Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53results about "Wave producing pumps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

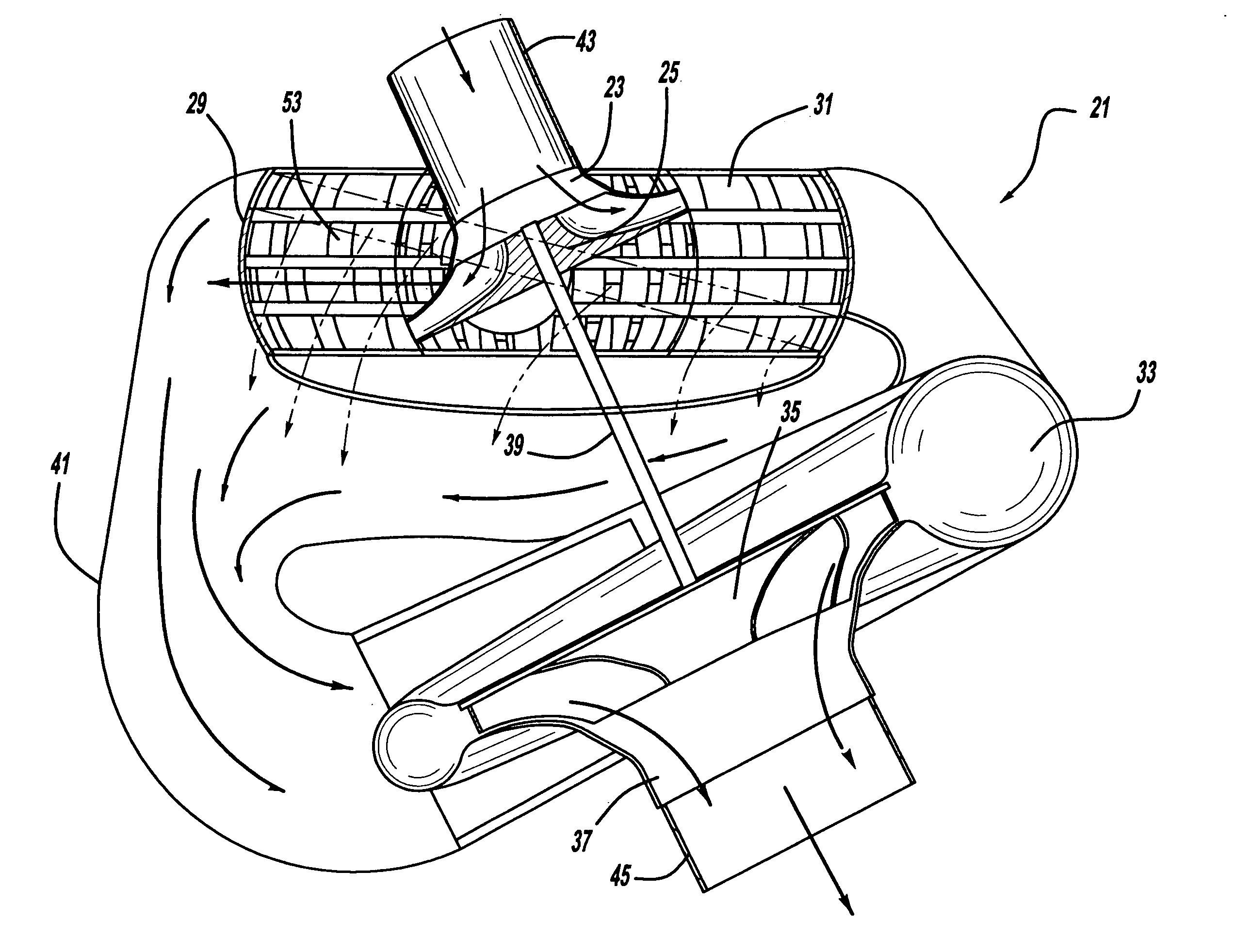

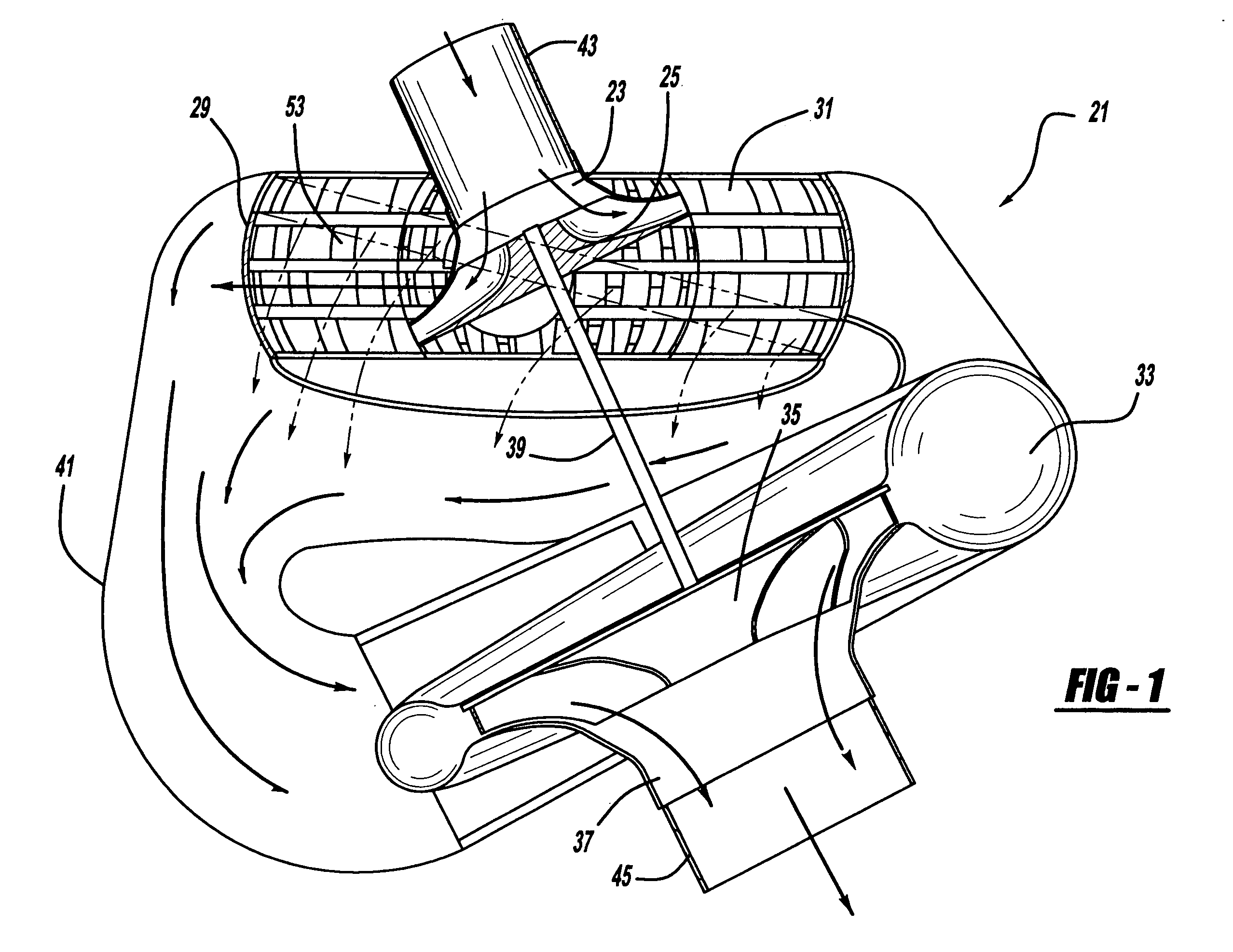

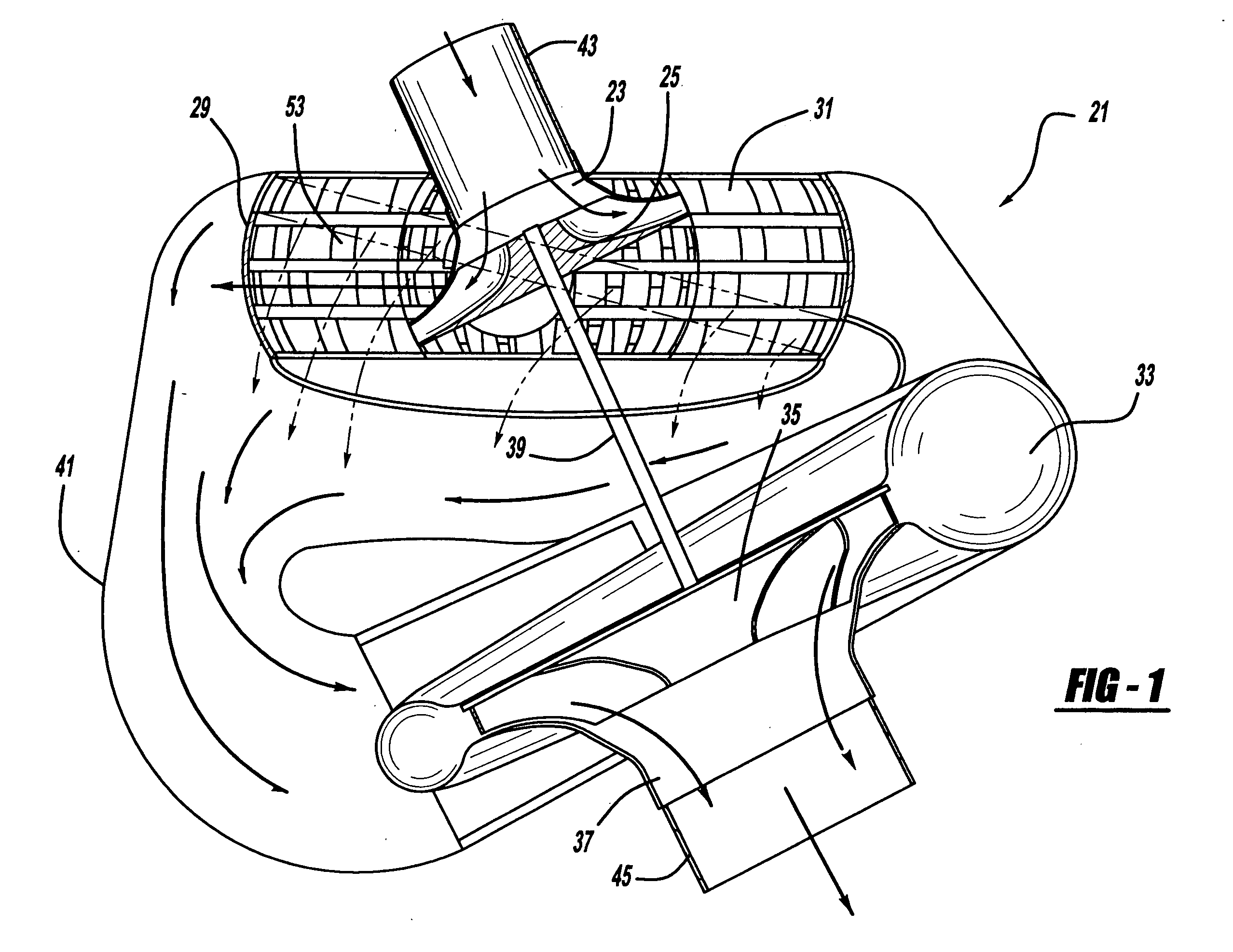

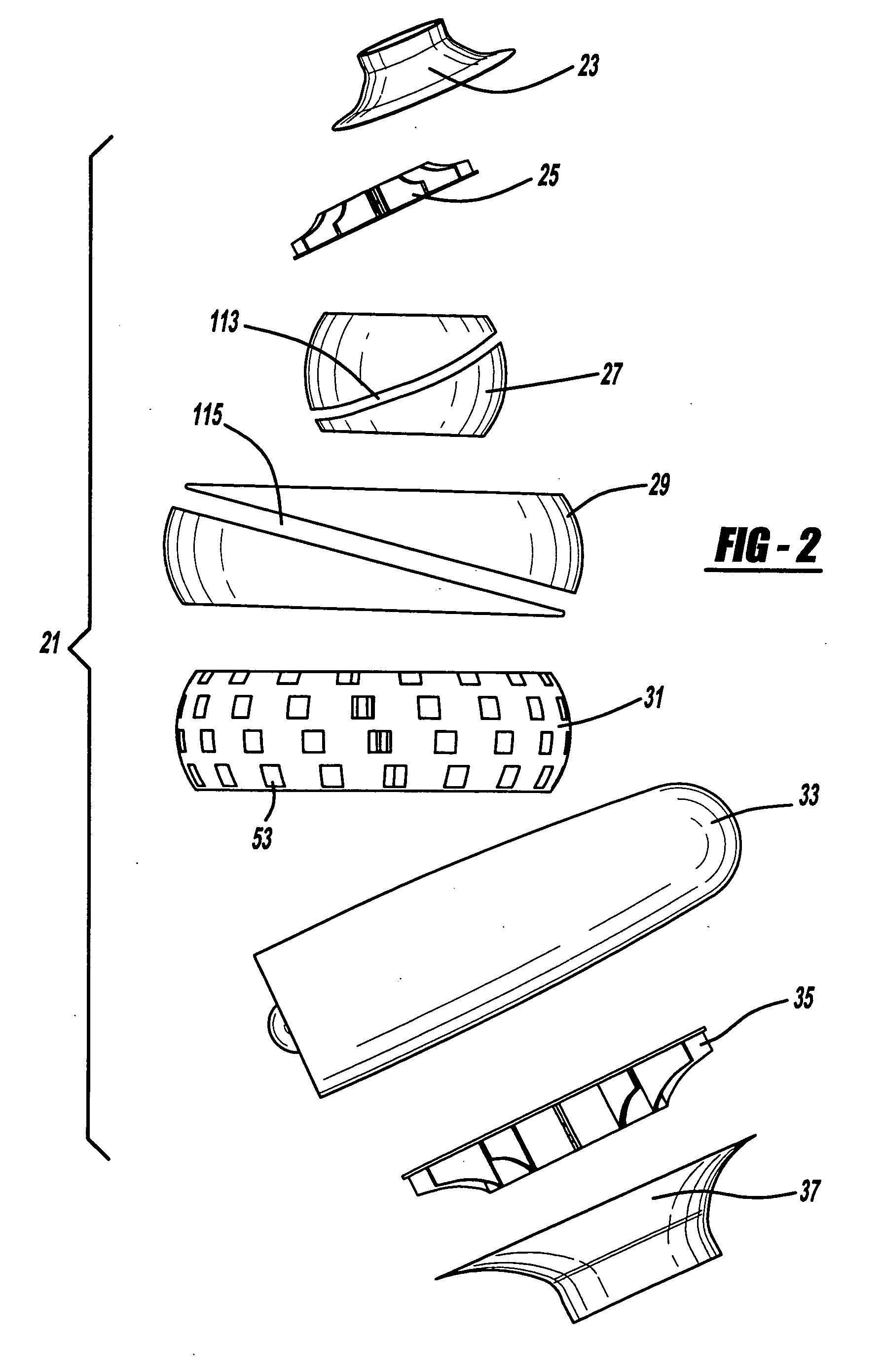

Wave rotor apparatus

ActiveUS7555891B2Easy and less-expensive to manufactureImprove power densityEngine manufactureCombustion enginesRotational axisEngineering

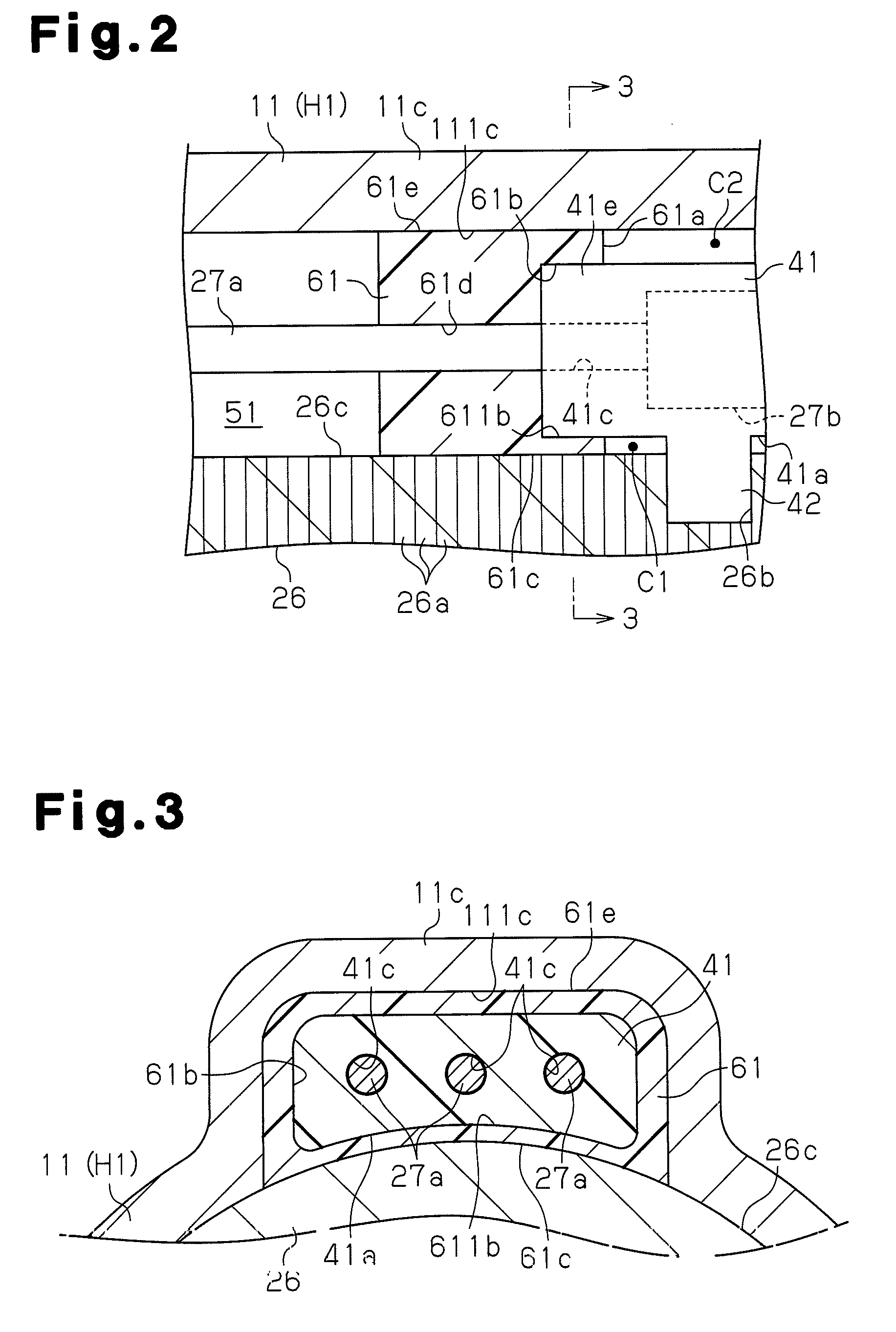

A wave rotor apparatus is provided. In another aspect of the present invention, a radial wave rotor includes fluid passageways oriented in a direction offset from its rotational axis. A further aspect of the present invention employs stacked layers of generally radial channels in a wave rotor. Moreover, turbomachinery is located internal to a wave rotor in yet another aspect of the present invention. In yet another aspect of the present invention, a radial wave rotor has an igniter and fuel injector. Correctional passages are employed in still another aspect of the present invention wave rotor.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

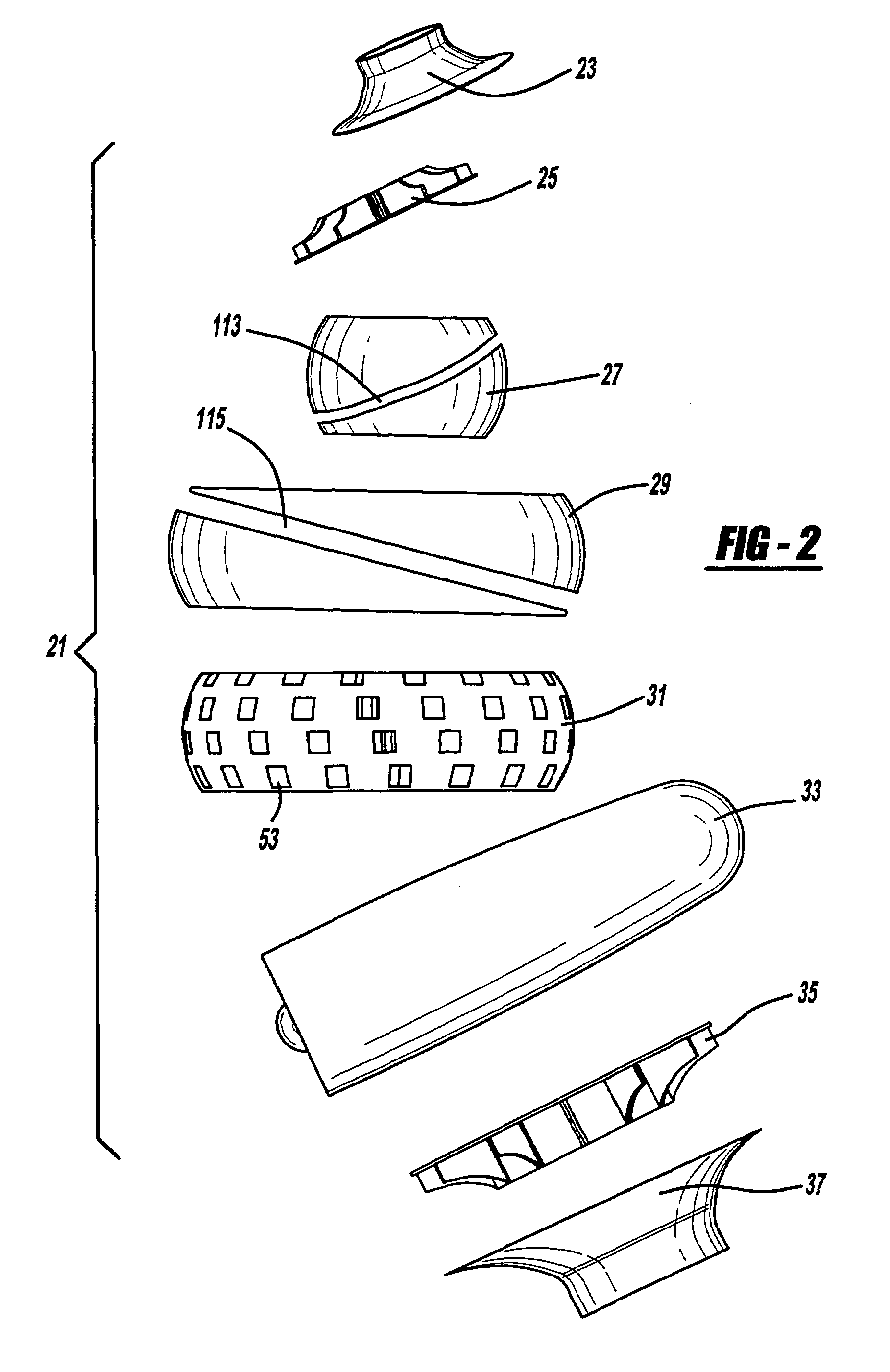

Heat sound water pumping system using solar energy as driving source and its water pumping method

InactiveCN1670365AFor irrigation purposesGood practical valueFrom solar energyWave producing pumpsAudio power amplifierWater level

This invention discloses a hot voice pumping system of drive source is solar energy ad its pumping method. The system includes solar energy collector, resonatron, hot voice board, cold end hot exchanger, hot end hot exchanger, water level oscillation amplitude value amplifier, water charging system and high and low position pool. Pressure oscillation is generated by hot making voice effect by driving source is solar energy. Little amplitude water level oscillation generated by hot voice effect is amplified to a large amplitude water level oscillation through a slender coil pipe to elevate water from low water level to high water level. The intension of this invention is to use the regenerable energy solar energy (other residual heat and waste heat also) to drive a hot making voice conversion system, so the function of pumping water can be realized in place lacking electric power (for example field) to reach the goal of irrigation.

Owner:ZHEJIANG UNIV

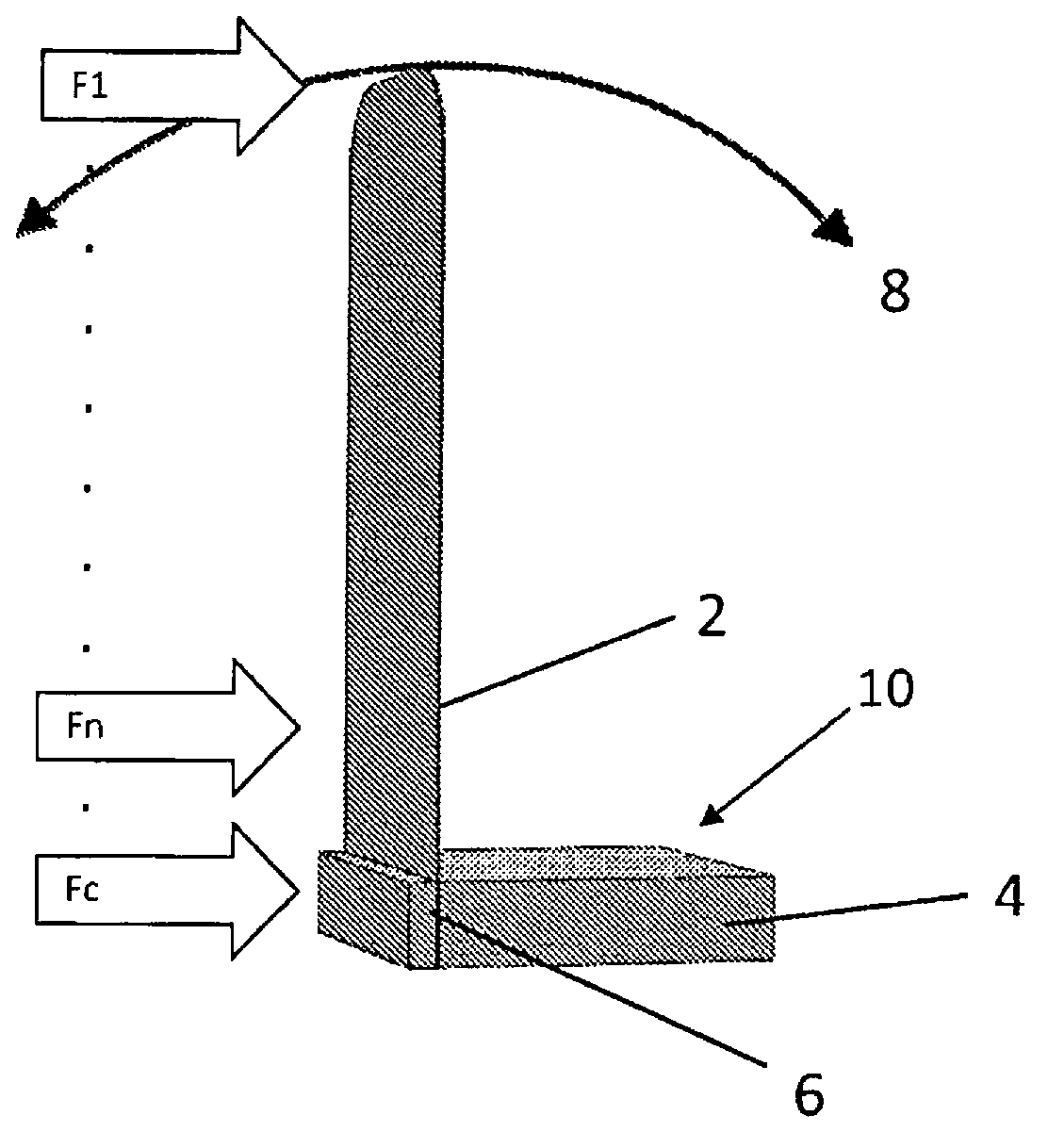

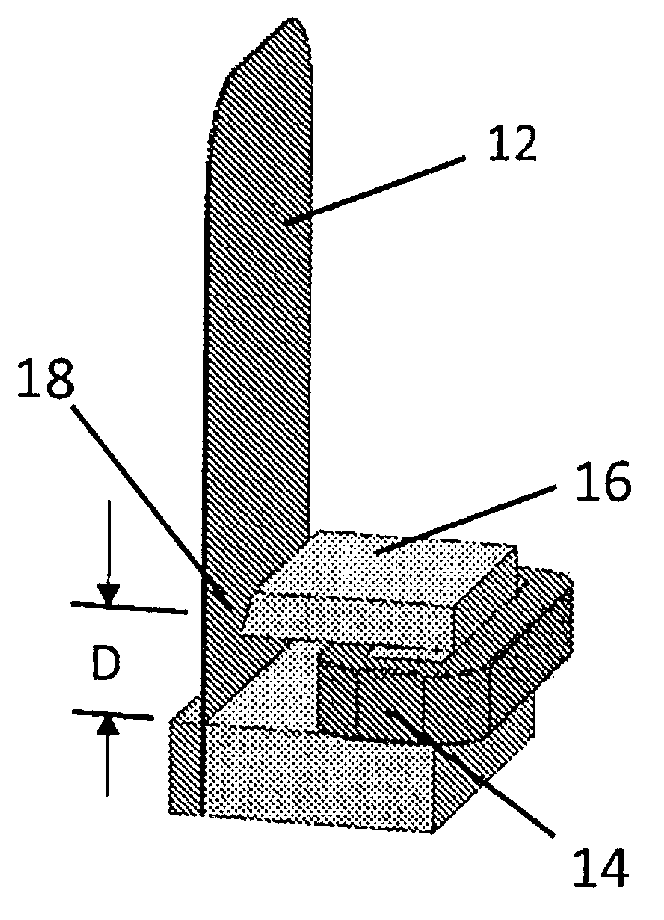

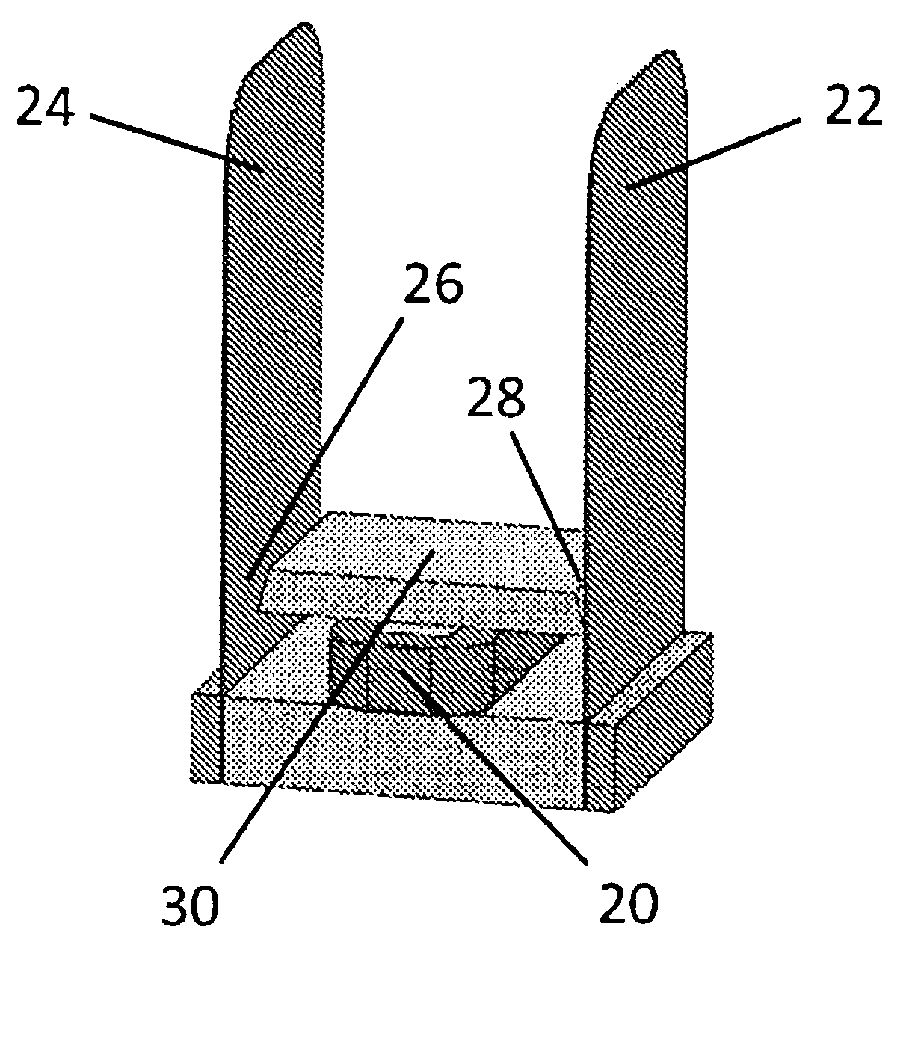

Cantilever fan

A cantilever fan including a cantilever blade that is clamped at one end. The fan includes an actuator that applies a periodic force to the blade resulting in periodic deflections of the blade.

