Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

308 results about "Clip forceps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

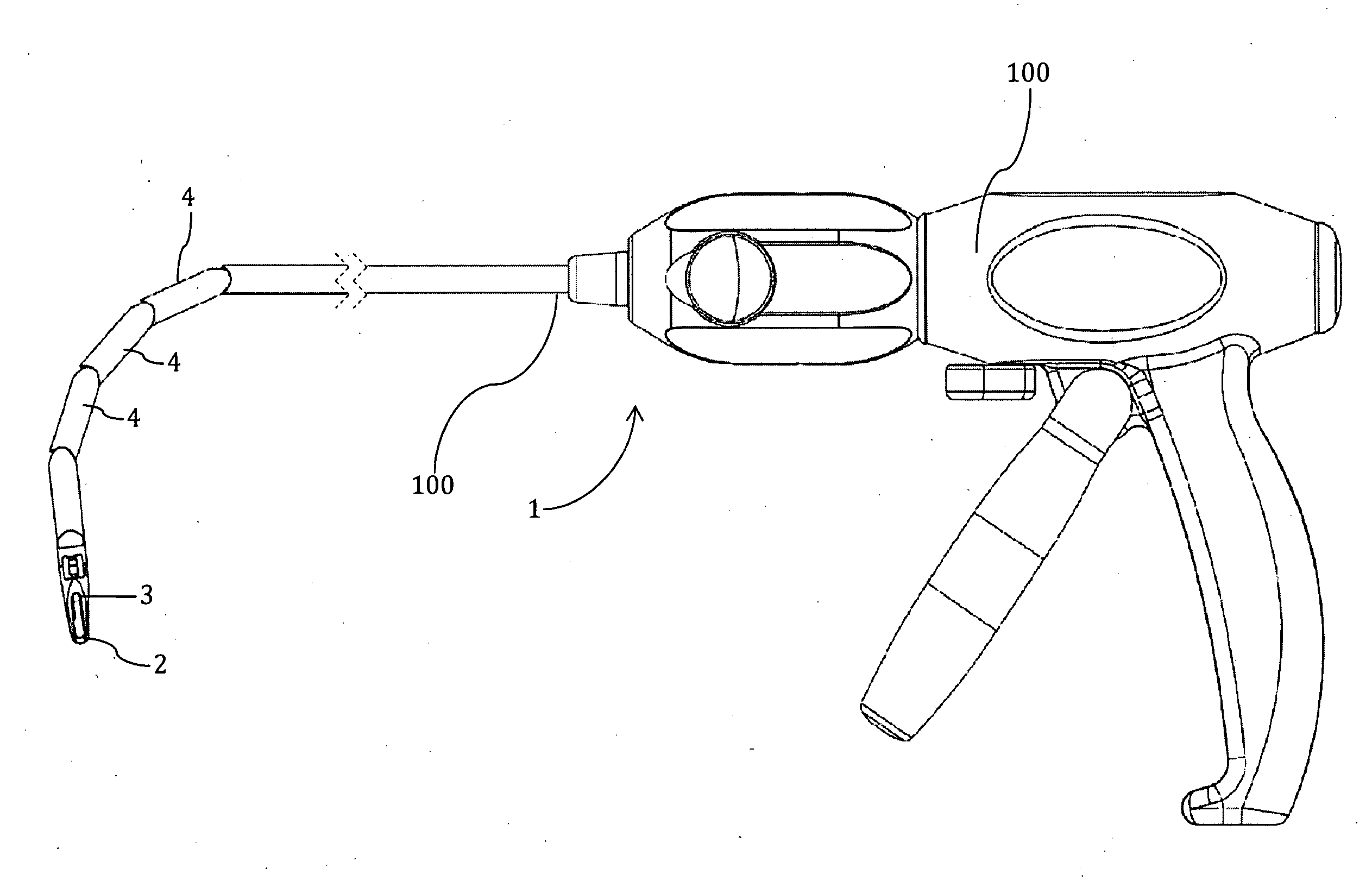

Articulating Steerable Clip Applier for Laparoscopic Procedures

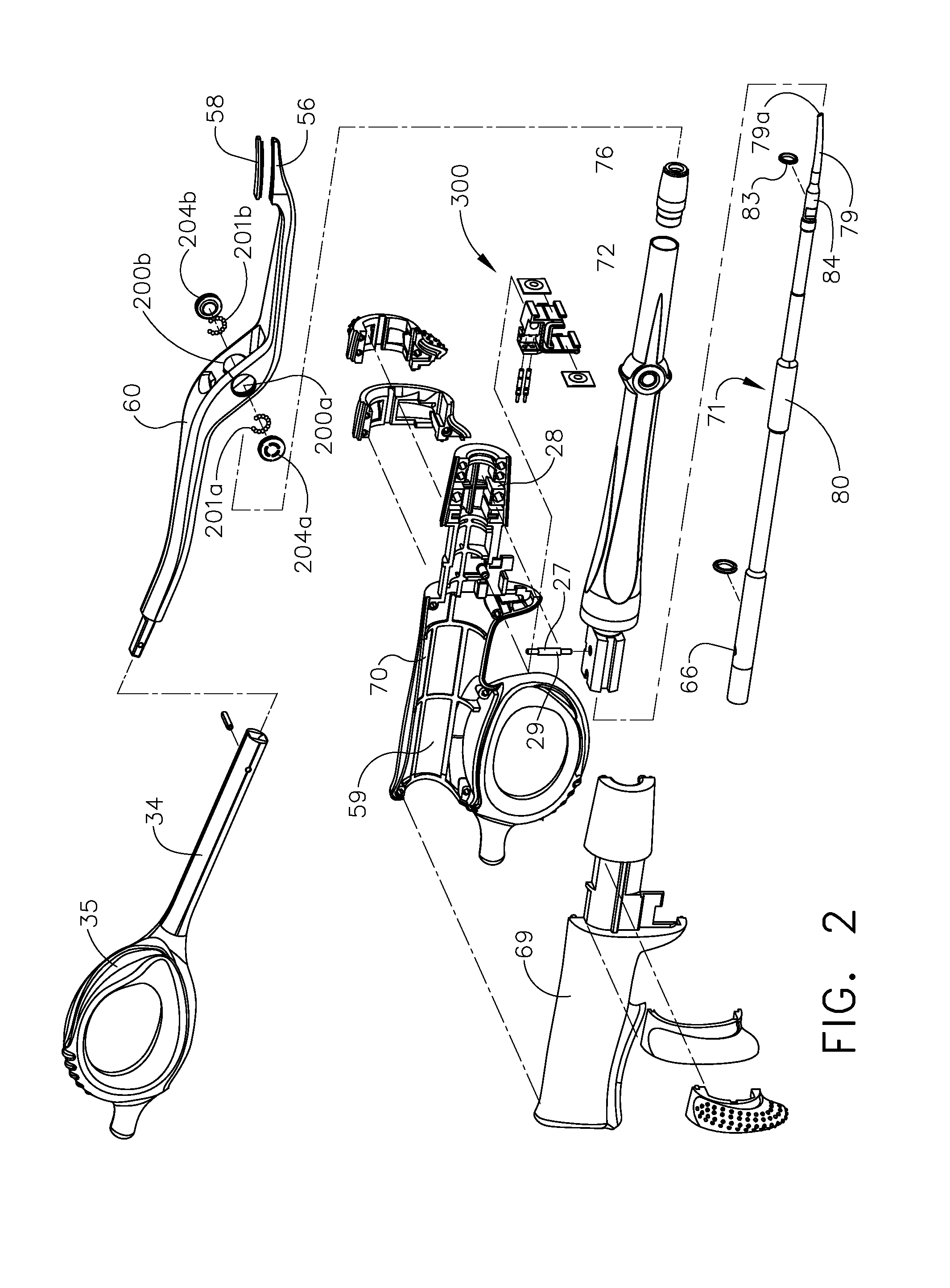

A long articulating steerable clip applier affixed to a user-operated handle. A surgical jaw assembly is attached to the other end of the clip applier. The clip applier is composed of articulating phalanges that are connected end to end by pivoting links and capable of angulations relative to one another when subjected to a tensile force. Each phalange has opposing s-shaped exterior grooves that form two continuous spiral-shaped channels for holding tension wires once the phalanges are assembled. Multiple tension wires are attached to opposite ends of adjacent phalanges. When each wire is pulled, this tensile force causes the phalanges to pivot at equivalent angles with each other. As each individual phalange pivots by an equivalent angle, the sum of these angles causes the free end of the clip applier to pivot by a large angle or a cascading actuation effect.

Owner:CONMED CORP

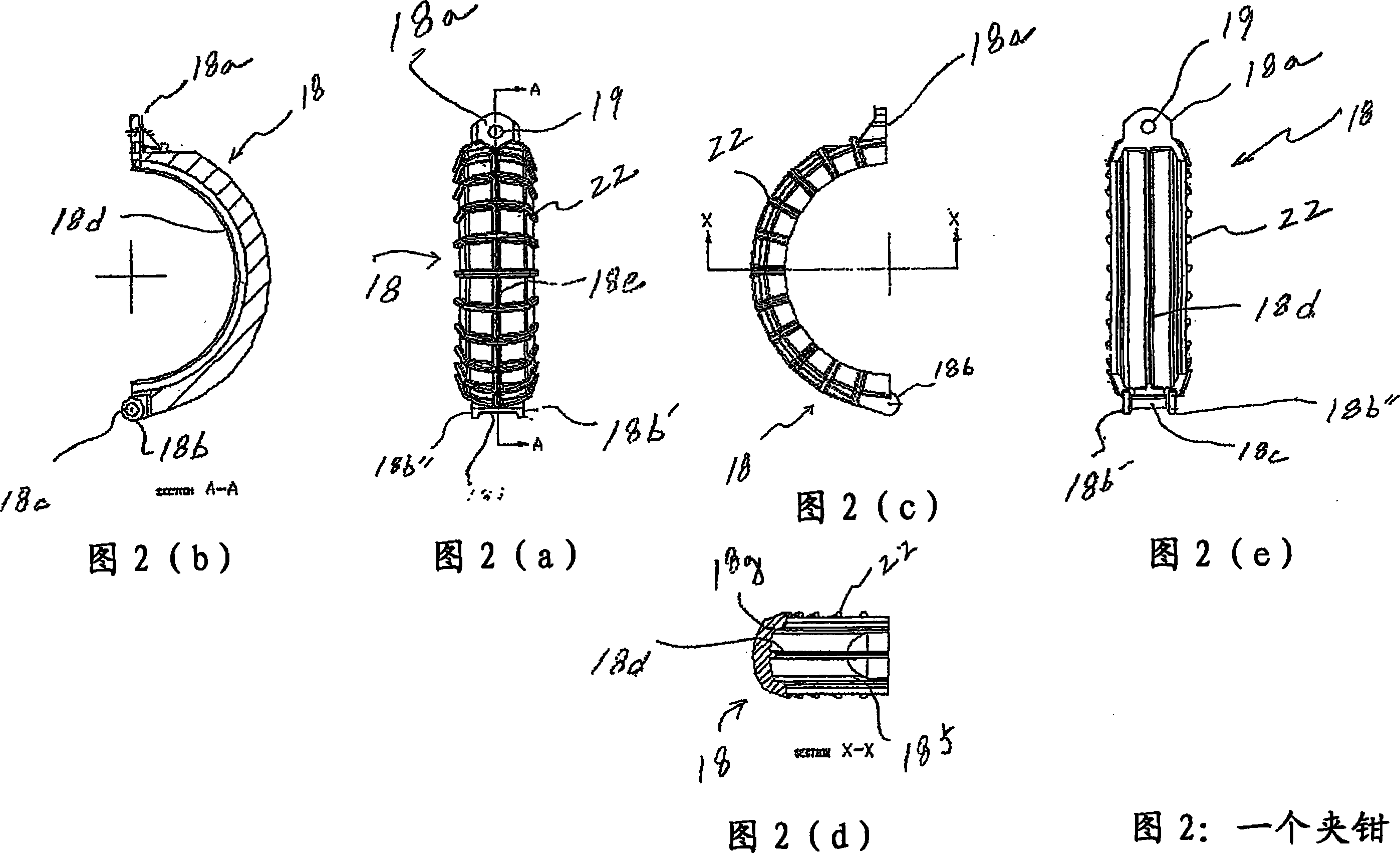

Clamp

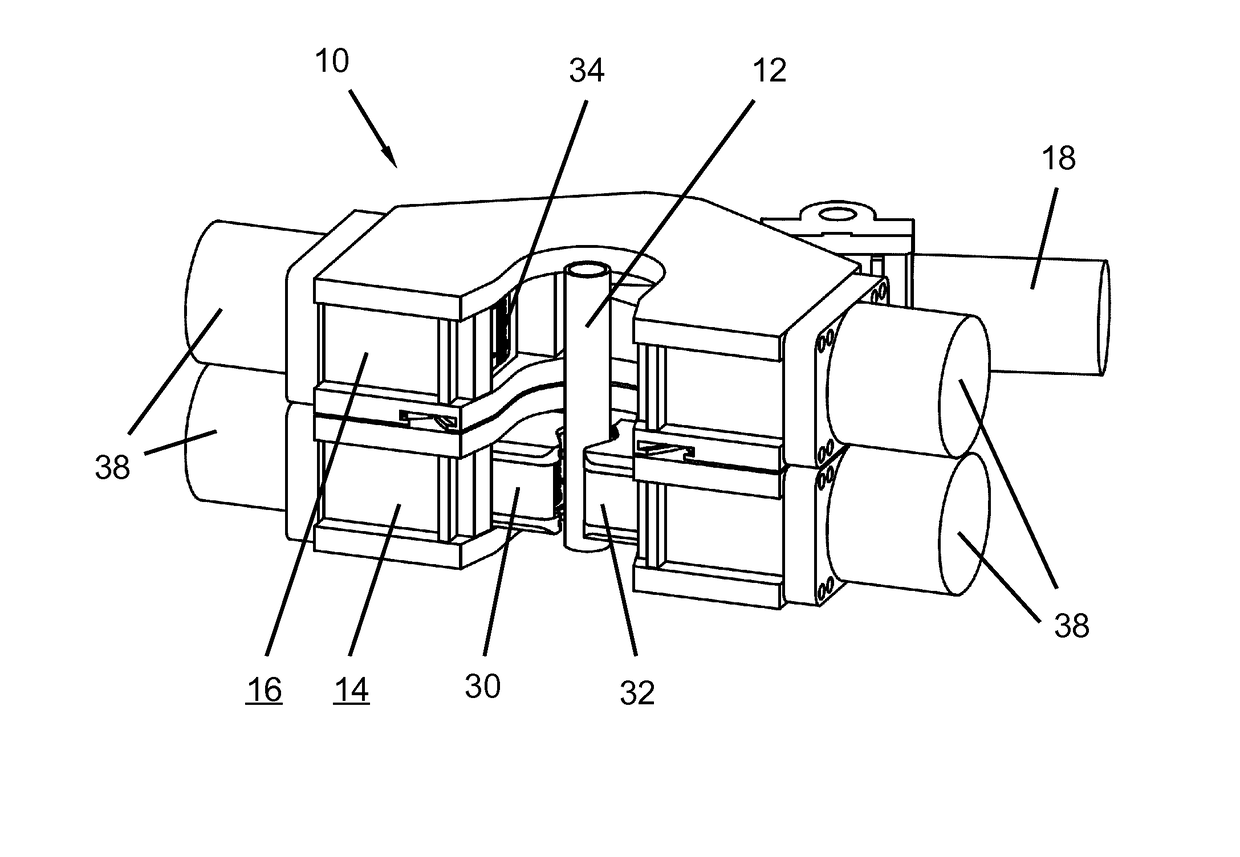

ActiveUS20070176425A1Easy to openImprove sealingSleeve/socket jointsFlanged jointsClassical mechanicsClip forceps

The present invention pertains to a clamp that includes a collar. The collar has first and second ends from which first and second lugs extend. Each of the first and second lugs has a thick portion and a thin portion, and the lugs are connected by a fastener. The clamp is positioned around tubes, and the fastener is tightened to tighten the clamp around the connection. The fastener may be tightened from an open position OP, when the lugs are not touching, to a closed position CP, when the thick portions of the lugs are touching. The fastener may be tightened further to a third position, so that the thin portions of the lugs move closer to one another. The clamp may also include a hinge area in which a gasket seal may be attached to the clamp or one of the tubes.

