Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32 results about "Check weigher" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A checkweigher is an automatic or manual machine for checking the weight of packaged commodities. It is normally found at the offgoing end of a production process and is used to ensure that the weight of a pack of the commodity is within specified limits. Any packs that are outside the tolerance are taken out of line automatically.

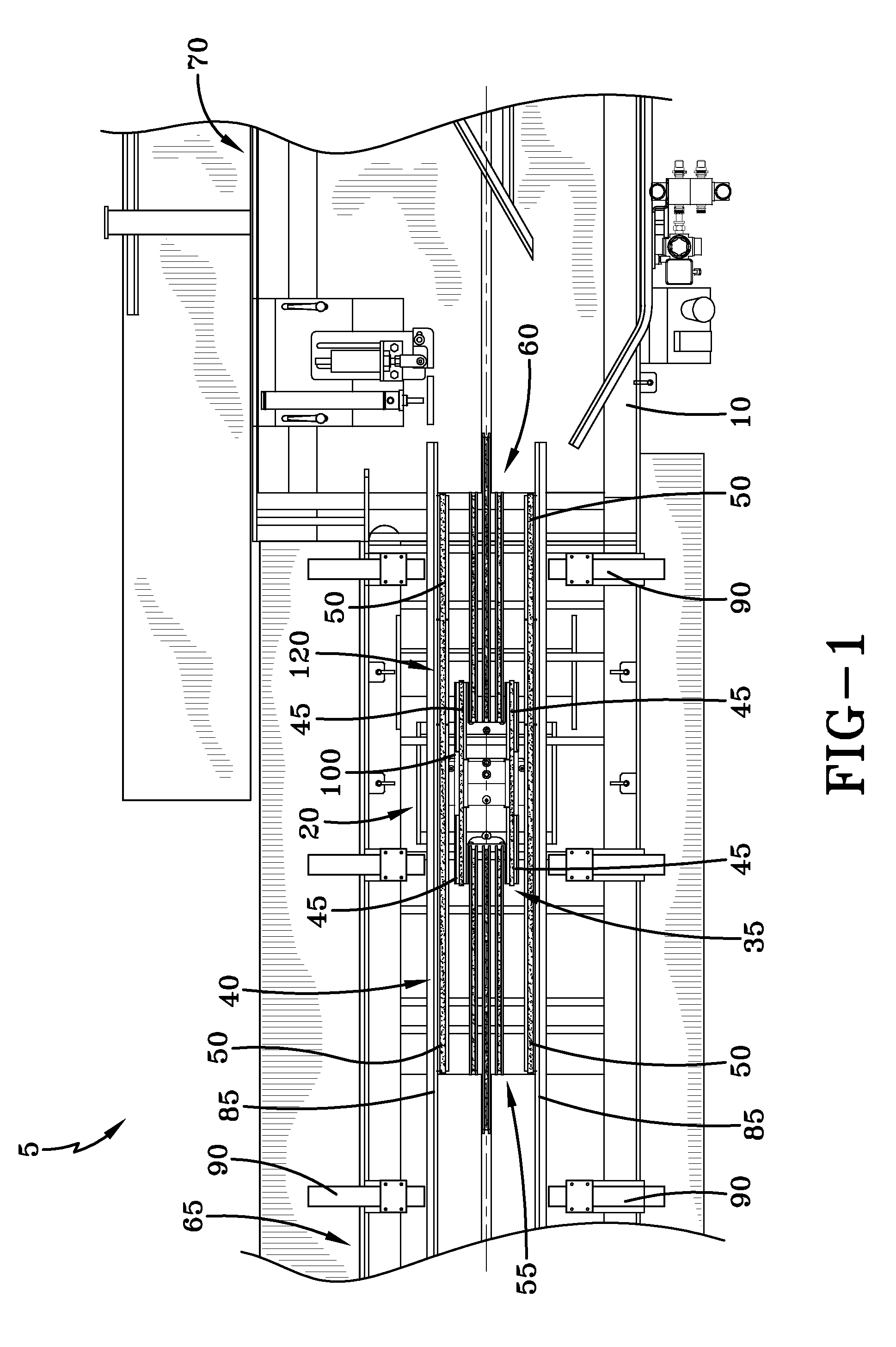

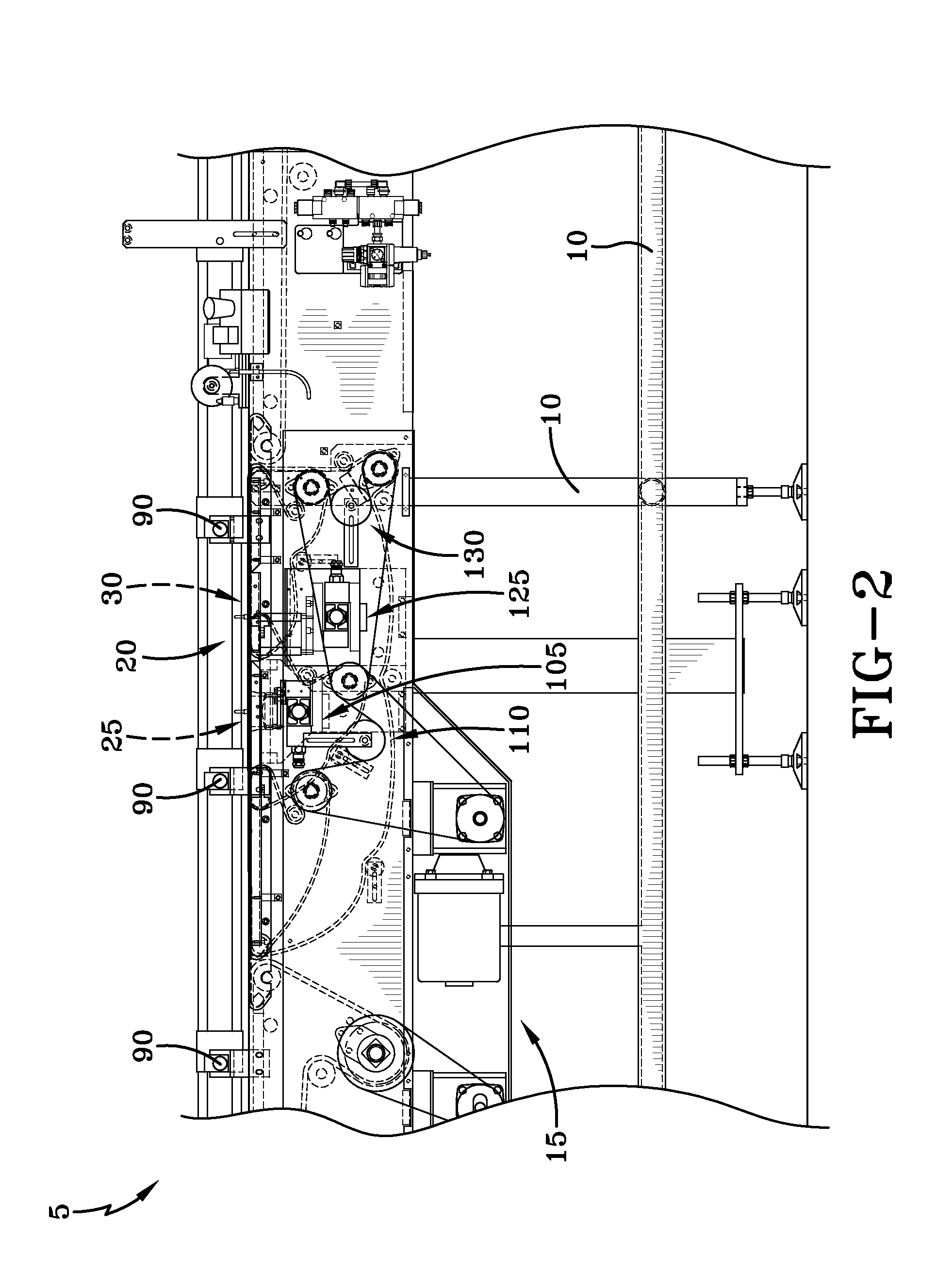

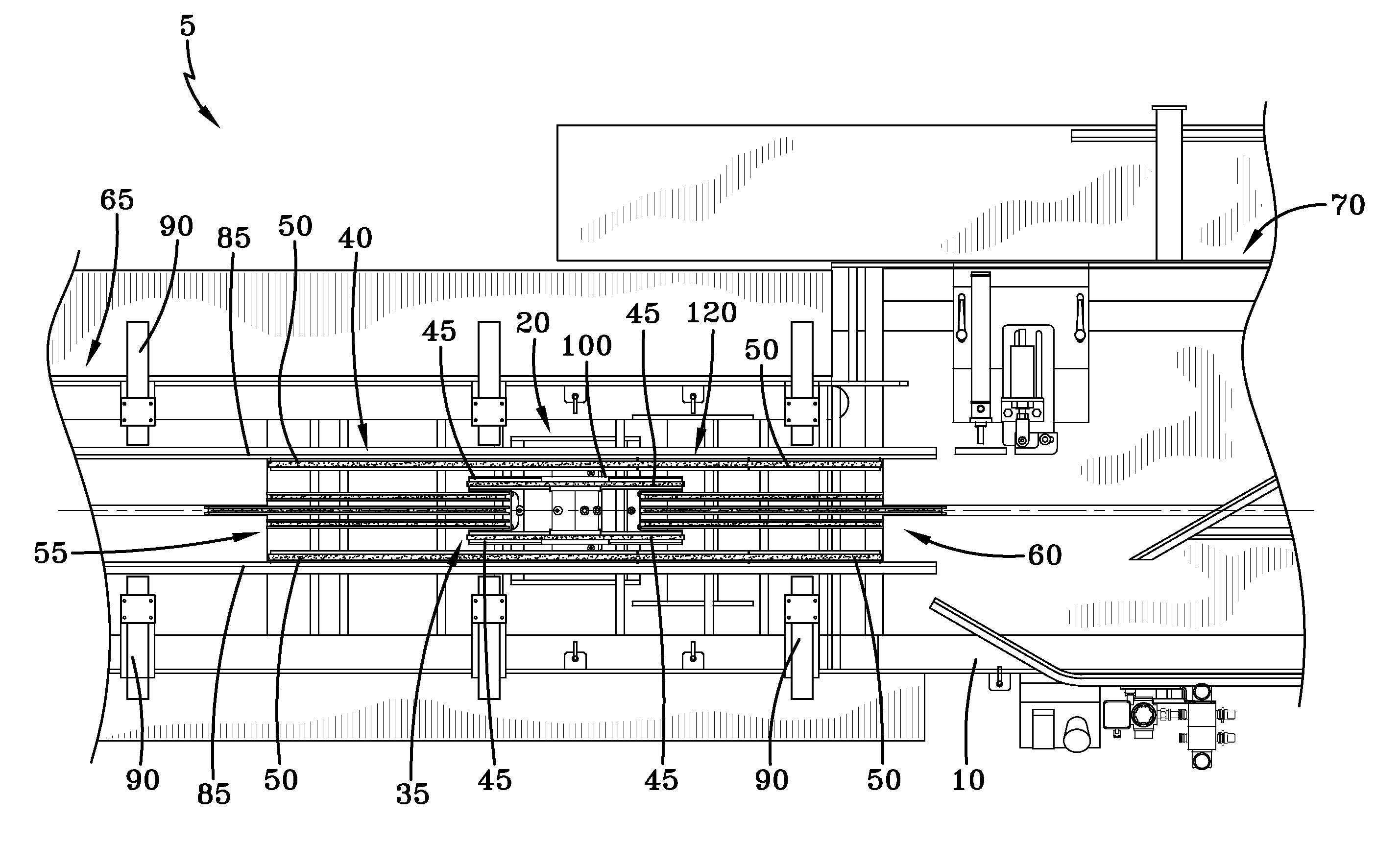

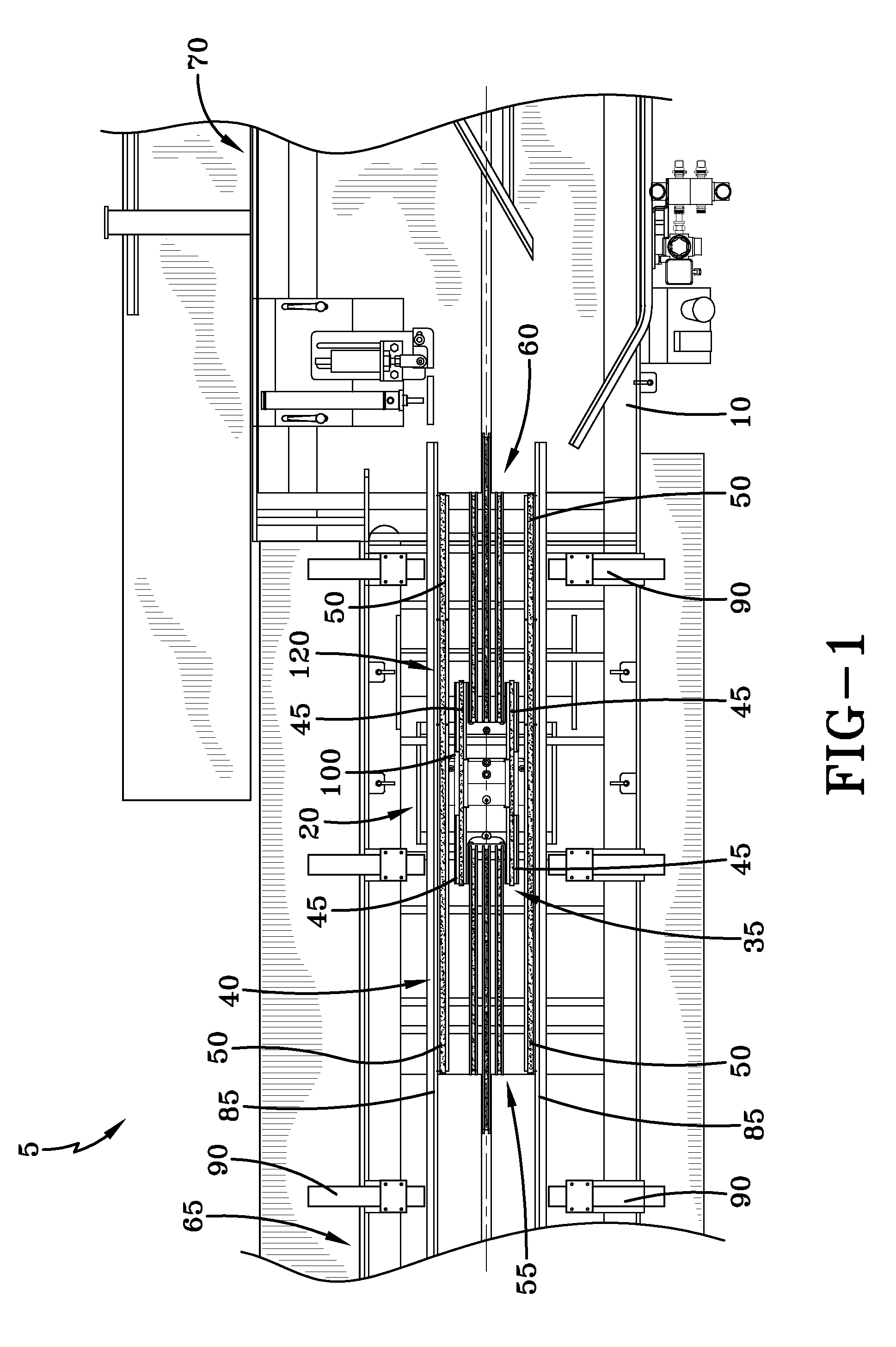

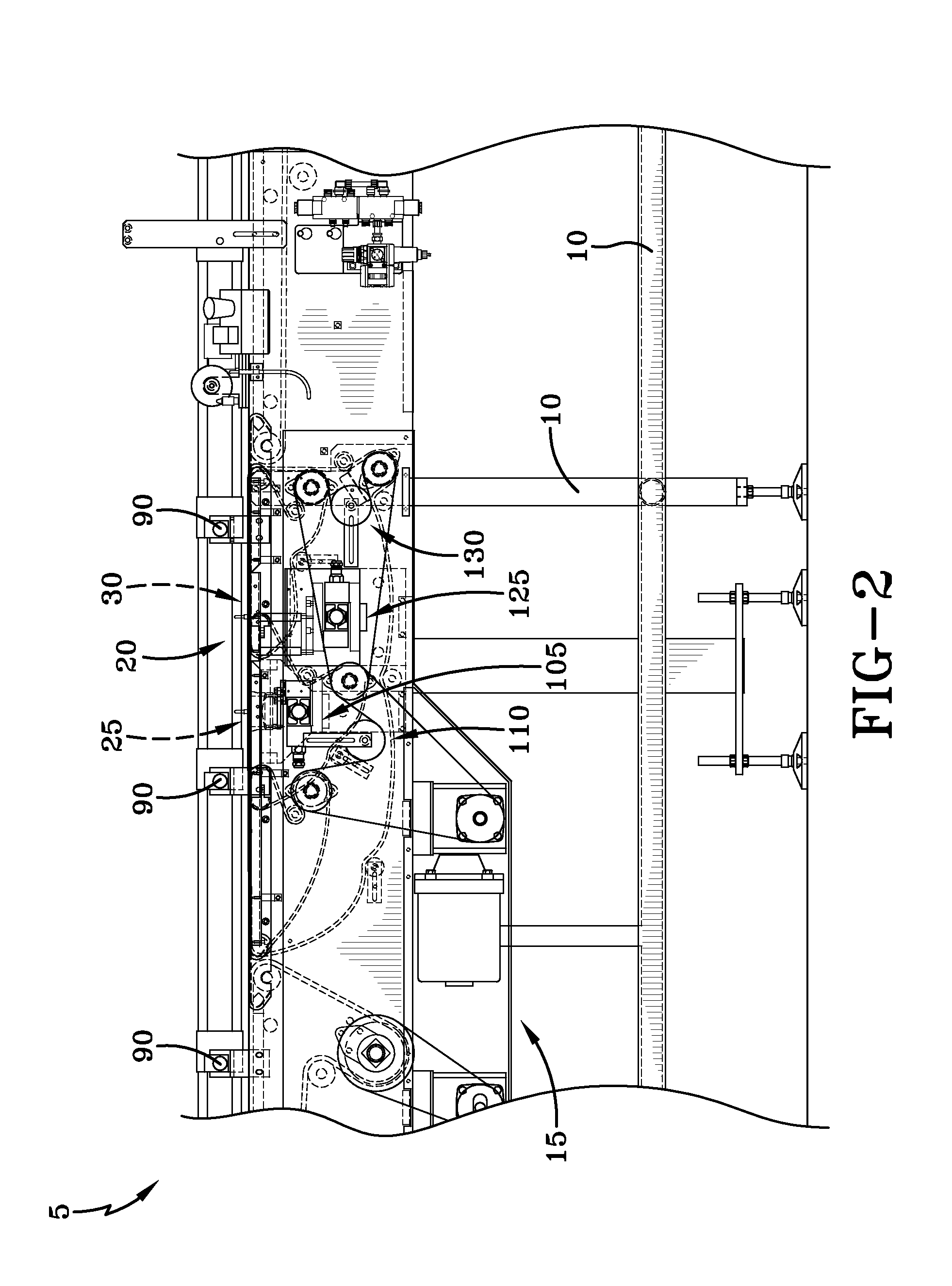

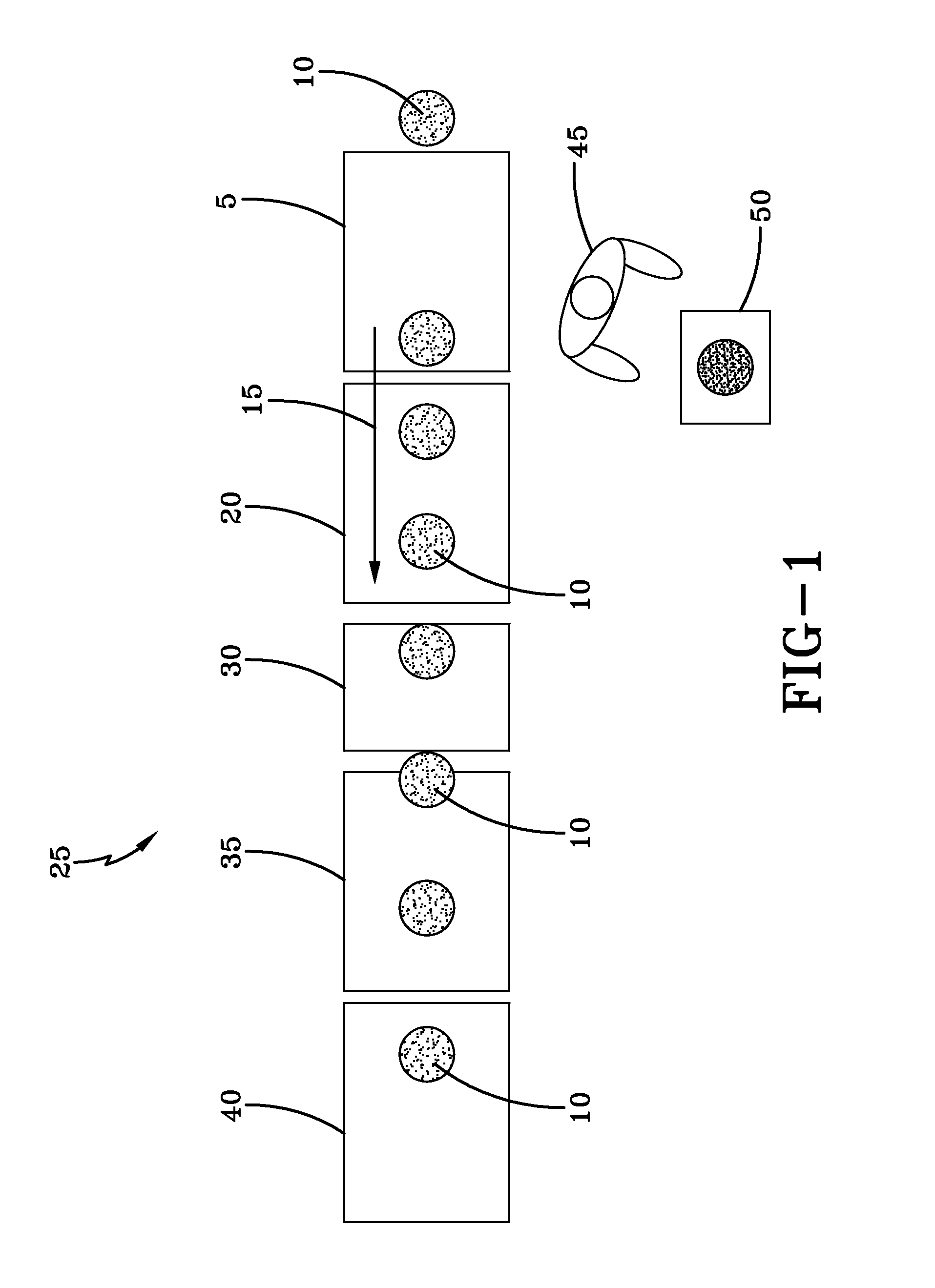

Checkweigher performance validation

ActiveUS20120285218A1Minimize and eliminate needEasy to useWeighing apparatus testing/calibrationForce/torque/work measurement apparatus calibration/testingTransfer mechanismComputer science