Owner:艾菲德塞洛墨依公司

Wave making device

InactiveUS20100158611A1Reduce energy consumptionRapid exhaust of airWave producing pumpsPisciculture and aquariaExhaust valveEngineering

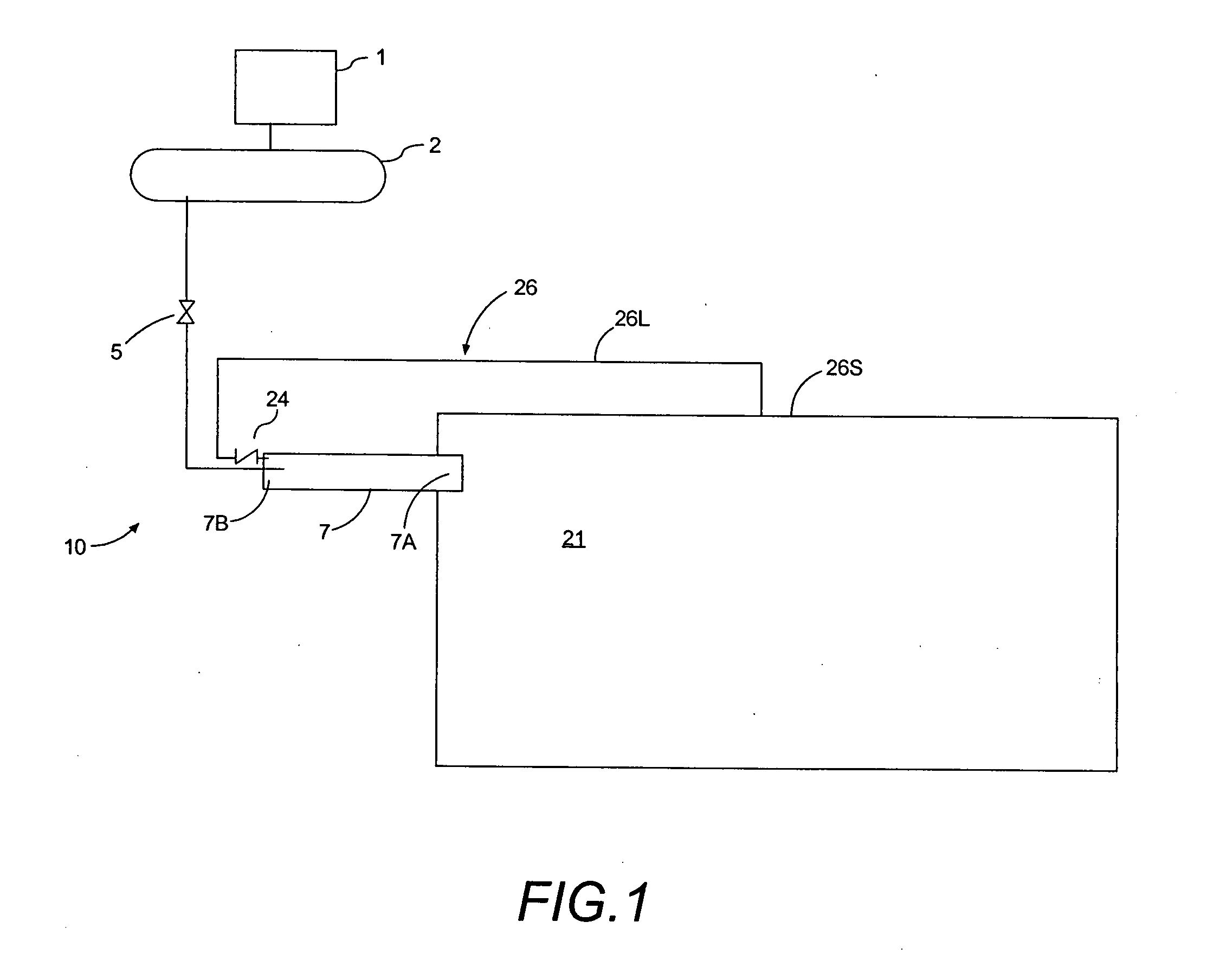

The wave making device comprises a caisson connected to an air blower and to a control valve mechanism comprising an exhaust valve adapted to move between a closed position and an open position, and a system adapted to move the exhaust valve and to maintain said exhaust valve into said position. The control valve mechanism is adapted to ensure continuously an air pressure within the caisson at least equal to the atmospheric pressure.

Owner:WOW!

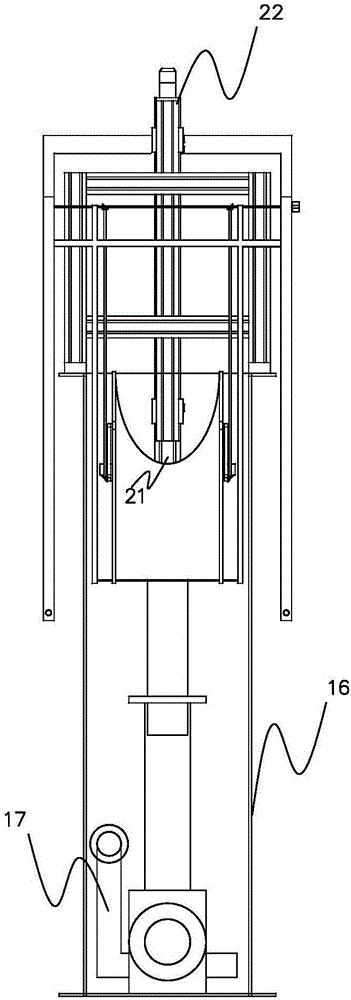

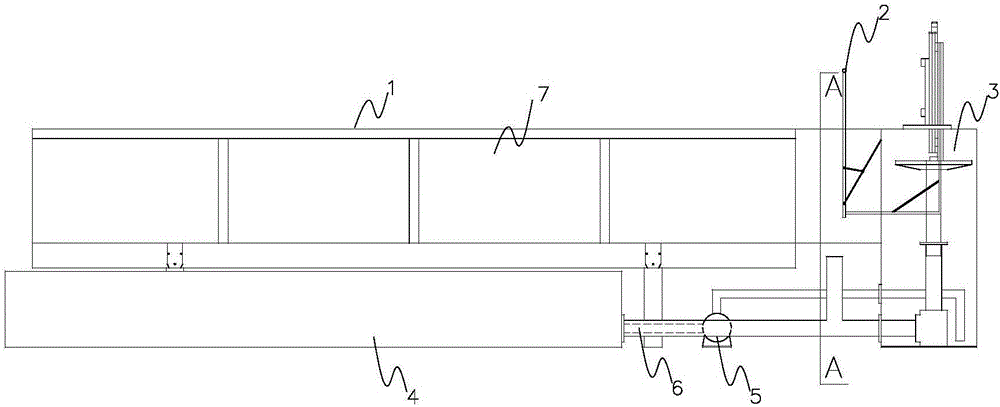

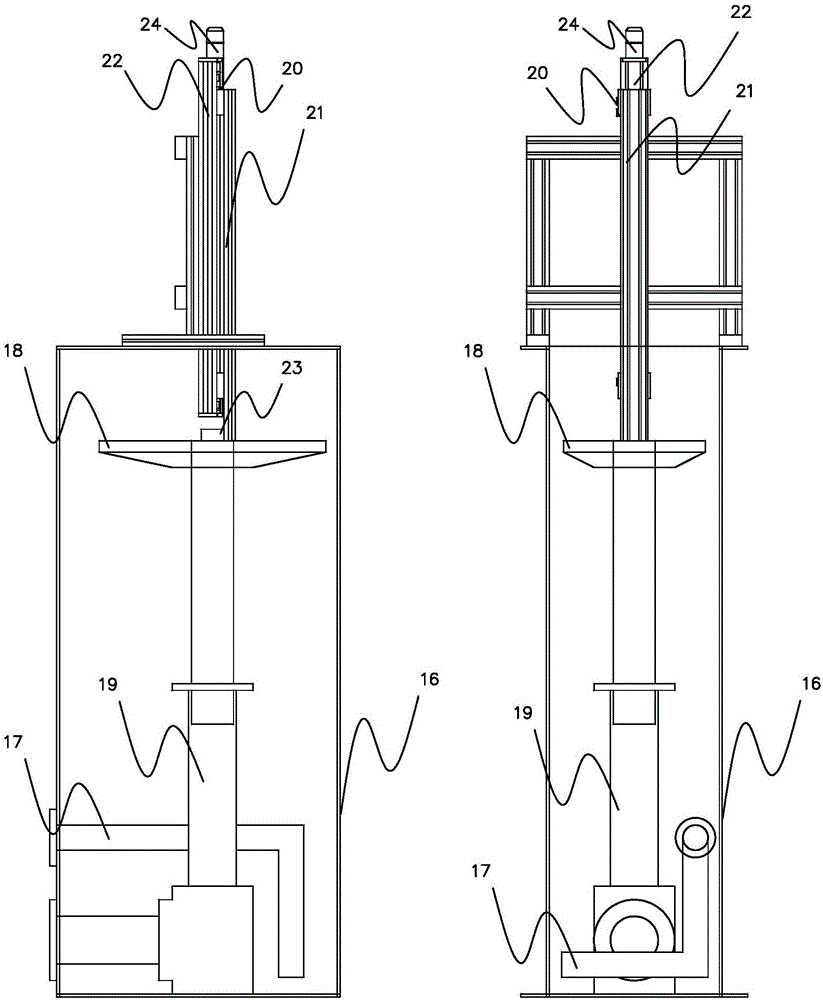

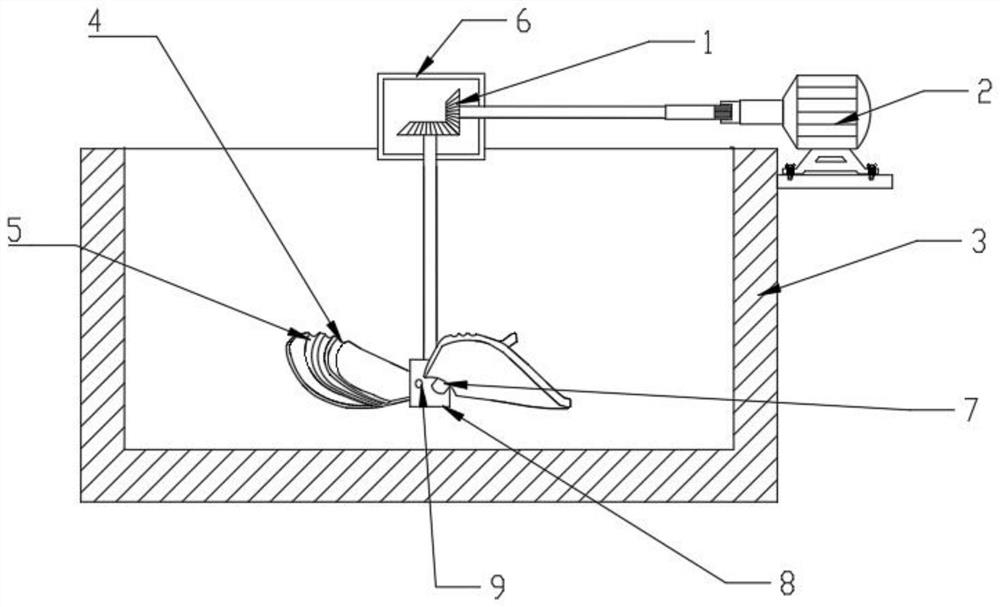

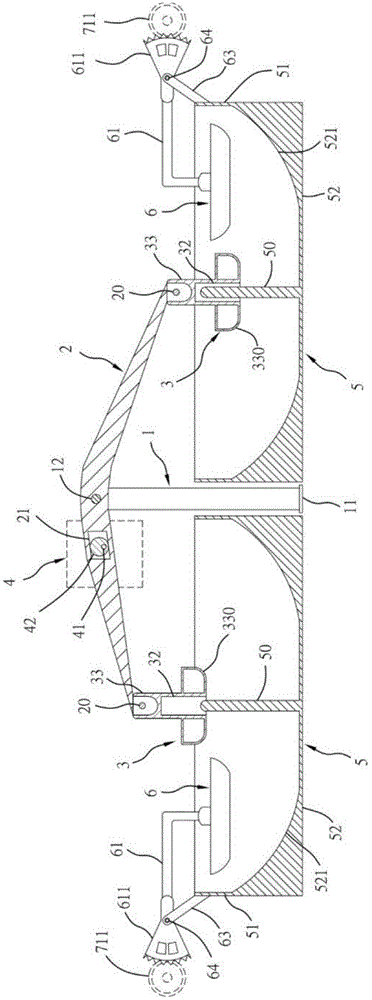

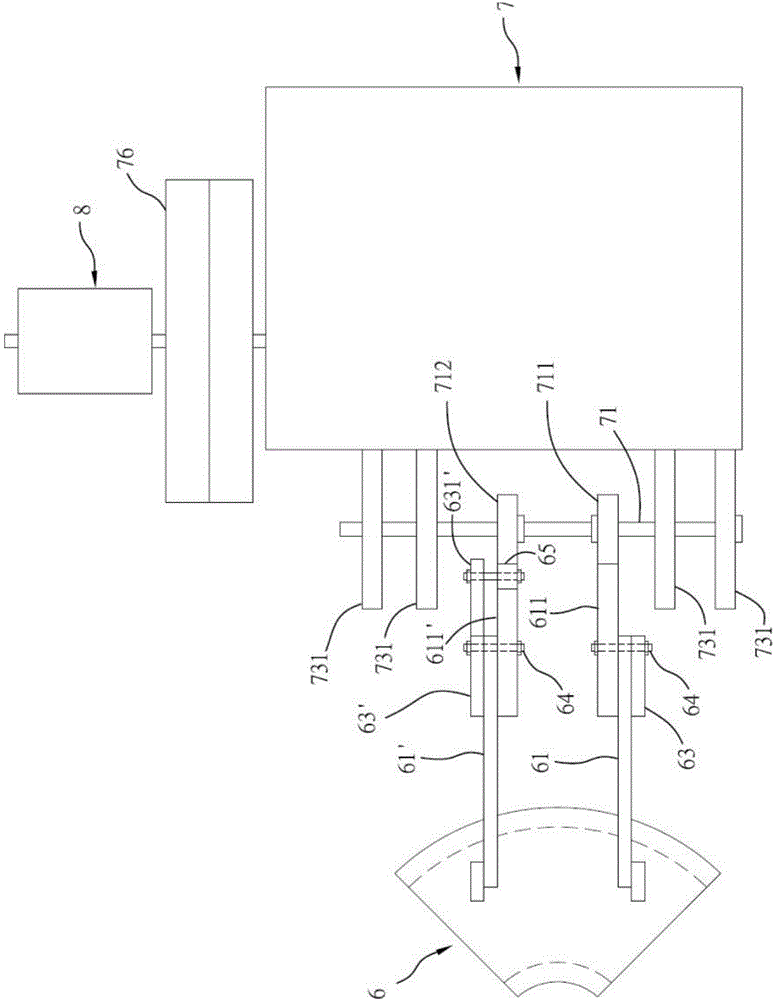

Device and method for generating irregular tidal wave tides in laboratory by coupling

InactiveCN106842999AMeet follow-up requirementsReasonable physical simulation relationshipWave producing pumpsProgramme control in sequence/logic controllersCouplingWater flow

The invention discloses a device and method for generating irregular tidal wave tides in a laboratory by coupling. The device includes a water tank, a single pendulum type wave maker, an automatic lifting type tidal generator and a control computer; the most upstream portion of the device is provided with the automatic lifting type tidal generator, the downstream end of the automatic lifting type tidal generator is connected with an inlet of the water tank, the single pendulum type wave maker is arranged at the inlet of the water tank, and the control computer controls water flow of the water tank, movement of the single pendulum type wave maker and lifting of the automatic lifting type tidal generator. The invention further discloses the working method of the device. The tide generating device can meet the requirement of water level following, and after the device is connected with the wave maker through a high-course connecting rod, and a reasonable physical analogue relation is established for coupling of the wave with the tide.

Owner:HOHAI UNIV

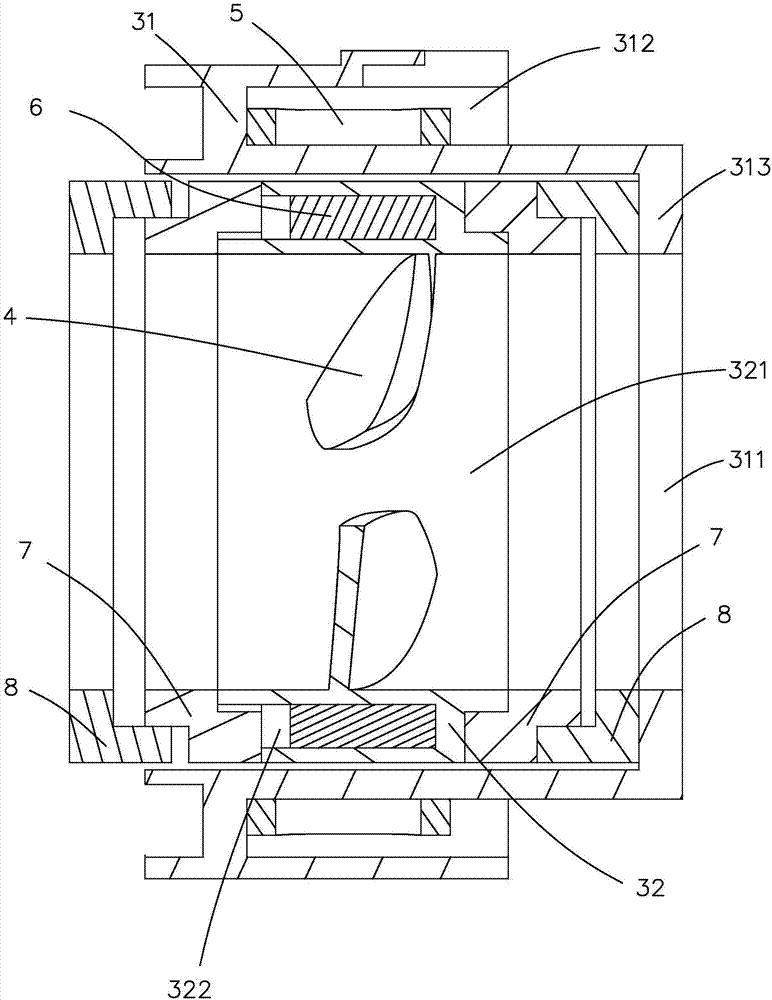

Antifreezing valve with self-cleaning function

InactiveCN104315184APrevent freezingPrevent scalingPlug valvesValve members for heating/coolingLiquid mediumInlet channel

The invention discloses an antifreezing valve with a self-cleaning function. The antifreezing valve comprises a valve body, wherein a valve cavity is formed in the valve body; a ball valve is arranged in the valve cavity; a valve rod is connected with the ball valve; the valve rod extends out from a valve rod hole in the valve body to be connected with a hand wheel; a valve cover covers the valve rod hole; a water inlet channel and a water outlet channel which are both communicated with the valve cavity, are connected with the valve body; the valve rod is a hollow valve rod in which a stirring shaft is arranged in a penetrating manner; the lower end of the stirring shaft extends into the ball valve to be connected with a stirrer which is arranged in the valve body; the upper end of the stirring shaft is connected with a micro motor which is used for driving the stirring shaft to work; the micro motor is arranged in a cavity of the hand wheel; electromagnetic coils are arranged on the inner walls of both the water inlet channel and the water outlet channel respectively in a winding manner, and are electrically connected with a pulse current generator. According to the antifreezing valve with the self-cleaning function, the micro motor controls the stirrer to work intermittently, so that the liquid medium in the valve is in a non-static state, the scale deposition and medium freezing are avoided and the aims of scale prevention and self-cleaning are achieved.

Owner:SUZHOU FURUN MACHINERY

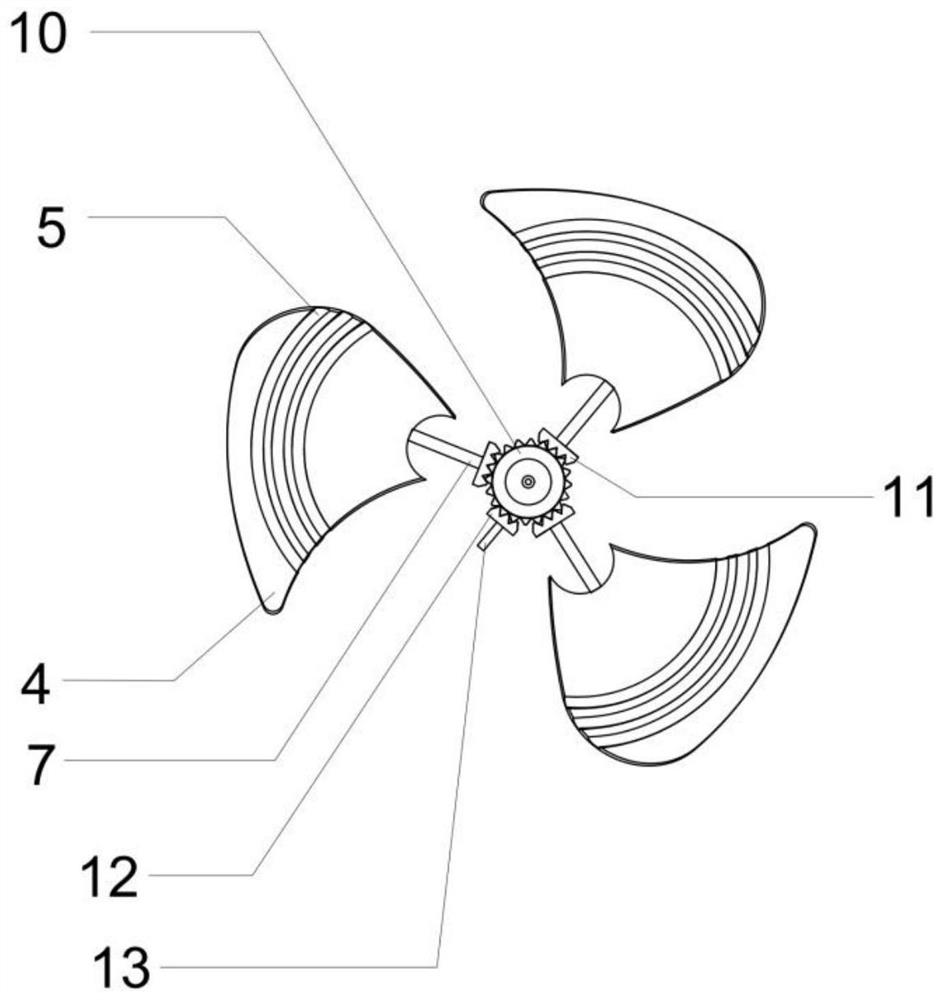

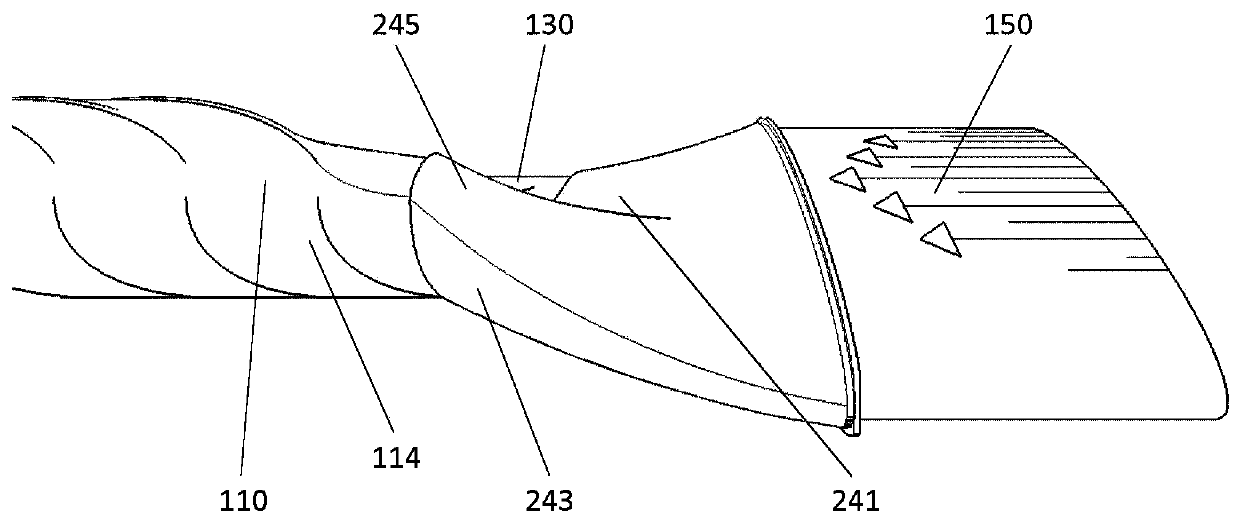

Fan blade device, wave making equipment and wave making method

PendingCN111692124AChange tilt anglePump componentsWave producing pumpsTurbine bladeMetallic materials

The invention is suitable for the technical field of corrosion and protection of metal materials, and provides a fan blade device, wave making equipment and a wave making method. The fan blade devicecomprises a center bevel gear, a turbine blade, a driving bevel gear and a rotating shaft, wherein at least one side bevel gear is meshed with a side edge of the center bevel gear; the turbine blade is fixedly connected to the end, which is away from the center bevel gear, of the side bevel gear through a connecting shaft; the driving bevel gear is meshed with the center bevel gear and is used fordriving the center bevel gear to rotate; and the rotating shaft is coaxially and fixedly connected to the end, which is away from the center bevel gear, of the driving bevel gear and is used for applying rotating torsion of the driving bevel gear. According to the fan blade device, the wave making equipment and the wave making method, torsion is applied to the rotating shaft, the rotating shaft drives the driving bevel gear to rotate so as to drive the center bevel gear to rotate, the center bevel gear drives the side bevel gear to rotate so as to enable the connecting shaft to drive the turbine blade to rotate, then the inclination angle of the turbine blade is changed, the height and the amplitude of discharged air and splashed liquid of the turbine blade are controlled, and thus, control of the wind blowing or wave making mode is completed.

