Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55 results about "Valve job" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A valve job is an operation which is performed on any four stroke cycle, internal combustion engine, the purpose of which is to resurface the mating surfaces of the poppet valves and their respective valve seats that control the intake and exhaust of the air/fuel mixture that powers the motion of the pistons after the start cycle.

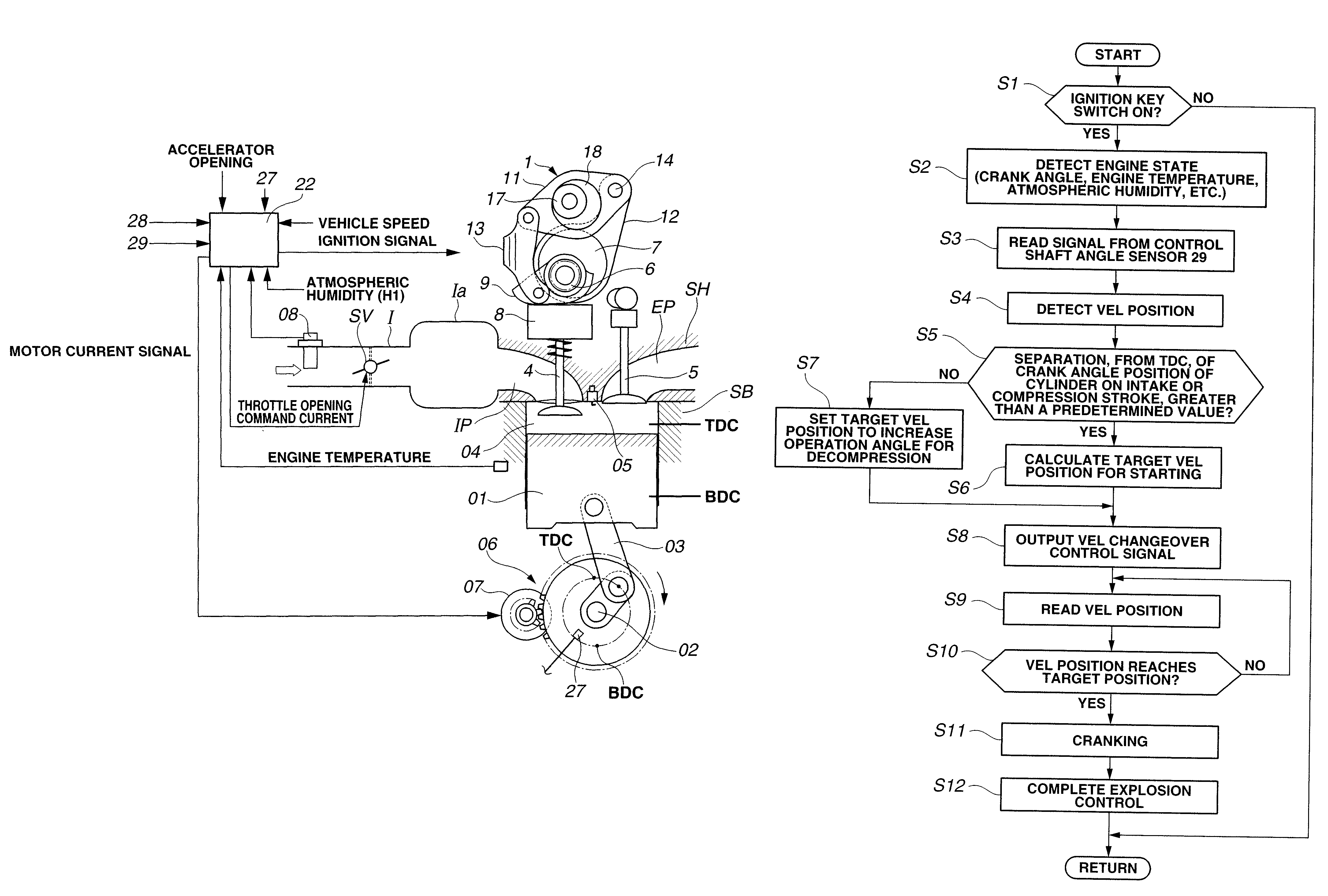

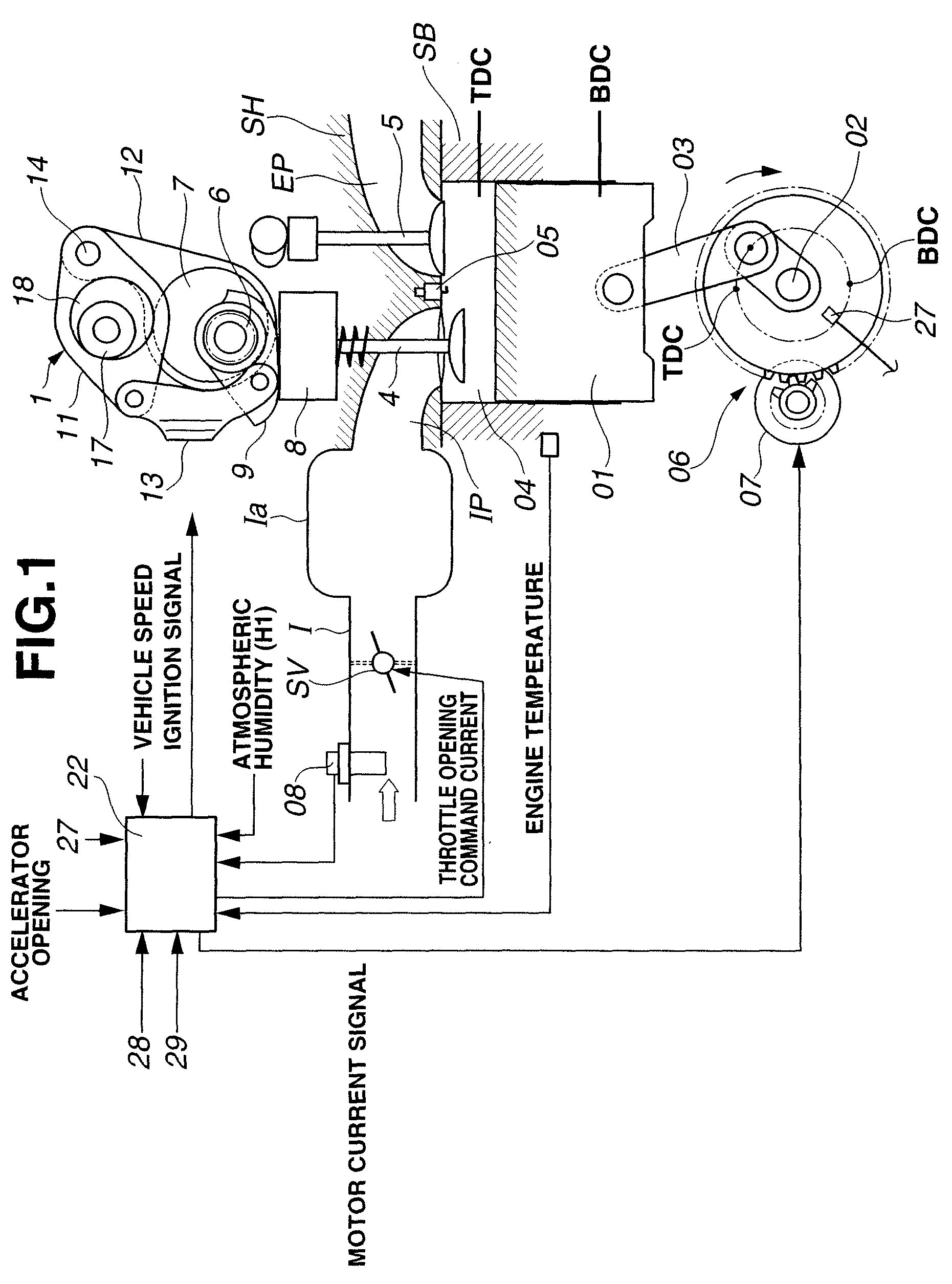

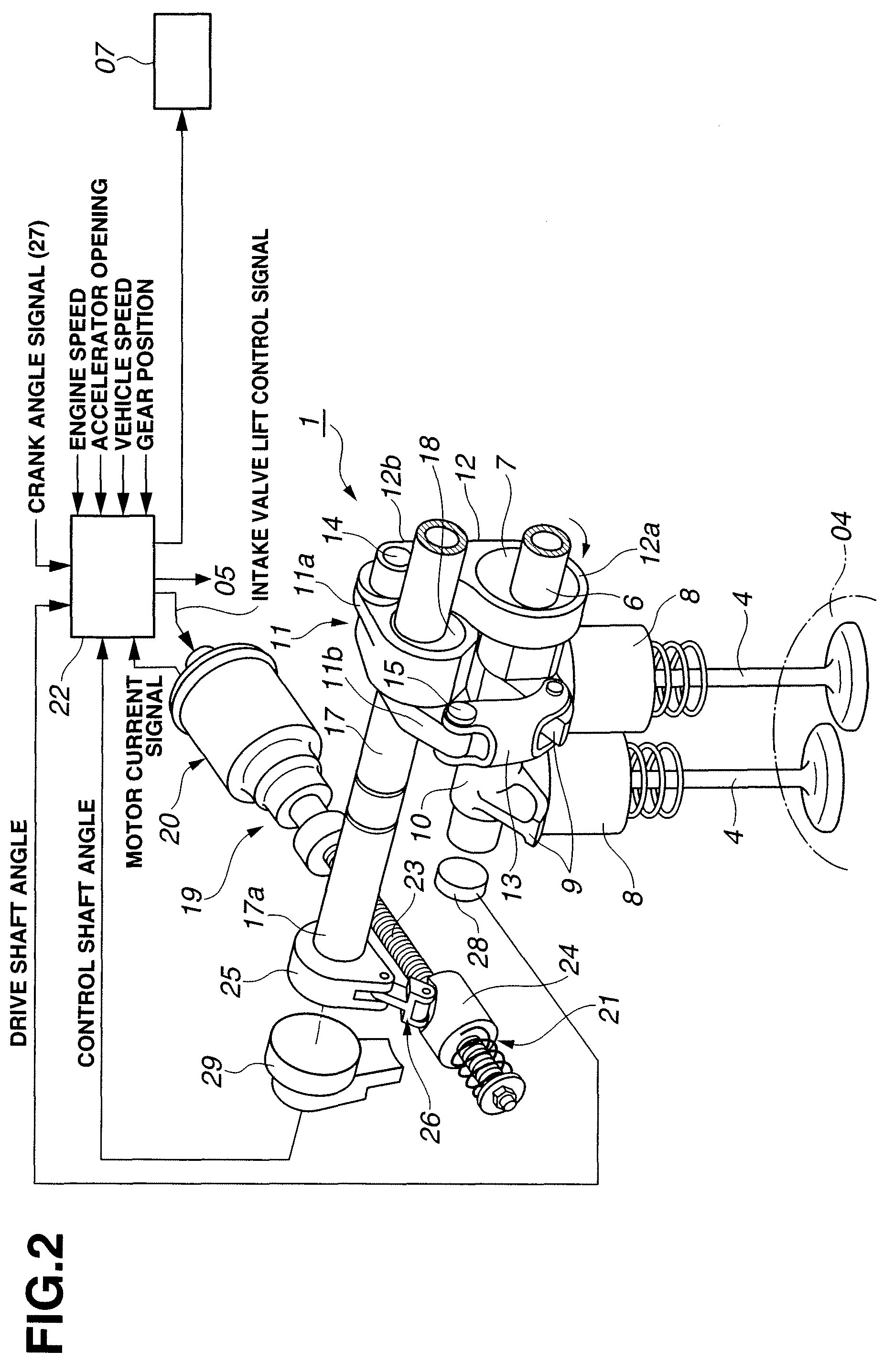

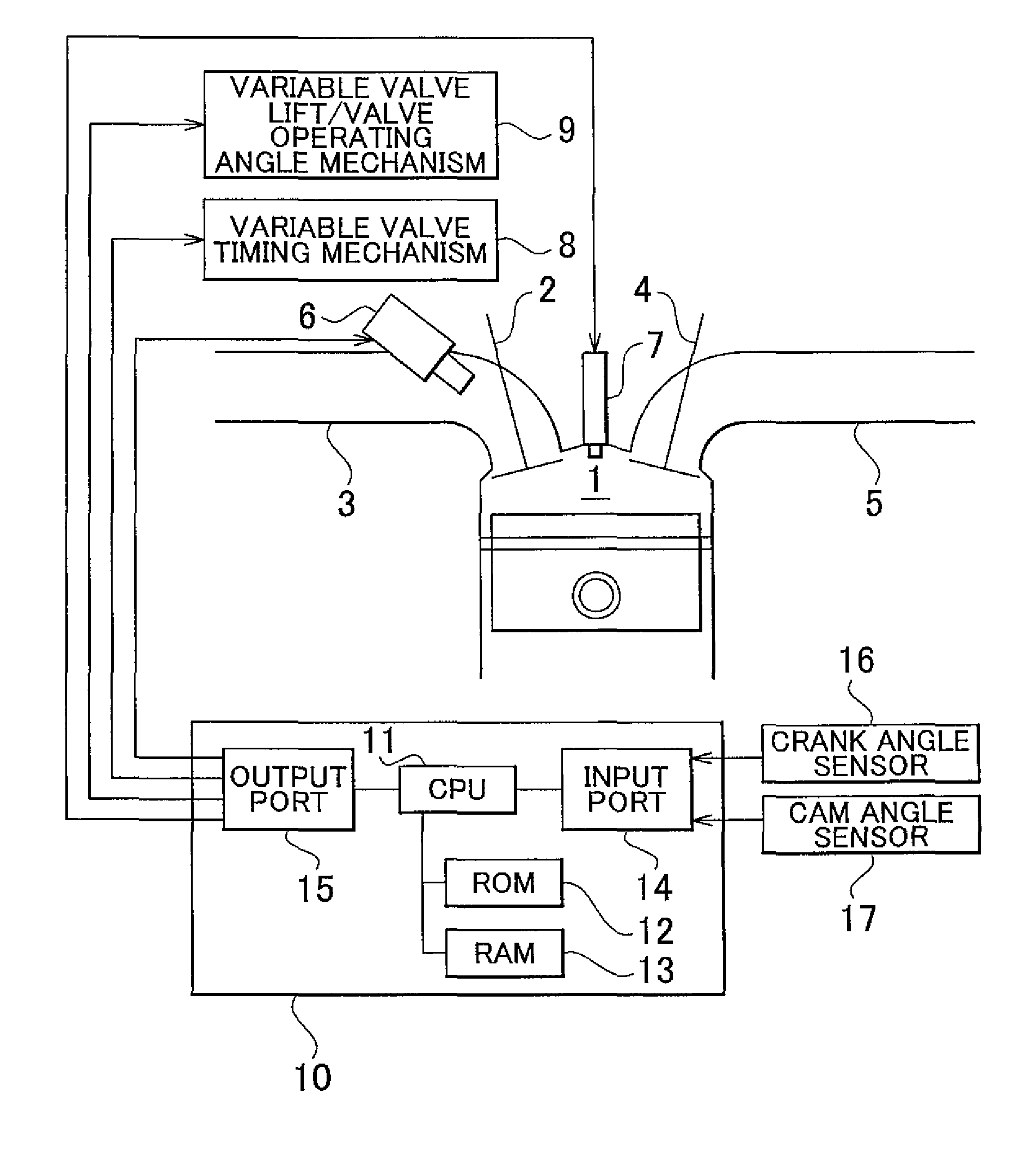

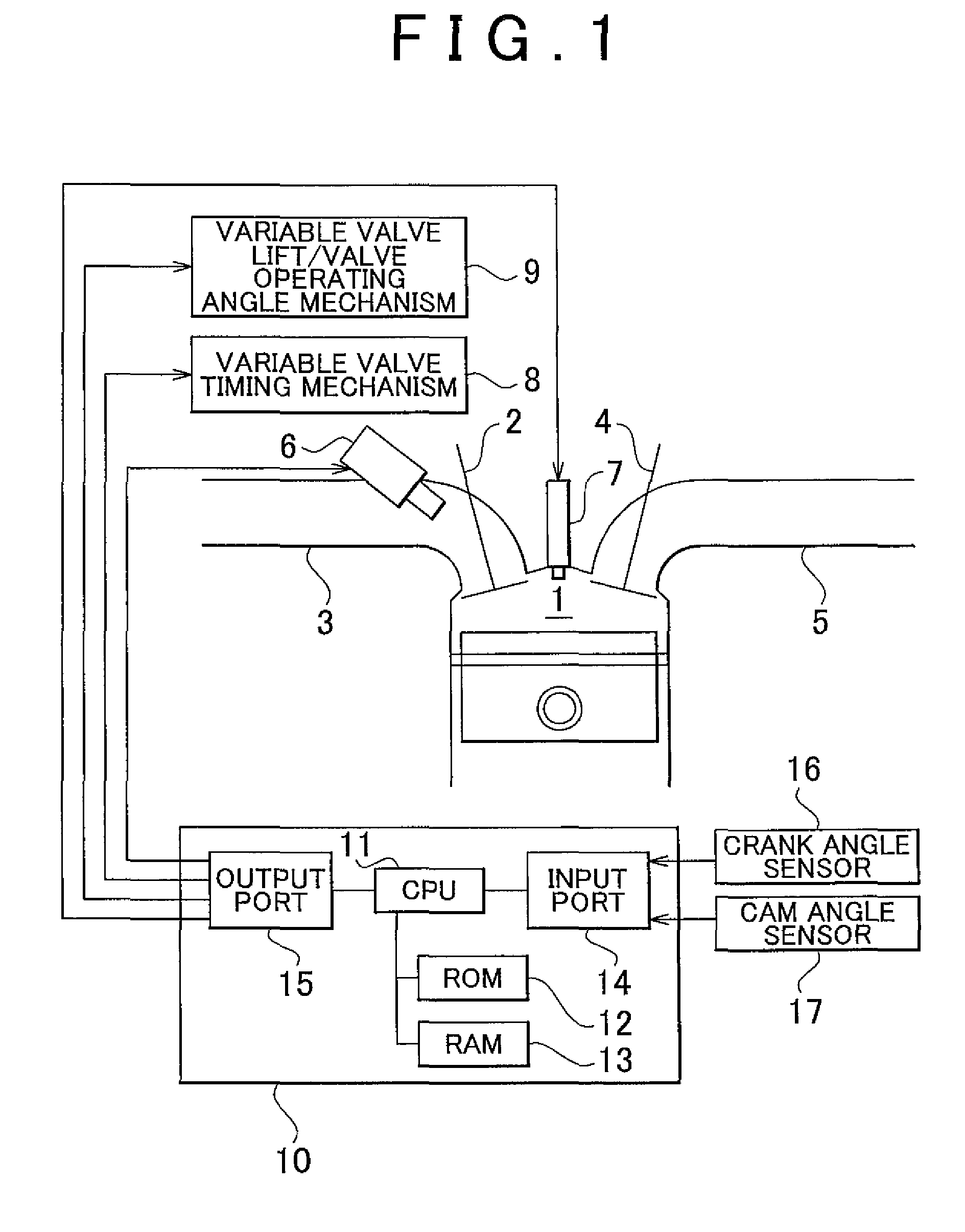

Variable valve actuating apparatus for internal combustion engine

InactiveUS20080011253A1Improve performanceImprove startabilityValve arrangementsOutput powerValve jobVariable valve timing