Owner:NORMA US HOLDING LLC

Ultrasonic device for cutting and coagulating

An ultrasonic clamp coagulator assembly that is configured to permit selective cutting, coagulation, and fine dissection required in fine and delicate surgical procedures. The assembly includes a clamping mechanism, which is specifically configured to provide for variable tissue clamping forces.

Owner:CILAG GMBH INT

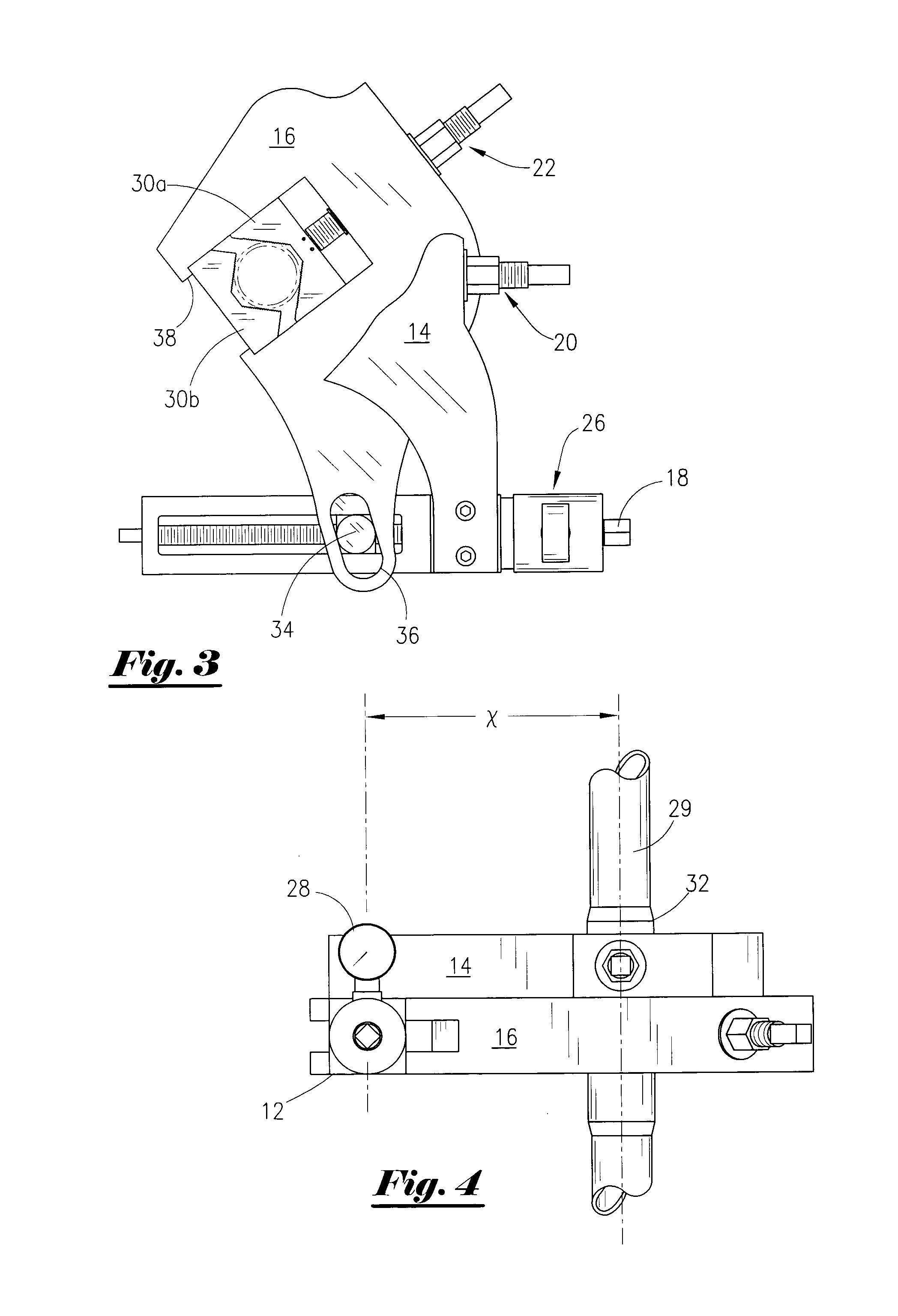

Portable pipe tong and method of use

InactiveUS6931965B1The right amountQuickly applying torqueDrilling rodsSpannersThreaded pipeEngineering

A relatively compact portable tong assembly utilizing adaptable jaws for gripping the threaded box and pin ends of adjacent pipe joints without the use of an external support and thus applying final make-up torque or applying initial breakout torque to threaded pipe joints using only a spanner, socket and ratchet or other such hand tools for quickly applying torque to at least one of the tong jaws. An integral means is also provided for accurately measuring the amount of torque being applied to the joints.

Owner:FANGUY ROBERT P

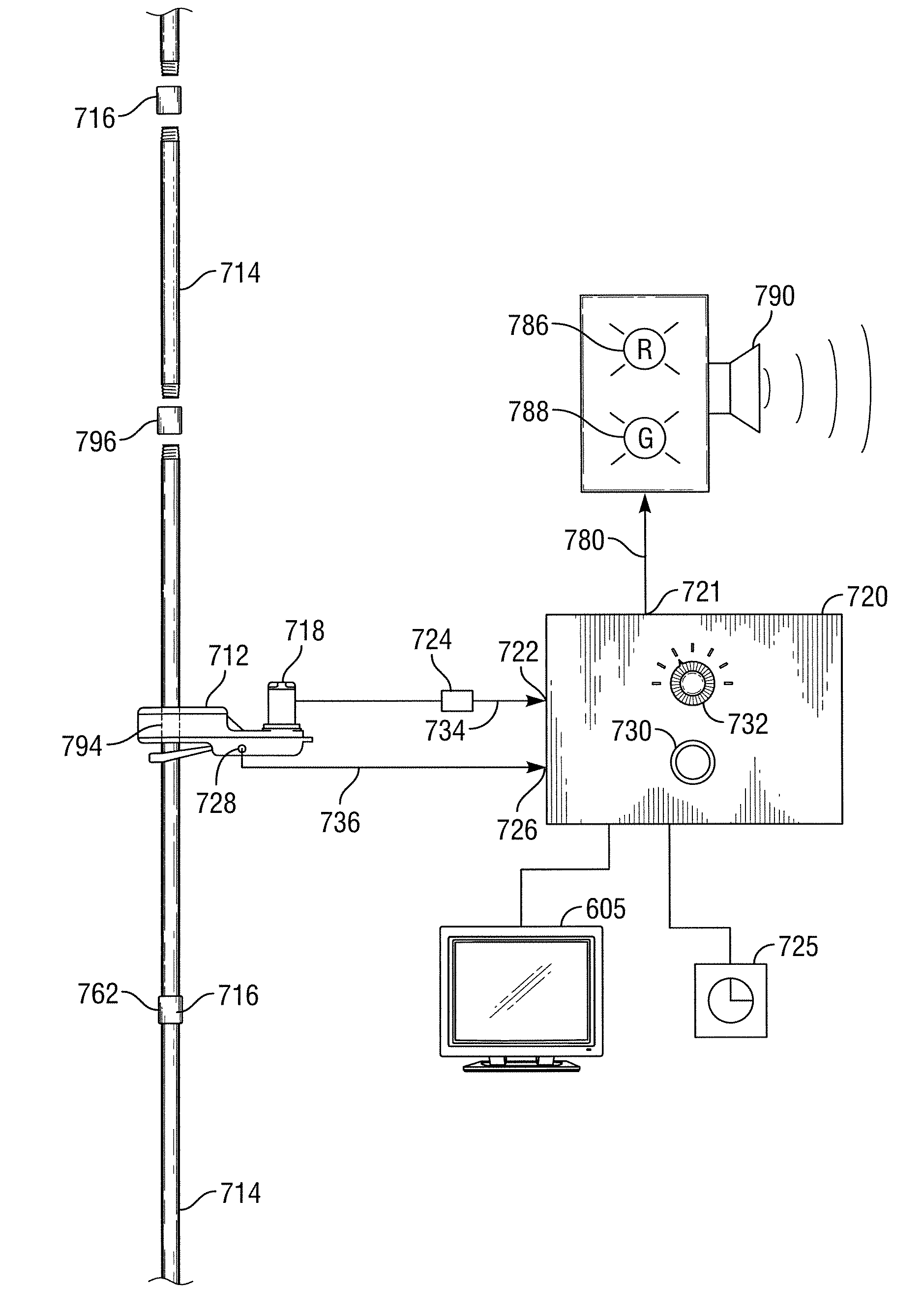

Method and System for Evaluating Rod Breakout Based on Tong Pressure Data

ActiveUS20090056467A1Drilling rodsMeasurement of torque/twisting force while tighteningBurst pressureLower limit

A method for evaluating rod quality and wellbore dynamics includes receiving information about the rod size and tong type for a rod pulling operation. Expected breakout pressures can be determined based on the rod size and / or tong type and can be input into an evaluation system. Upper and lower limits for acceptable rod breakout pressures can be calculated based on the expected breakout pressure and / or rod size. Actual rod breakout pressures can be evaluated while pulling rods from a well and compared to the upper and lower limits. Rod breakout pressures below the lower limit or above the upper limit can generate an alarm notifying a rig operator to evaluate the condition of the rod to determine if the rod can be reused. The rod breakout pressures can be recorded as breakout pressure data for further evaluation, including determinations of improper rod make-up and poor well conditions.

Owner:KEY ENERGY SERVICES

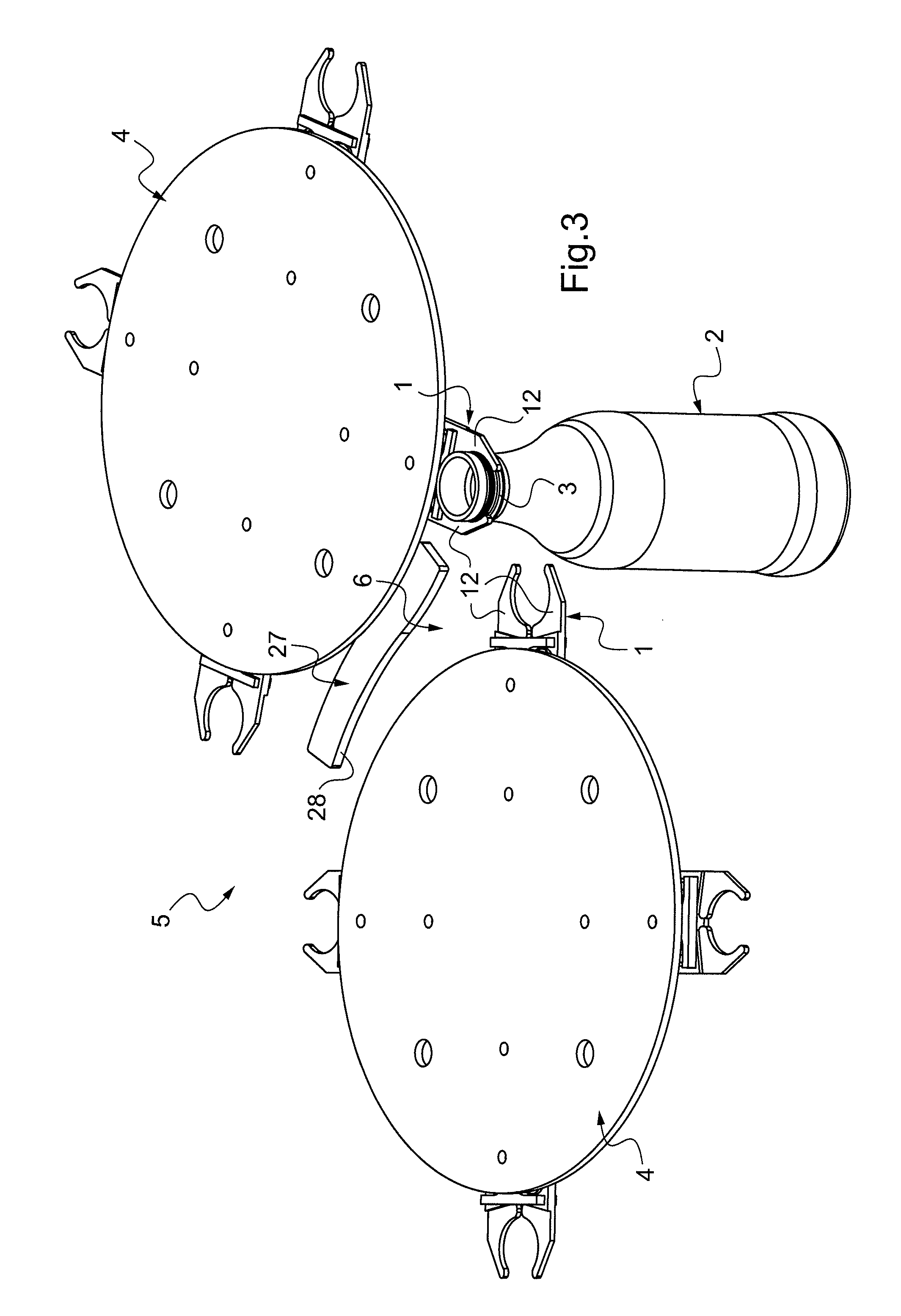

Resilient clamp for holding a container by the neck

InactiveUS20110109110A1Sufficient resilienceSafe gripConveyorsDrilling rodsEngineeringMechanical engineering

