Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

267results about "Arrangements for reliveing mechanical tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

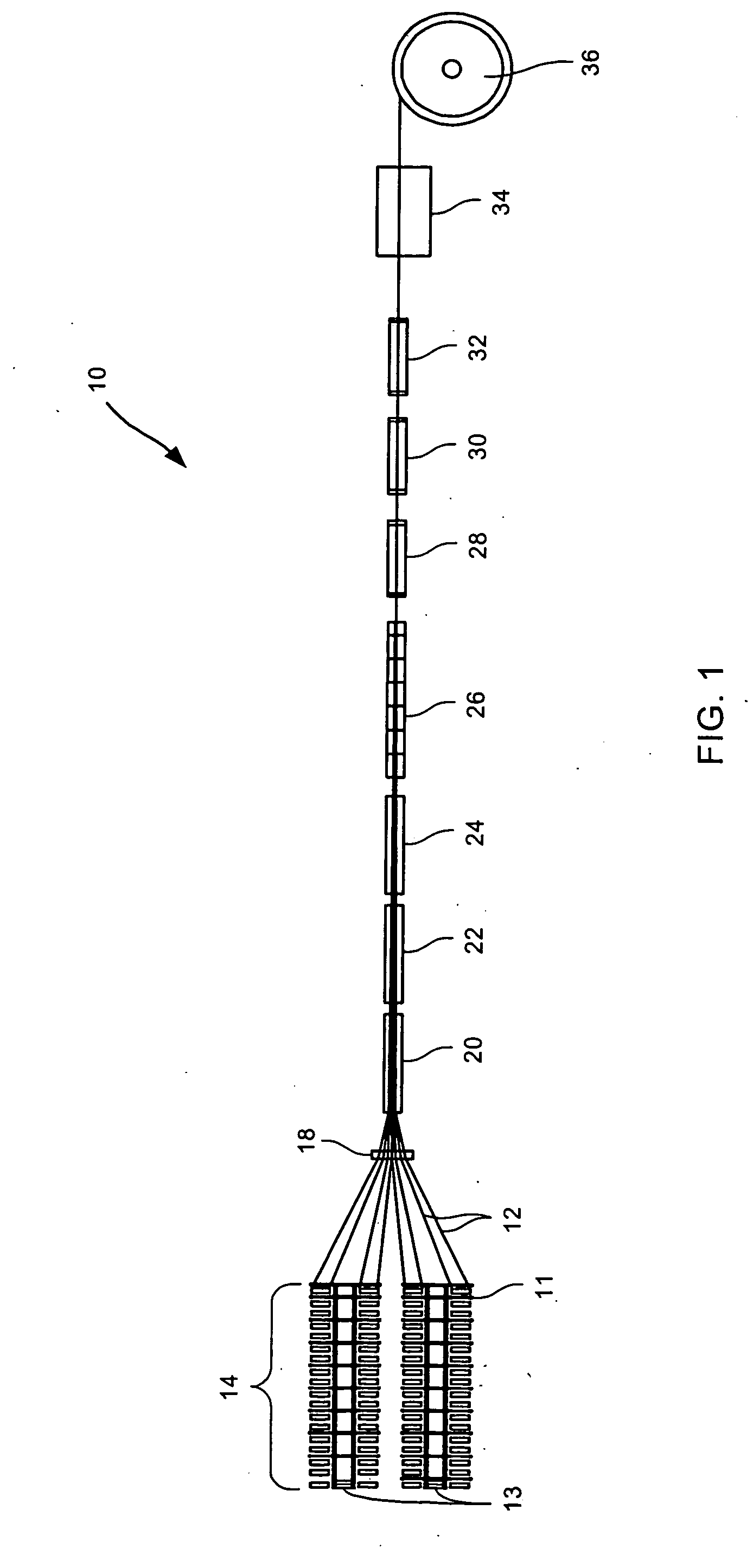

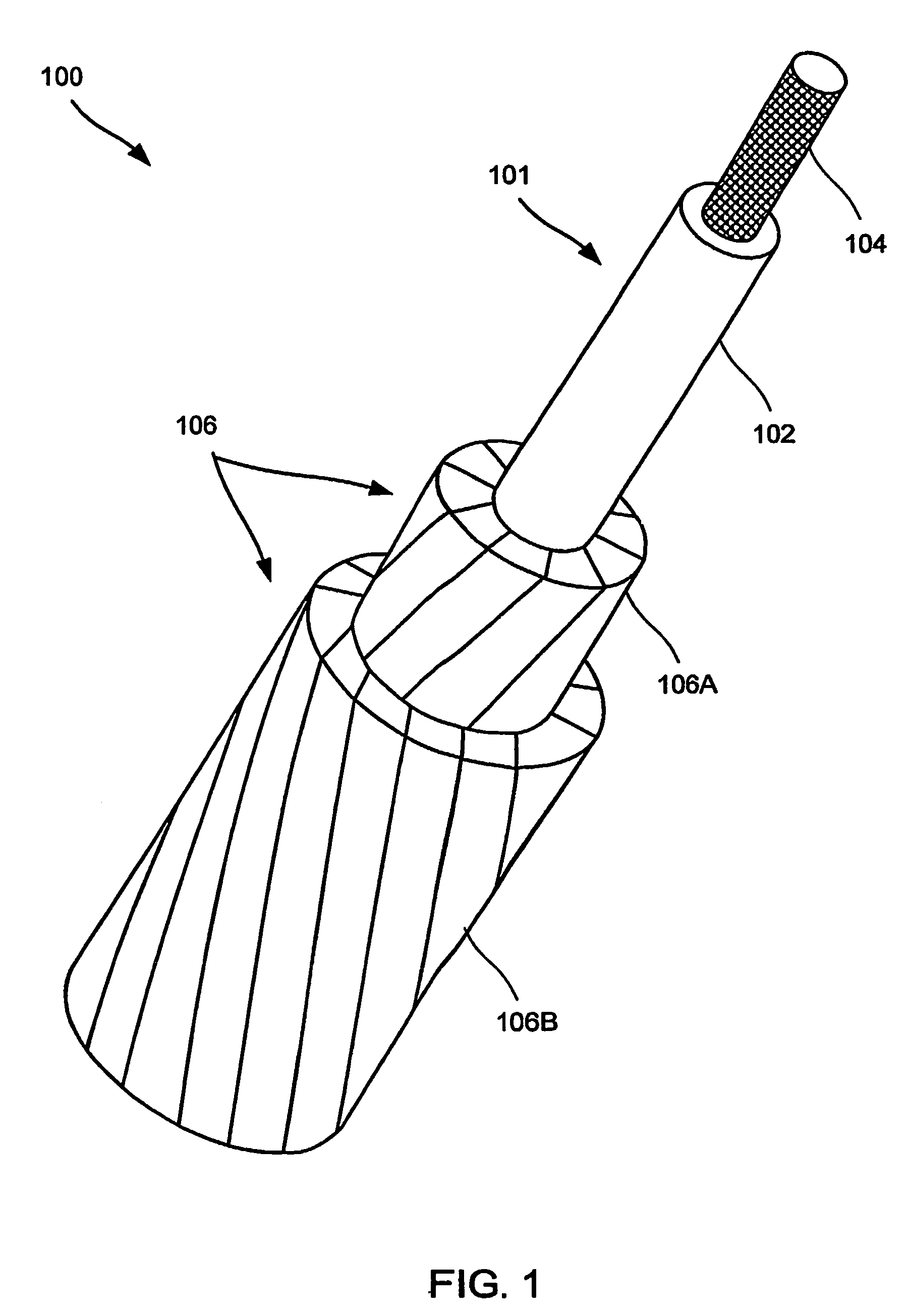

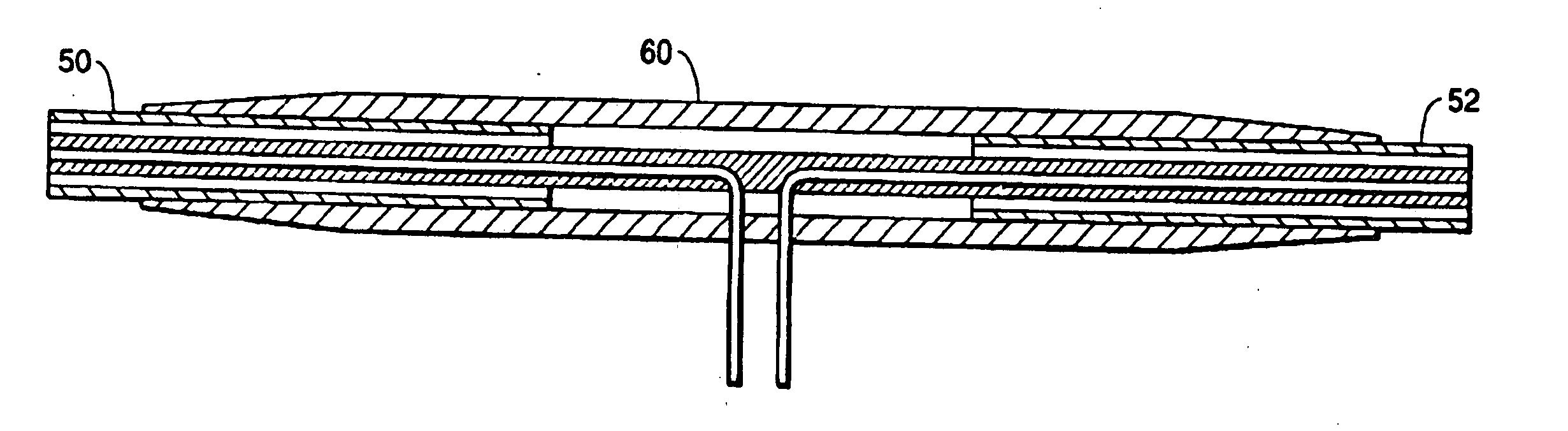

Composite reinforced electrical transmission conductor

InactiveUS7015395B2Avoid excessive labor intensityLow costNon-insulated conductorsPower cables with screens/conductive layersFiberElectrical conductor

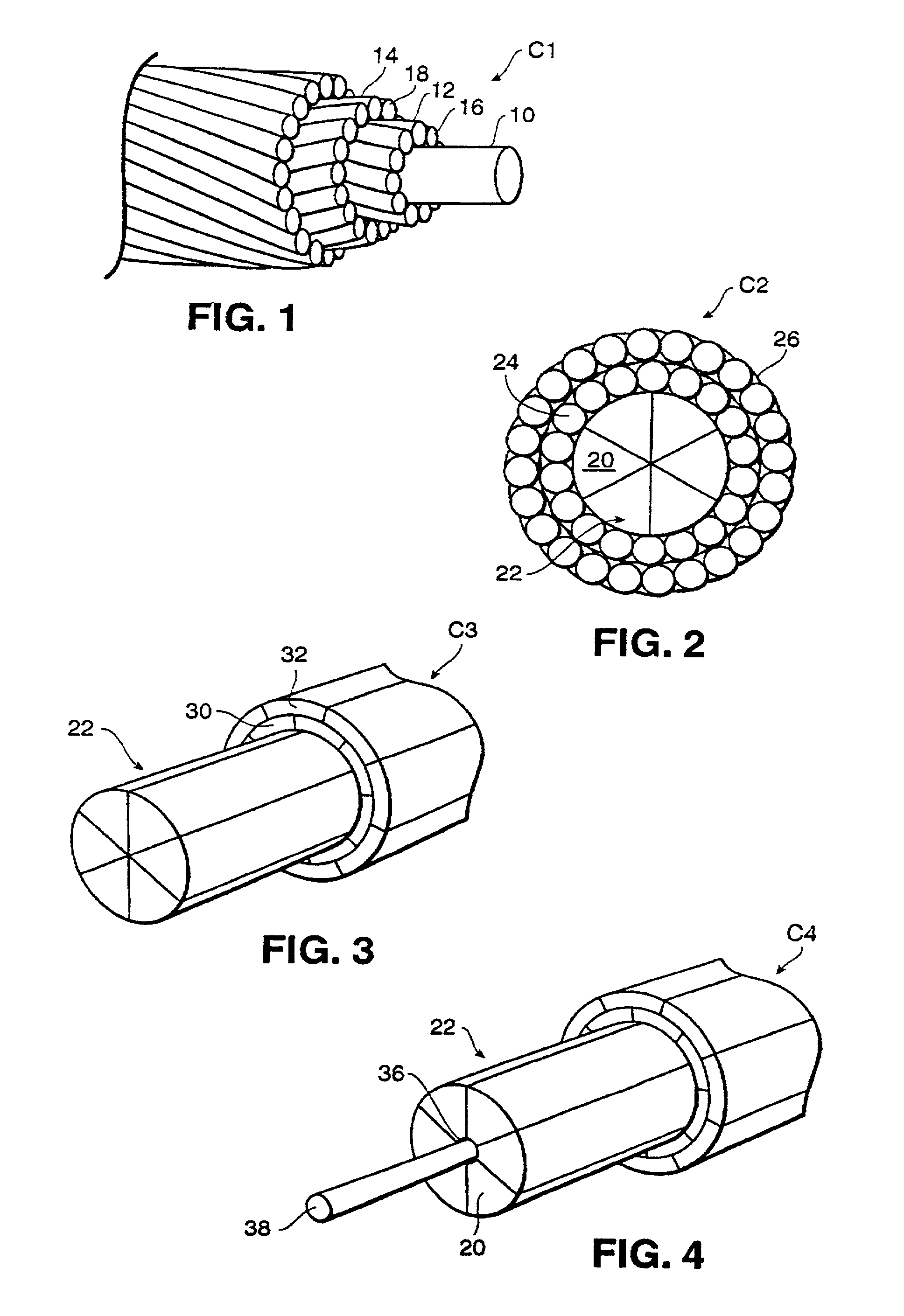

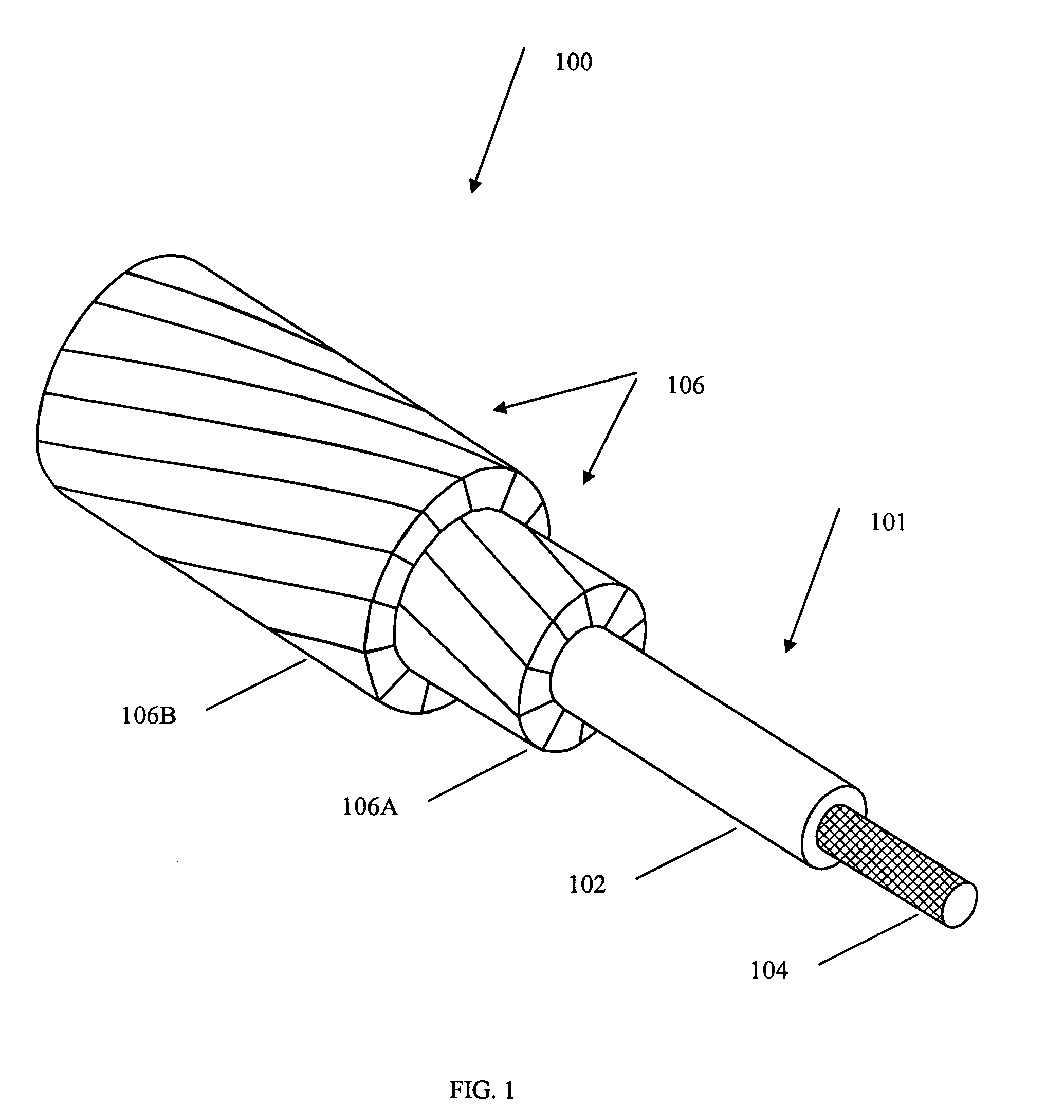

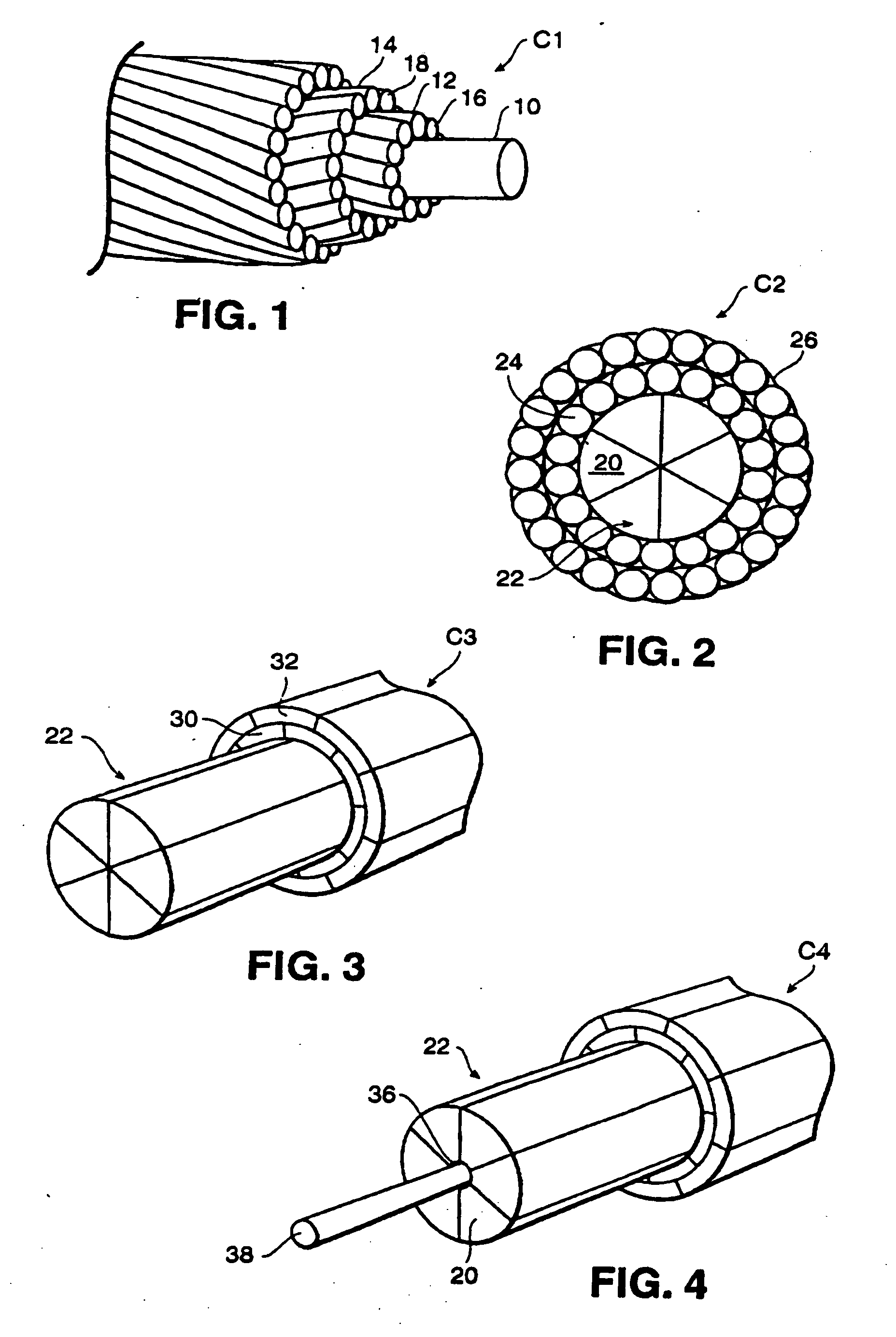

A composite reinforced electrical transmission conductor primarily designed for transmission of electrical signals. The conductor is comprised of a reinforced plastic composite inner core along with an outer highly electrically conductive sheath therearound. In this way, the inner core provides the necessary strength and the outer sheath provides for transmission of the electrical signals. In a preferred embodiment, the reinforced composite core is comprised of individual sections which cooperate together to provide the necessary loading capabilities. Further, a fiber optic cable may also be carried by the composite reinforced core. A splicing arrangement for securing ends of the cable together is also provided.