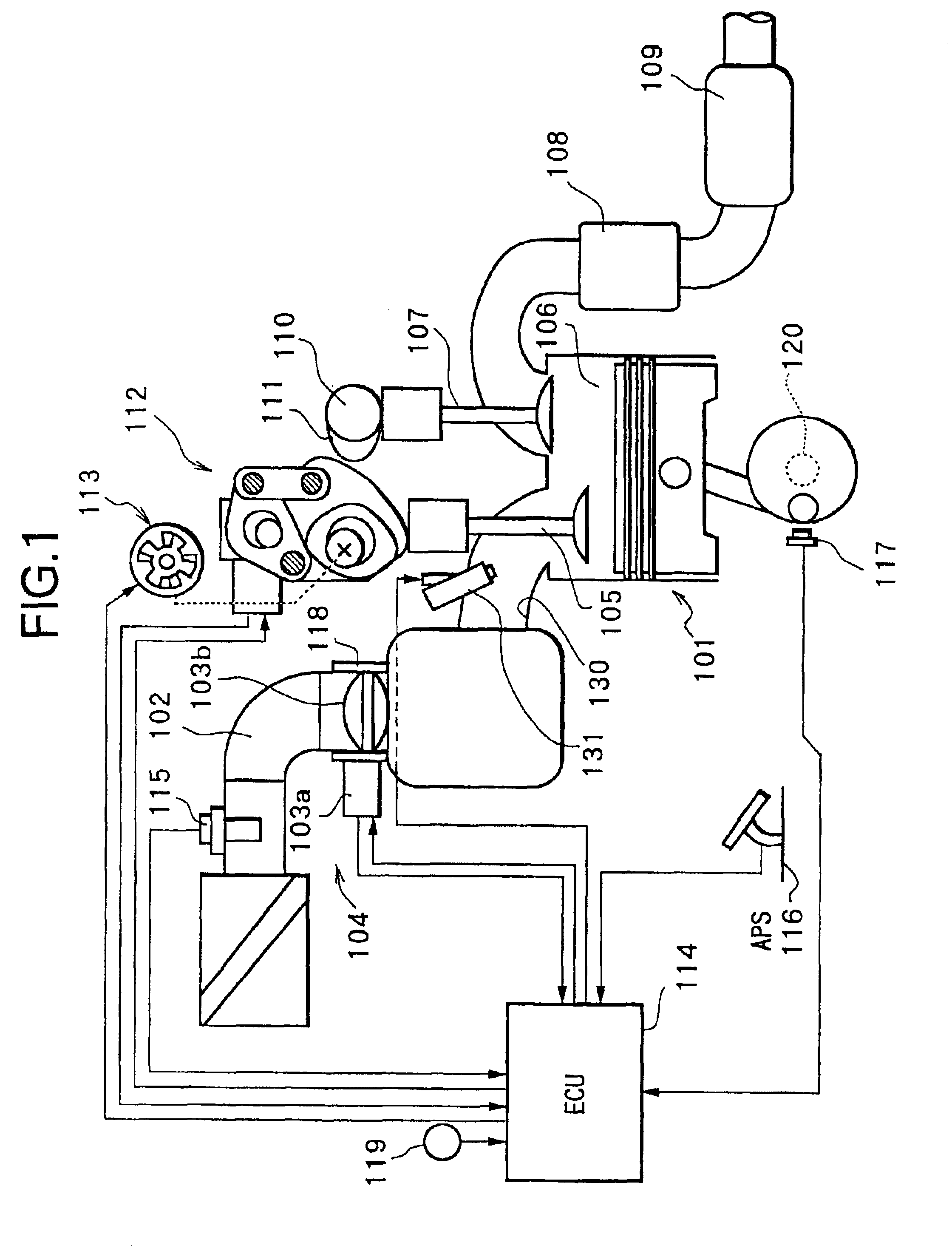

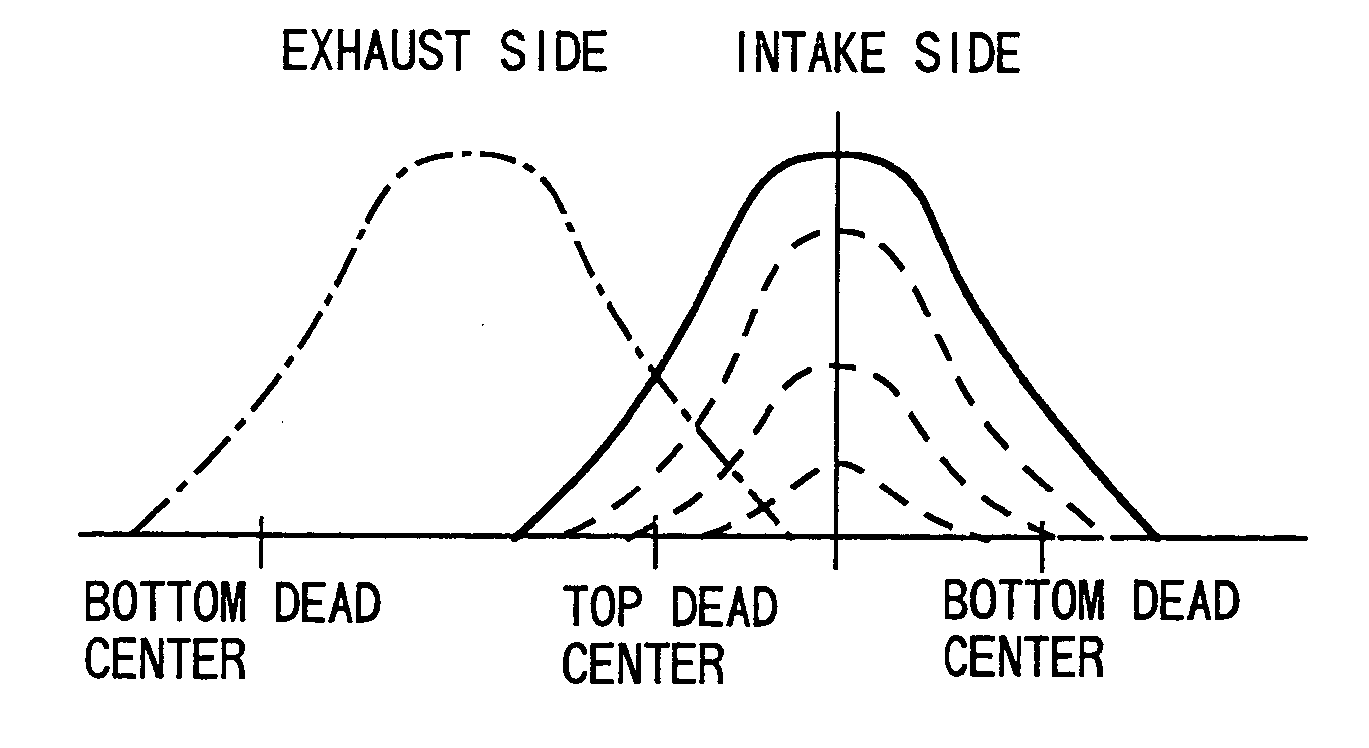

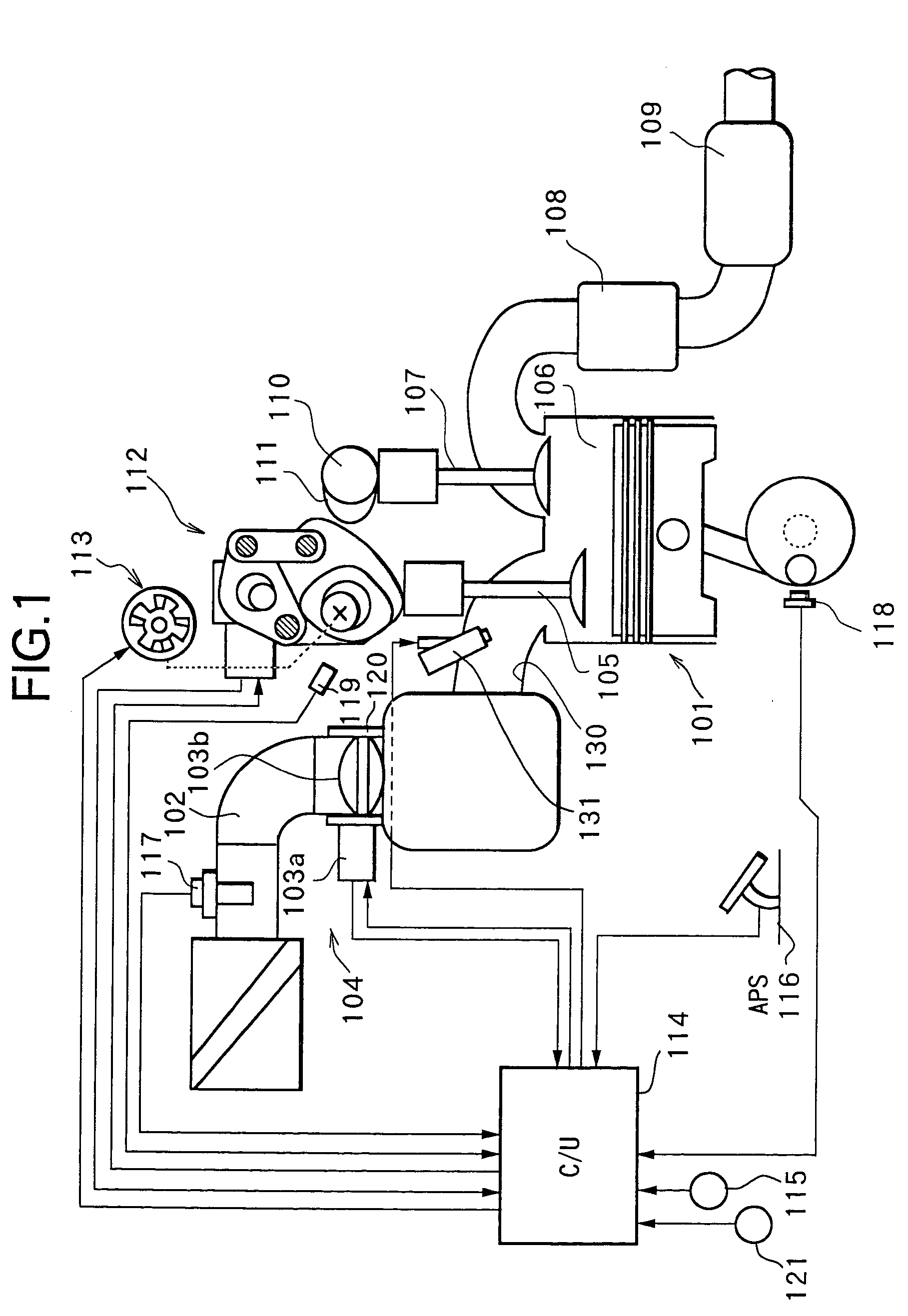

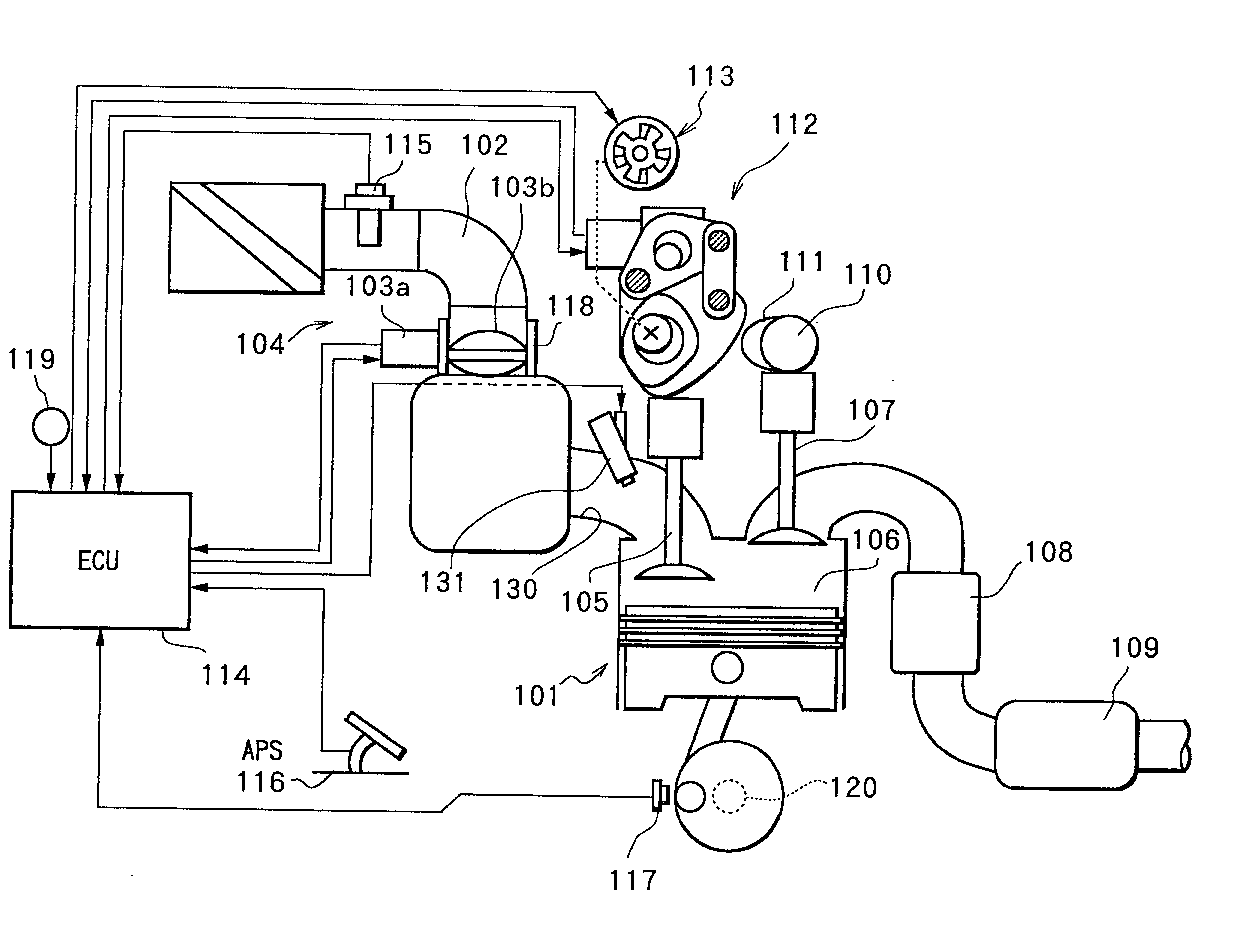

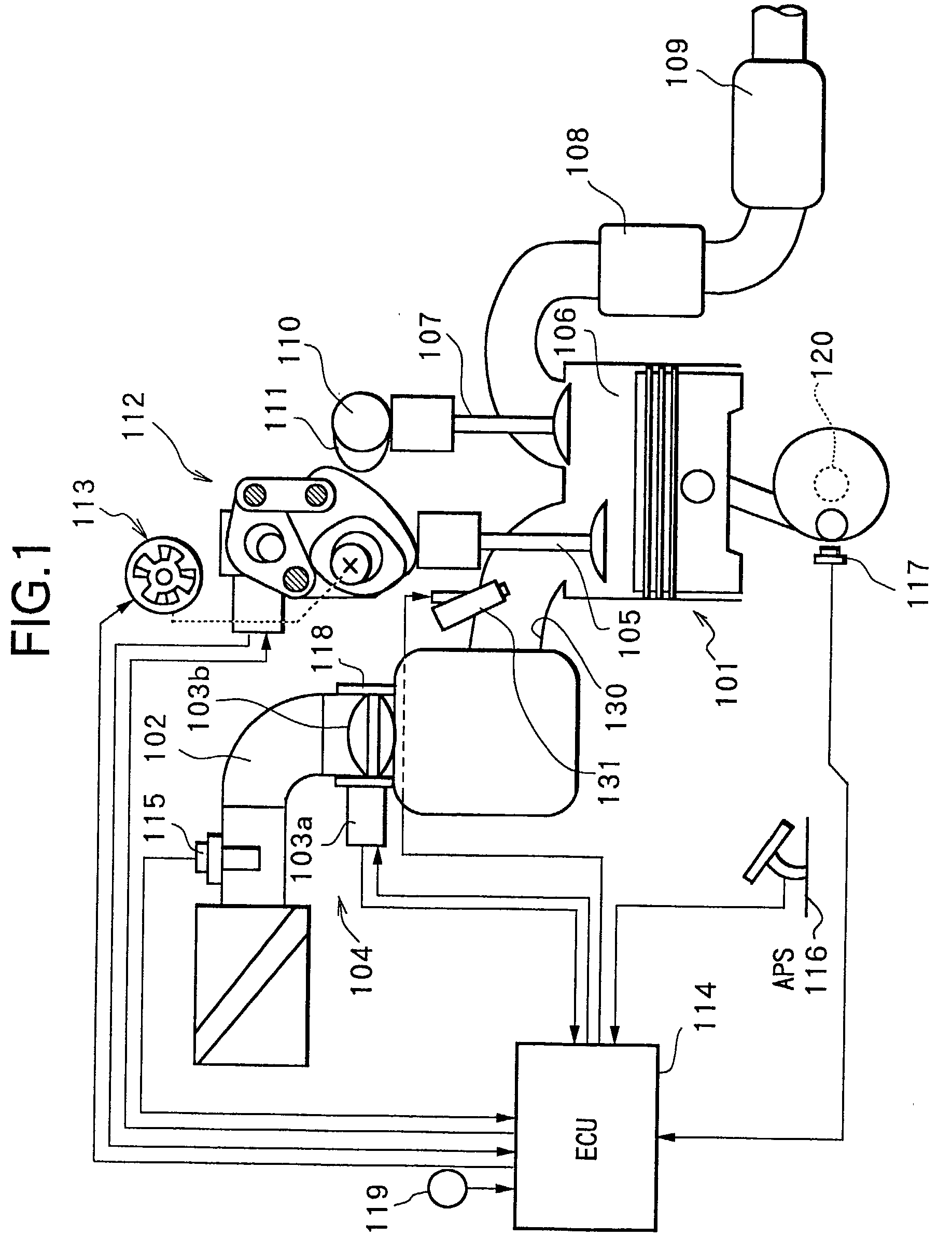

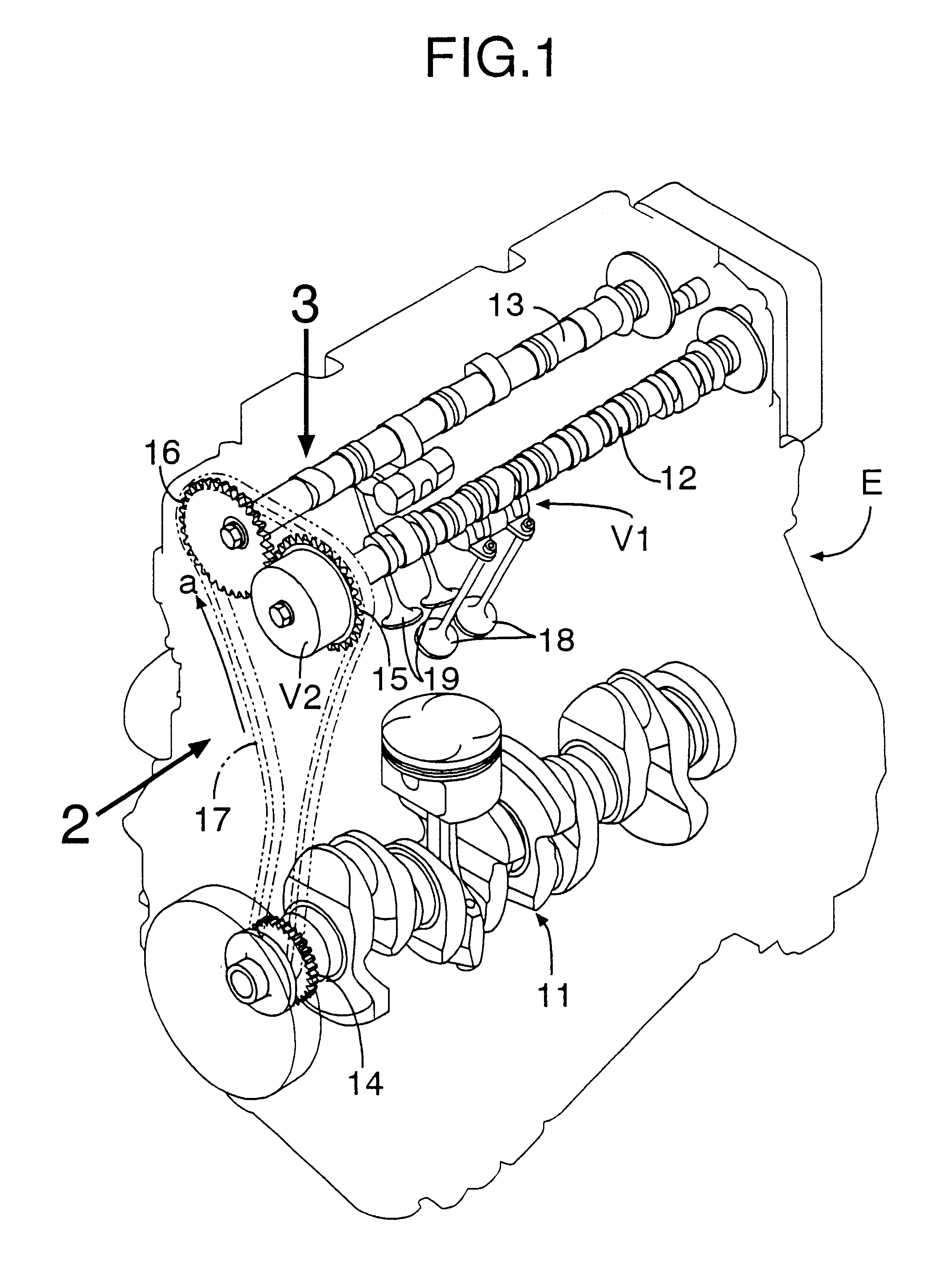

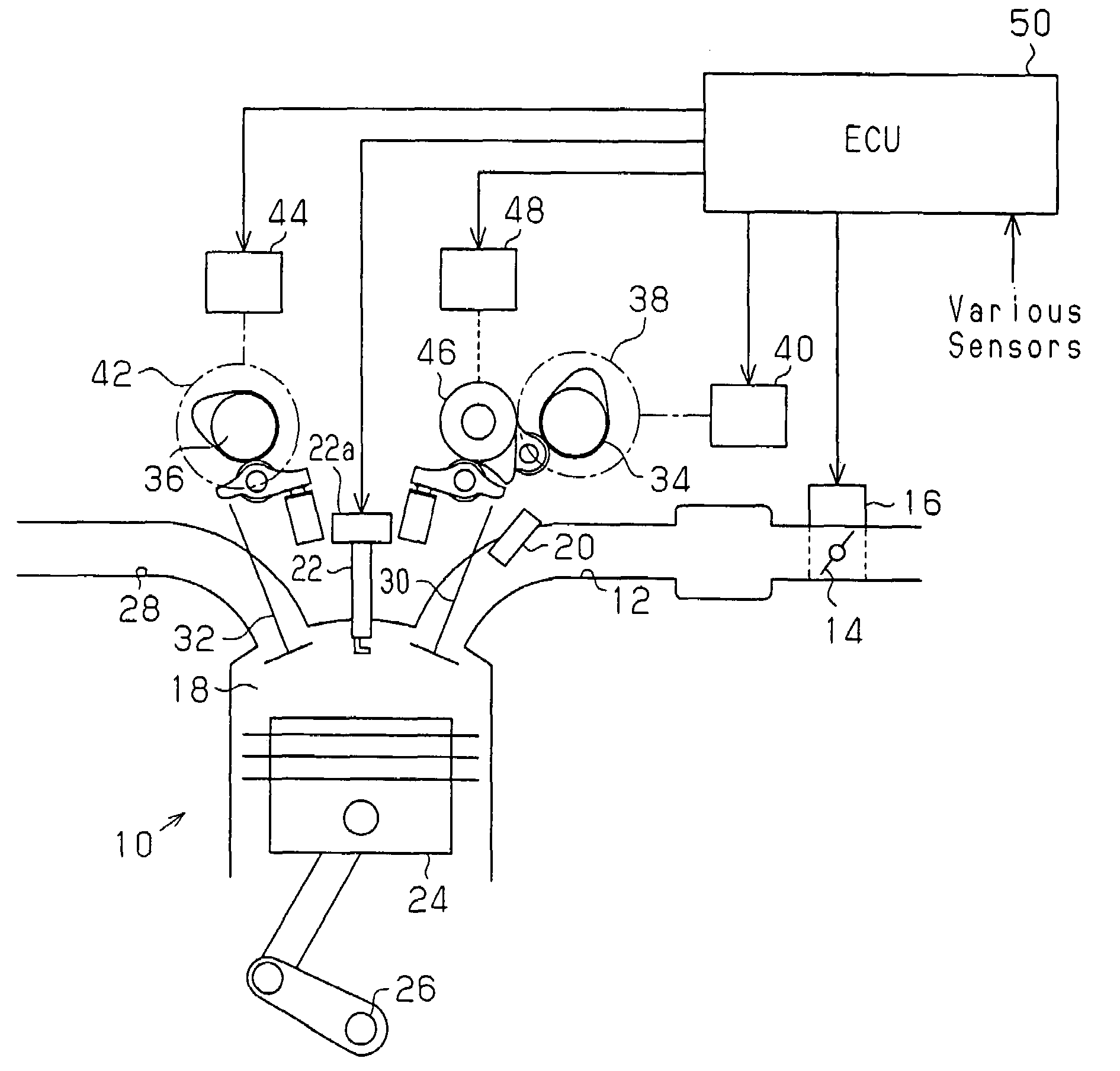

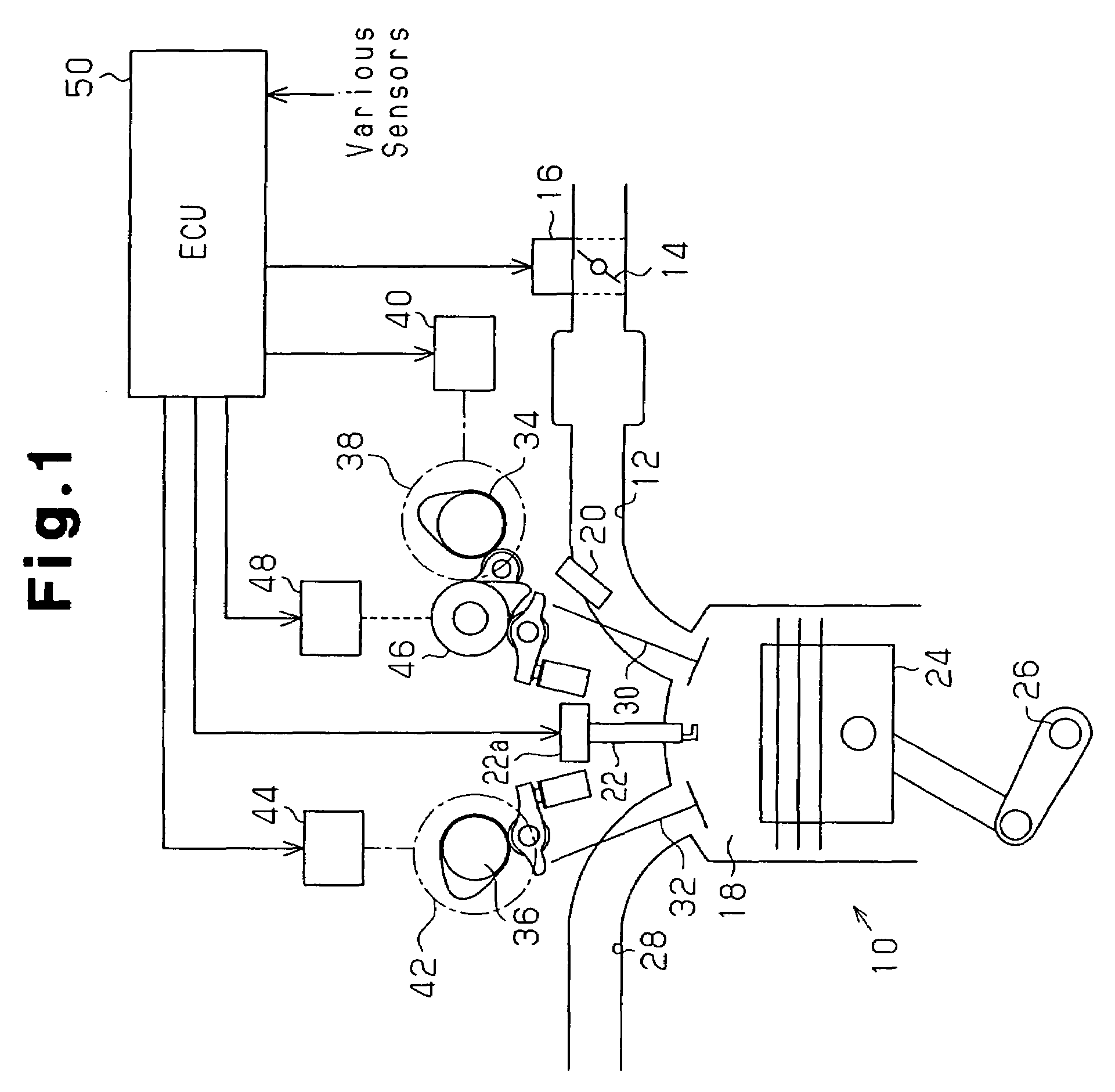

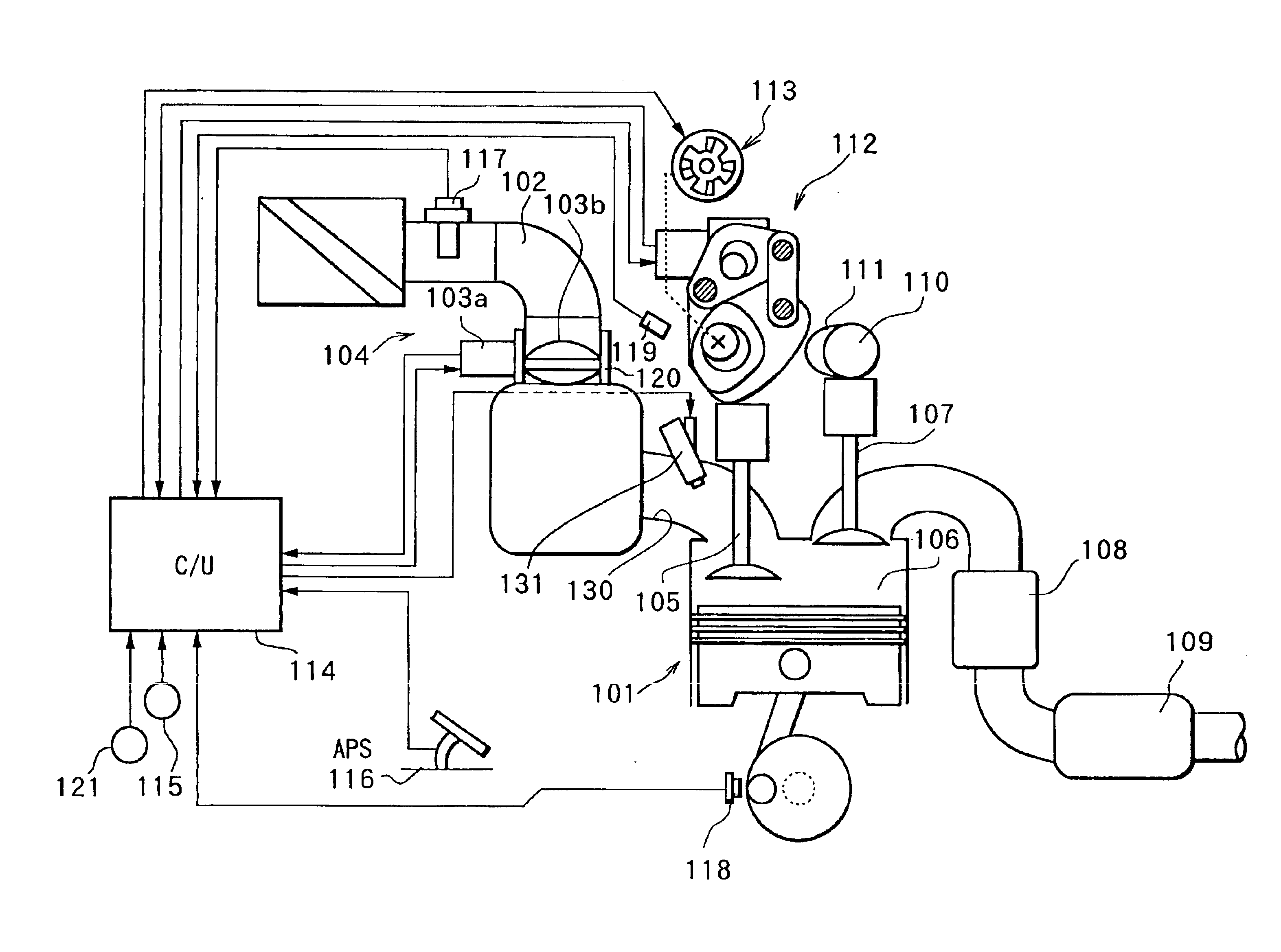

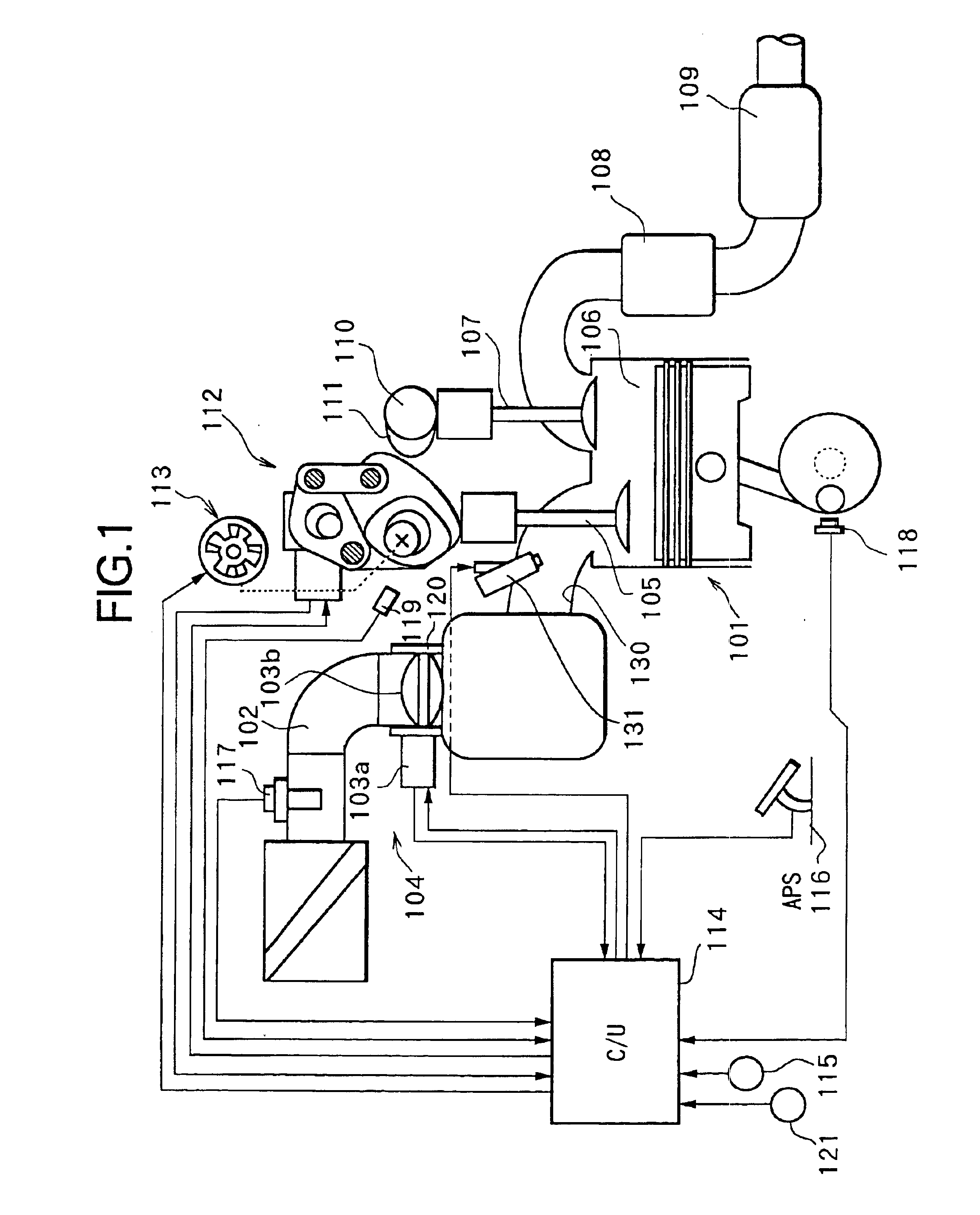

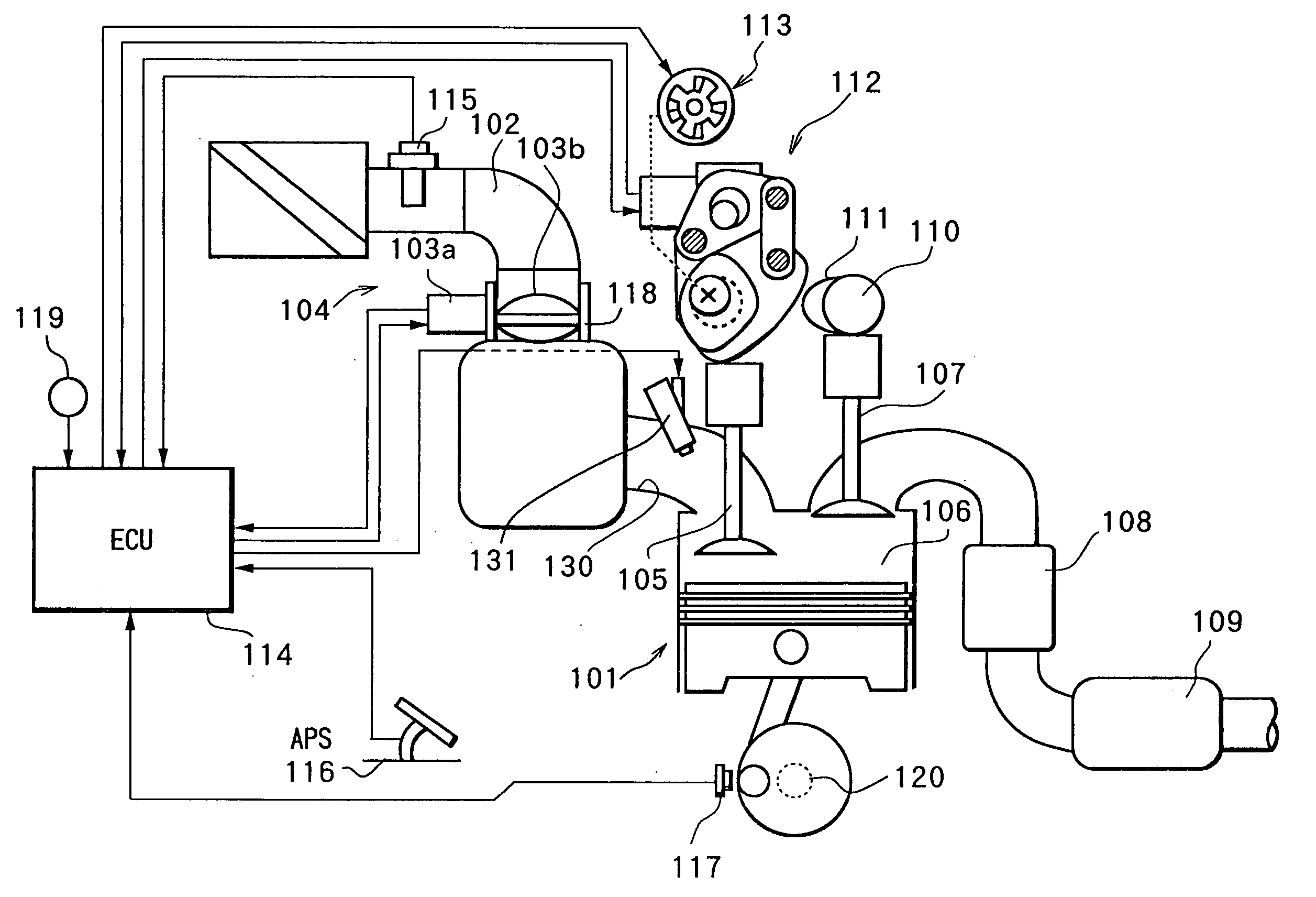

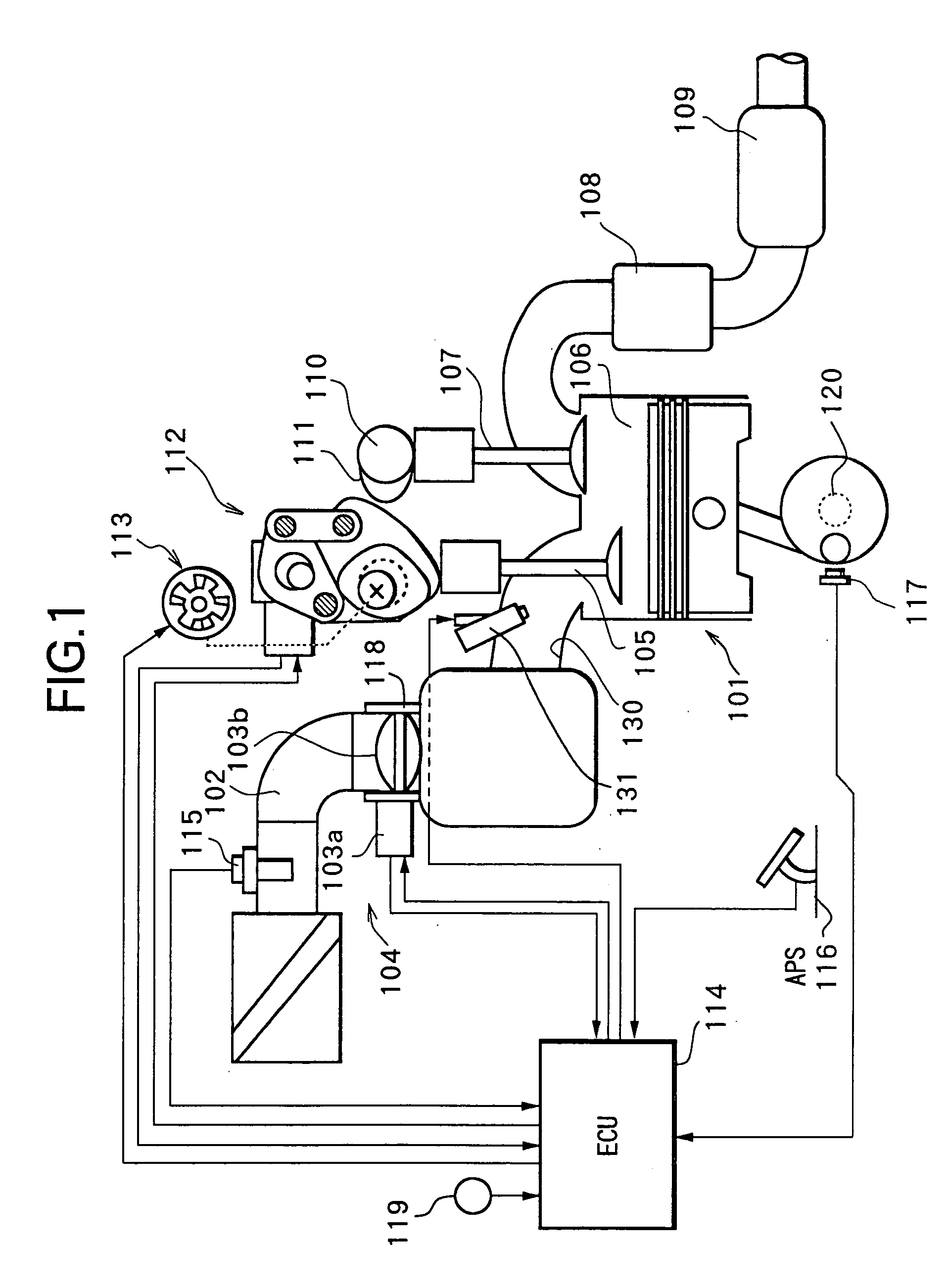

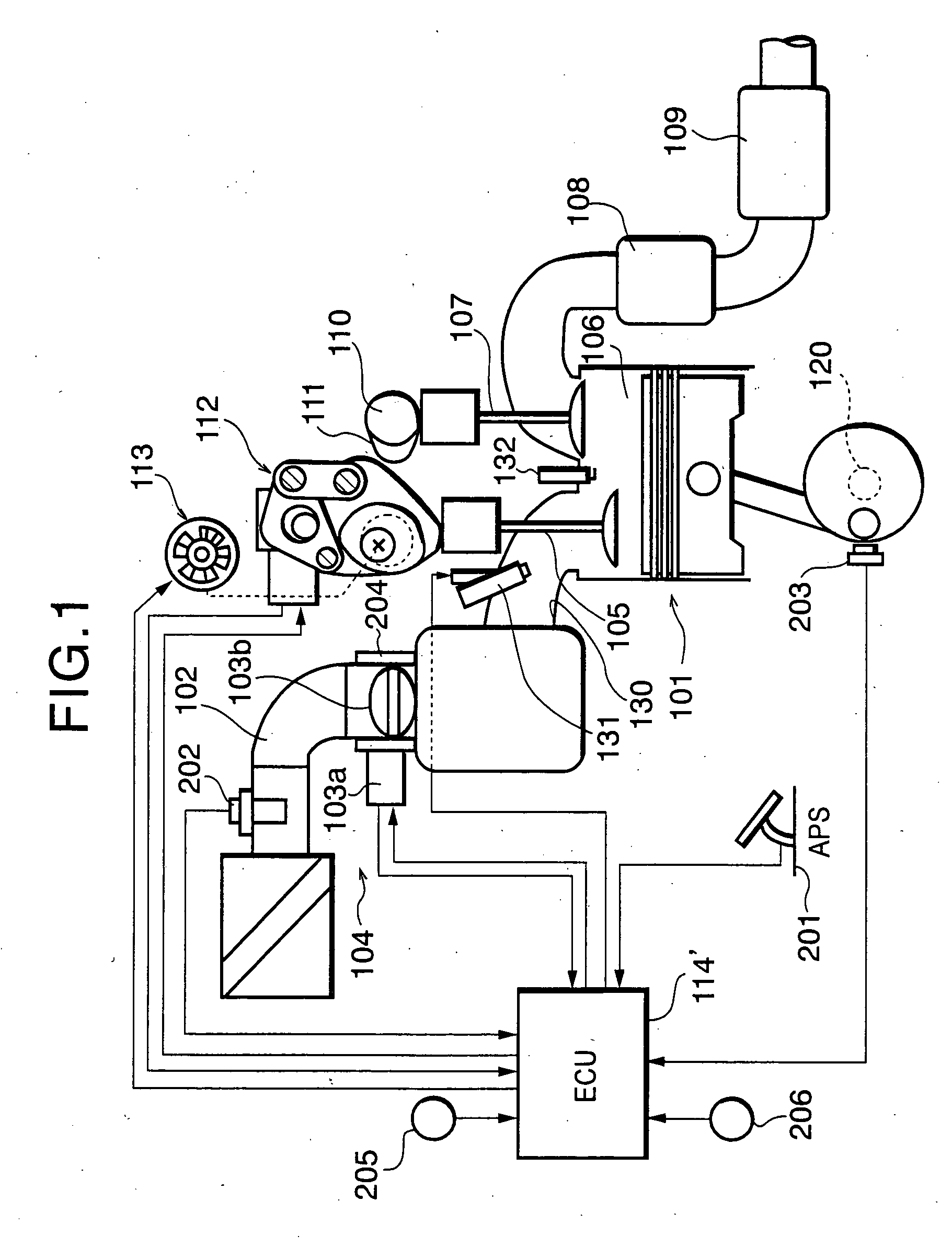

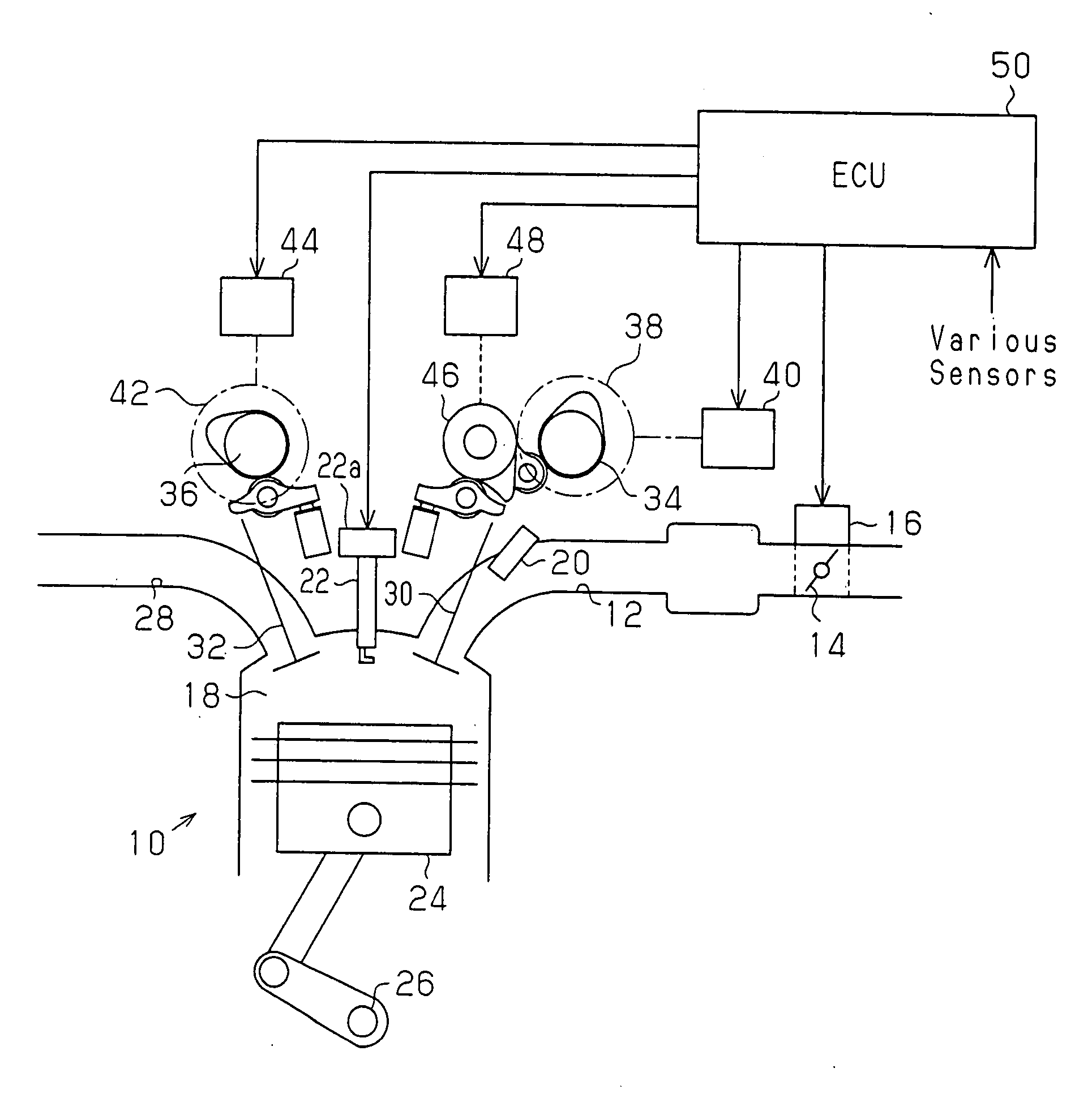

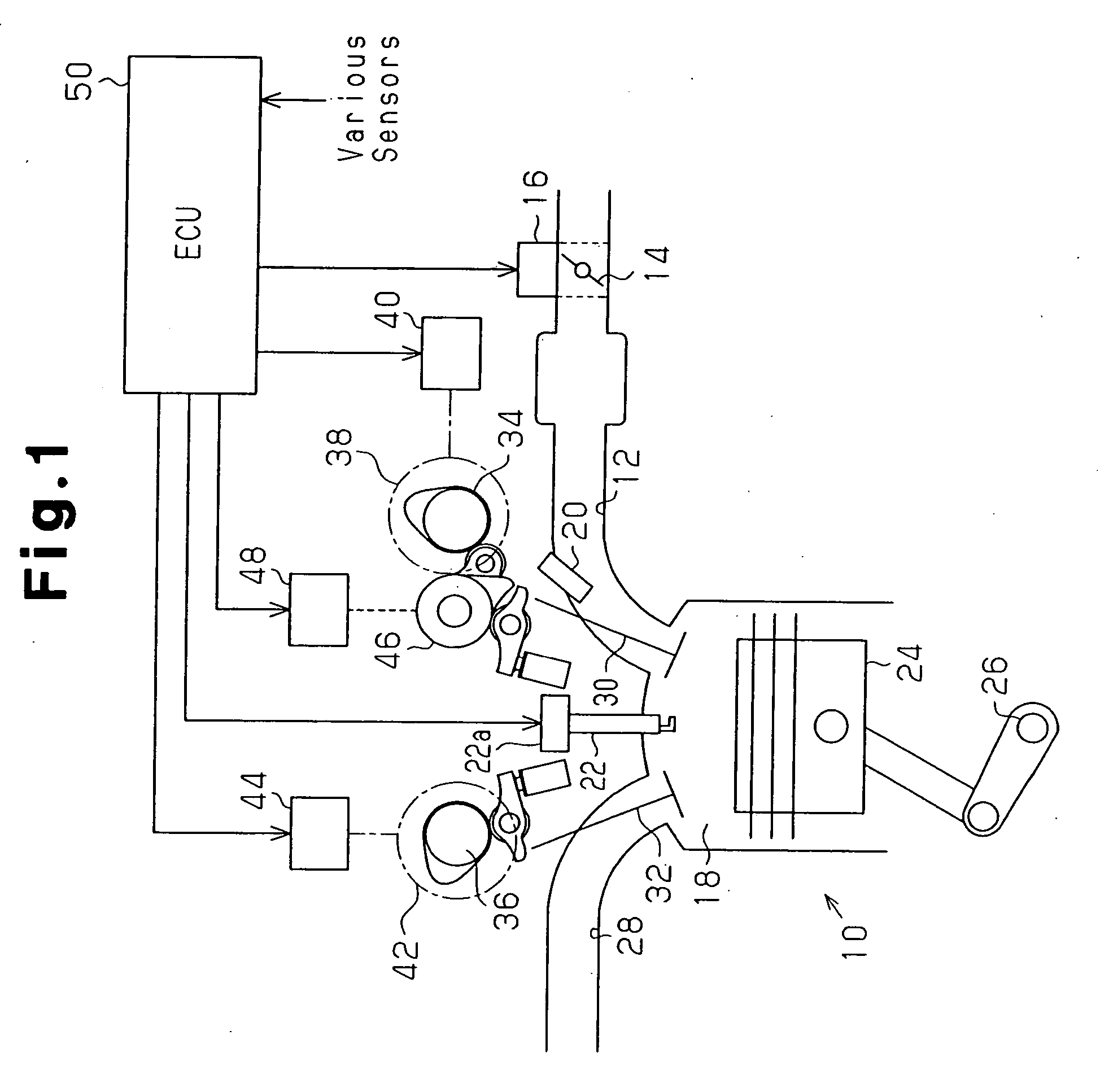

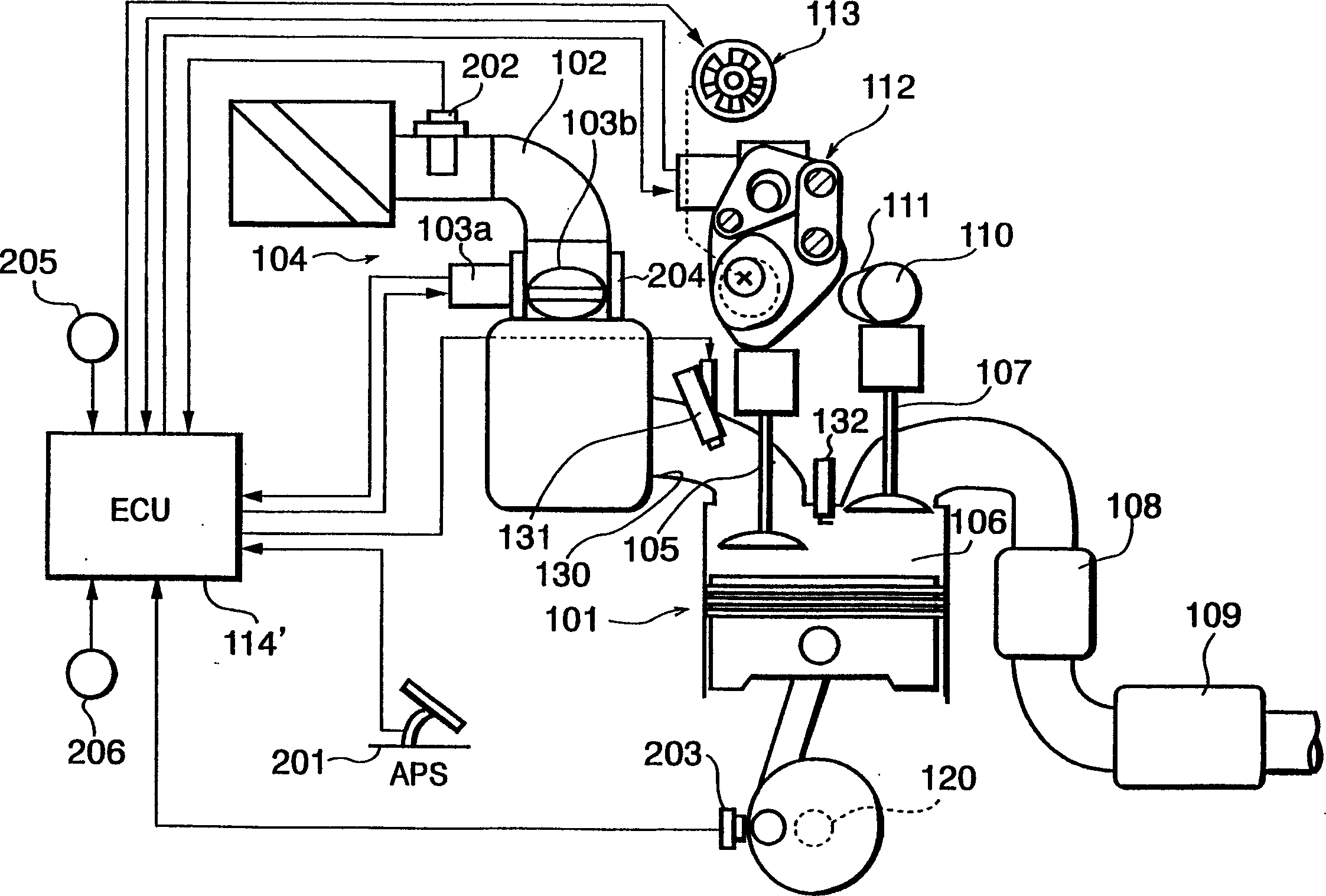

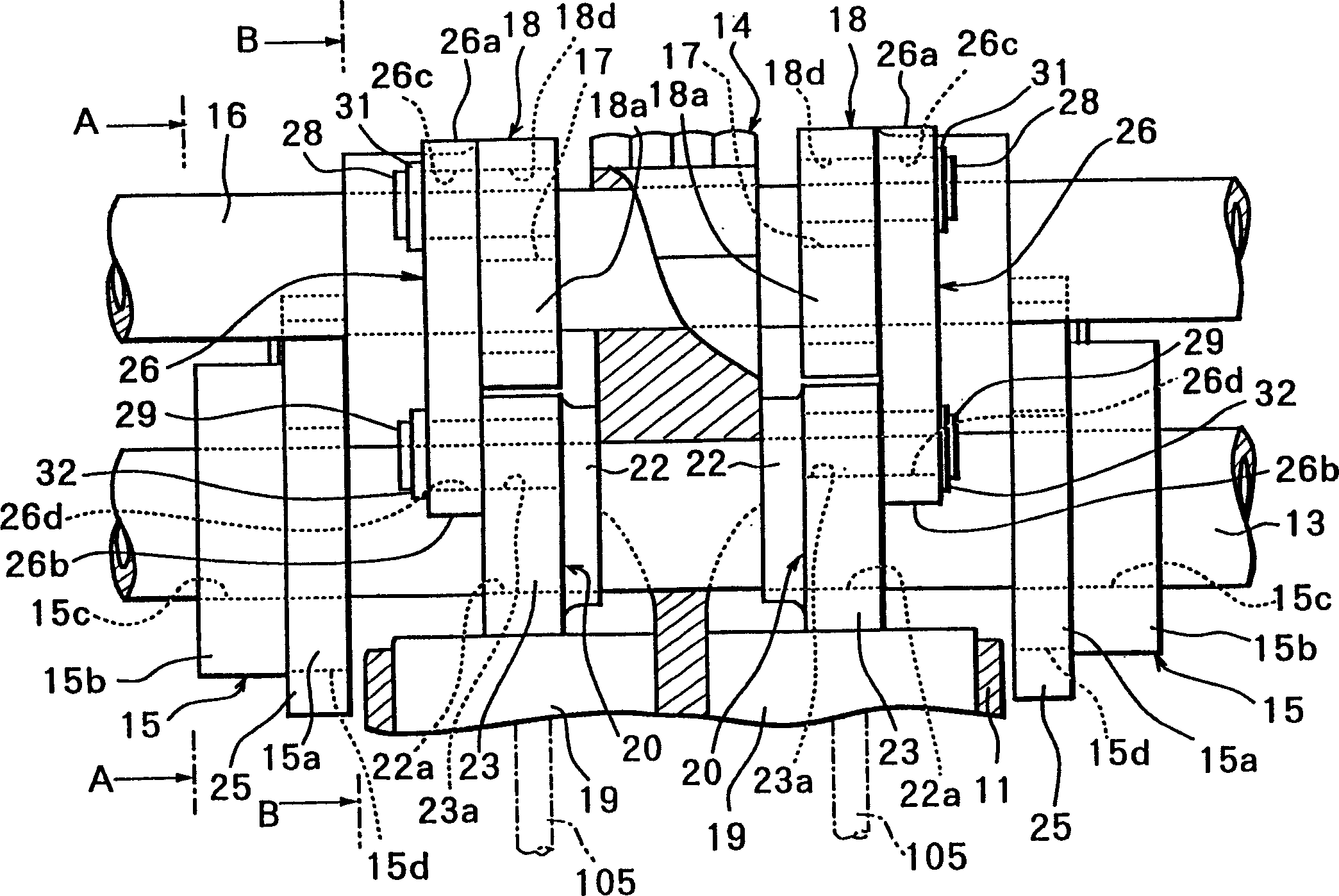

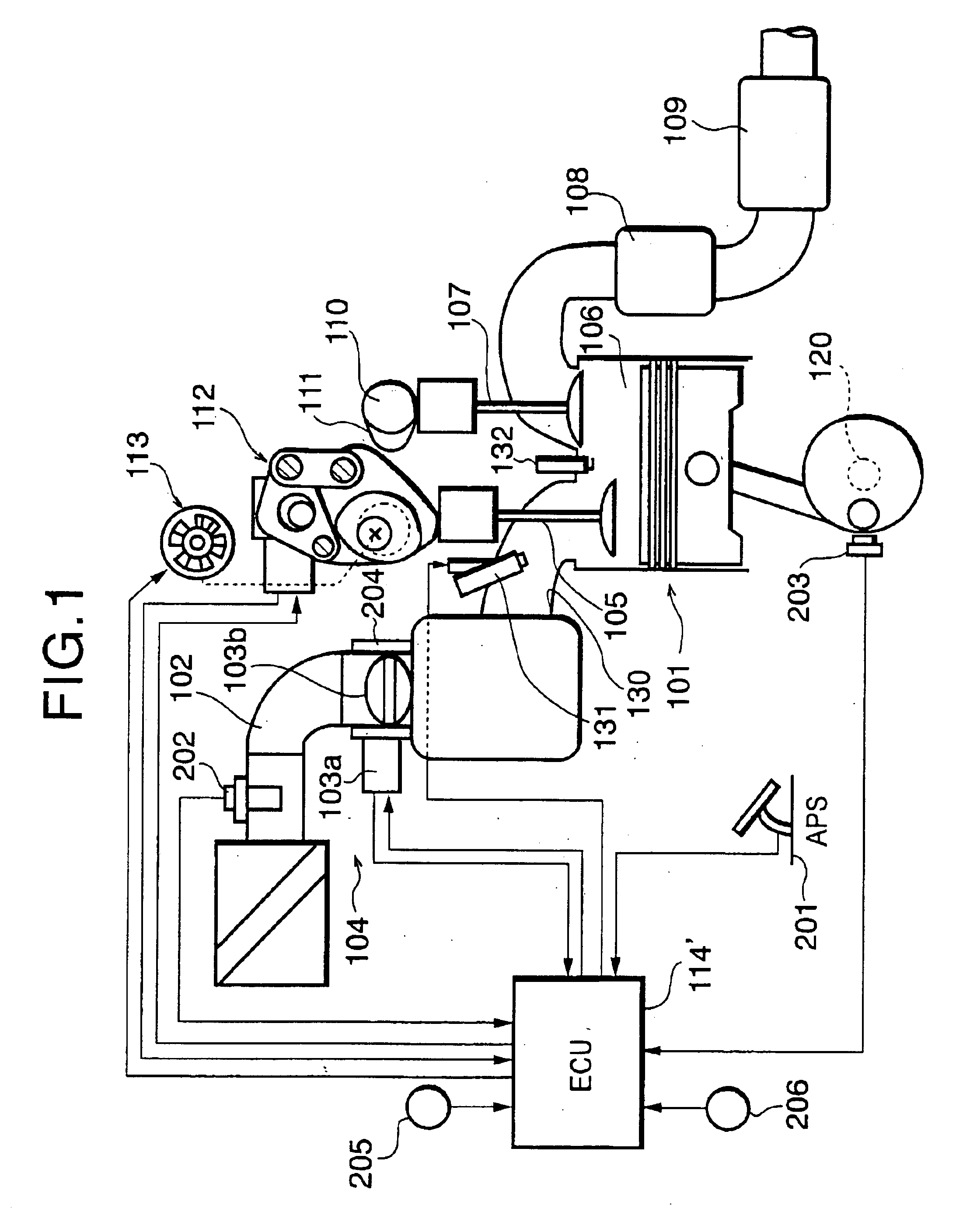

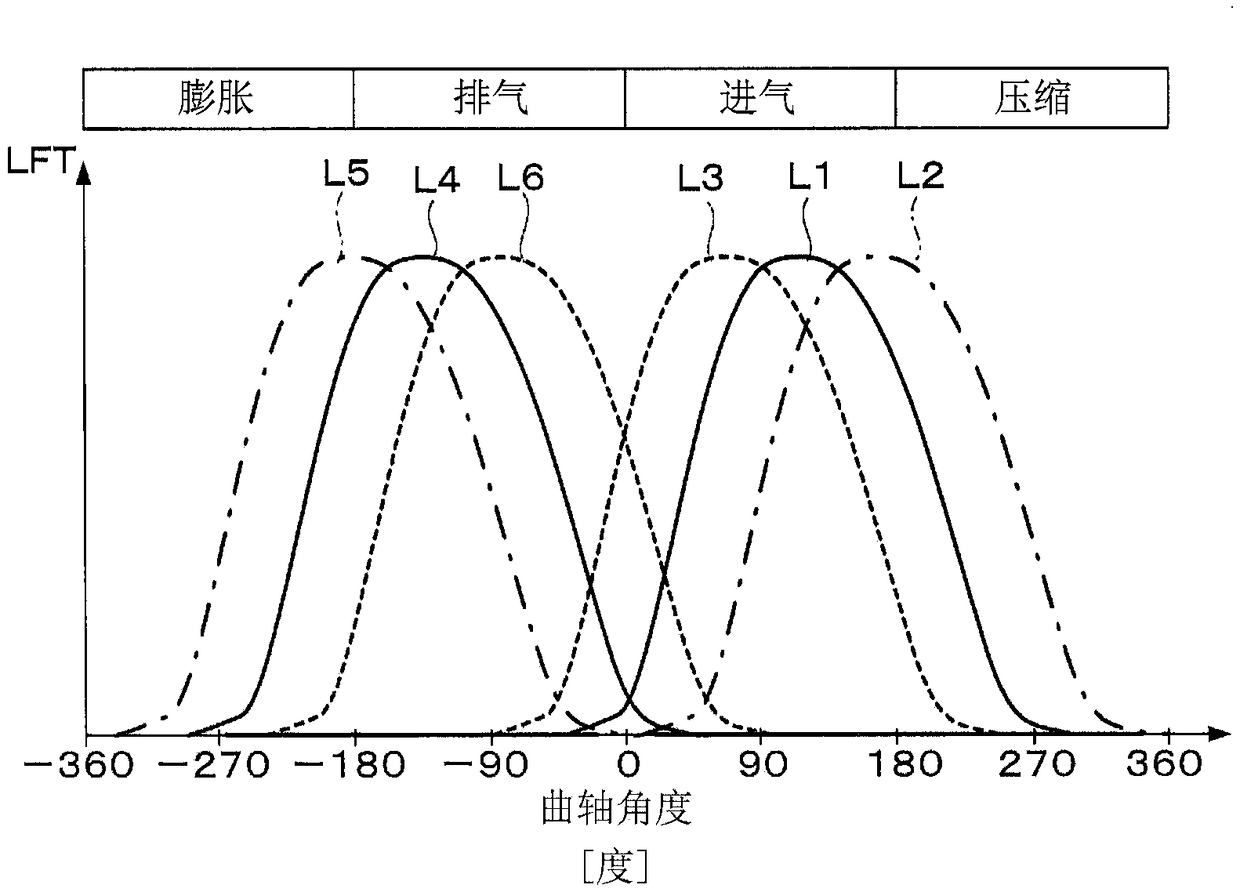

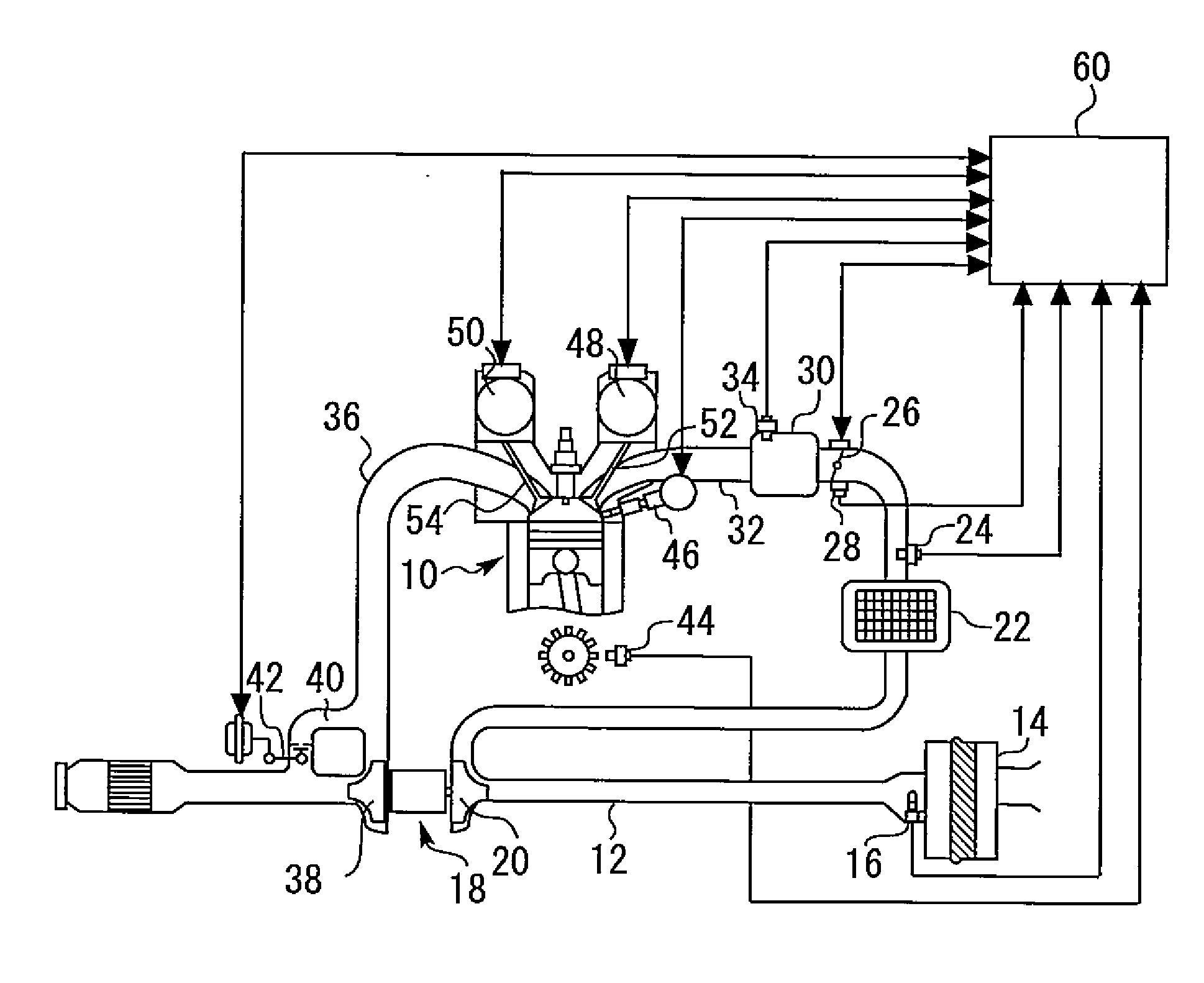

