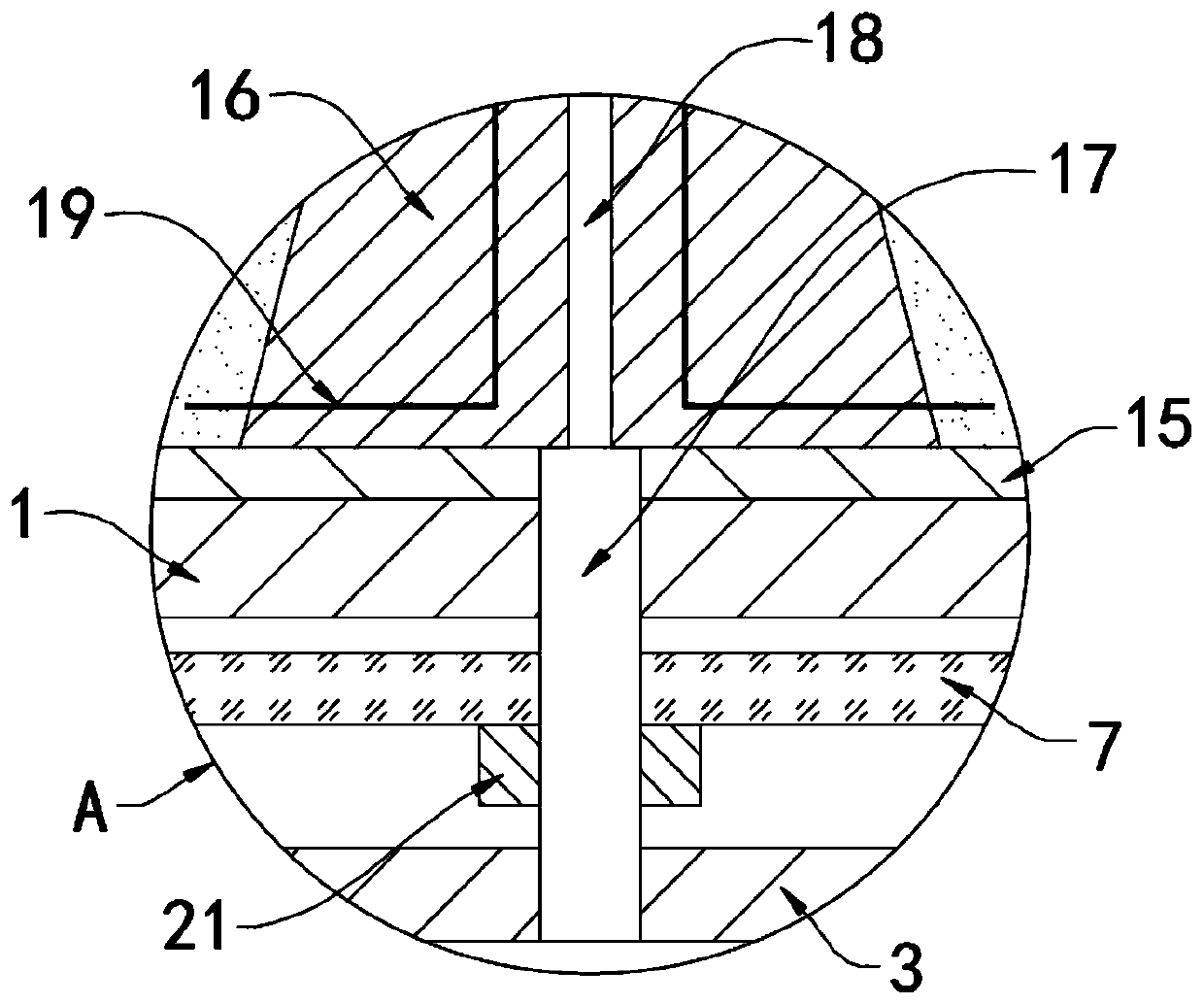

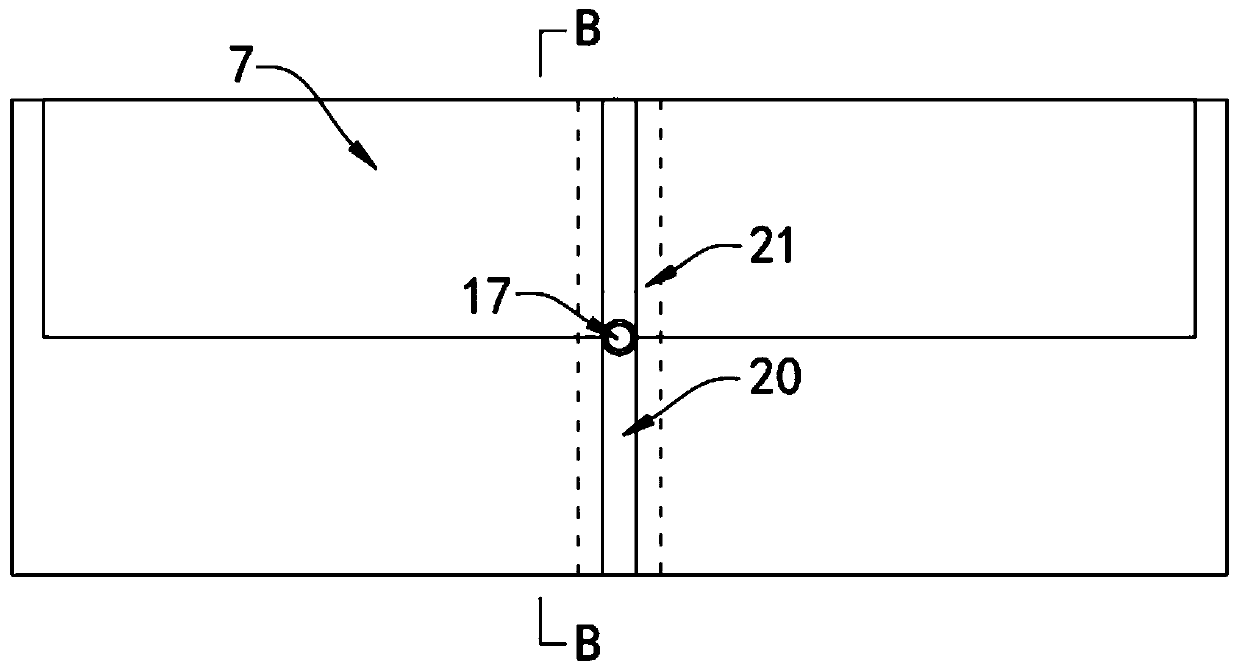

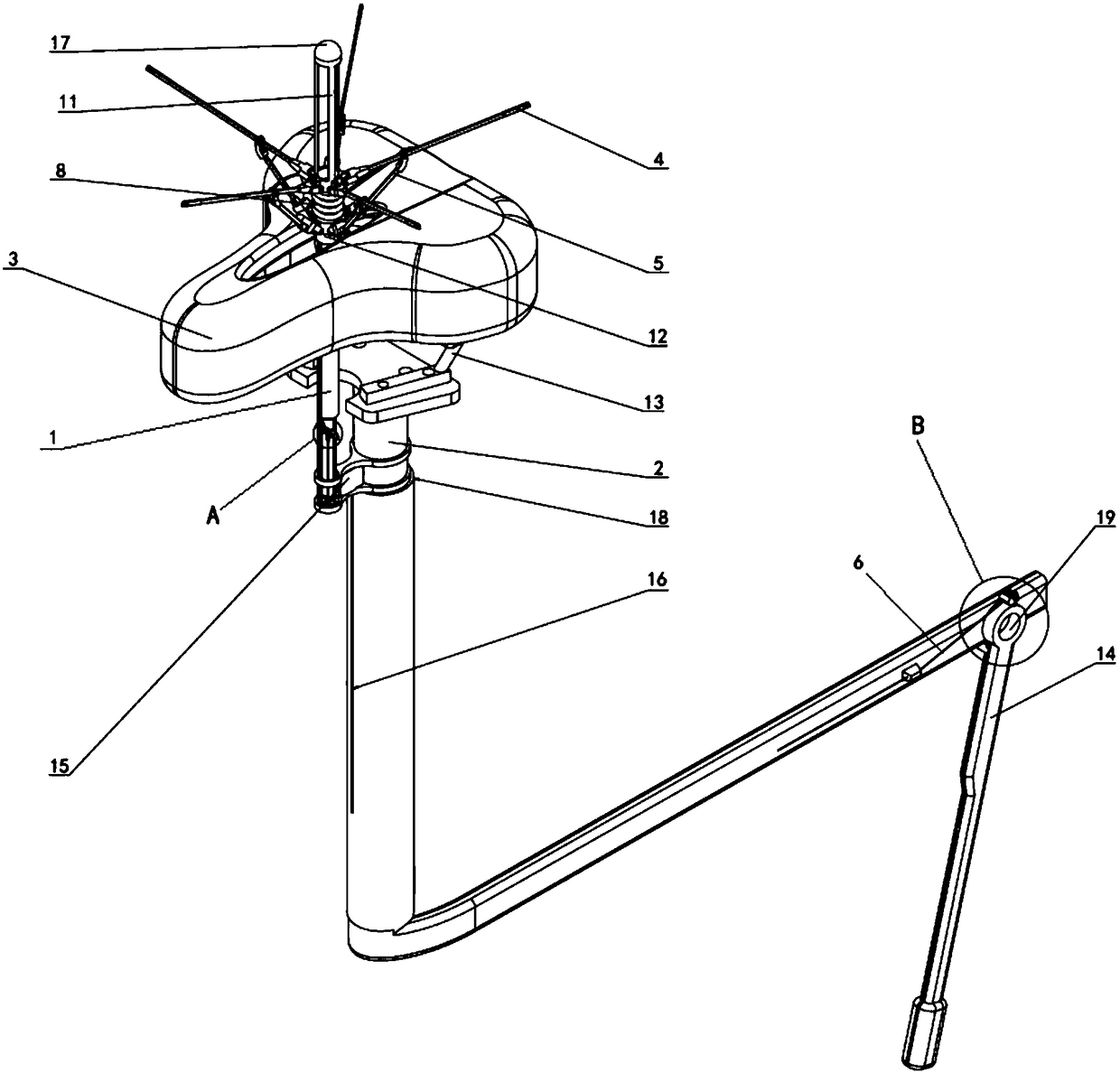

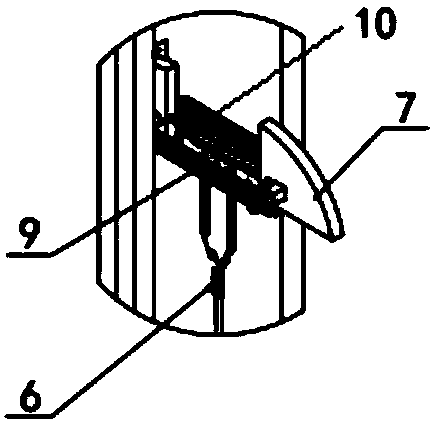

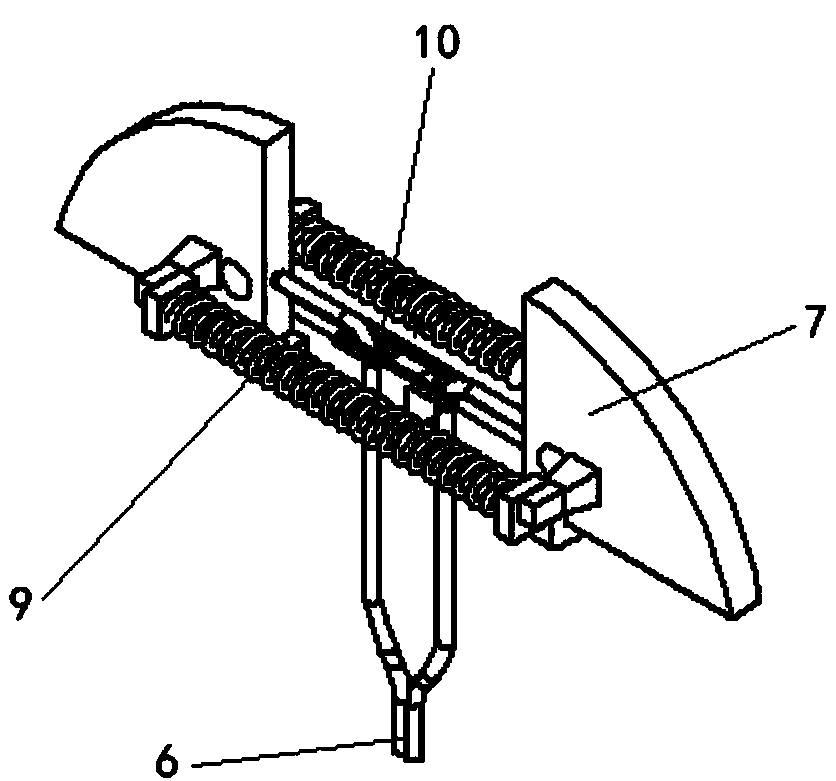

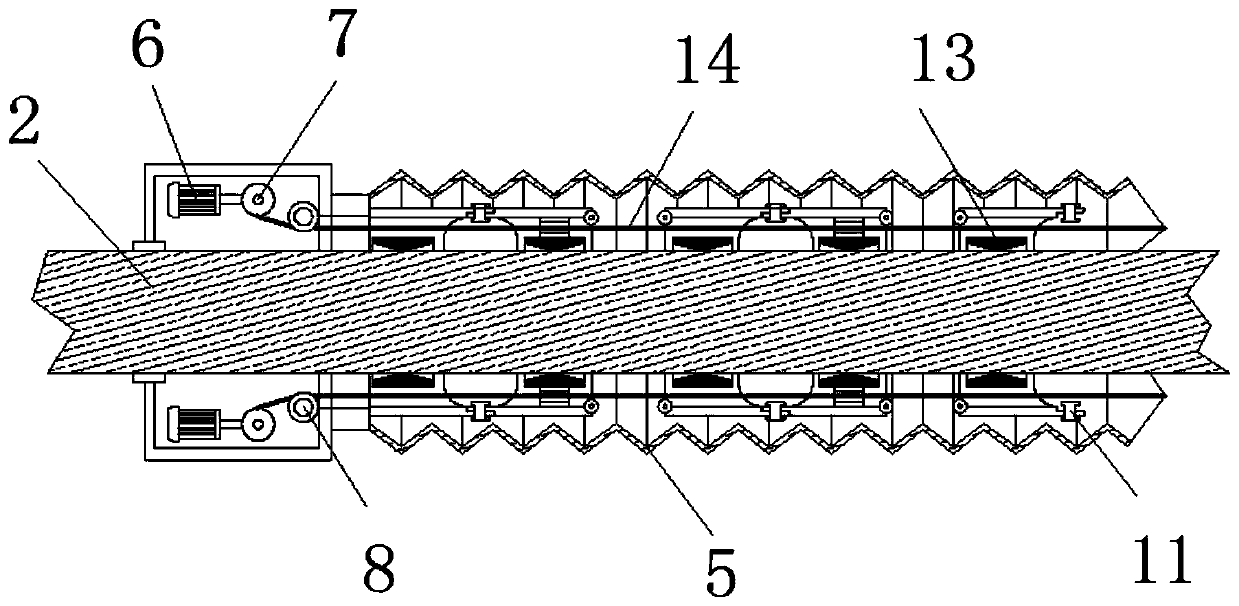

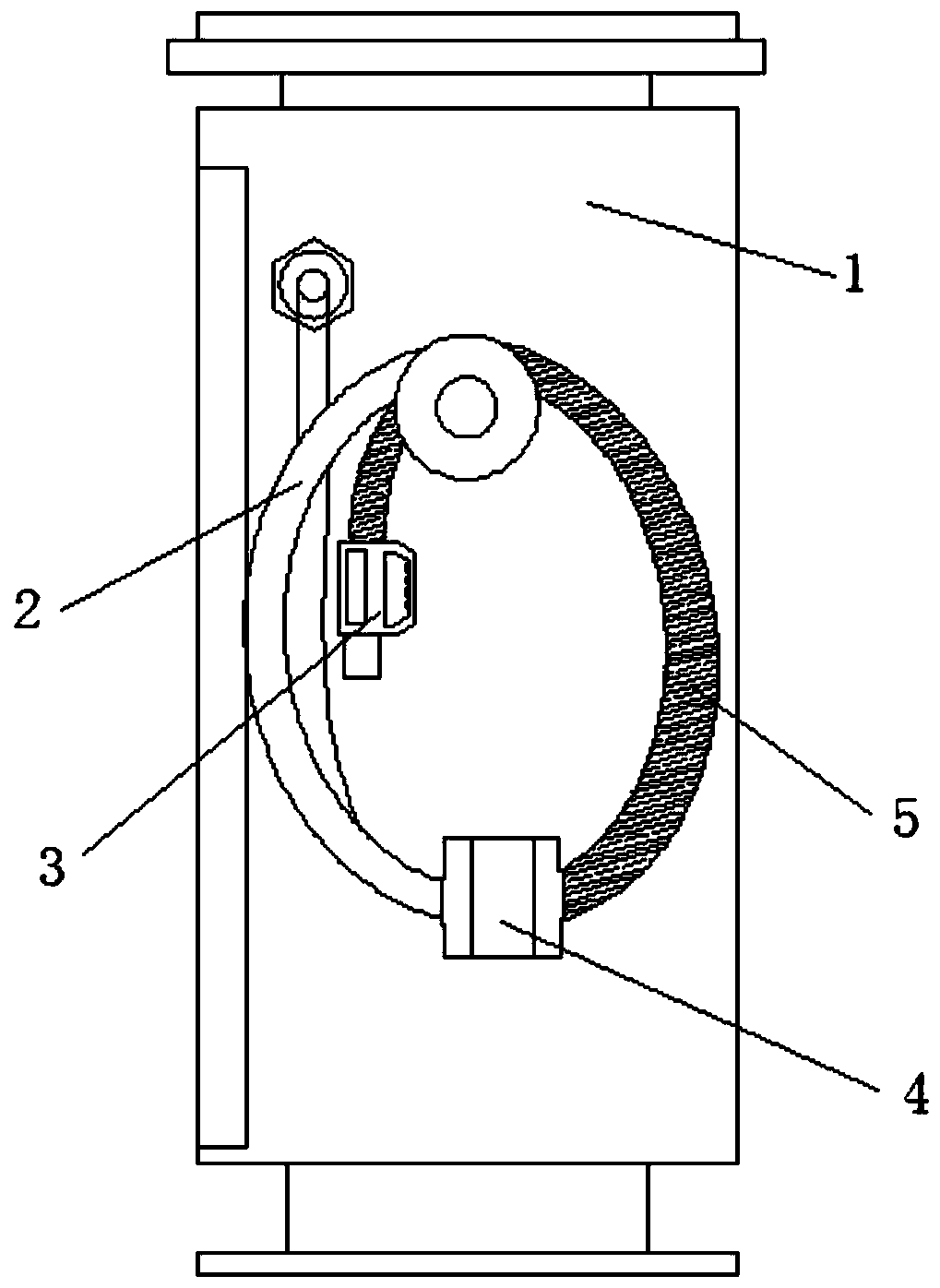

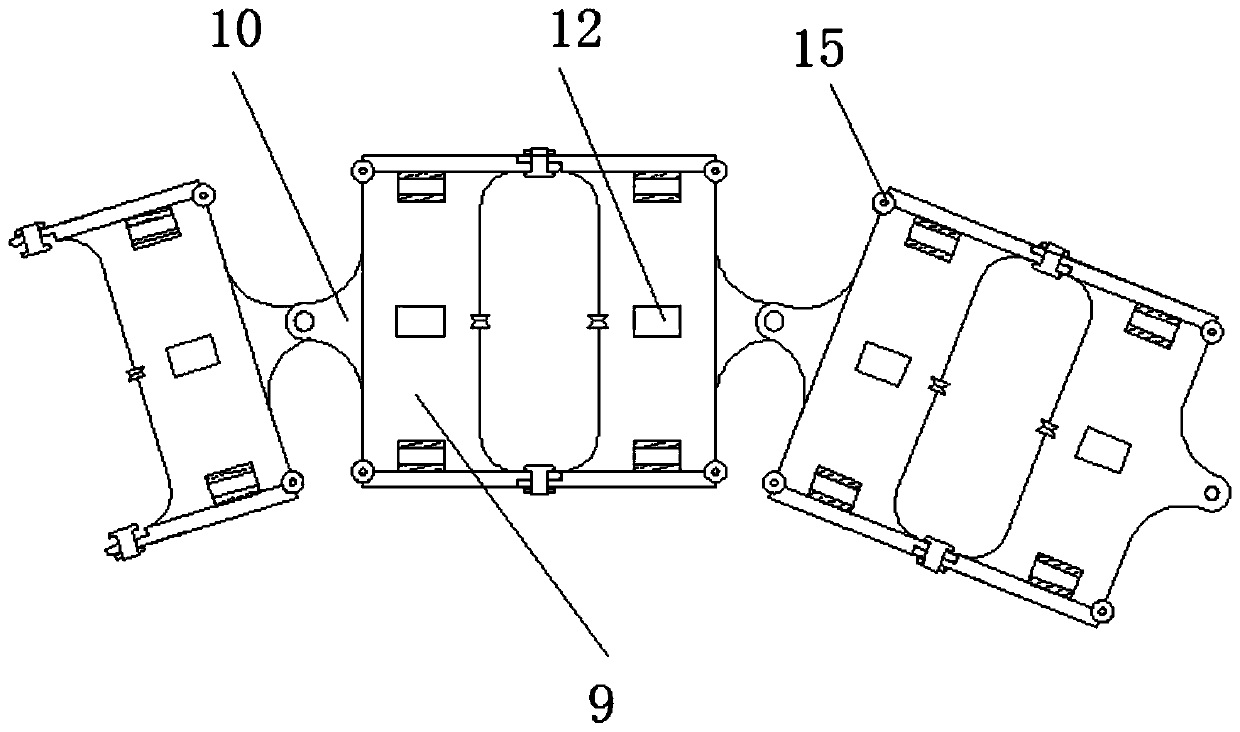

Optical cable cross connection cabinet special for FTTB (fiber to the building) and FTTH (fiber to the home)

InactiveCN101566712ANo change in capacityExpand the number of users coveredCoupling light guidesFibre mechanical structuresAccess networkCross connection

The invention relates to an optical cable cross connection cabinet special for FTTB (fiber to the building) and FTTH (fiber to the home), which is used as an interface of a trunk optical cable and an optical distribution cable specially for EPON and GPON systems of a fiber access network. The optical cable cross connection cabinet comprises a base (8), a cabinet body (19), a fiber storage chamber(16), a fusion distribution integrated single-disk mounting frame (21), a straight-through device (12), an optical cable fixing device (7), a fusion distribution integrated single disk (14), a straight-through optical cable (9), a homing optical cable (10), a feeder optical cable (11), an optical cable fixing device (7), a straight-through device (12), a cable manager (17) and a right cable passing ring (15). The optical cable cross connection cabinet is characterized in that the optical cable cross connection cabinet also comprises an additional fusion distribution integrated single disk (13), an optical splitter frame (3), an optical splitter (6), a left cable passing ring (1) and an optical splitter tail fiber (2). One optical cable cross connection cabinet can cover 288 users by addingone fusion distribution integrated single disk and the optical splitter frame, and achieve the aim of increasing the quantity of covered users; and 165 jumper wires are saved during full configuration by adopting a tail fiber type optical splitter, and the investment cost can be greatly reduced.

Owner:JIANGYIN FAERSHENG CHANGING OPTICAL DEVICES

Lifting type police stand capable of multi-directionally sheltering from rain

ActiveCN109518997AReduce damageAvoid direct sunlightClimate change adaptationSpecial buildingIrritationEngineering

The invention relates to a lifting type police stand capable of multi-directionally sheltering from rain. The lifting type police stand capable of multi-directionally sheltering from rain comprises abase and a snap joint plate, wherein a sliding rod is connected in the base, the base is fixedly connected with the sliding rod, the middle of the sliding rod is provided with a sliding groove, the sliding rod is tightly attached to the sliding groove, the