Owner:GIFT TECH LP

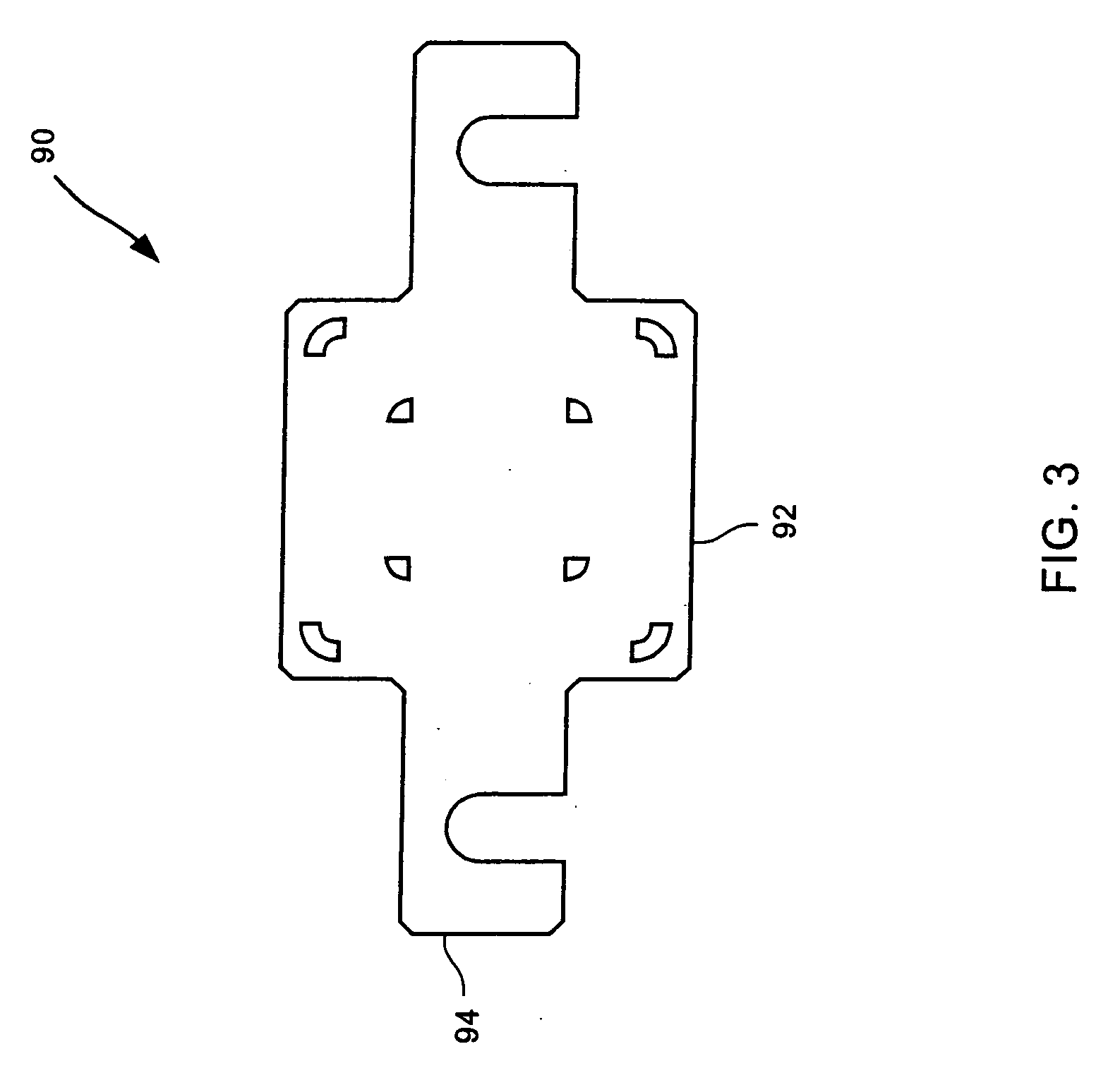

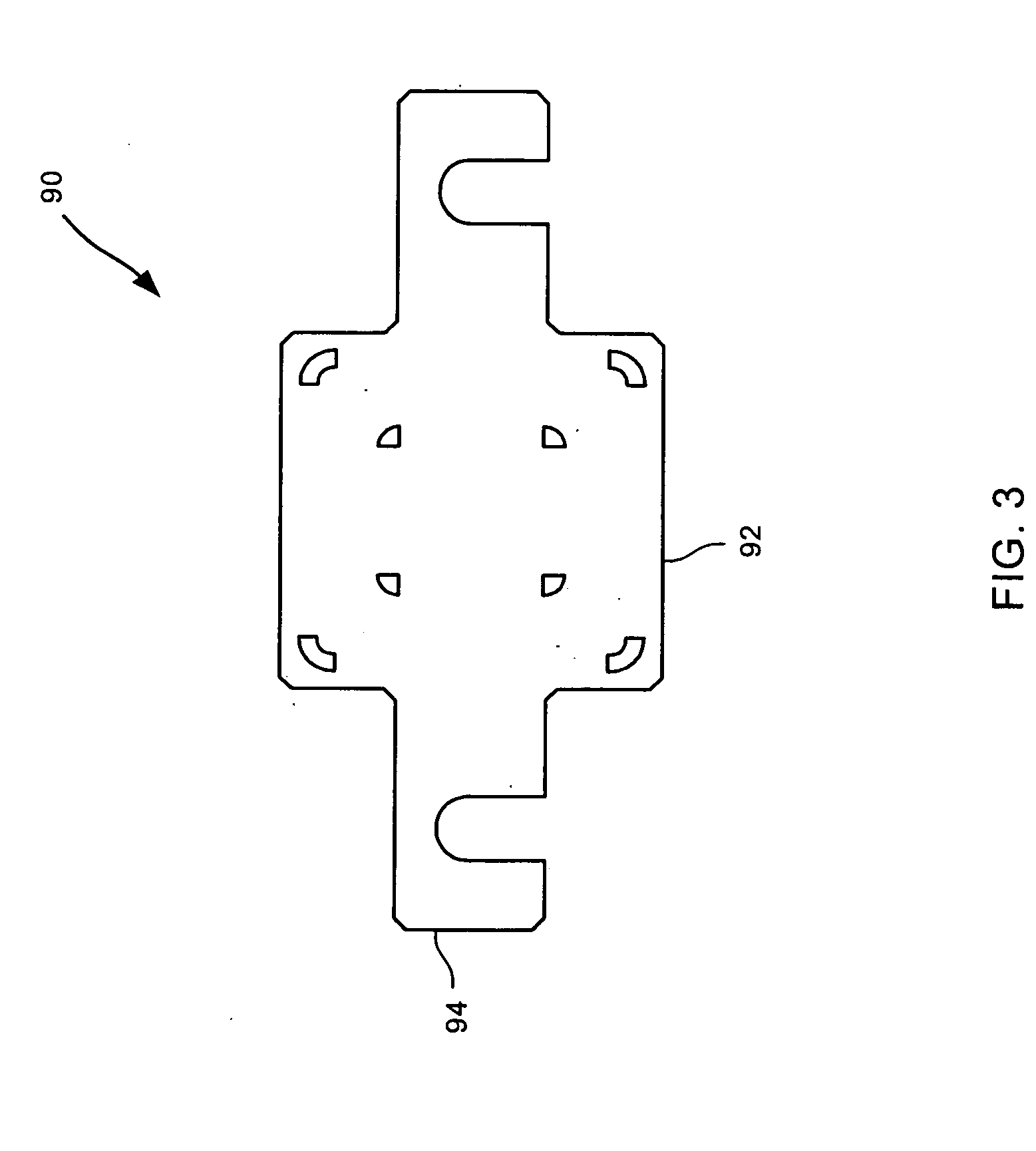

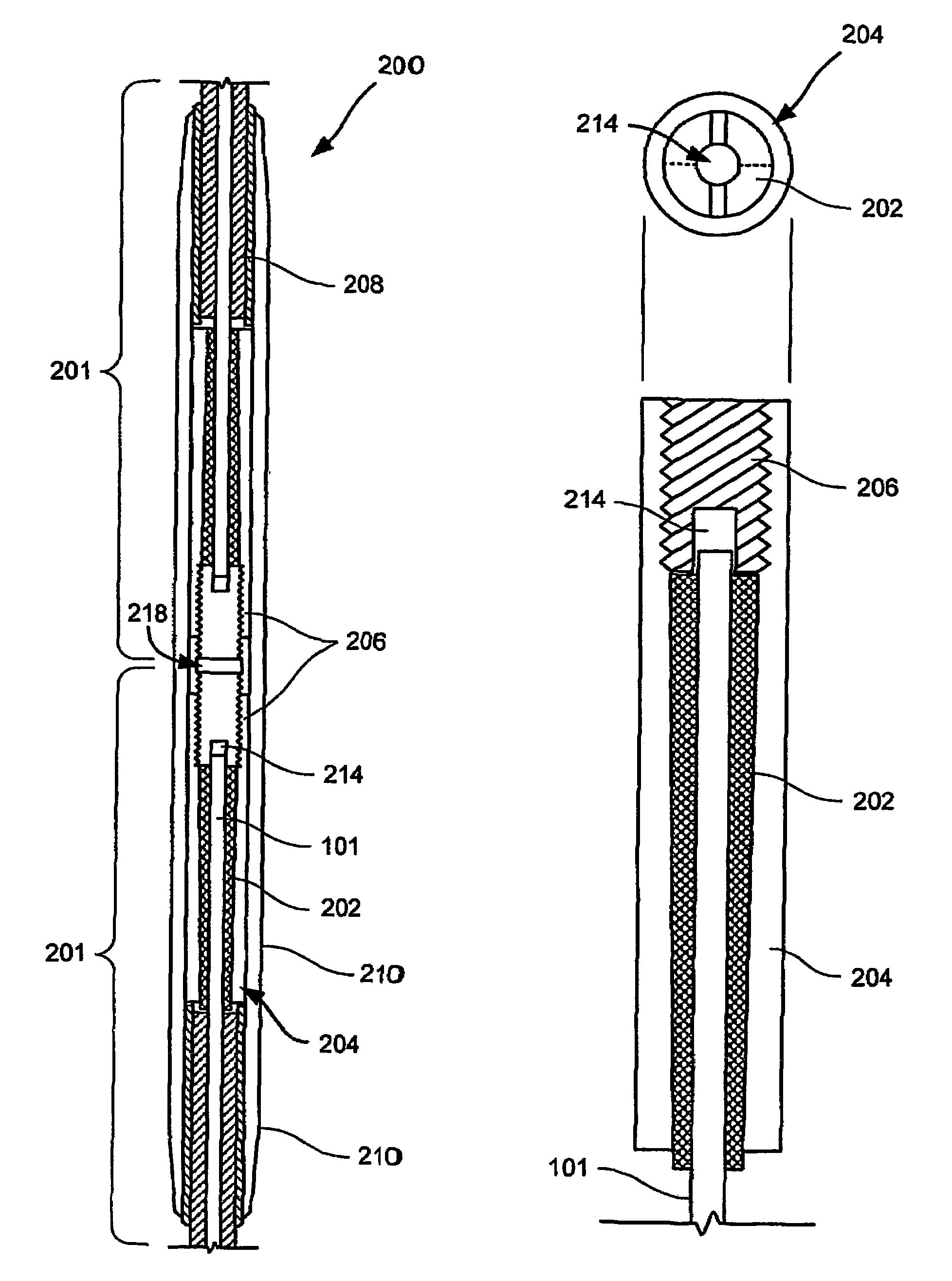

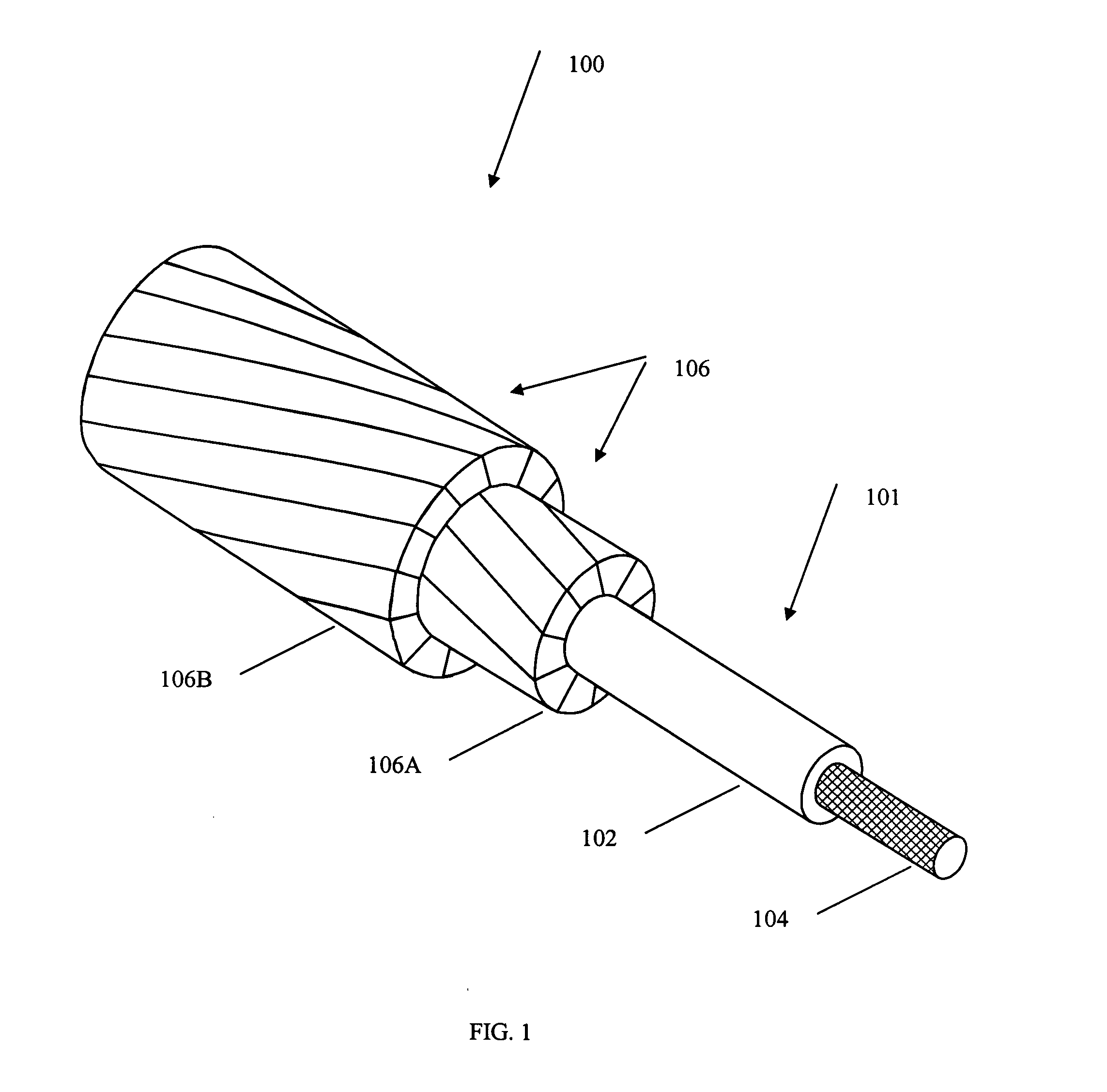

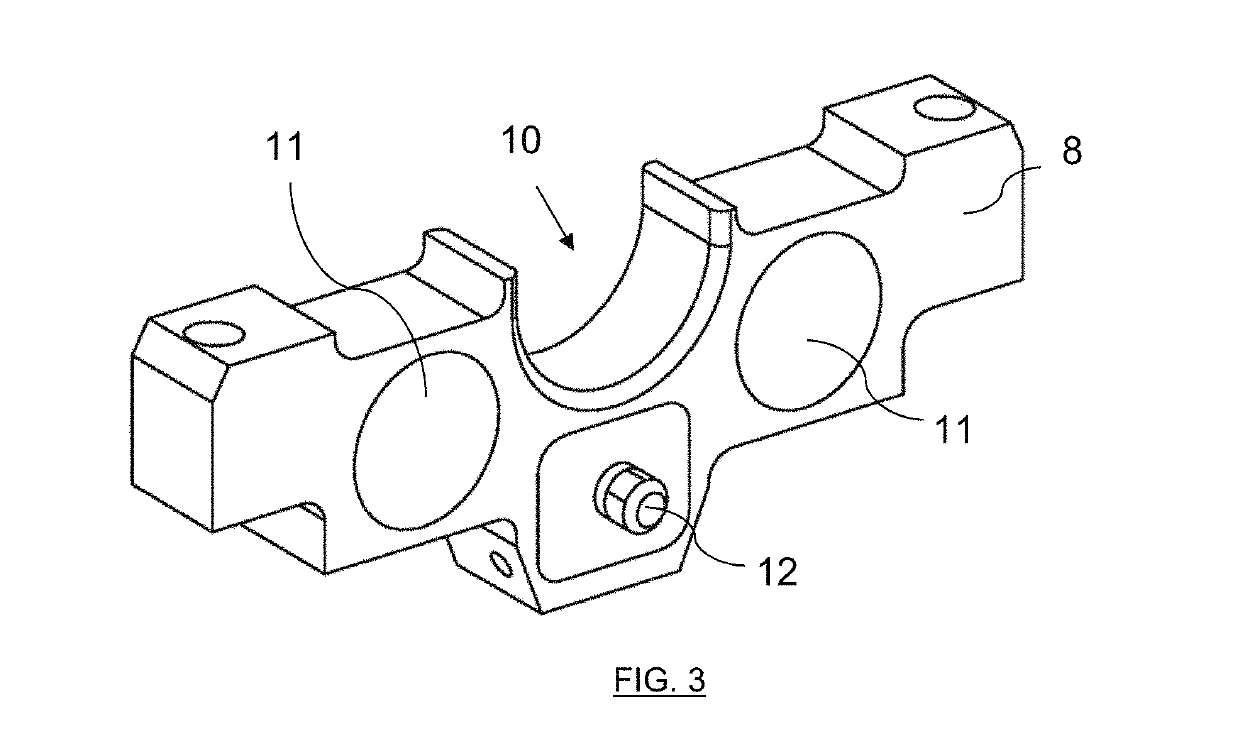

Collet-type splice and dead end use with an aluminum conductor composite core reinforced cable

InactiveUS7019217B2Easy to compressGood junctionSynthetic resin layered productsArrangements for reliveing mechanical tensionElectrical conductorEngineering

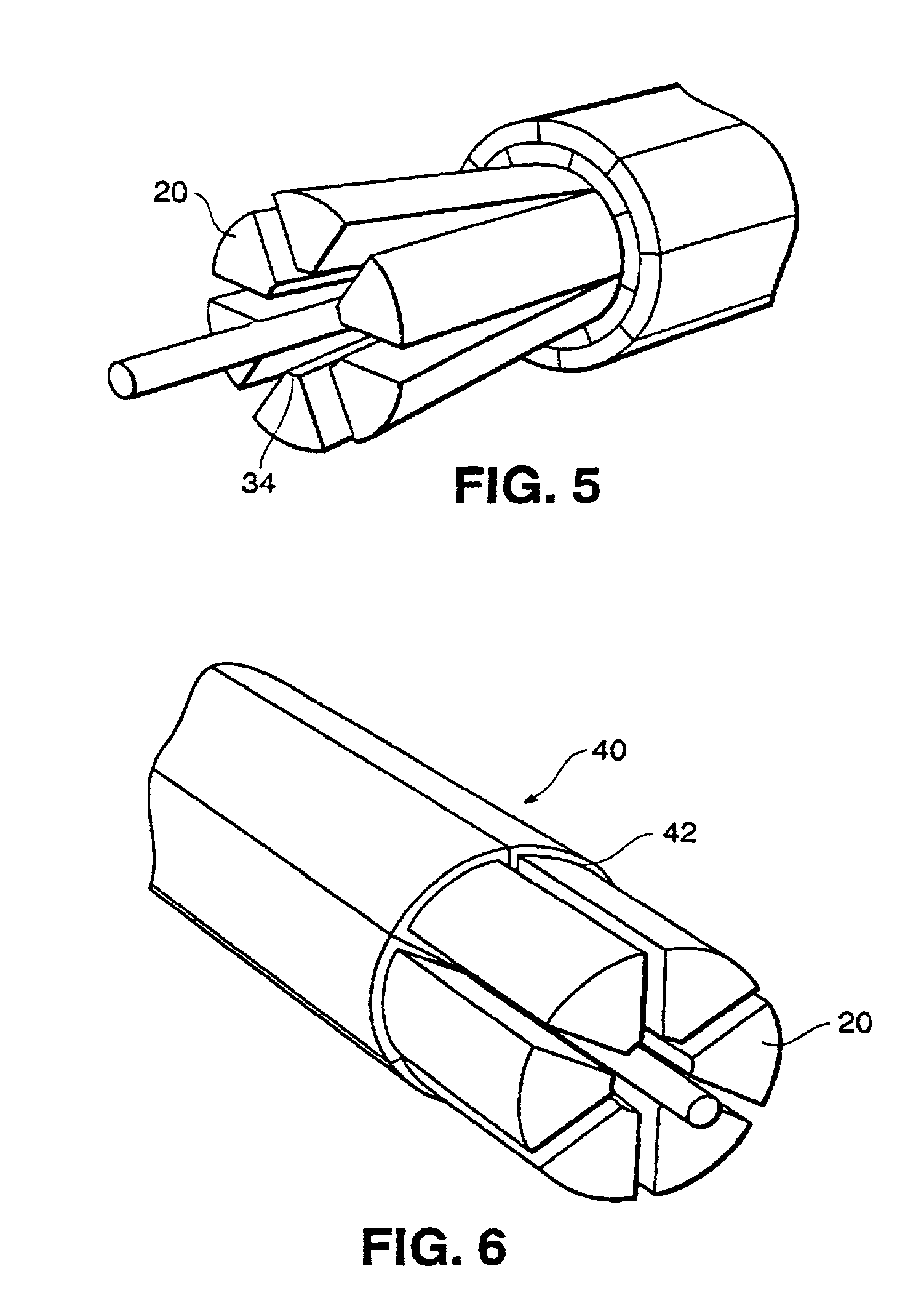

This invention relates to collet-type splices and collet-type dead ends and methods for splicing together two aluminum conductor composite core reinforced cables (ACCC) or terminating one ACCC cable. The collet-type fittings use a collet inside a collet housing to hold the composite cores. The composite cores can be stripped of the aluminum conductor to provide a bond between the collet and the composite core. After inserting the composite core into the collet, a compression implement compresses the collet. The collet holds the composite core with frictional forces and the collet further compresses and strengthens the hold on the composite core if the composite core pulls the collet further into the collet housing.