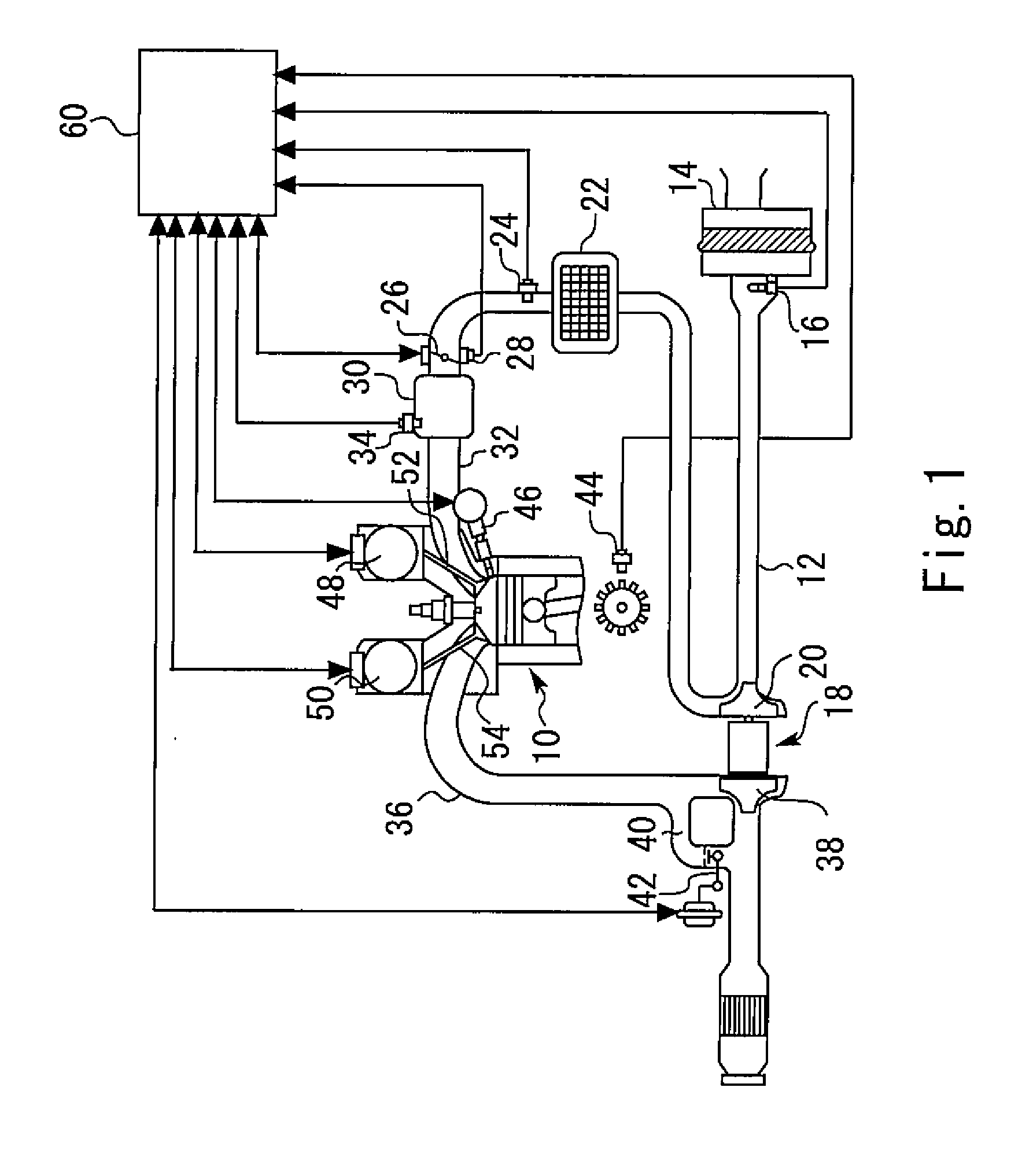

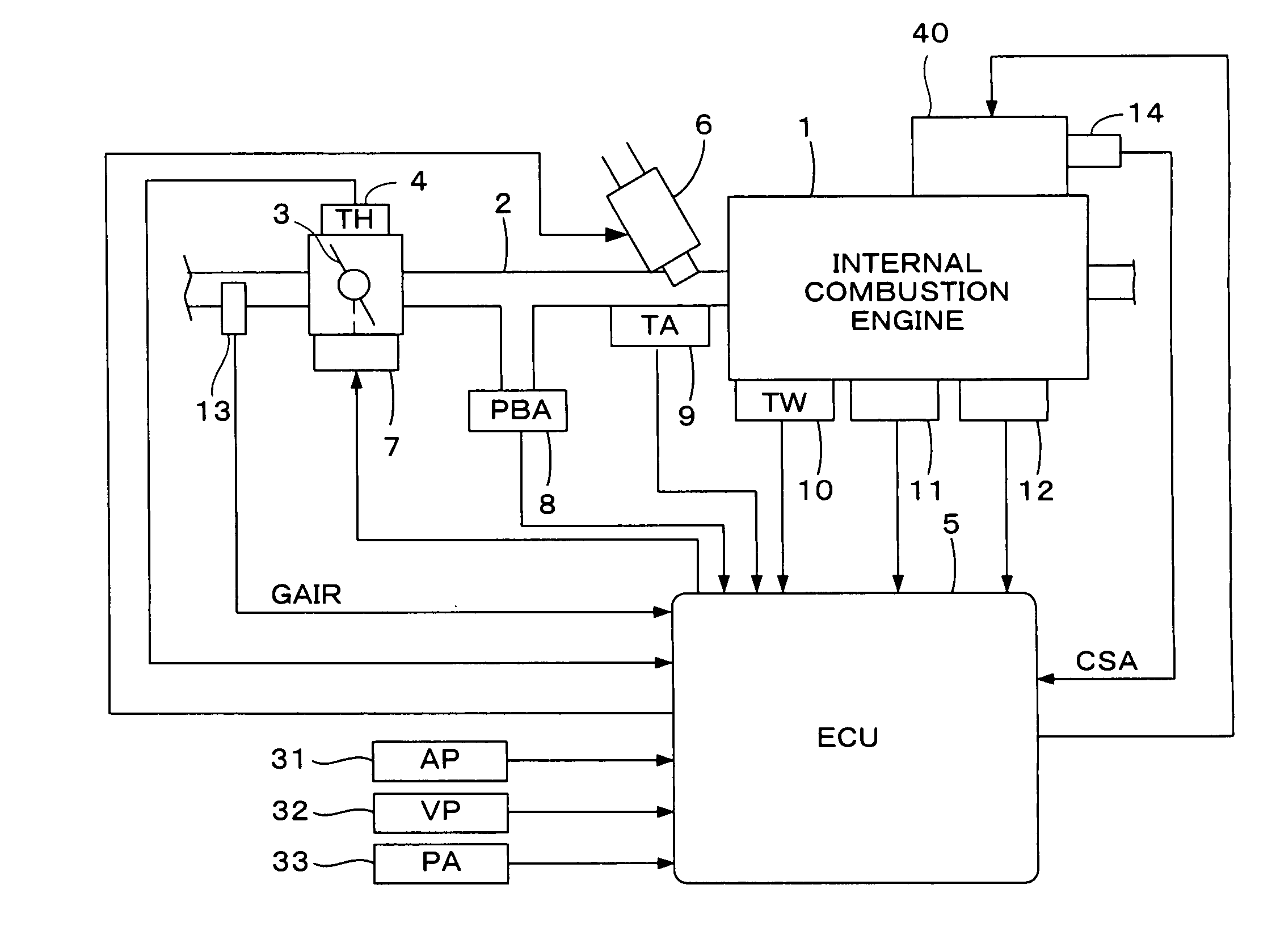

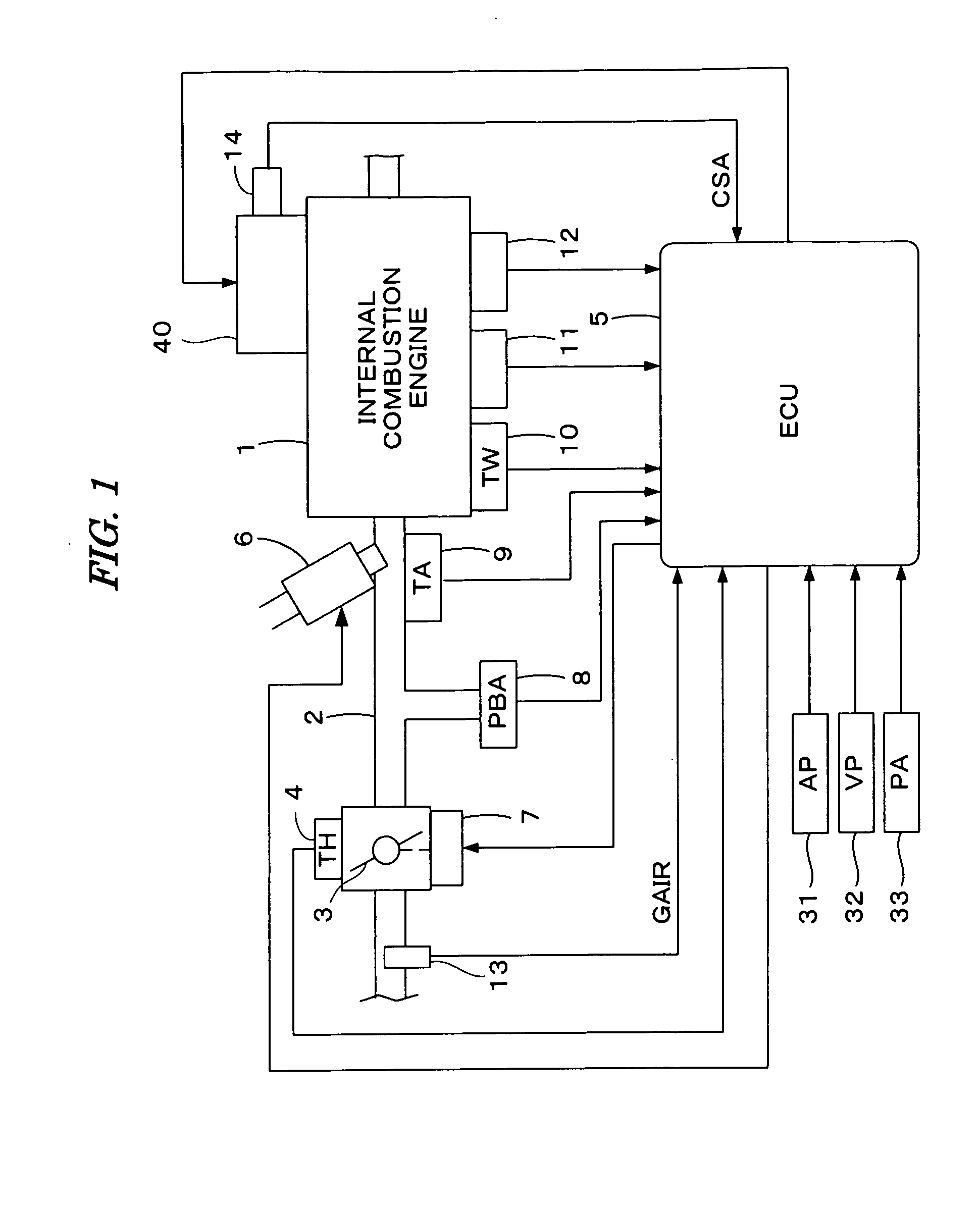

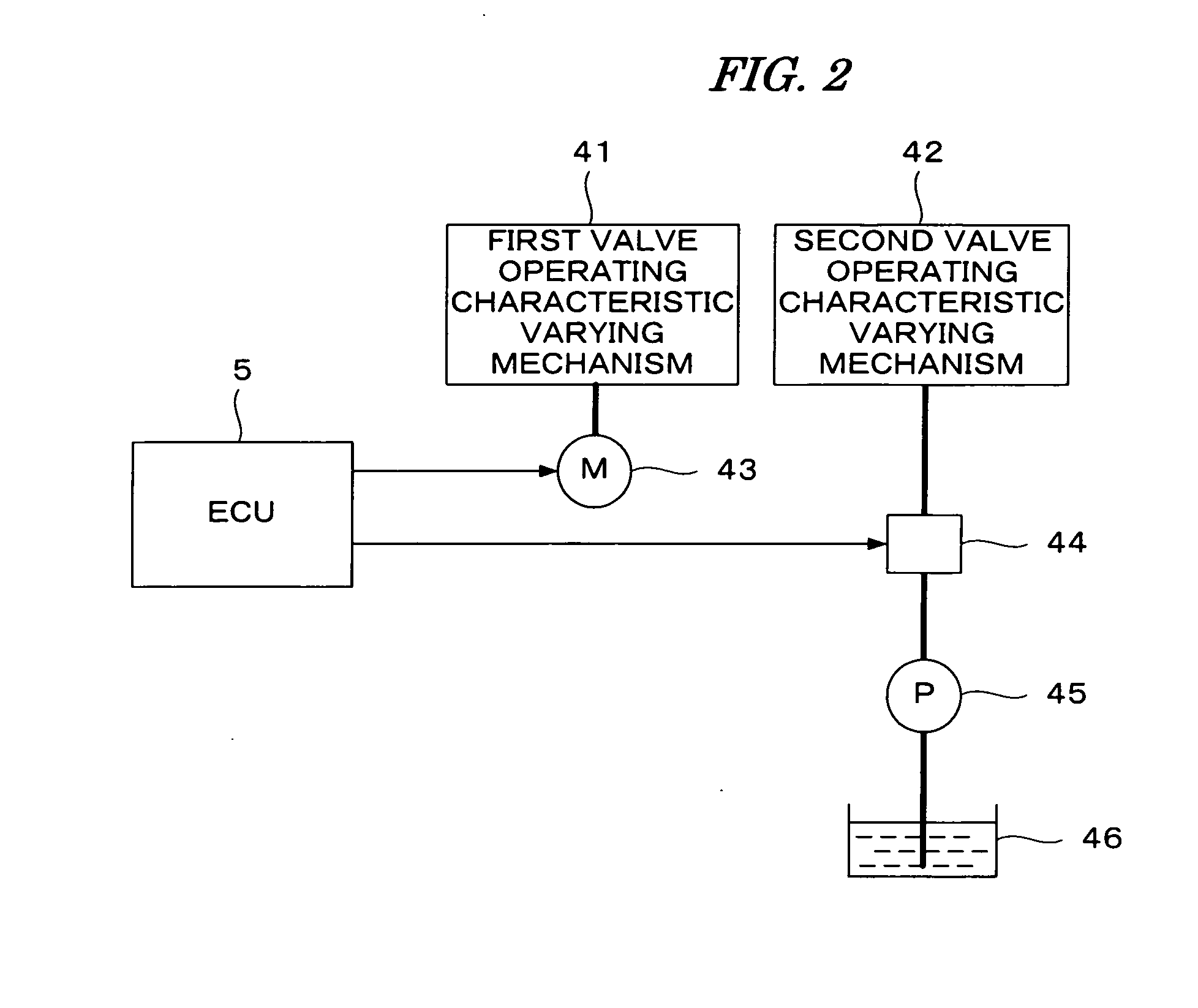

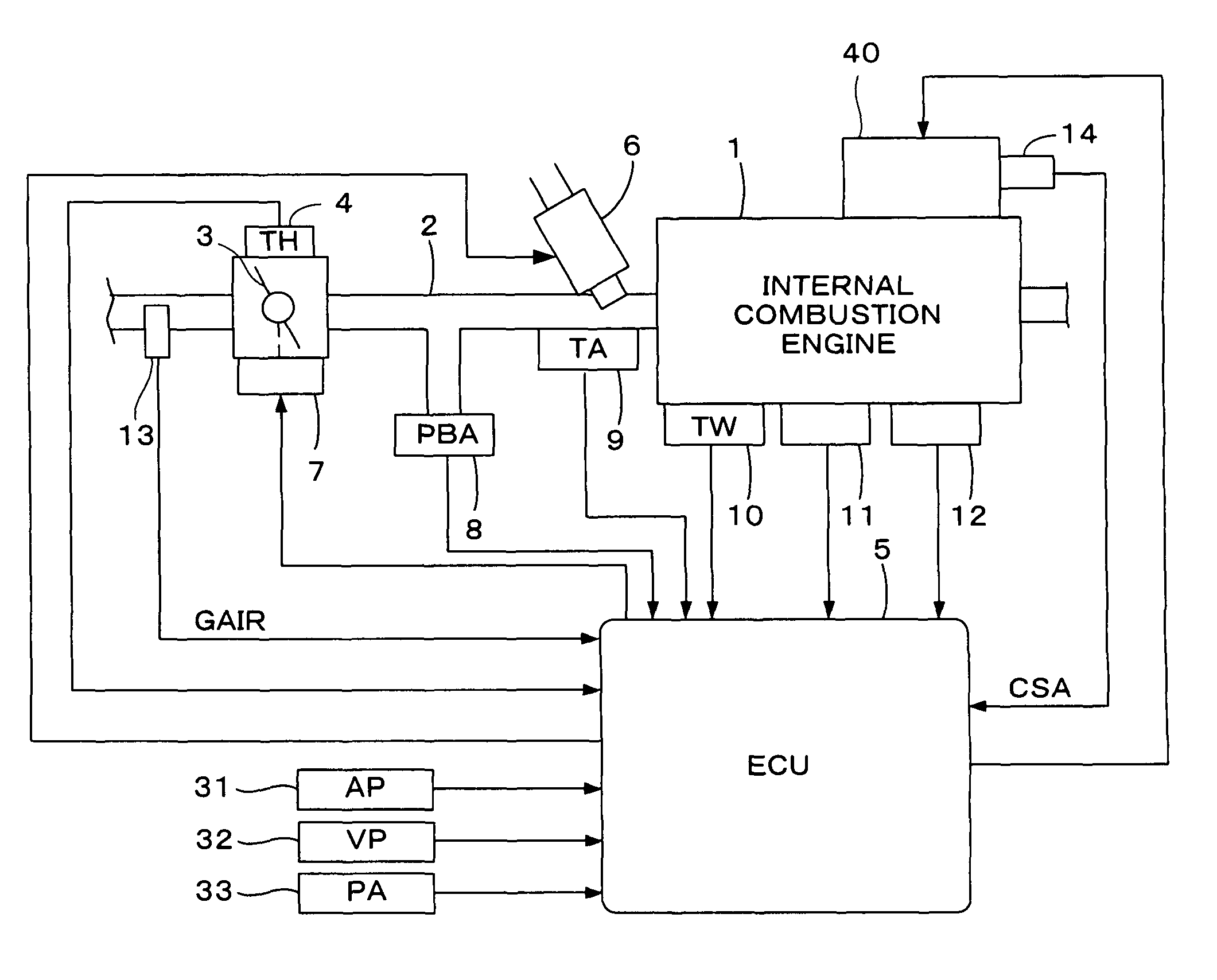

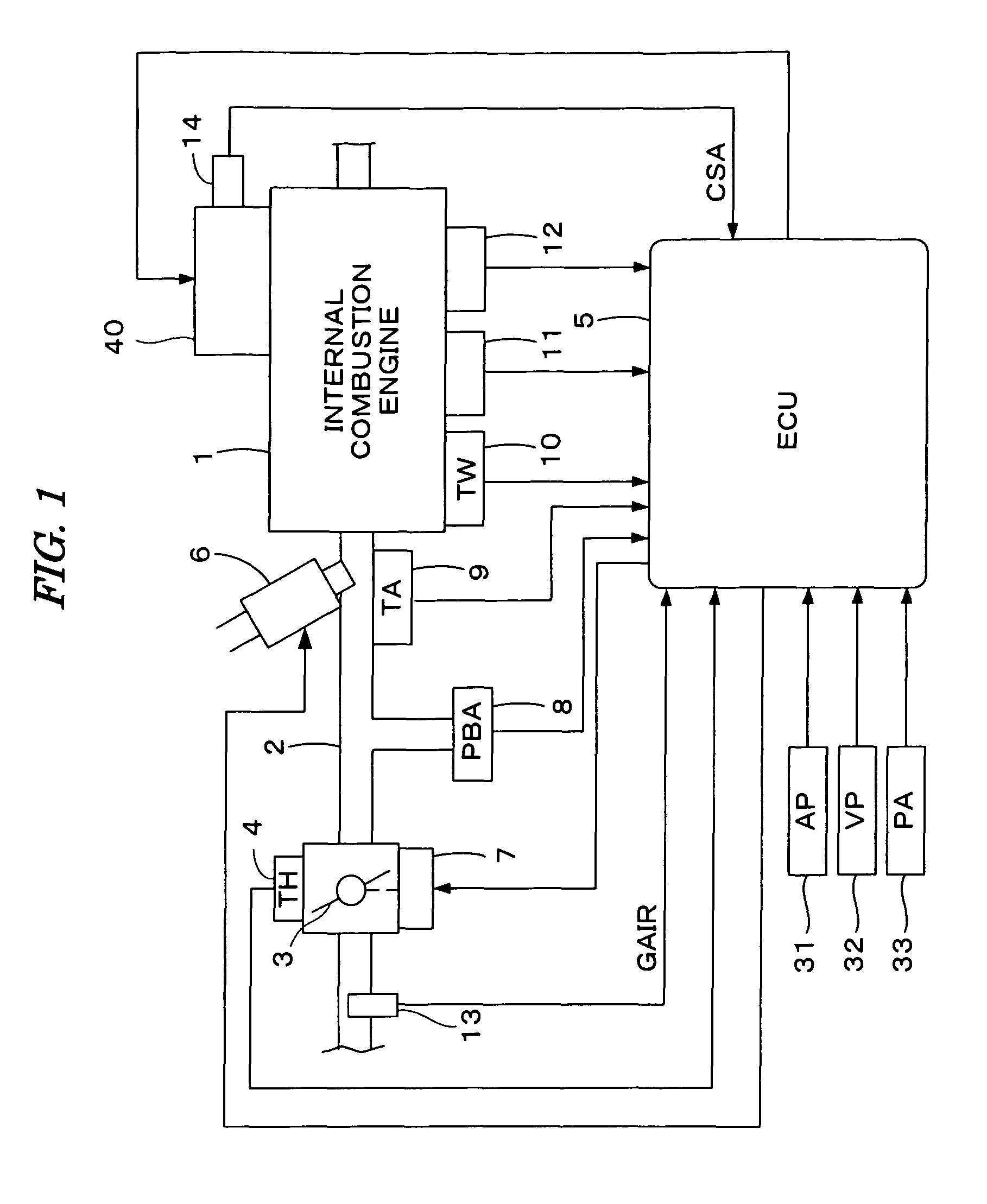

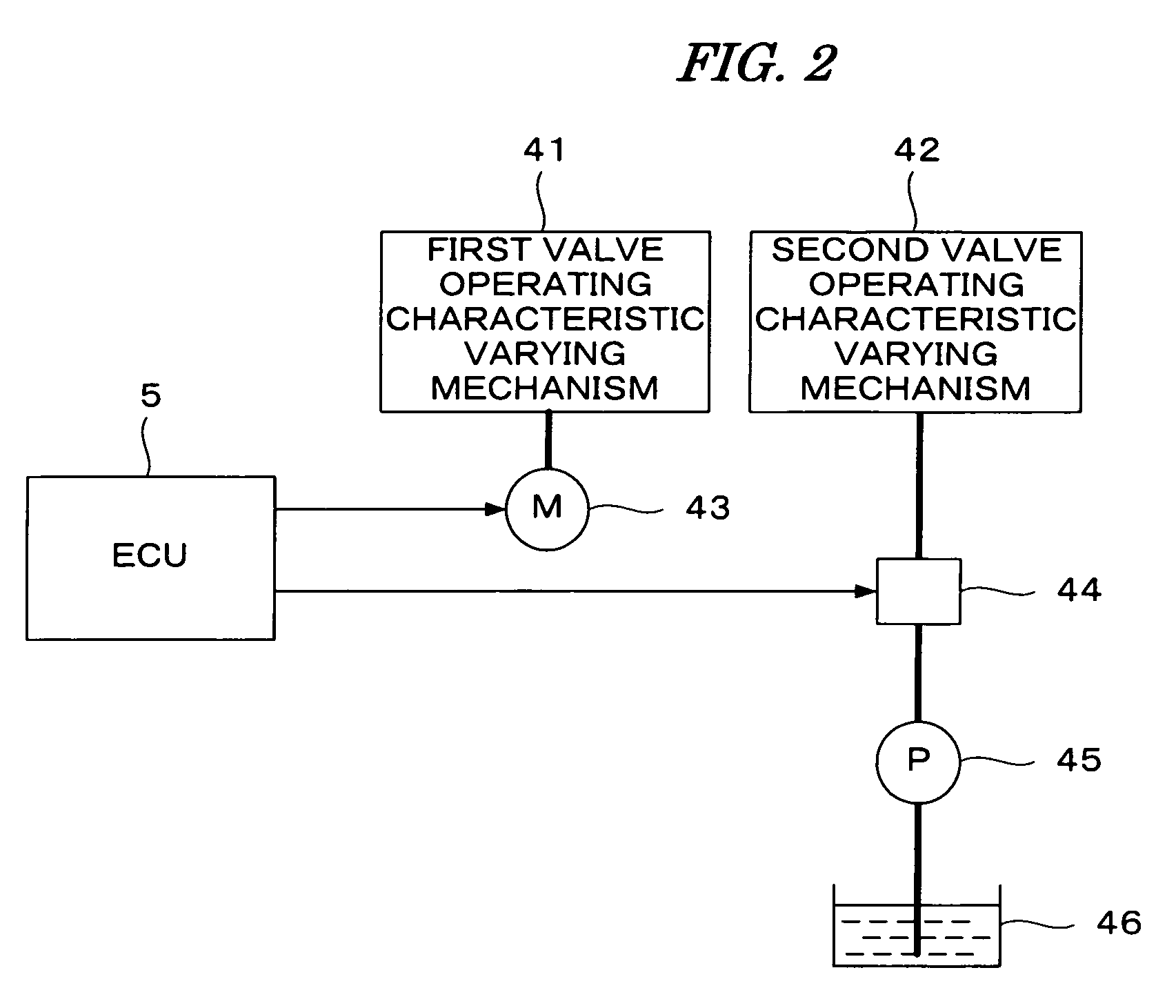

A variable valve actuating apparatus for an internal combustion engine includes a valve actuating mechanism to vary an actual valve operating characteristic of the engine. A controller sets a target valve operating characteristic in accordance with a crank angle position of the engine before a start of the engine, and delivers a changeover control signal to the valve actuating mechanism to control the actual valve operating characteristic to the target valve operating characteristic before an end of a cranking operation of the engine.