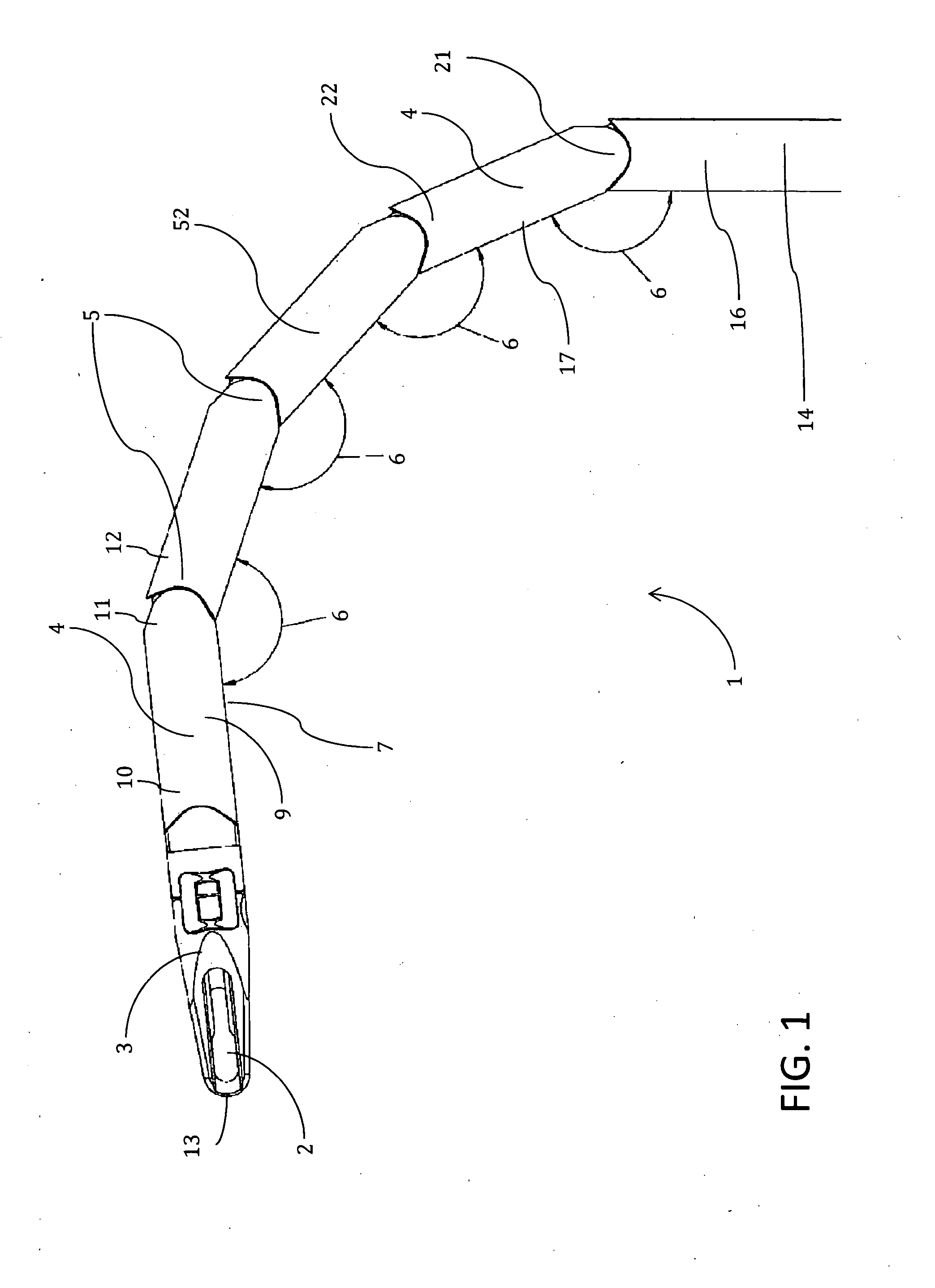

Clamp (1) for holding a container (2) by a neck (3) in a container handling machine (5), said clamp comprising a body (7) for mounting the clamp (1) on a rotary support (4), and a pair of resilient arms (11) protruding sidewise from the body (7) and each provided with a gripping jaw (12), wherein each resilient arm (11) comprises:an inner section (13) extending along the body (7) and connected thereto at a first back end junction (16);an intermediate section (14) extending substantially parallel to the inner section (13) and connected thereto at a front end junction (17);an outer section (15), provided, at a front end, with a gripping jaw (12), and extending substantially parallel to the intermediate section (14) and connected thereto at a second back end junction (18).

Owner:SIDEL PARTICIPATIONS SAS

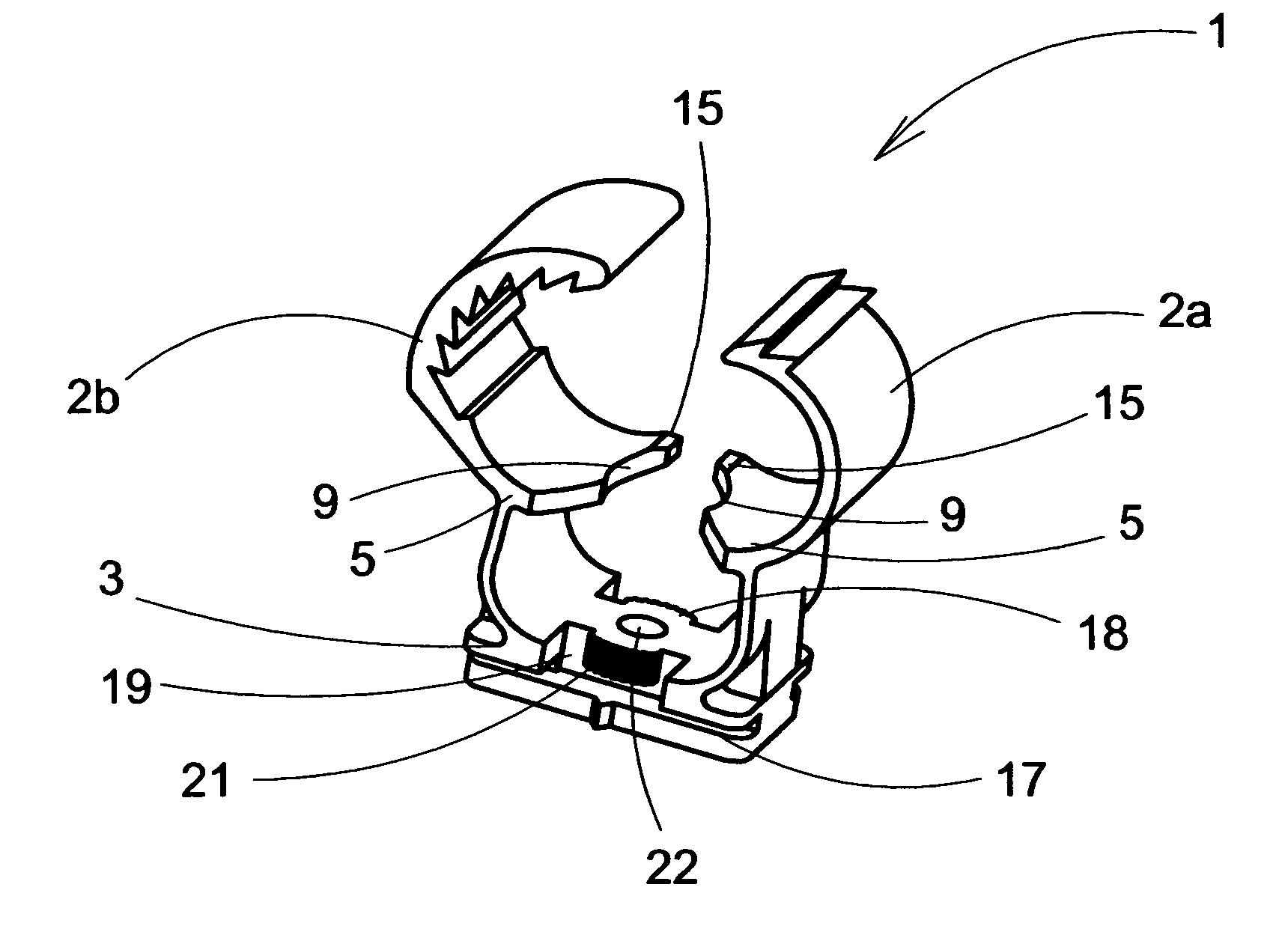

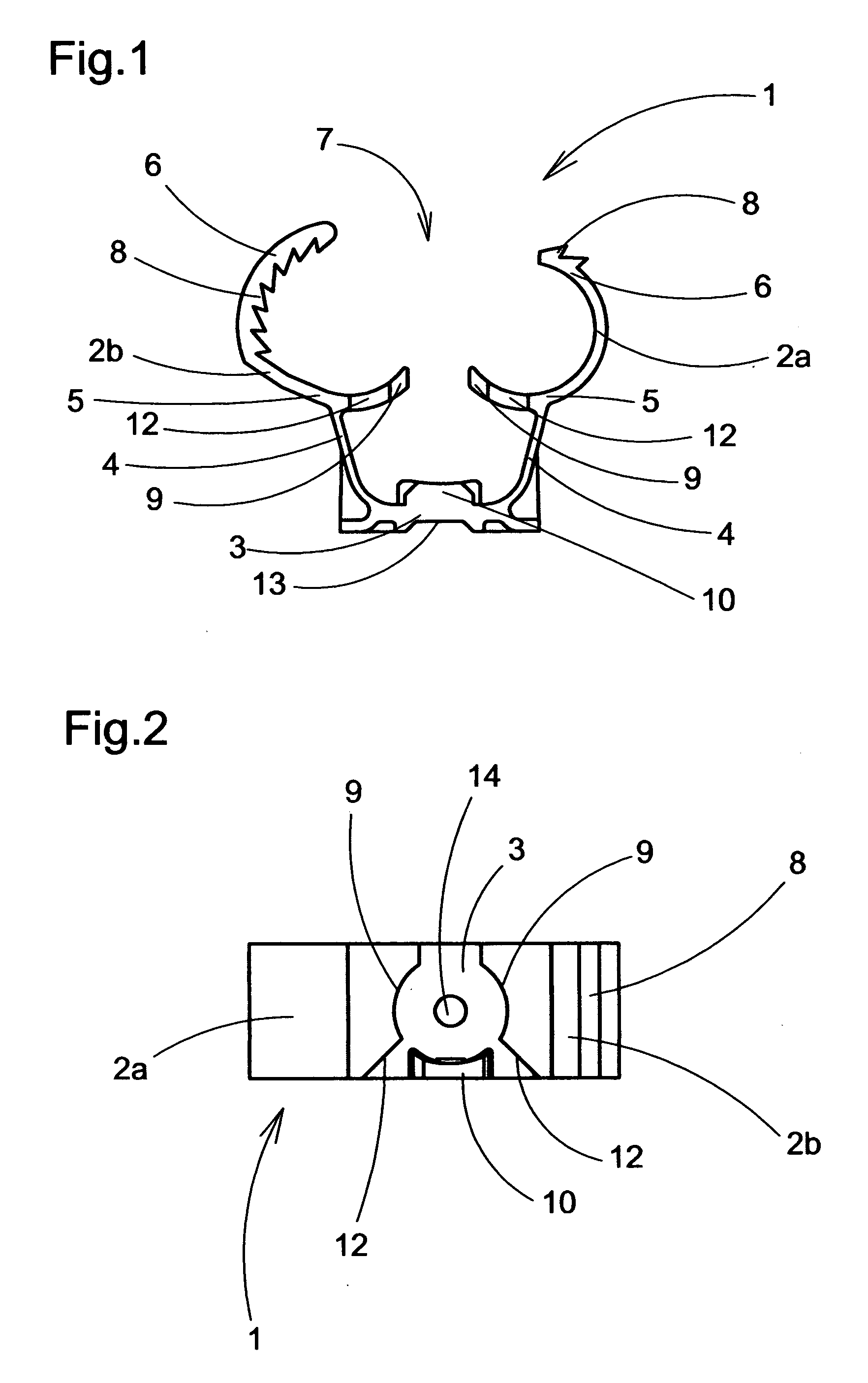

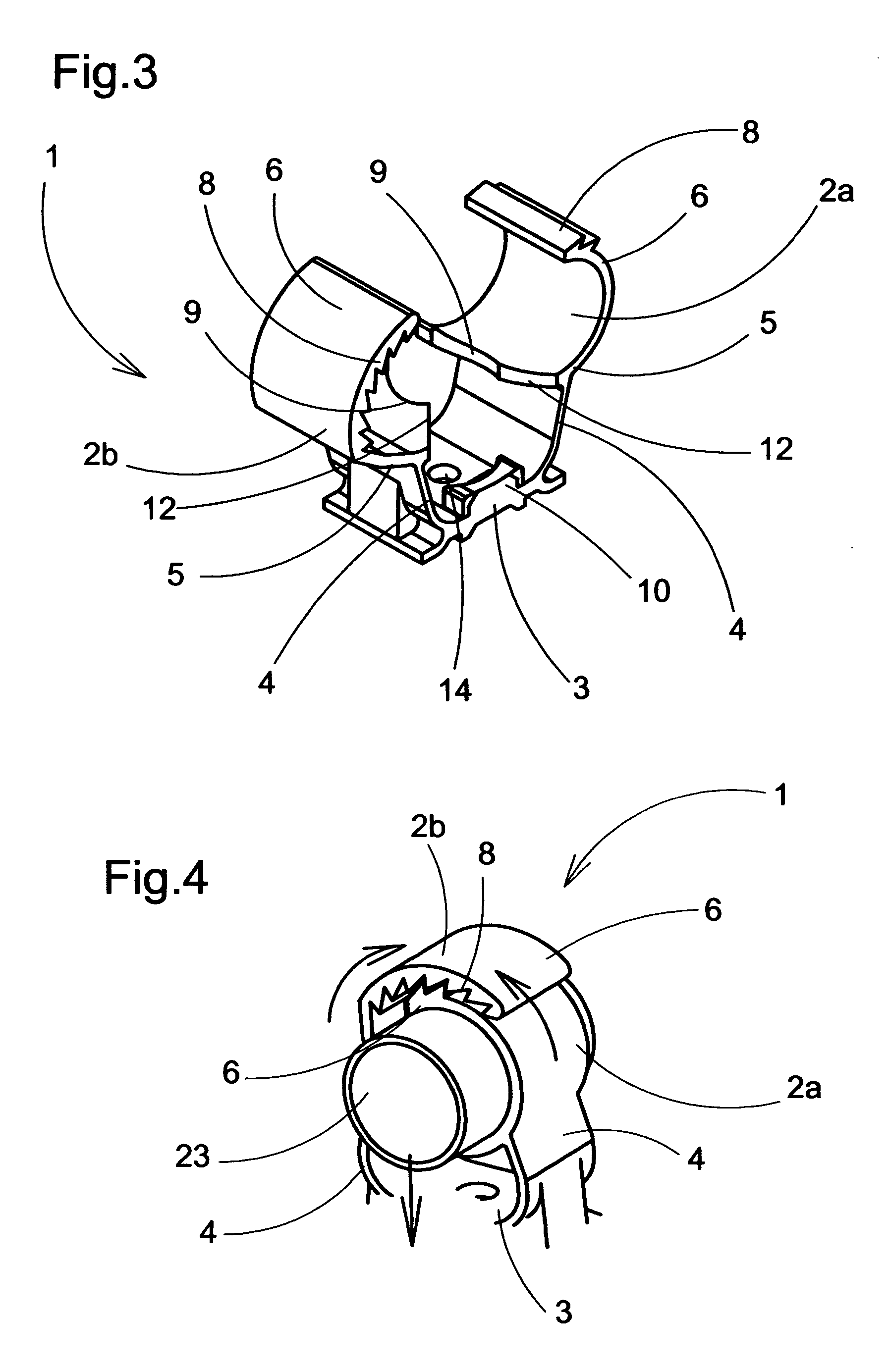

Clamp

InactiveUS20060076462A1Easy to placeGood adhesionPipe supportsFlexible pipesEngineeringMechanical engineering

Each one of the arms (2a, 2b) includes a lower end (5) closer to said base (3) which closes the arms (2a, 2b) when pushing a pipe against it, and an upper end (6) farther from said base (3) which includes means for blocking both arms (2a, 2b) when they are closed. The clamp (1) comprises, at the lower end (5) of the arms (2a, 2b), attaching means to the end of the outlet mouth (11) of a fixing device.