Owner:CTC GLOBAL CORP

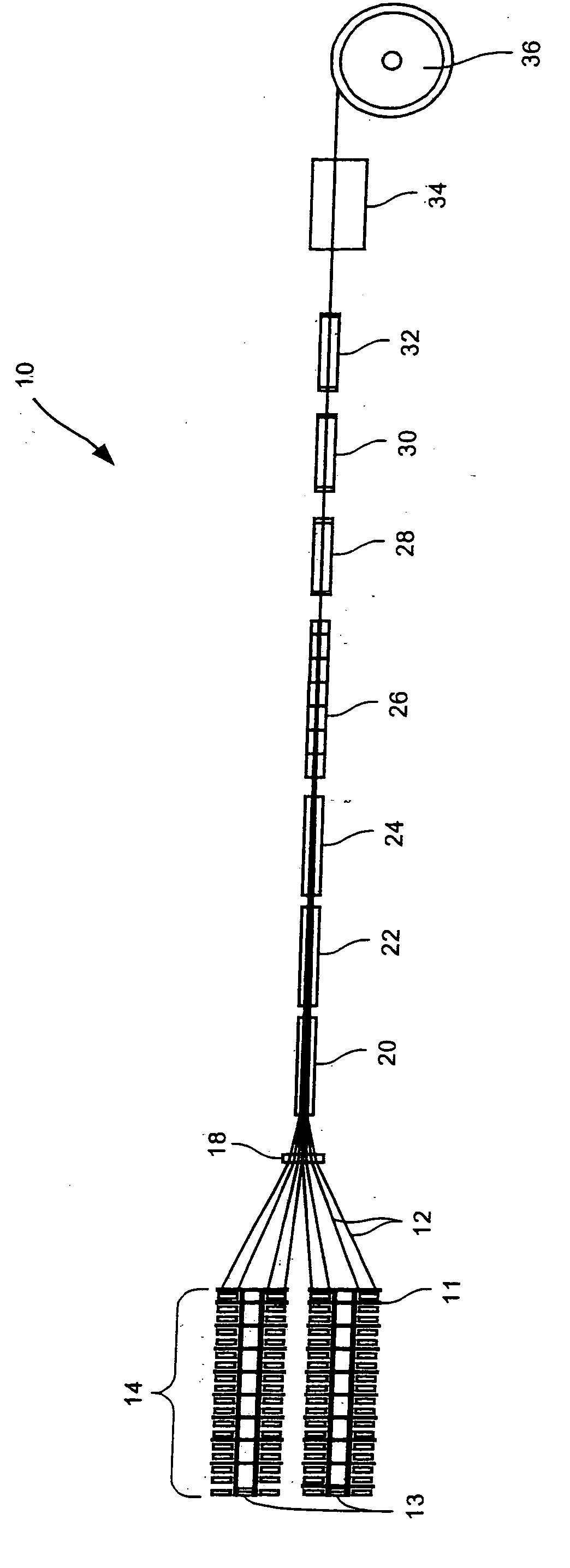

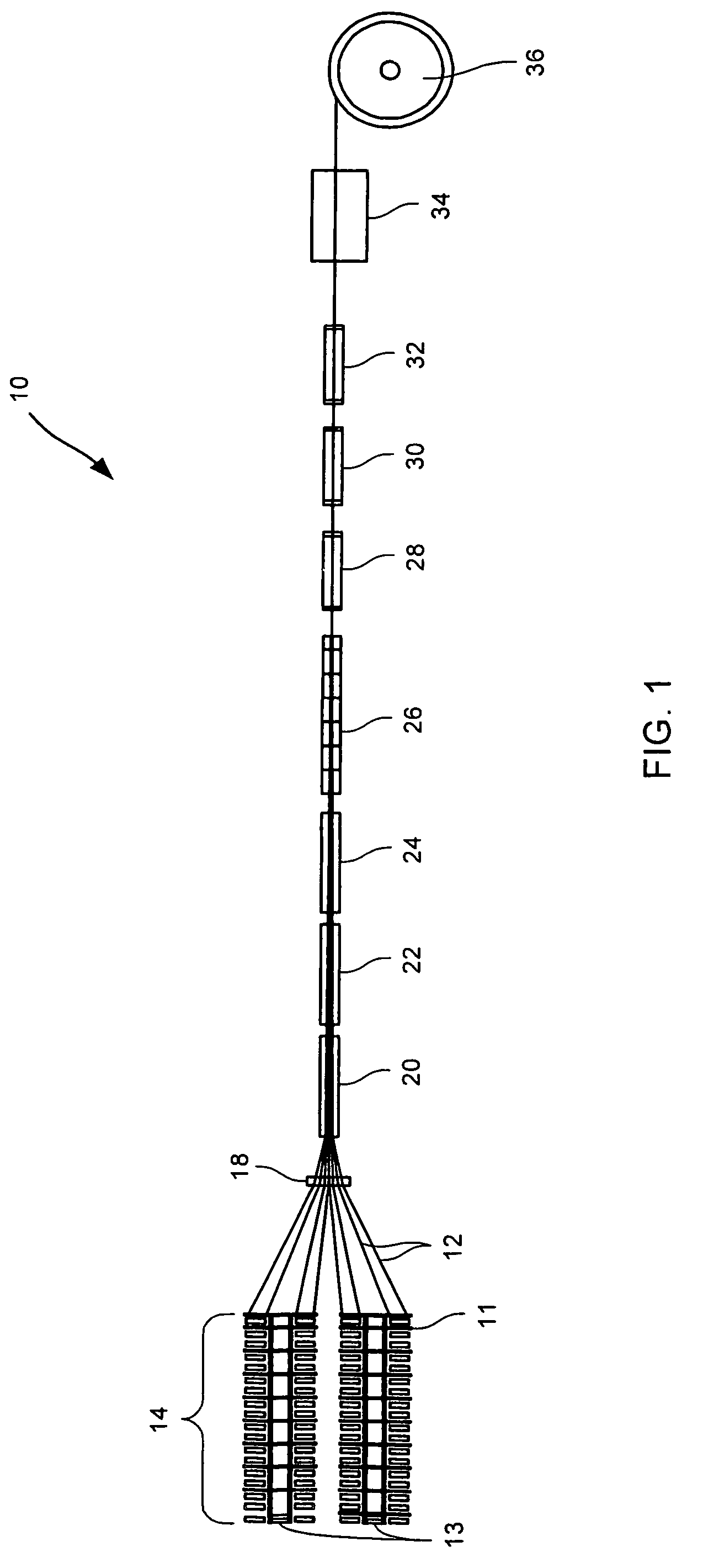

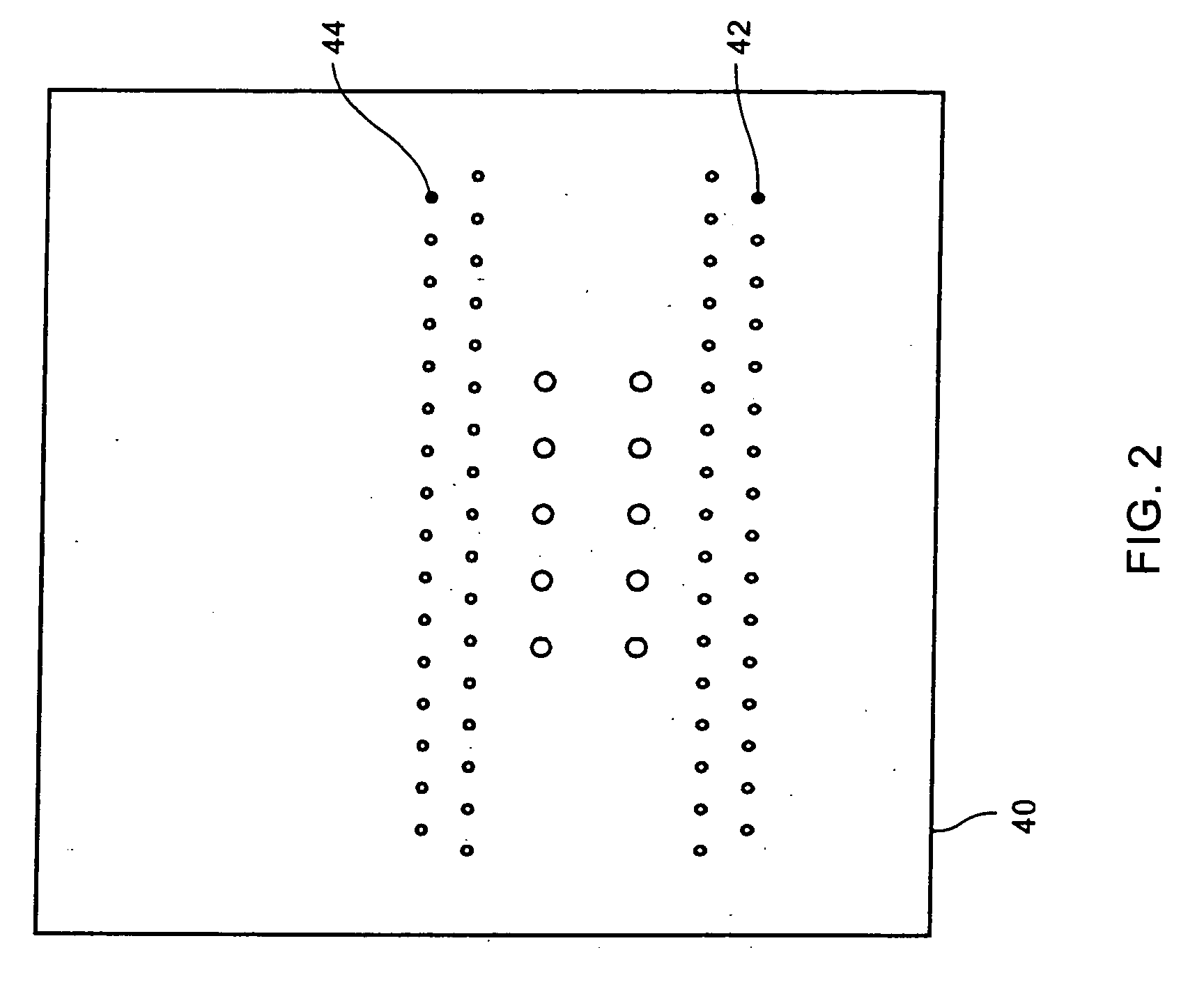

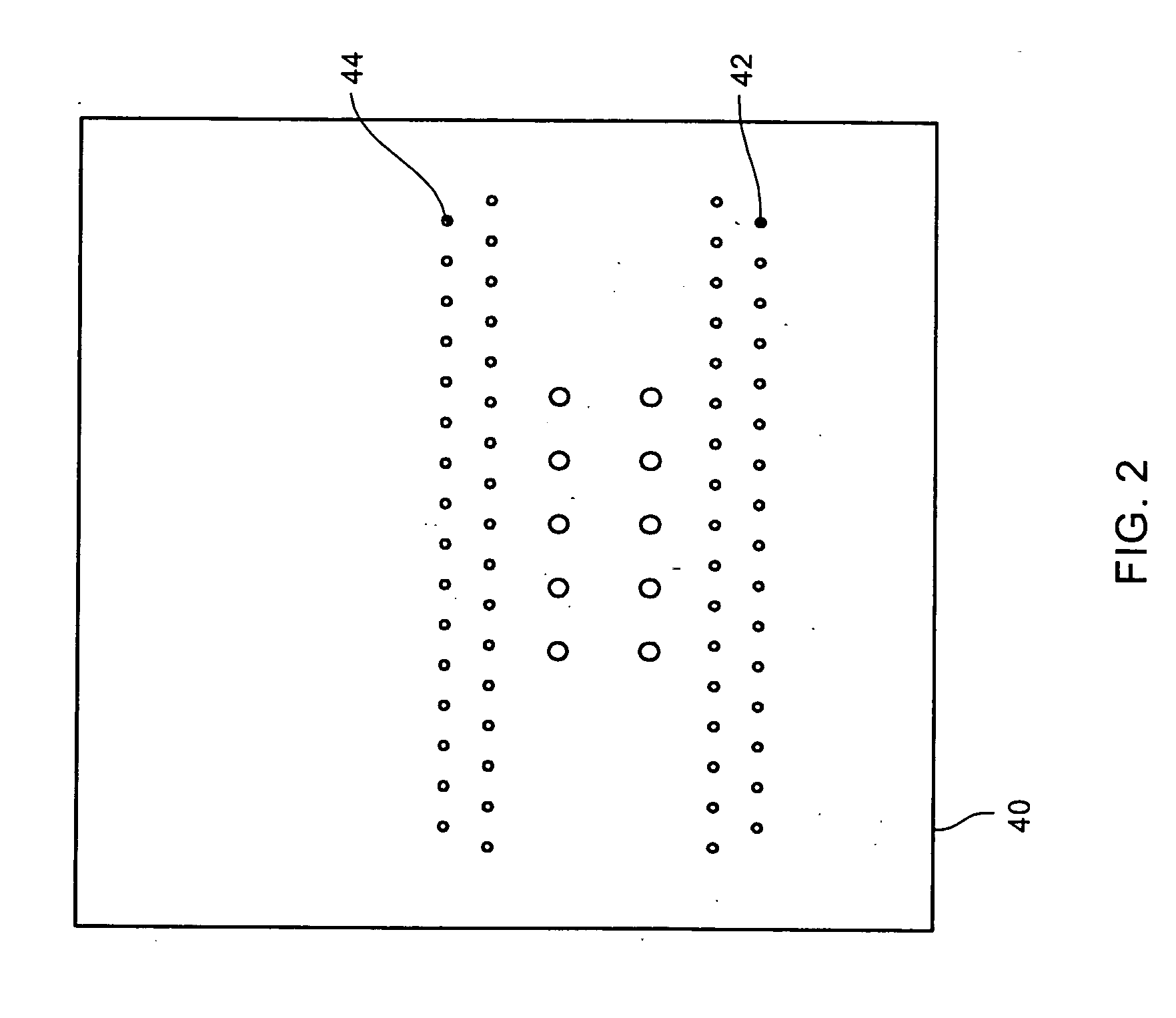

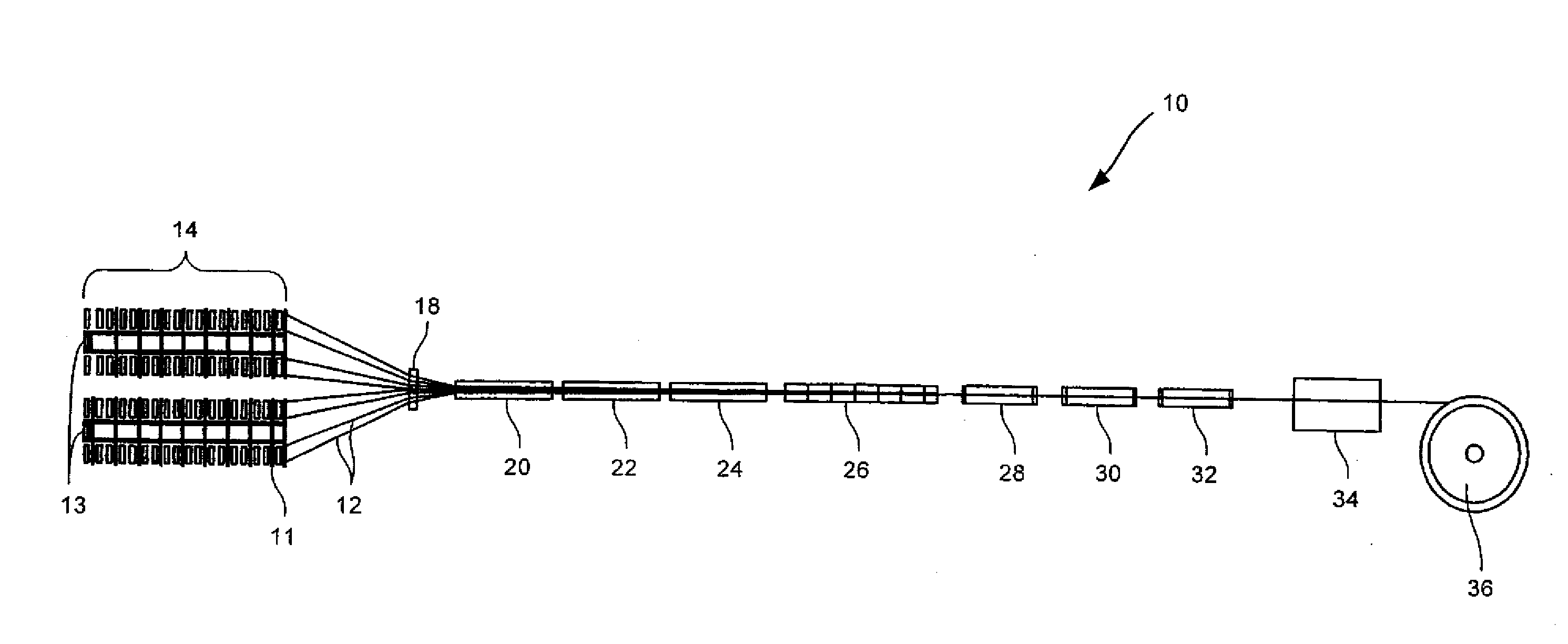

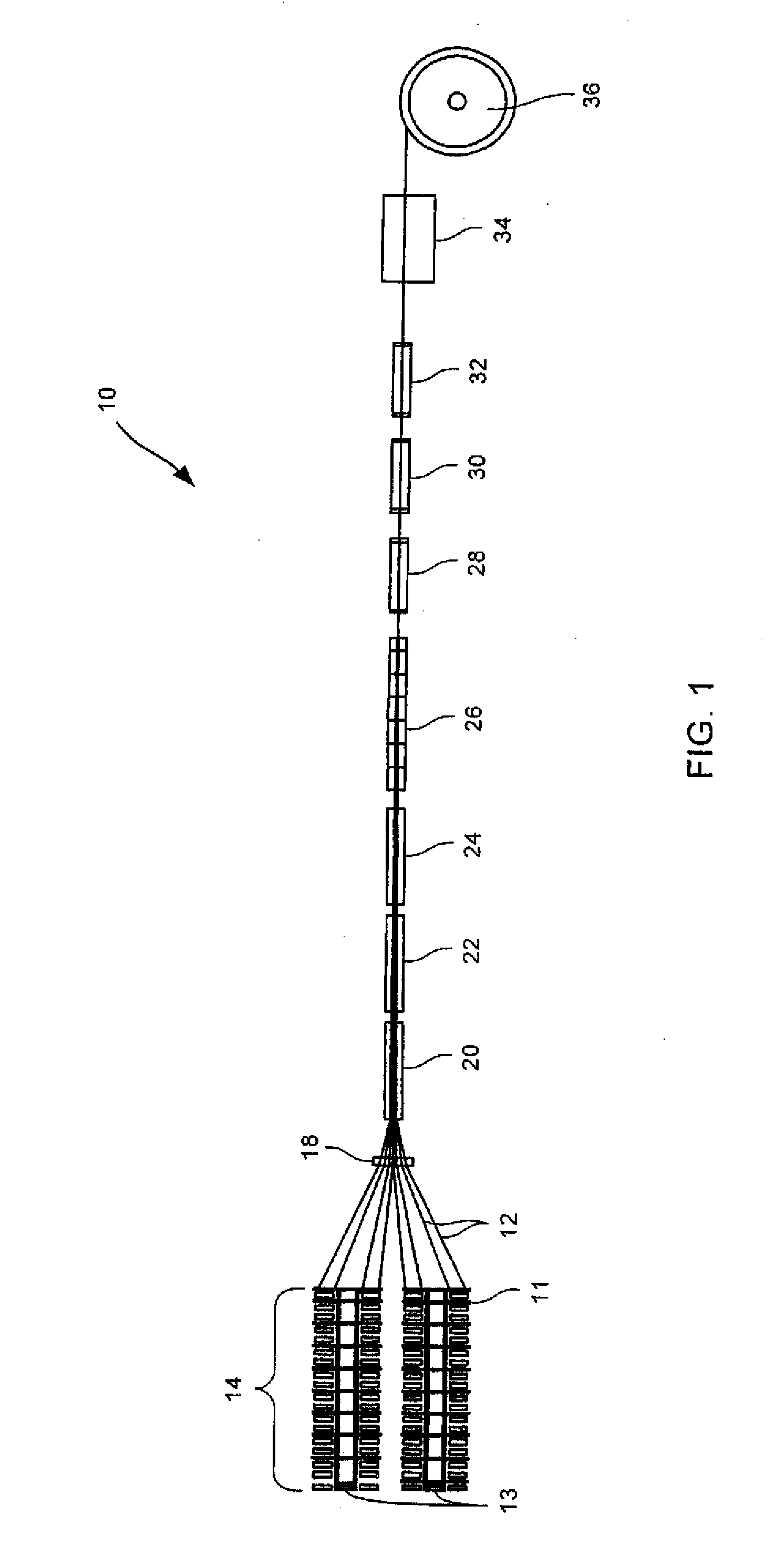

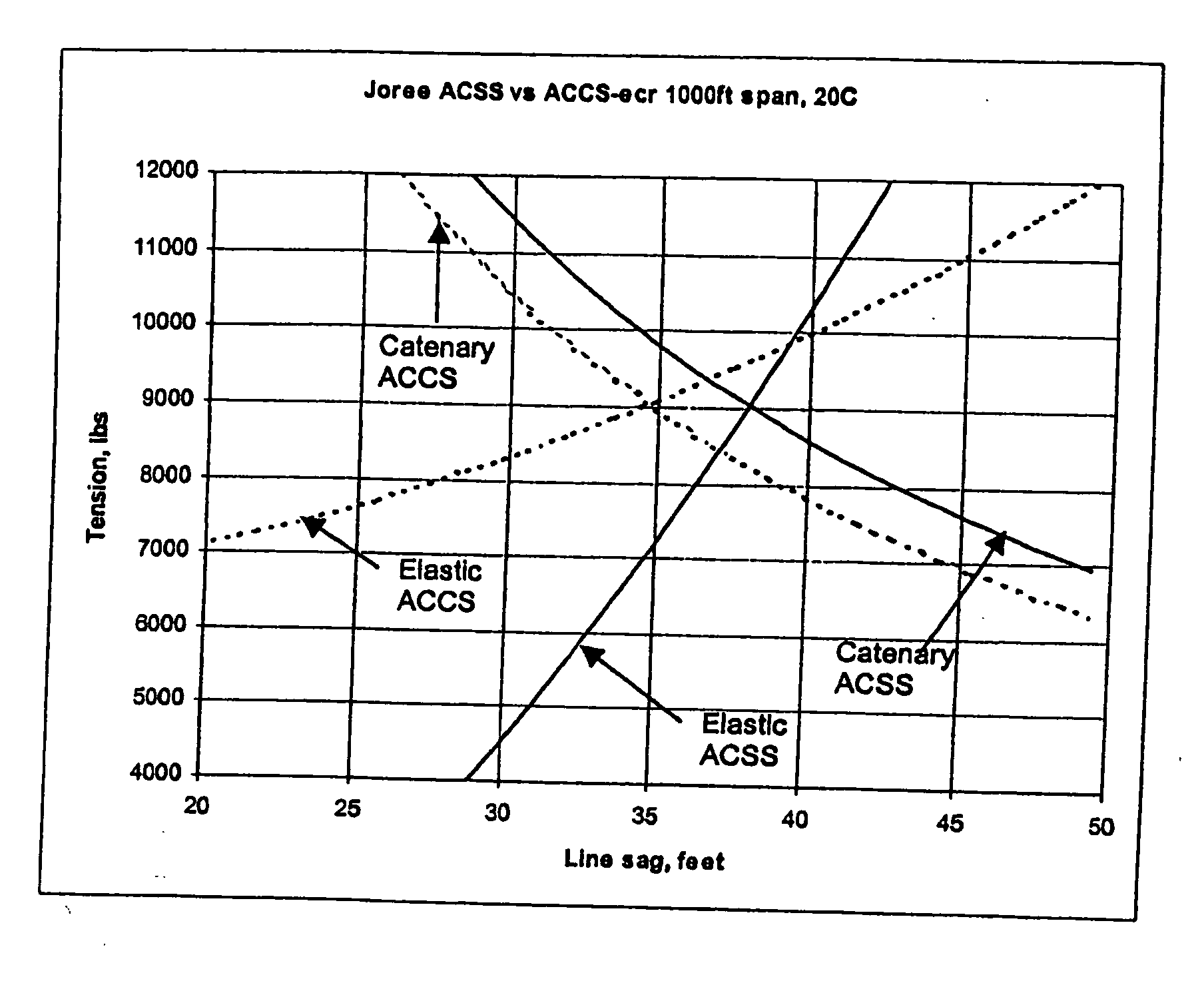

Aluminum conductor composite core reinforced cable and method of manufacture

InactiveUS20040131834A1High strengthIncrease ampacityNon-insulated conductorsApparatus for heat treatmentElectrical conductorThermal expansion

This invention relates to an aluminum conductor composite core reinforced cable (ACCC) and method of manufacture. An ACCC cable has a composite core surrounded by at least one layer of aluminum conductor. The composite core comprises a plurality of fibers from at least one fiber type in one or more matrix materials. The composite core can have a maximum operating temperature capability above 100° C. or within the range of about -45° C. to about 230° C., at least 50% fiber to resin volume fraction, a tensile strength in the range of about 160 Ksi to about 370 Ksi, a modulus of elasticity in the range of about 7 Msi to about 37 Msi and a coefficient of thermal expansion in the range of about -0.7x10<-6 >m / m / ° C. to about 6x10<-6 >m / m° C. According to the invention, a B-stage forming process may be used to form the composite core at improved speeds over pultrusion processes wherein the speeds ranges from about 9 ft / min to about 60 ft / min.

