Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

78results about "Viscosity control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

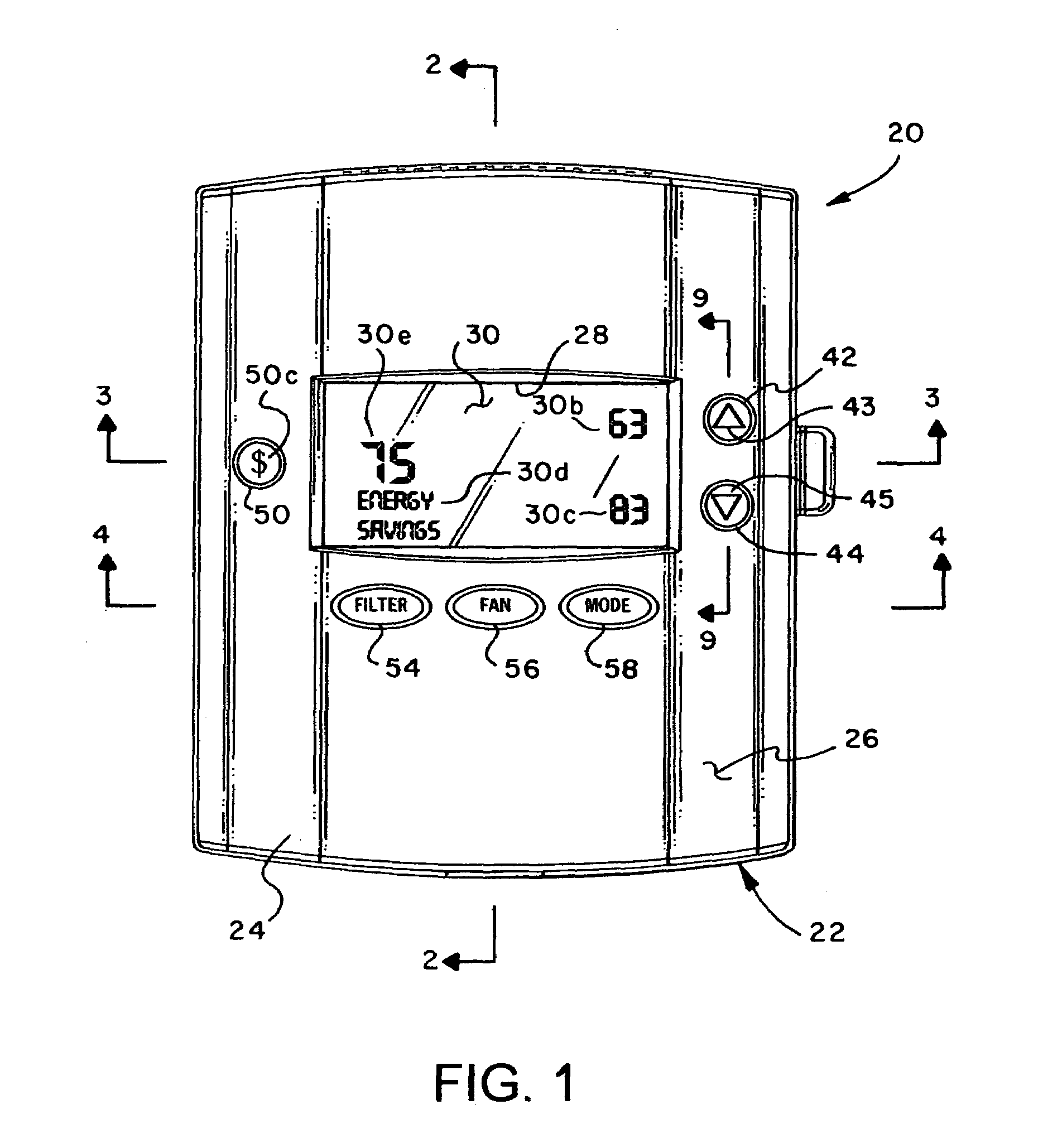

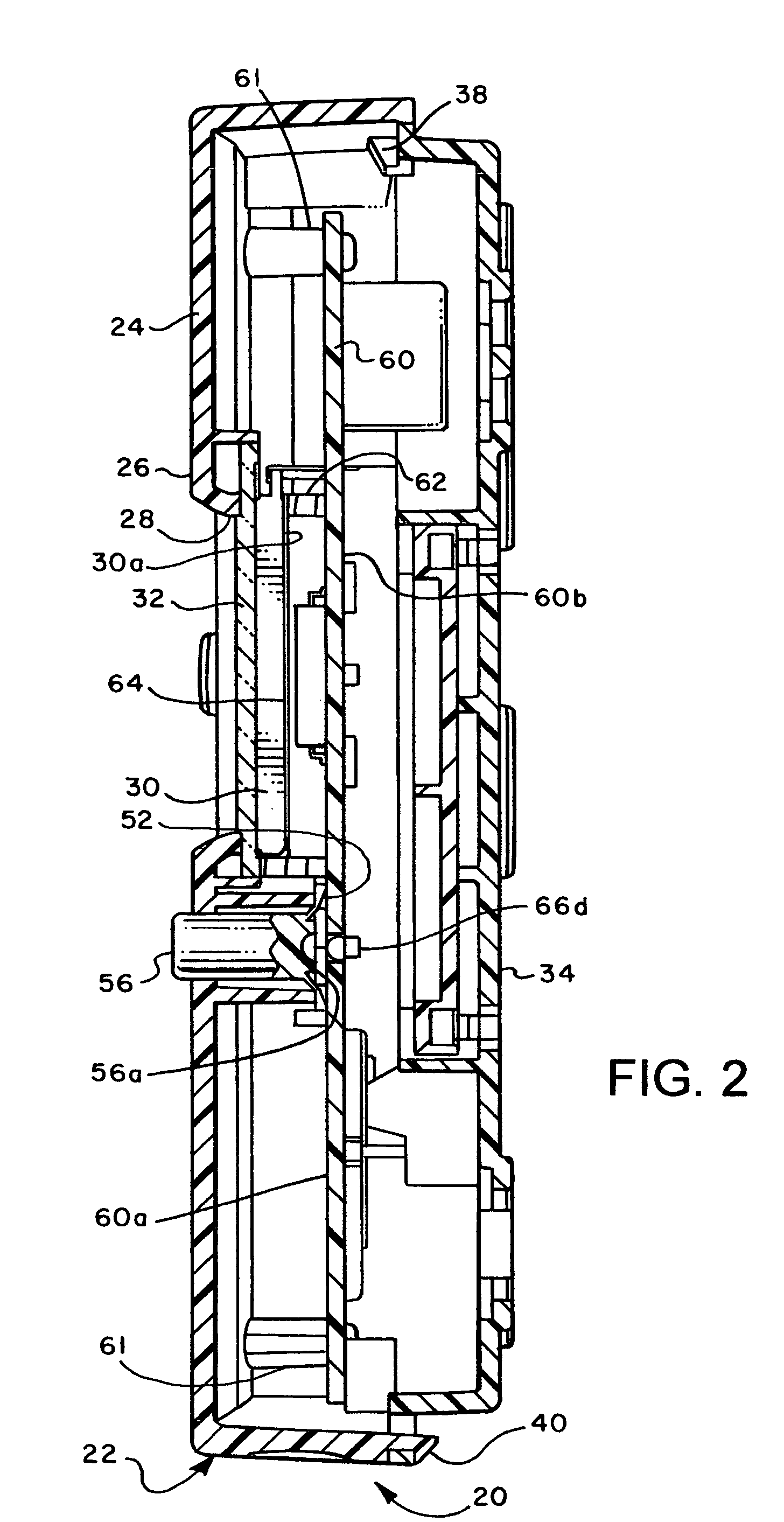

Thermostat with energy saving backlit switch actuators and visual display

ActiveUS7299996B2Convenient ArrangementConveniently changedInput/output for user-computer interactionAir-treating devicesElectricityDisplay device

An air conditioning system thermostat includes a visual display and plural switch actuators, respectively backlit by an electroluminescent lamp and LED light sources mounted on a circuit board disposed in a thermostat housing. A control circuit causes at least one switch actuator to be illuminated continuously and the light sources for the display and the remaining switch actuators are illuminated in response to actuation of any one of the switch actuators. Switch contact elements mounted on the switch actuators and the circuit board provide advantageous positioning of the LED light sources for the switch actuators. An energy savings switch actuator allows the control circuit to directly assume setback temperature settings in response to a first actuation and a second actuation resets the thermostat to the initial user set temperature settings.

Owner:TRANE INT INC

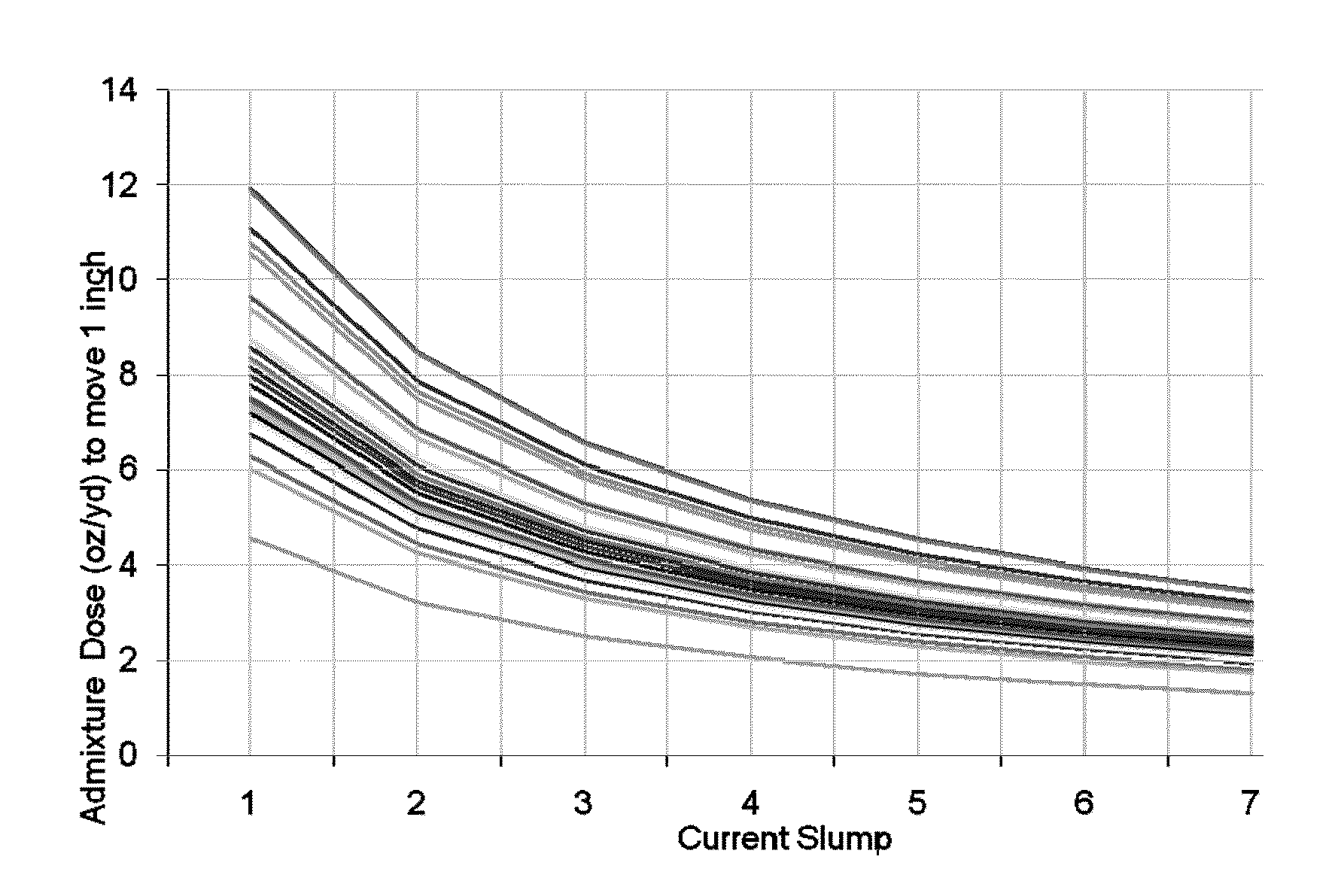

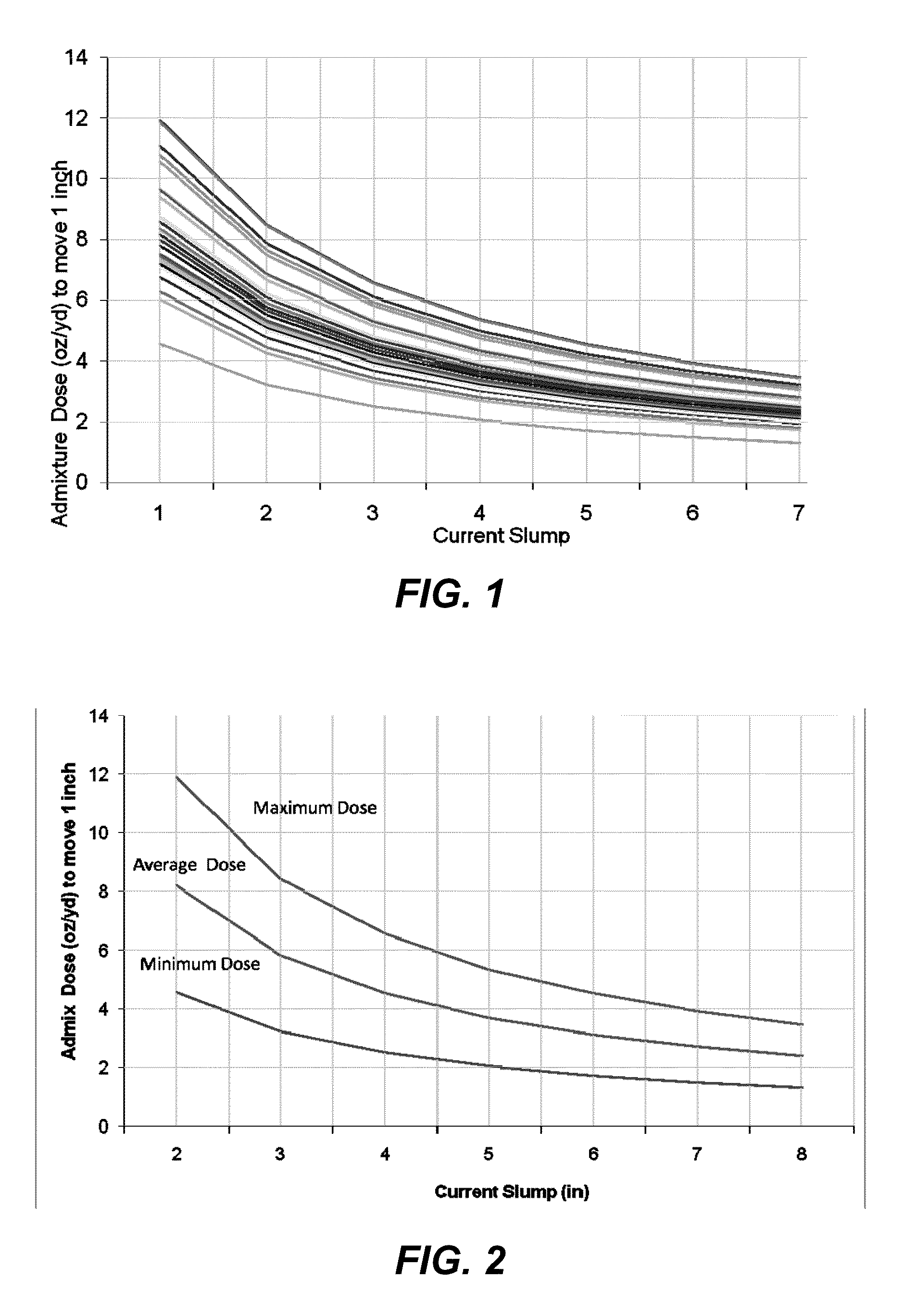

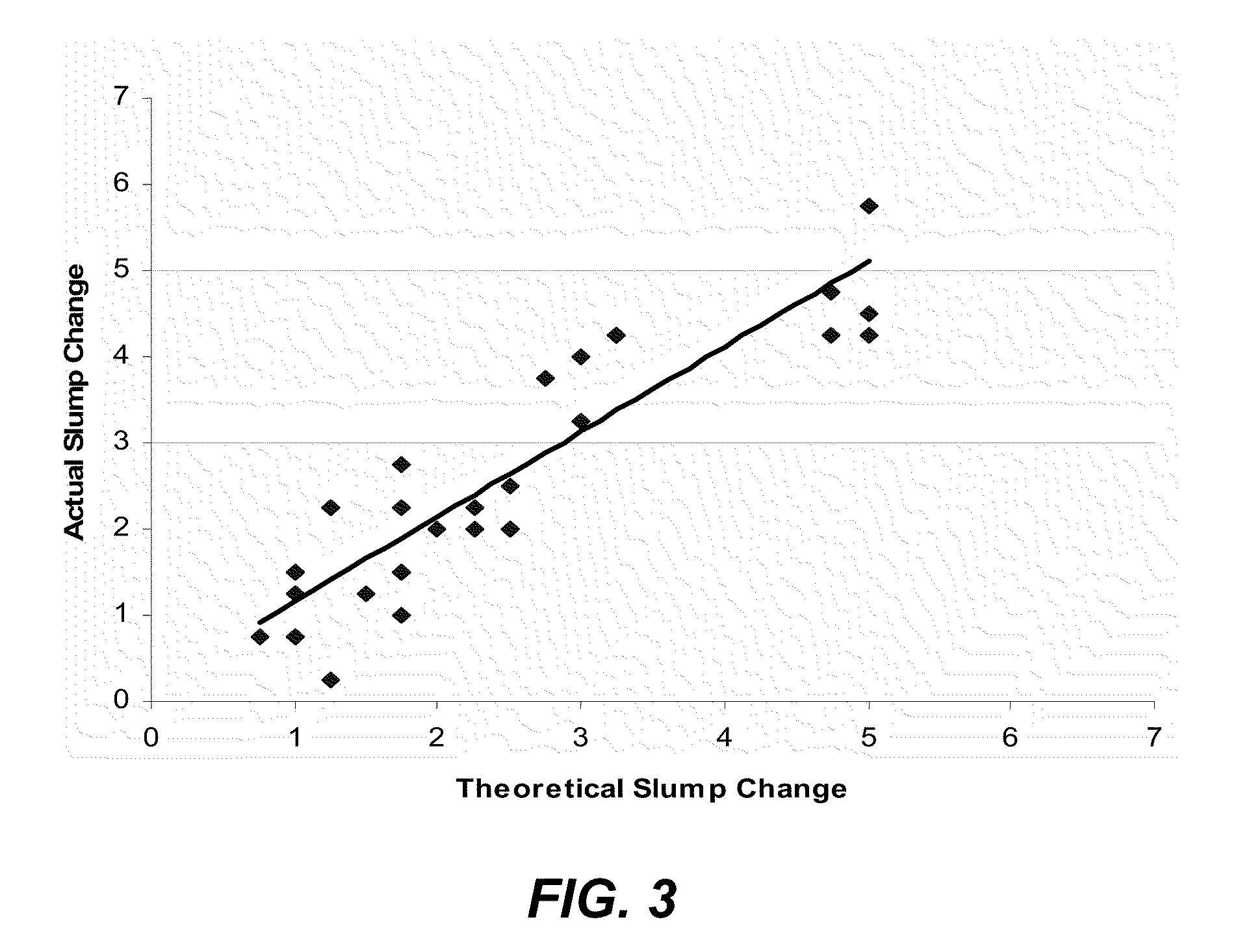

Method for adjusting concrete rheology based upon nominal dose-response profile

ActiveUS8311678B2Increased complexityAvoid overdoseSampled-variable control systemsControlling ratio of multiple fluid flowsEngineeringLookup table

The invention relates to a method for adjusting concrete rheology requiring only that load size and target rheology value be selected initially rather than requiring inputs into and consultation of a lookup table of parameters such as water and hydration levels, mix components, temperature, humidity, aggregate components, and others. Dosage of particular rheology-modifying agent or combination of rheology-modifying agents is calculated based on a percentage of a nominal dose calculated with reference to a nominal dose response (“NDR”) curve or profile. The NDR profile is based on a correlation between a rheology value (e.g., slump, slump flow, yield stress) and the rheology-modifying agent(s) dose required to change rheology value by one unit (e.g., slump change from 2 to 3 inches) such that exemplary methods can employ corrective dosing based on the NDR and the measured deviation by the system.