Owner:CERAVALLS PUJOL RAMON +1

Reusable ultrasonic surgical instrument

ActiveCN107280735ASolve the problem that it is not easy to clean and cannot be reusedReduce use costCannulasEngineeringOuter Cannula

The application provides a reusable ultrasonic surgical instrument. The reusable eultrasonic surgical instrument comprises a cannula assembly, a cutter bar, a base and a clamping driving assembly. The cannula assembly comprises a pair of clip forceps at the far end, an outer cannula and an inner cannula. The outer cannula, the inner cannula and the cutter bar are coaxially arranged. The near end of the pair of clip forceps is provided with two rotary shafts. One end of the two rotary shafts is rotatably connected with the pair of clip forceps and the other one rotary shaft is rotatably connected with the inner cannula. The cannula assembly can be detached towards the far end direction of the axis of the cutter bar from the base and the clamping driving assembly or can be installed on the base and the clamping driving assembly towards the near end direction of the axis of the cutter bar. The outer cannula is connected with the base through one or multiple first detachable structures. The inner cannula is connected with the clamping driving assembly through one or multiple second detachable structures. The reusable ultrasonic surgical instrument is advantaged by being simple in structure and low in cost.

Owner:SHANGHAI YISI MEDICAL TECH CO LTD

Tong positioning and alignment device

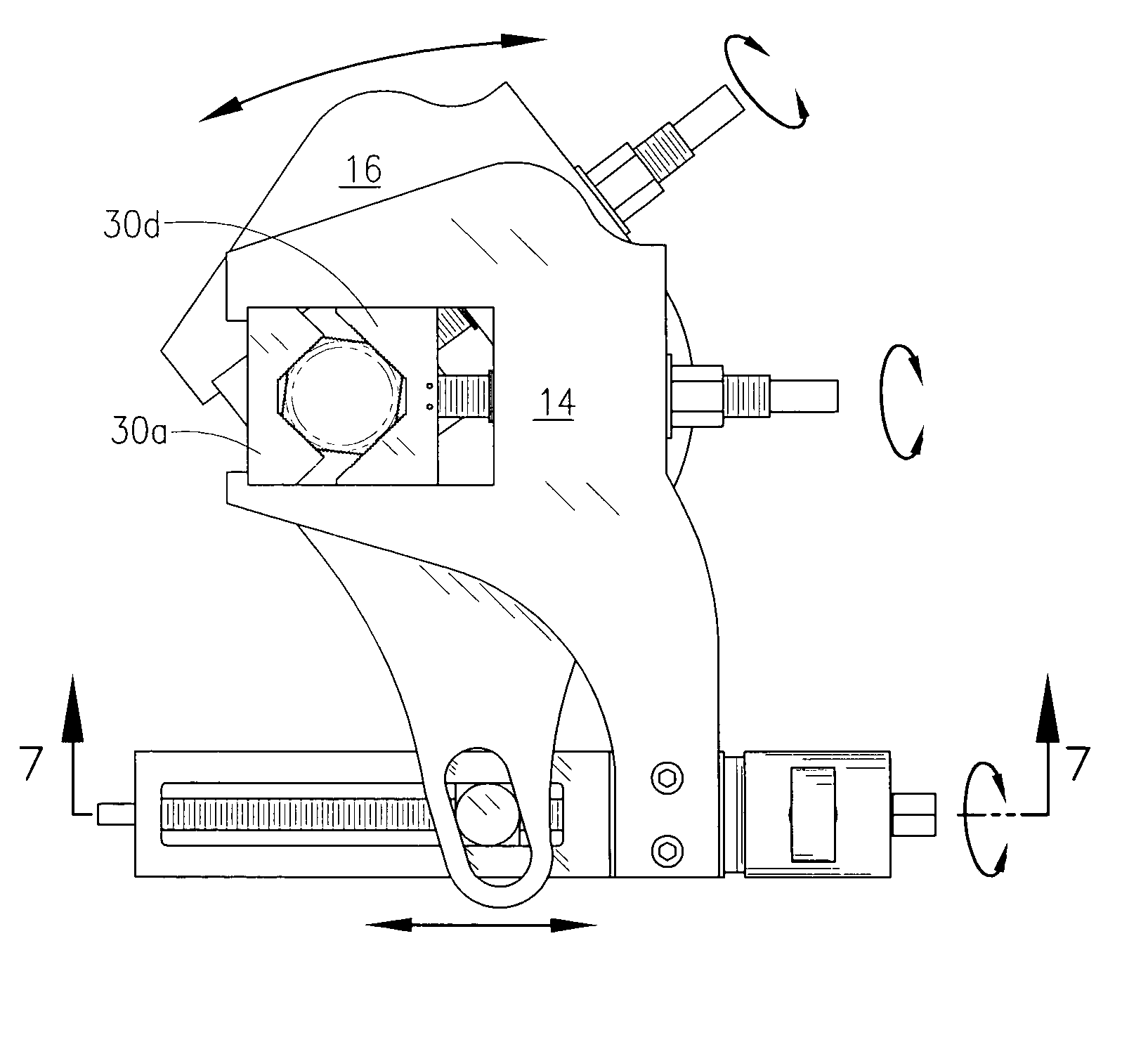

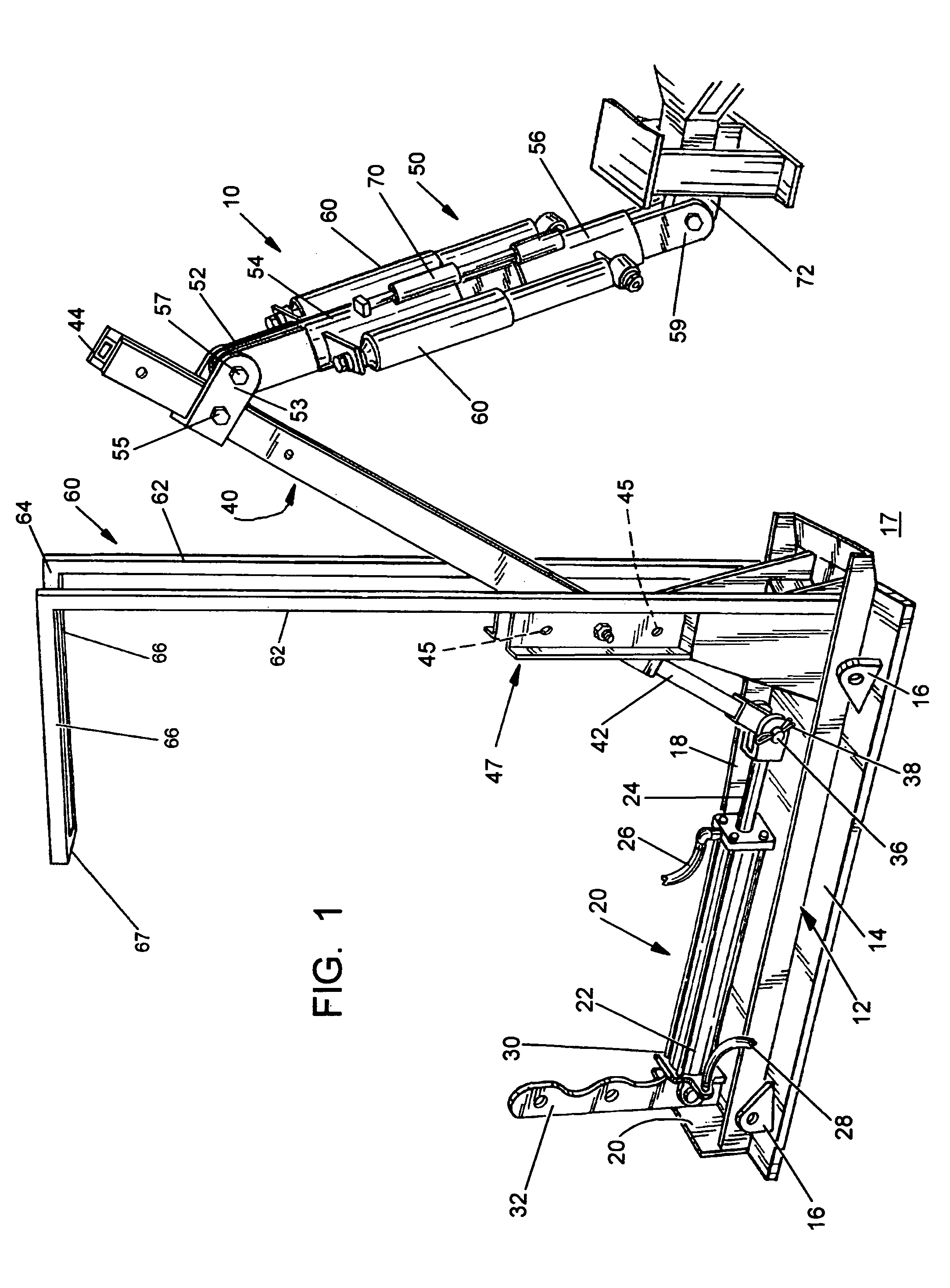

InactiveUS7104316B1Eliminate the effects ofImprove stabilityDrilling rodsConstructionsHydraulic cylinderEngineering

An improved tong positioning apparatus which includes a base positionable on the rig floor; a hydraulic cylinder positioned on the base, having a first end engageable to a rear support member and a second end engageable to a pivotal moment arm; a forward shock attachment arm engaged at a first end to one of three attachment points on the moment arm, and a second end which attaches to a tong frame attachment point on the tong. The forward shock attachment arm includes a pair of shock absorbers engaged along its length to provide a smooth, non-jerking motion both vertically and horizontally in moving the power tong. The tong positioning apparatus is designed to be remotely operated by hydraulic, air, air over hydraulics, electronically, by a single operator. There is further provided a plurality of attachment points on the rear support member, and a plurality of pivot points for the moment arm, to allow for various vertical and horizontal positioning of the tong during makeup and breakup of pipe on the rig floor. Further, the apparatus includes a safety shield system to insure the workers are protected from inadvertent contact with moving parts of the apparatus. Further, the apparatus includes a pipe section guide, digital or VHS video taping capability and positioning and alignment system to further align the upper tong and lower tong in relation to the pipe sections when mating with the jaw-die of the upper tong and the jaw-die combination of the lower tong. Further to the safety of the deck members, the tong operator controls the operation of the forward door of the upper tong during the torque process.

Owner:HOBGOOD JOHN PAUL

Clamp holder

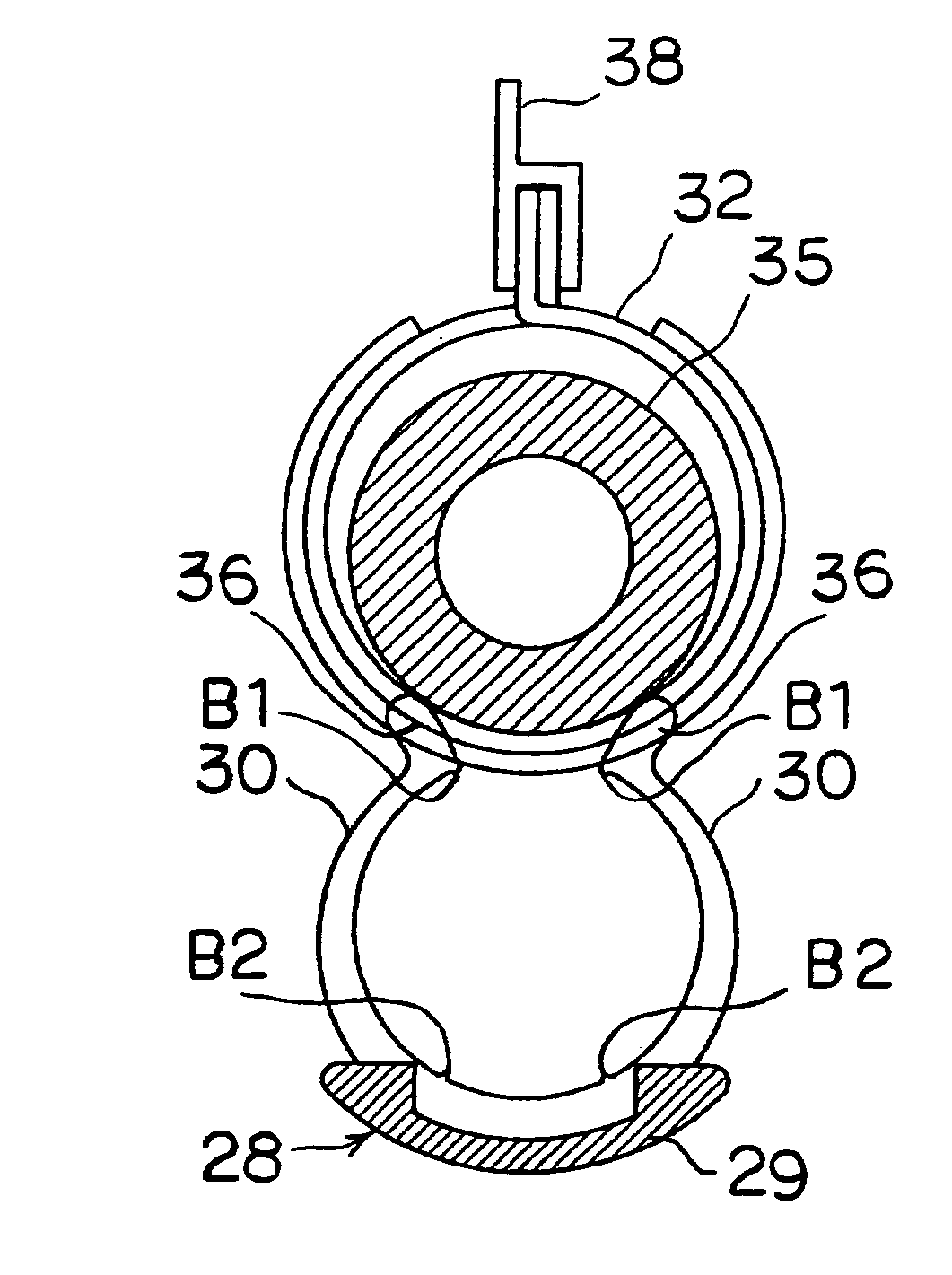

InactiveUS7093808B2Easy to packAvoid damageSnap fastenersPipe supportsEngineeringMechanical engineering

In a holder having a holder base and holding arms and used for holding a hose clamp in position, the holder base is so constructed as to be capable of being positioned on the outer periphery of an annular hose clamp and a pair of holding arms protrude from each of a pair of opposite lateral edges of the holder base. Each pair of holding arms are so shaped as to define a pair of opposed arcs extending along a circumference A having a diameter somewhat smaller than the outside diameter of a hose. Each holding arm has a sharp projection B1 formed on its inner peripheral surface at its distal end and directed substantially toward the center of the circumference A, or more inwardly than it. The clamp holder facilitates the preliminary holding of a hose clamp in position on a hose without damaging the hose, and without slipping off the hose or being displaced easily.