Owner:CTC GLOBAL CORP

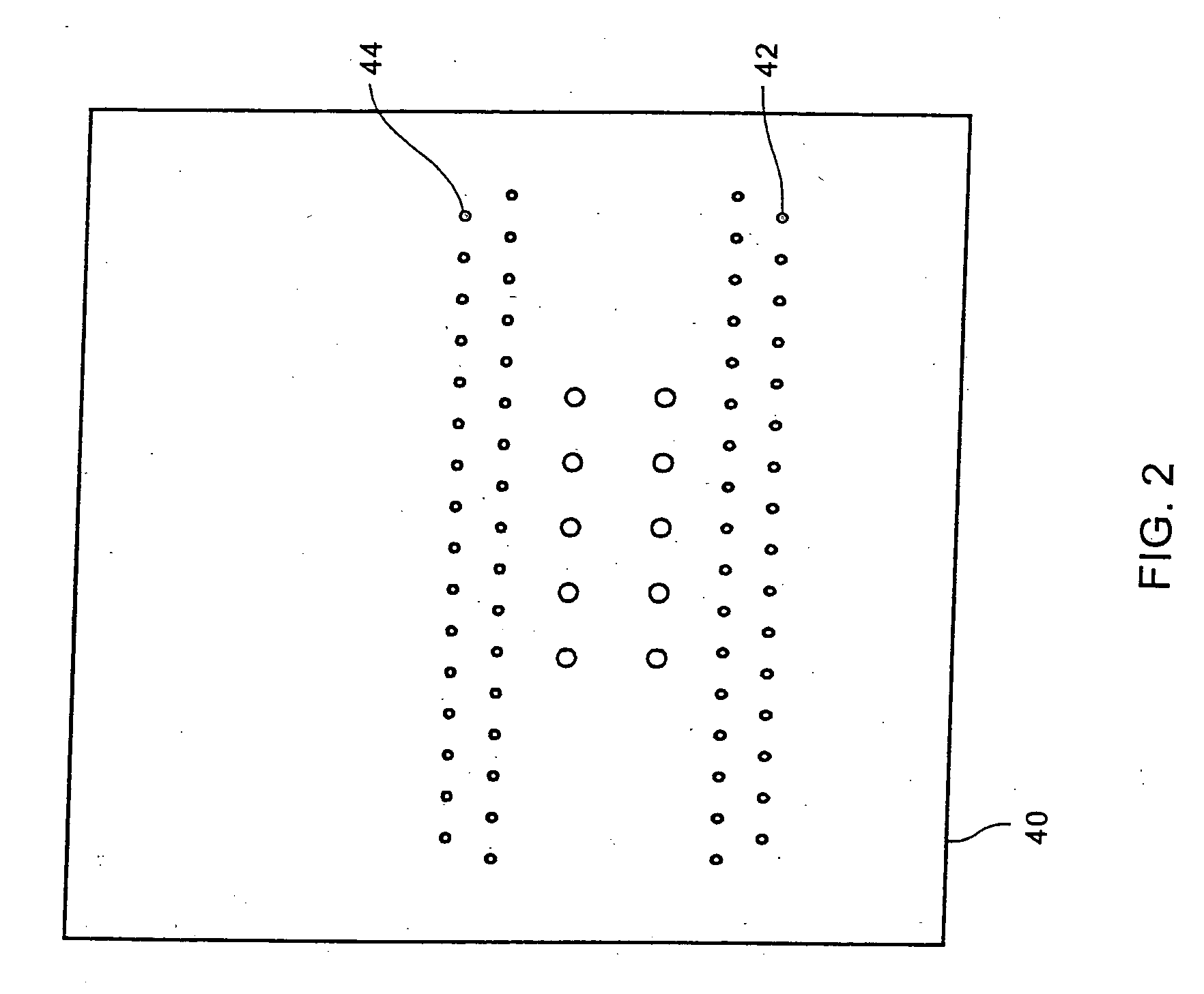

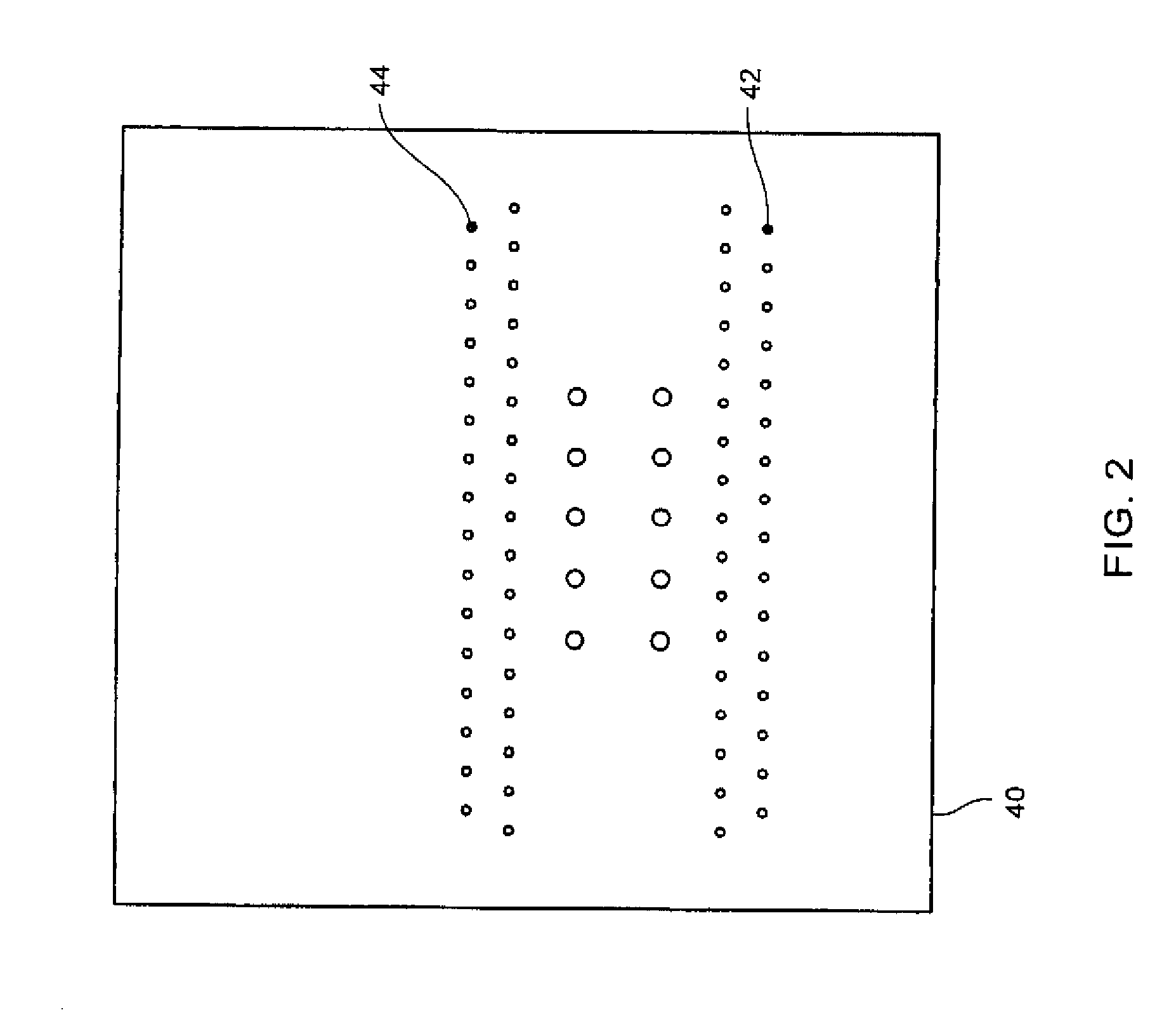

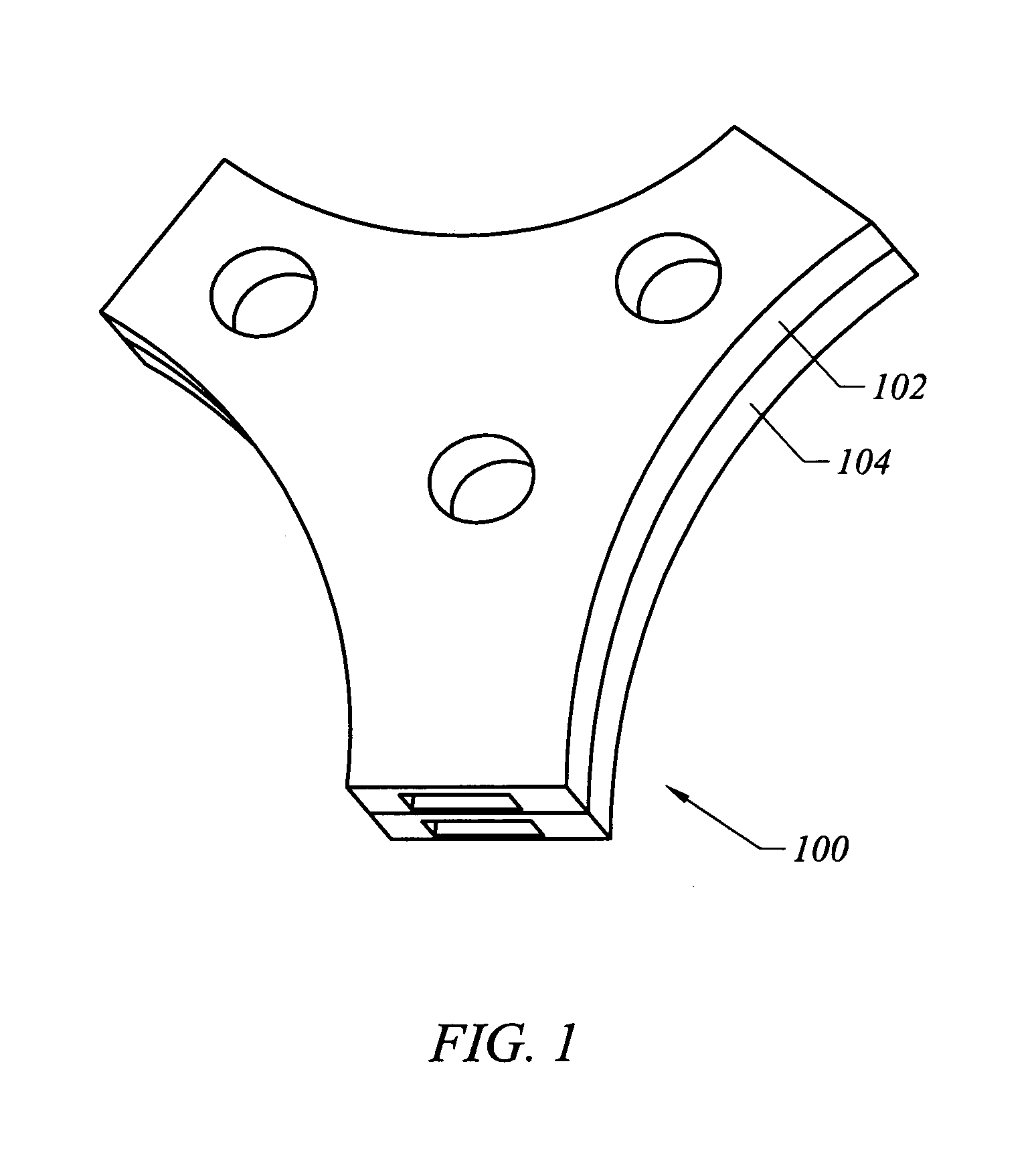

Off-axis fiber reinforced composite core for an aluminum conductor

ActiveUS20080233380A1Reduce decreaseNon-insulated conductorsApparatus for heat treatmentElectrical conductorResin matrix

A composite core for an electrical cable, the composite core defining a longitudinal axis that defines a center of the composite core, the core comprising a plurality of longitudinally extending reinforcing fibers embedded in a resin matrix, the fibers oriented substantially parallel to the longitudinal axis and a sheath surrounding the plurality of longitudinally oriented fibers. The sheath may further comprise a plurality of off-axis reinforcing fibers oriented at an angle relative to the longitudinal axis surrounding the longitudinally extending fibers. The sheath may comprise a type of resin, including for example, thermosetting resin or thermoplastic resin.

Owner:CTC GLOBAL CORP

Aluminum conductor composite core reinforced cable and method of manufacture

InactiveUS20040131851A1High strengthIncrease ampacityNon-insulated conductorsApparatus for heat treatmentElectrical conductorThermal expansion

This invention relates to an aluminum conductor composite core reinforced cable (ACCC) and method of manufacture. An ACCC cable has a composite core surrounded by at least one layer of aluminum conductor. The composite core comprises a plurality of fibers from at least one fiber type in one or more matrix materials. The composite core can have a maximum operating temperature capability above 100° C. or within the range of about 45° C. to about 230° C., at least 50% fiber to resin volume fraction, a tensile strength in the range of about 160 Ksi to about 370 Ksi, a modulus of elasticity in the range of about 7 Msi to about 37 Msi and a coefficient of thermal expansion in the range of about -0.7x10<-6 >m / m / ° C. to about 6x10<-6 >m / m / ° C. According to the invention, a B-stage forming process may be used to form the composite core at improved speeds over pultrusion processes wherein the speeds ranges from about 9 ft / min to about 60 ft / min.

Owner:CTC GLOBAL CORP

Aluminum conductor composite core reinforced cable and method of manufacture

InactiveUS20050227067A1Increase ampacityMaintain stable propertiesNon-insulated conductorsApparatus for heat treatmentElectrical conductorResin matrix

This invention relates to an aluminum conductor composite core reinforced cable (ACCC) and method of manufacture. An ACCC cable having a composite core surrounded by at least one layer of aluminum conductor. The composite core comprises at least one longitudinally oriented substantially continuous reinforced fiber type in a thermosetting resin matrix having an operating temperature capability within the range of about 90 to about 230° C., at least 50% fiber volume fraction, a tensile strength in the range of about 160 to about 240 Ksi, a modulus of elasticity in the range of about 7 to about 30 Msi and a thermal expansion coefficient in the range of about 0 to about 6×10−6 m / m / C. According to the invention, a B-stage forming process may be used to form the composite core at improved speeds over pultrusion processes wherein the speeds ranges from about 9 ft / min to about 50 ft / min.

Owner:CTC GLOBAL CORP

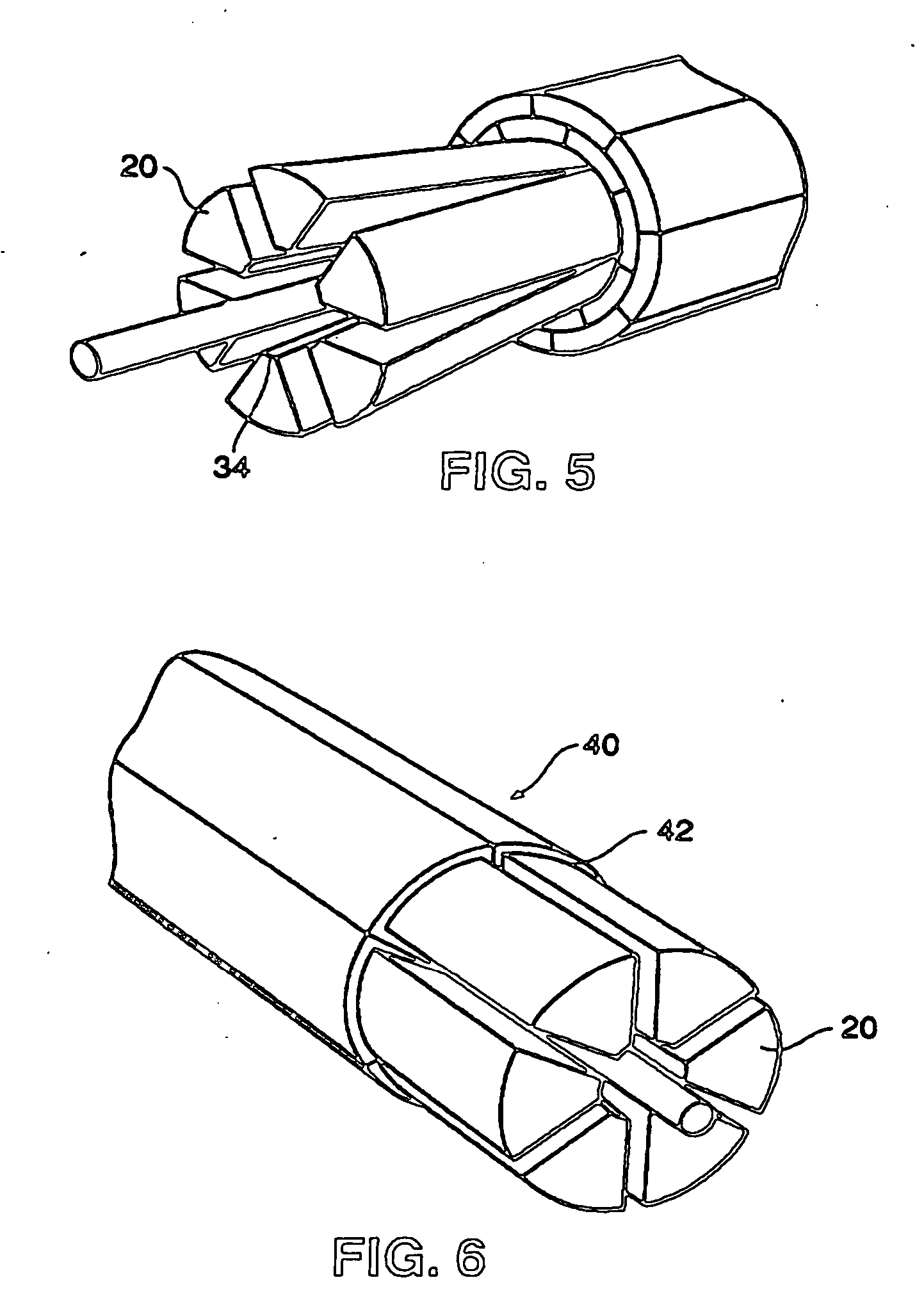

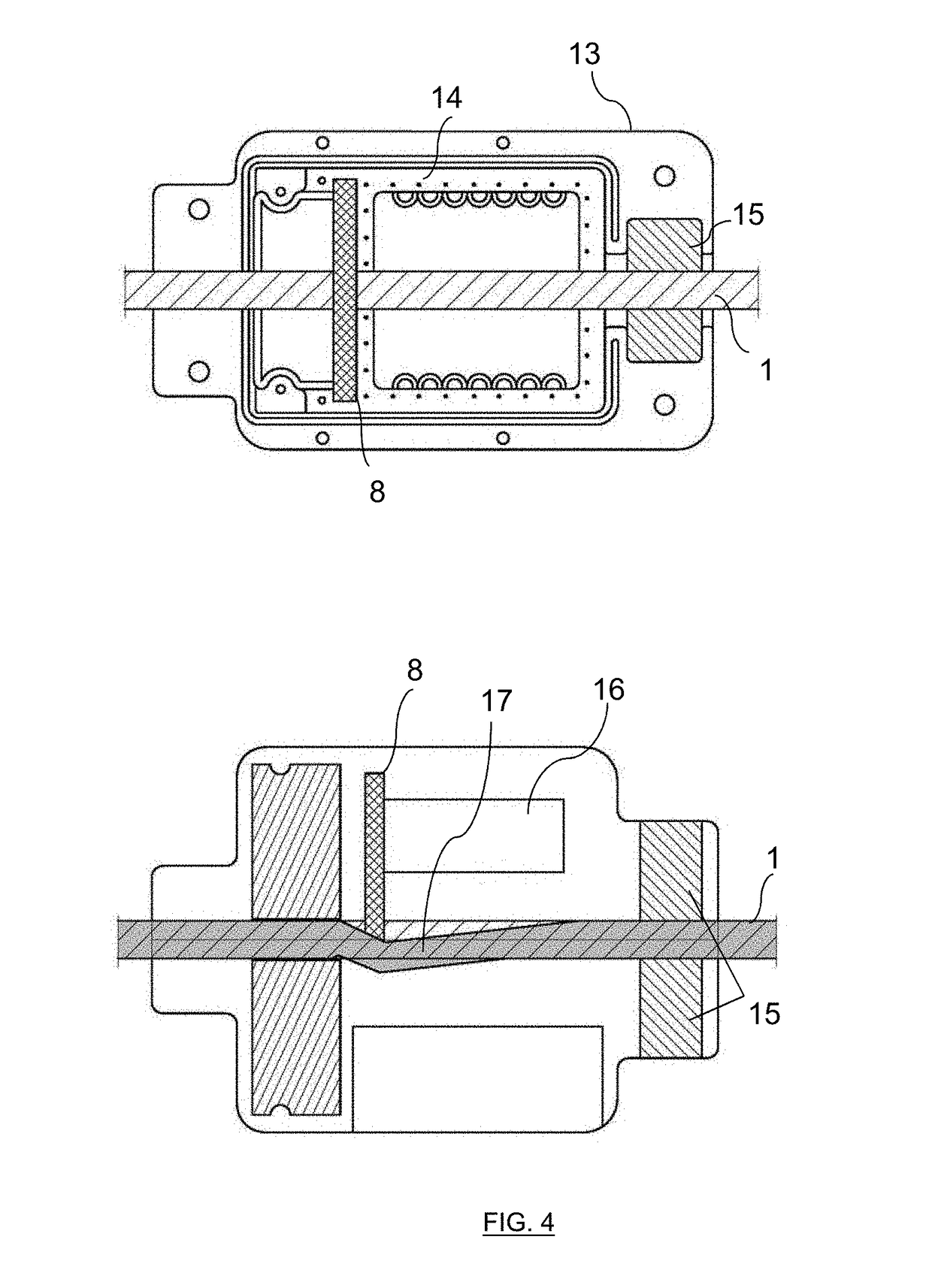

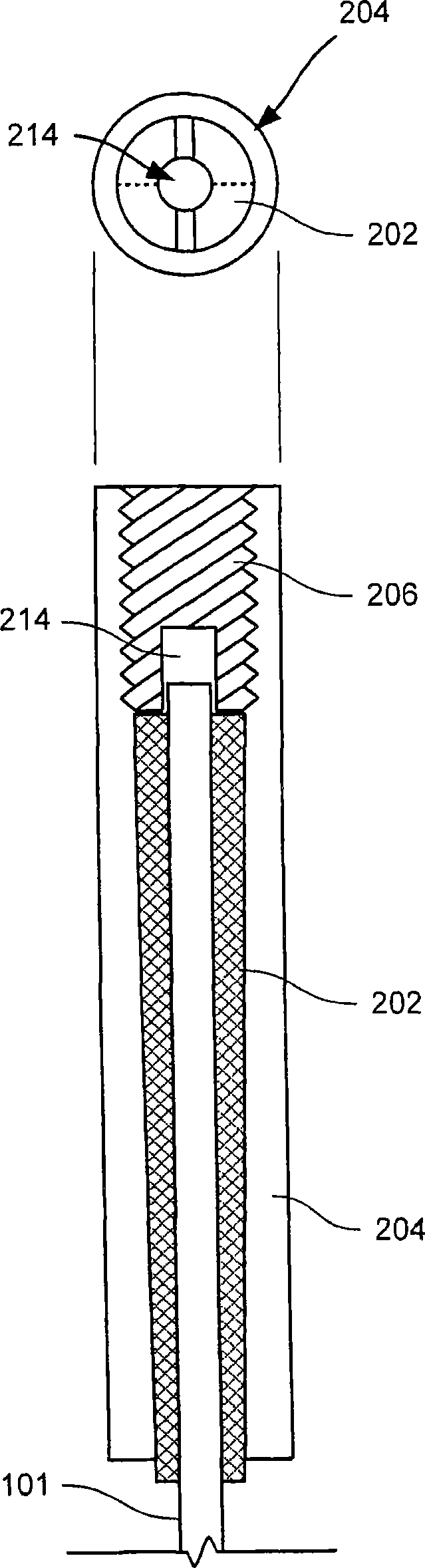

Collet-type splice and dead end for use with an aluminum conductor composite core reinforced cable

