Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

161results about "Oblique crank gearings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

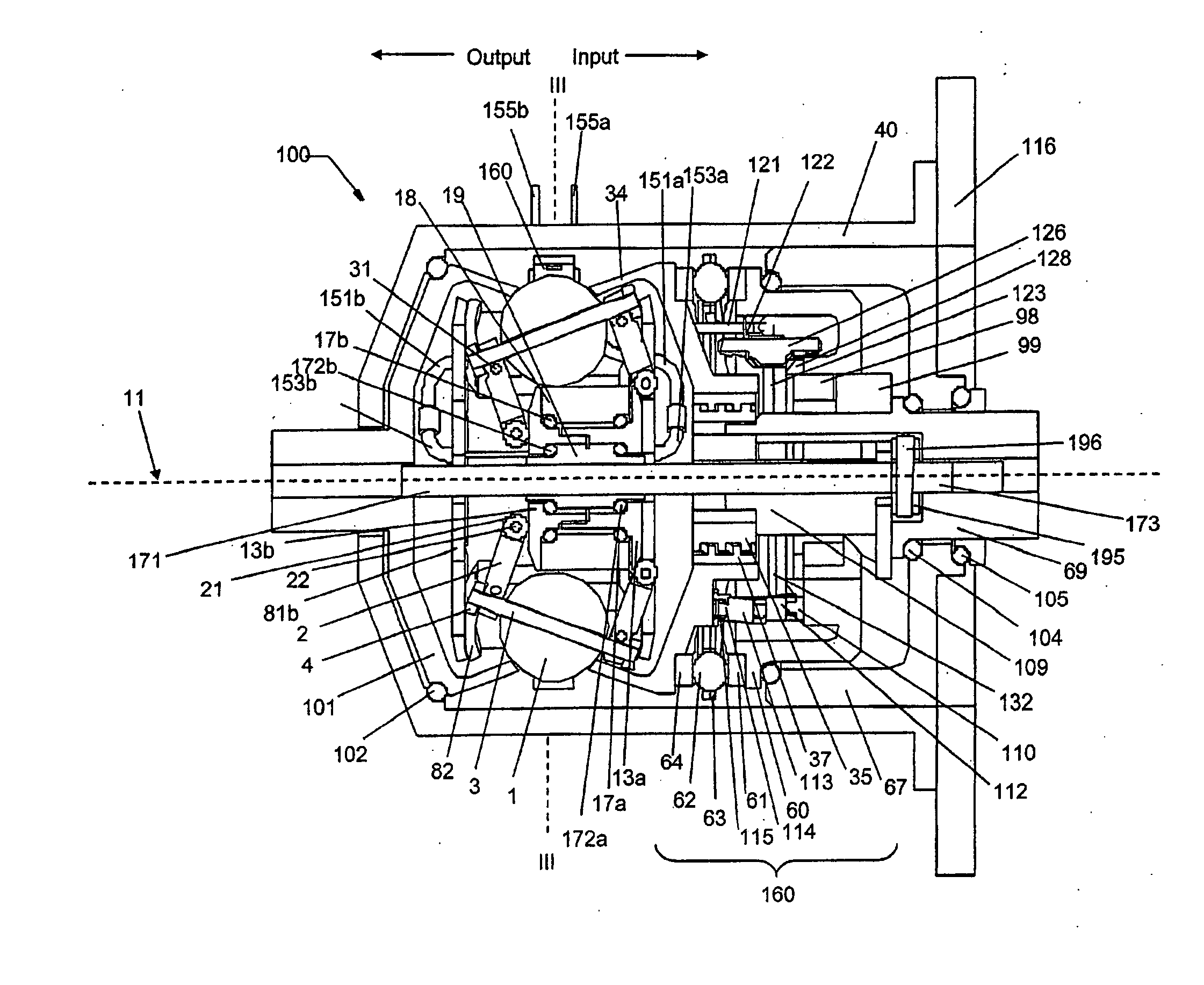

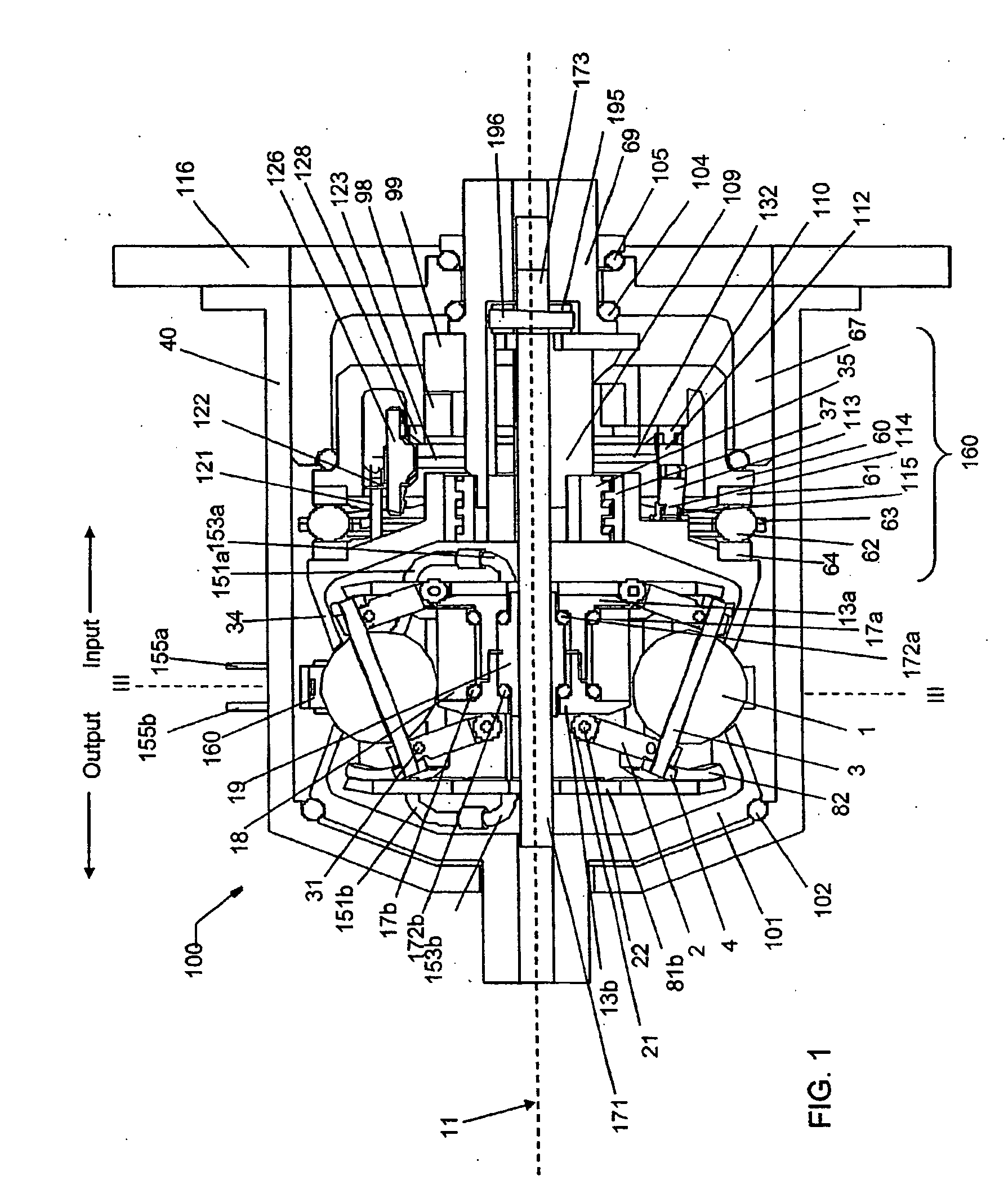

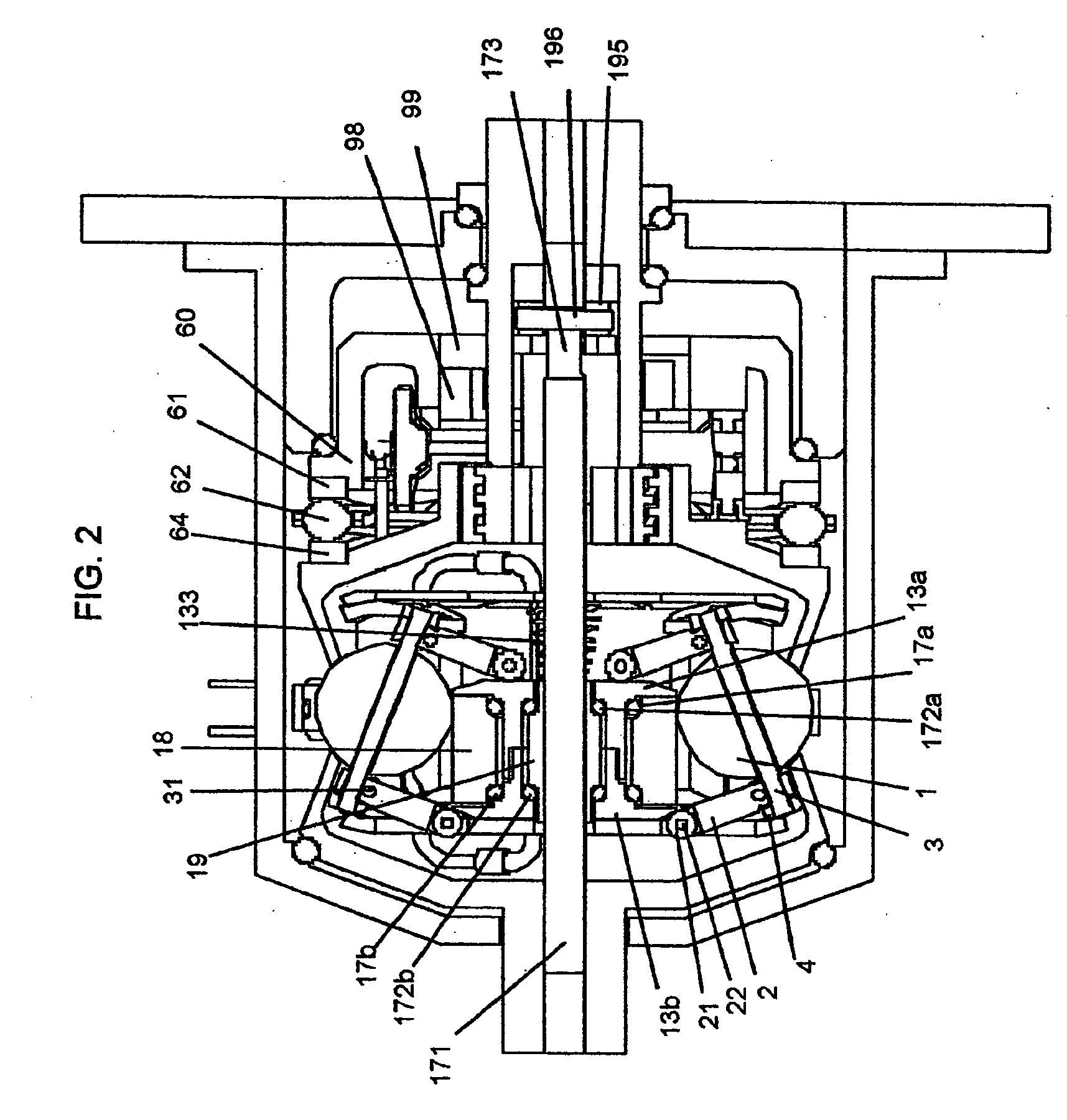

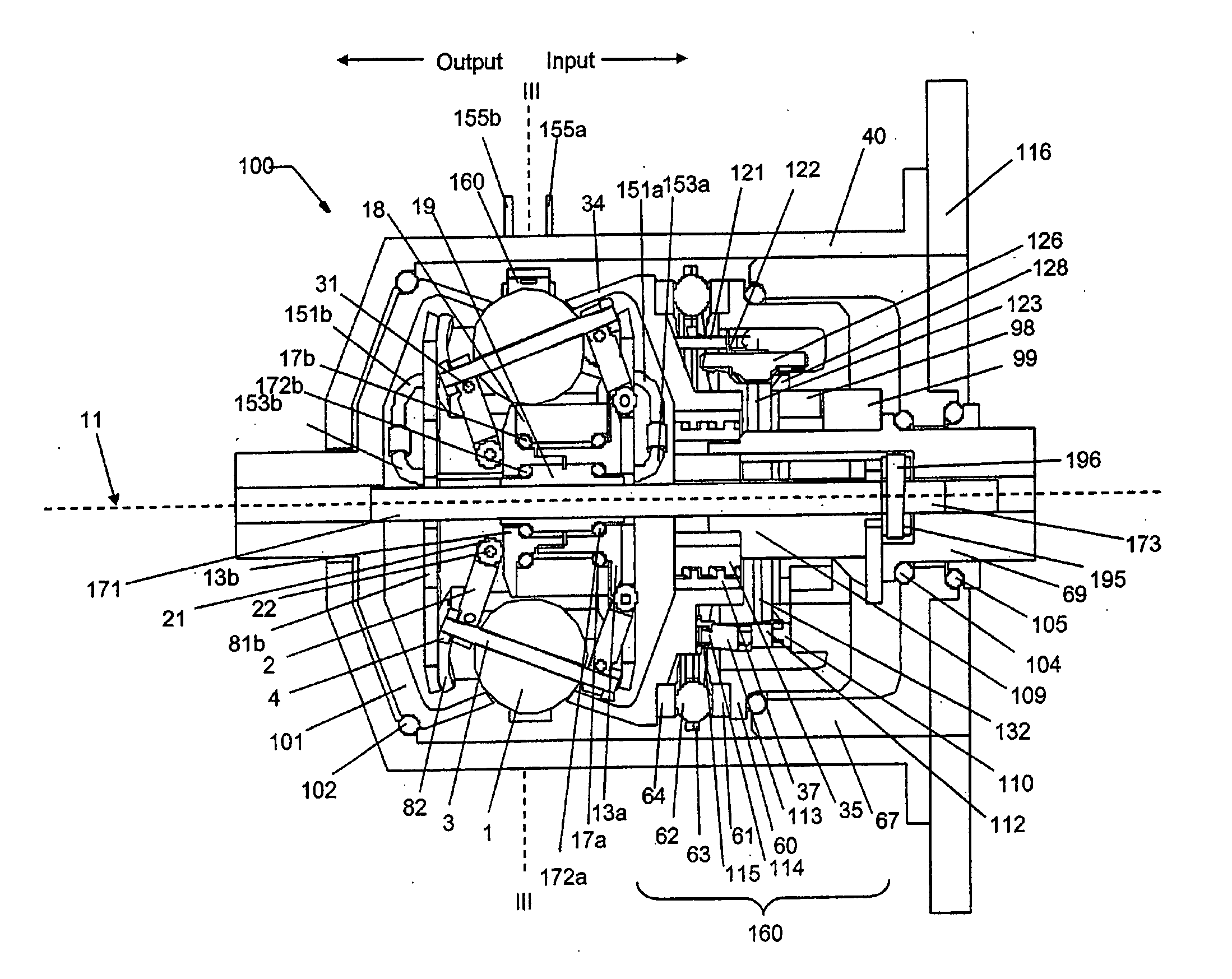

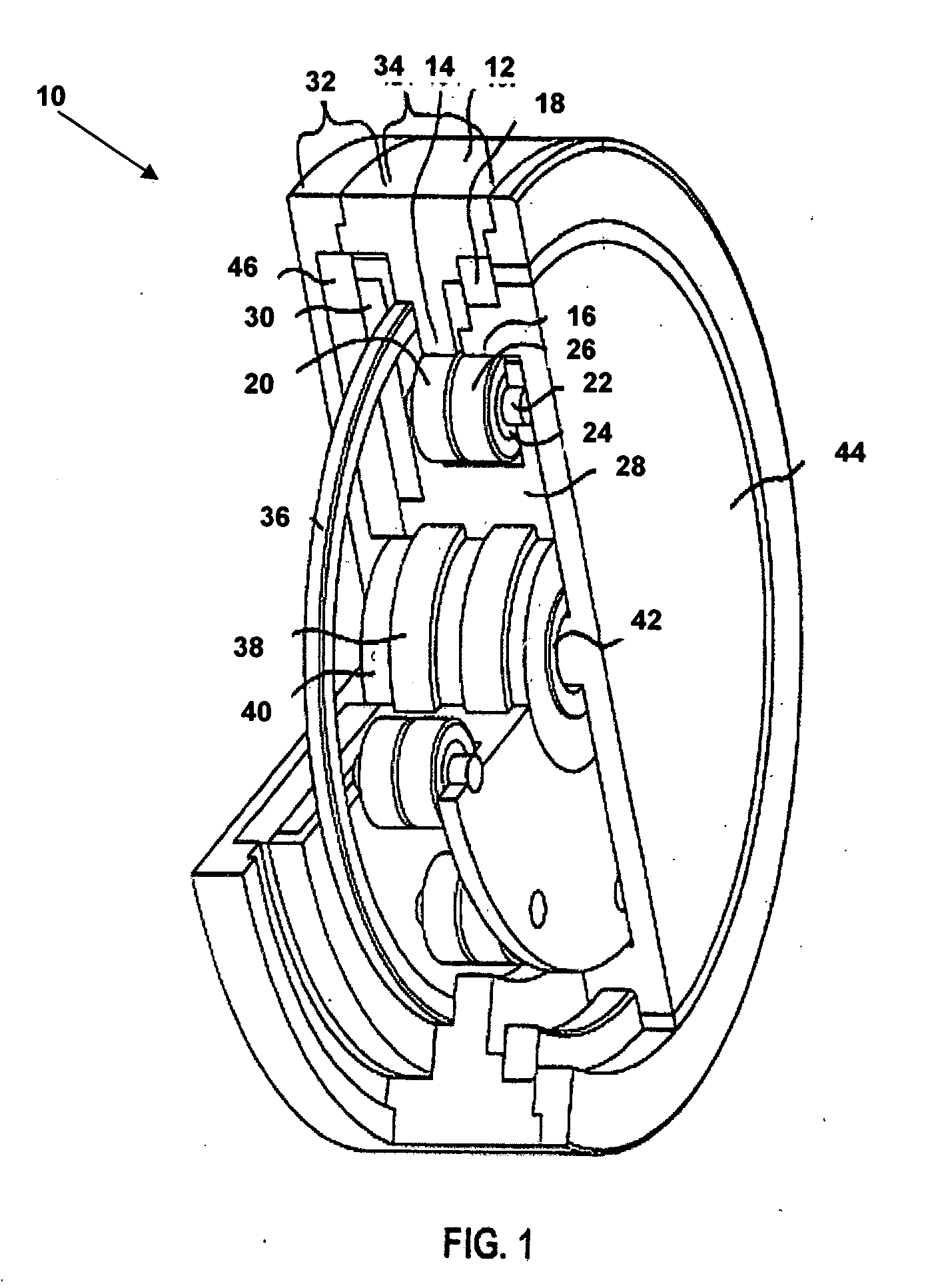

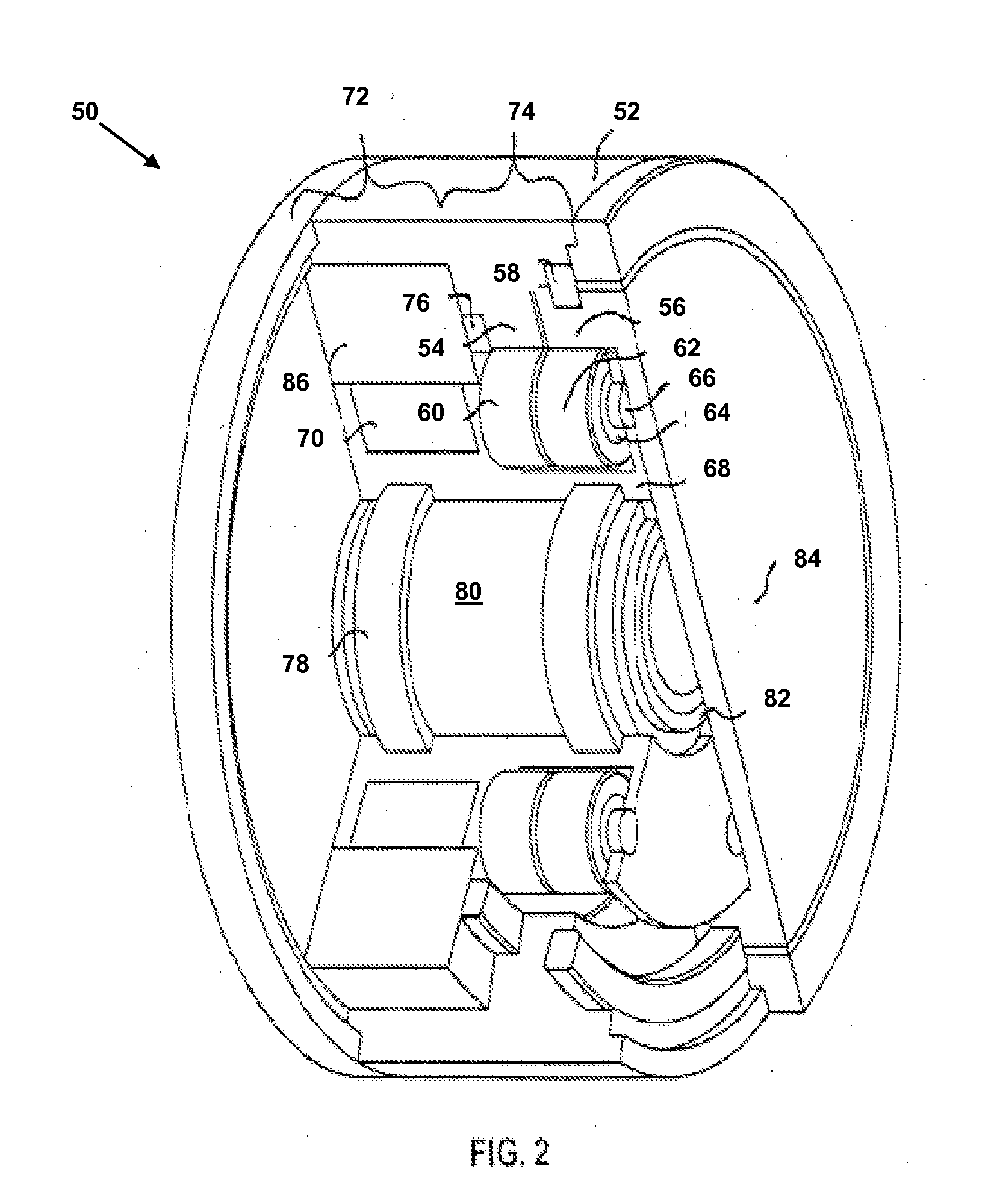

Continuously variable transmission

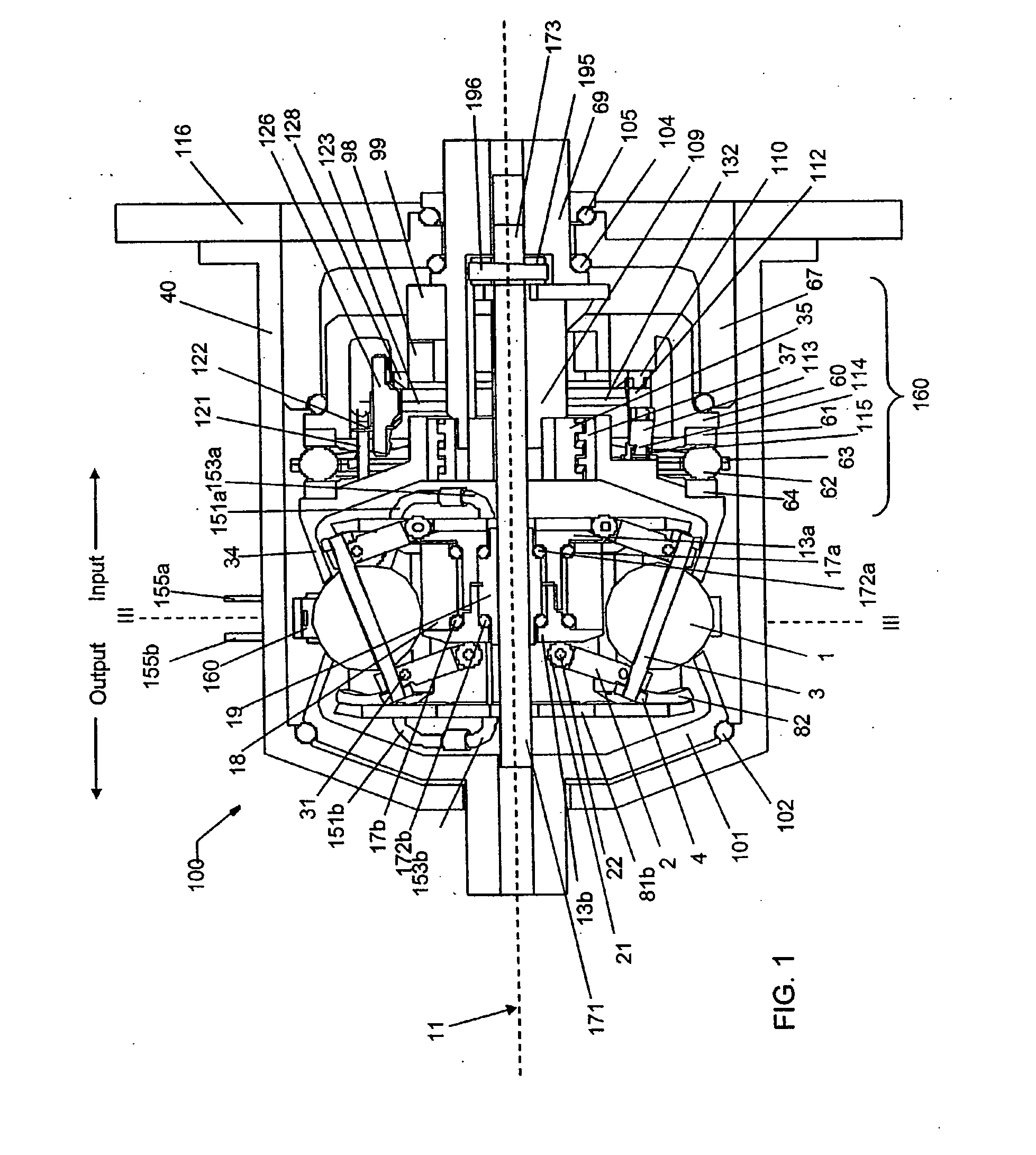

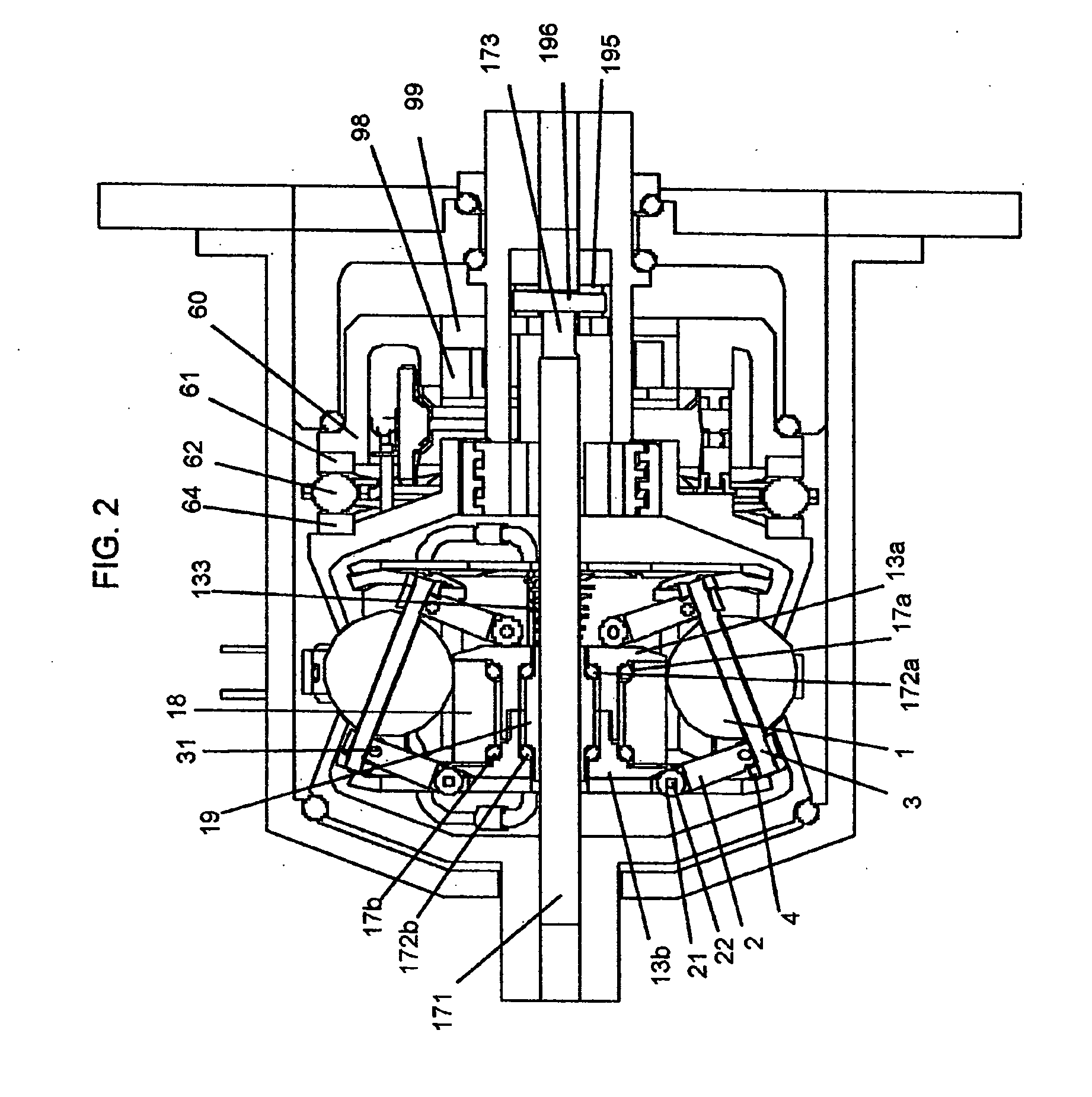

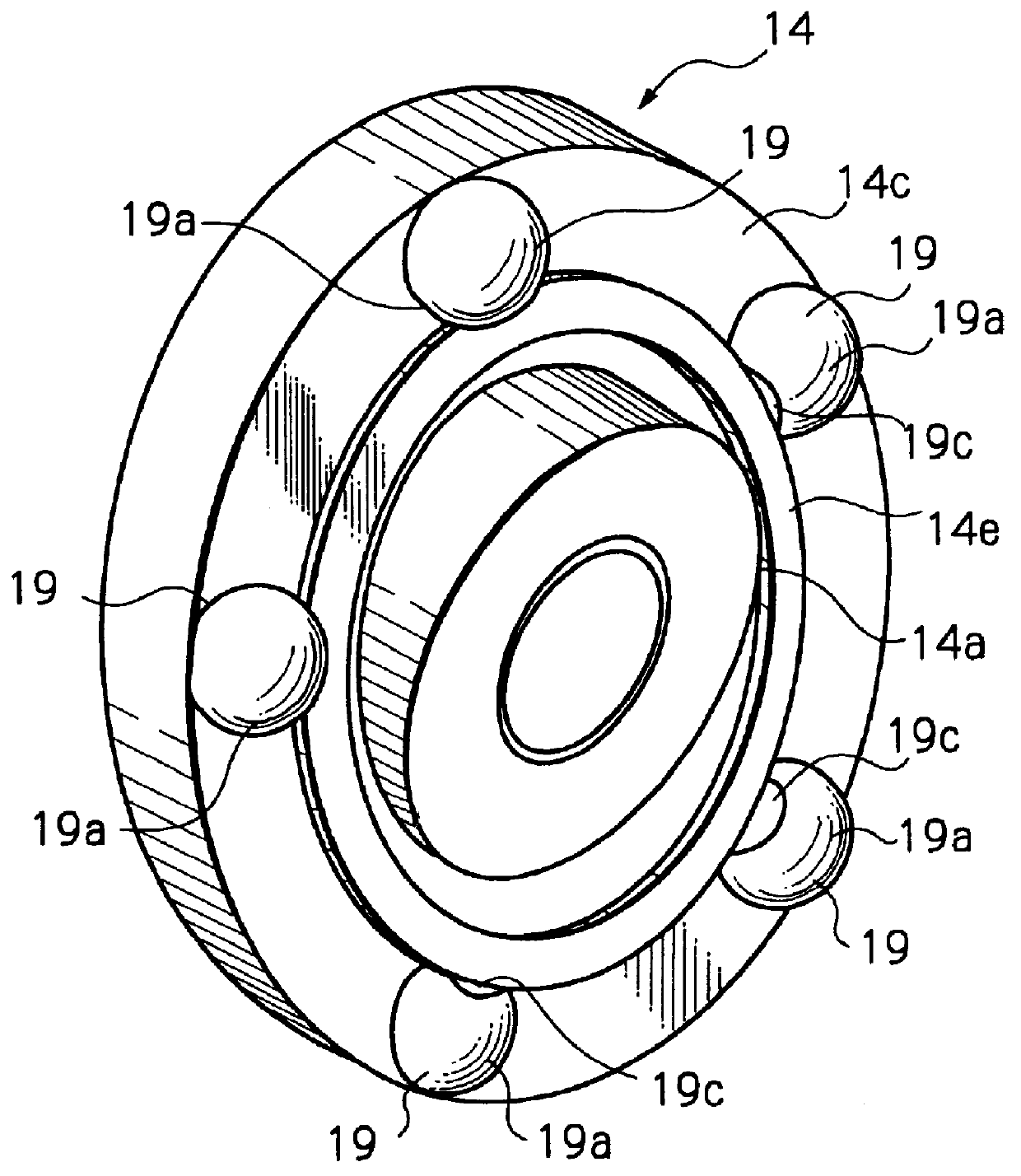

A variable speed transmission having a plurality of tilting balls and opposing input and output discs is illustrated and described that provides an infinite number of speed combinations over its transmission ratio range. The use of a planetary gear set allows minimum speeds to be in reverse and the unique geometry of the transmission allows all of the power paths to be coaxial, thereby reducing overall size and complexity of the transmission in comparison to transmissions achieving similar transmission ratio ranges.