Owner:UNIV OF SCI & TECH LIAONING

Wave rotor apparatus

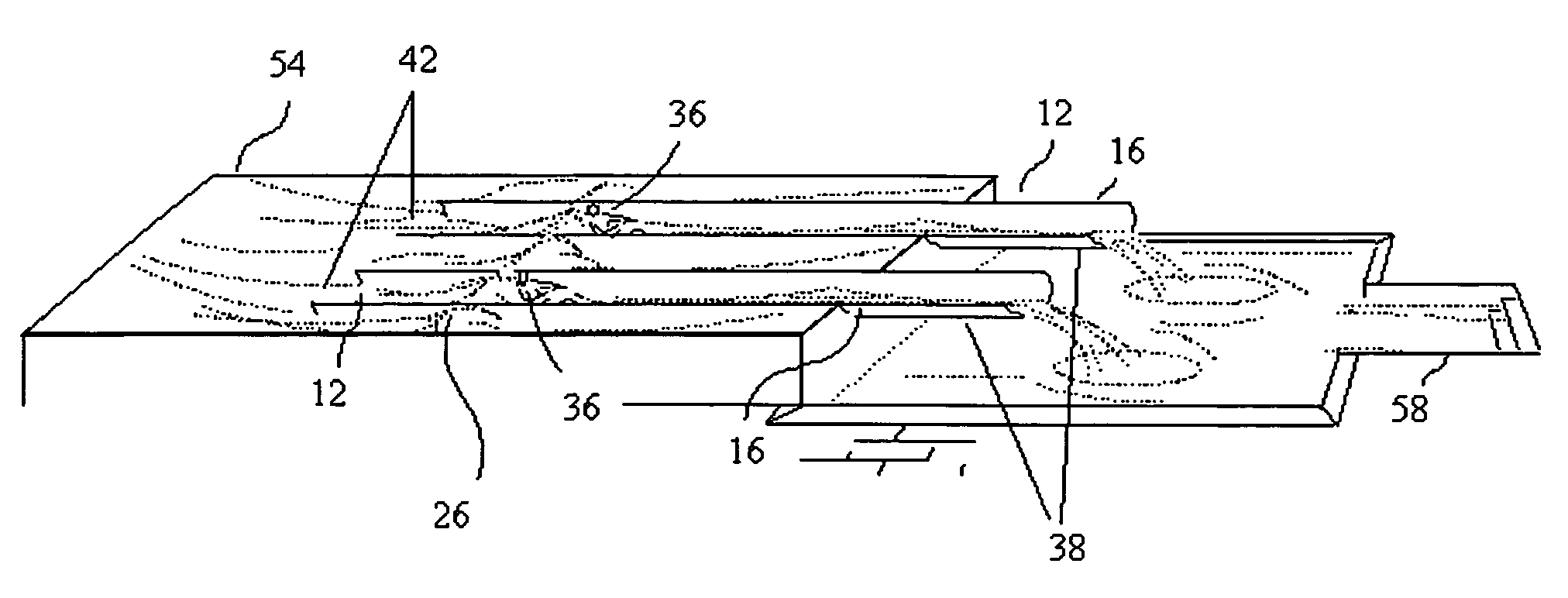

ActiveUS20060130478A1Improve power densityImprove efficiencyEngine manufactureCombustion enginesRotational axisEngineering

A wave rotor apparatus is provided. In another aspect of the present invention, a radial wave rotor includes fluid passageways oriented in a direction offset from its rotational axis. A further aspect of the present invention employs stacked layers of generally radial channels in a wave rotor. Moreover, turbomachinery is located internal to a wave rotor in yet another aspect of the present invention. In yet another aspect of the present invention, a radial wave rotor has an igniter and fuel injector. Correctional passages are employed in still another aspect of the present invention wave rotor.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

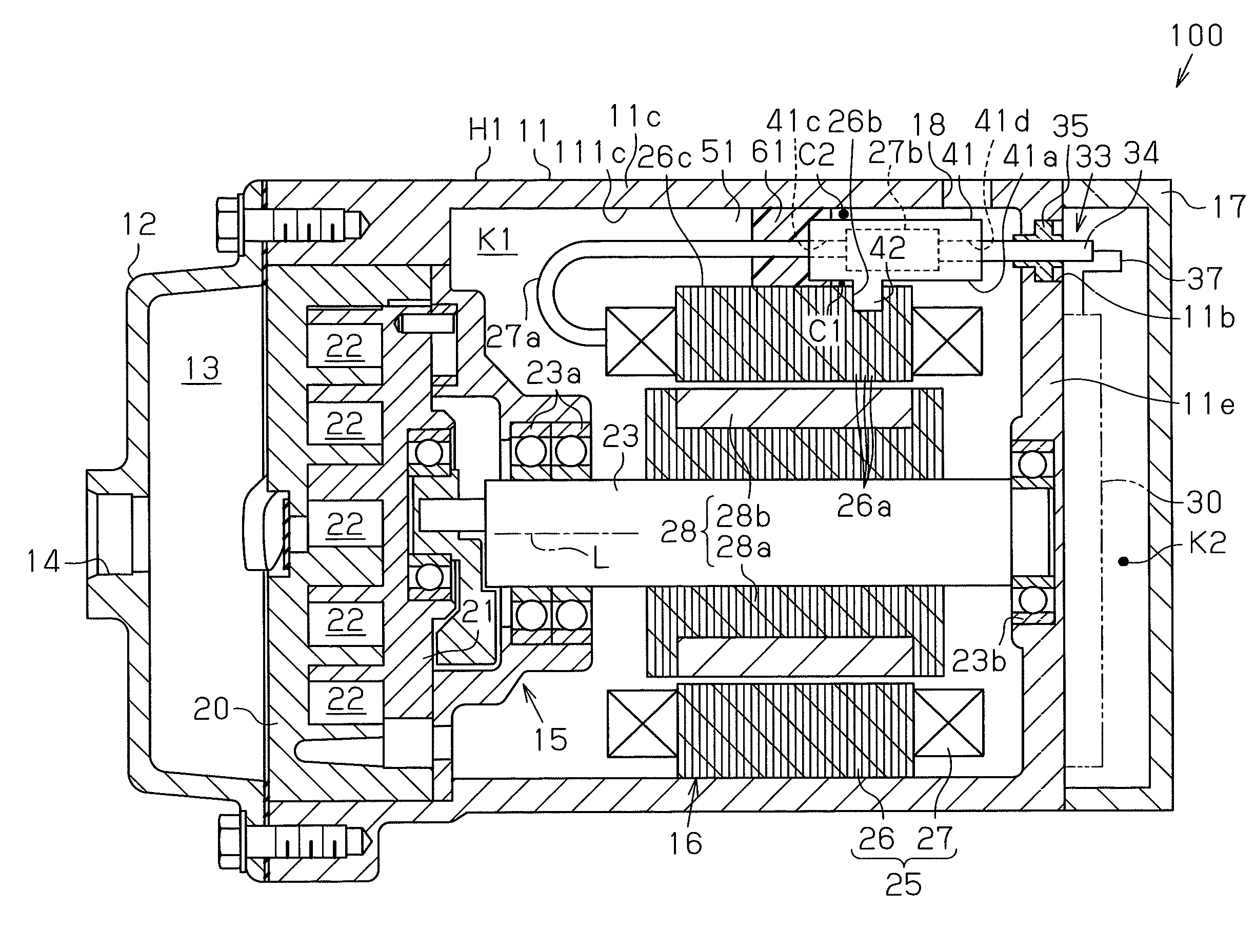

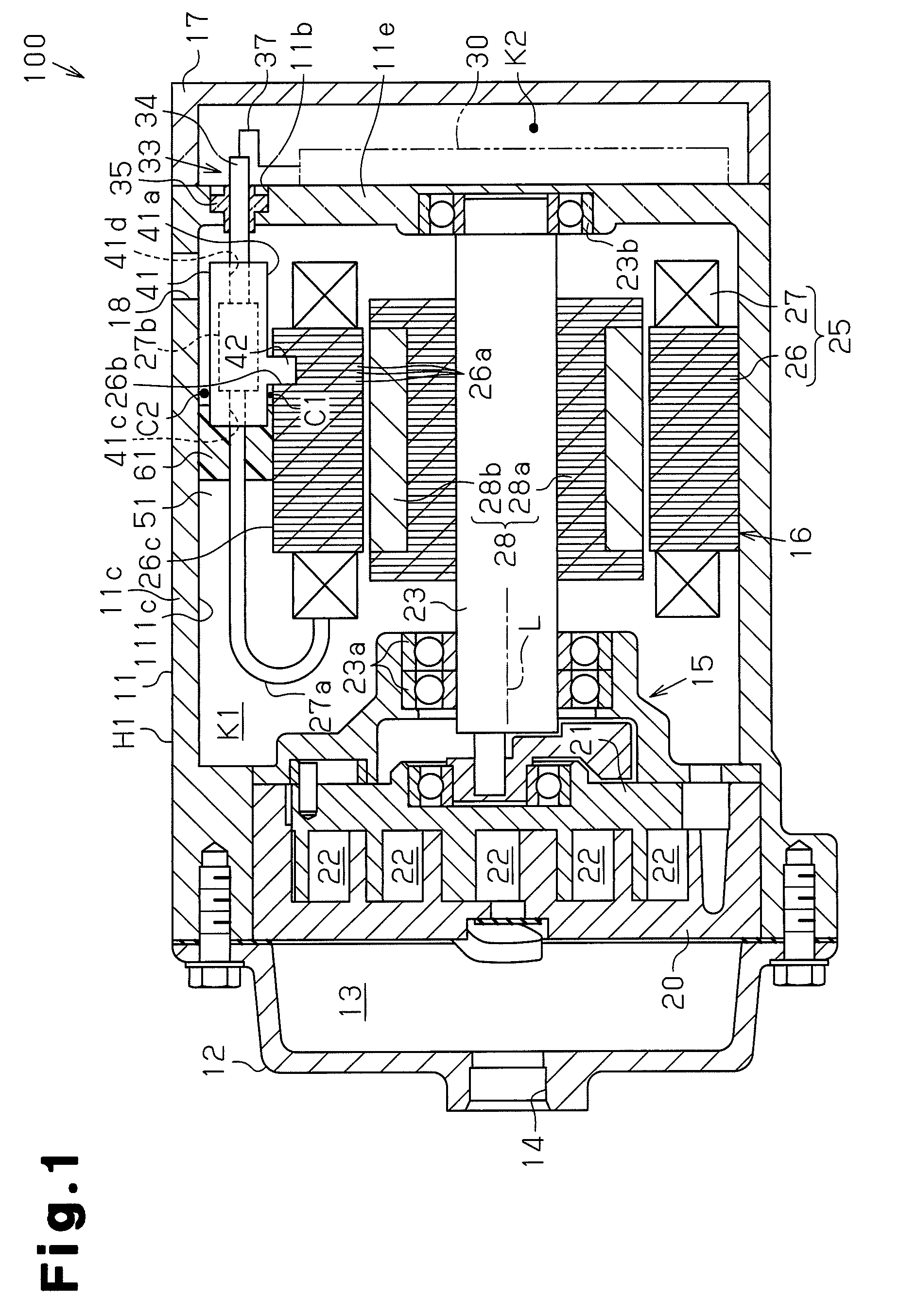

Electric connector for cooling a compressor drive circuit

InactiveUS9068563B2Improve cooling effectDissipationRotary/oscillating piston combinations for elastic fluidsPositive displacement pump componentsElectricityMotor drive

A motor-driven compressor has a housing and a partition. A compressing portion and an electric motor as the drive source of the compressing portion are accommodated in a first area. A drive circuit for the motor is arranged in a second area so as to have dissipation of the drive circuit. The compressor further includes a conductive member electrically connected to the circuit and fixed to the partition, and an electrical connection portion electrically connecting the conductive member to the motor. The connection portion is partly received in a passing area formed between the housing and the motor. The housing has a suction port and a discharge port. The discharge port is located at a position farther from the partition than the suction port and the passing area. An insertion member in the passing area restricts flow of refrigerant in the housing toward the discharge port via the passing area.