middle of the sliding groove is provided with a snap joint hole, the snap joint plate is installed at the top of the sliding groove, a base plate is fixed to the inner side of the sliding rod, the left side and the right side of the inside of the base plate are provided with supports, the supports are fixedly connected with the base plate, and the inner sides of the tops of the supports are connected with standing plates. The lifting type police stand has the advantages that the snap joint plate can be bilaterally adjusted through left-right sliding between the sliding rod and the base plate in the sliding groove, the left-right movement of a guidance protection device on the snap joint plate can be adjusted, accordingly position adjustment can be executed according to sunlight irritation angles, the degree of damage to the high temperature in summer can be reduced, and direct sunlight irradiation can be avoided by left-right movement.

Owner:FOSHAN UNIVERSITY

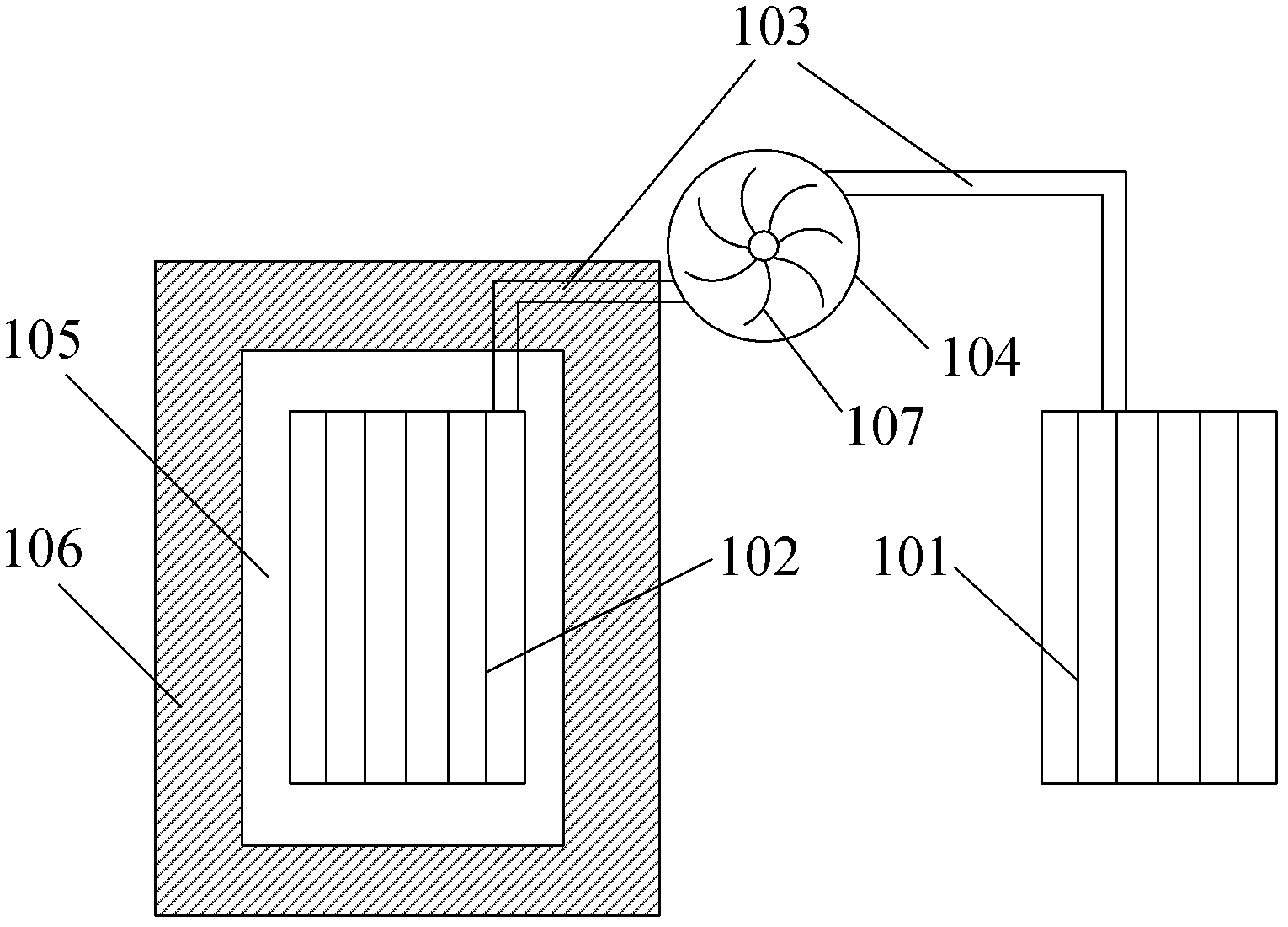

Temperature-adjustable hog house

Owner:ANHUI JIUKESONG ECOLOGICAL AGRI

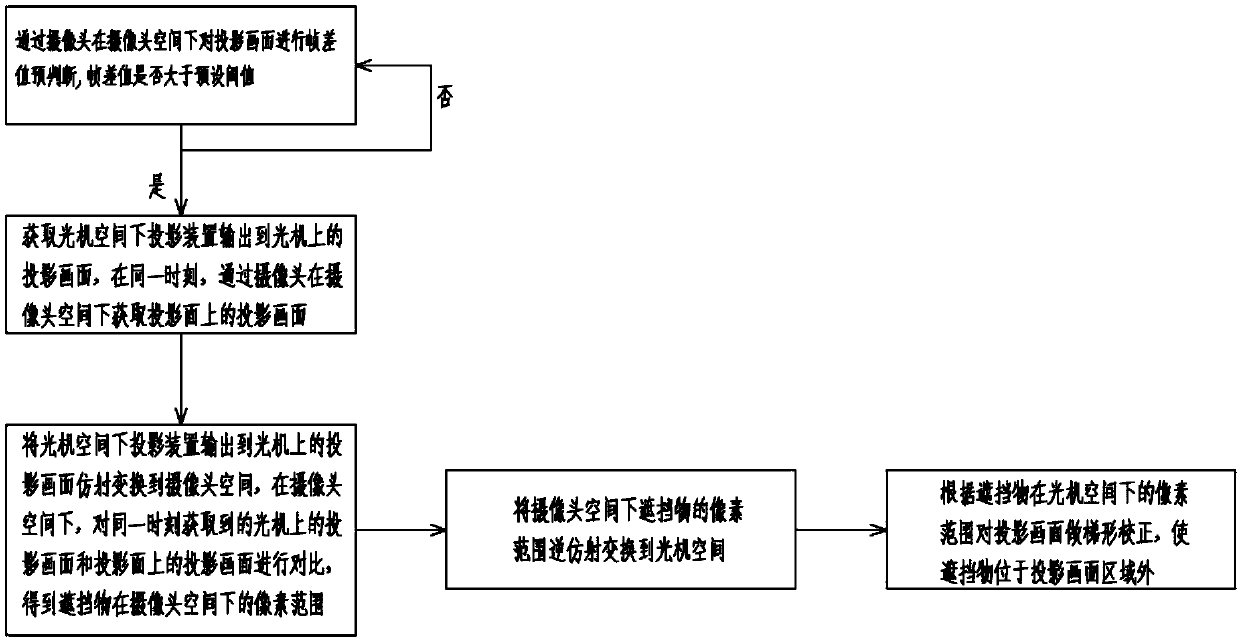

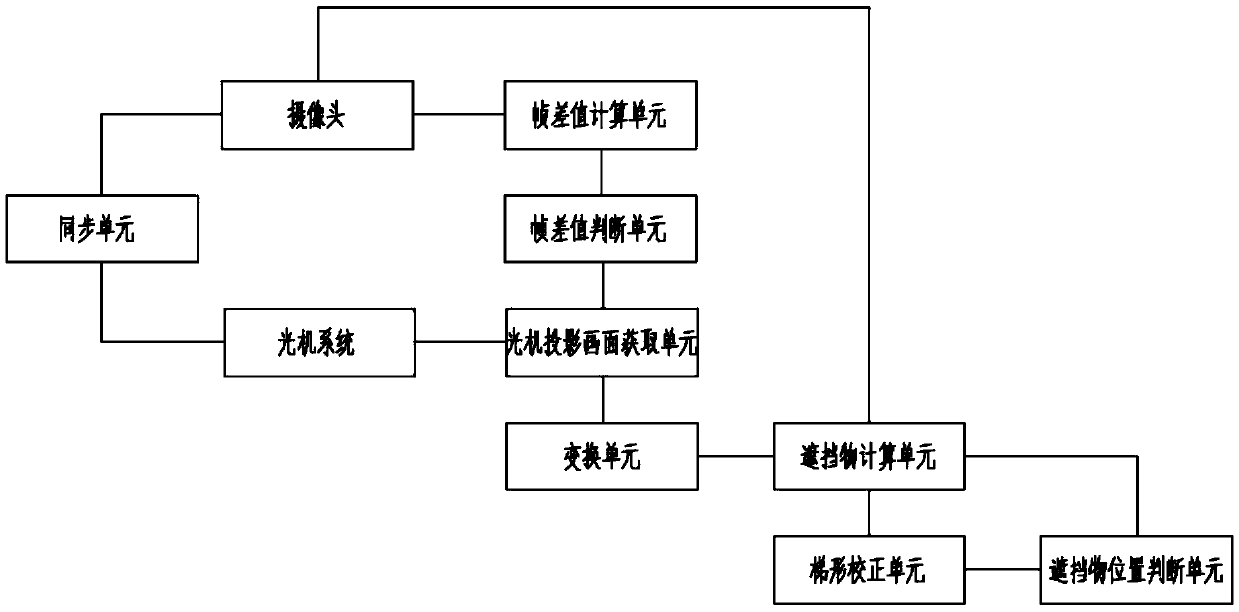

Automatic tracking projection method and device based on frame difference value

InactiveCN110769214AAvoid direct raysImprove experienceGeometric image transformationPicture reproducers using projection devicesComputer graphics (images)Ray

The invention discloses an automatic tracking projection method based on a frame difference value. The method comprises the following steps: performing frame difference value pre-judgment on a projection picture through a camera; acquiring a projection picture output to the ray machine by the projection device in the ray machine space, and acquiring the projection picture on the projection surfacethrough the camera at the same moment; carrying out affine transformation on a projection picture output to an optical machine by a projection device in an optical machine space to a camera space, and in the camera space, comparing the projection picture on the optical machine with a projection picture on a projection surface to obtain a pixel range of a shielding object in the camera space; carrying out inverse affine transformation on the pixel range of the shielding object to an optical machine space; and performing trapezoidal correction on the projection picture according to the pixel range of the shielding object in the optical-mechanical space, so that the shielding object is located outside the projection picture area. According to the invention, the light directly projected by the projector can be prevented from directly irradiating the eyes, the user experience is improved, and meanwhile, a viewer can continuously view the content explained by a speaker.