Owner:FALLBROOK INTPROP COMPANY

Continuously variable transmission

A variable speed transmission having a plurality of tilting balls and opposing input and output discs is illustrated and described that provides an infinite number of speed combinations over its transmission ratio range. The use of a planetary gear set allows minimum speeds to be in reverse and the unique geometry of the transmission allows all of the power paths to be coaxial, thereby reducing overall size and complexity of the transmission in comparison to transmissions achieving similar transmission ratio ranges.

Owner:FALLBROOK INTPROP COMPANY

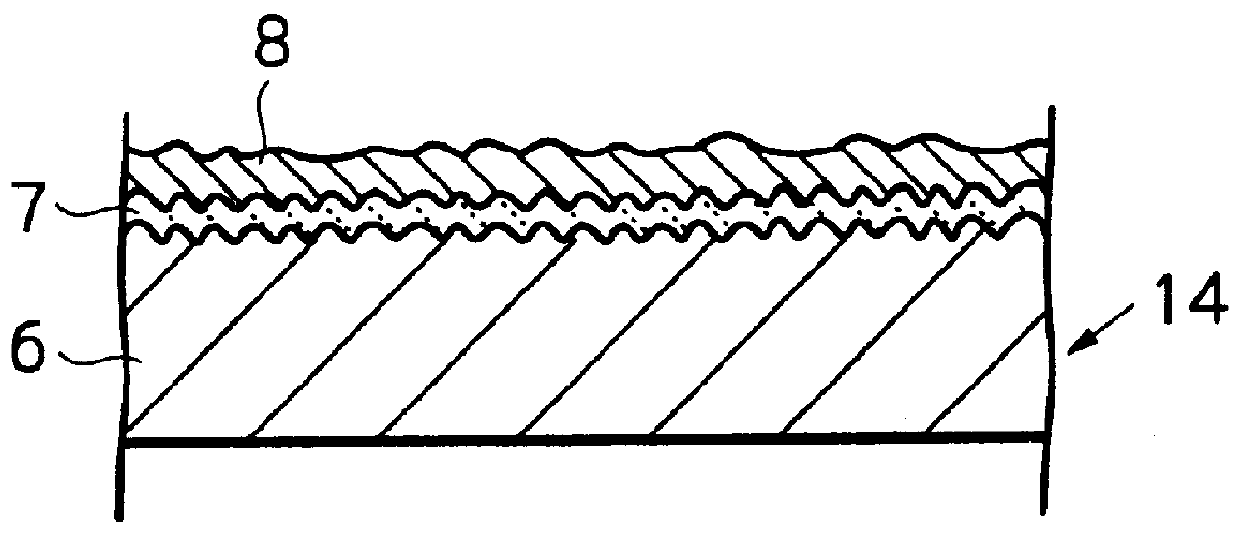

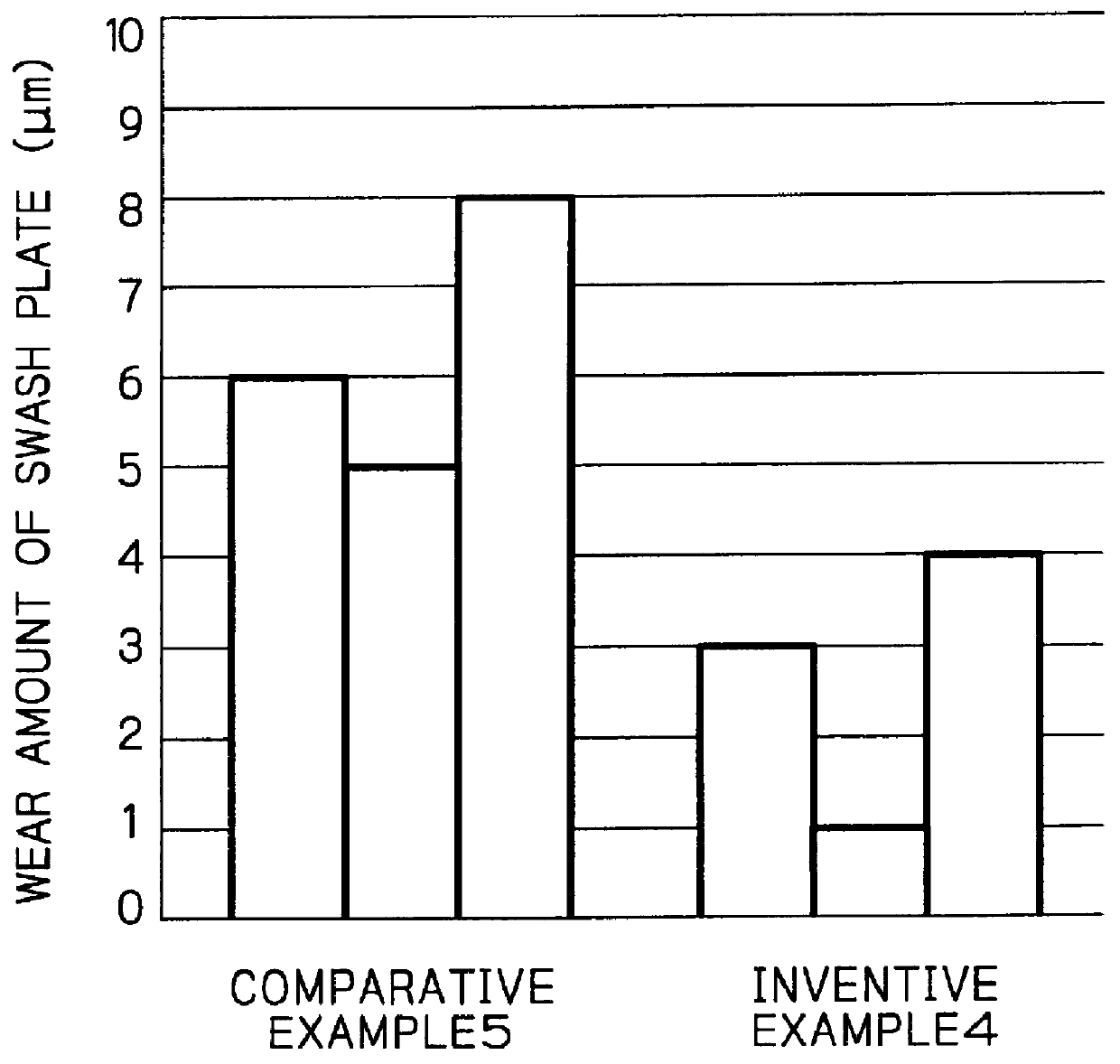

Swash plate of swash-plate compressor

InactiveUS6123009AReduce coating thicknessReduce loadPositive displacement pump componentsAdditivesGas compressorGraphite

A swash plate of a swash-plate compressor is subjected to sliding on shoes and is required to have excellent seizure resistance and wear resistance under the dry lubricating condition. The swash plate according to the present invention is provided with the surface-treated layer, i,e., the intermediate layer consisting of Cu, Sn or metal phosphate, and a sliding contact layer consisting of MoS2 and / or graphite and thermosetting resin.

Owner:TAIHO INDUSTRIES CO LTD +1

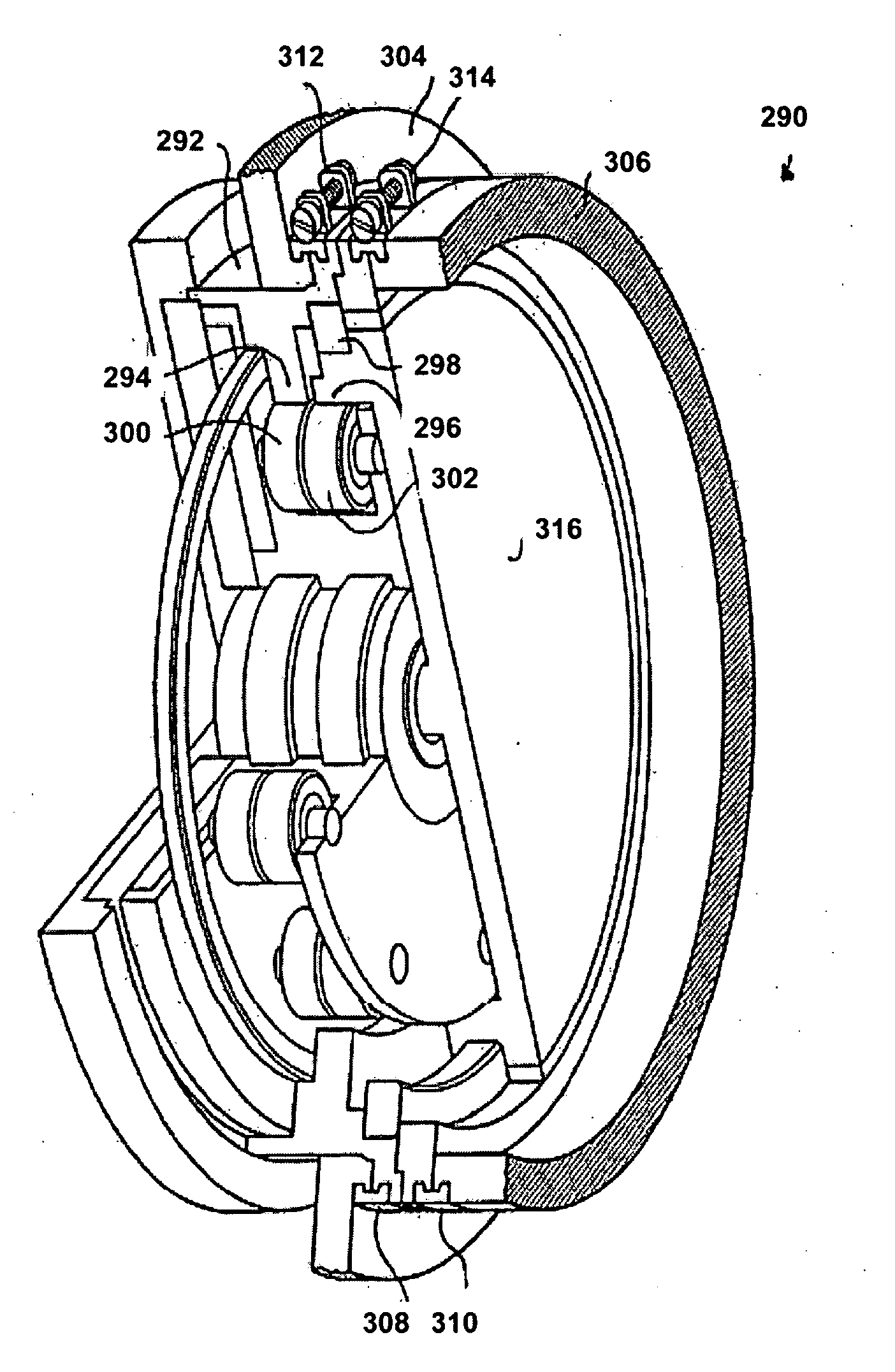

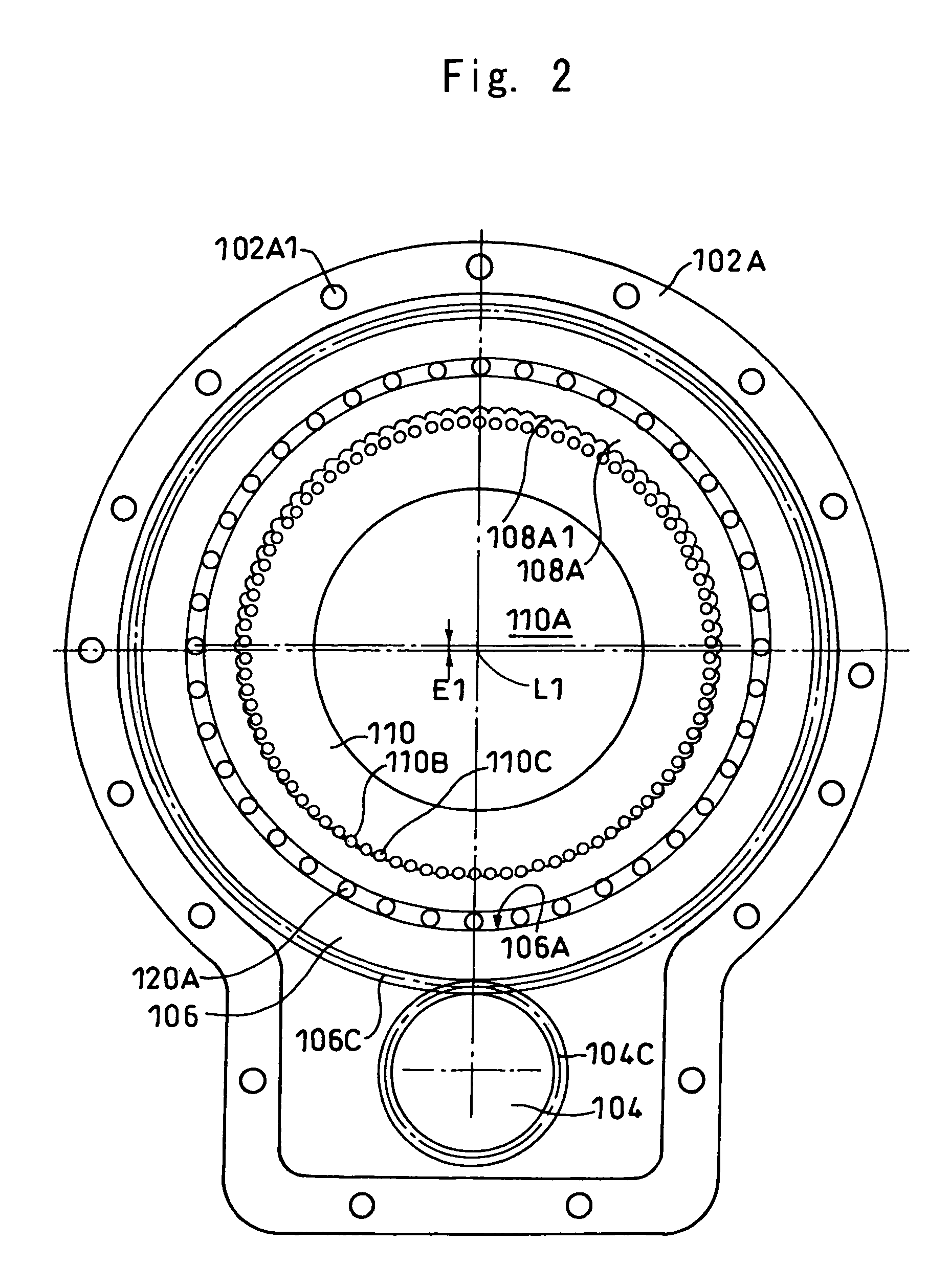

Self-contained rotary actuator

ActiveUS20070249457A1Lower Level RequirementsGearboxesWithout power ampliicationDrive shaftGear train

A self-contained rotary actuator provides motive power in automated mechanical systems and includes a cross-roller bearing operating as a structural joint. An outer attachment shell rigidly interfaces the automated mechanical system and contains a motor stator and an internal bull gear. The internal bull gear interfaces the cross-roller bearing and provides stiffness and includes internal gear teeth. An output attachment plate mechanism includes an internal ring gear and supports drive shaft bearings. The internal ring gear rigidly interfaces the output attachment plate and includes internal gear teeth. A drive shaft holds a prime mover rotor and an eccentric and associates with the output attachment plate via the drive shaft bearings. A gear train includes a meshing gear having external gear teeth with circular arc surfaces for meshing with the internal gear teeth of the internal bull gear and the internal gear teeth of the internal ring gear and walks a minimal number of the external gear teeth for each rotation of the prime mover rotor. The cross-roller bearing, the outer attachment shell, the drive shaft, and the meshing gear train provide a self-contained, integrated, actuation torque transmitting force from the prime mover along a shortest-possible transmission path.