Owner:TOYOTA IND CORP

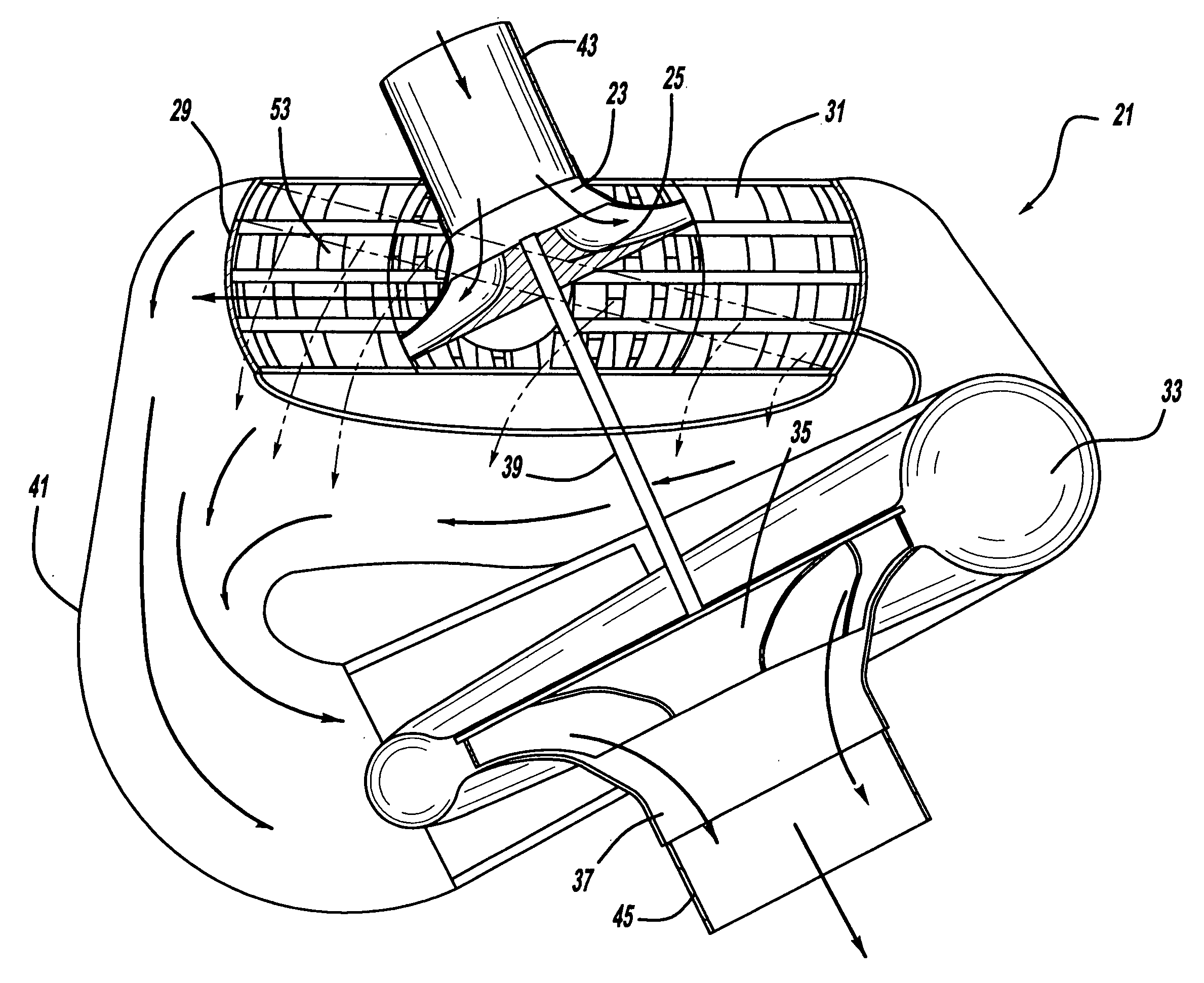

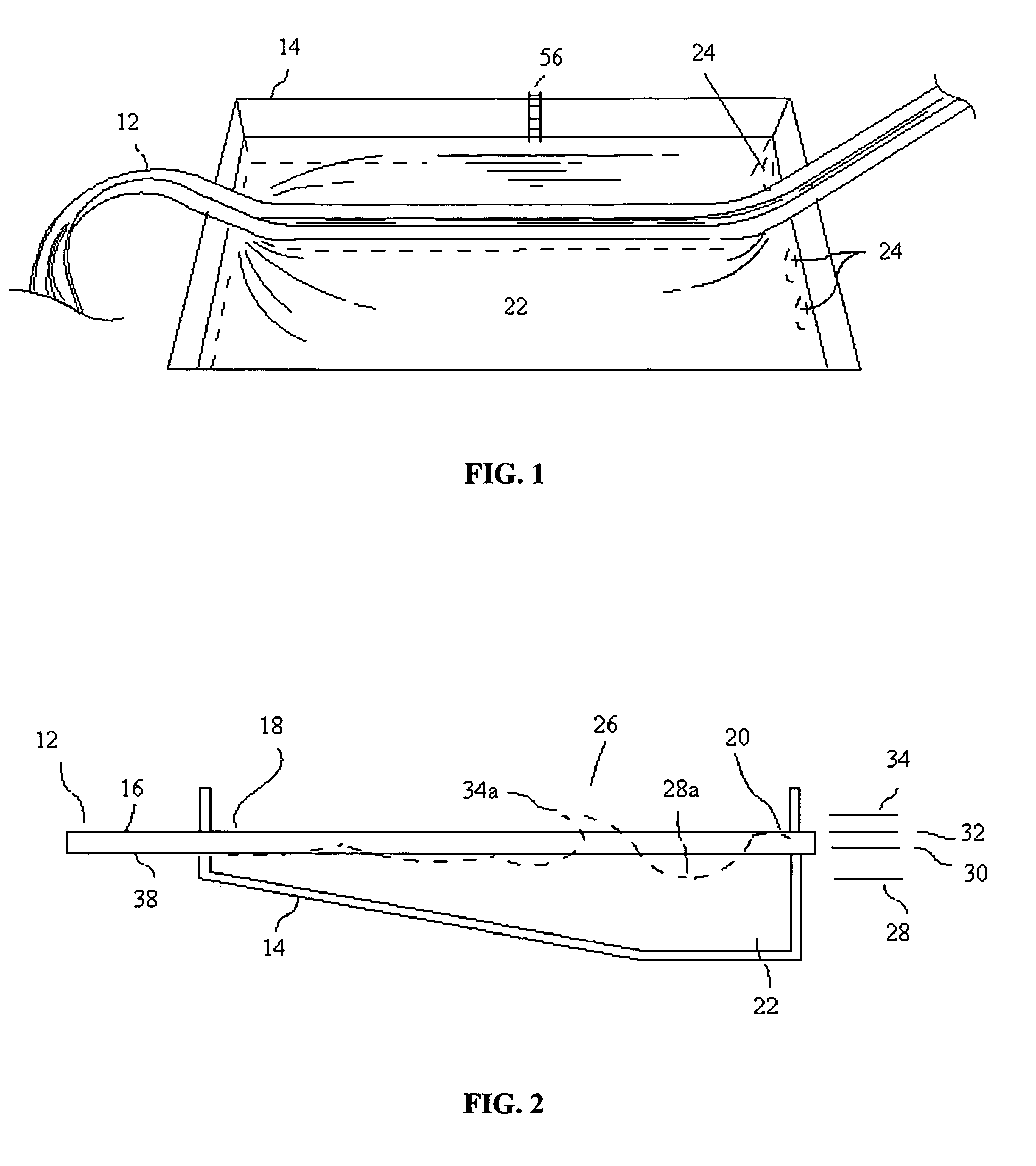

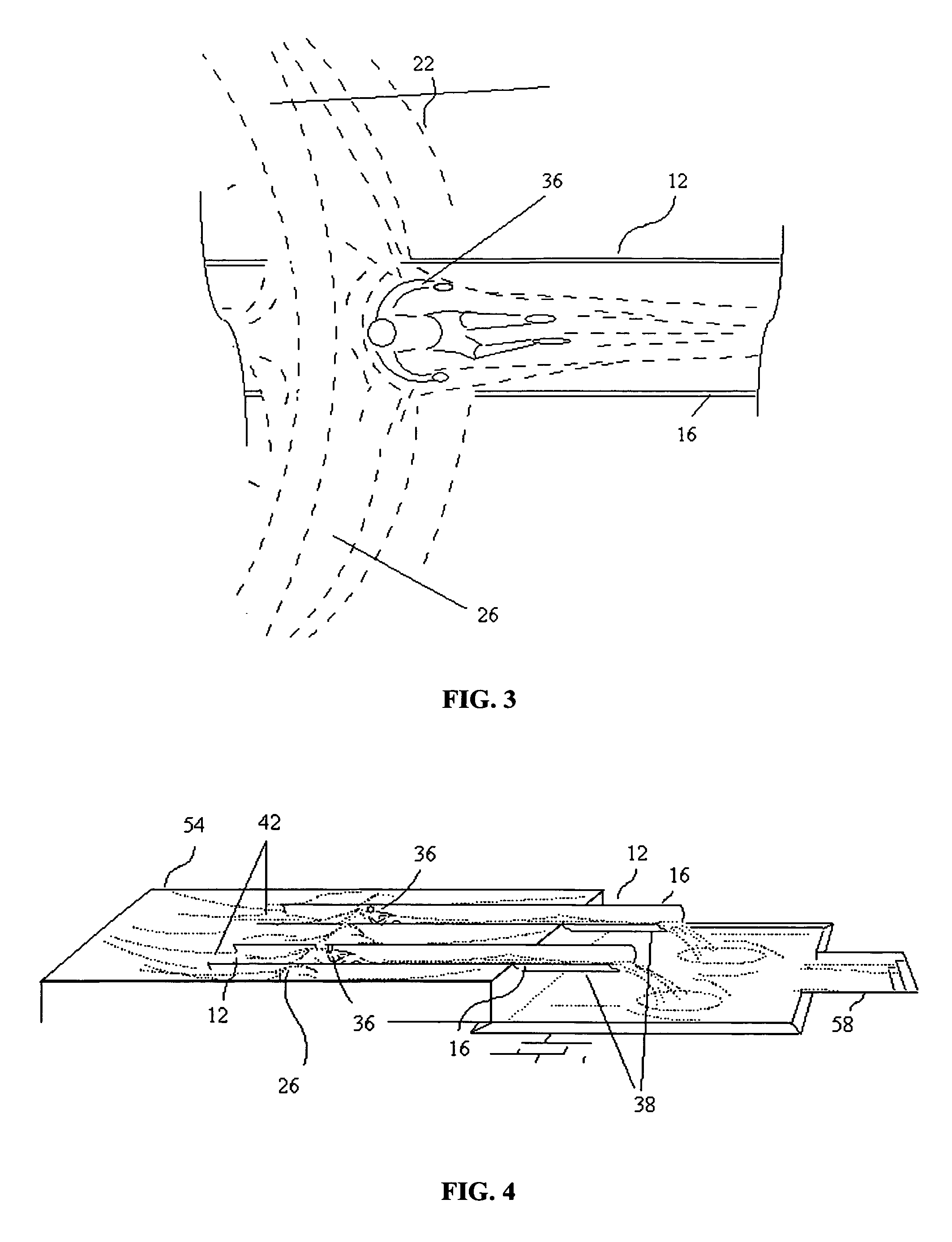

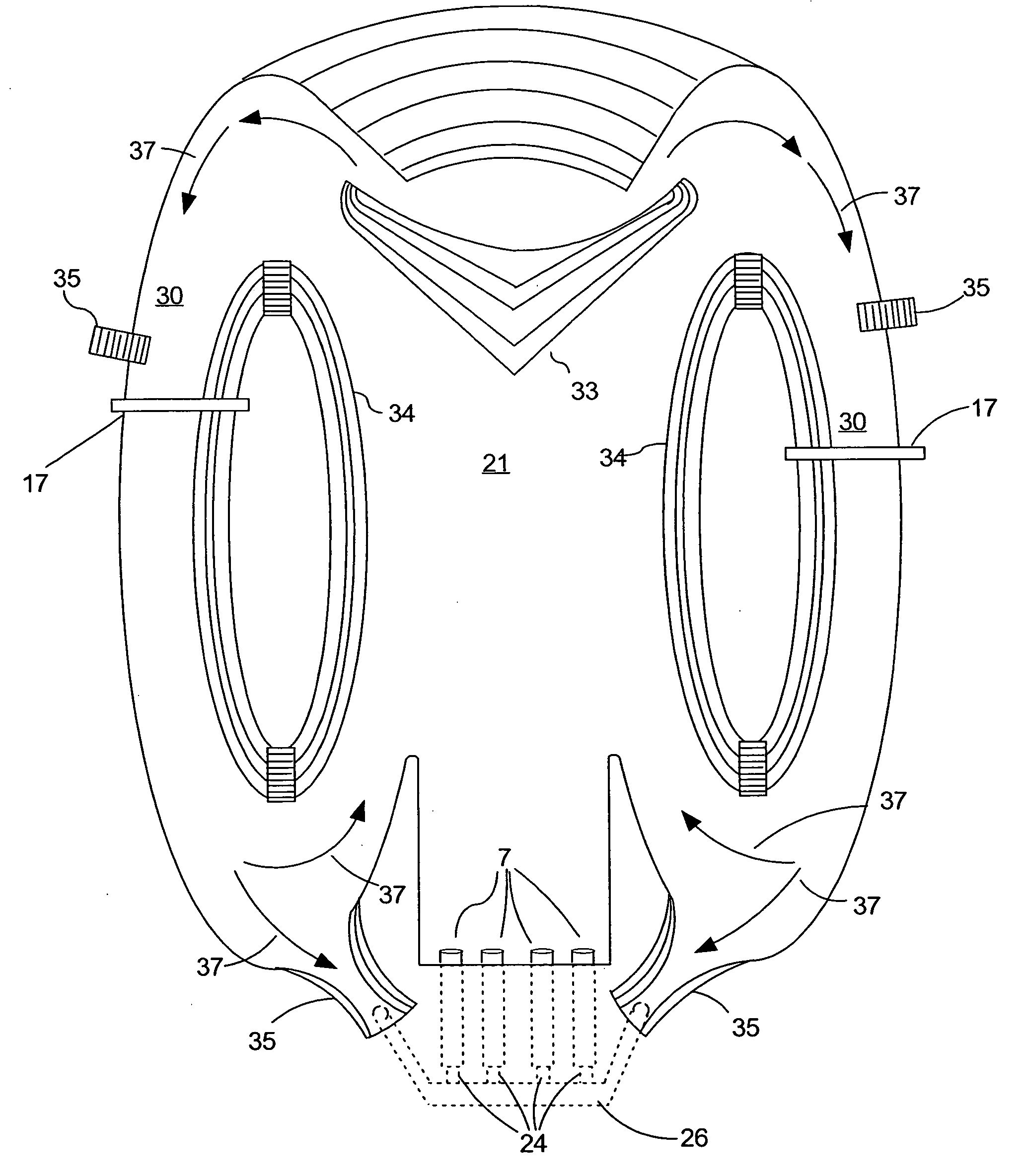

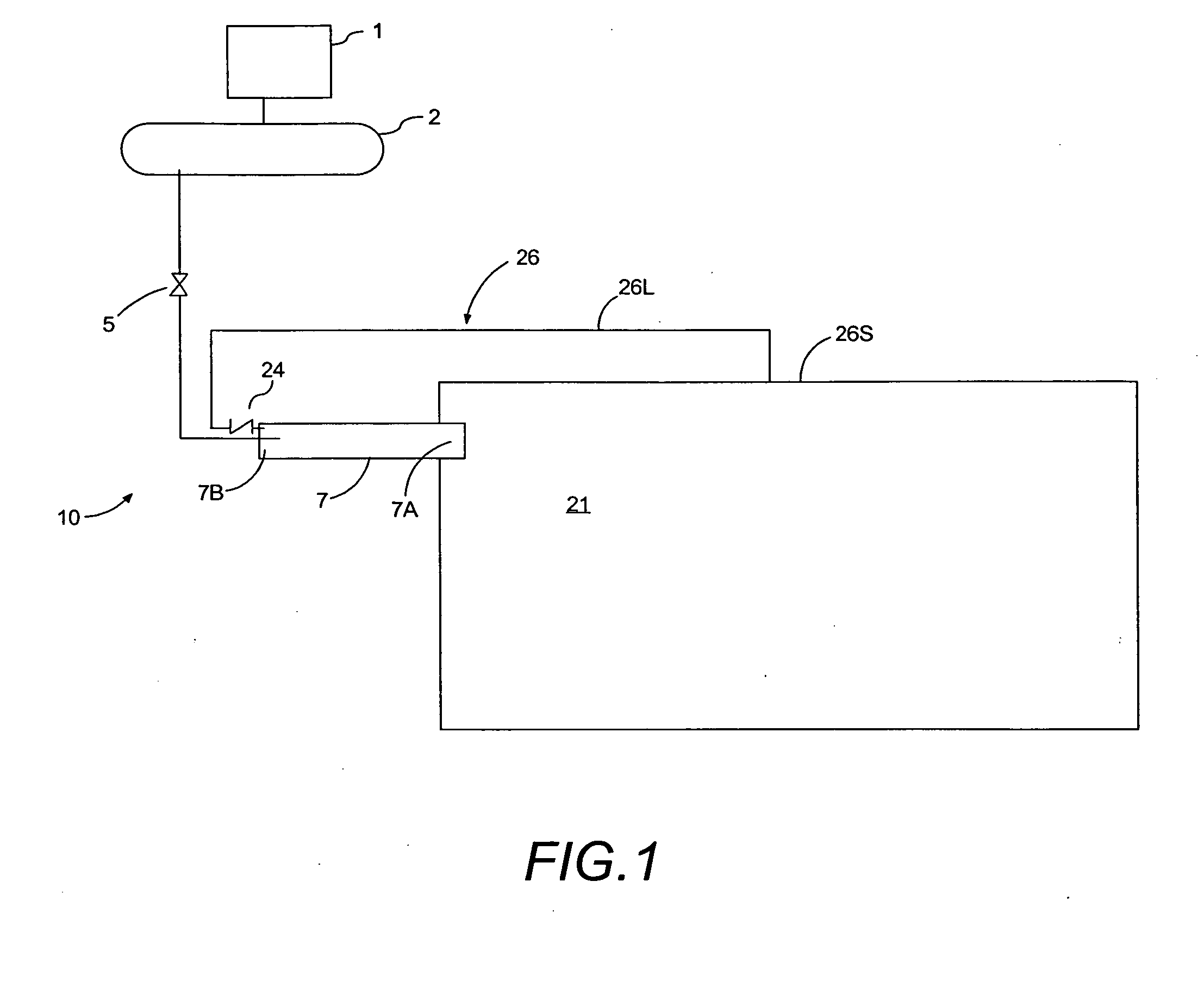

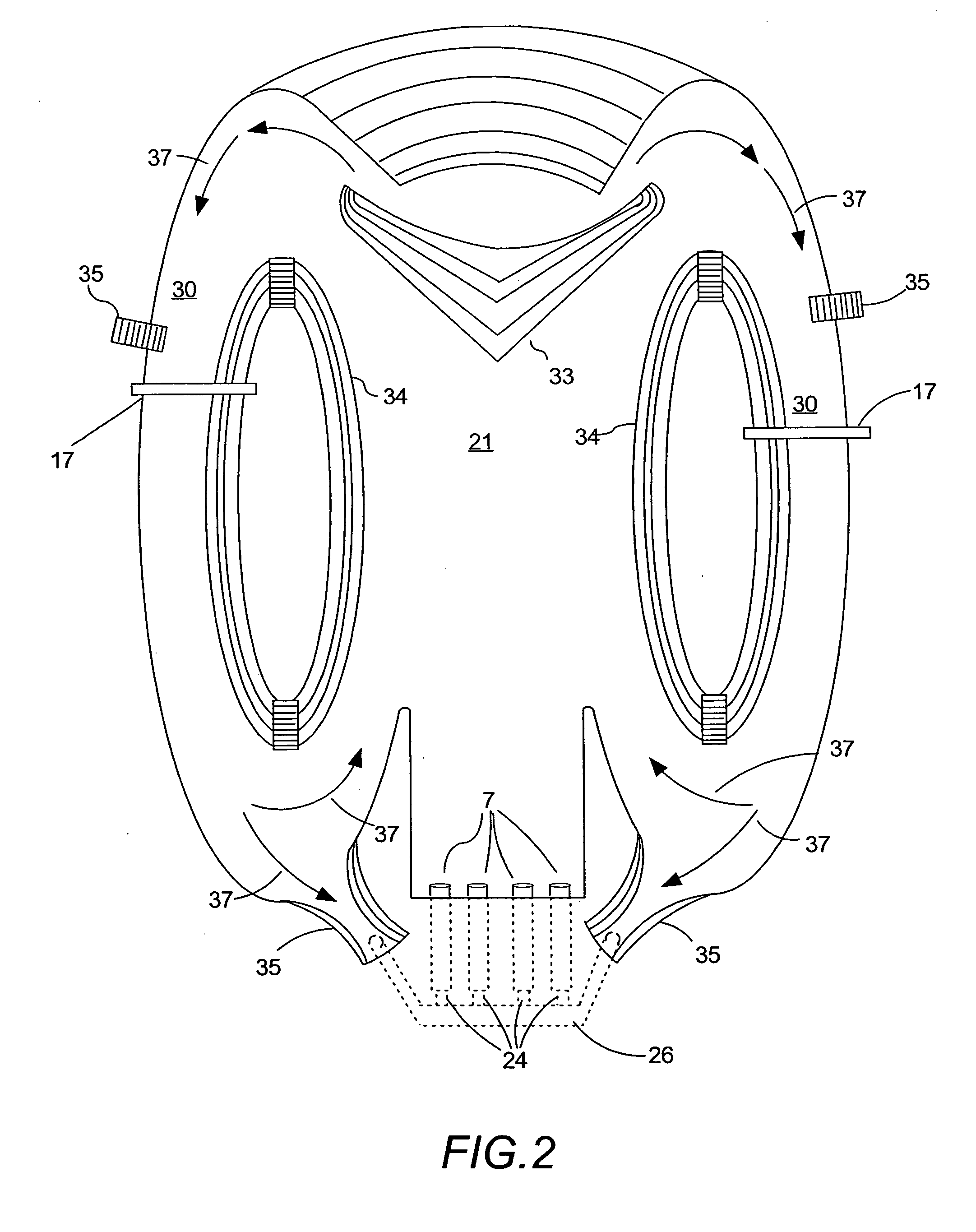

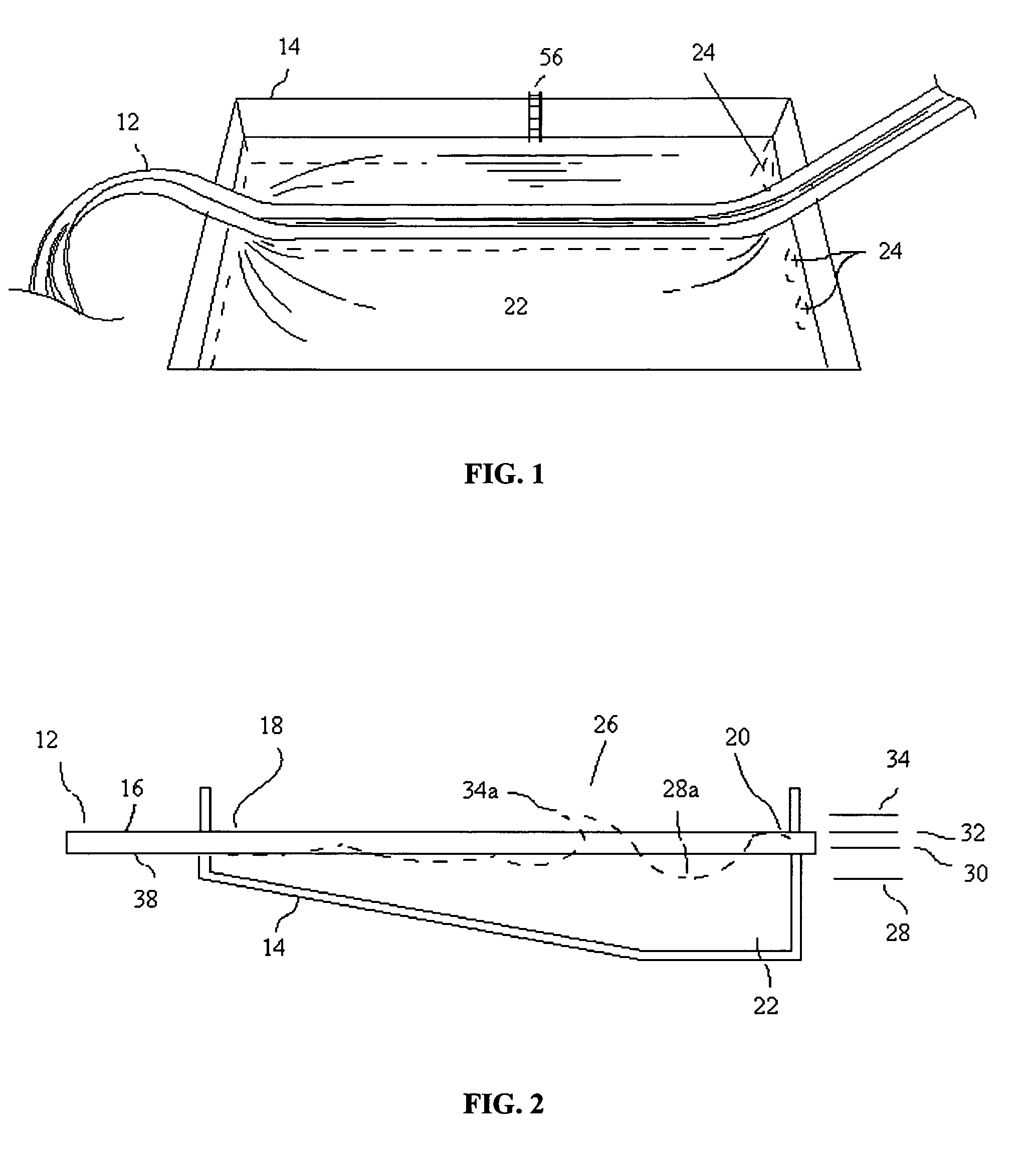

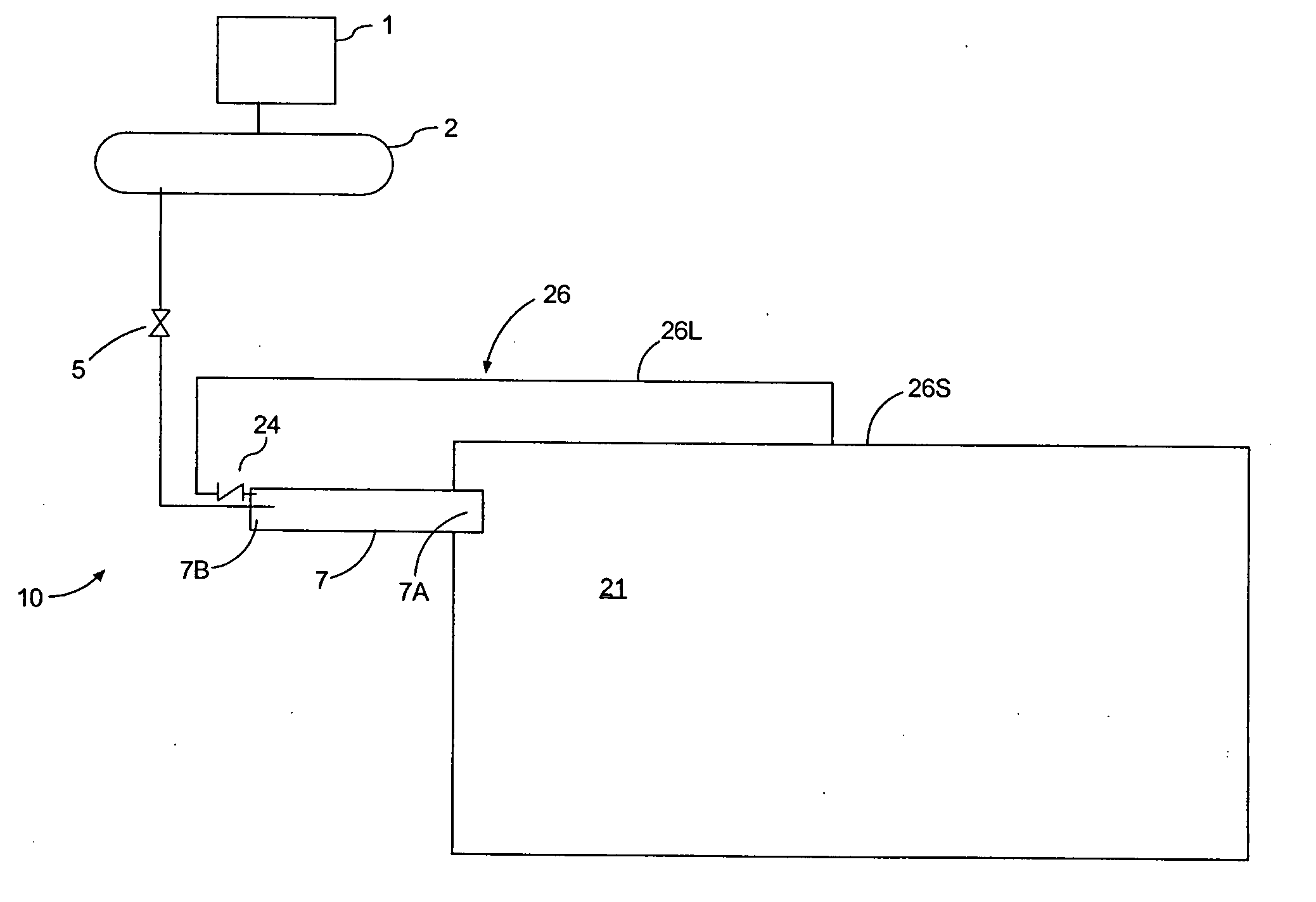

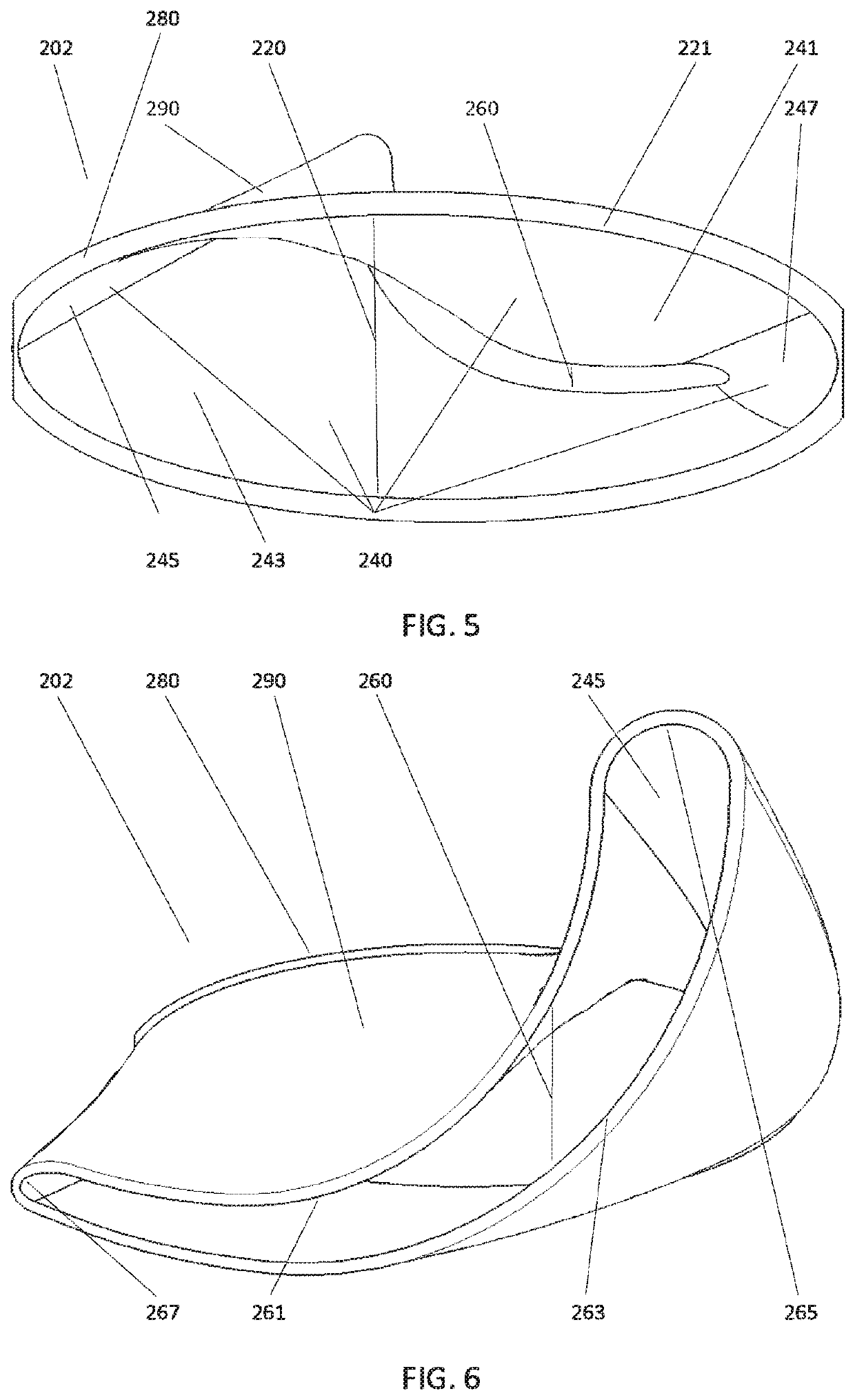

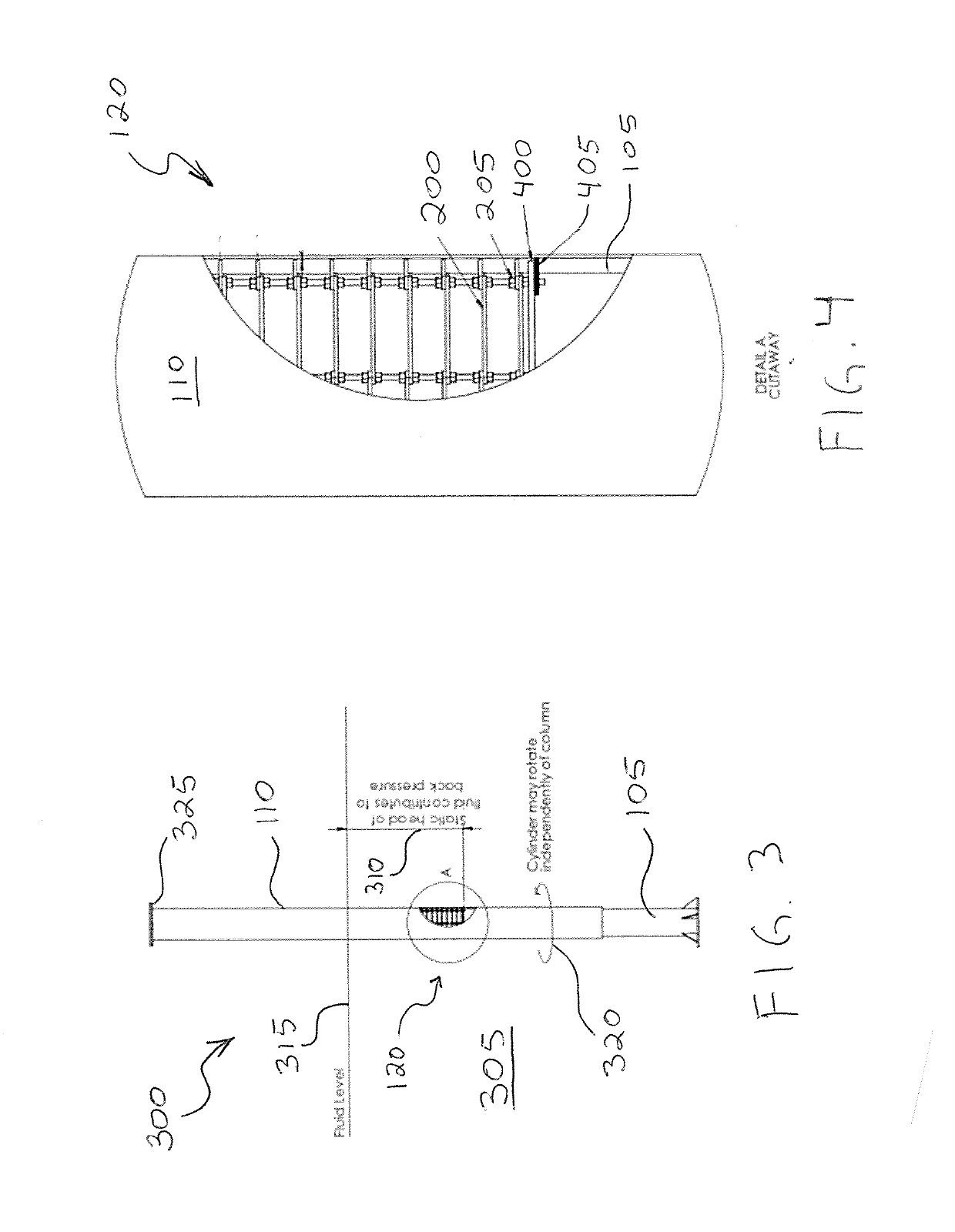

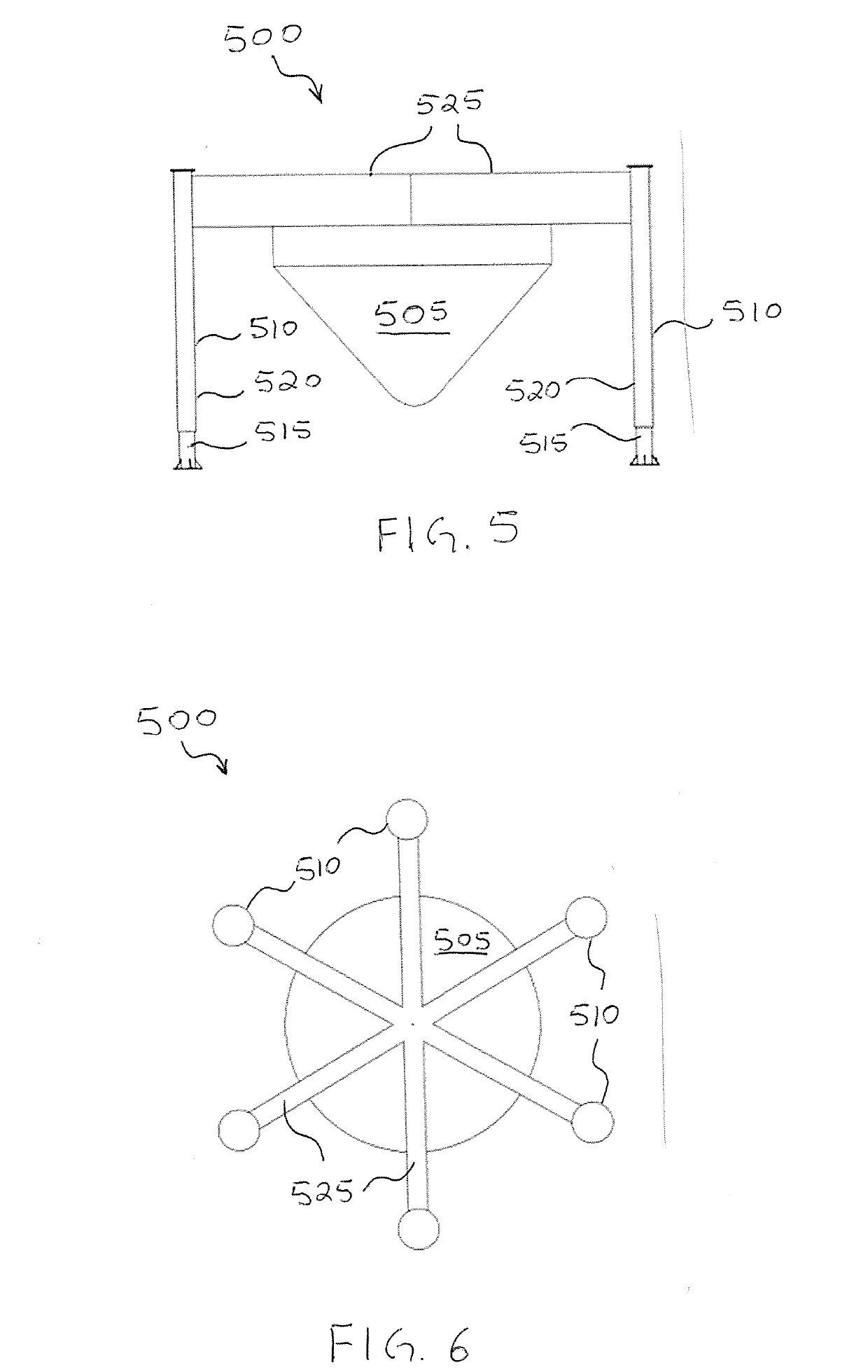

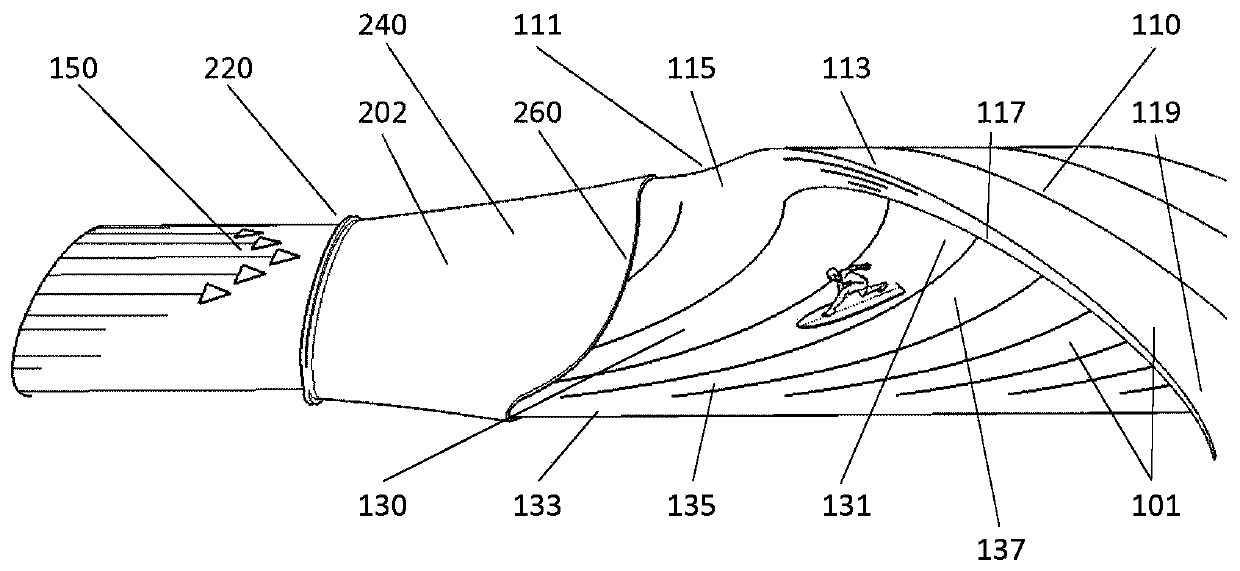

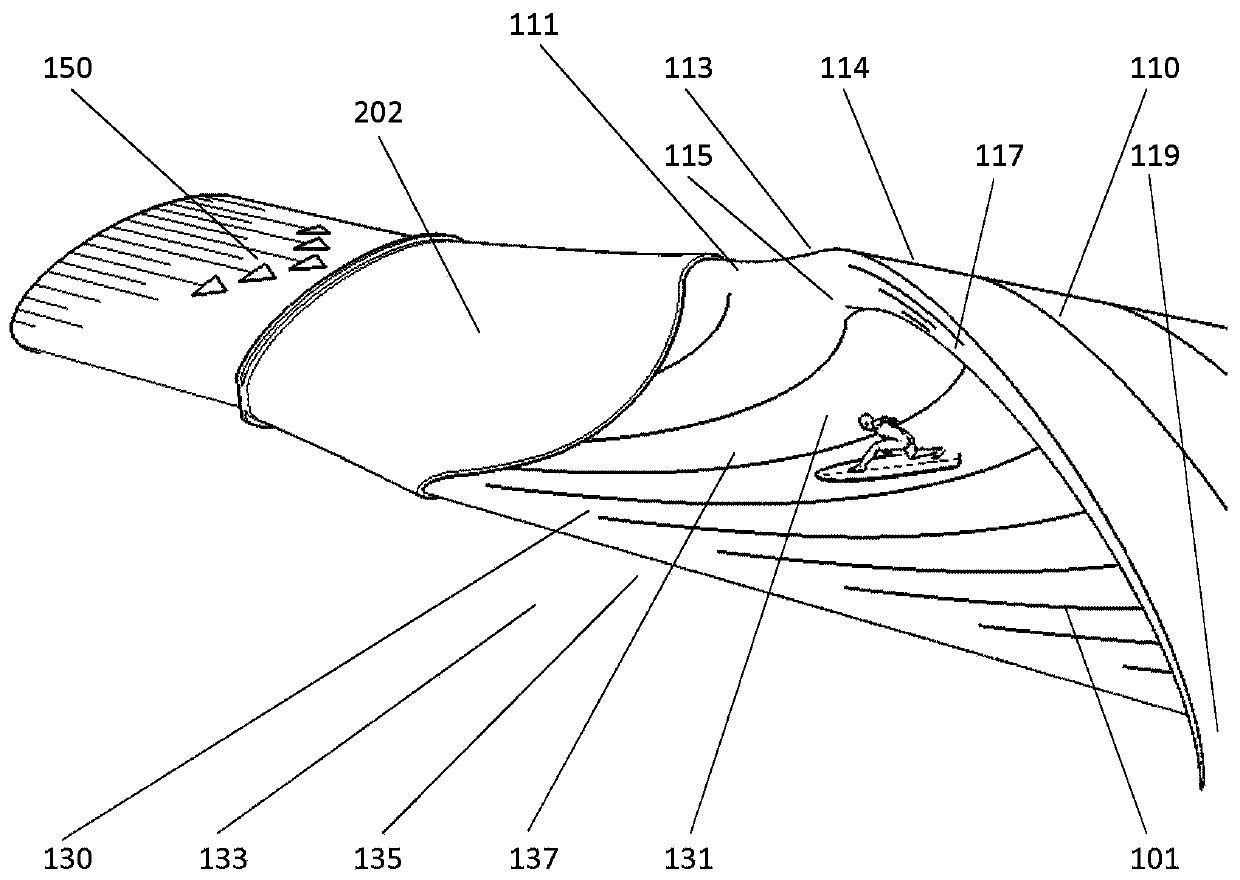

Generated wave propulsion water feature

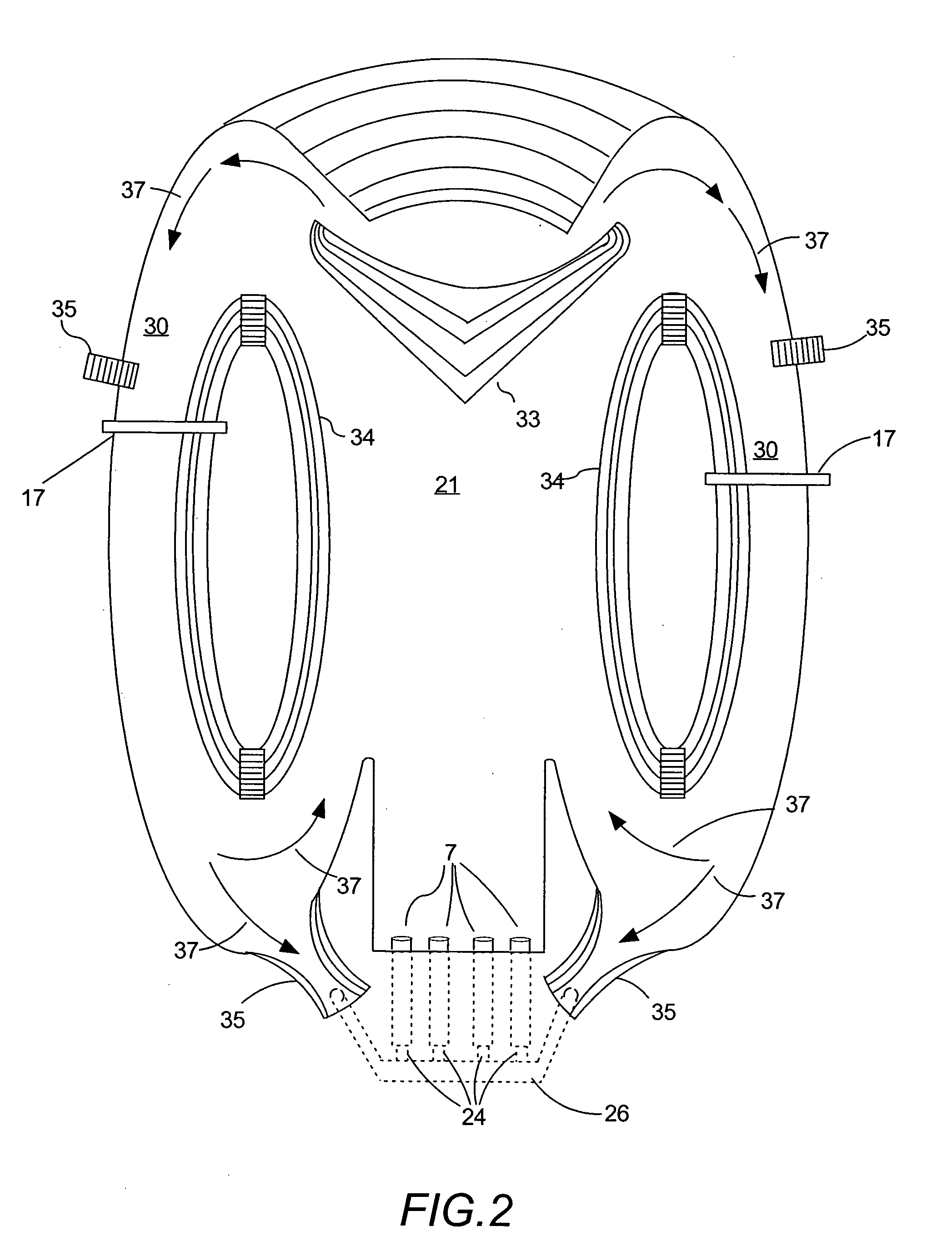

An alternative propulsion or motive force for the riders of water features based on generated waves. A wave generator may be used to propel individuals or vessels within a chute for recreation or transportation. In one form, a pool or container having a body of water is configured to support an artificial wave generator which uses compressed gas to discharge water and generate a wave-like motion within a body of water. A source of make-up fluid is configured to mitigate internal low pressure conditions caused by the water discharge to enable effective wave generation with reduced quantities of compressed air. Portions of the waves generated in a pool may be captured in a variety of ways by chutes for stand-alone rides or for portions of chutes in water slides.