Owner:HITACHI ASTEMO LTD

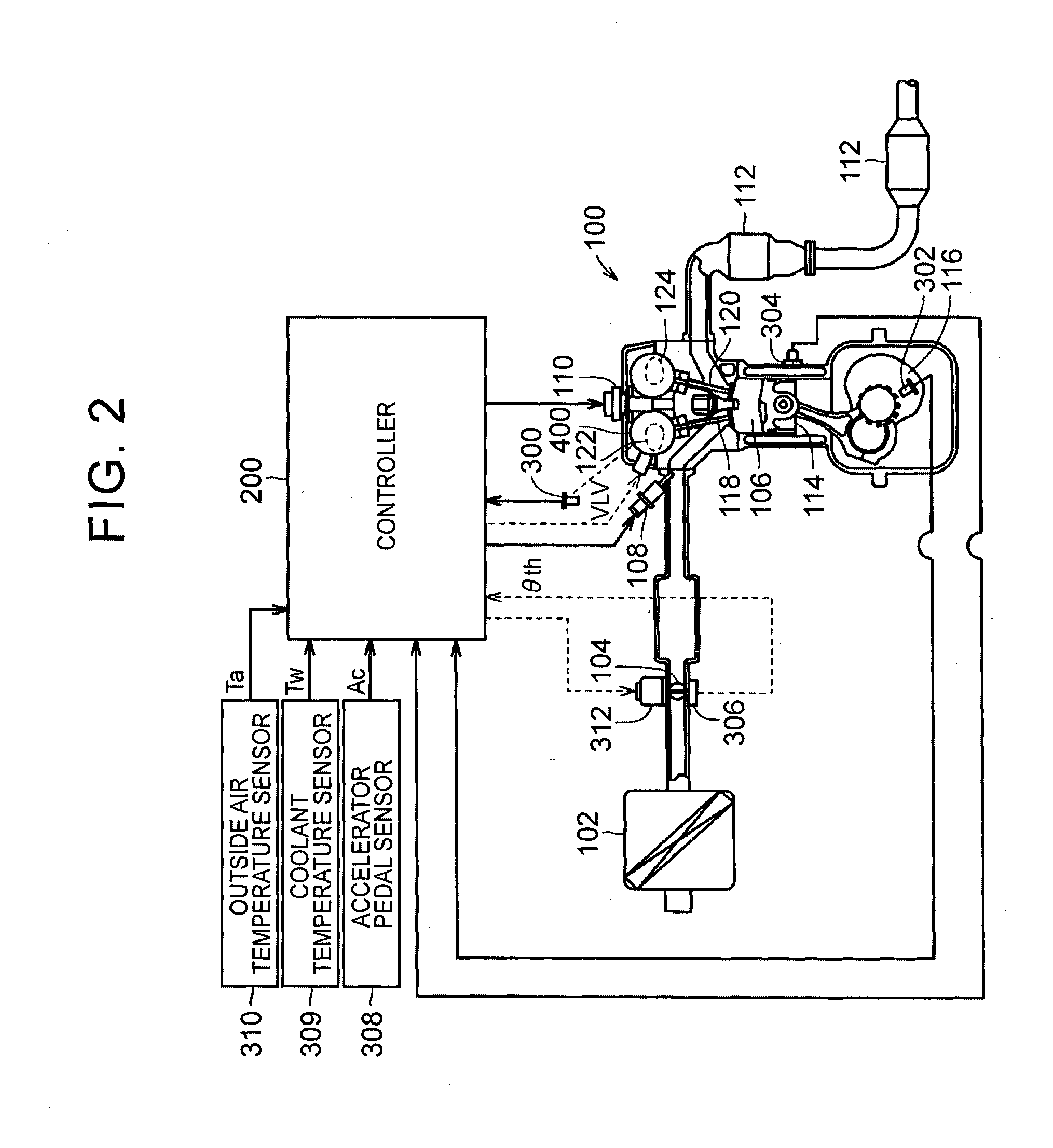

Apparatus and method for controlling intake air amount of internal combustion engine

InactiveUS6851409B2Improve accuracyValve arrangementsInternal combustion piston enginesValve jobEngineering

Owner:HITACHI ASTEMO LTD

Apparatus and method for controlling intake air amount of internal combustion engine