Owner:VERIFI INC

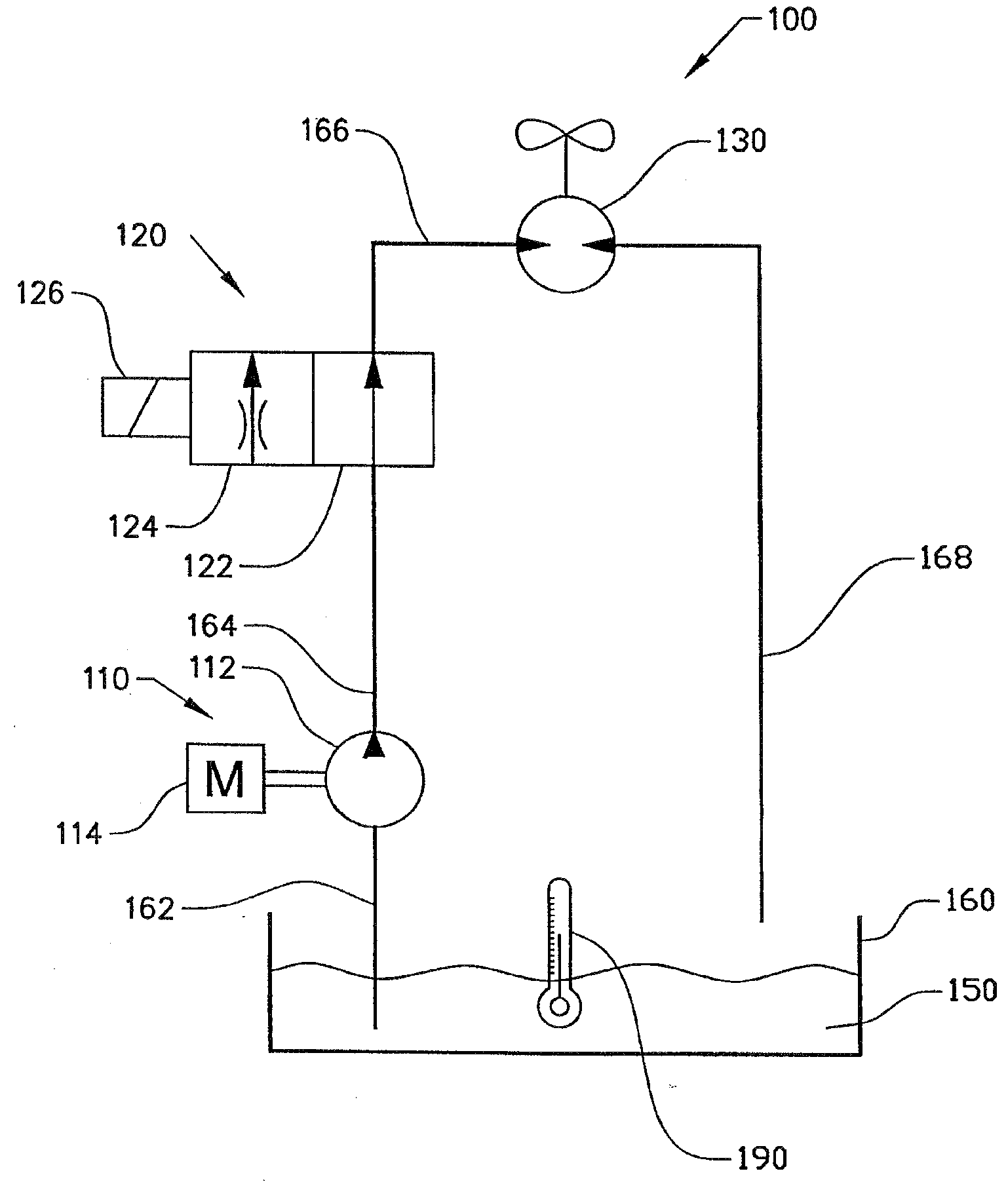

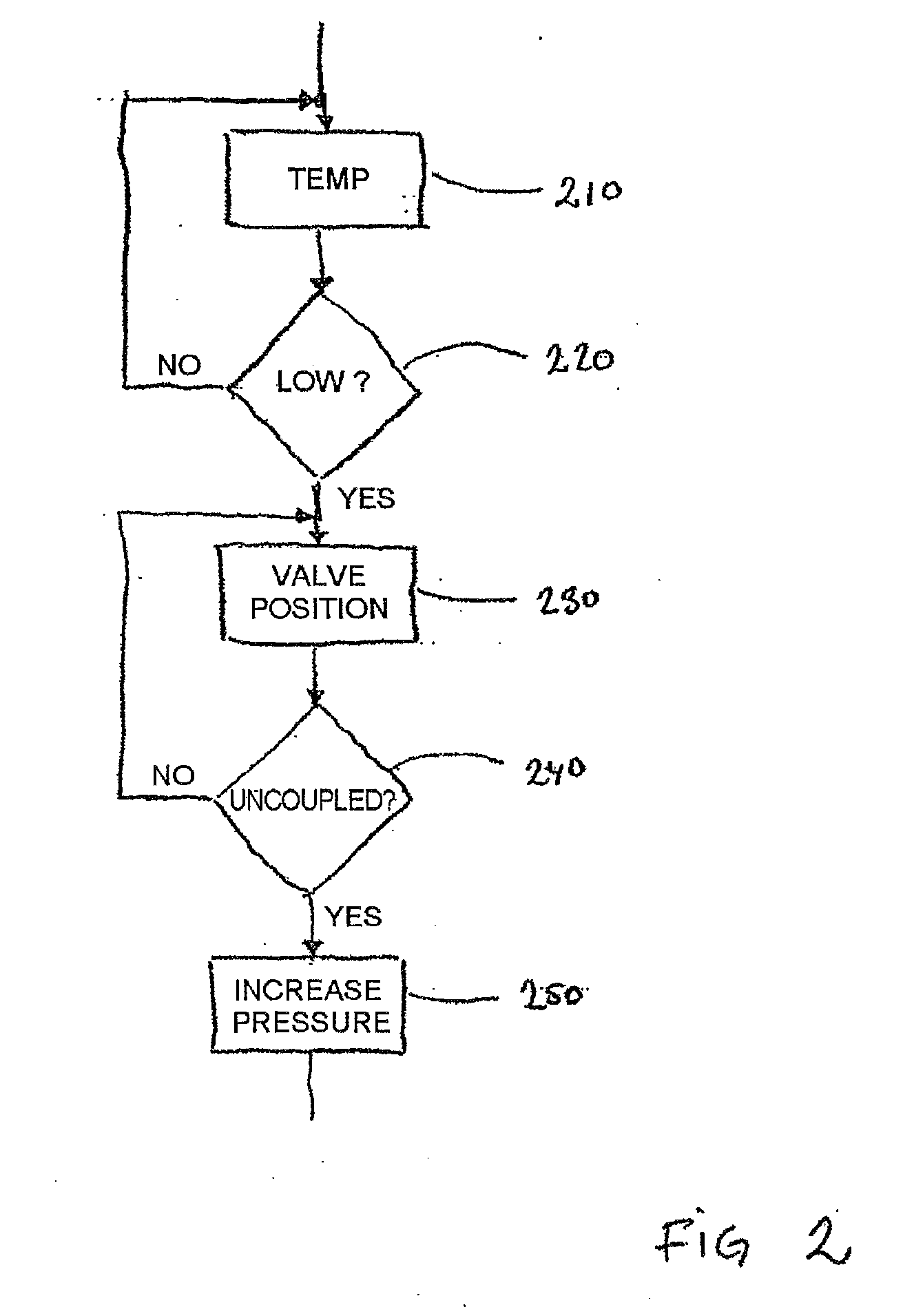

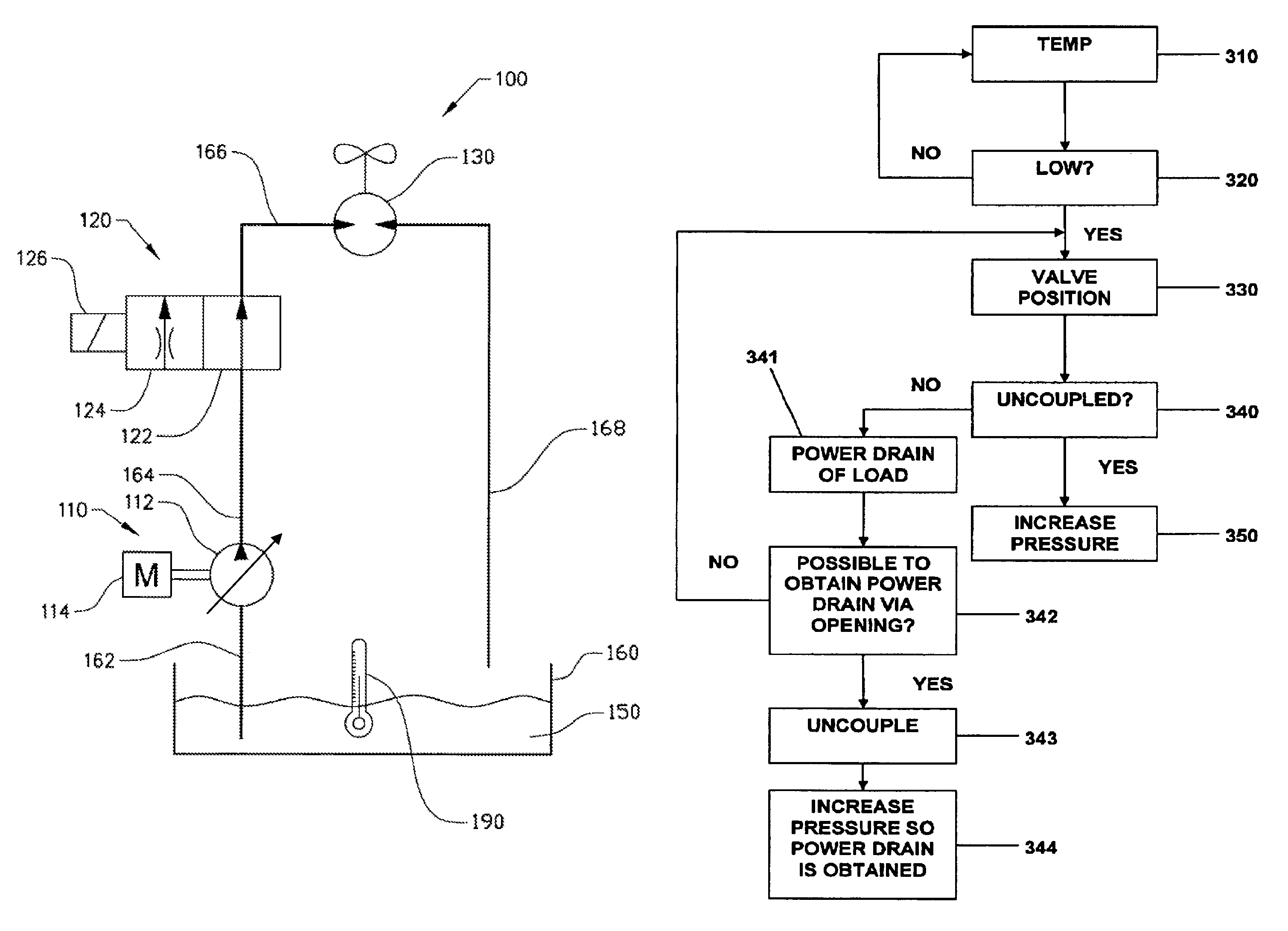

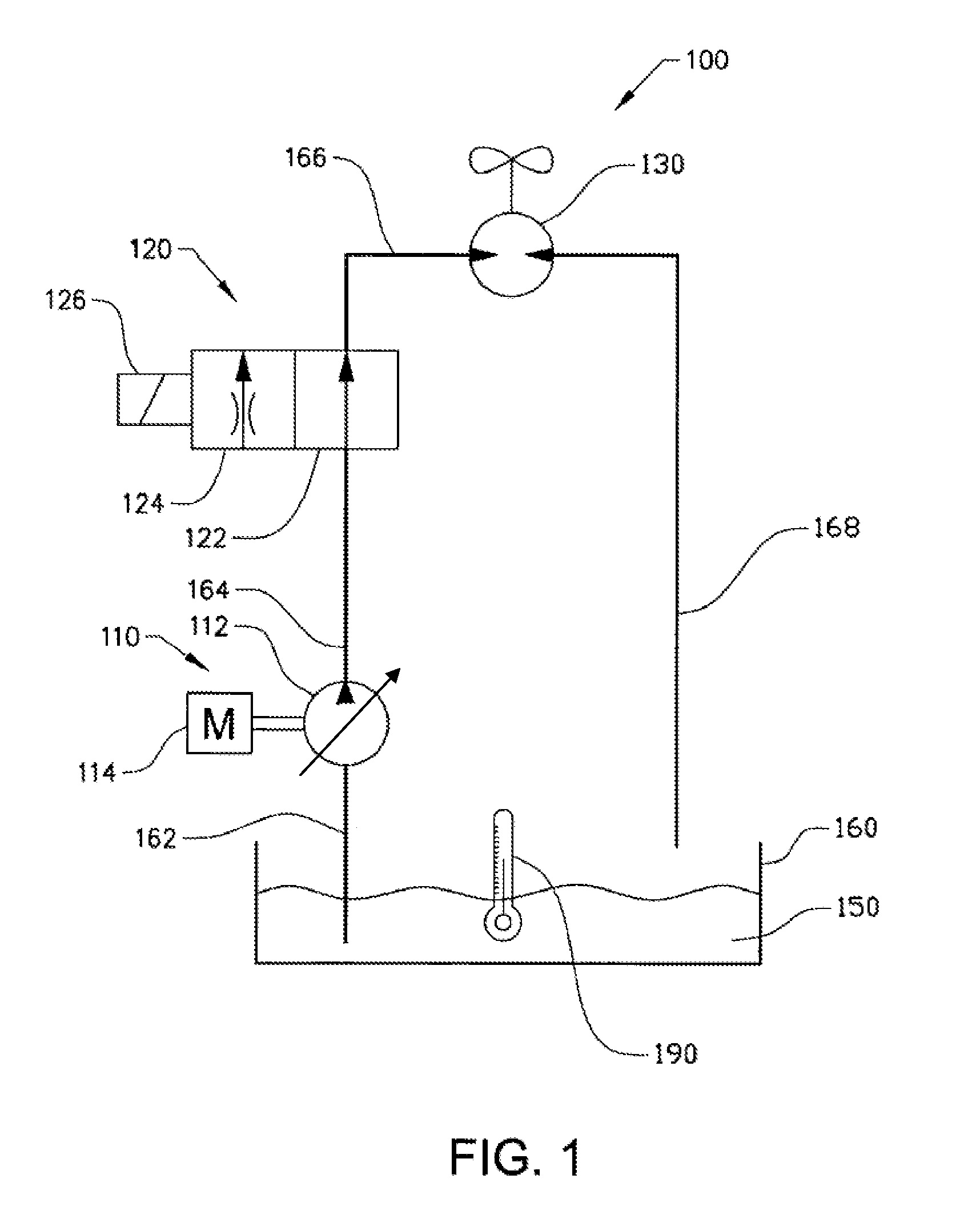

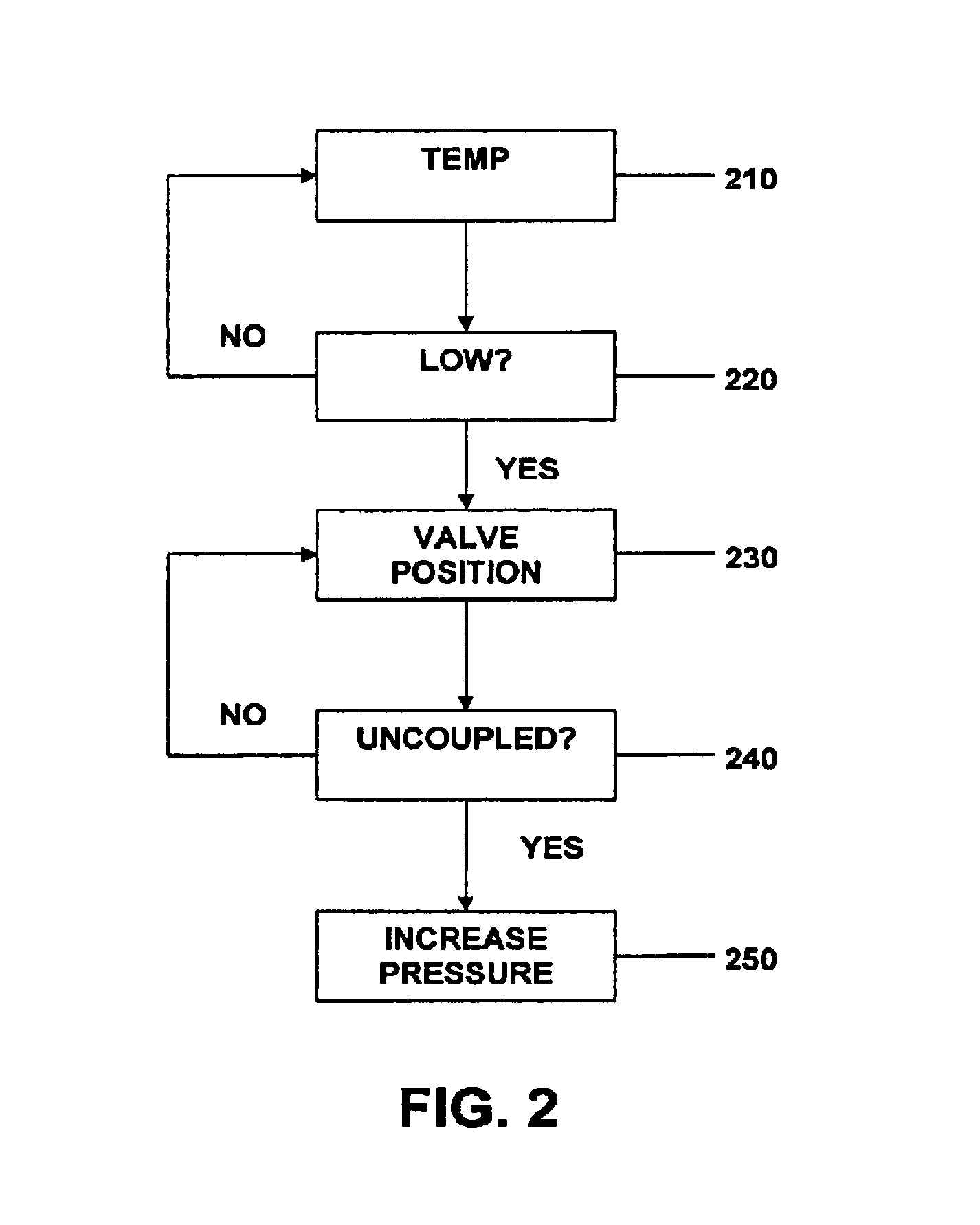

System and method for controlling viscosity of a fluid and a working vehicle containing such a system

ActiveUS20060021340A1Increase pressureRaise priorityFluid couplingsCoolant flow controlEngineeringHydraulic fluid

The invention relates to a method and system for controlling viscosity of a hydraulic fluid. The viscosity of a hydraulic fluid is usually very much dependent on temperature. By using existing throttles which generate a pressure drop, the hydraulic fluid can be heated by creating a power drain in these existing throttles through a controlled increase of the pressure through them. By controlled heating, the viscosity of a hydraulic fluid can be controlled. According to the invention, the existing throttles are preferably cavity-preventing openings in valves.

Owner:VOLVO CONSTR EQUIP

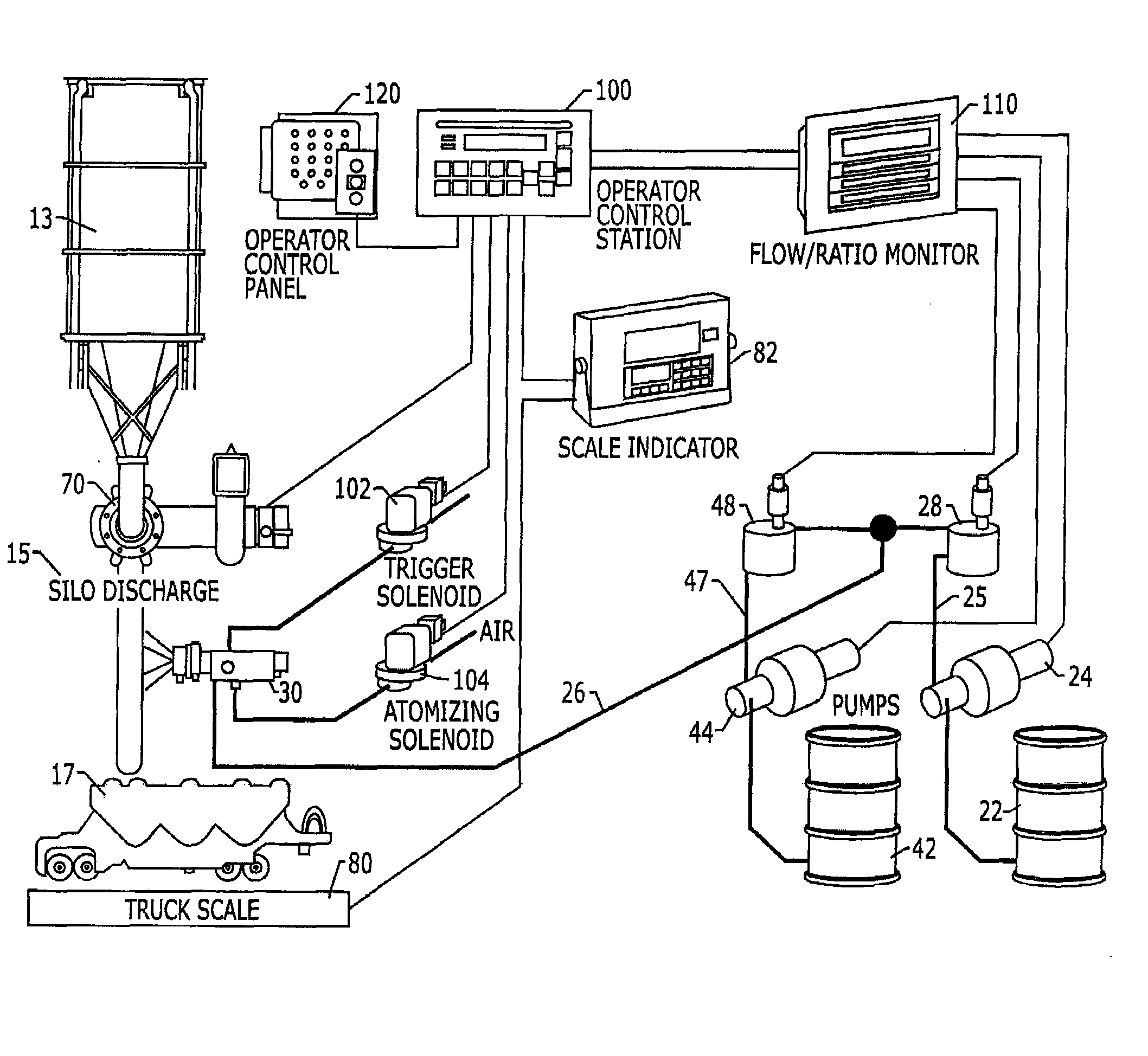

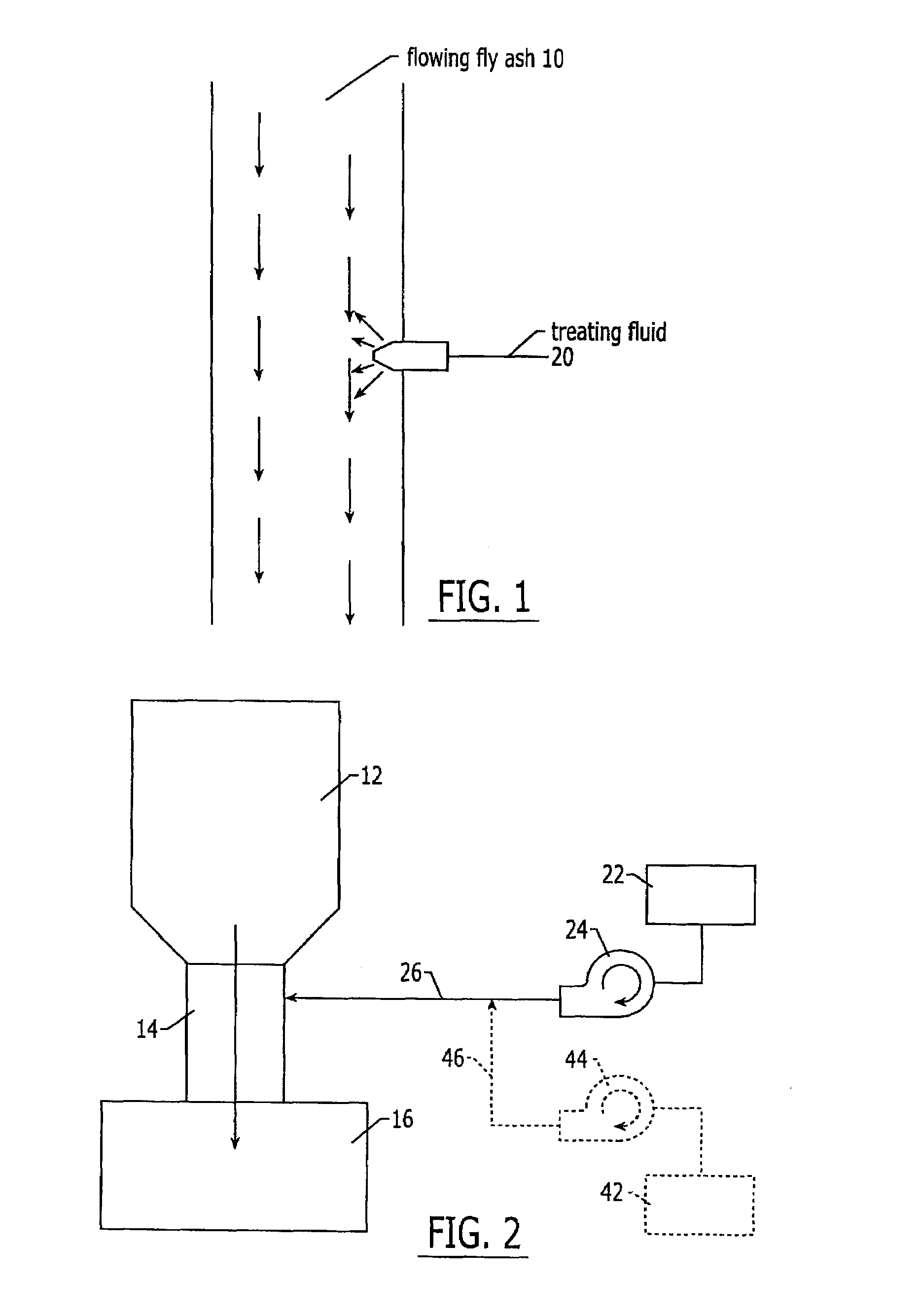

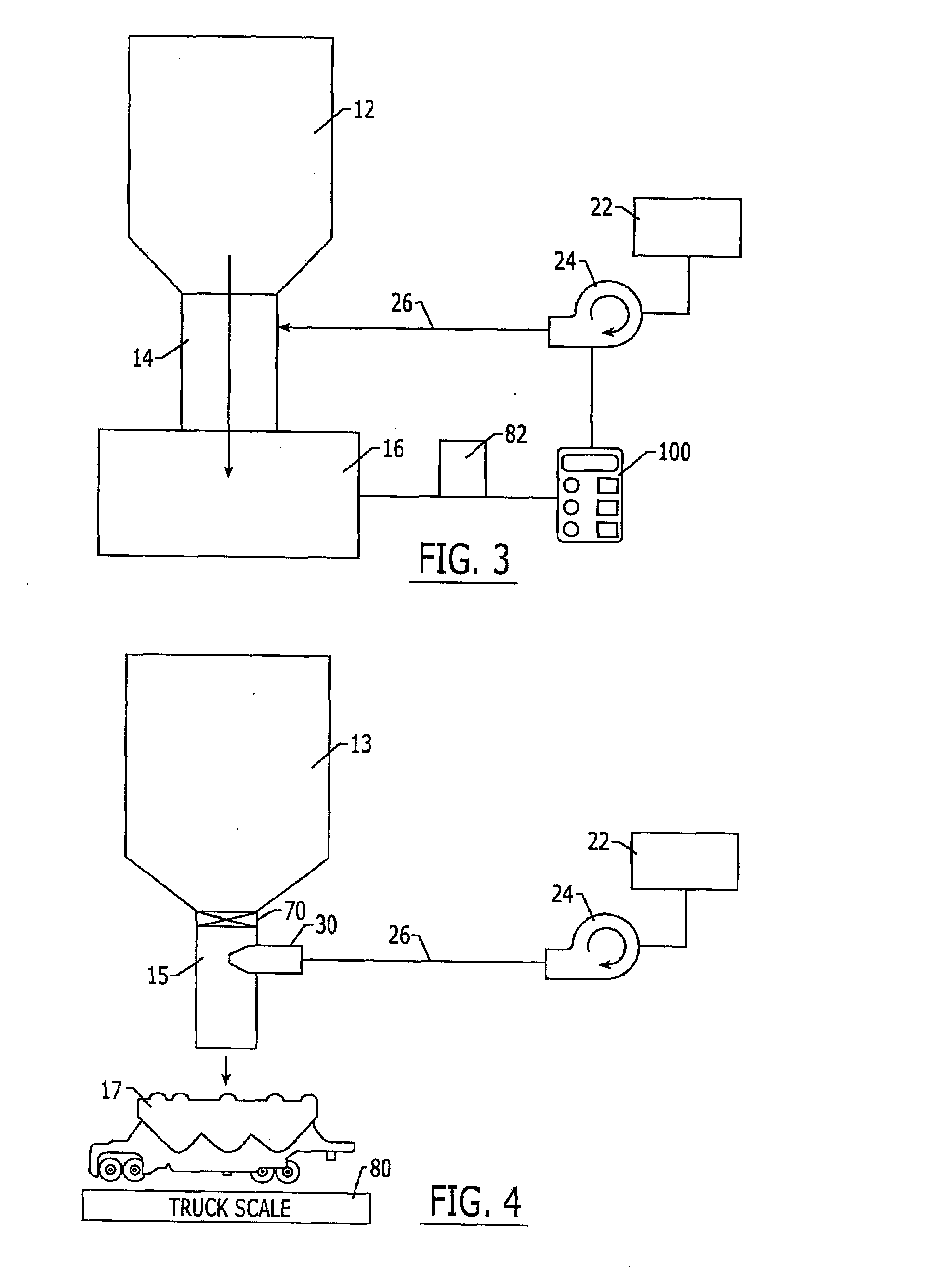

System and method for treating fly ash

InactiveUS20090258777A1Well mixedEnhanced interactionSolid waste managementExhaust apparatusEngineeringFly ash

A method and system for treating fly ash with a treating fluid by evenly dispersing a treating fluid into a flowing stream of fly ash. By dispersing the treating fluid into the fly ash as the fly ash is flowing, the method takes advantage of natural mixing and particle motion that occurs during flow of the bulk solid. The application of treating fluid is advantageously controlled by an automated controller that has inputs and outputs that allow the controller to adjust flow rate of the treating fluid in correspondence with a measured flow rate of the fly ash.

Owner:BORAL MATERIAL TECH

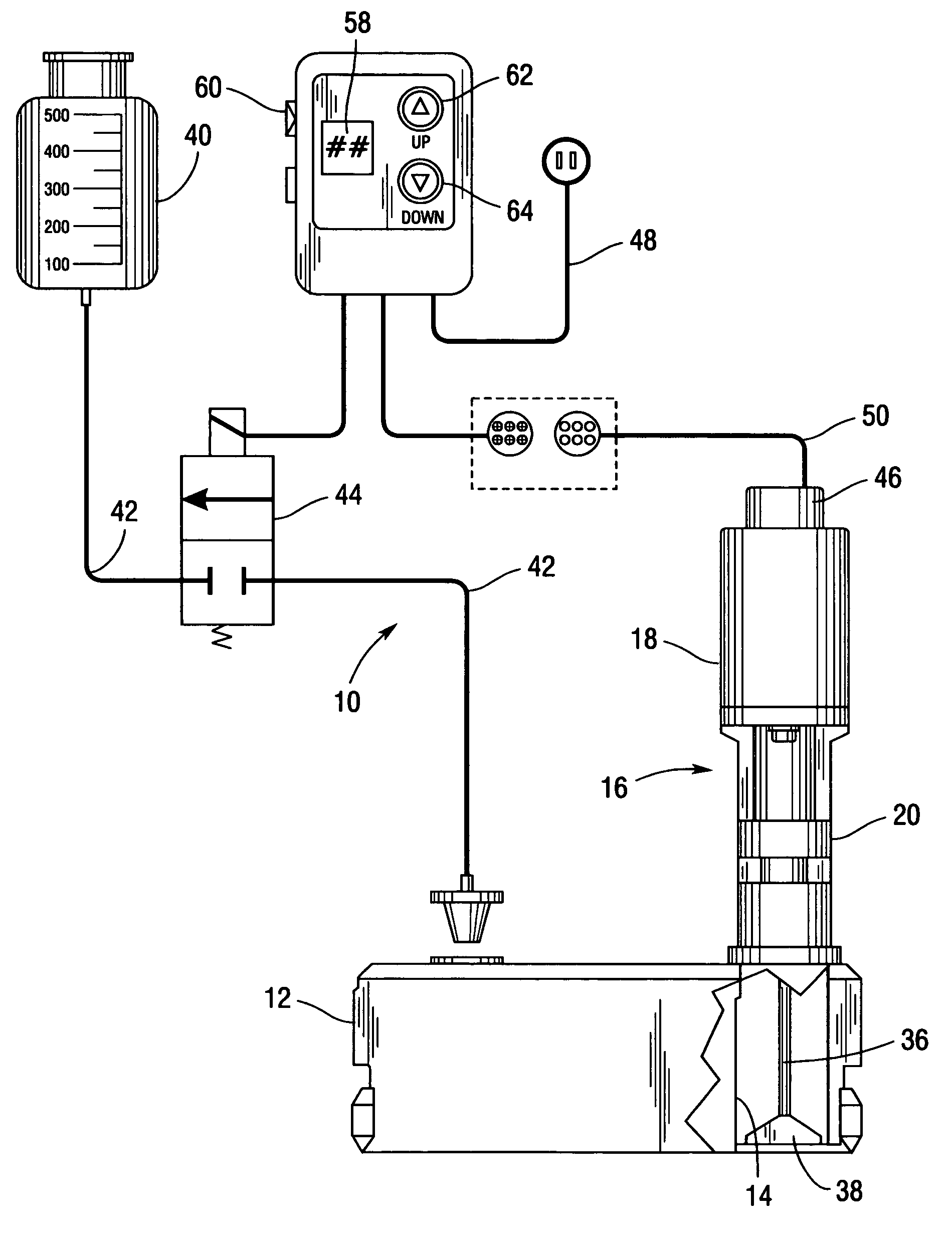

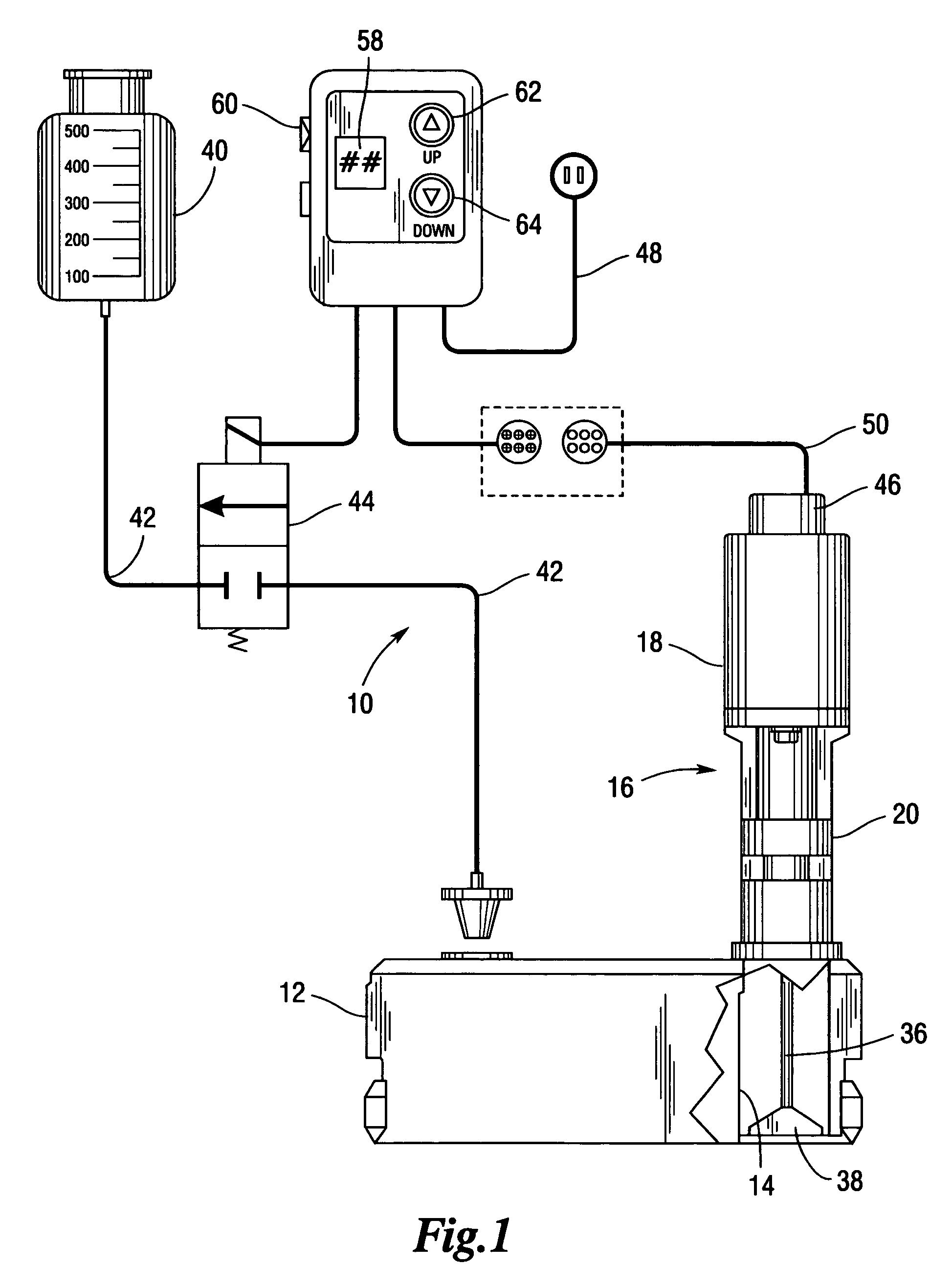

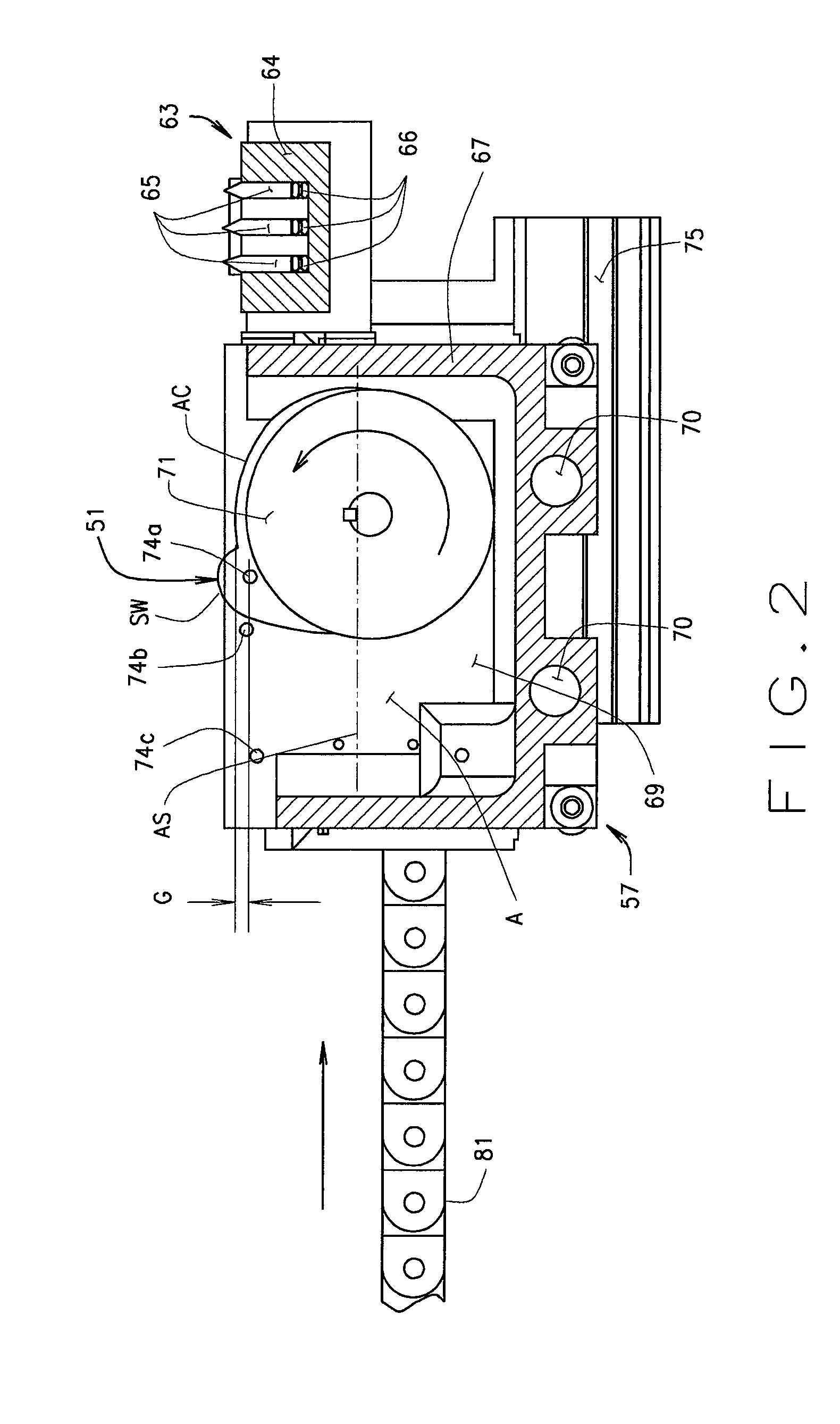

Viscosity controller for ink pad printers

InactiveUS7331703B1Improve productivityFast coloringControlling ratio of multiple fluid flowsFlow propertiesPad printingEngineering

A viscosity controller automatically monitoring and controlling the viscosity of ink in a pad printing device on a continuous basis throughout the printing process includes a sealed ink cup having mounted thereon a motor with a paddle extending into the ink cup, a solvent tank in flow communication with the ink cup, and a valve for allowing selective amounts of the solvent to be added to the ink cup from the solvent tank. The viscosity of the ink in the cup creates torque on the paddle that affects the number of encoder pulses that are counted per time period by a motor encoder mounted to the motor, and the encoder pulses are counted and compared to a look up table stored in the microprocessor of the controller to determine if the valve should be opened to add diluting agent to the ink cup so that the ink viscosity can be maintained at a preset or predetermined value.