Owner:FATHOM5 CORP

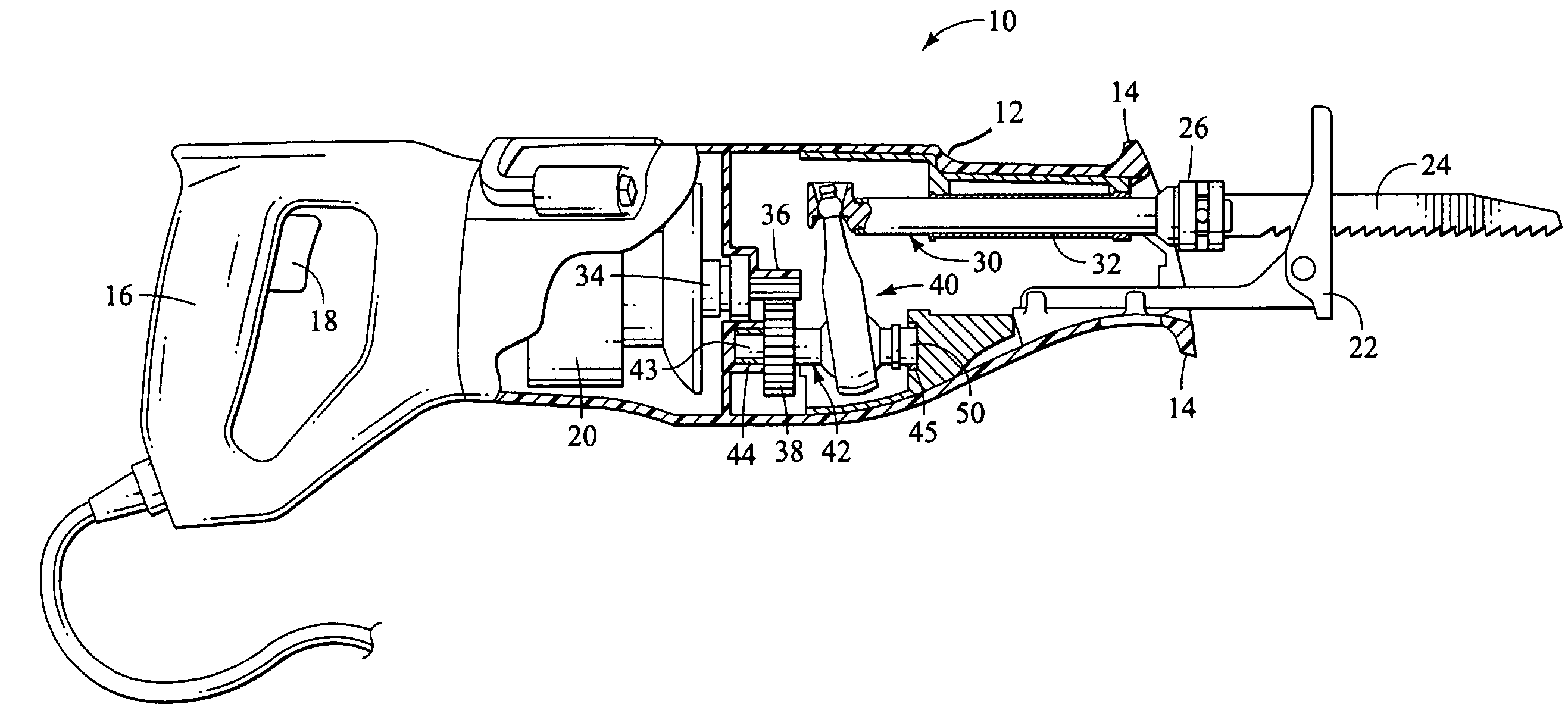

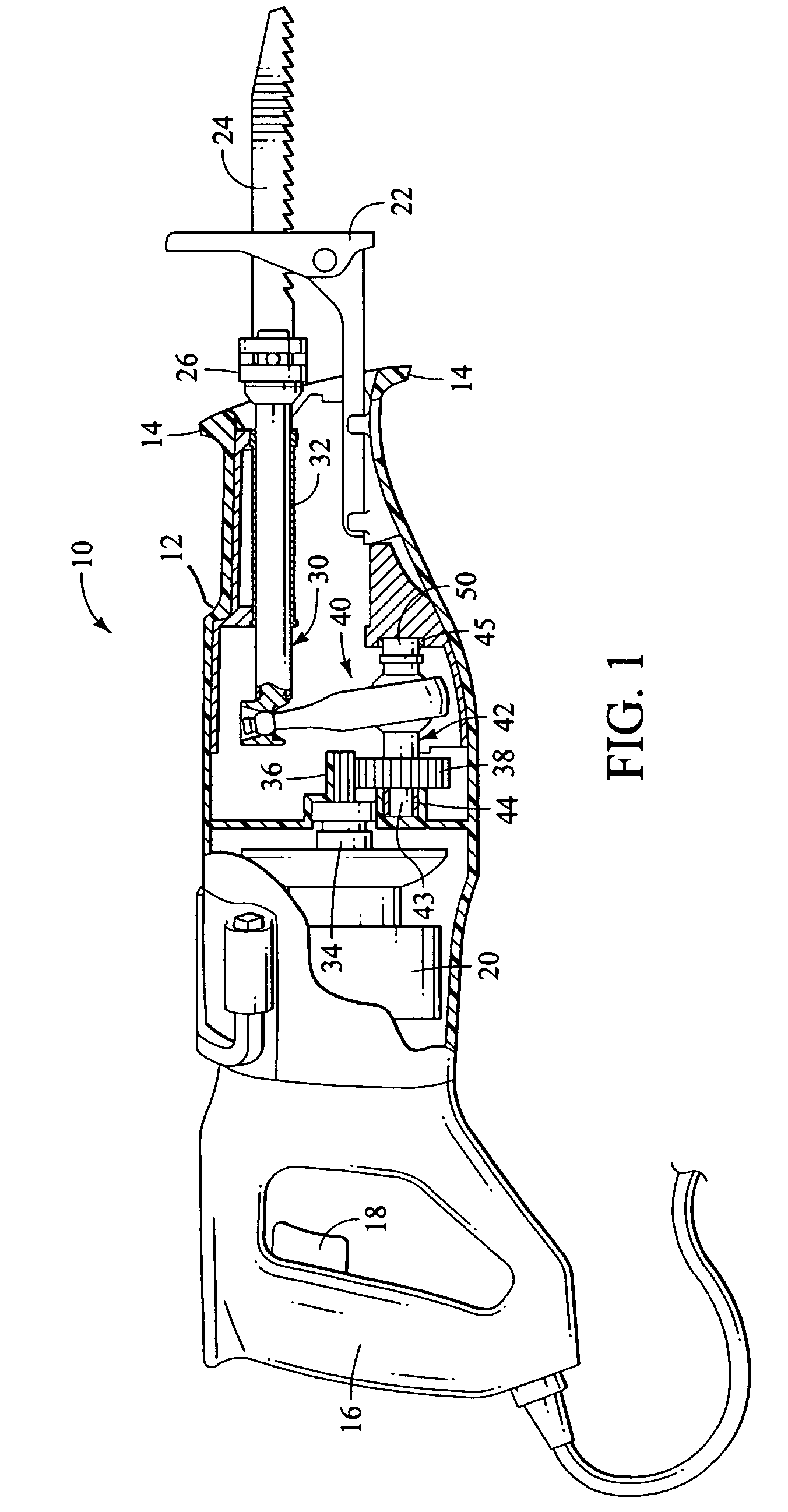

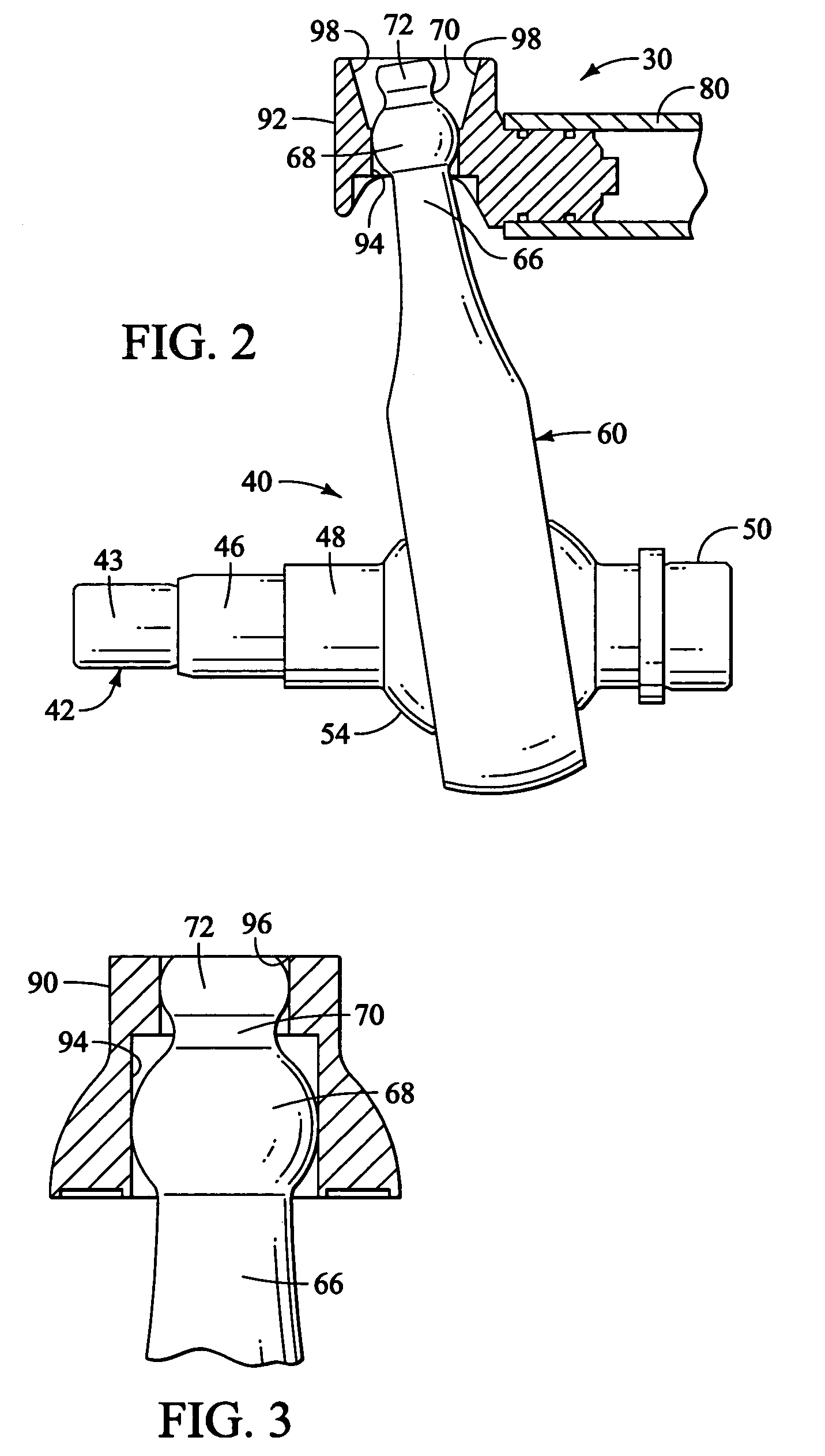

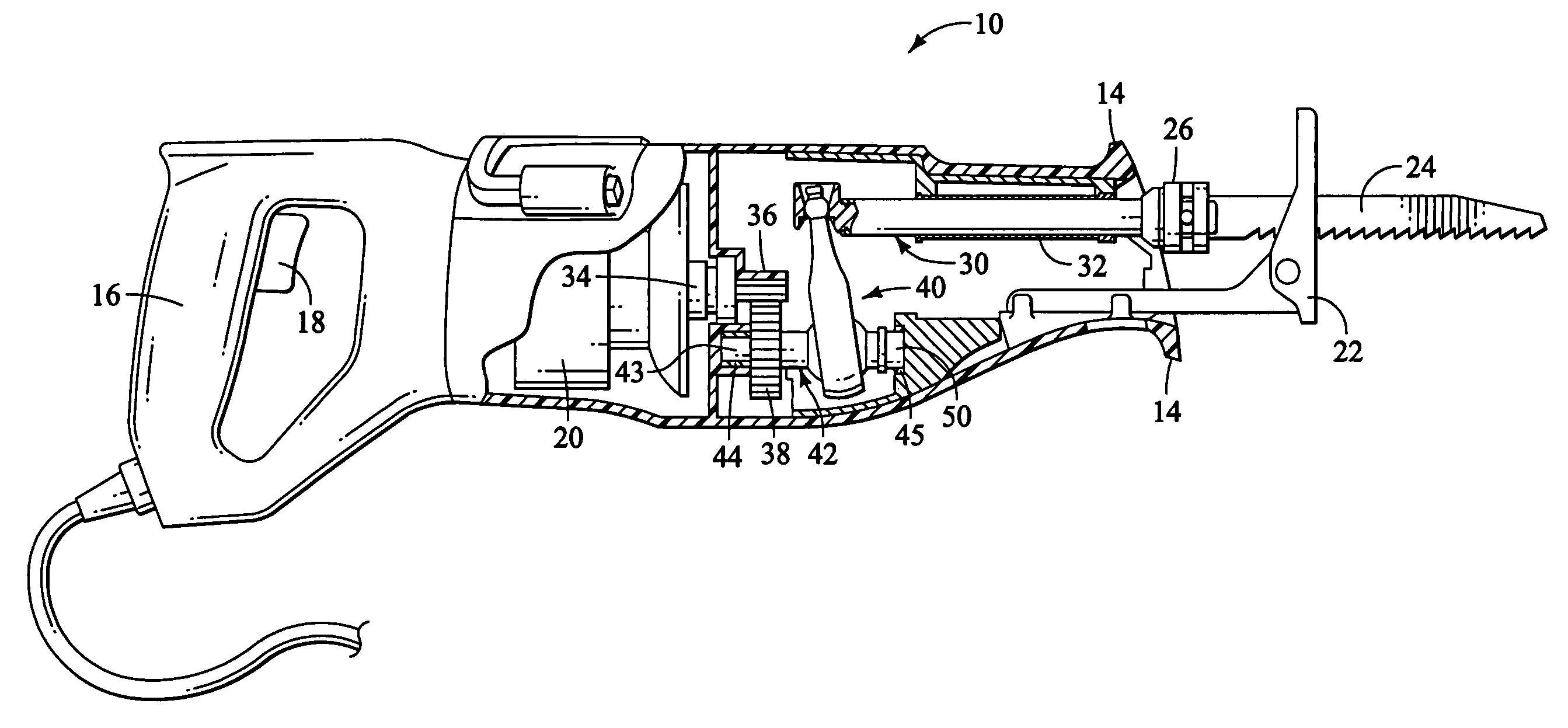

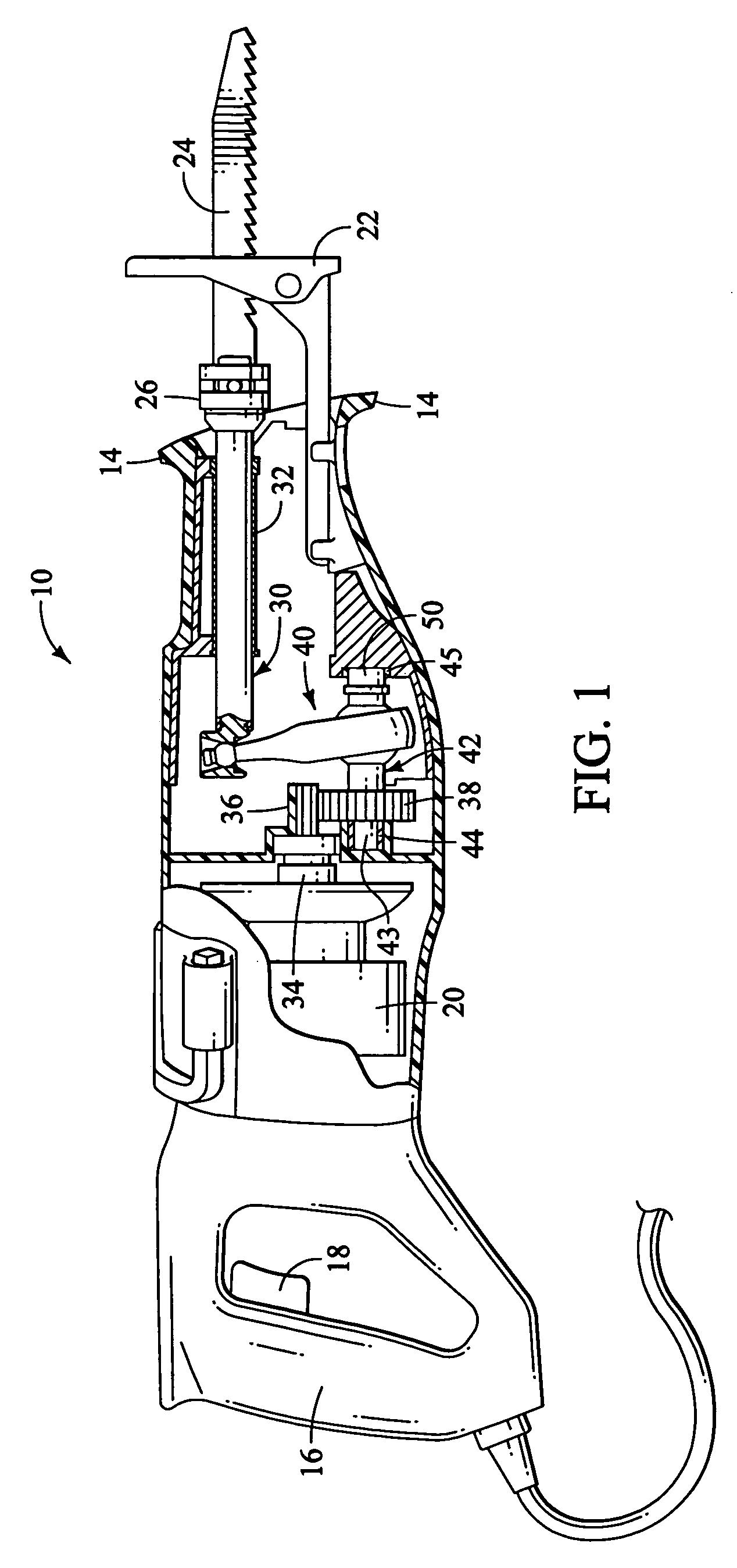

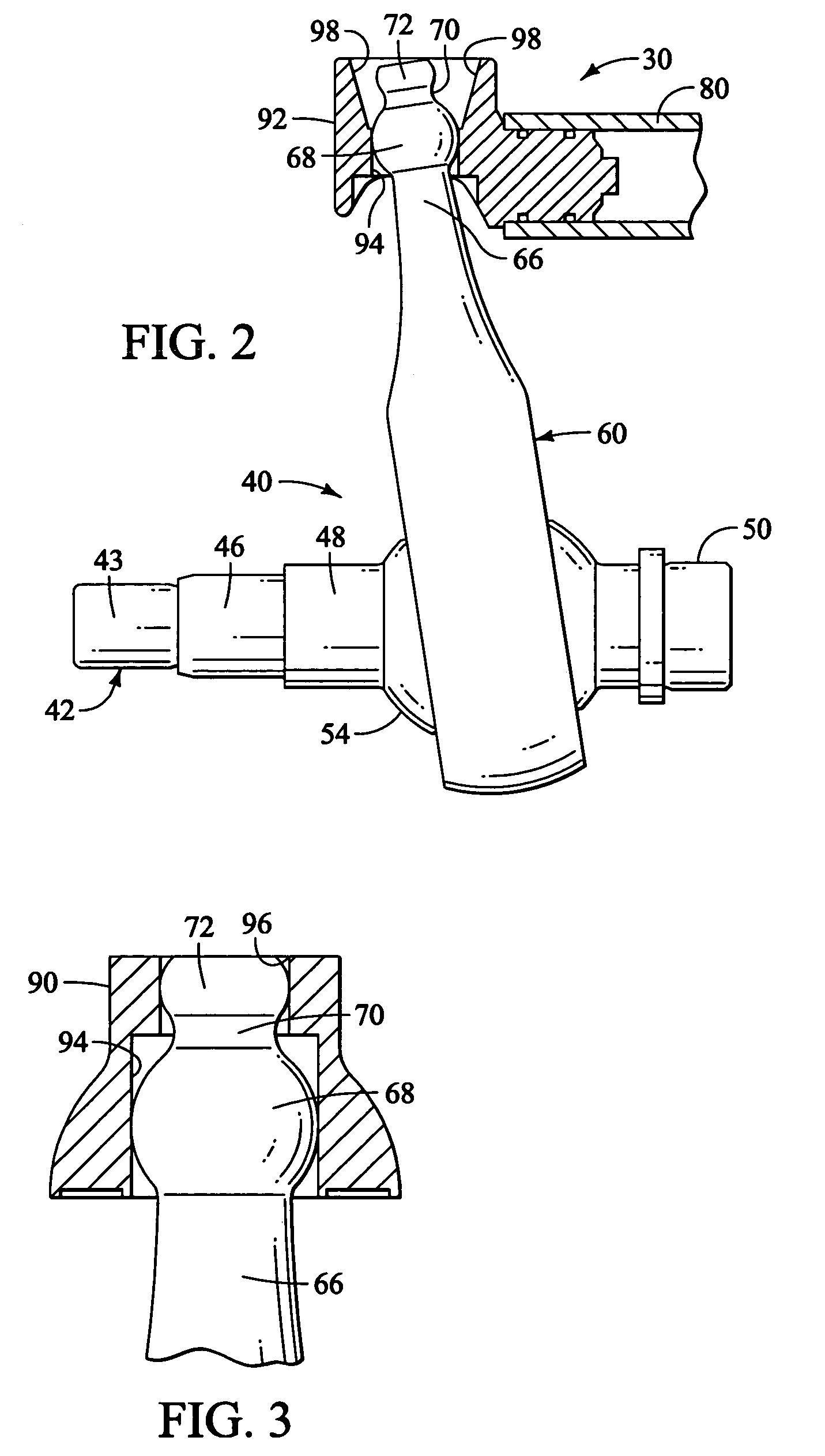

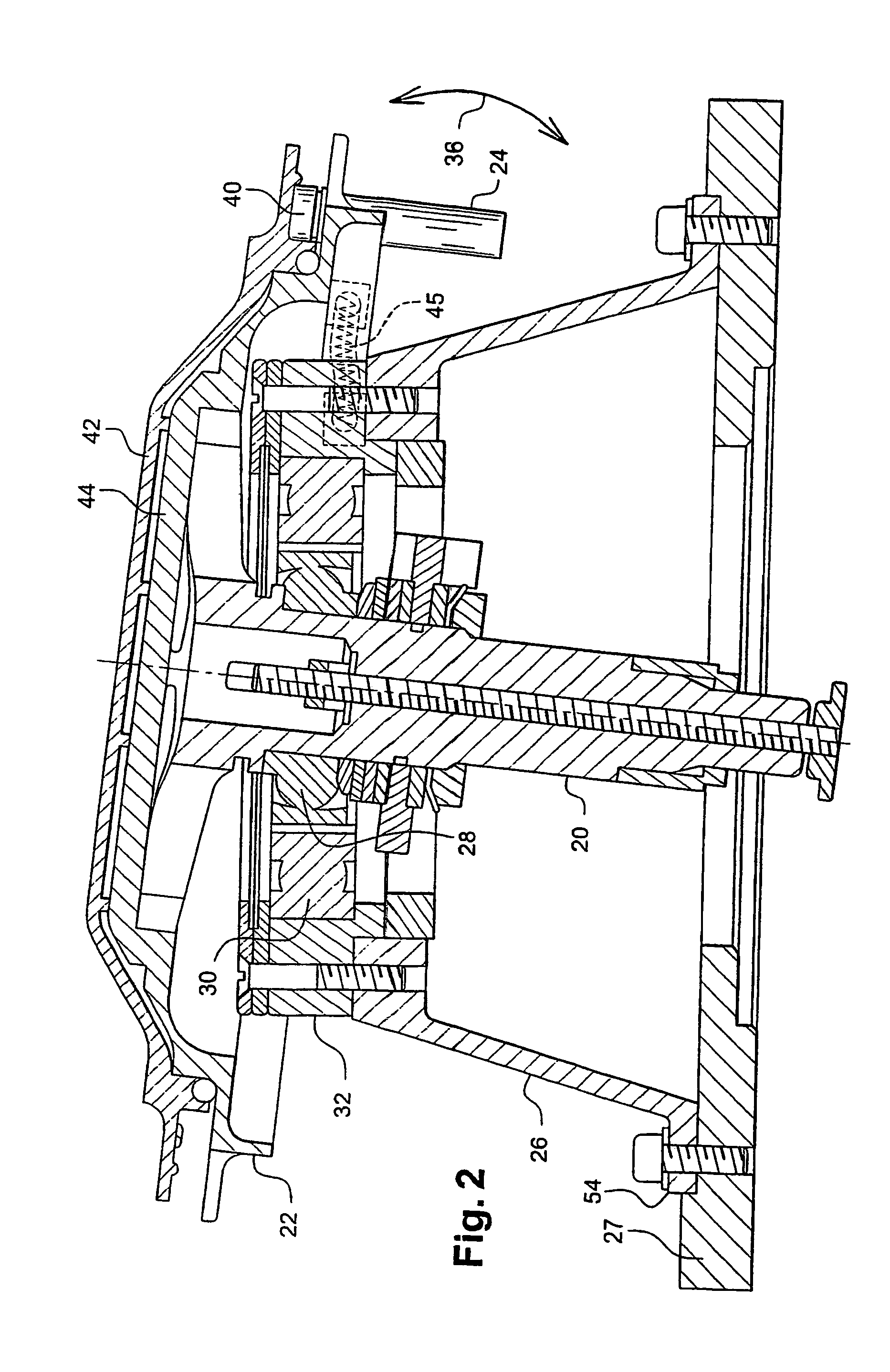

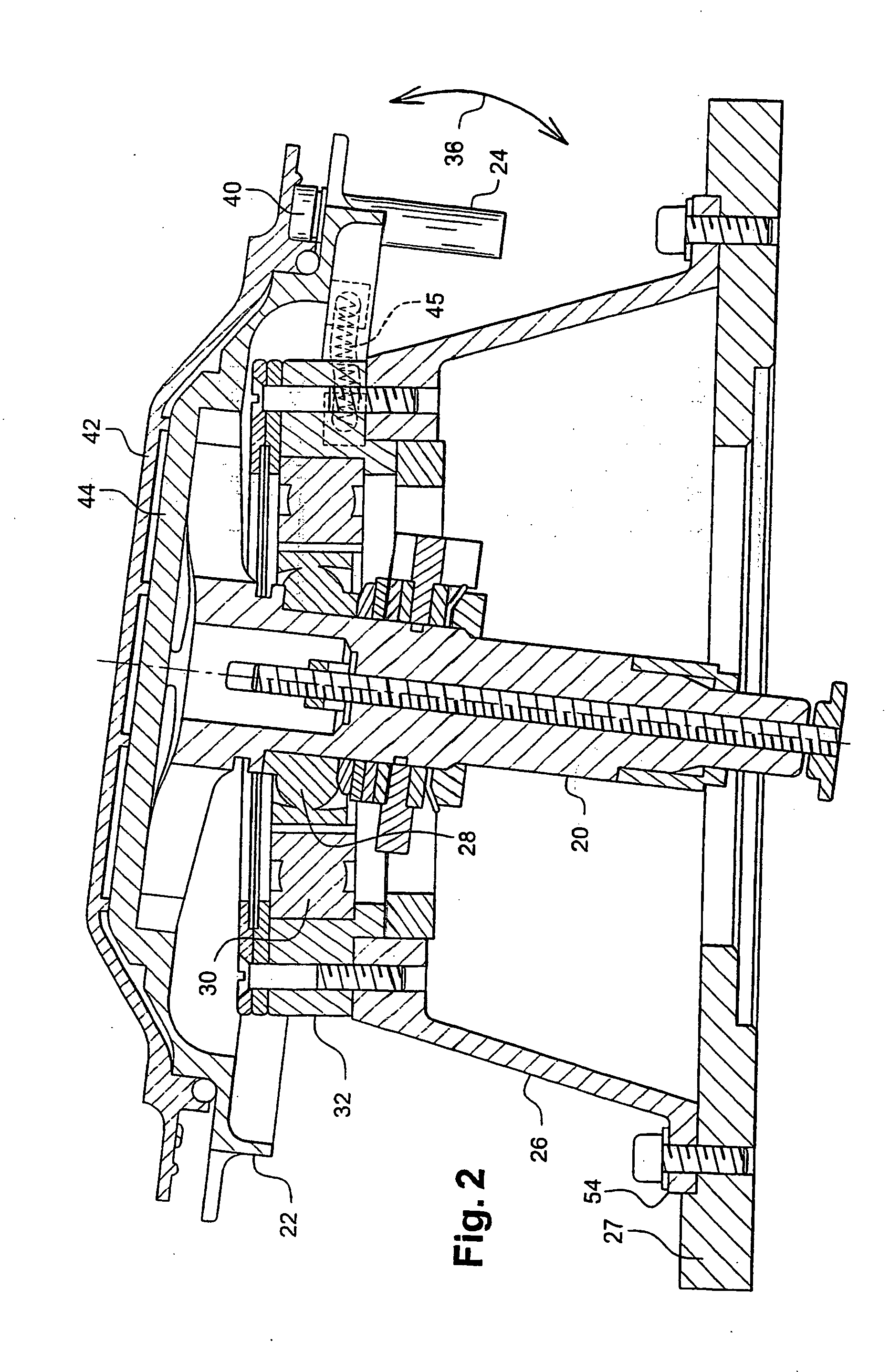

Anti-rotation drive mechanism for a reciprocating saw

ActiveUS7168169B2Reduces operating friction and wearMetal sawing devicesConstructionsReciprocating motionDrive shaft

An anti-rotation reciprocating drive apparatus for a reciprocating saw utilizes a wobble plate assembly that includes a drive shaft and an elongated arm with an interface structure for engaging a spindle. The interface structure has two ball-type interfaces that are concentrically aligned with one another, with the outer one being smaller than the inner one and both engaging a receiver portion of the spindle. The larger ball-type interface causes reciprocating movement of the spindle and the smaller outer interface prevents rotation of the spindle. The contact between the interfaces and the spindle receiver is a single point contact which reduces operating friction, wear of the parts and heat being generated.

Owner:CREDO TECH CORP +1

Elastic crawler traveling apparatus and sprocket for crawler belt used in the same

An elastic crawler traveling apparatus having an elastic crawler in a shape of an endless belt, a sprocket for a crawler belt arranged to be brought into contact with an inner face of the elastic crawler, a driven wheel, and a rolling wheel, the elastic crawler including a belt main body, a plurality of projections formed to project at intervals along a peripheral direction on an inner face of the belt main body, and a tension member embedded at an inner portion of the belt main body for restricting elongation of the belt main body, in which the sprocket has a contact portion to contact the belt main body and a contact width of the contact portion in a belt width direction of the elastic crawler is wider than a root width of the projection in the belt width direction.

Owner:SUMITOMO RUBBER IND LTD

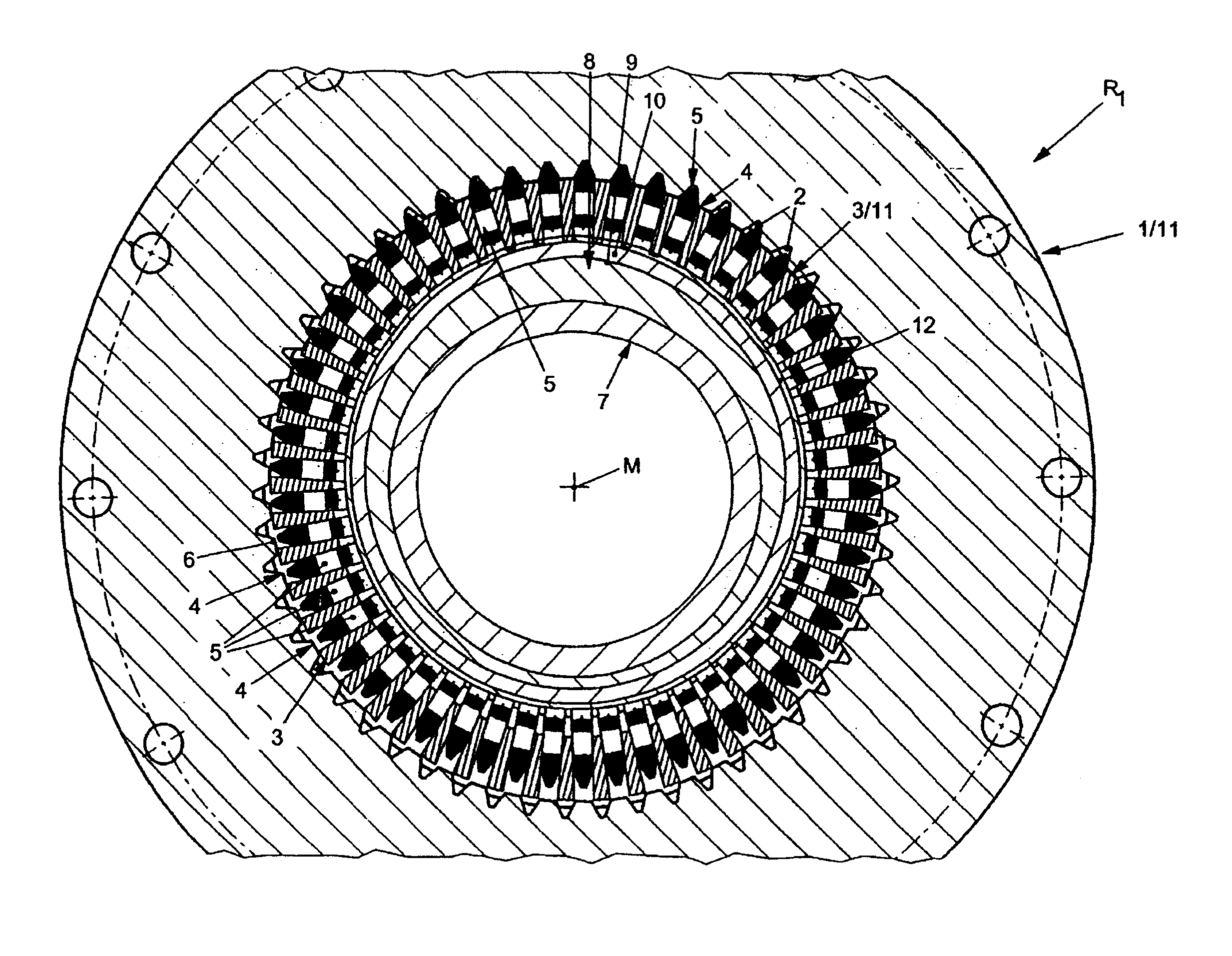

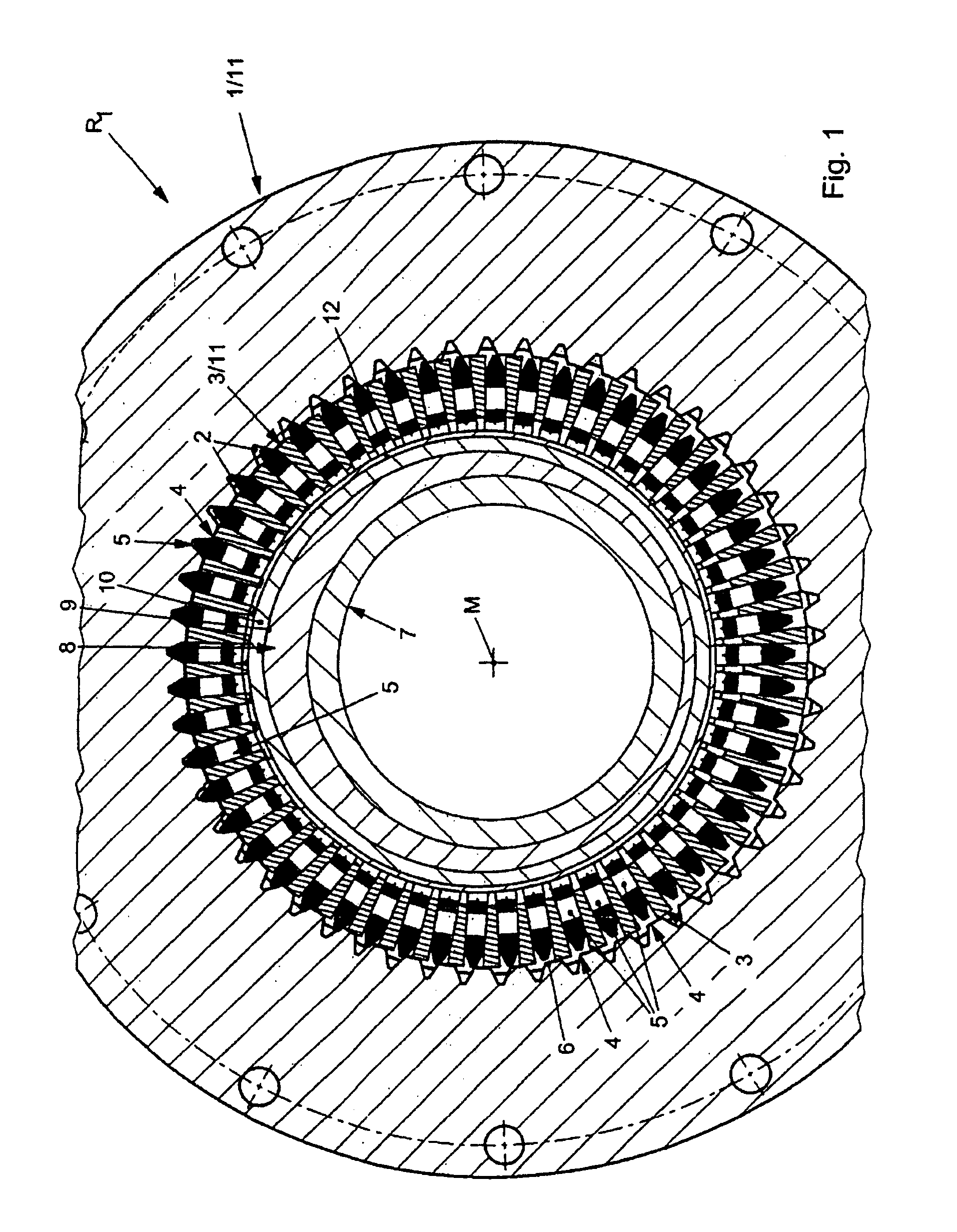

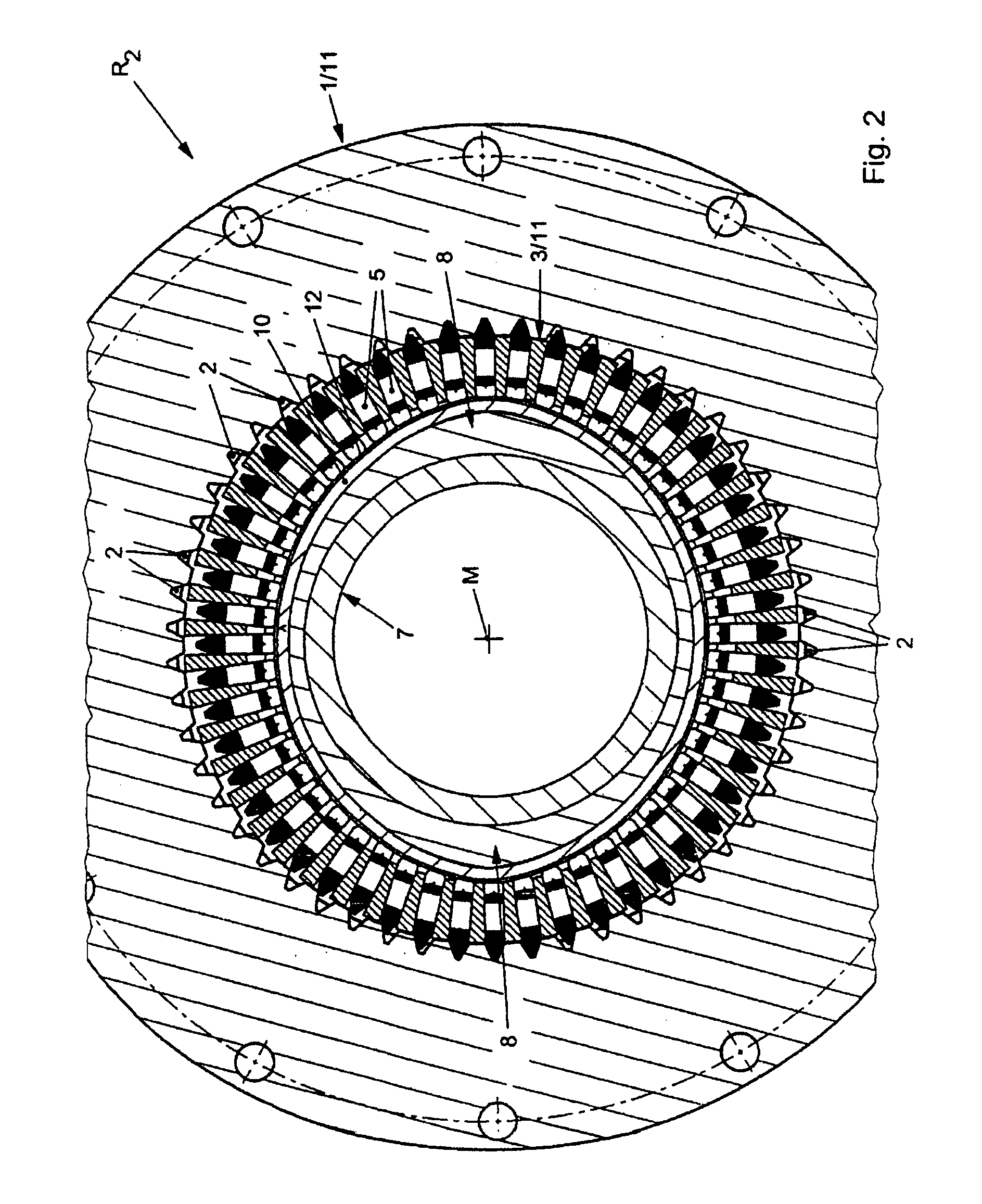

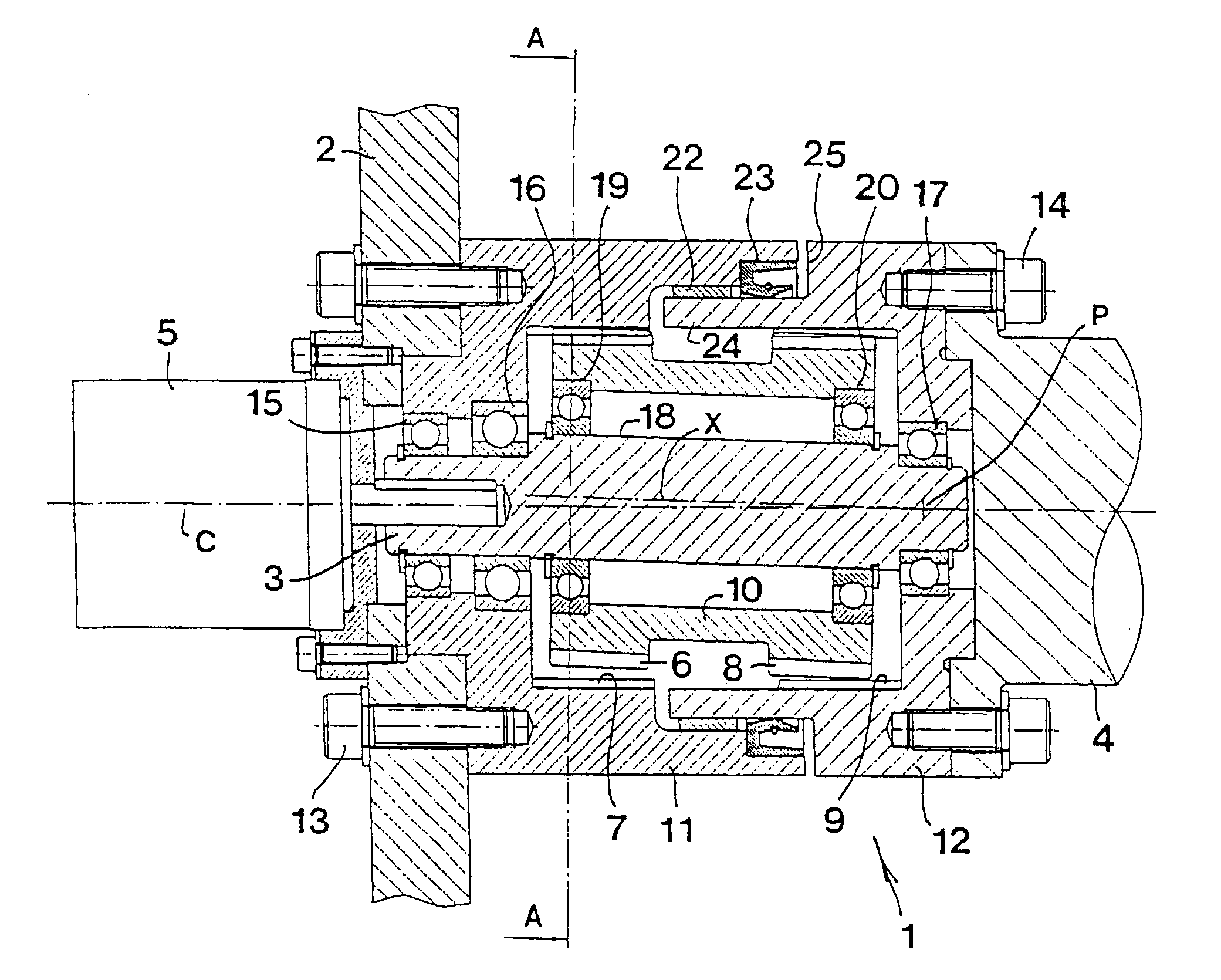

Gearing

ActiveUS8656809B2High level of compactness and complexitySmall spacingToothed gearingsDifferential gearingsTooth segmentControl theory

Owner:WITTENSTEIN SE

Anti-rotation drive mechanism for a reciprocating saw

ActiveUS20050262710A1Reduces operating friction and wearMetal sawing devicesConstructionsDrive shaftReciprocating motion

An anti-rotation reciprocating drive apparatus for a reciprocating saw utilizes a wobble plate assembly that includes a drive shaft and an elongated arm with an interface structure for engaging a spindle. The interface structure has two ball-type interfaces that are concentrically aligned with one another, with the outer one being smaller than the inner one and both engaging a receiver portion of the spindle. The larger ball-type interface causes reciprocating movement of the spindle and the smaller outer interface prevents rotation of the spindle. The contact between the interfaces and the spindle receiver is a single point contact which reduces operating friction, wear of the parts and heat being generated.

Owner:CREDO TECH CORP +1

Nutating Gear Drive Mechanism for Surgical Devices

InactiveUS20090090201A1Reduce speedIncrease rotational forceToothed gearingsWobble plate gearingsLow speedGear drive

A drive mechanism for transmitting rotation force in surgical devices comprises a nutating gear reduction drive having an input and an output. The input is configured to be driven at high speed, low torque by a proximal drive shaft of a surgical device. The output is configured to transmit a low speed, high torque rotational force. The proximal drive shaft can be flexible. In one embodiment, the nutating gear reduction drive includes a wobble plate. This nutating gear reduction drive may include at least one crown gear. In an alternative embodiment, the nutating gear drive includes at least one ring gear. The ring gear is fixed in place. This embodiment can also include at least one spur gear.