Owner:JOHNSON GARRETT T

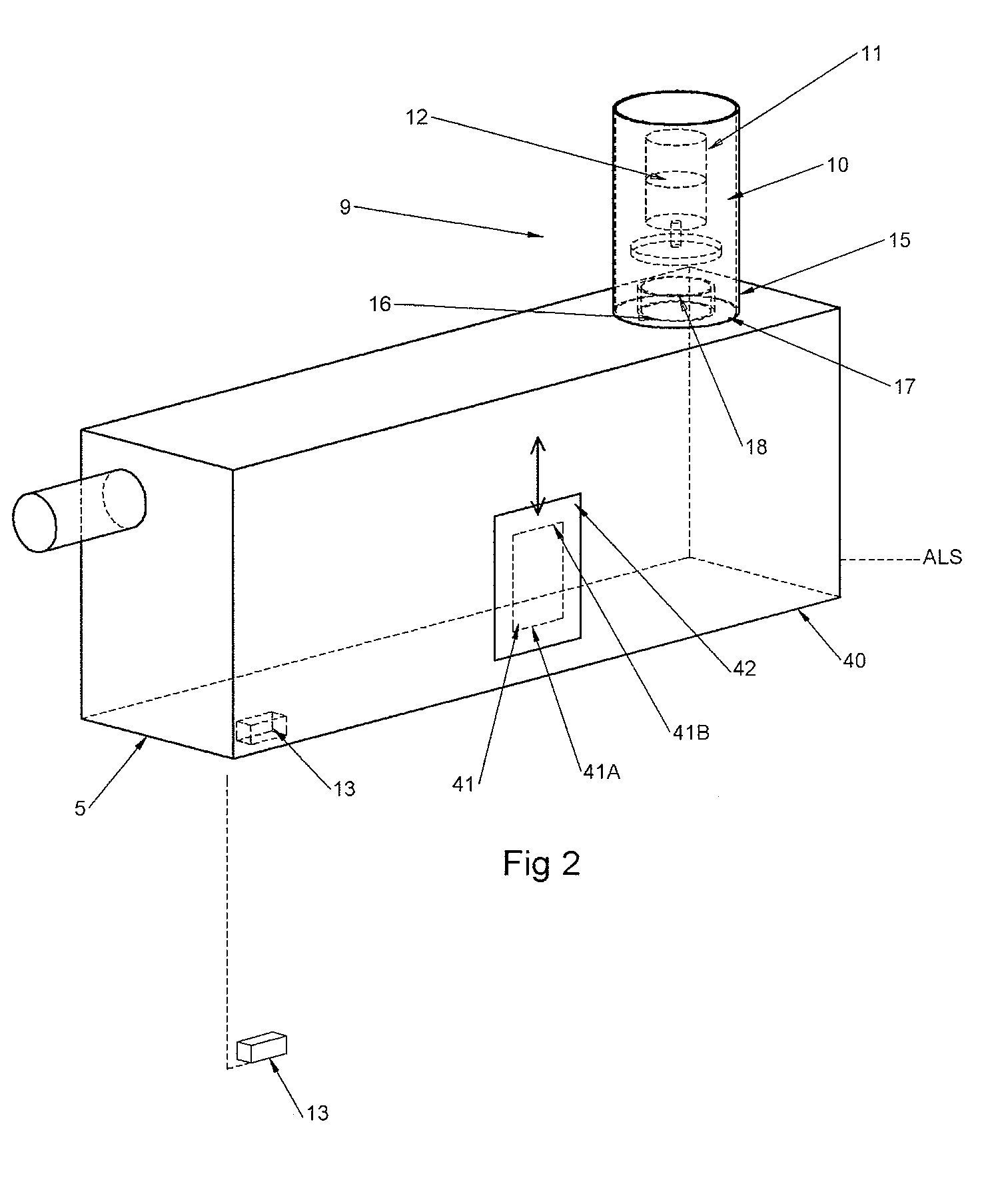

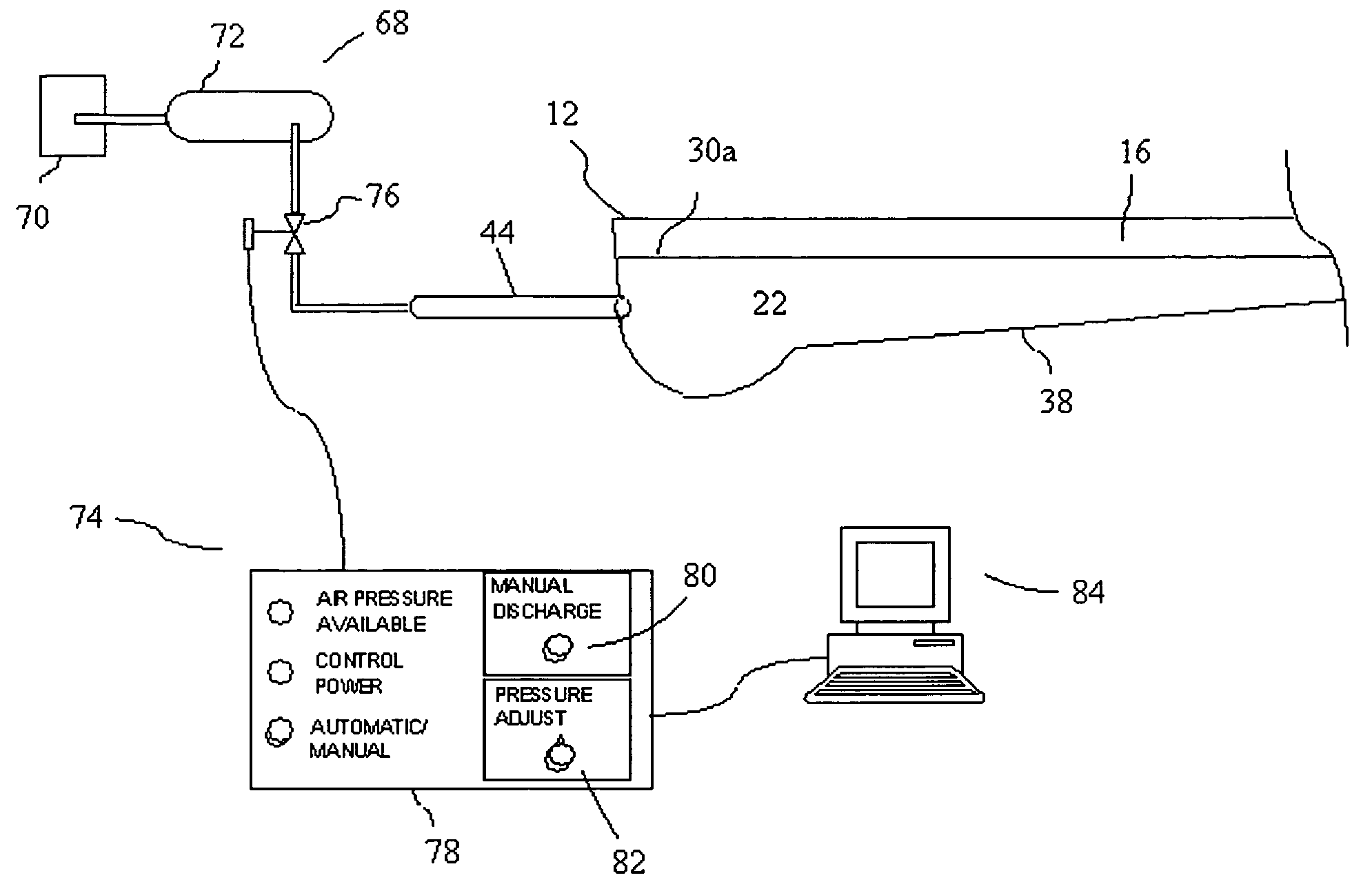

Wave generating system

An improved device for discharging water that is capable of efficiently generating an effective wave-like motion within a body of water. Wave generation devices based on water filled elongated tubular chambers having a substantially closed rear end and a substantially open front end and using compressed air to discharge water, such as the wave cannon, may experience operational inefficiencies from variations in quantities of compressed air. Reducing the quantity of compressed gas may result in ineffective waves and damage to the elongated tube as internal low pressure conditions collapse. A source of make-up fluid configured to mitigate internal low pressure conditions can enable effective wave generation with reduced quantities of compressed air.

Owner:JOHNSON GARRETT T

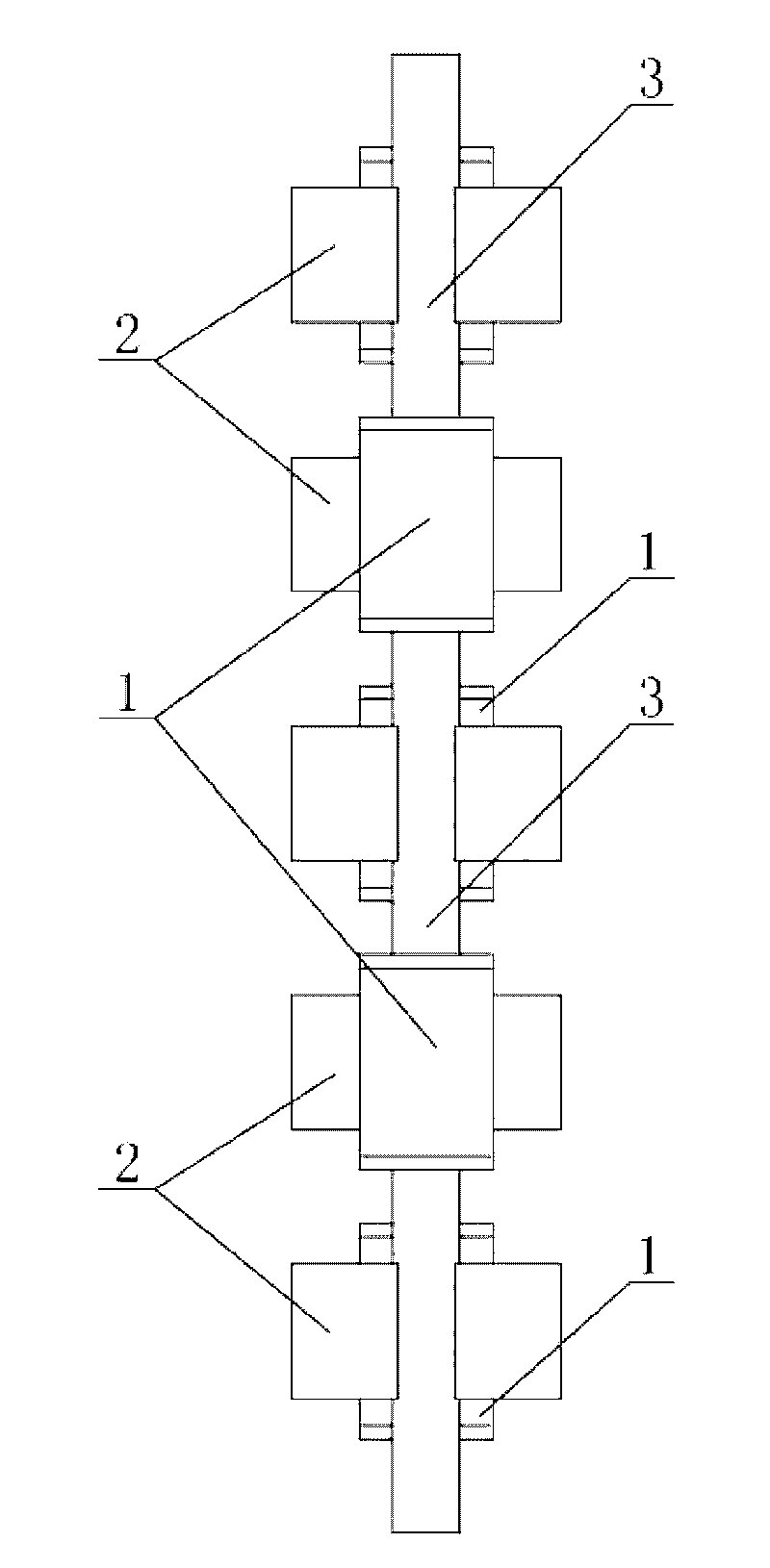

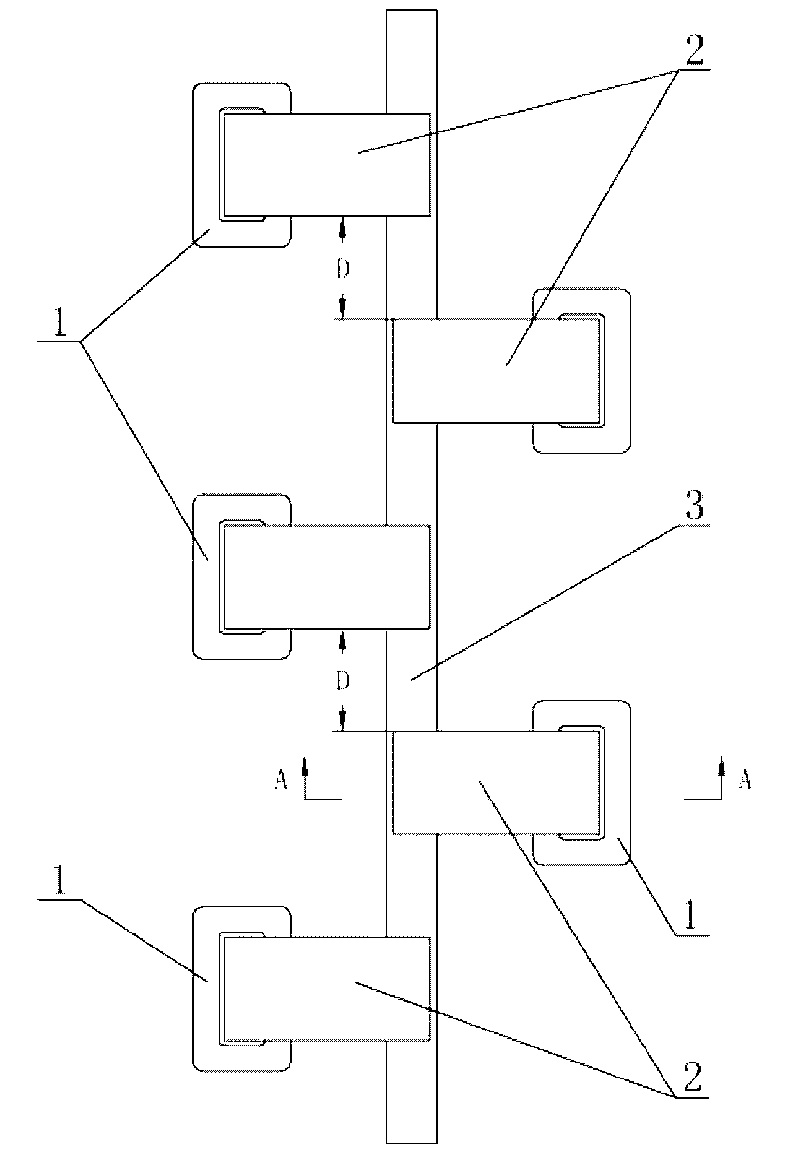

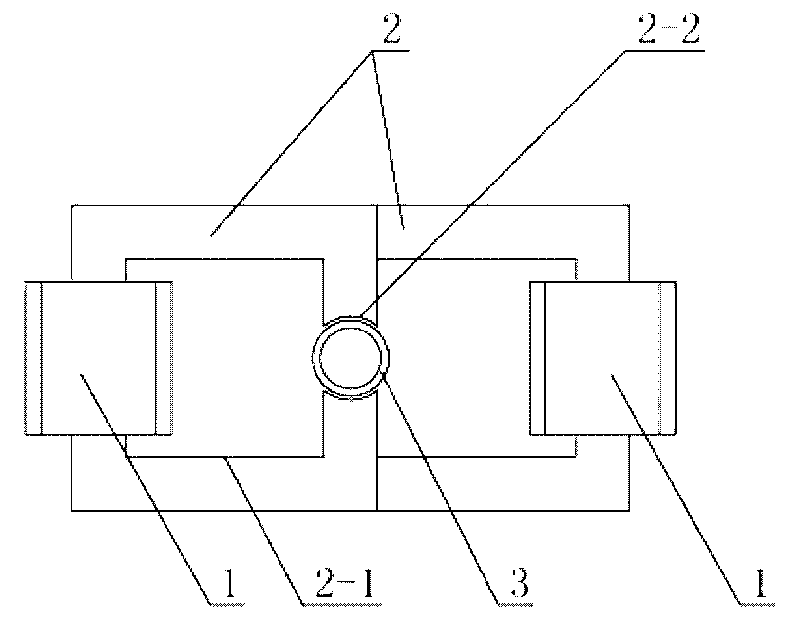

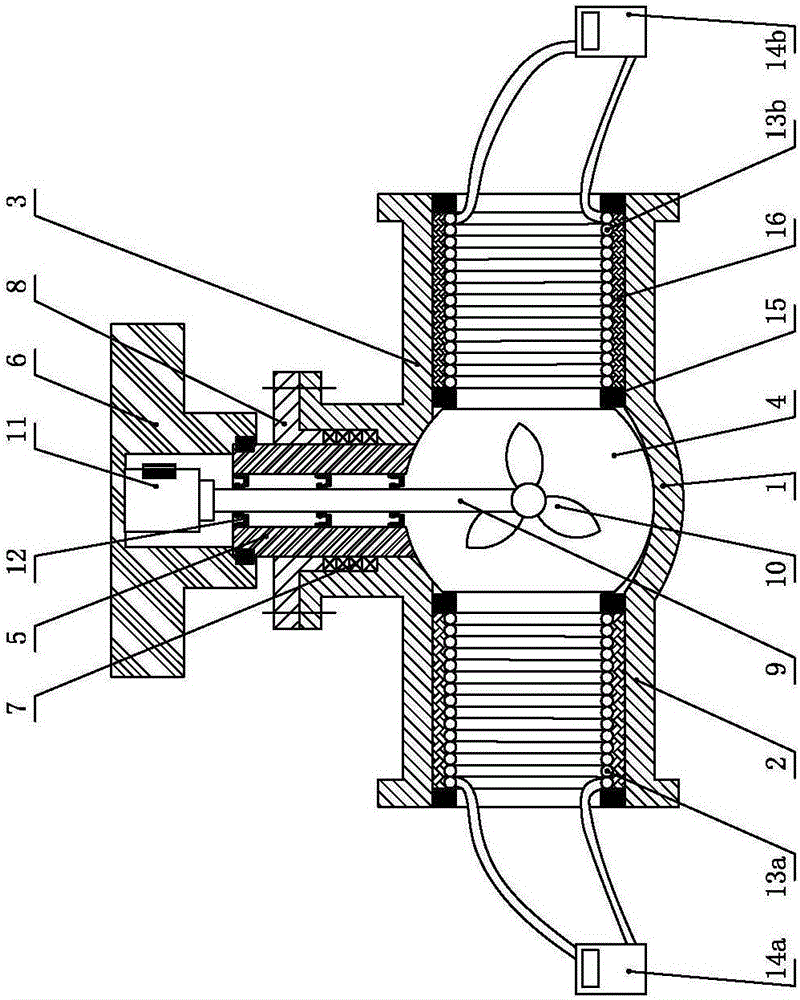

Linear type magnetic fluid traveling wave pump

InactiveCN101718283AVerify Transport PropertiesWave producing pumpsNon-positive displacement fluid enginesElectricityNon magnetic

The invention relates to a linear type magnetic fluid traveling wave pump, in particular to a magnetic fluid traveling wave pump. The invention solves the problem that the linear type magnetic fluid traveling wave pump for analyzing the movement law of the magnetic field of traveling wave on the magnetic fluid does not exist at present. The middle parts of magnetic steel bodies are provided with through holes along the direction of the thickness of the magnetic steel bodies; one side walls of the magnetic steel bodies are provided with breaches communicated with the through holes along the direction of the thickness of the magnetic steel bodies; the number of electrifying coils is set to be identical with the number of the magnetic steel bodies; the electrifying coil winds around the other side walls corresponding to the breach on each magnetic steel body; a pipe sequentially passes through the breaches of three to ten magnetic steel bodies; two adjacent magnetic steel bodies are staggered to be arranged at both sides of the pipe; the distance between the two adjacent magnetic steel bodies along the axis direction of the pipe is two to three times the thickness of the magnetic steel bodies; and the pipe is made of non-magnetic materials. The invention utilizes the principle of magnetic fluid dynamics to provide the linear type magnetic fluid traveling wave pum, and can validate the transport properties of magnetic fluid, thereby opening a new field of application of the magnetic fluid.