Owner:AUTOMATED INDAL SYST

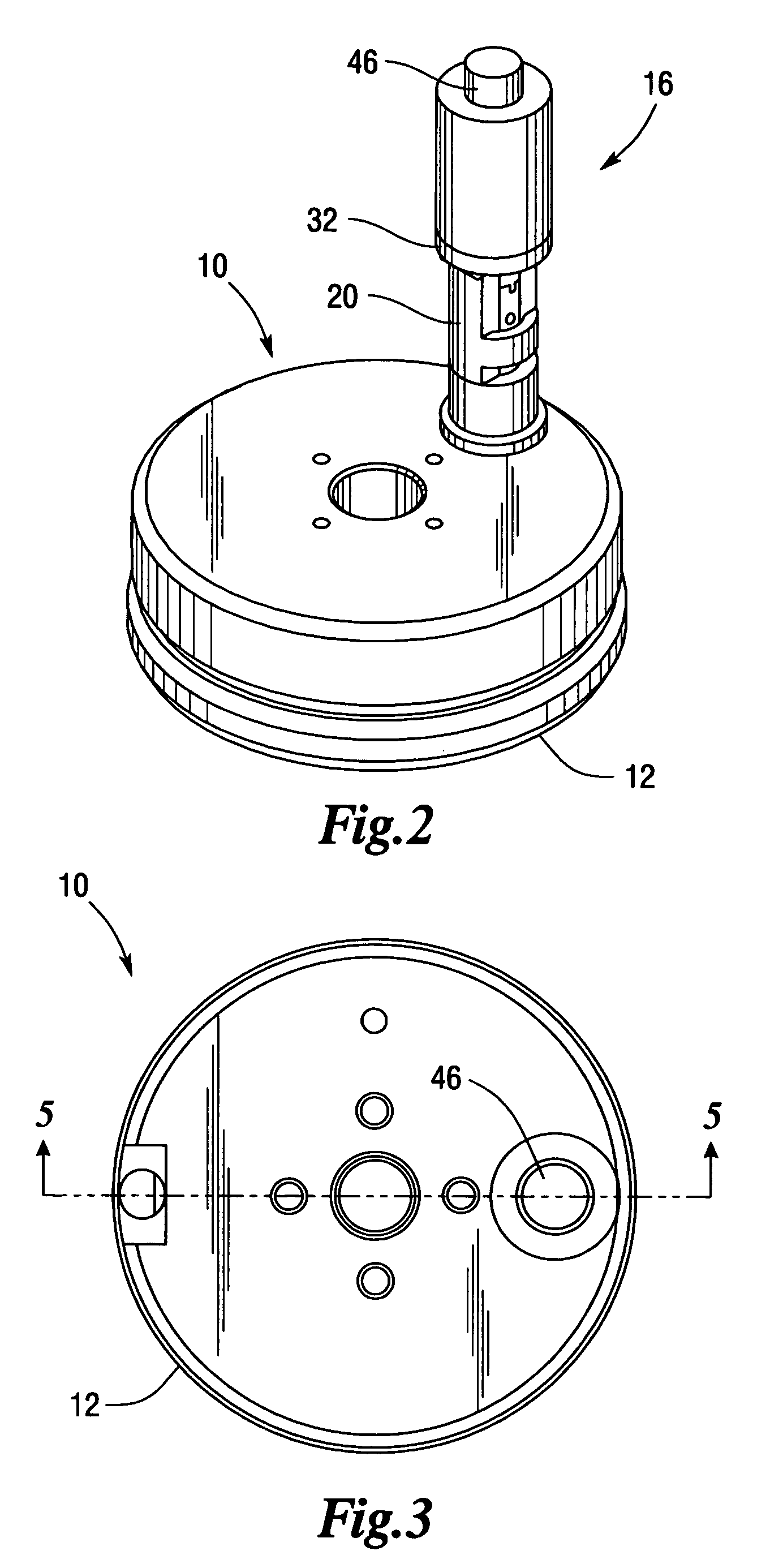

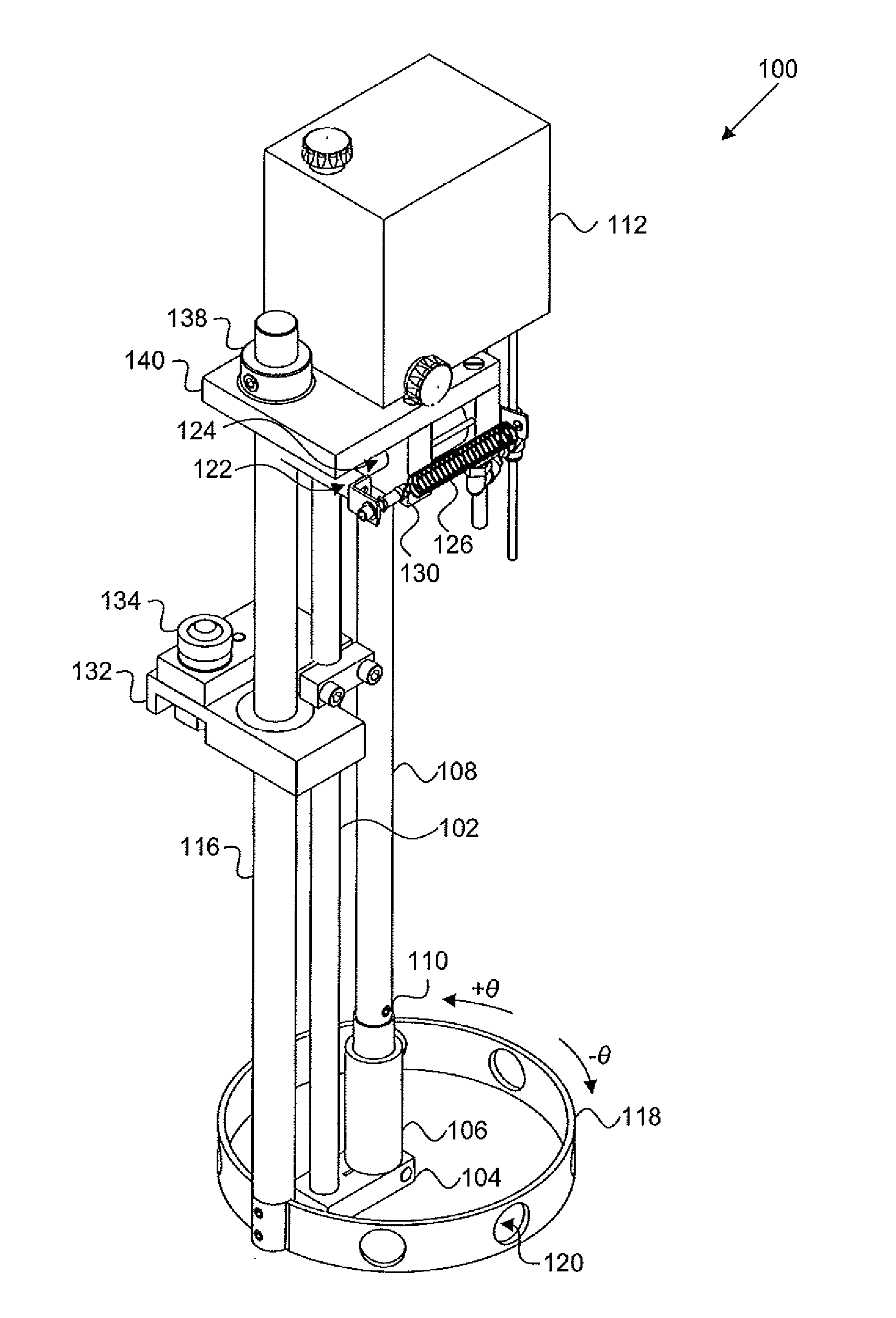

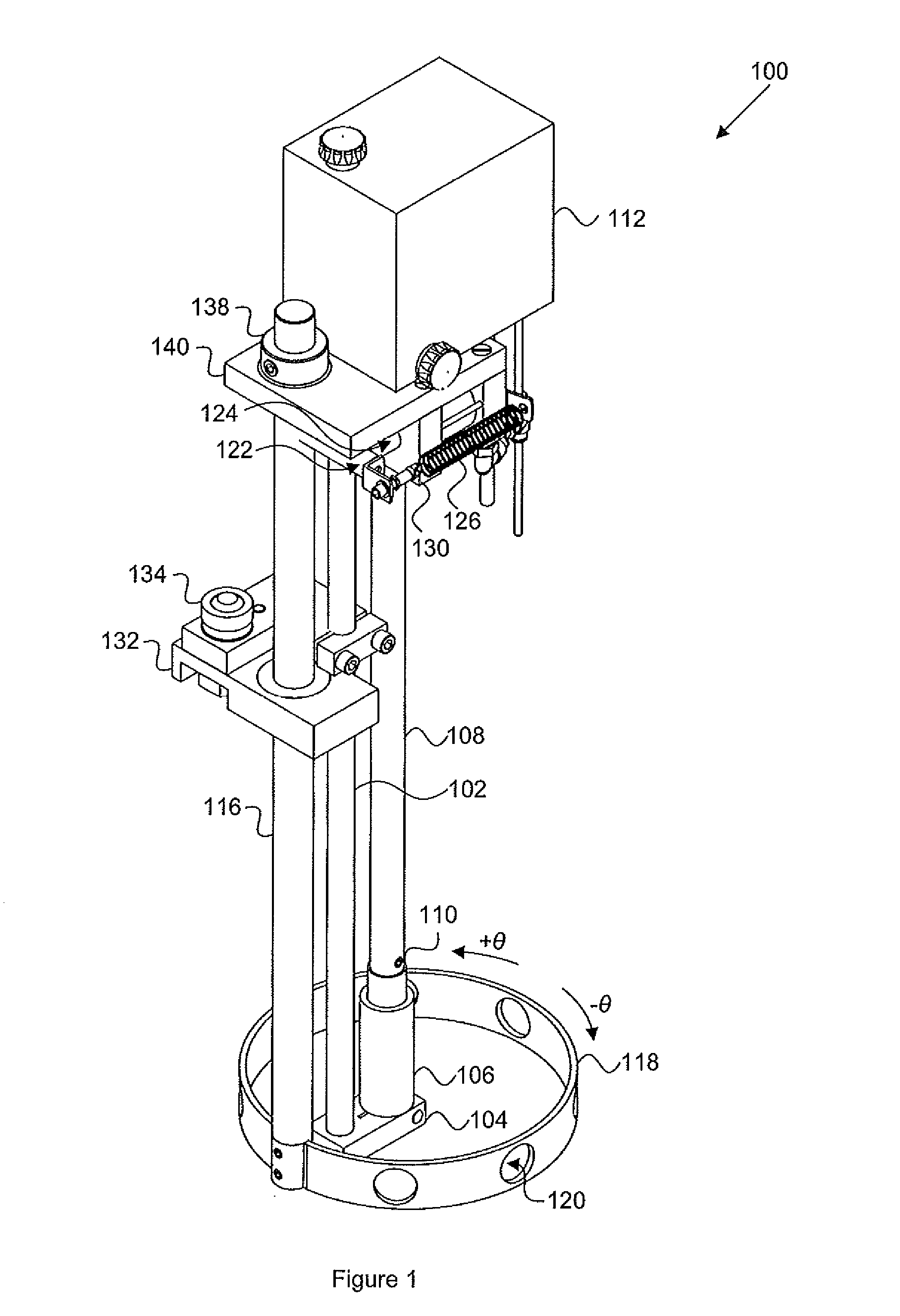

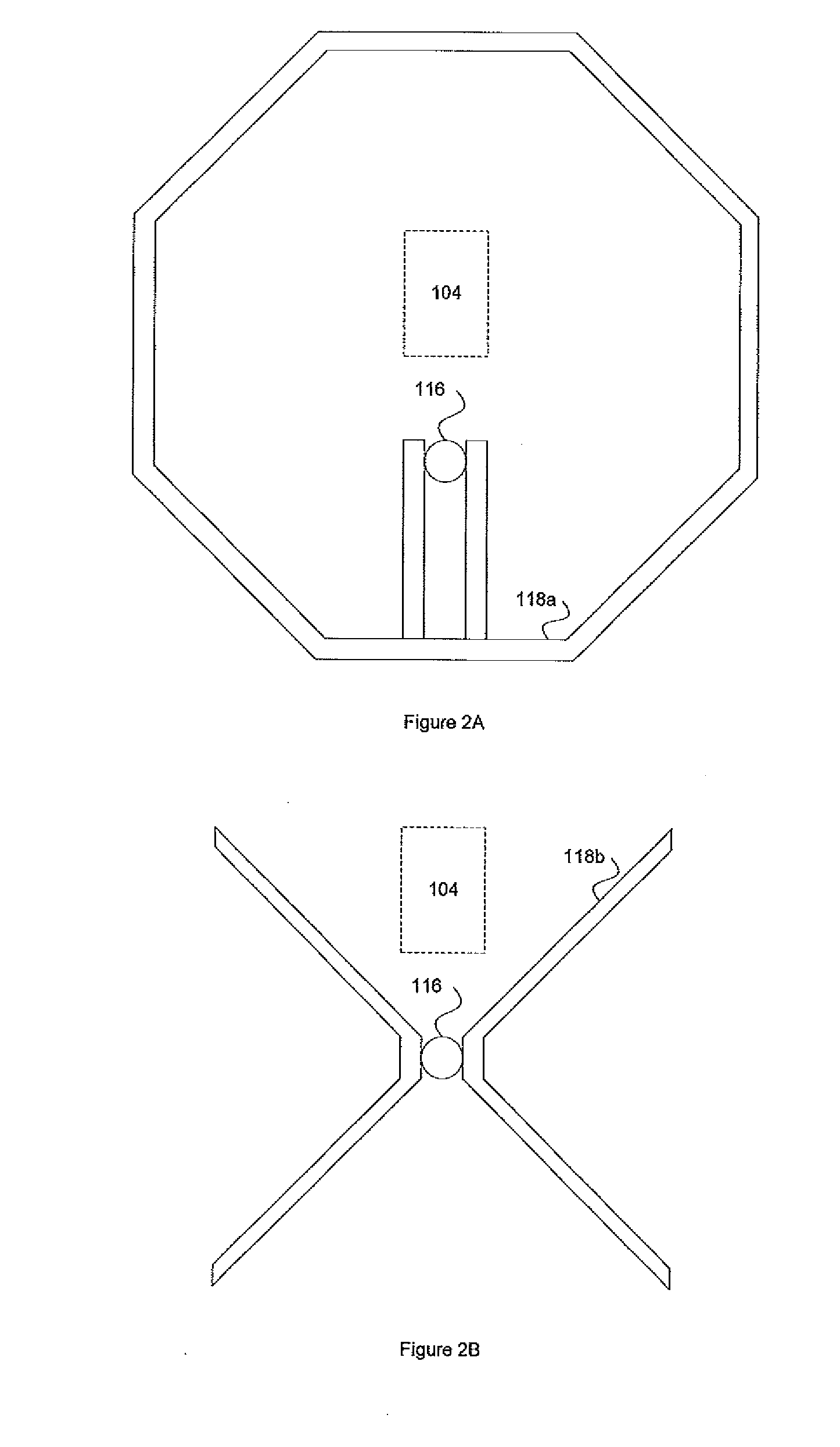

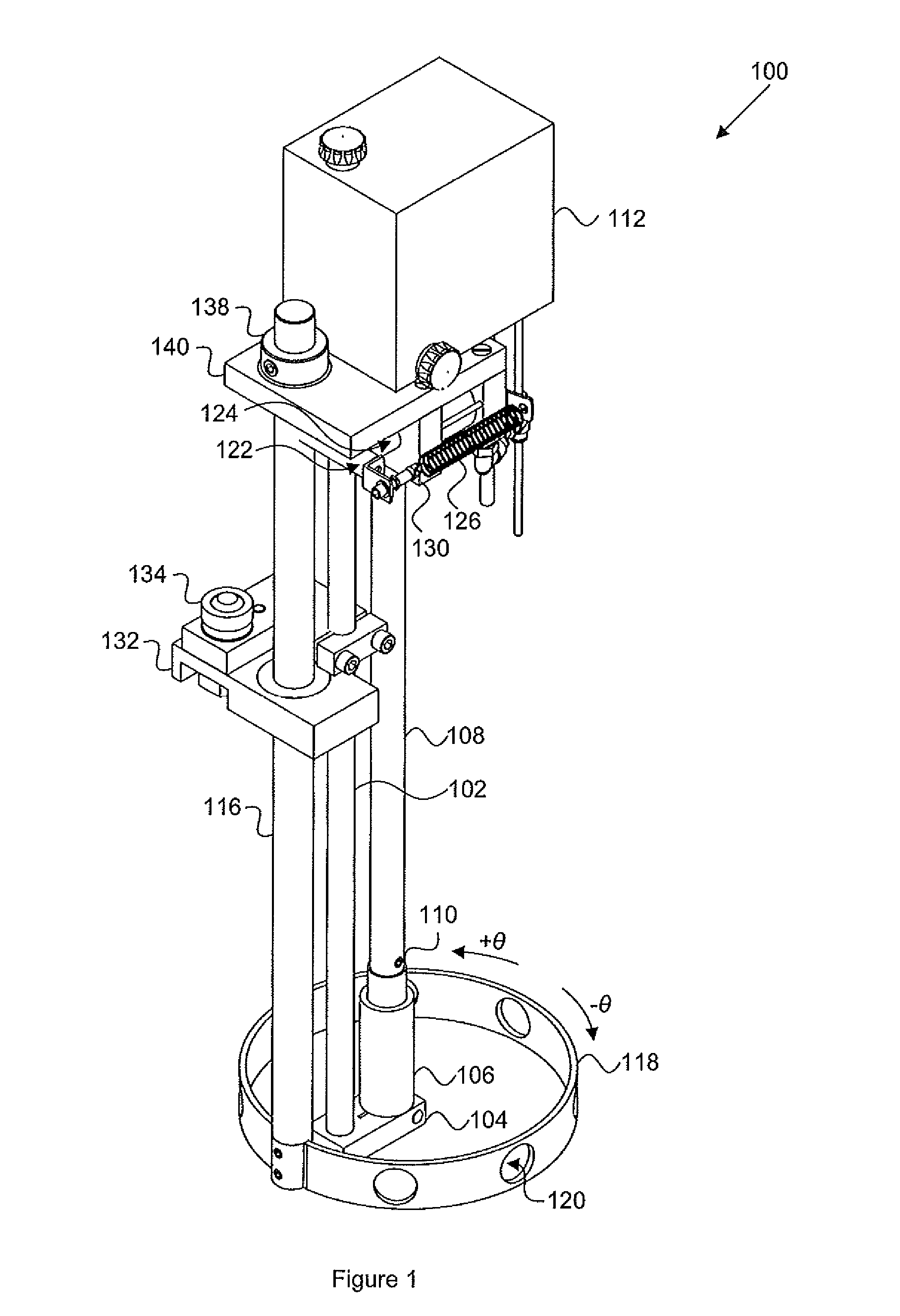

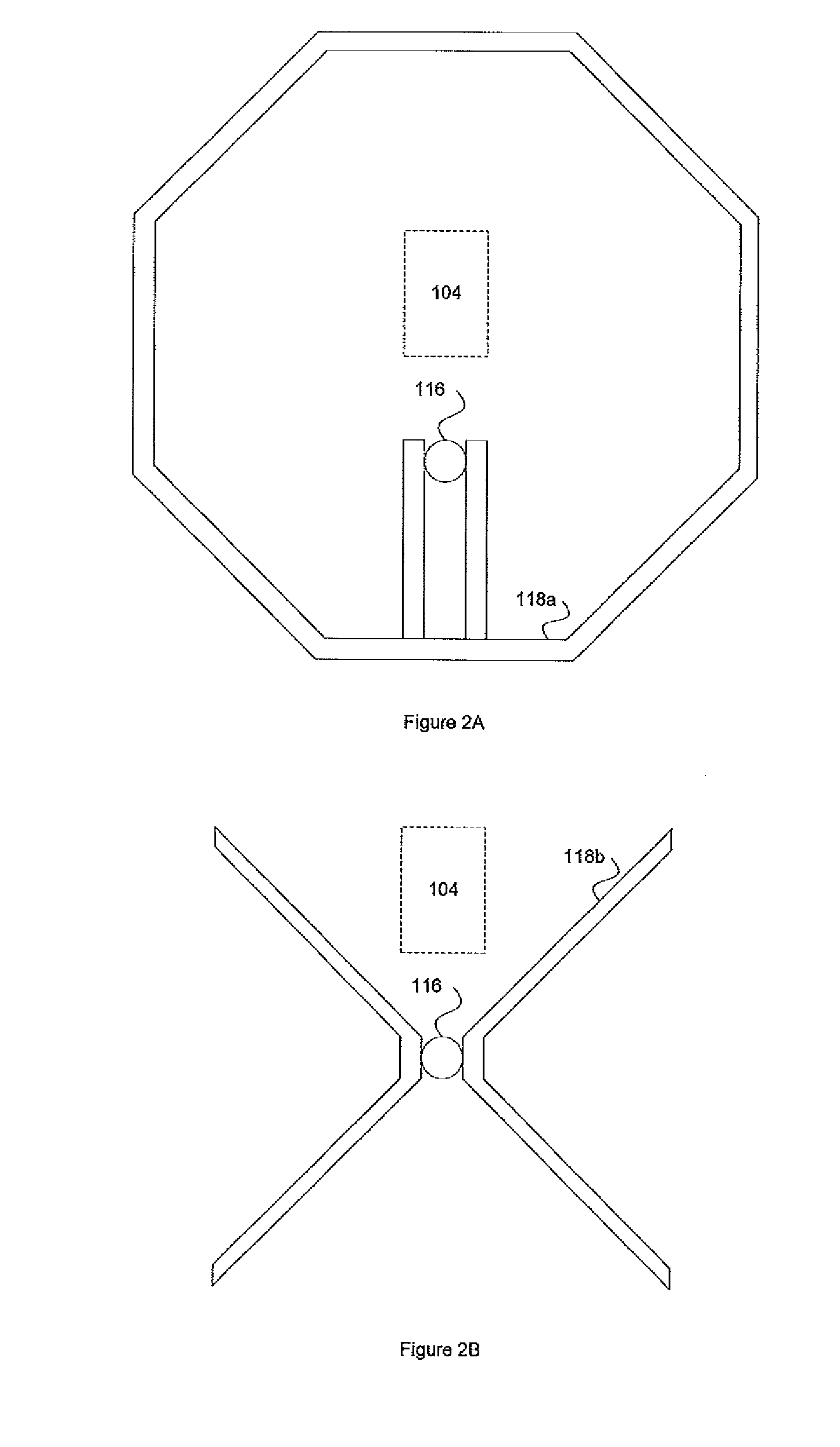

Mixers for a viscometer and methods and computer-readable meadia for using the same

InactiveUS20120075949A1Shaking/oscillating/vibrating mixersControlling ratio of multiple fluid flowsControl systemEngineering

The present invention is directed to mixers for viscometers and methods of using the same. Such inventions are applicable, for example, to industrial processes such as printing. One embodiment of the invention is directed to a viscosity control system including a viscosity sensor, a mixing element, a shaft fixedly attached to the mixing element, and an actuator interfacing with the viscosity sensor and the shaft. The annular mixing element is oscillatable about an axis lying in a plane tangent to a point on a wall of the mixing element. The shaft is centered about the axis. The actuator receives a signal from the viscosity sensor and rotates the shaft and the mixing element in an oscillating manner about the axis. In some embodiments, the shaft rotates through an angle of less than 360 degrees.