Owner:TYCO HEALTHCARE GRP LP

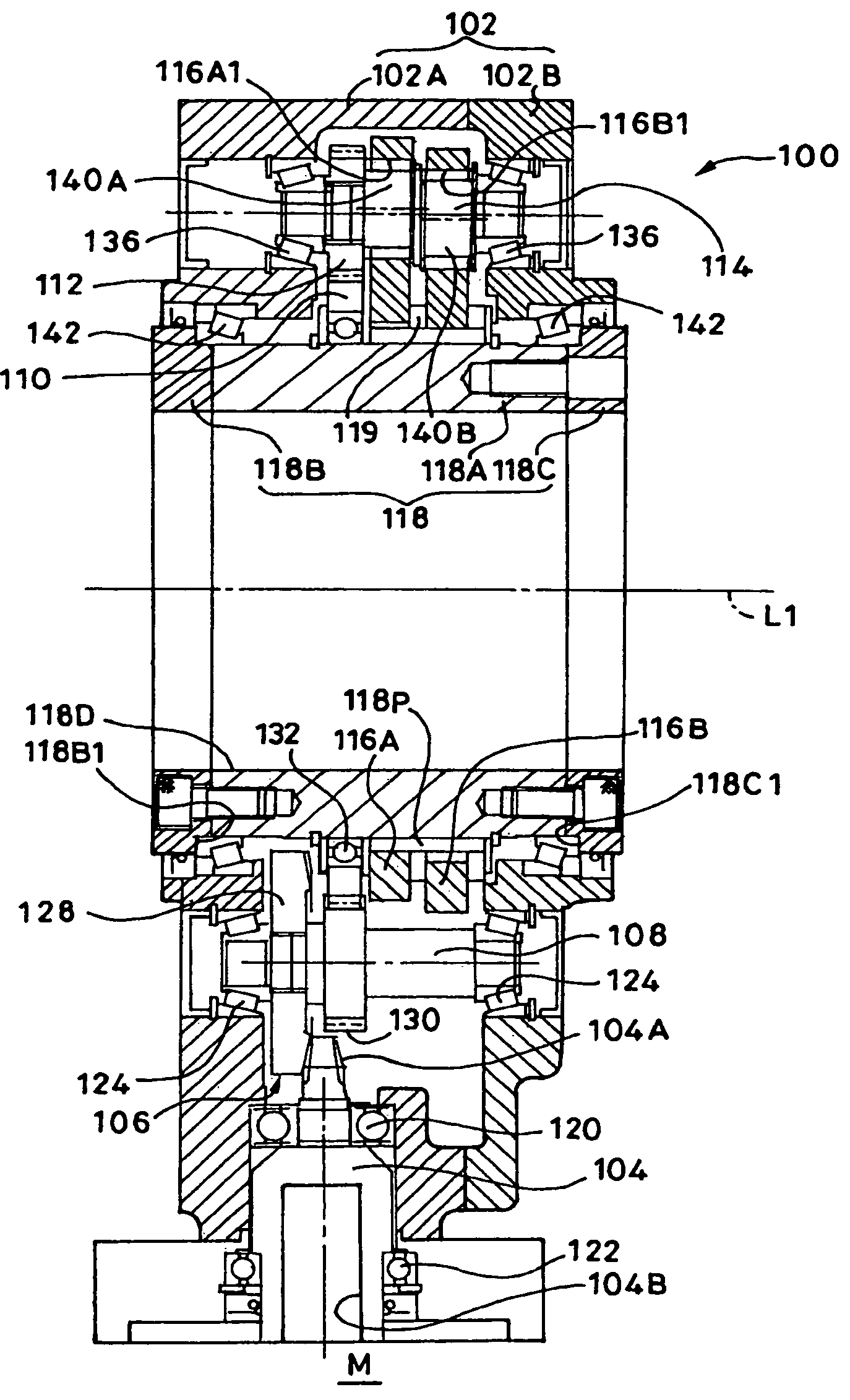

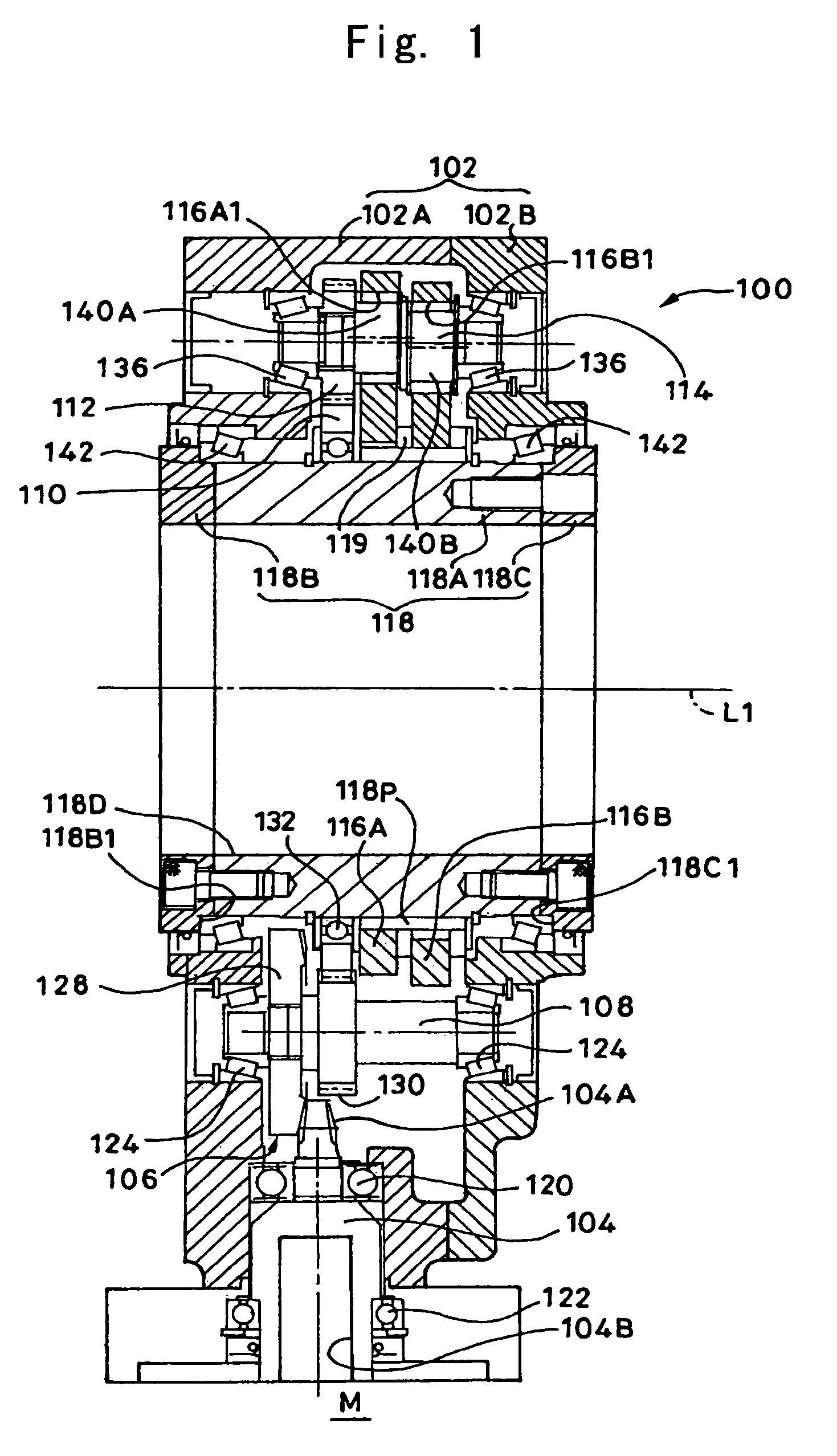

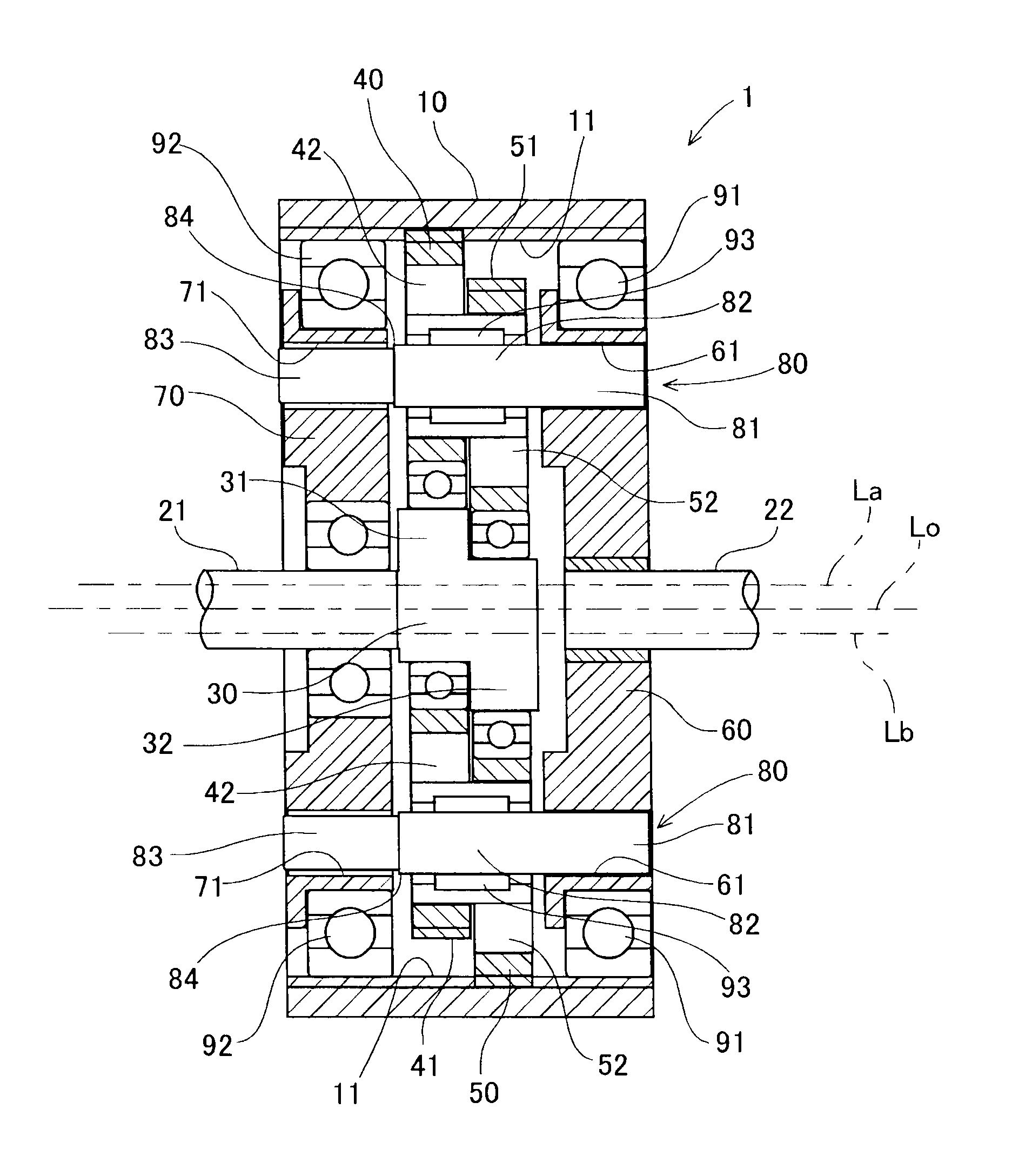

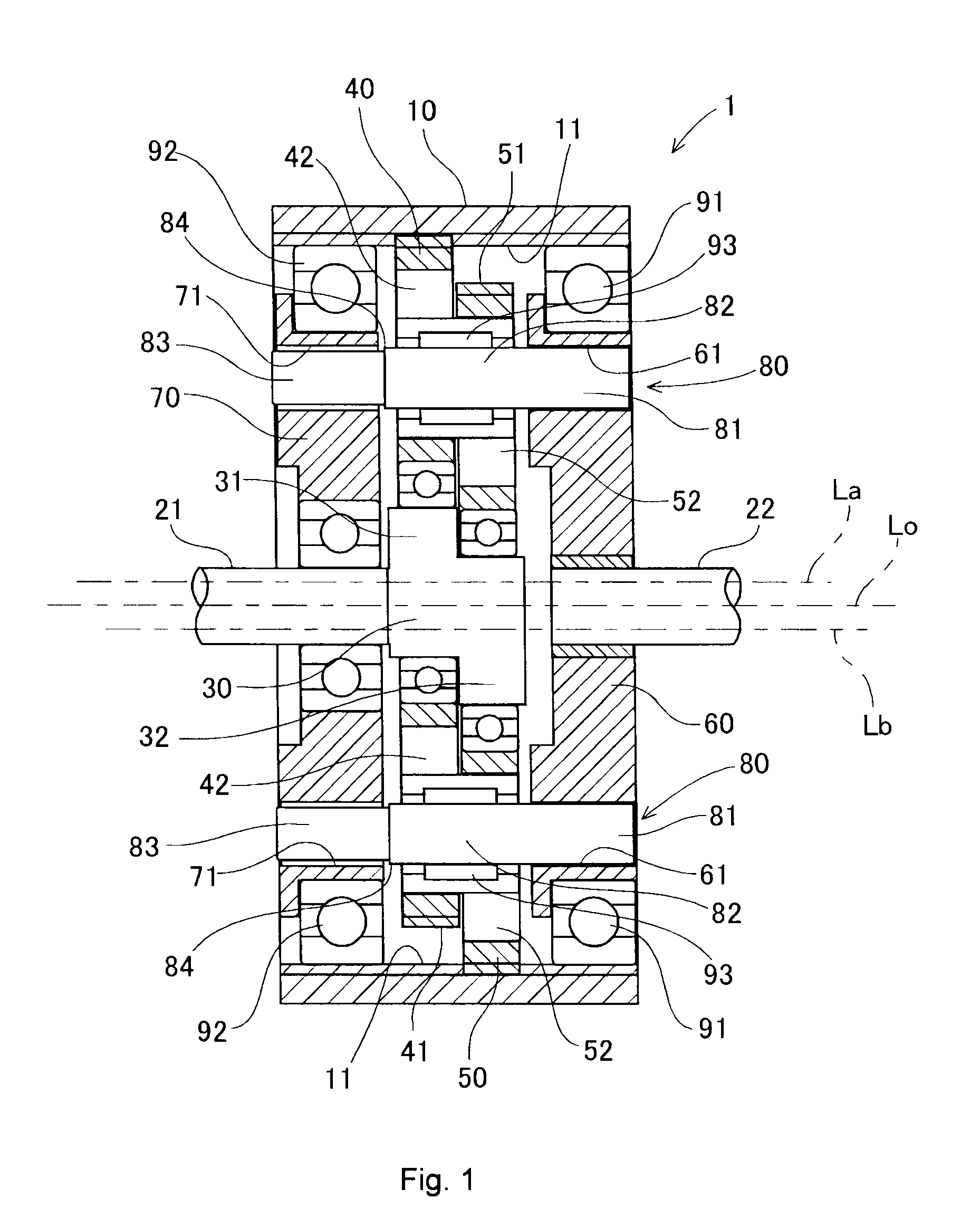

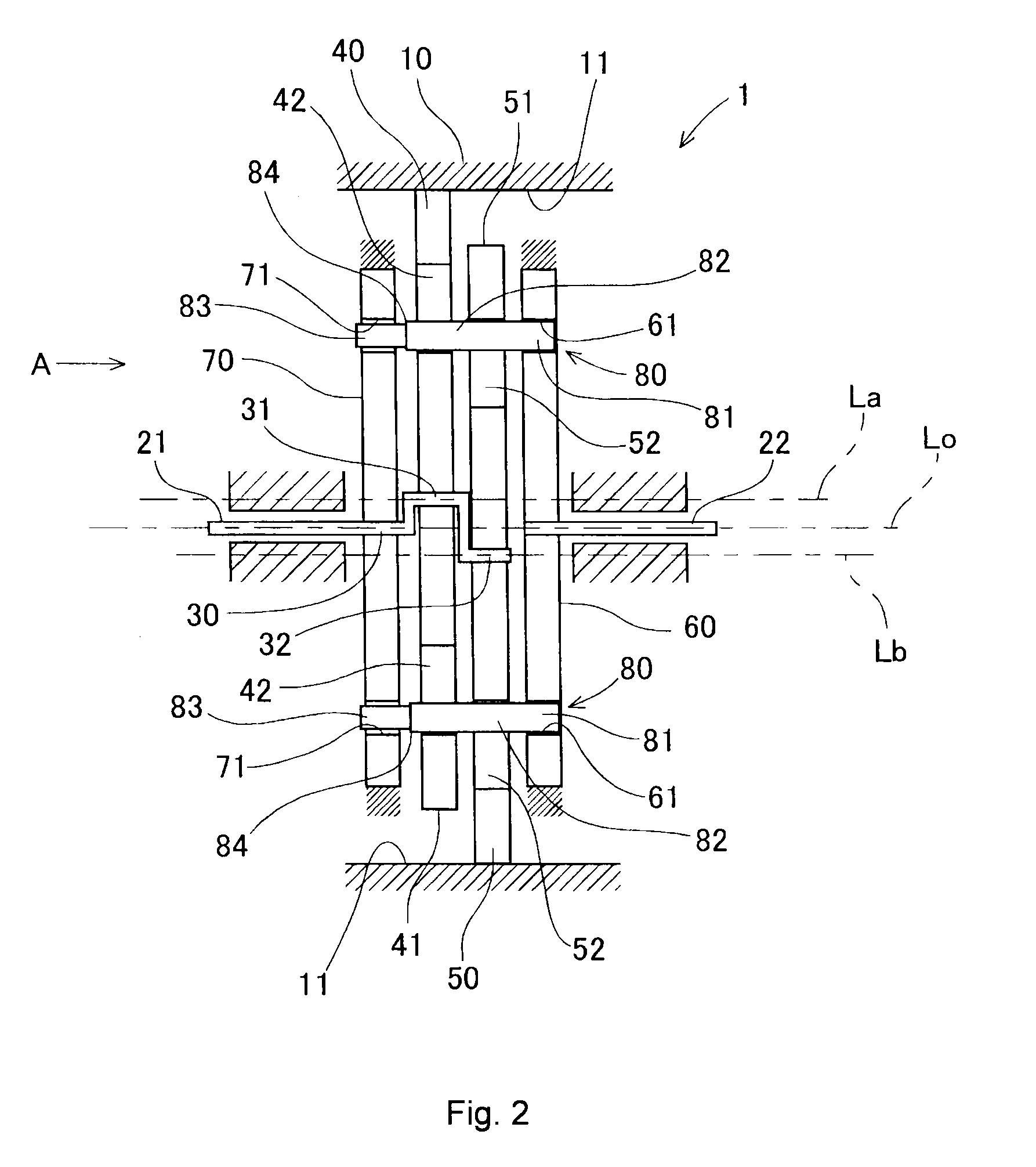

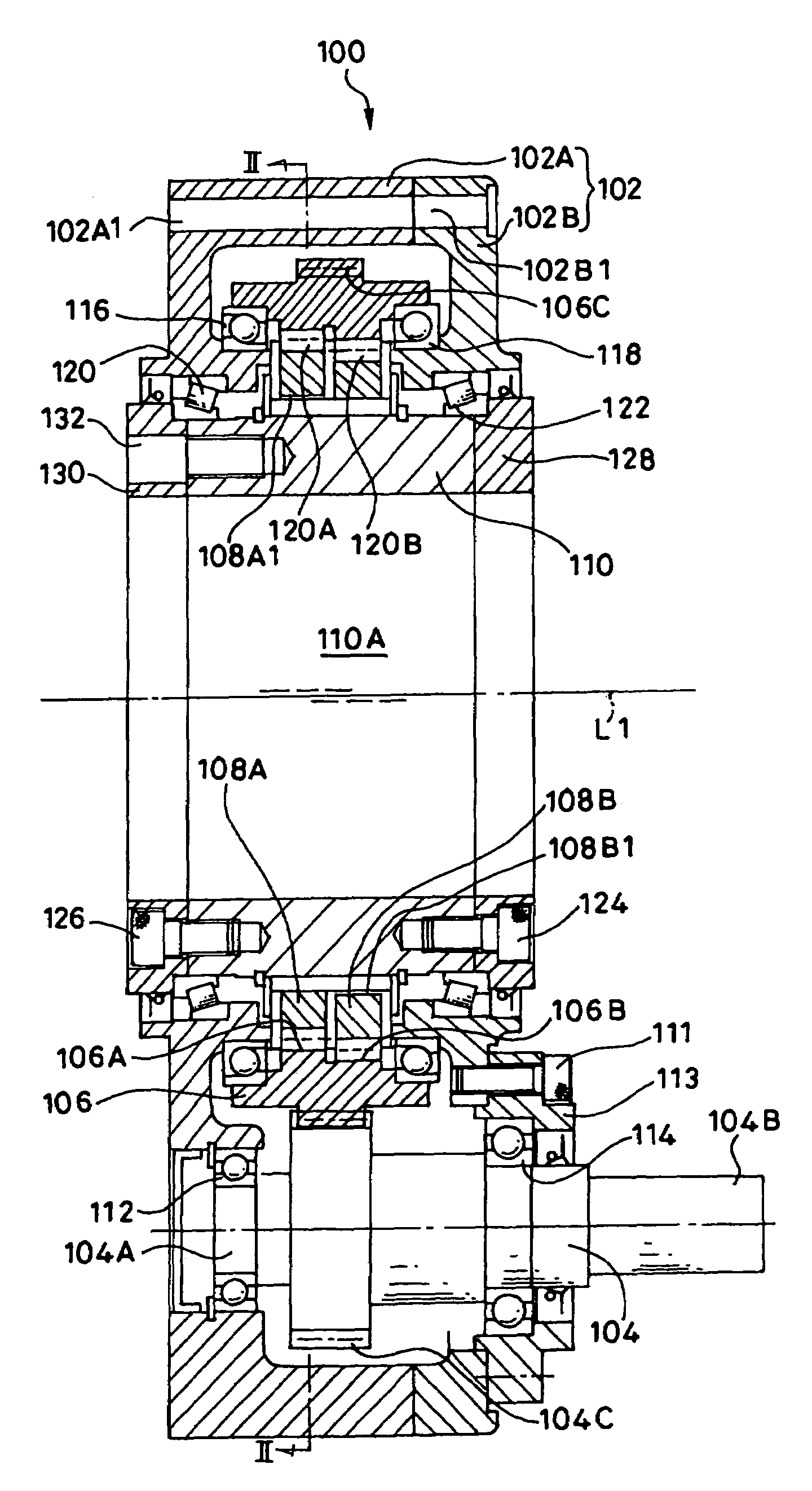

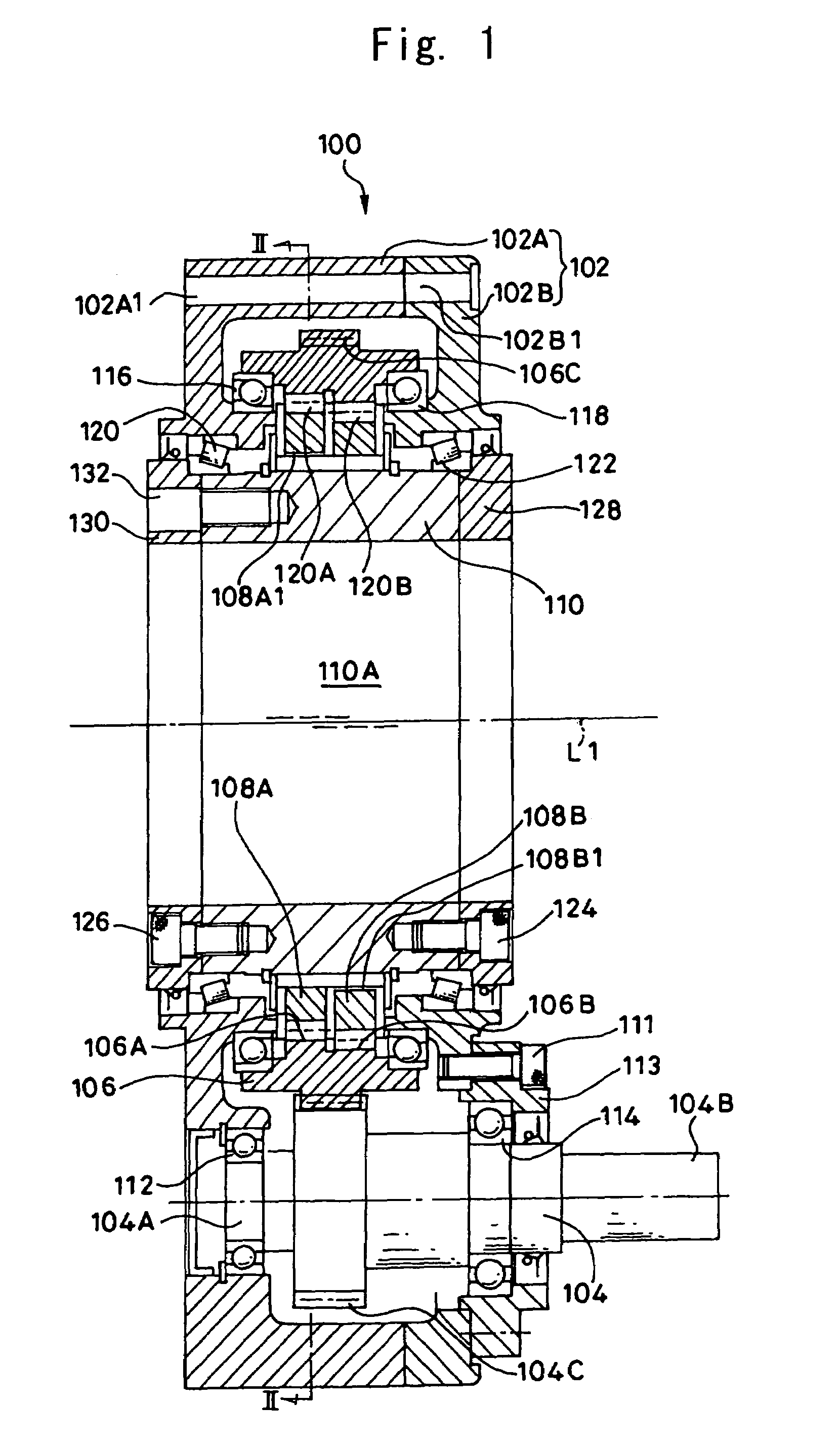

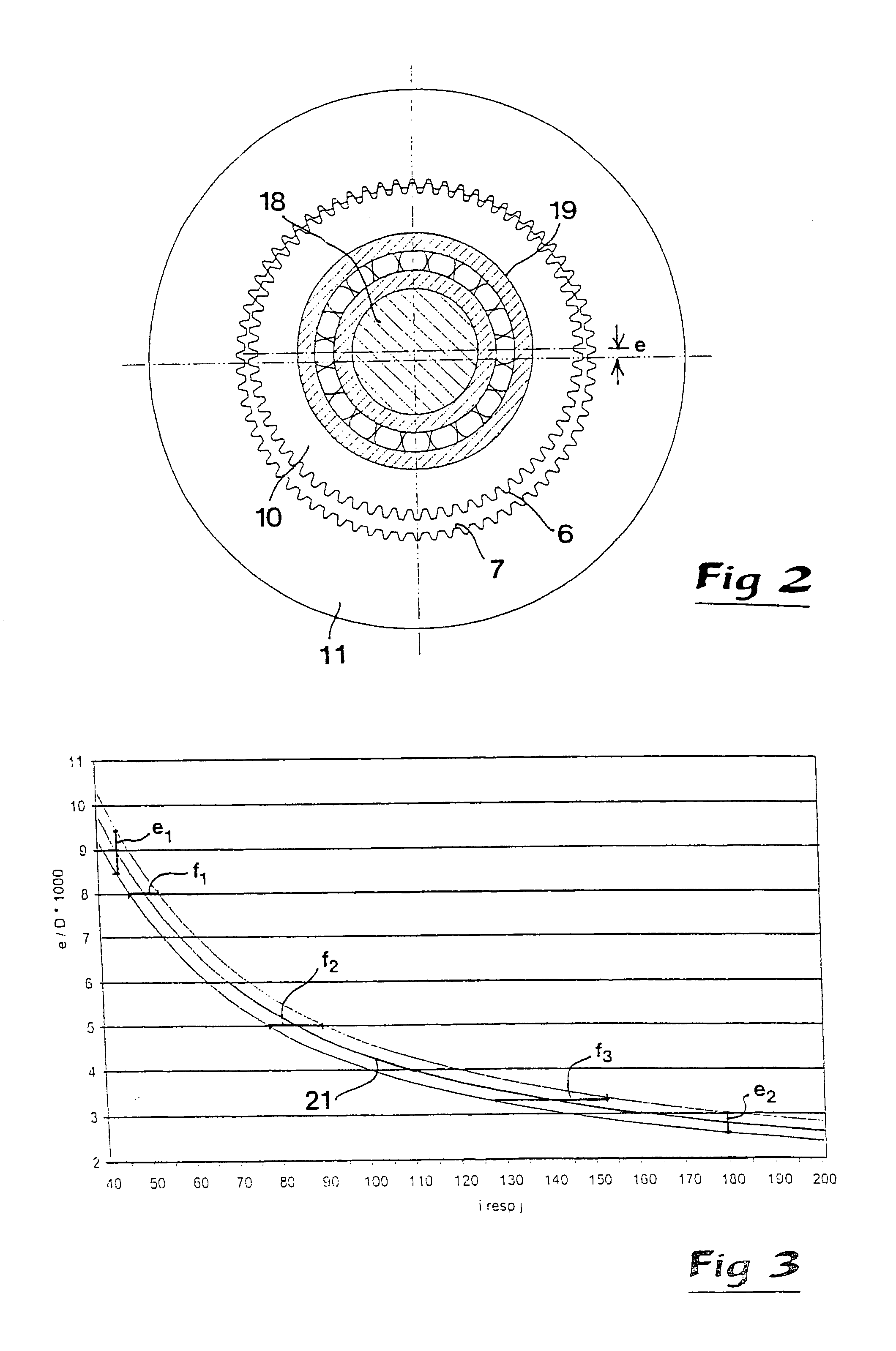

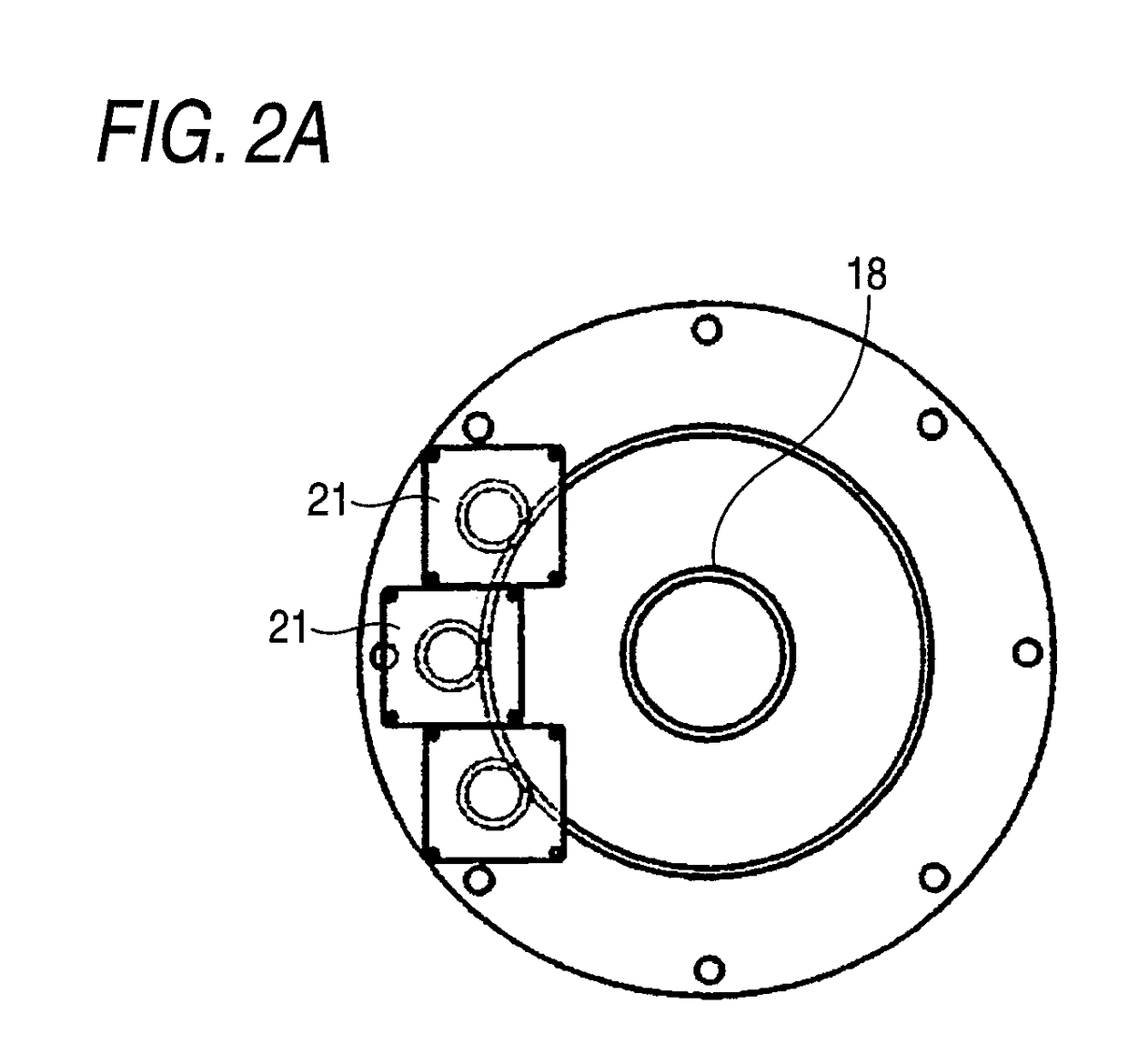

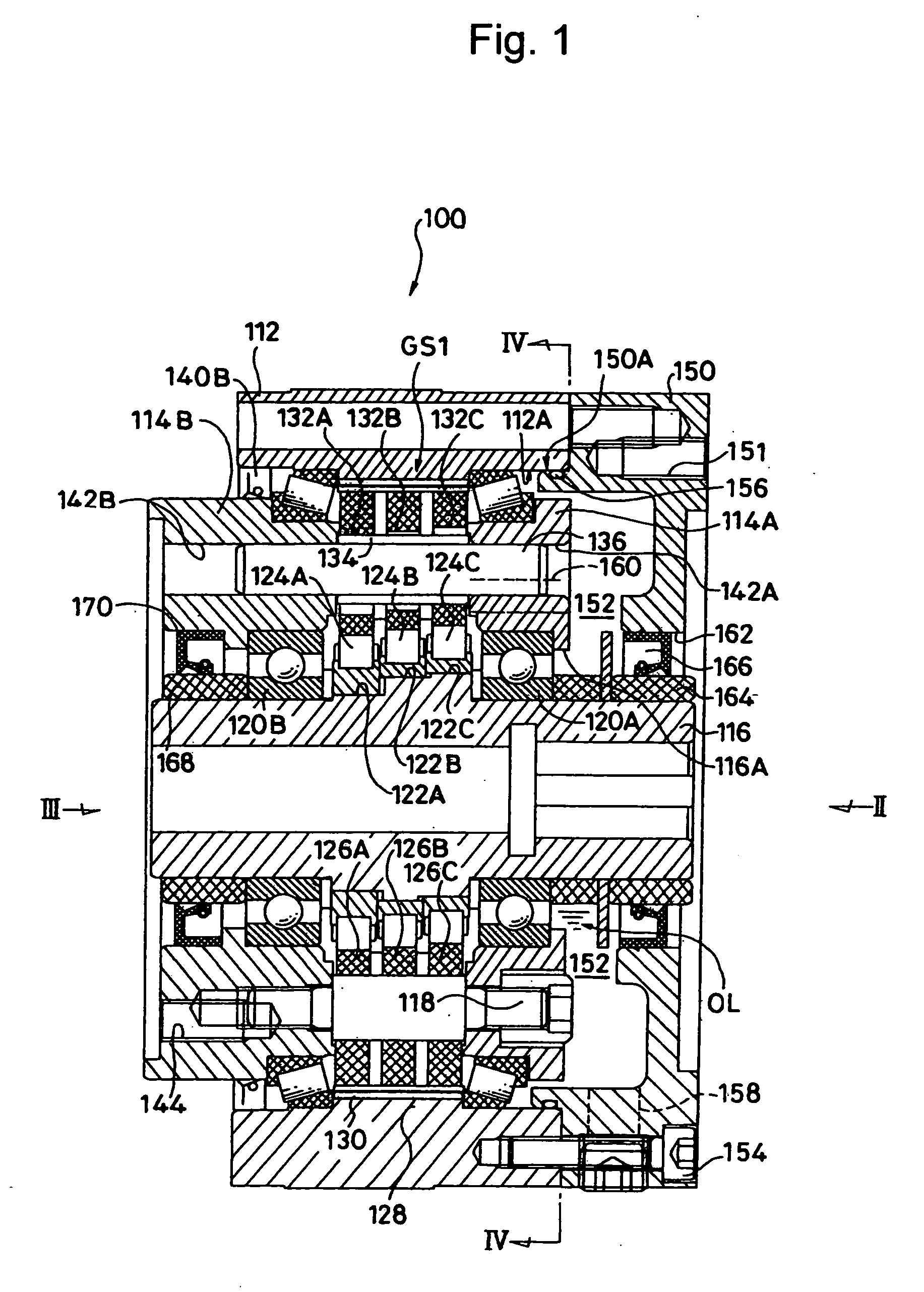

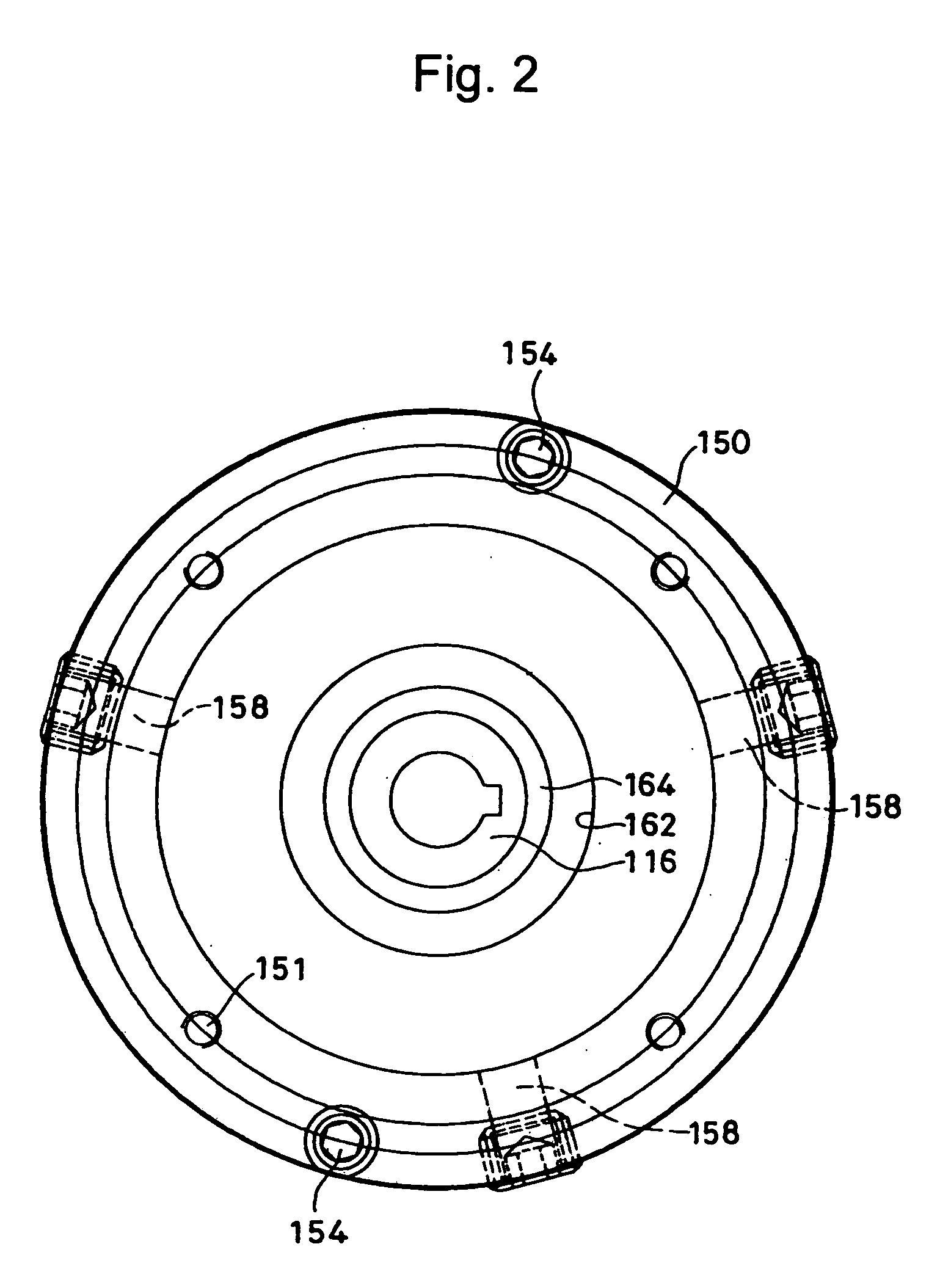

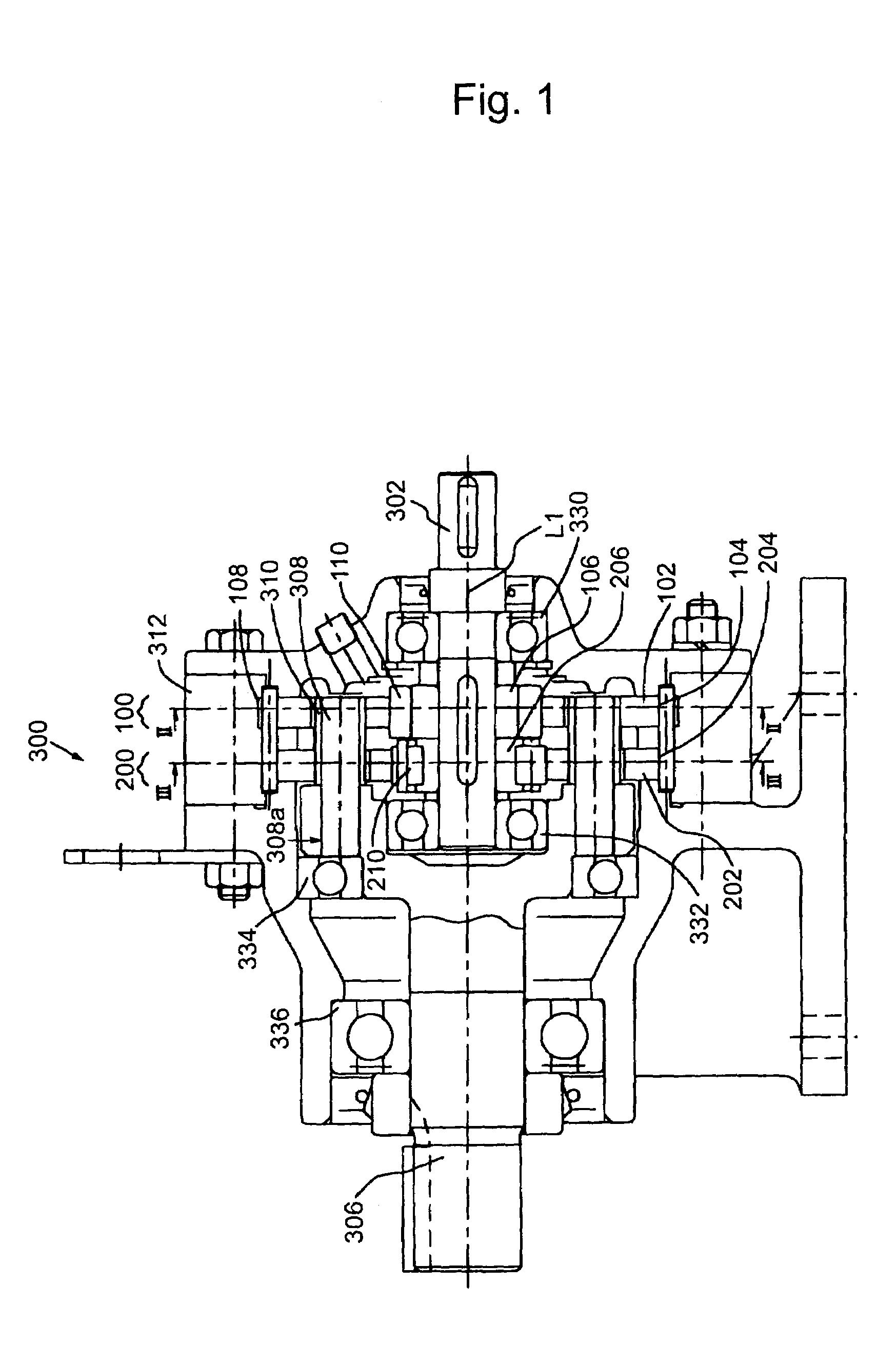

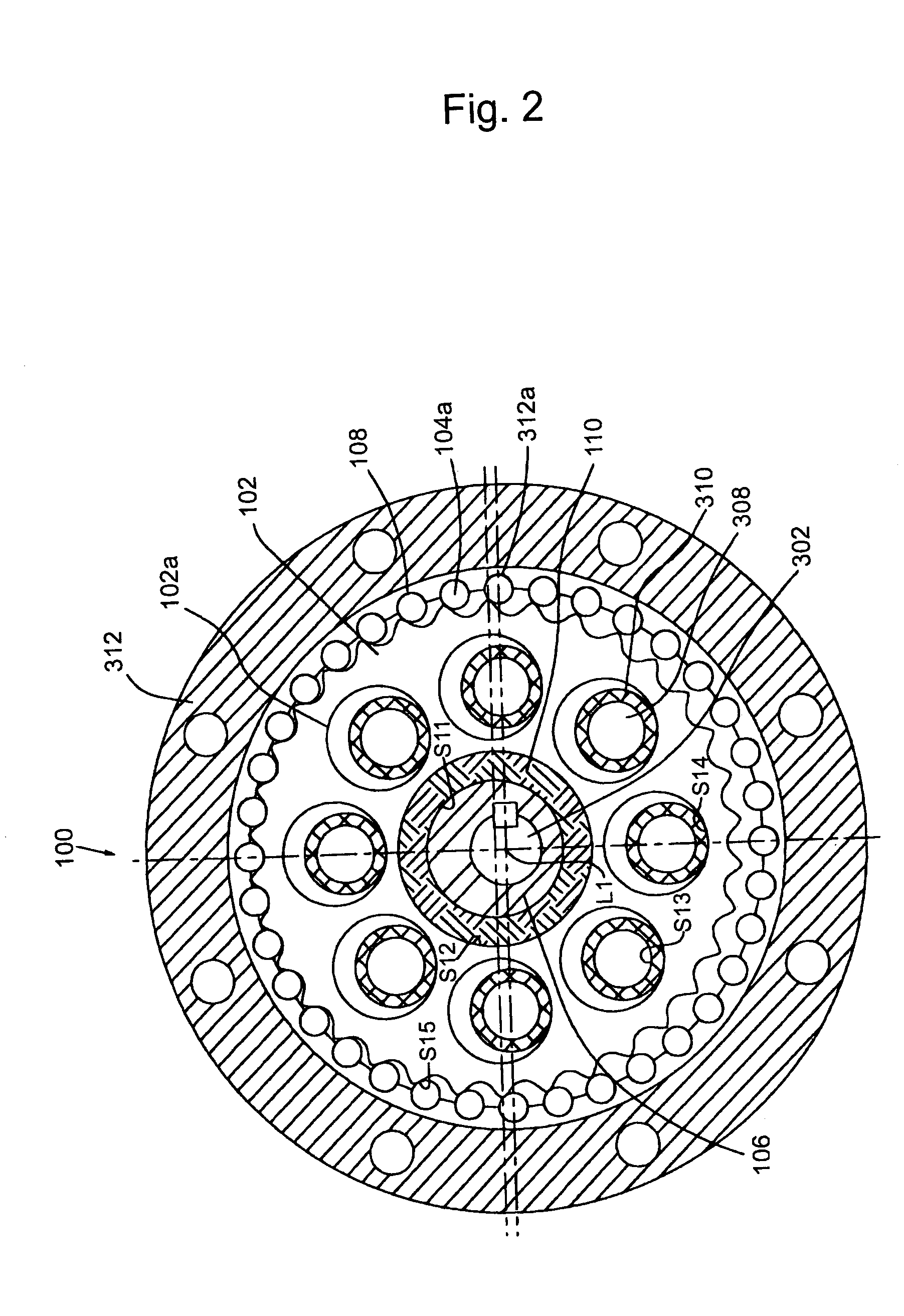

Oscillating inner gearing planetary gear system

InactiveUS7534184B2Large caliberShorten the axial lengthToothed gearingsWobble plate gearingsGear wheelGear system

An oscillating inner gearing planetary gear system is provided which does not need to occupy a large space even in a state where a driving source is joined. In particular, the axial length thereof can be shortened, and a large diameter hollow shaft therethrough can be formed. The oscillating inner gearing planetary gear system (100) is configured in such a manner that rotation of an input shaft (104) is reduced by internal oscillating bodies (116A,116B) oscillatingly rotating relative to an external gear (118), and the reduced output is delivered by the external gear (118) also serving as an output shaft. A middle shaft (108) is located parallel to the external gear (118) at a position more radially outward than the internal oscillating bodies (116A,116B). An orthogonal gearset (106) connects the middle shaft (108) and the input shaft (104) at a right angle. Power from the input shaft (104) is inputted from a direction radially outward of the internal oscillating bodies (116A,116B) through the middle shaft (108).

Owner:SUMITOMO HEAVY IND LTD

Power transmission device and method of producing the same

ActiveUS20100004087A1Smooth rotationEasy to operateWind motor controlEngine fuctionsInterference fitEngineering

The power transmission device has an internally meshing planetary gear mechanism that has an input shaft, an eccentric body provided on the input shaft, an externally toothed gear eccentrically oscillating via the eccentric body, and an internally toothed gear with which the externally toothed gear internally meshes. The externally toothed gear is assembled to the internally toothed gear in an interference fit.