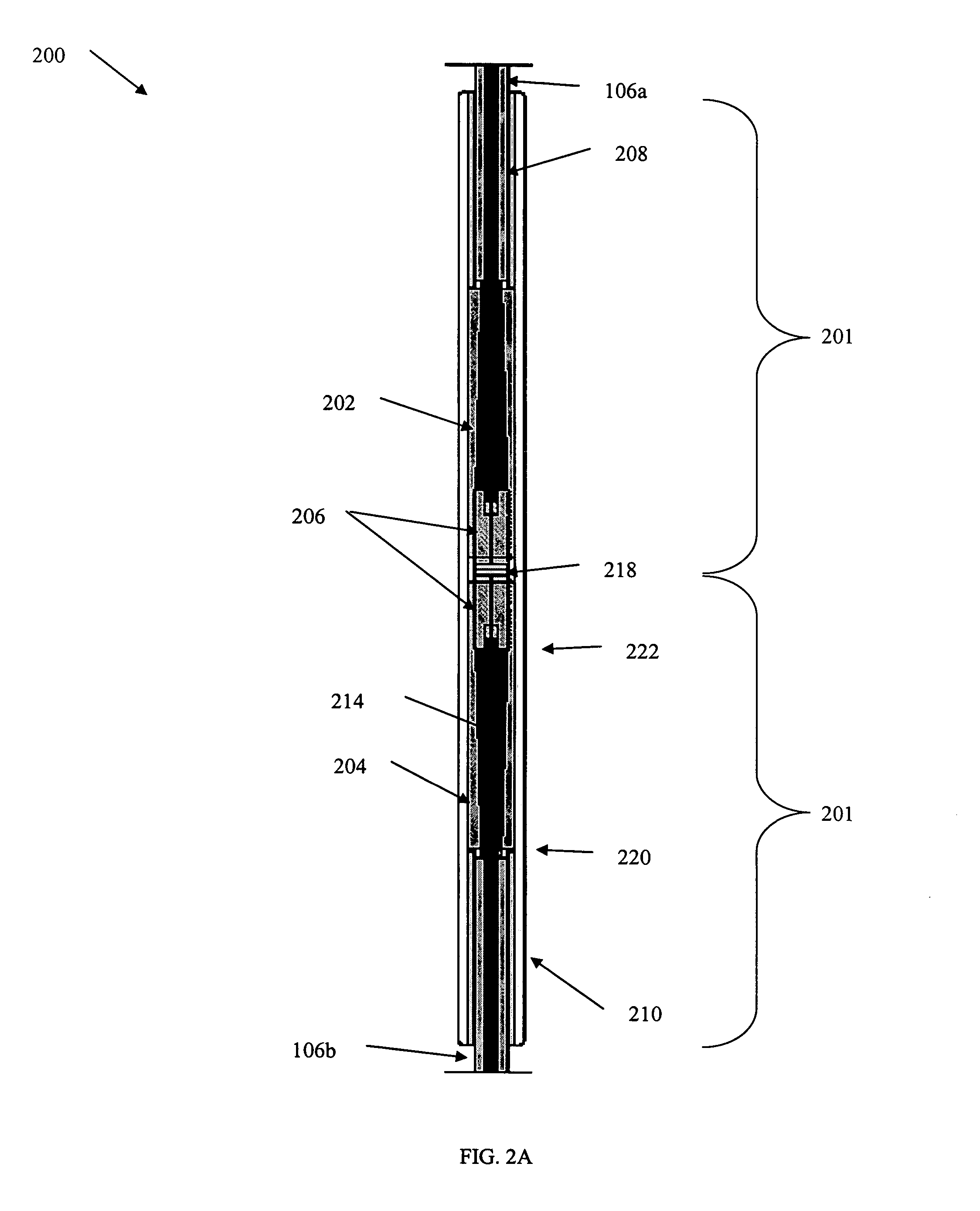

InactiveUS7563983B2Satisfactory initial gripEasy to compressElectrically conductive connectionsArrangements for reliveing mechanical tensionElectrical conductorEngineering

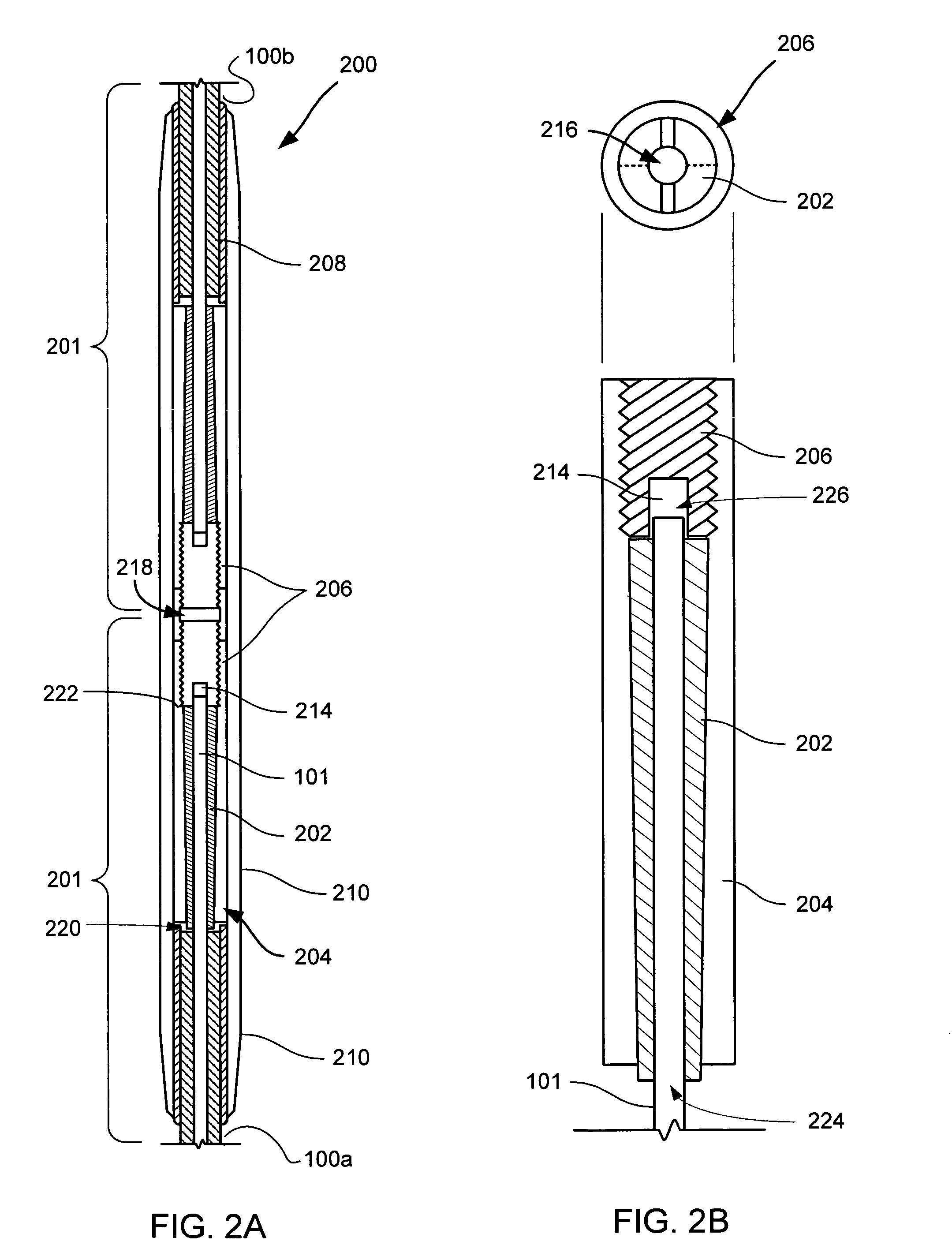

This invention relates to collet-type fittings (201) for use in collet-type splices and collet-type dead ends and methods for splicing together two aluminum conductor composite core reinforced cables (ACCC) or terminating one ACCC cable. The collet-type fittings (201) comprise a collet (202) coincident with a collet housing (204) to hold the composite cores. The composite cores can be stripped of the aluminum conductor to provide a bond between the collet (202) and the composite core. After inserting the composite core into the collet (202), a compression element (206) compresses the collet (202). The collet (202) holds the composite core with frictional forces and the collet (202) further compresses and strengthens the hold on the composite core if the composite core pulls the collet (202) further into the collet housing (204).

Owner:CTC GLOBAL CORP

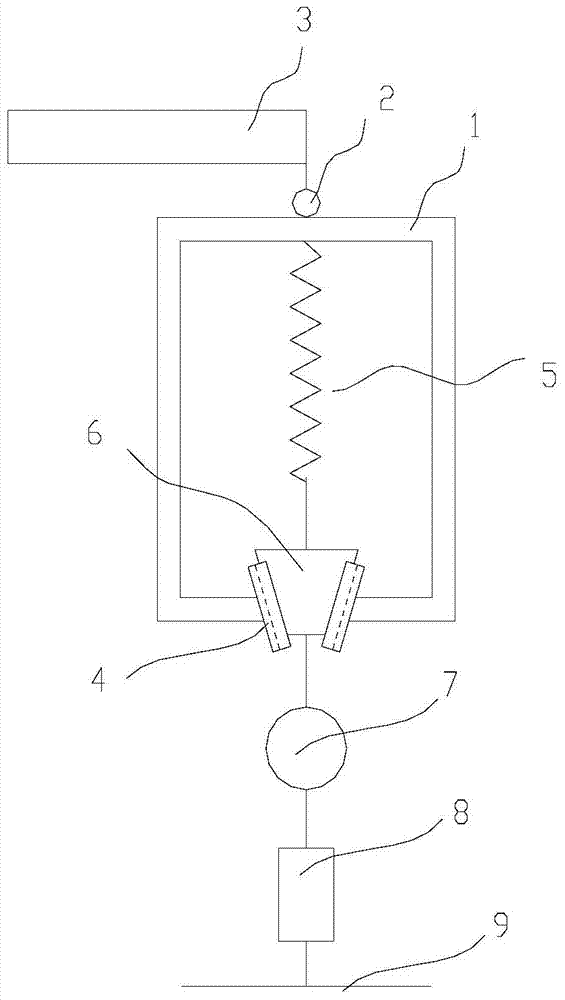

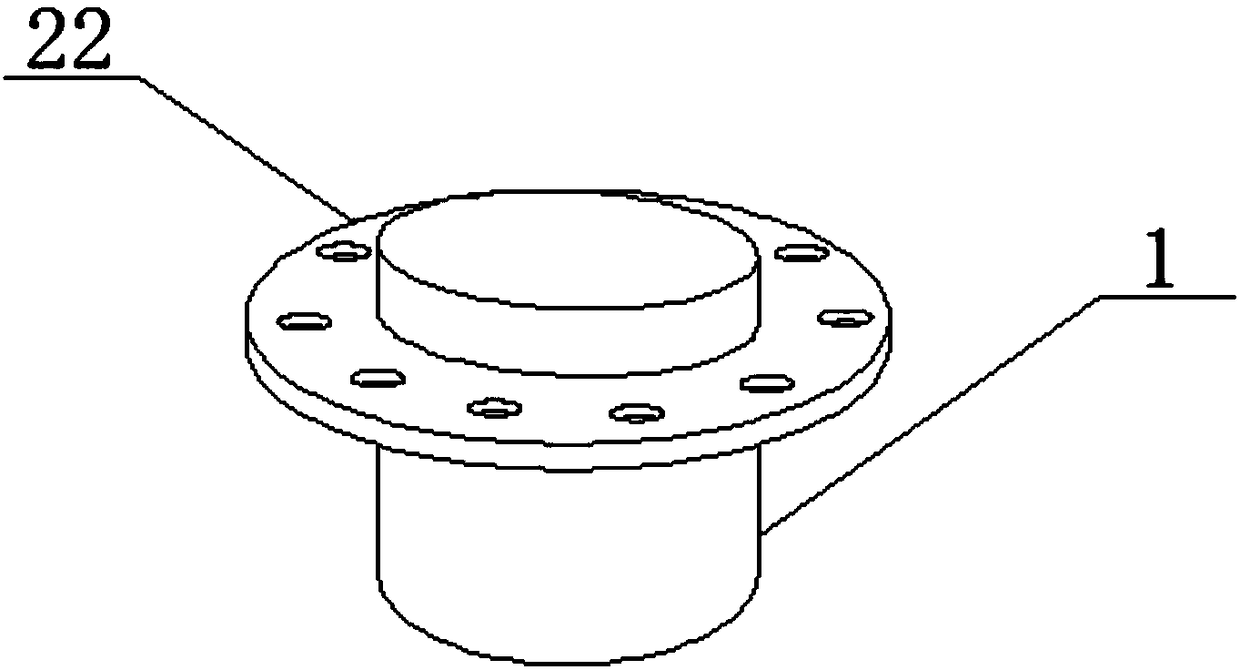

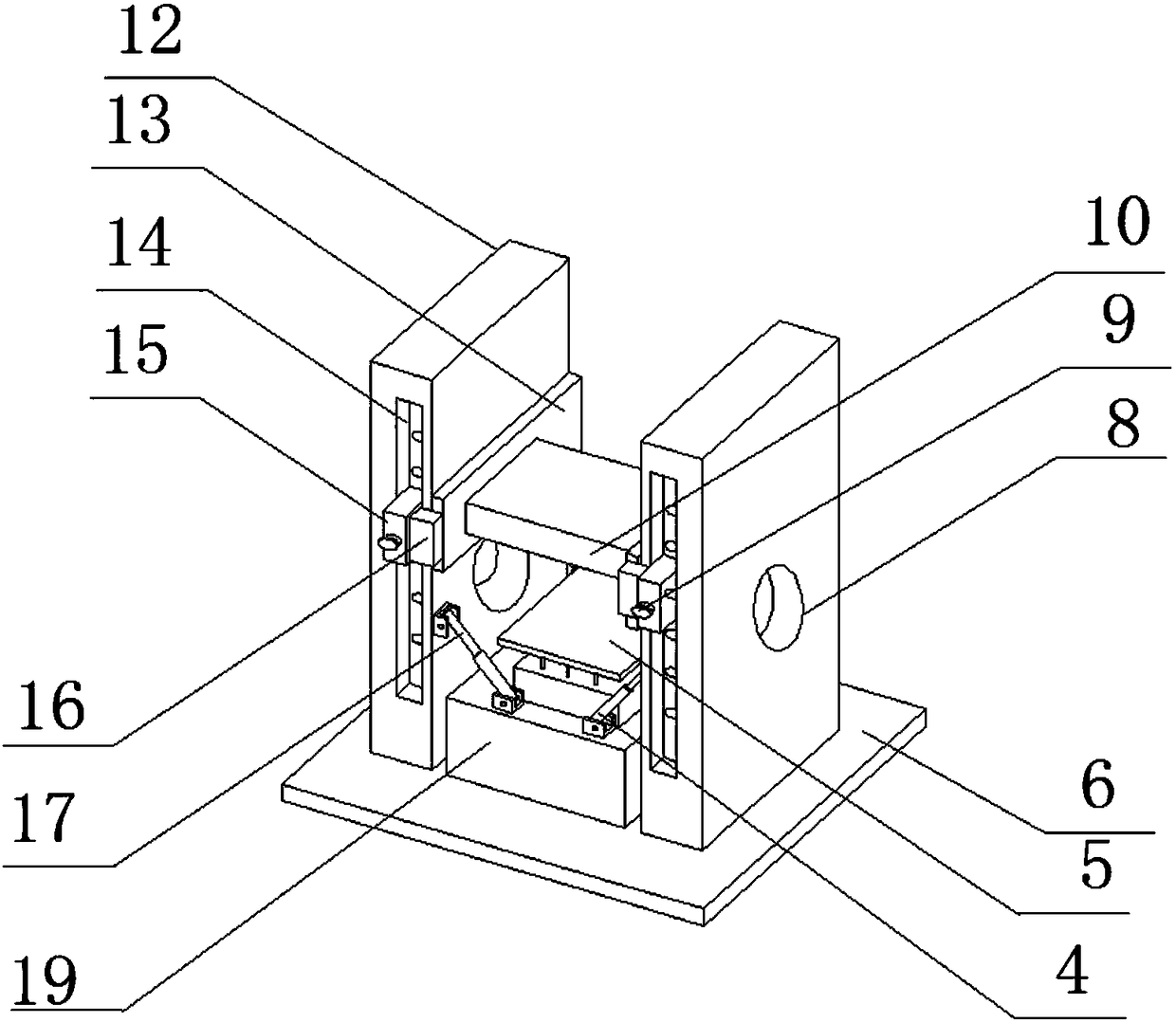

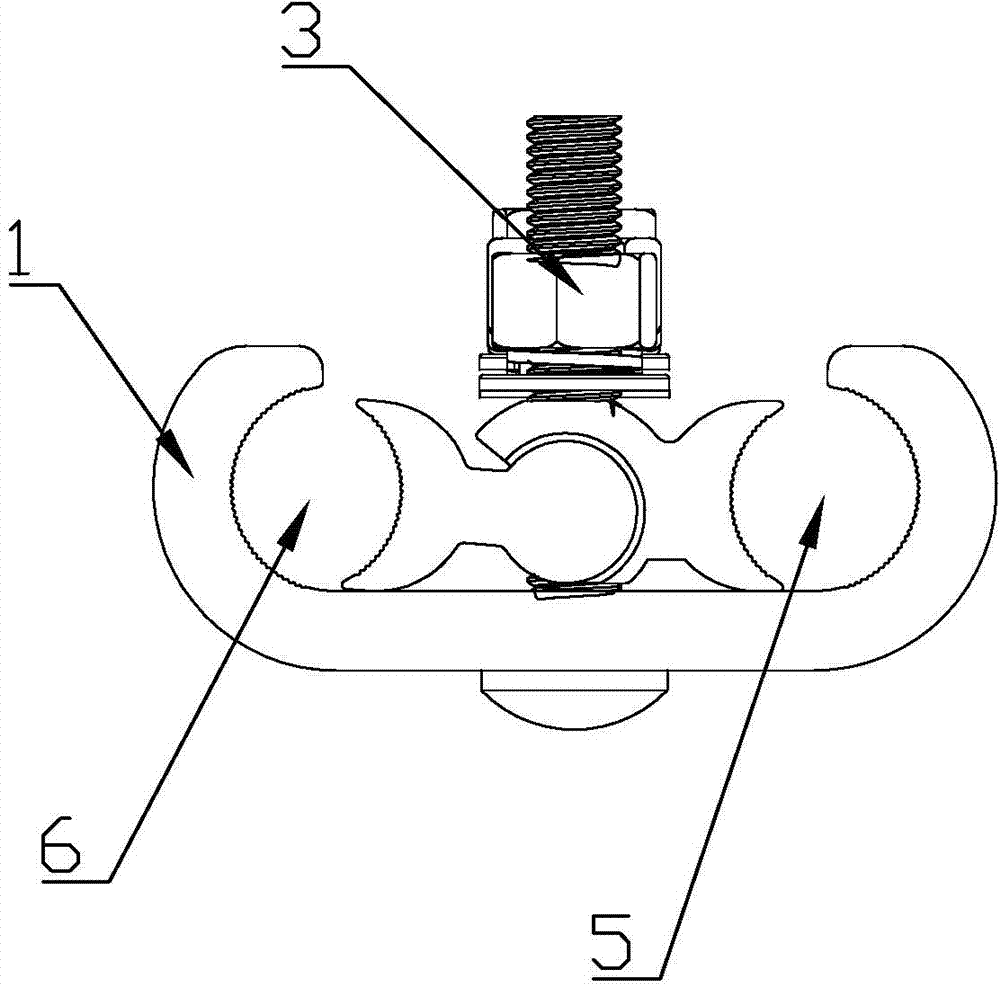

Distribution line typhoon-preventing integrated device capable of achieving pole and wire protecting and achieving pole protecting, wire abandoning, energy absorbing and disengaging

ActiveCN103904603AImprove wind resistanceAvoid accidents of broken poles and tower collapsesDevices for damping mechanical oscillationsArrangements for reliveing mechanical tensionEngineeringTower

The invention discloses a distribution line typhoon-preventing integrated device capable of achieving pole and wire protecting and achieving pole protecting, wire abandoning, energy absorbing and disengaging. The distribution line typhoon-preventing integrated device structurally comprises a notched elastic frame clamp (1). A clamping end of a clamping sliding block (6) is formed through a downward notch. The upper end of the clamp (1) is connected to a pole and tower cross arm end (3) of a distribution line through a spherical hinge (2), two chucks of the clamping end are respectively and fixedly provided with a long groove type plate (4), the upper ends of the two long groove type plates (4) incline towards the two sides while the lower ends of the two long groove type plates (4) incline towards the middle, a wide-end-up groove with a certain dip angle is formed by combining the two chucks, the middle of the top end in the frame clamp is provided with a tension spring (5), the tension spring (5) is connected with the clamping sliding block (6), connected with a rewinding spring (7) through a steel rope and downwards connected with an insulator / armor clamp (8) of the distribution line, and the insulator / armor clamp (8) is connected with a wire (9) of the distribution line. According to the integrated device, a pole and the wire can be protected when wind is weak, and when the line cannot resist the attack of violent typhoon, the pole can be protected, the wire can be abandoned, energy is saved for enabling the wire to disengage from the pole, the line and the line pole can be effectively prevented from broken, and the tower can be effectively prevented from falling down.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