Owner:SAINT CLAIR SYST INC

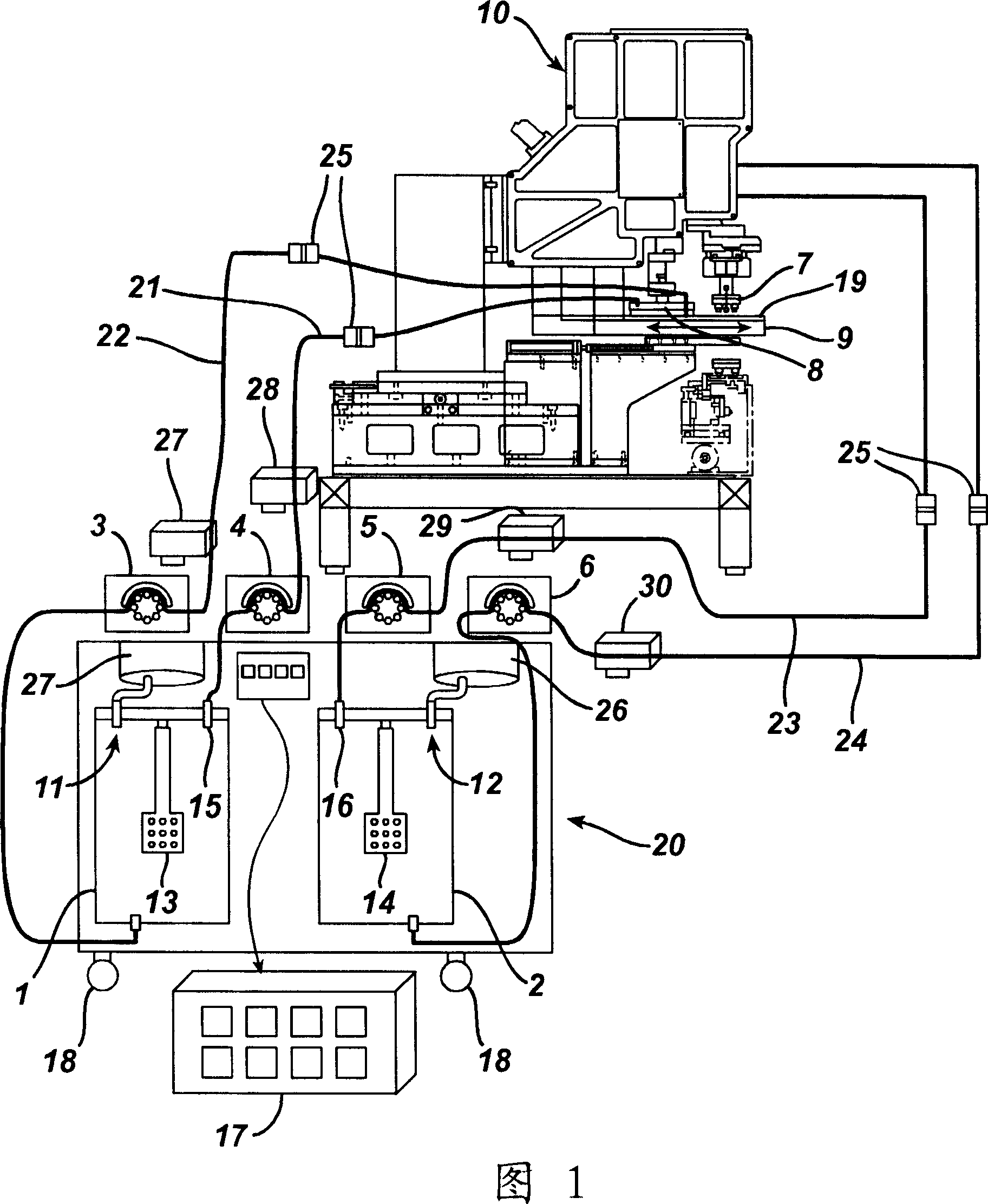

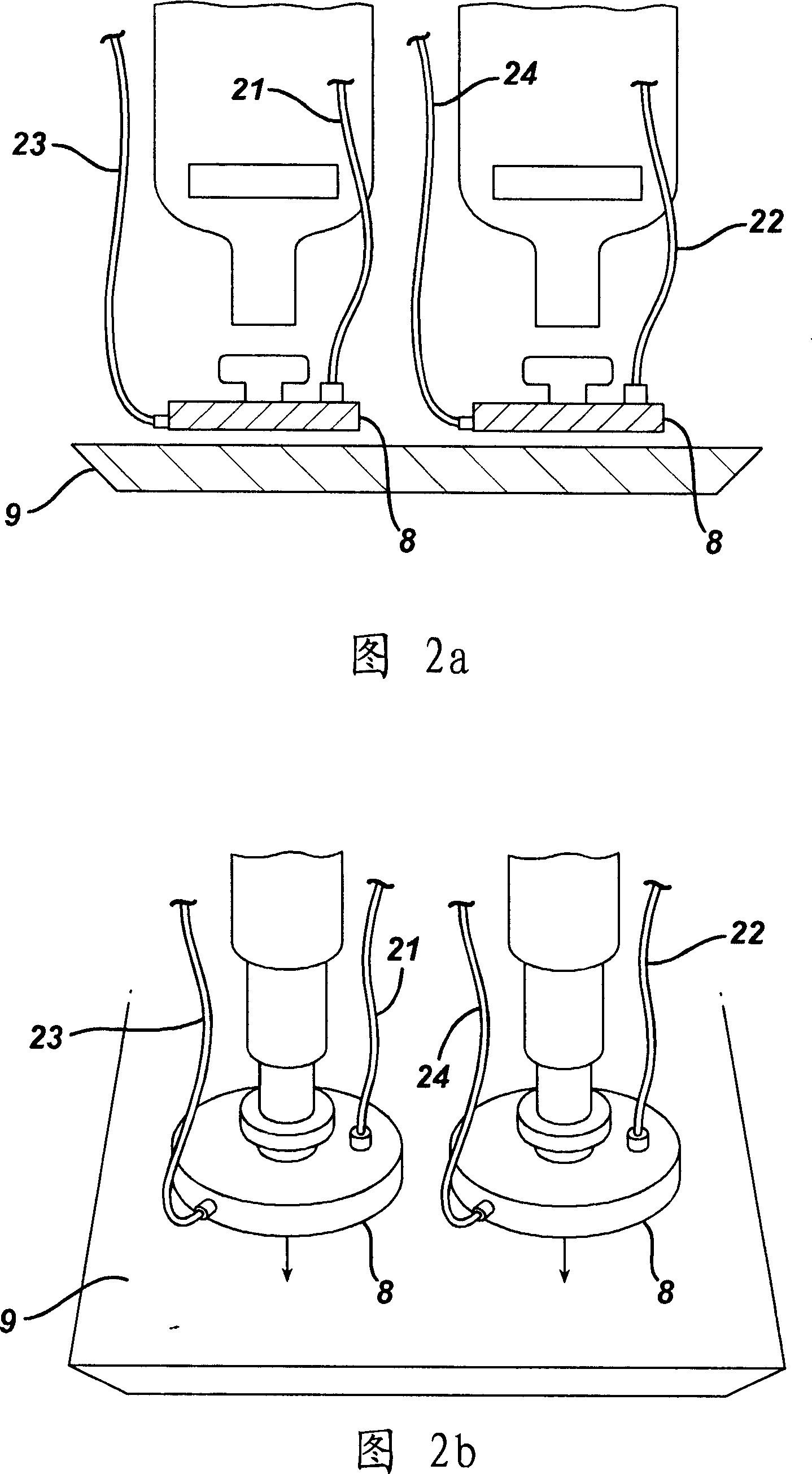

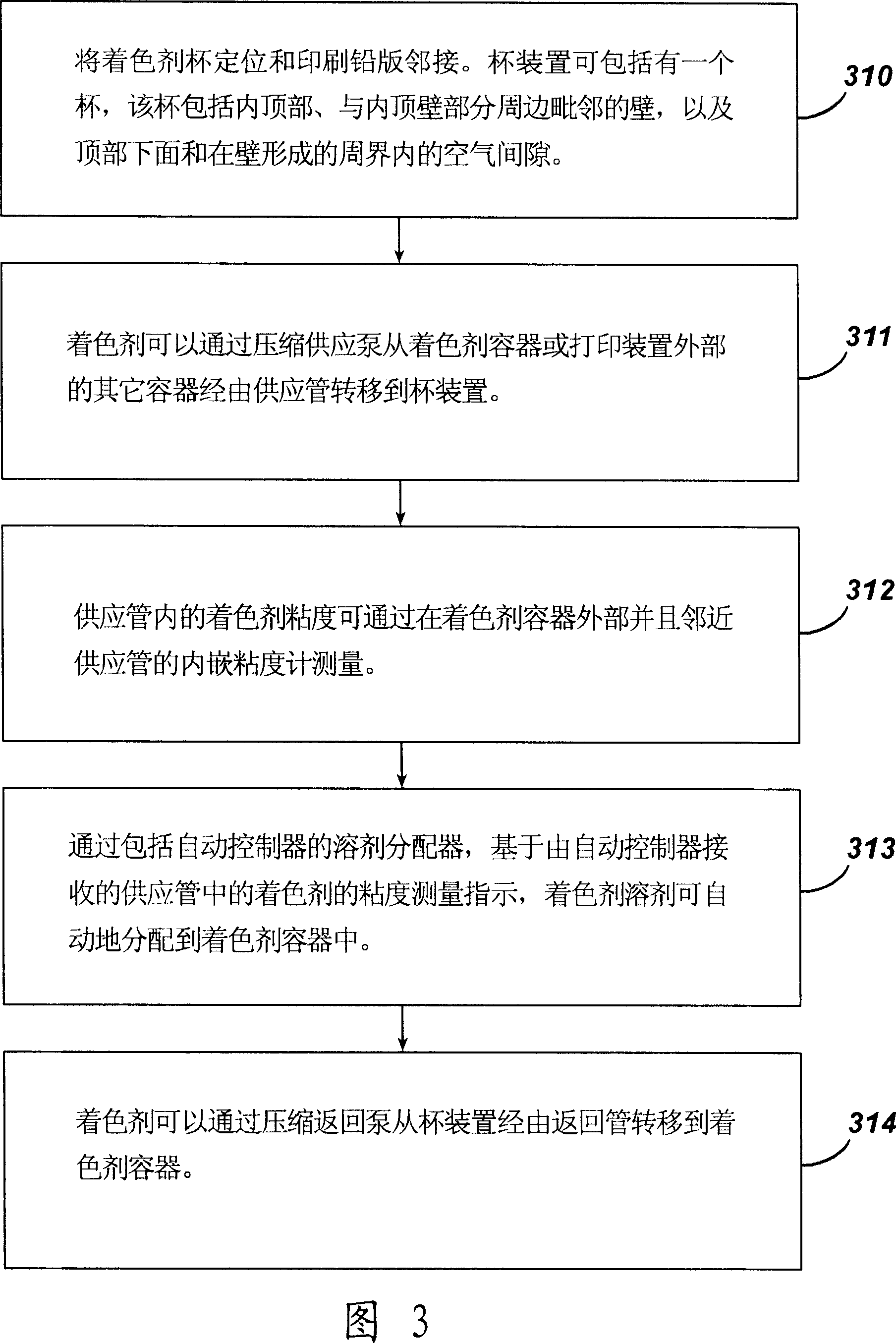

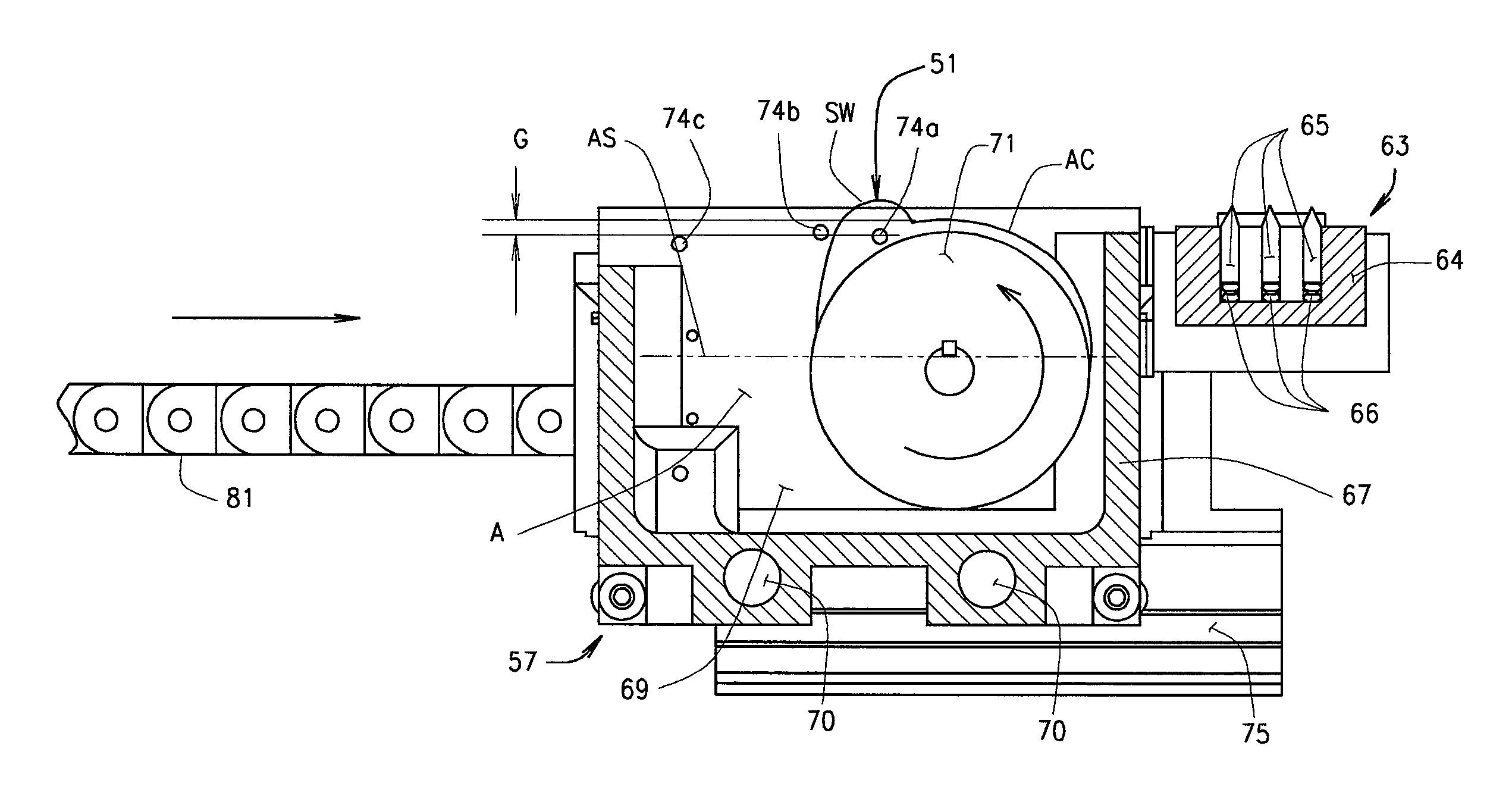

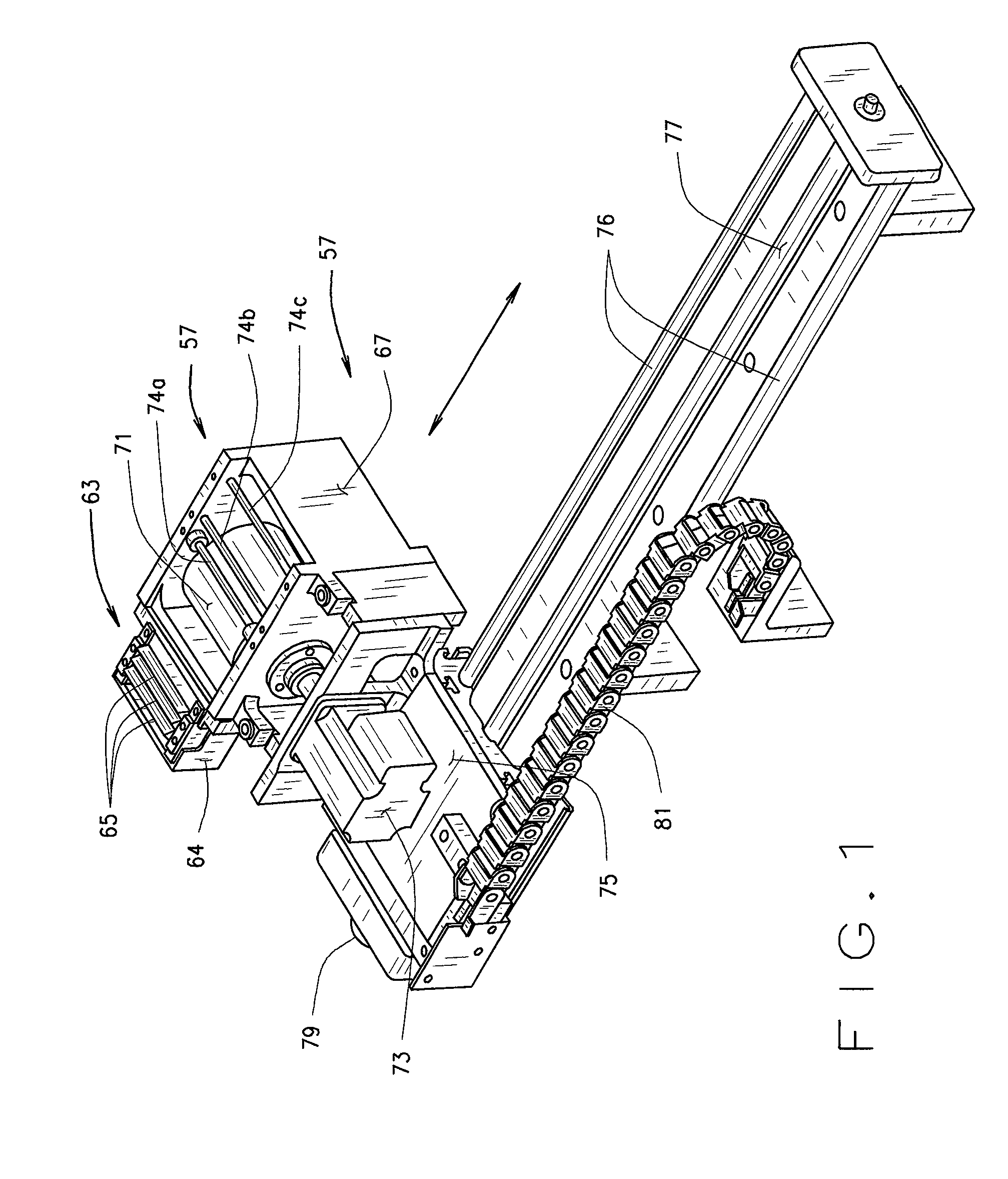

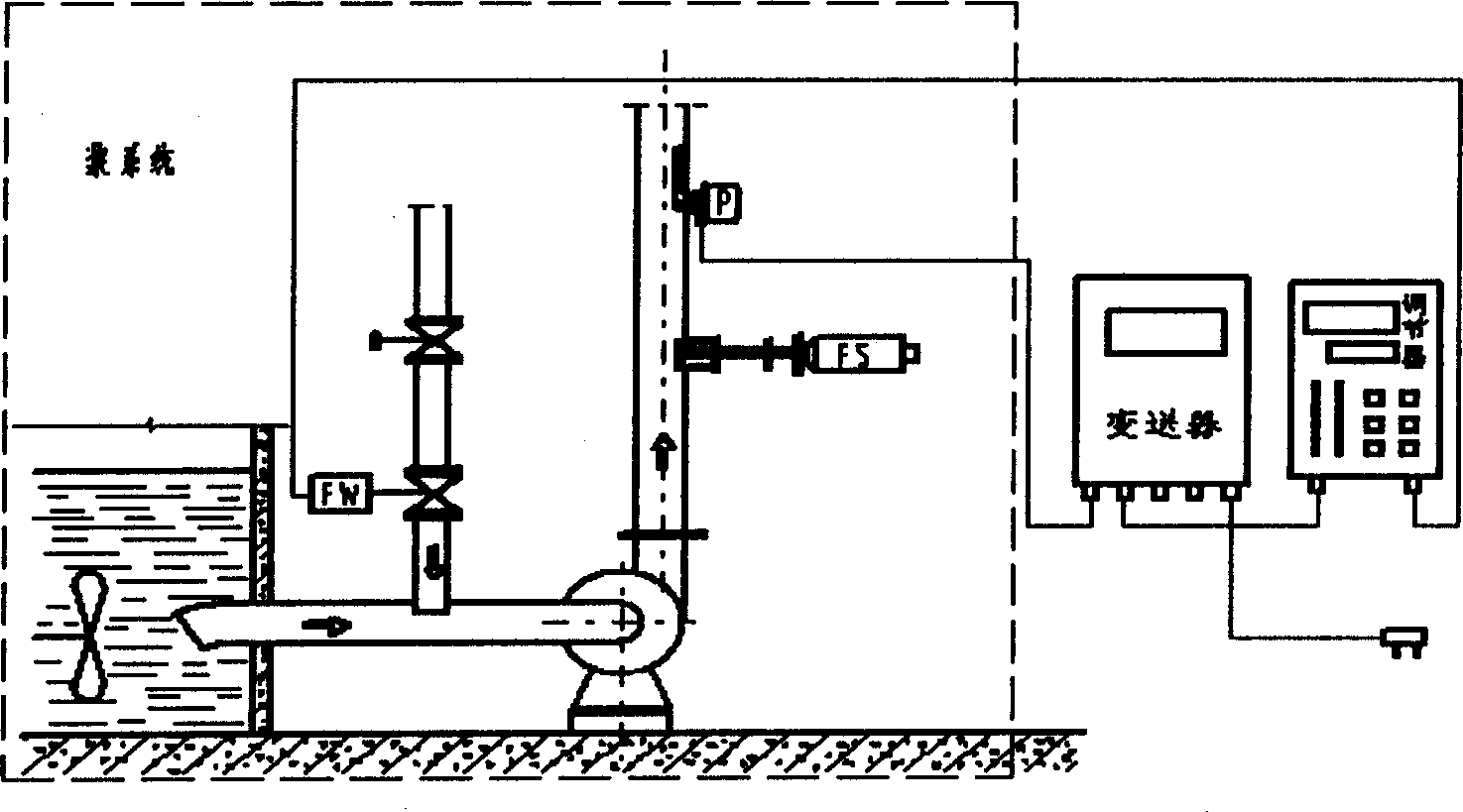

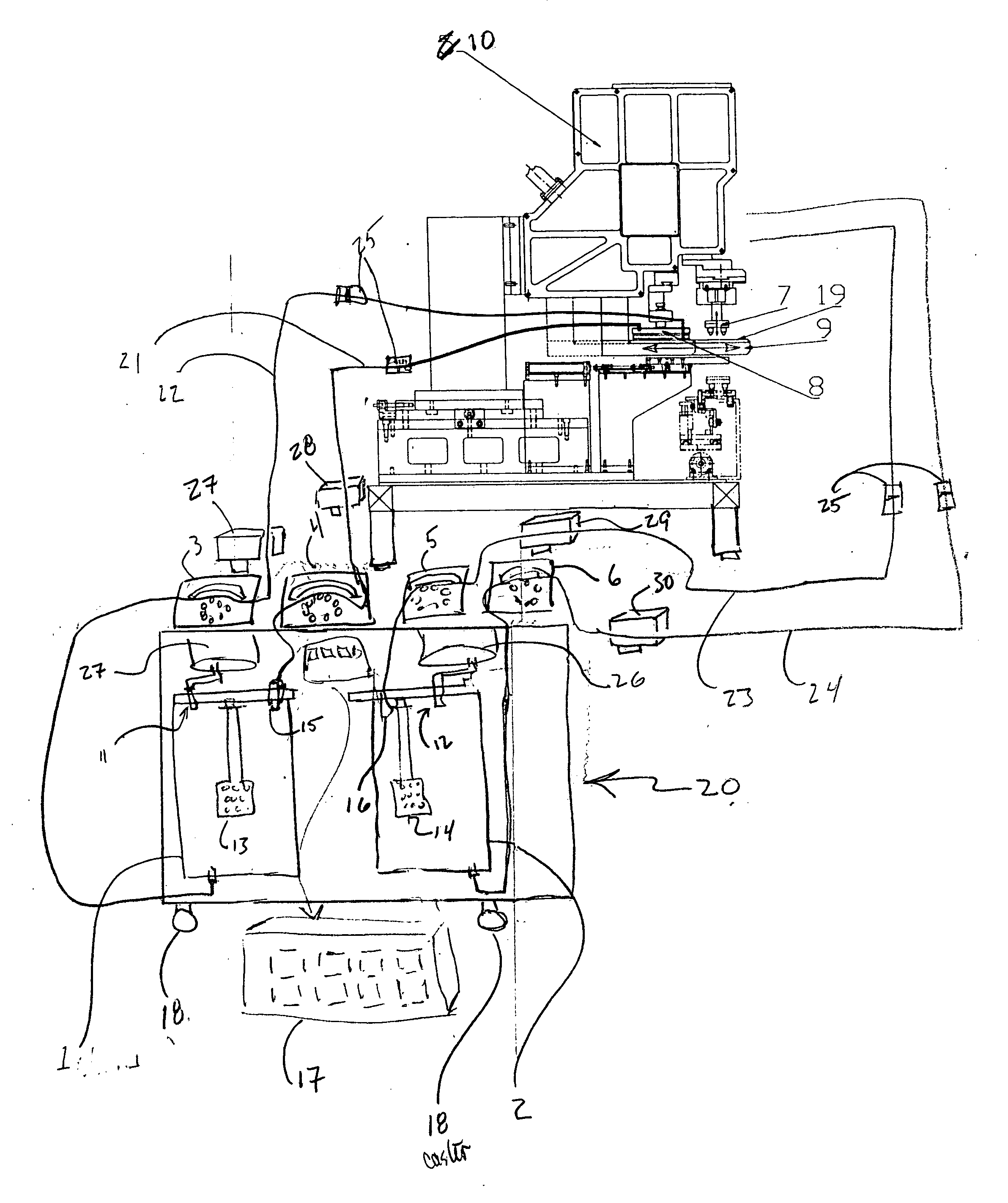

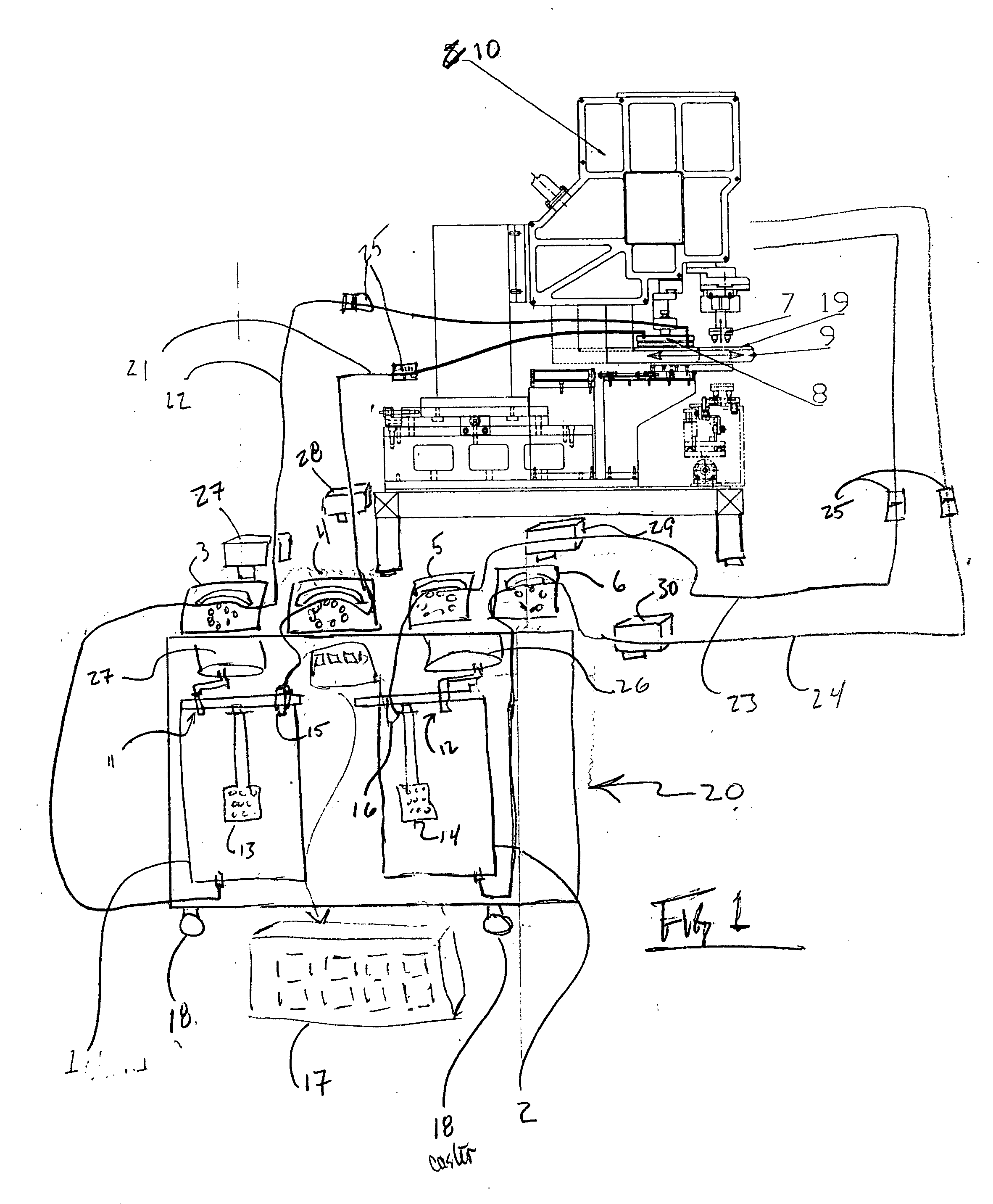

Colorant presentation for pad printing

The present invention provides systems and methods for providing colorant to a colorant cup apparatus that is adjacent to a pad printing cliche. The fluid colorant is fed from a colorant container through a feed conduit to the cup and an inline viscometer external to the colorant container measures the viscosity of colorant within the feed conduit. A control mechanism can dispense colorant solvent into the colorant container based upon a viscosity measurement performed by the inline viscometer. The disclosed systems, colorant cups and methods are useful in the preparation of tinted contact lenses.

Owner:JOHNSON & JOHNSON VISION CARE INC

System and method for controlling viscosity of a fluid and a working vehicle containing such a system

ActiveUS7287374B2Low viscosityEasy to upgradeCoolant flow controlRotary clutchesFluid viscosityEngineering

The invention relates to a method and system for controlling viscosity of a hydraulic fluid. The viscosity of a hydraulic fluid is usually very much dependent on temperature. By using existing throttles which generate a pressure drop, the hydraulic fluid can be heated by creating a power drain in these existing throttles through a controlled increase of the pressure through them. By controlled heating, the viscosity of a hydraulic fluid can be controlled. According to the invention, the existing throttles are preferably cavity-preventing openings in valves.

Owner:VOLVO CONSTR EQUIP HLDG SWEDEN AB

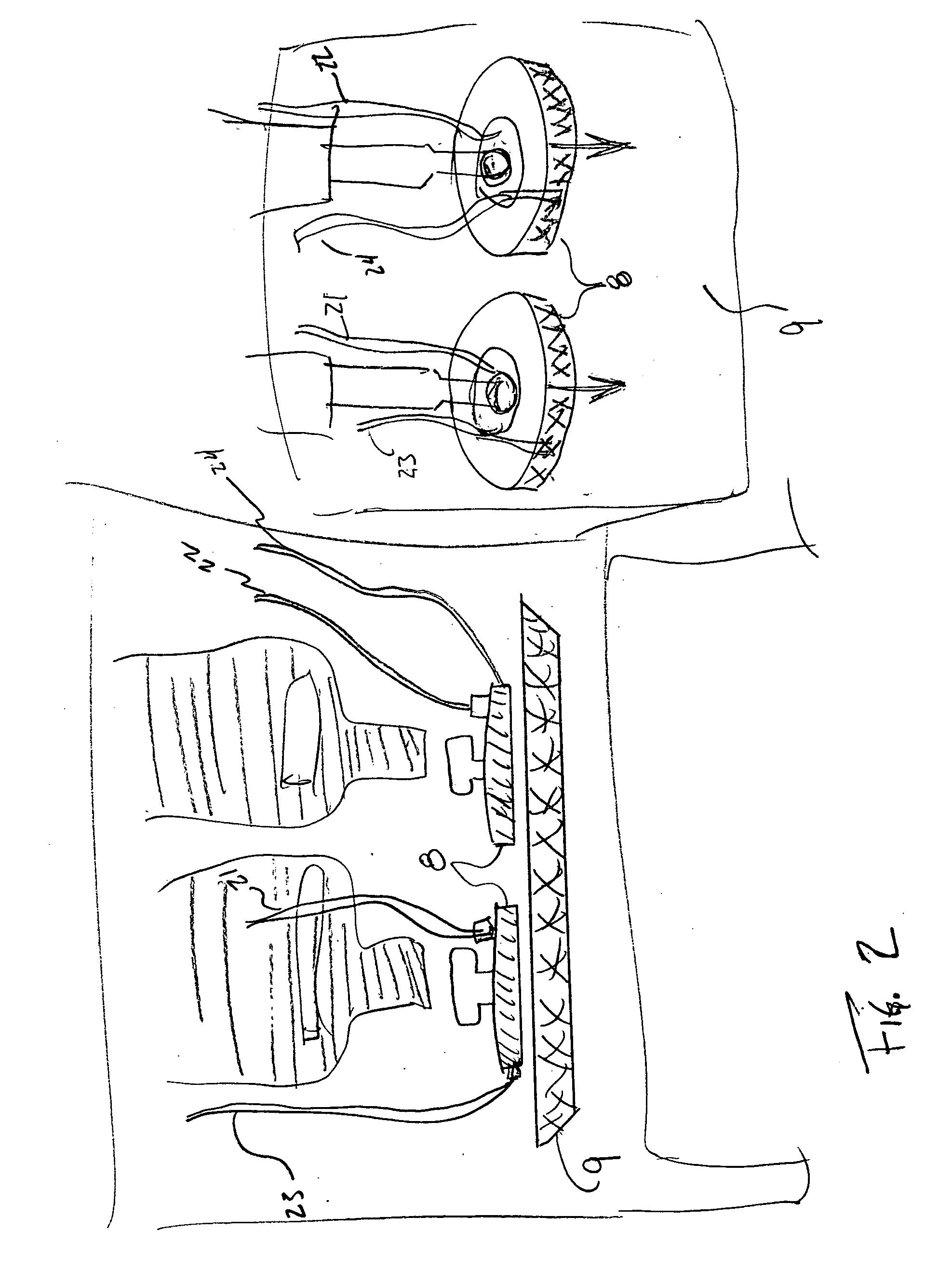

Apparatus for and a method of determining condition of hot melt adhesive for binding of a perfect bound book

Apparatus is disclosed for controlling the depth of a layer of a layer of adhesive on a peripheral surface of a rotary member (e.g., a wheel) for the application of the adhesive to an object. The apparatus comprises a heated reservoir containing a supply of hot melt adhesive maintained within a desired temperature range, where the rotary member is partially immersed in the adhesive and is rotated by a motor such that the as the rotary member is rotated up out of the peripheral surface of the rotary member has the layer of adhesive thereon. A computer controls system controls the motor such that the speed of the rotary member may be increased or decreased so as to vary the depth of the adhesive on the peripheral surface of the rotary member.

Owner:MARSH JEFFREY D

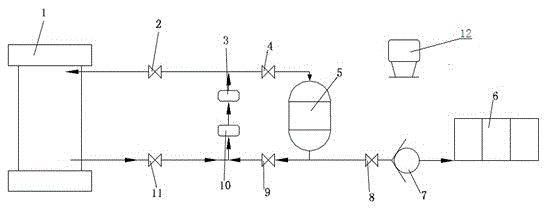

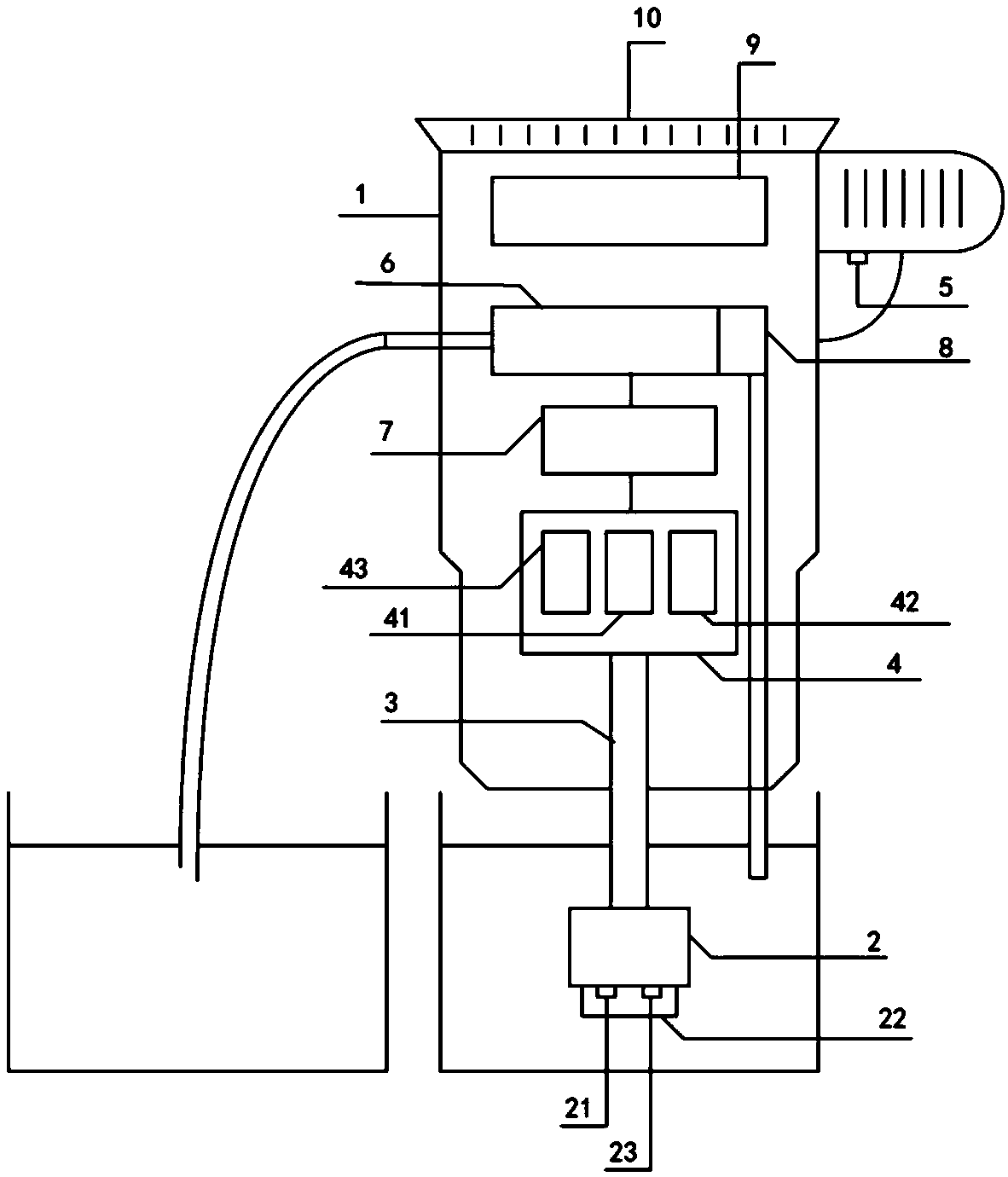

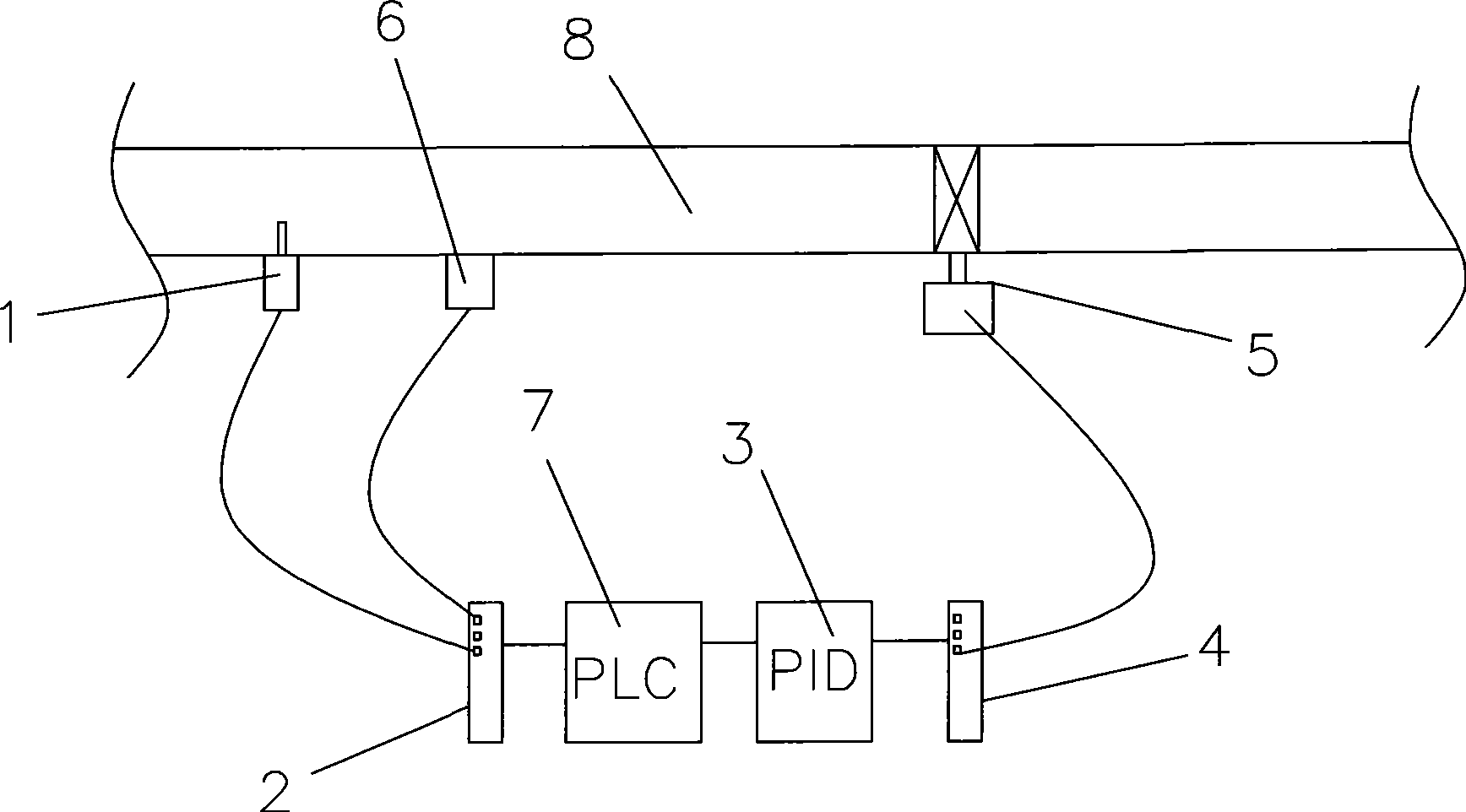

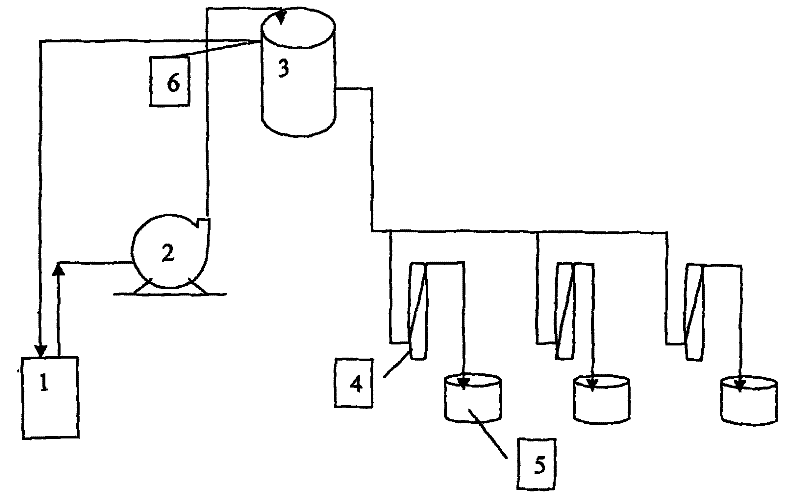

Control system for automatically adjusting viscosity of lithium battery slurry

ActiveCN105561858ASimple structureReasonable designFinal product manufactureTransportation and packagingControl systemEngineering