Owner:SUMITOMO HEAVY IND LTD

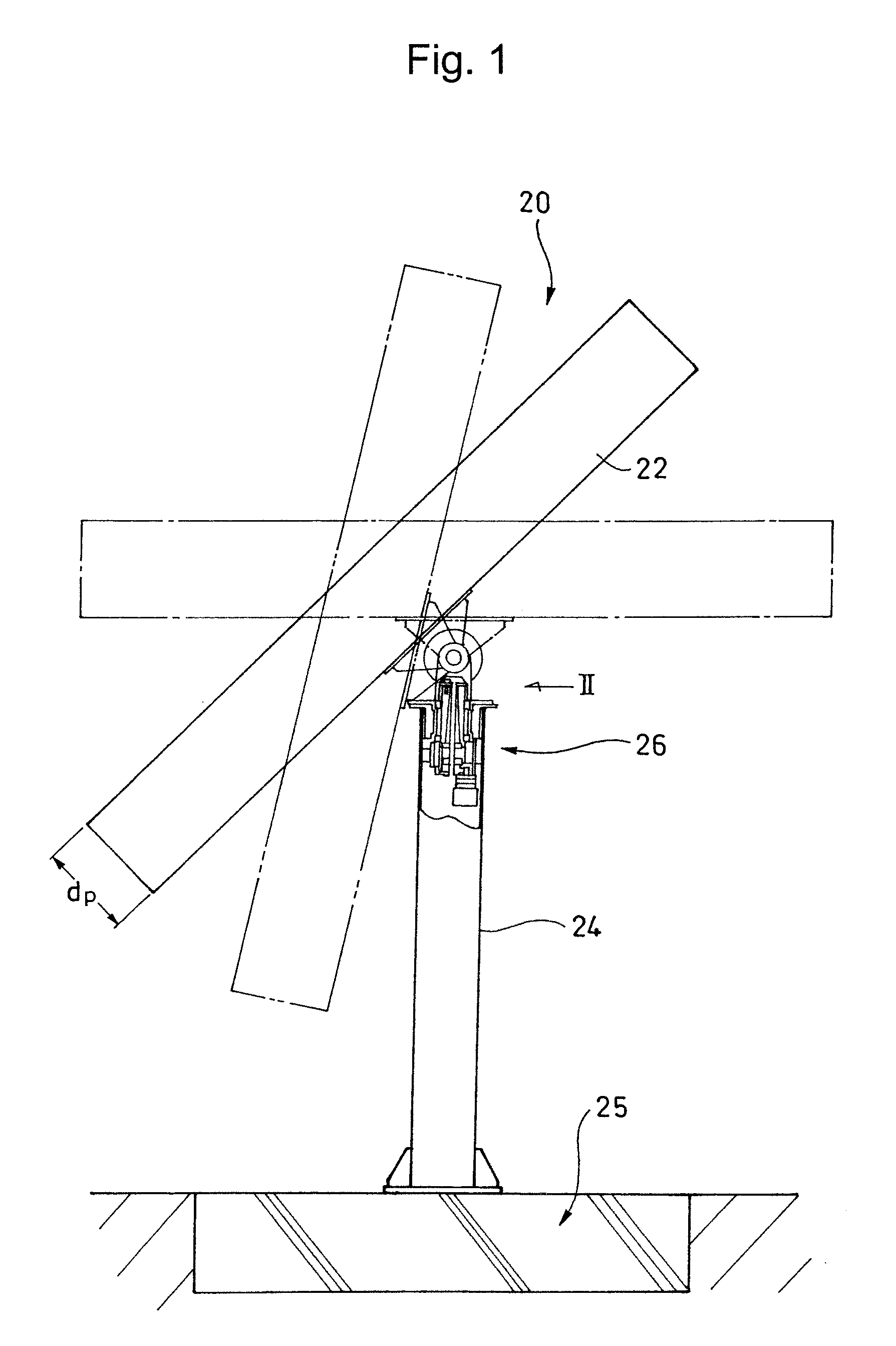

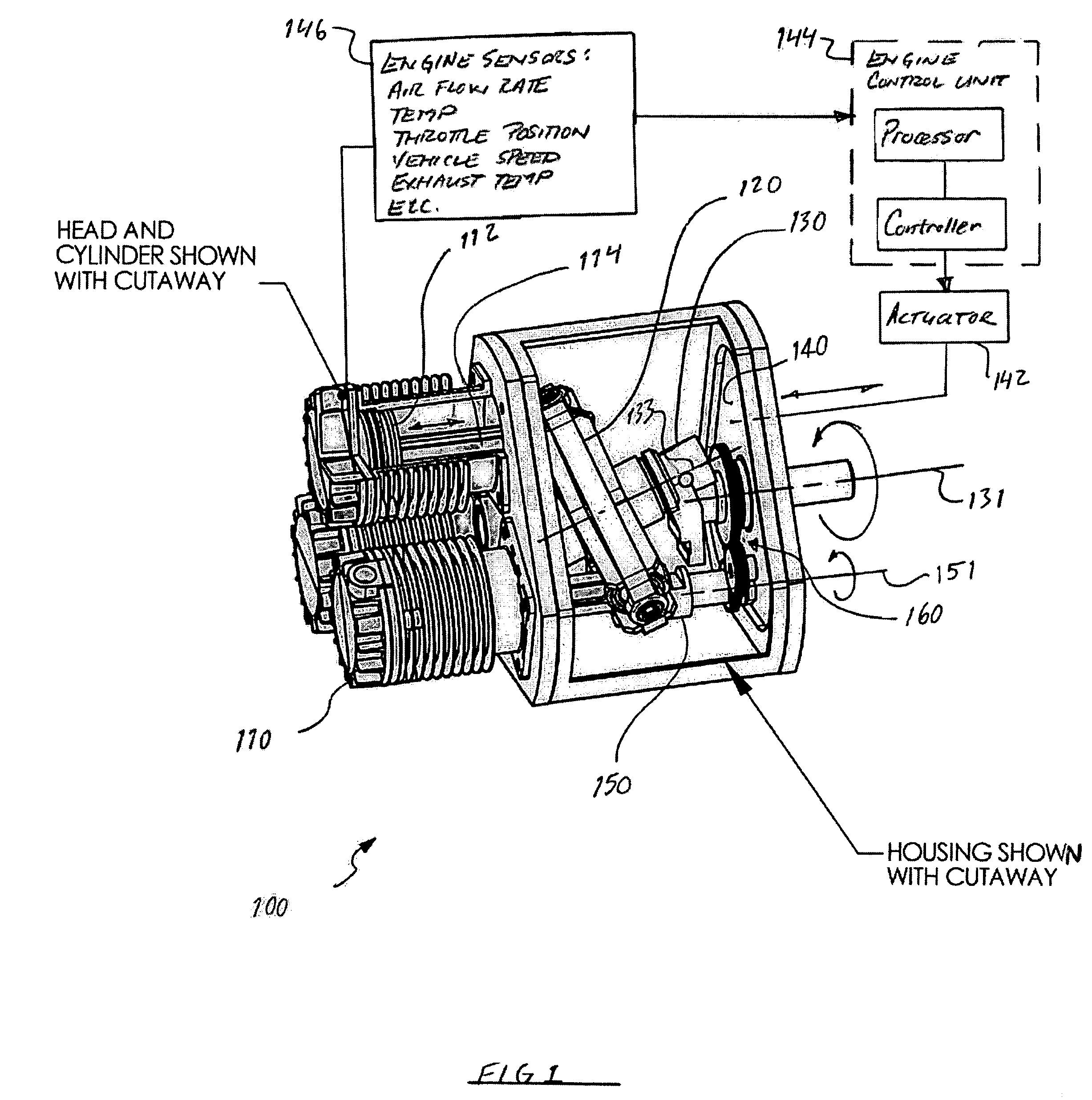

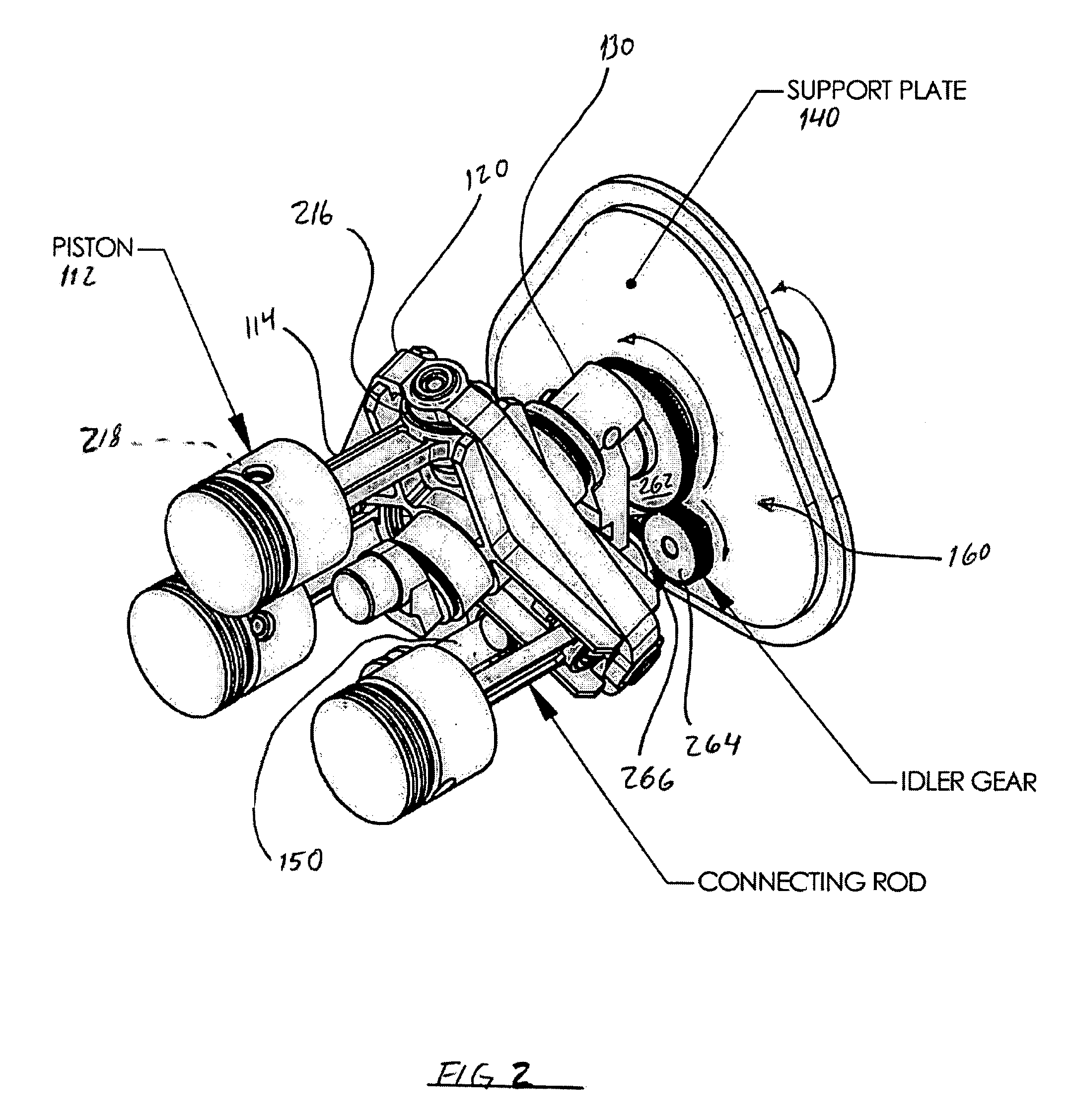

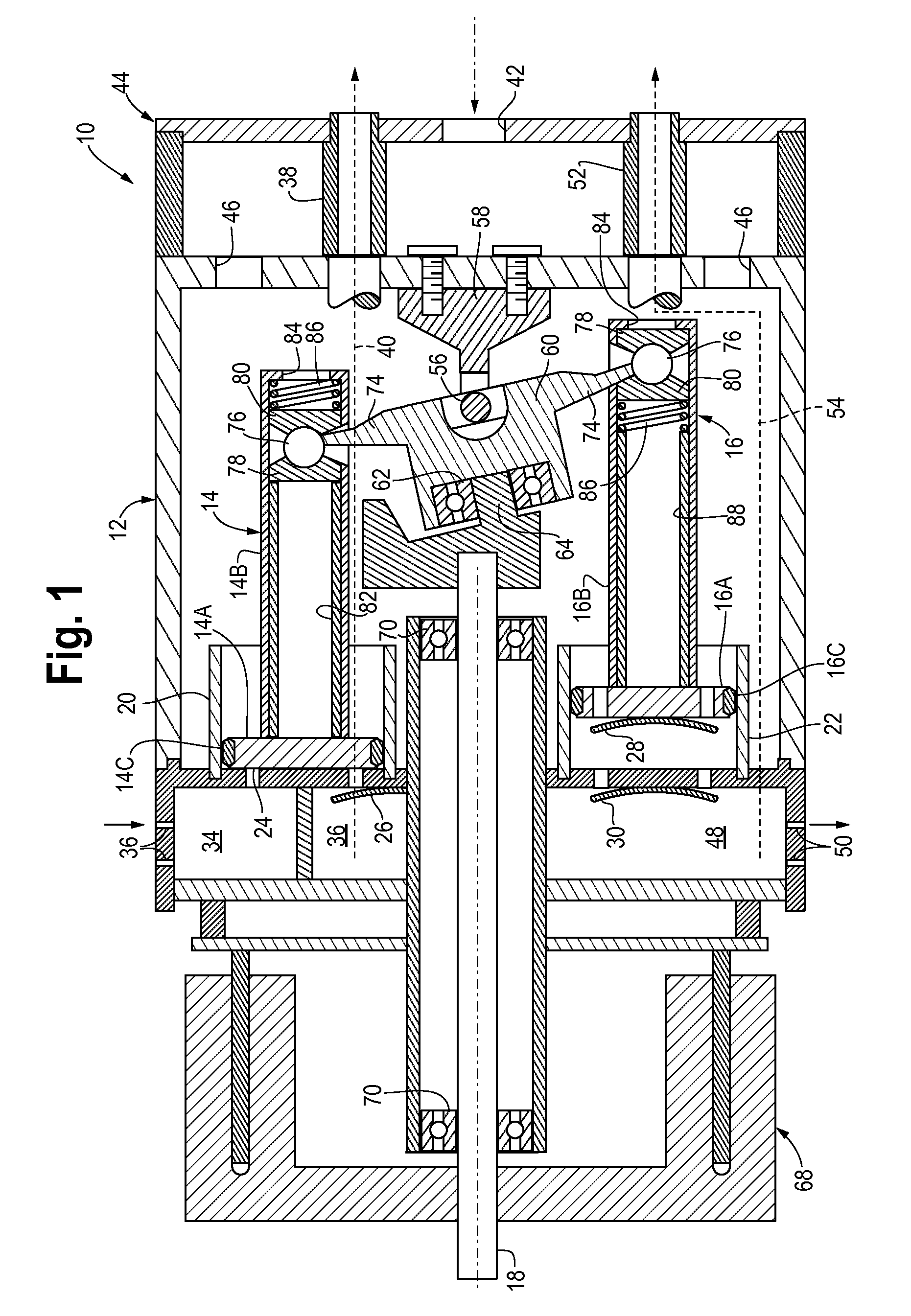

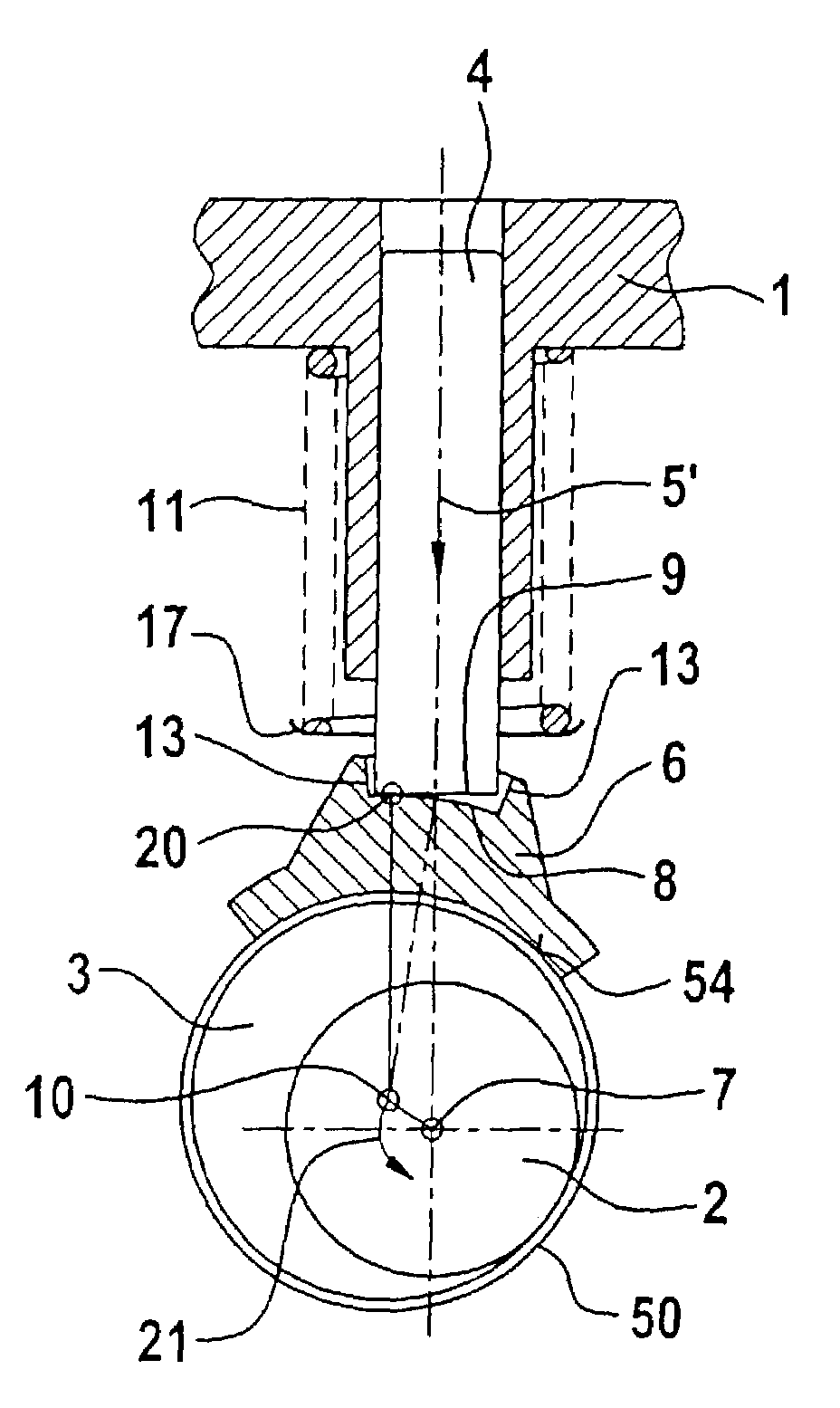

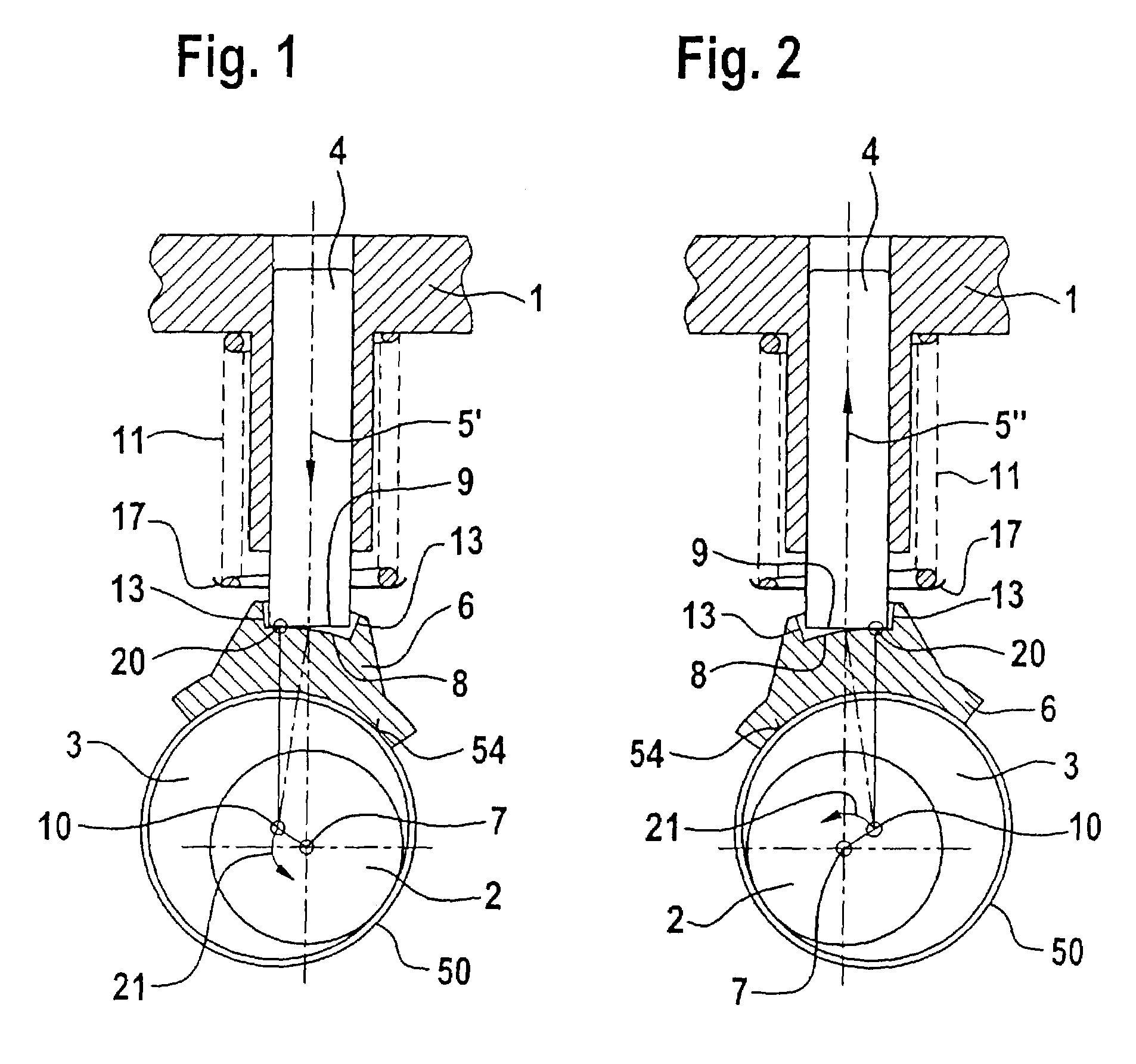

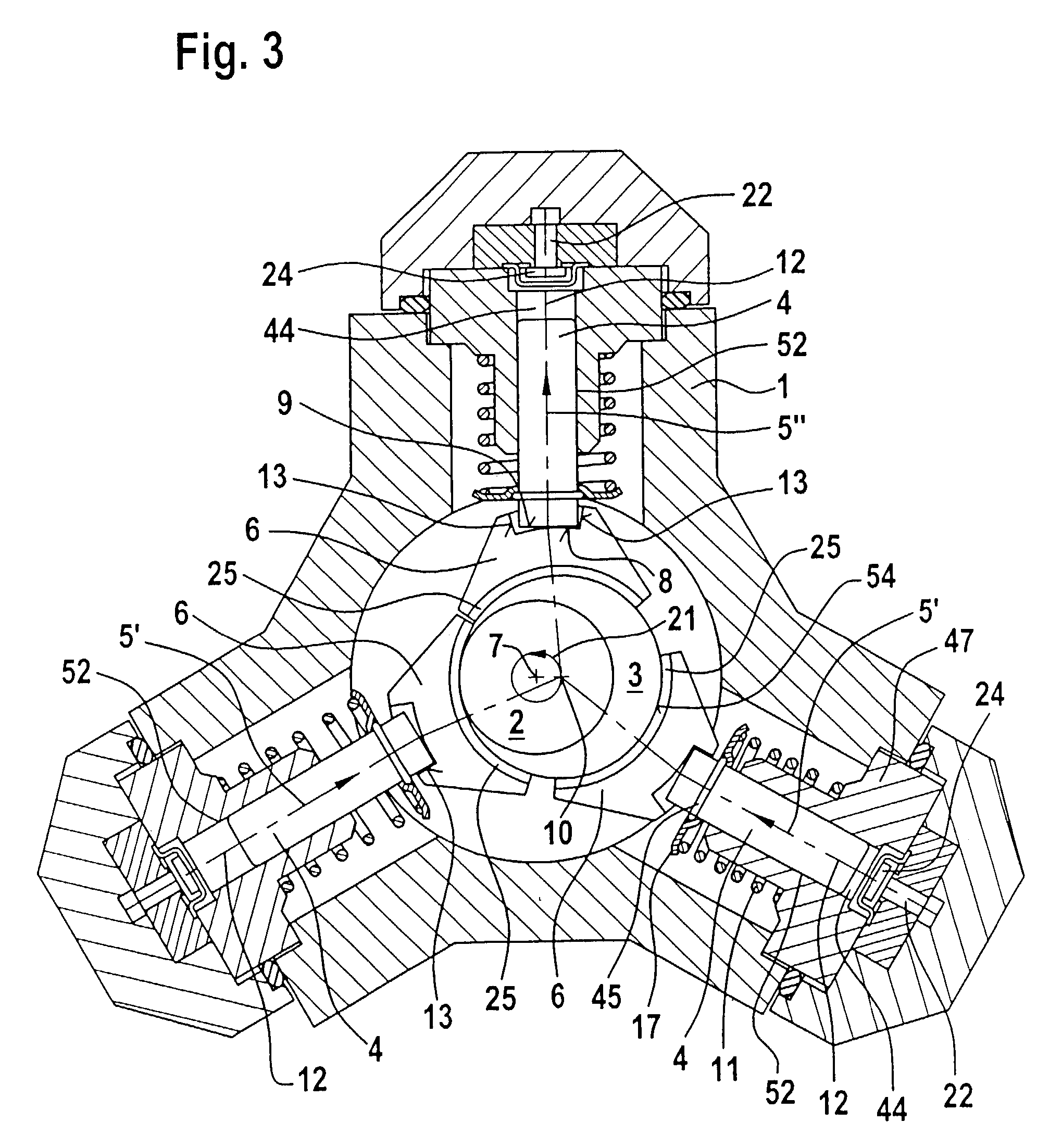

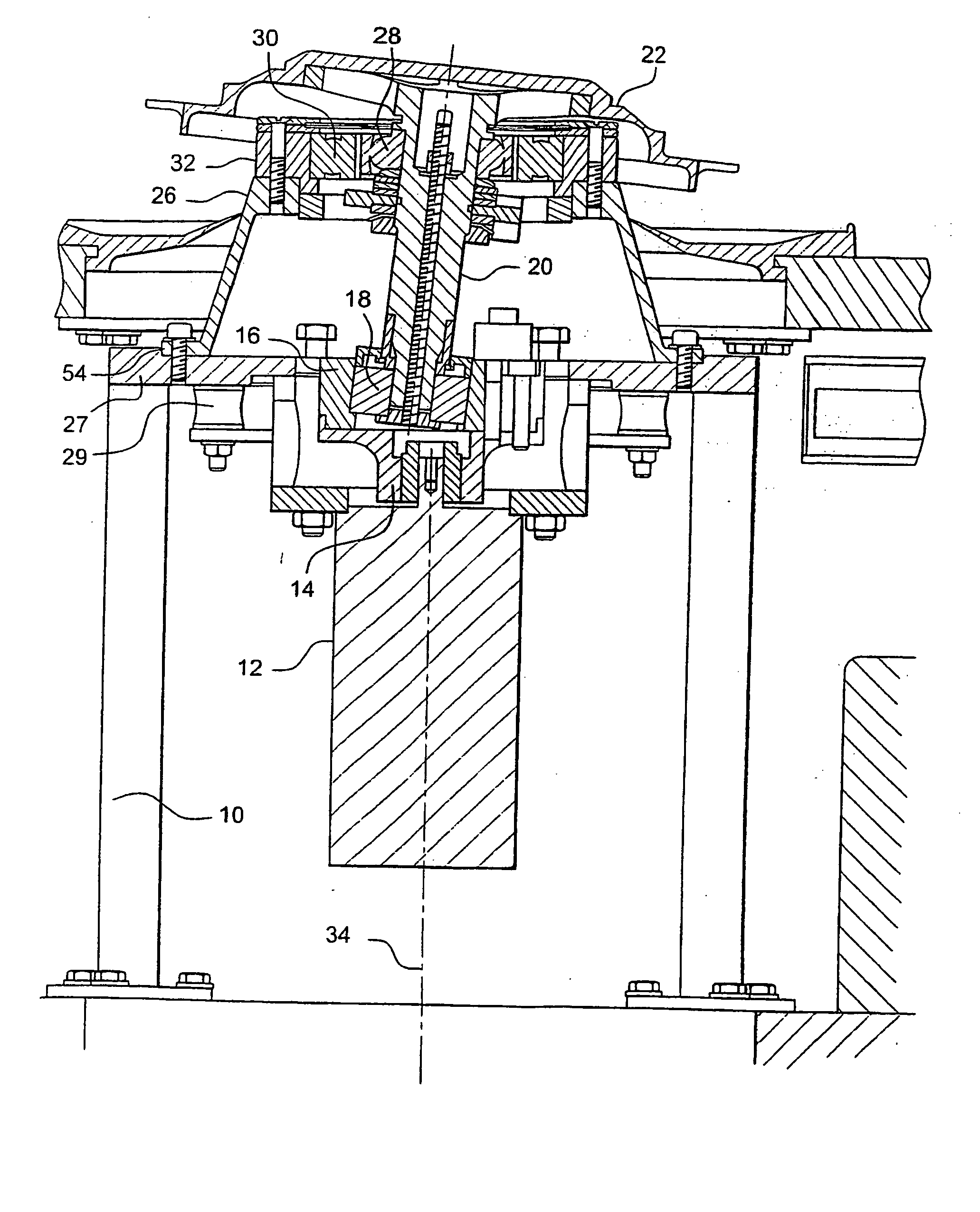

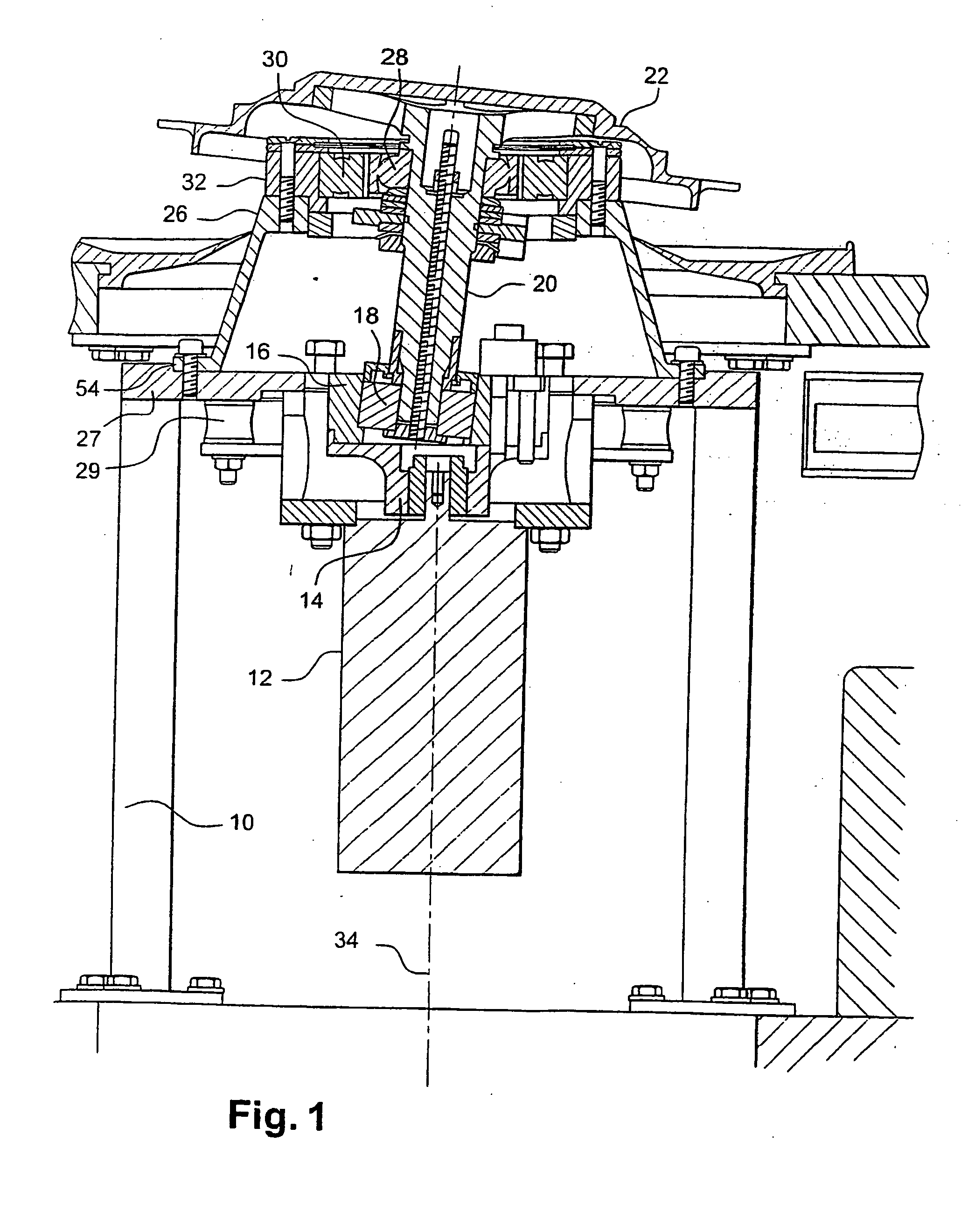

Axial piston machines

InactiveUS6968751B2Reduce friction lossImprove balanceWobble plate gearingsOblique crank gearingsCombustionReciprocating motion

This invention relates to internal combustion engines with cylinders arranged parallel to the main shaft and where reciprocating movements of the pistons are converted to rotation by means of a Z-crank mechanism and motion converter, or conversely to systems such as pumps and compressors wherein rotation of the Z-crank and motion converter produces reciprocating motions of the pistons. The motion converter is prevented from rotation by a reaction control shaft or by a gear train. Connecting rods are prevented from rotating about their long axes. Double-ended configurations can be either opposed cylinder or opposed piston, and may include multiple pairs of pistons with each pair in a common cylinder. The Z-crank may be moved axially for the purpose of varying the compression ratio. Variation of the compression ratio is controlled by an engine control unit and is adjusted to optimize engine performance under varying loads and other conditions.

Owner:INNOVATION ENG

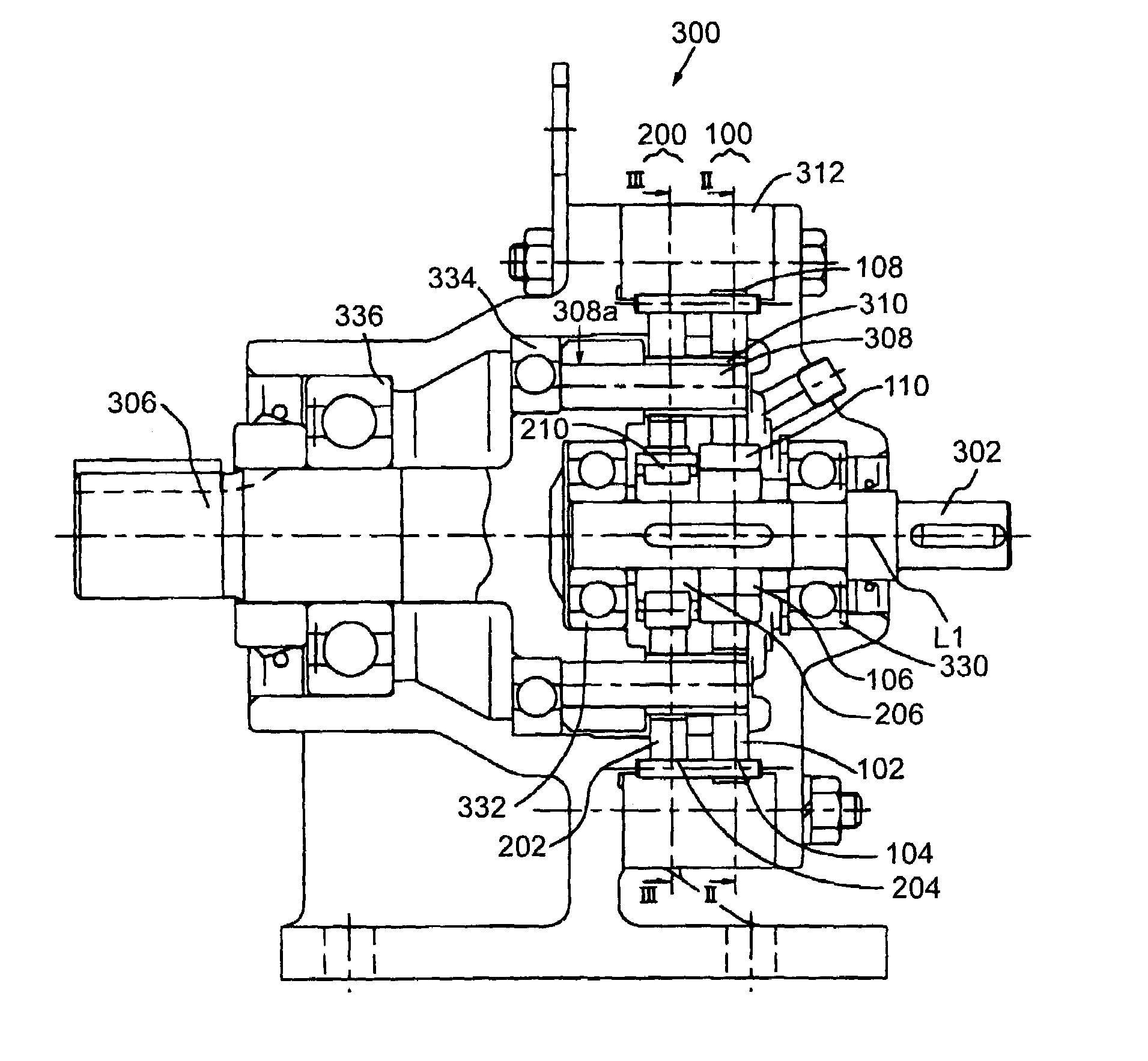

Manufacture and use of parallel eccentric electro-mechanical actuator

ActiveUS20080257088A1Reduce the total massReduce weightToothed gearingsPortable liftingRelative motionEngineering

A parallel eccentric electro-mechanical actuator provides motive power and includes an electric prime mover that drives the reducer's pinion gear. This pinion drives minimum three star gears with stationary shaft bearings. Each shaft contains an eccentric which are completely in parallel with each other. These eccentrics can be thought of as parallel / in-phase driven crankshafts. Each eccentric drives the parallel eccentric (PE) gear through a bearing. The PE gear exhibits a circular motion (without rotation) which in itself is unbalanced. The crankshafts have another eccentric which create an opposite inertia force to balance that of the PE gear. The PE gear contains an external toothed gear on its periphery. It meshes with the internal teeth of the output ring gear. The relative motion between the PE gear and the ring gear is that the PE gear rolls inside the ring gear. This relative motion is called hypo-cycloidal motion.

Owner:TESAR DELBERT

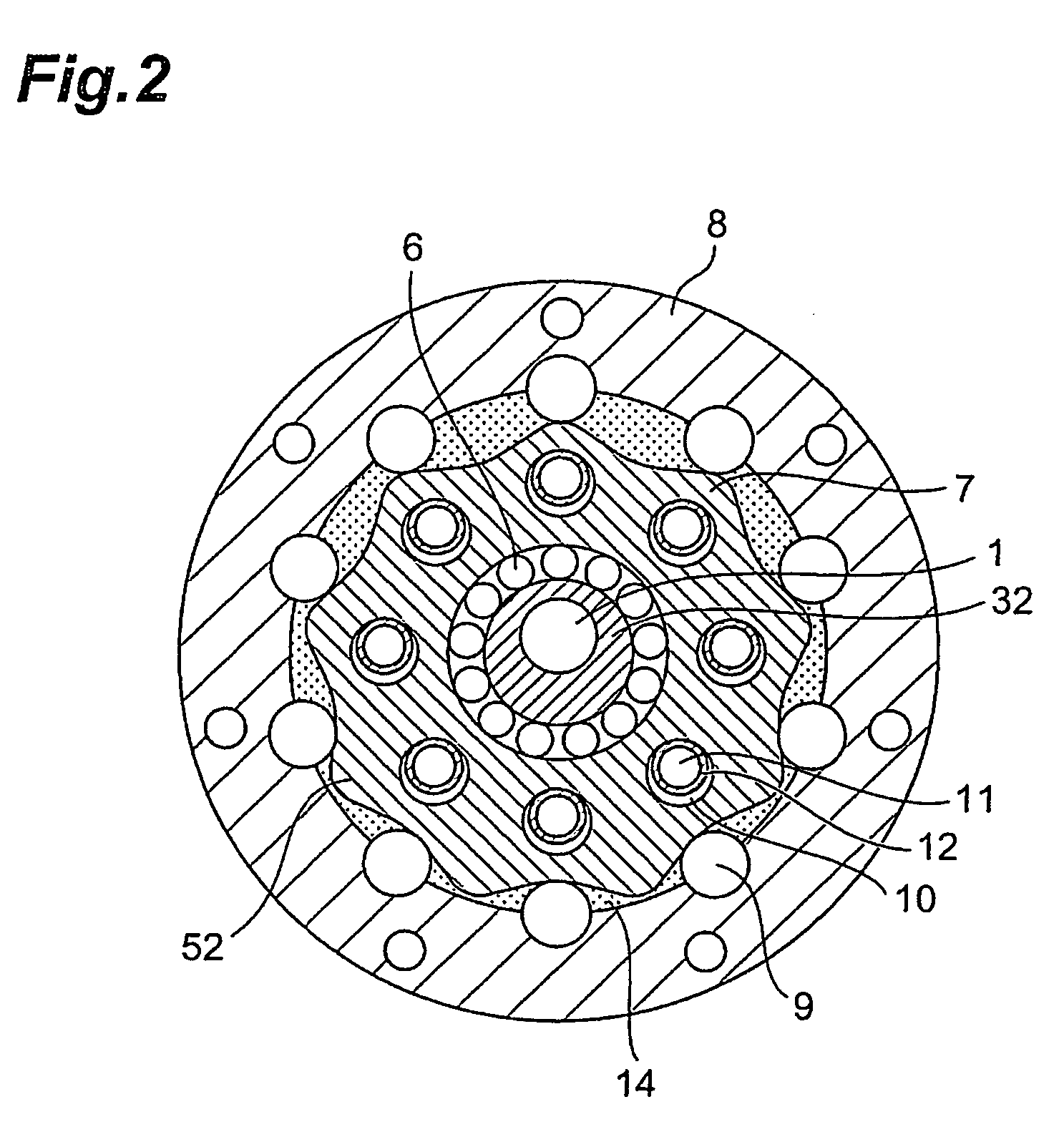

Oscillating internal-meshing planetary gear system and method for improving the durability thereof

InactiveUS20040248688A1Solution to short lifeLong operationToothed gearingsGear lubrication/coolingDrivetrainAdipic acid

In the oscillating internal-meshing planetary gear system of the present invention, a space formed between a external gear (52) and a internal gear (8) is filled up with a grease (14), which contains base oil whose kinetic viscosity is equal to or higher than 10 mm<2> / s at 100° C. and lithium complex thickener synthesized from adipic acid. Such construction of the oscillating internal-meshing planetary gear system of the present invention provides a power transmission system using a trochoidal tooth profile gear and a circular-arc tooth profile gear that enables to realize a long life and keeping a high efficiency, even without applying grease containing sodium nitrite.

Owner:SUMITOMO HEAVY IND LTD

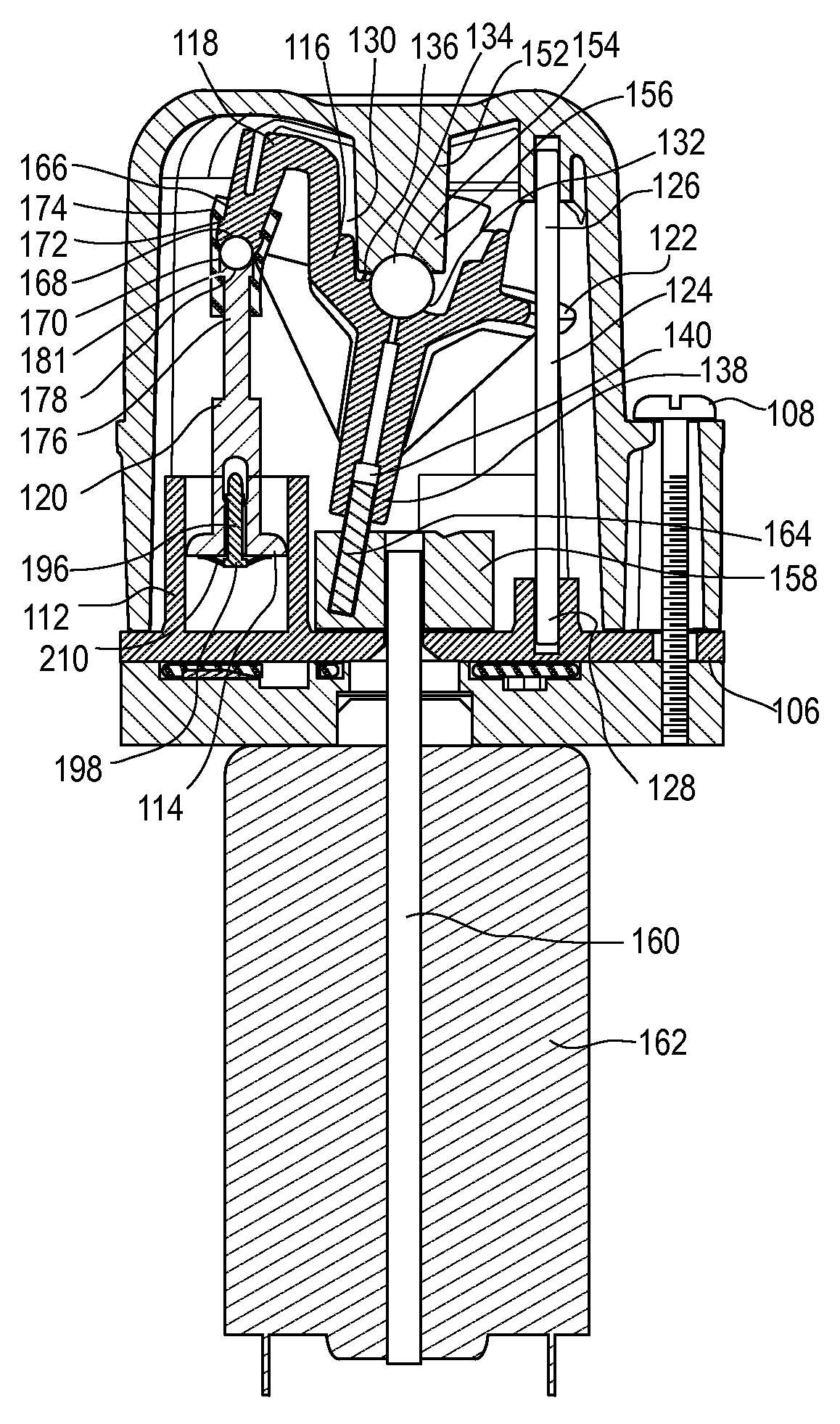

Hybrid nutating pump

InactiveUS7451687B2Eliminate connectionMinimize wobble motionPositive displacement pump componentsPressure pumpsReciprocating motionDrive shaft

A nutating pump for creating pressure or a vacuum. The nutating pump includes a housing with a center support positioned within said housing. The center support includes a semi-spherical recess. The pump also includes a drive shaft adapted to be connected to an electric motor and an eccentric adapted to be connected to the drive shaft. The pump further includes a ball adapted to form a ball joint and is adapted to be positioned within the semi-spherical recess of said center support. In addition the pump includes a nutating yoke positioned within the housing. The yoke includes a semi-spherical recess adapted to accept said pivot ball. The nutating yoke is adapted to be connected to the eccentric, such that rotation of the eccentric causes the yoke to move about the ball. The pump also includes a connecting rod connected to the yoke, a piston connected to the connecting rod and a cylinder adapted to accept the piston, wherein the movement of the yoke about the ball causes the piston to reciprocate within the cylinder.