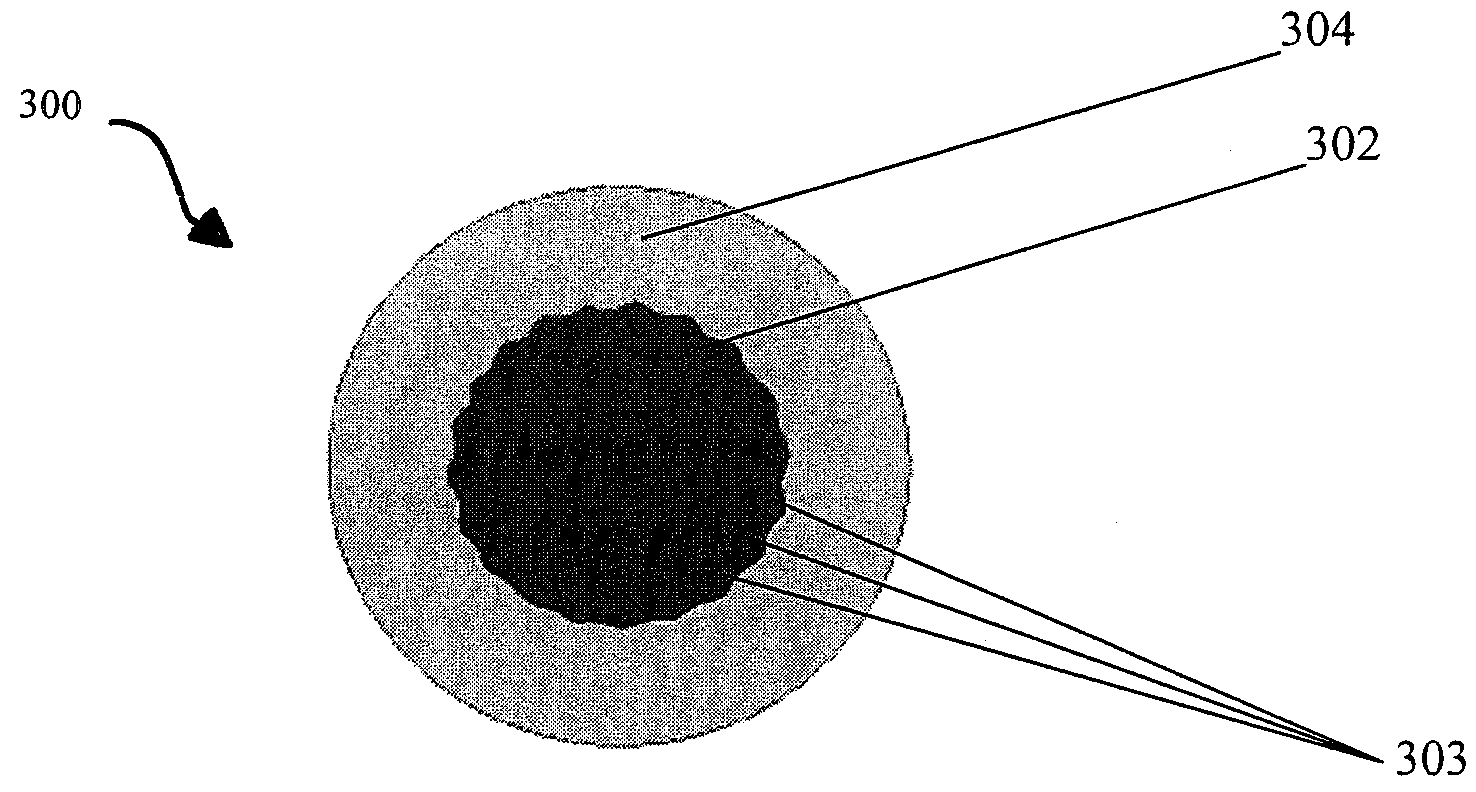

Method for the manufacture of a composite core for an electrical cable

A method for the manufacture of a composite core for an electrical cable. The method may include pulling carbon fiber tows and glass fiber tows through a composite core processing system. The carbon fiber tows and the glass fiber tows are contacted with a resin, such as a thermosetting resin, to impregnate the fiber tows with the resin. The glass fiber tows are disposed on the outside of the carbon fiber tows to form a glass fiber layer around the carbon. The resin is then cured to form the composite core, which is adapted for use in an electrical transmission and distribution cable.

Owner:CTC GLOBAL CORP

Collet-type splice and dead end use with an aluminum conductor composite core reinforced cable

InactiveUS20050006129A1Easy to compressImprove mechanical propertiesSynthetic resin layered productsArrangements for reliveing mechanical tensionAluminiumEngineering

This invention relates to collet-type splices and collet-type dead ends and methods for splicing together two aluminum conductor composite core reinforced cables (ACCC) or terminating one ACCC cable. The collet-type fittings use a collet inside a collet housing to hold the composite cores. The composite cores can be stripped of the aluminum conductor to provide a bond between the collet and the composite core. After inserting the composite core into the collet, a compression implement compresses the collet. The collet holds the composite core with frictional forces and the collet further compresses and strengthens the hold on the composite core if the composite core pulls the collet further into the collet housing.

Owner:CTC GLOBAL CORP

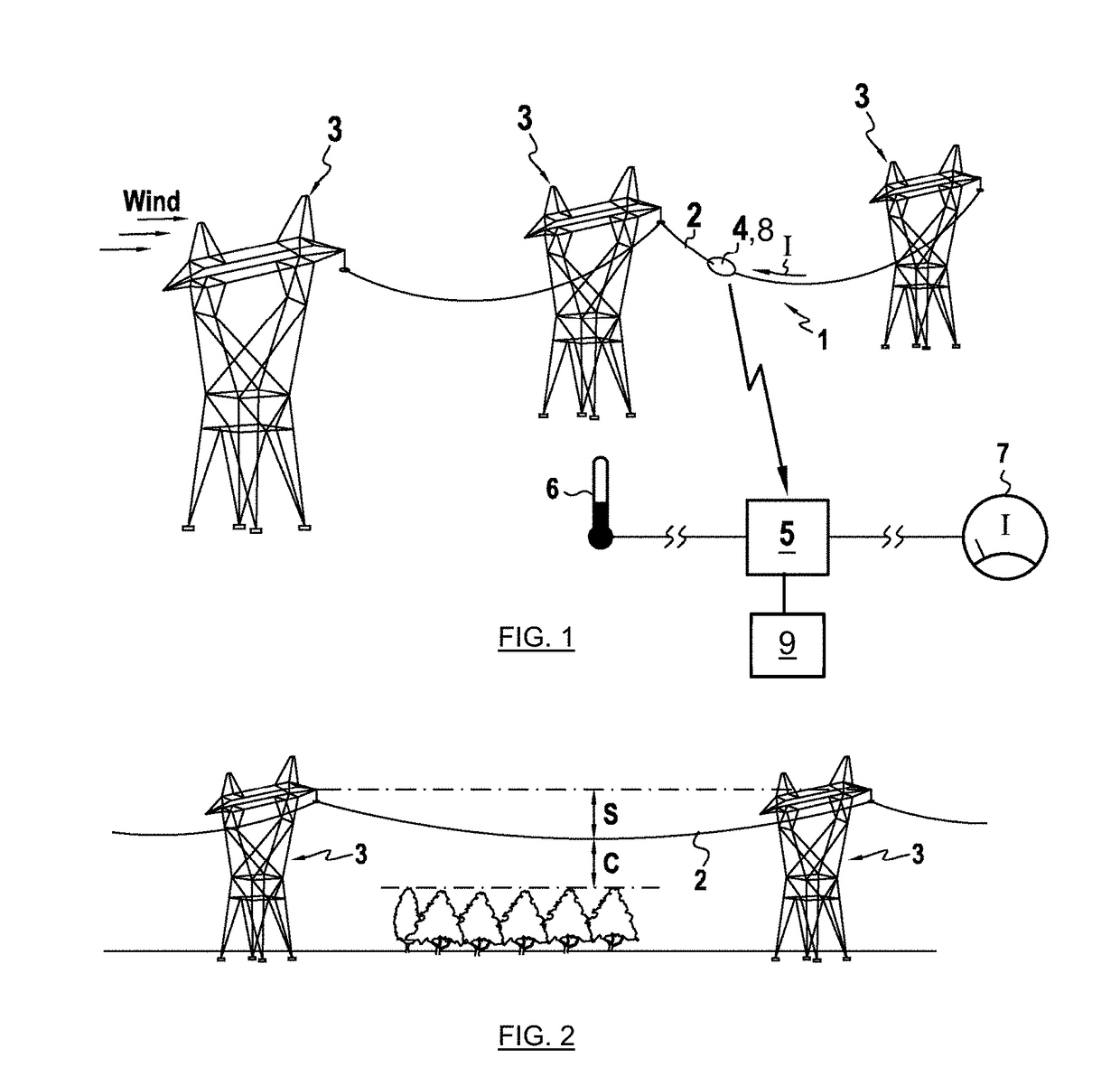

Apparatuses, Systems and Methods for Determining Effective Wind Speed

ActiveUS20140260598A1Facilitates properLong-term reliabilityVolume/mass flow by thermal effectsArrangements for reliveing mechanical tensionElectrical conductorEngineering

Systems and methods for determining an effective wind speed are disclosed. A system includes a first detector, a second detector and a processing unit. The first detector includes a heated temperature-sensing element having a heater and a first temperature sensor, and a first housing at least partially housing the heated temperature-sensing element. The second detector includes a non-heated temperature-sensing element having a second temperature sensor, a second housing at least partially housing the non-heated temperature-sensing element. The processing unit can be adapted to determine the effective wind speed according to a temperature at the heated temperature-sensing element, a temperature at the non-heated temperature-sensing element, and / or a difference between these temperatures and in accordance with an algorithm or table of values. The heated and non-heated temperature-sensing elements and their respective first housing and second housing are collinear, proximal and parallel to the conductor, and protected from precipitation by a shield.

Owner:HUBBELL INC

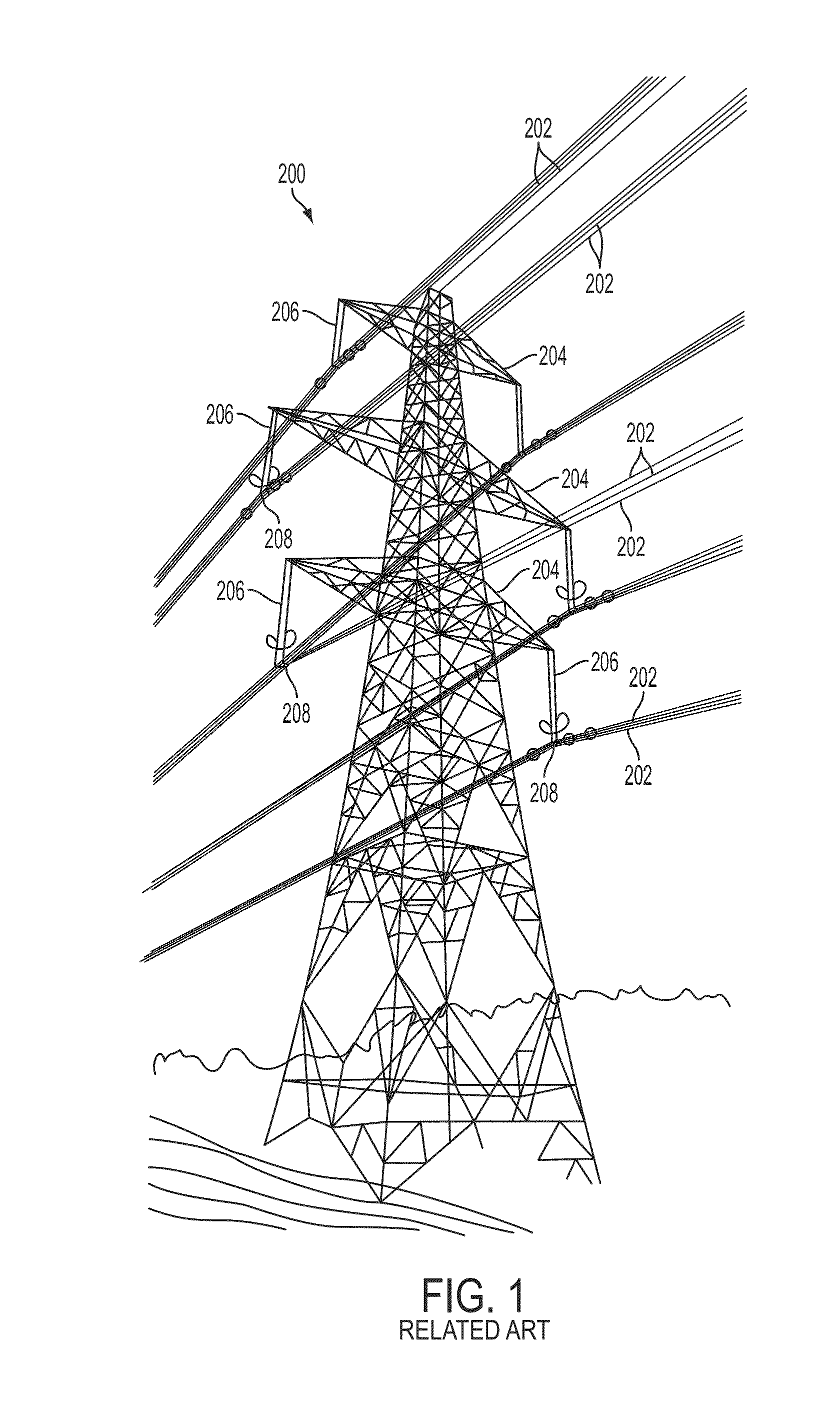

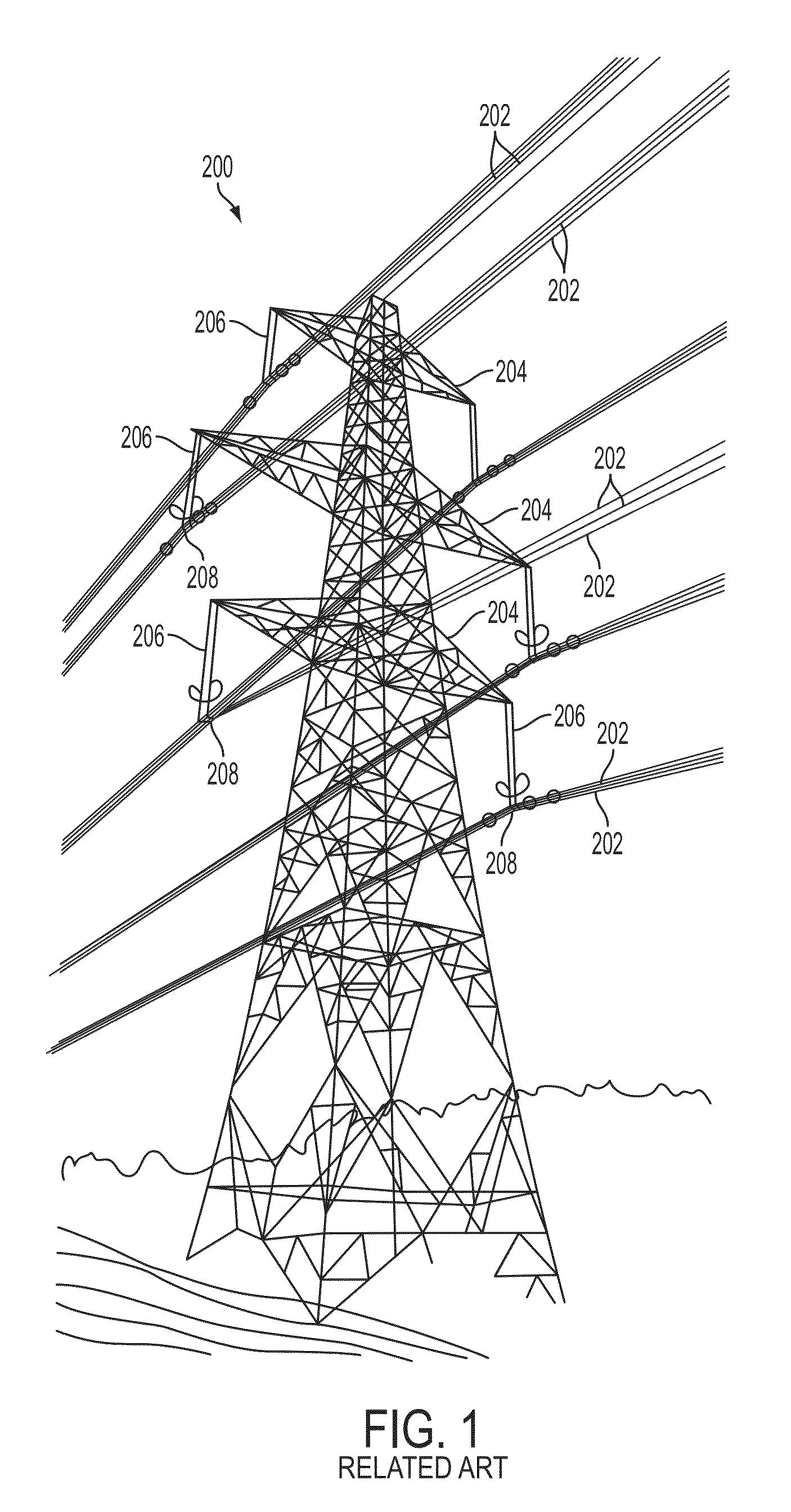

Method for increasing the current carried between two high voltage conductor support towers

InactiveUS20060016616A1Easily reheatedAvoid excessive labor intensityNon-insulated conductorsInsulated cablesElectrical conductorEngineering

A method for increasing the current carried between two high voltage conductor support powers is provided. The method includes removing a first high voltage carrying cable mounted between the towers and replacing it a composite core cable.

Owner:GOLDSWORTHY WILLIAM BRANDT +1

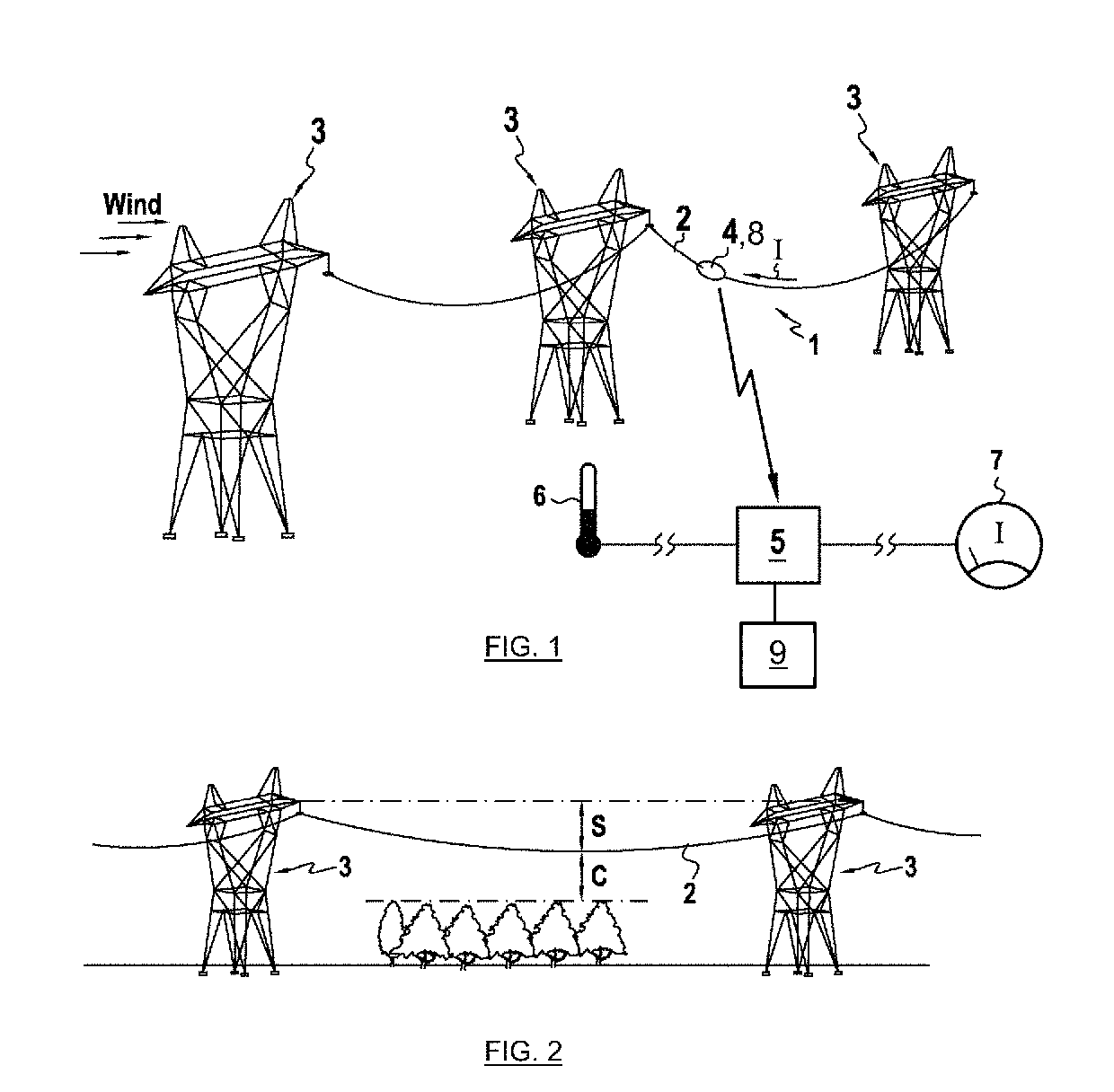

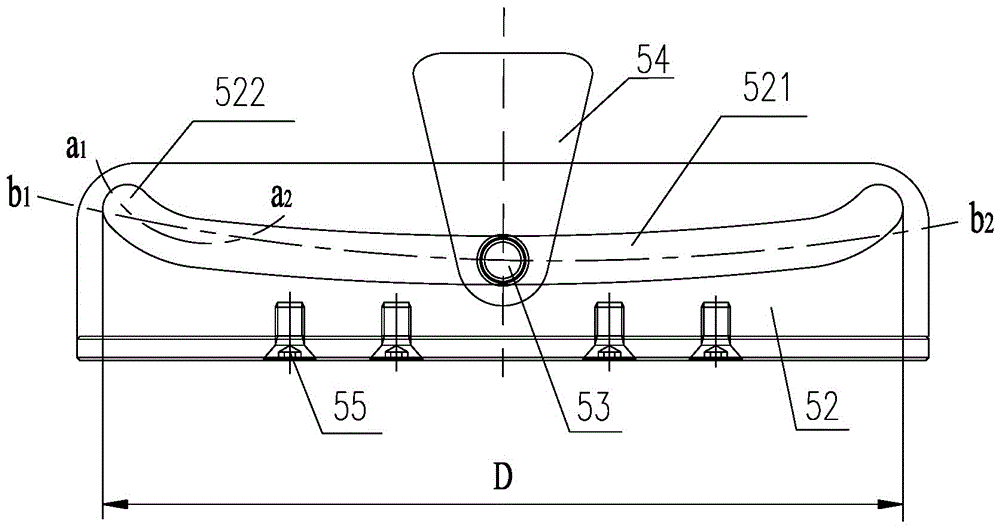

Method and System for Measuring/Detecting Ice or Snow Atmospheric Accretion on Overhead Power Lines

ActiveUS20170227677A1Rainfall/precipitation gaugesArrangements for reliveing mechanical tensionTime rangeAtmospheric layer

The present invention is related to a method for detecting and / or measuring atmospheric accretion on a suspended electrical cable span (2) of overhead power lines, said suspended electrical cable span (2) having a sag (D) and a local tension (H), and being submitted to wind pressure (wwind), comprising the steps of independently:measuring said sag (D), and optionally measuring the wind pressure (wwind), over a first time range,measuring the local tension (H) over a second time range,the results of both steps being complemented and / or combined, so that to allow atmospheric accretion detection and / or measurement.