The invention discloses a control system for automatically adjusting the viscosity of lithium battery slurry. The control system comprises a vacuum planetary dispersion stirrer, a circulating pipeline A, a circulating pipeline B, a circulating pipeline C, a coating production device and a main control system, wherein the vacuum planetary dispersion stirrer is connected with the circulating pipeline A, the circulating pipeline A is connected with the circulating pipeline B, the circulating pipeline B is connected with the circulating pipeline C, and the circulating pipeline C is connected with the coating production device. The control system has the advantages that: the structure is simple, the design is reasonable, a novel lithium battery slurry preparation method is provided, and the control way for producing the lithium battery slurry is enlarged; the situation that the viscosity of the slurry is manually detected by using a laboratory is reduced, and the automatic detection and the automatic adjustment are realized; and the lagging phenomenon for adjusting the viscosity of the slurry during the slurry preparation of the lithium battery is reduced, and the viscosity is automatically and stably controlled during the slurry preparation process of the lithium battery, so that the device is more intelligent.

Owner:ZHONGTIAN ENERGY STORAGE TECH

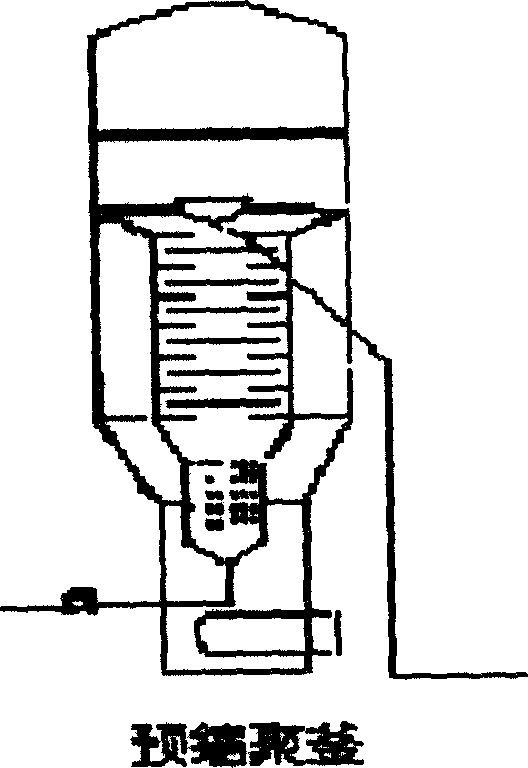

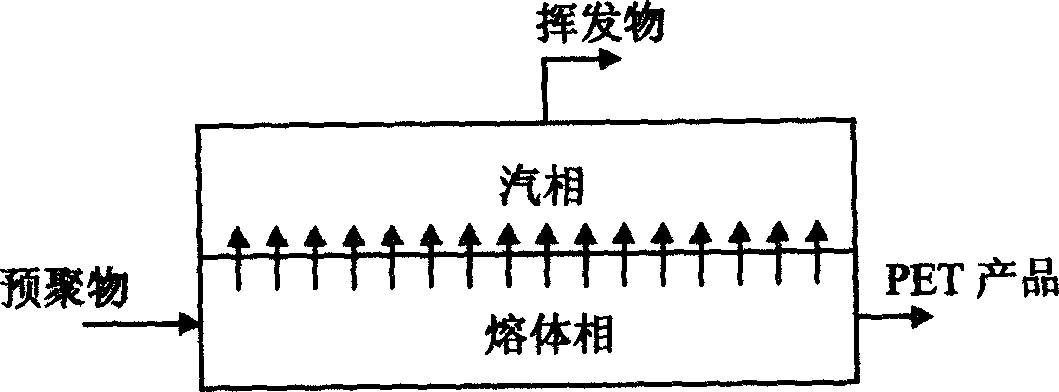

Soft measure for polyester product quality target and process operating optimization method

InactiveCN1552753AGuaranteed uptimeMeet the precision requirementsFlow propertiesMaterial testing goodsPolyesterExperimental research

A soft measuring system for in-line measurement to the quality specifications of polyester (PET) product, such as the esterified rate, terminated carboxy, viscosity, content of diglycol, etc. is disclosed. A guide software system for optimizing the operations in producing PET is also disclosed, which features that the esterified rate and viscosity and used as the control targets and a non-linear optimal algorithm is used.

Owner:EAST CHINA UNIV OF SCI & TECH

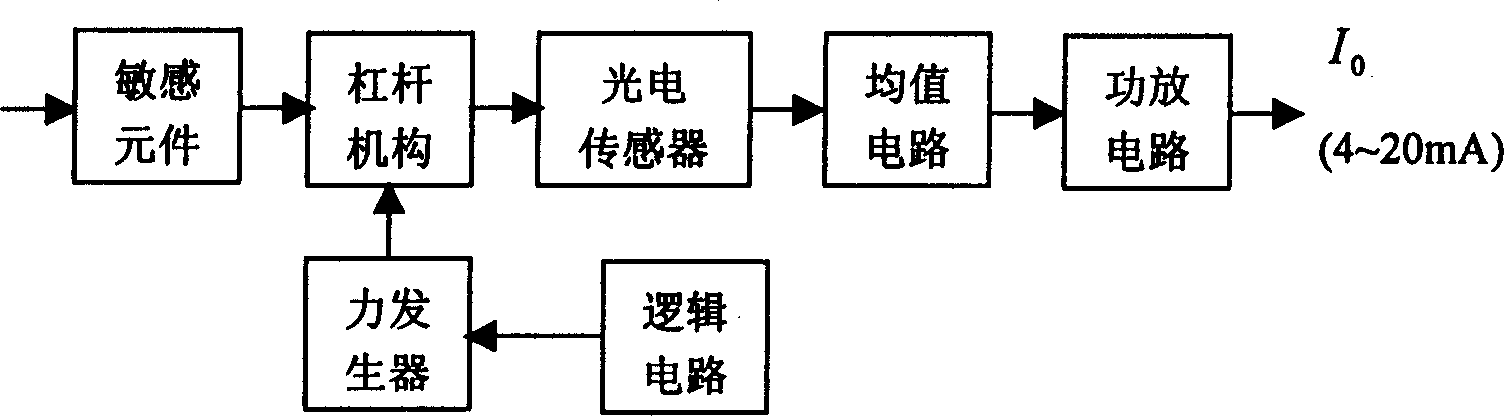

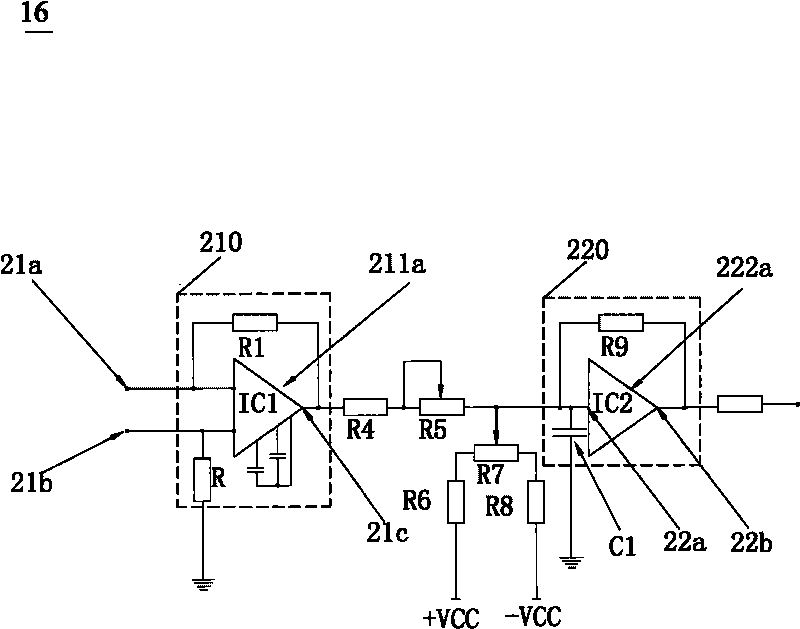

Concentration changing and sending adjusting device

InactiveCN1544912ASolve the problem of poor control effectAchieve direct controlSpecific gravity using flow propertiesViscosity controlEngineeringFuzzy relation matrix

The invention is a temperature transducing and adjusting device, specially relating to a device of measuring and controlling fluid concentration, including power concentration transducer, fuzzy adjuster, solid-state relay, valve machine and adjusting valve, all electrically connected in turn, where the power concentration transducer includes sensing component, lever mechanism, photoelectric sensor and force generator, the fuzzy adjuster includes matrix unit and programmable pulse-width modulation (PWM) unit, and the output signal of the fuzzy adjuster is connected to the input end of the solid-state relay. It implements direct control of valve machine; the solid-state relay has no contractor, light control current and high acting speed; it omits adjuster and valve servo amplifier, reduces cost, and enhances reliability, and the control system has small overshoot and responds quickly.

Owner:HUAZHONG UNIV OF SCI & TECH

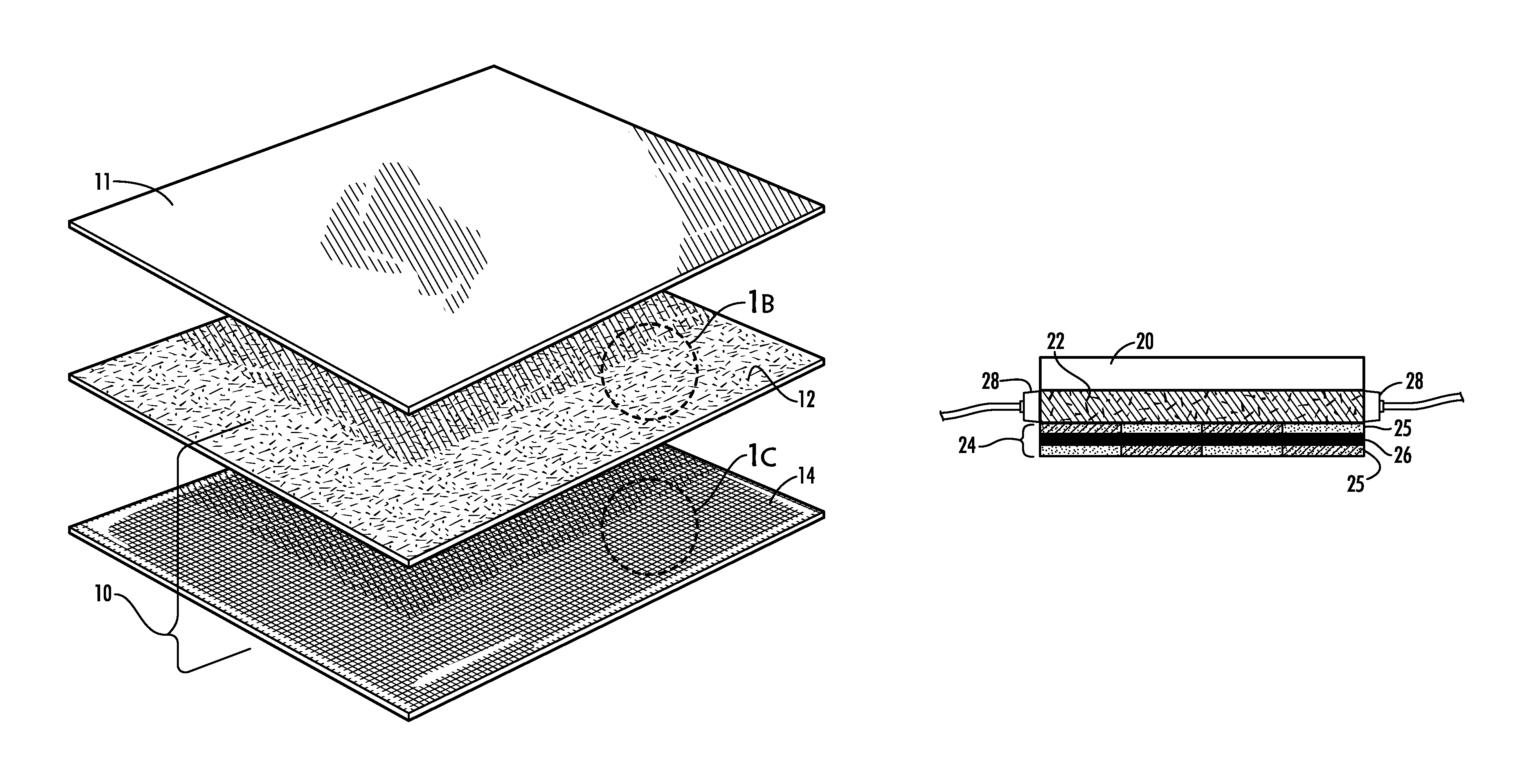

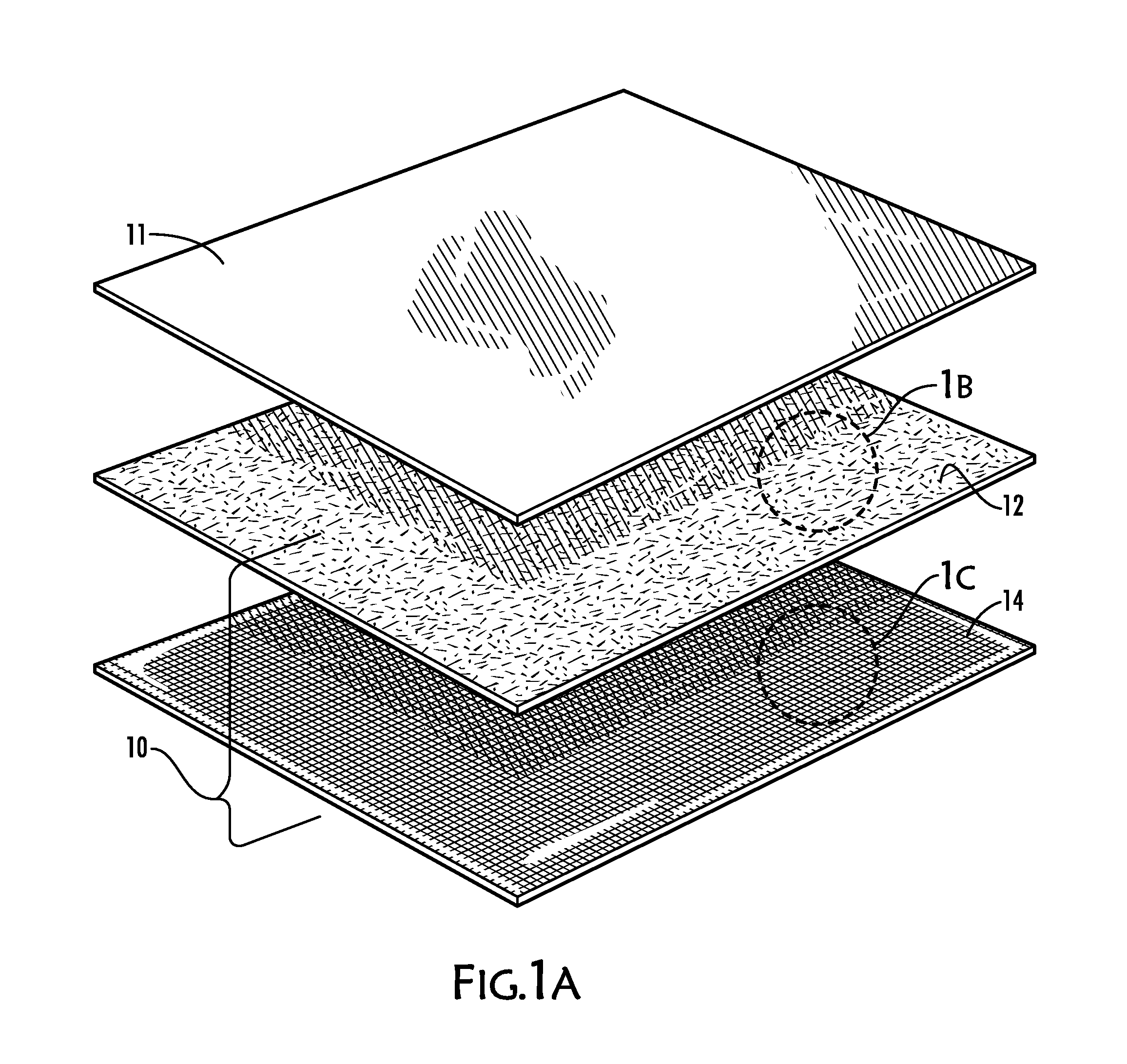

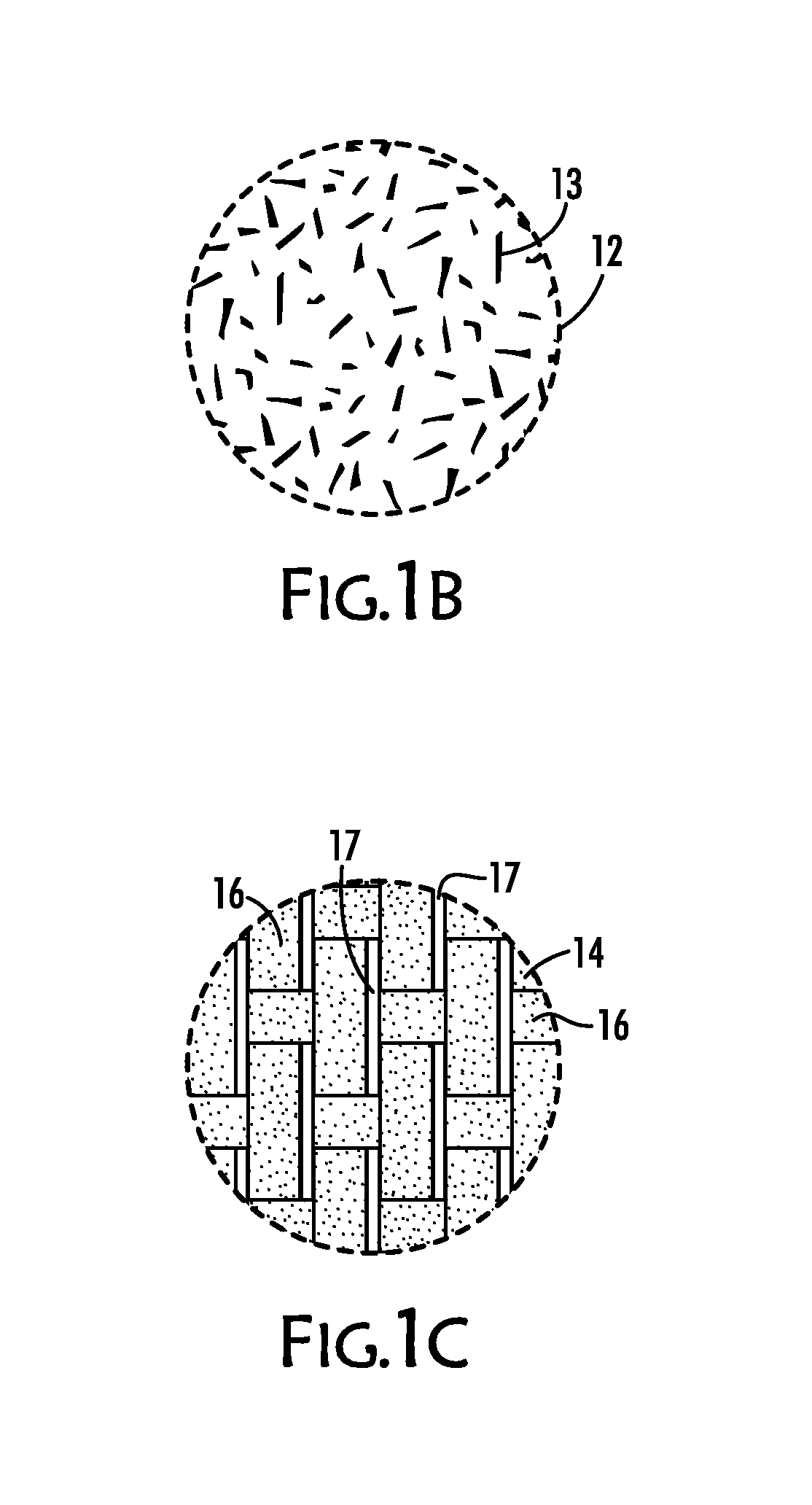

Multilayer system having reconfigurable dynamic structure reinforcement using nanoparticle embedded supramolecular adhesive and method

Owner:THE BOEING CO

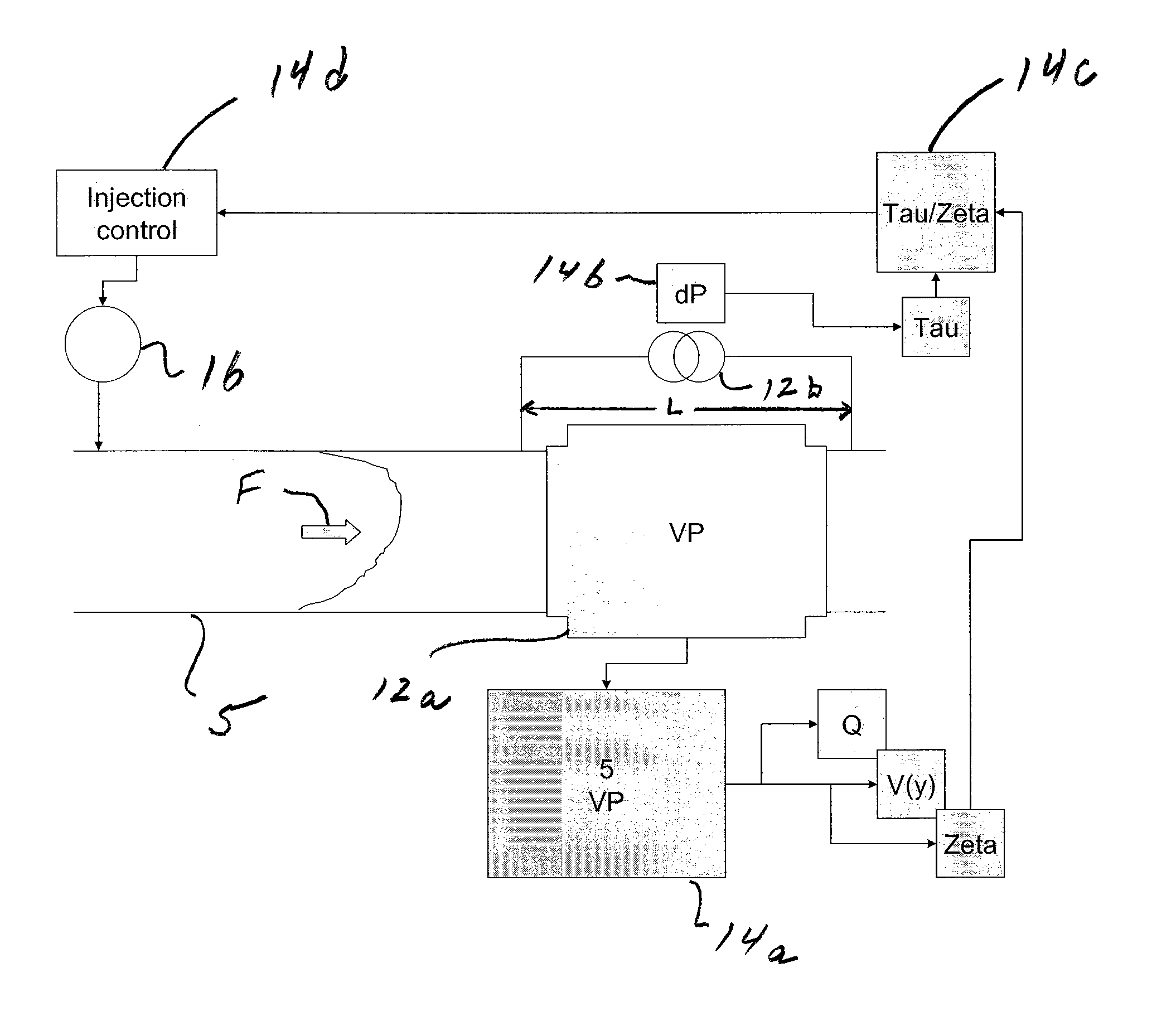

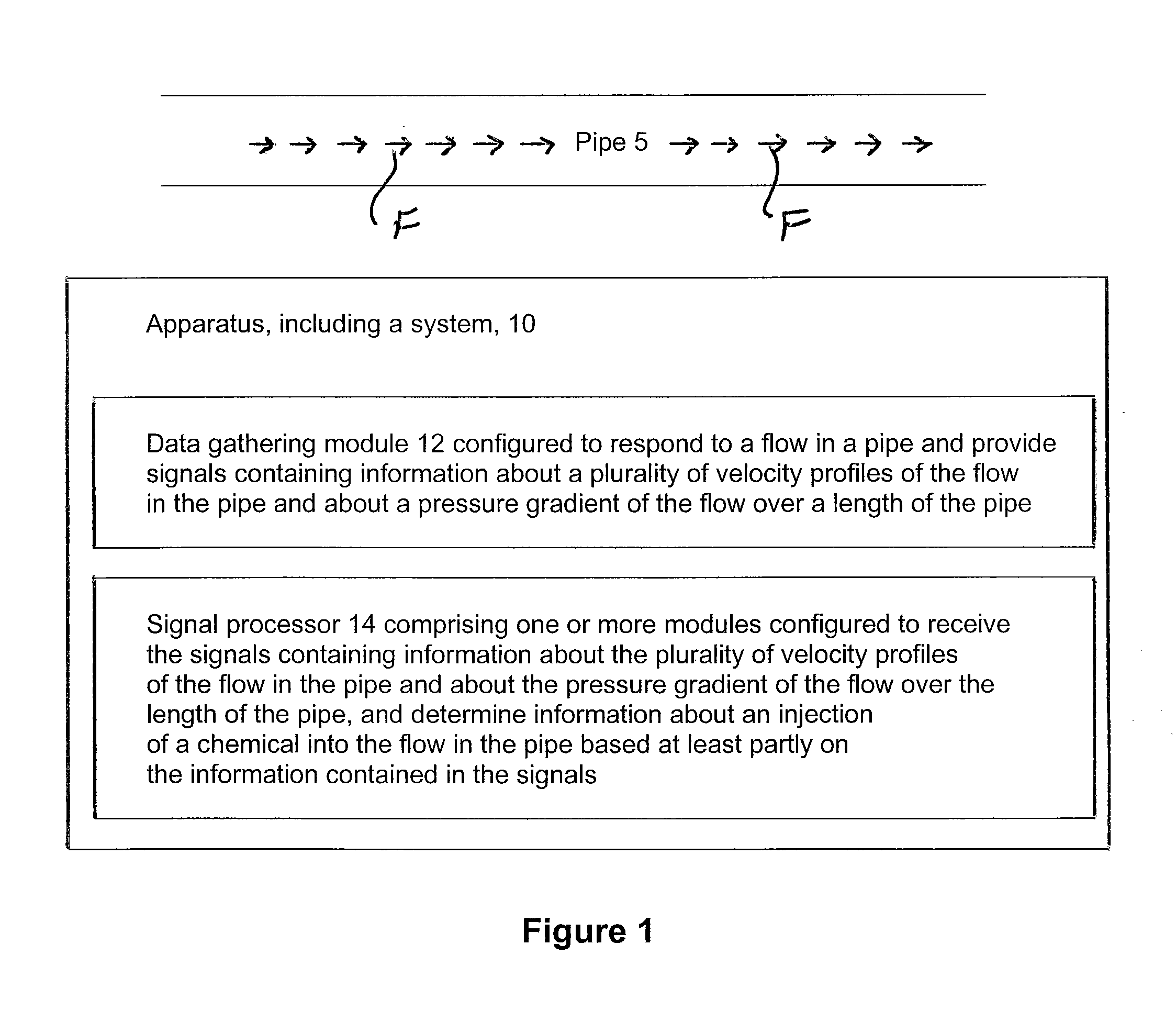

Determining shear rate and/or shear stress from sonar based velocity profiles and differential pressure

ActiveUS20120060930A1Increase shear rateWell mixedControlling ratio of multiple fluid flowsMixing methodsShear stressDifferential pressure

The present invention provides a new method and apparatus for receiving signals containing information about a plurality of velocity profiles of a flow in a pipe and about a pressure gradient of the flow over a length of the pipe; and determining information about an injection of a chemical into the flow in the pipe based at least partly on the information contained in the signals.