Owner:CHENGDU XGIMI TECH CO LTD

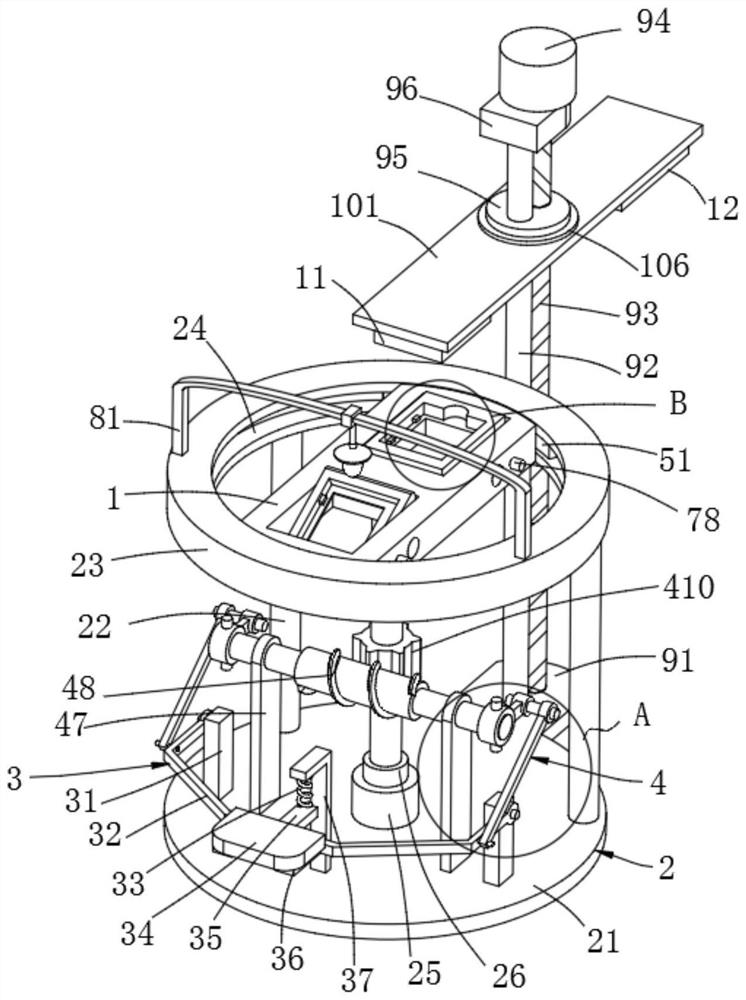

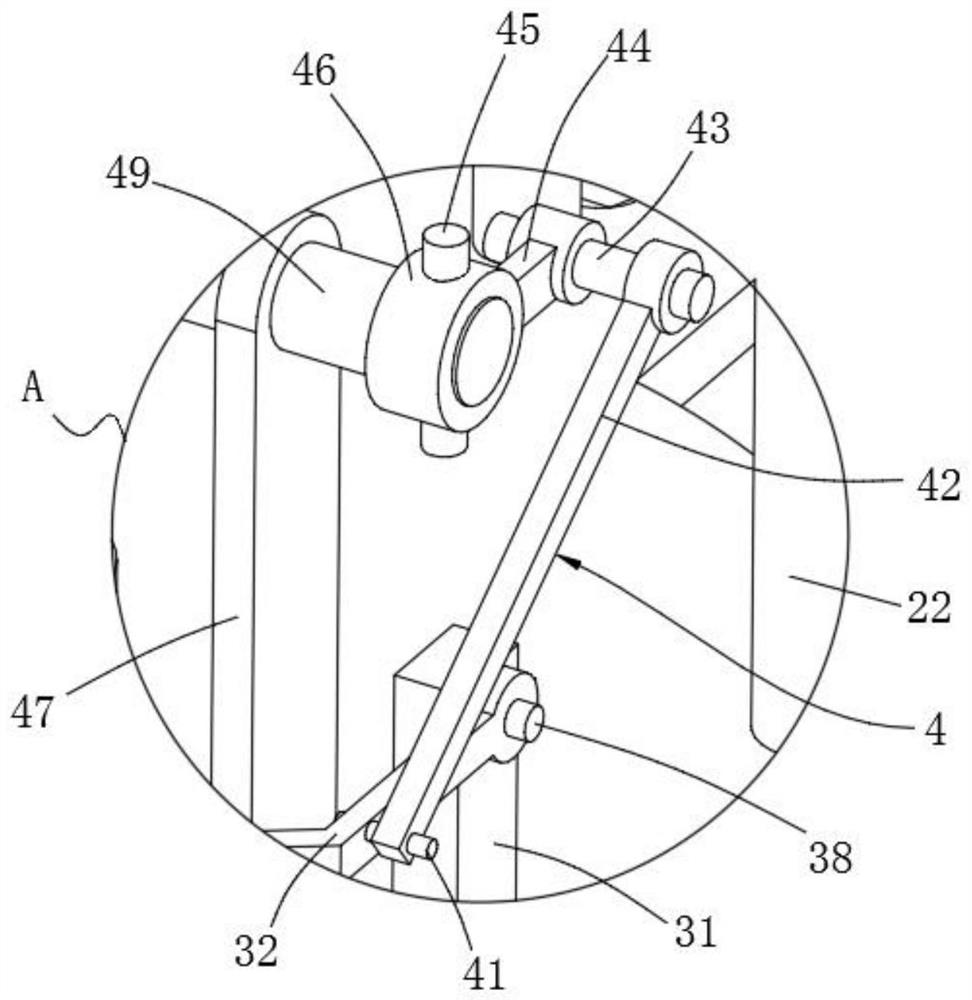

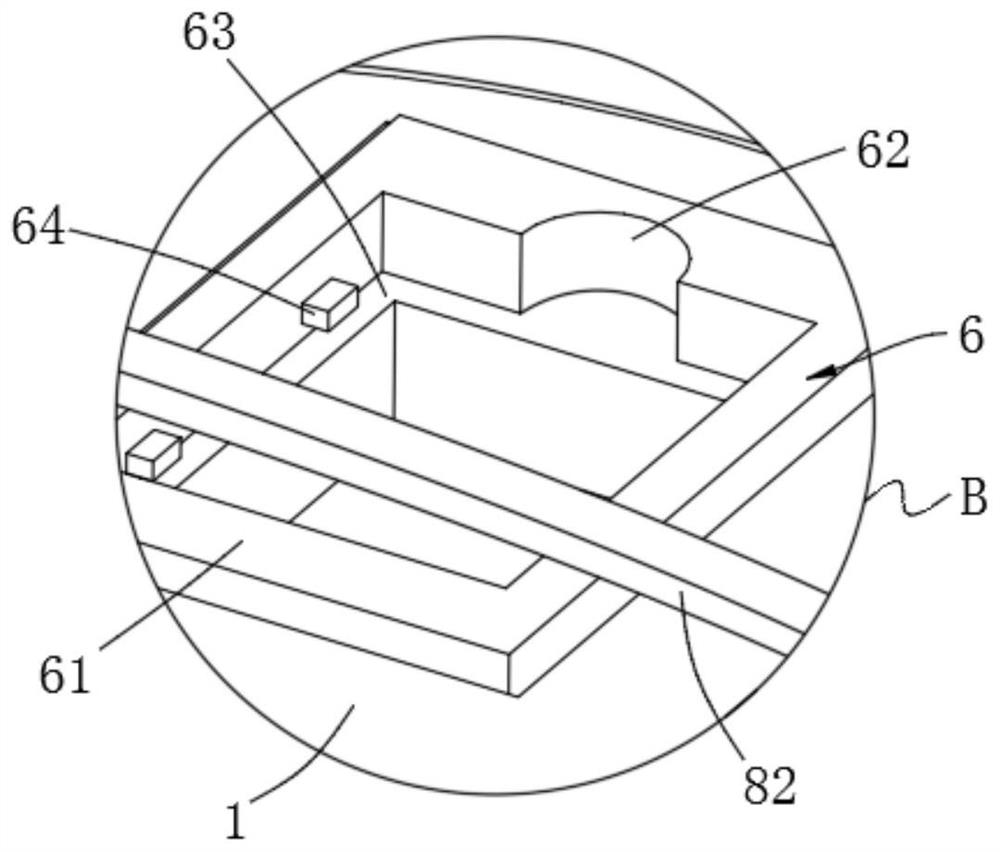

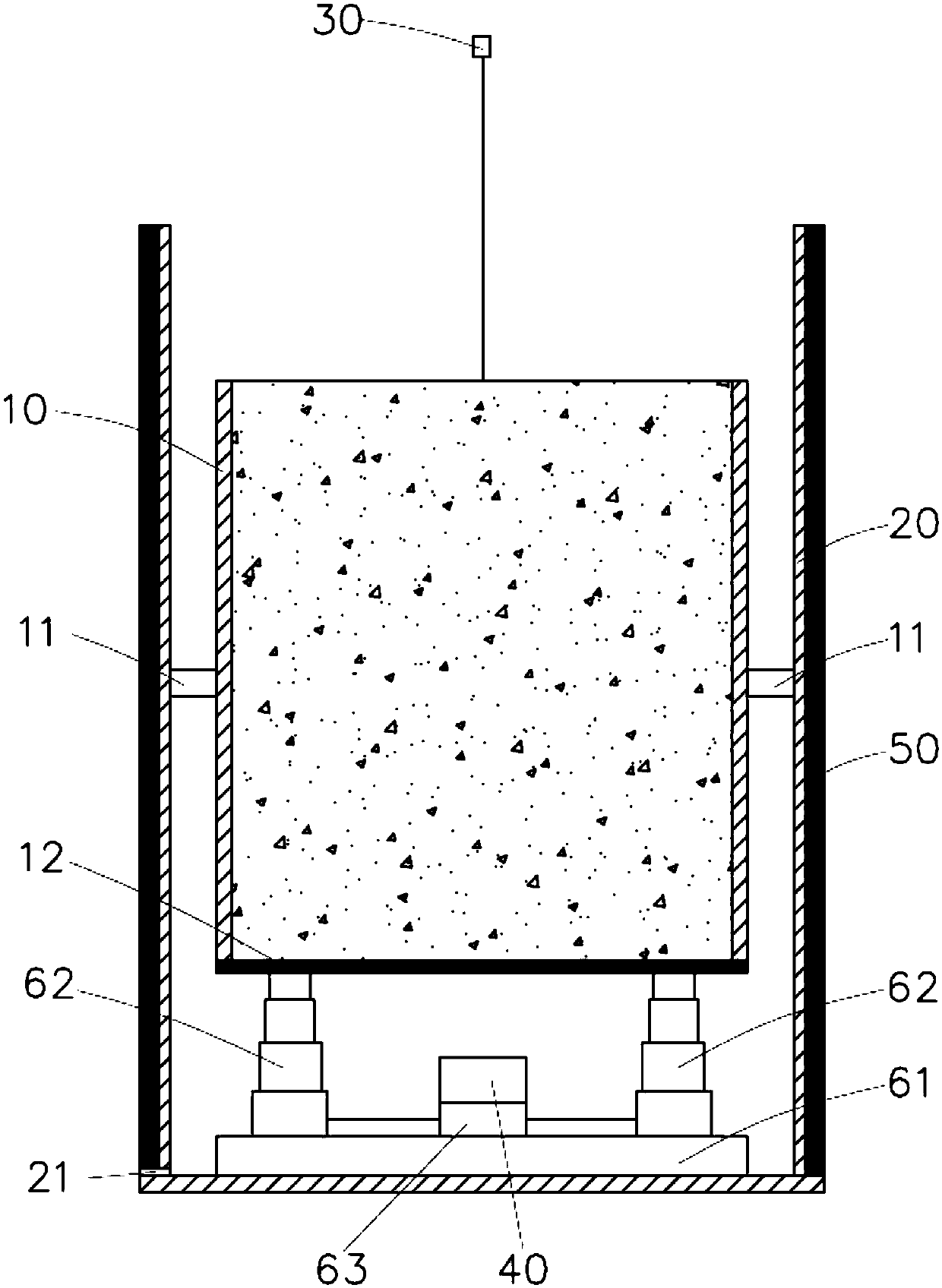

Detection device and detection method for PCB

InactiveCN112433141AObserve the appearance qualityEasy to observeMaterial analysis by optical meansPrinted circuit testingStructural engineeringManual handling

The invention discloses a detection device and a detection method for a PCB. The detection device comprises a rotating plate, a supporting unit, a rotating power unit, a rotating transmission unit, asliding unit, a circuit board bearing unit, a lifting unit and a detection alternating unit. The supporting unit comprises a base plate, a supporting column, a supporting ring, an annular groove, a shaft seat and a bearing, the rear side of the surface of the base plate is connected with the supporting ring through the supporting column, the annular groove is formed in the inner side of the supporting ring, the shaft seat is fixed to the center of the surface of the base plate, and the bearing is installed on the shaft seat; and the two ends of the rotating plate are slidably connected with the annular grooves through sliding units correspondingly, the bottom of the rotating plate is connected with a rotating transmission unit, and the base plate is provided with a rotating power unit fordriving the rotating transmission unit. The device and the method are simple in structure and convenient to operate, reduce the operation steps during manual detection, reduce the influence of manualoperation on a detection result, can improve the detection efficiency, and facilitate the improvement of the detection accuracy.

Owner:温州市凌度电子科技有限公司

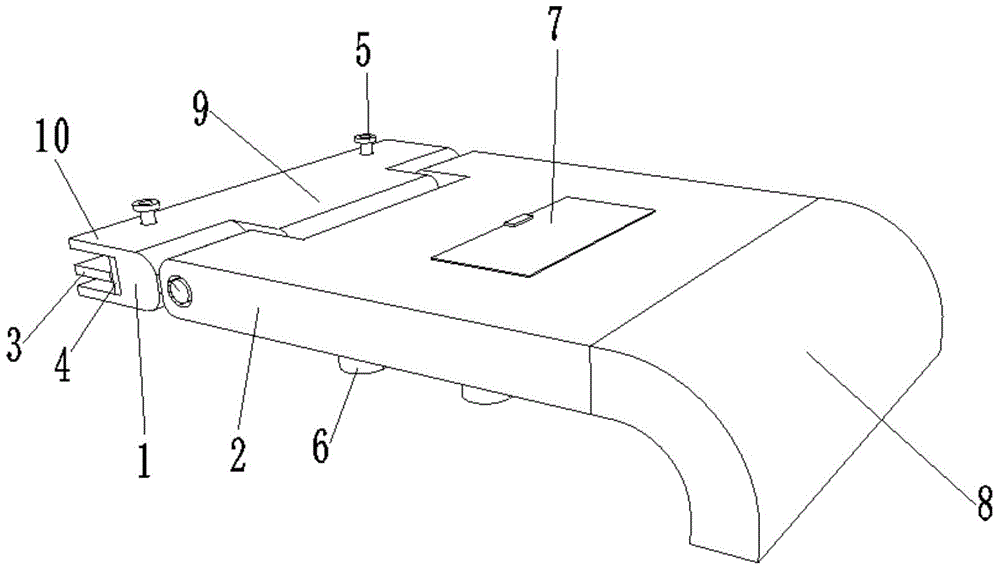

Notebook computer lighting device

InactiveCN104482482ALow pricePracticalLighting support devicesWith built-in powerElectricityLight irradiation

The invention provides a notebook computer lighting device. The notebook computer lighting device comprises a supporting plate, a battery box and a lamp body, wherein the supporting plate comprises a fixed plate and a rotating plate; a clamping unit is arranged at one end portion of the fixed plate; the end portion, opposite to the end portion with the clamping unit, of the supporting plate further extends towards a lower surface with the lamp body to form a baffle plate. According to the notebook computer lighting device, the supporting plate is divided into a fixed plate and a rotating plate, the two of which are hinged to each other; the fixed plate can be clamped at the top end of the display screen of the notebook computer, while the rotating plate is capable of rotating around a rotating shaft, and therefore, the light irradiation angle of the lighting device is adjusted according to the opening degree of the display screen of the notebook computer to light the keyboard; the lighting device is cheap and has high practicability.