Owner:AMPACIMON

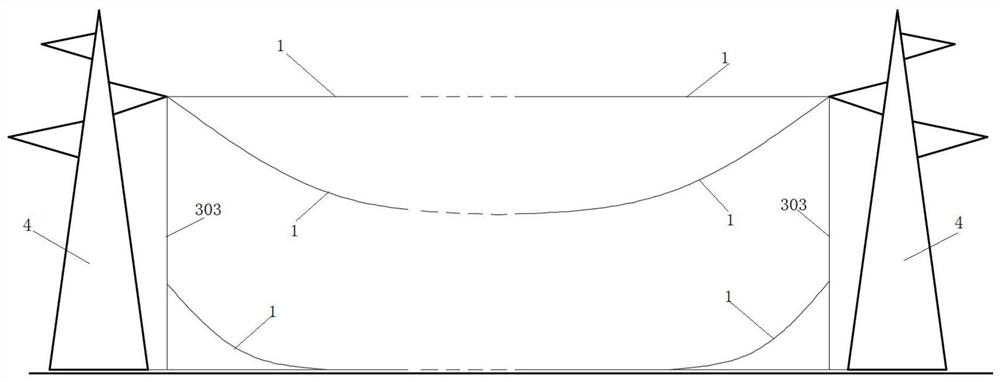

Method for controlling sagging of a power transmission cable

InactiveUS20070009224A1Low sag with temperatureLow costElectric devicesAdjusting/maintaining mechanical tensionElectric power transmissionEngineering

A method is provided for controlling the sagging of a power transmission cable hang between two towers. The cable has a first supporting portion and a second conductive portion. The method includes a first act of mounting the cable between the two towers, such that when mounted between the towers the cable has a cable load. The method further includes a second act of stretching the first portion to have a cable sag less than a desired sag, a third act of releasing at least some of the tension to obtain the desired sag, and a fourth act calculating a load magnitude carried by the first portion. If the load magnitude is less than a desired load magnitude the method includes repeating the second, third and fourth acts until the load magnitude is at the desired level.

Owner:GIFT TECH LLC

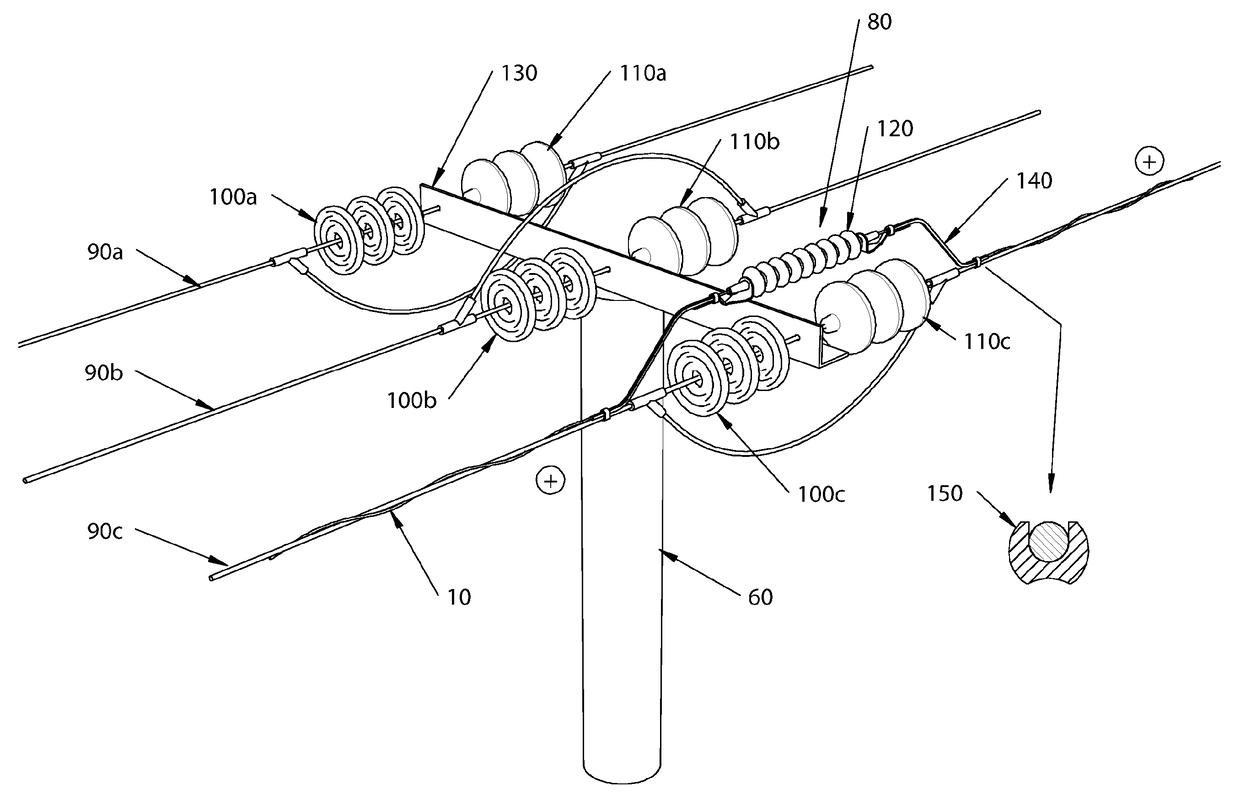

Jumper insulator

ActiveUS20170176703A1Suspension arrangements for electric cablesArrangements for reliveing mechanical tensionFiberEngineering

A method of installing a fibre optic cable (10) upon an overhead power line structure, the overhead power line structure including an overhead power line support (60)and an overhead power line (90) carried by the overhead power line support (60), the method comprising the steps of passing an end of the fibre optic cable (10) through a bore formed in an insulator (120); positioning the insulator (120) at an installation location adjacent to the overhead power line support (60) with the fibre optic cable (10) located within the bore in the insulator (120); bonding the insulator (120) in place once positioned in the said installation location; connecting the insulator (120) to a first end of a conductive carrier (160); and connecting a second end of the conductive carrier (160) to the overhead power line (90) such that the fibre optic cable (10) is supported by the conductive carrier (160) and the insulator (120) as it passes from a first side of the overhead power line support (60) to a second side thereof.

Owner:AFL GLOBAL

Device for preventing power transmission tower from collapsing caused by overload

InactiveCN101515706AProtection from being pulled down and damagedImprove construction standardsArrangements for reliveing mechanical tensionEngineeringTower

The invention discloses a device for preventing power transmission tower from collapsing caused by overload. The structure of the device comprises a stayed pole, an extended rope and a barrel-shaped crust wrapping up the stayed pole and the extended rope, wherein, the stayed pole is made of conducting material, the upper end of the stayed pole is fixedly connected with the lower end of the insulator string of the power transmission tower, and the lower end of the stayed pole is fixedly connected with a suspension clamp; the extended rope intertwines over the stayed pole or entwines in the cavity of the barrel-shaped crust, the two ends of the extended rope are fixed with the two ends of the stayed pole; the barrel-shaped crust is made of conducting material, which seals and wraps up the main part of the stayed pole and the whole extended rope. When the load bearing of transmission line reaches 60%-80% of the self breaking force value, the stayed pole breaks off and the transmission line falls to the ground to protect the power transmission tower from collapsing.

Owner:王国彬

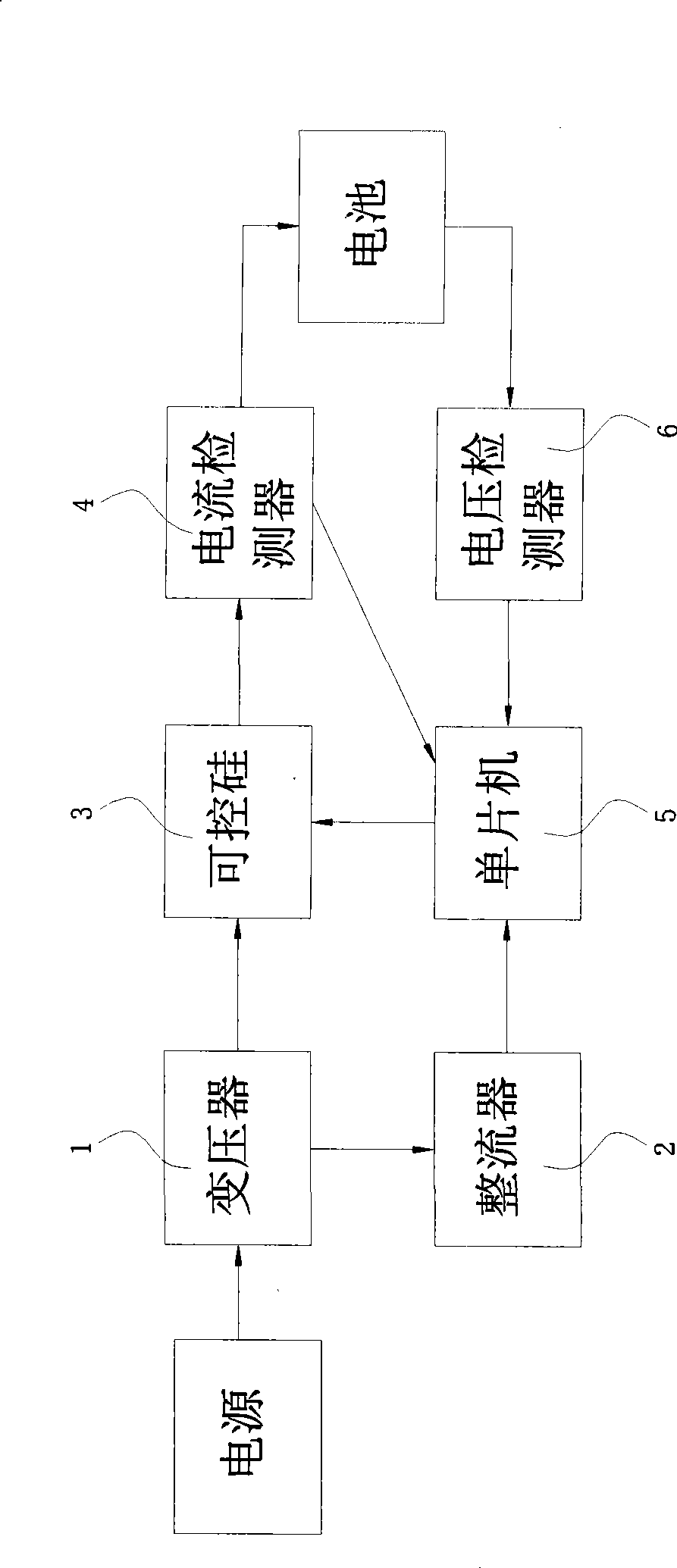

Charger for automatically recognizing battery

InactiveCN101478134ALess hurtArrangements for reliveing mechanical tensionMicrocontrollerBattery charge

The invention relates to a battery charger, in particular to a charger for automatically identifying batteries. The battery charger comprises a transformer, a rectifier, controllable silicon, a current detector, a singlechip and a voltage detector. The controllable silicon is connected with the transformer and the singlechip respectively, which converts alternating current output by the transformer into constant DC which is provided for batteries. The current detector is connected with the controllable silicon and the singlechip respectively. The current detector detects the current of batteries charged from time to time, and feeds the current signals back to the singlechip; the singlechip is connected between the rectifier and the voltage detector, and used for determining the types and the capacities of the batteries and outputting control signals for adjusting the turn-on time of the controllable silicon; the voltage detector monitors the voltages at the two ends of the batteries charged from time to time, and feeds the voltage information back to the singlechip. The battery charger can automatically determine the types of the batteries, and can control the time and the magnitude of charging current and charge various types of batteries.

Owner:CHANGZHOU JUTAI ELECTRONICS

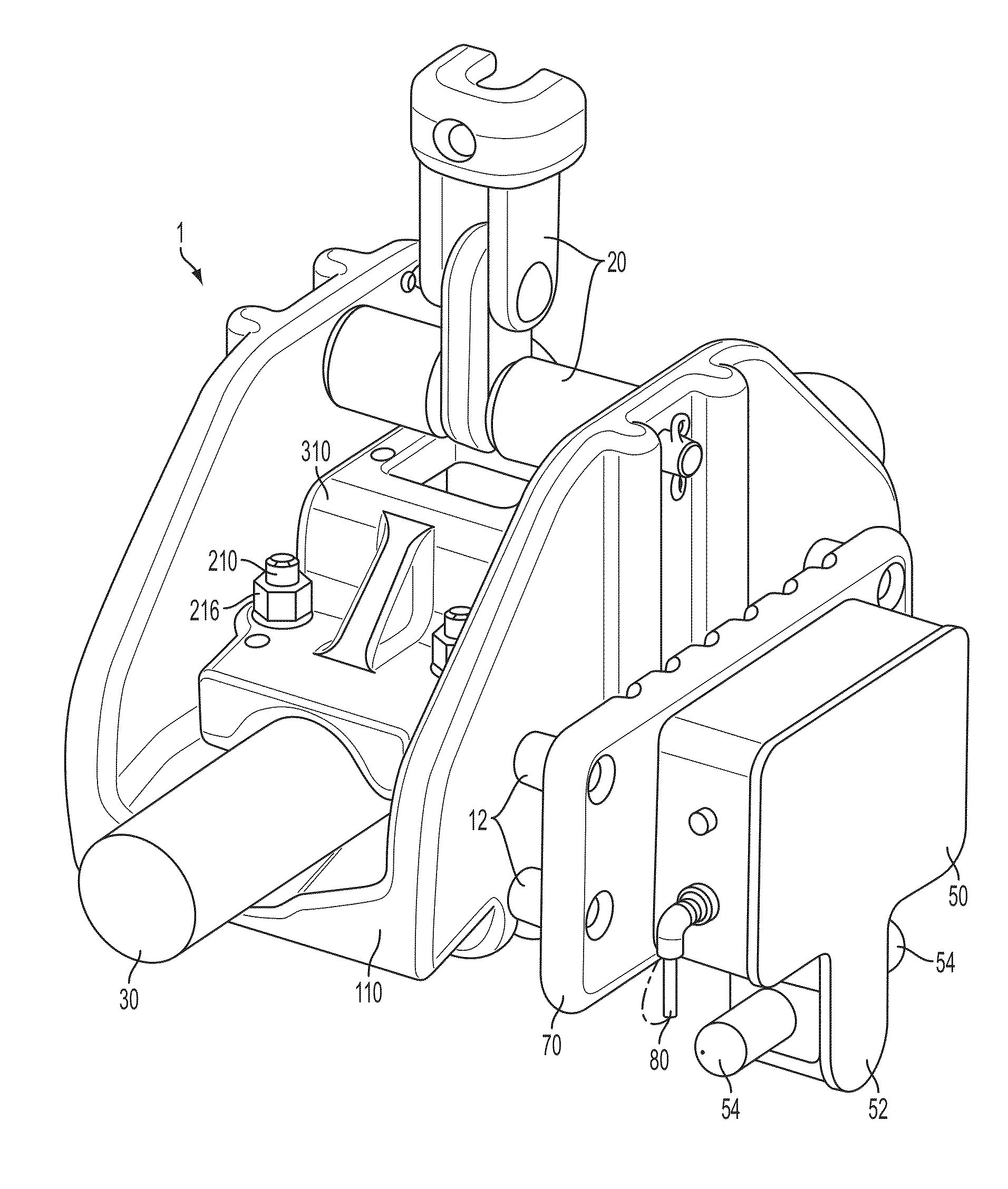

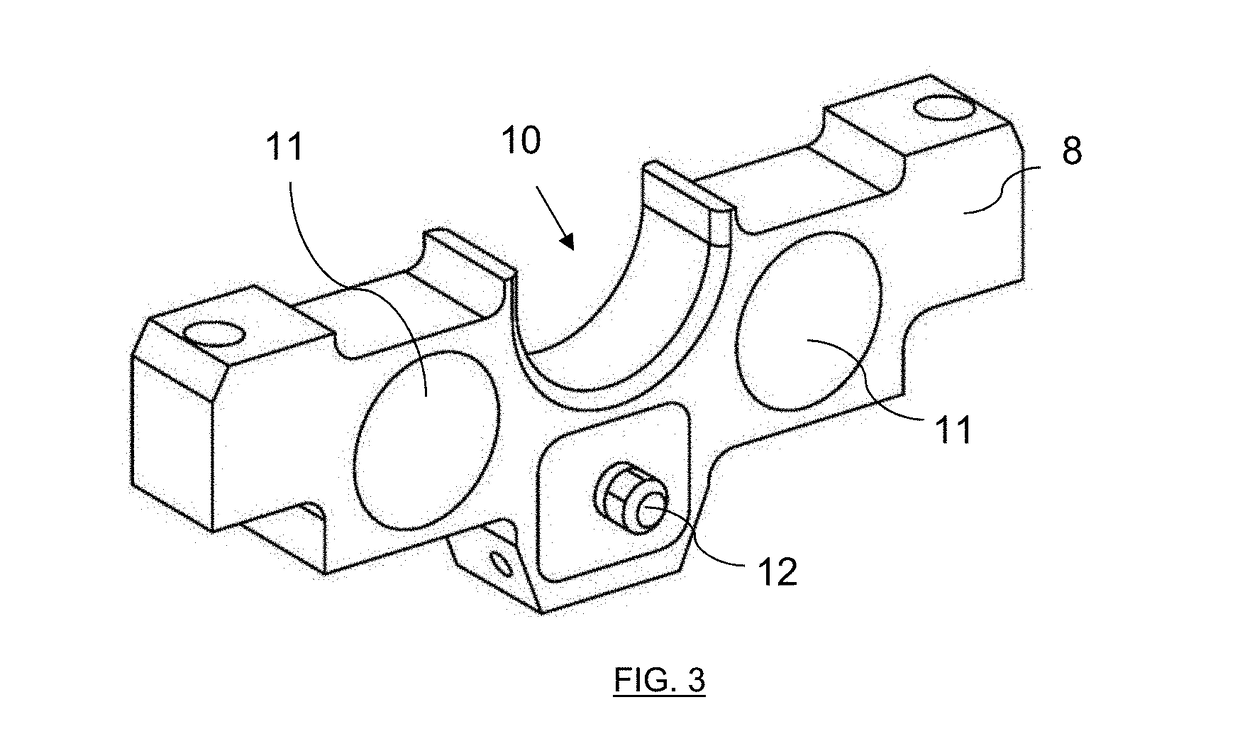

Quick Disconnect Method and Apparatus for Utility Power Distribution Systems

ActiveUS20150132981A1Easy to reachEngagement/disengagement of coupling partsArrangements for reliveing mechanical tensionDistribution power systemElectric power distribution

A quick release connector for tensioned power lines, the connector comprising: a first component, said first component attached to a power line segment; and a second component attached to a second generally collinear power line segment, said second component comprising a locking clamp mechanism that selectively clamps the first component and automatically releases upon the application of a longitudinal force of predetermined magnitude along the clamp.

Owner:SKYSIGHT TECH

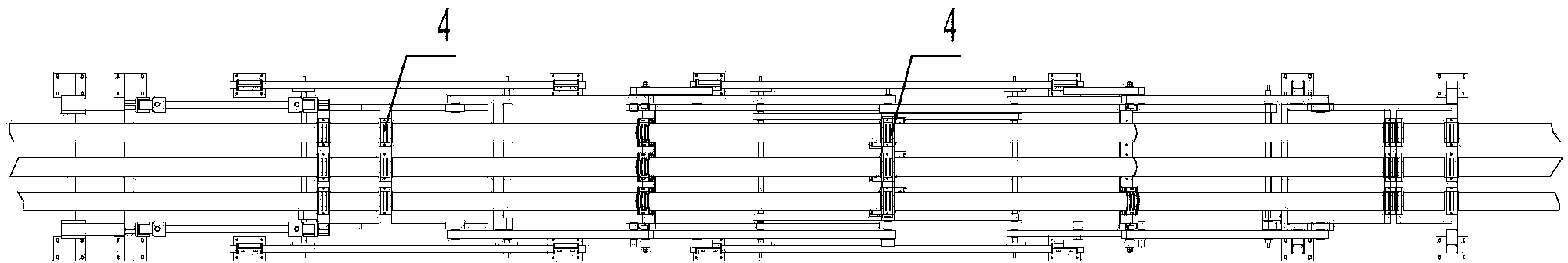

Cable suspension device

InactiveUS9010695B2Reduce pressureMaintaining distance between parallel conductorsPipe supportsMechanical overloadBiomedical engineering

Owner:NKT CABLES GRP

Method and system for measuring/detecting ice or snow atmospheric accretion on overhead power lines

ActiveUS10451770B2Rainfall/precipitation gaugesArrangements for reliveing mechanical tensionSnowpackTime range

Owner:AMPACIMON

A telescopic compensation device for bridge cables

InactiveCN103061256BSimple structureEasy to installArrangements for reliveing mechanical tensionReciprocating motionRelative motion

The invention discloses a bridge crossing cable expansion and contraction compensation device. The device comprises a fixed portion and a movable portion which are arranged on two sides of a bridge seam respectively, the fixed portion comprises a support, the movable portion comprises one section of rail, a pulley and two groups of parallelogram four-bar mechanisms sequentially arranged from front to back, the rail is double tracks in interval arrangement, the pulley is supported on the rail to reciprocate along the rail, a knuckle device is arranged between the fixed portion and the movable portion, and one end of the knuckle device is connected onto the fixing portion while the other end thereof is connected with the pulley on the movable portion. By the aid of the compensation mode that a cable moves along movement of the parallelogram four-bar mechanisms, the bridge crossing cable expansion and contraction compensation device is simple structure and firm in architecture, the cable and the architecture are free of relative movement, and the whole device is stable in operation and capable of achieving full compensation to expansion and contraction of the cable.