Owner:HARBIN INST OF TECH

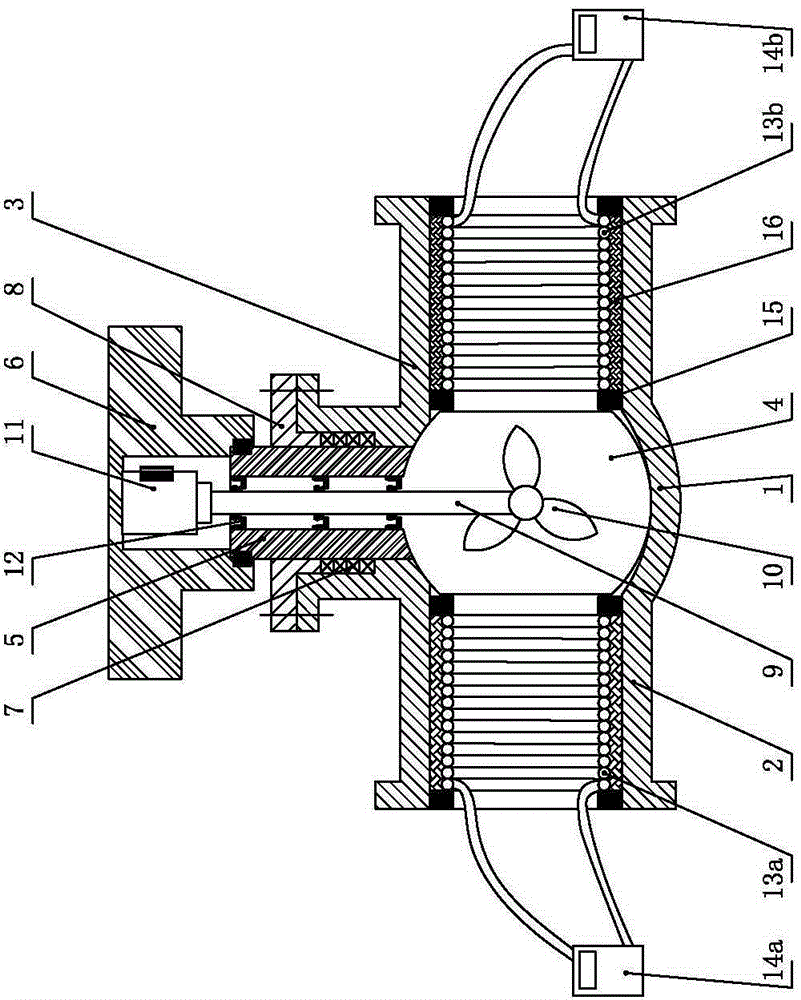

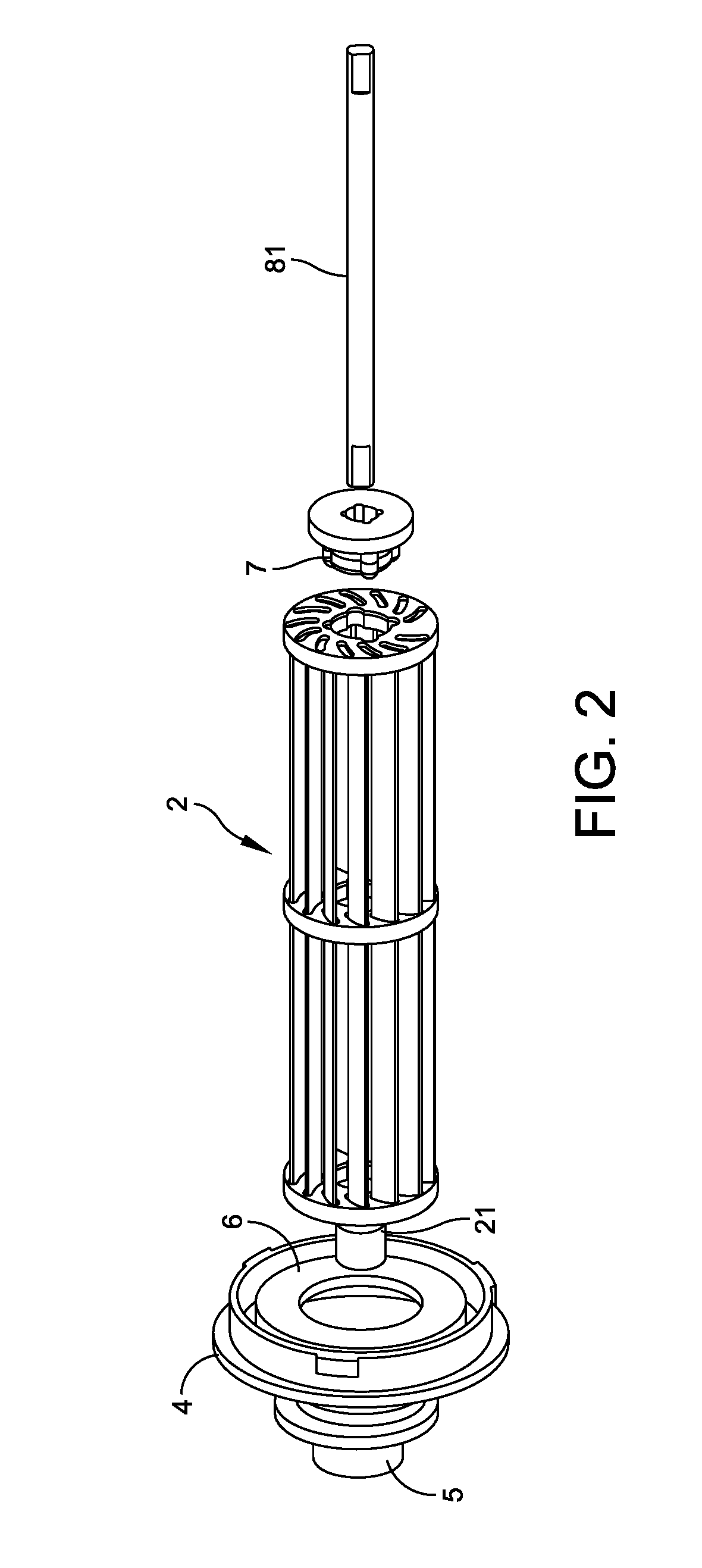

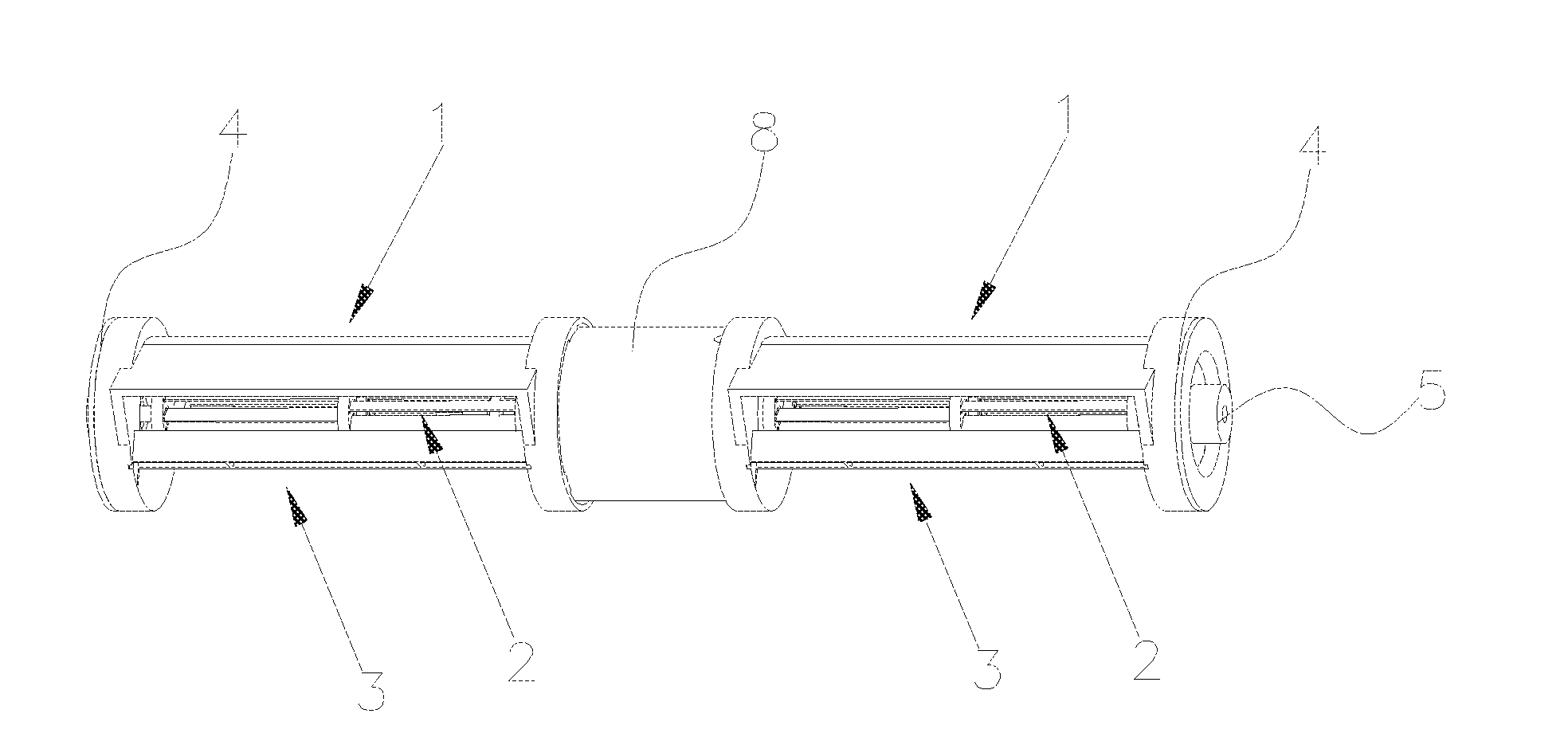

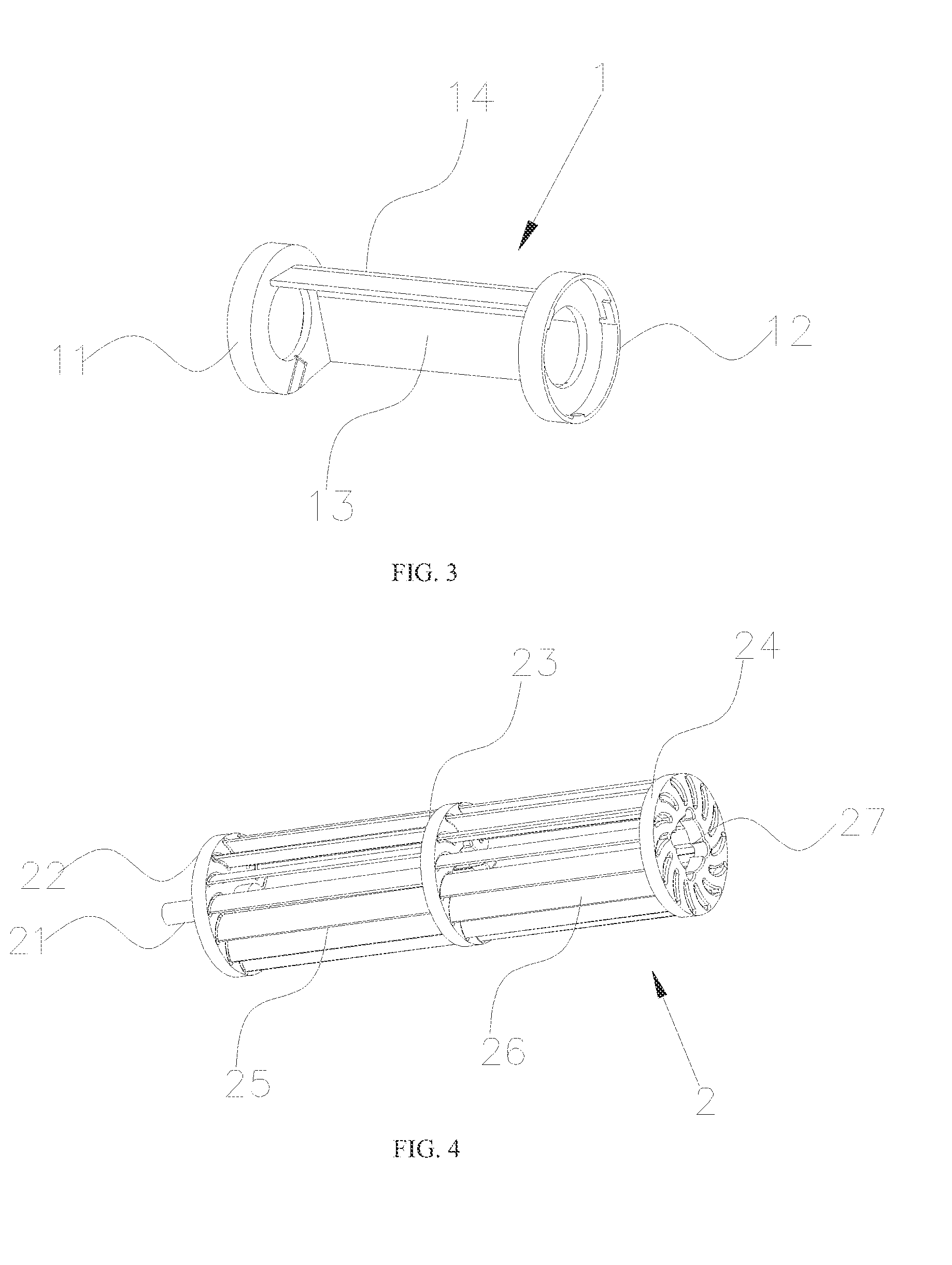

Cross-flow wave making pump

ActiveUS20170248141A1Reduce liquid flowIncrease torquePump componentsWave producing pumpsImpellerEngineering

This invention relates to a cross-flow wave making pump comprising an impeller shell forming a water intake and a water outlet, an impeller assembly pivotally connected to two ends of the impeller shell, and a motor used for driving the impeller assembly; wherein, the impeller assembly comprises an impeller used for driving a liquid flow, a first turntable and a second turntable respectively fixed at two ends of the impeller, wherein the first turntable is provided with a shaft rotatably mounted in the impeller shell, the second turntable is provided with a cavity used for receiving a rotor shaft of the motor. The embodiments of the present invention can provide a sufficient liquid-circulation in a container, and significantly reduce the dead zone where the liquid flows extremely slowly. Other embodiments are disclosed.

Owner:GUANGZHOU MAIGUANG ELECTRONIC TECHNOLOGY CO LTD

Wave propelling power generation system

InactiveCN104976045AImprove powerImprove efficiencyWave producing pumpsEngine componentsEnvironmental resistanceMotor speed

A wave propelling power generation system uses a motor speed reducer to drive a swing rod to move, and the swing rod drives a wave barrel, pivoted with the swing rod, to make up-down reciprocating motions, so water in a water container can generate high-low fluctuating waves; a floating board in the water container can rise or decrease along with high-low fluctuating water level in the water container; when the floating plate rises, a link rod can drive a speed changer or a transmission unit, and at least one inertia rotary disc group can transmit kinetic energy to at least one generator for generating power energy. The system uses less power to drive the wave barrel and enable the generators to generate high efficiency power energy, and can be widely applied without being limited by places; the system cannot generate pollution and waste material; the water in the container can be repeatedly used, so a environmental protection principle is followed; the wave propelling power generation system is low in making cost, and can be widely applied when compared with a solar or wind power generating system with high making cost.

Owner:彭 圣博

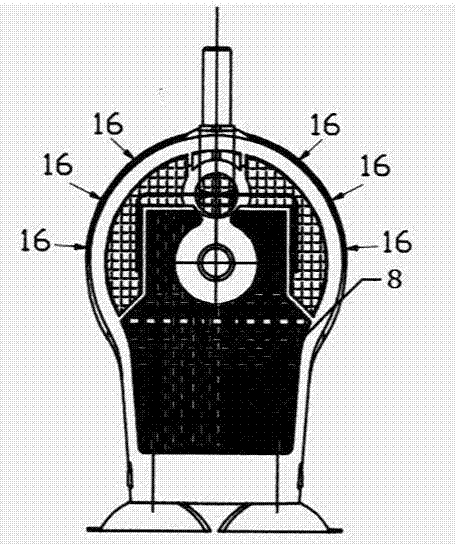

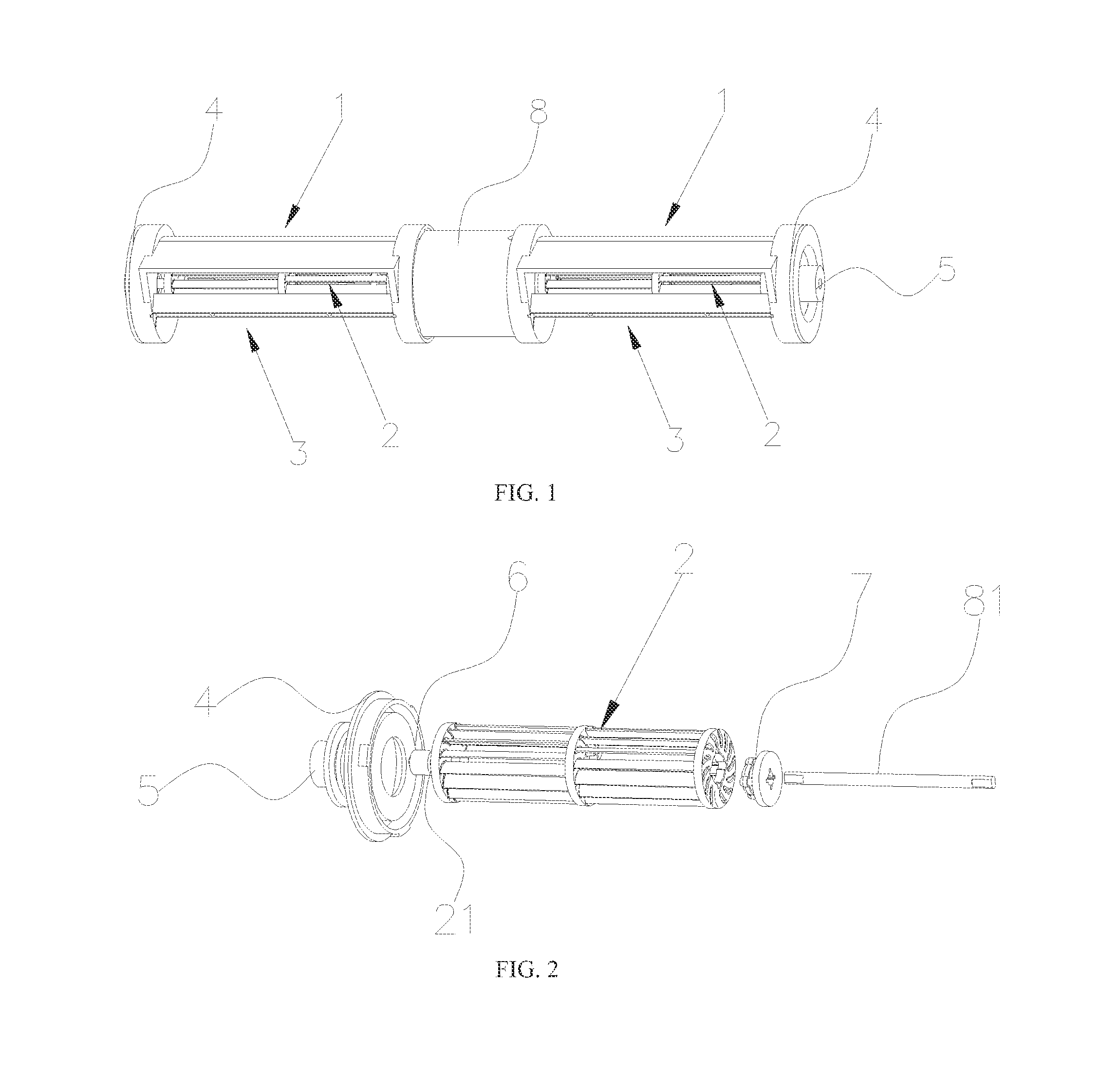

Novel four-in-one multifunctional pump

ActiveCN104500412ALess power consumptionSave spaceWave producing pumpsPisciculture and aquariaImpellerFilter system

The invention discloses a novel four-in-one multifunctional pump comprising a pump body (17), a front end cover (11), a rear end cover (5), a rotor shaft (6), a ferromagnet permanent magnetic rotor (7), a motor coil (8), a motor iron core (9) and a power supply wire (19). A first impeller (3) and a second impeller (12) are installed on two sides of the ferromagnet permanent magnetic rotor (7); the first impeller (3) rotates to form a water circulating supply filtering system; a partition (20) is arranged between the first impeller (3) and the second impeller (12); a water absorption shielding plate (21) is arranged on the second impeller (12) additionally; an inclined air incoming pipe (18) is inserted into the most thin position (22) of a pump water incoming hollow pipe; the second impeller (12) rotates to realize the oxygen increasing and wave producing functions in a fish tank. The pump has the advantages that the oxygen increasing, wave producing, circulating and filtering functions are combined, power consumption is reduced, space is saved, noise is reduced, and placement is facilitated.

Owner:南京一品红水族用品科技发展有限公司

Pipe-free massage water pump

InactiveCN103256259AComfortable massageWave producing pumpsNon-positive displacement fluid enginesImpellerMassage

The invention discloses a pipe-free massage water pump. The pipe-free massage water pump comprises a pump body, a motor, an impeller, a front cover, at least two water inlets and a water outlet, wherein the motor is arranged inside the pump body, the impeller is driven by the motor, the water inlets and the water outlet are arranged on the front cover, the water outlet is arranged on the front side of the front cover, and at least one water inlet is arranged on the lateral side of the front cover. Since the water inlets can be arranged on both the front side and the lateral side of the front cover, when the water inlets are arranged on both the front side and the lateral side and a human body is unaware, simultaneous closing of the water inlets on the front side and the lateral side is quite difficult. Besides, in the presence of a plurality of water inlets rather than only one water inlet, complete closing of the water inlets is more difficult, so that a water inflowing function and water inflowing effect of the front cover are guaranteed, and a variety of inconveniences caused by the fact that water inflows only from the front side of the front cover in the prior art are overcome effectively.

Owner:石泰山

Generated wave propulsion water feature

An alternative propulsion or motive force for the riders of water features based on generated waves. A wave generator may be used to propel individuals or vessels within a chute for recreation or transportation. In one form, a pool or container having a body of water is configured to support an artificial wave generator which uses compressed gas to discharge water and generate a wave-like motion within a body of water. A source of make-up fluid is configured to mitigate internal low pressure conditions caused by the water discharge to enable effective wave generation with reduced quantities of compressed air. Portions of the waves generated in a pool may be captured in a variety of ways by chutes for stand-alone rides or for portions of chutes in water slides.

Owner:JOHNSON GARRETT T

Water flow wave generating water pump

InactiveCN106402044ADoes not take up spaceImprove securityWave producing pumpsPisciculture and aquariaImpellerFiltration

The invention discloses a water flow wave generating water pump. The water pump comprises a motor part, a rotor part and a water impeller part; the motor part comprises a motor shell and a motor cover; a motor and a magnet rotating disc are mounted inside the motor shell; the magnet rotating disc is connected to a motor shaft; the motor cover is connected with the motor shell; the motor cover is connected with a fish tank outer wall sucking disc; the motor is connected with a control box; the control box is connected with a power adapter; the power adapter is connected with a power plug; the rotor part comprises a rotor holder; a rotor is mounted on the rotor holder; a rotor cover is arranged on the rotor; the rotor is connected with a switching head after passing through the rotor cover; the switching head is connected with the water impeller part; a fish tank inner wall sucking disc is arranged on the rotor holder; the motor part is totally separated from the rotor part; the magnet rotating disc and the rotor are capable of realizing power transmission through magnetism. The water flow wave generating water pump disclosed by the invention is high in safety, high in filtration efficiency, simple to maintain, small in noise and capable of only occupying a small water body space; the motor part is totally separated from the rotor part, and power is transmitted through magnetism, so the use safety for a user is guaranteed.

Owner:GUANGZHOU ZETLIGHT ELECTRONICS CO

Cross-flow wave making pump

ActiveUS20150292507A1Reduce liquid flowIncrease torqueFlow mixersCircumferential flow pumpsImpellerLiquid circulation

This invention relates to a cross-flow wave making pump comprising an impeller shell forming a water intake and a water outlet, an impeller assembly pivotally connected to two ends of the impeller shell, and a motor used for driving the impeller assembly; wherein, the impeller assembly comprises an impeller used for driving a liquid flow, a first turntable and a second turntable respectively fixed at two ends of the impeller, wherein the first turntable is provided with a shaft rotatably mounted in the impeller shell, the second turntable is provided with a cavity used for receiving a rotor shaft of the motor. The embodiments of the present invention can provide a sufficient liquid-circulation in a container, and significantly reduce the dead zone where the liquid flows extremely slowly.

Owner:GUANGZHOU MAIGUANG ELECTRONIC TECHNOLOGY CO LTD

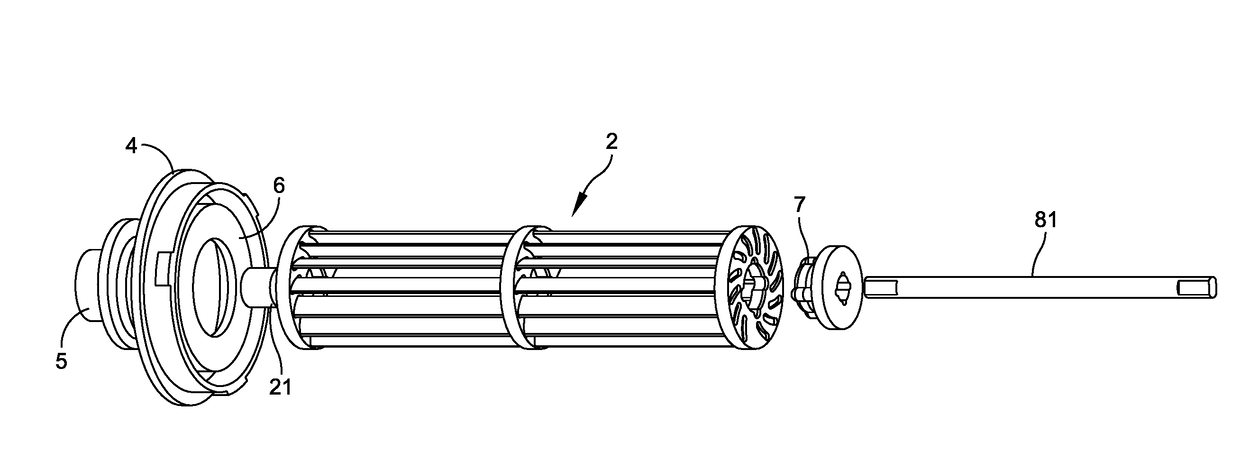

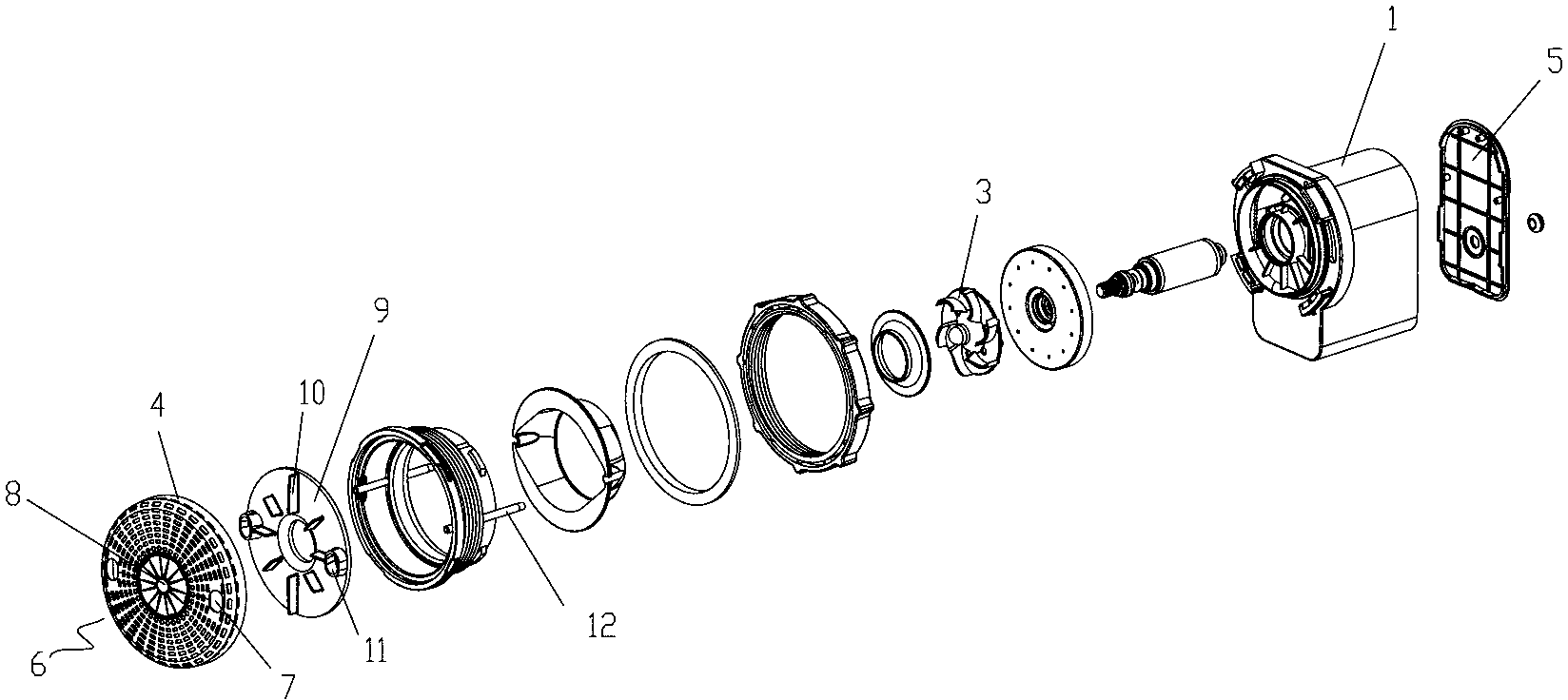

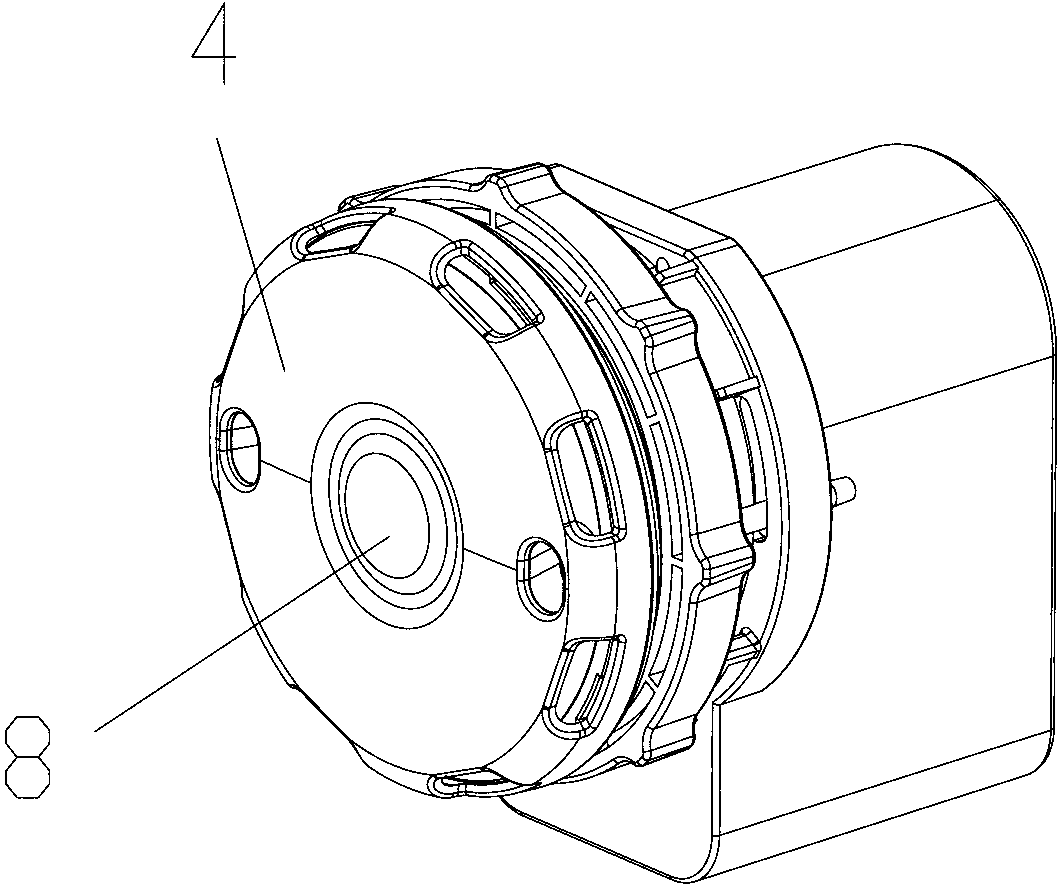

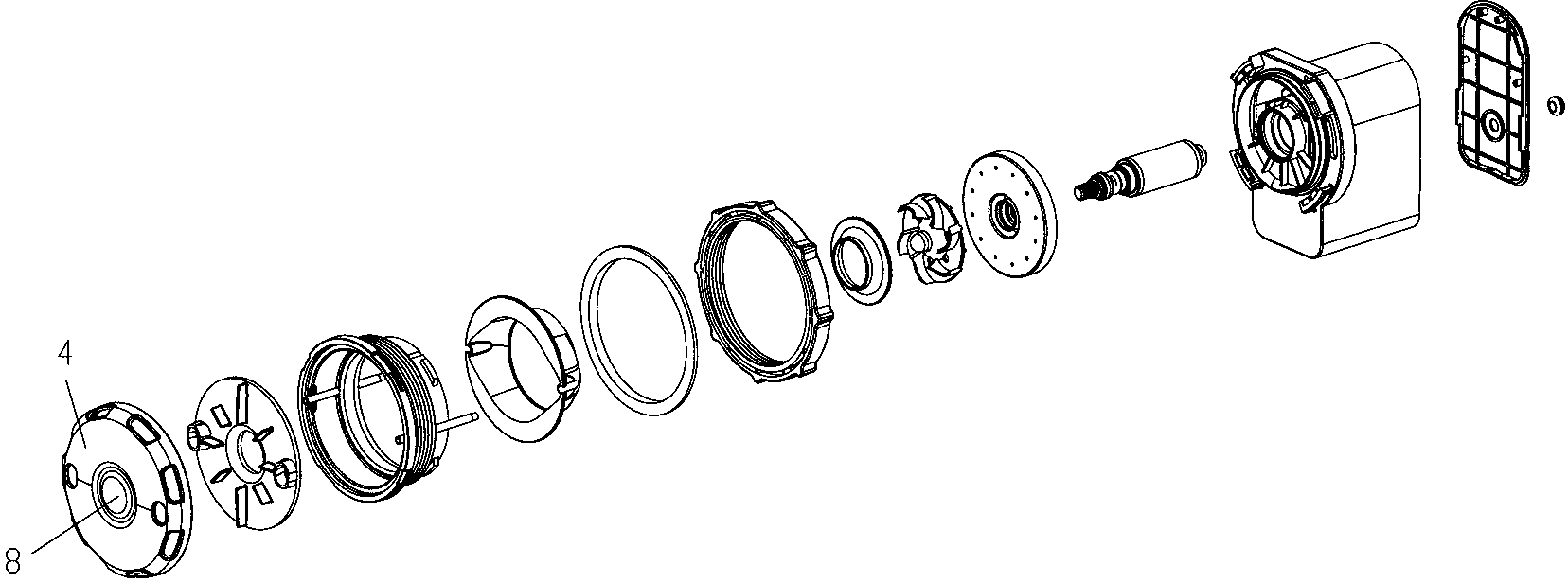

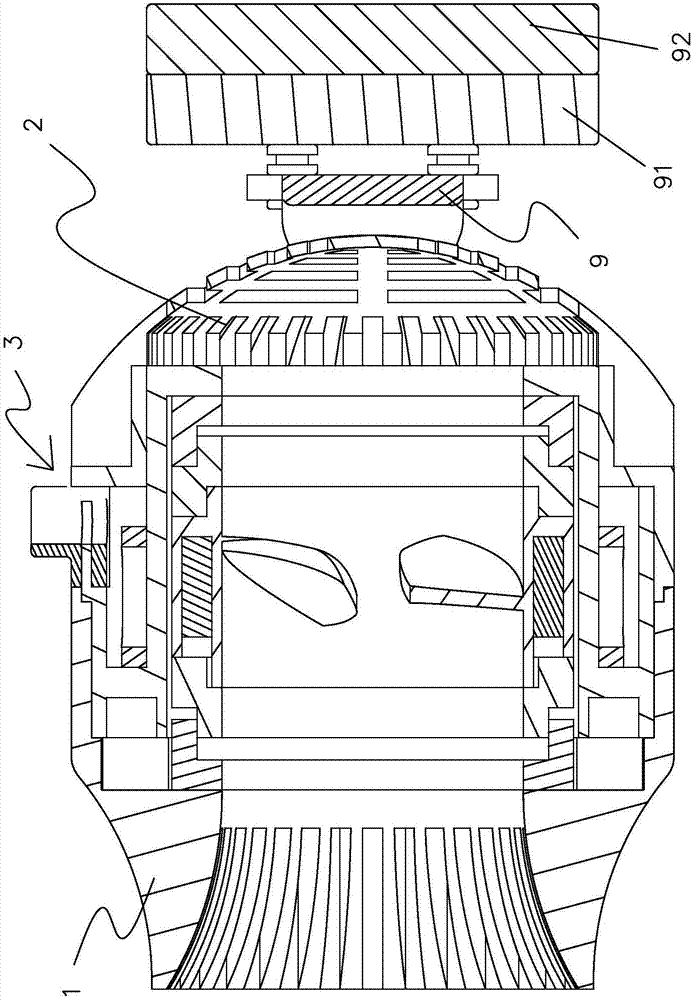

Direct-current brushless shaftless frequency conversion wave making pump

PendingCN107489660AAvoid noiseReduce noiseWave producing pumpsPisciculture and aquariaPermanent magnet rotorImpeller

The invention provides a direct-current brushless shaftless frequency conversion wave making pump. The direct-current brushless shaftless frequency conversion wave making pump comprises a hollow front end cover, a hollow back sand separating cover and a motor arranged between the front end cover and the back sand separating cover; the motor comprises a motor shell and an impeller permanent magnet rotor, the motor shell is provided with a motor shell inner wall through hole in the axial direction, the impeller permanent magnet rotor is rotationally arranged in the motor shell inner wall through hole, the impeller permanent magnet rotor is provided with a rotor inner wall through hole in the axial direction, a water way for water flow to pass through is formed by hollow cavities of the front end cover and the back sand separating cover and the rotor inner wall through hole, and blades for driving flowing of the water flow are arranged in the rotor inner wall through hole in the circumferential direction; under driving of the blades, water in a fish tank continuously passes through the water way formed by the hollow cavity of the back sand separating cover, the rotor inner wall through hole and the hollow cavity of the front end cover, and therefore water in the fish tank sufficiently flows; and in addition, as a motor center shaft is not adopted in the structure, in the working process, vibration is small, the service life is long, generated noise is small, and the pump is silent relatively.