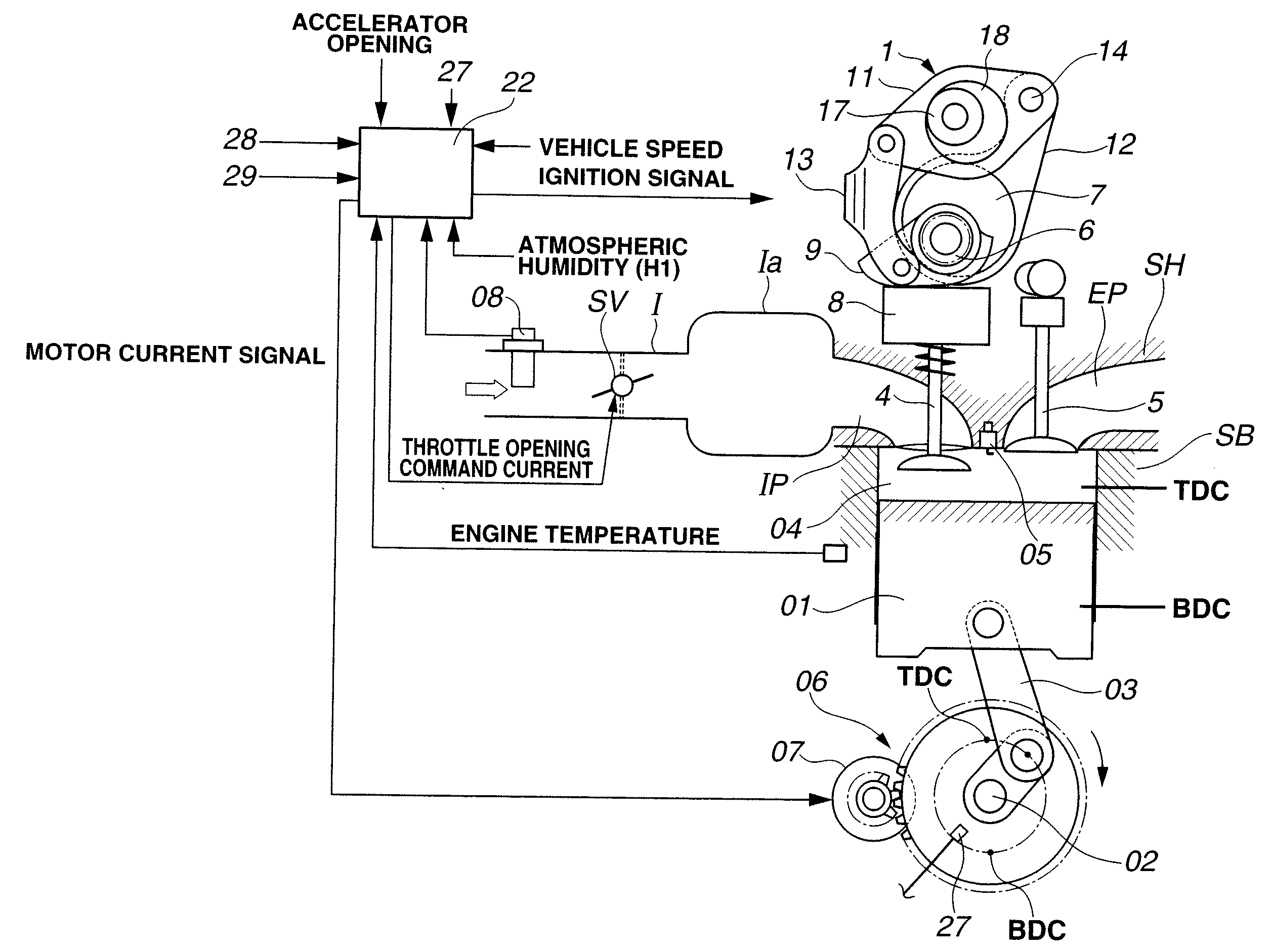

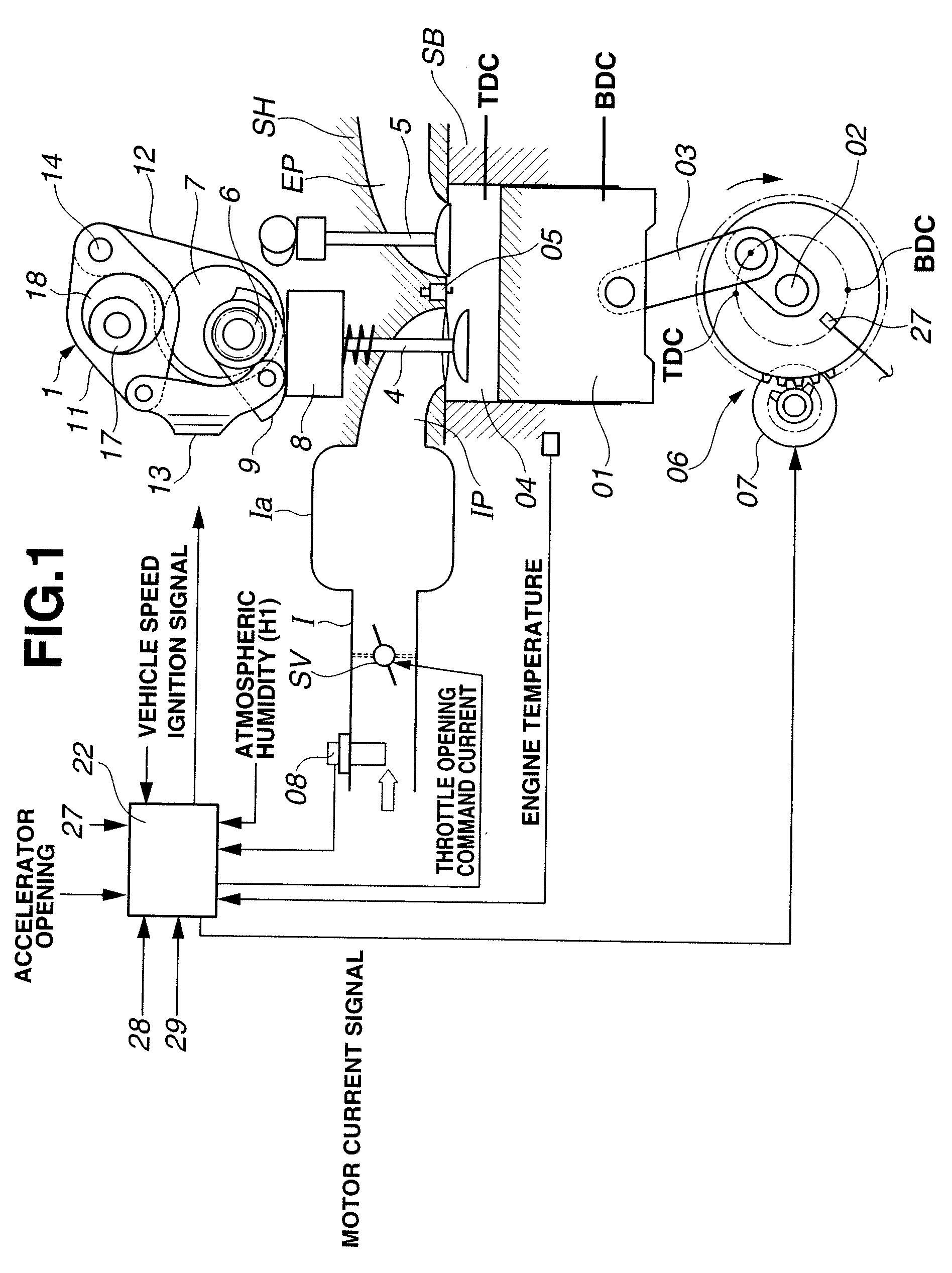

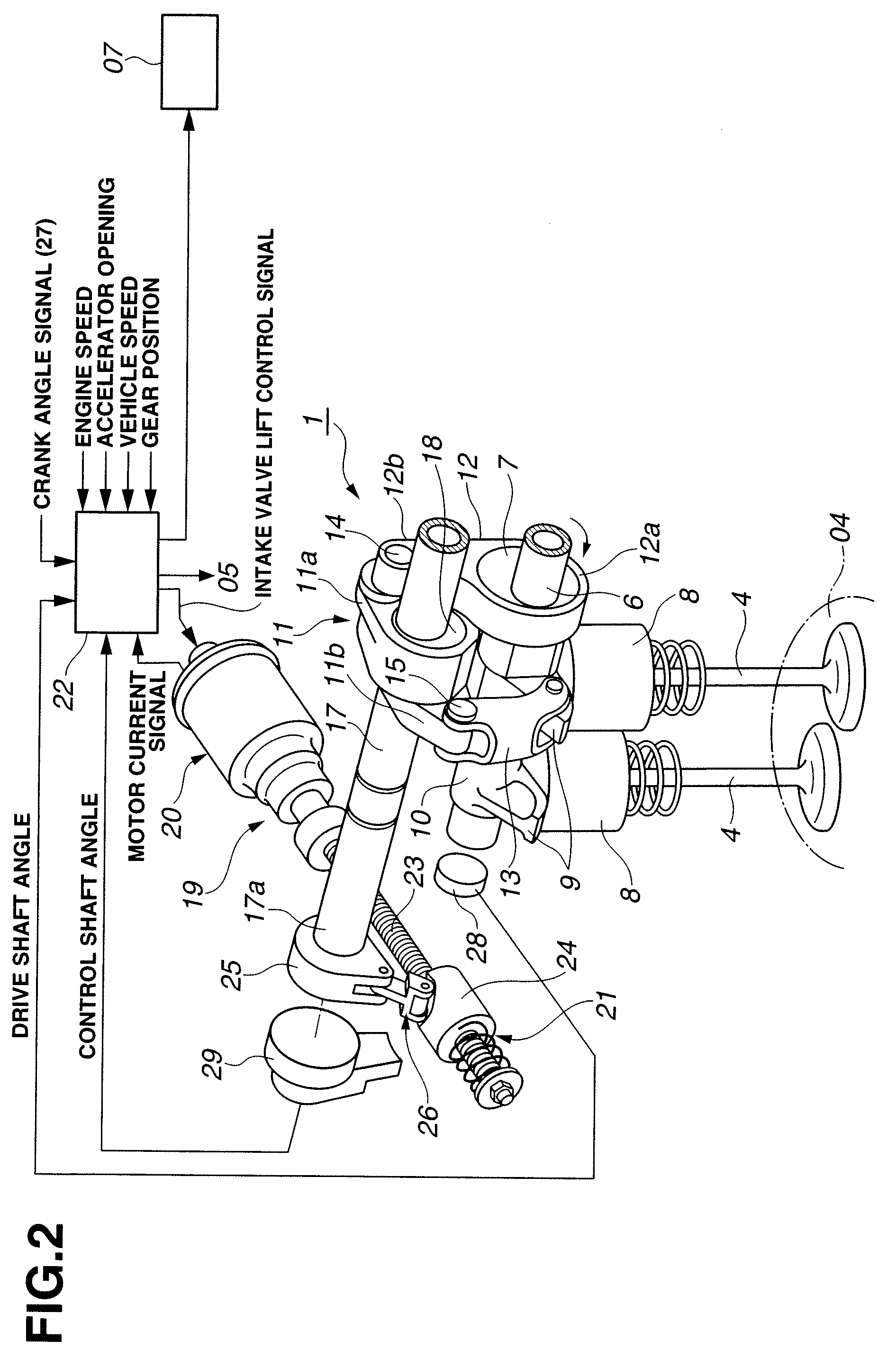

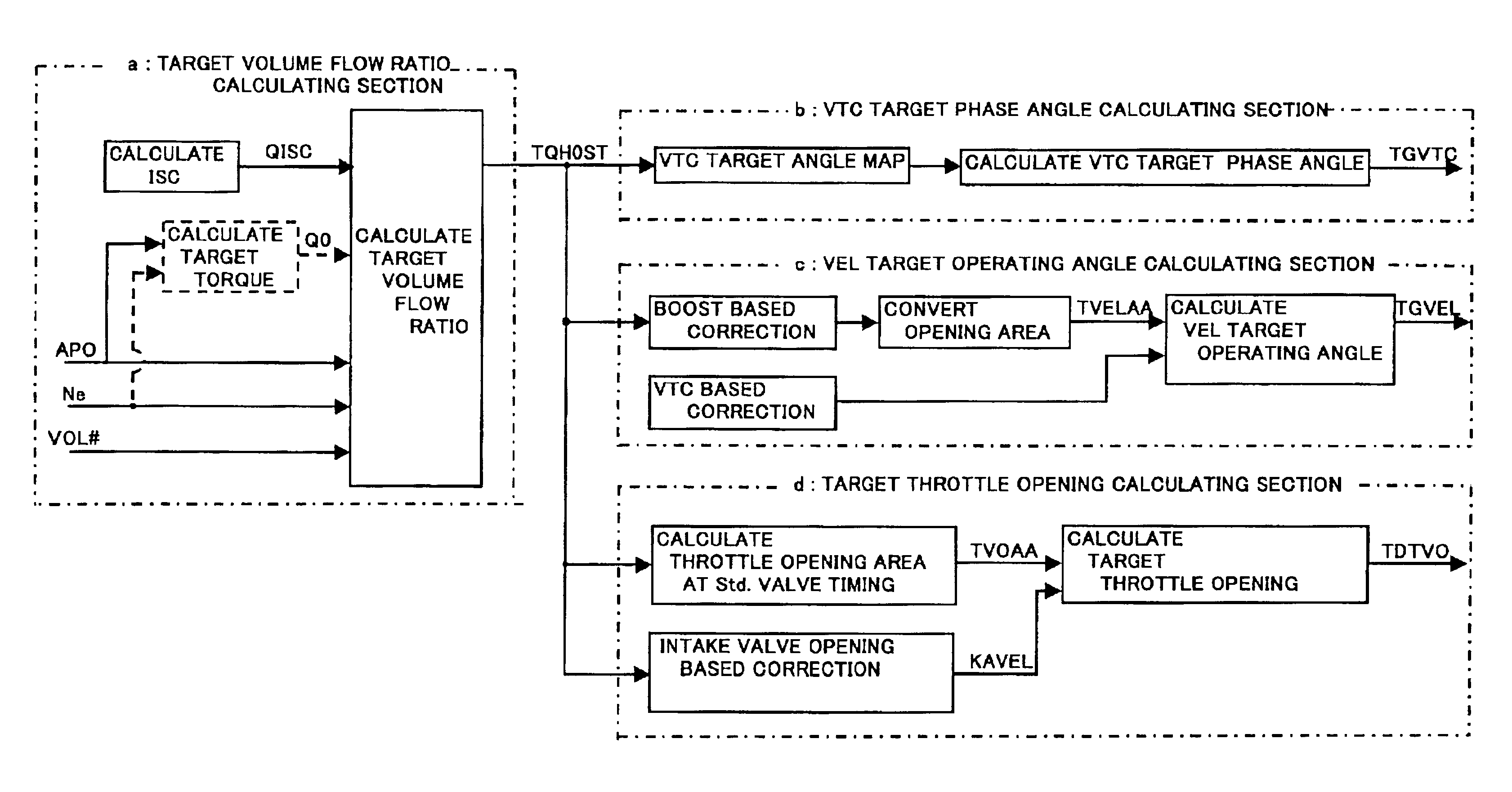

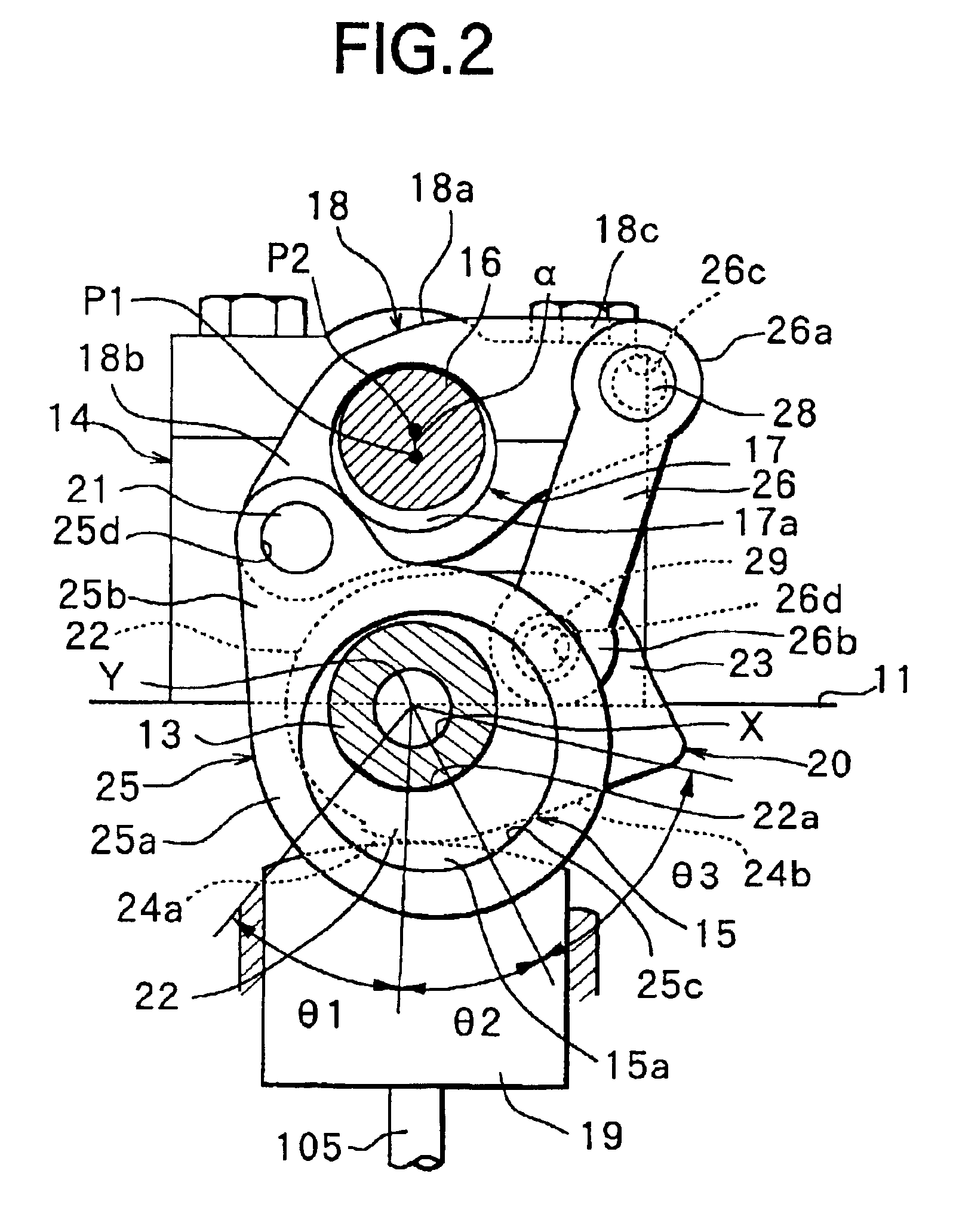

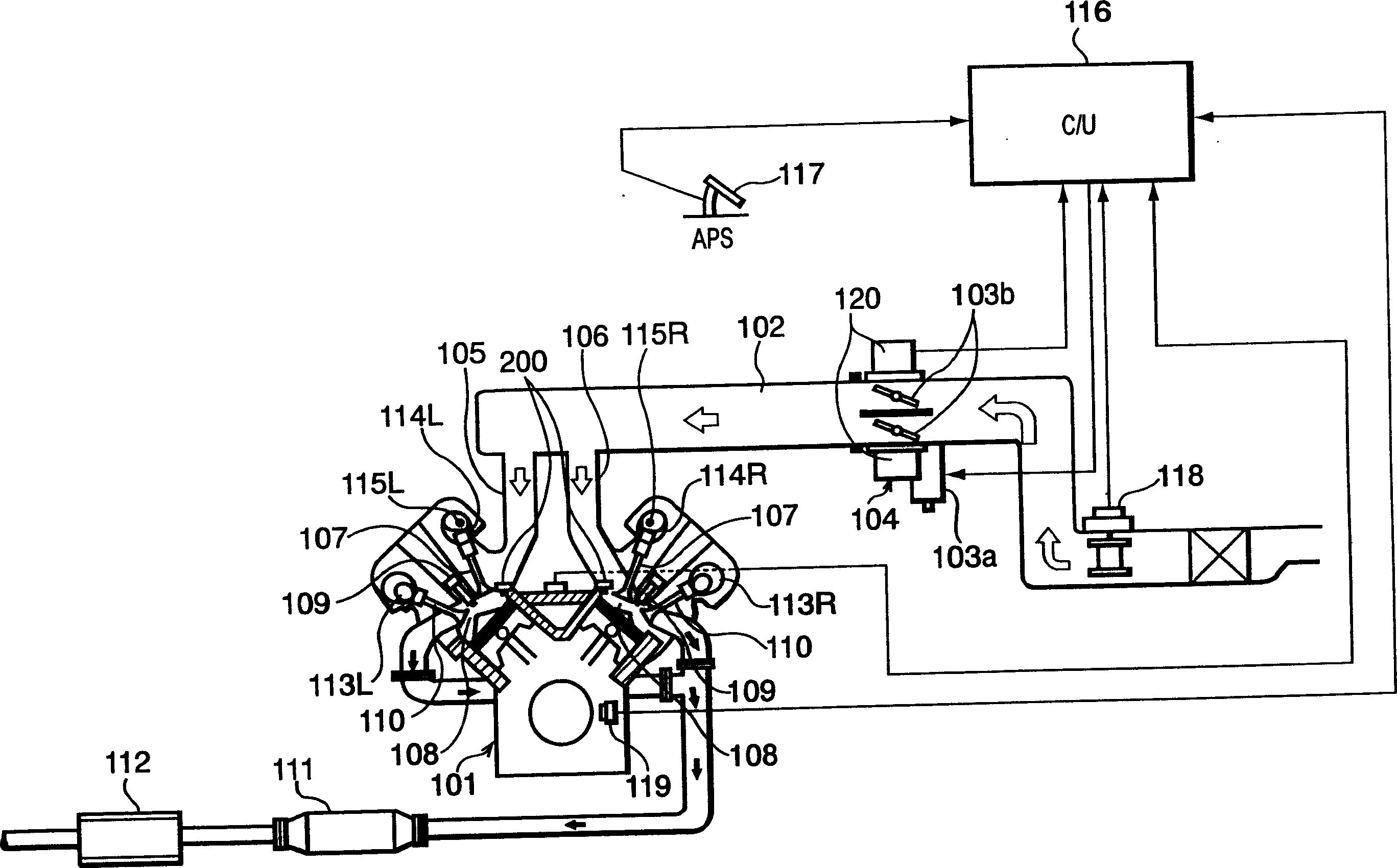

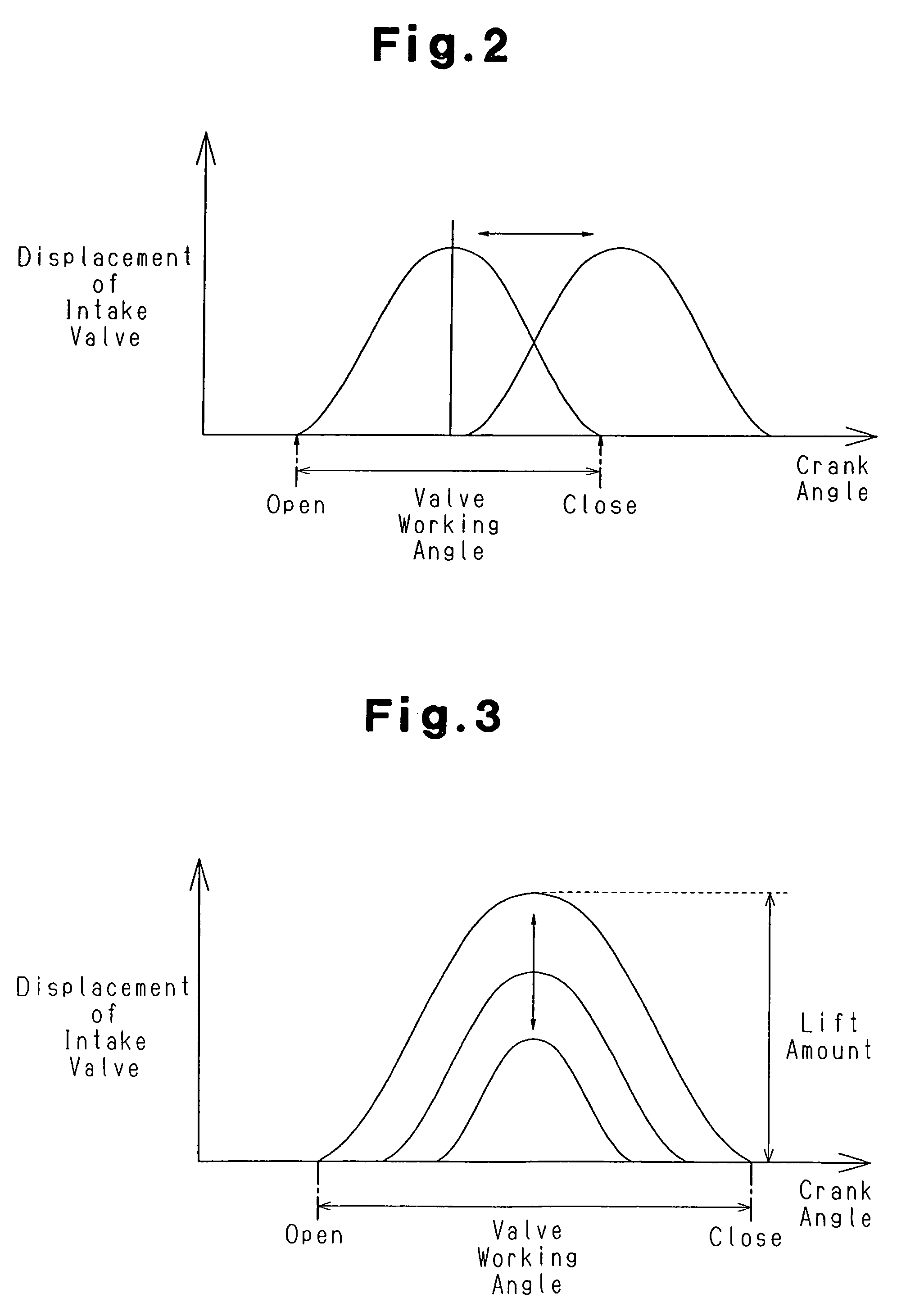

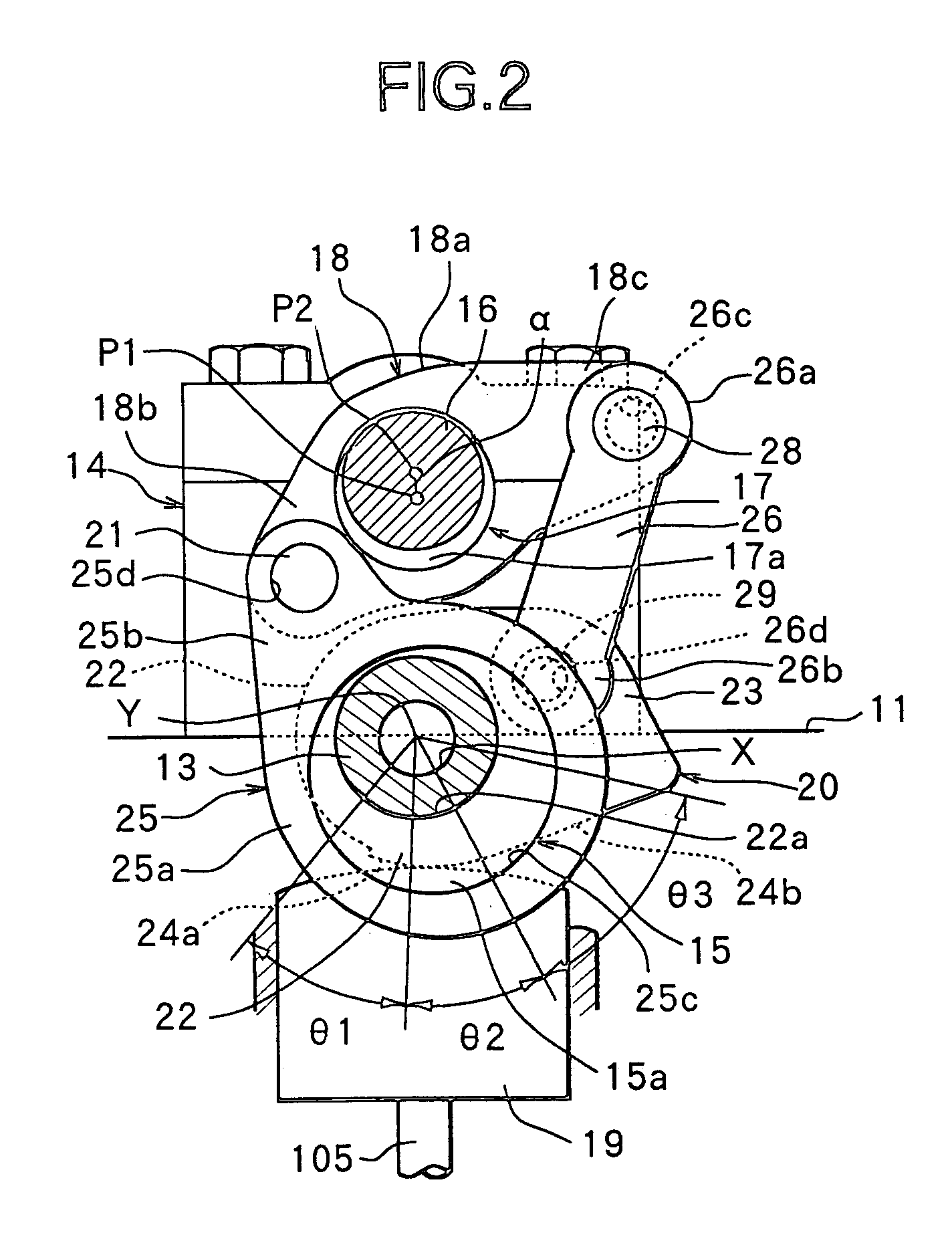

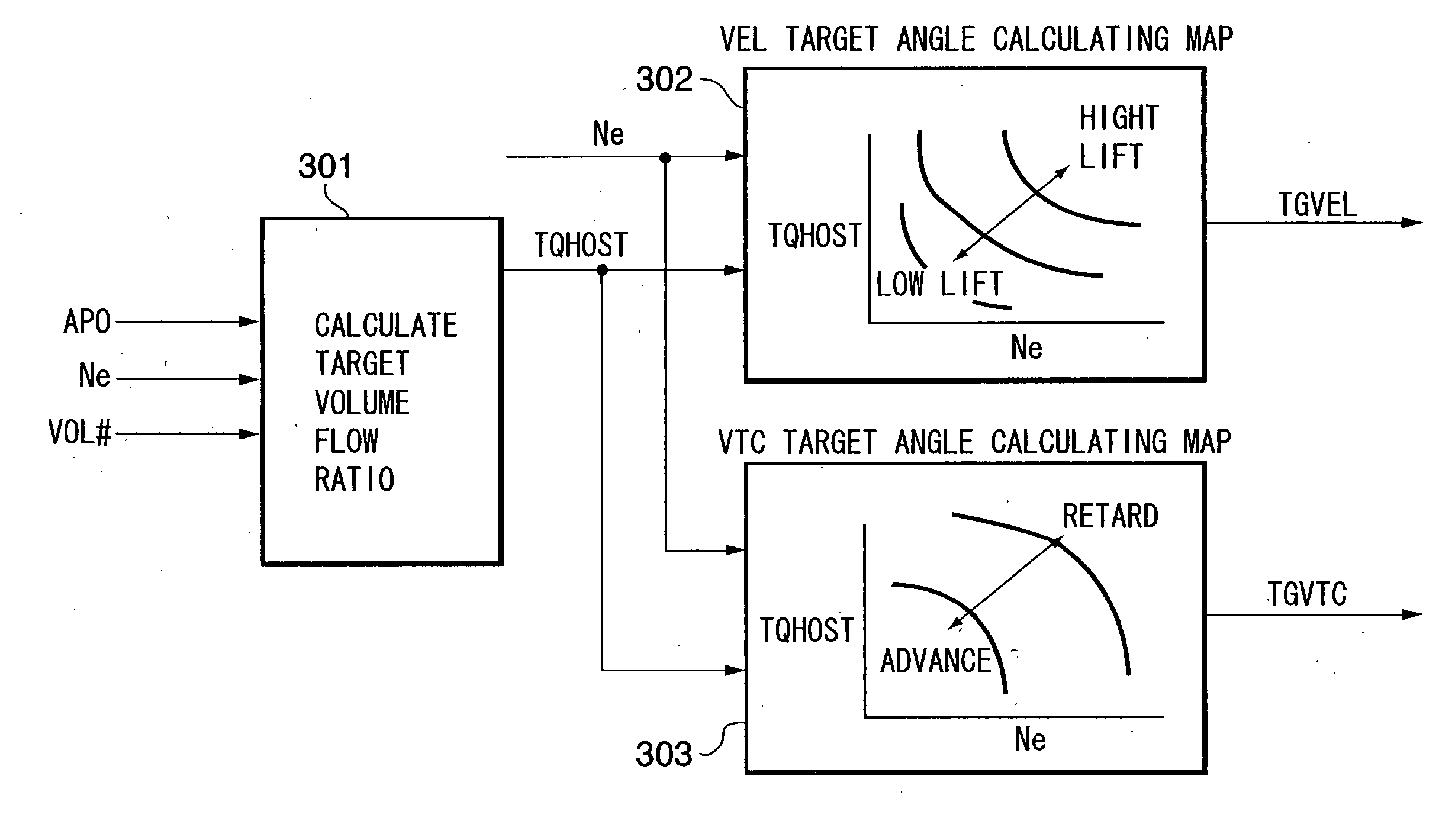

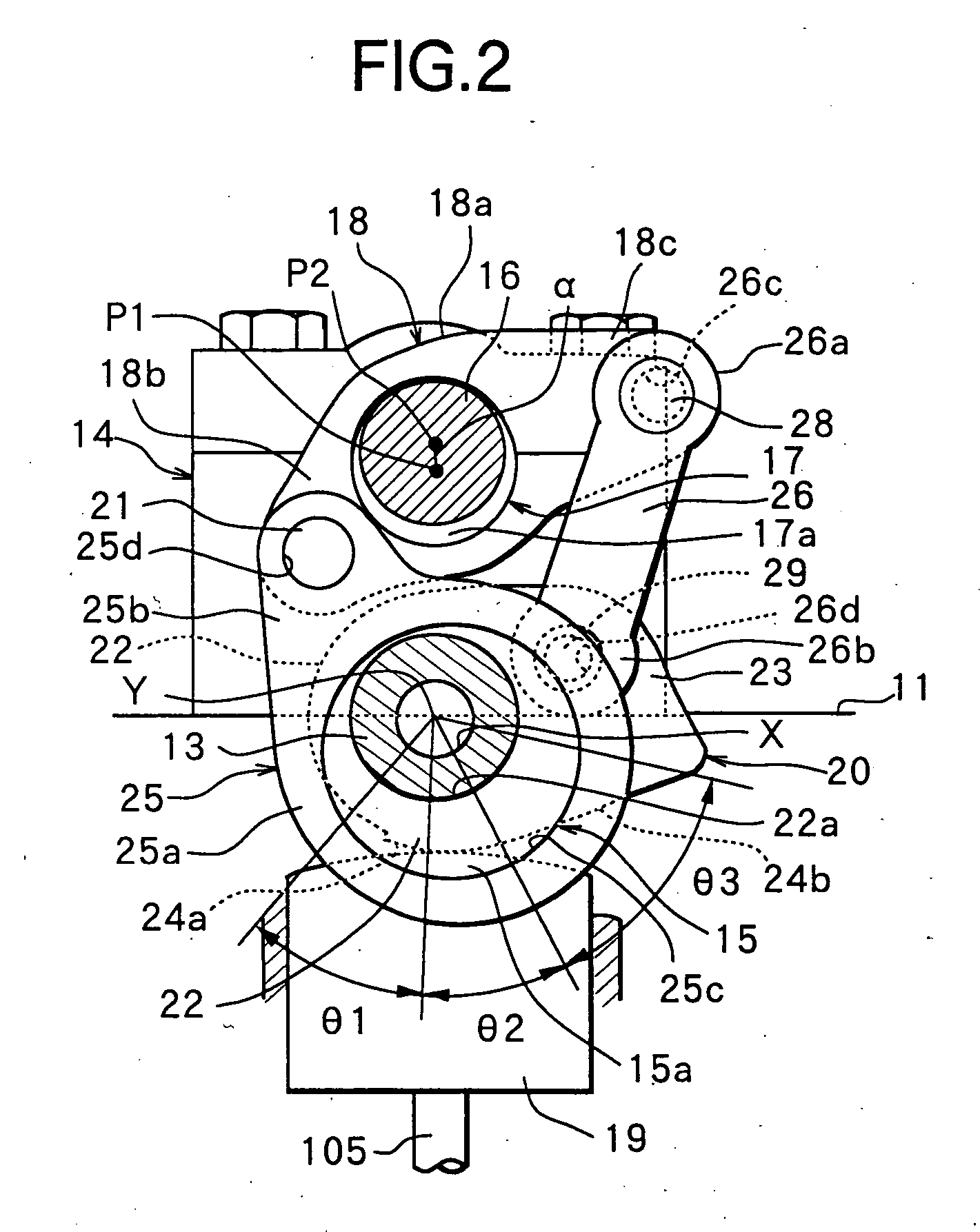

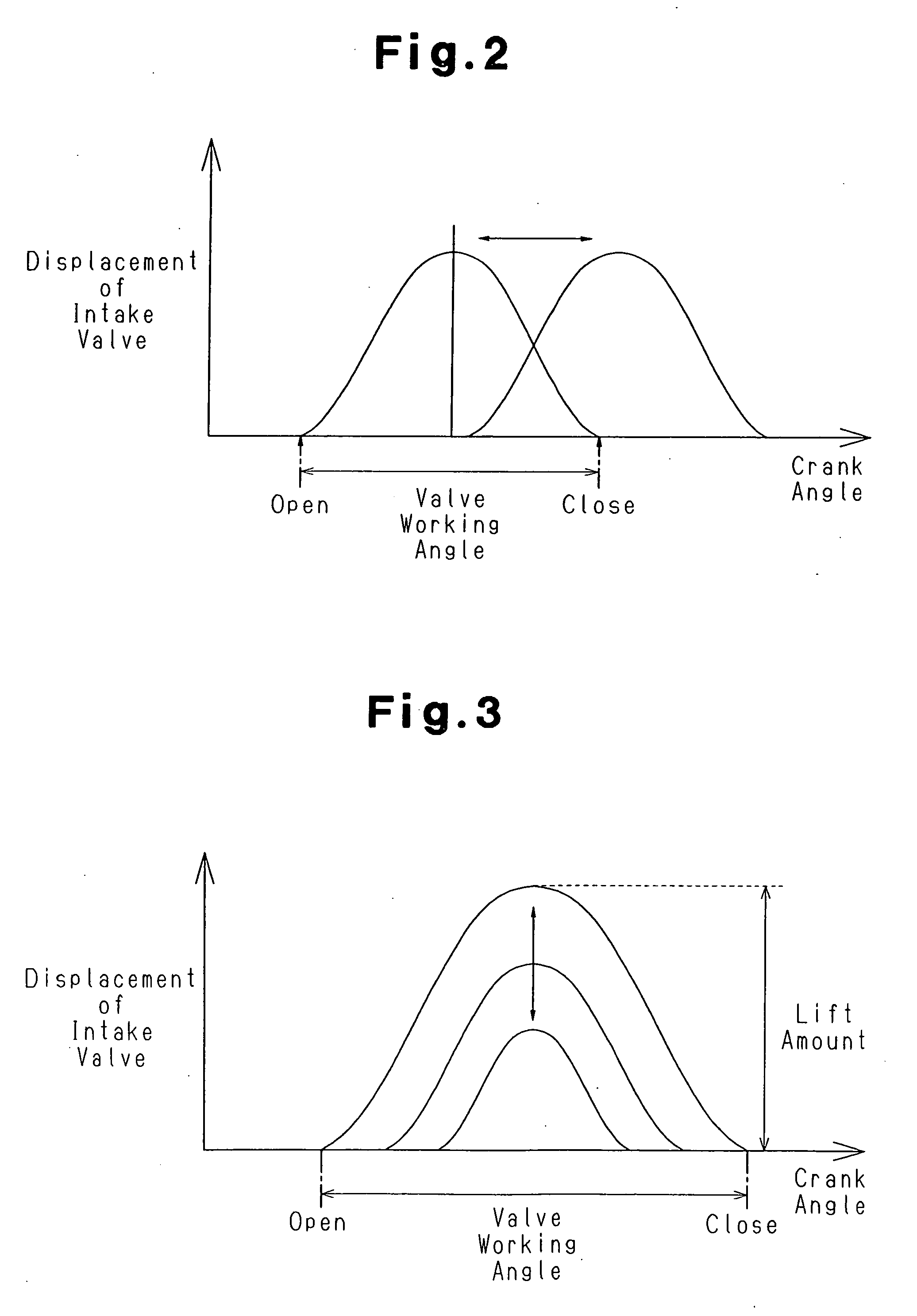

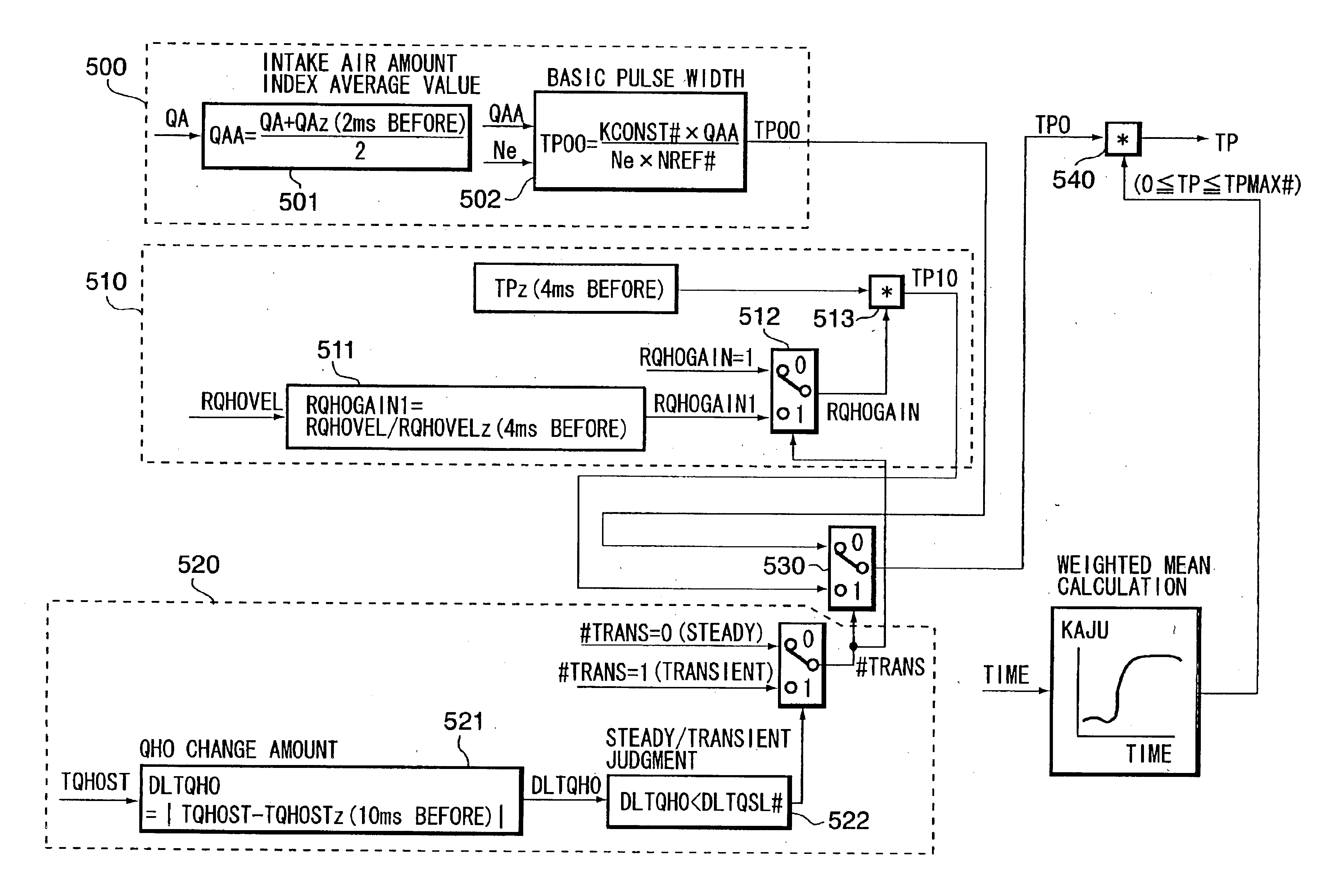

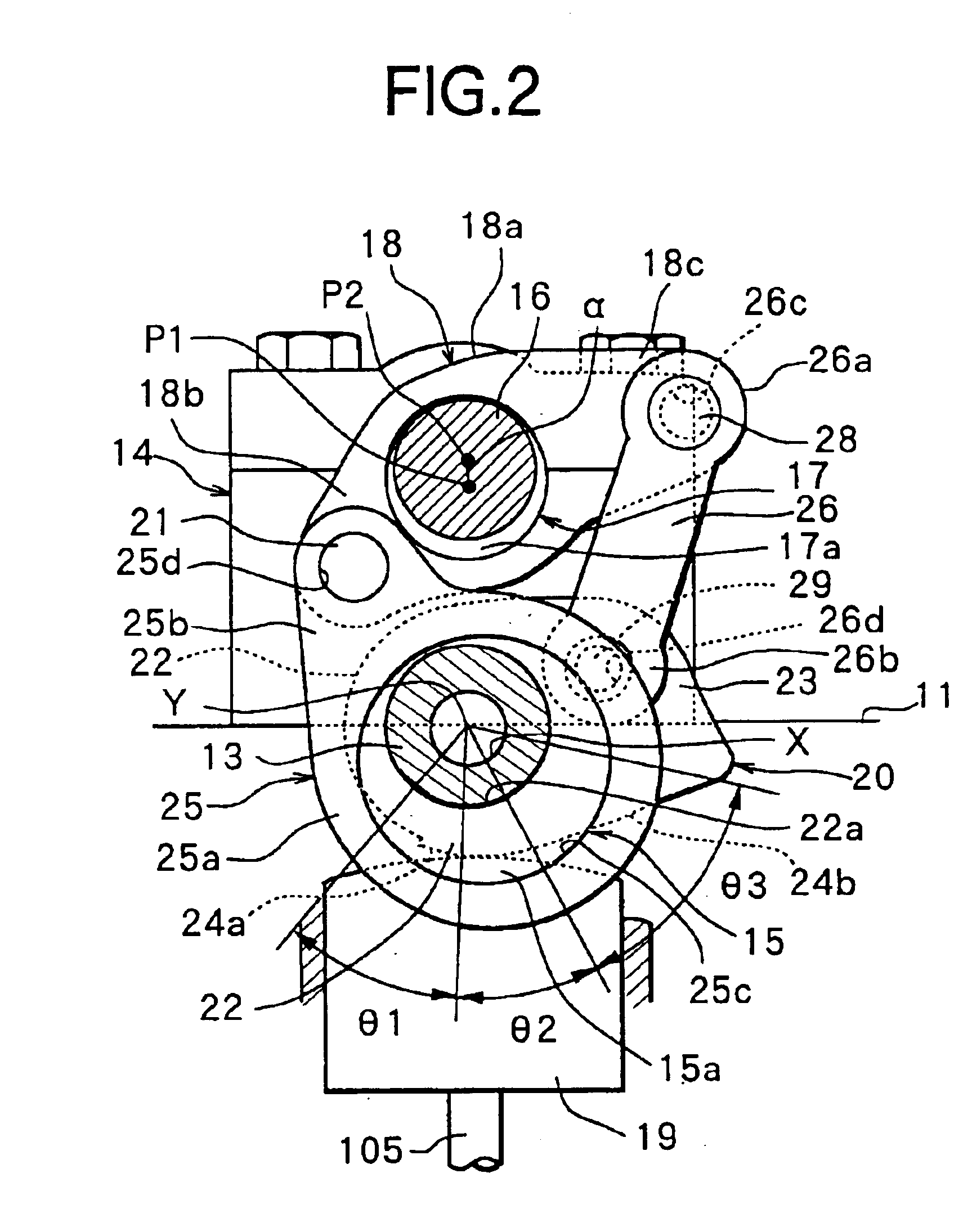

In an internal combustion engine provided with a variable valve mechanism that varies at least a valve operating characteristic (valve lift amount and the like) of an intake valve, a target intake air amount equivalent to a target torque is set based on operating conditions of the engine, to calculate a target volume flow ratio by dividing the target intake air amount by an engine rotation speed and total cylinder volume. The target volume flow ratio is corrected according to closing timing of the intake valve. If the valve lift amount of the intake valve is in a low valve lift region, the target volume flow ratio is further corrected according to the valve lift amount, and the post corrected target volume flow ratio is converted into a valve opening area of the intake valve to be set as a target valve opening area. Then, based on the target valve opening area, a target valve operating characteristic of the intake valve is set. Thereafter, the variable valve mechanism is controlled so that the valve operating characteristic of the intake valve reaches the target valve operating characteristic.

Owner:HITACHI LTD

Apparatus and method for controlling intake air amount of internal combustion engine

In an internal combustion engine provided with a variable valve mechanism that varies at least a valve operating characteristic (valve lift amount, valve operating angle and the like) of an intake valve, a target volume flow ratio equivalent to a target torque of the engine is obtained to be converted into a valve opening area, and a target valve operating characteristic of the variable valve mechanism is set based on the converted valve opening area, to control the variable valve mechanism so that an actual valve operating characteristic reaches a target valve operating angle, thereby executing with high accuracy an intake air amount control mainly by the variable valve mechanism.

Owner:HITACHI ASTEMO LTD

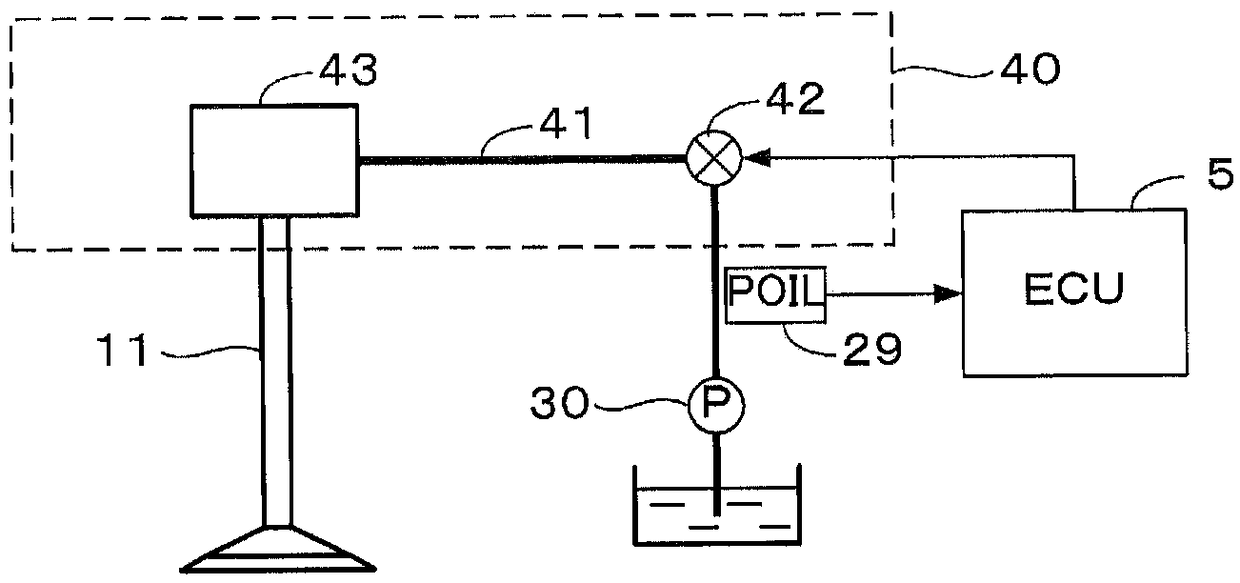

Timing chain lubricating structure for engine

InactiveUS6520139B2Reduce in quantityWell formedLubrication of auxillariesValve drivesValve jobCylinder head

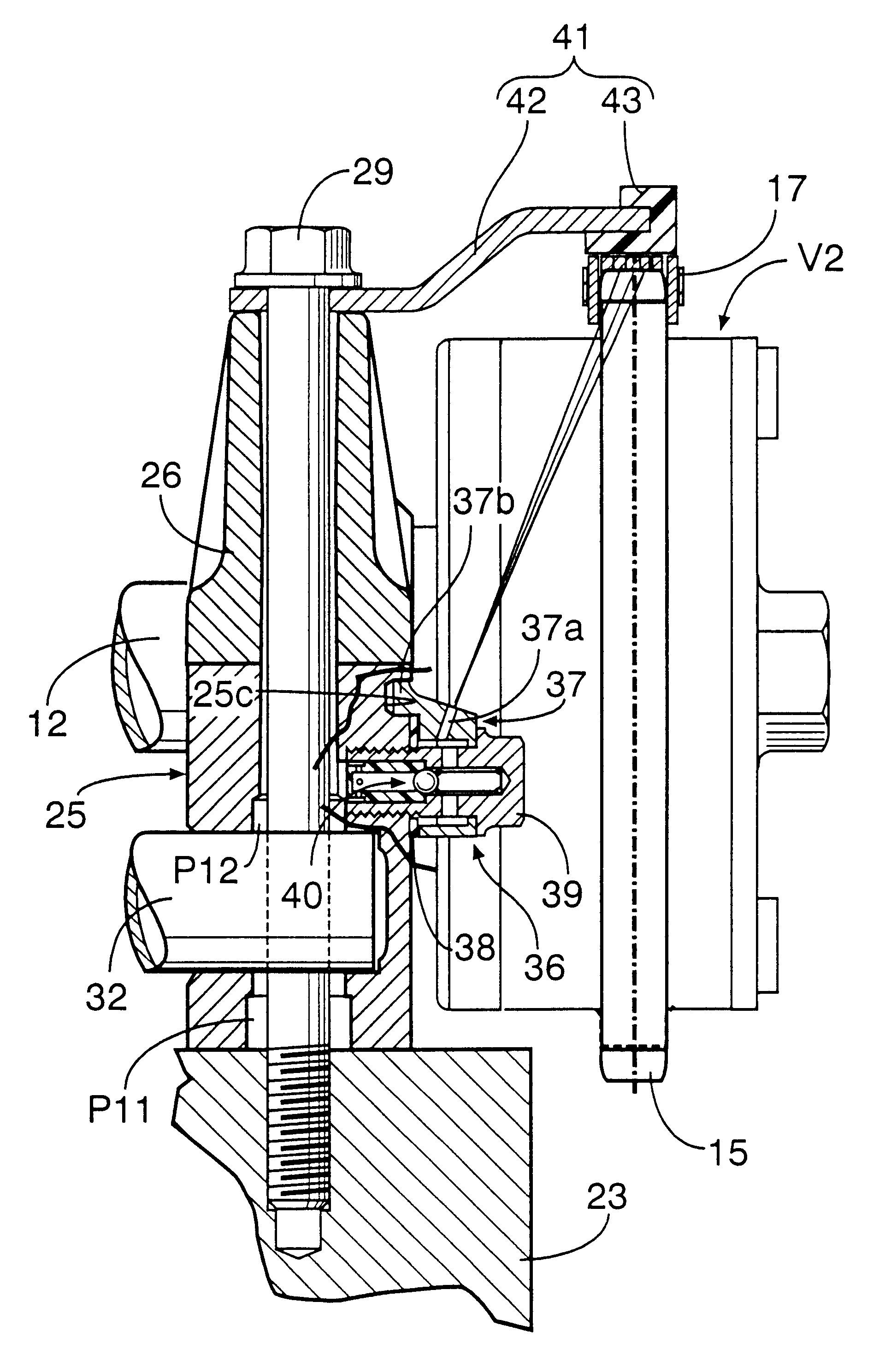

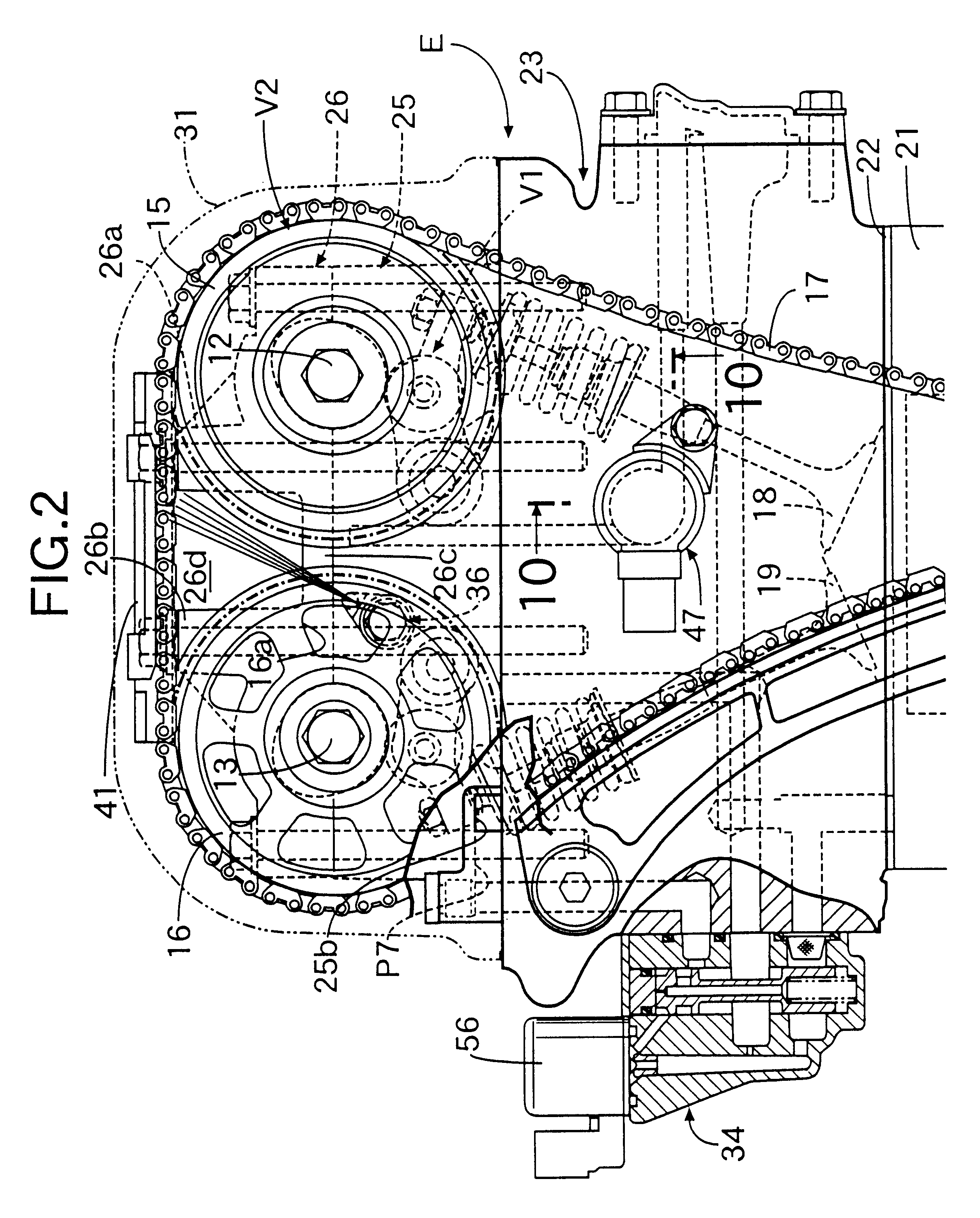

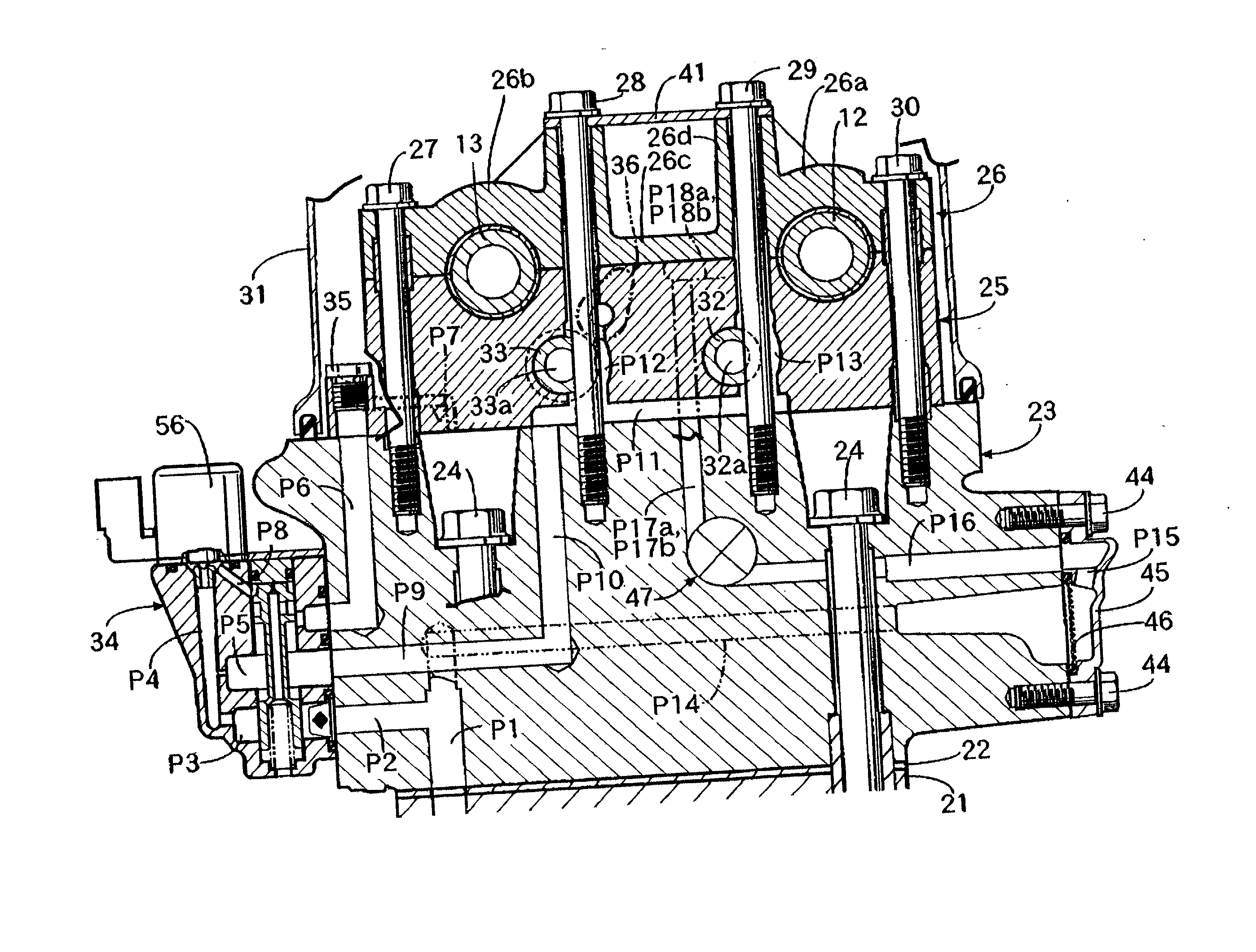

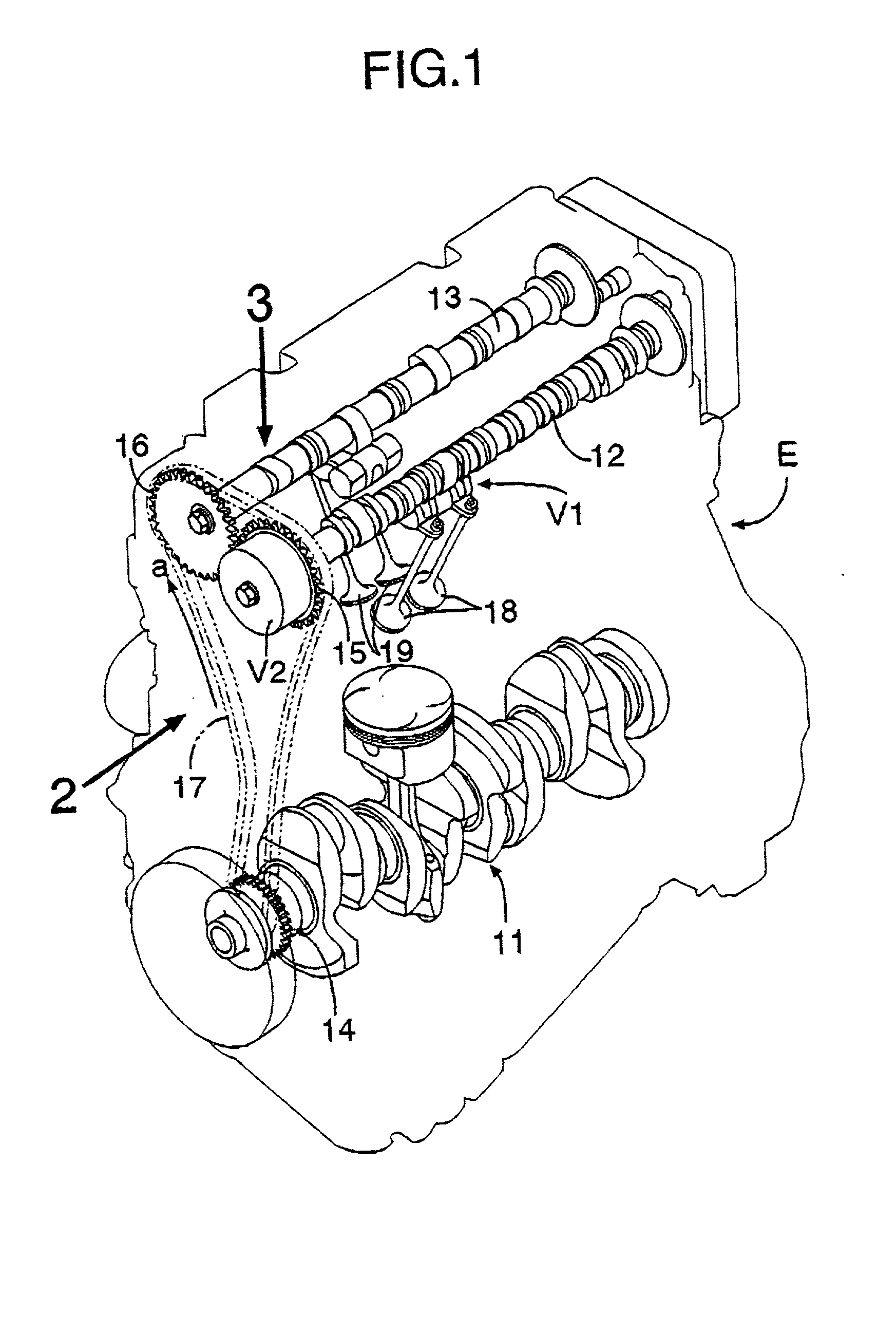

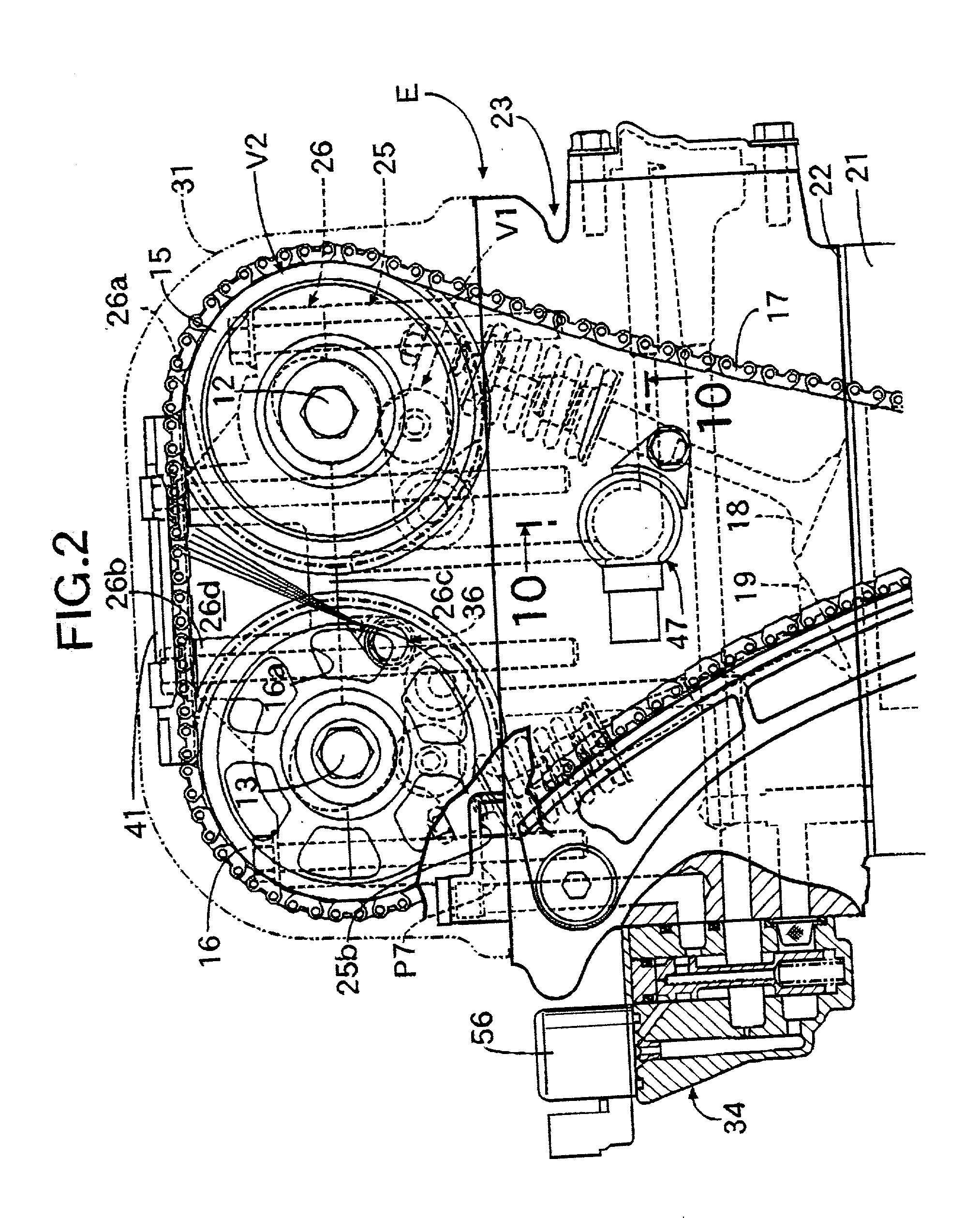

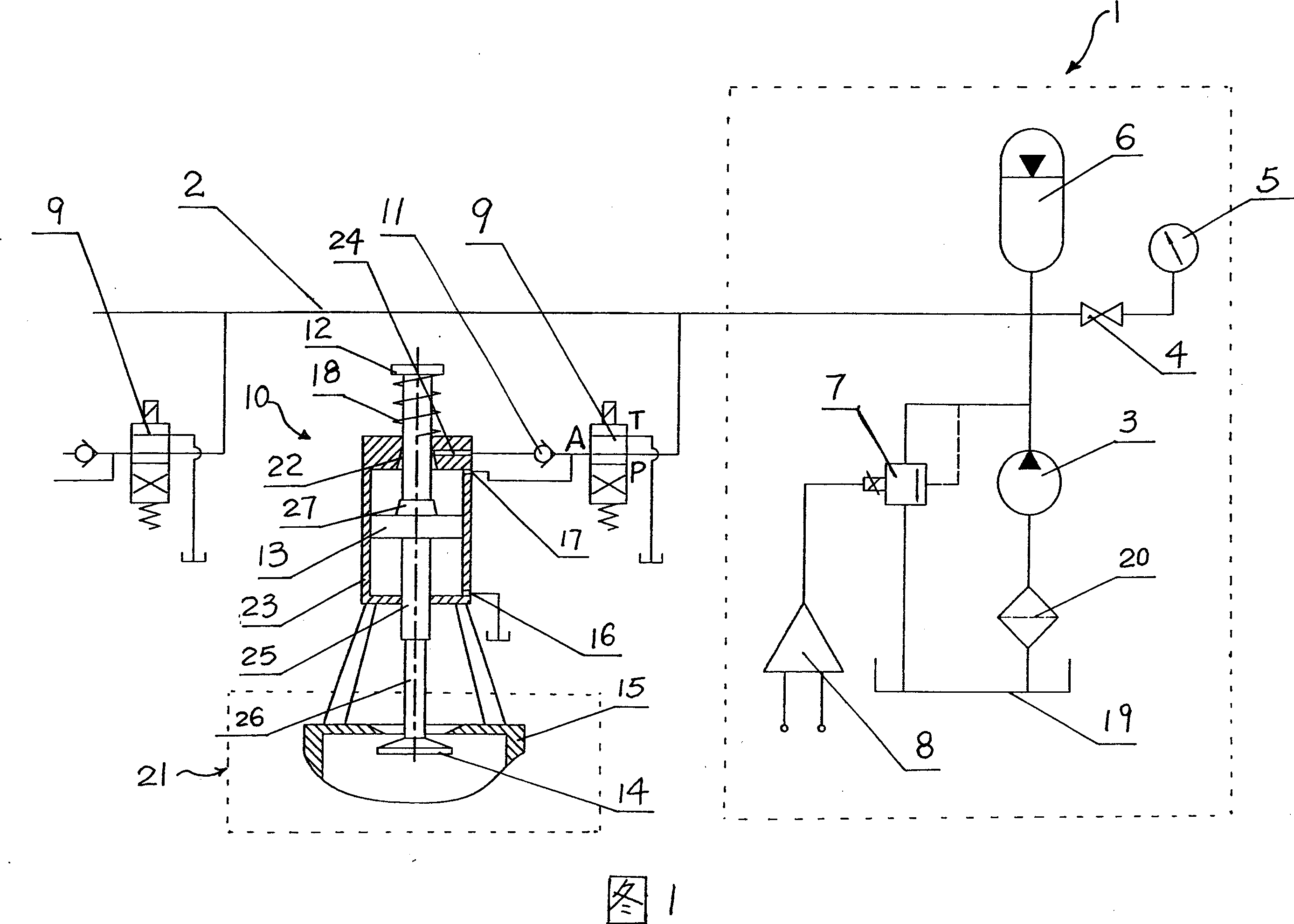

Sprockets are fixed to ends of camshafts supported in a cylinder head via camshaft holders. A timing chain is wrapped around these sprockets. The relief oil from a hydraulic control value for controlling a variable valve operating characteristic mechanism passes through an oil passage formed in the plane in which the cylinder head and the camshaft holder are joined and flows out of an oil drain hole, thus lubricating the section where the sprocket is meshed with the timing chain. The section where the sprocket of the camshaft is meshed with the timing chain can thereby be lubricated reliably by a simple structure.

Owner:HONDA MOTOR CO LTD

Fail-safe control apparatus for internal combustion engine equipped with variable valve characteristic mechanism and method thereof

When it is detected that any one of a plurality of variable valve characteristic mechanisms disposed for every cylinder groups is failed, an effective opening degree (valve lift amount, valve operating angle or the like) in a valve characteristic in the failed state, is obtained. When the effective opening degree is judged to be a predetermined value or above, the valve characteristic of the normal variable valve characteristic mechanism is controlled to be coincident with the valve characteristic in the failed state. When the effective opening degree is judged to be less than the predetermined value, there is performed a control for limiting the control to coincide the valve characteristic of the normal variable valve characteristic mechanism with the valve characteristic in the failed state.

Owner:HITACHI LTD

Idle speed controller for internal combustion engine

InactiveUS7168410B2Avoid it happening againValve arrangementsElectrical controlIdle speed controlValve job

An idle speed controller for an internal combustion engine provided with an intake variable valve timing mechanism for varying valve timing and a variable working angle for varying a valve working angle of an intake valve. The controller performs idle speed control. When an advancement failure occurs in the intake variable valve timing mechanism, the controller performs idle-up control to increase the target idle speed. When the valve working angle of the intake variable working angle mechanism is less than a predetermined value, the electronic control unit changes an increase amount of the target idle speed to a lower value if an advancement failure occurs when performing the idle-up as compared to when the valve working angle is greater than the predetermined value.

Owner:TOYOTA JIDOSHA KK

Apparatus and method for controlling intake air amount of internal combustion engine

In an internal combustion engine provided with a variable valve mechanism that varies at least a valve operating characteristic (valve lift amount and the like) of an intake valve, a target intake air amount equivalent to a target torque is set based on operating conditions of the engine, to calculate a target volume flow ratio by dividing the target intake air amount by an engine rotation speed and total cylinder volume. The target volume flow ratio is corrected according to closing timing of the intake valve. If the valve lift amount of the intake valve is in a low valve lift region, the target volume flow ratio is further corrected according to the valve lift amount, and the post corrected target volume flow ratio is converted into a valve opening area of the intake valve to be set as a target valve opening area. Then, based on the target valve opening area, a target valve operating characteristic of the intake valve is set. Thereafter, the variable valve mechanism is controlled so that the valve operating characteristic of the intake valve reaches the target valve operating characteristic.

Owner:HITACHI LTD

Apparatus for controlling fuel injection of engine and method thereof

ActiveUS7013875B2Improve combustion stabilityElectrical controlInternal combustion piston enginesValve jobInlet valve

In an engine provided with a variable valve event and lift mechanism that varies a valve lift and a valve operating angle of an intake valve, a pressure of fuel supplied to a fuel injection valve is controlled according to an opening period of the intake valve, which is varied according to the valve operating angle and an engine rotation speed.