Owner:TIANJIN XINJIA TIMES TECH

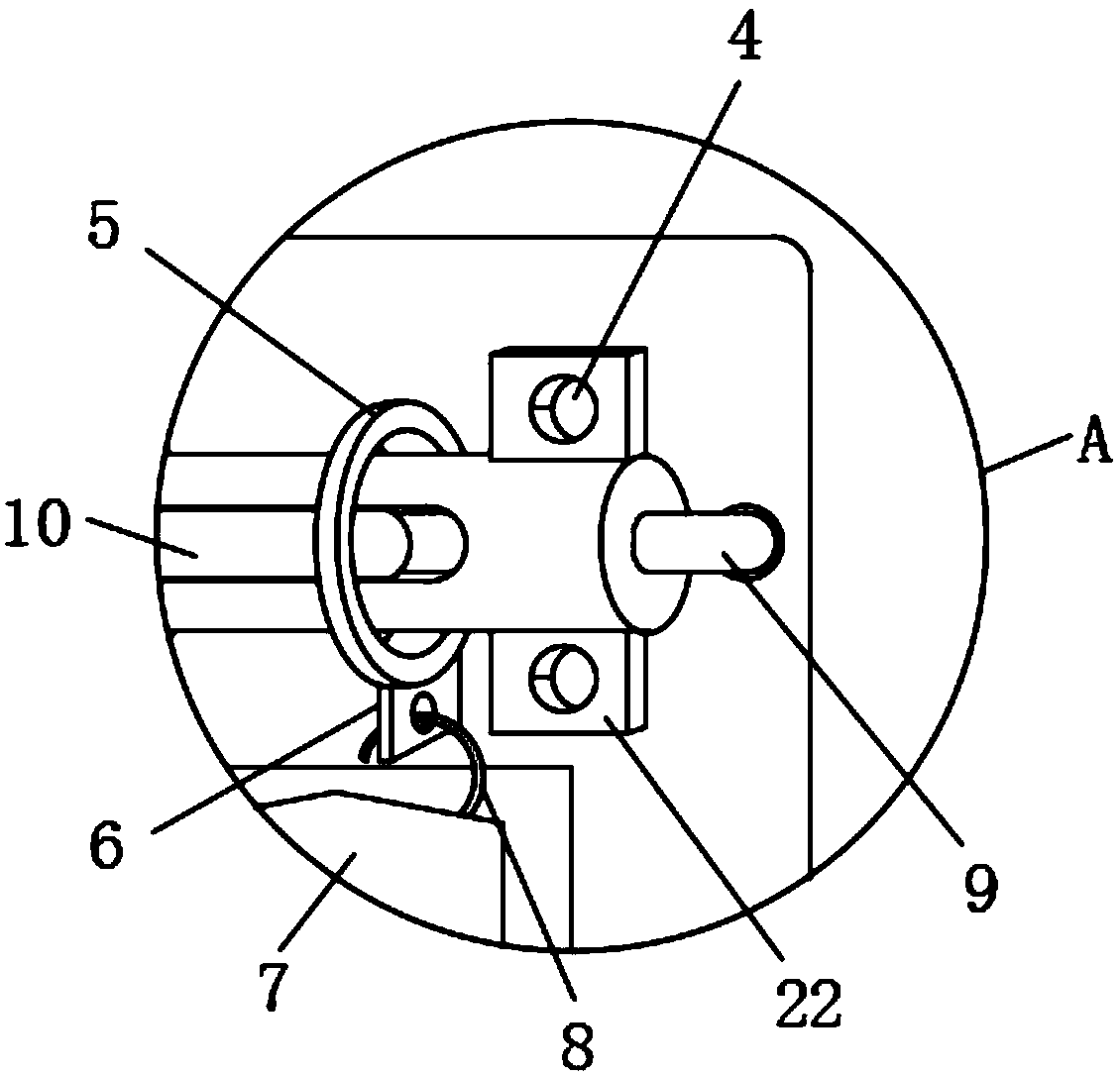

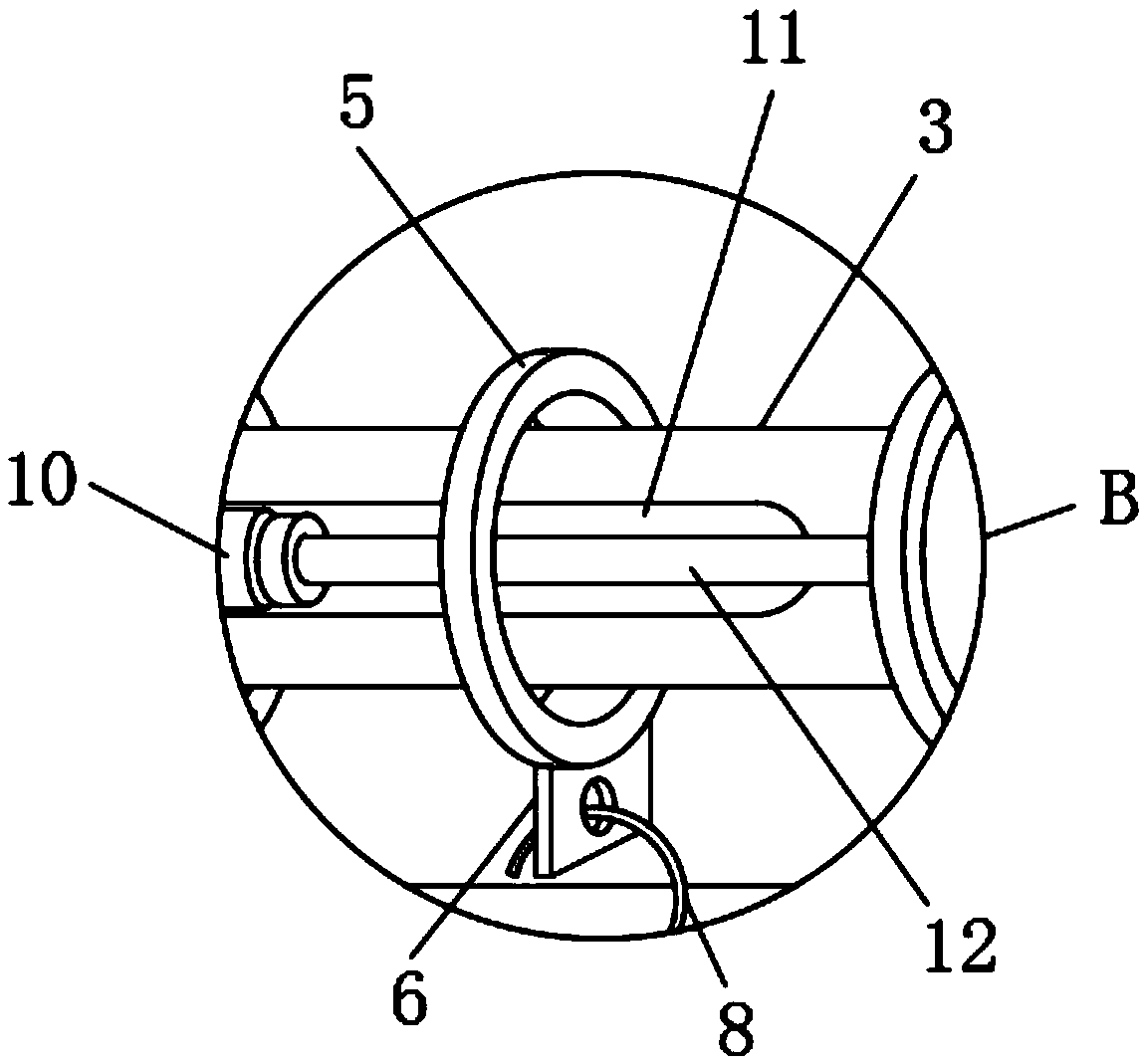

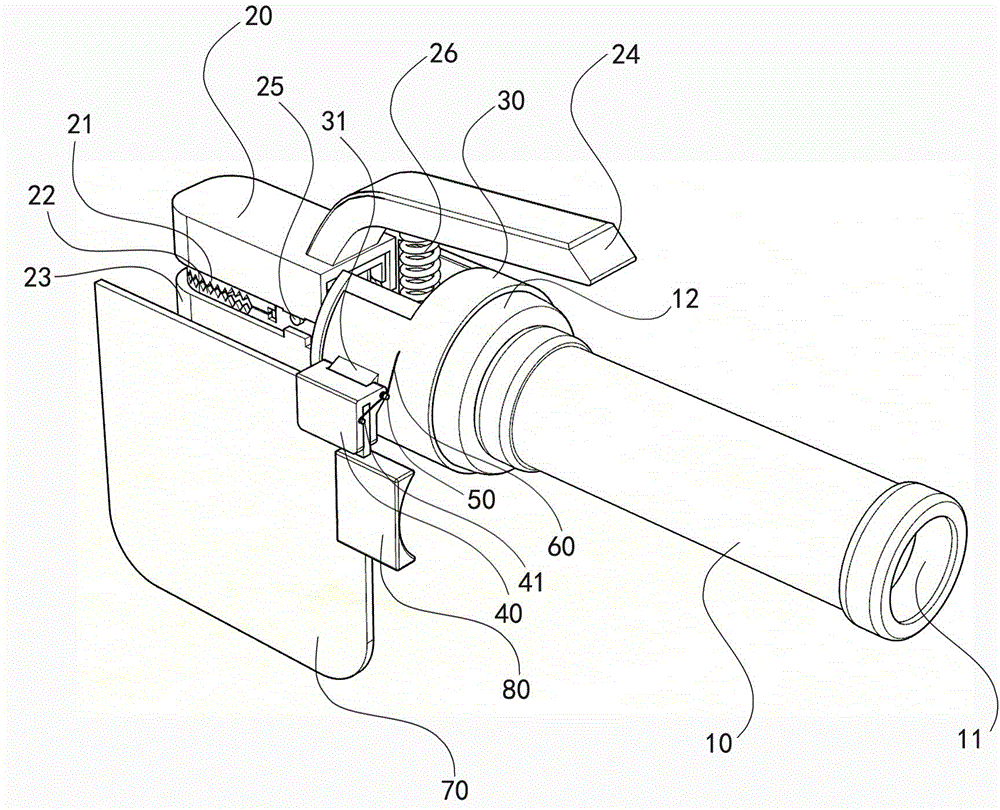

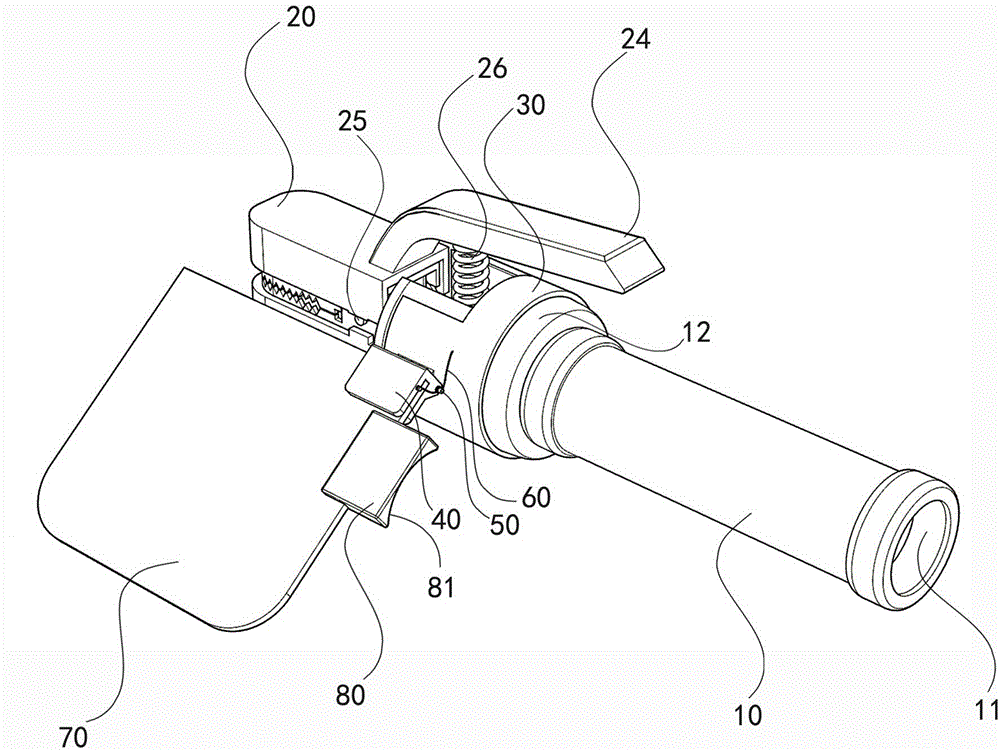

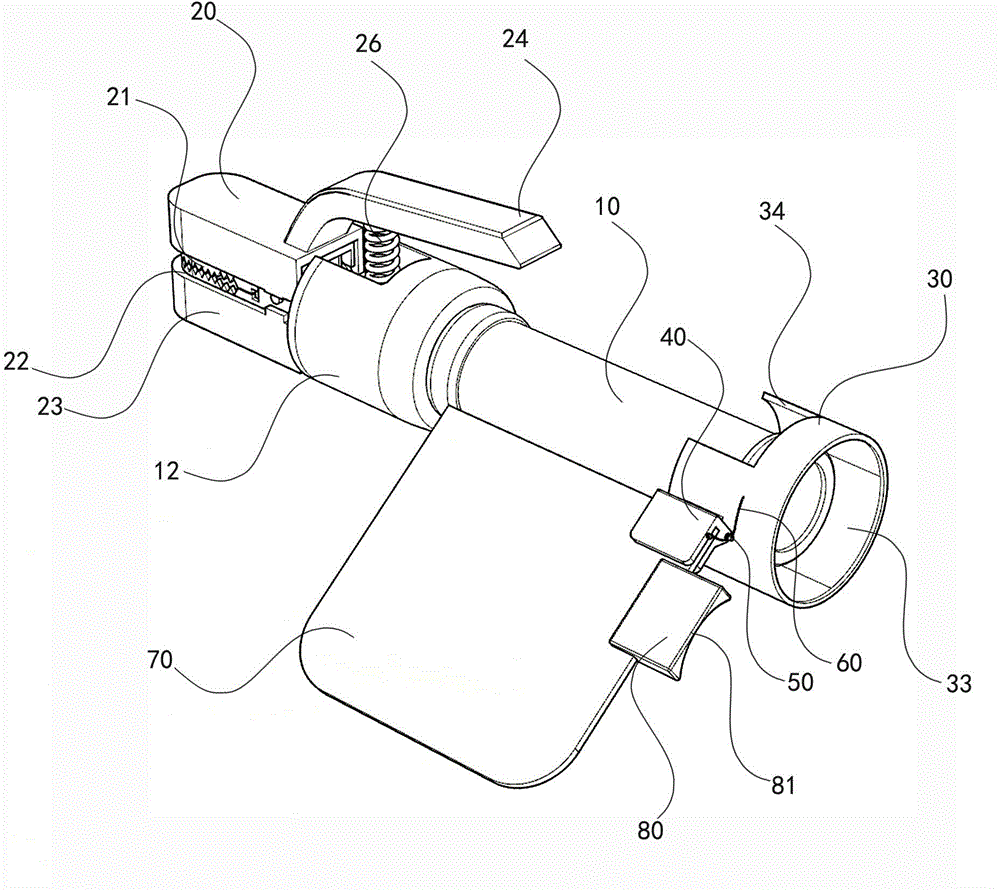

Electric welding fixture capable of being controlled by one hand and provided with welding shielding lens and use method of electric welding fixture

ActiveCN104526138AAvoid direct raysEasy to useSupport devices with shieldingInterference fitRubber ring

An electric welding fixture capable of being controlled by one hand and provided with a welding shielding lens comprises a handle, a wire guide hole, a handle front end, an upper insulating sleeve, an upper copper tooth, a lower copper tooth, a lower insulating sleeve, a hand grip, a large shaft pin, a large spring, a sleeve ring, a protruding head, an inner sleeve ring, a positioning block, a spring clamping strip, a positioning block hole, a positioning clamping groove, a limiting block, a small shaft pin, a small spring, a positioning elbow, a spring ring, a conical head, the black electric welding lens, an edge block, a concave arc edge and an edge block clamping groove, wherein the front end of the handle is sleeved with the sleeve ring, and the sleeve ring is provided with the protruding head, the inner sleeve ring, the positioning block, the spring clamping strip, the positioning block hole, the positioning clamping groove, the limiting block, the small shaft pin, the small spring, the positioning elbow, the spring ring, the conical head, the black electric welding lens, the edge block, the concave arc edge and the edge block clamping groove. An elastic rubber ring is fixed into the sleeve ring. The elastic rubber ring is in interference fit with the front end of the handle. The small shaft pin makes the protruding head on the sleeve ring connected with the positioning block through a pin by means of a protruding head hole and a positioning block hole. By means of the welding fixture, a user can complete the welding work and control the electric welding lens additionally arranged at the front end of the handle by one hand in the welding work process, an operator can emancipate a hand which holds a mask, and the welding efficiency and welding quality can be easily improved.