Owner:王和平 +2

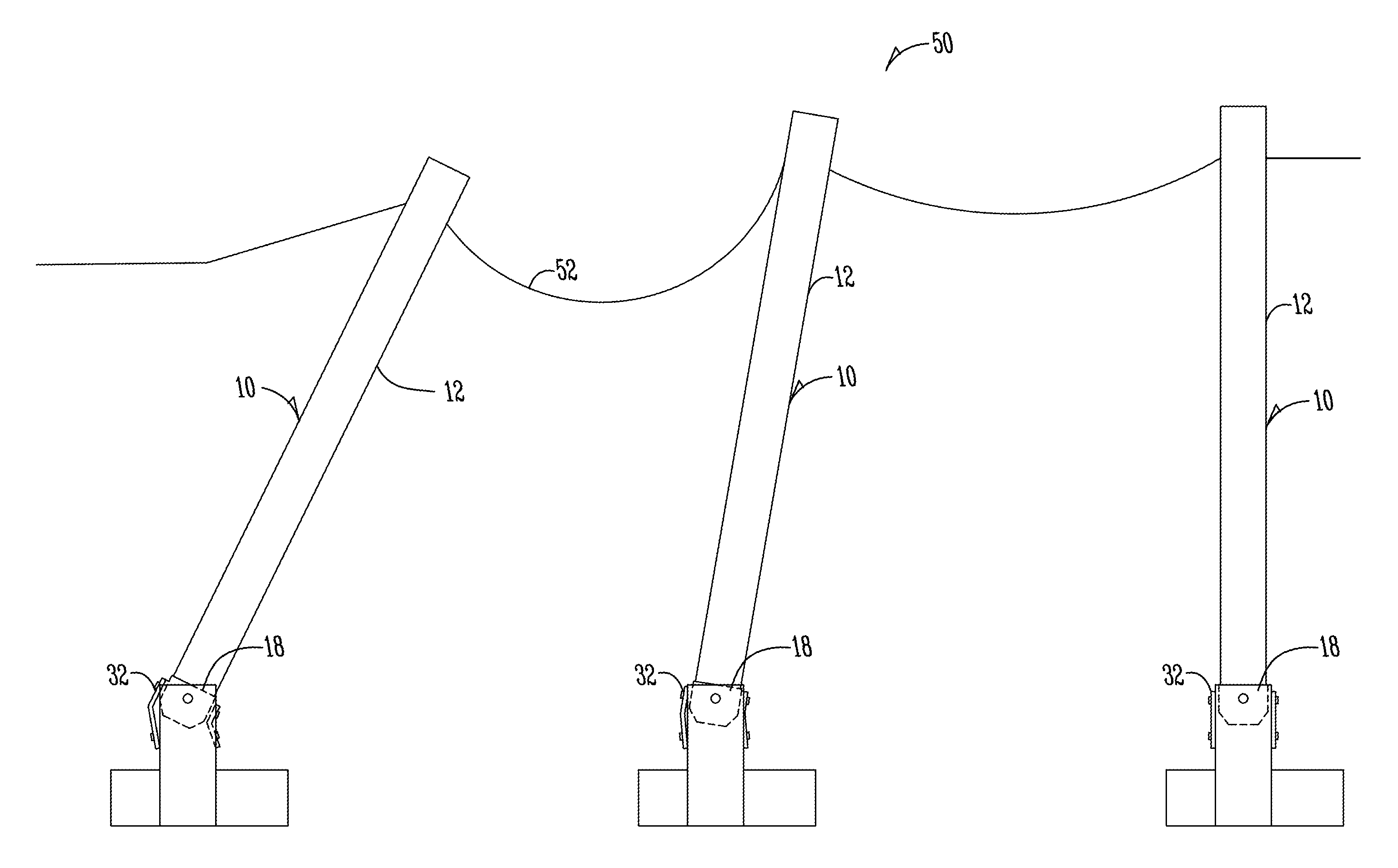

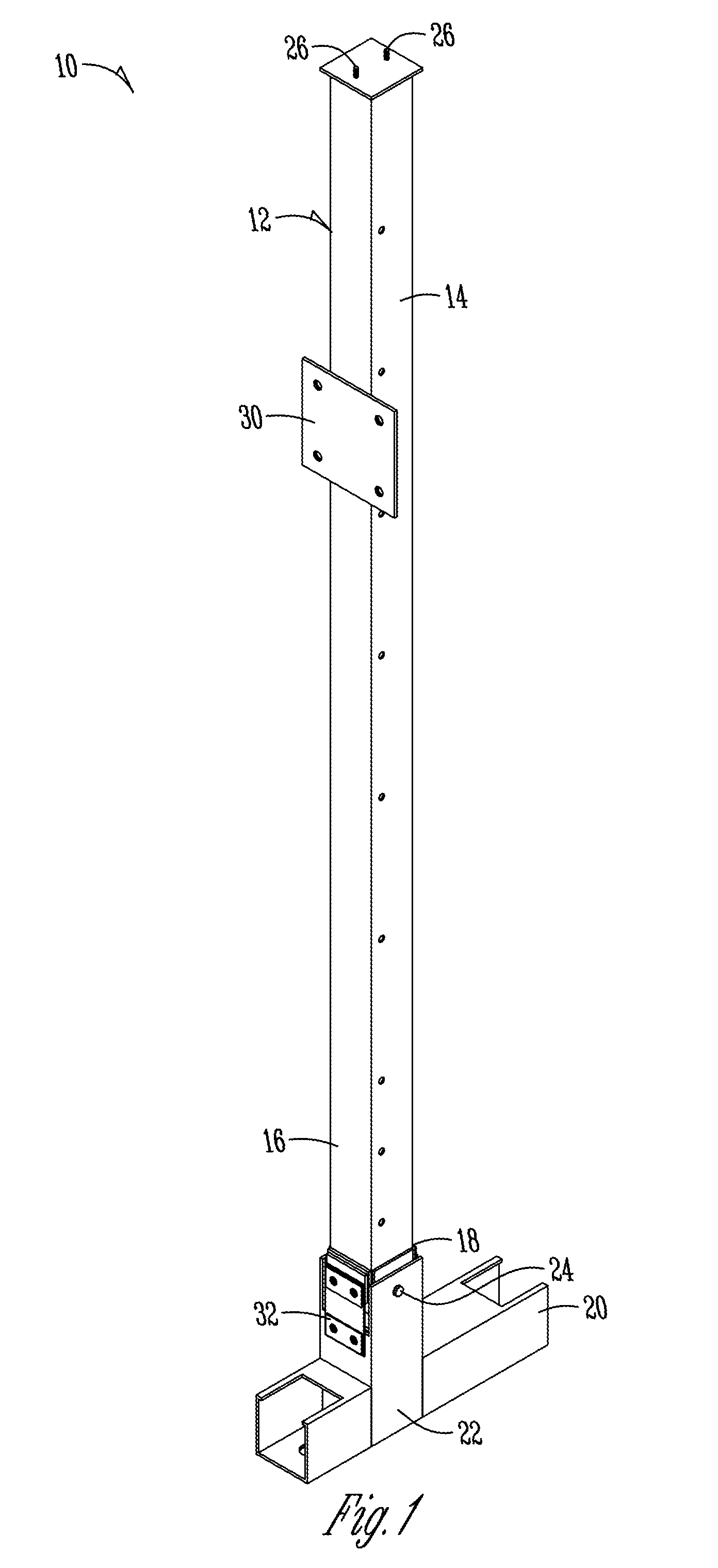

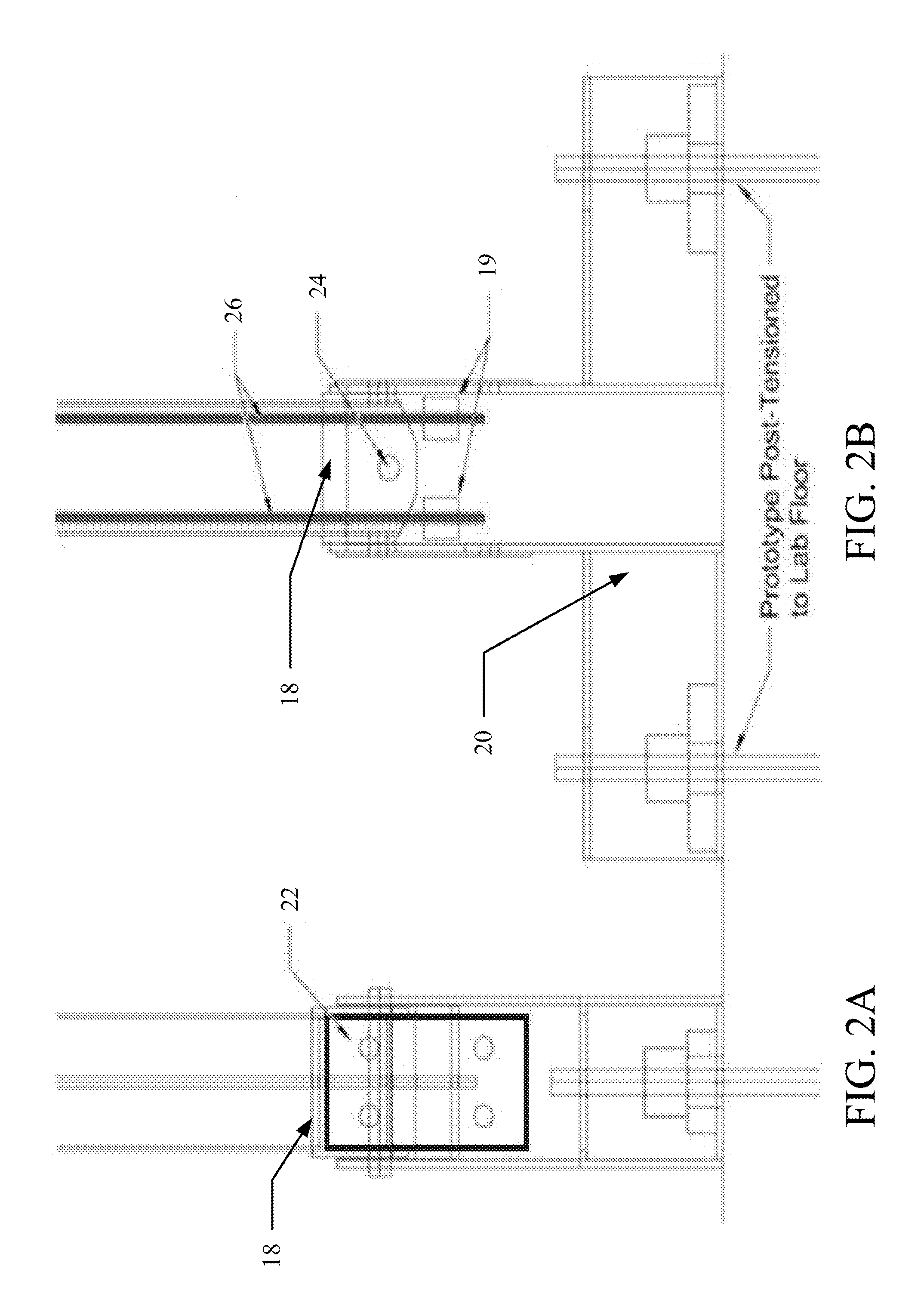

Damage resistant power transmission structures

InactiveUS20110272190A1Cheap to repairQuickly and easily repairedAdjusting/maintaining mechanical tensionArrangements for reliveing mechanical tensionStructural engineeringEngineering

An overhead transmission line support structure includes a base segment and a main segment extending upwardly from the base segment. The overhead transmission line structure further includes a hinge operatively connecting the base segment with the main segment such that the hinge provides deflection capacity parallel to overhead transmission lines supported by the overhead transmission line support structure and such that with sufficient longitudinal loading on the overhead transmission line support structure, the main segment rotates about the hinge. The overhead transmission line support structure may include a post-tensioning system extending along the main segment and / or at least one fuse plate operatively connected between the base segment and the main segment and configured to deform upon the sufficient longitudinal loading on the overhead transmission line support structure.

Owner:IOWA STATE UNIV RES FOUND

Sliding fitting for electric equipment

InactiveCN106786282AAvoid collisionGood displacement slidingDevices for damping mechanical oscillationsArrangements for reliveing mechanical tensionPower gridHeight difference

The invention discloses a sliding fitting for electric equipment. The sliding fitting comprises a bracket for connecting a pipe bus and a connecting plate for connecting electric equipment; landing legs are arranged at the lower end of the bracket, a supporting shaft is arranged in each landing leg, and the supporting shaft penetrates a supporting plate; the supporting plate is fixed on the connecting plate, a sliding slot is formed in the supporting plate, and the supporting shaft penetrates in the sliding slot and capable of sliding along the sliding slot, wherein the sliding slot is a circular arc. The sliding fitting can well displace and slide under the seismic effect so as to balance the height difference caused by equipment deformation in a loop system, thereby reducing the bad influence on the electric equipment by the seismic effect; the structure system of the electric equipment is protected, the safety running of a power grid system is maintained, and the anti-seismic property of the electric equipment is improved.

Owner:CHINA ELECTRIC POWER RES INST +3

Apparatuses, systems and methods for determining effective wind speed

ActiveUS9366688B2Volume/mass flow by thermal effectsArrangements for reliveing mechanical tensionElectrical conductorEngineering

Systems and methods for determining an effective wind speed are disclosed. A system includes a first detector, a second detector and a processing unit. The first detector includes a heated temperature-sensing element having a heater and a first temperature sensor, and a first housing at least partially housing the heated temperature-sensing element. The second detector includes a non-heated temperature-sensing element having a second temperature sensor, a second housing at least partially housing the non-heated temperature-sensing element. The processing unit can be adapted to determine the effective wind speed according to a temperature at the heated temperature-sensing element, a temperature at the non-heated temperature-sensing element, and / or a difference between these temperatures and in accordance with an algorithm or table of values. The heated and non-heated temperature-sensing elements and their respective first housing and second housing are collinear, proximal and parallel to the conductor, and protected from precipitation by a shield.

Owner:HUBBELL INC

Power conveying device with adjustable support directions and angles

InactiveCN108134356AImplementation locationImplementation angleArrangements for reliveing mechanical tensionEconomic benefitsEngineering

The invention discloses a power conveying device with adjustable support directions and angles. The power conveying device comprises a support column, wherein a rotating disc is fixed on the support column; a bearing plate is rotationally connected with the upper end of the support column; a fixing device is arranged at the lower end of the bearing plate; two first chutes parallel to each other are formed in the upper end of the bearing plate; two first sliding blocks are respectively mounted in the two first chutes; a first moving plate is fixed at the upper ends of the four first sliding blocks; four first insert rods are arranged at the upper end of the first moving plate in a penetration manner; and a plurality of first insert holes corresponding to the first insert rods are distributed in the bottom ends inside the first chutes. The power conveying device is advanced in design, convenient to use, wide in application range, good in economic benefit and applicable to popularization;different variation positions and angles of a power wire are achieved; meanwhile, due to adoption of a plurality of damping buffer devices and protection devices, the problem that a conventional lineis inconvenient to fix, mount and use is solved; and the construction progress can be accelerated.

Owner:王珣

10KV distribution line cable erection fixture and application method

ActiveCN105655952AWon't fall offHow to use short answerSuspension arrangements for electric cablesArrangements for reliveing mechanical tensionChinese charactersLocking mechanism

The invention discloses a 10KV distribution line cable erection fixture and an application method and provides a convenient and fast device capable of effectively avoiding adverse impact caused by wind vibration. The 10KV distribution line cable erection fixture comprises a shell, wherein a main cavity is formed at the middle of the shell, and two assistant cavities are formed on the two sides; three rope sheaves and a pair of assistant locking mechanisms are mounted in the main cavity; the three rope sheaves are arranged in a shape of Chinese character 'Pin'; the rope sheaves are close to an entrance, and the locking mechanism is close to an exit. When a cable passes by, a clamping force is formed against the cable under the effect of reversed tension of the cable; a pull rod is mounted in each assistant cavity, and the tensioning effect is good; and three rope sheaves are arranged inside, the cable is wound on the three rope sheaves which are mutually bent in a roundabout manner, and locking and fixing are formed in the roundabout bending process to firmly lock the cable inside and form a relatively good locking effect.

Owner:CHUZHOU KERNUM ELECTRIC CO LTD

Collet-type splice and dead end fitting

ActiveCN1894827ALarge current carrying capacitySynthetic resin layered productsArrangements for reliveing mechanical tensionElectrical conductorMaterials science

This invention relates to collet-type fittings(201) for use in collet-type splices and collet-type dead ends and methods for splicing together two aluminum conductor composite core reinforced cables(ACCC) or terminating one ACCC cable. The collet-type fittings(201) comprise a collet(202) coincident with a collet housing(204) to hold the composite cores. The composite cores can be stripped of the aluminum conductor to provide a bond between the collet(202) and the composite core. After inserting the composite core into the collet(202), a compression element(206) compresses the collet(202). The collet(202) holds the composite core with frictional forces and the collet(202) further compresses and strengthens the hold on the composite core if the composite core pulls the collet(202) further into the collet housing(204).

Owner:CTC GLOBAL CORP

Apparatus and method for electrically and mechanically connecting and disconnecting a power line

InactiveUS6971898B2Safely and effectively disconnectsReduce the possibility of damageEngagement/disengagement of coupling partsArrangements for reliveing mechanical tensionElectrical conductorBody contact

Owner:ELECTRIC POWER RES INST INC

Protection device for preventing cable from being excessively tensioned

InactiveCN111711146AAvoid breakingAvoid vulnerableSuspension arrangements for electric cablesArrangements for reliveing mechanical tensionExtreme weatherTower

The invention discloses a protection device for preventing a cable from being excessively tensioned, which relates to the technical field of power transmission cables. The device comprises a cable, acable sliding device, a cable breaking and closing device and a wire tower, wherein one end of the cable is provided with a cable joint and a plurality of fixed joints; the plurality of fixed joints are fixed on the peripheral side surface of the cable joint; the length of the cable joint is greater than that of the fixed joint; a guide block is fixed on the other end surface of the cable connecting seat; a double-sided jack line board is fixedly mounted at the top end of the wire tower; cable joints are inserted into opposite surfaces of the double-sided jack line board; and the cable joint penetrates through a cable storage groove. Through the effects of the cable, the cable sliding device and the cable breaking and closing device, the problems that the cable is broken due to too large tensioning force in extreme weather, personnel are prone to being hurt in the cable throwing process due to breaking of the cable, and even the serious consequence of collapse of the tower is caused are solved.

Owner:合肥智瑞工程科技有限公司

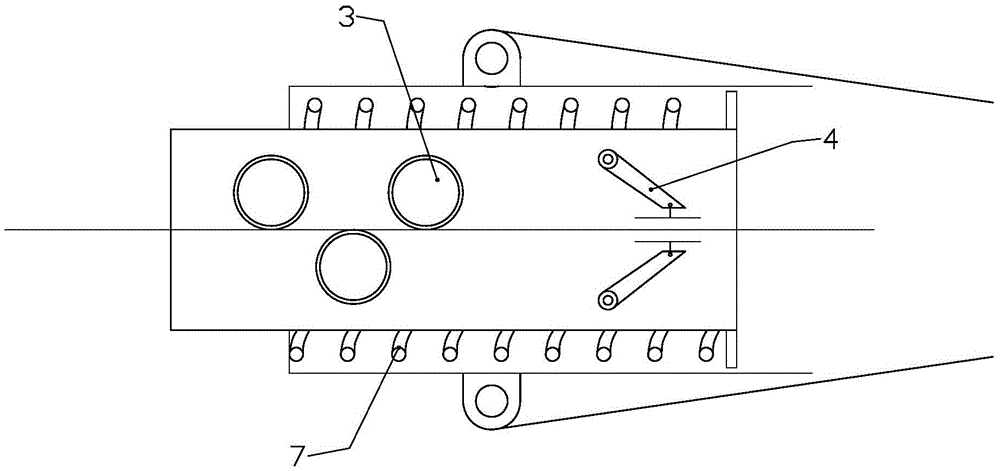

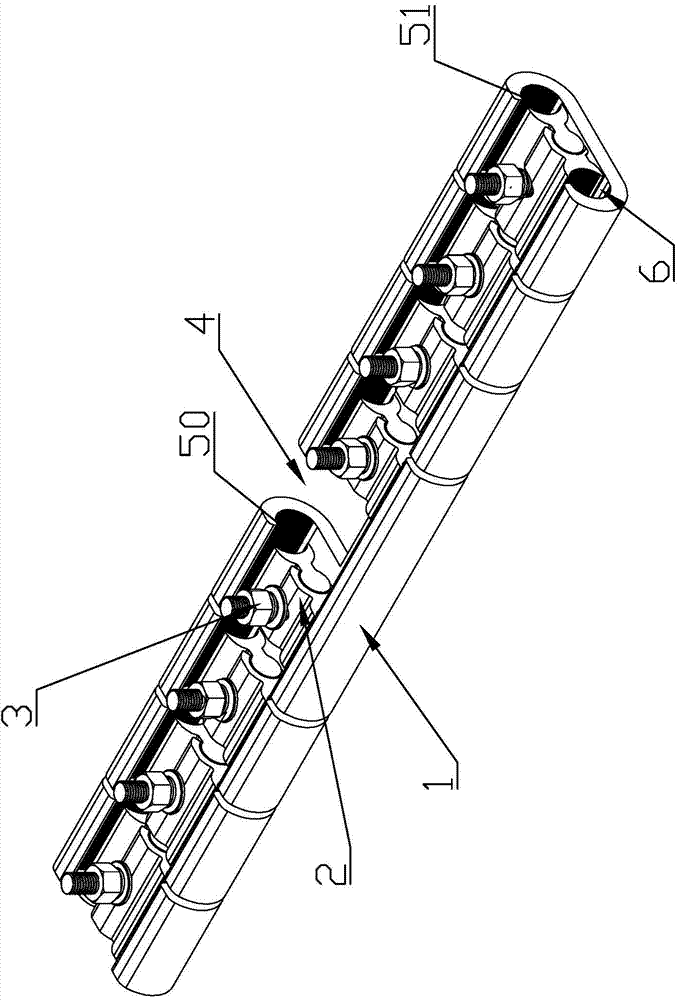

Wire abandoning and pole protecting device for transmission and distribution line and installation method for wire abandoning and pole protecting device

ActiveCN103904602ADoes not have any effect on mechanicalDoes not affect electrical performance in any wayArrangements for reliveing mechanical tensionApparatus for overhead lines/cablesElectrical performanceRelative slip

The invention discloses a wire abandoning and pole protecting device for a transmission and distribution line. The wire abandoning and pole protecting device comprises a long-strip-shaped metal shell, a first wire installation channel is arranged on one side of the metal shell, a notch is formed in the middle of the metal shell, the notch divides the first wire installation channel into a first wire channel and a second wire channel, a first wire can be embedded in the first wire channel, a second wire can be embedded in the second wire channel, the first wire channel and the second wire channel achieve mechanical clamping on the corresponding wires, and the first wire and the second wire are not fixedly connected and are in electric connection through the metal shell. During normal operation, the wire abandoning and pole protecting device for the transmission and distribution line should not glide relative to the wires, and mechanical performance and electrical performance of an original line are not influenced at all. When applied force of external force on a distribution network line exceeds a set action value, the first wire and the second wire can be completed released, the applied force of the wires to the pole is released, and it is ensured that the external force is not continuously exerted on the pole any more.

Owner:广州开能电气技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com