Owner:GARDNER DENVER THOMAS

Radial piston pump with piston rod elements in rolling contact with the pump pistons

In a piston pump for providing high-pressure fuel in a common-rail fuel injection system including a camshaft (2), which is mounted rotatably in a pump housing (1) and which has at least one eccentric cam 93) for operating a pump piston (4, 14) in an approximately radial direction with respect to the camshaft (2), in order to reduce the wear of the piston pump, a piston-rod element (6, 16, 26, 36, 46) is arranged between each pump piston (4, 14) and the eccentric cam (3) so as to transmit the stroke movement (5) and the force from the eccentric cam of the camshaft (2) to the pump piston (4, 14) by a rolling movement.

Owner:DAIMLER AG

Self-contained rotary actuator

InactiveUS7431676B2Lower Level RequirementsGearboxesWithout power ampliicationDrive shaftEngineering

Owner:FATHOM5 CORP

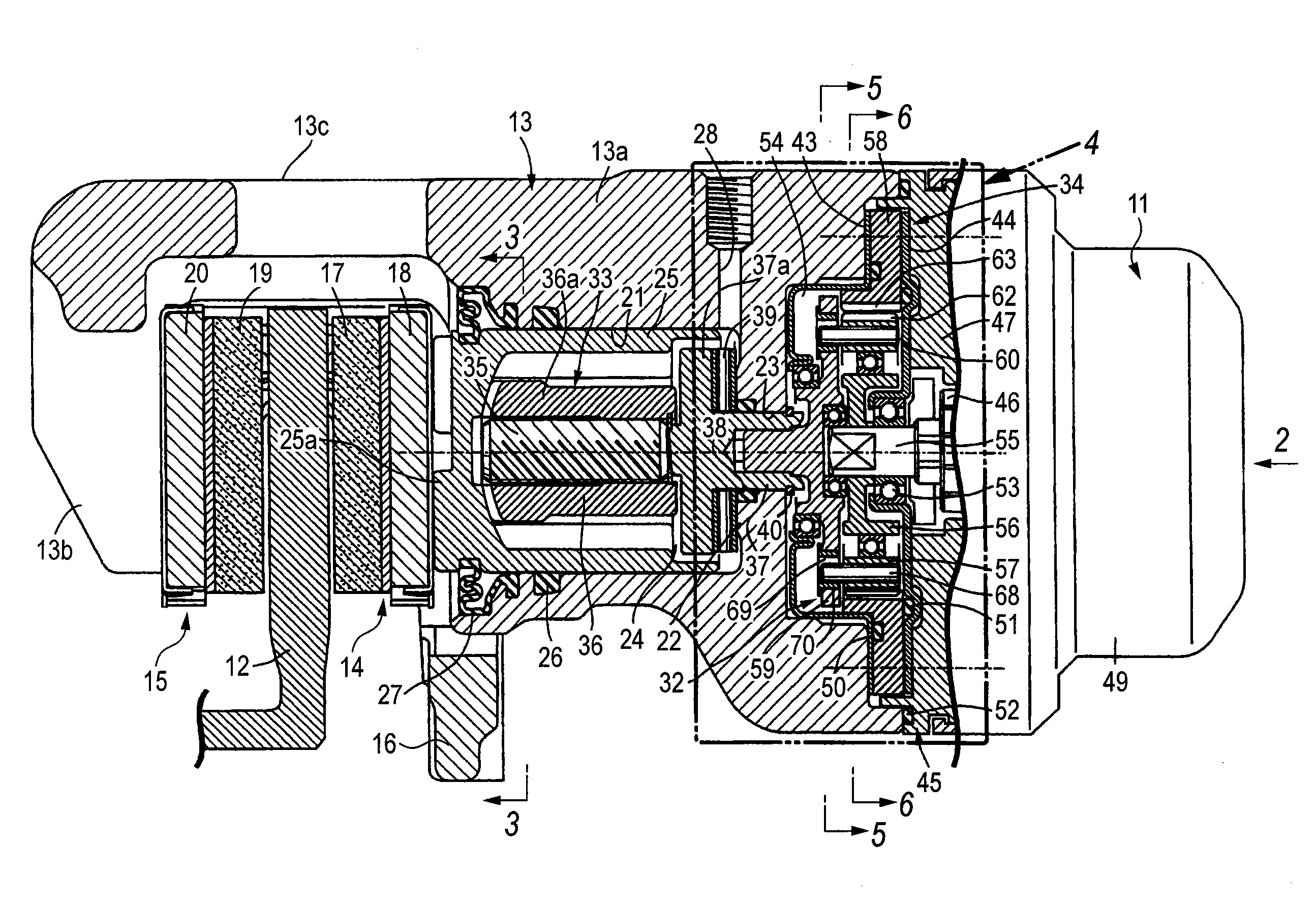

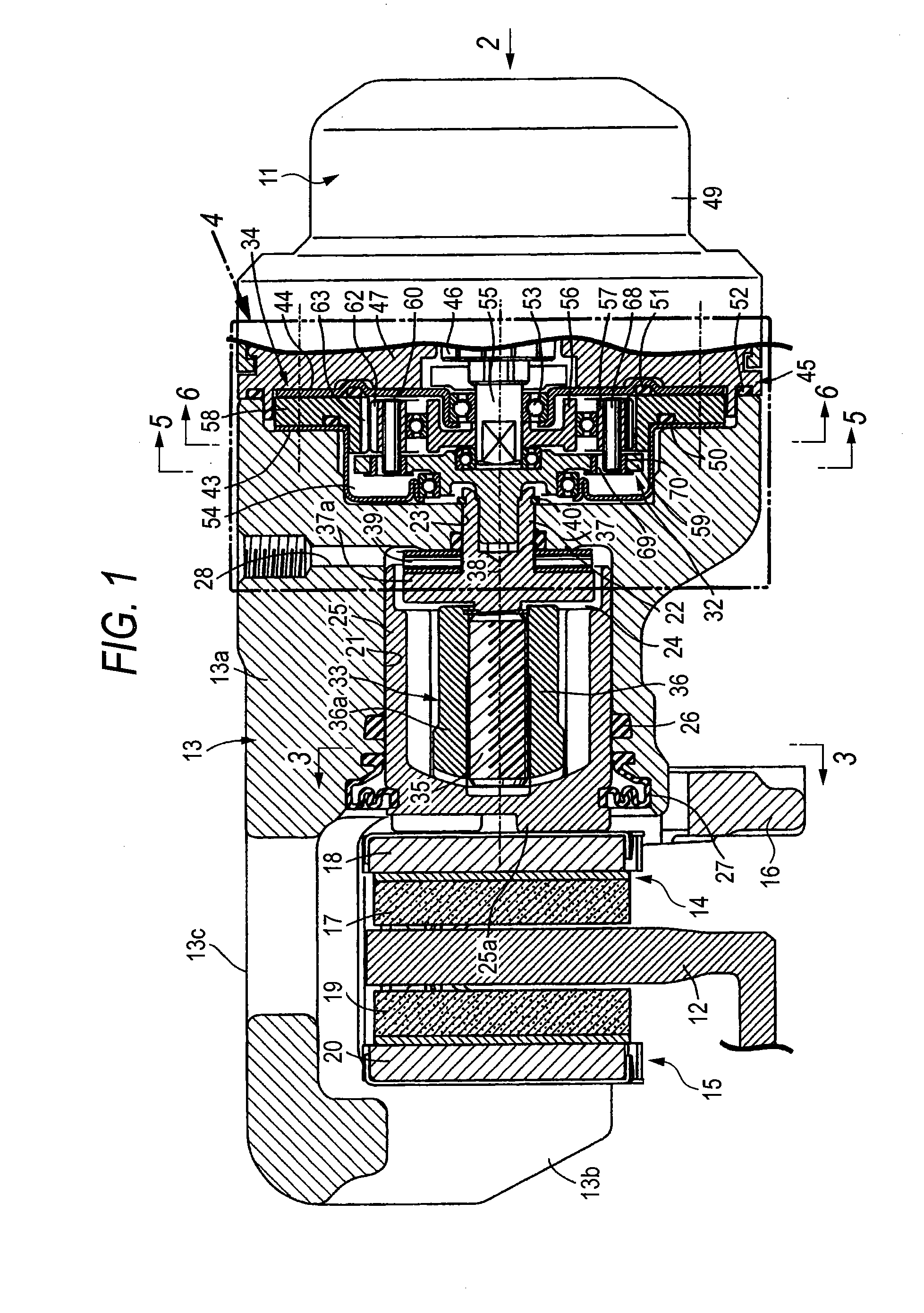

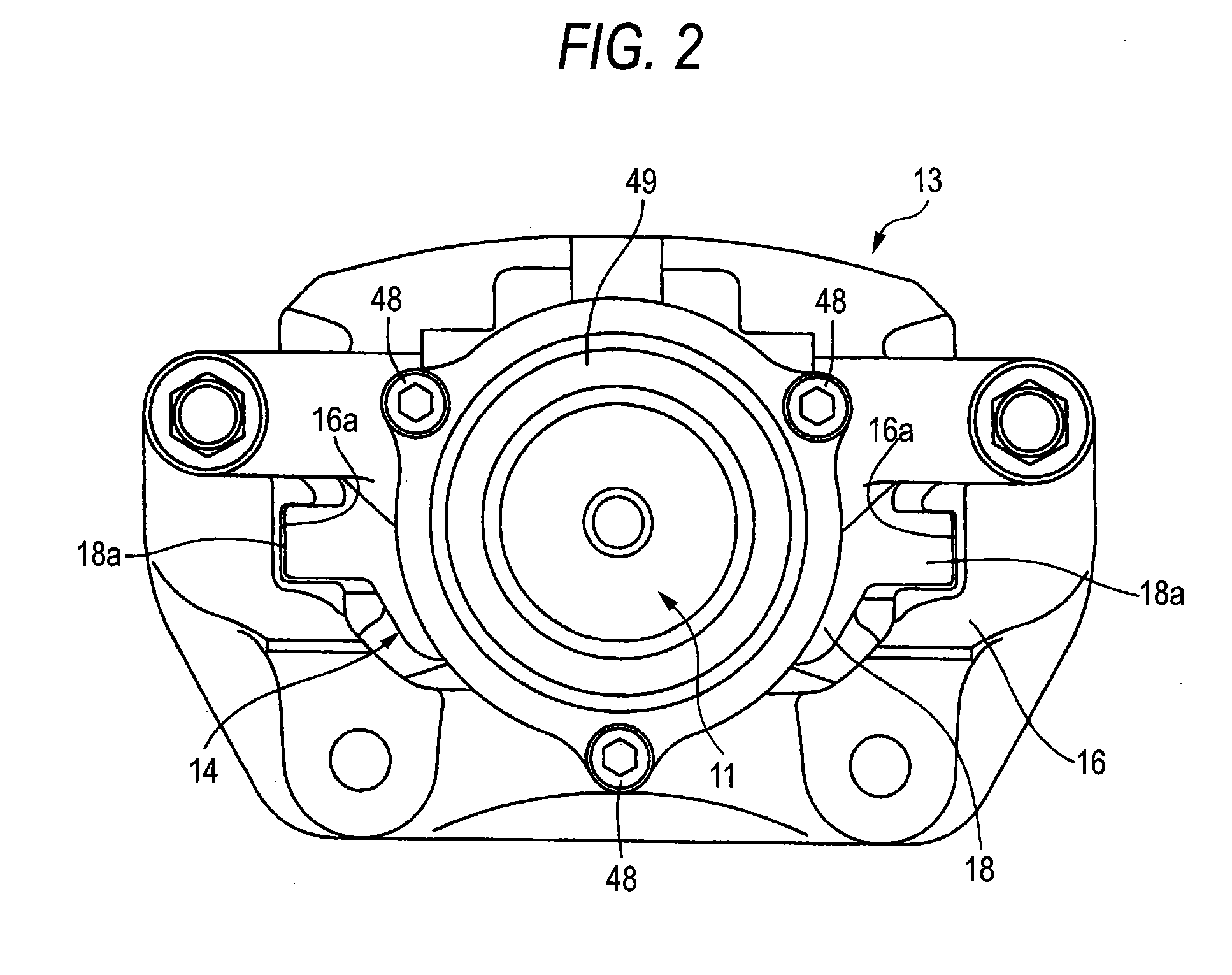

Vehicular disk brake

InactiveUS20070209888A1Simple configurationAvoid shakingMechanically actuated brakesElectrodynamic brake systemsEngineeringReducer

A speed reducer 32 has an eccentric rotating member 56 which rotates along with a motor shaft 55 of an electric motor 11, an outer gear 57 which is rotatably supported by the outer circumference of the eccentric rotating member 56, an inner gear 58 which is fixedly disposed so as to be coaxial with the motor shaft 55 so as to engage with the outer gear 57, an output member 59 which is connected to an input member 37 of the motion converting mechanism 22 disposed so as to be coaxial with the motor shaft 55 so as to be not relatively rotatable about the input member 37, and an Oldham mechanism 60 which is disposed between the outer gear 57 and the output member 59 so as to transmit only a rotational component of the outer gear 57.

Owner:NISSIN KOGYO CO LTD

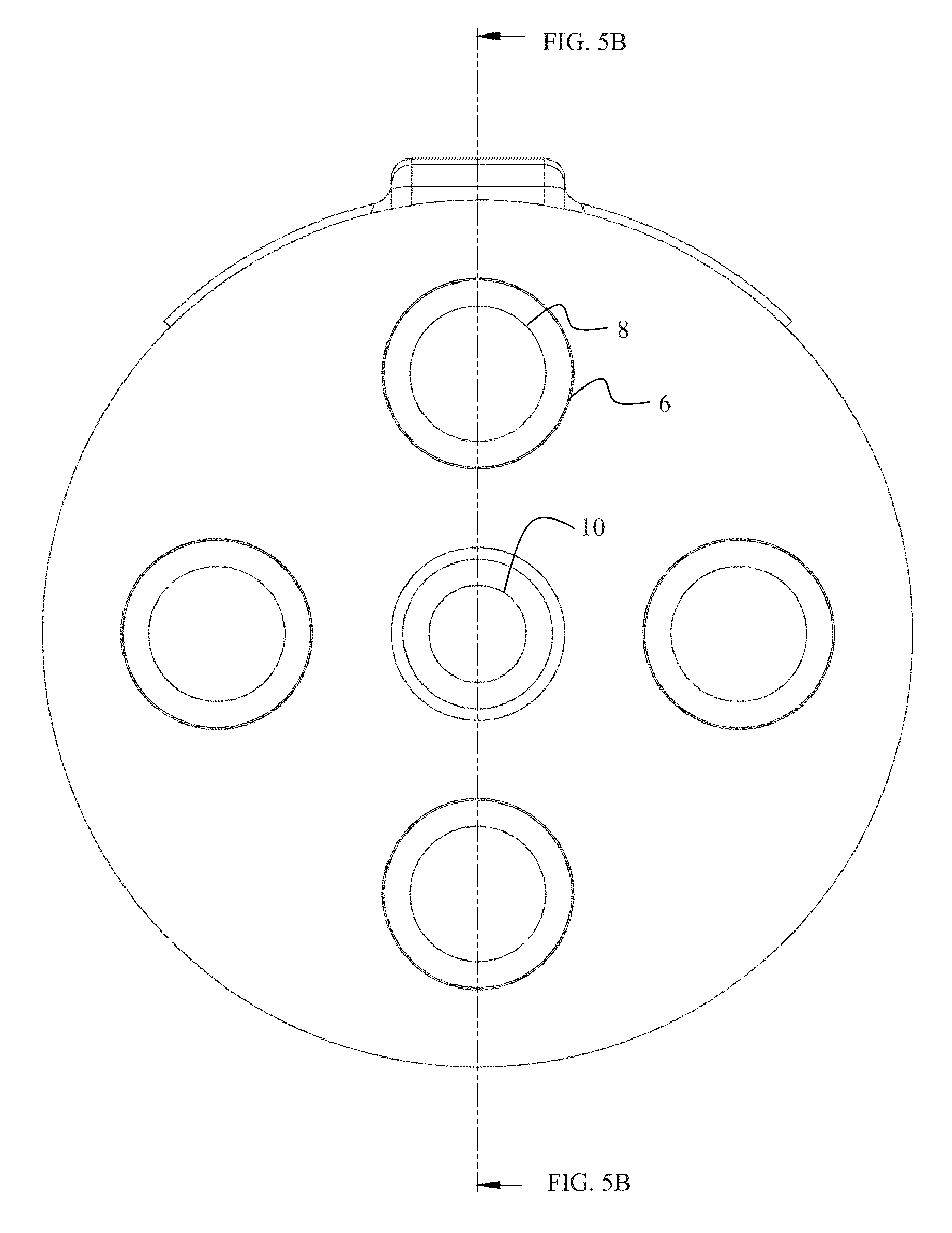

Device for fast vibration of tubes containing samples

InactiveUS7101077B2Simple and effective and inexpensiveBioreactor/fermenter combinationsBiological substance pretreatmentsReciprocating motionRolling-element bearing

Apparatus for rapidly vibrating tubes containing samples, e.g. biological samples, comprises a tube-support disk and concentric bearings for mounting the disk in a ring that is resiliently-suspended from a frame, the bearings comprising two rolling bearings mounted one within the other. The invention enables the tubes containing samples to be subjected to curvilinear reciprocating motion at high frequency.

Owner:BERTIN TECHNOLOGIES

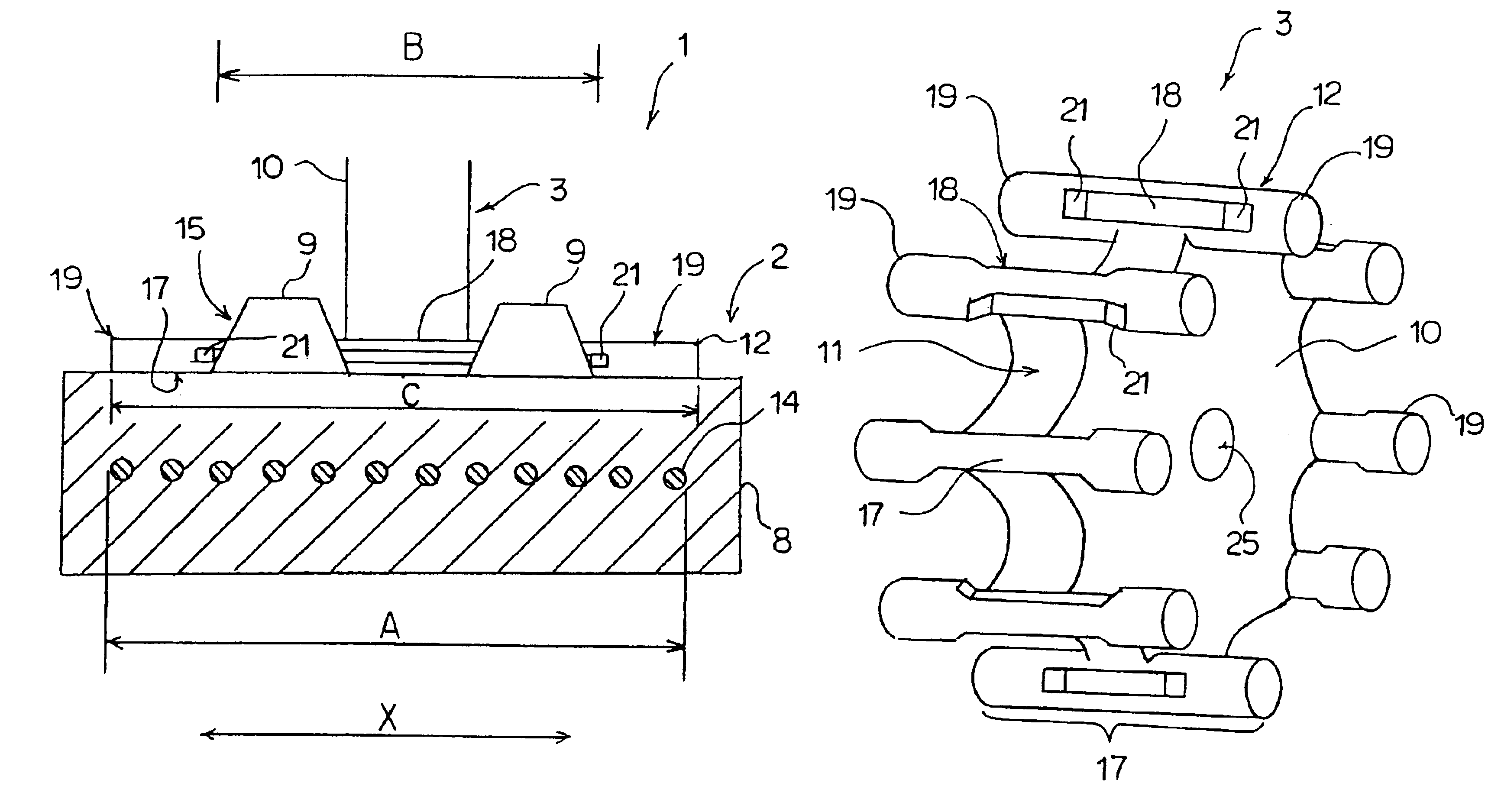

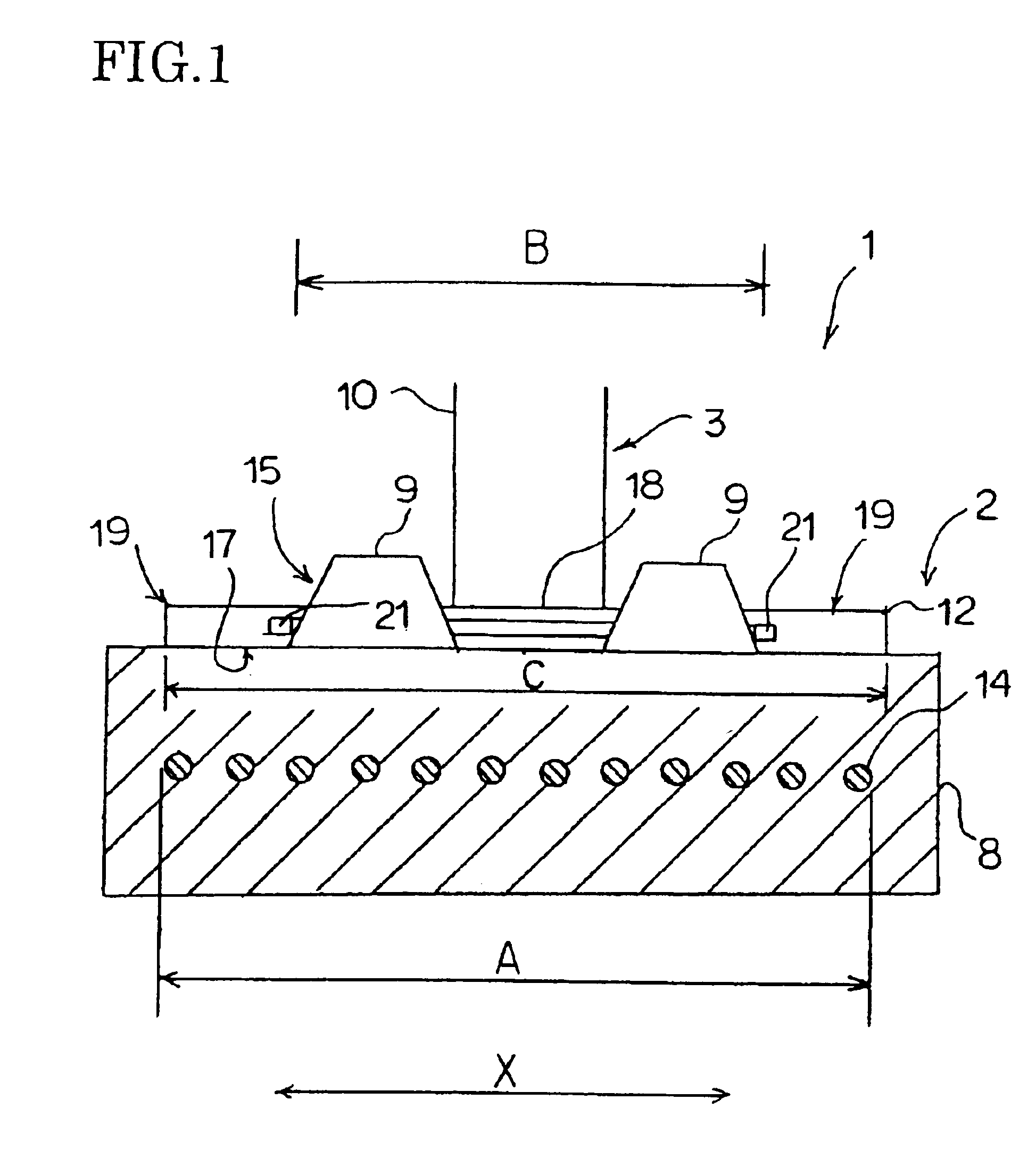

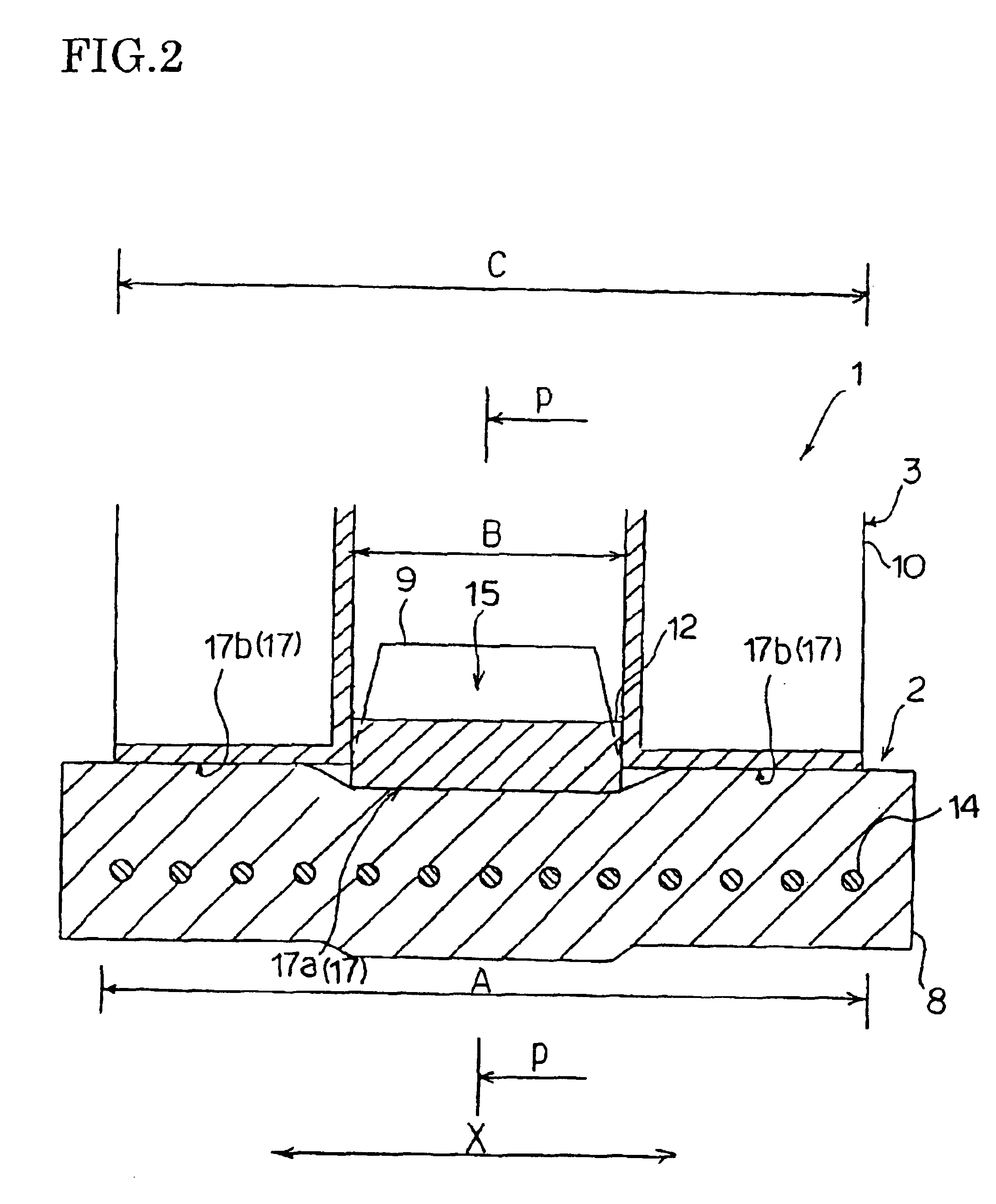

Speed change gear and manufacturing method therefor

ActiveUS20110245030A1Without impairing assembling efficiencyReliable forceMetal-working apparatusToothed gearingsEngineeringMechanical engineering

A speed change gear includes: an internal gear member; an eccentric member; an oscillating member; a pair of first and second rotating members; and a pin that is supported at both ends by insertion holes of the first and second rotating members. The insertion hole and the insertion hole have the same diameter. The outside diameter of the other side end portion of the pin is smaller than the outside diameter of one side end portion of the pin such that the one side end portion is press-fitted in the corresponding insertion hole and the other side end portion is supported by the corresponding insertion hole.

Owner:JTEKT CORP

Manufacture and use of parallel eccentric electro-mechanical actuator

InactiveUS8033942B2Simple designImprove versatilityPortable liftingToothed gearingsGear wheelRelative motion

A parallel eccentric electro-mechanical actuator provides motive power and includes an electric prime mover that drives the reducer's pinion gear. This pinion drives minimum three star gears with stationary shaft bearings. Each shaft contains an eccentric which are completely in parallel with each other. These eccentrics can be thought of as parallel / in-phase driven crankshafts. Each eccentric drives the parallel eccentric (PE) gear through a bearing. The PE gear exhibits a circular motion (without rotation) which in itself is unbalanced. The crankshafts have another eccentric which create an opposite inertia force to balance that of the PE gear. The PE gear contains an external toothed gear on its periphery. It meshes with the internal teeth of the output ring gear. The relative motion between the PE gear and the ring gear is that the PE gear rolls inside the ring gear. This relative motion is called hypo-cycloidal motion.

Owner:TESAR DELBERT

Internal teeth oscillating inner gearing planetary gear system

InactiveUS7056253B2Improve smoothnessReduce component countToothed gearingsWobble plate gearingsGear systemEngineering

An internal teeth oscillating inner gearing planetary gear system is provided with an input shaft, an eccentric gear rotated by the input shaft, the internal oscillating body oscillatingly rotated through the inner circumferential surface of the eccentric gear, and an external gear meshed with the internal oscillating body.

Owner:SUMITOMO HEAVY IND LTD

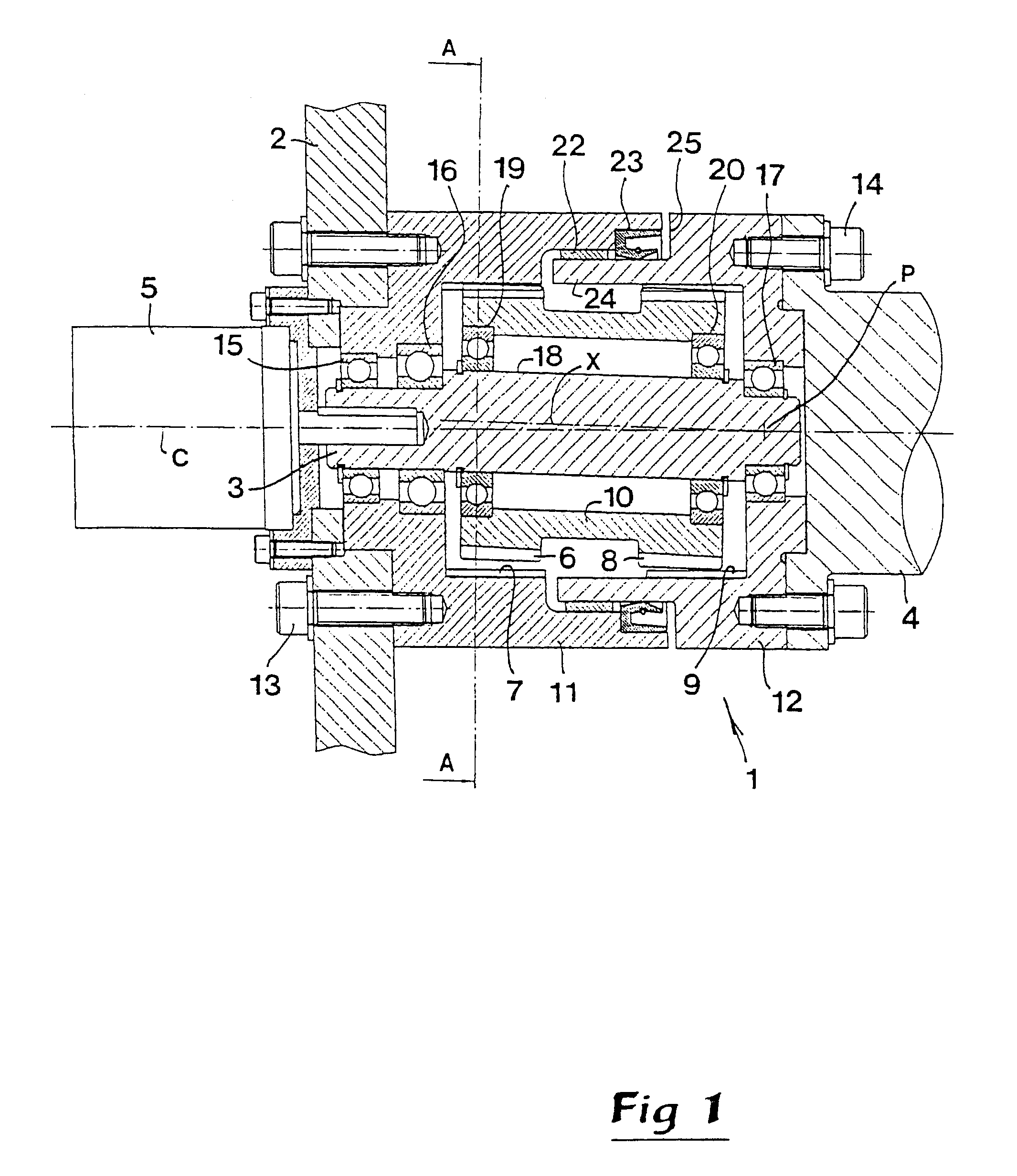

Eccentric gear

An eccentric gear for providing a speed difference between two machine elements which are rotatably journalled in relation to a reference member and individually rotatable around a symmetry axis. The gear includes two pairs of co-operating gear rims, one of which in each pair is eccentric in relation to the axis and one of which is in the form of a male gear rim with out-turned teeth, and the other one is a female gear rim with in-turned teeth. One of the gear rims in each pair is rigidly connected to a homologous gear rim in the other pair of gear rims and situated along a common axis that is eccentric and oblique in relation to the axis while the other gear rims are rotatable in relation to each other.