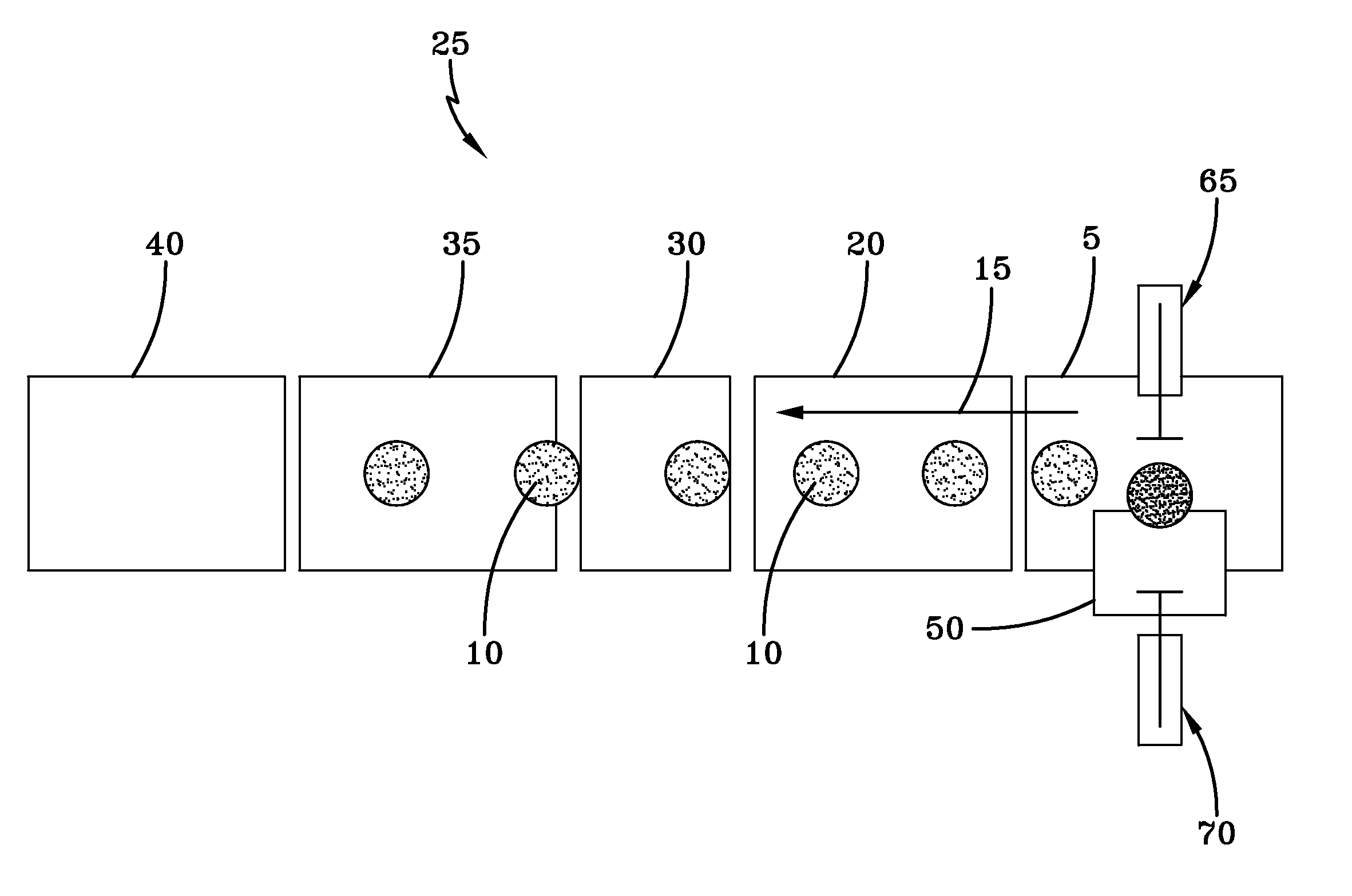

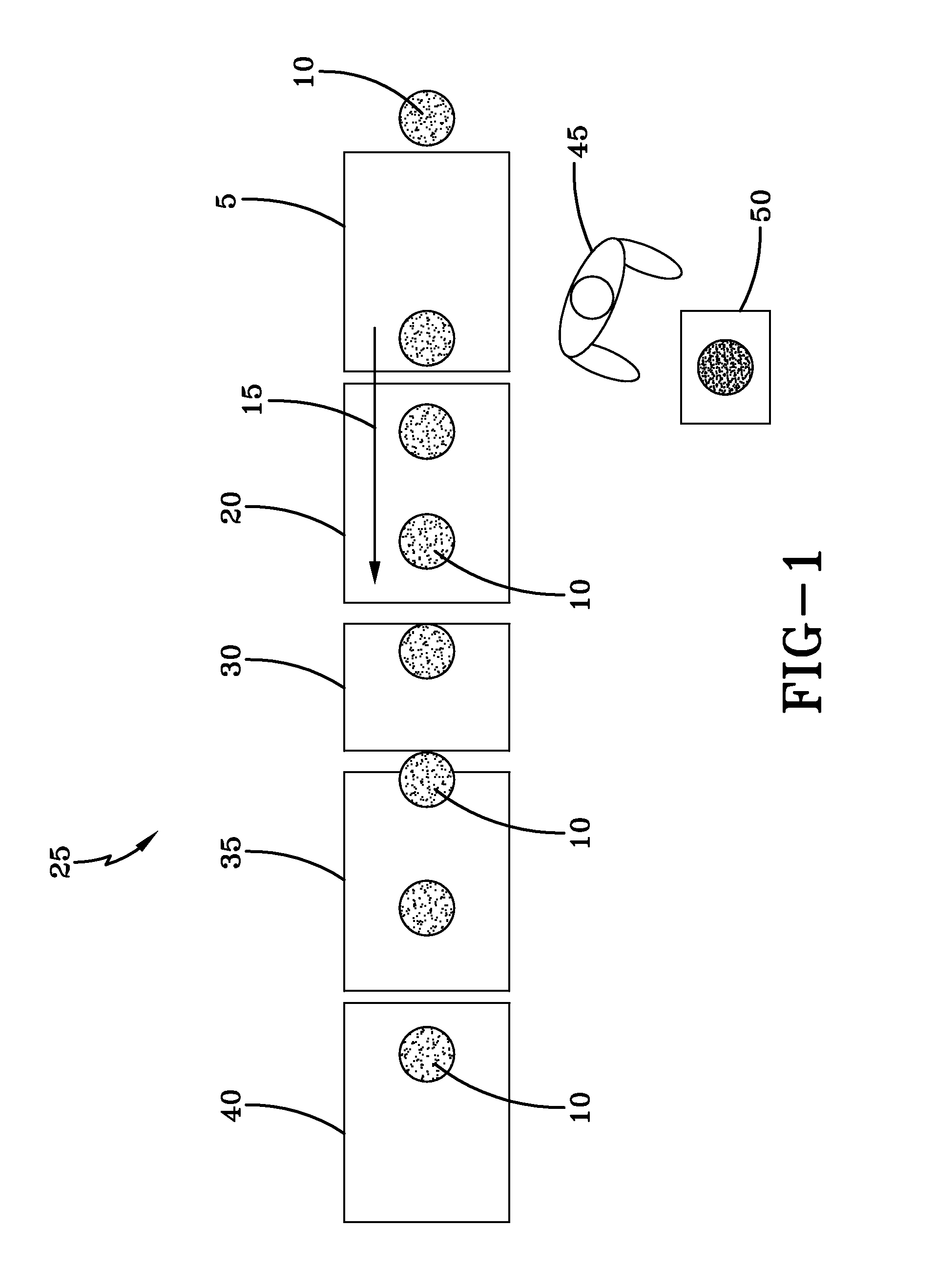

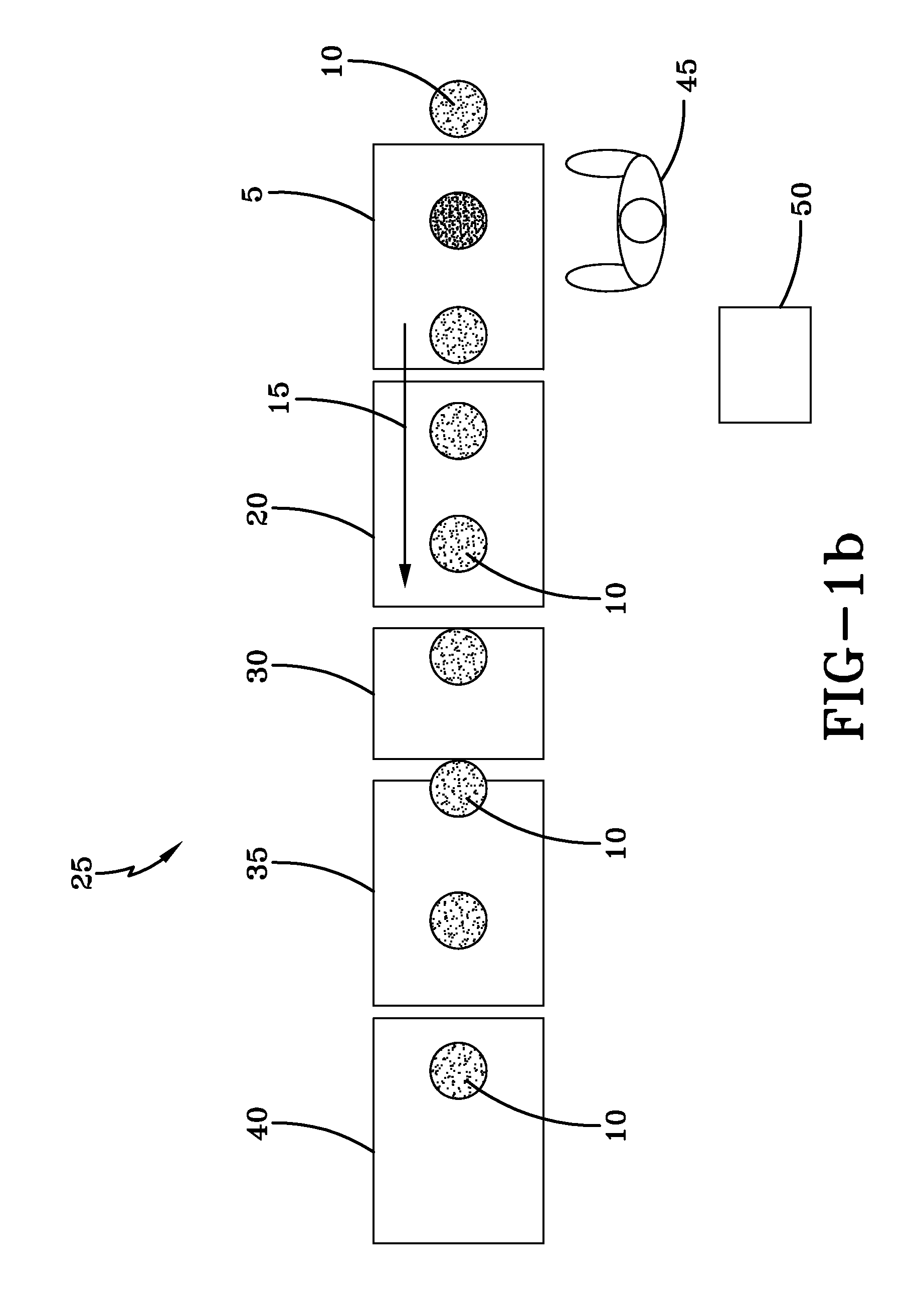

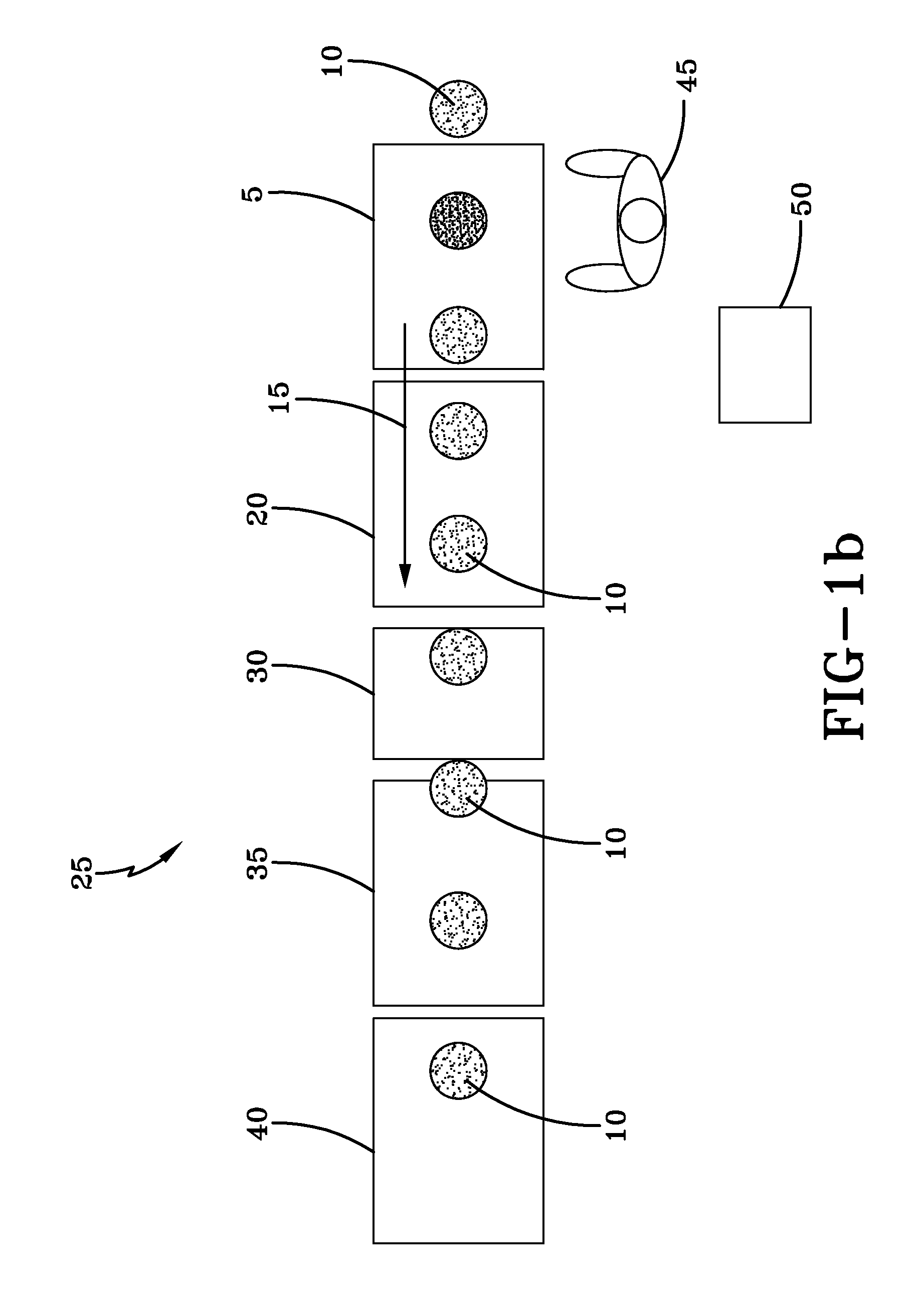

A system and method of validating checkweigher performance (weighing accuracy). The invention involves removing an object to be weighed from a conveyor prior to the object reaching a checkweigher to be validated, weighing the object on a static scale, reintroducing the object to the conveyor upstream of the checkweigher, weighing the object with the checkweigher, and comparing the two weight readings of the object to determine if the checkweigher is accurately weighing objects. Validation objects may be automatically removed from the conveyor by a transfer mechanism.