Owner:桐城市建设投资发展有限责任公司

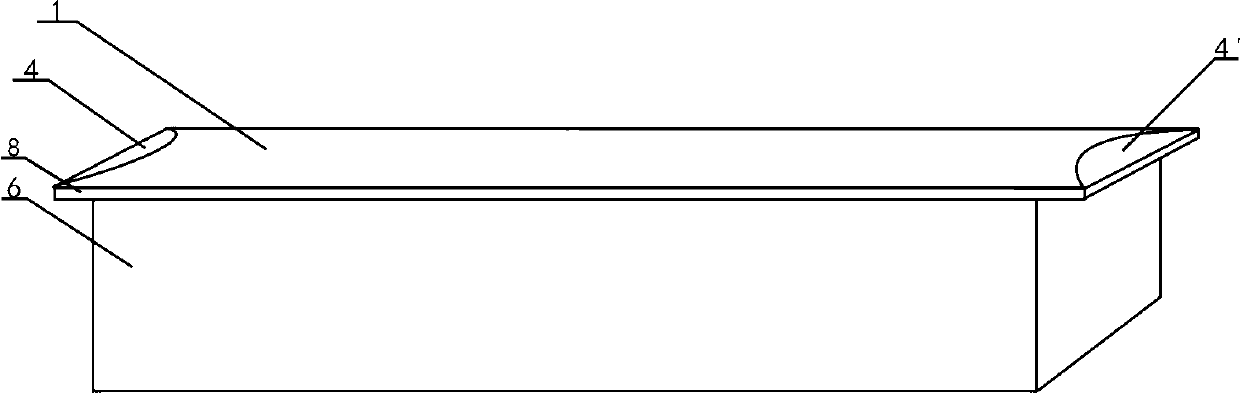

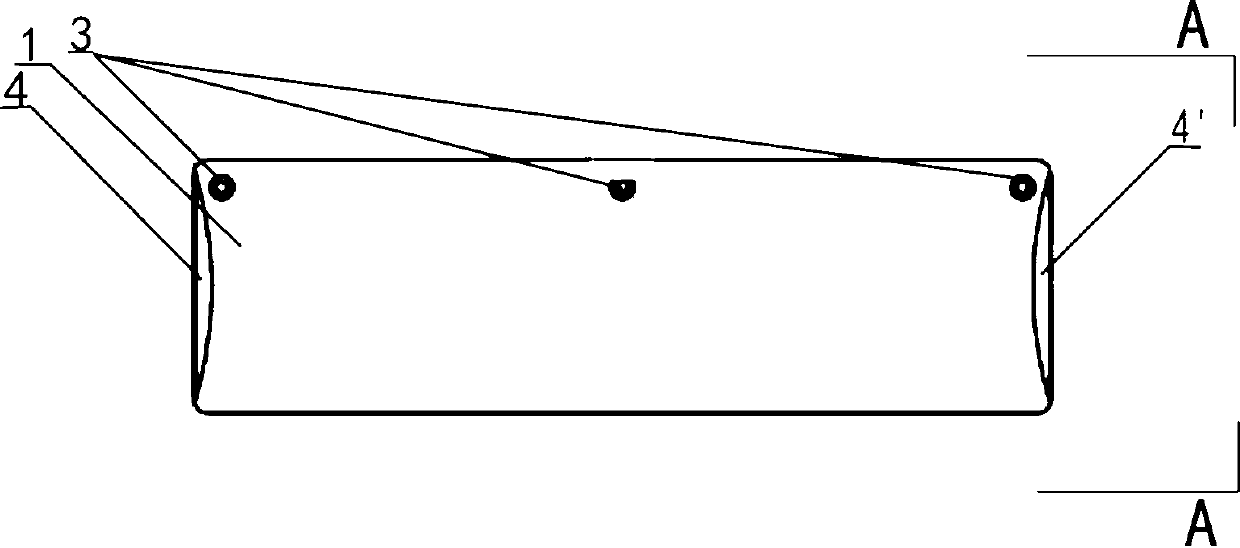

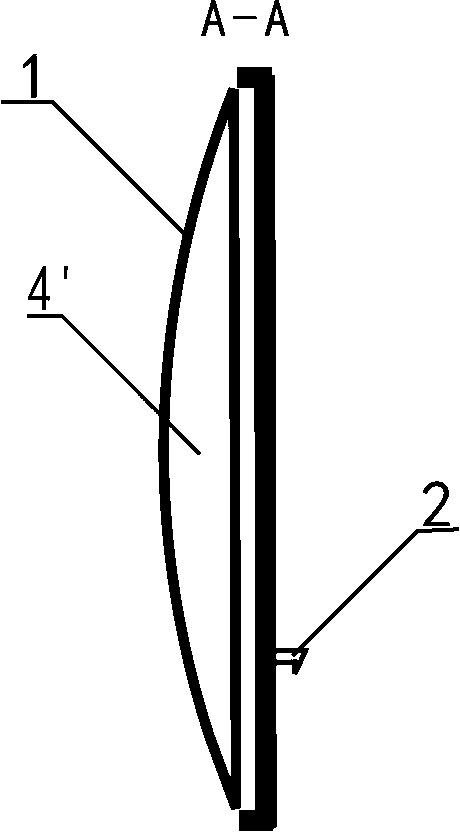

Light box of refrigerated display cabinet

InactiveCN103104892AClosely connectedEasy to disassembleShow cabinetsGlobesChinese charactersEngineering

A light box of a refrigerated display cabinet mainly comprises a face cover and a box body. The light box of the refrigerated display cabinet is characterized in that the face cover comprises clamped buckles, screw holes and a refraction face. The face cover is buckled on the box body in a clamped mode and fixed in a threaded connection mode. The face cover is a rectangular transparent plate body part. The middle portion of the face cover is in an arc-shaped upheaval. Two arc-shaped slope faces are formed by two ends of the arc-shaped upheaval portion and two end portions of the face cover. The refraction face is arranged on the inner face of the arc-shaped upheaval portion of the face cover. Three clamped buckles are arranged on one side of the refraction face inside the face cover. Three screw holes are arranged at the edge of the other side of the face cover at equal intervals, wherein the screw holes at the two ends are respectively close to the two end portions of the face cover. The clamped buckles, the refraction face and the screw holes are formed integrally. The box body is a rectangular-box-shaped body. The edge portion of the upper opening of the box body extends towards the periphery by an equal distance of 2 cm to 3 cm so that a connection part shaped like a Chinese character 'Hui' is formed. Three screw holes are formed in one side of the connection part in a mode of corresponding to the three screw holes of the face cover. The inner edge of the other side of the connection part extends towards the inside of the box body by 1 cm to 1.5 cm so that a clamped connection part is formed, wherein the clamped connection part and the connection part are placed in the same plane. The clamped connection part, the connection part and the box body are formed integrally.

Owner:JIANGSU STAR COLD CHAIN TECH CO LTD

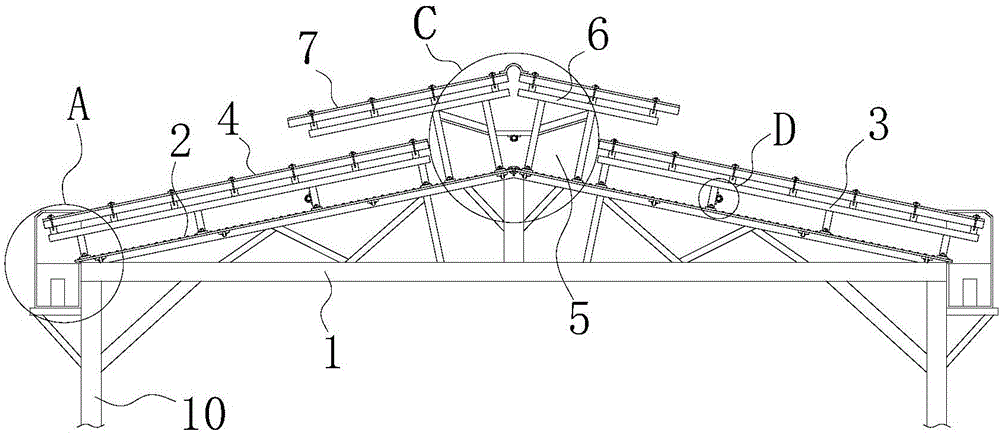

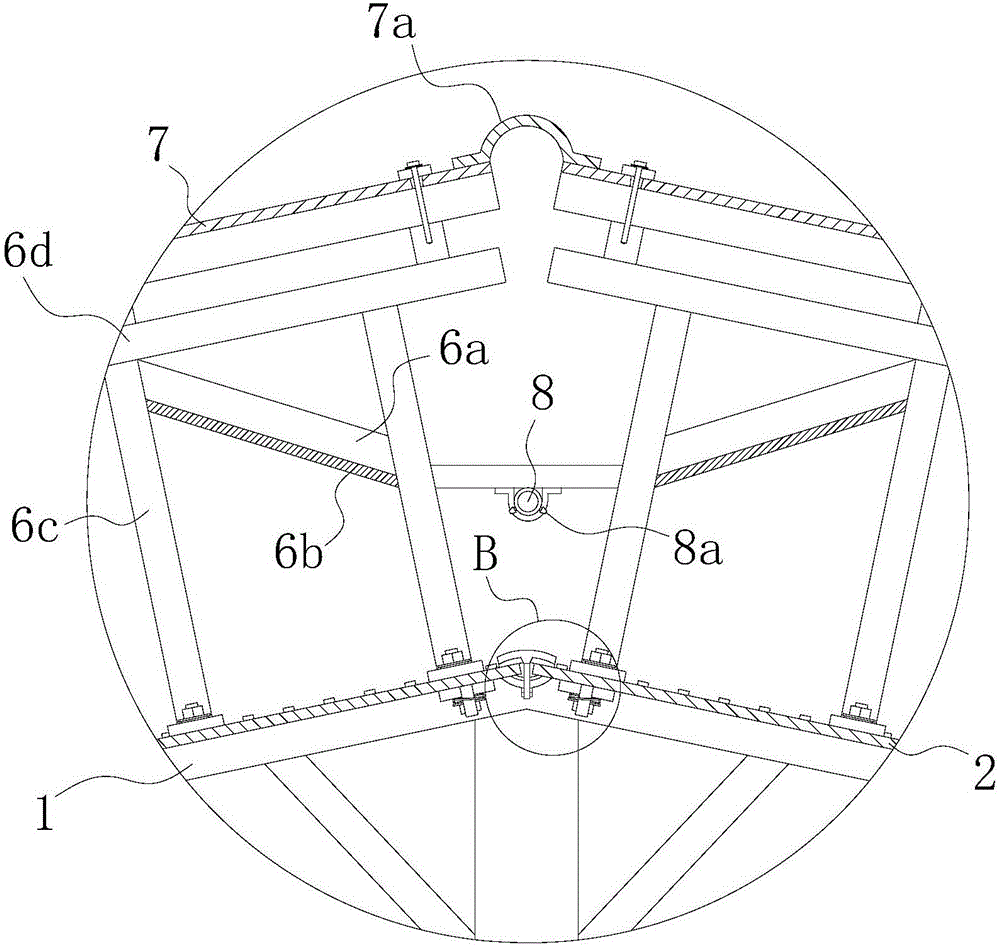

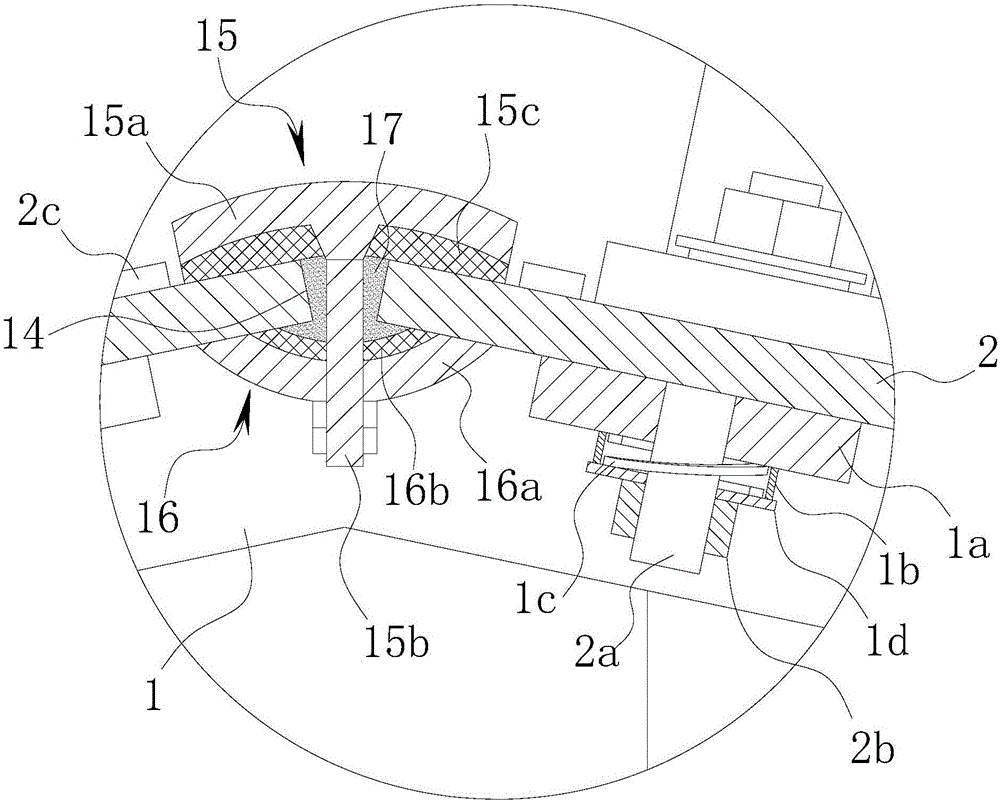

Combined heat insulation type steel-structured ceiling

ActiveCN106193475AEffective coverageImprove distributionBuilding roofsRoof covering using slabs/sheetsEnergy consumptionRadiation effect

The invention discloses a combined heat insulation type steel-structured ceiling, and belongs to the technical field of steel-structure ceilings. The combined heat insulation type steel-structured ceiling is technically characterized by comprising a bracket, wherein the section of the bracket is triangular; water-insulating layers cover two oblique surfaces of the bracket; the upper ends of the water-insulating layers are hermetically connected; auxiliary brackets cooperating with the bracket are arranged above the water-insulating layers on two sides; heat-insulating layers mutually parallel to the corresponding water-insulating layers are arranged on all the auxiliary brackets; a heat-radiating and flow-guiding gap is formed between the two heat-insulating layers; a flow-guiding bracket cooperating with the bracket is arranged in the heat-radiating and flow-guiding gap; a splayed flow-guiding and sun-shading layer is arranged on the flow-guiding bracket; the upper end of the flow-guiding and sun-shading layer is connected by a sealing element; the flow-guiding and sun-shading layer is located above the heat-insulating layers; inclined struts are arranged on the flow-guiding bracket; flowing-guiding plates are arranged on the lower end surfaces of the inclined struts. The invention aims at providing the combined heat insulation type steel-structured ceiling which is compact in structure and good in heat radiation effect, further, is relatively low in energy consumption, and is used for heat insulation of a steel-structure building.

Owner:GUANGDONG ZHENGHUA STEEL STRUCTURE

Multifunctional street lamp based on decomposition reaction

ActiveCN110762430AIncrease air pressureNo input requiredMechanical apparatusLighting elementsPhysicsLamp shell

The invention belongs to the field of street lamps, and especially relates to a multifunctional street lamp based on a decomposition reaction. The multifunctional street lamp comprises a lamp shell and a lamp tube; a plurality of upper vent holes are arranged at the upper end of the side wall of the lamp shell; a plurality of lower vent holes are arranged at the lower end of the side wall of the lamp shell; a transmission box is arranged at the upper end of the lamp tube; sliding plates which are vertically arranged are in sealing sliding connection with the left end and the right end of the inner cavity of the transmission box; a gas storage cavity is formed between two sliding plates; one end, far away from the gas storage cavity, of each sliding plate forms a driving cavity with the transmission box; a driving agent is contained in the driving cavity; an adjusting cylinder is rotationally connected outside the transmission box through a rotating mechanism; and vertically arranged bearing strips are arranged at the two ends of the adjusting cylinder. According to the multifunctional street lamp based on the decomposition reaction provided by the invention, the driving agent in the driving cavity generates a gas reaction under the irradiation of the light of the lamp tube, so that the air pressure in the driving cavity is increased, the sliding plates are pushed to slide, whenthe light is blocked, a reverse reaction occurs in the driving cavity, the sliding plates are driven to slide reversely, power can be provided for heat dissipation and insect expelling of the lamp body, and external energy input is not needed.

Owner:江苏轩朗照明电器有限公司

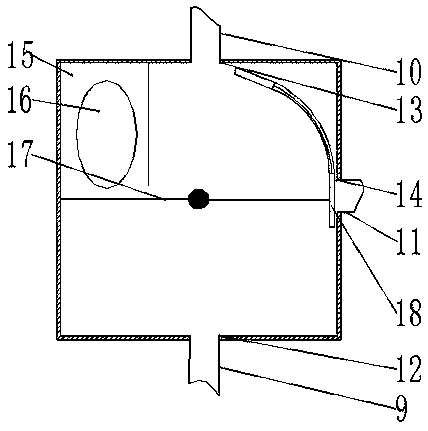

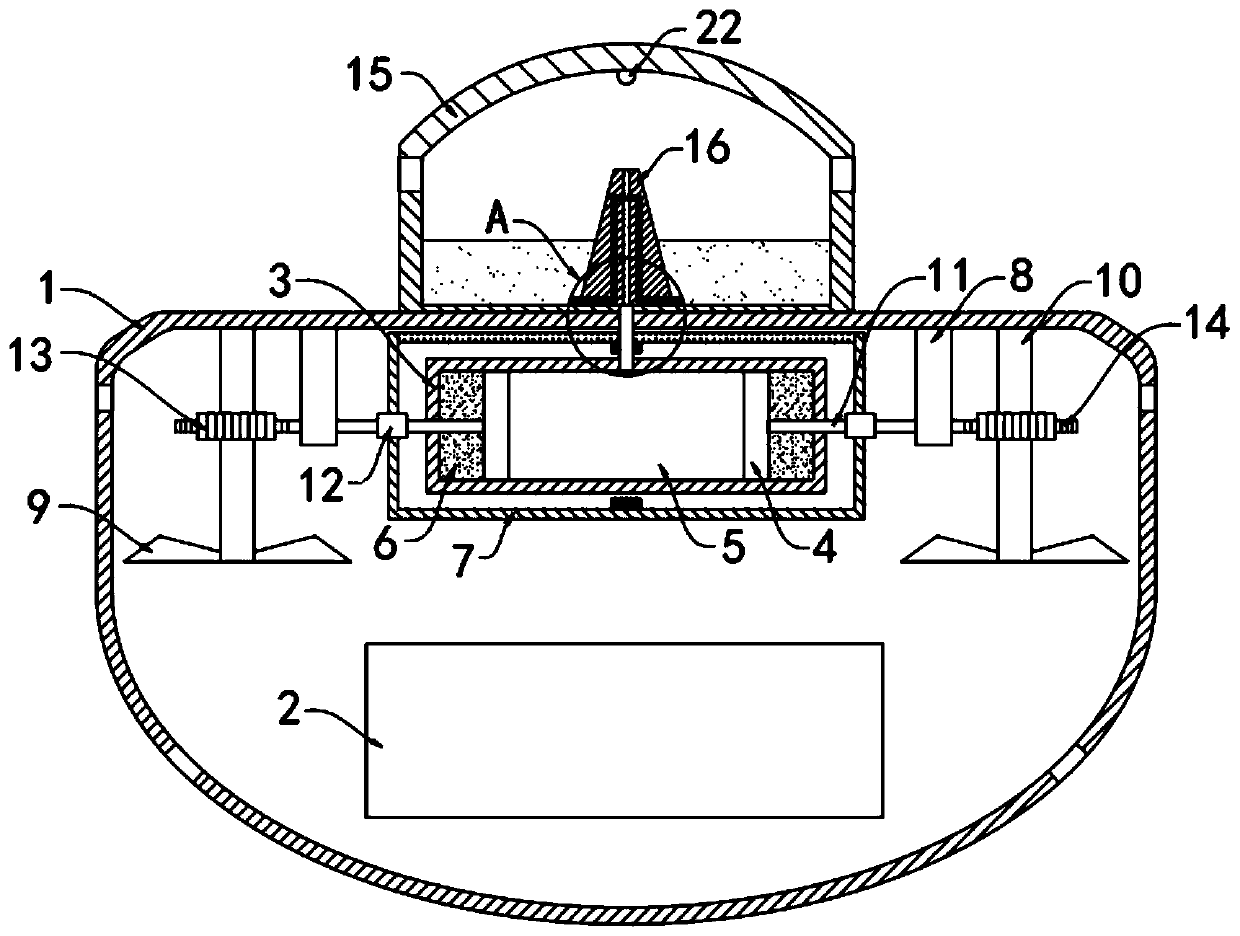

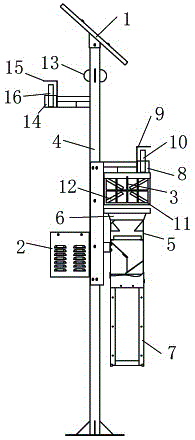

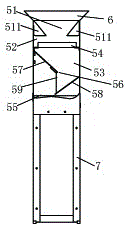

Power cabin assembly of multipurpose splitlevel winged insect trap

ActiveCN105076089APrevent reverse escapeExpand the range of suctionInsect catchers and killersInlet channelEngineering