Owner:SUMITOMO RIKO CO LTD

Method for operating a tongs system for use on a rig and corresponding tongs system, computer program for implementing the method and rig comprising a tongs system

InactiveUS20170211344A1Reliably achievedTightening torque is also not exceededDrilling rodsMeasurement of torque/twisting force while tighteningSystems designEngineering

The invention relates to a method for operating a tongs system (10) designed for assembling a drill string element (12) and an often stationary drill string element (12) or for separating a drill string element (12) from another drill string element (12), said tongs system having lower tongs and upper tongs that can be moved relative to the lower tongs by means of a drive unit (18). A displacement-measuring system (44) detects a position (46) of the upper tongs relative to the lower tongs. A control unit (48) compares an application torque determined as a function of the detected position (46) with a defined or definable desired application torque (54). The assembly of the two drill string elements (12) is terminated when the determined application torque reaches or exceeds the desired application torque (54). The invention also relates to a tongs system (I 0) operating according to said method.

Owner:BENTEC DRILLING & OILFIELD SYST

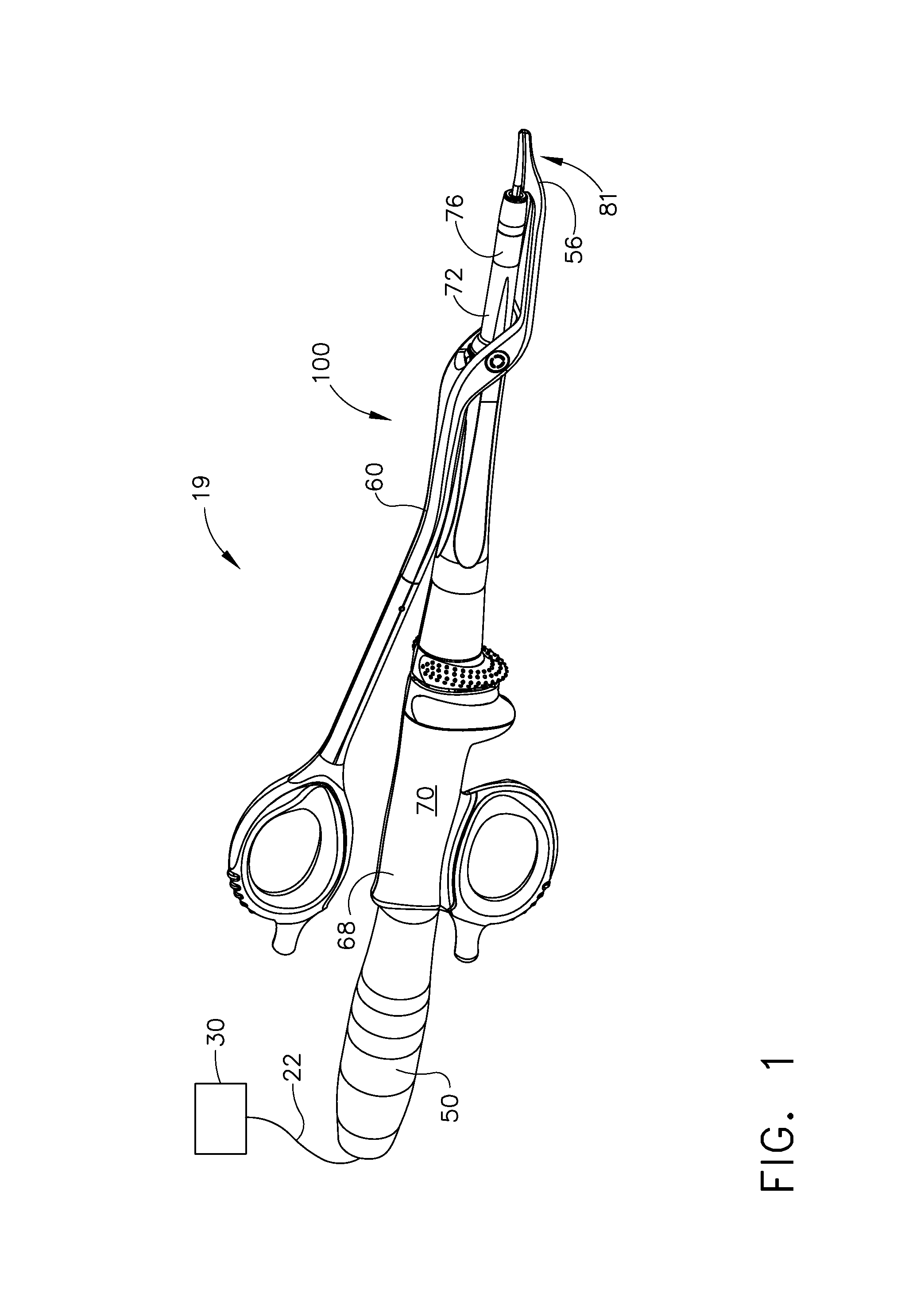

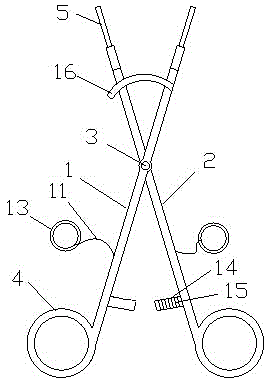

Surgical gripping forceps

ActiveUS20090259248A1Easy to disinfectOperational securitySurgical forcepsMaximum diameterEngineering

The invention relates to surgical gripping forceps with two gripping jaws movable relative to a main body, with each gripping jaw having a stationary pivot axis relative to the main body, and a lever arm, and with the lever arms being articulated via at least one push element. Each gripping jaw has its own pivot axis. The distance between the individual pivot axis and the midline of the main body is at least greater than 38% of the maximum width of the main body or the maximum diameter of the main body. The present invention also provides microsurgical gripping forceps that a substantial clamping force between the gripping jaws with customary force for actuating the forceps.

Owner:KARL STORZ GMBH & CO KG

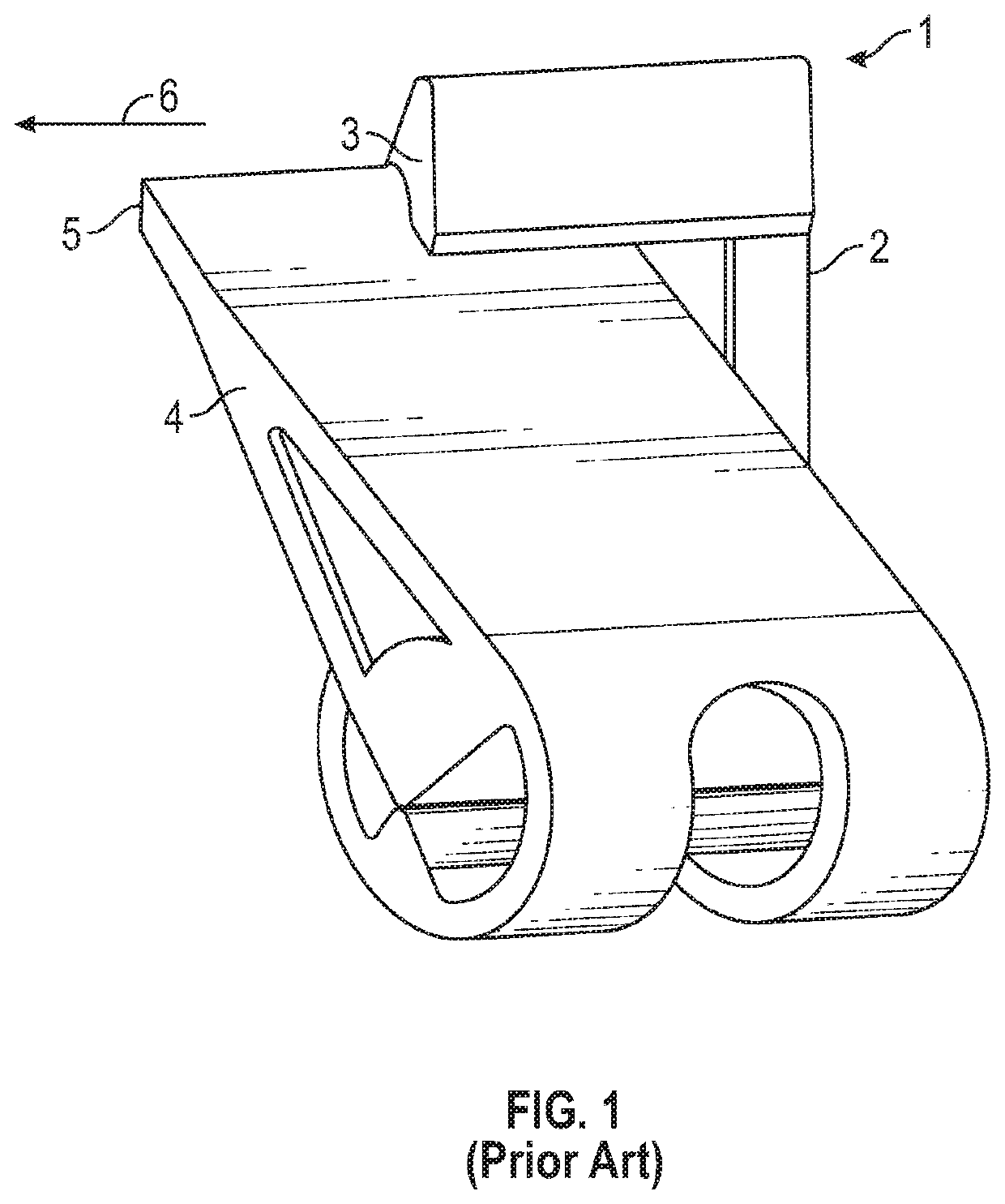

Angle steel relieving back-gouging machine

InactiveCN102218562AWide applicabilityReduce labor intensityMilling equipment detailsPositioning apparatusMilling cutterMechanical engineering

The invention relates to an angle steel relieving back-gouging machine, which comprises a lathe body (1), a machine frame (2), a straight guide rail (3), a milling deceleration motor (4), a relieving milling cutter (5), an adjusting dovetail groove (6), an adjusting nut (7), a handwheel (8), an adjusting screw (9), an adjusting dovetail (10), a right jaw (11), a left jaw (12), a clamp nut (13), a clamp screw (14), a clamping deceleration motor (15), a clamping bearing pedestal (16), a clamping dovetail (17), a slide block (18), a main leading screw (19), a main bearing pedestal (20), a main deceleration motor (21), a main nut (22), a back-gouging milling cutter (23), and a railing (24). The right jaw (11) and the left jaw (12) can rapidly clamp an angle steel opening upwardly or downwardly by the driving of the clamping deceleration motor (15), and the angle steel is processed by relieving through the relieving milling cutter or is processed by back-gouging through the back-gouging milling cutter. The invention has the advantages of extensive applicability, low labor intensity for workers, simple operations, rapid relieving and back-gouging speed, high efficiency, simple structure, low cost, and convenient maintenance.