Owner:METTLER TOLEDO INC

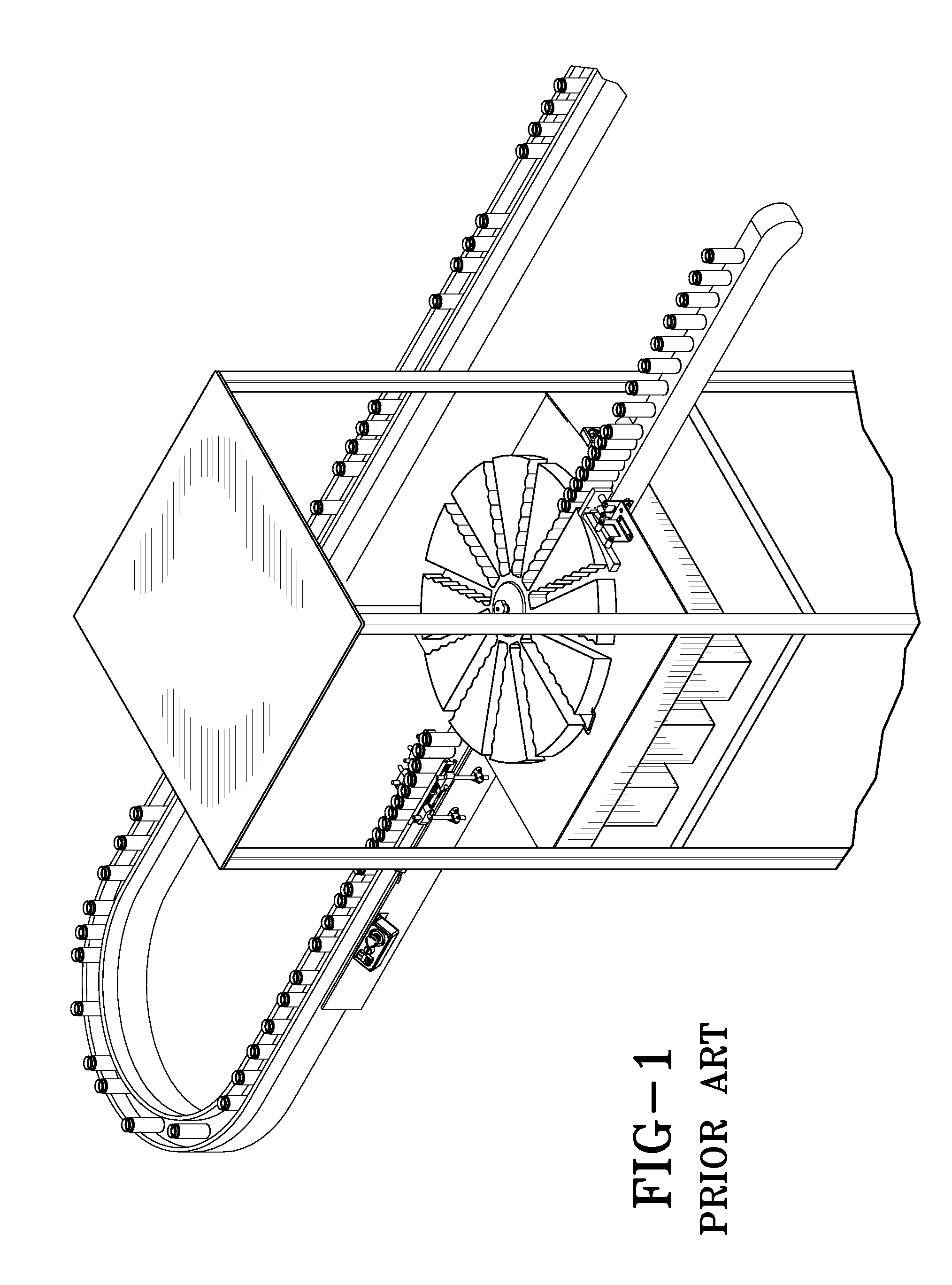

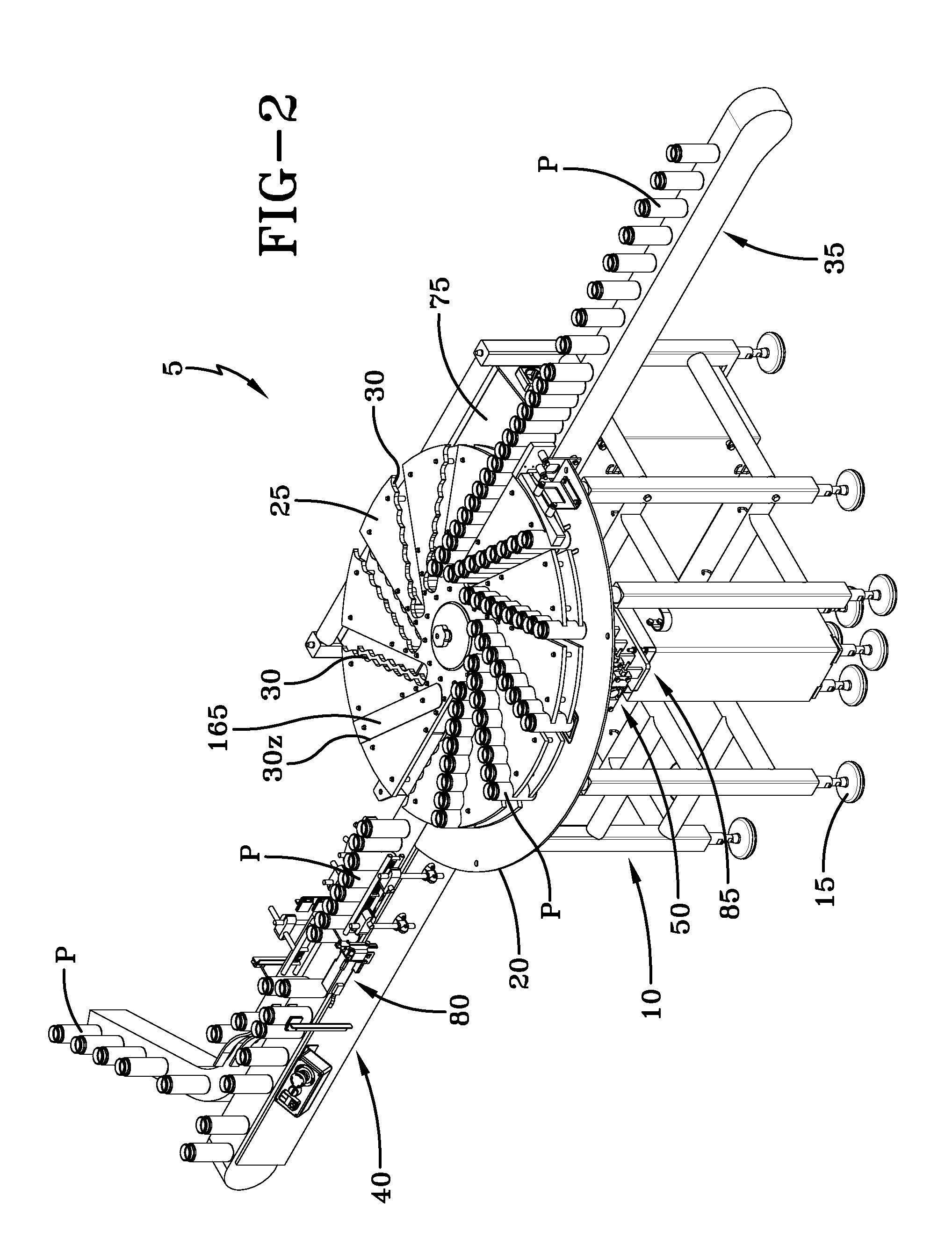

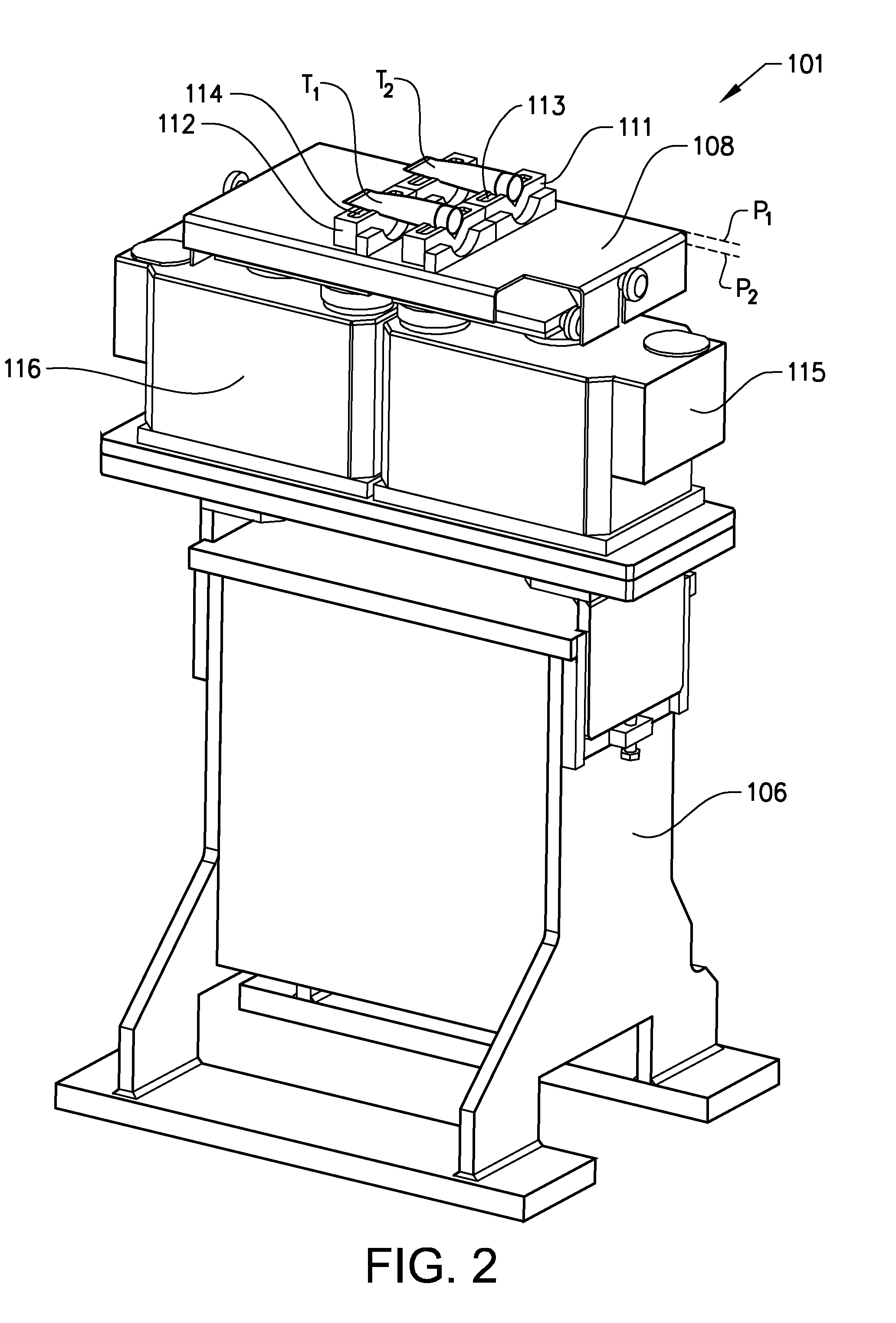

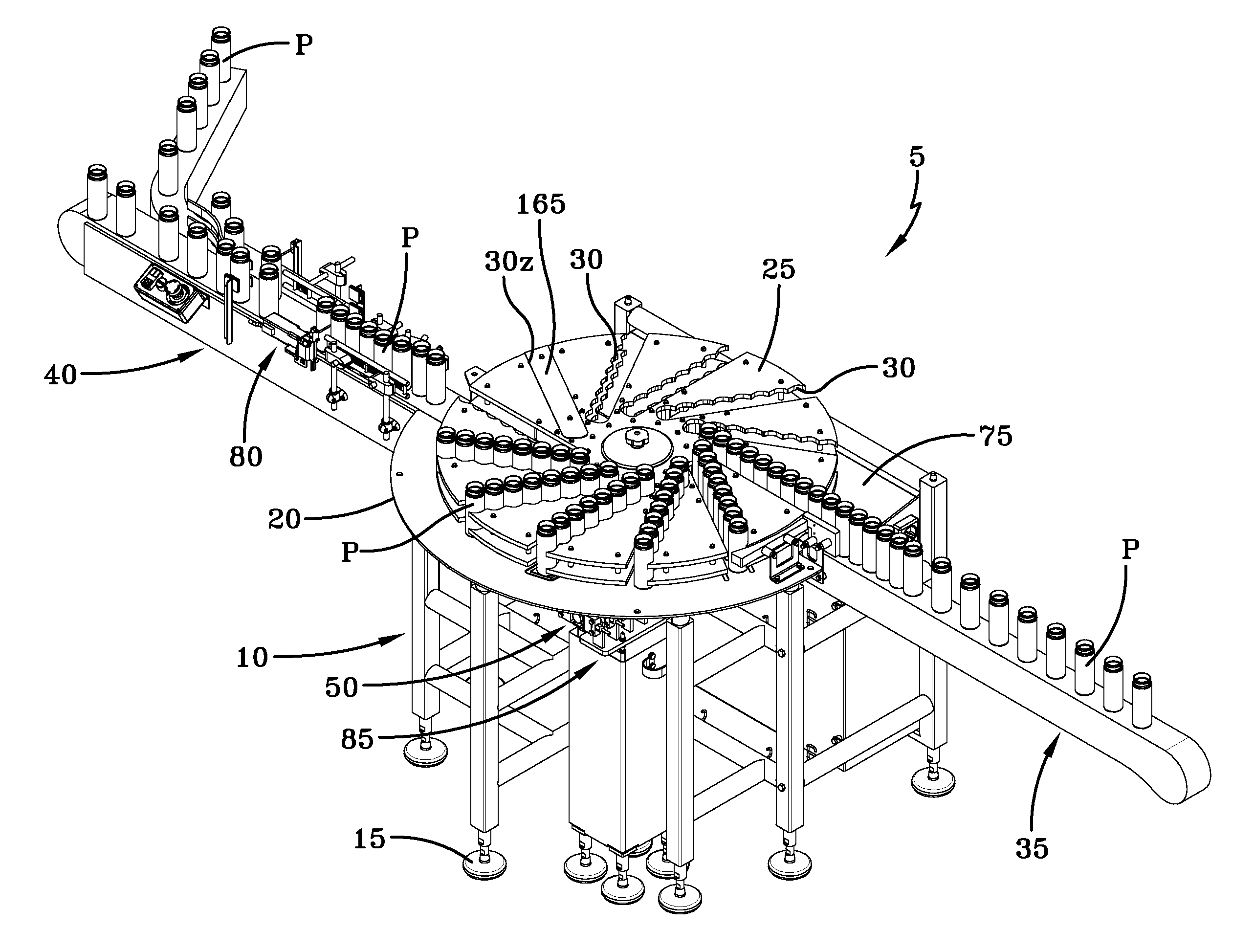

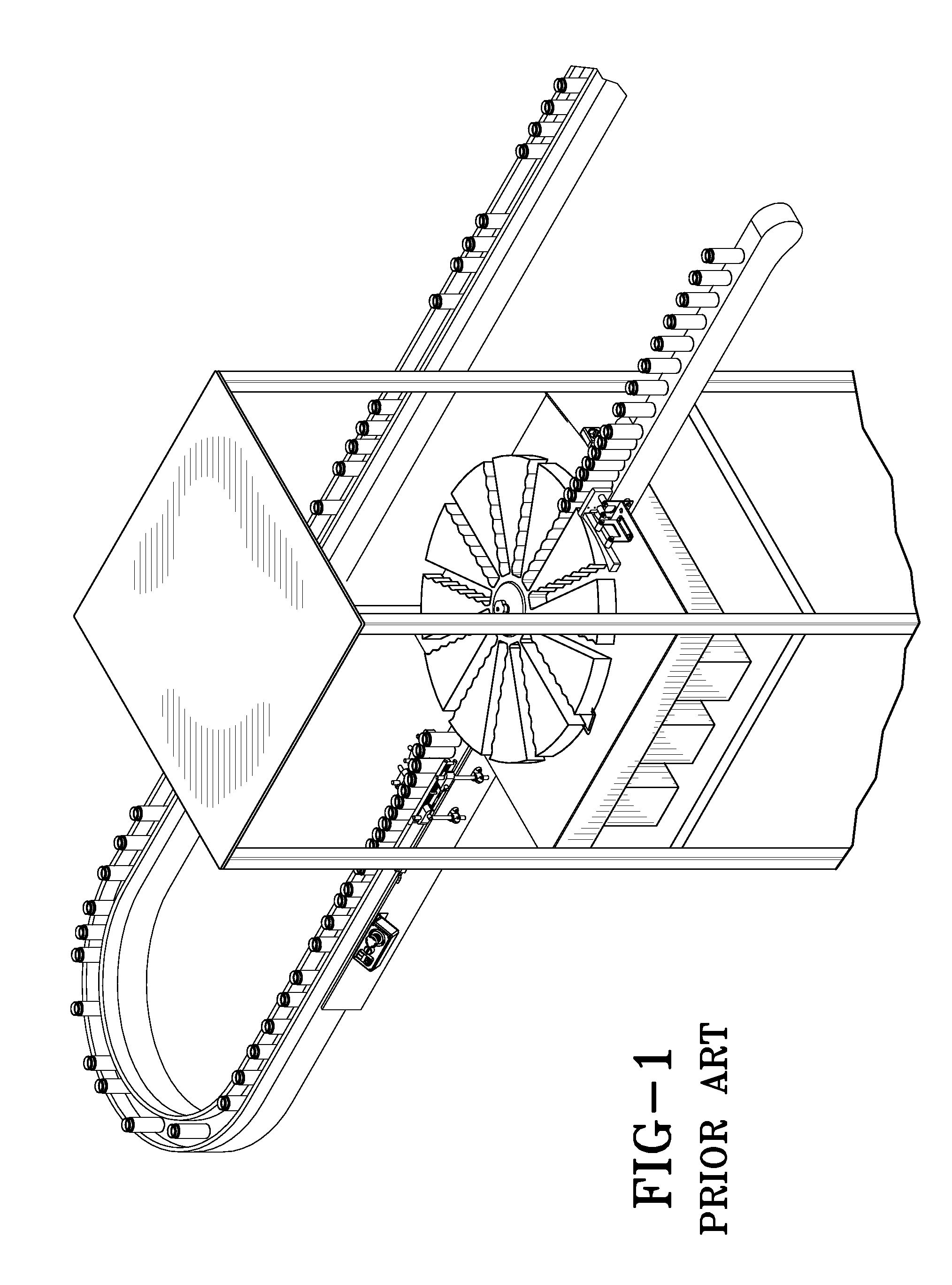

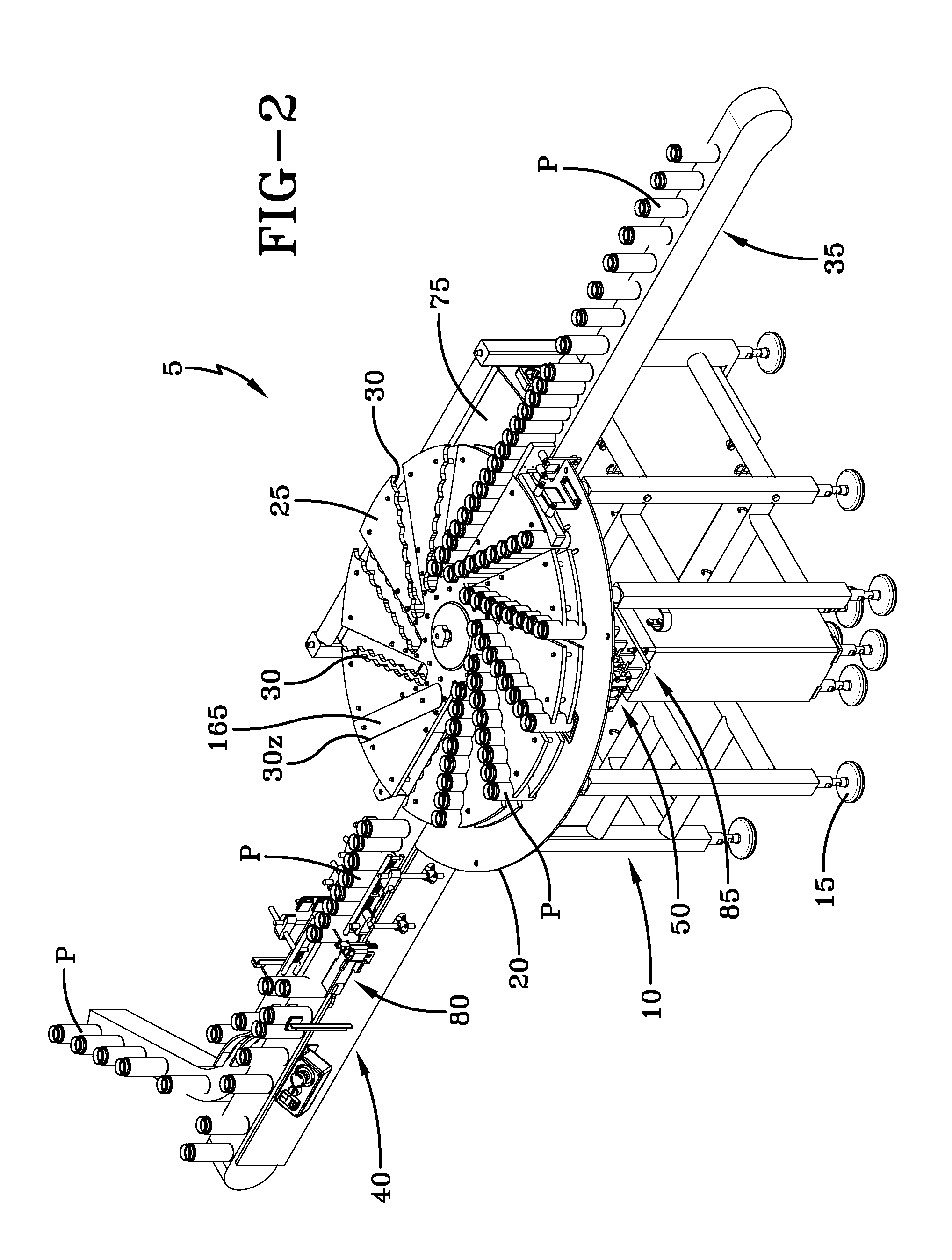

Intermittent motion checkweigher with offset product pockets

ActiveUS8247711B2Eliminates any loss of sightImprove rigidityWeighing apparatus testing/calibrationControl devices for conveyorsIntermittent motionCheck weigher

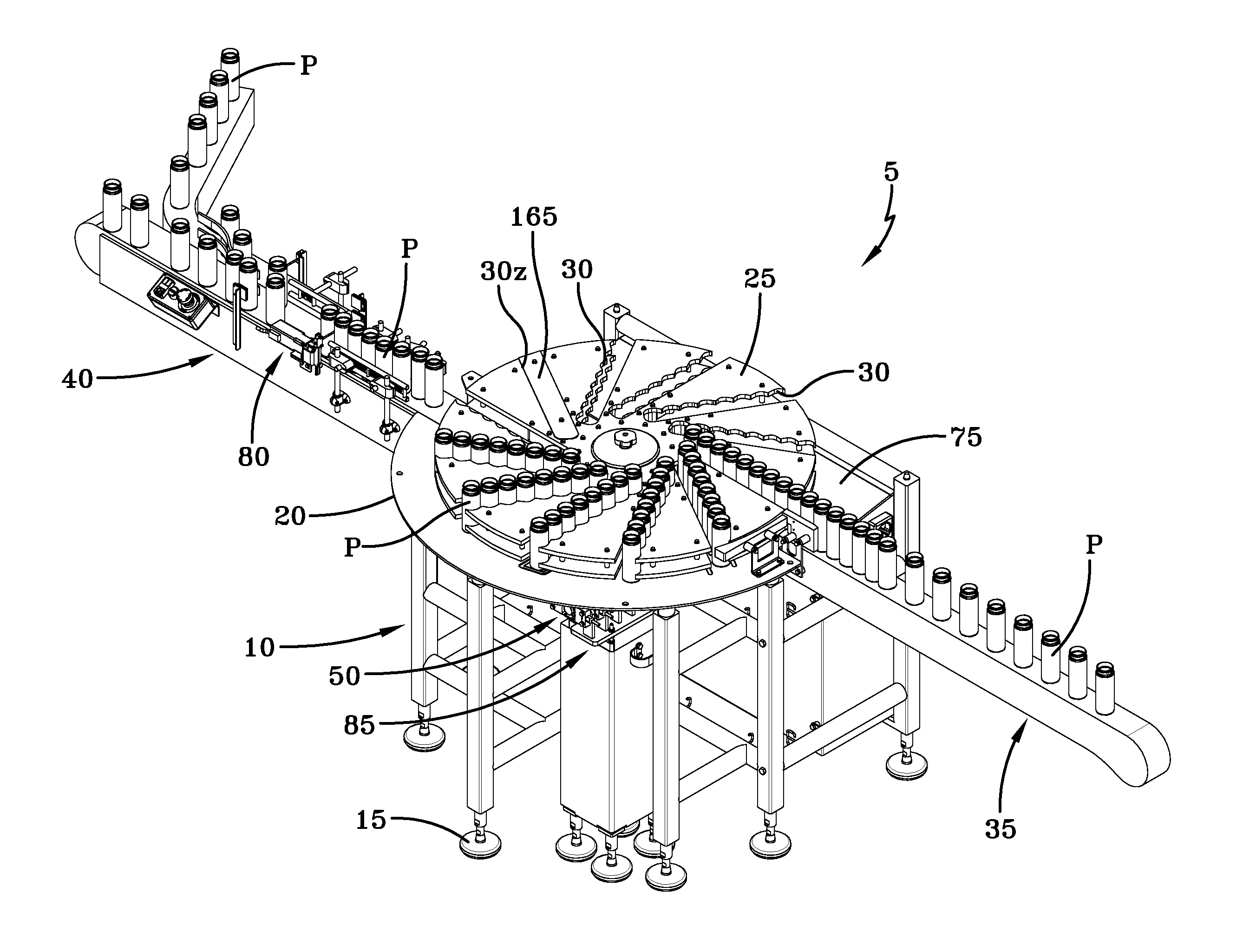

An intermittent motion checkweigher for weighing products of interest. The checkweigher includes a product transport wheel having a plurality of product retention pockets, each of which retains one or more products of interest throughout the weighing operation. Products are loaded into a product retention pocket by an in-feed conveyor or similar device, after which the product transport wheel is indexed to advance the products in the product retention pocket toward one or more weighing devices where the products will be weighed while still located in the product retention pocket. After weighing, the products are advanced to a discharge conveyor or similar device by further indexing of the product transport wheel.

Owner:METTLER TOLEDO INC

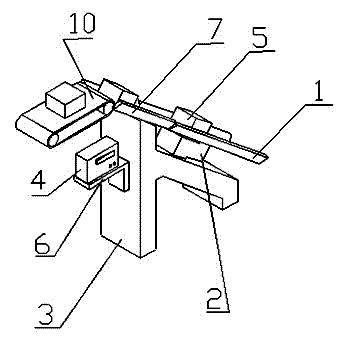

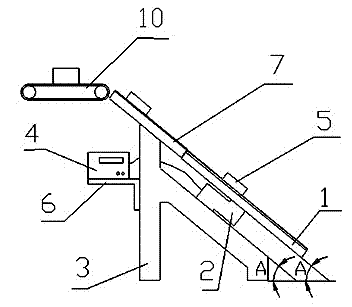

Check-weigher

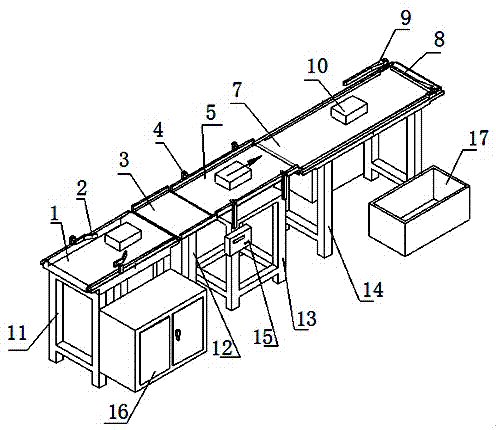

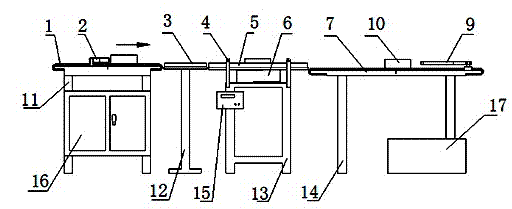

InactiveCN104501923ASolve the problem of dynamic weighing accuracyNo balanceWeighing apparatus for continuous material flowEngineeringLoad cell

Owner:SHANDONG SETAQ INSTR

Checkweigher with independent scales

ActiveUS8237067B2Valuable line spaceLow costWeighing apparatus for continuous material flowWeighing apparatus with automatic feed/dischargeHeavy weightCheck weigher

Owner:METTLER TOLEDO INC

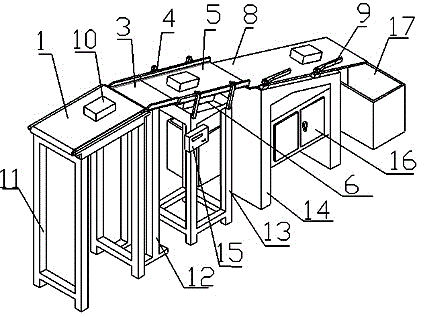

Electronic measuring and weighing unit of checkweigher

ActiveCN104501922ASolve the problem of dynamic weighing accuracyHigh outputWeighing apparatus for continuous material flowElectricityShortest distance

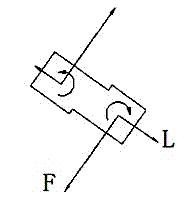

The invention provides an electronic measuring and weighing unit of a checkweigher. The electronic measuring and weighing unit of the checkweigher comprises a supporting frame, and a weighing sensor which is fixedly arranged on the supporting frame; a rigid weighing chute is fixedly arranged in the weighing sensor. The electronic measuring and weighing unit of the checkweigher is characterized in that the rigid weighing chute is in an angle A with the level in the length direction, wherein A is more than 0 degree and less than 90 degrees; a rigid feeding chute is fixedly arranged in the supporting frame or a feeding device or an independent bracket; the chute is parallel to and opposite in a short distance with the weighing chute, does not contact with the weighing chute and is slightly higher than the weighing chute; the bearing end of the weighing sensor is rigidly connected with the rigid weighing chute, and the designed bearing stress direction of the weighing sensor is vertical to the length direction of the rigid weighing chute; a weighing control instrument is provided and electrically connected with the weighing sensor.