The present invention belongs to the technical field of winged insect trap appliances, and especially relates to a power cabin assembly of a multipurpose splitlevel winged insect trap. The present invention discloses a power cabin assembly of a multipurpose splitlevel winged insect trap. The power cabin assembly is composed of an air inlet duct, a power cabin and an air exhausting duct; an upper end of the air inlet duct is connected with a hopper type insect receiving air inlet device; a turbine fan is disposed in the power cabin; the bottom of the air exhausting duct is provided with an air exhausting insect inlet channel to be connected with an insect storage chamber; and a lower end of a suspension type winged insect escape prevention apparatus is separated from a lower light baffle plate to open an air exhausting insect entering channel. The power cabin assembly of the multipurpose splitlevel winged insect trap has the beneficial effects that light rays of the light source can be prevented from downwardly entering into the insect storage chamber, wind is prevented from upwardly whirling when the fan is used, and winged insect capture efficiency of a light source type capture apparatus can be improved.

Owner:德清科中杰生物科技有限公司

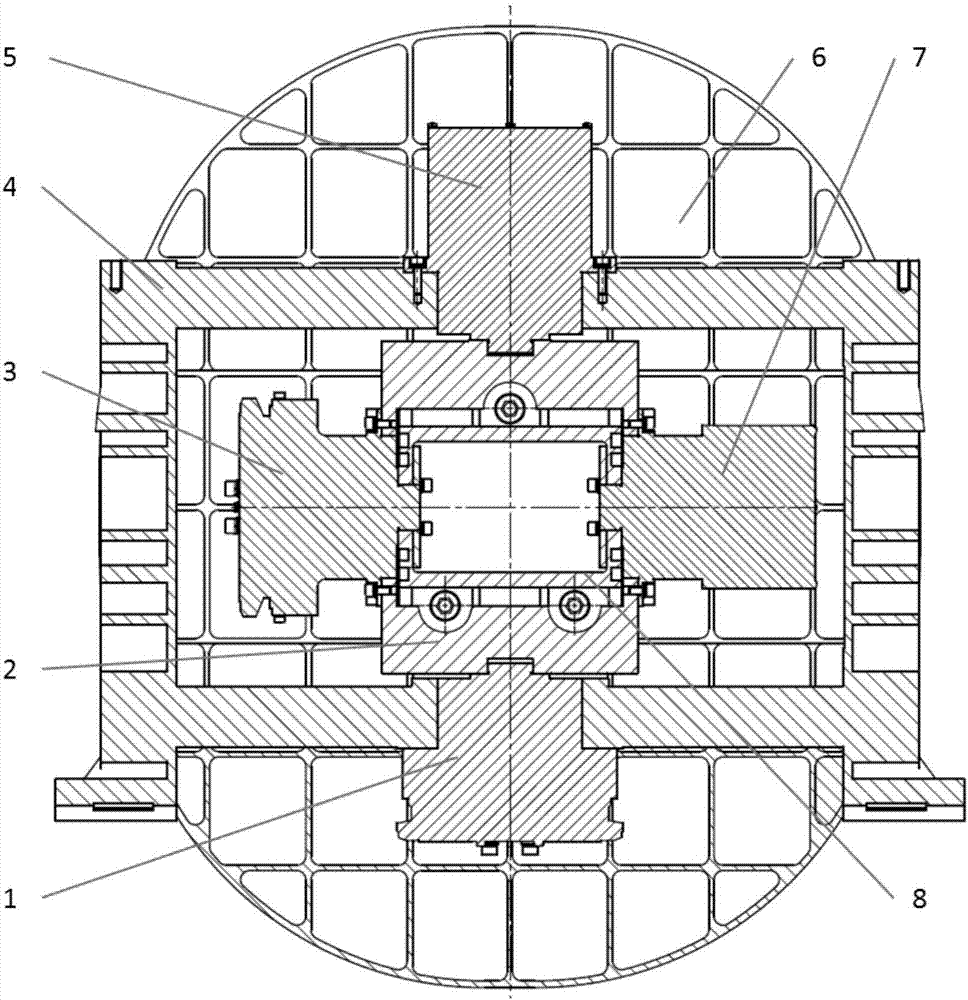

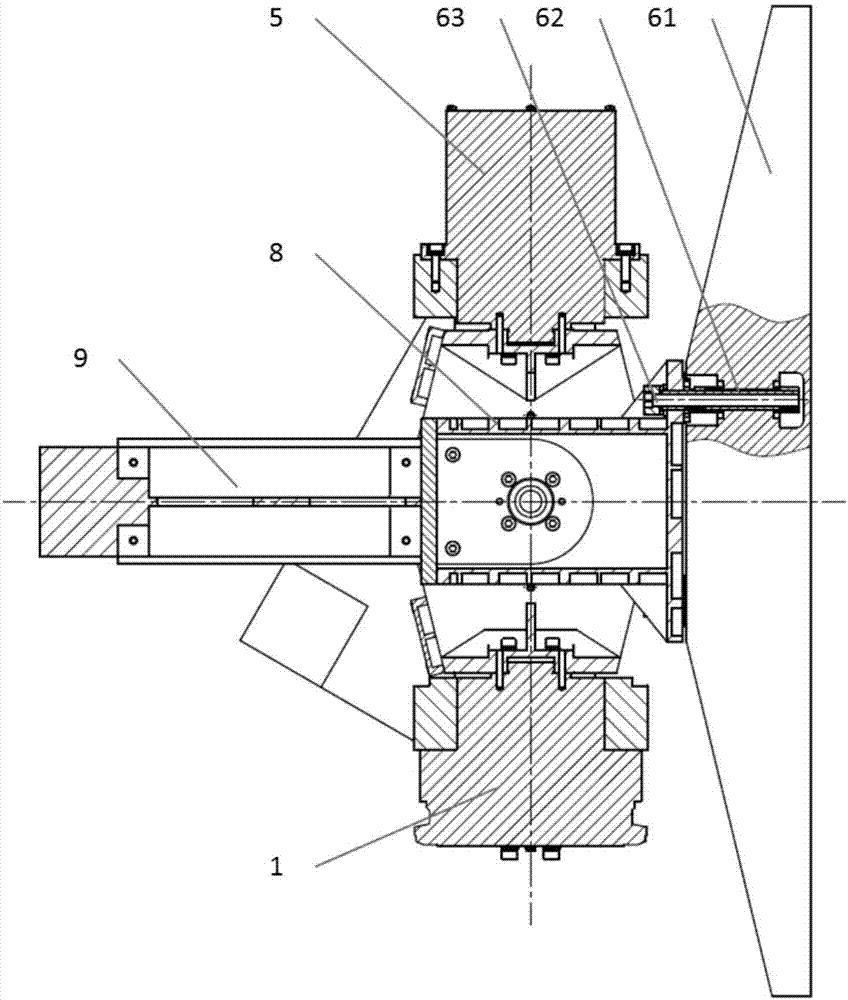

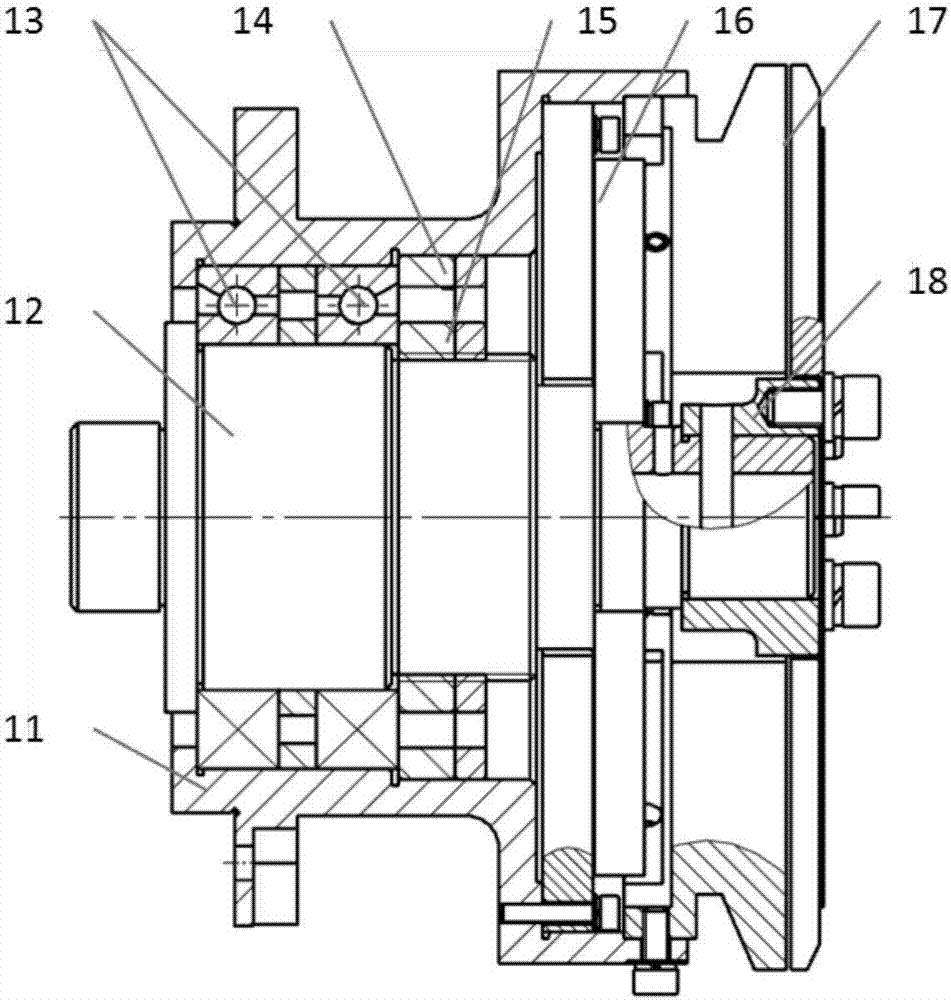

Two-dimensional directing mechanism for optical remote sensing instrument

ActiveCN107218960AImprove pointing accuracyLong axis decreaseMeasurement apparatus componentsGear wheelEngineering

The invention discloses a two-dimensional directing mechanism for an optical remote sensing instrument. The two-dimensional directing mechanism comprises an upper half shaft assembly, a lower half shaft assembly, a left half shaft assembly, a right half shaft assembly, a directing mirror assembly, an inner frame, an outer frame, a support frame and a counterweight. The lower half shaft assembly and the left half shaft assembly have the same structure. The upper half shaft assembly and right half shaft assembly have the same structure. The upper half shaft assembly, the lower half shaft assembly and the inner frame constitute a pitch axis system. The left half shaft assembly, the right half shaft assembly, the outer frame and the pitch axis system form an azimuth axis system. The two-dimensional directing mechanism is high in directing precision, light in weight, low in moment of inertia, small in interference torque of satellite platform, compact in structure, simple in structure, and directly driven to avoid a complex harmonic reducer or gear reduction mechanism, and highi in reliability.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

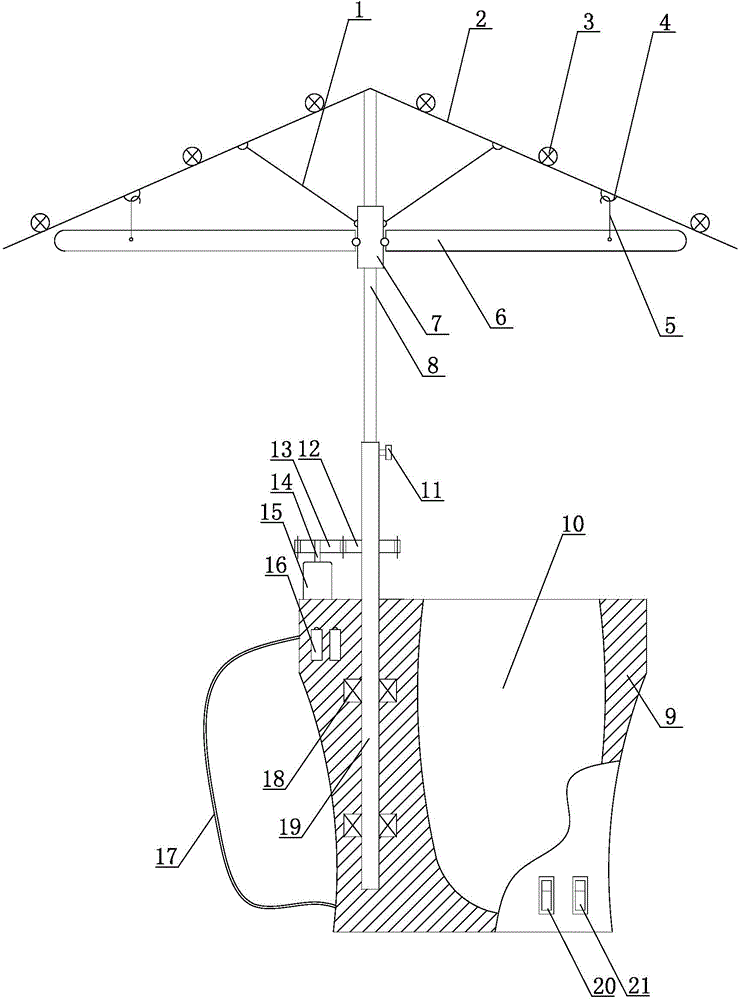

Pack basket sunshade umbrella

InactiveCN104957926ASimple structureHigh degree of automationWalking sticksChildren furnitureDrive motorEngineering

The invention discloses a pack basket sunshade umbrella. The pack basket sunshade umbrella comprises a pack basket body, the front portion of the pack basket body is provided with a strap, a pack basket cavity is formed in the pack basket body, a supporting pole is inserted in the pack basket body, a telescopic rod is inserted in the supporting pole, the top of the telescopic rod is provided with an umbrella body, the telescopic rod is sleeved with a slide block, a plurality of supporting rods are arranged between the slide block and the umbrella body, one end of each supporting rod is hinged to the umbrella, the other end of the each supporting rod is hinged to the slide block, a plurality of fan blades are also hinged to the slide block, the other ends of the fan blades are provided with hooks, a plurality of hanging rings are uniformly distributed on the umbrella body, a driving motor is fixed onto the top face of the pack basket body, a spindle is arranged on the driving motor, a driving gear is fixed onto the spindle, a transmission gear is fixed onto the supporting pole, and the transmission gear is meshed with the driving gear. The pack basket sunshade umbrella has the advantages that the structure is simple, the sunshade function and the cool enjoying function are achieved, the cool enjoying function is automatically completed by the driving motor, and the automation degree is high.

Owner:郭上一

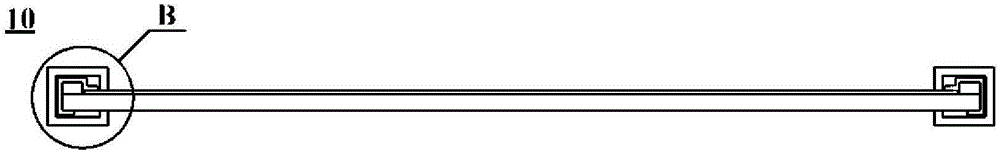

Object placement rack and refrigerator provided with rack

InactiveCN106766634ACompact structureImprove light utilizationLighting and heating apparatusLighting arrangementRefrigerated temperatureComputer science

The invention provides an object placement rack. The object placement rack comprises an object placement substrate used for supporting objects and is characterized in that the object placement rack further comprises illuminating members and reflective foils; the illuminating members are arranged on the object placement substrate and arrayed at least one lateral edge of the object placement rack in a linear manner and used for providing light for the object placement rack; and the reflective foils are arranged to wrap the surfaces of the illuminating members and used for preventing light emitted by the illuminating members from overflowing the object placement rack. The object placement rack and the refrigerator provided with the rack have following beneficial effects: by linearly arraying the illuminating members on the edge of the object placement substrate and wrapping the reflective foils on the surfaces of the illuminating members, the object placement rack has a simple and compact structure; no extra storage space is occupied; the arrangement of the reflective foils helps prevent light emitted by the illuminating members from overflowing the object placement rack and prevent light from directly shining into human eyes, thereby increasing light utilization rate of the illuminating members; and in addition, the reflective foils help dissipate heat of the illuminating members so that service lifetime of lamp beads is prolonged.