Owner:贺自清

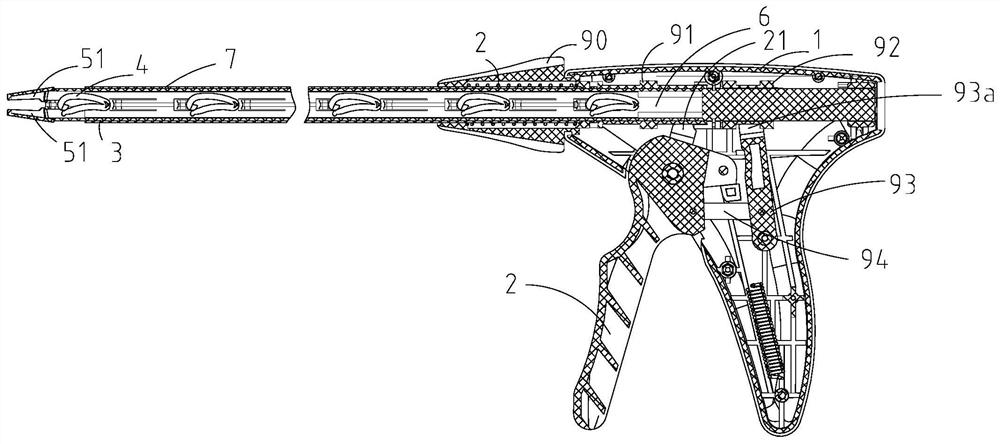

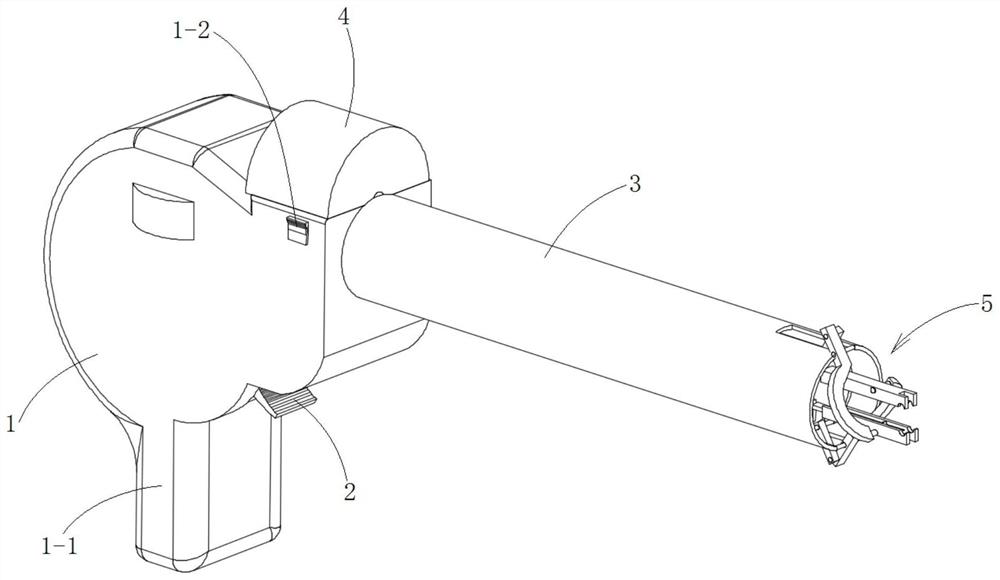

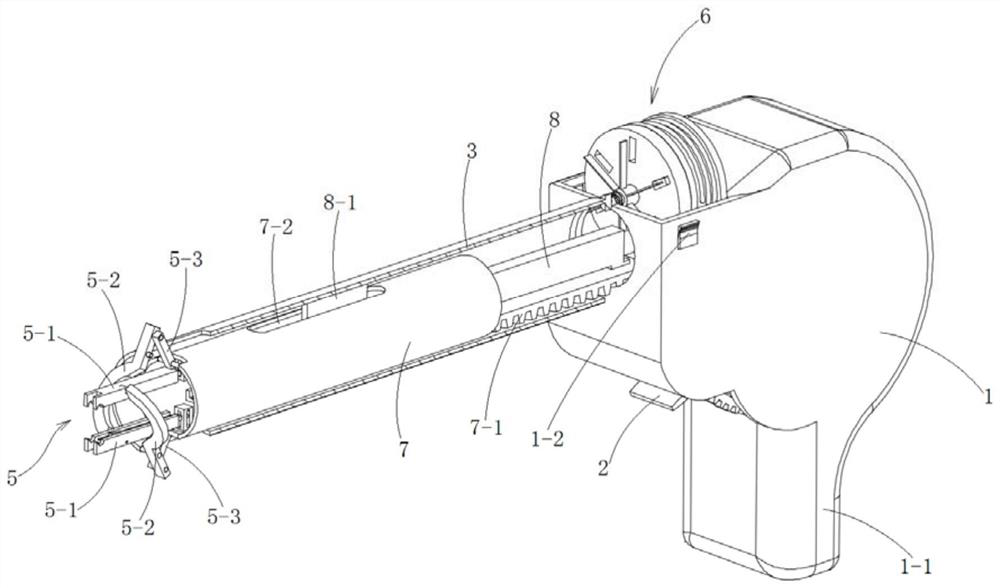

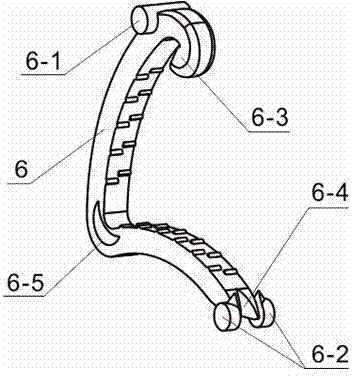

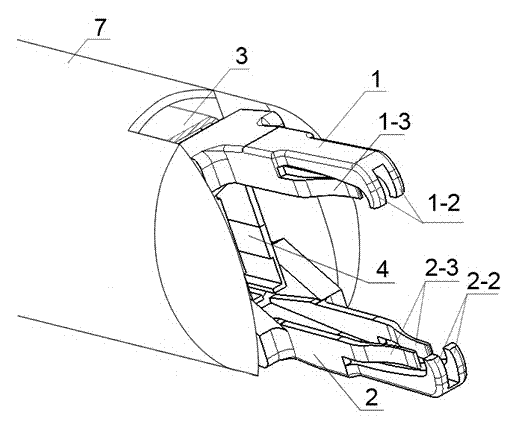

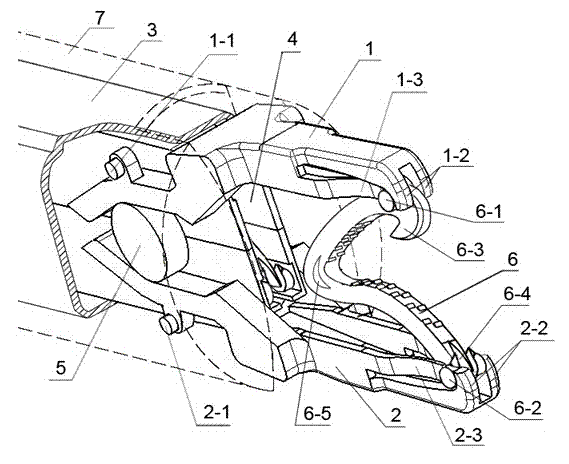

Repeating type clip applier

The invention discloses a repeating type clip applier which comprises a handle component, a clip bin, a clipper head, a clamping and pushing plate and a clipper push rod. The handle component comprises a handle shell, a front handle movably connected to the handle shell and a transmission mechanism connected with the front handle; at least two ligature clamps are suitable for being placed in the clip bin in the front-back direction; the clipper head is mounted at the front end part of the clamping bin, the clipper head comprises two forceps arms which relatively keep an opening trend, and the two forceps arms are suitable for accommodating ligature clamps; the clamping and pushing plate is connected with the transmission mechanism, and the clamping and pushing plate is suitable for being driven by the front handle through the transmission mechanism to move forwards and backwards in the clip bin, so that a ligature clamp in the clip bin is pushed forwards, and the foremost ligature clamp is pushed to the position between the two forceps arms; the clipper push rod is connected with the transmission mechanism and is suitable for being driven by the front handle through the transmission mechanism to move forwards to act on the two forceps arms to enable the two forceps arms to be close to each other so that the ligature clamp between the two forceps arms can be closed. The ligature clamp can be continuously applied, and is simple to use and convenient to operate.

Owner:JIANGSU NRS MEDICAL INSTR CO LTD

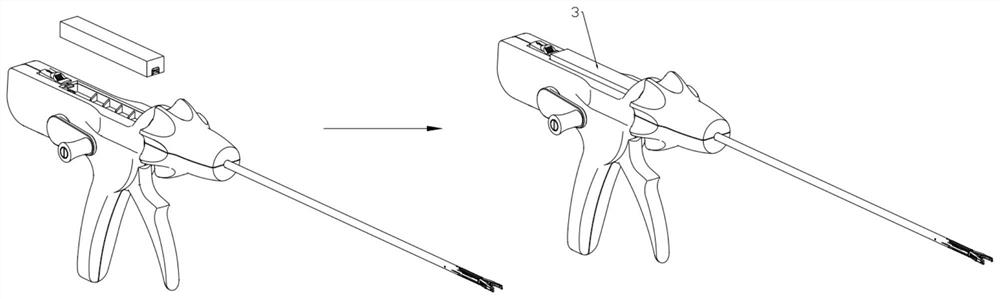

Repeating clip applier capable of being provided with tissue clip bin

The invention provides a repeating clip applier capable of being provided with a tissue clip bin. The repeating clip applier capable of being provided with a tissue clip bin comprises a handle assembly, a tissue clip bin assembly, a propulsion adjusting assembly, a clip pushing assembly and a clip applying assembly. The tissue clip bin assembly comprises a tissue clip bin (20), a pressing spring (21), a spring cover plate (22), a plurality of tissue clips (23) and a tissue clamp bin cover plate (24) are arranged in the tissue clamp bin from top to bottom, wherein the tissue clips are stacked from top to bottom and in a natural stretching state. A tissue clip bin is needed to be loaded according to operation requirements before an operation, a fixed number of the tissue clips are arranged in each tissue clip bin, the tissue clips in the tissue clip bin are in a natural telescopic state, after the tissue clips in the tissue clip bin pushed into a forceps rod to be stored, the tissue clips can enter an endoscope channel, and repeating clip of the tissue clips in a process of closing the tissue or the blood vessel is realized.

Owner:GUANGDONG TAIBAO MEDICAL SCI TECH

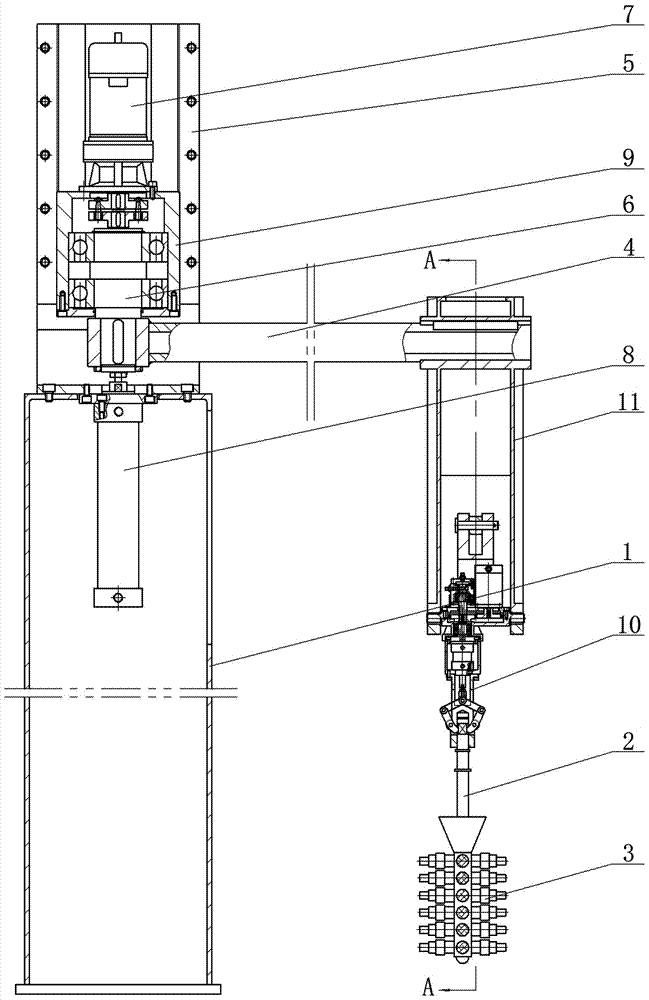

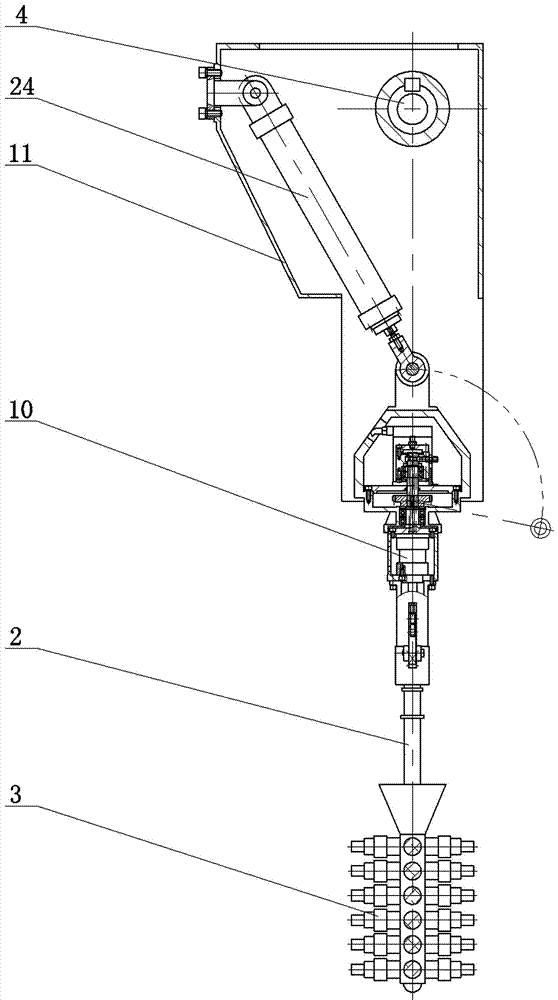

Wax pattern conveying mechanical hand

PendingCN107042517AReduce labor intensityLow costProgramme-controlled manipulatorGripping headsRobot handInvestment casting

The invention relates to a wax pattern conveying mechanical hand. The wax pattern conveying mechanical hand mainly solves the problems that the labor intensity of workers is large and working efficiency is low during wax pattern casting shell manufacturing. The wax pattern conveying mechanical hand is characterized by further comprising a rotating arm (4), a lifting sliding rail (5), a rotating shaft (6), a rotating arm servo motor (7), a lifting air cylinder (8), a sliding base (9), a pneumatic clamping device (10) and a clamping device support (11), wherein the rotating arm (4) is fixed to the rotating shaft (6) and can rotate in the horizontal plane through the rotating shaft (6), a clamp air cylinder (15) acts to enable a connecting rod type clamp (14) to be tightened or loosened, an oscillating cylinder (24) is hinged to the upper end of the clamping device support (11), and a piston rod of the oscillating cylinder (24) is hinged to the top of a basket frame (13). The wax pattern conveying mechanical hand can firmly grasp a wax pattern tree set, the wax pattern tree set is made to move up and down, rotate and uplift and swing in the transverse direction, manual conveying of the wax pattern tree set is replaced, the labor intensity of operators is lowered, and the working efficiency is improved.

Owner:WENZHOU POLYTECHNIC

Surgical forceps with coil spring

InactiveCN101467911AAchieve condensationPrevent overloadSuture equipmentsDiagnosticsSurgical ClampsCoil spring

A surgical clamp (1) is provided with branch parts (4, 5) which are articulated on the far-middle end of tubular handle part (2) with a mode of movable with each other. The branch parts are driven by a handle (15) through the relative movement of connecting rod (7) penetrating a shank through the shank. In two handle components (14, 16) of handle, the handle component (16) of connecting rod is detachably articulated on the far-middle end of connecting rod (7), and the handle component (14) of shank is connected with the near-middle end of handle through a sleeve (21). The sleeve surrounds the connecting rod (7) and is supported on the handle component (14) of shank with a mode that the longitudinal movement is allowed. The sleeve is detachable fixed on the near-middle end of shank and is surrounded by a spiral spring (19) which is supported on the sleeve with the far-middle end and is supported on the handle component of shank with the near-middle end. The invention is characterized in that the sleeve is installed to project from the handle component of shank with a mode of supporting at least one bigger component of the area of spiral spring in the far-middle direction.

Owner:OLYMPUS WINTER & IBE

Surgical gripping forceps

Surgical gripping forceps are provided with one or two gripping jaws movable relative to a main body, wherein each moveable one of the gripping jaws has a pivot pin, fixed in position relative to the main body, and a lever arm. The lever arms are articulated via at least one push element. For this purpose each movable one of the gripping jaws has its own pivot pin. From the midline of the main body, the individual pivot pin has at least a distance greater than 38% of the maximum width of the main body or maximum diameter of the main body. The microsurgical gripping forceps operate with customary force for actuating the forceps, and permit a substantial applied clamping force.