Owner:HITACHI ASTEMO LTD

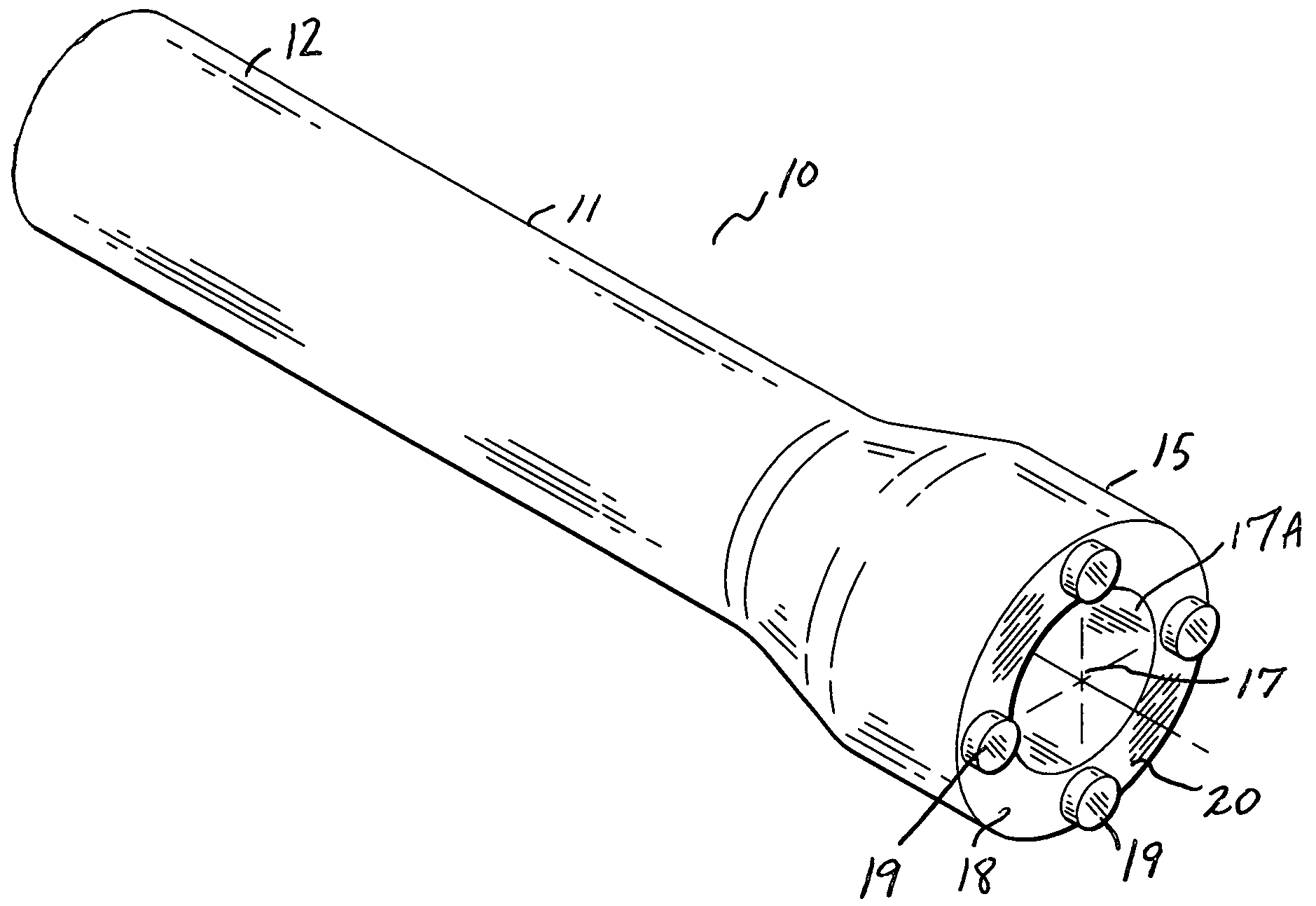

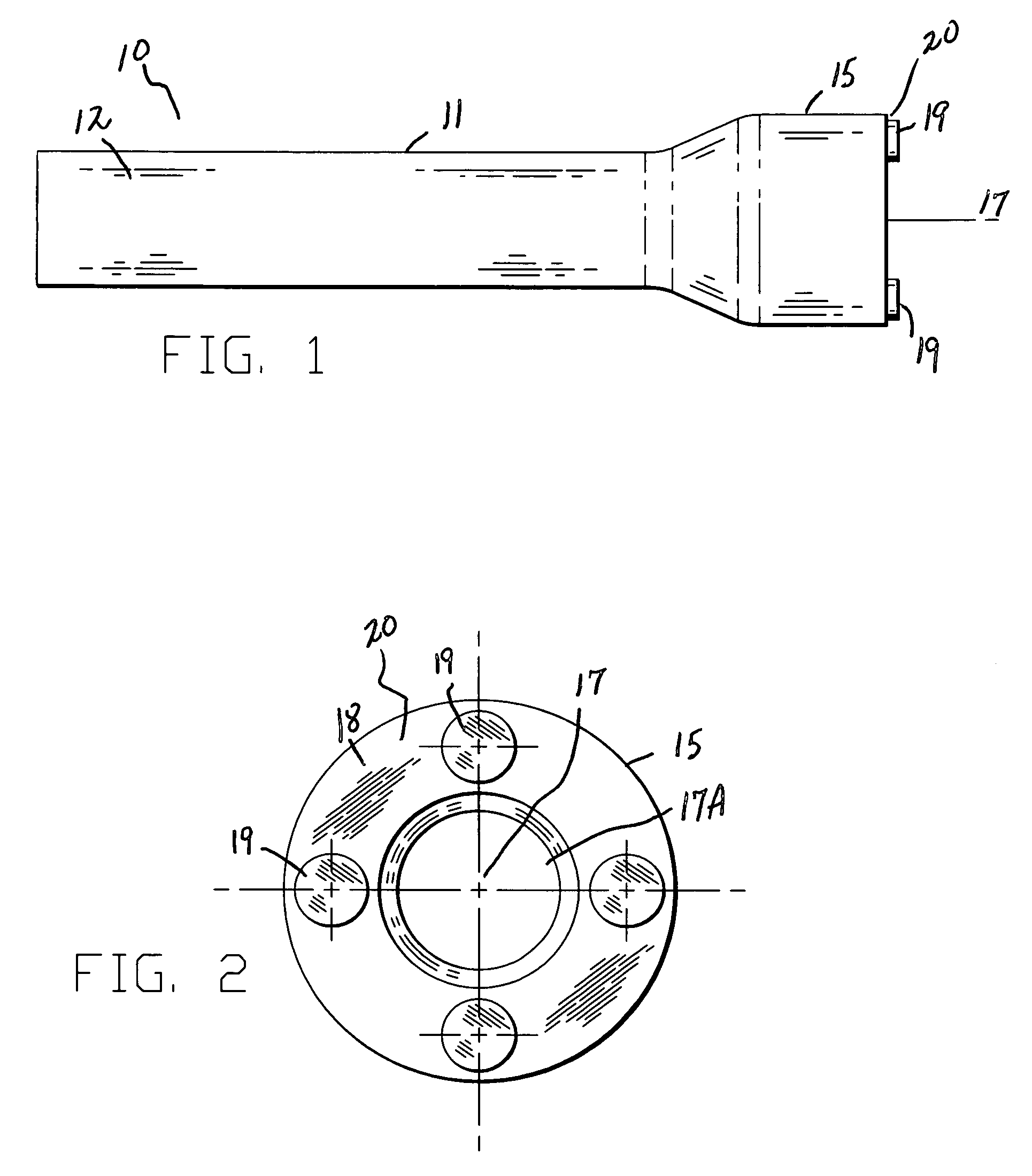

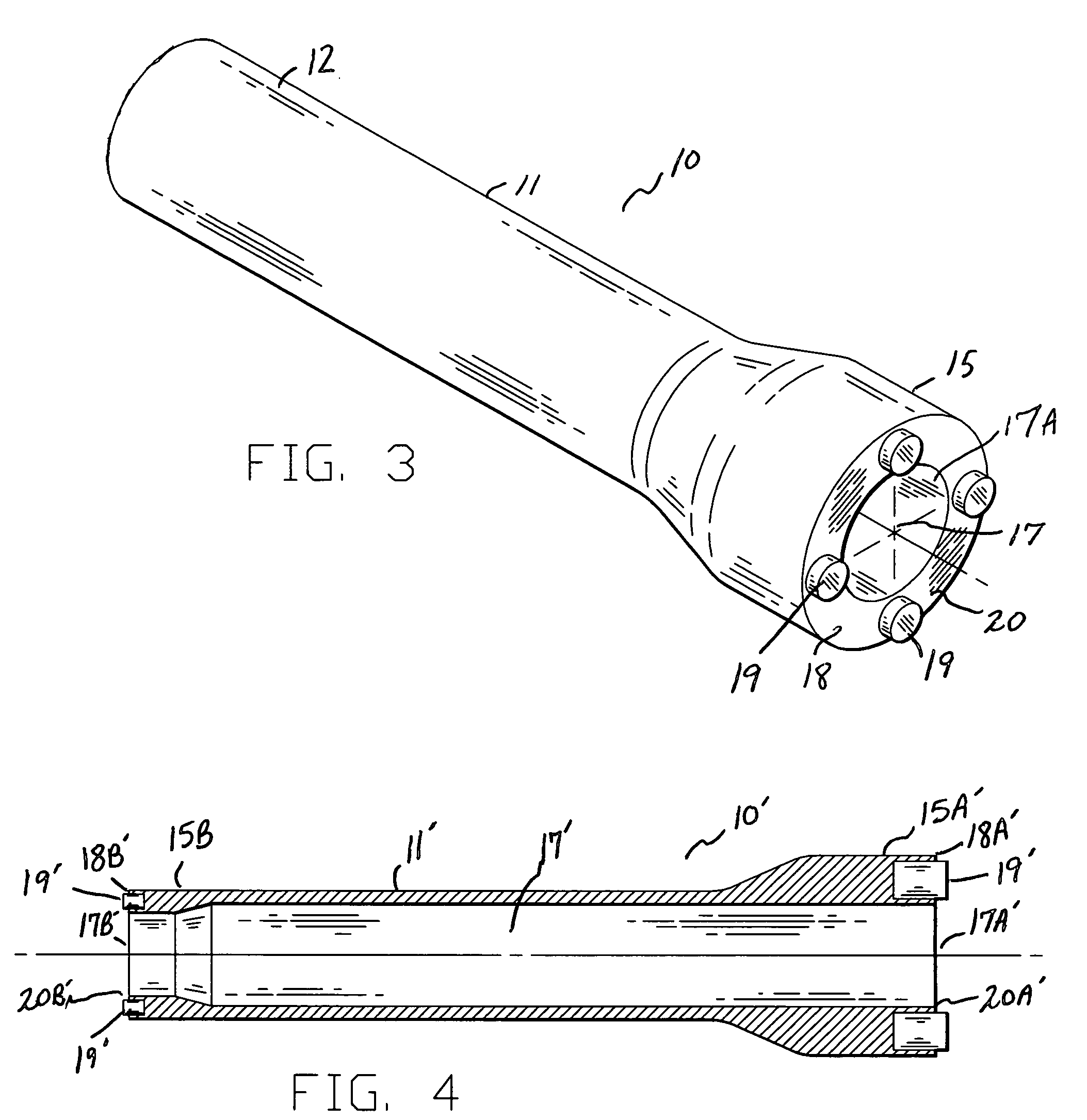

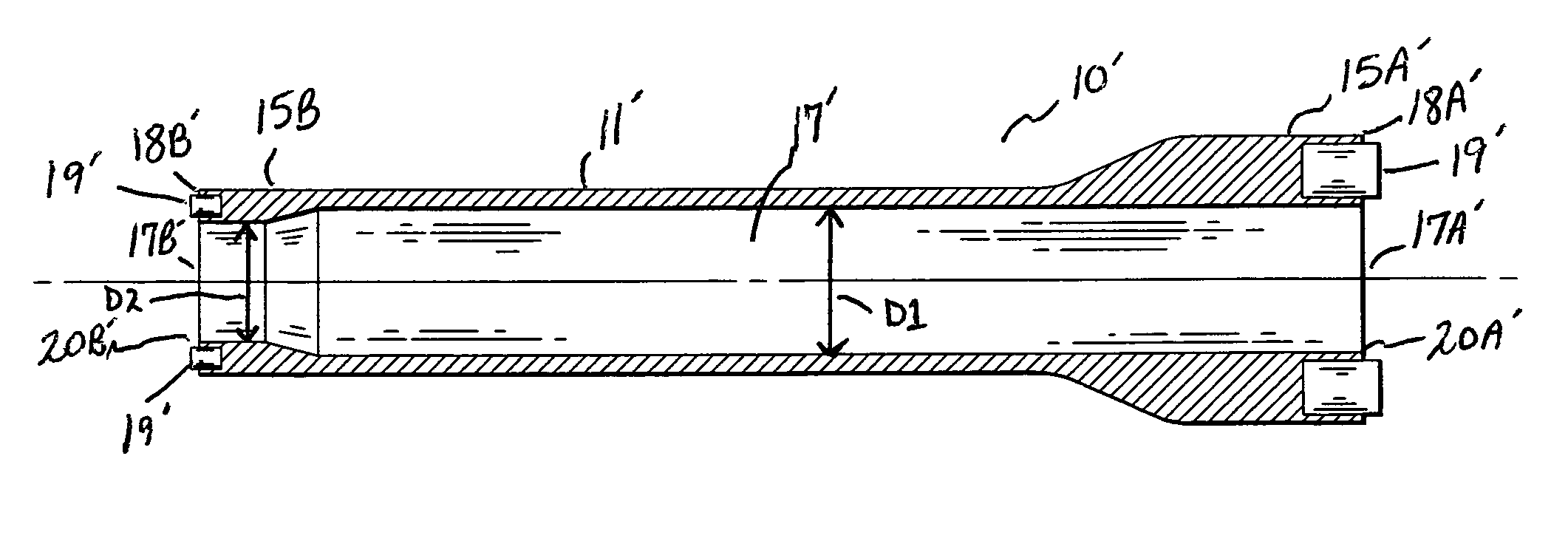

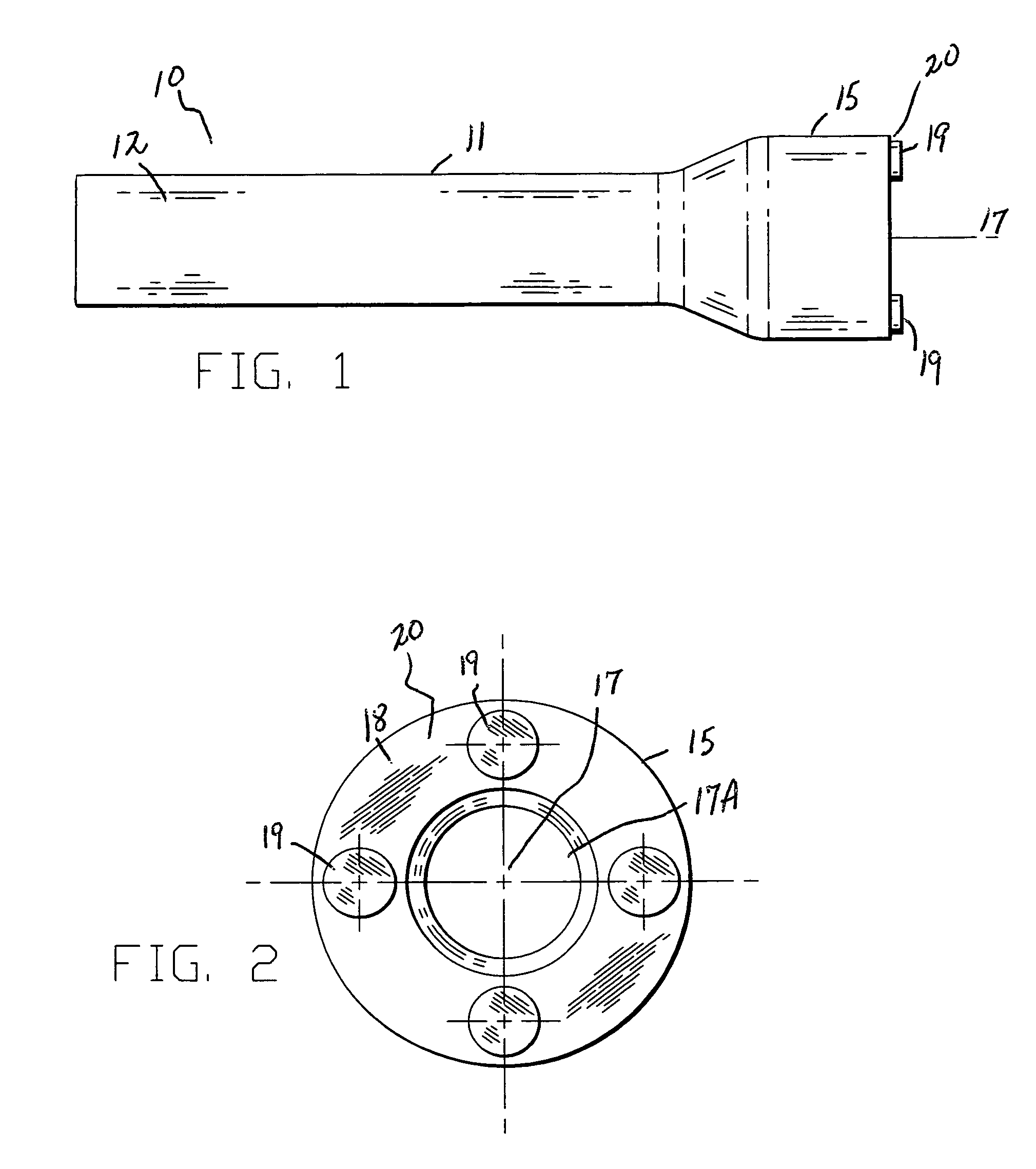

Magnetic cylinder head washer removal tool

InactiveUS20100037442A1Difficult to manipulateEasy to disassembleWork treatment devicesWork holdersValve jobCylinder head

A removal tool for removing washers located on each cylinder head stud when performing a valve job on an automobile engine. The removal tool includes a cylindrical body having a handle portion and a washer removal end opposite the handle. The cylindrical body includes a central bore that extends the axial length of the body. The removal end includes an end surface having at least one embedded magnet member and defines a pickup surface for use in attracting and securing the easy removal of automotive cylinder head stud washers and automotive cylinder head valve spring spacers valve from the cylinder head.

Owner:BRANON TIMOTHY J

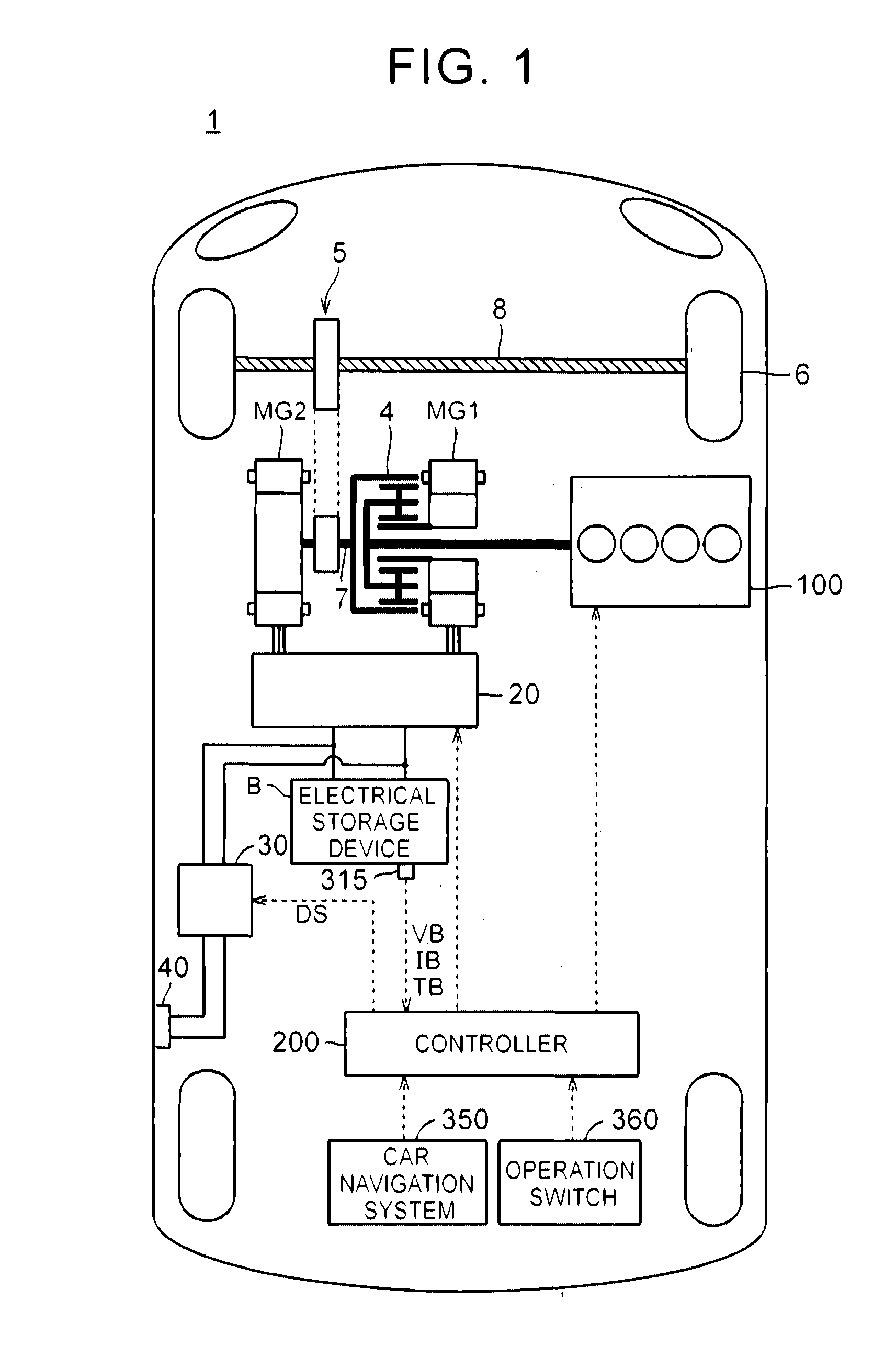

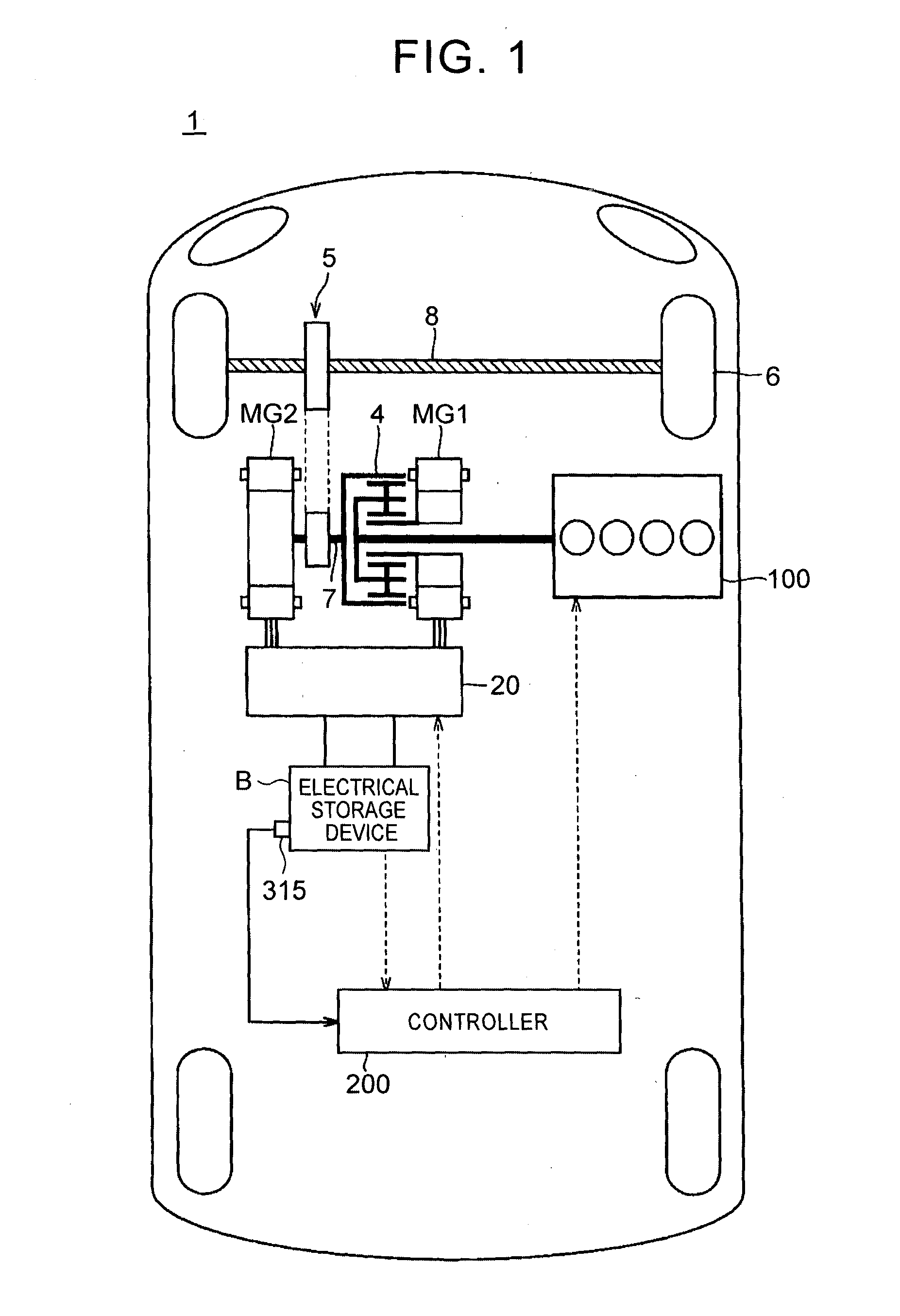

Hybrid vehicle, controller for a variable valve timing (lift and/or angle) device for the combustion engine of the hybrid vehicle, and control method for such hybrid vehicle

InactiveUS20160252069A1Raise priorityCharacteristic suppressionHybrid vehiclesValve arrangementsCombustionValve job

A hybrid vehicle includes a rotary electric machine, an internal combustion engine, and a controller. The rotary electric machine generates driving force for the hybrid vehicle. The internal combustion engine includes a variable valve actuating device configured to change an operation characteristic of an intake valve. The controller controls travel of the vehicle by selectively applying one of a first driving mode and a second driving mode. The controller controls the variable valve actuating device such that at least one of a valve lift of the intake valve and a valve operating angle of the intake valve at start-up of the internal combustion engine when the first driving mode is selected is smaller than the corresponding at least one of the valve lift of the intake valve and the valve operating angle of the intake valve at start-up of the internal combustion engine when the second driving mode is selected.

Owner:TOYOTA JIDOSHA KK

Magnetic cylinder head washer removal tool

A removal tool for removing washers located on each cylinder head stud when performing a valve job on an automobile engine. The removal tool includes a cylindrical body having a handle portion and a washer removal end opposite the handle. The cylindrical body includes a central bore that extends the axial length of the body. The removal end includes an end surface having at least one embedded magnet member and defines a pickup surface for use in attracting and securing the easy removal of automotive cylinder head stud washers and automotive cylinder head valve spring spacers valve from the cylinder head.

Owner:BRANON TIMOTHY J

Timing chain lubricating structure for engine

InactiveUS20020035983A1Reduce in quantityWell formedLubrication of auxillariesValve drivesValve jobCylinder head

Sprockets are fixed to ends of camshafts supported in a cylinder head via camshaft holders. A timing chain is wrapped around these sprockets. The relief oil from a hydraulic control valve for controlling a variable valve operating characteristic mechanism passes through an oil passage formed in the plane in which the cylinder head and the camshaft holder are joined and flows out of an oil drain hole, thus lubricating the section where the sprocket is meshed with the timing chain. The section where the sprocket of the camshaft is meshed with the timing chain can thereby be lubricated reliably by a simple structure.

Owner:HONDA MOTOR CO LTD

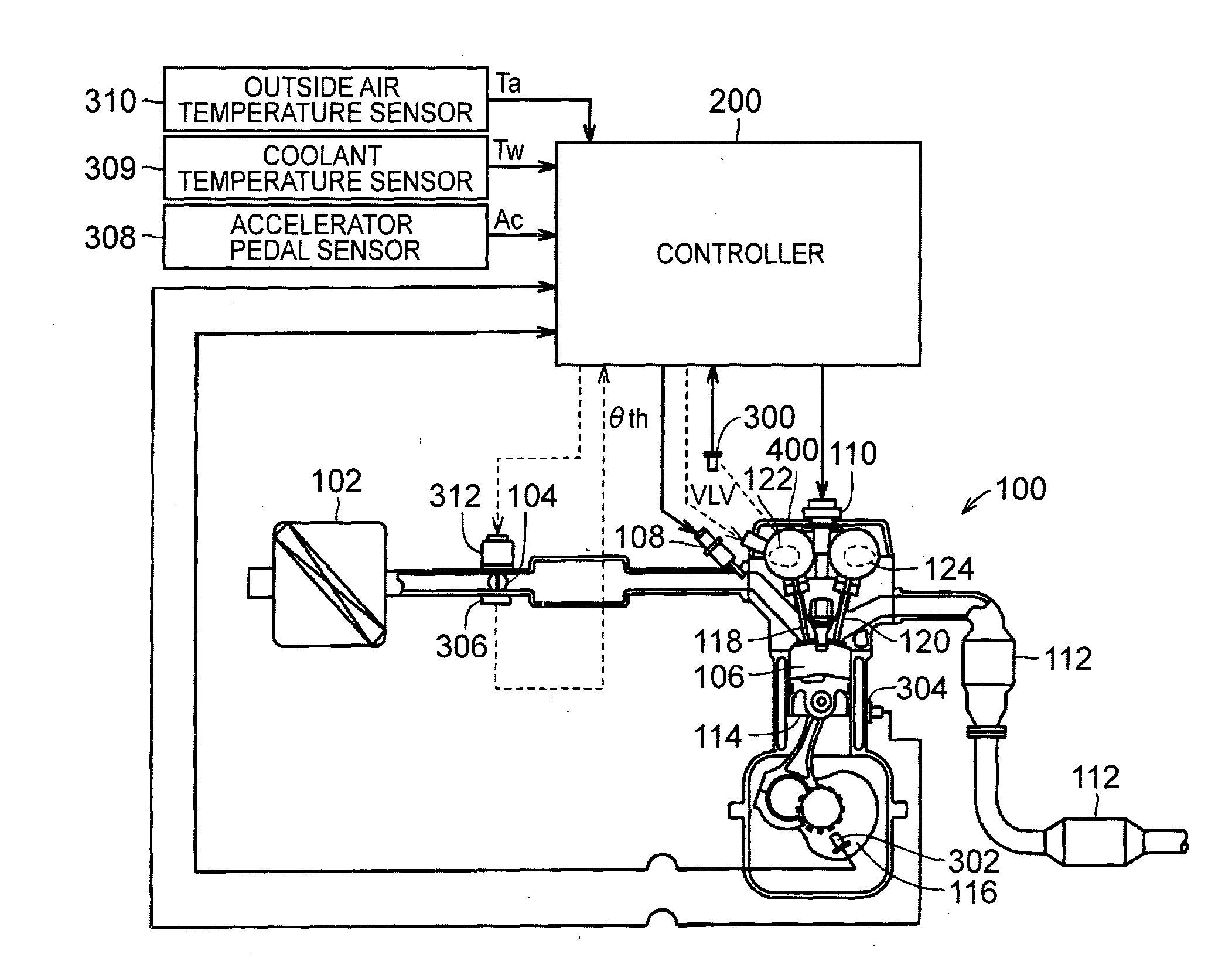

Control apparatus and control method of internal combustion engine

InactiveUS20040129250A1Electrical controlInternal combustion piston enginesValve jobExternal combustion engine

In an internal combustion engine provided with a variable valve mechanism that varies a valve operating characteristic (valve lift amount and valve operating angle) of an intake valve, the valve operating characteristic of the intake valve is detected and an intake air amount controlled by the intake valve is calculated based on the detected valve operating characteristic. Then, a change (change rate, change amount) between the newest intake air amount calculation value and a past intake air amount calculation value is calculated, and the newest engine controlled variable is calculated based on the change and engine controlled variable (basic fuel injection quantity and the like) set in the past, and then the calculated newest engine controlled variable is output for executing an engine control.

Owner:HITACHI LTD

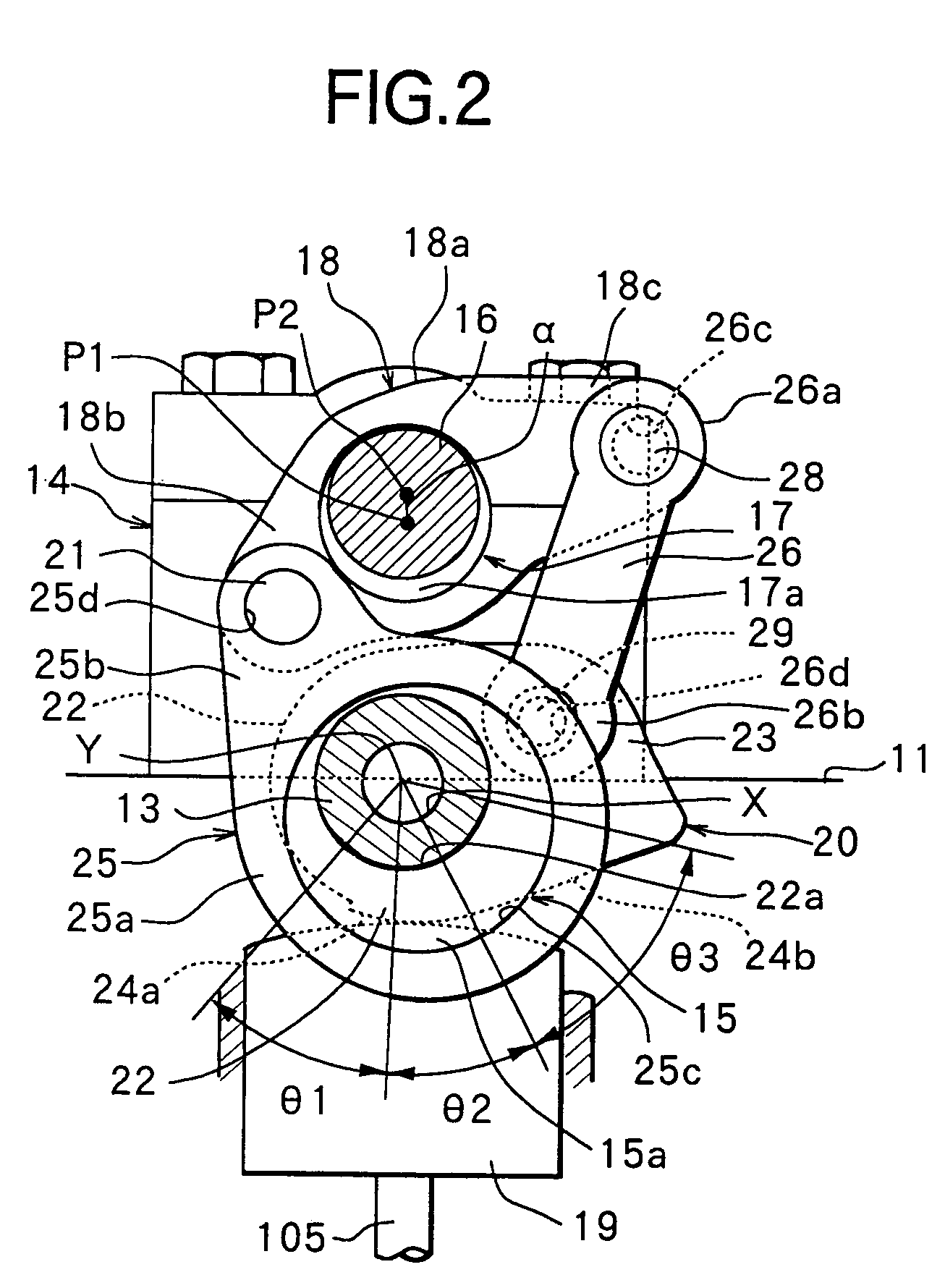

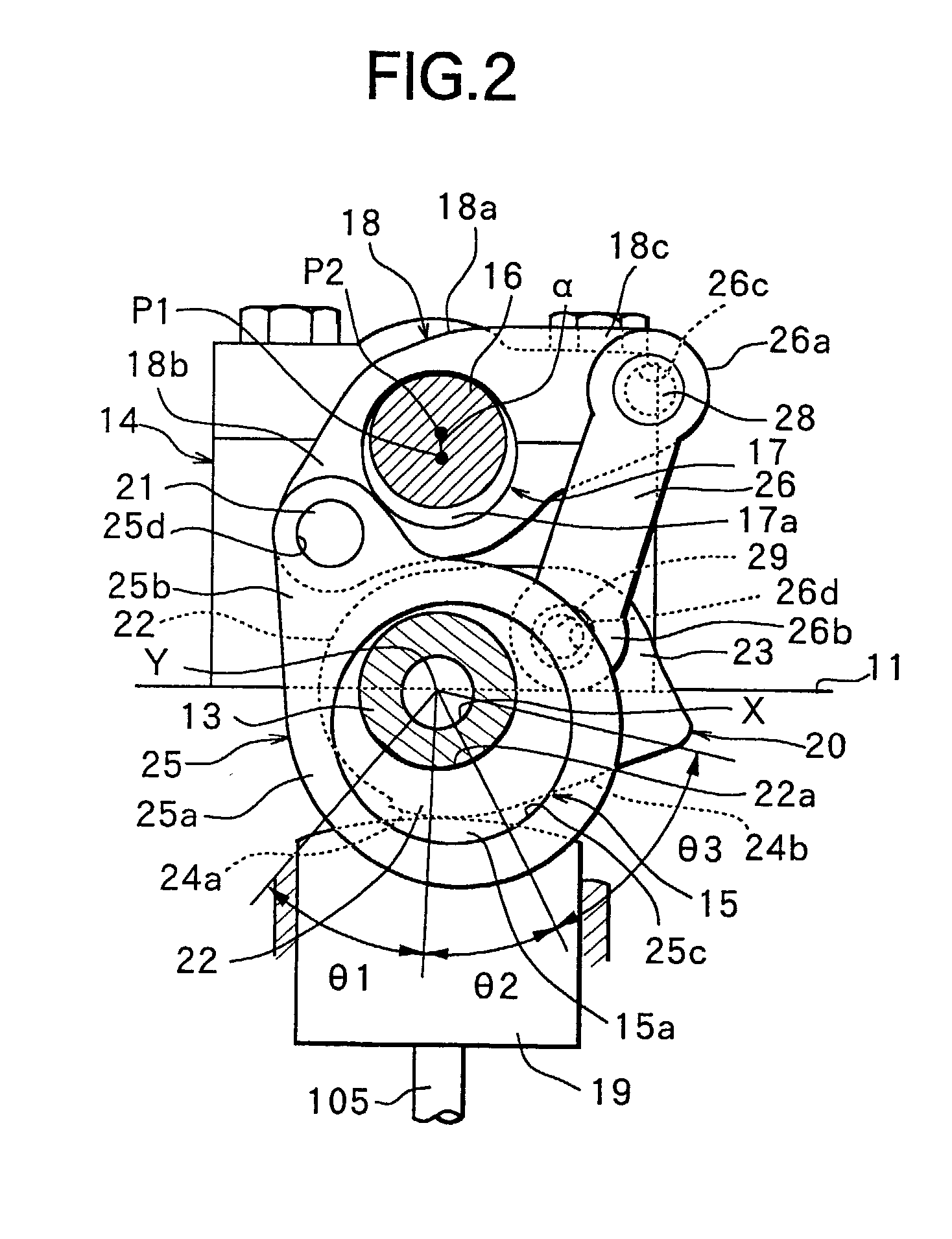

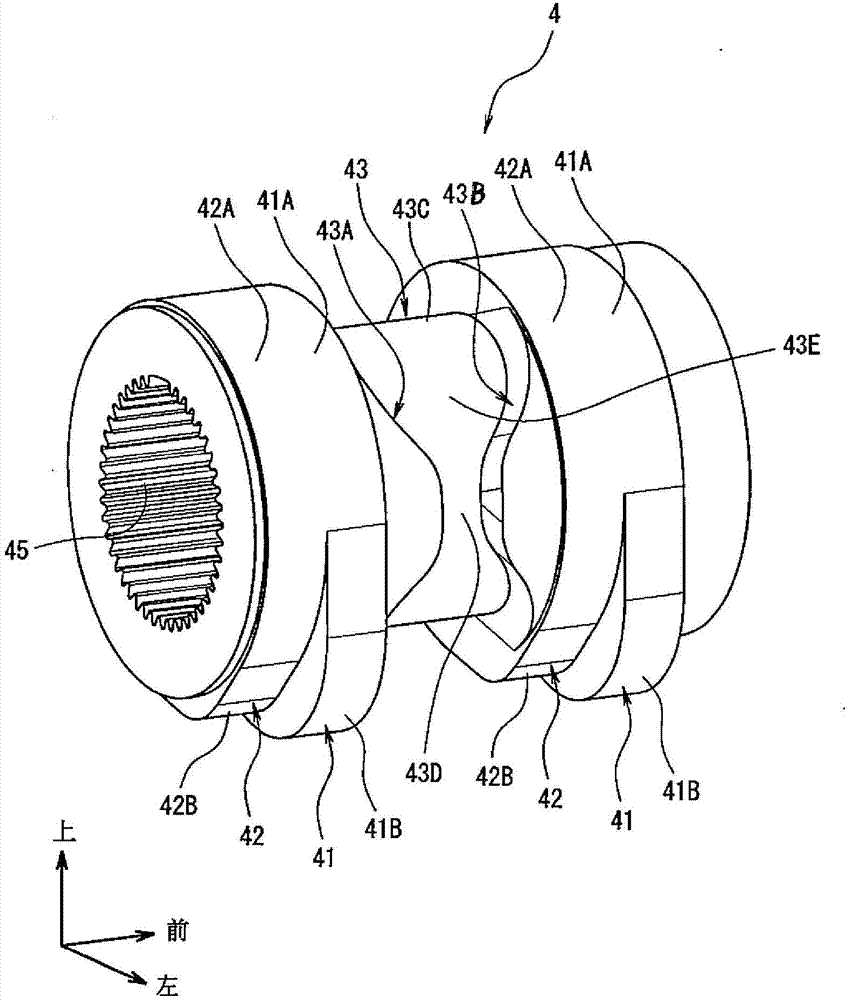

Variable valve device of internal combustion engine

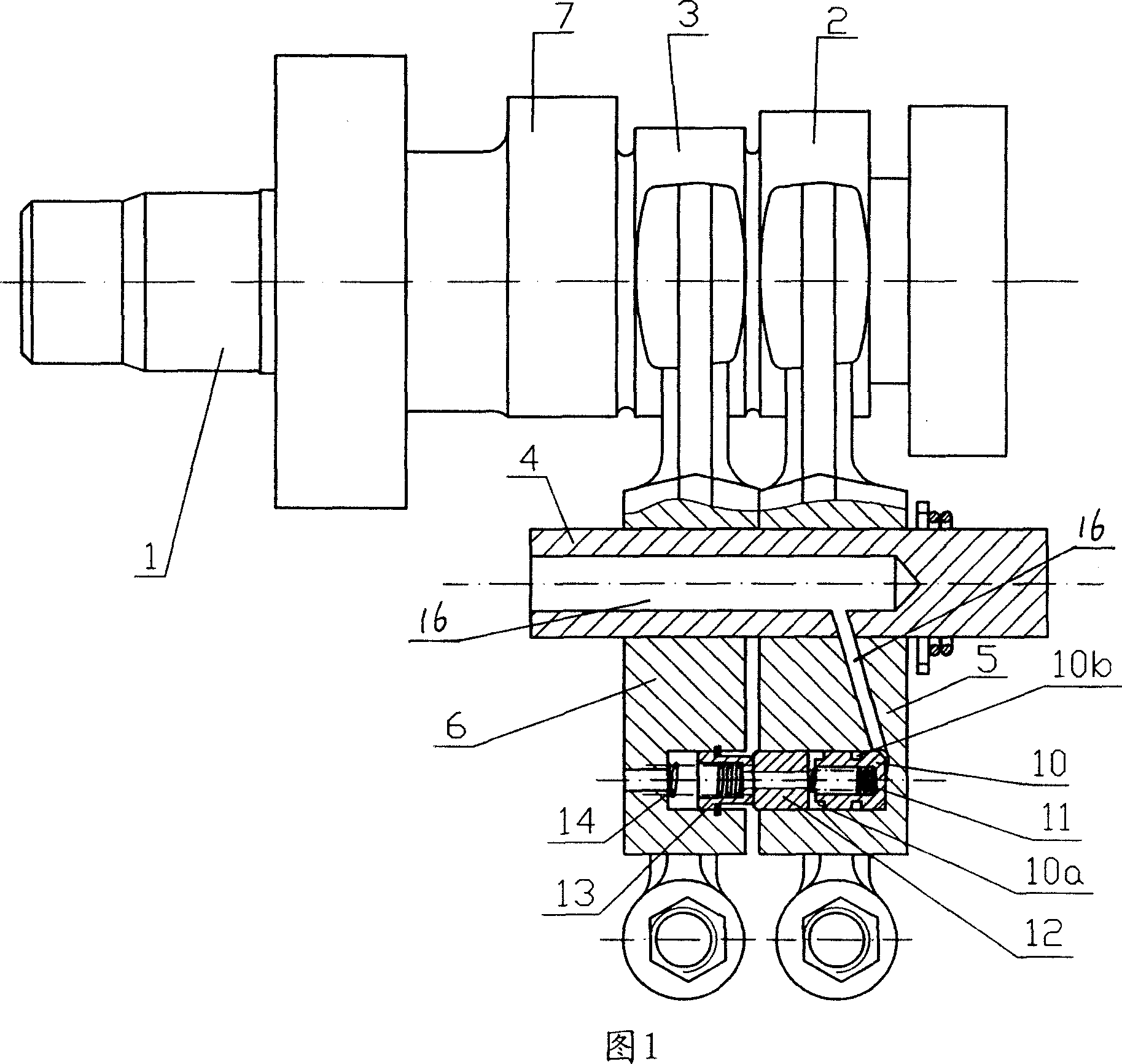

InactiveCN104514589ASimple structureSimplify working methodsValve arrangementsMachines/enginesLow speedValve job