Owner:SHANDONG SETAQ INSTR

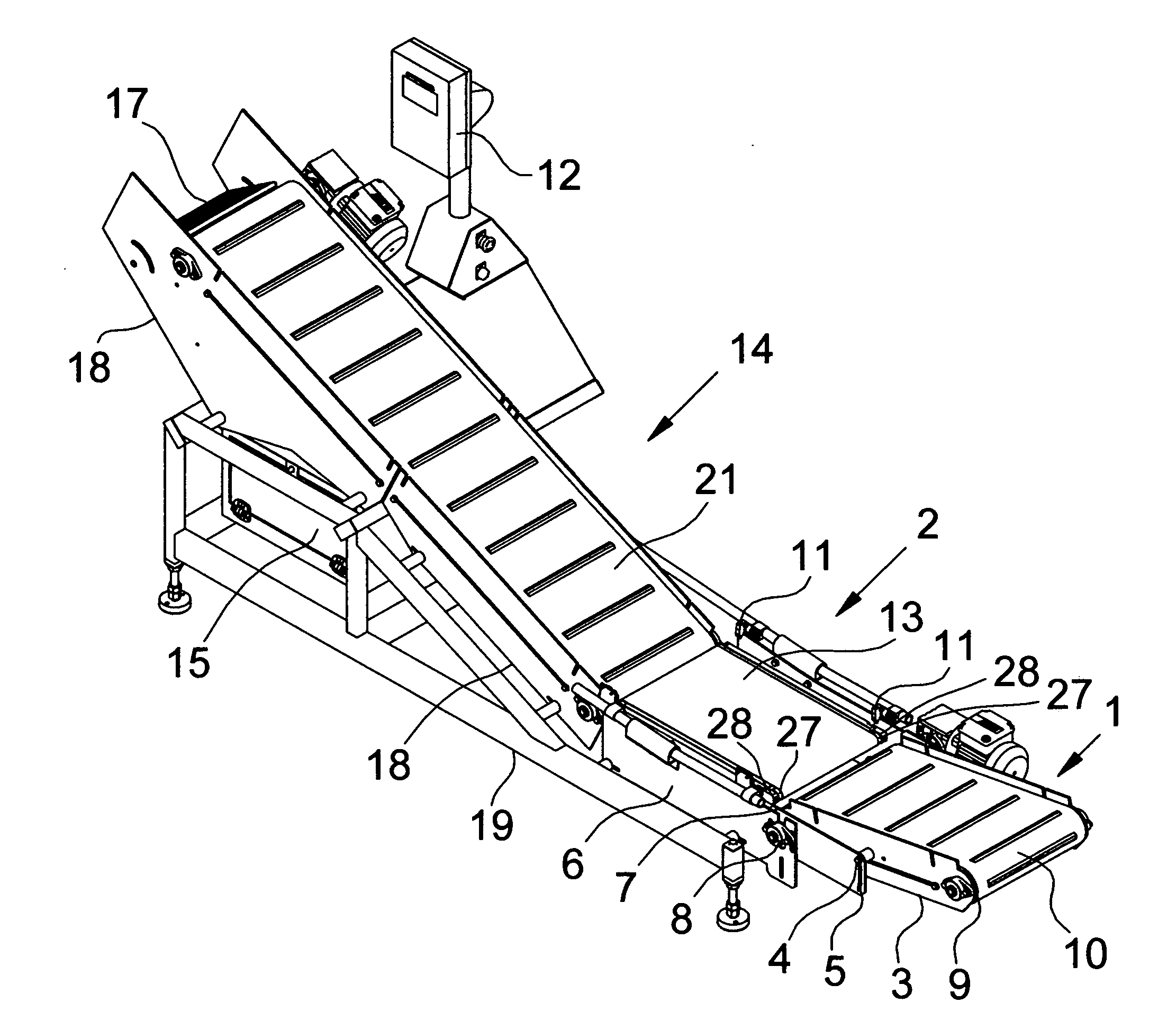

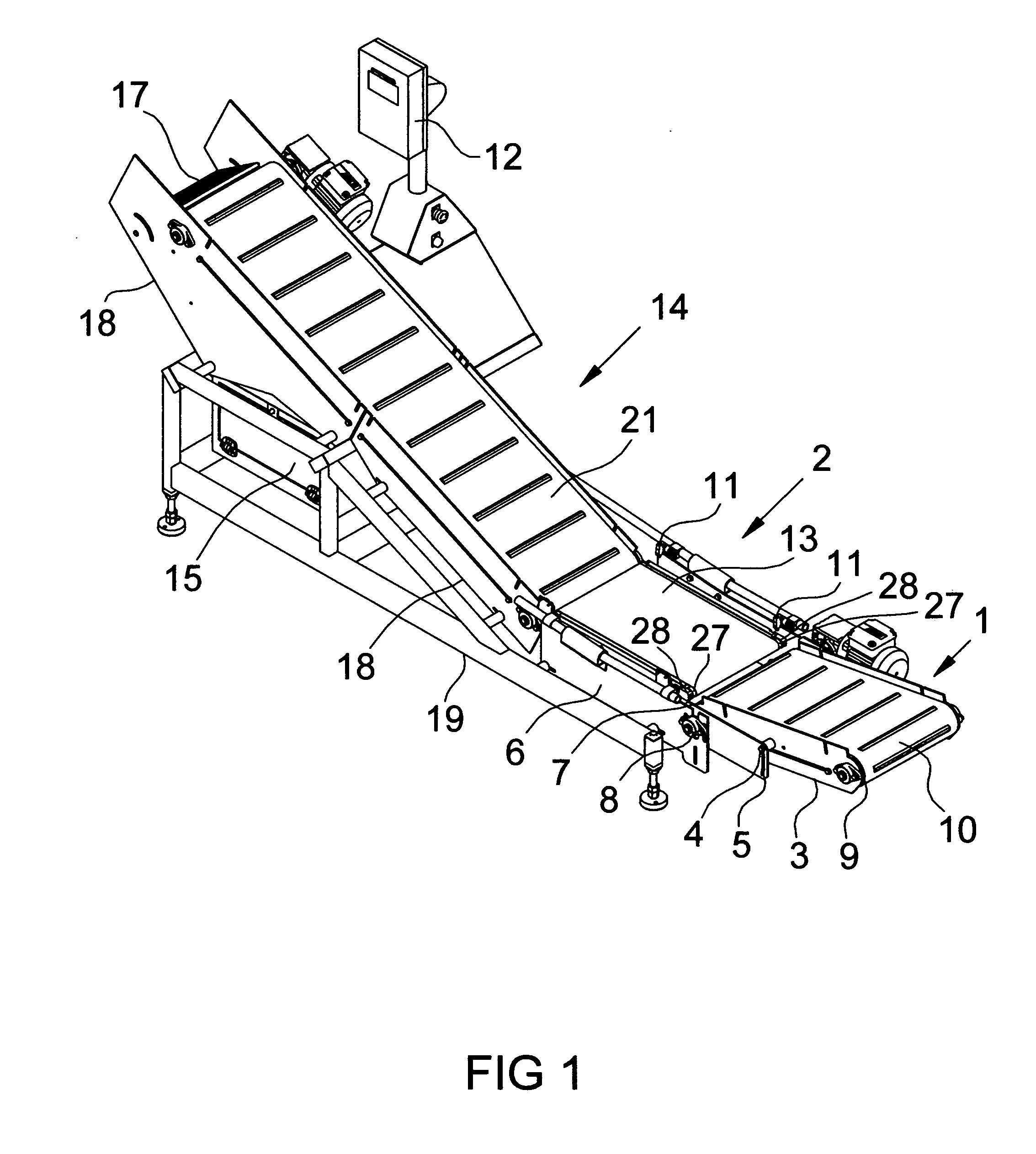

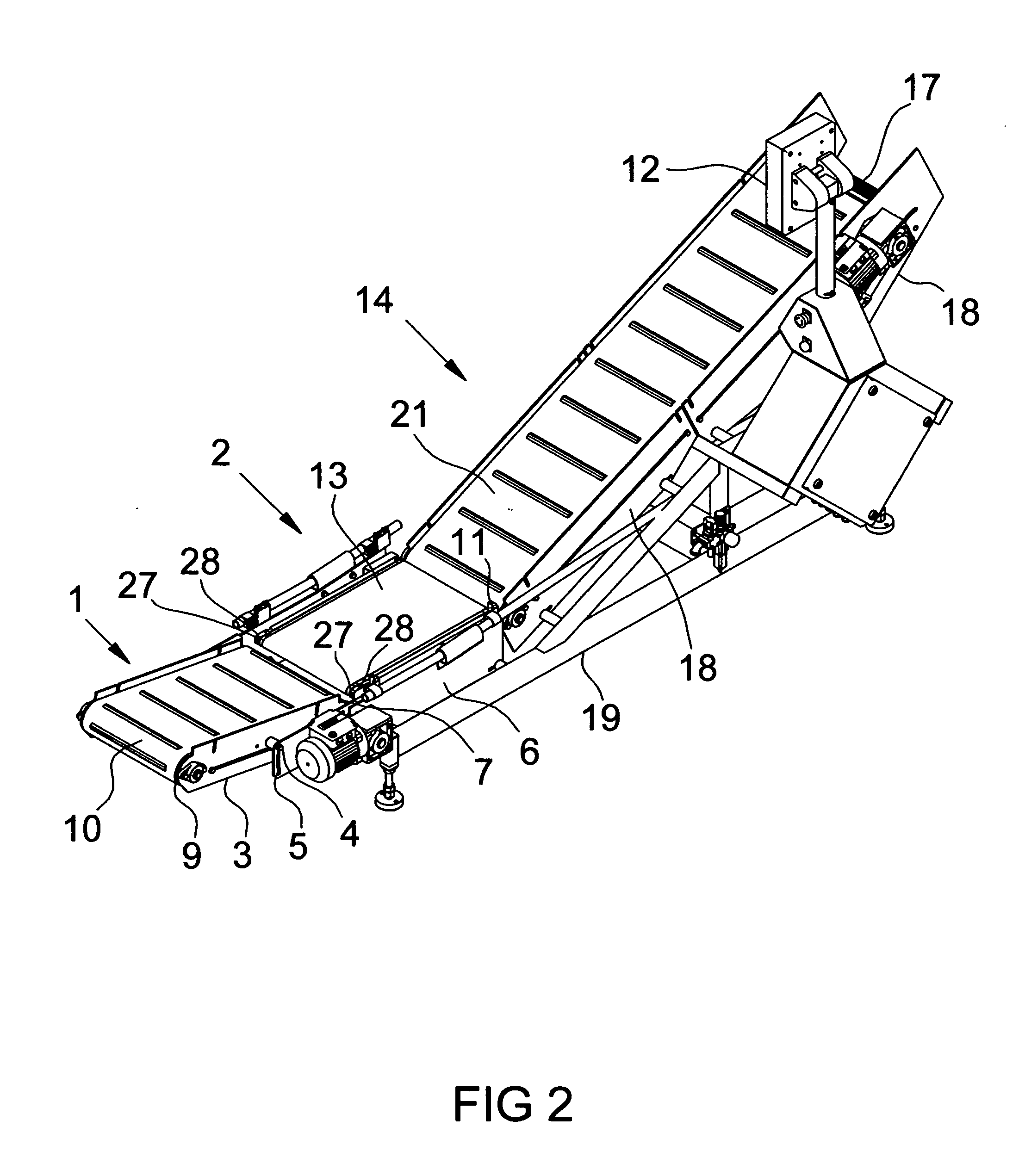

Weight checking conveyor with adjustable infeed section

InactiveUS20100101871A1Avoid damageImprove weighing accuracyMaterial check-weighingWeighing apparatus for materials with special property/formEngineeringCheck weigher

An automatic conveyor comprising an angularly adjustable infeed, check weighing, and take-away sections. The conveyor relies on a pivotal infeed section with no frontal supporting structure to reduce the clearance required between a bag making machine and the conveyor. The check weighing section is controlled by a photoelectric eye before and after the check weighing section. A signal from the check weigher instructs the inclined takeaway section to accept or reject the weighed product using a deflecting plate to dispense or contain the product in a secure holding area.

Owner:DALE CHRISTOPHER

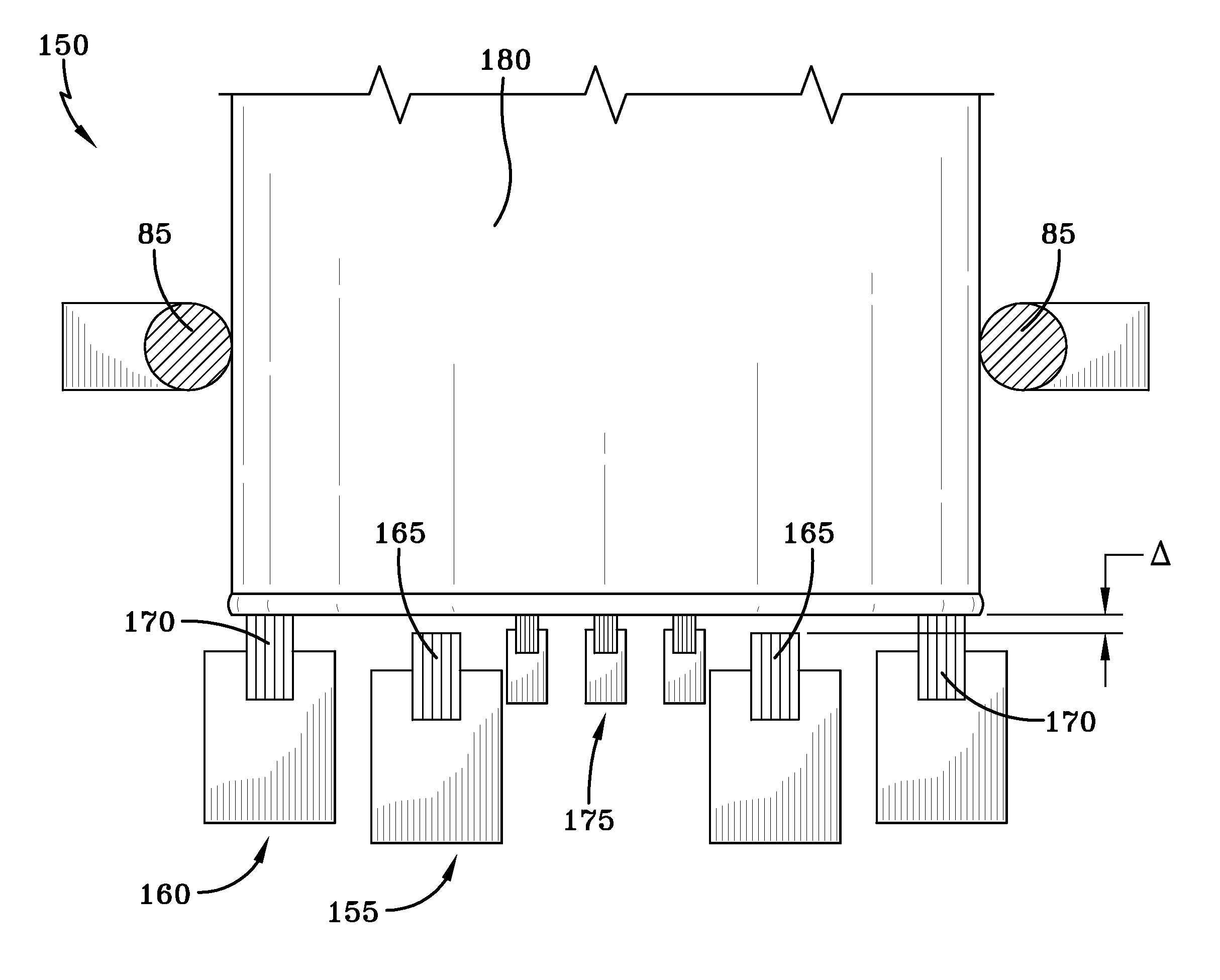

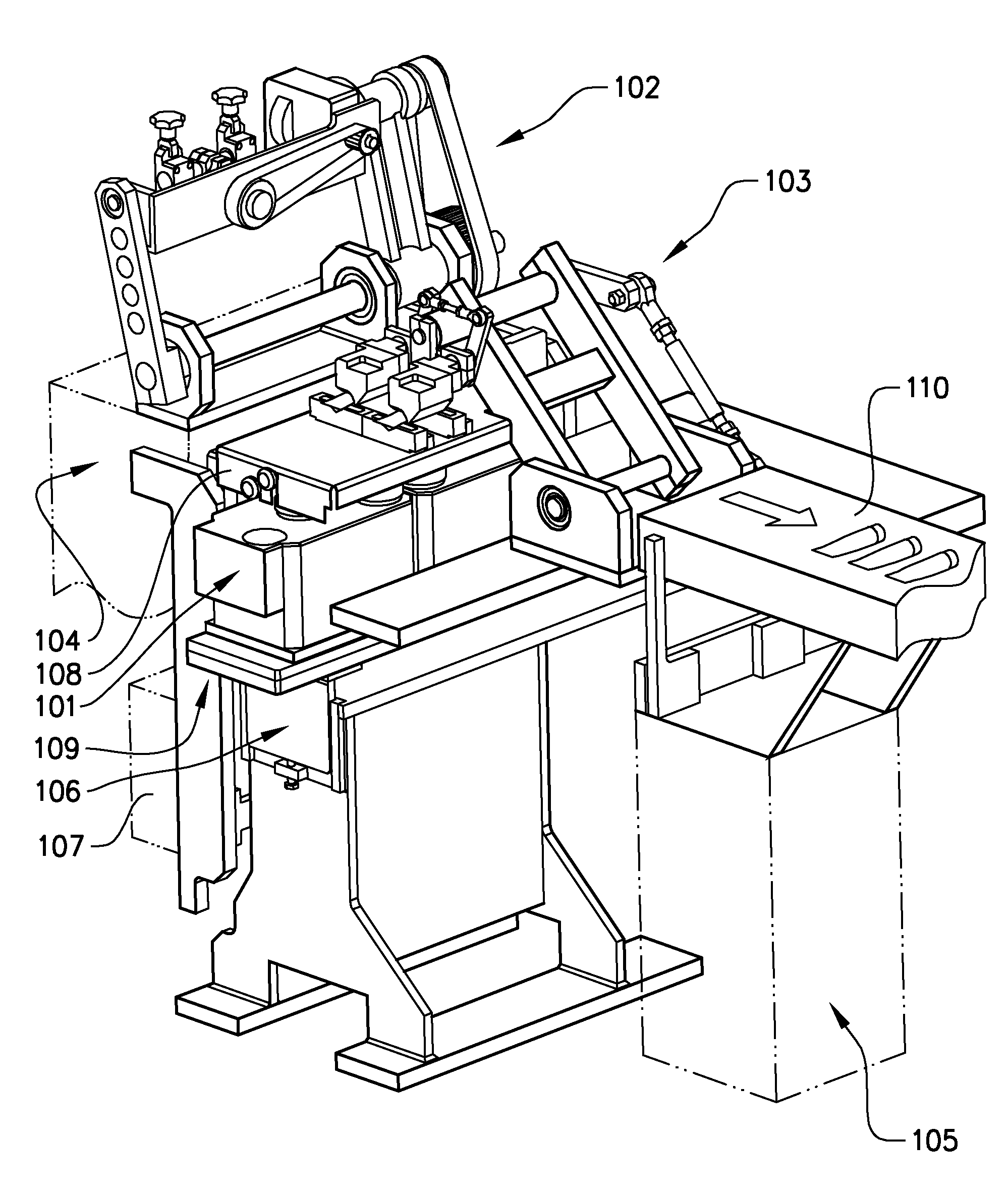

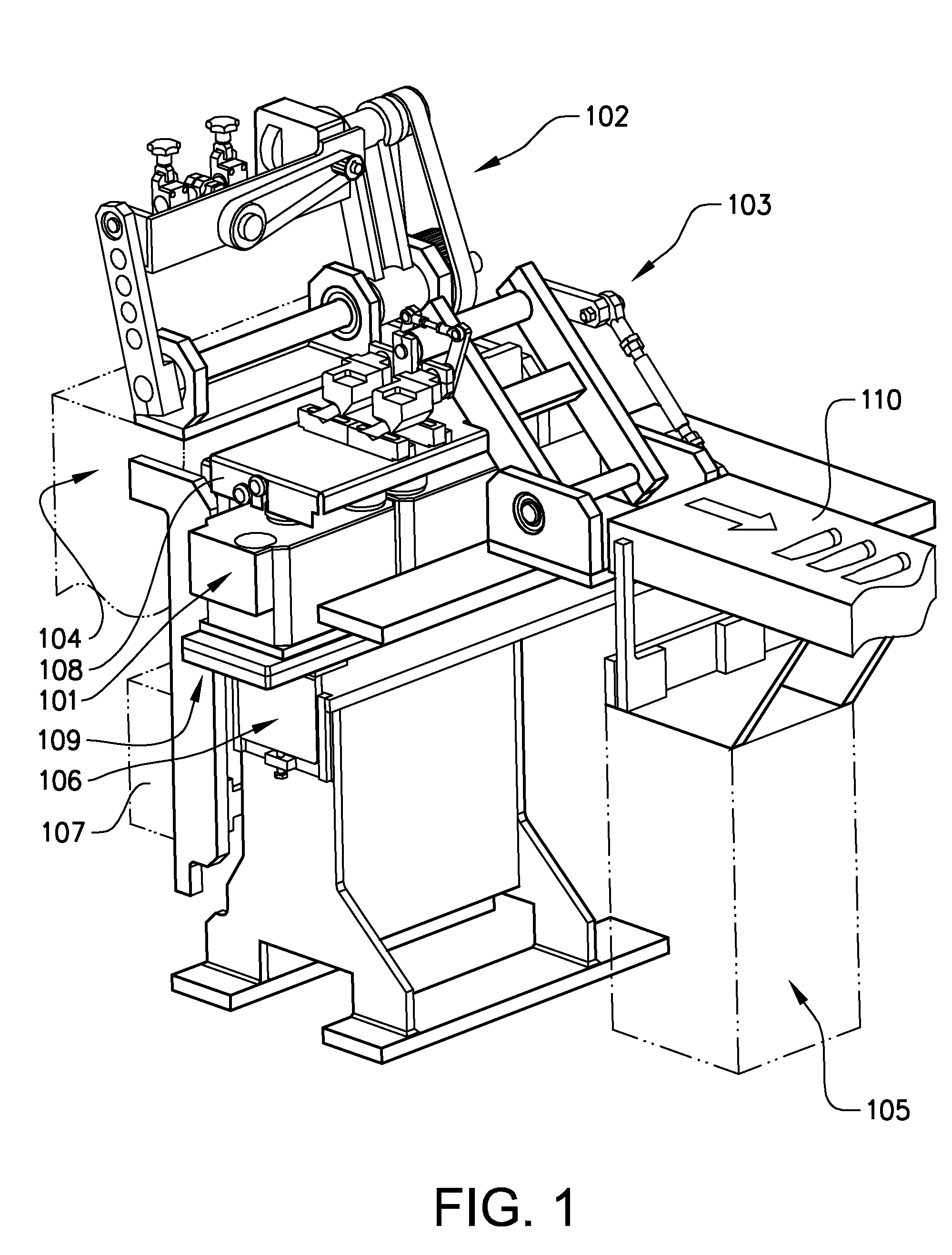

Method for weighing products and a checkweigher with roller assemblies that dampen the movement of the produce prior to weighing

ActiveUS8716608B2Reduce impactShorten the timeMaterial check-weighingWeighing apparatus for materials with special property/formProduction lineCheck weigher

Embodiments of the invention relate to a method and a checkweigher for weighing individual products moved along a production line. In various embodiments, the method compromises transferring at least one product from the production line to a checkweigher comprising at least one weighing cell; placing at least one product in a first position on a first support above a corresponding weighing cell; displacing the at least one product by means of said first support and placing said at least one product in a second position on a second support on the weighing cell; weighing the at least one product; displacing the at least one product back to the first position by means of said first support; and transferring the at least one product from the checkweigher back to the production line.

Owner:NORDEN MASCH AB

Checkweigher with independent scales

ActiveUS20100314177A1Saving valuable line spaceLow costWeighing apparatus for continuous material flowWeighing apparatus with automatic feed/dischargeEngineeringHeavy weight

A checkweigher for the in-motion weighing of objects being transported along a conveyor line. A checkweigher of the present invention employs a plurality of scales each having its own set of weighing conveyor elements. For example, a first scale may be associated with a set of lighter weight chains to convey and weigh smaller objects, while a second scale may be associated with a set of heavier weight chains to convey and weigh larger objects. This design essentially allows the incorporation of a lightweight and heavyweight checkweigher within one common checkweigher frame. The problem of noise caused by one set of conveyor elements associated with one scale affecting the accuracy of the other scale(s) is eliminated by locating the conveying surfaces of the conveyor elements associated with the individual scales in different planes. Thus, objects transported by one weighing conveyor exert no load on the conveyor elements of the other weighing conveyor(s).

Owner:METTLER TOLEDO INC

Checkweigher for weighing slide way

InactiveCN104535145AReduce frictional energySmall dynamic weighing accuracy problemWeighing apparatus for continuous material flowControl engineeringLoad cell

The invention relates to a checkweigher for weighing a slide way. The checkweigher comprises a third support frame and a fourth support frame, wherein a weighing sensor is arranged on the third support frame, and a weighed slide way which is obliquely placed is arranged on the weighing sensor; an eliminating platform and an eliminating and grading mechanism are arranged on the fourth support frame; the eliminating platform is arranged below a discharge outlet of the weighed slide way; and the weighed slide way is in rigid connection with the stressed end of the weighing sensor through a force guide rod, an included angle between the design stressed direction of the weighing sensor and the material sliding direction of the weighed slide way is B, and B is more than 0 degree and less than 90 degrees or B is more than 90 degrees and less than 180 degrees. The back end of the weighed slide way and the front end of the eliminating platform are opposite with a spacing interval and are not in contact, and the weighed slide way is higher than the front end of the eliminating platform, so that the checkweigher solves the problems that a rotating motion part in a weighing and metering unit of an existing separating and checking scale seriously affects weighing precision, economy, practicality and efficiency, as well as the problems that an eliminating and grading device affects the weighing precision and the manufacturing, debugging and maintenance cost.