Owner:KARL STORZ GMBH & CO KG

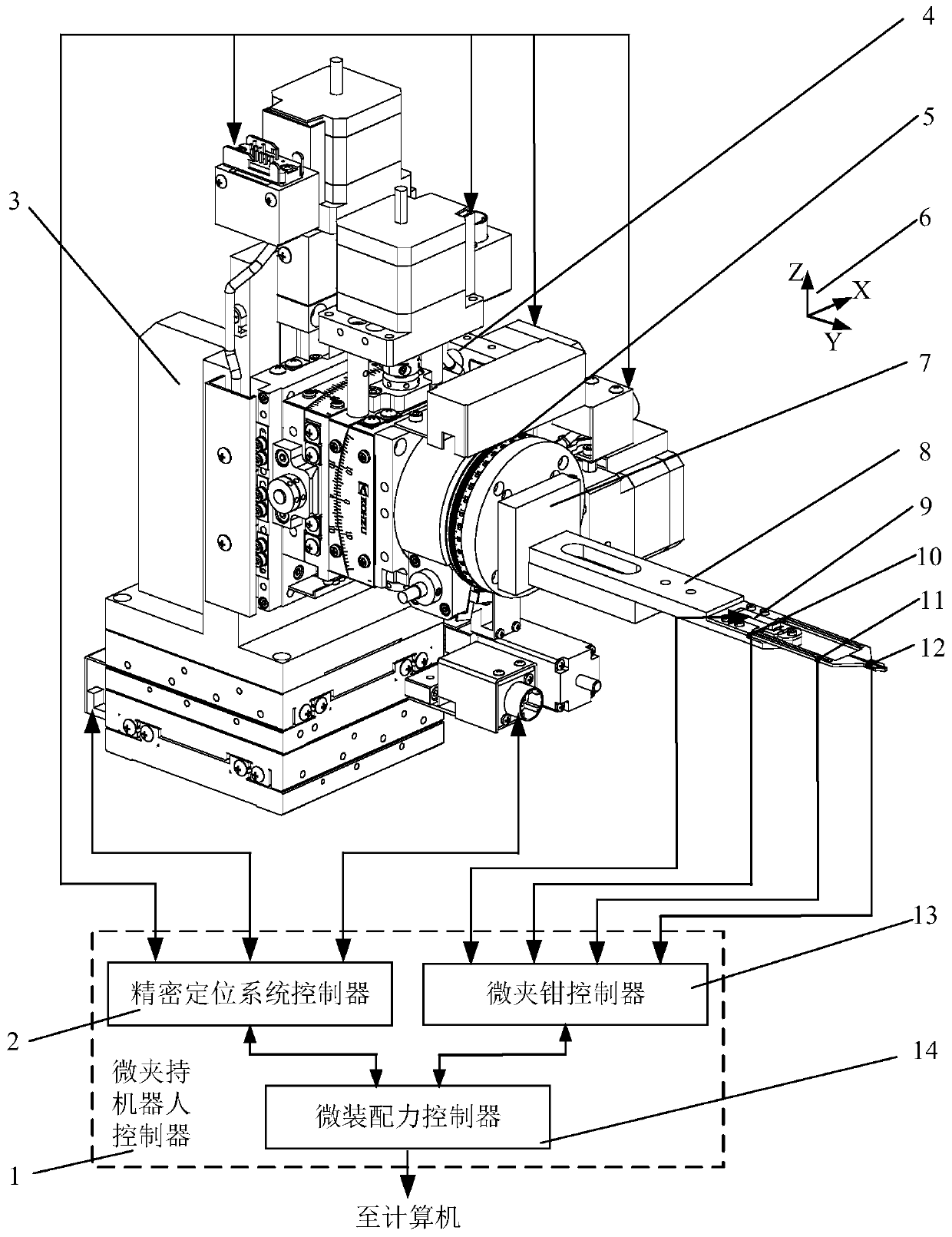

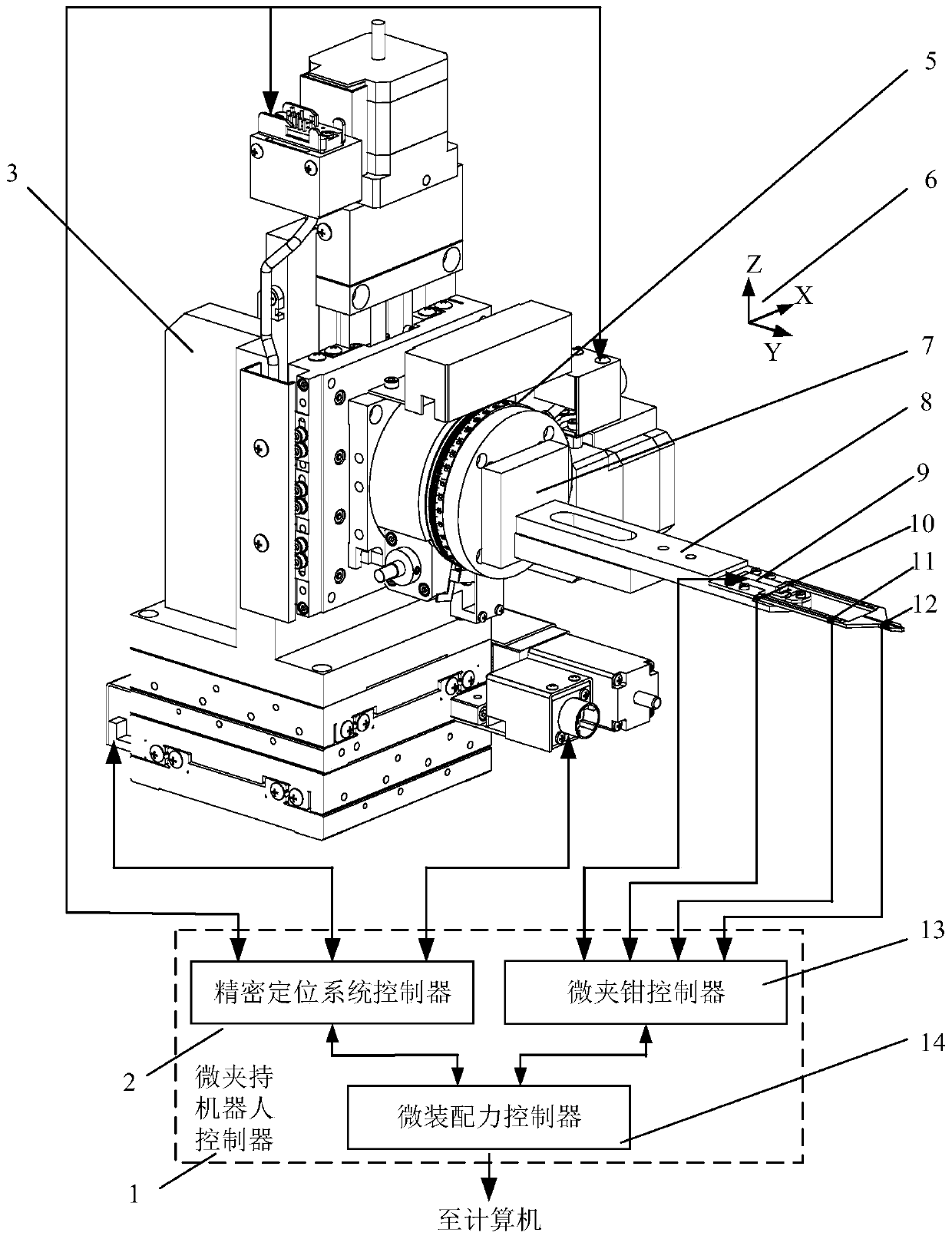

Micro-clamping robot

ActiveCN111299996ARealize high precision positioningRealize large-scale spatial positioningProgramme-controlled manipulatorMicromanipulatorCompliant mechanismLinear motion

The invention relates to a micro-clamping robot. According to the robot, micro parts can be clamped, high-precision motion positioning can be achieved, and meanwhile, the detection and feedback control over clamping jaw displacement, clamping force and micro-assembly force can be achieved. The micro-clamping robot is composed of a micro-clamp which can achieve clamping jaw displacement detection,clamping force detection and micro-assembly force detection at the same time, a precision positioning system and a micro-clamping robot controller, linear motion and rotary motion along X axis, Y axisand Z axis are achieved, and meanwhile, detection, sense and feedback of clamping jaw displacement, clamping force and micro-assembly force can be achieved at the same time; the micro-clamp is composed of a base, a single-piece compliant mechanism fixed on the base, an actuator and a micro-clamp controller; and first-stage lever mechanisms which are symmetrically arranged, third-stage series parallelogram mechanisms which are symmetrically arranged and clamping jaws which are symmetrically arranged are arranged on the single-piece compliant mechanism.

Owner:CHONGQING UNIV

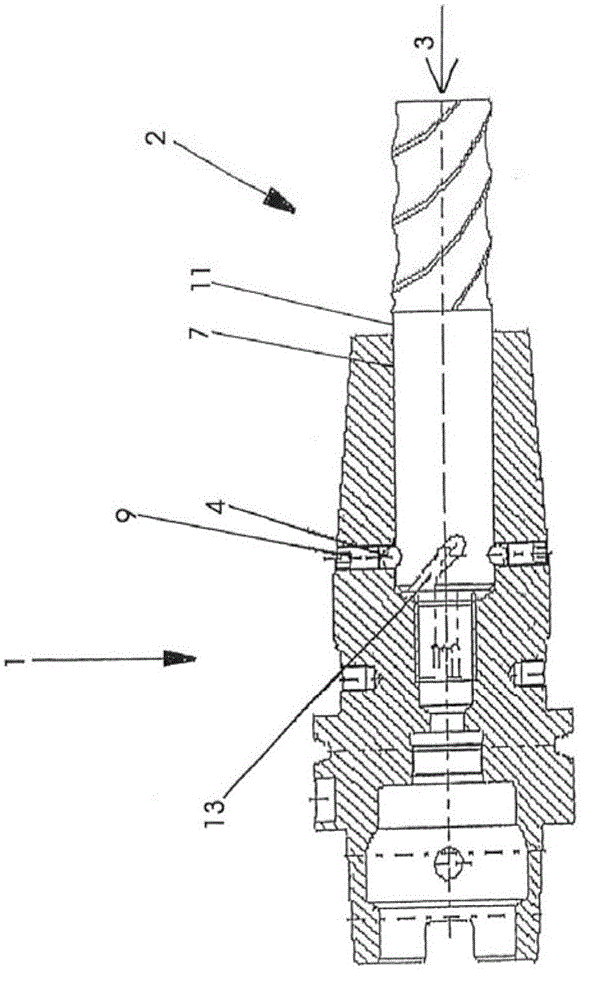

Means for preventing tools from being pulled out from tool holders with a tool holding fixture

ActiveCN105057722AEasy to importPrevent axial movementGrinding wheel securing apparatusSleeve/socket jointsEngineeringClip forceps

Owner:FRANZ HAIMER MASCHINENBAU KG

Stringer skin tooling structure

ActiveCN110877221AEffectively fixedAvoid deformationWork holdersPositioning apparatusStringerMechanical engineering

The invention provides a stringer skin tooling structure which comprises workpiece fixing devices, workpiece positioning devices, fixed beams and a frame body. The fixed beams are vertically arrangedon the frame body; the workpiece fixing devices comprise pincers parts, support parts and sucker parts; the support parts are arranged on the fixed beams and are provided with protruding support platforms; the pincers parts and the sucker parts are arranged on the support parts; the lower pressing ends of the pincers parts can be abutted against the upper end surfaces of the support platforms; theadsorption planes of the sucker parts and the outer end surfaces of the support platforms are co-directional; and the workpiece positioning devices are arranged on side beams and / or cross beams of the frame body and are used for positioning stringers and skins. Through the stringer skin tooling structure provided by the embodiment of the invention, by utilizing two acting forces with opposite directions, the stringer and the skin can fit closely and are not easy to deform, the hole making work can be carried out conveniently, and the hole making coverage rate can be improved.

Owner:北京神工科技有限公司

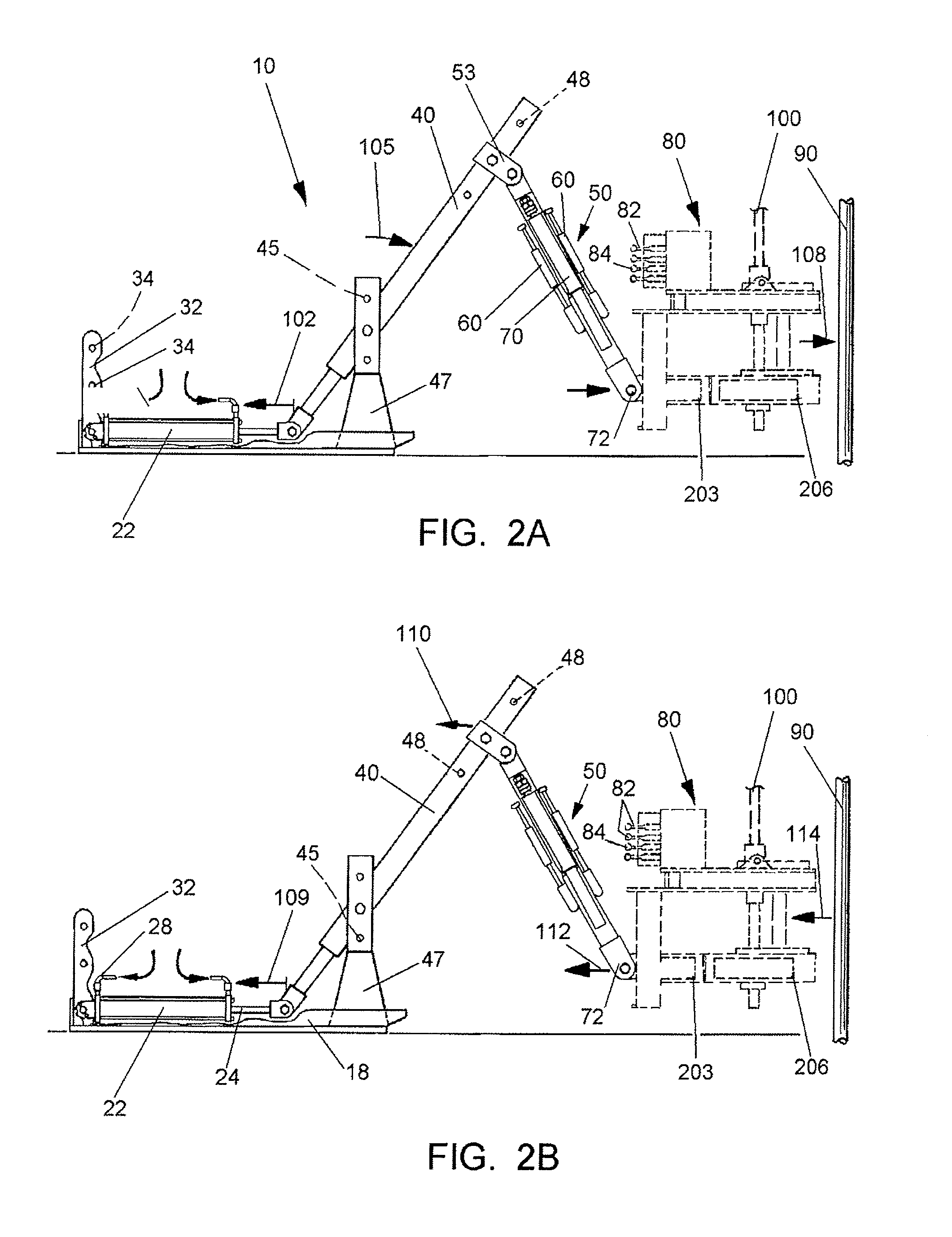

Tong positioning and alignment device

InactiveUS7559360B2Eliminate the effects ofImprove stabilityDrilling rodsFluid removalHydraulic cylinderEngineering

An improved tong positioning apparatus which includes a base positionable on the rig floor; a hydraulic cylinder positioned on the base, having a first end engageable to a rear support member and a second end engageable to a pivotal moment arm; a forward shock attachment arm engaged at a first end to one of a plurality of attachment points on the moment arm, and a second end which attaches to a tong frame attachment point on the tong. The forward shock attachment arm includes a pair of shock absorbers engaged along its length to provide a smooth, non-jerking motion both vertically and horizontally in moving the power tong. The tong positioning apparatus is designed to be remotely operated by hydraulic, air, air over hydraulics, electronically, by a single operator.