Owner:SUNCOR ENERGY INC

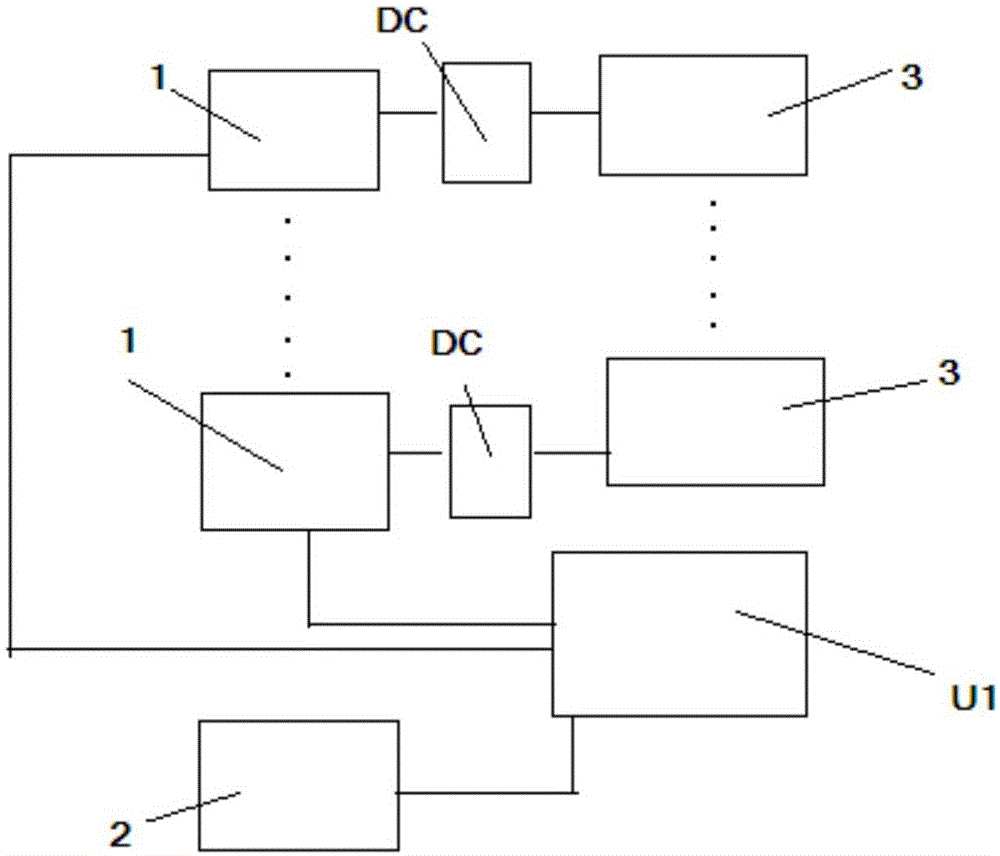

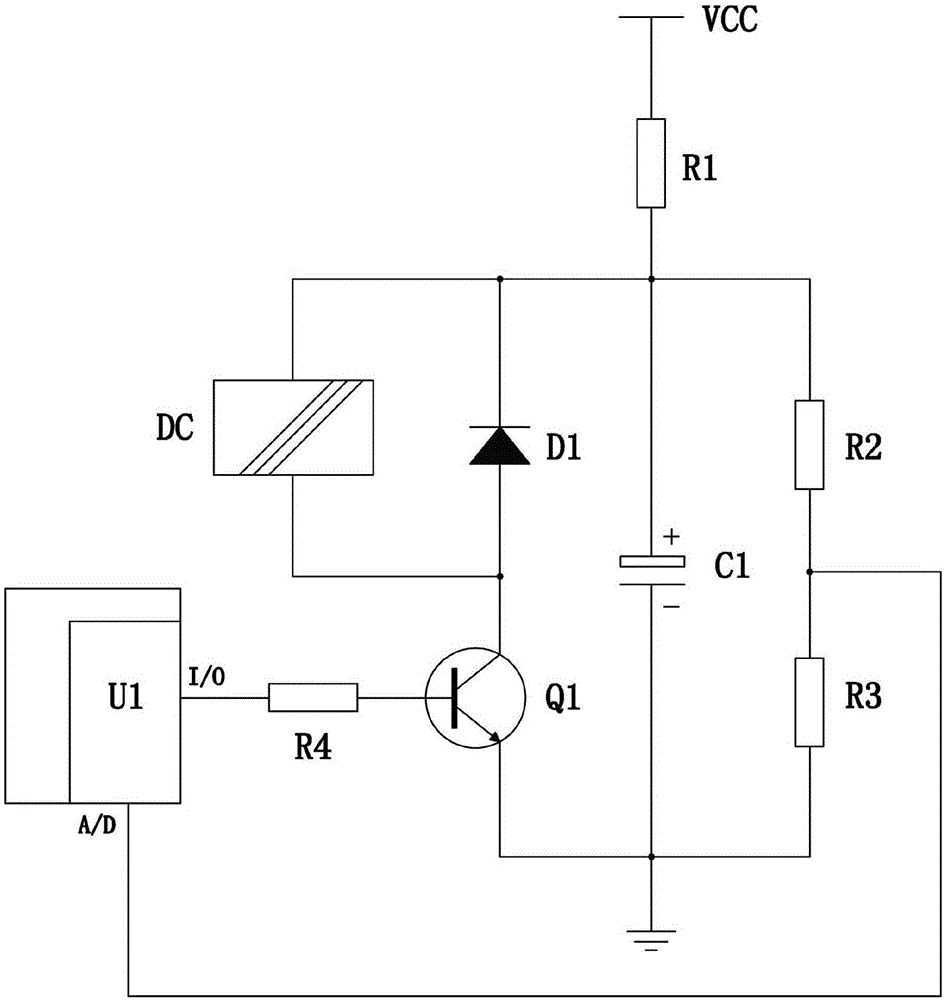

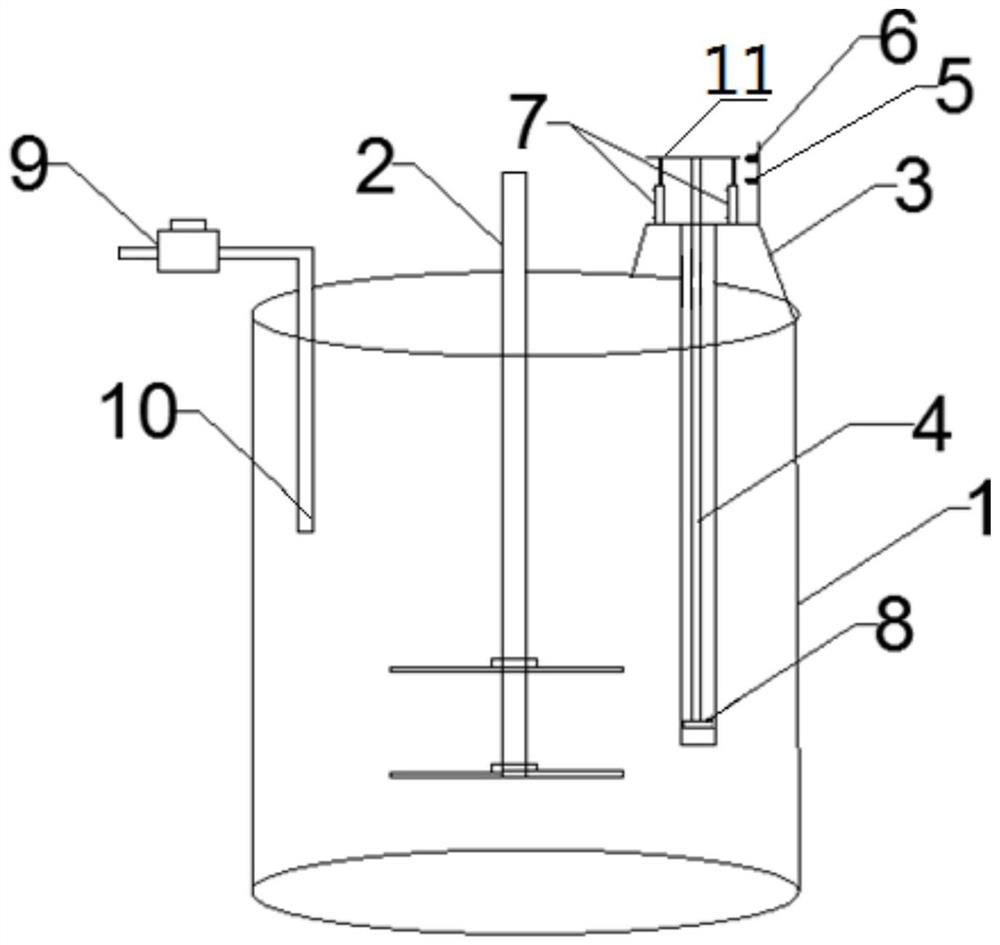

Automatic viscosity regulating apparatus during material stirring

ActiveCN105094179AReduce workloadRealize online real-time controlOperating means/releasing devices for valvesMixer accessoriesMicrocontrollerEngineering

The invention discloses an automatic viscosity regulating apparatus during material stirring. The automatic viscosity regulating apparatus comprises a viscometer, a plurality of component accommodation devices, a plurality of corresponding electric control valves, a plurality of corresponding flow control circuits, and a microcontroller; the viscometer installed at the inner wall of a stirring container is used for detecting viscosity of a material in real time; the electric control valves are connected with the component accommodation devices; and the flow control circuits control the electric control valves. The viscometer and the multiple flow control circuits are connected with the microcontroller; and each flow control circuit is connected with one corresponding electric control valve. According to the technical scheme, manual material adding does not required; the workload of the worker can be reduced; and the work efficiency is improved.

Owner:BEIJING HAIHETIAN TECH DEV

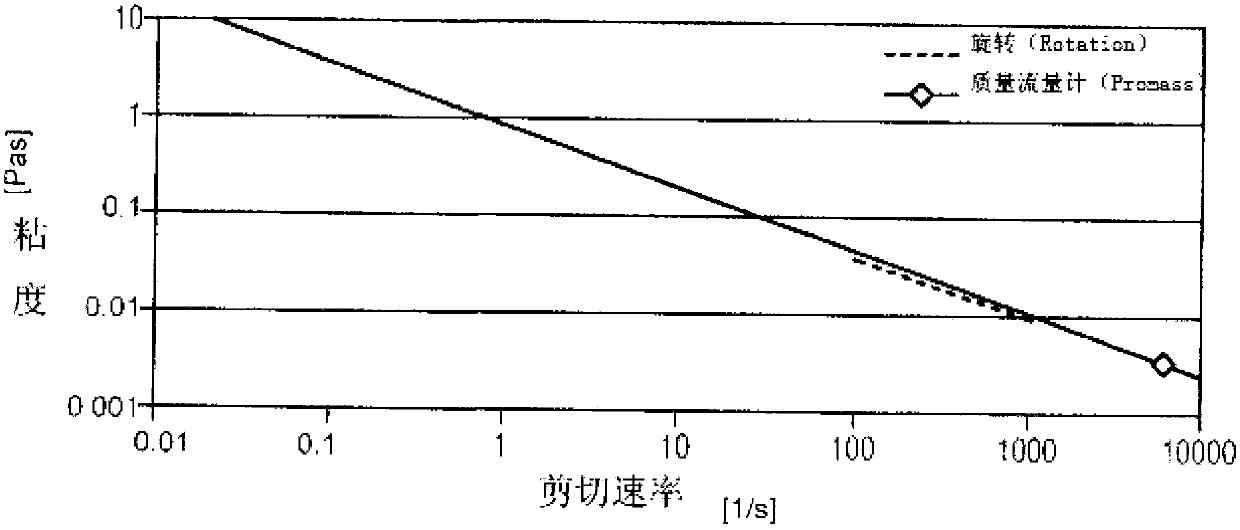

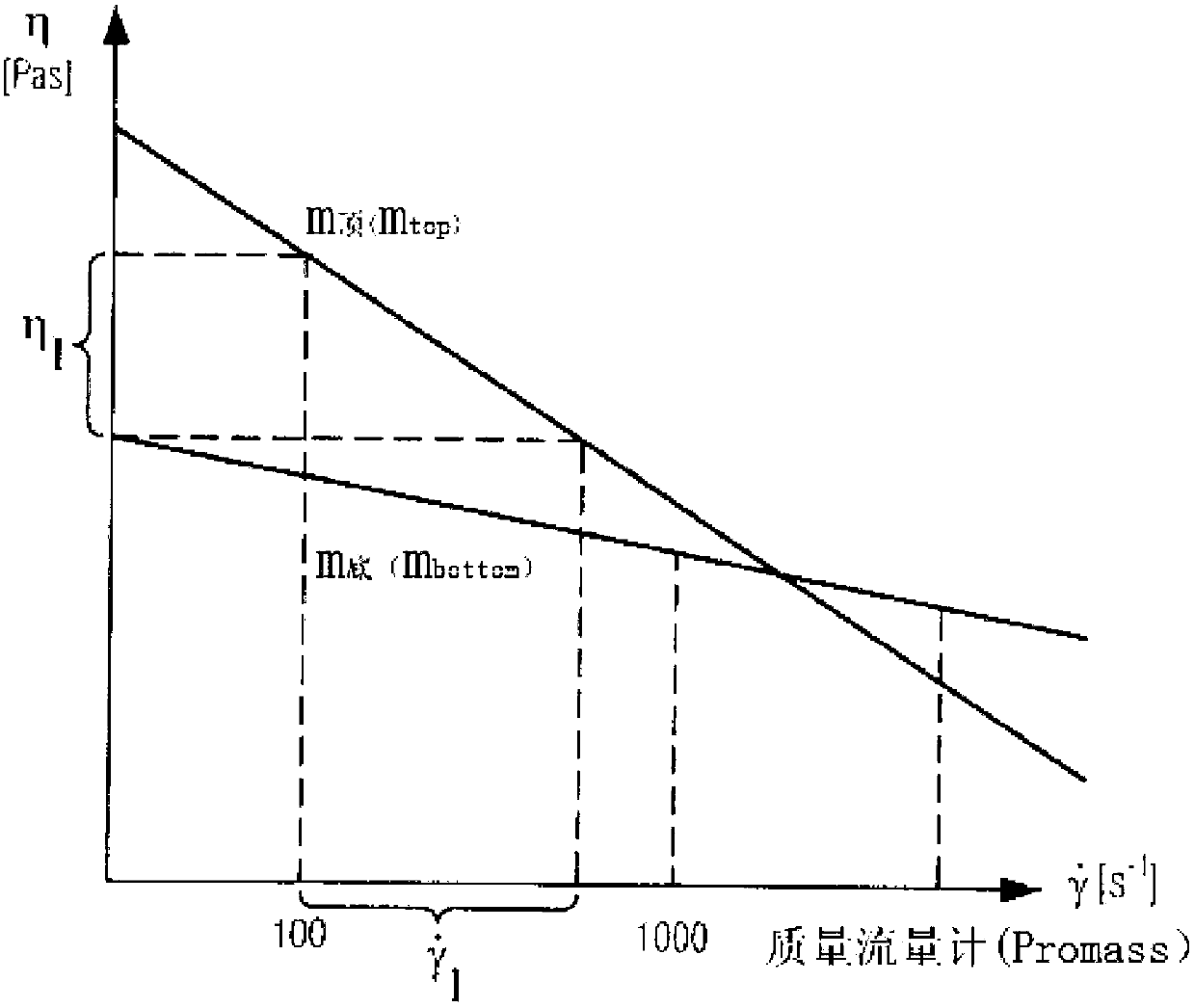

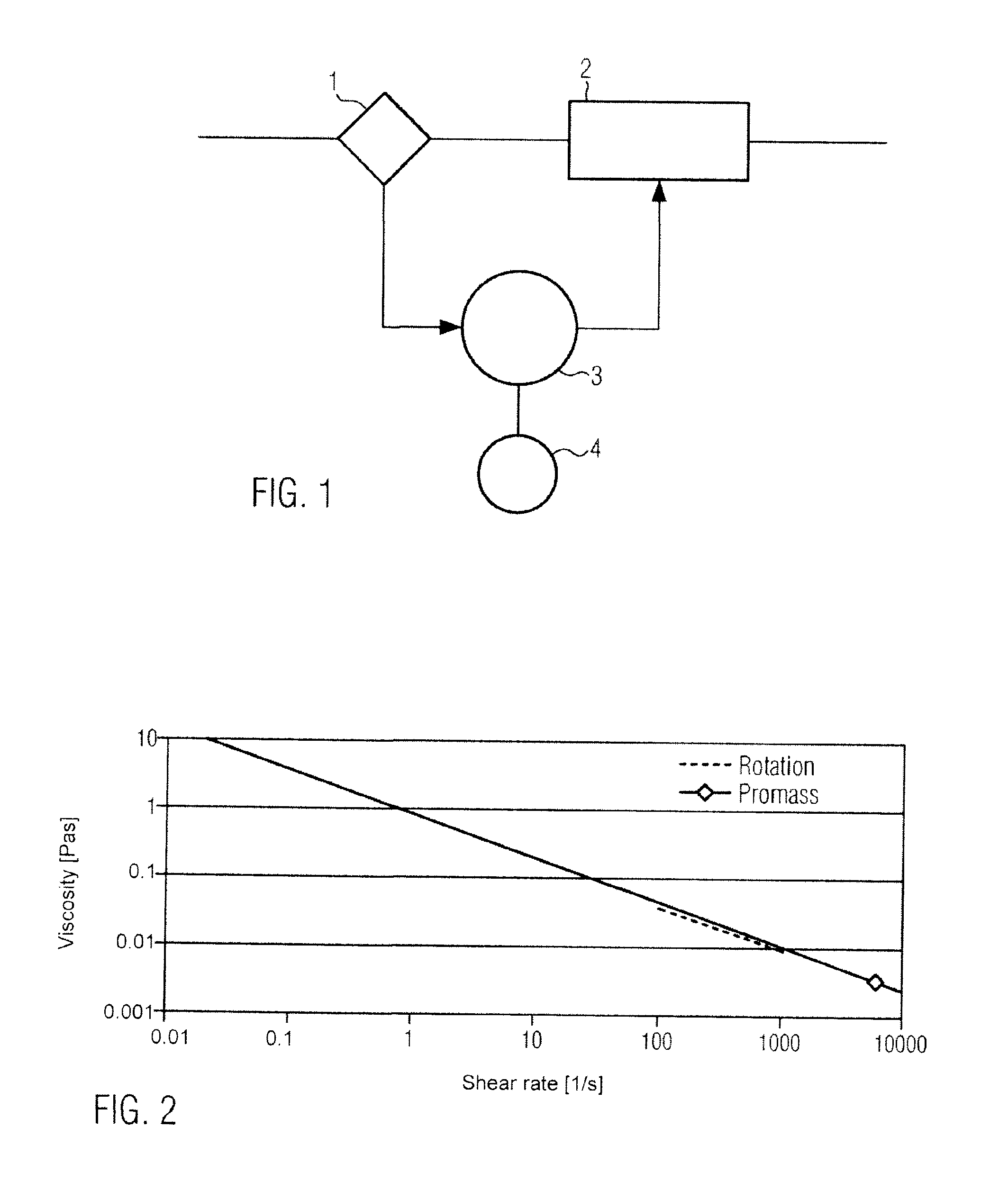

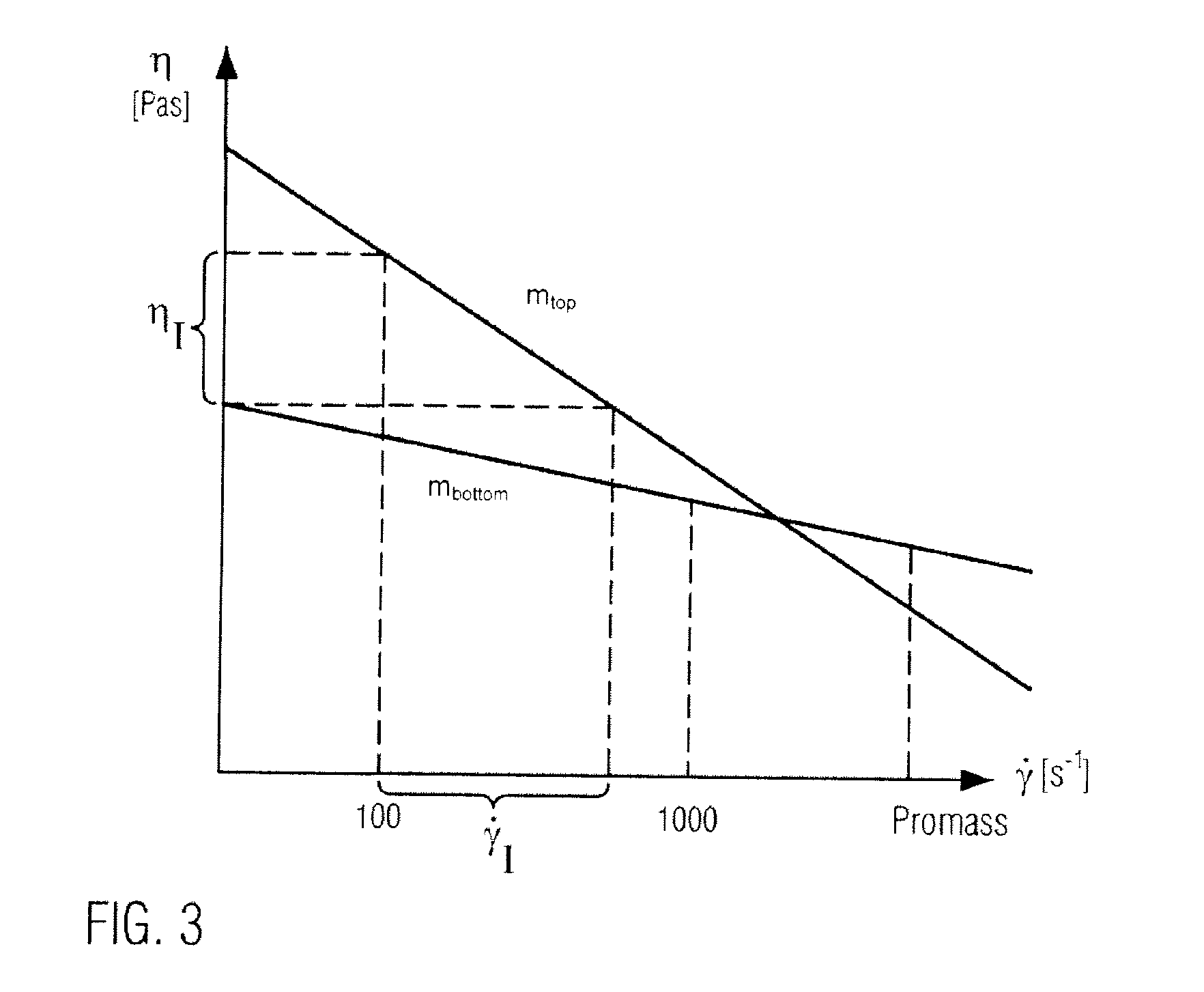

Viscosity-controlled processing of liquid food

The present invention relates to a method of controlling, by open-loop or closed-loop control, the processing of a liquid food product, comprising the steps of providing data that are obtained from mathematical modeling of the dependency of the viscosity of liquid food products on the shear rate, measuring the viscosity of the liquid food product to be processed at a predetermined shear rate at a measuring point, and controlling, by open-loop or closed-loop control, the processing of the liquid food product at a working device downstream of the measuring point in response to the viscosity measured at the measuring point and on the basis of the provided data.

Owner:KRONES AG

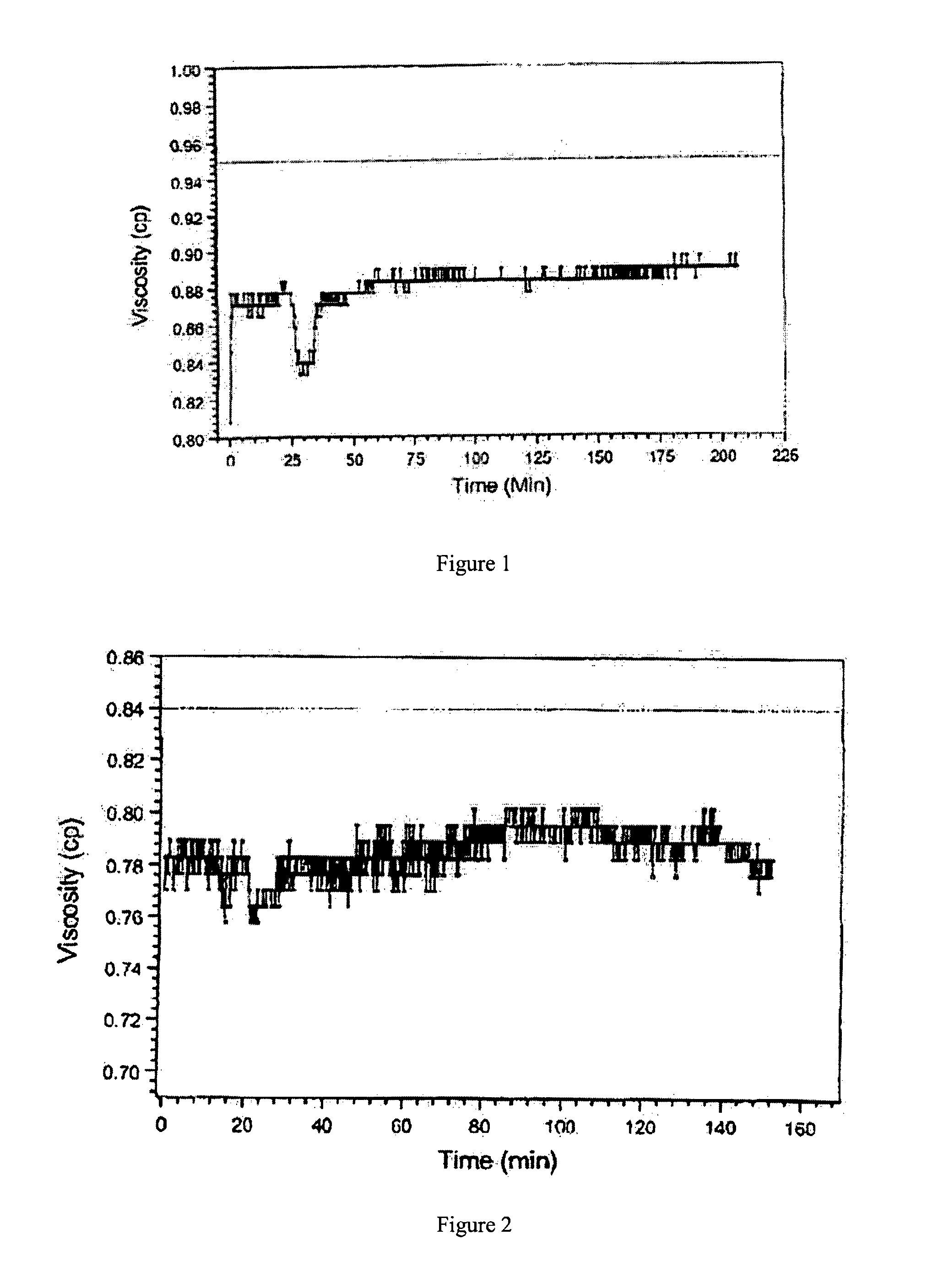

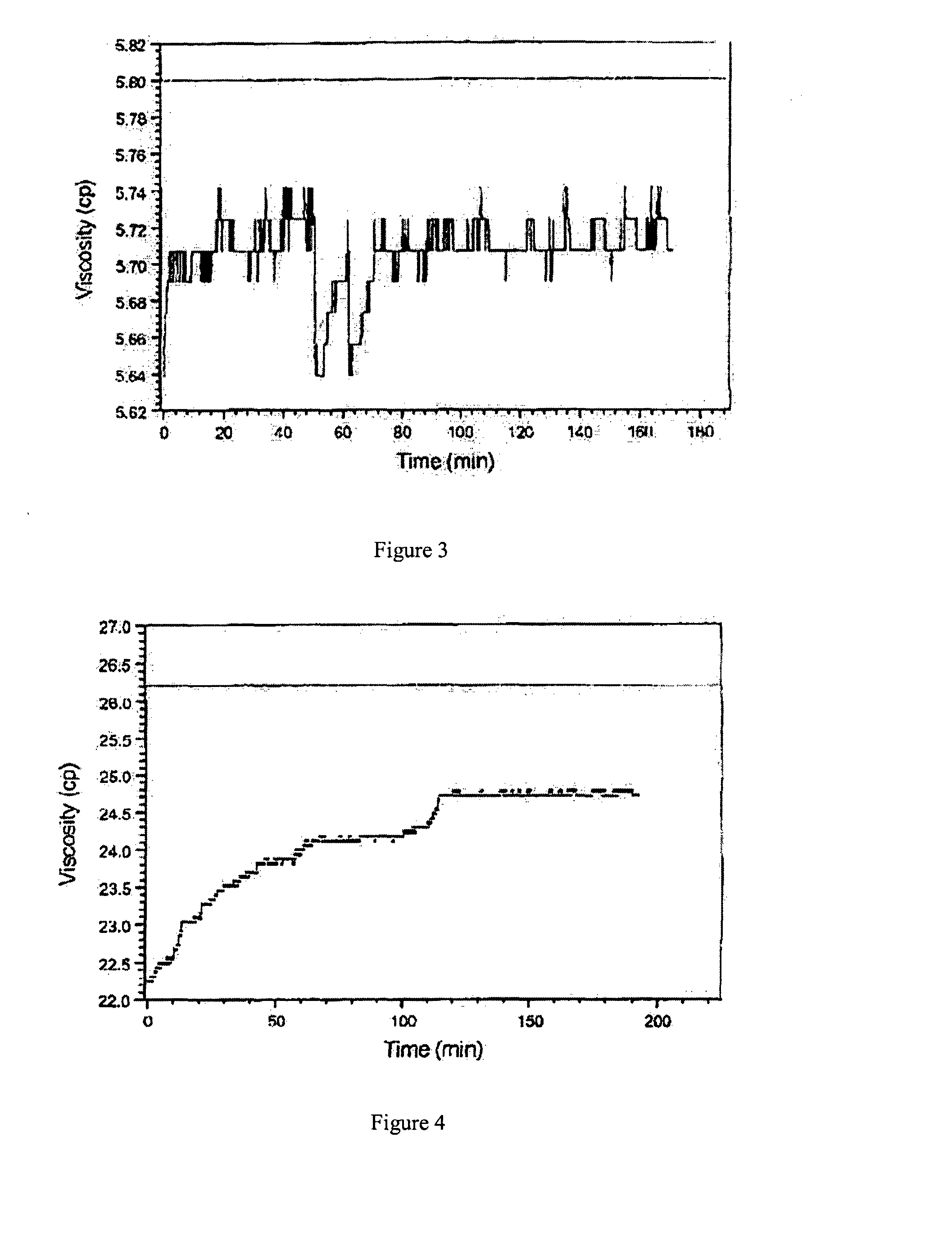

Method and Apparatus for Treatment of a Fluid

ActiveUS20080190771A1Reduce liquid viscosityReduce apparent viscosityElectrostatic separatorsSludge treatmentClassical mechanicsCritical magnetic field

An apparatus for the magnetic treatment of a fluid which produces at least one magnetic field for a period of time, Tc at or above a critical magnetic field strength, Hc, the period Tc and the field strength Hc determined relative to one another and dependant upon the properties of the fluid.