Owner:邓耀钊

Wave generating system

InactiveUS20080166187A1Improve efficiencyReduce the impactWave producing pumpsBulk conveyorsEngineeringCompressed air

An improved device for discharging water that is capable of efficiently generating an effective wave-like motion within a body of water. Wave generation devices based on water filled elongated tubular chambers having a substantially closed rear end and a substantially open front end and using compressed air to discharge water, such as the wave cannon, may experience operational inefficiencies from variations in quantities of compressed air. Reducing the quantity of compressed gas may result in ineffective waves and damage to the elongated tube as internal low pressure conditions collapse. A source of make-up fluid configured to mitigate internal low pressure conditions can enable effective wave generation with reduced quantities of compressed air.

Owner:JOHNSON GARRETT TYLER

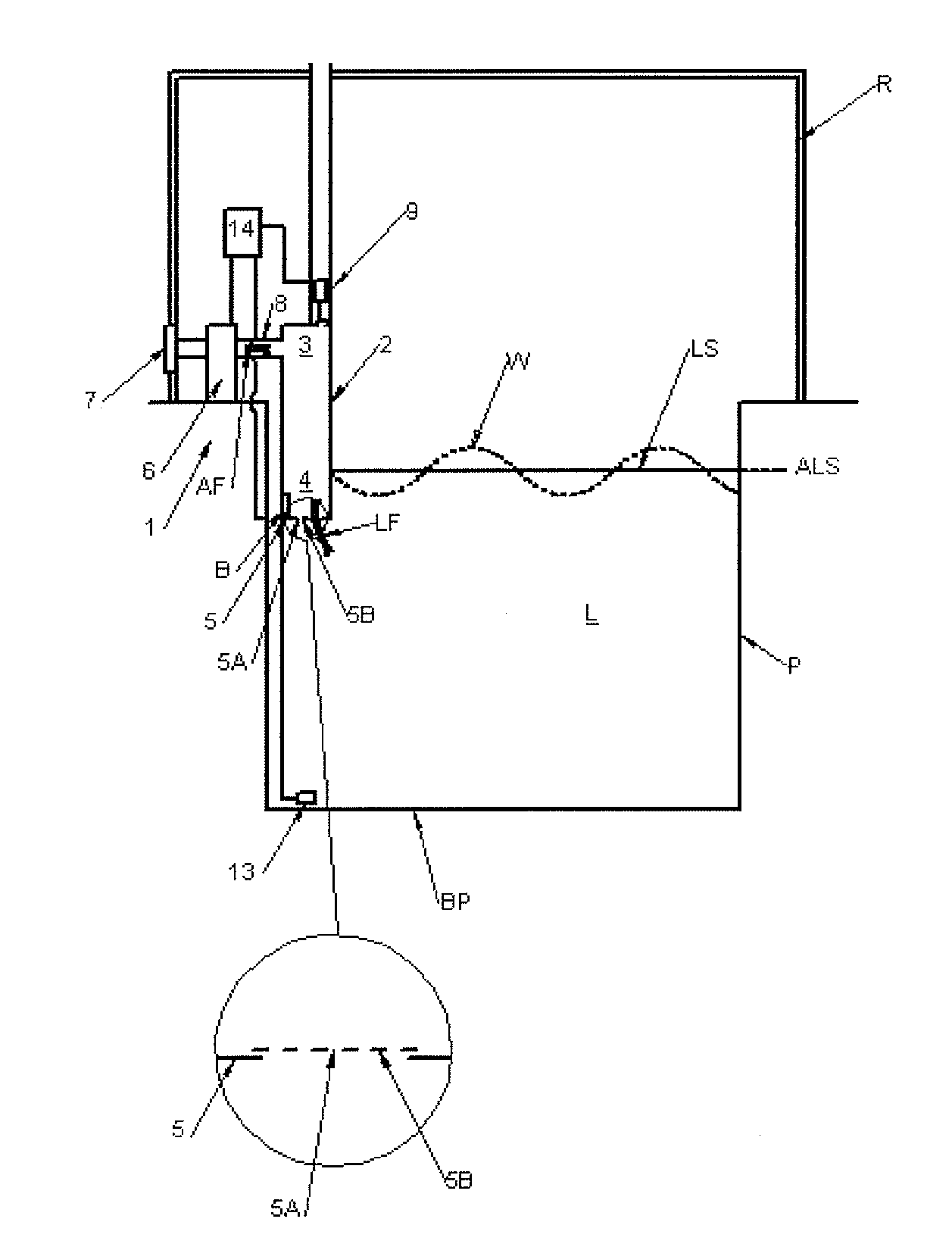

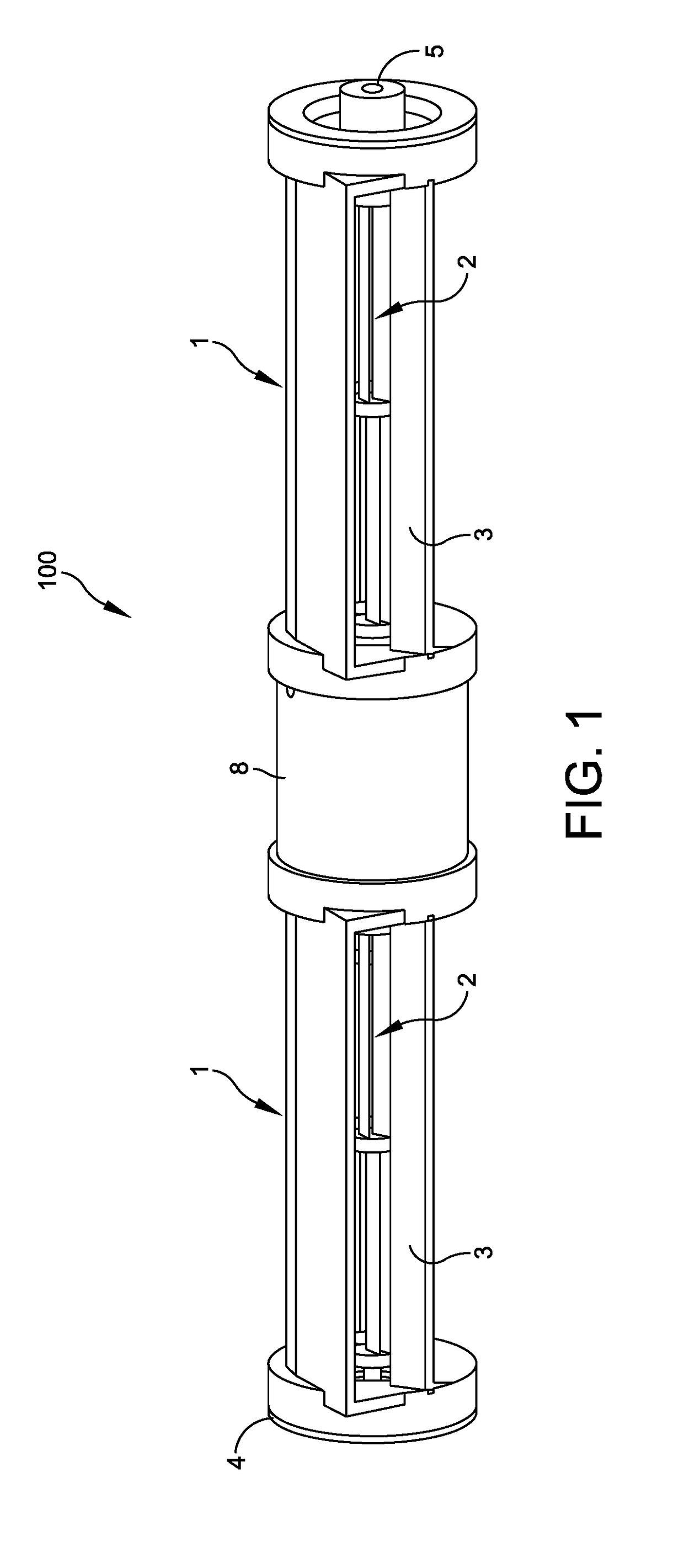

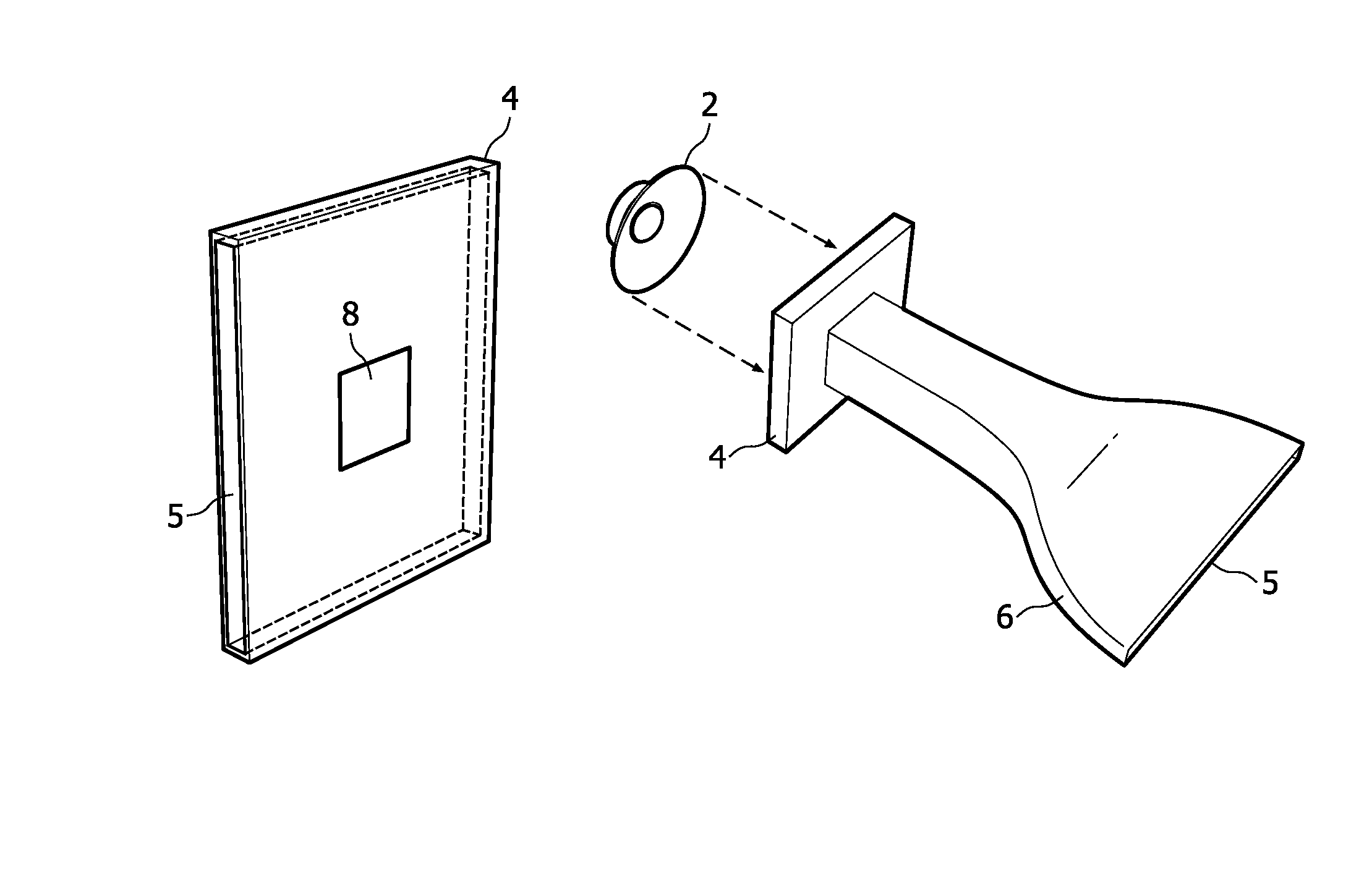

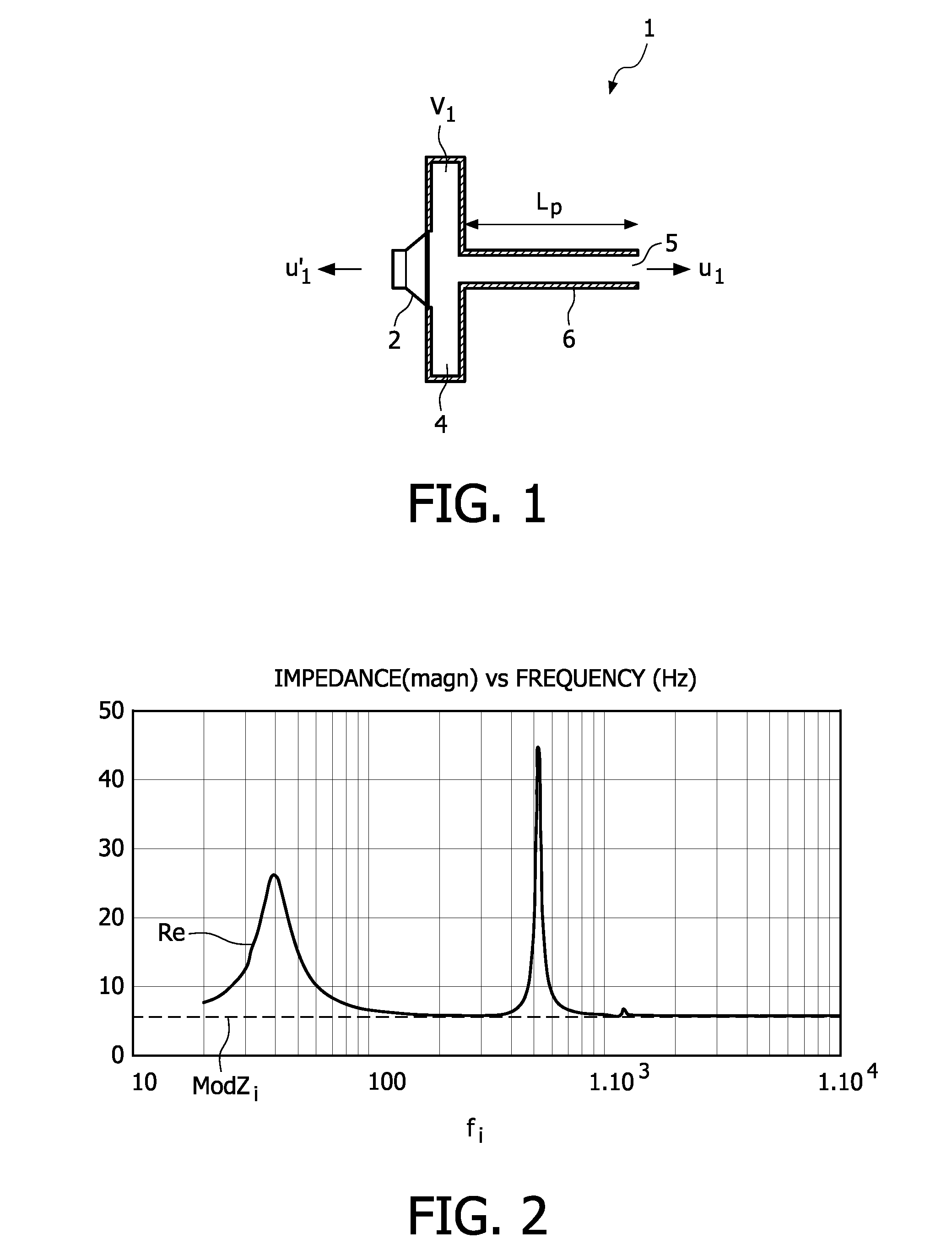

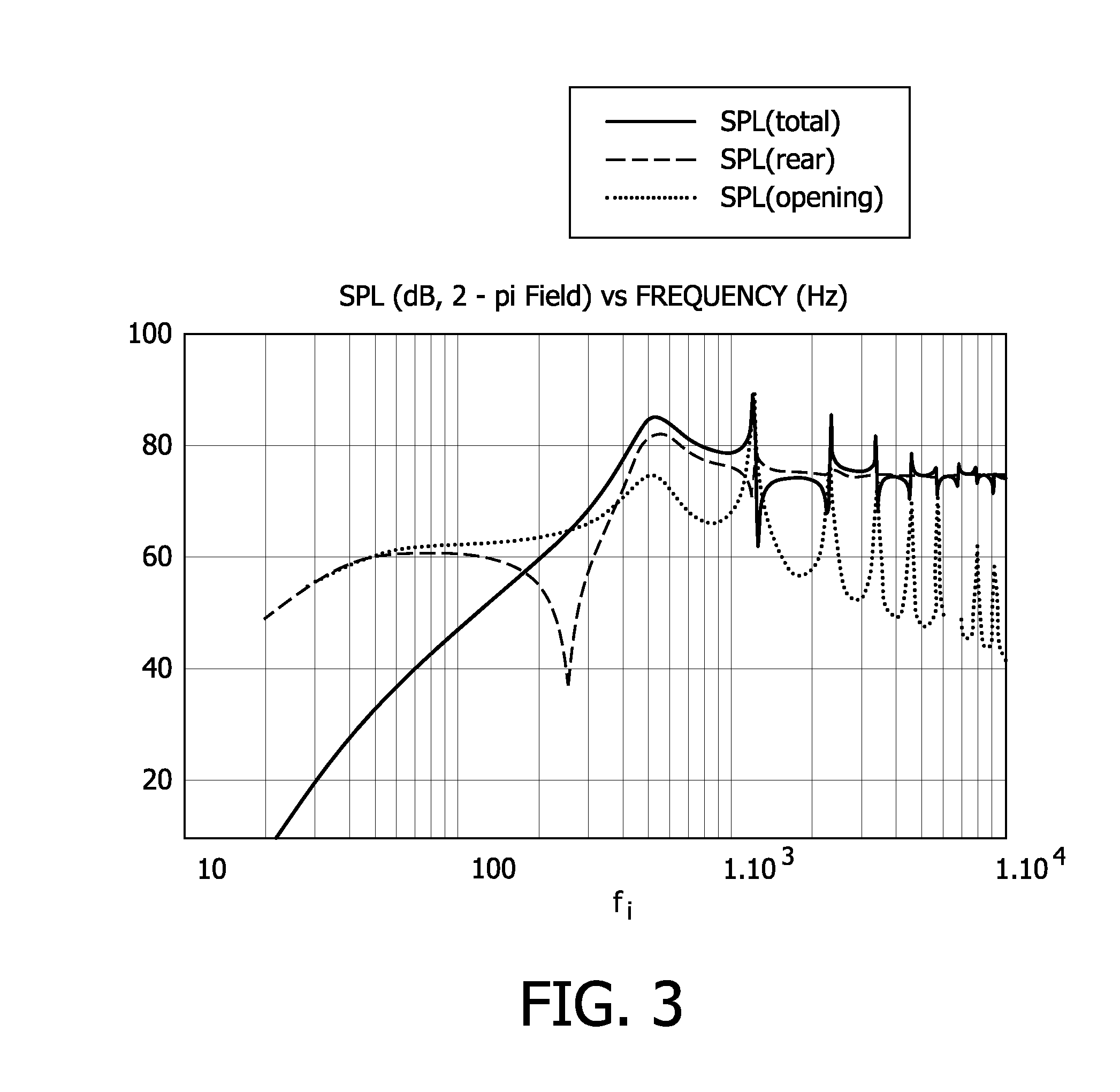

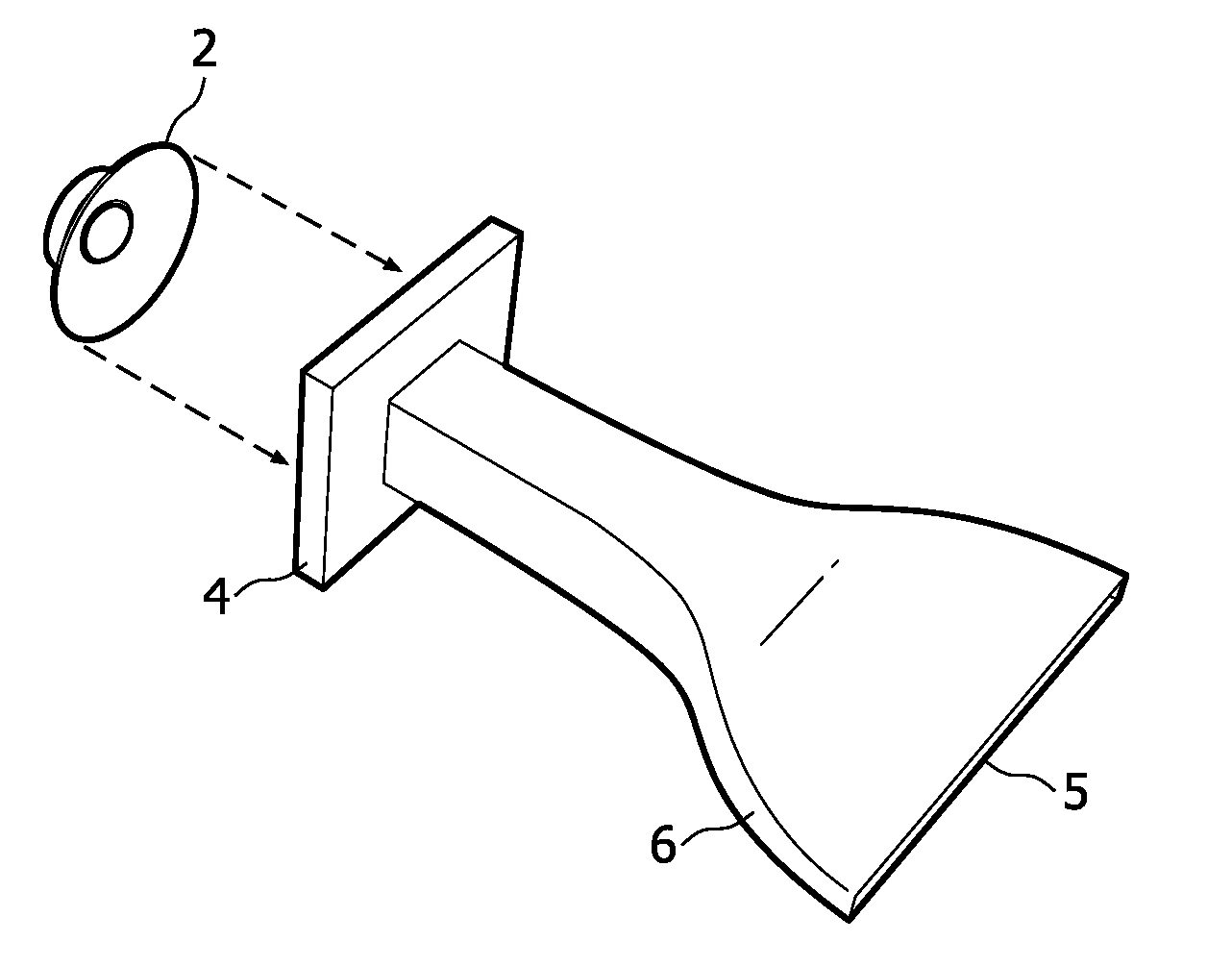

Low noise cooling device

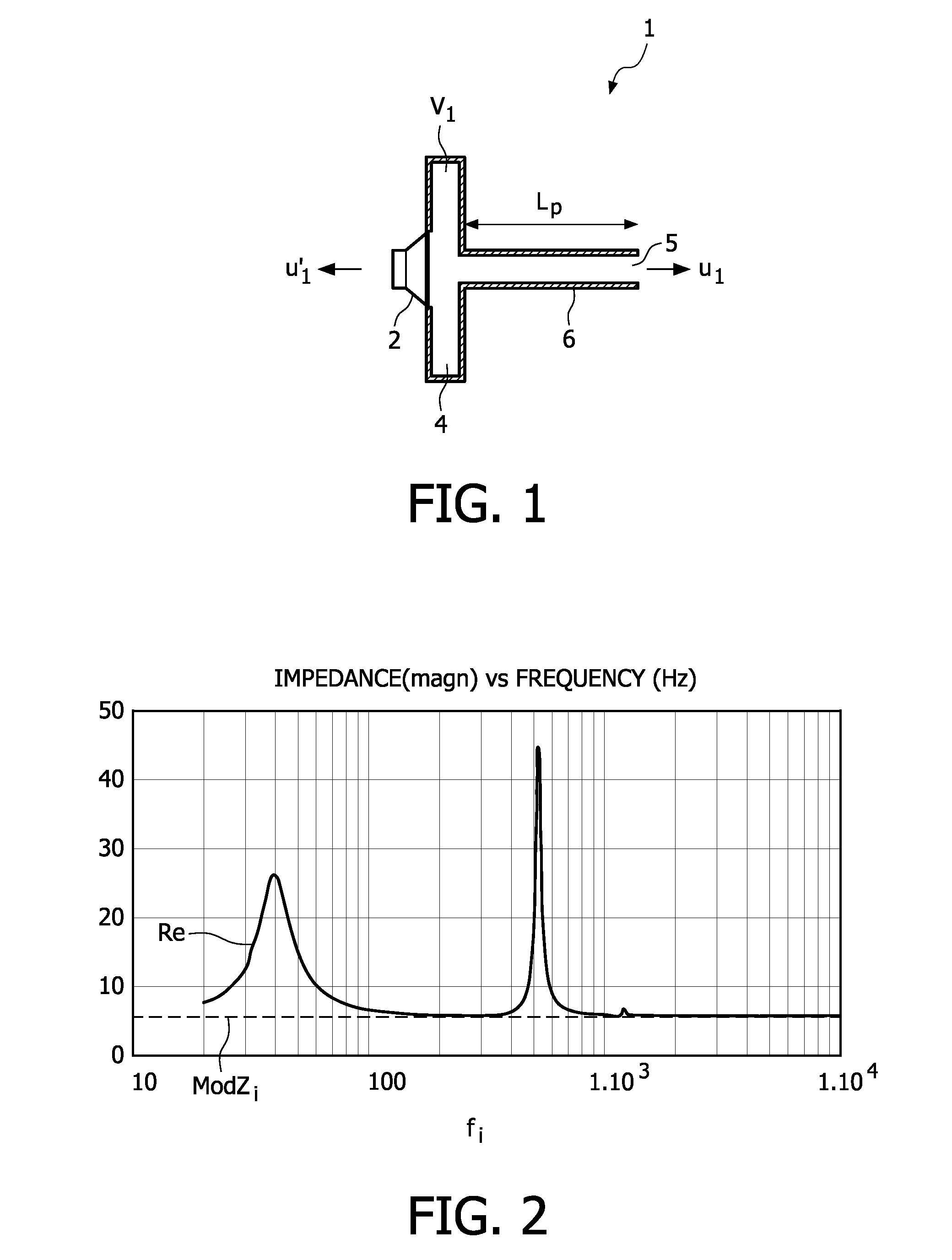

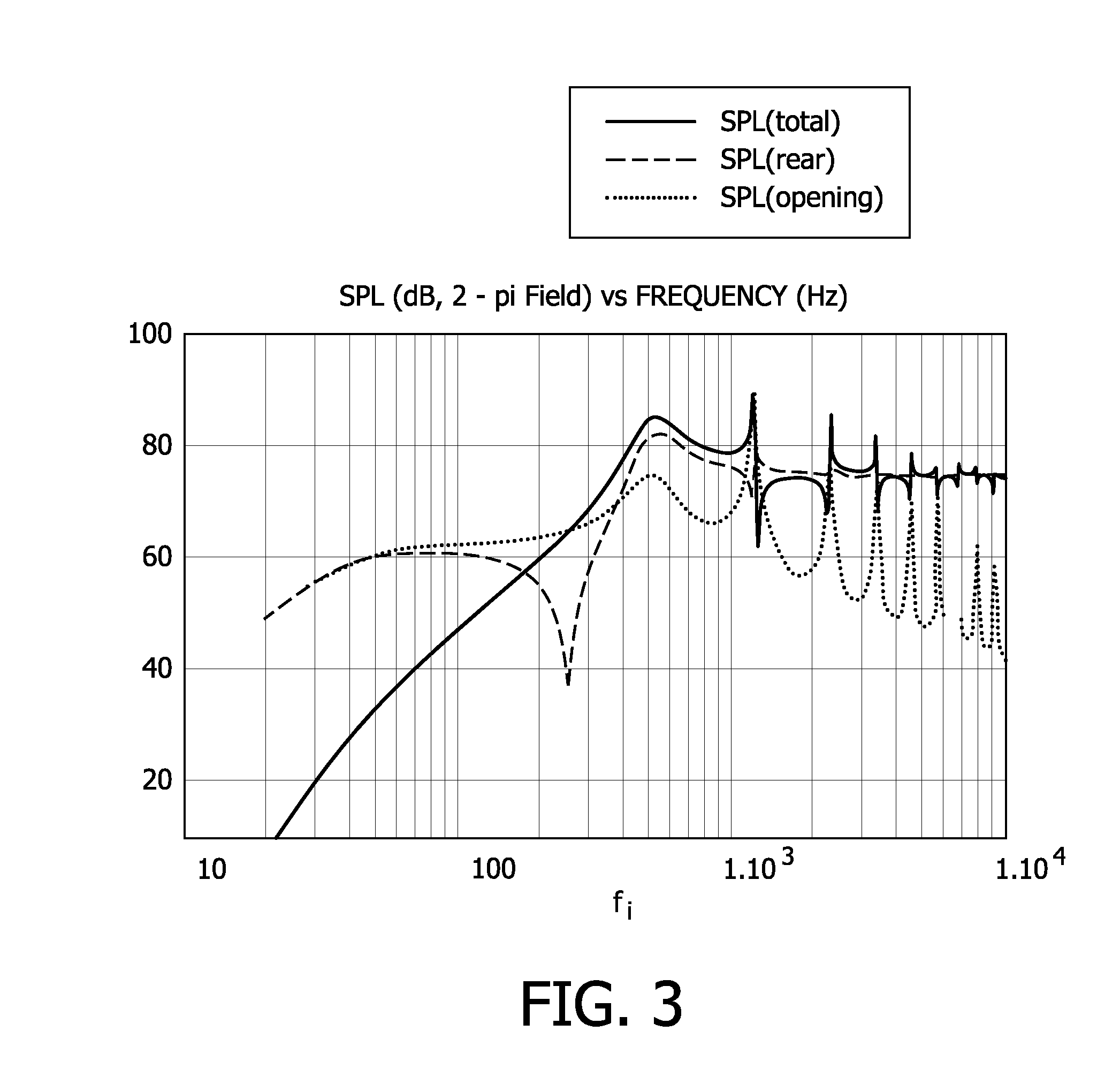

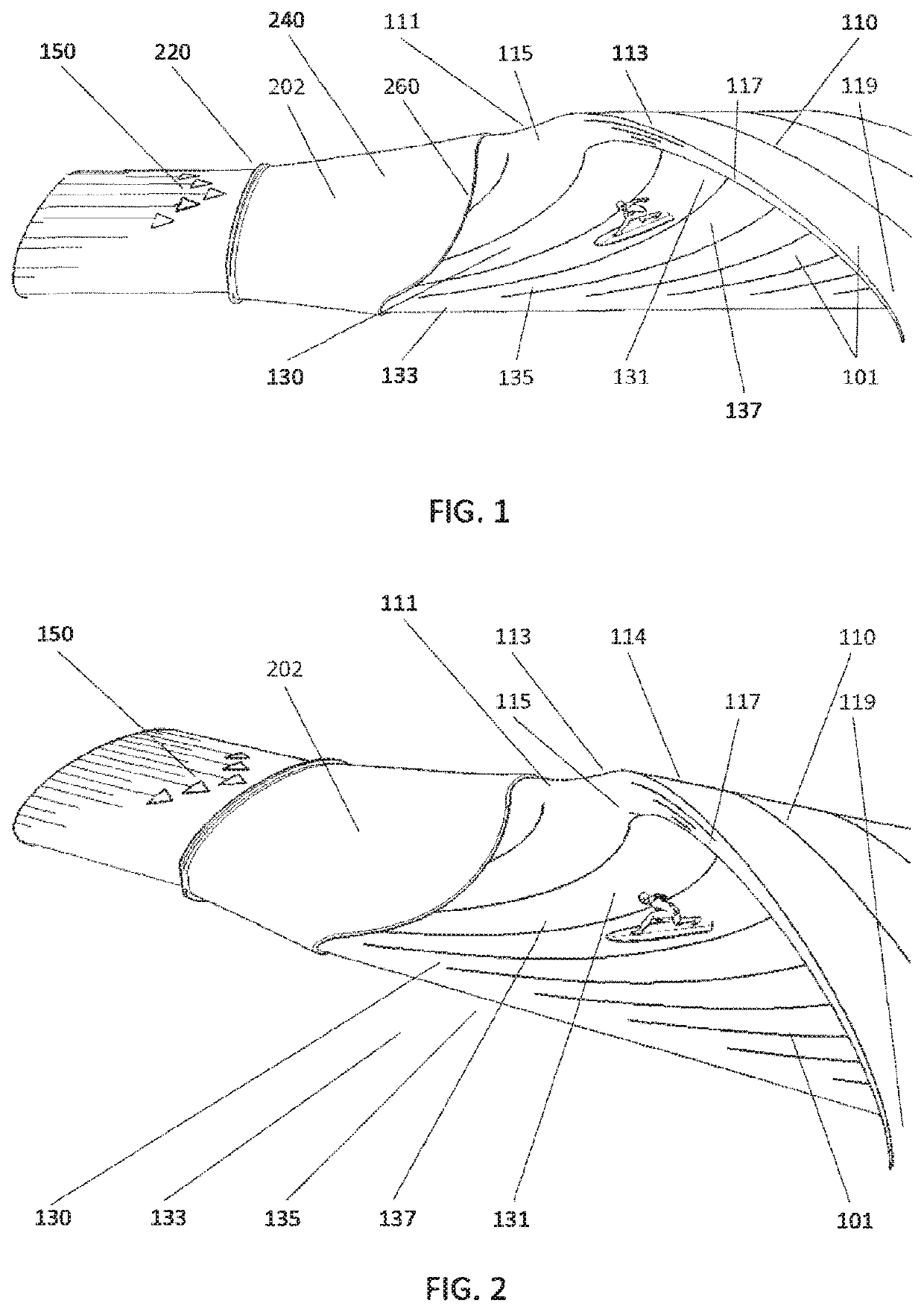

A cooling device (1) using pulsating fluid for cooling of an object, comprising: a transducer (2) having a membrane adapted to generate pressure waves at a working frequency (fw), and a cavity (4) enclosing a first side of the membrane. The cavity (4) has at least one opening (5) adapted to emit a pulsating net output fluid flow towards the object, wherein the opening (5) is in communication with a second side of the membrane. The cavity (4) is sufficiently small to prevent fluid in the cavity (4) from acting as a spring in a resonating mass-spring system in the working range. This is advantageous as a volume velocity (u1) at the opening is essentially equal to a volume velocity (u1′) at the second side of the membrane, apart from a minus sign. Thus, at the working frequency the pulsating net output fluid can be largely cancelled due to the counter phase with the pressure waves on the second side of the membrane resulting in a close to zero far-field volume velocity. Thus a low sound level is achieved, at a low cost, without requiring mechanical symmetry.

Owner:SIGNIFY HLDG BV

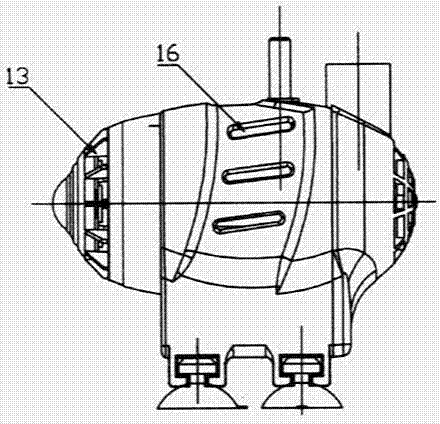

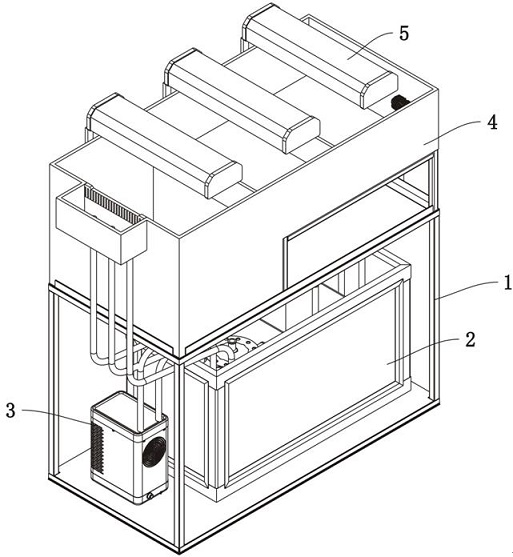

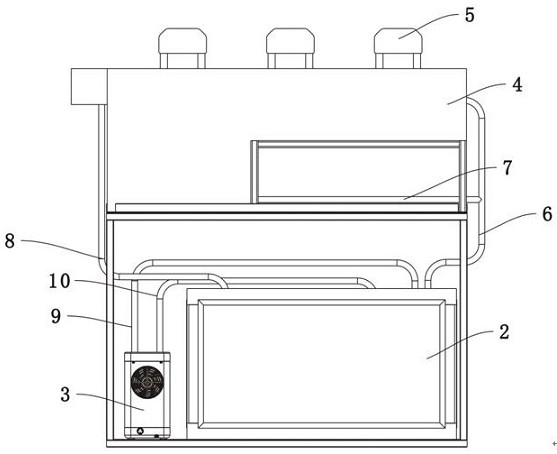

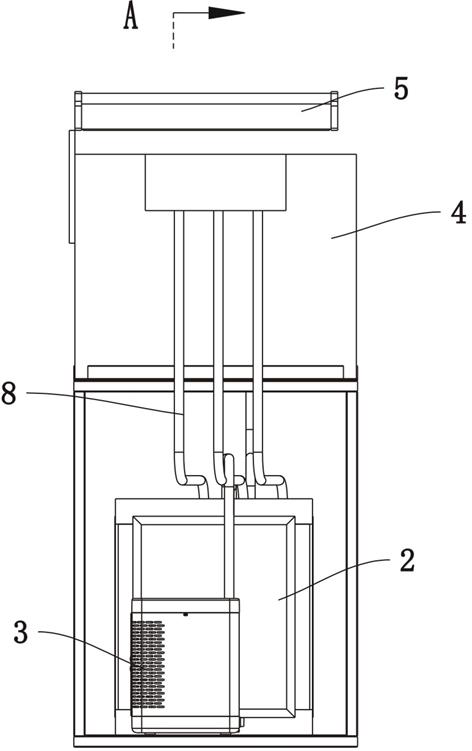

Mangrove forest seaweed bed coral reef ecological connectivity indoor simulation system

PendingCN114586671AIncrease the number ofAvoid clogged overflow situationsClimate change adaptationWave producing pumpsTemperature controlSea grass

A mangrove forest sea grass bed coral reef ecological connectivity indoor simulation system disclosed by the present invention comprises a frame, a main cylinder, a wave making pump, a lamp, a bottom cylinder, a water pump, a protein separator and a temperature control device, the main cylinder is arranged on the frame, the main cylinder comprises a coral area, a sea grass area and a mangrove area, the coral area is deeper than the sea grass area and the mangrove area, and the water pump is arranged on the bottom cylinder. An overflow area is arranged on one side of the coral area, and the overflow area and the coral area are separated through a fish comb. The mangrove forest-sea grass bed-coral reef indoor simulation system is constructed, and important reference and scientific basis can be provided for clarification of the principle and mechanism of ecological connectivity and overall protection and function recovery of an ecological system.

Owner:THIRD INST OF OCEANOGRAPHY MINIST OF NATURAL RESOURCES

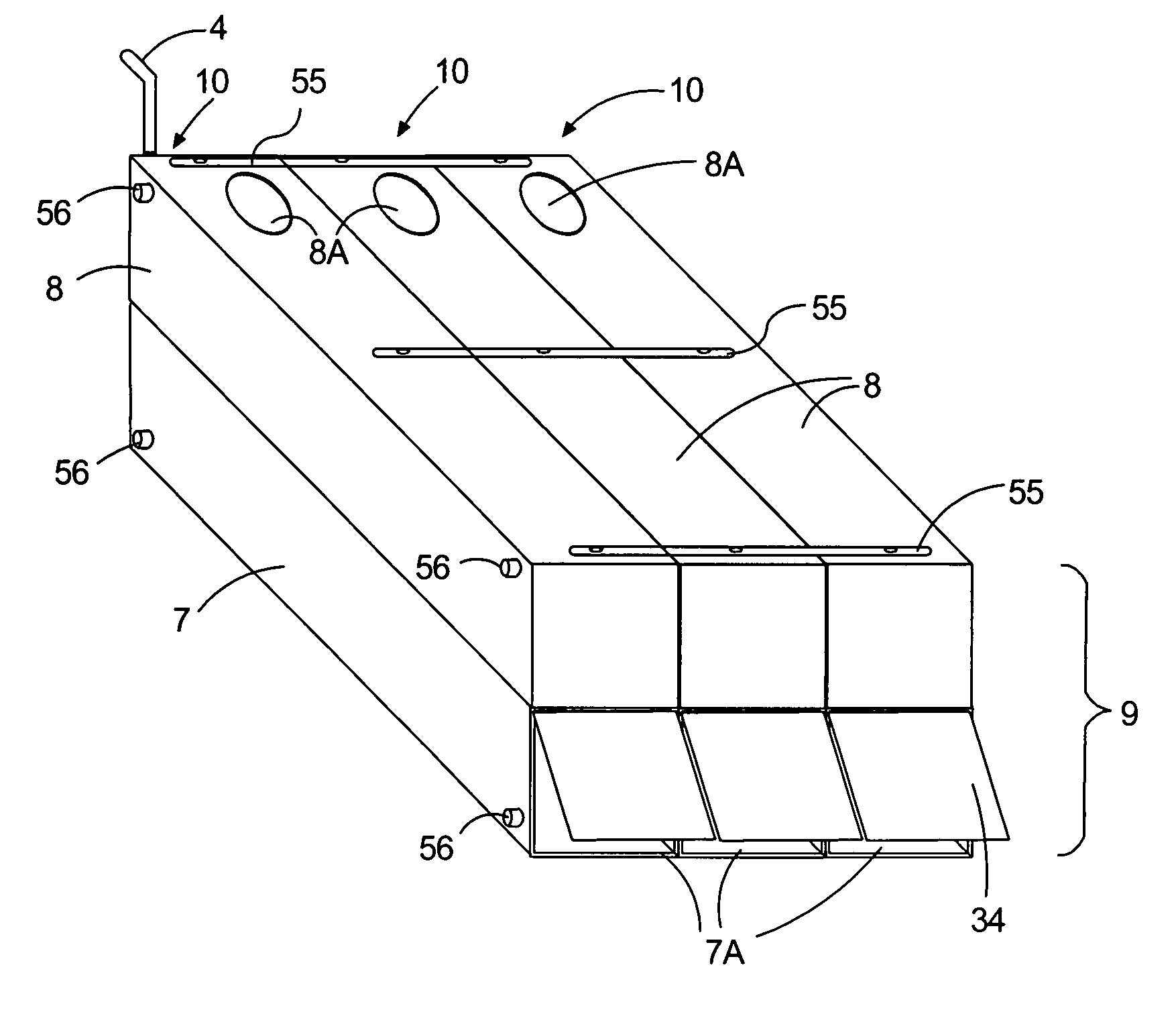

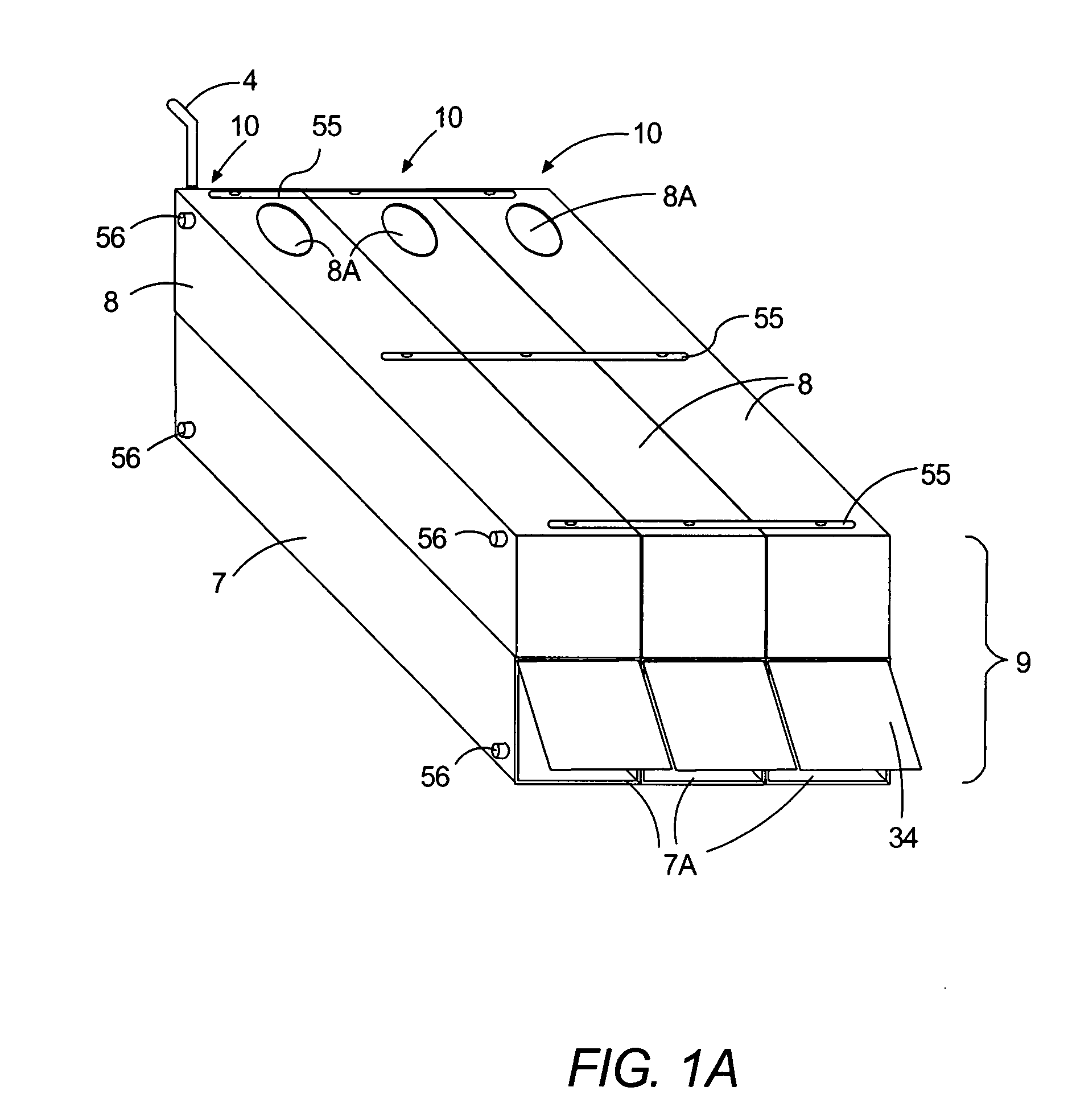

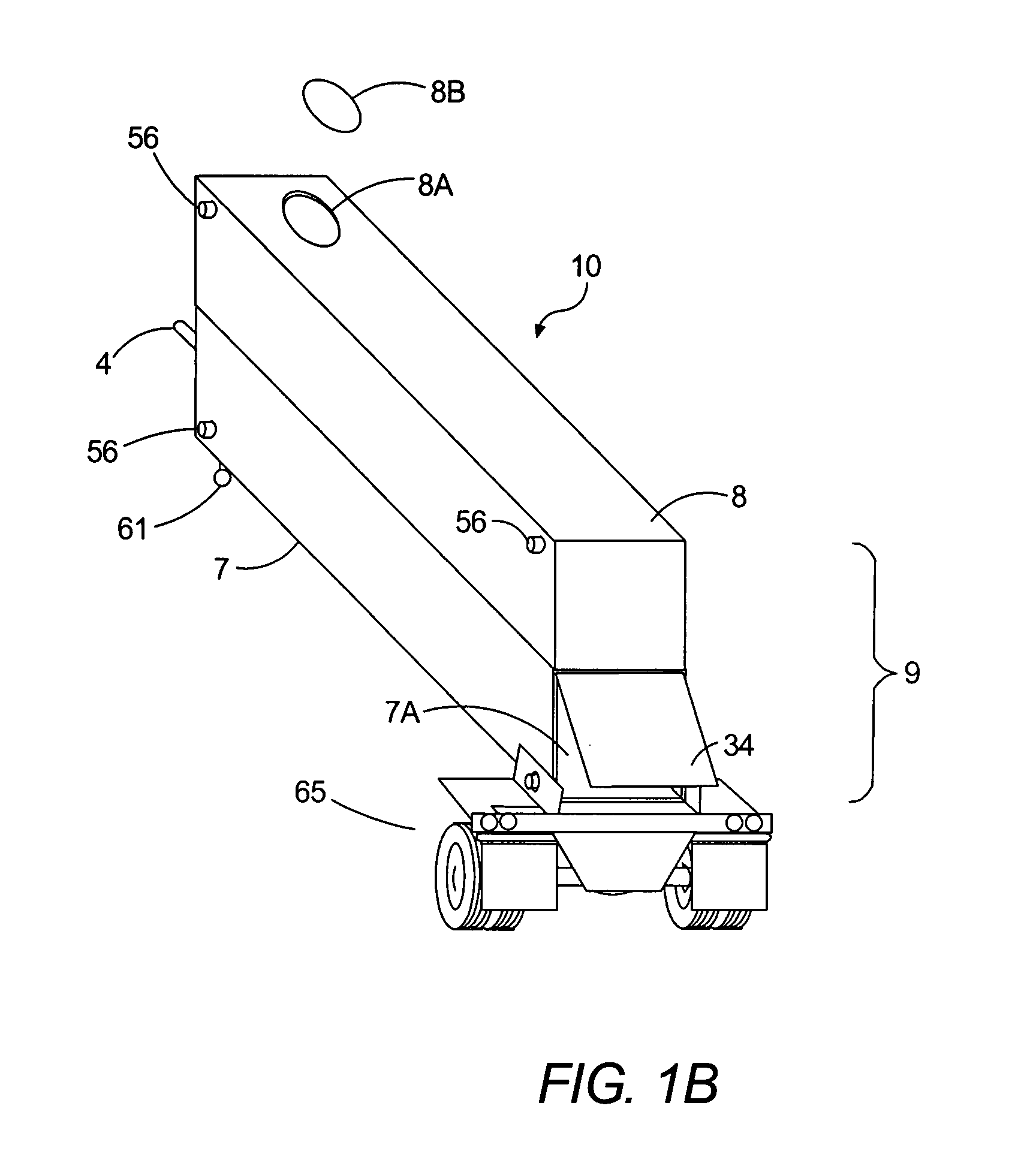

Transportable wave generating module and watercraft

A transportable module for use in generating waves in a body of water, having a tubular chamber with a predetermined length and width equal to or less than the maximum length permitted for transportation on a predetermined type of road. The chamber includes a rear valve located at the rear end to permit flow into the chamber and substantially block flow out of the chamber and a gas port proximate to the rear end for the admission of compressed gas into the chamber. The module includes an anchoring system, such as an integrated ballast tank, a connecting system mounted on the outer surface of the module by which the module may be detachably connected in parallel with other such modules in a side to side manner to form a barge or scalable wave generator. Individually, the modules are is capable of being transported by road to a desired body of water for use.

Owner:JOHNSON GARRETT T

Low noise cooling device

ActiveUS20100243217A1Low costIncrease the scope of applicationAir heatersRotary non-positive displacement pumpsLow noiseTransducer