Owner:SHANDONG SETAQ INSTR

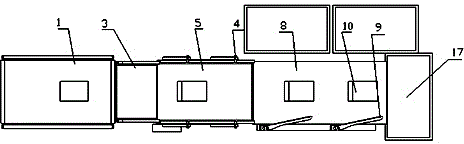

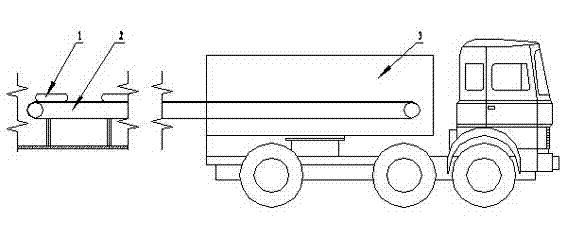

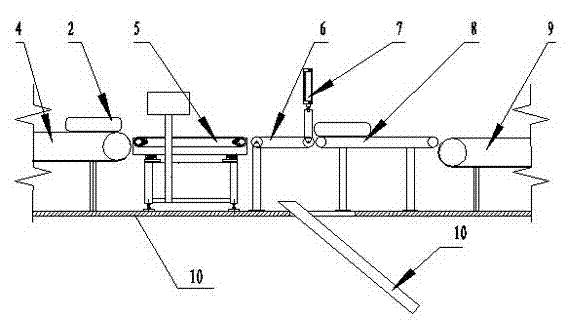

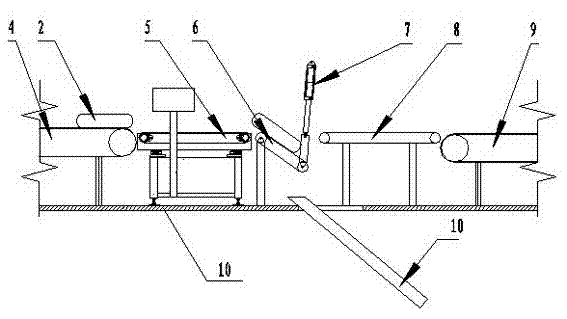

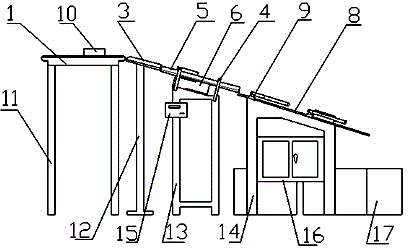

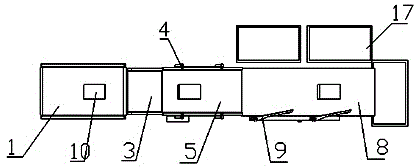

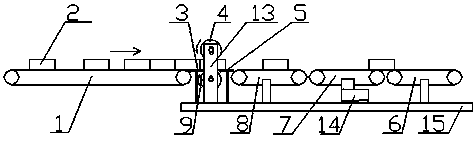

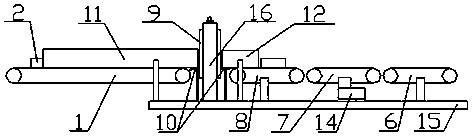

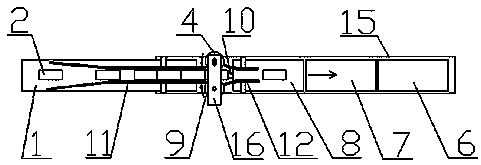

Sacked cement loading system with check-weighing function

InactiveCN102730388ALoading will notMake sure the factory is qualifiedControl devices for conveyorsLoading/unloadingButt jointEngineering

The invention relates to sacked cement loading systems and particularly relates to a sacked cement loading system with a check-weighing function. The sacked cement loading system comprises a system platform and a rubber belt conveyor, wherein the rubber belt conveyor is composed of a front rubber belt conveyor and a back rubber belt conveyor, the two rubber belt conveyors are arranged on the system platform in the same horizontal straight line; a check-weighing balance and a bag dropping machine are sequentially arranged between the two rubber belt conveyors; the front part of the conveying belt of a check-weighing balance is in butt joint with the front rubber belt conveyor, and the rear part of the conveying belt of the check-weighing balance is in butt joint with the back rubber belt conveyor; the rear of the fixing segment of the bag dropping machine is in butt joint with the back rubber belt conveyor; an inclined chute is arranged below the pitching segment of the bag dropping machine; and the rear of the back rubber belt conveyor is located on a truck. The sacked cement loading system provided by the invention can weigh the loaded sacked cement by adding the check-weighing balance and sort the sacked cement exceeding the range by adding the bag dropping machine to prevent the sacked cement with super bad weight from being loaded, thereby guaranteeing that the weight index of the sacked cement is qualified when the sacked cement is discharged from a factory.

Owner:唐山智能电子有限公司

Intermittent motion checkweigher with offset product pockets

ActiveUS20110147097A1High strengthImprove rigidityWeighing apparatus testing/calibrationControl devices for conveyorsIntermittent motionCheck weigher

An intermittent motion checkweigher for weighing products of interest. The checkweigher includes a product transport wheel having a plurality of product retention pockets, each of which retainins one or more products of interest throughout the weighing operation. Products are loaded into a product retention pocket by an in-feed conveyor or similar device, after which the product transport wheel is indexed to advance the products in the product retention pocket toward one or more weighing devices where the products will be weighed while still located in the product retention pocket. After weighing, the products are advanced to a discharge conveyor or similar device by further indexing of the product transport wheel.

Owner:METTLER TOLEDO INC

Checkweigher for weighing slide way

InactiveCN104535146AReduce frictional energySmall dynamic weighing accuracy problemWeighing apparatus for continuous material flowControl engineeringLoad cell

The invention relates to a checkweigher for weighing a slide way. The checkweigher comprises a third support frame and a fourth support frame, wherein a weighing sensor is arranged on the third support frame, and a weighed slide way which is obliquely placed is arranged on the weighing sensor; an eliminating platform and an eliminating and grading mechanism are arranged on the fourth support frame; the eliminating platform is arranged below a discharge outlet of the weighed slide way; and the carrying end of the weighing sensor is in rigid connection with the weighed slide way, and the designed direction of carrying stress of the weighing sensor is vertical to the length direction of the weighed slide way. The checkweigher solves the problems that a rotating motion part in a weighing and metering unit of an existing separating and checking scale seriously affects weighing precision, economy, practicality and efficiency, as well as the problems that an eliminating and grading device affects the weighing precision and the manufacturing, debugging and maintenance cost.

Owner:SHANDONG SETAQ INSTR

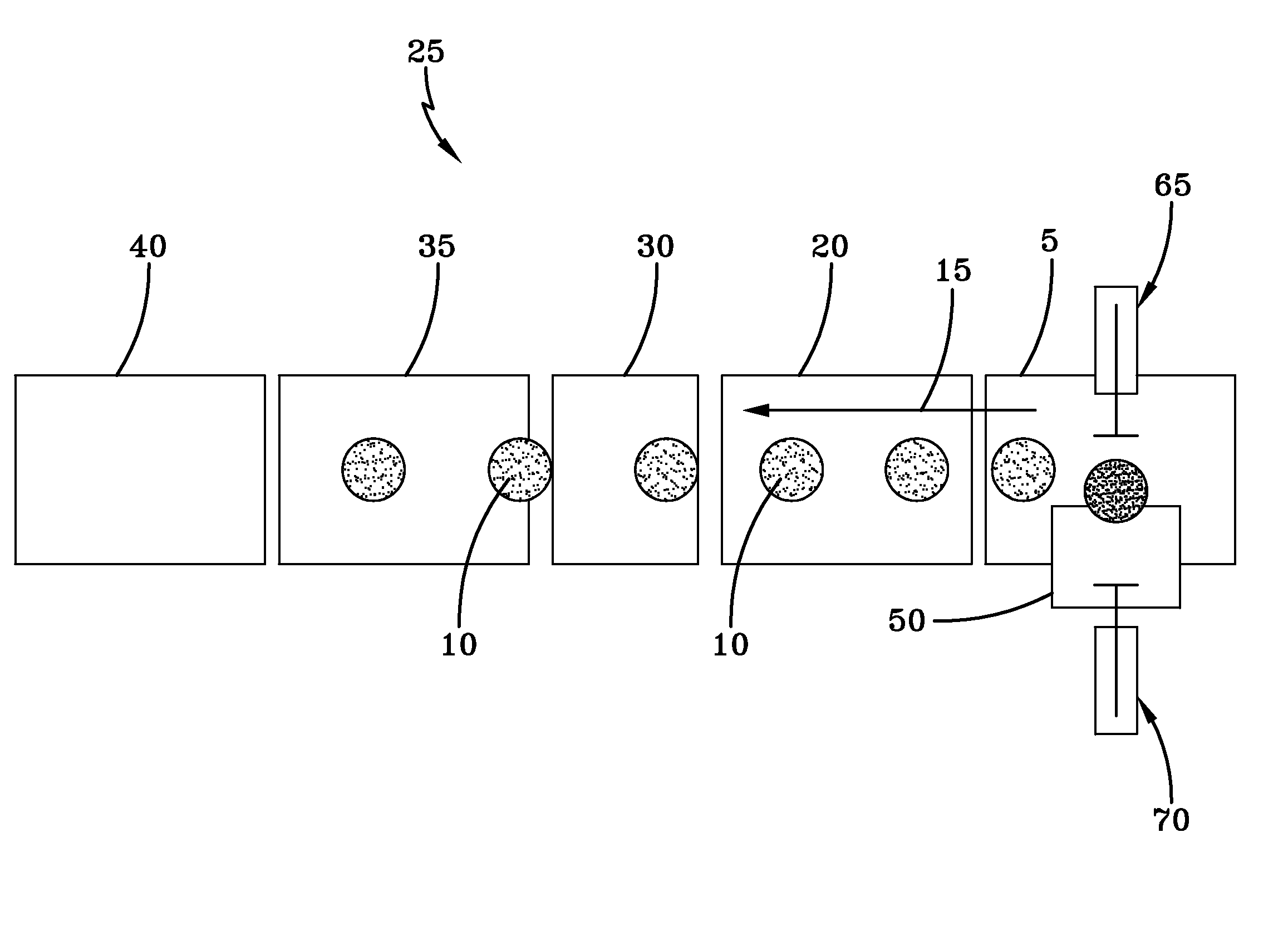

Checkweigher performance validation

ActiveUS8459092B2Minimize and eliminate needEasy to useWeighing apparatus testing/calibrationForce/torque/work measurement apparatus calibration/testingTransfer mechanismComputer science

A system and method of validating checkweigher performance (weighing accuracy). The invention involves removing an object to be weighed from a conveyor prior to the object reaching a checkweigher to be validated, weighing the object on a static scale, reintroducing the object to the conveyor upstream of the checkweigher, weighing the object with the checkweigher, and comparing the two weight readings of the object to determine if the checkweigher is accurately weighing objects. Validation objects may be automatically removed from the conveyor by a transfer mechanism.

Owner:METTLER TOLEDO INC

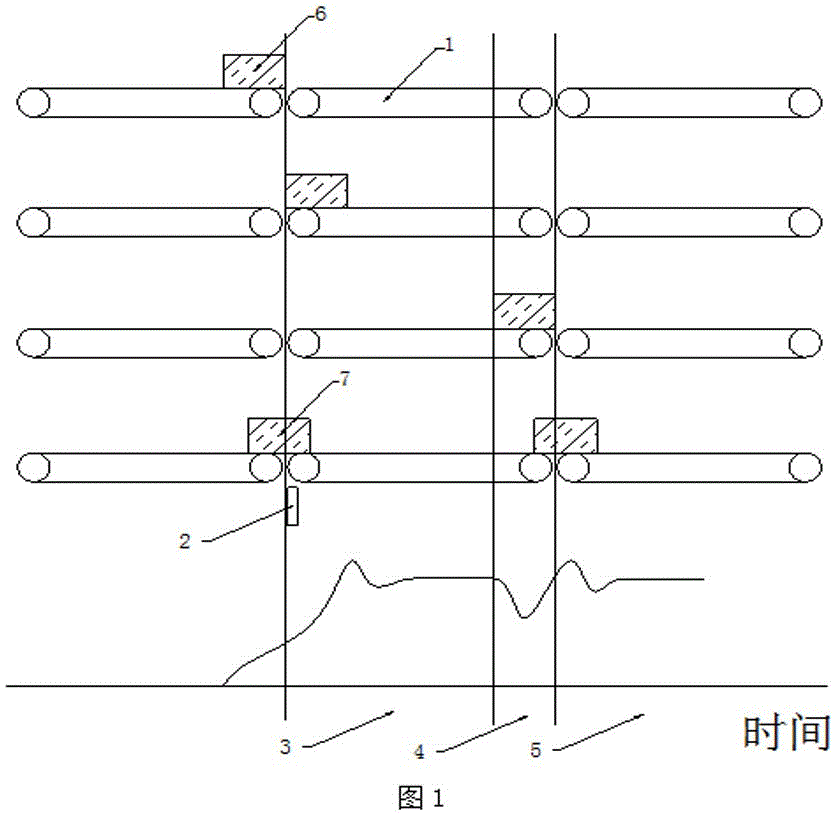

High-speed dynamic weighing system of automatic weight checker and work flow thereof

InactiveCN106323431AReduce labor costsSolve the problem of monopolizing the weighing platformSpecial purpose weighing apparatusHuman–machine interfaceMan machine

The invention discloses a high-speed dynamic weighing system of an automatic weight checker. The system comprises a dynamic weighing unit, a photoelectric sensor, a weighing sensor, a microprocessor circuit and a man-machine interface. The invention further discloses a work flow of the high-speed dynamic weighing system of the automatic weight checker. The high-speed dynamic weighing system of the automatic weight checker settles a problem of scale platform occupation by a single product in weighing by an existing automatic weight checker, and determines whether to start weighing of a next product through intelligent determining to a product state in the weighing process. Through the algorithm of the high-speed dynamic weighing system, the automatic weight checker allows overlapping of the product on the scale platform, thereby reducing weighing time of the single product, improving productivity, reducing labor cost of enterprise employees, and realizing wide application prospect.

Owner:上海芝研检测技术有限公司

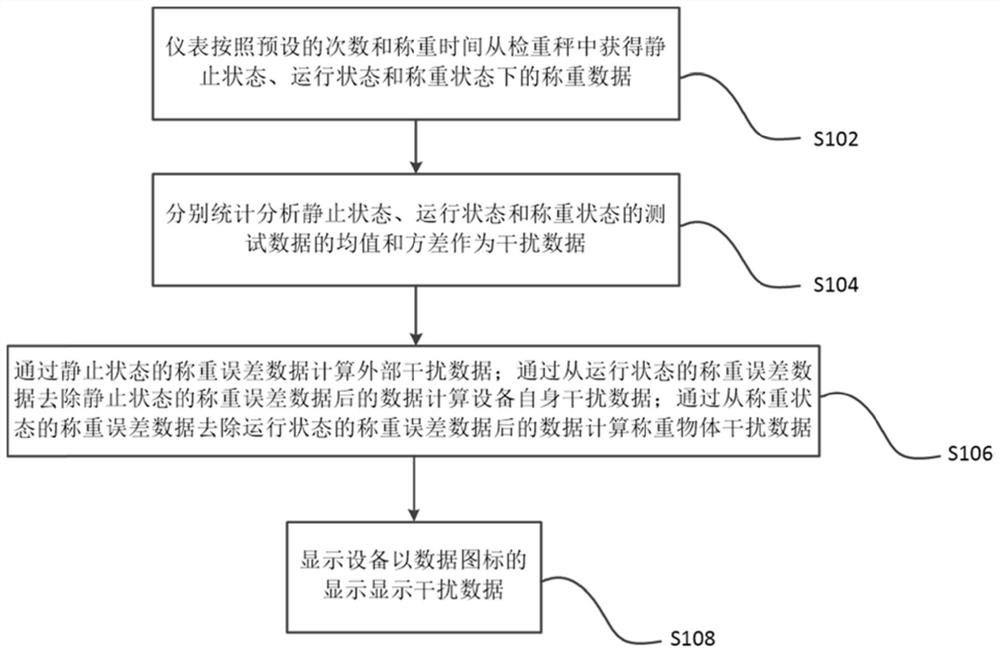

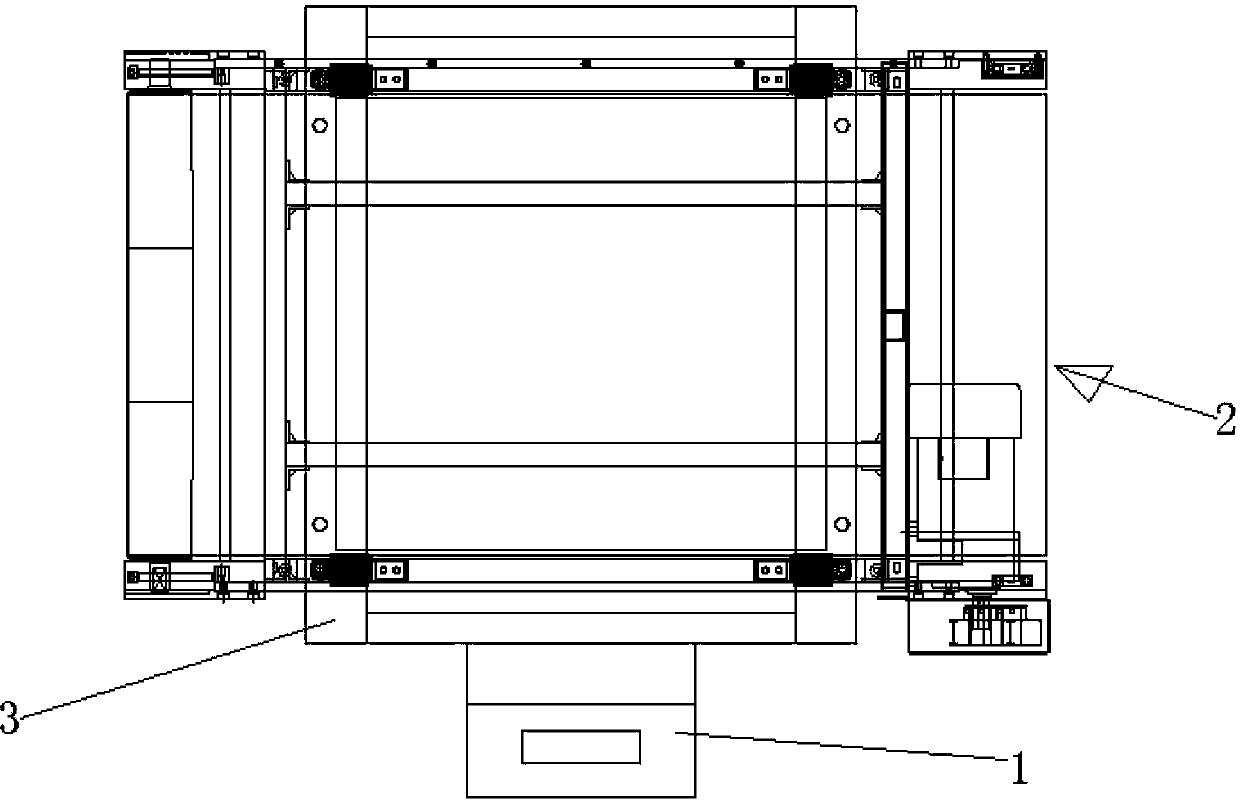

Automatic checkweigher with ball bearing units

InactiveCN103630224AEasy 3D MobilityGood three-dimensional mobilityWeighing apparatus detailsSpecial purpose weighing apparatusBall bearingElectric machine

The invention discloses an automatic checkweigher with ball bearing units. The automatic checkweigher includes an electric box, a weighing platform, a rack and a motor; with a use direction as a benchmark, the weighing platform is horizontally arranged on the rack; the electric box is located at one side of a front-back direction of the weighing platform and is in positioned and fixed connection with the rack; the weighing platform is fixedly provided with a plurality of weighing sensors in a positioned manner; the weighing sensors are electrically connected with the electric box; the motor is fixedly arranged on the weighing platform in a positioned manner; the left side and the right side of the weighing platform are fixedly provided with a driving roller and a driven roller respectively; the motor can drive the driving roller to rotate; the driving roller can drive the driven roller to rotate; one surface of the rack, which backs the weighing platform, is provided with a plurality of bottom feet; and the weighing platform can be adjust to be horizontal through the bottom feet. The automatic checkweigher with the ball bearing units of the invention has the advantages of convenient installation, convenient implementation, avoidance of problems existing in the coordination of an old-type bearing seat and a ball bearing, reduction of the wear degree of the rollers, prolonging of the service life of equipment and the like.

Owner:KUNSHAN LIGU WEIGHING IND

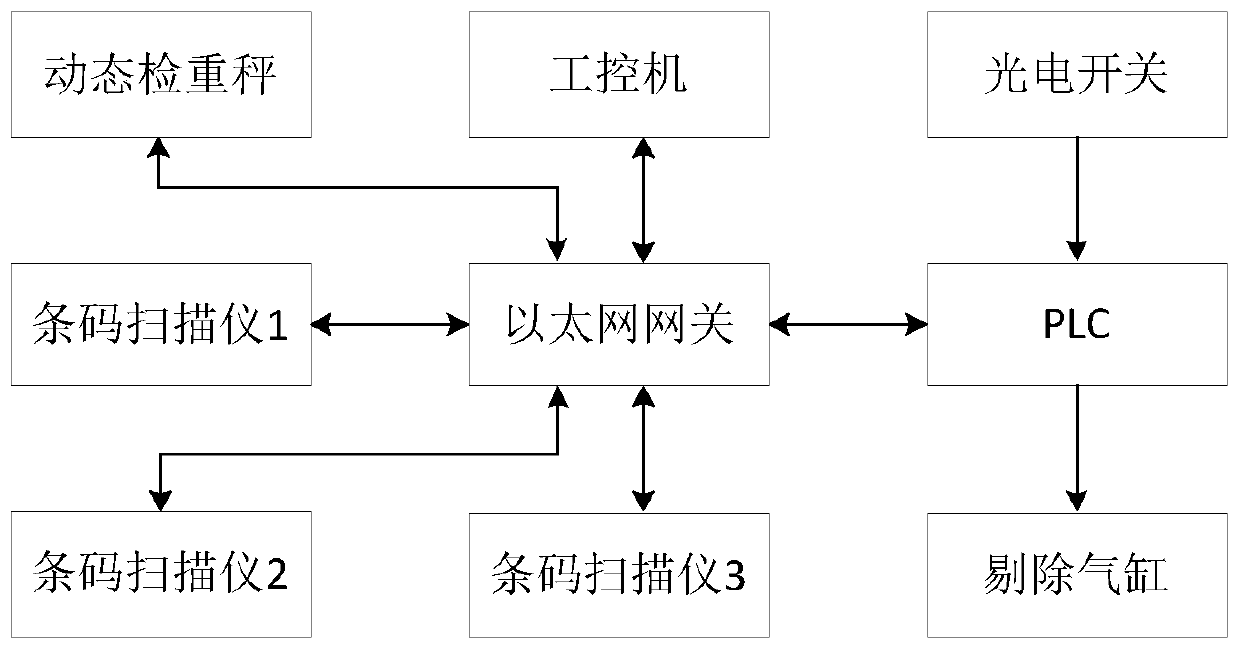

Dynamic weighing detection device with self-learning function

ActiveCN110806254AReduce workloadImprove usabilitySortingSpecial purpose weighing apparatusAutomatic learningCheck weigher

The invention discloses a dynamic weighing detection device with a self-learning function and in particular relates to the field of product package production. The device comprises a dynamic check weigher, an industrial control computer, a programmable logic controller and a plurality barcode scanners, wherein the dynamic check weigher, the industrial control computer, the programmable logic controller and the barcode scanners are mutually connected and communicate with each other by virtue of an Ethernet gateway, a digital quantity input port of the programmable logic controller is connectedwith an entrance photoelectric switch signal, a digital output port of the programmable logic controller is connected with a rejection cylinder. The device is mounted on a product conveyor line, whena product on the product conveyor line passes the device, two barcode scanners scan a project code and a case code at the same time, when both of the two barcodes can be scanned, a working mode is setto be consistency comparison, if consistency is achieved, whether weight is in a normal range is judged, if the weight is in the normal range, the product is released, and if the weight is not in thenormal range, the product is rejected; and if the consistency is not achieved, the product is rejected as a product with abnormal barcodes no matter whether the weight is qualified or unqualified.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

