Variable pneumatic door control system

A valve control system and valve technology, applied to non-mechanically actuated valves, engine components, machines/engines, etc., can solve the problems of complex system structure, unsatisfactory response speed, and high energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

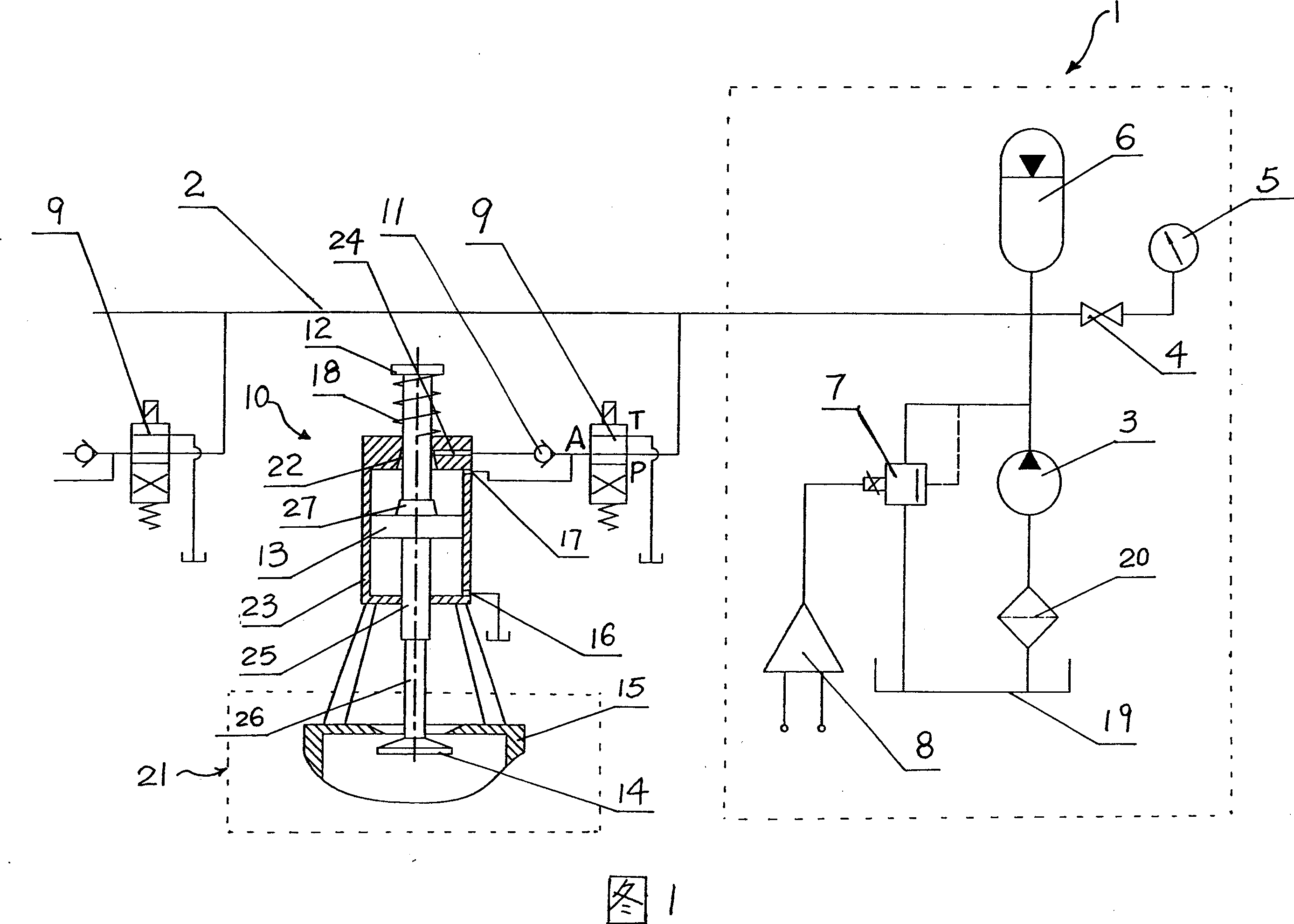

[0019] Accompanying drawing 1 is a schematic diagram of an embodiment of the present invention. As shown in FIG. 1 , the control system of the present invention is mainly composed of a hydraulic supply system 1 , a high-speed switching valve 9 , a hydraulic actuator 10 and an air valve 21 . The hydraulic supply system 1 is composed of an oil pump 3 , an oil tank 19 , an oil filter 20 , a controller 8 and a proportional pressure valve 7 . The controller 8 selects a proportional amplifier, and the proportional pressure valve 7 selects a proportional overflow valve. The oil inlet of the oil pump 3 communicates with the fuel tank 19 through the oil filter 20 , and the oil outlet of the oil pump 3 is connected to the main oil pipe 2 . The total oil inlet pipe 2 is equipped with a pressure accumulator 6, a pressure gauge switch 4 and a pressure gauge 5. The output end of the proportional amplifier 8 is connected with the electromagnet of the proportional overflow valve 7, the oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com