A cooling device (1) using pulsating fluid for cooling of an object, comprising: a transducer (2) having a membrane adapted to generate pressure waves at a working frequency (fw), and a cavity (4) enclosing a first side of the membrane. The cavity (4) has at least one opening (5) adapted to emit a pulsating net output fluid flow towards the object, wherein the opening (5) is in communication with a second side of the membrane. The cavity (4) is sufficiently small to prevent fluid in the cavity (4) from acting as a spring in a resonating mass-spring system in the working range. This is advantageous as a volume velocity (u1) at the opening is essentially equal to a volume velocity (u1′) at the second side of the membrane, apart from a minus sign. Thus, at the working frequency the pulsating net output fluid can be largely cancelled due to the counter phase with the pressure waves on the second side of the membrane resulting in a close to zero far-field volume velocity. Thus a low sound level is achieved, at a low cost, without requiring mechanical symmetry.

Owner:SIGNIFY HLDG BV

Wave producing method and apparatus

ActiveUS20190366182A1Easy to transportLow costEngine manufacturePump componentsWater resource managementWater body

Owner:KAANA WAVE CO INC

Non-contact liquid sealing actuator system

A liquid sealing actuator system enables use in anon-contact or low-friction manner. The system includes: an inner shaft having a first end; a hollow outer shaft having a first end that receives the first end of the inner shaft; at least one sealing ring positioned adjacent an internal surface of the hollow outer shaft, wherein the at least one sealing ring has an outer diameter that is less than an inner diameter of the outer shaft, thereby defining an annular seal gap; a mass attached to a distal end of either the inner shaft or the outer shaft; and a pressure source that injects a pressurised fluid into the hollow outer shaft, thereby applying a pressure against both the first end of the inner shaft and the at least one sealing ring that assists in lifting the mass; wherein the system is at least partially immersed in an external liquid such that the at least one sealing ring is submerged in the external liquid and a head of the external liquid above the at least one sealing ring defines a backpressure in the annular seal gap that opposes the pressure applied by the pressure source.

Owner:SURF LAKES HLDG LTD

Wave producing method and apparatus

Owner:KAANA WAVE CO INC

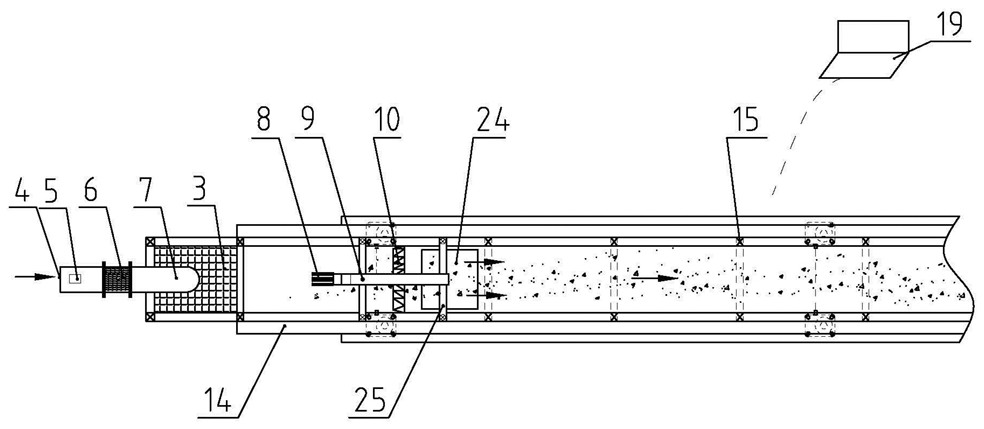

Water tank wave flow generation system with rear-mounted flow outlet

ActiveCN113639959ASatisfy the principle of unlimited useMeet the test requirementsHydrodynamic testingWave producing pumpsWater flowEngineering

The invention relates to the technical field of hydraulic model tests, and provides a water tank wave flow generation system with a rear-mounted flow outlet. The rear-mounted flow outlet and a rectifying device located below a water tank are arranged, the rectifying device comprises a rectifying chamber and a built-in rectifying grid, one end of the rectifying chamber is communicated with a water collecting tank, and the other end of the rectifying chamber is communicated with the bottom wall of a water tank unit; a flow outlet in the bottom wall is located at the front end of a wave pushing direction of a wave maker, water flow subjected to preliminary energy dissipation in the water collecting tank is rectified into smooth fluid through the rectifying grid and then is input into the water tank for steady flow, and the water flow pushed by a wave pushing plate arranged on the wave maker is steady flow meeting the test requirement; the water inlet amount of the water inlet and the wave pushing speed of the wave pushing plate are intelligently controlled through a computer, the requirements of flow generation and wave generation tests are met, the technical problem that water flow needs to be stabilized through a long transition section due to the fact that the water flow is in a vortex shape when a water inlet pipeline is installed in front of the wave pushing plate is thoroughly solved, and the infinite length use principle of linear water tank flow generation is met.

Owner:FISHERY ENG RES INST CHINESE ACAD OF FISHERY SCI

Antifreeze valve with self-cleaning function

InactiveCN104315184BPrevent freezingPrevent scalingPlug valvesValve members for heating/coolingInlet channelLiquid medium

The invention discloses an antifreezing valve with a self-cleaning function. The antifreezing valve comprises a valve body, wherein a valve cavity is formed in the valve body; a ball valve is arranged in the valve cavity; a valve rod is connected with the ball valve; the valve rod extends out from a valve rod hole in the valve body to be connected with a hand wheel; a valve cover covers the valve rod hole; a water inlet channel and a water outlet channel which are both communicated with the valve cavity, are connected with the valve body; the valve rod is a hollow valve rod in which a stirring shaft is arranged in a penetrating manner; the lower end of the stirring shaft extends into the ball valve to be connected with a stirrer which is arranged in the valve body; the upper end of the stirring shaft is connected with a micro motor which is used for driving the stirring shaft to work; the micro motor is arranged in a cavity of the hand wheel; electromagnetic coils are arranged on the inner walls of both the water inlet channel and the water outlet channel respectively in a winding manner, and are electrically connected with a pulse current generator. According to the antifreezing valve with the self-cleaning function, the micro motor controls the stirrer to work intermittently, so that the liquid medium in the valve is in a non-static state, the scale deposition and medium freezing are avoided and the aims of scale prevention and self-cleaning are achieved.

Owner:SUZHOU FURUN MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com