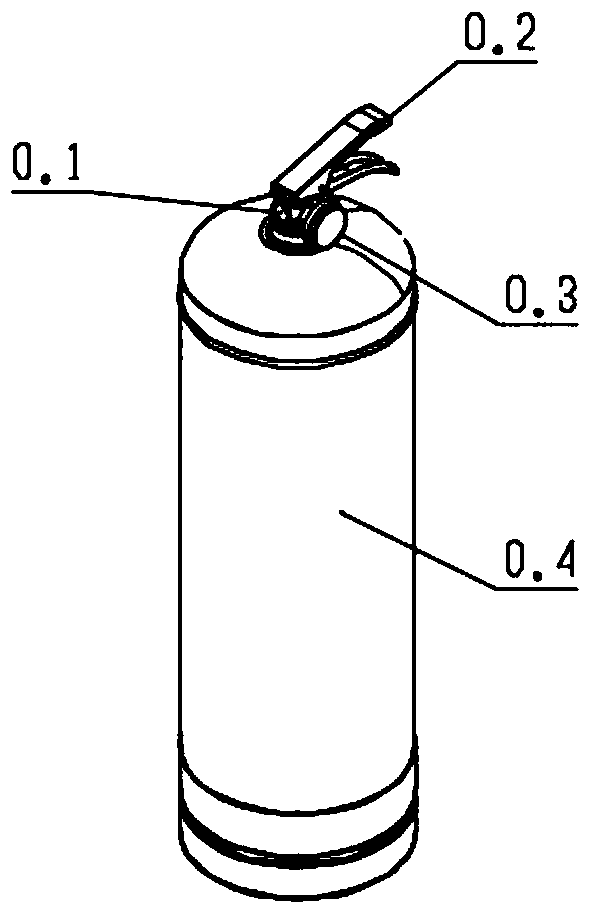

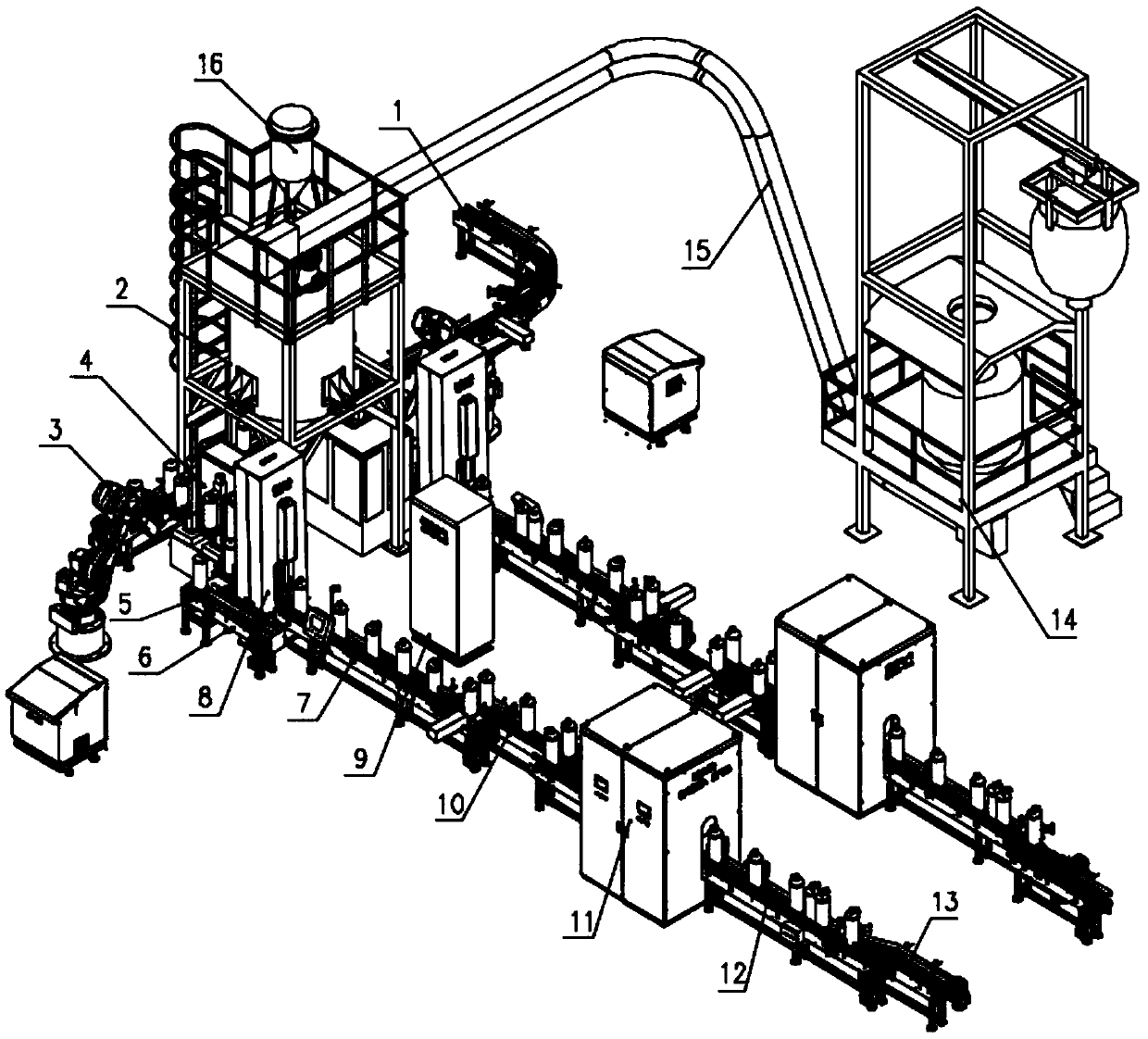

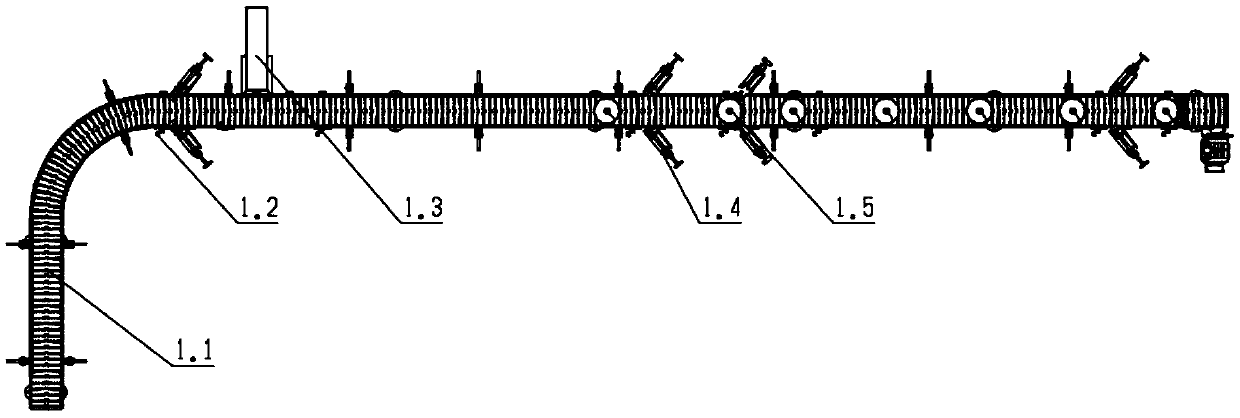

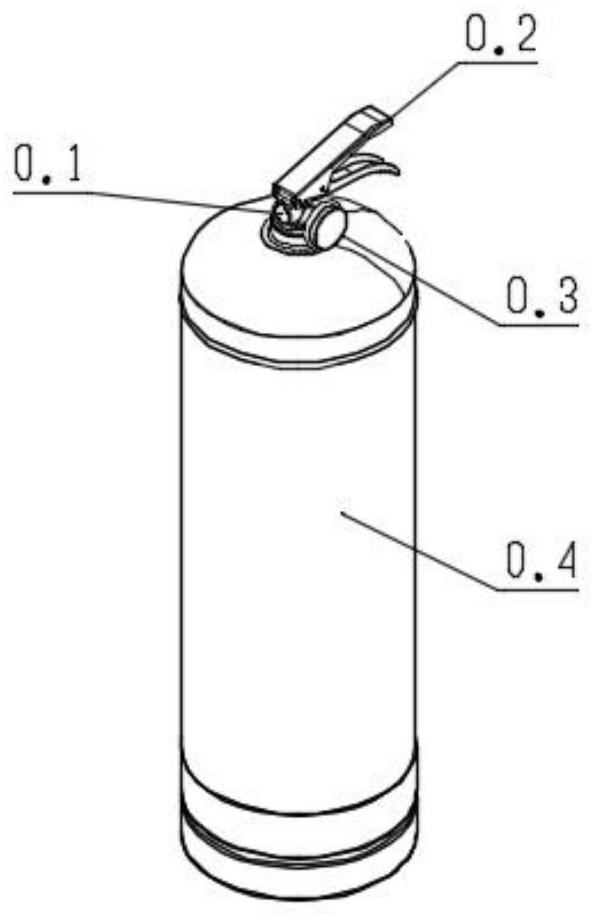

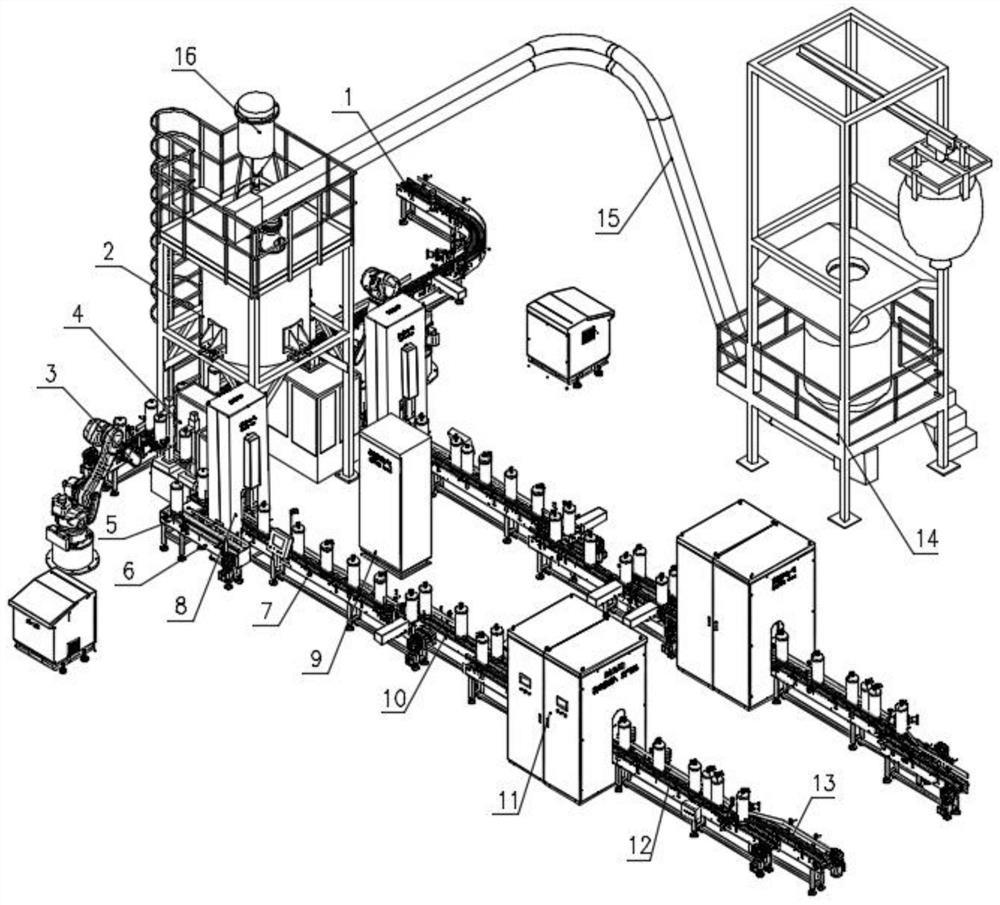

Automatic filling and inflating system of dry powder extinguisher

ActiveCN109607166ACompounding ScienceIncrease productivityFire rescueConveyor partsProduction lineEngineering

The invention discloses an automatic filling and inflating system of a dry powder extinguisher. The automatic filling and inflating system comprises a bottle supplying device, a powder bin and an electric control cabinet, wherein a plurality of filling and inflating production lines are arranged on the system by cooperating with a transfer conveyor, each of the filling and inflating production lines comprises a bottle moving manipulator for transferring the dry powder extinguisher, a filling machine, a check weigher, an elimination conveyor, a powder detacher, a powder detaching conveyor, a tightening aerator, a marshalling conveyor, a tightening conveyor and an exporting conveyor, wherein a filling scale is arranged at the bottom of a filling station of the filling machine; the check weigher is electrically connected with the filling scale; the elimination conveyor is used for transferring the unqualified dry powder extinguisher; the powder detacher is used for detaching the dry powder extinguisher; the powder detaching conveyor is used for transferring the qualified dry powder extinguisher to the powder detacher; the tightening aerator is used for carrying out tightening and inflating on the dry powder extinguisher; the marshalling conveyor is used for marshalling; the tightening conveyor is used for carrying the marshalling conveyor, passes through the self tightening aerator and provides a plurality of tightening and inflating stations for the dry powder extinguisher in the tightening aerator, and the exporting conveyor is used for carrying the dry powder extinguisher outputted by the tightening conveyor. With adoption of the automatic filling and inflating system, the production efficiency, the filling and inflating quality and the reliability are improved.

Owner:SAIMO ELECTRIC

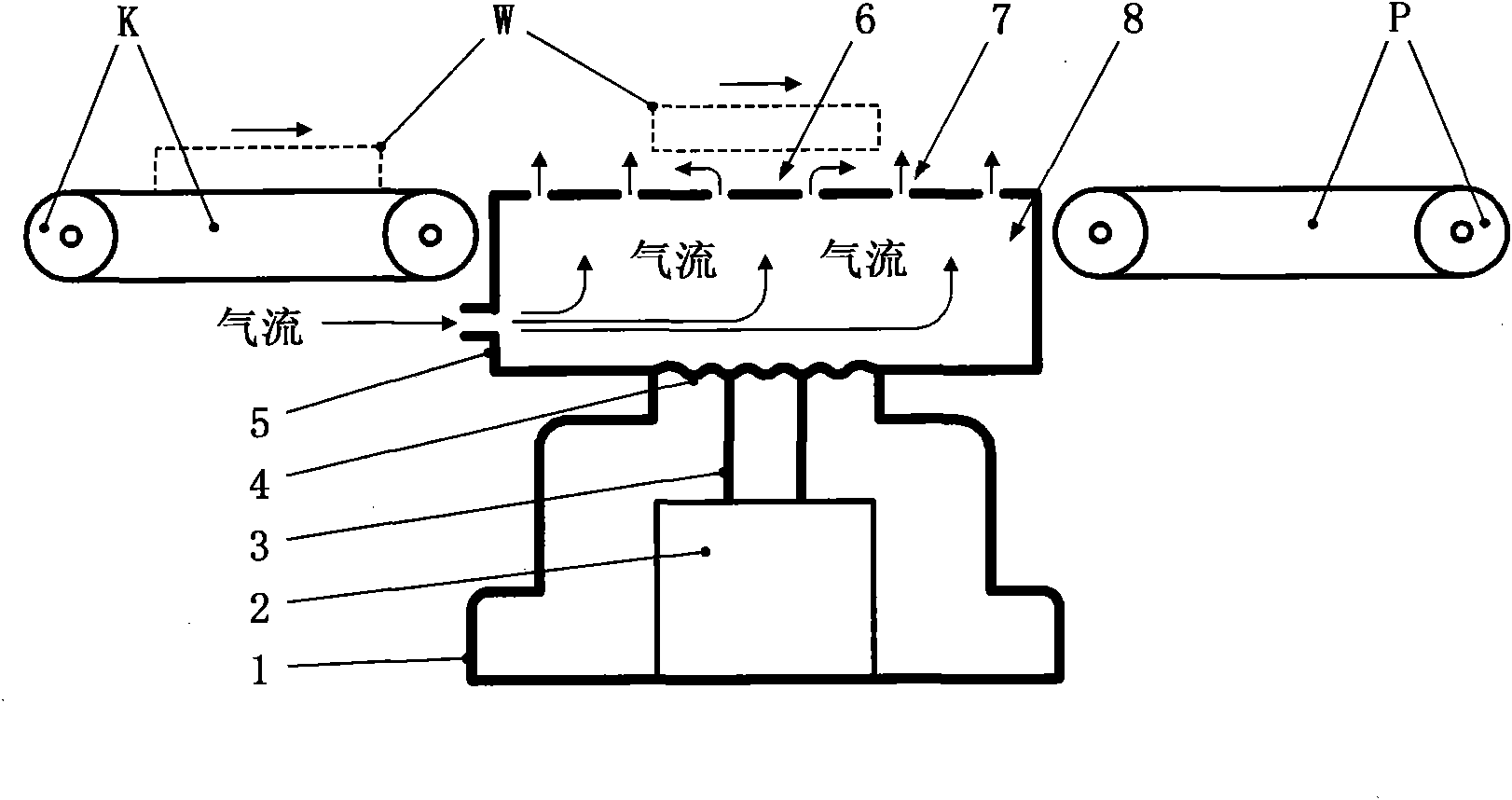

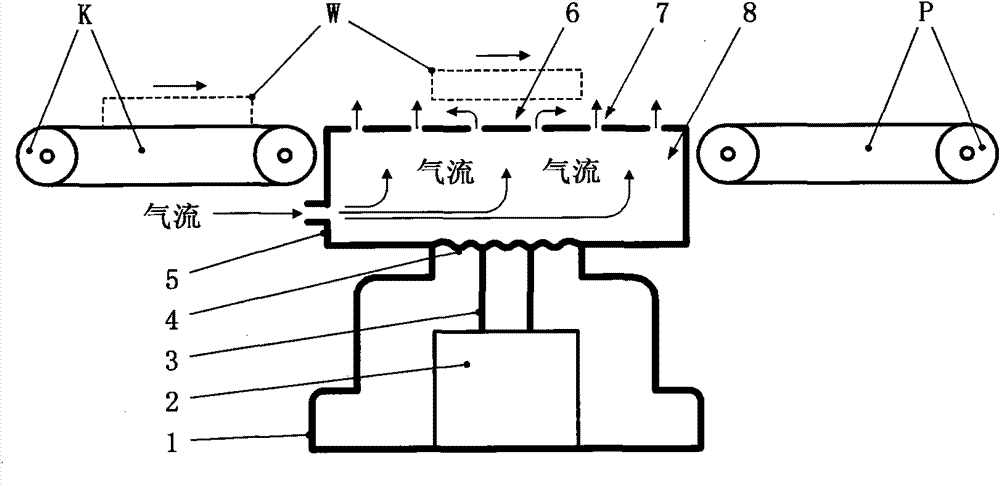

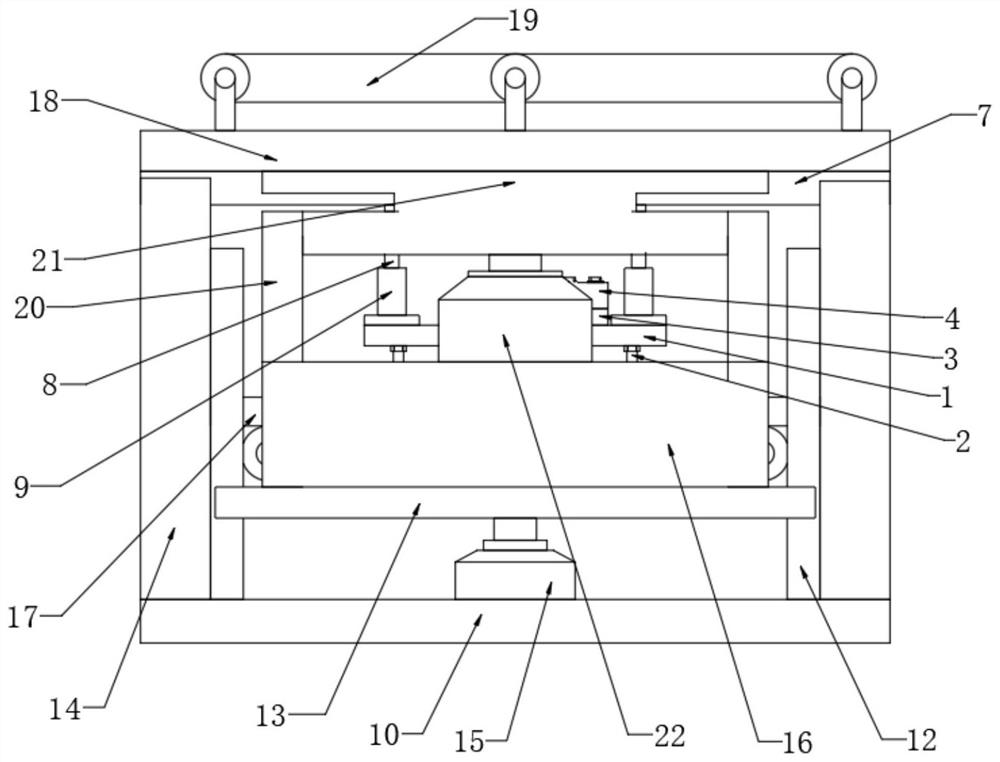

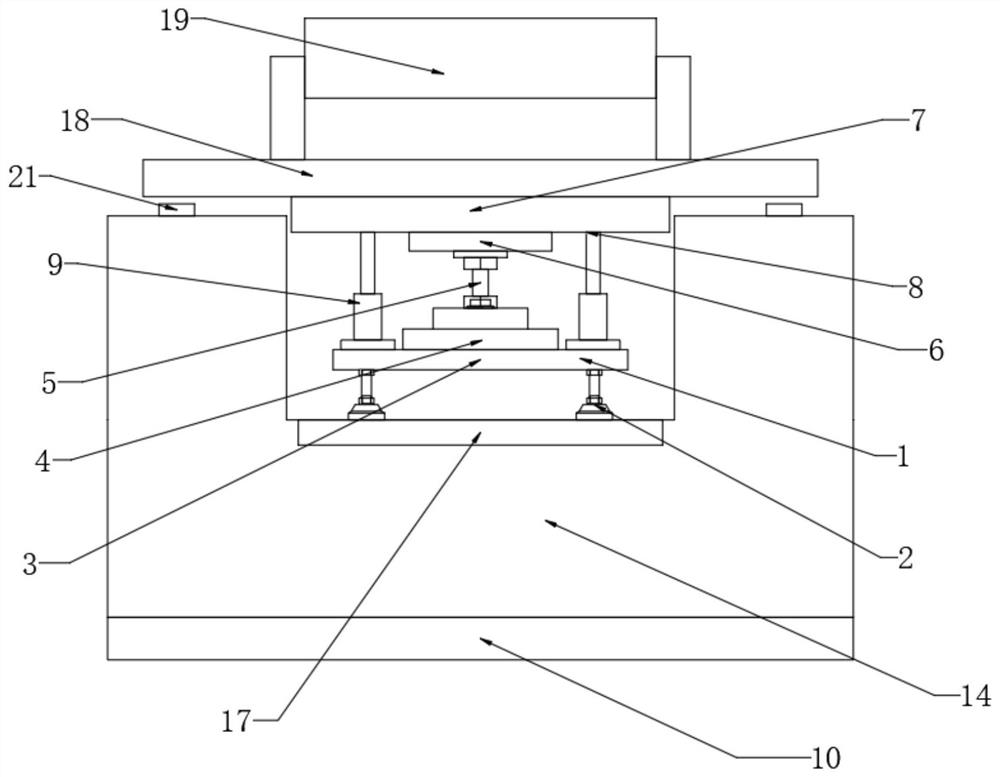

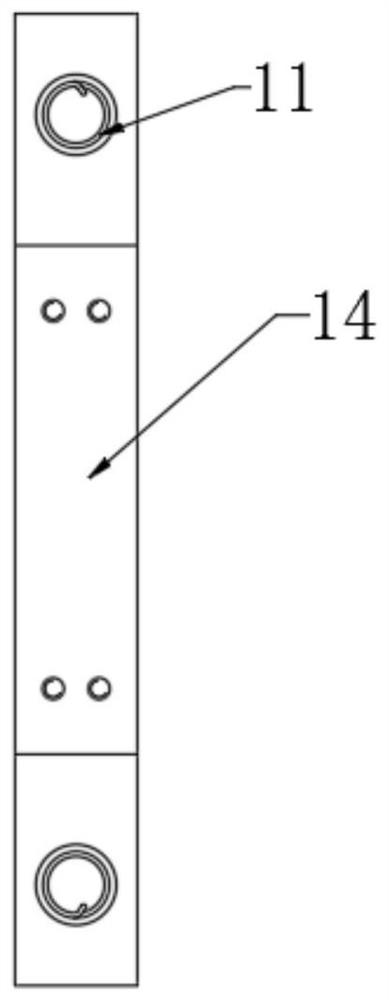

Air-floating type automatic checkweigher

InactiveCN102486397AEasy to convertImprove check weighing accuracyWeighing apparatus using fluid action balancingWeighing apparatus for continuous material flowEngineeringElectromagnetic radiation

The invention relates to an air-floating type automatic checkweigher, and relates to an automatic check weighing technology used for a boxed product, and the air-floating type automatic checkweigher is designed for solving the problems of large vibration noise and low check weighing accuracy existing in the prior art. The air-floating type automatic checkweigher is realized by utilizing an air floating transferring cushion which is uniform, stable and has no electro-magnetic radiation interference, as well as a high-precision pressure-sensitive sensing element and a signal processor as technical assurance. The air-floating type automatic checkweigher is suitable for automatically detecting the weight value of the boxed product within a size range and a certain weight range, such as the weight of a boxed medicine, and can be used for quickly judging whether the weight is qualified or not.