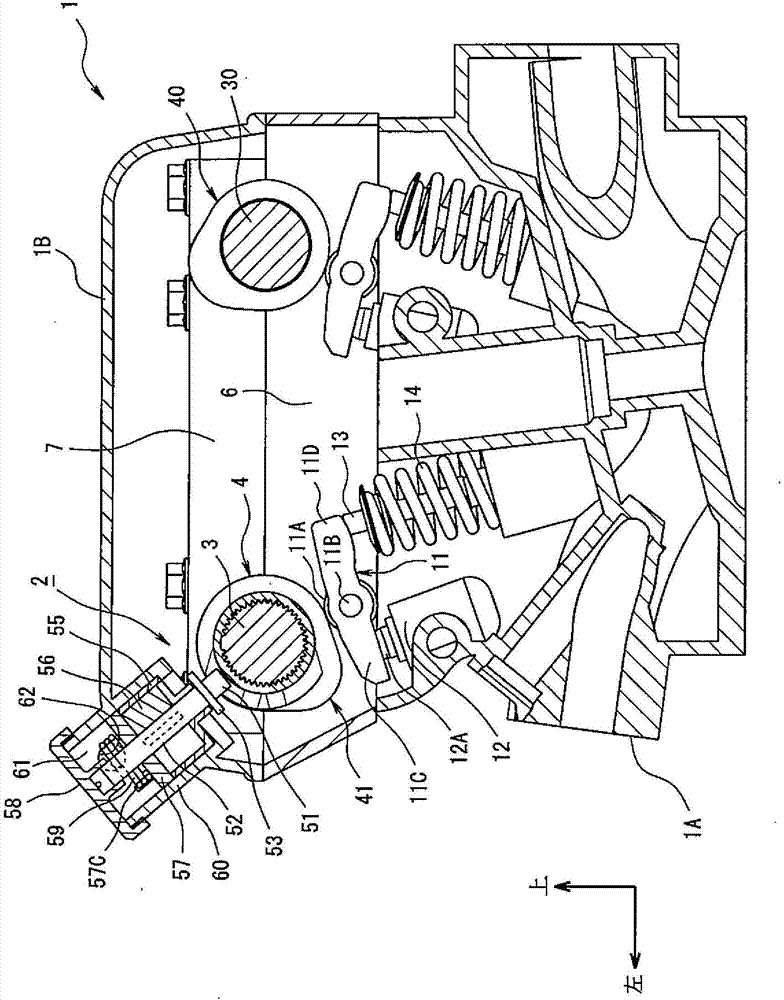

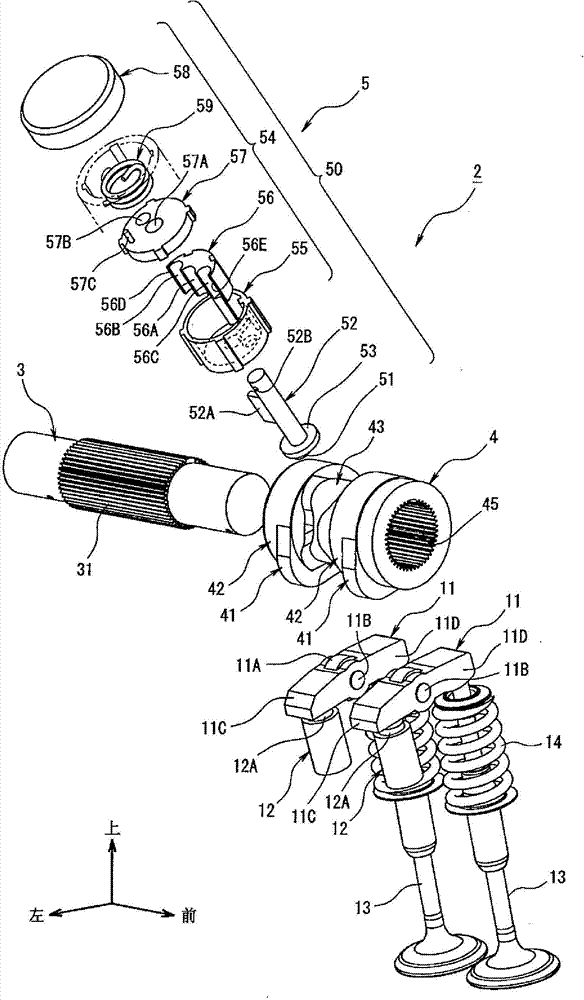

Provided is a variable valve device of an internal combustion engine, and structure and working method of the device are simplified. The device is provided with a cam support (4) and a cam switchover portion (5). The cam support (4) makes the valve operate to move to a first position through a high-speed cam (41) and makes the valve operate to move to a second position through a low-speed cam (42). The outer peripheral surface of the device is provided with a guide groove (43). The guide groove (43) is provided with a pair of opposite side walls. One of the pair of side walls is a first switchover cam (43A) which makes the cam support (4) move to the first position, and the other is a second switchover cam (43B) which makes the cam support (4) move to the second position. The cam switchover portion is provided with a switchover pin (51) which is inserted into the guide groove (43), and a driving portion (50) which makes the switchover pin (51) move to a first pin position or a second pin position on an axial direction of a cam shaft (3), in the first pin position, the switchover pin can contact with the first switchover cam (43A), and in the second pin position, the switchover pin can contact with the second switchover cam (43B).

Owner:SUZUKI MOTOR CORP

Variable valve actuating apparatus for internal combustion engine

InactiveUS7789051B2Improve performanceImprove startabilityValve arrangementsOutput powerValve jobVariable valve timing

Owner:HITACHI ASTEMO LTD

Idle speed controller for internal combustion engine

InactiveUS20060086338A1Avoid it happening againValve arrangementsElectrical controlIdle speed controlValve job

An idle speed controller for an internal combustion engine provided with an intake variable valve timing mechanism for varying valve timing and a variable working angle for varying a valve working angle of an intake valve. The controller performs idle speed control. When an advancement failure occurs in the intake variable valve timing mechanism, the controller performs idle-up control to increase the target idle speed. When the valve working angle of the intake variable working angle mechanism is less than a predetermined value, the electronic control unit changes an increase amount of the target idle speed to a lower value if an advancement failure occurs when performing the idle-up as compared to when the valve working angle is greater than the predetermined value.

Owner:TOYOTA JIDOSHA KK

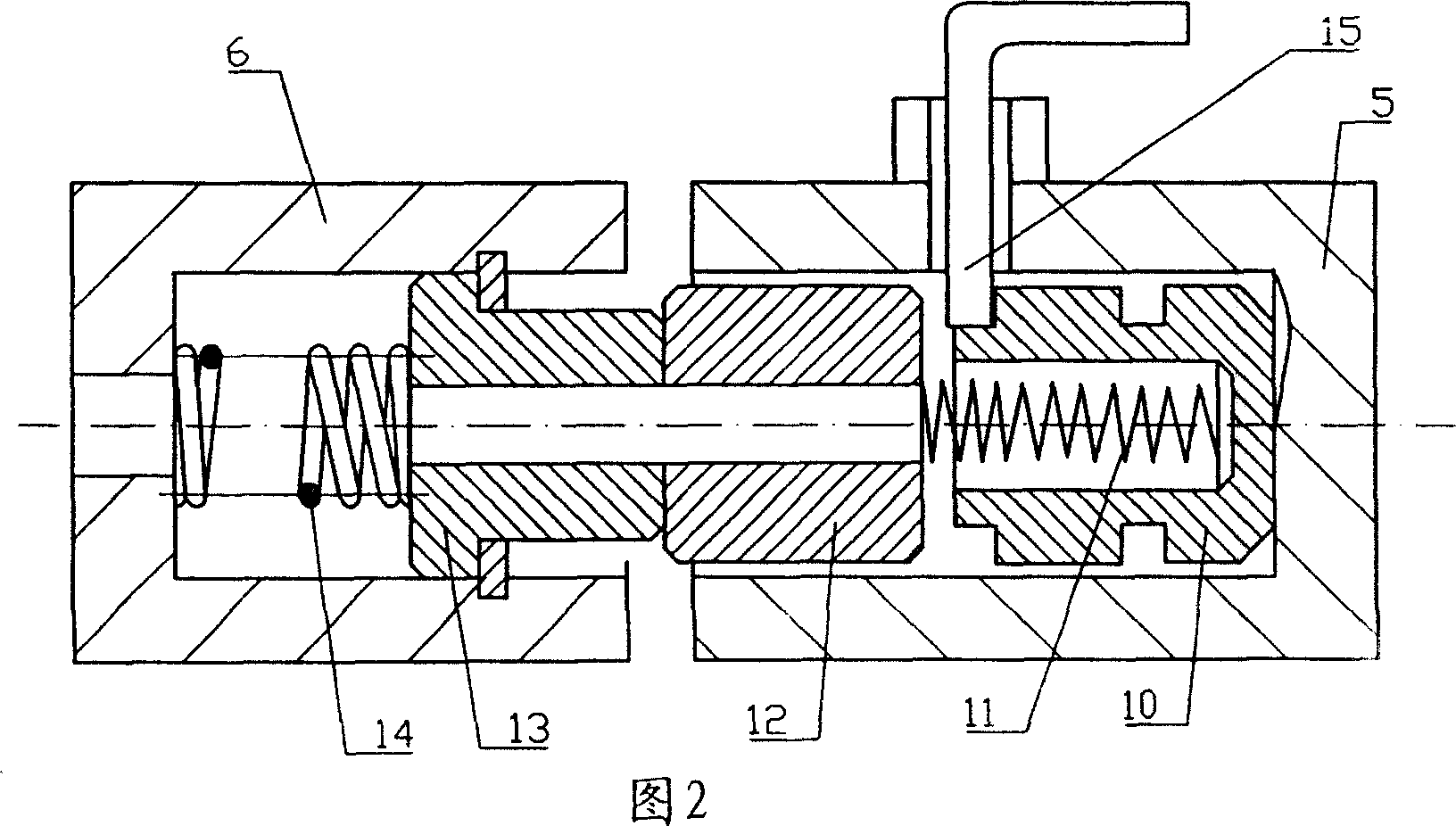

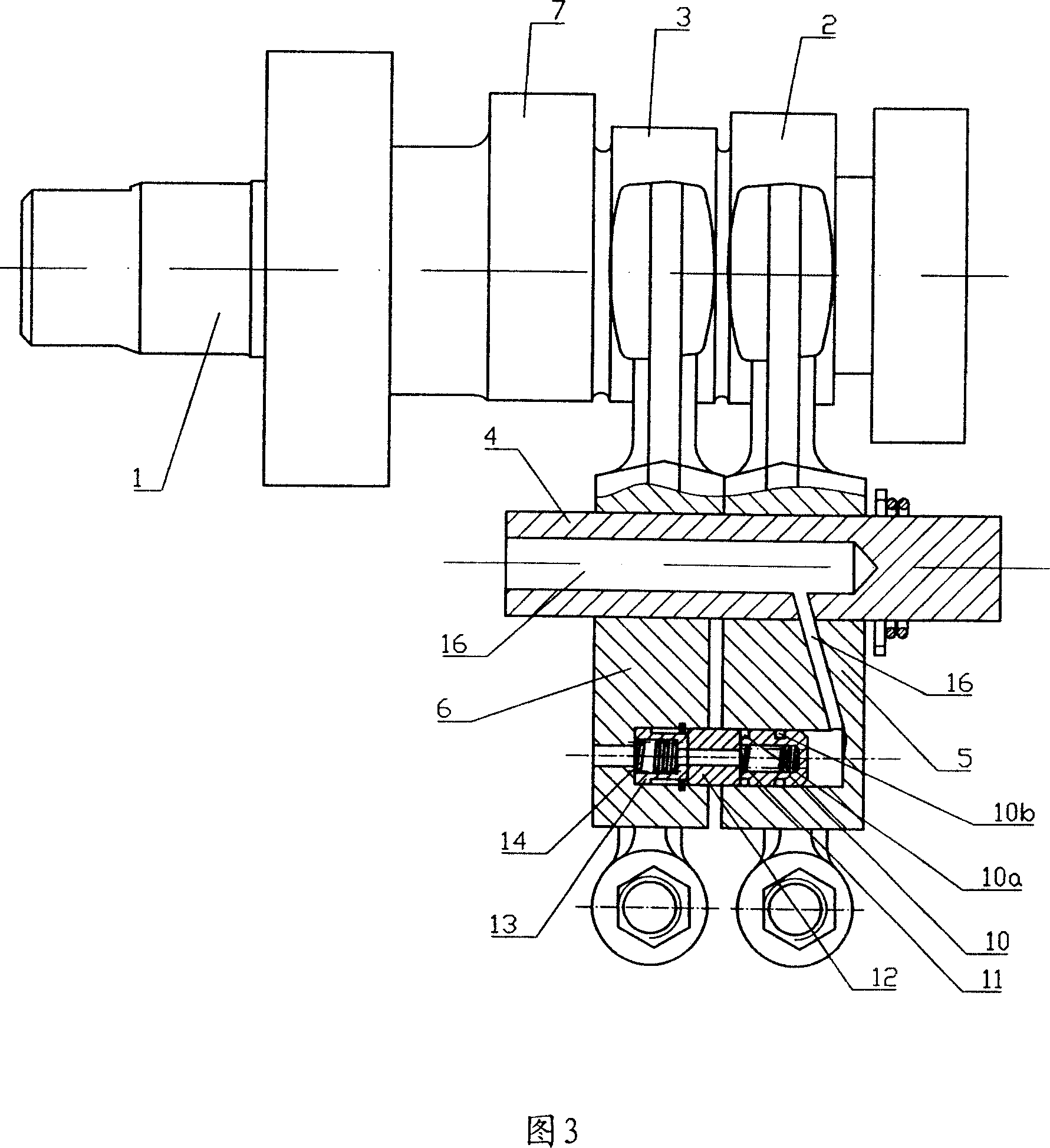

Three air valve motorcycle motor variable air inlet valve air distribution device

InactiveCN1948721AImprove powerImprove economyValve arrangementsMachines/enginesValve jobInlet valve

An admission device with the variable intake valve of the three-valve motorcycle engine is provided in the invention. The exhaust cam (7), the main inlet cam (2) and the inlet Idler (3) are on the camshaft (1), the line of the inlet Idler (3) is the entire round, its diameter is the same as the base diameter of the main inlet cam (2). The inlet rocker axis (4) has the major and the minor Inlet Rocker (5, 6). The clutch device composed of the initiative piston (10), the spacing spring (11), the switching piston (12), the blocking piston(13), the blocking Spring (14) and the lock sheet is between the major and the minor Inlet Rocker(5,6). According to the engine speed and load condition, the engine can switch between the single-intake valve and double-valve modes automatically. So it can increase the power, economy and emission characteristic in the whole speed and loading condition scope of the motorcycle. The whole structure is simple and contract, it has a small change to the original admission device.

Owner:CHONGQING UNIV

Apparatus and method for controlling internal combustion engine

This invention relates to a method for controlling the motor by controlling the air input, characterized in that: in the combustion engine with changeable air gate mechanism, checking the operation characteristics of air input gate, and basing on the above step calculating the air input controlled by air gate, then calculating the variation( change rate, change amount) between the later computational value of air input and former one, and calculating the latest engine controlling variable based on the said change and engine controlling variable set in advance, then outputting the latest engine controlling variable to execute the control of engine.

Owner:HITACHI LTD

Control apparatus and control method of internal combustion engine

InactiveUS6843230B2Electrical controlInternal combustion piston enginesValve jobExternal combustion engine

In an internal combustion engine provided with a variable valve mechanism that varies a valve operating characteristic (valve lift amount and valve operating angle) of an intake valve, the valve operating characteristic of the intake valve is detected and an intake air amount controlled by the intake valve is calculated based on the detected valve operating characteristic. Then, a change (change rate, change amount) between the newest intake air amount calculation value and a past intake air amount calculation value is calculated, and the newest engine controlled variable is calculated based on the change and engine controlled variable (basic fuel injection quantity and the like) set in the past, and then the calculated newest engine controlled variable is output for executing an engine control.

Owner:HITACHI LTD

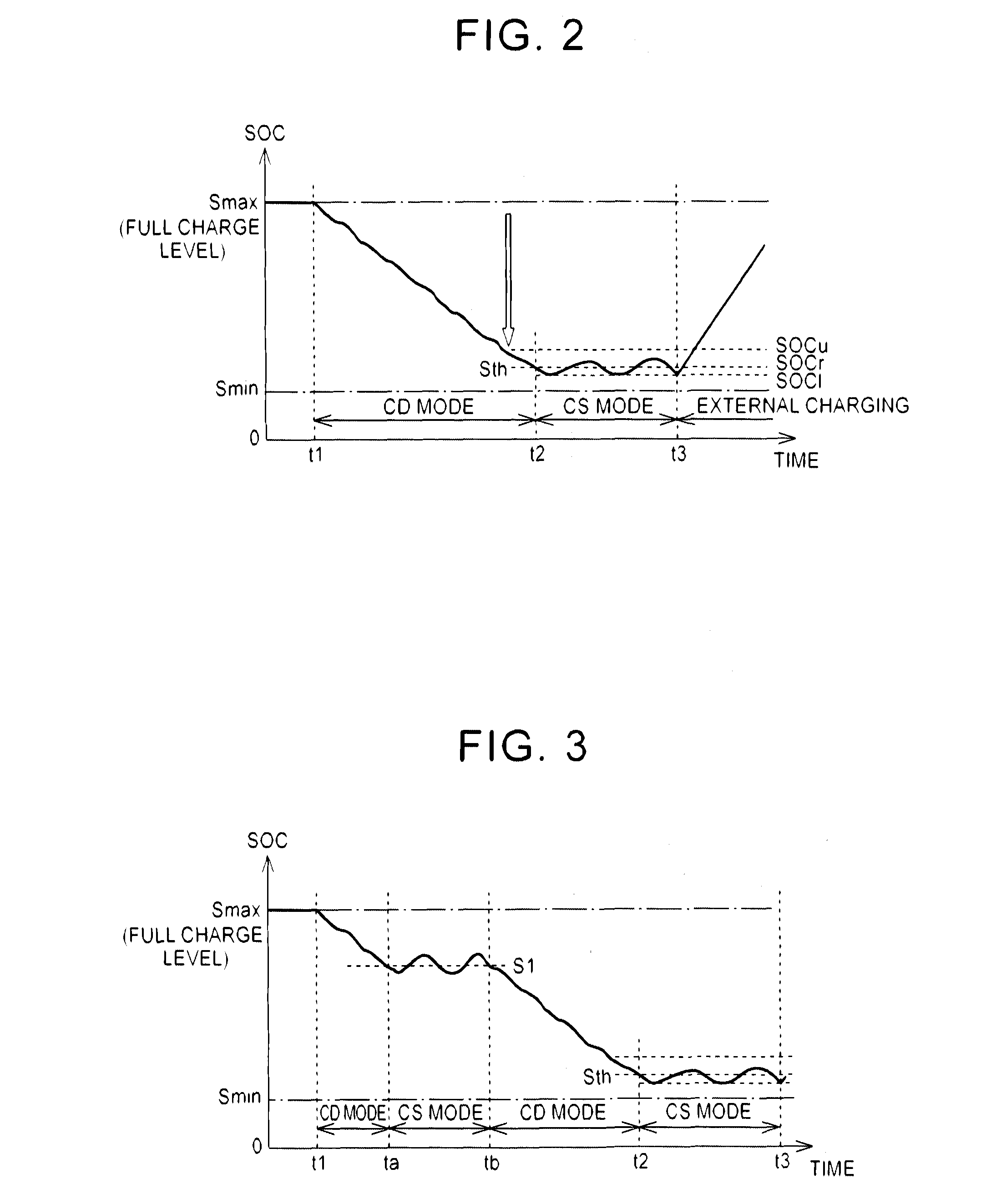

Hybrid vehicle, controller for hybrid vehicle, and control method for hybrid vehicle for reducing the compression ratio at start-up of the engine according a battery level

InactiveUS20160244064A1Difficult is not experiencedReduce vibrationHybrid vehiclesOutput powerValve jobElectrical battery

A hybrid vehicle includes an internal combustion engine, a rotary electric machine, an electrical storage device, and a controller. The internal combustion engine includes a variable valve actuating device configured to change an operation characteristic of an intake valve. The rotary electric machine is configured to start up the internal combustion engine. The electrical storage device is configured to store electric power for driving the rotary electric machine. The controller is configured to control the variable valve actuating device such that at least one of a valve lift of the intake valve and a valve operating angle of the intake valve at start-up of the internal combustion engine when performance of the electrical storage device is in a second state is smaller than the corresponding at least one of the valve lift of the intake valve and the valve operating angle of the intake valve at start-up of the internal combustion engine when the performance of the electrical storage device is a first state. The performance of the electrical storage device in the second state is more limited than the performance of the electrical storage device in the first state.

Owner:TOYOTA JIDOSHA KK

Control method of internal combustion engine

The invention provides a control method of an internal combustion engine. A control method capable of accurately executing transient control at the time of being shifted from whole cylinder operationto partial cylinder operation and capable of preventing generation of abnormal noises at the time of executing switching operation from whole cylinder operation to the partial cylinder operation in aninternal combustion engine provided with a cylinder deactivation mechanism and a valve operation phase variable mechanism for changing an operation phase of an intake valve and / or exhaust valve is provided. A preparation control for suppressing fluctuation of an output torque of the engine at the time of executing switching operation from the whole cylinder operation to the partial cylinder operation is executed when having made a switching request from the whole cylinder operation to the partial cylinder operation. The target switching time executing the switching operation is calculated inaccordance with the valve operation phase after the preparation time is completed. The cylinder deactivation mechanism is controlled such that the switching operation is executed at the target switching time. The target switching time is set in accordance with the valve operation phase at the timing in which the abnormal noises are not generated.