Owner:HAIER SMART HOME CO LTD +1

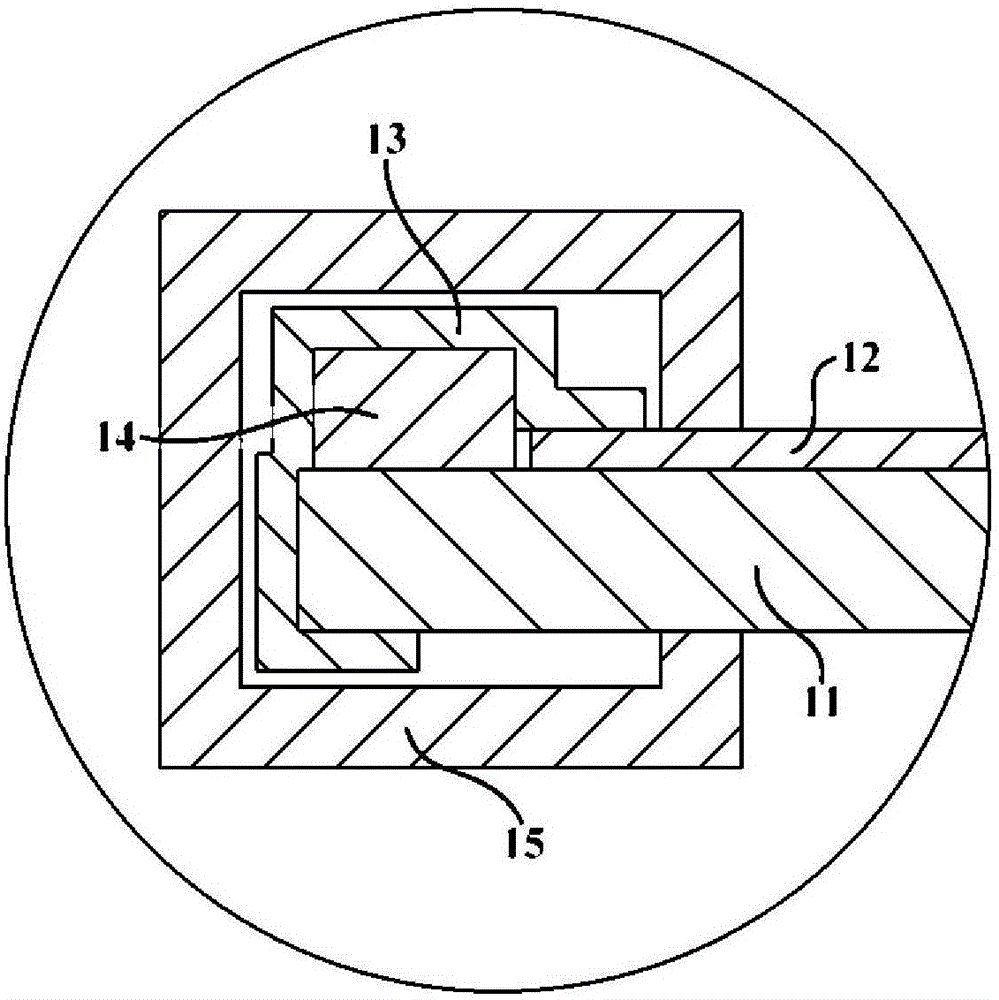

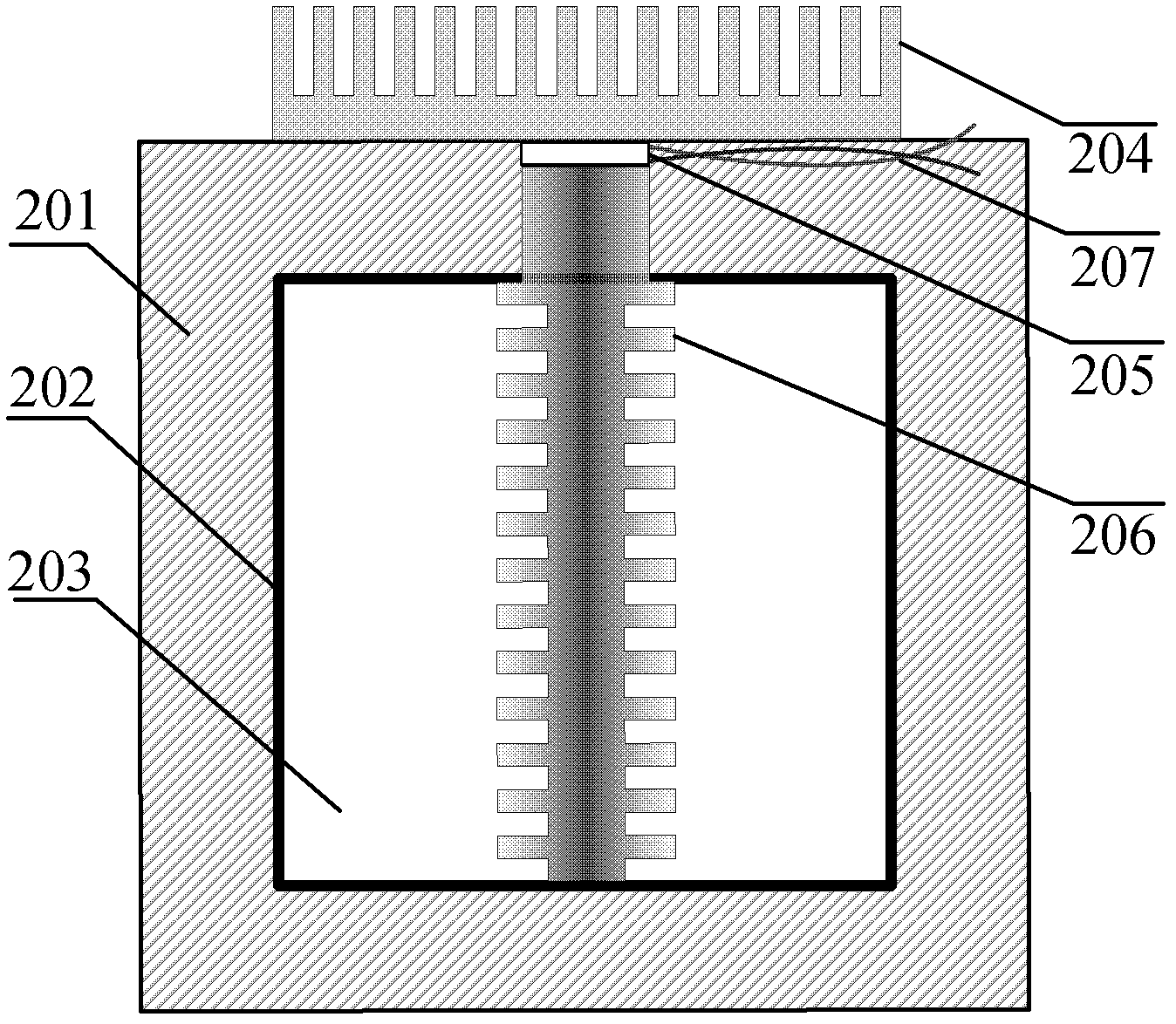

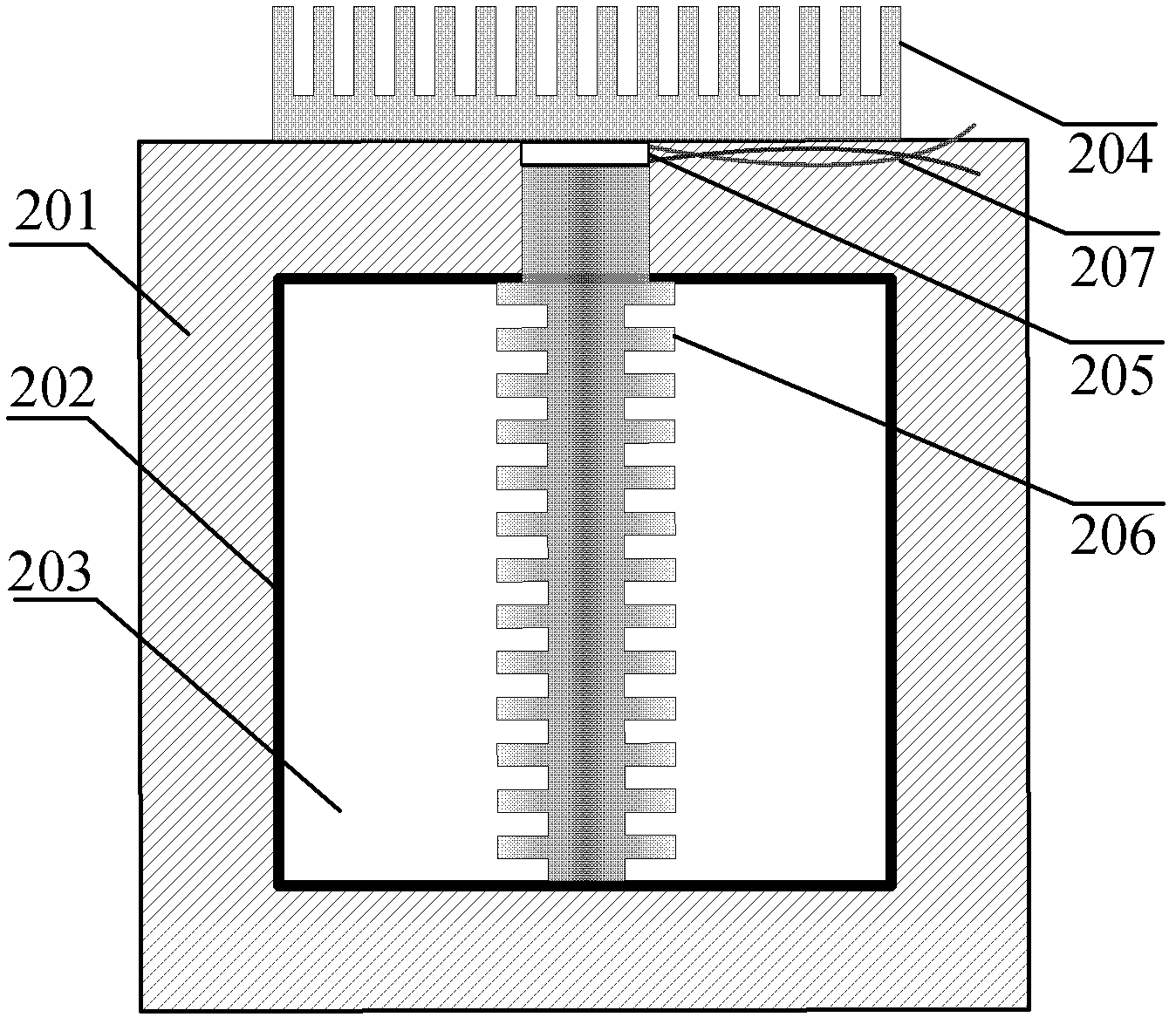

Atmospheric temperature difference power generation device

InactiveCN102545715AAvoid the link of mechanical energy conversionImprove thermal power generation efficiencyGenerators/motorsThermoelectric devicesInsulation layerAtmospheric air

The invention discloses an atmospheric temperature difference power generation device, which mainly solves the problems of low efficiency and heat utilization rate, poor stability and the like of the conventional device. The device comprises a heat storage box (201) with a heat insulation layer (202), an external heat exchange fin (204), an internal heat exchange fin (206), and a semiconductor temperature difference power generation sheet (205) between the external heat exchange fin (204) and the internal heat exchange fin (206), wherein a liquid heat storage working medium (203) of which the temperature slowly changes along with fluctuation of air temperature is filled in the heat storage box (201); after long-term accumulation and counteracting of heat, the temperature of the liquid heat storage working medium (203) tends to be an average air temperature; and dynamic temperature difference between dynamic air temperature and average air temperature is formed inside and outside the heat storage box (201), is fed into the two ends of the semiconductor temperature difference power generation sheet (205) through the external heat exchange fin (204) and the internal heat exchange fin (206) and is further converted into voltage which is directly proportional to the dynamic temperature difference and output. The device has the characteristics of high efficiency and heat utilization rate and continuous electric energy output and can be used for providing power for low-power-consumption electronic equipment such as a distributed wireless sensor node for a long time.

Owner:XIDIAN UNIV

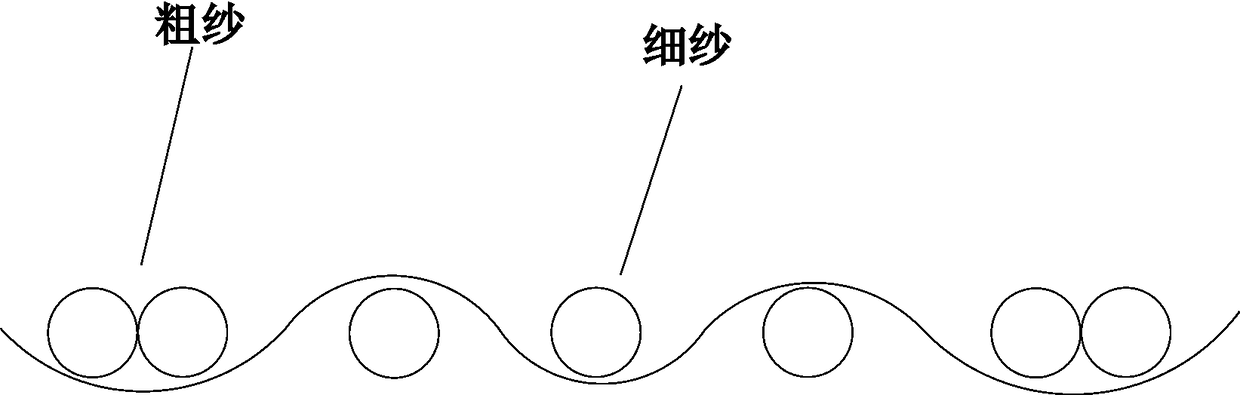

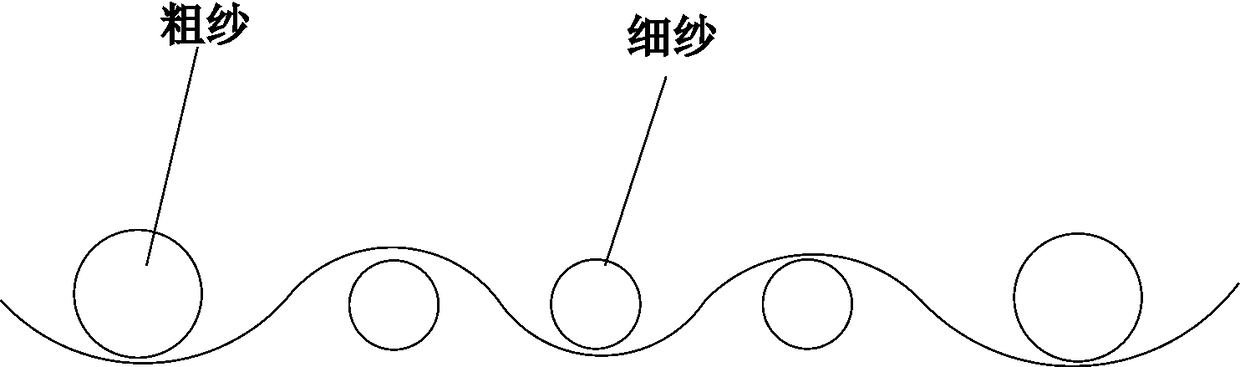

Breathable cool ultraviolet ray proof woven fabric

The invention discloses a breathable cool ultraviolet ray proof woven fabric, and relates to a woven fabric. The fabric is formed by interlacing warp yarns and weft yarns, at least one of the warp yarns or the weft yarns has a structure in which roving and spun yarns are uniformly mixed and arranged, the warp yarns and the weft yarns are interlaced to form a uniformly distributed and convex line structure or mesh structure on the fabric surface, the cross sections of fibers in the warp yarns and the weft yarns are polygons with a plurality of lobes, and the adjacent fibers conform to each other. Compared with the prior art, special weaving is conducted on the yarns with special structures, so that the fabric is provided with a concave-convex structure, does not fully fit a human body, canmaintain the ventilation between the fabric and the human body, and has the effect of quick sweat absorption and perspiration, the special structures of the yarns also keep the tightness between the yarns, and prevent ultraviolet rays from irradiating, and the fabric has the effect of isolating the ultraviolet rays.

Owner:MAXWIN CHINA CO LTD

Bicycle rainproof saddle

PendingCN108516034AAvoid getting the car seat wet or exposed to direct sunlightAvoid getting wetCycle saddlesEngineeringSunlight

The invention discloses a bicycle rainproof saddle. The saddle comprises a saddle body and a support column which are connected in sequence from top to bottom; a vertically penetrating through hole isformed in the middle of the saddle body, and a folding umbrella is arranged in the through hole. The folding umbrella comprises a sleeve, a trigger spring, a steel ring and a center cylinder which are coaxially arranged from top to bottom in sequence; the inner diameters of the sleeve, the trigger spring and the steel ring are the same as the outer diameter of the center cylinder, and the sleeve,the trigger spring and the steel ring can slide vertically along the center cylinder; the center cylinder is internally provided with a clamp component; the clamp component is connected with and fixed to a kickstand rotating shaft through a tensile steel wire, the winding direction of the tensile steel wire is the same as the rotating direction of the kickstand rotating shaft when a kickstand isput down, and the tensile steel wire is in a loose condition when the kickstand is put away. Accordingly, when a bicycle is not used, the folding umbrella in the middle of the saddle body can be opened to cover the saddle body, and then the phenomenon that the saddle gets wet or is exposed to the sunlight can be avoided; when a person rides the bicycle, the unfolding umbrella is folded and put into the through hole formed in the middle of the saddle body, and then the person can ride the bicycle.