Owner:TEMPLE UNIVERSITY

Handheld printing ink viscosity controller

ActiveCN109318585AEasy to operateAdjustable viscosityPrinting press partsViscosity controlSolventPrinting ink

The invention discloses a handheld printing ink viscosity controller. The handheld printing ink viscosity controller comprises a shell; a probe part which is positioned below and is placed in a printing ink barrel which contains the printing ink to be detected for triggering vibration to produce an acoustic signal, and a processor which is positioned above the probe part and is used for calculating to obtain the viscosity value of the printing ink to be detected are arranged in the shell; the probe part converts the acoustic signal into an electric signal through a sensor and transmits the electric signal to the processor; the processor is used for controlling a solvent to be added into the printing ink barrel to regulate the viscosity of the printing ink according to the viscosity value;and a switch which is used for controlling the on-off state of the probe part, the sensor and the processor is arranged on the outside wall of the shell. The handheld printing ink viscosity controlleris convenient to operate and accurate in control, and can complete viscosity measurement and viscosity regulation synchronously; and moreover, the labour intensity can be reduced and the production efficiency can be improved to a certain degree.

Owner:CHANGDE JINPENG PRINTING

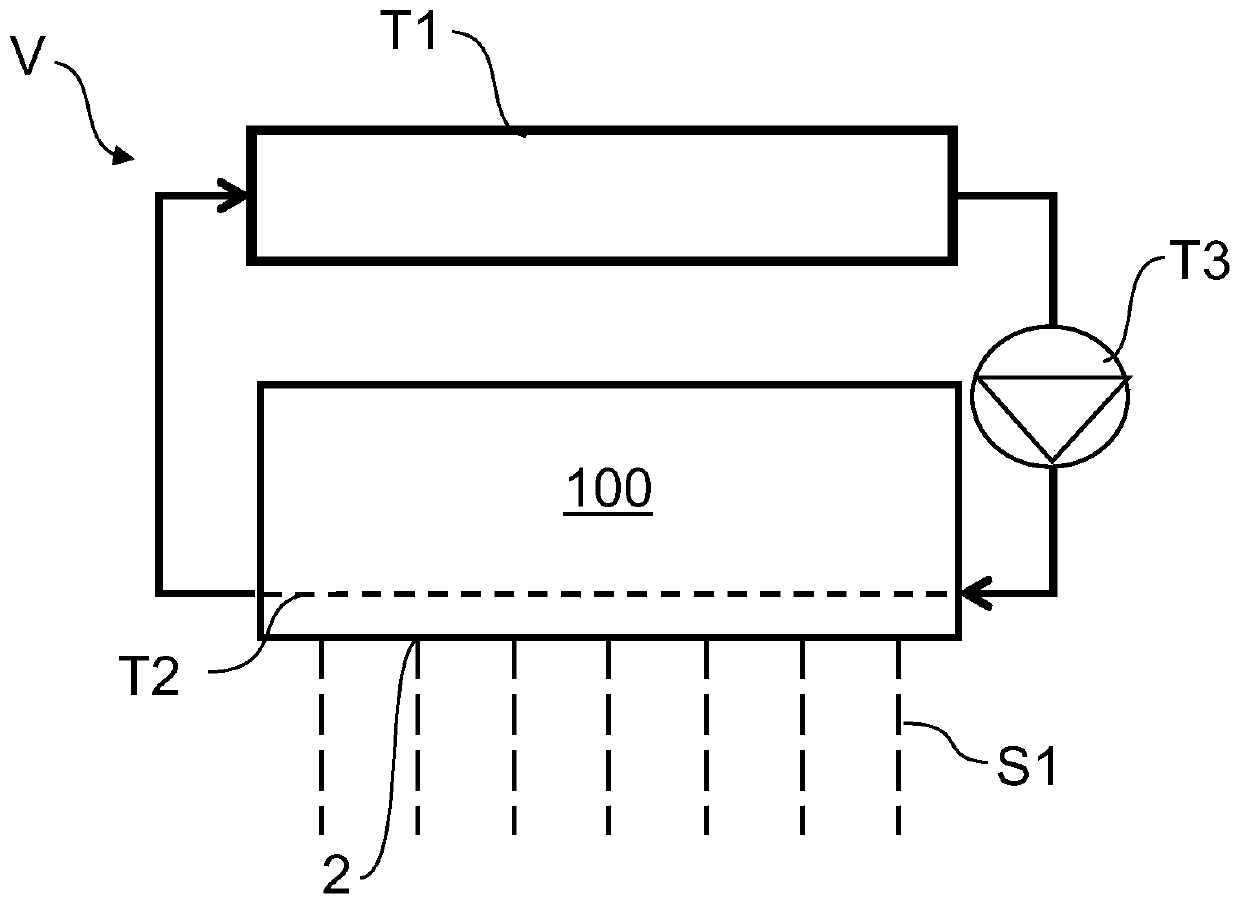

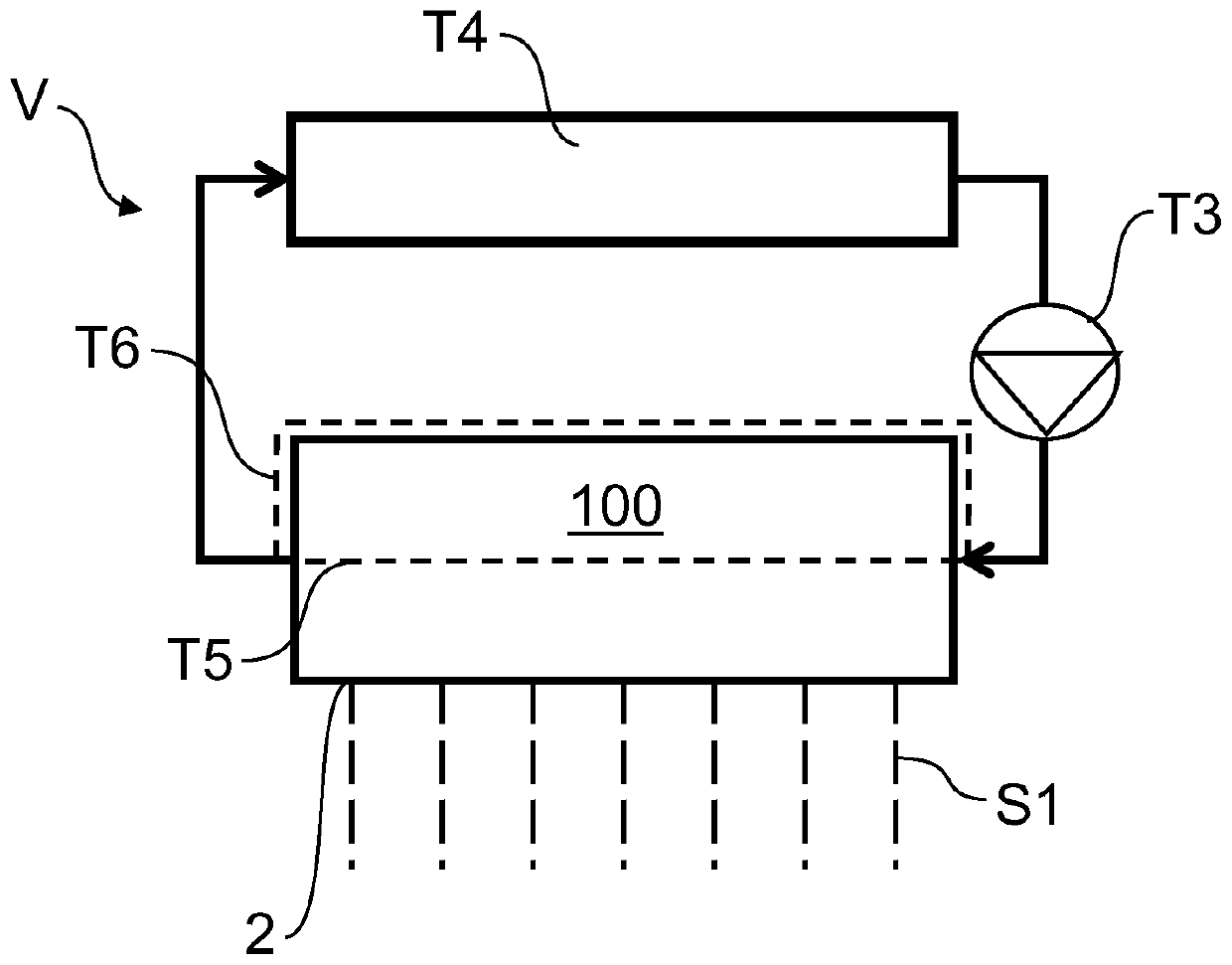

Printhead having a temperature-control device

ActiveCN110099750AConstant frame conditionAvoid or at least reduce application resultsInking apparatusLiquid surface applicatorsTemperature controlSpray nozzle

The invention relates to an application device (V) for applying an application agent to a component, preferably for applying a coat to a motor-vehicle body component. The application device (V) comprises a printhead (100) for preferably serially and / or continuously applying the application agent, wherein the printhead (100) has: a nozzle plate (1), at least one nozzle (2) in the nozzle plate (1) for dispensing the application agent, at least one valve element (9) movable relative to the nozzle plate (1) for controlling the dispensing of the application agent by means of the at least one nozzle(2), wherein the at least one movable valve element (9) closes the at least one nozzle (2) in a closed position and opens the at least one nozzle in an open position, and at least one drive (A) for moving the at least one valve element (9). The application device (V) is characterized in particular in that the application device comprises at least one temperature-control device (T1-T8) for reducing heating of the at least one drive (A) during the application of the application agent.

Owner:DUERR SYST GMBH

System and method capable of controlling viscosity of electric spindle lubricating fluid

ActiveCN102270002ASolve the problem of temperature riseAutomatic Viscosity ControlMaintainance and safety accessoriesViscosity controlElectricityLow speed

The invention discloses a system capable of controlling the viscosity of electric spindle lubricant and a method thereof. The system comprises an electric spindle, a monitoring module, a control module, a base fluid box, a thickening agent box, a liquid distribution module, a liquid supply module and a liquid return module. The monitoring module is used for monitoring the operation condition of the electric spindle and transmitting a monitoring signal to the control module. The control module is used for operating the monitoring signal to obtain a lubricant viscosity value required in a current working condition, converting the monitoring signal into a viscosity control signal and transmitting the viscosity control signal to the liquid distribution module. The liquid distribution module is used for configuring the base fluid in the base fluid box and the thickening agent in the thickening agent box into the lubricant with the required viscosity according to the viscosity control signal. The liquid supply module is used for pressurizing the lubricant, filtering and inputting to the electric spindle. The liquid return module is used for recycling the lubricant. According to the system and the method disclosed by the invention, the viscosity of the lubricant can be controlled in real time according to working conditions; the working condition application range of the electric spindle is enlarged; the system and the method are applicable from a low speed to a high speed and from light load to heavy load, therefore, the electric spindle can be born and lubricated by the lubricant with the proper viscosity; and the operation stability is improved.

Owner:TIANJIN UNIV

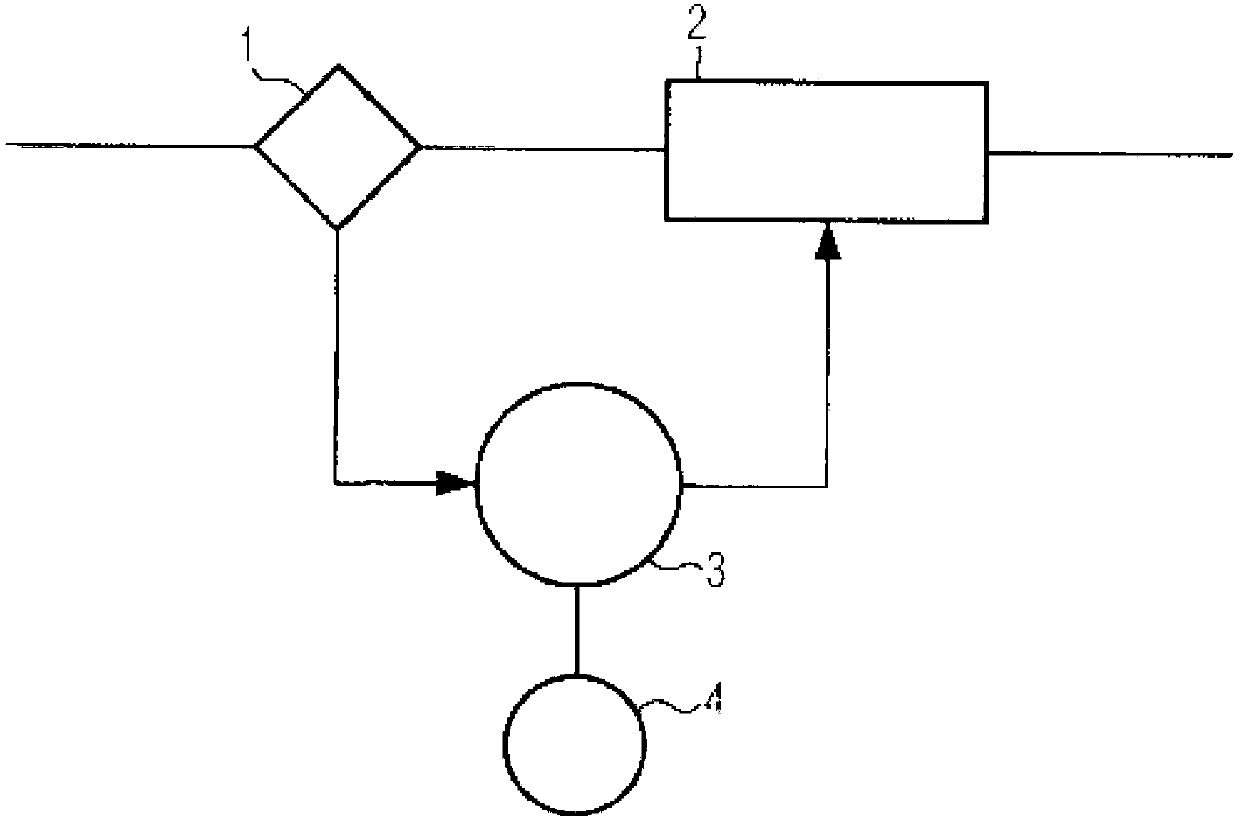

Colorant presentation for pad printing

InactiveUS20070070130A1Promote circulationMonitor viscosityRotary pressesViscosity controlPad printingEngineering

The present invention provides systems and methods for providing colorant to a colorant cup apparatus that is adjacent to a pad printing cliché. The fluid colorant is fed from a colorant container through a feed conduit to the cup and an inline viscometer external to the colorant container measures the viscosity of colorant within the feed conduit. A control mechanism can dispense colorant solvent into the colorant container based upon a viscosity measurement performed by the inline viscometer. The disclosed systems, colorant cups and methods are useful in the preparation of tinted contact lenses.

Owner:JOHNSON & JOHNSON VISION CARE INC

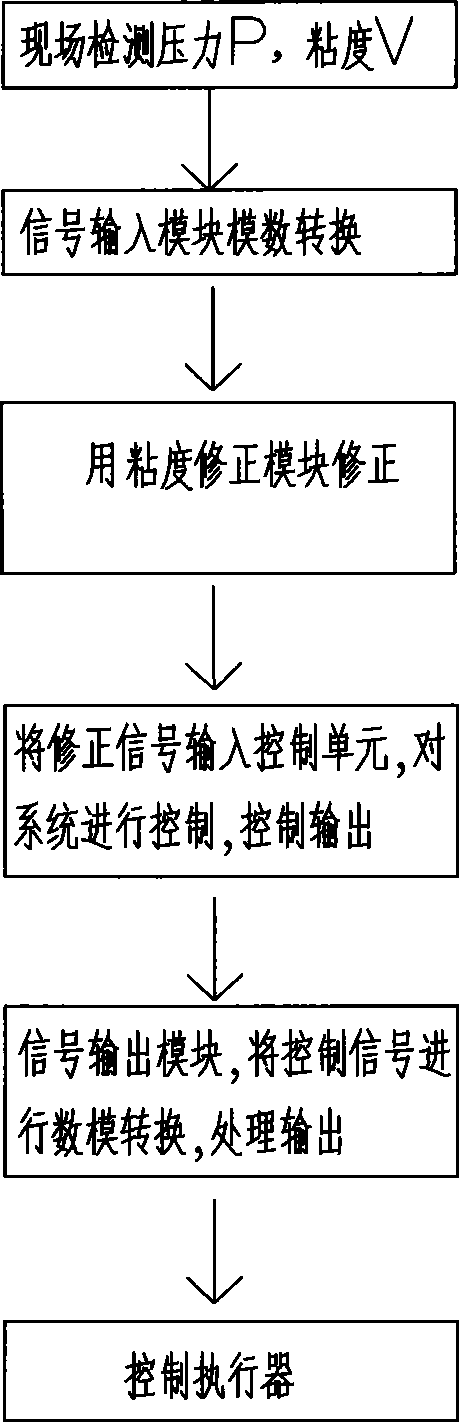

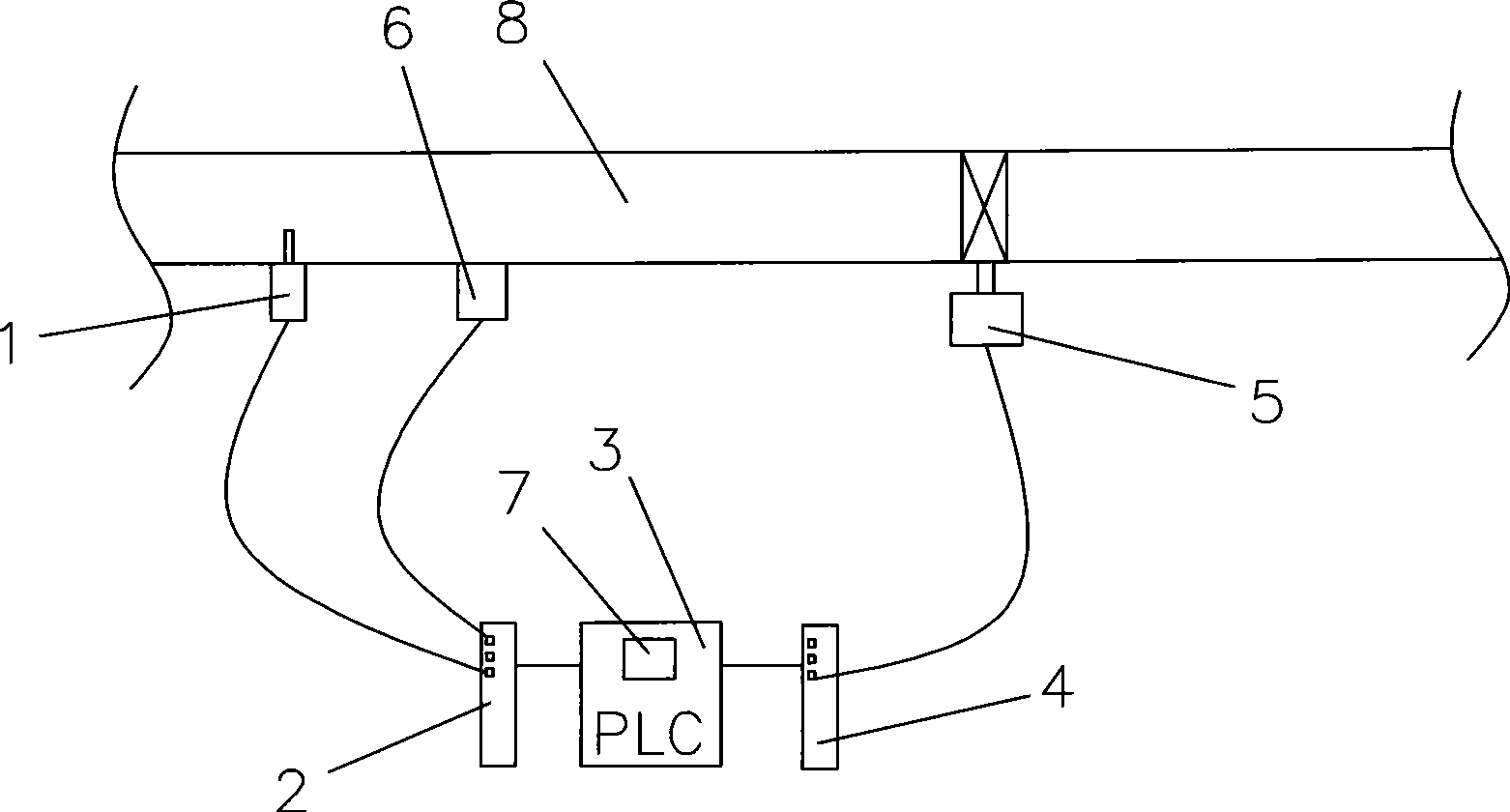

Polyester melt viscosity control system and control method thereof

The invention designs a polyester melt viscosity control system, mainly including a vibration-typed viscosity meter, a signal input unit, a control unit, a signal output unit and an actuator; the actuator is arranged on a polyester pipe; the vibration-typed viscosity meter is connected with the signal of the signal input unit; the signal output unit is connected with the actuator signal; a pressure detector is arranged on the polyester pipe; and the pressure detector and the vibration-typed viscosity meter are connected with a viscosity revising unit by signal. The control method of the control system adopts the viscosity signal of the melt in the polyester pipe which is detected by the vibration-typed viscosity meter and the pressure signal which is detected by the pressure detector as the detection signals, corrects the viscosity signal which is detected by the vibration-typed viscosity meter by making use of the relationship between the pressure and the viscosity in the polyester pipe, and uses the revised viscosity signal as a control signal to control the system; and the correction is carried out by a formula V=(1+K*((P-P0) / P0)) V (detection viscosity). The invention effectively eliminates the influence of the pressure fluctuation in the polyester pipe on the measurement of a viscometer.

Owner:XINFENGMING GRP HUZHOU ZHONGSHI TECH CO LTD

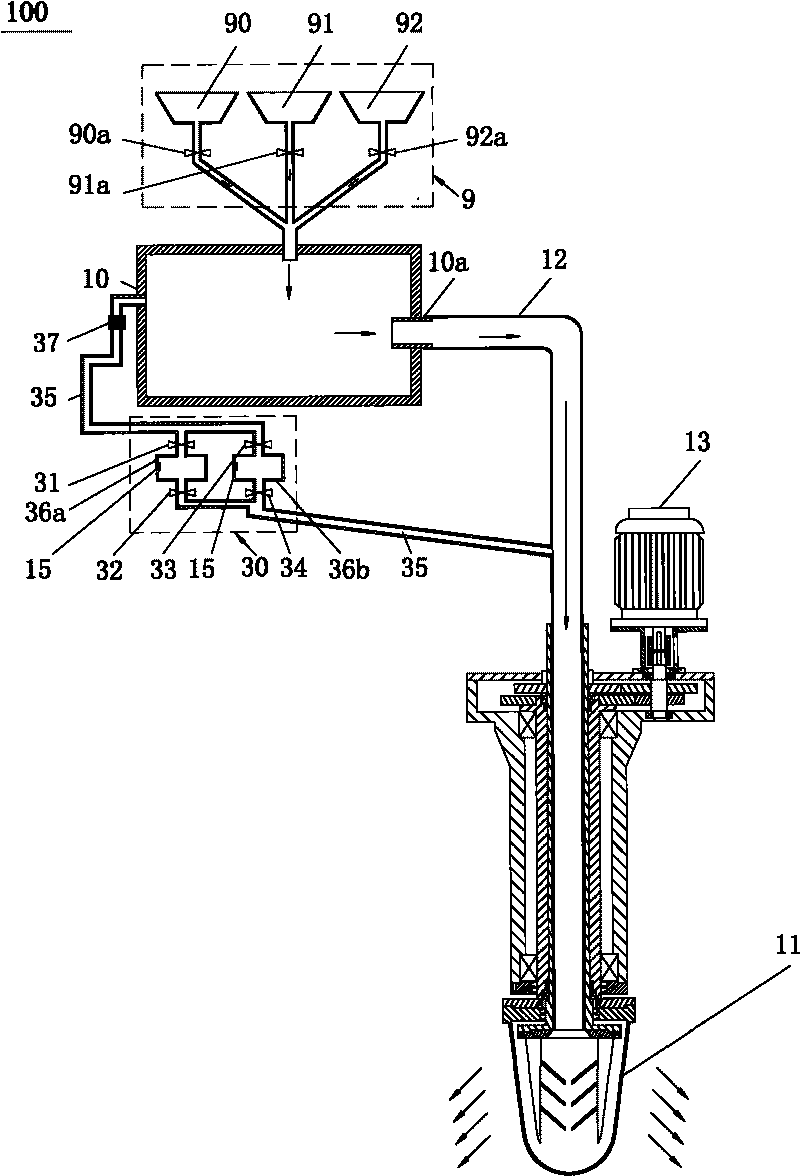

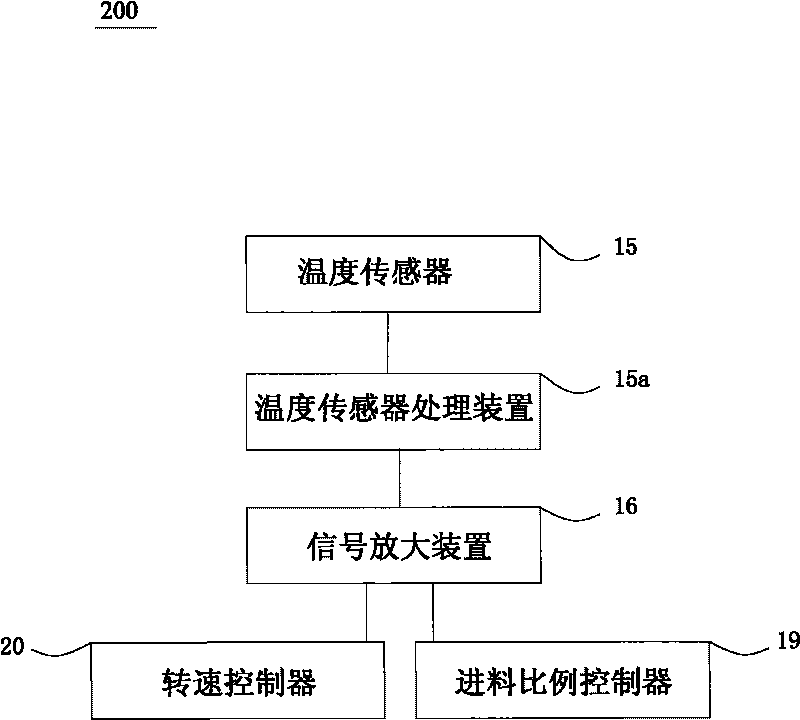

Compound fertilizer grain volume control system

ActiveCN101709019AIncrease speedHigh viscosityControlling ratio of multiple fluid flowsFertiliser formsProportional controlControl signal

The invention discloses a compound fertilizer grain volume control system comprising a feeding mechanism, a mixing trough, a rotary spray head, a slurry conduit, a rotary spray head motor and a control system. Compound fertilizer slurry in the mixing trough enters the rotary spray head driven by the rotary spray head motor for granulation through the slurry conduit. The control system comprises a temperature sensor device, a temperature sensor processing device, a signal amplifying device, a rotating speed controller and a feeding ratio controller, wherein the temperature sensor device outputs the detected temperature value of the compound fertilizer slurry in a mode of detecting current; the temperature sensor processing device receives the detecting current and forms a detecting current signal; and a control signal is formed through the signal amplifying device and output to the rotating speed controller and the feeding ratio controller so as to control the rotating speed of the spray head motor and the feeding ratio of the compound fertilizer slurry. The invention provides a compound fertilizer production system which can produce fertilizers with uniform volume of grains and is beneficial to improving the fertilization effect.

Owner:广东福利龙复合肥有限公司

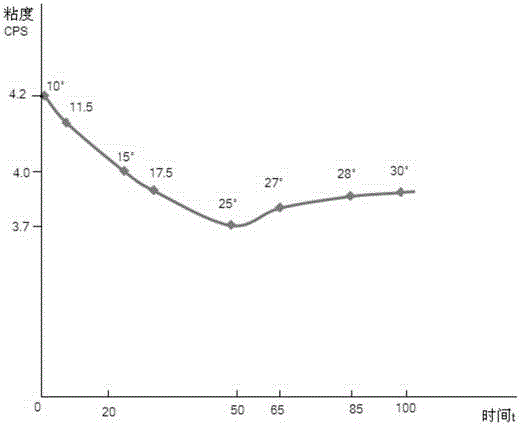

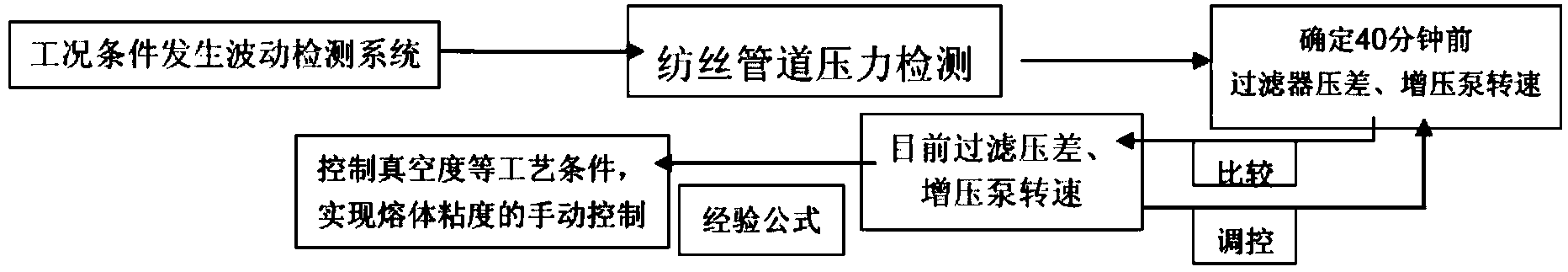

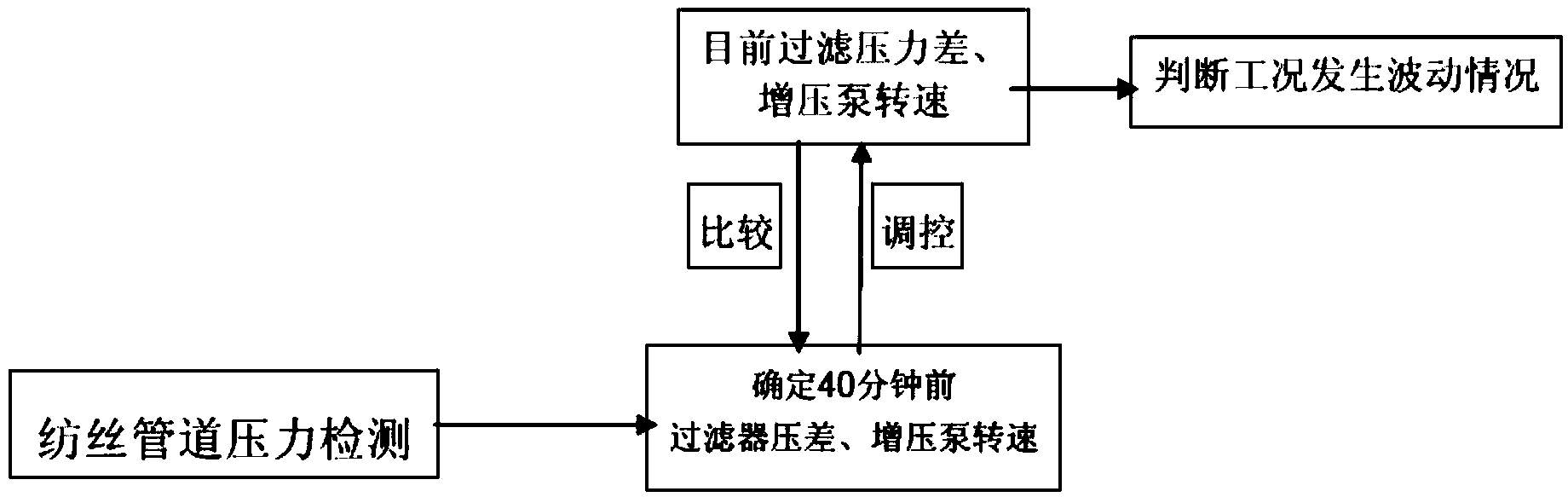

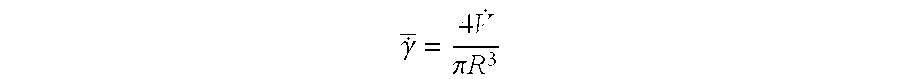

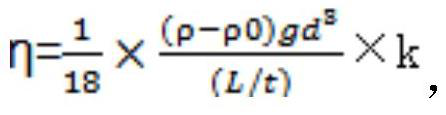

Novel method for manual viscosity control

ActiveCN103926957AAvoid Judgment InterferenceImprove stabilityFlow propertiesViscosity controlControl flowEngineering

The invention relates to a novel method for manual viscosity control. The novel method for the manual viscosity control is used for guiding melt viscosity control when production conditions are changed. The novel method for the manual viscosity control concretely comprises the following concrete control steps that abnormal production conditions are found; melt pressure in a pipeline is measured through a spinning pipeline pressure measurement system; the pressure difference of a filter and the rotational speed of a boost pump before 40 minutes are deduced; melt viscosity drop is calculated in a conversion mode through a pressure conversion formula I and a modification formula II of an actual viscosity change; the melt viscosity drop which is calculated in the conversion mode is used as production instructions to adjust the vacuum degree and other process conditions; manual control over melt viscosity is achieved. The novel method for the manual viscosity control has the advantages that the melt viscosity control is achieved by the adoption of the control method; the melt pressure change is measured on line, the melt viscosity drop is calculated in the conversion mode through the empirical formulas, and therefore the control over the melt viscosity is finally achieved; in this way, the novel method further has the advantages that equipment investment costs are low, installation is simple, and operation is convenient.