Owner:CHINA JILIANG UNIV

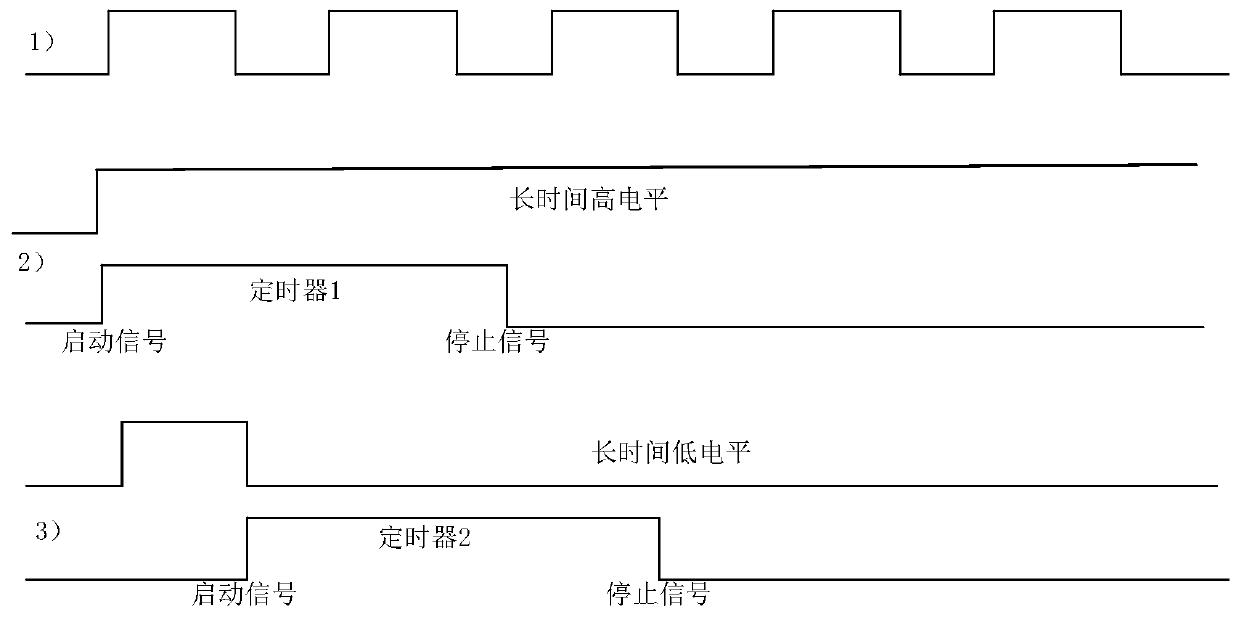

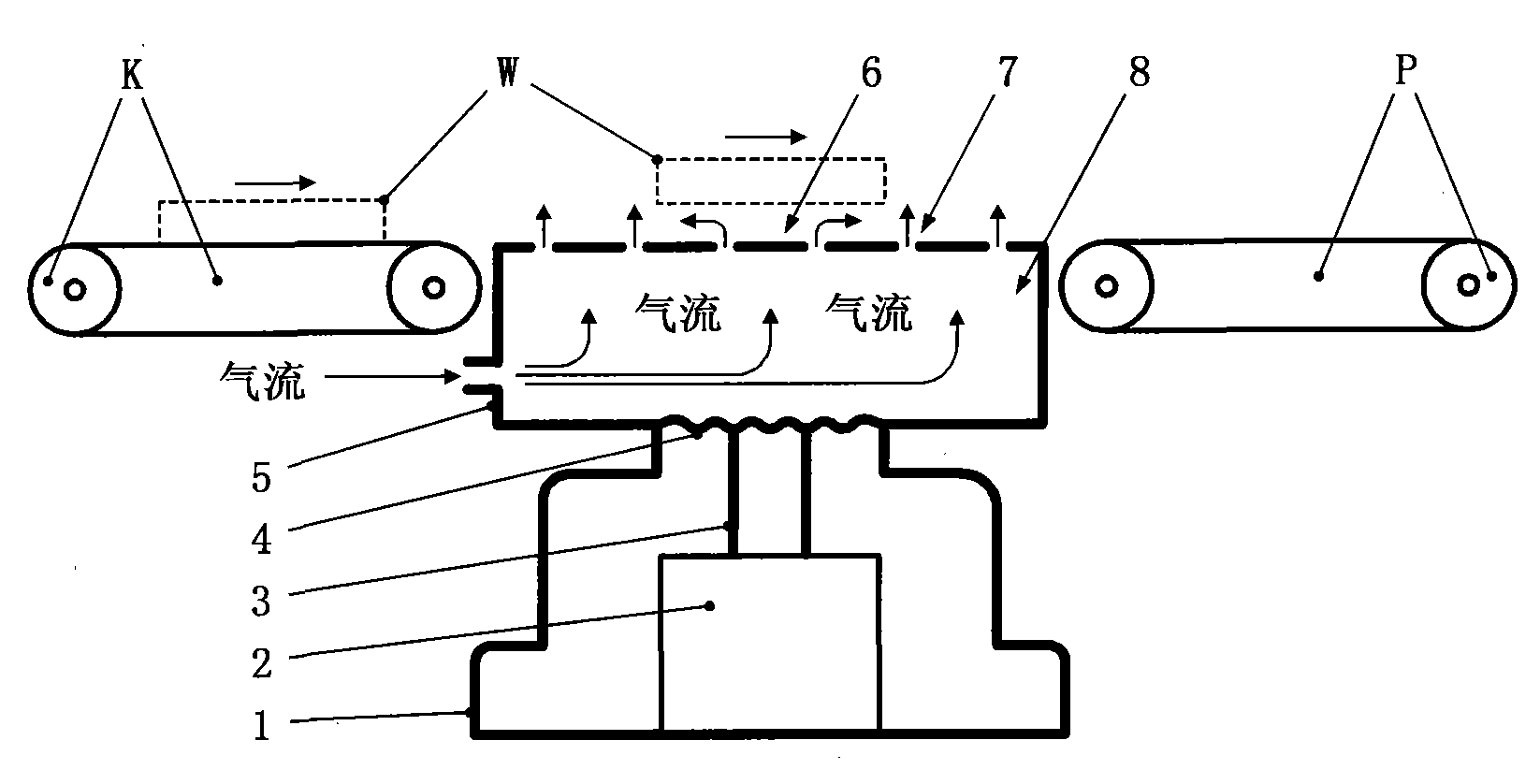

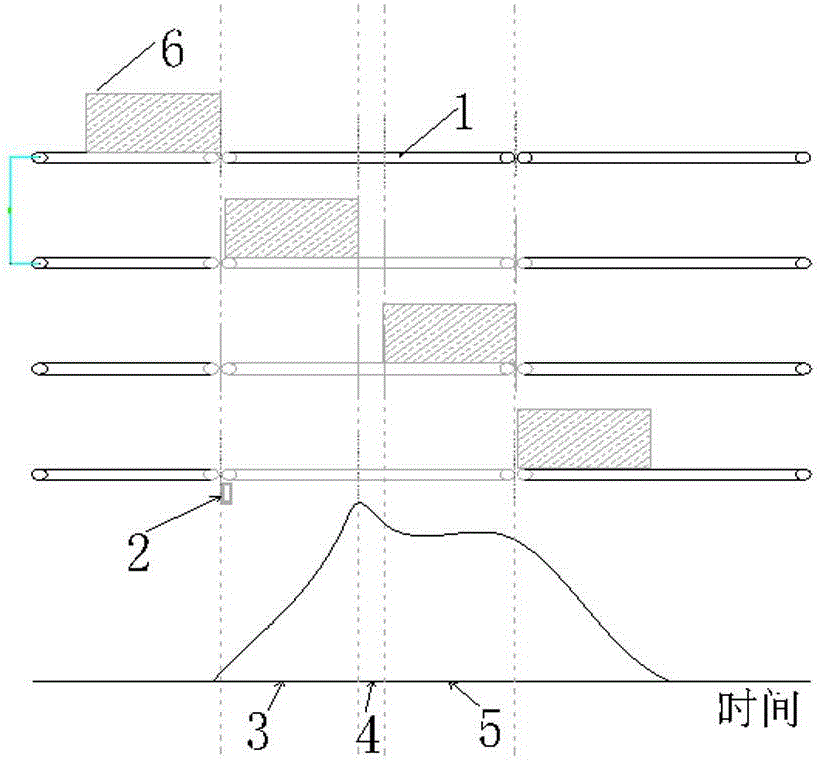

Method and system for measuring interference of weight checking equipment

PendingCN113588062AHelp productionHelp with debuggingWeighing apparatus testing/calibrationOscillations damping for weighingStatistical analysisTested time

The invention discloses a method and a system for measuring interference of weight checking equipment. The method comprises the steps of obtaining weighing test data which are output after preset weighing test time according to preset weighing test times when the weight checking equipment is in a static state, an operation state and a weighing state; obtaining weighing error data of the static state, the operation state and the weighing state through statistical analysis; and calculating or mapping the weighing error data in the static state, the weighing error data in the operation state and the weighing error data in the weighing state to obtain external interference data, equipment self-interference data and weighing object interference data. The interference measuring system for the weight checking equipment comprises an instrument and a processing device; the instrument and the processing device perform an interference measurement and compensation method. According to the invention, the interference intensity of the weight checking equipment in each state and the influence intensity of the weight checking equipment on the weighing performance can be obtained, so that the production, debugging, maintenance and use of a checkweigher are facilitated.

Owner:METTLER TOLEDO (CHANGZHOU) MEASUREMENT TECH CO LTD +2

Automatic checkweigher with balance fine adjustment architecture

InactiveCN103630223AEasy to adjustPractical and convenientWeighing apparatus detailsSpecial purpose weighing apparatusElectricityEngineering

The invention discloses an automatic checkweigher with a balance fine adjustment architecture. The automatic checkweigher includes an electric box, a weighing platform and a rack; the weighing platform is horizontally located on the rack; the electric box is located at one side of the weighing platform and is in positioned and fixed connection with the rack; the balance fine adjustment architecture is arranged between the rack and the weighing platform; one surface of the balance fine adjustment architecture, which faces the weighing platform, is provided with a plurality of weighing sensors; the weighing sensors are in positioned connection with the weighing platform through reset mechanisms; the weighing sensors are electrically connected with the electric box; and the weighing platform can be adjusted horizontally through the balance fine adjustment architecture. According to the automatic checkweigher with the balance fine adjustment architecture of the invention adopted, the horizontal adjustment of the automatic checkweigher is diversified, and the weighing platform can be adjusted to be horizontal more precisely in a short period of time. The automatic checkweigher with the balance fine adjustment architecture of the invention is advantageous in convenient operation, easiness in implementation as well as assembly and disassembly, and convenient repair.

Owner:KUNSHAN LIGU WEIGHING IND

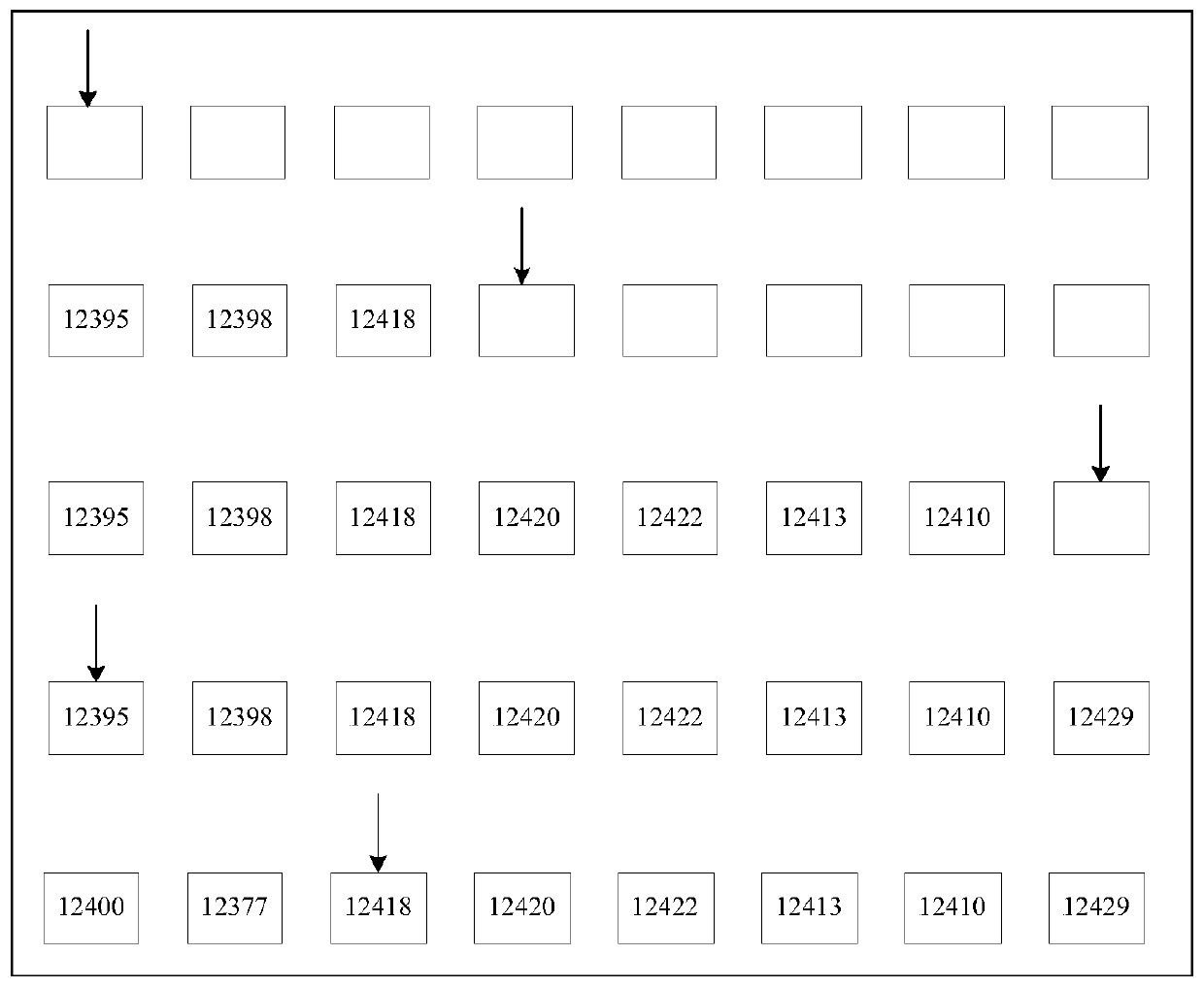

Adaptive dynamic weight system and work process of automatic checkweigher

InactiveCN106352964ASimplified operational requirementsSimplified skill requirementsWeighing auxillary devicesSpecial purpose weighing apparatusHuman–machine interfaceVia device

This invention discloses an adaptive dynamic weight system and work process of automatic checkweigher comprising a dynamic weighing unit, a photosensor, a weighing sensor, microprocessor-based circuit, and a man-machine interface. It further discloses the work process of the adaptive dynamic weight system of the automatic checkweighter. This invention can solve the problems concerning the matching of the dynamic weight and the static weight and the manual setting of complex electric filter parameters and weighing time. Using adaptive algorithm, this invention can complete the automatic setting of all parameters including those of the electric filter and weighing time through automatic learning steps of the equipment by solely inputing the product length and productivity to be detected, therefore, it simplifies the requirements for the operation and techniques of production line personnel and saves the labor cost of enterprises, representing a broad application prospect.

Owner:上海芝研检测技术有限公司

Dynamic calibration method for checkweigher

PendingCN112033517ADon't worry about wear and tearNo worries about wear and tearWeighing apparatus testing/calibrationProcess engineeringIndustrial engineering