Owner:EWELLIX AB

Eccentric oscillating gear mechanism and industrial robot joint construction using the same

ActiveUS20090124446A1Easy constructionConvenience to workProgramme-controlled manipulatorToothed gearingsEngineeringMechanical engineering

There is provided an eccentric oscillating gear mechanism including an internal gear, an external gear meshing with the internal gear, a crankshaft for moving the external gear eccentrically, and a carrier for supporting rotatably the crankshaft, the internal gear and the carrier being made to rotate relatively, wherein a cylindrical tube body, which penetrates the eccentric oscillating gear mechanism in an axial direction, is supported rotatably on the carrier.

Owner:NABLESCO CORP

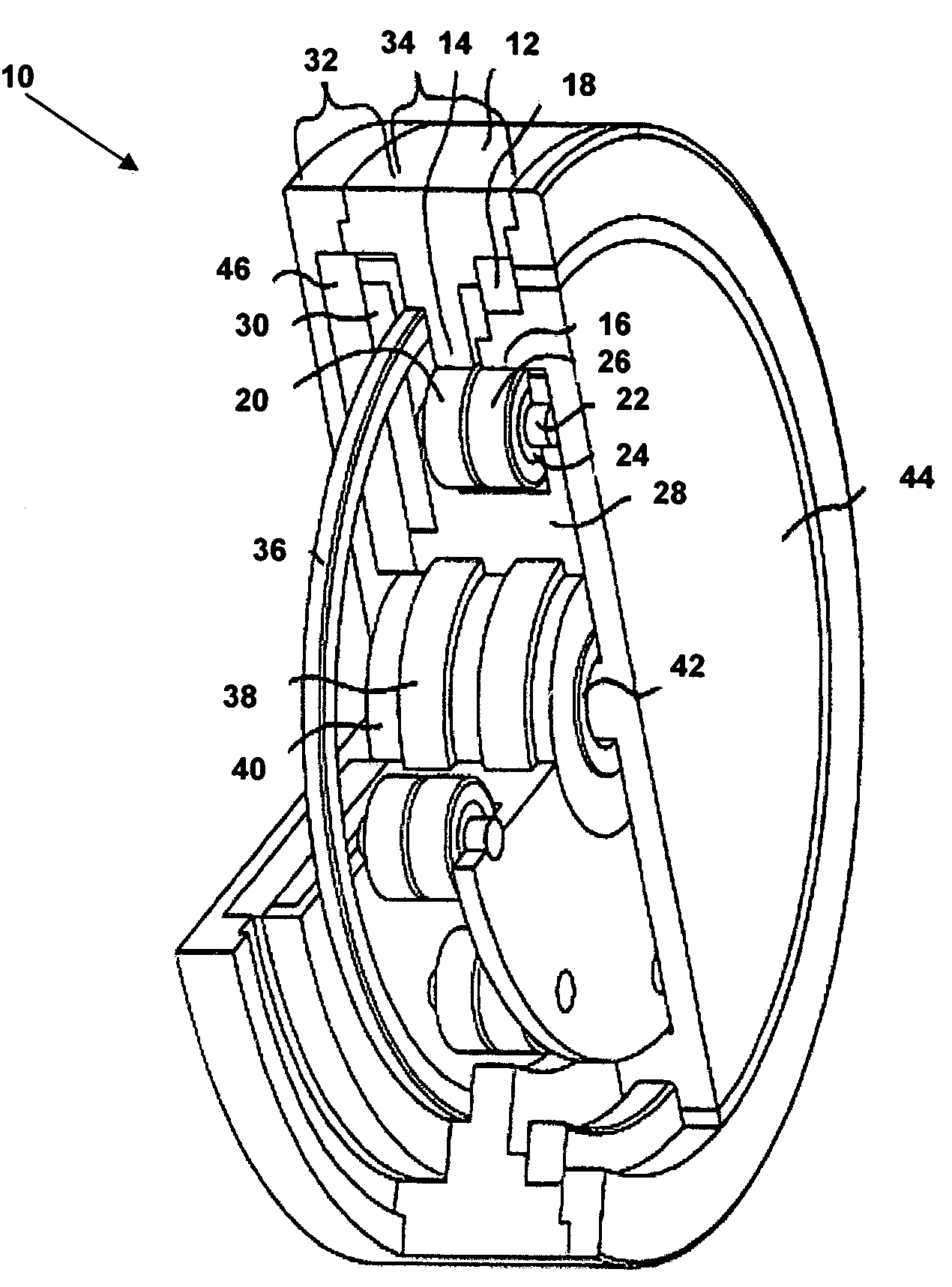

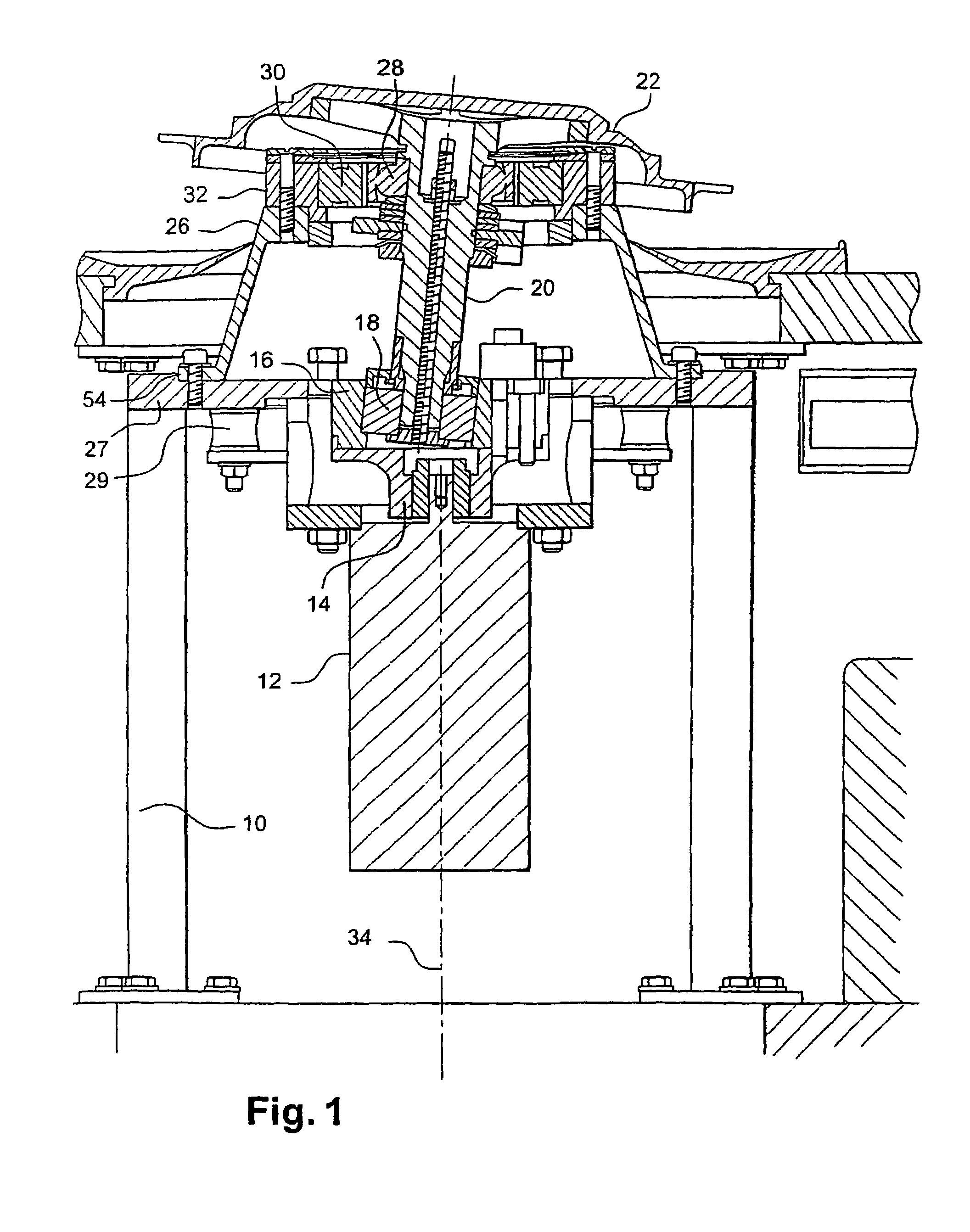

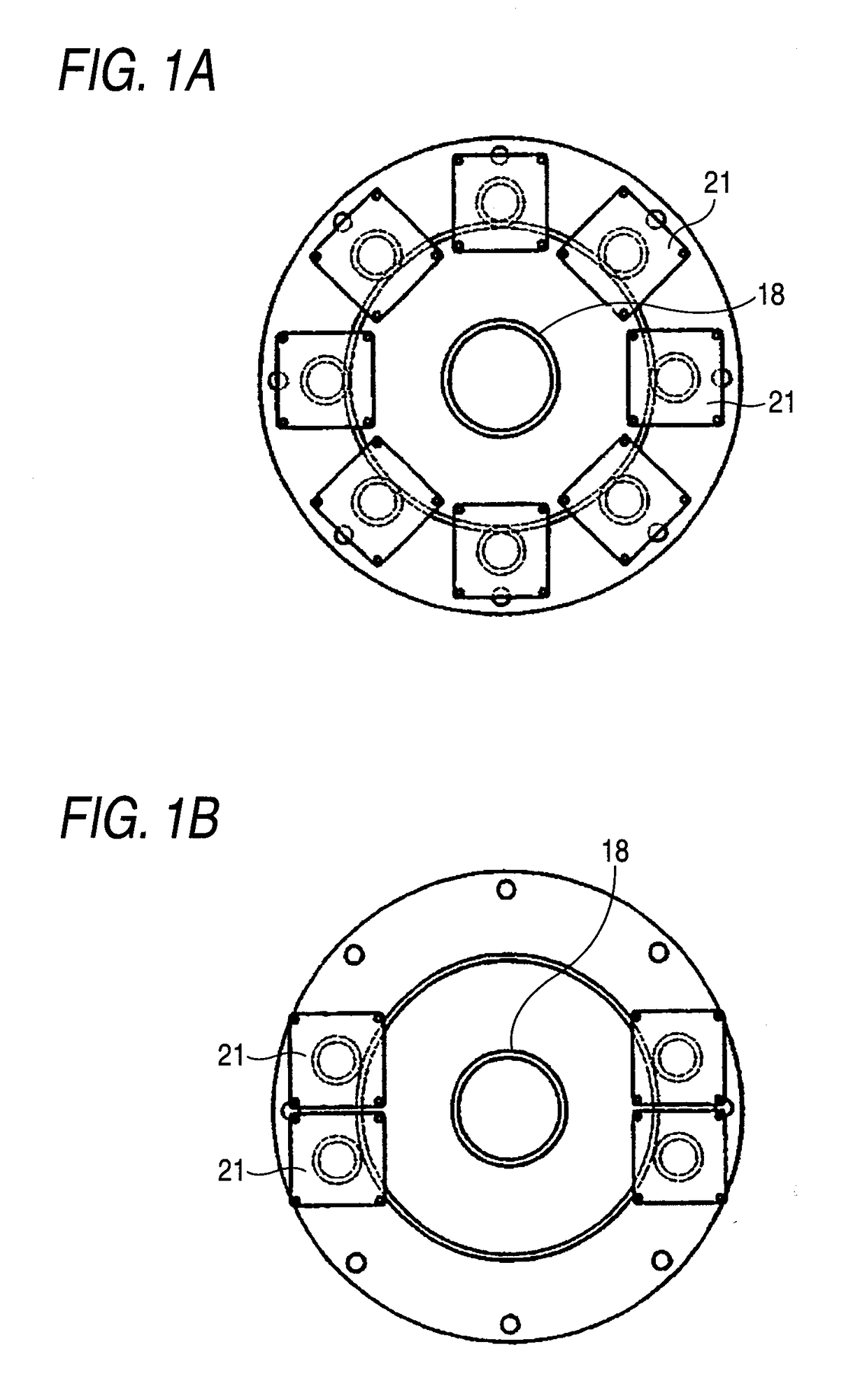

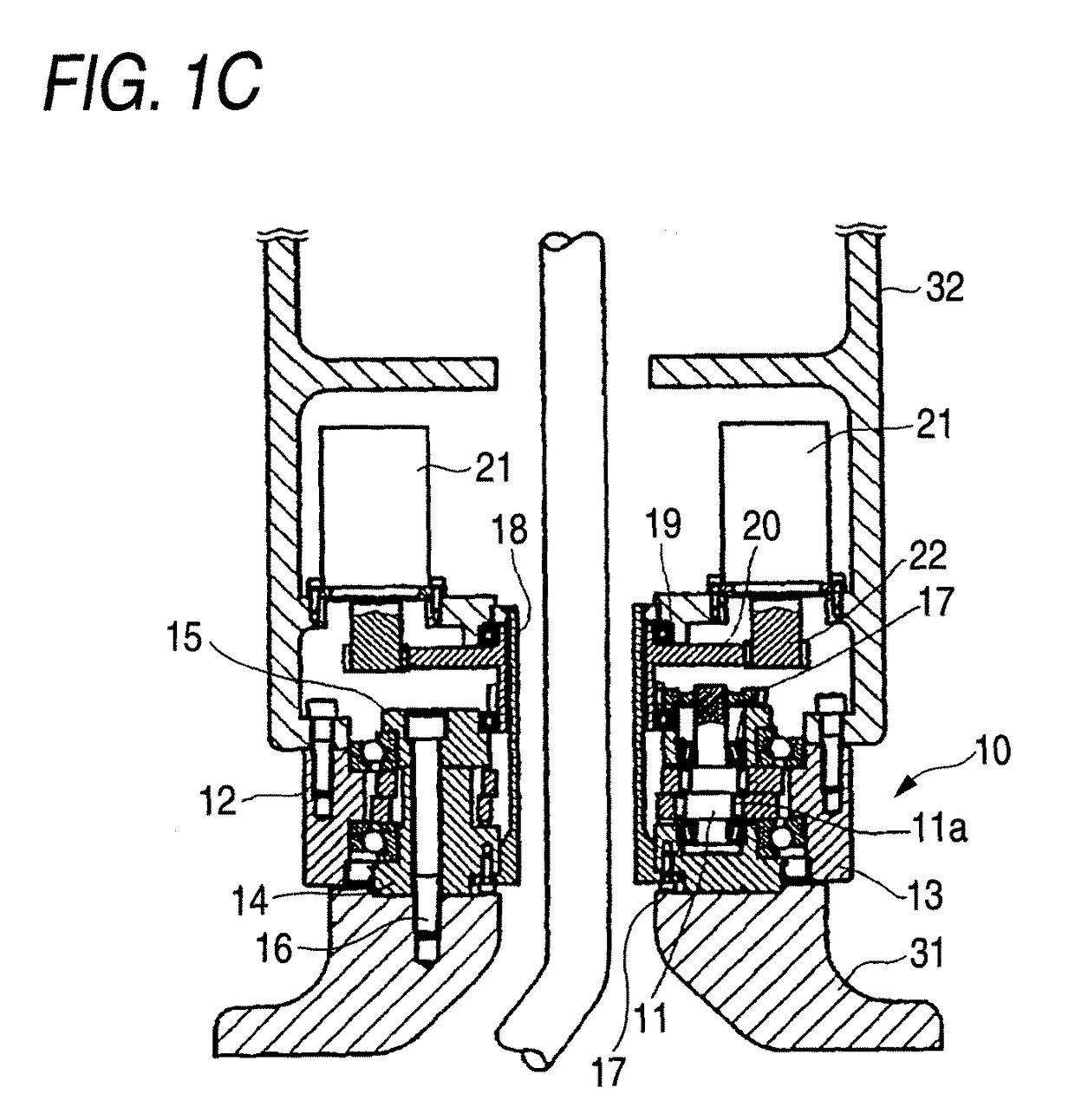

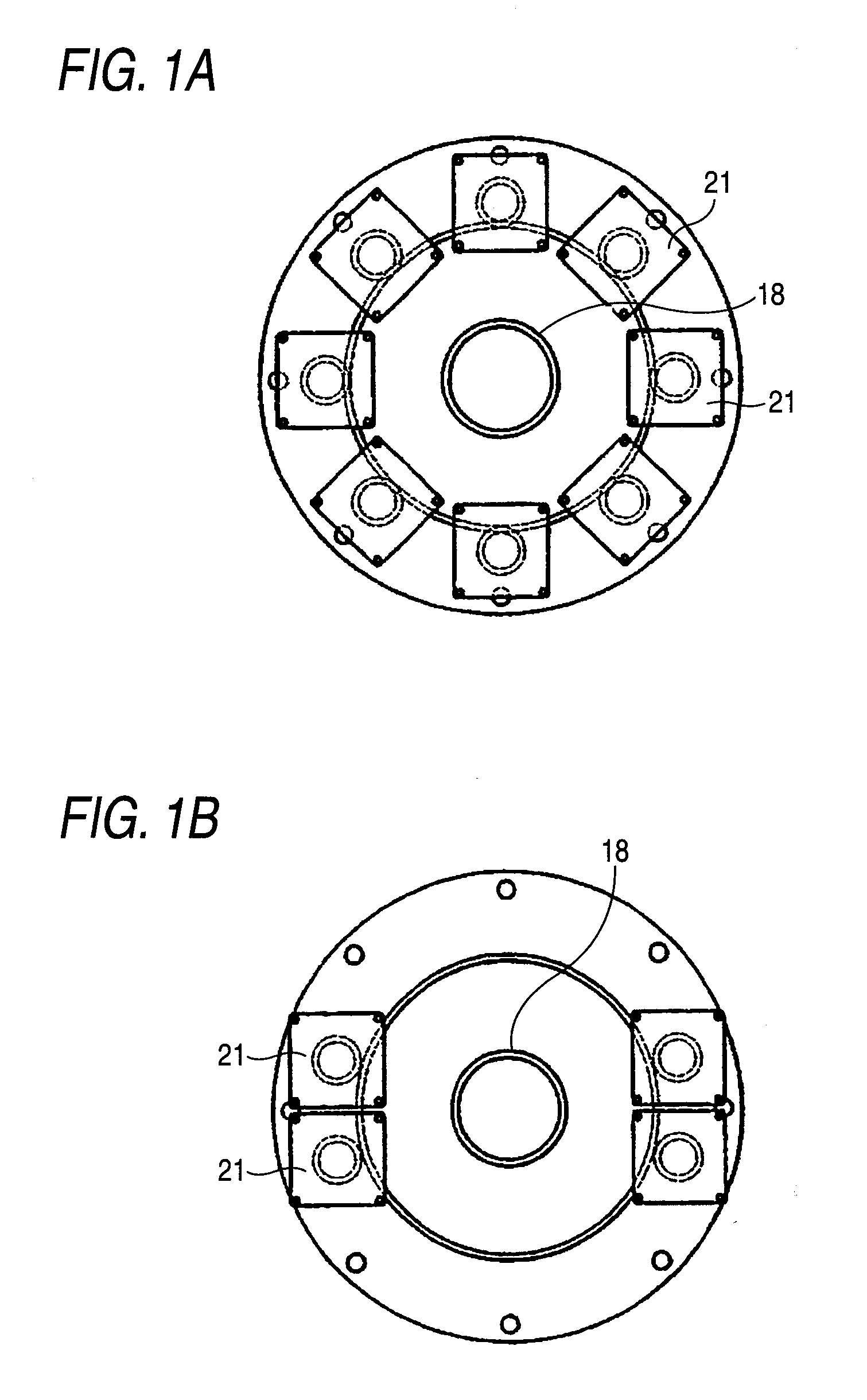

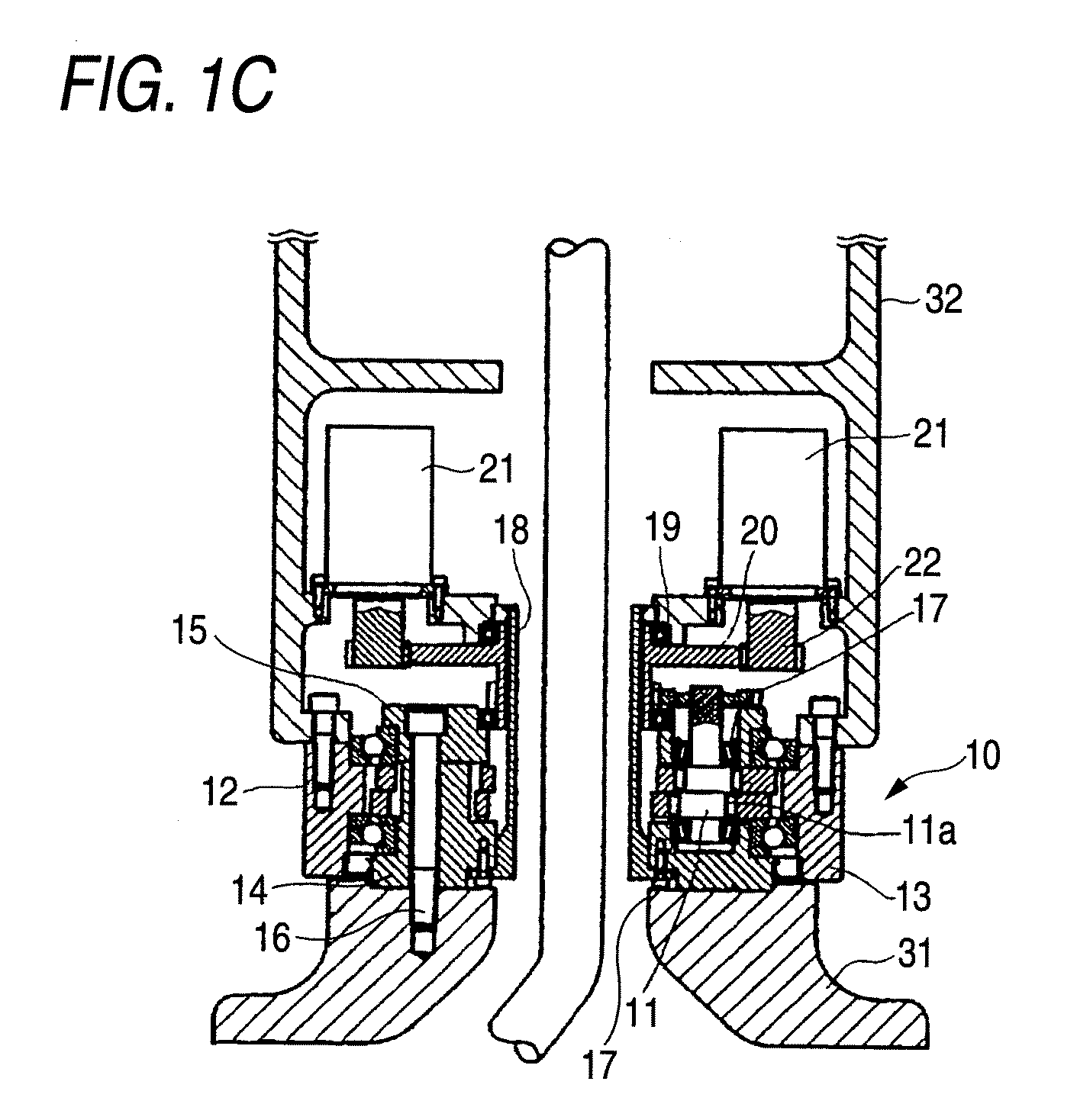

Hollow speed reducer

ActiveUS8117945B2Shorten the lengthStructure per se is not considerably changedToothed gearingsMechanical energy handlingGear wheelReduction drive

A speed reducer capable of shortening a length in an axial direction of a turning structure by arranging a plurality of small-sized motors is provided. The hollow speed reducer 10 is a planetary gear apparatus having a crankshaft 11, a pinion 12 formed with outer teeth at an outer periphery thereof, fitted to a crank portion of the crank shaft 11 and eccentrically moved, and a case 13 an inner peripheral face of which is formed with inner teeth brought in mesh with the outer teeth of the pinion 12, in which an inner portion of the hollow speed reducer 10 is formed with a hollow hole, a center gear for an input of the hollow speed reducer 10 is provided at a position of the hollow hole, and small gears provided at output shafts of a plurality of motors 15 are simultaneously brought in mesh with the center gear.

Owner:NABLESCO CORP

Reducer with internally meshing planetary gear mechanism and device incorporating the reducer

InactiveUS20060025271A1Solution to short lifeImprove efficiencyGearboxesToothed gearingsReduction driveGear wheel

The device includes a cover coupled to a first flange on the opposite side from an internally meshing planetary reduction gear part. The cover has a hole through which the input shaft of the reduction gear extends. An oil reservoir section is formed between the cover and the first flange. Oil seals are provided between the input shaft and the cover, and between the input shaft and a second flange, respectively.

Owner:SUMITOMO HEAVY IND LTD

Device for fast vibration of tubes containing samples

InactiveUS20050128863A1Simple and effective and inexpensiveBioreactor/fermenter combinationsBiological substance pretreatmentsReciprocating motionRolling-element bearing

Apparatus for rapidly vibrating tubes containing samples, e.g. biological samples, comprises a tube-support disk and concentric bearings for mounting the disk in a ring that is resiliently-suspended from a frame, the bearings comprising two rolling bearings mounted one within the other. The invention enables the tubes containing samples to be subjected to curvilinear reciprocating motion at high frequency.

Owner:BERTIN TECHNOLOGIES

Hollow speed reducer

ActiveUS20090233750A1Shorten the lengthEasy to manufactureToothed gearingsMechanical energy handlingReduction driveGear wheel

There is provided a speed reducer capable of shortening a length in an axial direction of a turning structure by arranging a plurality of small-sized motors.A hollow speed reducer 10 is a planetary gear apparatus comprising a crankshaft 11, a pinion 12 formed with outer teeth at an outer periphery thereof, fitted to a crank portion of the crank shaft 11 and eccentrically moved, and a case 13 an inner peripheral face of which is formed with inner teeth brought in mesh with the outer teeth of the pinion 12, in which an inner portion of the hollow speed reducer 10 is formed with a hollow hole, a center gear for an input of the hollow speed reducer 10 is provided at a position of the hollow hole, and small gears provided at output shafts of a plurality of motors are simultaneously brought in mesh with the center gear.

Owner:NABLESCO CORP

Power transmission device

InactiveUS7147582B2Easy to prepareIncreased Design FreedomToothed gearingsPortable liftingElectric power transmissionGear wheel

It is an object to obtain a power transmission device capable of allowing conflicting needs to coexist rationally and effectively in accordance with a driving situation. As powertransmitting mechanisms of a power transmission device, there are provided a plurality of characteristically-differentiated internally meshing planetary gear mechanisms, each having an external gear and an internal gear having external teeth and internal teeth the difference in the number of teeth between which is slight. In this structure, at least two of the internally meshing planetary gear mechanisms are disposed in parallel on a path of power transmission, and power transmission characteristics of the two mechanisms are designed to differ from each other.

Owner:SUMITOMO HEAVY IND LTD

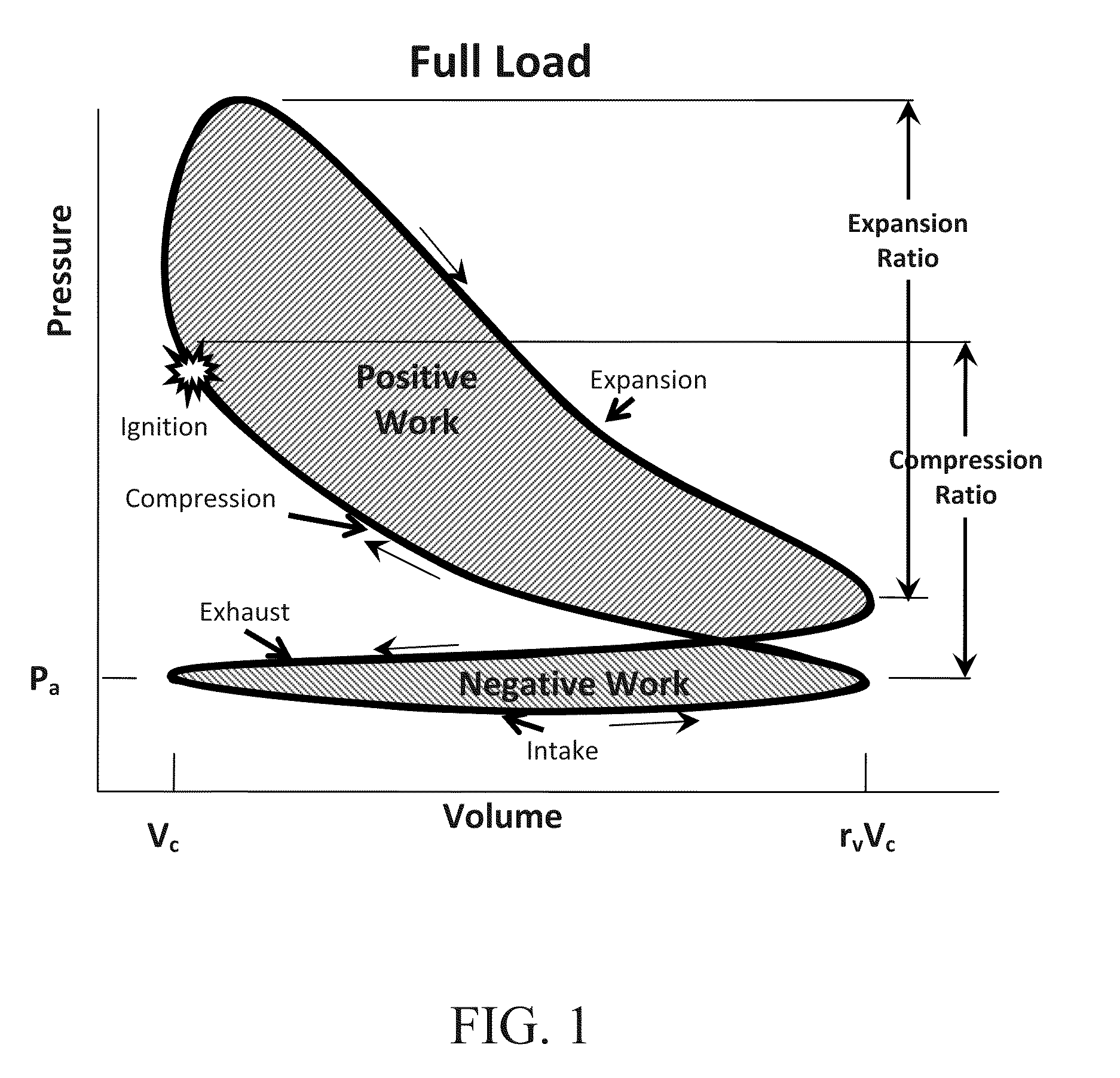

Variable stroke and compression ratio engine

A variable stroke and compression ratio engine employs multiple pistons connected to a wobbler. A crank with an axis of rotation has an upper journal with a first angle relative to the axis and a lower journal with a second angle with respect to the axis. A cradle connected for rotational motion with respect to the wobbler is carried by the crank with sliding engagement to the upper and lower journals for translation between a first high eccentricity position and second low eccentricity position.

Owner:ARNOLD STEVEN DON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com