Owner:SOUTHWEST JIAOTONG UNIV

Snakelike movement-based charging pile plug adjusting device

ActiveCN110228387AEasy to insertSave human effortCharging stationsElectric vehicle charging technologyRubber ringEngineering

The invention discloses a snakelike movement-based charging pile plug adjusting device that comprises a control pile; a cable is arranged on a side wall of the control pile; one end is fixedly connected with the interior of the control pile; the end, away from the control pile, of the cable is fixedly connected with a charging gun. A surface of the end, close to the charging gun, of the cable is fixedly connected with a power assisted machine shell in a surrounding mode; two ends of the power-assisted machine shell are sealed with the cable surface through rubber rings. A telescopic sleeve isarranged on the side, close to the charging gun, of the power assisted machine shell; the telescopic sleeve is arranged on the outer surface of the cable in a surrounding mode; the power assisted machine shell is cylindrical; four electric motors are arranged in the power assisted machine shell in a surrounding mode, and winding shafts are arranged at side ends, close to the telescopic sleeve, ofthe four electric motors. The problem that a charging cable cannot be smoothly bent when a high-power charging pile is used can be effectively solved, and the cable can be protected.

Owner:ELECTRIC POWER RES INST OF GUANGXI POWER GRID CO LTD +1

Automatic-lifting flowerpot device

InactiveCN107548794ASimple structureAvoid direct raysReceptacle cultivationElectricityImproved survival

The invention relates to an automatic-lifting flowerpot device which comprises a flowerpot body, a flowerpot frame, an extensible mechanism, a temperature sensor, a control mechanism and a solar component. Each of the flowerpot body and the flowerpot frame is of a hollow structure with an opening at the upper end, the flowerpot body slidably sleeves inside the flowerpot frame, and the extensible mechanism is mounted at and connected with the bottom of the flowerpot frame; the temperature sensor is mounted above the flowerpot body and sends sensing signals to the control mechanism, the controlmechanism controls moving state of the extensible mechanism according to the sensing signals, and the solar component is arranged on the outer wall of the flowerpot body and electrically connected with the control mechanism. The automatic-lifting flowerpot device is ingenious in structural design and capable of automatically adjusting height of a flowerpot according to surrounding environment, thereby avoiding the circumstance that flowers and grass receive excessive illumination for a long time and improving survival rate of the flowers and the grass.

Owner:张彩银

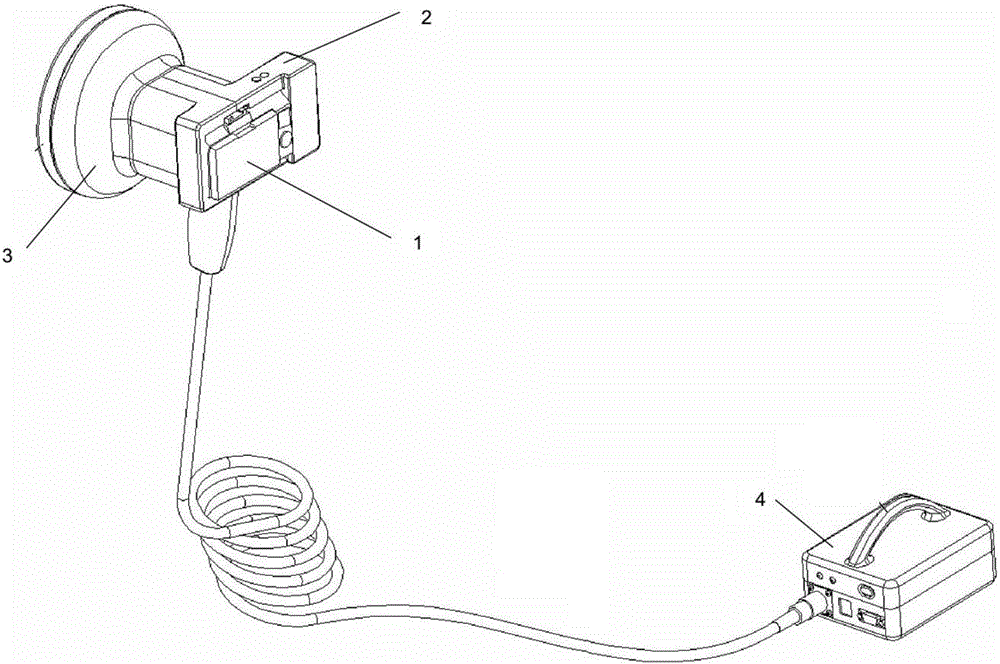

Mobile tongue picture and face picture instrument

PendingCN106037659AReduce weightEasy to carry and useDiagnostic recording/measuringSensorsMedicineComputer graphics (images)

The invention relates to a mobile tongue picture and face picture instrument. The mobile tongue picture and face picture instrument comprises a camera, an outer shell and a light source shell, wherein one side of the outer shell is provided with a camera connecting groove, the camera connecting groove is connected with the camera, and the end surface of the outer part, vertical to the camera connecting groove, of the outer shell is provided with a handheld handle; the small end, of the funnel-shaped light source shell is fixedly connected to one side, opposite to the camera connecting groove, of the outer shell, and the light source shell communicates with the camera connecting groove. The mobile tongue picture and face picture instrument is light in weight and can be conveniently moved for use, meanwhile, the collected face picture, tongue surface picture or tongue root picture is clear and real, so that the correct diagnosis is guaranteed, and the mobile tongue picture and face picture instrument can be applied to a ward for use or used for the door-to-door diagnosis and treatment.

Owner:郭福生

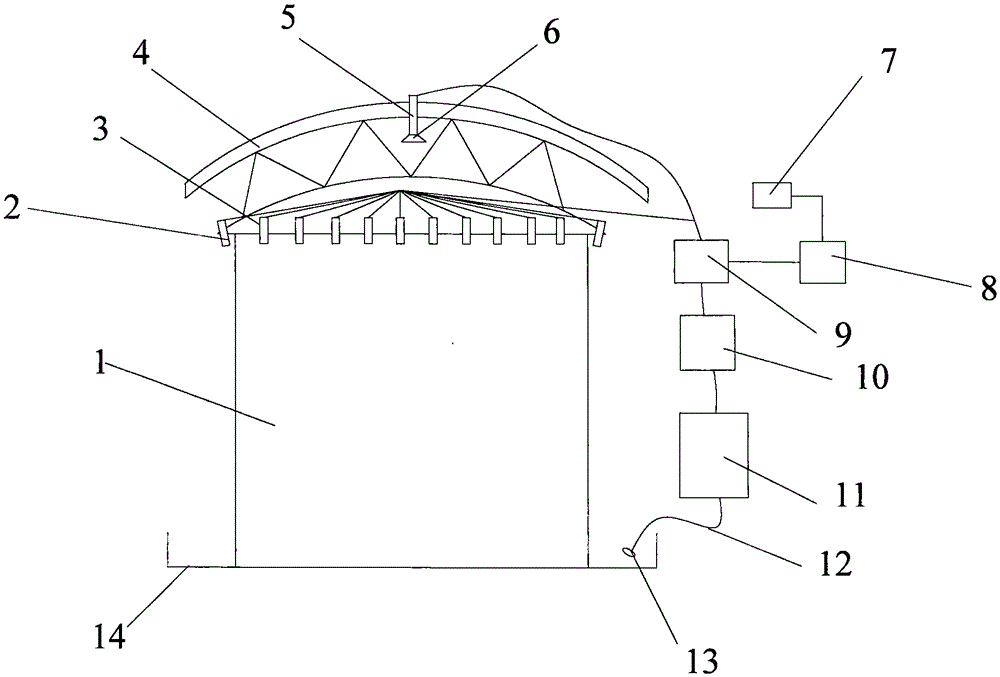

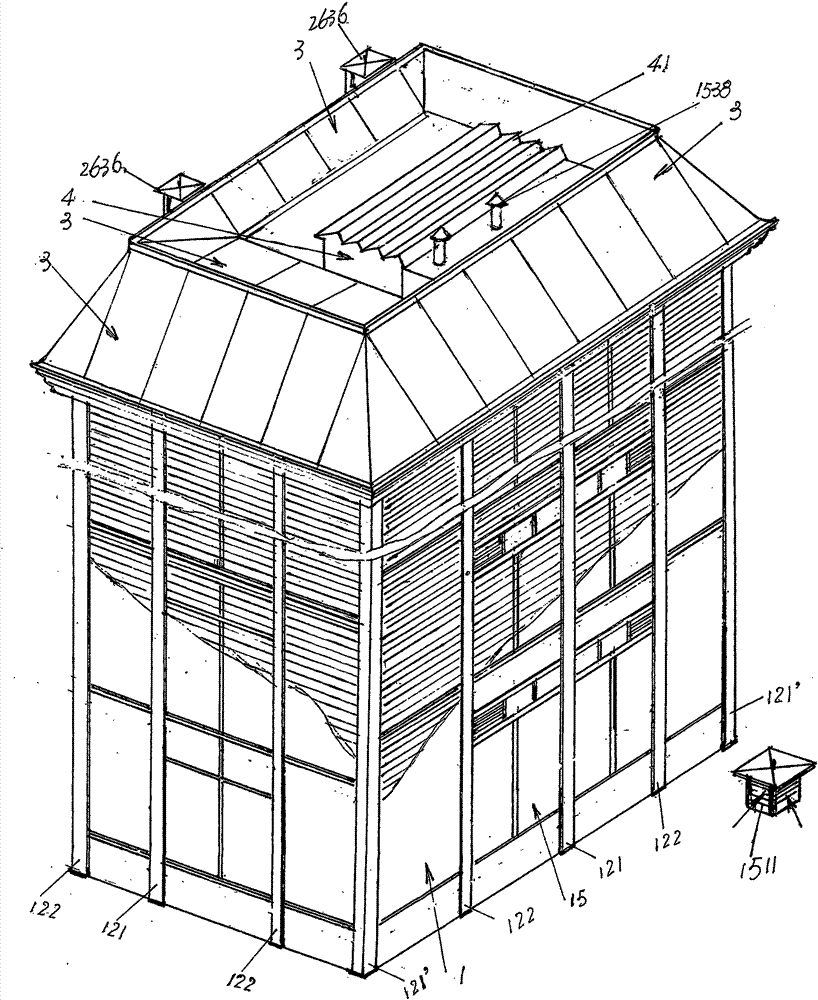

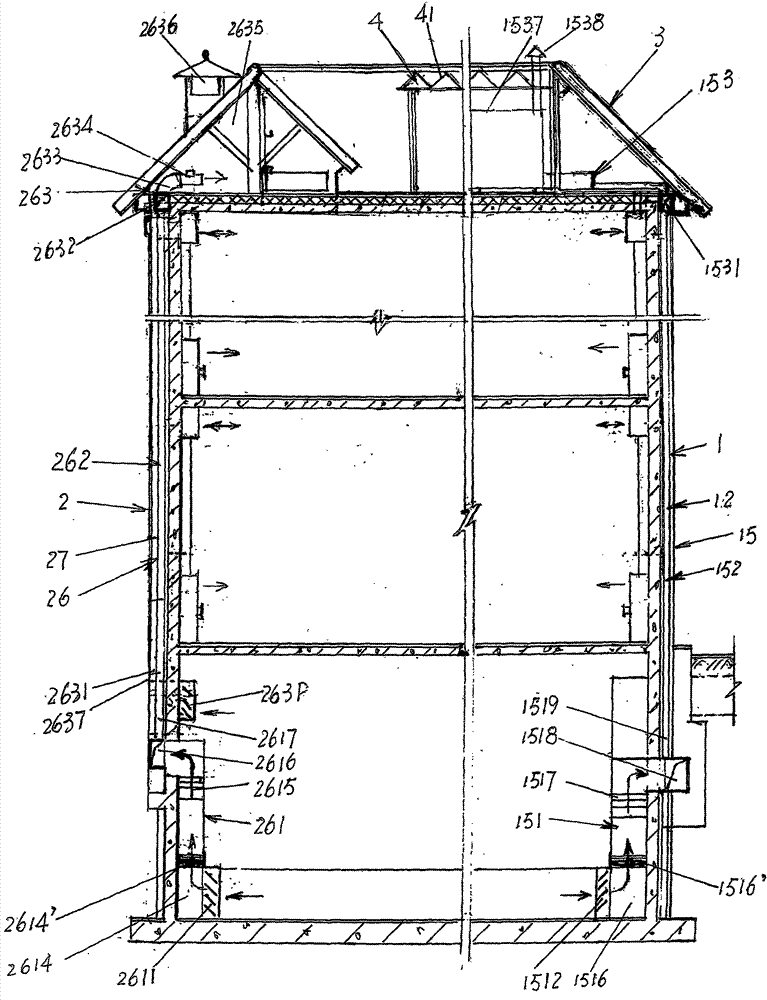

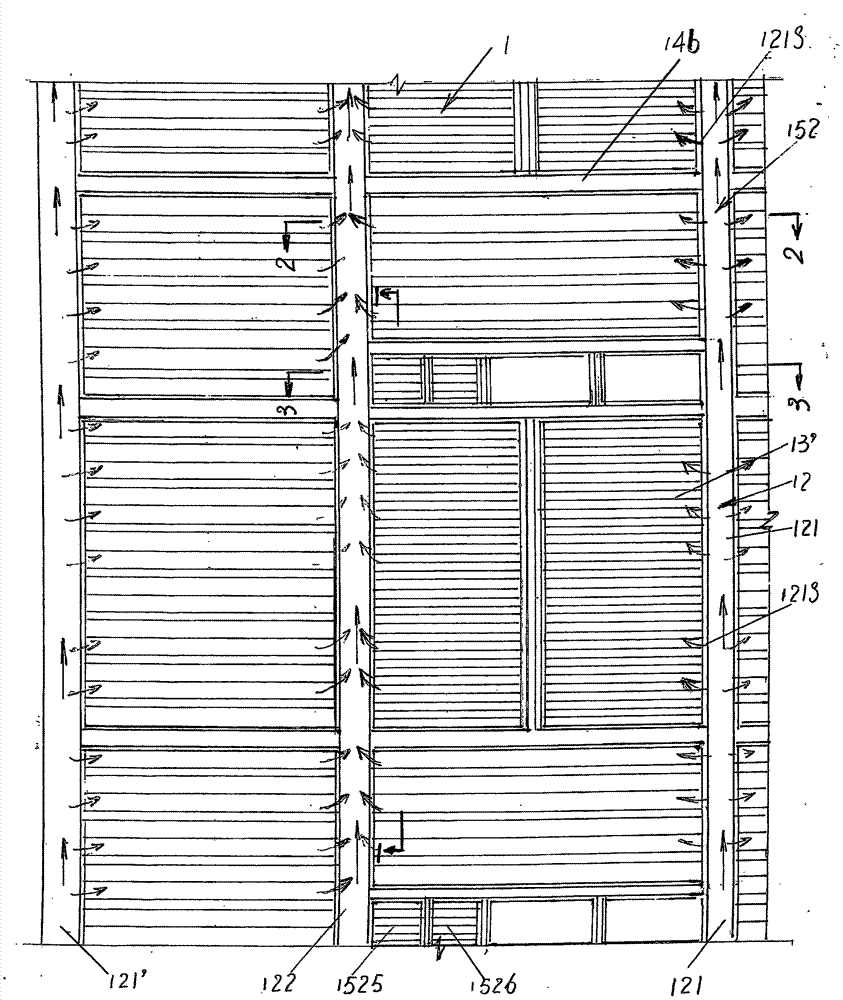

Ground-source heat solar ecological type building

InactiveCN106930446AStrengthen winter heat preservation and heatingAvoid direct raysSolar heating energyRoof covering using slabs/sheetsBasementControl system

The invention relates to a ground-source heat solar ecological type building. The ground-source heat solar ecological type building is composed of a ground-source heat solar heat preservation, heating and ventilating air conditioner curtain wall body 1, a ground-source heat heat-preservation and ventilating air conditioner curtain wall body 2, solar heat-collecting heating roofs 3 and a solar air conditioner room control system 4. The curtain wall 1 and the curtain wall 2 strengthen heat insulation of an outer wall, and by utilizing the air density difference, ground-source heat warm in winter and cool in summer in a basement is sent to a heat preservation and ventilating cavity layer through heating and ventilating air conditioner systems 15 of the curtain wall 1 and the curtain wall 2 as well as air supplying and exhausting vertical pipes 122 and air supplying vertical pipes 22 in a ground-source heat ventilating air conditioner system 26; then the ground-source heat is sent to indoor space through an electric air supplying opening 1521; and by utilizing the heat absorbing and reflective effects of a heat absorbing and energy storage plate, a shutter blind and a sun shading roller blind in the curtain wall 1, heat preservation and heating in the winter and sun shading and hear insulation in the summer of the curtain wall 1 are strengthened. According to the ground-source heat solar ecological type building, heat and cool supplying, outer wall heat preservation and decoration, heat recovery air purifying and filtering are integrated together with the ground-source heat and air-source heat being complementary with solar energy, energy saving, low carbon, health and comfort are achieved.

Owner:冯刚克

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com