Owner:HOBGOOD JOHN PAUL

Rotary-feedingligature clip running applier with replaceable chuck

ActiveCN112826564AImprove operational flexibilityImprove operational stabilityWound clampsLigation clipSurgery

The invention discloses a rotary-feeding ligature clip running applier with replaceable chuck, and belongs to the field of medical clip appliers. The rotary-feeding ligature clip running applier comprises a shell, a trigger, an outer tube, a clip head mechanism, a clip bin mechanism, a clip head clamping and closing transmission mechanism and a clip pushing mechanism, wherein the clip bin mechanism of the continuous-shooting clip applier adopts a clip storage disc design for rotating clip replacement, and the clip pushing mechanism is used for pushing ligature clips in a clip storage disc to the clip head mechanism for clip applying; therefore, the clamping bin mechanism occupies a small size in the length direction of the clip applier, the length of an outer tube of the clip applier is conveniently and reasonably set, and the operation flexibility and stability of the clip applier are improved; moreover, the ligature clips are uniformly and independently arranged in the circumferential direction of the clip storage disc, so that the continuous shooting number of the clip applier can be flexibly set; meanwhile, the ligature clips do not influence one another, the clip applying action is more stable and reliable, the clip storage disc is simple and convenient to replace, and the clip applier is convenient to reuse; therefore, the ligation clip is compact and stable in connection before and after continuous percussion action, and flexible and convenient to operate.

Owner:SINOLINKS MEDICAL INNOVATOIN INC

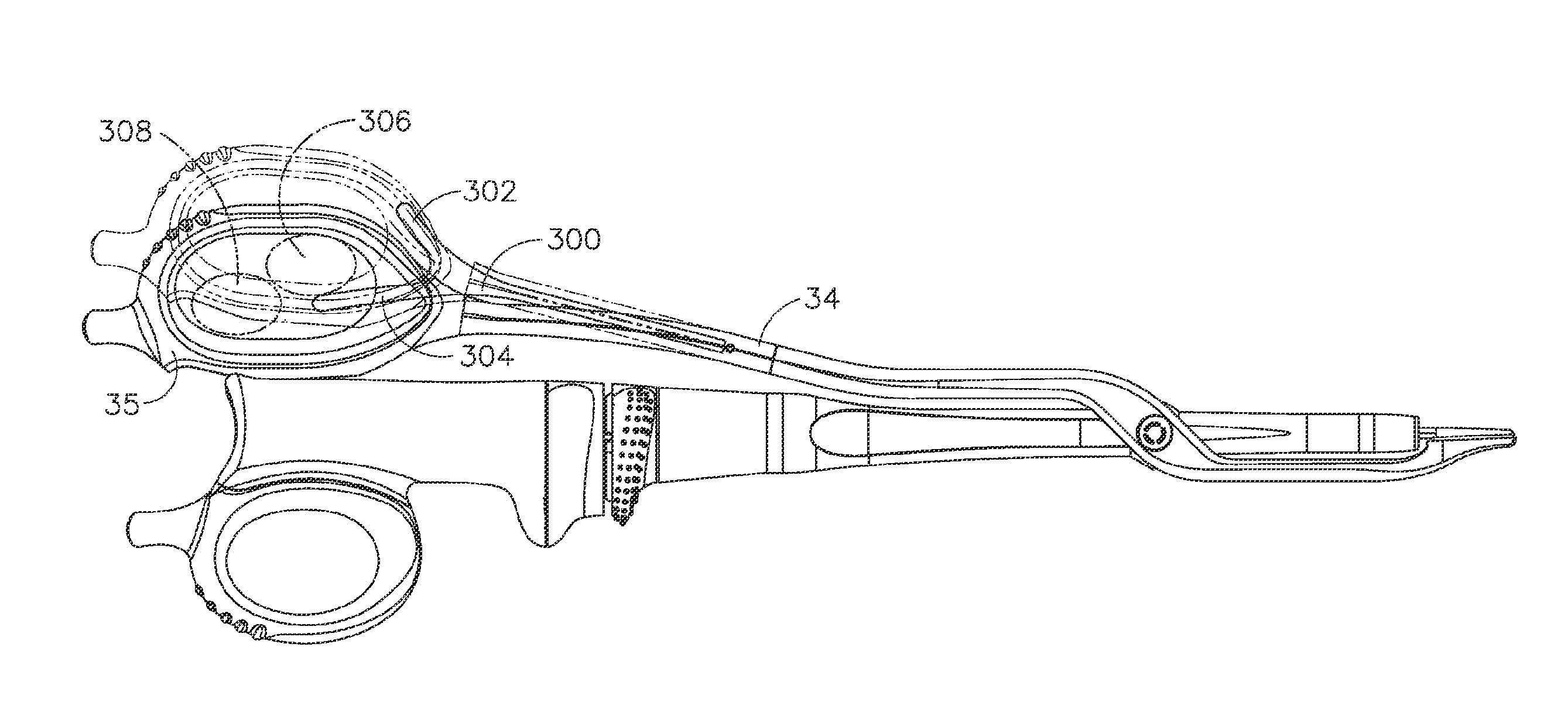

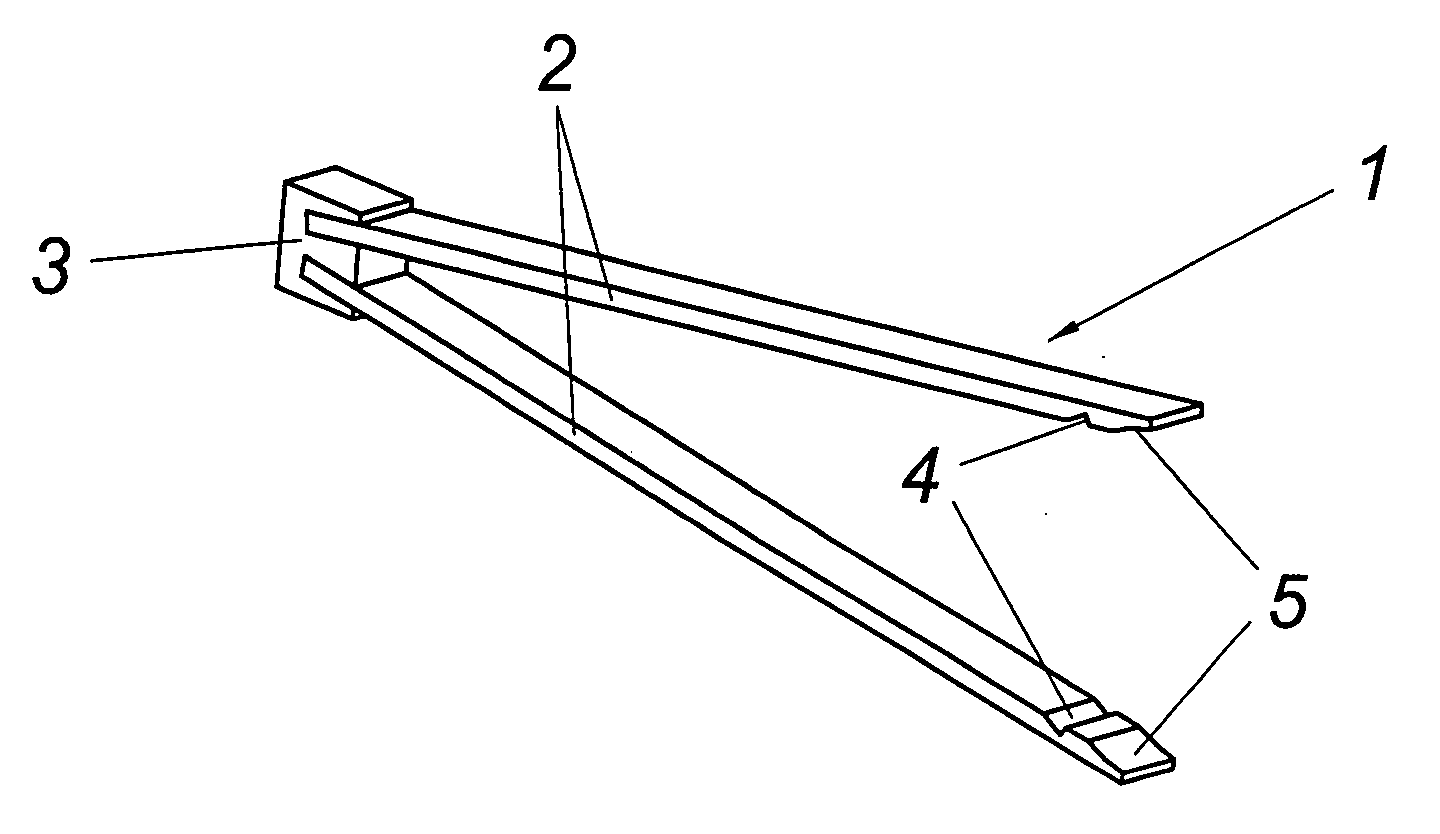

Ligation clip continuous shooting clip applier and use method thereof

The invention provides a ligation clip continuous shooting clip applier and a using method thereof. The ligation clip continuous shooting clip applier comprises a gun body assembly used for holding and shooting and composed of a left shell, a right shell, a clip feeding assembly, a shooting assembly and a clip bin loading and unloading button, a gun barrel assembly is movably installed at one end of the gun body assembly, an upper connecting pipe and a lower connecting pipe are connected by buckles, an annular cavity structure formed by an upper shooting connecting ring and a lower shooting connecting ring is movably arranged on the outer side of the upper connecting pipe and the outer side of the lower connecting pipe in a sleeving mode and axially moves outside the upper connecting pipe and the lower connecting pipe, and barbs are arranged at the front end of a pushing clamping plate and the front end of a clamping storage groove; and the ligation clip continuous shooting clip applier further comprises a clip bin assembly used for loading and unloading the ligation clip, the clip bin assembly can be replaced, the ligation clip can be quickly supplemented after being used up in the operation process, the clip applying time is shortened, meanwhile, the ligation clip is basically in a natural state in the clip bin assembly, the failure rate of the ligation clip is greatly reduced, and the gun body assembly and the gun barrel assembly can be repeatedly used in the same operation, so that the economic burden of a patient is reduced.

Owner:常州缤纷智造科技有限公司

Tongs

ActiveUS20060091684A1Decrease expenditureImprove securingPliersMetal-working hand toolsStructural engineeringMechanical engineering

Owner:FRAUSCHER JASMINA

Surgical ligation clip applier capable of realizing continuous shooting

The invention discloses a surgical ligation clip applier capable of realizing continuous shooting. The clip applier comprises a tubular shell, forceps and a magazine; one end of the magazine is arranged in the tubular shell; a guide groove is formed in the tubular shell; the magazine is glidingly arranged on the guide groove; the magazine is provided with a drive shaft; the drive shaft is clamped at the revolving shaft hinge joint of an upper jaw and a lower jaw; the lower jaw is provided with lower jaw stop elastic plates; the forceps comprise the upper jaw, the lower jaw, an upper jaw revolving shaft and a lower jaw revolving shaft; the upper jaw is fixedly arranged on the guide groove through the upper jaw revolving shaft; the upper jaw can rotate along the upper jaw revolving shaft; the lower jaw is fixedly arranged on the guide groove through the lower jaw revolving shaft; the lower jaw can rotate along the lower jaw revolving shaft; the upper jaw revolving shaft and the lower jaw revolving shaft are respectively arranged at the corresponding upper lower sides of the magazine. The surgical ligation clip applier disclosed by the invention is simple in structure and convenient in use, is capable of clamping and using a ligating clip, and is capable of realizing a function of continuous shooting.

Owner:徐保利

Five piston diaphragm pump

InactiveCN101142408AUniform pressureFlexible wall reciprocating enginesPositive displacement pump componentsDiaphragm pumpEngineering

A pump having top and bottom pieces coupled together by a coupling device features a circumferential clamp that is a lightweight plastic clamp having clamping members, each with one or more strengthening members oriented along a longitudinal axis defined in relation to the top and bottom pieces. The clamping members may include two semi-circular clamping members, each with circumferentially spaced strengthening rib members oriented along the longitudinal axis of the pump housing.

Owner:国际电话电报公司

Microsurgery forceps with double forceps heads capable of clamping and fixing

ActiveCN104921777AAchieve anastomotic dockingEasy to fixDiagnostic recording/measuringSensorsMedical equipmentButt joint

The present invention discloses microsurgery forceps with double forceps heads capable of clamping and fixing, and belongs to the technical field of medical equipment. The microsurgery forceps are used for performing clamping and fixing operation. The technical scheme is that the double forceps heads capable of clamping and fixing are added to traditional operating forceps, blood vessel or nerve can be clamped by clamping pieces at front ends of the forceps heads, the clamping pieces are connected with pull rods, a stay cable and pull rings, and a clamping spring is disposed between the two clamping pieces. After the blood vessel or the nerve is clamped by the forceps heads, the forceps heads at two sides are shut towards the middle by closing handles at two sides of the operating forceps, so that anastomosis butt joint of two broken ends can be achieved. The microsurgery forceps are reasonable in structure, simple and flexible in operation and firm in fixation, the blood vessel can be prevented from being repeatedly clamped during an operation, man-made damage can be prevented, and one-man operation of clamp, measurement, anastomosis and fixation is achieved. The microsurgery technology is innovated, the disadvantages in a microsurgery operation that broken ends of blood vessel and nerve are poorly anastomosed, and specially-assigned person auxiliary operation is usually required are effectively prevented, operation time is shortened, and patient pain is effectively relieved.

Owner:张英泽 +1

System and method for minimally invasive cutting instrument operation

A system and method of operating a minimally invasive cutting instrument includes a surgical cutting instrument. The surgical cutting instrument includes a drive unit, an end effector located at a distal end of the instrument, and a garage for housing the cutting blade when the cutting blade is not in use. The end effector includes gripping jaws and a cutting blade. To perform a cutting operation,the instrument extends the cutting blade from a first position to a second position, retracts the cutting blade from the second position to a third position between the first and second positions, and further retracts the cutting blade to the first position. While the cutting blade is not in use, the cutting blade is maintained in the first position using a restraining mechanism in the drive unit, force or torque applied by a motor or other active actuator to the drive unit, or both.

Owner:INTUITIVE SURGICAL OPERATIONS INC

Pinch clamp device

ActiveUS11040186B2Avoid abrasionsAvoid irritationInfusion devicesCatheterIntravenous tubingPatient comfort

Pinch-style clamps can be designed for use in clamping or occluding plastic tubing, such as intravenous tubing. These pinch clamps can include a soft, polymer material applied to various surfaces of the pinch clamp to prevent abrasion or irritation to the patient, increase friction between the pinch clamp and the user operating said pinch clamp, increase friction between engaged surfaces of the pinch clamp to prevent premature or unintended disengagement of the clamp, or increase friction between the outer surfaces of the tubing and the clamping surfaces of the clamp. Various features or components can be employed to prevent lateral disengagement of the pinch clamp. A pinch clamp may also be configured with rounded outer edges to enhance patient comfort.

Owner:BECTON DICKINSON & CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com