Owner:浙江佳人新材料有限公司

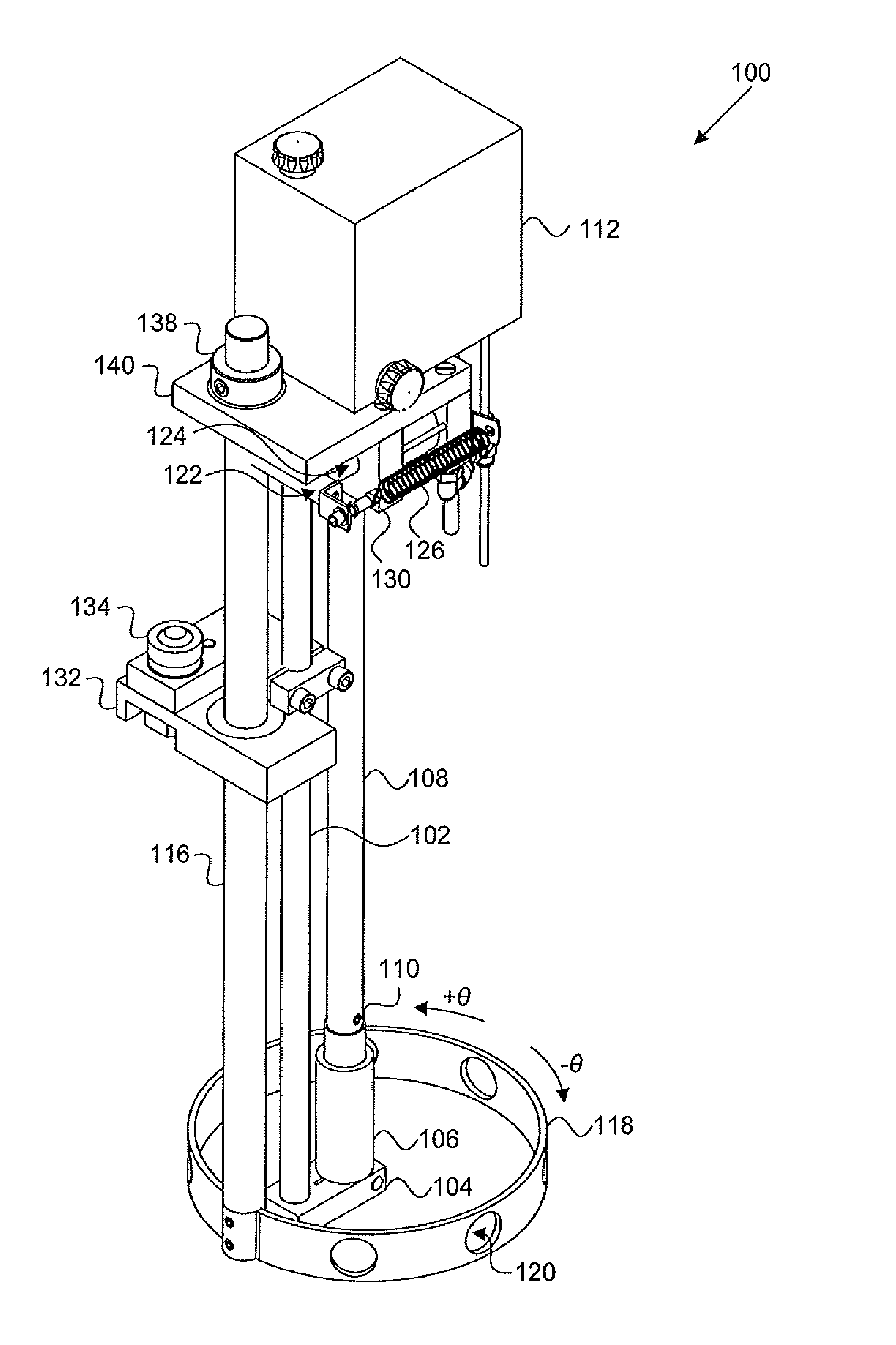

Mixers for a viscometer and methods for using the same

InactiveUS8313230B2Shaking/oscillating/vibrating mixersControlling ratio of multiple fluid flowsControl systemEngineering

The present invention is directed to mixers for viscometers and methods of using the same. Such inventions are applicable, for example, to industrial processes such as printing. One embodiment of the invention is directed to a viscosity control system including a viscosity sensor, a mixing element, a shaft fixedly attached to the mixing element, and an actuator interfacing with the viscosity sensor and the shaft. The annular mixing element is oscillatable about an axis lying in a plane tangent to a point on a wall of the mixing element. The shaft is centered about the axis. The actuator receives a signal from the viscosity sensor and rotates the shaft and the mixing element in an oscillating manner about the axis. In some embodiments, the shaft rotates through an angle of less than 360 degrees.

Owner:SAINT CLAIR SYST INC

Viscosity-controlled processing of liquid food

Owner:KRONES AG

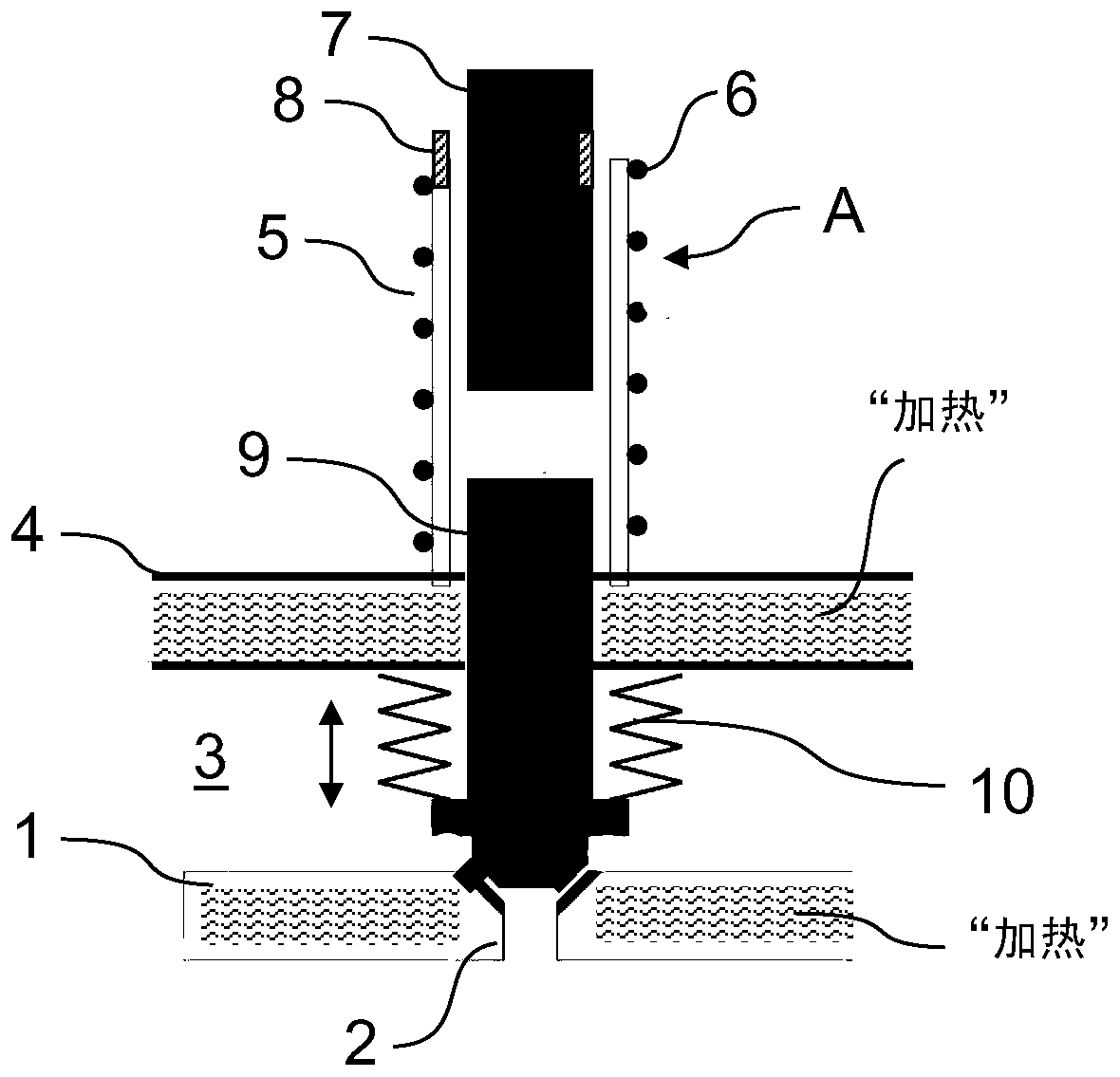

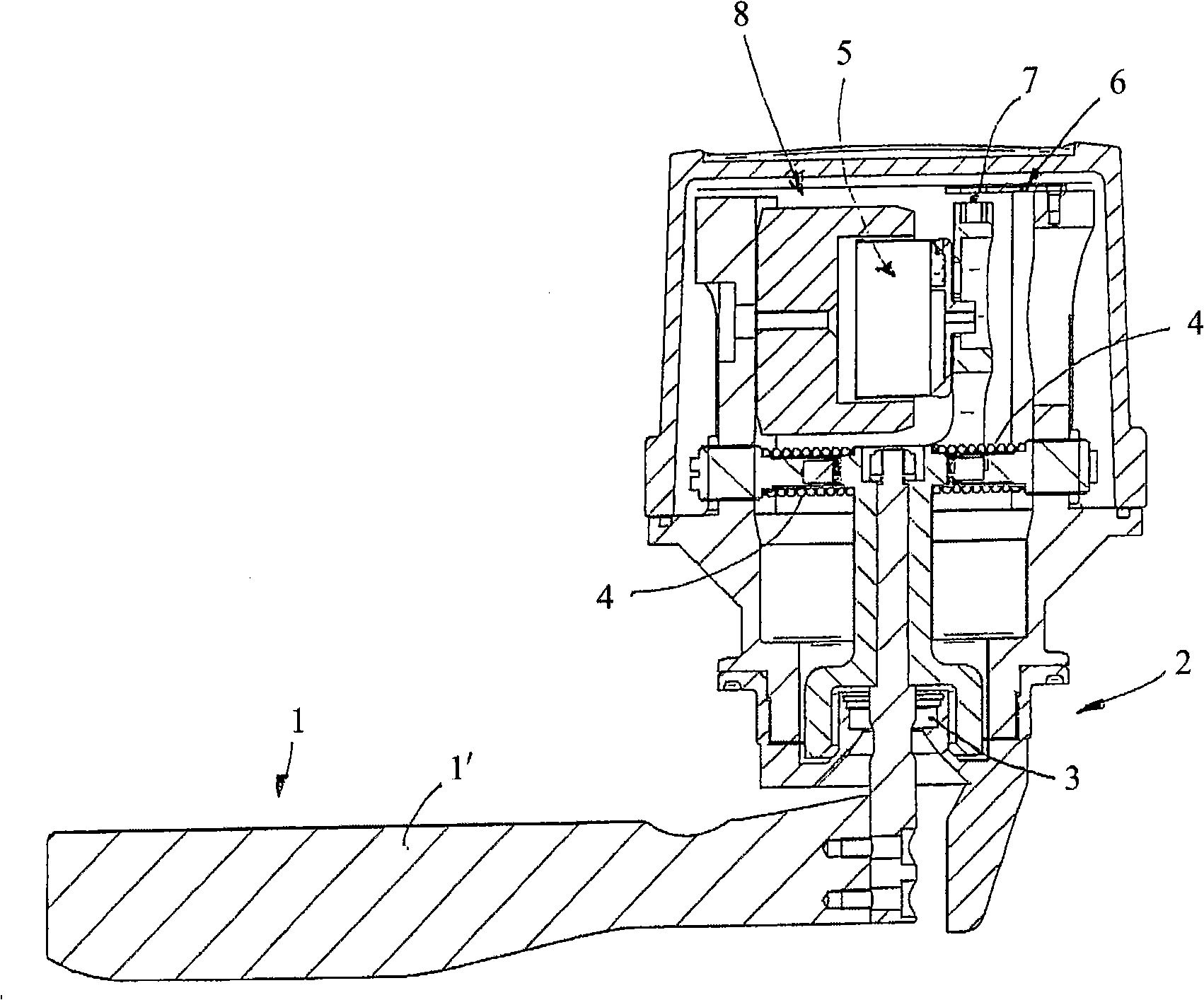

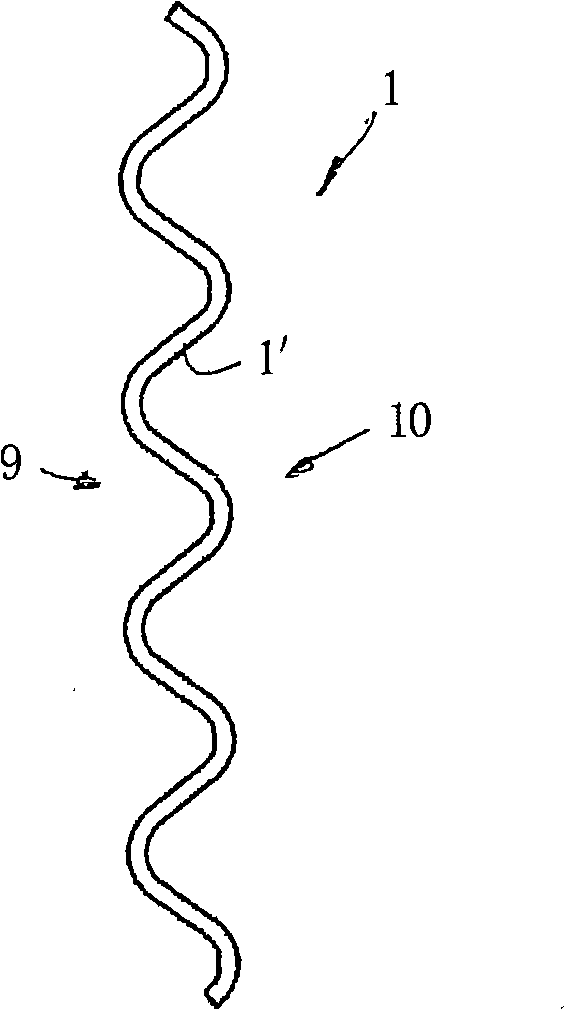

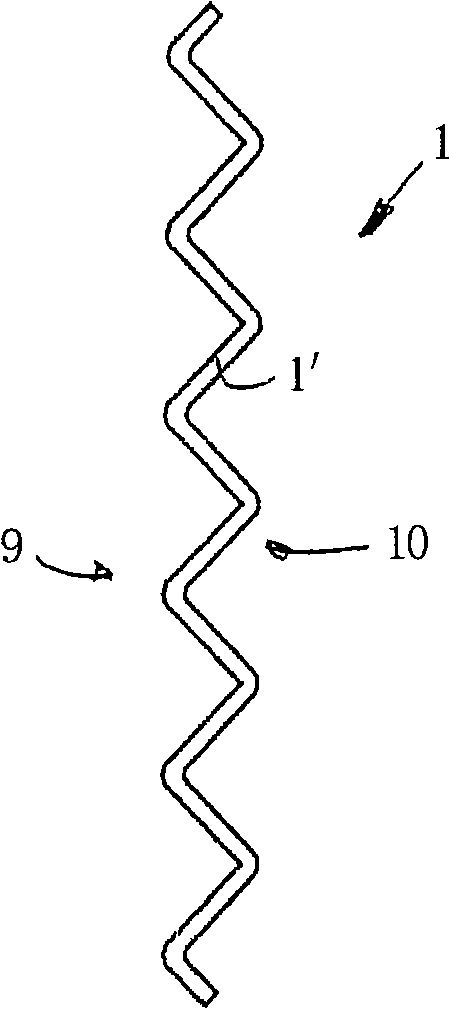

Vibrating transmitter for consistency measurement

The invention relates to a transmitter for consistency measuring of pulp suspensions at first hand, comprising a measuring body (1), shaped such as a blade, suspended in a vibration-producing apparatus. The measuring body (1) shaped such as a blade (I' ) shows wave-shaped side surfaces (9, 10) in its transverse direction and is vibratable in a frequency of oscillation between 20-80 Hz and with a predetermined amplitude of + / - 2-8 mm, that provides a combination of both shearing force measurement and a measurement of the resistance of conveyance of liquid through a fibre netting.

Owner:BTG PULP & PAPER SENSORS

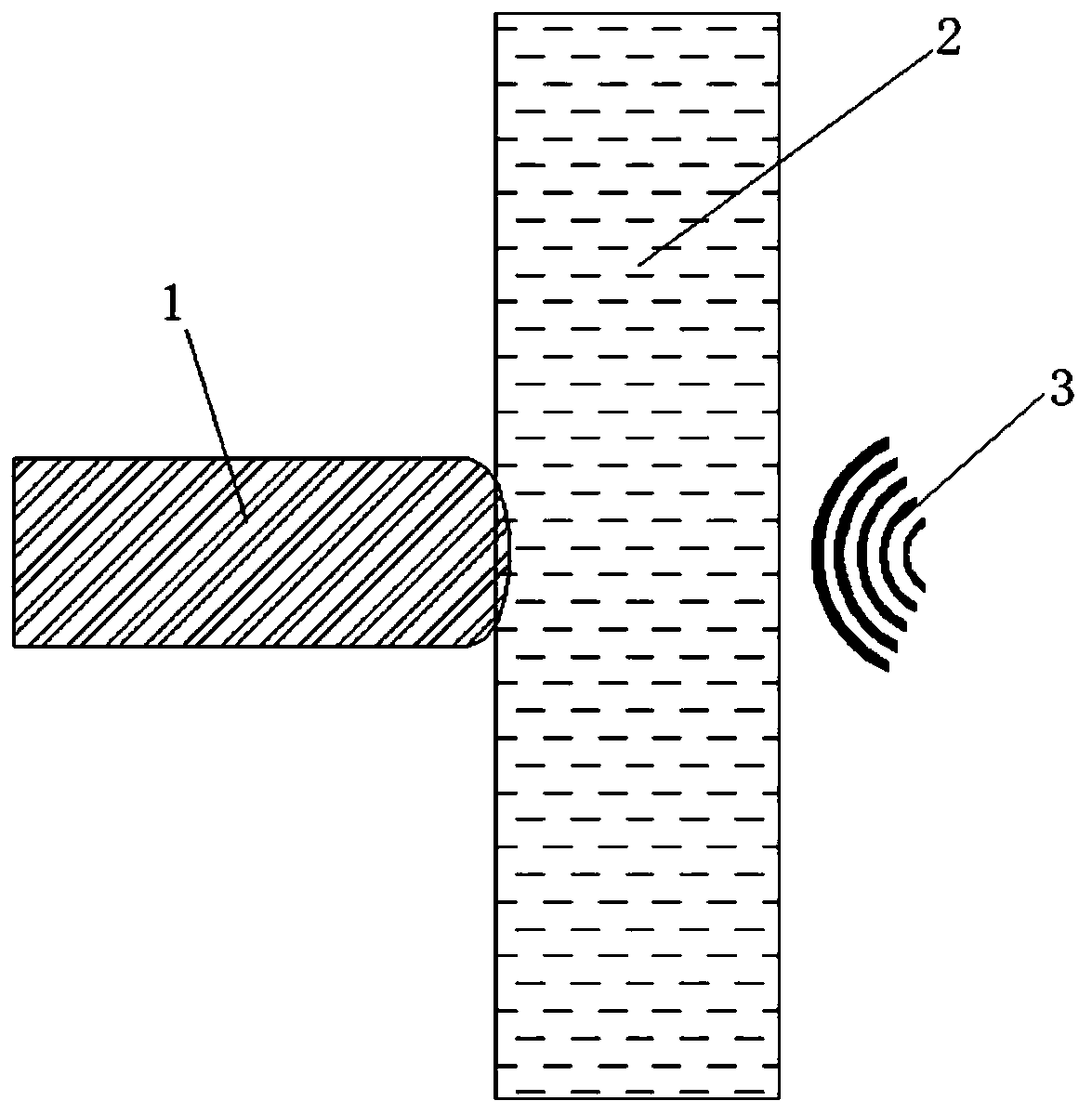

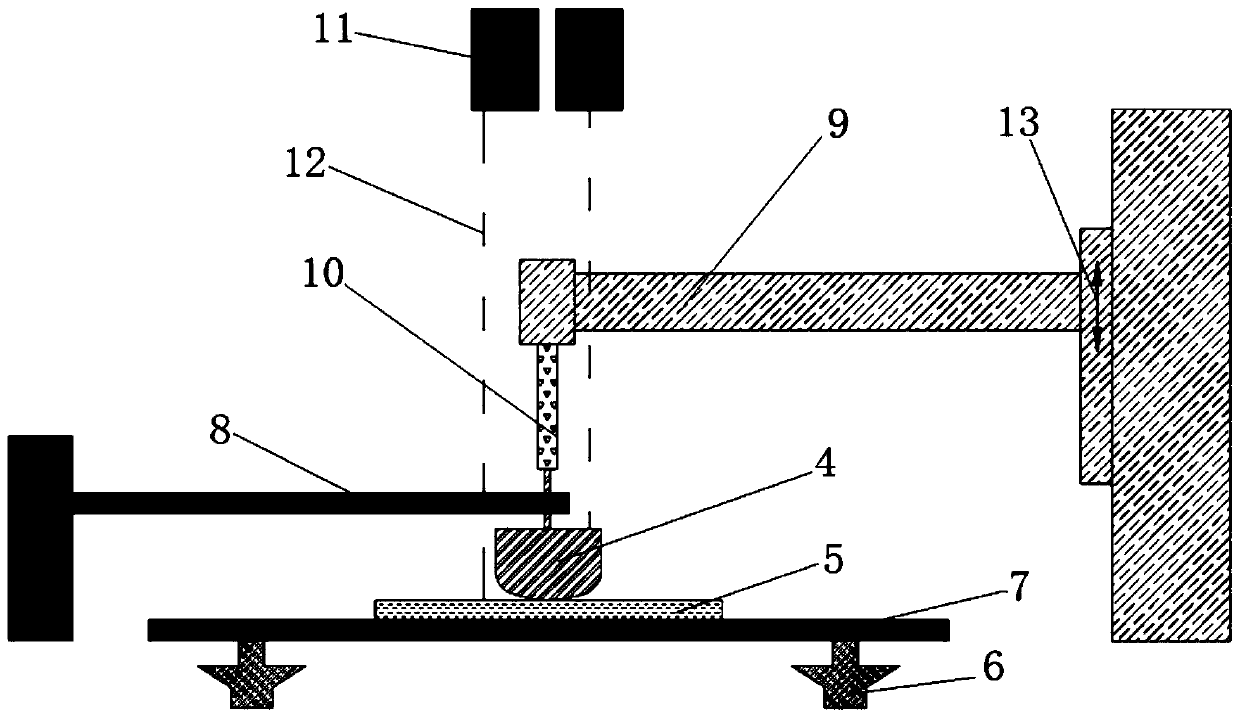

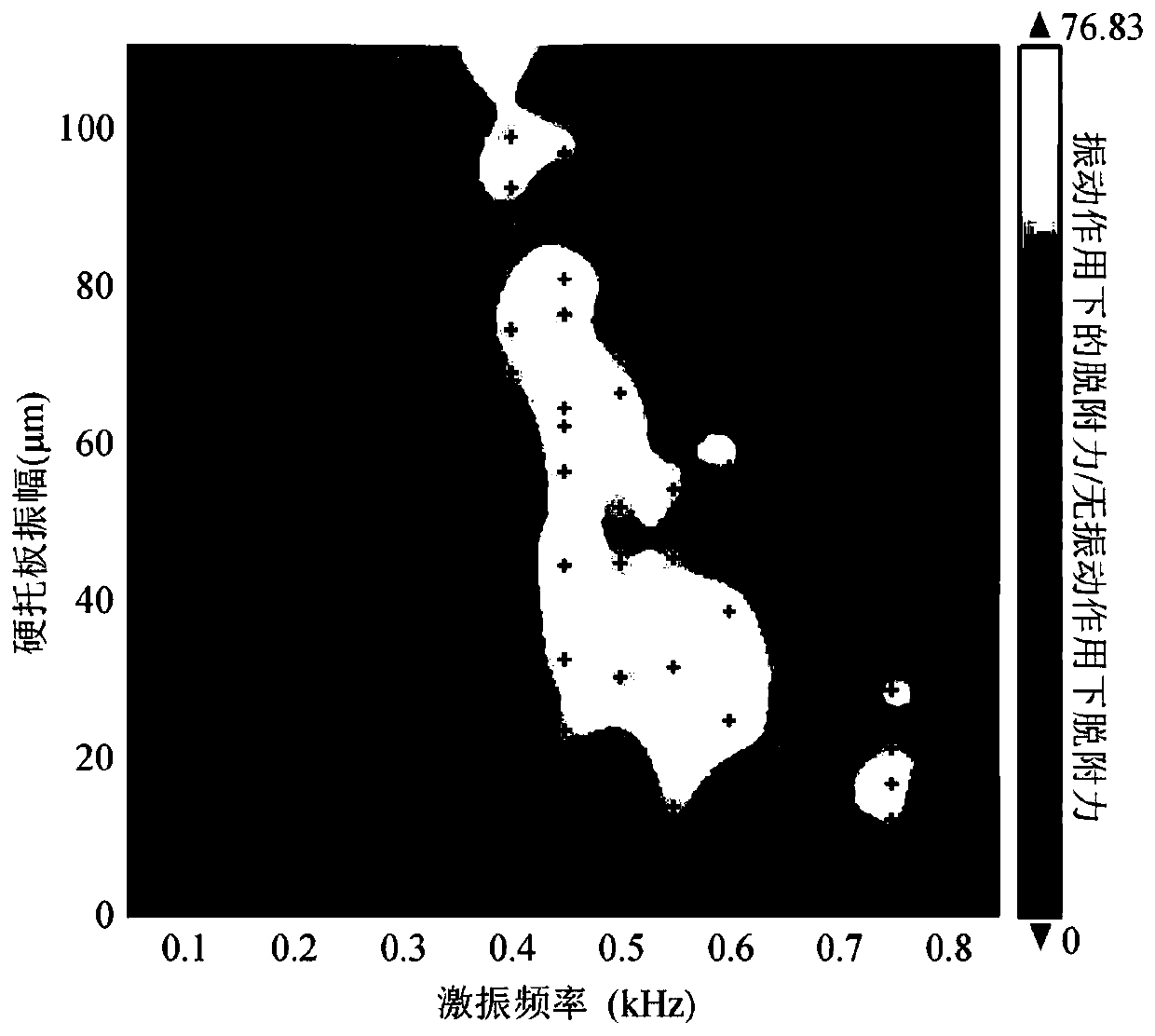

Method and test device for mechanically controlling object surface/interface adhesion strength

ActiveCN110865025AAdhesion strength increases or decreasesEasy to implementUsing mechanical meansMaterial analysisInterfacial adhesionAdhesion strength

The invention discloses a method and test device for mechanically controlling the object surface / interface adhesion strength. According to the method in the invention, on the premise of being independent of an object surface micro-structure, two object surfaces having the adhesion effect are contacted together, so that a contact pair is formed; two objects of the contact pair are stimulated to perform relative mechanical vibration; therefore, the contact area of the contact pair changes over time; and the object surface / interface adhesion strength is controlled by changing the excitation frequency or the amplitude. The method is simple to implement and high in controllability; the method is independent of the surface / interface micro-structure, and has universality; the adhesion strength control effect is obvious; and the fact that the contact interface adhesion strength is greatly increased or decreased can be realized.

Owner:WUHAN UNIV

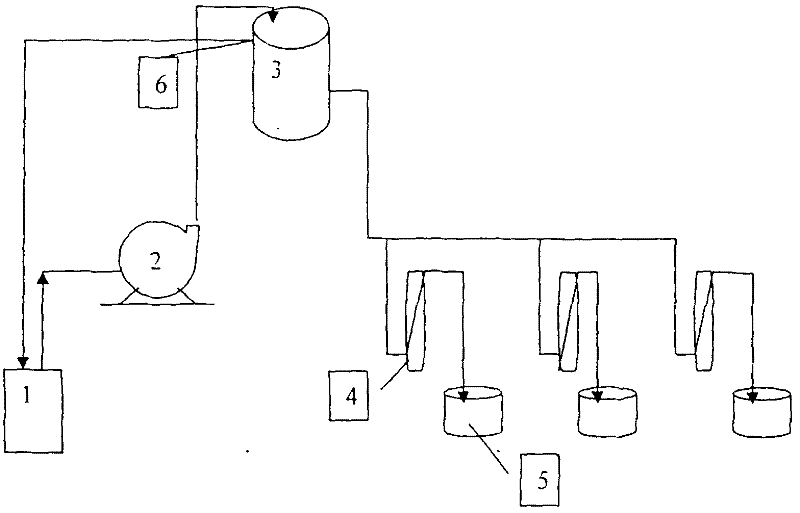

Viscosity precise control device

Viscosity precision control device, involving precise solvent control technology, including raw material tank, solvent delivery pump, several flowmeters and ink basins, the flowmeters in front of each ink basin are connected to a high-level storage tank by the same connecting pipe, and the solvent delivery pump The output pipe is connected to the top of the high-level storage tank. Through this device, the ink viscosity of the ink basin can be controlled within ±0.2 seconds (Zai En 4#), and the color difference ΔE≤0.5.

Owner:JIANGSU LIBA ENTERPRISE JOINT STOCK

Automatic glue viscosity adjusting system

InactiveCN112387545AHigh viscosityImprove performanceLiquid surface applicatorsCoatingsAdhesive glueMechanical engineering

The invention relates to an automatic glue viscosity adjusting system which comprises a viscosity detecting device, a control device and a diluent supplementing device. The viscosity detecting devicecomprises a sampling pipe extending downwards into glue in a sampling vessel, and a sampling rod component is arranged in the sampling pipe. The sampling rod component comprises a sampling rod, wherein the lower end of the sampling rod is provided with a sampling piston which is connected with the inner side of an opening in the lower end of the sampling pipe in a sealed sliding mode, the upper end, extending out of the upper end of the sampling pipe, of the sampling rod is provided with a signal triggering plate, and the signal triggering plate is in transmission connection with a sampling air cylinder. The control device comprises a PLC, a lower signal sensor and an upper signal sensor, wherein the lower signal sensor is arranged below the upper signal sensor. The automatic glue viscosity adjusting system adopts the scheme of automatically adding the diluent according to the glue viscosity measured in real time, and the automatic glue viscosity adjusting system has the advantages ofstable glue viscosity, stable product performance and high product quality.

Owner:上海远沙电子科技有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com