Owner:HONDA MOTOR CO LTD

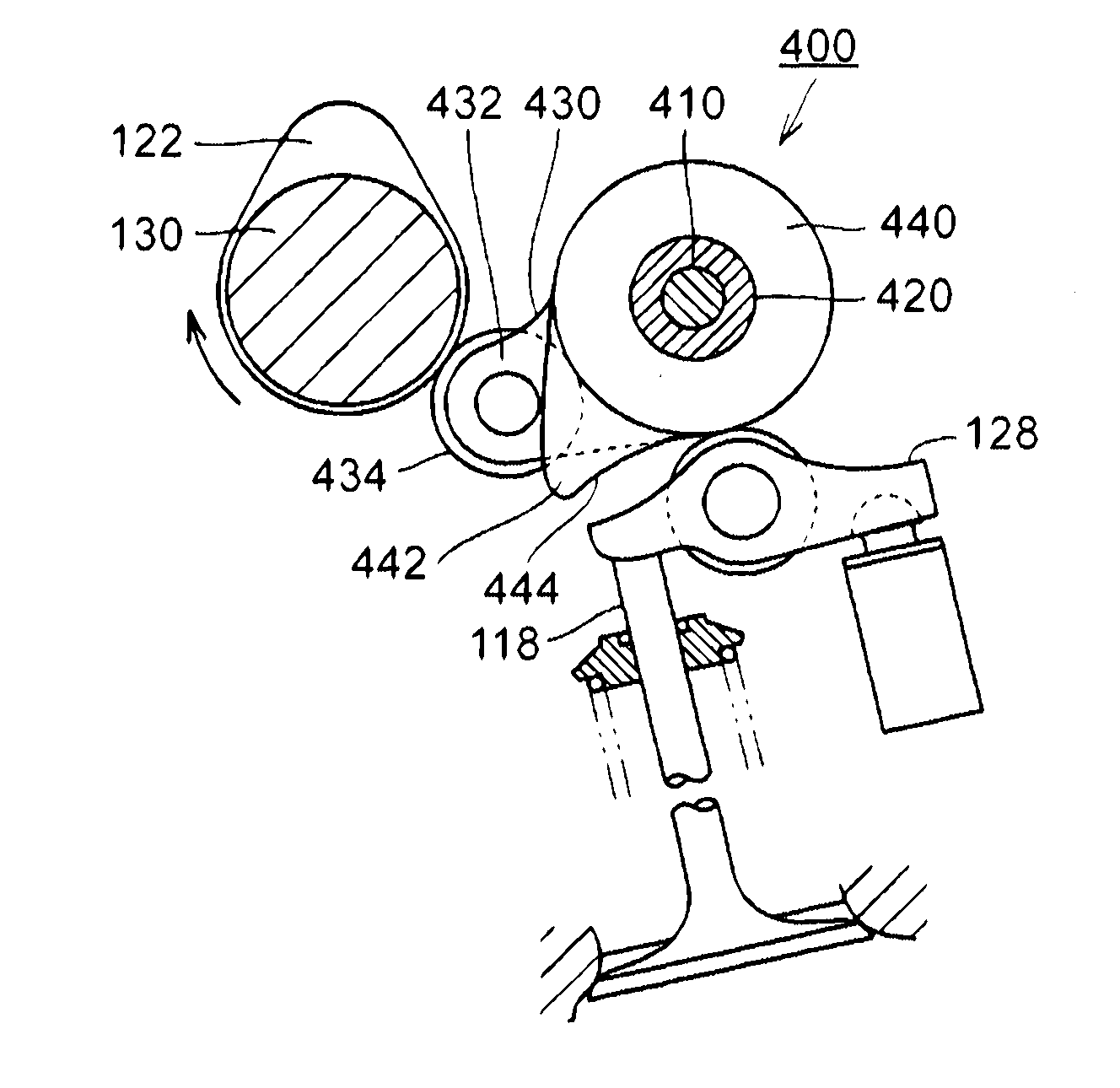

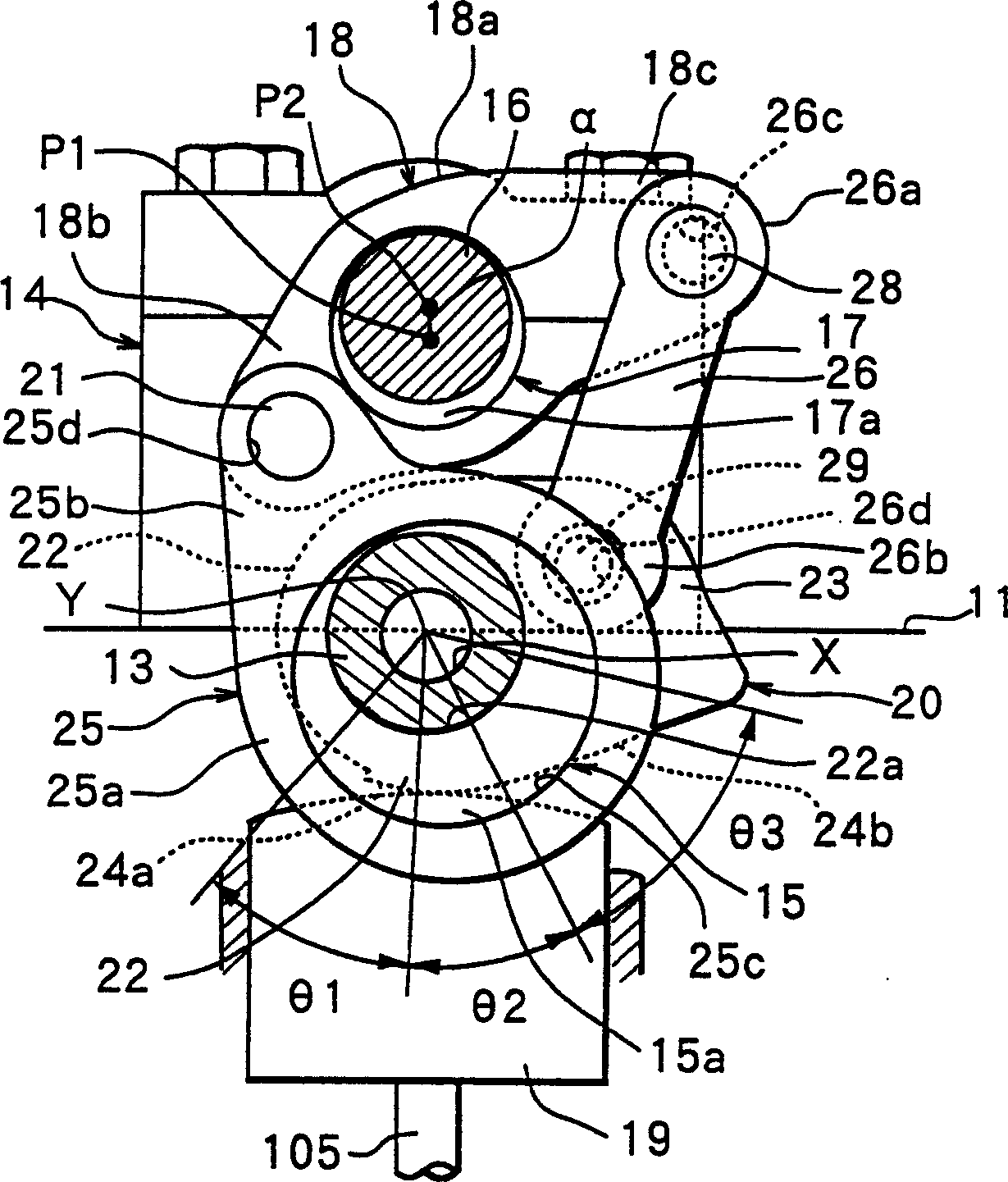

Variable valve mechanism

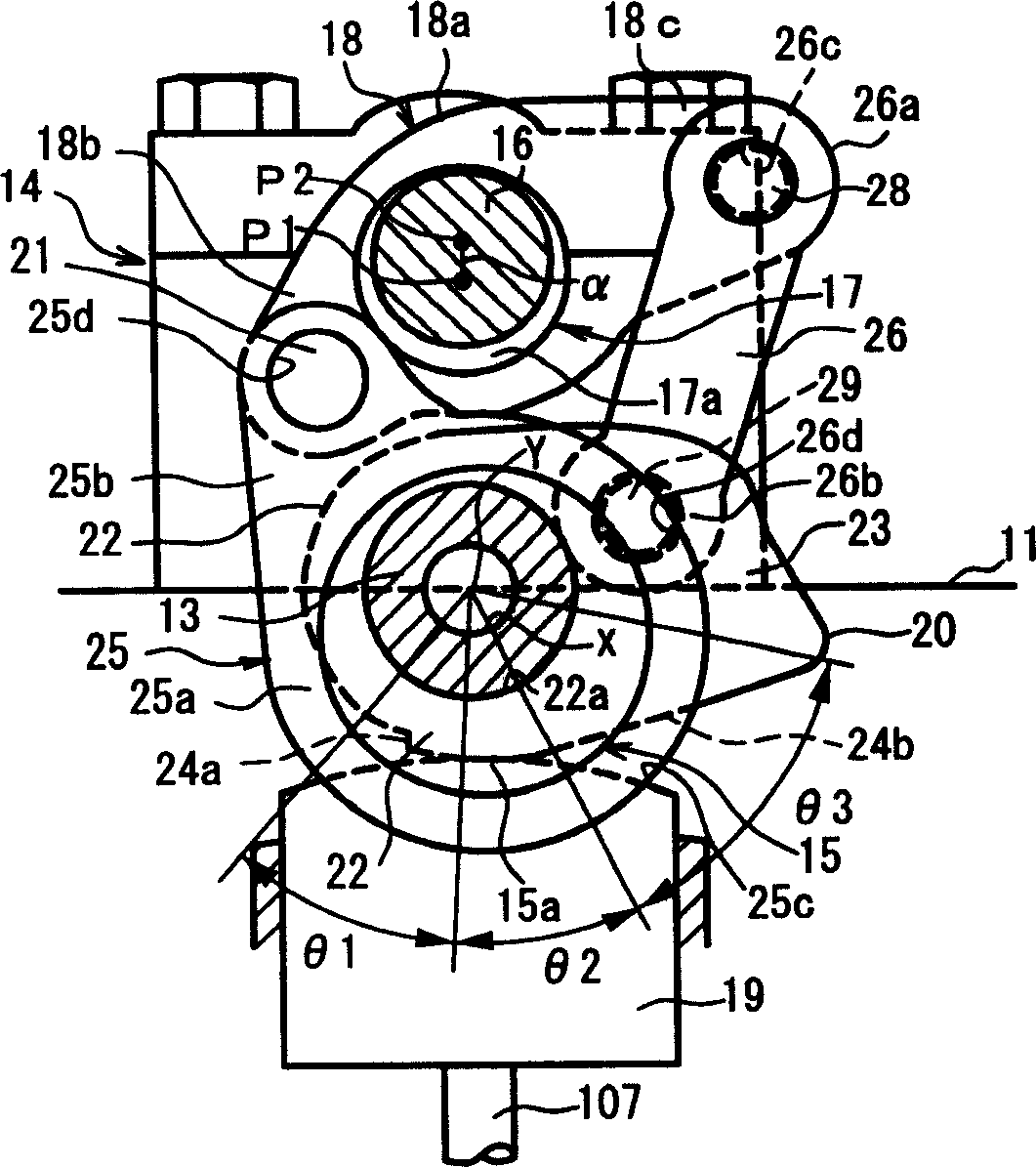

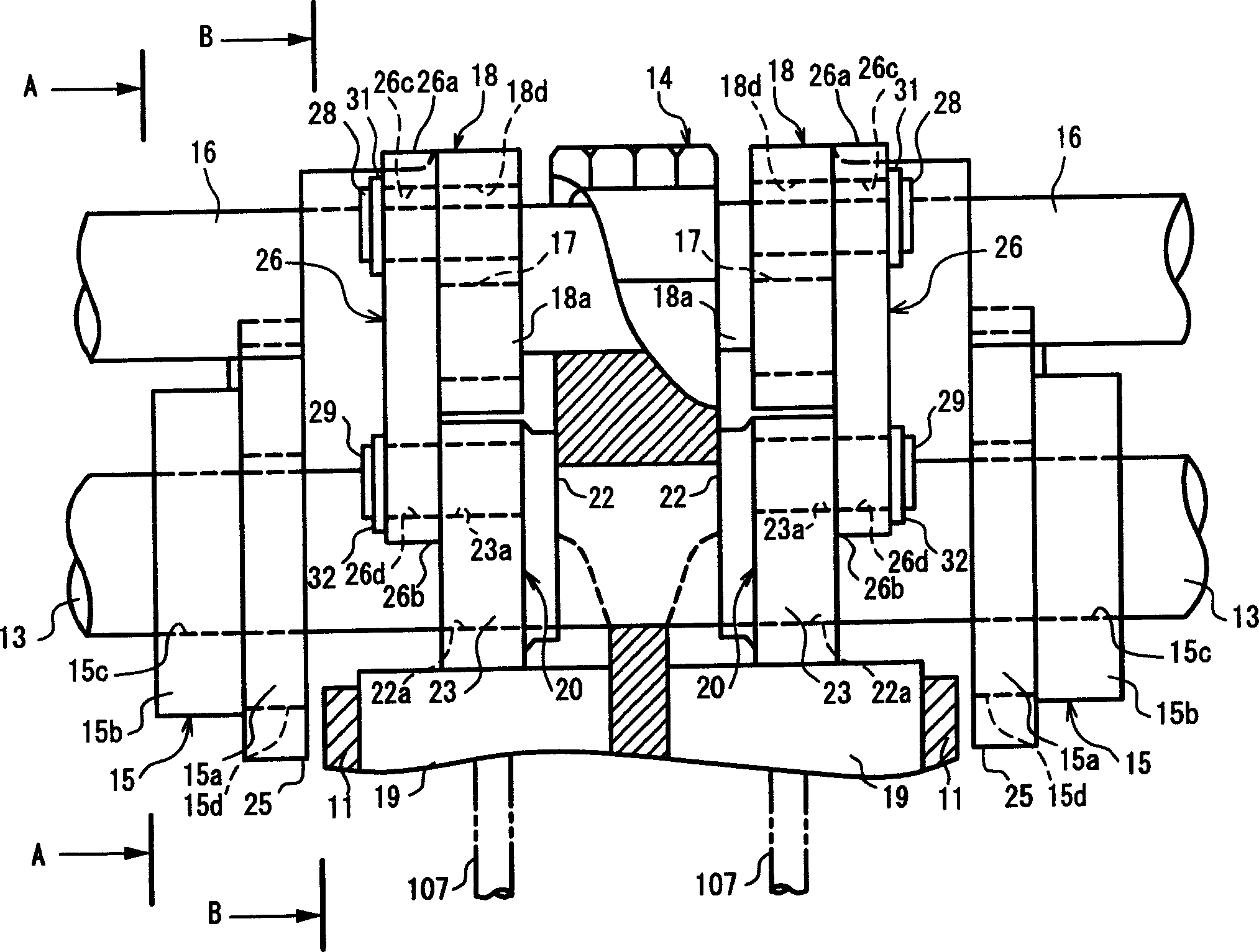

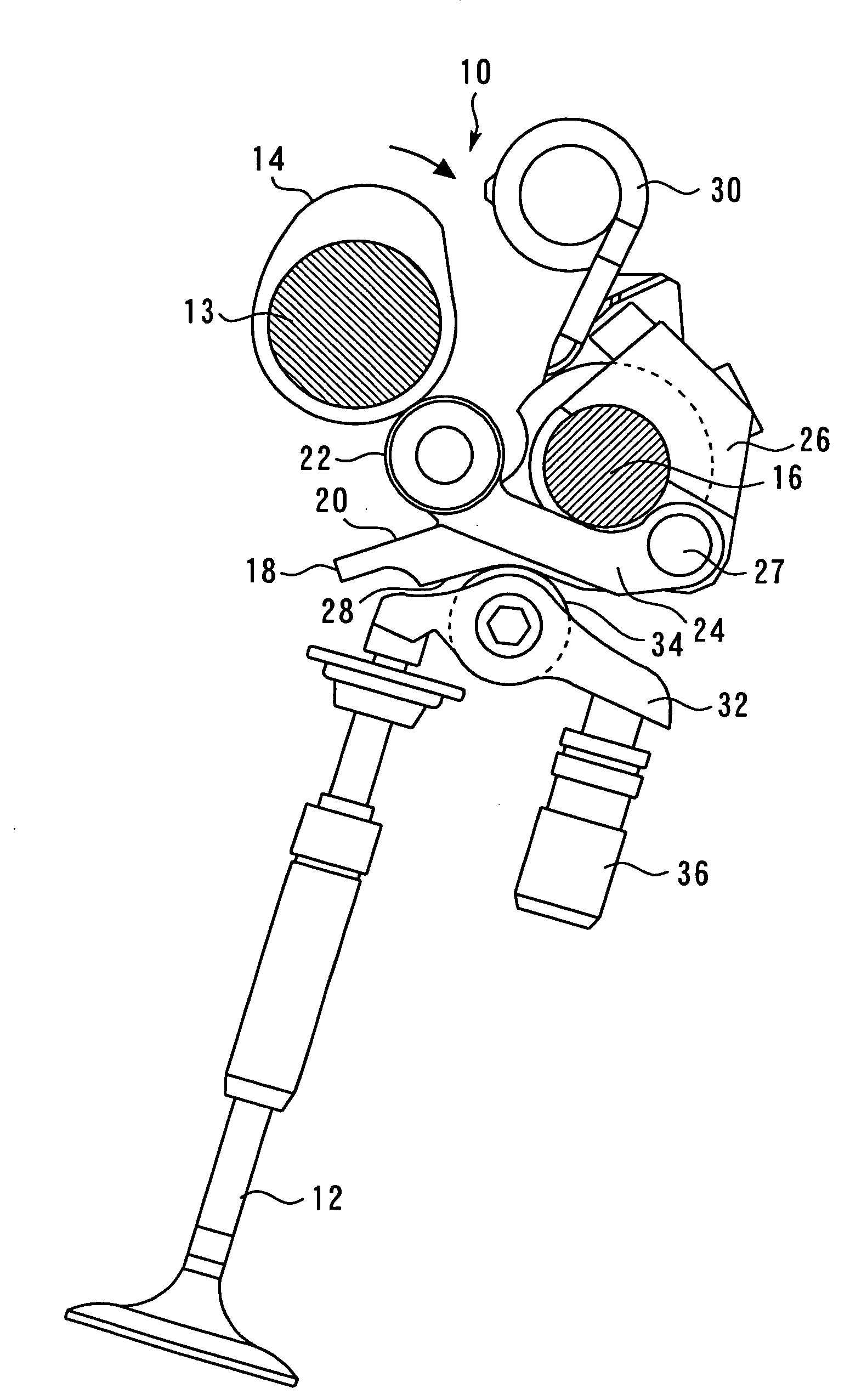

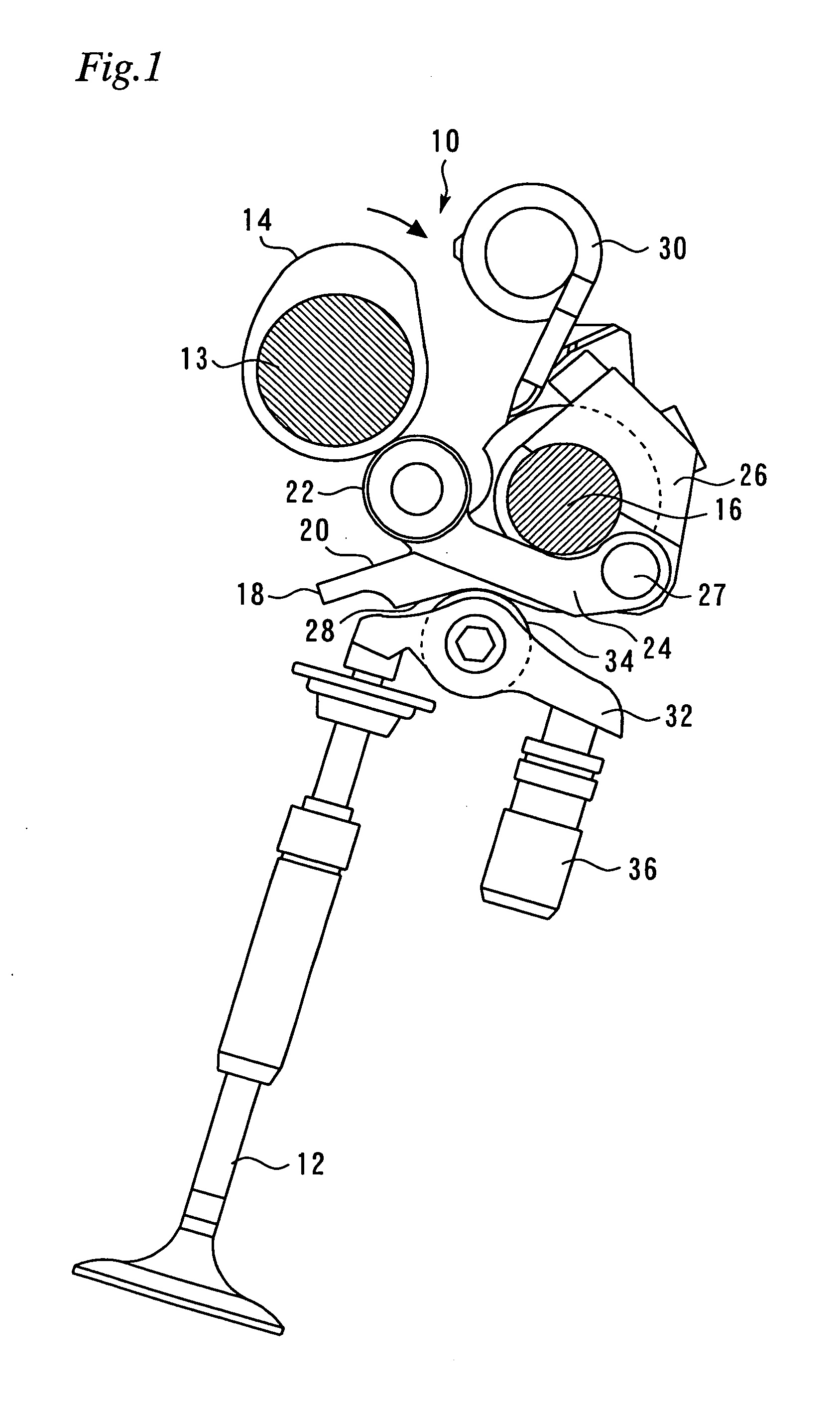

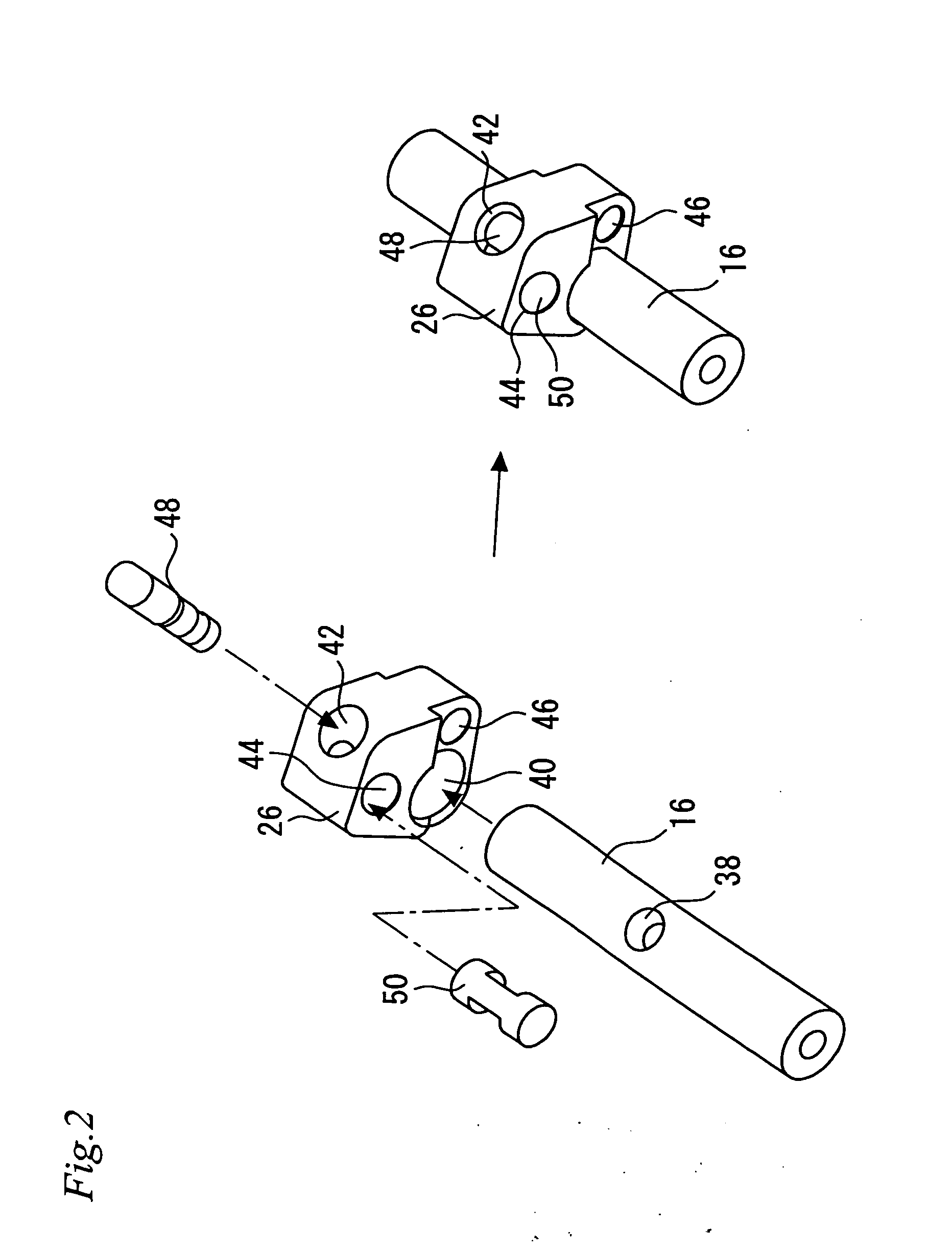

InactiveUS20090320779A1Prevent rotationReduce in quantityValve arrangementsMachines/enginesValve jobEngineering

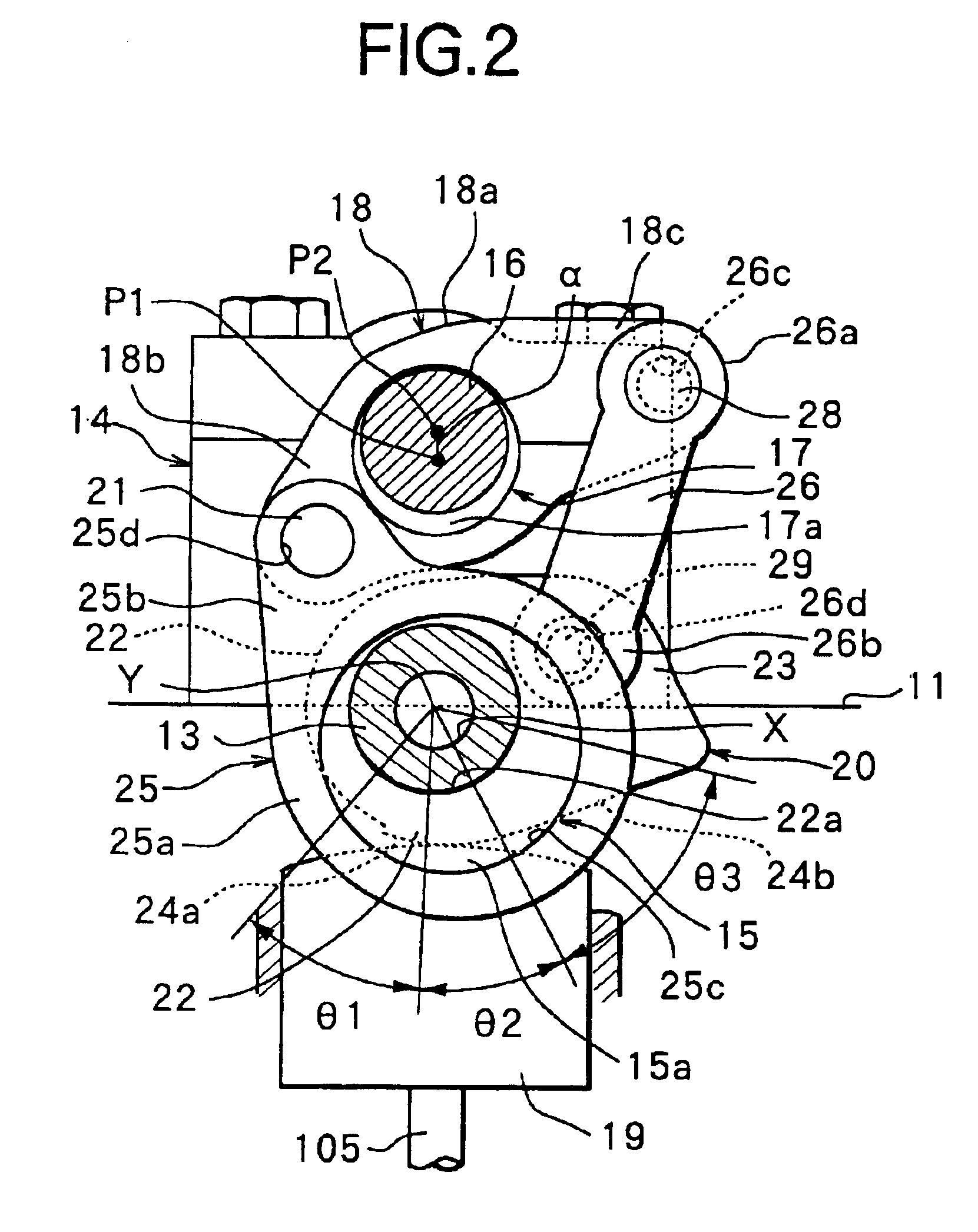

Disclosed is a variable valve mechanism for an internal combustion engine. The variable valve mechanism accurately adjusts the valve operating angle although its structure is simple. The variable valve mechanism includes a control pin 48, which is inserted into a pin insertion hole 38 in a control shaft 16; a bearing hole 44, which is formed in a control member 26; and an adjustment pin 50, which is rotatably supported by the bearing hole 44. The adjustment pin 50 comes into surface contact with the control pin 48 to inhibit the control member 26 from rotating relative to the control shaft 16. The valve operating angle is adjusted by replacing the adjustment pin 50 with another having a different dimension B. Such adjustment pin replacement changes the distance A between the center line of the bearing hole 44 and the center line of the control pin 48, thereby changing the relative angle θ between the control shaft 16 and control member 26. When the adjustment pin 50 rotates within the bearing hole 44, the surface contact between the adjustment pin 50 and control pin 48 is maintained irrespective of the magnitude of the relative angle θ.

Owner:TOYOTA JIDOSHA KK

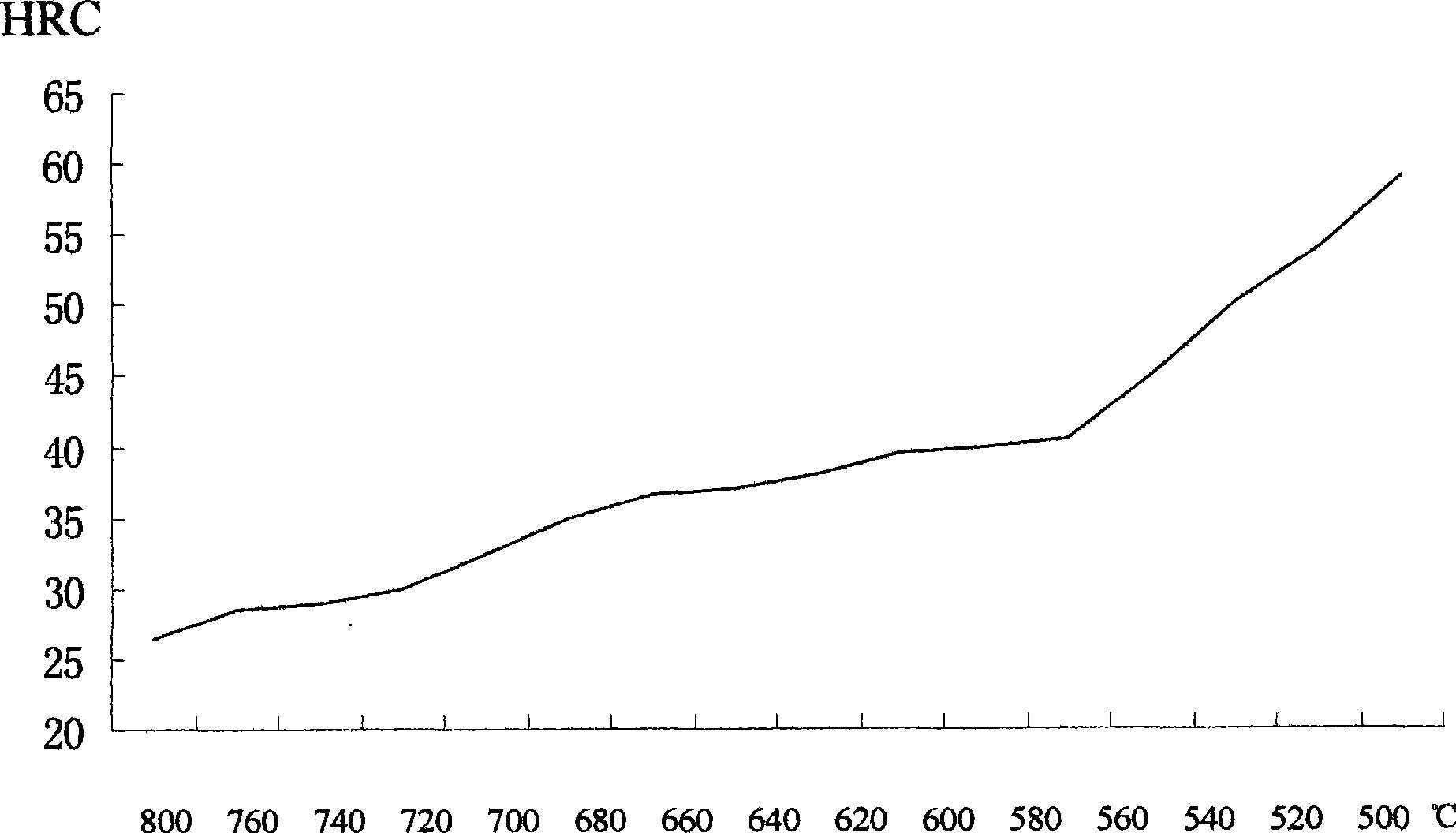

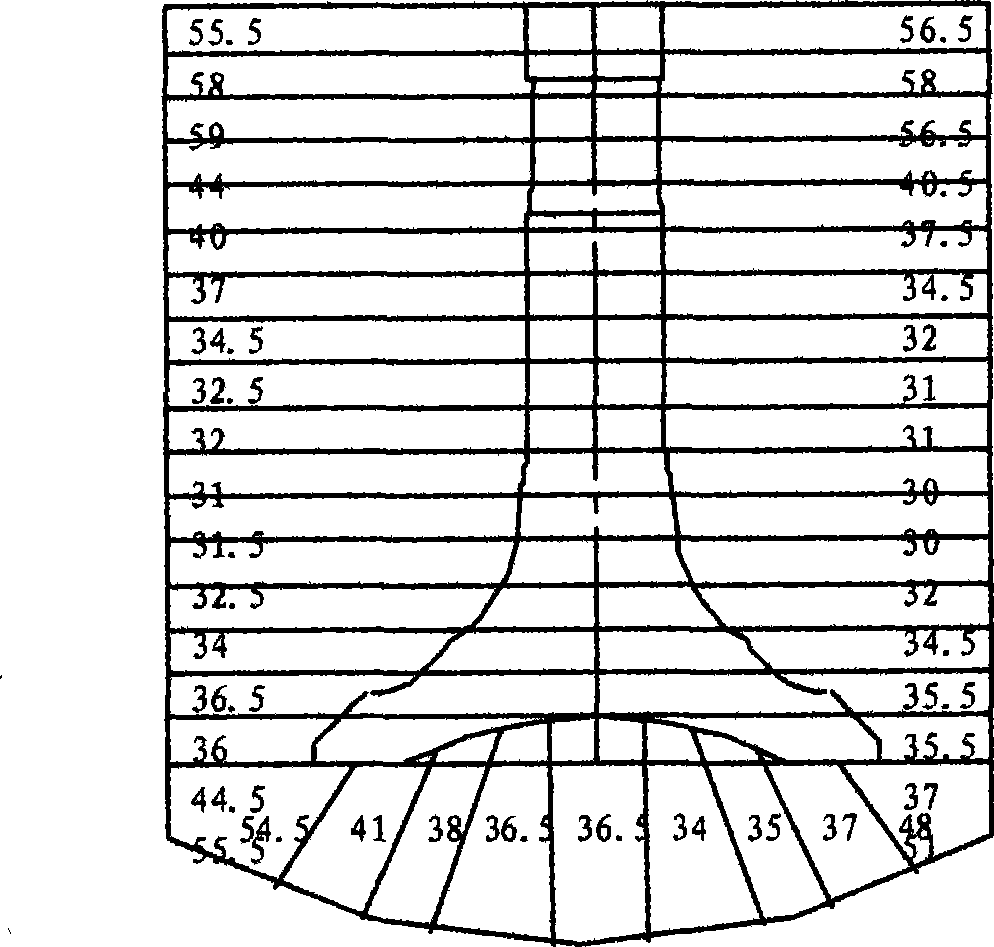

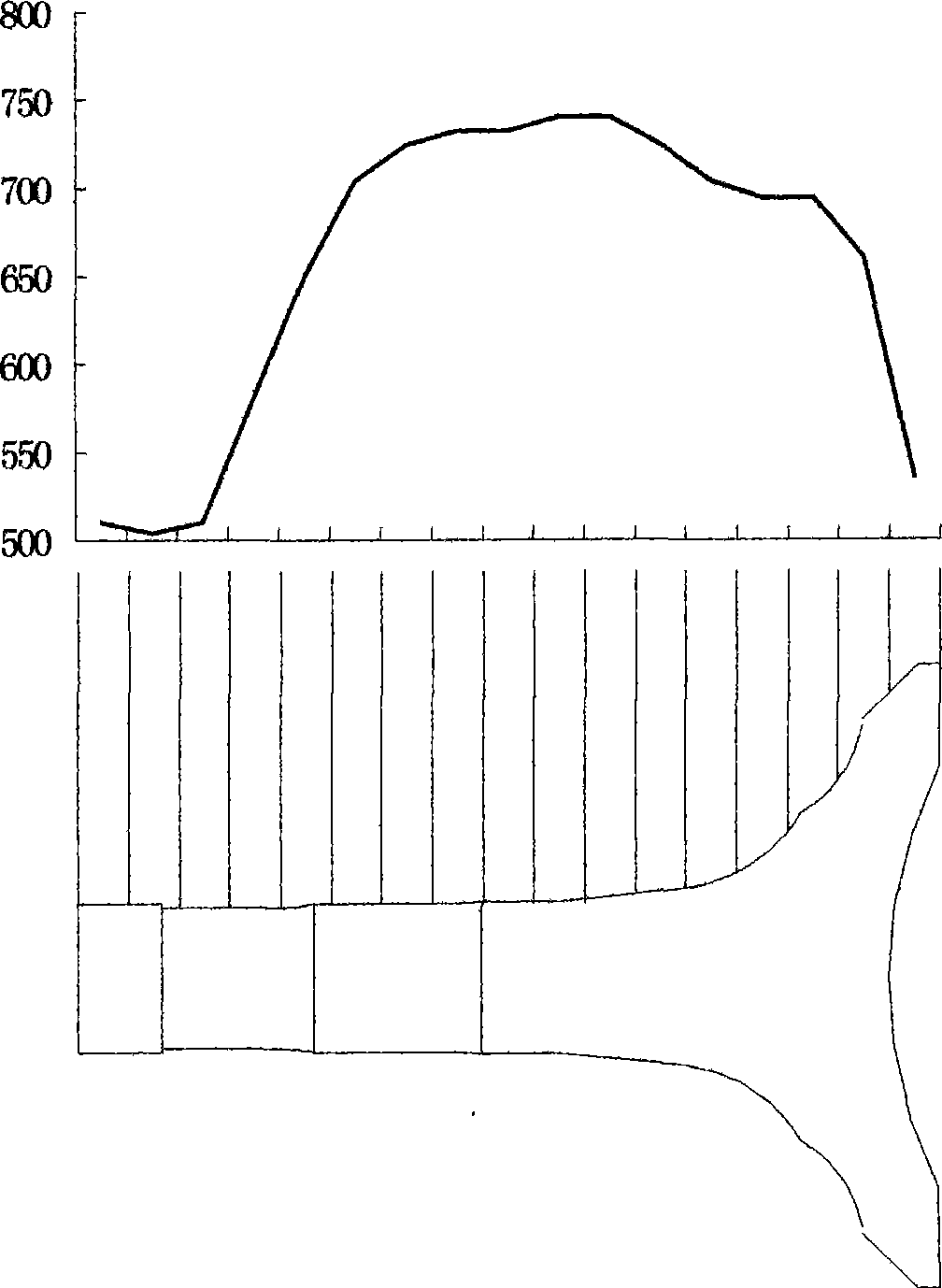

Method for detecting working temperature of valve

ActiveCN101458129ASolve the problem that the valve operating temperature cannot be measuredThermometer applicationsValve jobWorking temperature

The invention discloses a method for measuring working temperature of a valve, belonging to a method of temperature measurement, in particular to a method for measuring temperature of material samples by combining a sampling device. According to the principle that after tempering is carried out on material after hardening, different tempering temperatures correspond to different hardness, in the invention, after hardening is simultaneously carried out on a small barstock sample and the measured valve, temperings of different temperatures are carried out to measure the hardness, a standard tempering temperature-hardness corresponding curve of the barstock is charted, and temperature conditions of various parts of the valve are obtained by measuring the hardness of various parts of the valve and comparing the measured hardness with the standard tempering temperature-degree of hardness corresponding curve. The invention well solves the problem that the working temperature of the valve can not be measured and provides a new method for the research and development of new valve products.

Owner:济南沃德汽车零部件有限公司

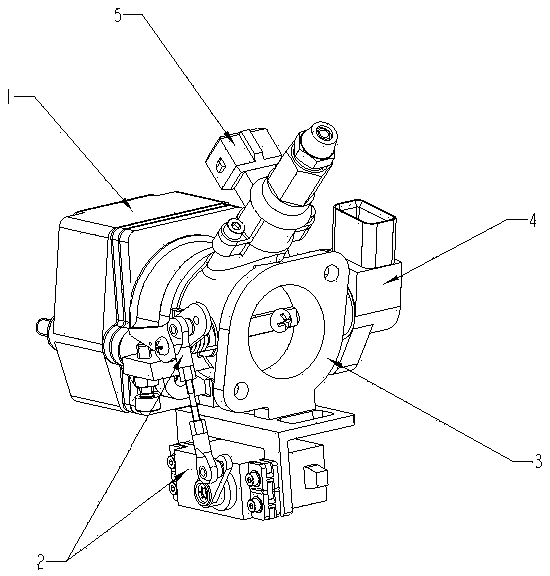

Electronic control system of single ECU sub-control throttle valve

The invention discloses an electronic control system of a single ECU sub-control throttle valve, and provides an electronic control fuel injection system structure for feeding fuel for a gasoline engine. The electronic control fuel injection system structure for feeding the fuel for the gasoline engine comprises a throttle valve body 3, a fuel injector 5, a steering engine and connecting piece 2 and an angle sensor 4. The throttle valve body is installed on an engine air inlet valve 1, the fuel injector, the steering engine and the angle sensor are installed on the throttle valve body, air enters from an air inlet, the fuel is atomized and injected into the throttle valve body through the fuel injector and mixed in the throttle valve body to enter an engine air inlet channel; the steeringengine controls the starting angle of a valve shaft piece, the amount of air inlet can be controlled, the angle sensor is connected to a valve shaft end, and the starting angle of the valve shaft piece can be detected, and the starting angle of the valve shaft piece is fed back to an ECU; and the ECU adjusts the working state of each throttle valve according to the flight condition of an unmannedaerial vehicle. The electric control fuel injection system has the advantages that the structure is compact, installation and debugging are convenient, the reliability is high, the weight is low, combustion is good, atomization mixing in advance achieves the optimal combustion medium ratio and the like, and the flight control function extension of the unmanned aerial vehicle is relatively convenient.

Owner:襄阳联航动力技术有限公司

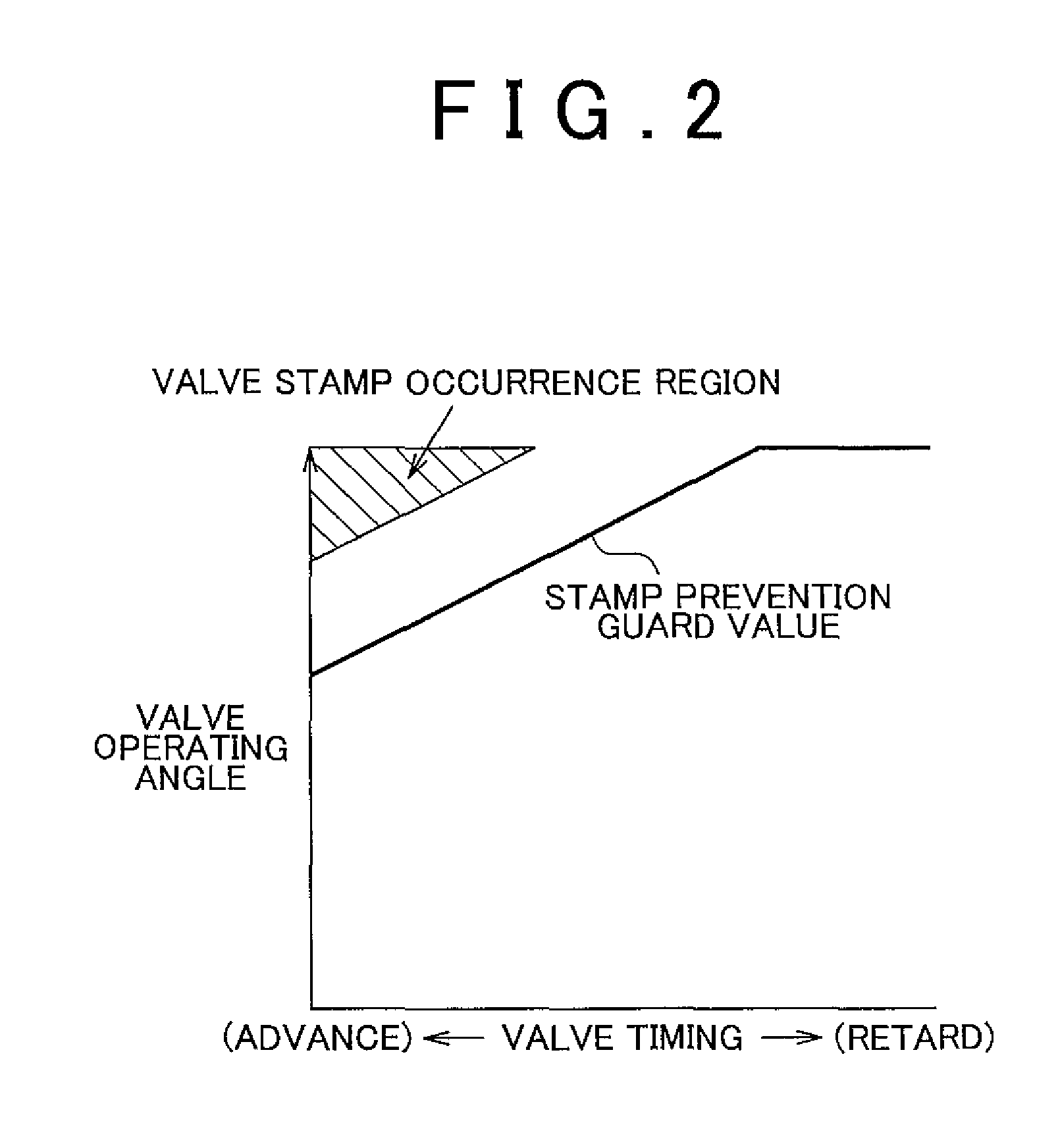

Control device for variable valve actuation system

InactiveUS20110178694A1Reliably avoid valve stampValve arrangementsElectrical controlValve jobVariable valve timing

A control device for a variable valve actuation system includes: an engine valve; a variable valve actuation mechanism that variably controls a valve timing of the engine valve and at least one of a valve operating angle and valve lift of the engine valve; a variable setting unit that variably sets a control range, in which at least one of the valve operating angle and the valve lift is controlled by the variable valve actuation mechanism, on the basis of the valve timing; a detecting unit that detects a plurality of valve timings of the engine valve in different modes in such a manner that the control range is changed; and a control range setting unit that variably sets the control range using one of the plurality of detected valve timings.

Owner:TOYOTA JIDOSHA KK

Control device for internal combustion engine

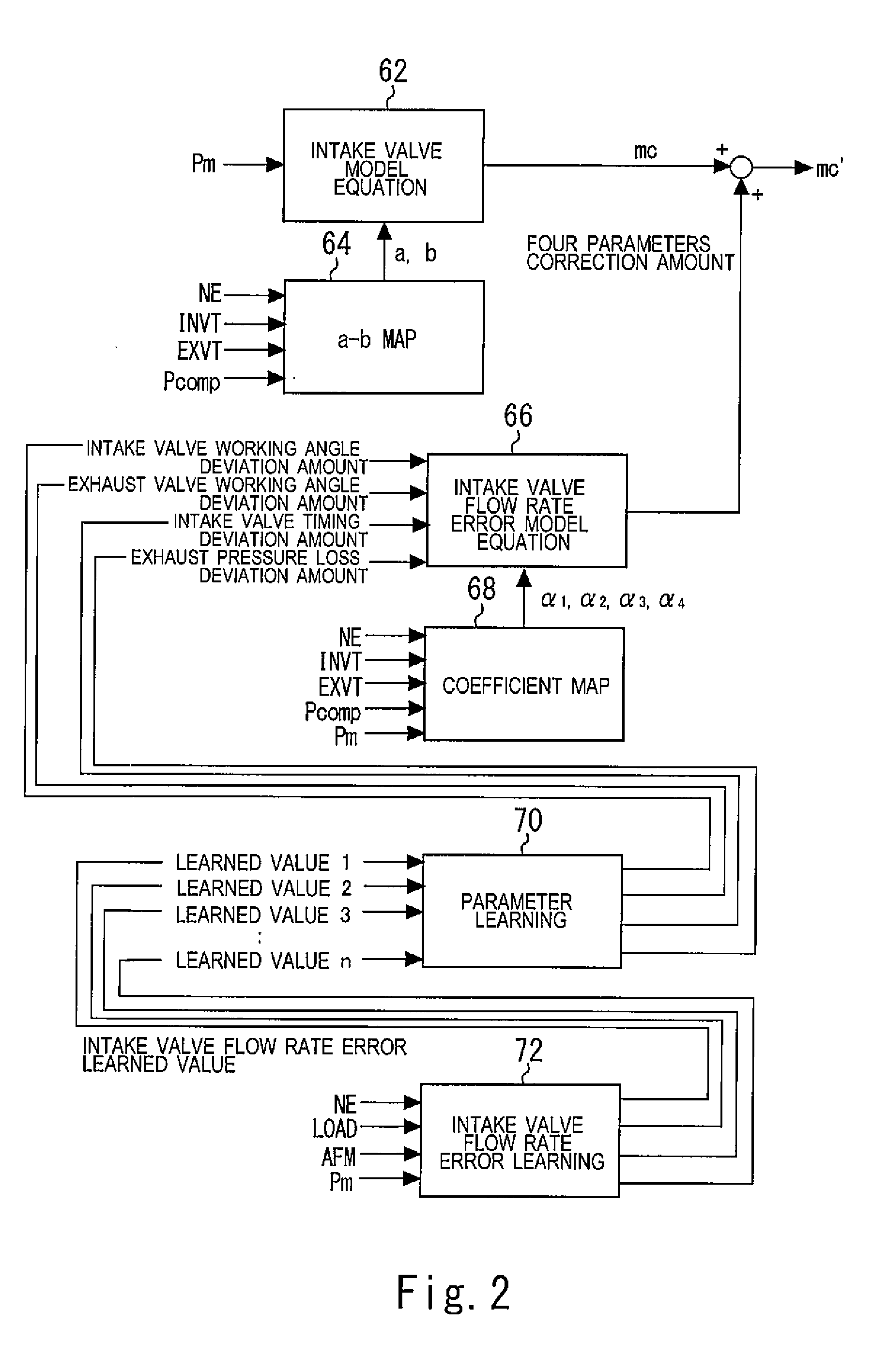

ActiveUS20170030284A1Improve estimation accuracyIncrease overlapElectrical controlOutput powerExhaust valveValve job

Respective learned values of four parameters, that are an intake valve working angle deviation amount, an exhaust valve working angle deviation amount, an intake valve timing deviation amount and an exhaust pressure loss deviation amount, are calculated based on learned values of an intake valve flow rate error that are obtained under at least four different operating conditions. A correction amount with respect to an intake valve flow rate that is calculated with an intake valve model equation is calculated based on respective learned values of the four parameters using an intake valve flow rate error model equation in which coefficients are represented by functions of state quantities of an engine that include an engine speed and an intake pipe pressure.

Owner:TOYOTA JIDOSHA KK

Variable pneumatic door control system

InactiveCN1959073ARealize timing controlEliminate shockMachines/enginesNon-mechanical valveHydraulic cylinderValve job

A control system of variable air door consists of air door, hydraulic actuating element connected with air door, hydraulic-supplying unit and controller. It is featured as connecting hydraulic cylinder to general oil tube through high speed switch valve, setting proportional pressure valve between general oil tube and oil box, connecting electromagnetic iron of proportional pressure valve to controller and connecting high speed valve of hydraulic cylinder with oil box.

Owner:NINGBO HOYEA MACHINERY MFG

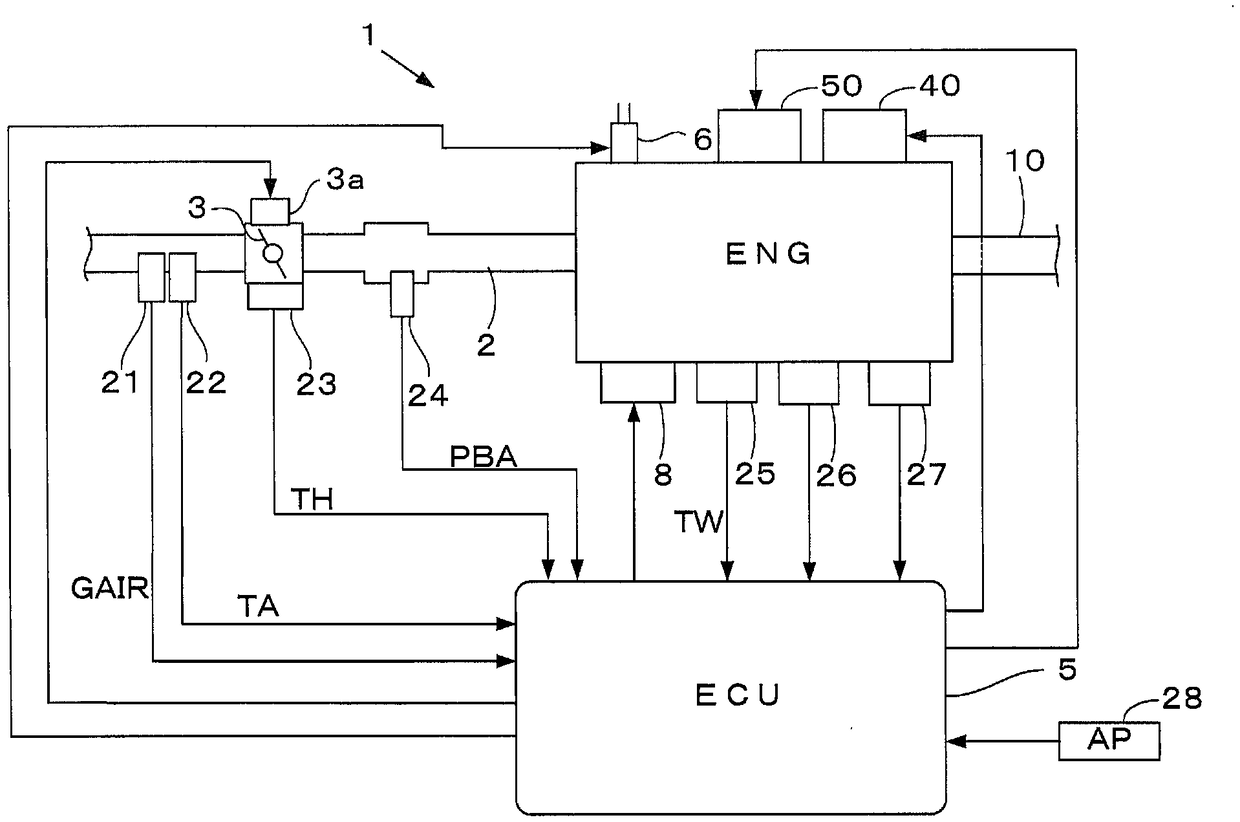

Intake air control system for internal combustion engine

An intake air control system for an internal combustion engine having at least one intake valve and a valve operating characteristic varying mechanism which continuously varies a lift amount of the at least one intake valve of the engine. A target intake air flow rate of the engine is calculated along with a command value of the lift amount according to a target engine rotational speed set in an idling condition of the engine and the target intake air flow rate when the engine is determined to be in an idling condition. The valve operating characteristic varying mechanism is controlled according to the calculated lift amount command value.

Owner:HONDA MOTOR CO LTD

Intake air control system for internal combustion engine

InactiveUS7770558B2Smooth shiftingValve arrangementsElectrical controlValve jobExternal combustion engine

An intake air control system for an internal combustion engine having at least one intake valve and a valve operating characteristic varying mechanism which continuously varies a lift amount of the at least one intake valve of the engine. A target intake air flow rate of the engine is calculated along with a command value of the lift amount according to a target engine rotational speed set in an idling condition of the engine and the target intake air flow rate when the engine is determined to be in an idling condition. The valve operating characteristic varying mechanism is controlled according to the calculated lift amount command value.

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com