Owner:HENAN PROVINCE INST OF METROLOGY

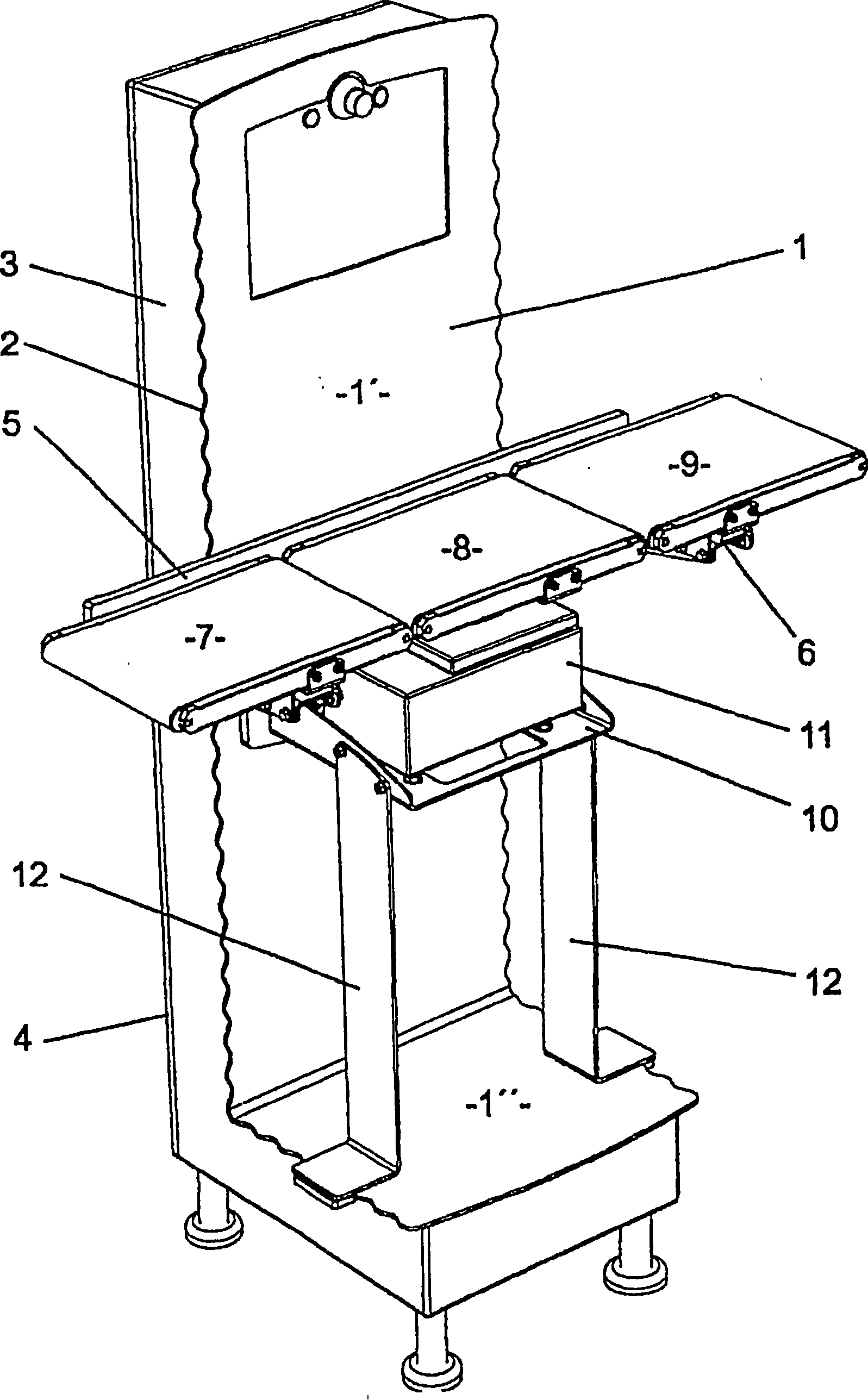

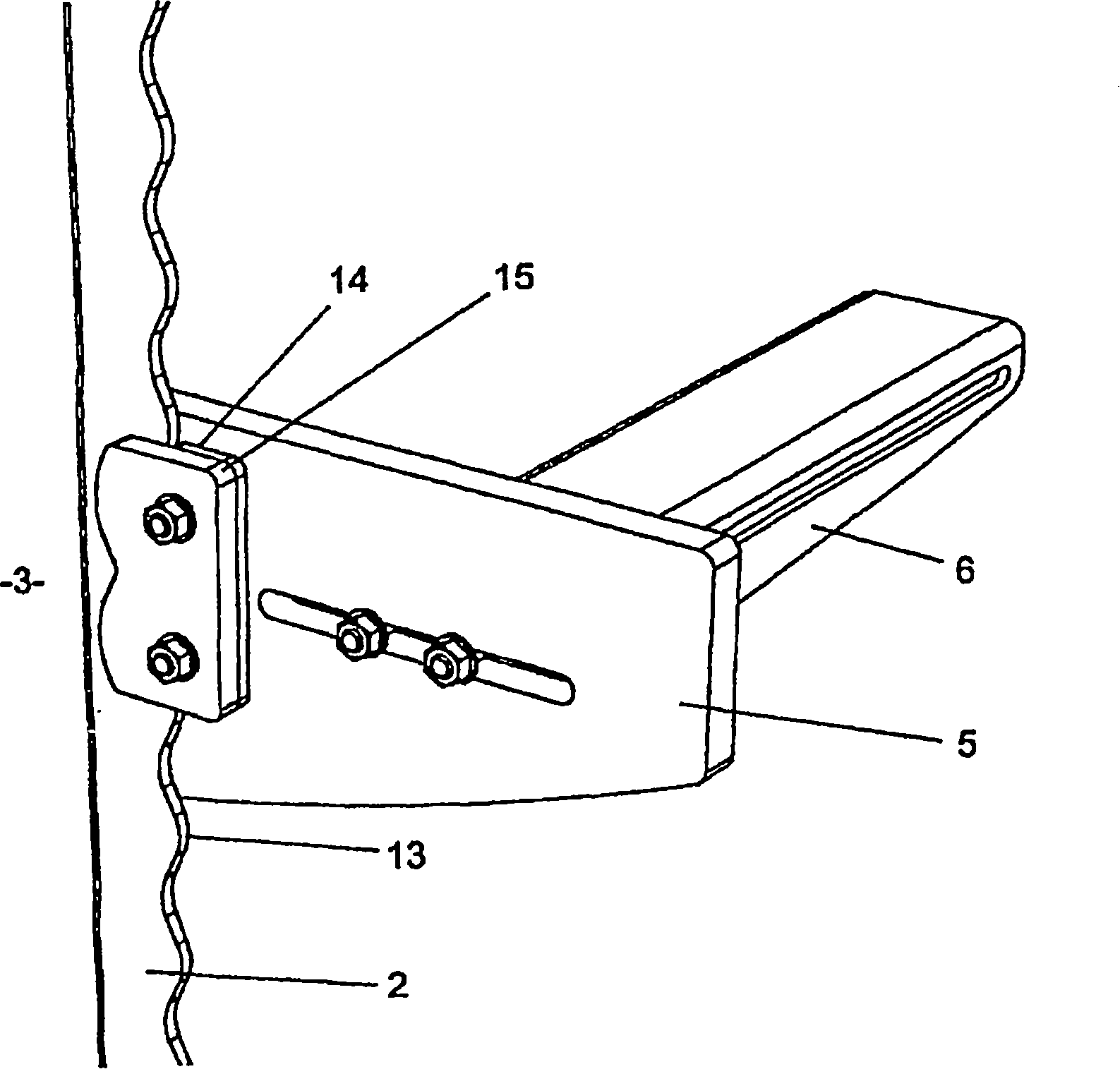

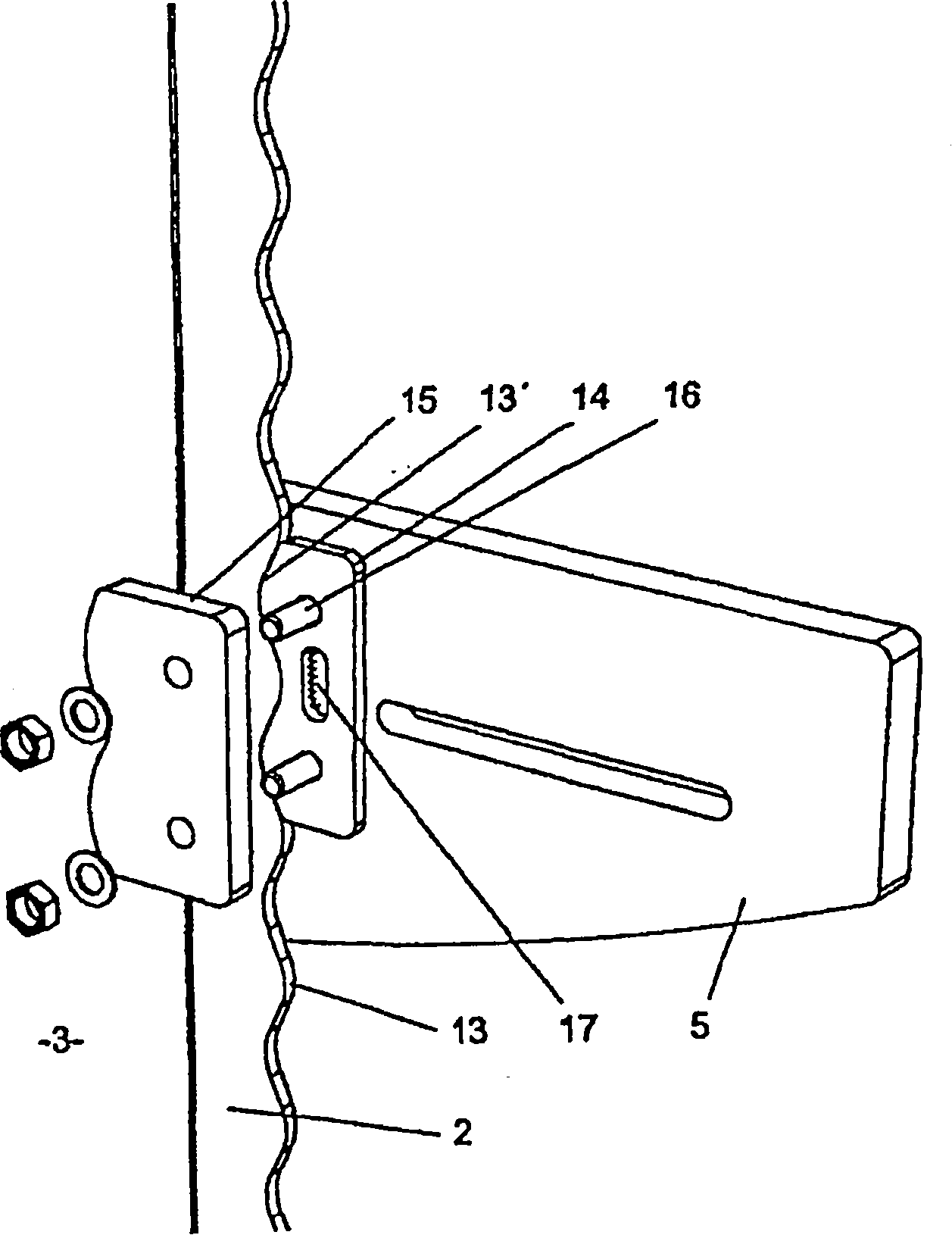

Check weigher

InactiveCN101208585AWeighing apparatus detailsMaterial check-weighingEngineeringElectronic component

The invention relates to a check weigher comprising a machine body consisting of a front clamping plate and a rear hollow body which is fixedly or detachably connected to said clamping plate and is preferably used as a cabinet for receiving necessary electric and electronic components. The clamping plate is projected on all sides across the hollow body, thereby forming a fastening flange. The outer edge of said fastening flange is provided with a recessed and projected contour which is subdivided into any grid and enables to obtain a positive or non-positive secure connection of accessories with the machine body by means of two clamping plates having a corresponding contour and fixedly connected to a holding plate and additional clamping elements.

Owner:SARTORIUS AACHEN

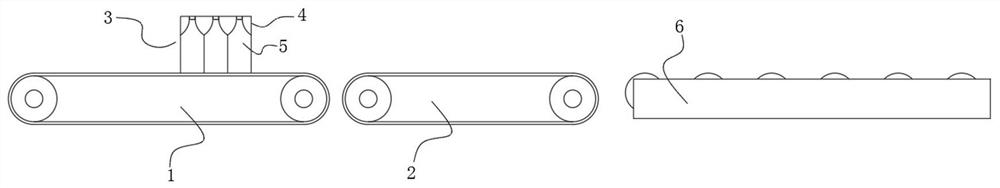

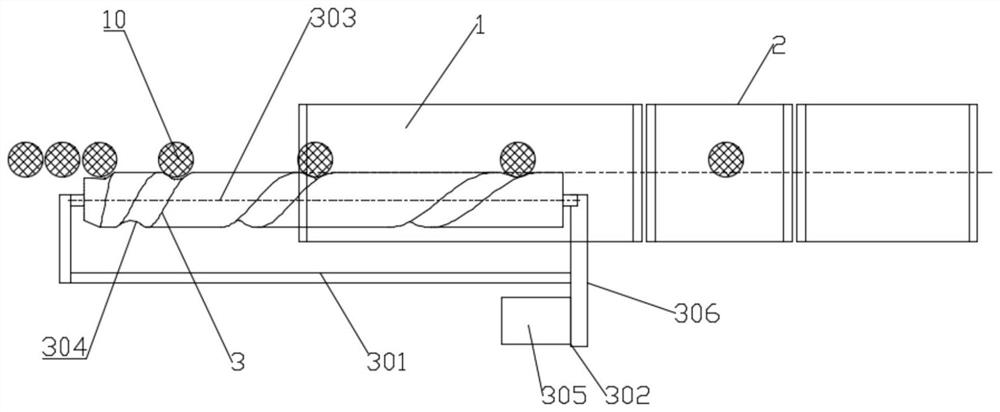

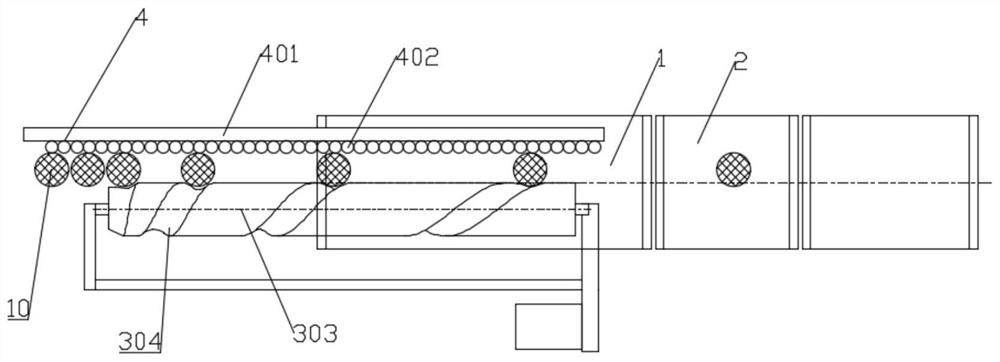

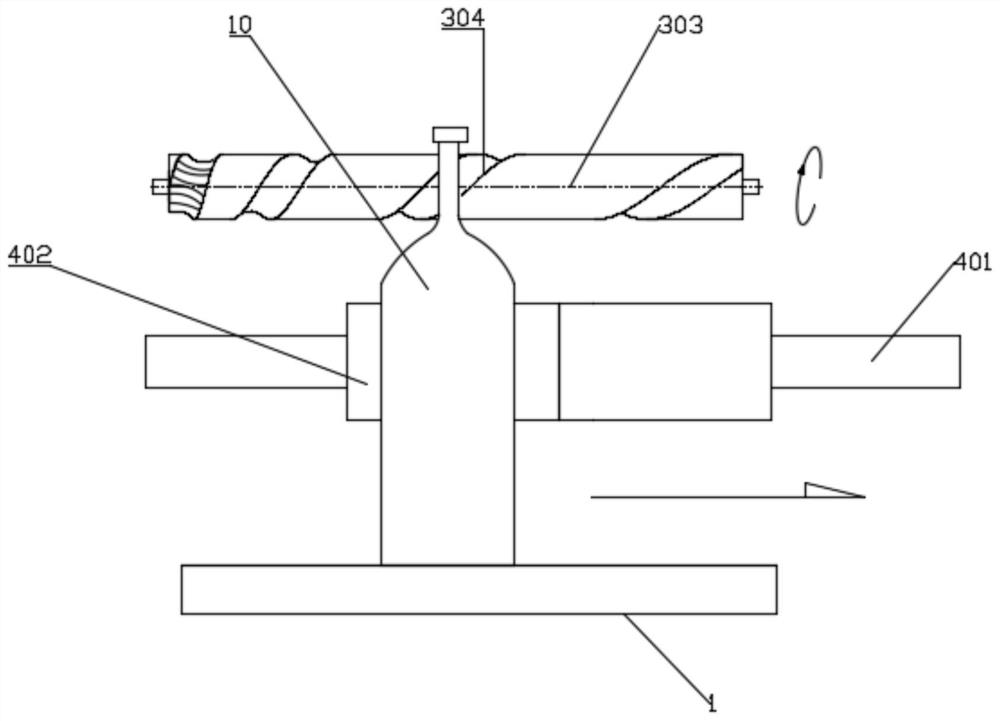

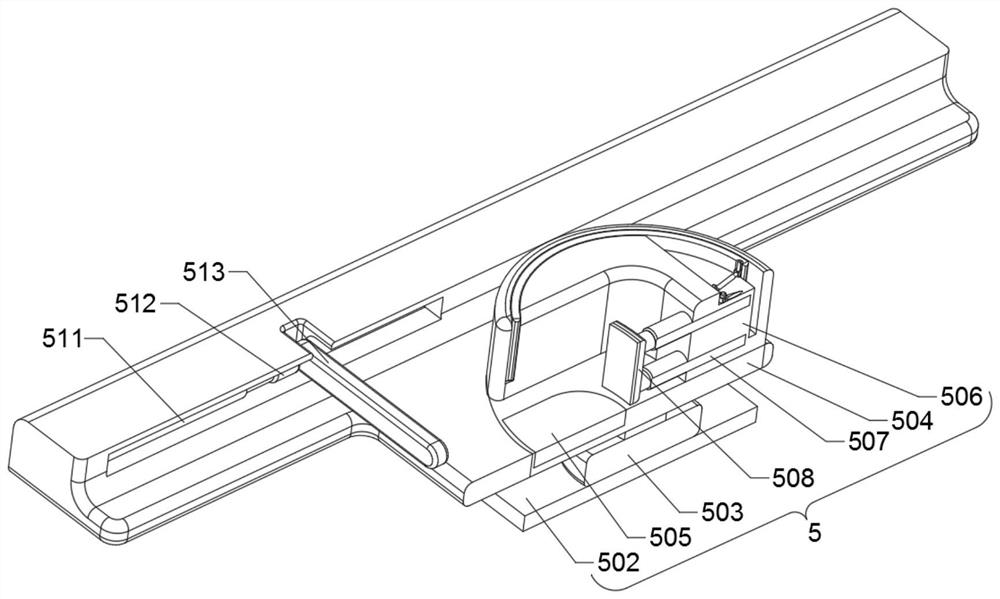

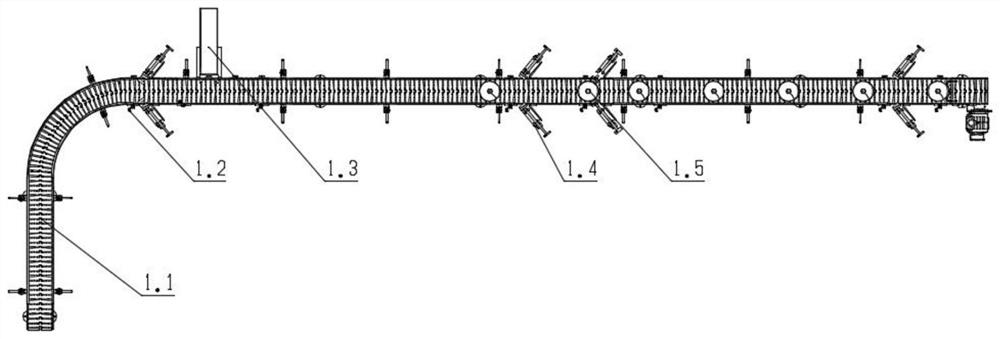

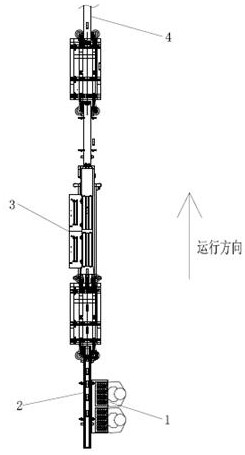

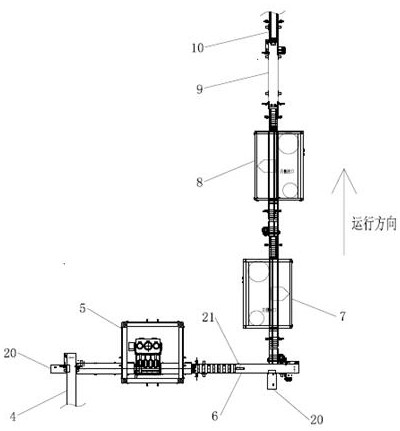

A material-feeding device of a high-speed checkweigher

The embodiment of the invention discloses a material issuing device of a high-speed checkweigher. The material issuing device of the high-speed checkweigher comprises a front-end conveyor and a weighing conveyor for weighing a bottle-shaped workpiece conveyed by the front-end conveyor, wherein a differential material stabilizing device for preventing the bottle-shaped workpiece from side turning in the speed-changing conveying process is arranged on one side of the front-end conveyor; the differential material stabilizing device comprises an installation support; a screw rod arranged parallelto a conveying direction of the front-end conveyor and driven by a power device so as to rotate is arranged on the installation support; a variable-pitch spiral groove is formed in the screw rod; andthe bottle-shaped workpiece is limited by the variable-pitch spiral groove and moves linearly along with the variable-pitch spiral groove along the conveying direction of the front-end conveyor. According to the material issuing device of the high-speed checkweigher provided by the invention, the differential material stabilizing device capable of synchronously conveying the bottle-shaped workpiece and the front-end conveyor is additionally arranged above the front-end conveyor, and the speed of the bottle-shaped workpiece gradually stays the same with the linear speed of the front-end conveyor under the clamping of the variable-pitch spiral groove on the screw rod, so that bottles are conveyed stably.

Owner:上海实干实业有限公司

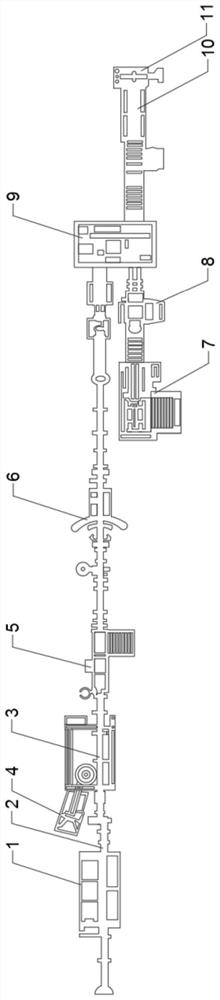

5-10L bottled liquid filling production process and production line

PendingCN113306812AImprove product qualityImprove work efficiencyWrapper twisting/gatheringPackaging automatic controlLiquid wasteIndustrial engineering

The invention discloses a 5-10L bottled liquid filling production process and production line. The production process flow comprises the following steps that A, an intelligent high-viscosity filling machine automatically fills a storage bottle, then the storage bottle is moved into a full-automatic following type cap screwing machine, and a bottle cap is screwed onto the storage bottle through a cap feeding machine; weight detection is carried out by a checkweigher, and qualified finished products are fed into a labeling machine for automatic labeling; B, a full-automatic case unpacking machine opens a packing case, and the packing case is conveyed to a full-automatic plate adding machine for plate adding; C, a full-automatic case filling machine fills the storage bottle into the packing case, and then a full-automatic cap folding and case sealing machine closes the packing case containing the storage bottle; and D, the packaging case is bundled through a full-automatic bundling machine. According to the technical scheme, automatic filling of the whole production line is achieved, manual operation and manual control between production lines are saved, the filling efficiency is improved, the filling accuracy can be improved, the yield can be improved, and liquid waste is prevented.

Owner:JIANGSU TENGLONG BIOLOGICAL PHARMA

A dry powder fire extinguisher automatic filling inflation system

ActiveCN109607166BIncrease productivityQuality improvementFire rescueConveyor partsProduction lineFire extinguisher

The invention discloses an automatic filling and inflating system of a dry powder extinguisher. The automatic filling and inflating system comprises a bottle supplying device, a powder bin and an electric control cabinet, wherein a plurality of filling and inflating production lines are arranged on the system by cooperating with a transfer conveyor, each of the filling and inflating production lines comprises a bottle moving manipulator for transferring the dry powder extinguisher, a filling machine, a check weigher, an elimination conveyor, a powder detacher, a powder detaching conveyor, a tightening aerator, a marshalling conveyor, a tightening conveyor and an exporting conveyor, wherein a filling scale is arranged at the bottom of a filling station of the filling machine; the check weigher is electrically connected with the filling scale; the elimination conveyor is used for transferring the unqualified dry powder extinguisher; the powder detacher is used for detaching the dry powder extinguisher; the powder detaching conveyor is used for transferring the qualified dry powder extinguisher to the powder detacher; the tightening aerator is used for carrying out tightening and inflating on the dry powder extinguisher; the marshalling conveyor is used for marshalling; the tightening conveyor is used for carrying the marshalling conveyor, passes through the self tightening aerator and provides a plurality of tightening and inflating stations for the dry powder extinguisher in the tightening aerator, and the exporting conveyor is used for carrying the dry powder extinguisher outputted by the tightening conveyor. With adoption of the automatic filling and inflating system, the production efficiency, the filling and inflating quality and the reliability are improved.

Owner:SAIMO ELECTRIC

Air-floating type automatic checkweigher

InactiveCN102486397BEasy to convertImprove check weighing accuracyWeighing apparatus using fluid action balancingWeighing apparatus for continuous material flowEngineeringElectromagnetic radiation

The invention relates to an air-floating type automatic checkweigher, and relates to an automatic check weighing technology used for a boxed product, and the air-floating type automatic checkweigher is designed for solving the problems of large vibration noise and low check weighing accuracy existing in the prior art. The air-floating type automatic checkweigher is realized by utilizing an air floating transferring cushion which is uniform, stable and has no electro-magnetic radiation interference, as well as a high-precision pressure-sensitive sensing element and a signal processor as technical assurance. The air-floating type automatic checkweigher is suitable for automatically detecting the weight value of the boxed product within a size range and a certain weight range, such as the weight of a boxed medicine, and can be used for quickly judging whether the weight is qualified or not.

Owner:CHINA JILIANG UNIV

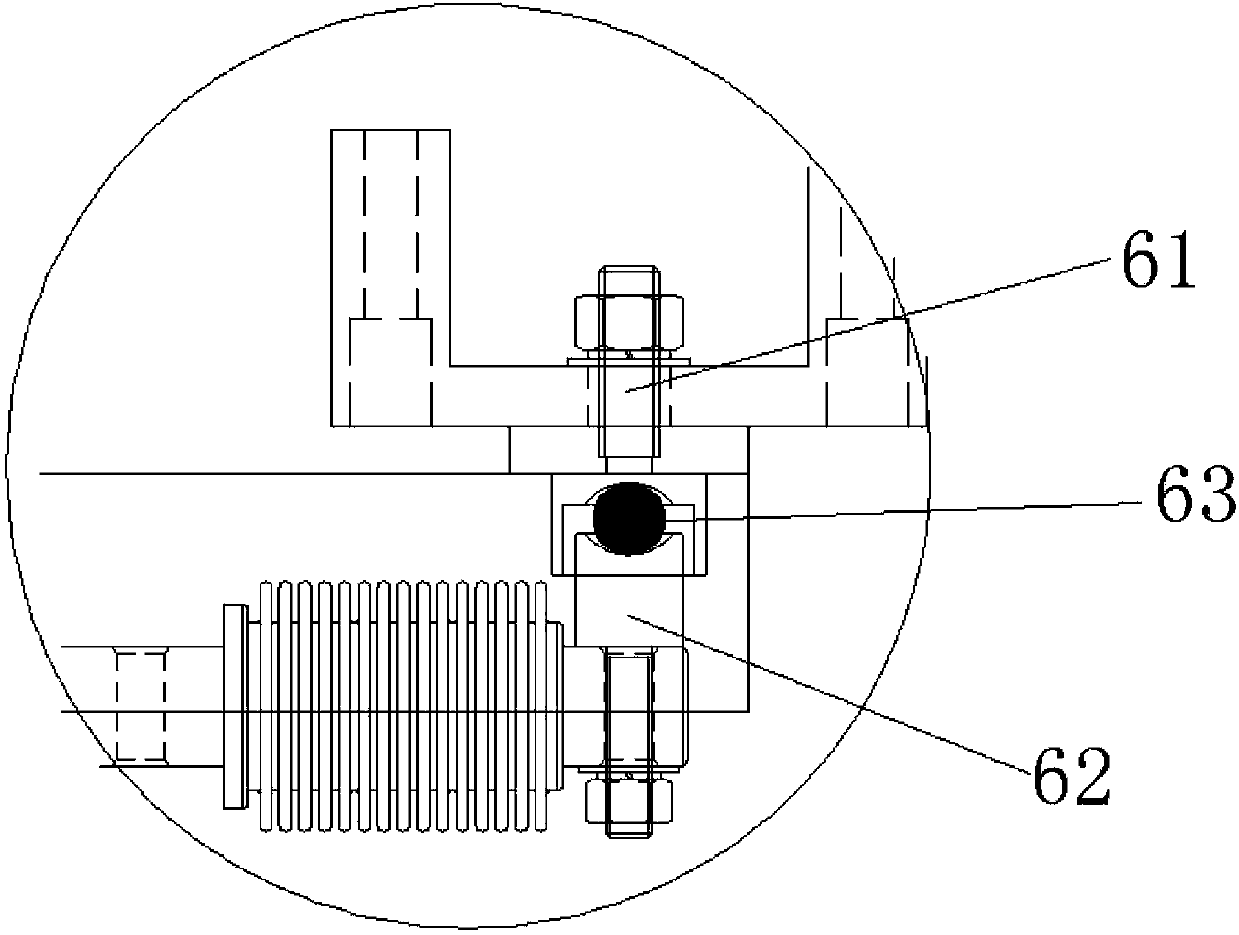

Weighing sensor assembly and dynamic automatic weight checking scale comprising same

InactiveCN112304403AAvoid direct impactAvoid disassemblyWeighing auxillary devicesSpecial purpose weighing apparatusControl theoryLoad cell

The invention belongs to the technical field of electronic scales, and particularly relates to a weighing sensor assembly and a dynamic automatic check weigher comprising the same. Foot cups are installed at the four corners of the lower portion of a fixing table, a base is installed above the fixing table, a weighing sensor is installed above the base, a screw is in threaded connection with the left side of the upper portion of the weighing sensor, a pressure bearing table is in threaded connection with the upper side of the screw, nuts are in threaded connection with the outer sides of the upper end and the lower end of the screw, the nuts on the upper side are attached to the pressure bearing table, the nuts on the lower side are attached to the weighing sensor, a weighing table is installed above the pressure bearing table, and limiting columns are mounted at four corners below the weighing table. According to the device, the screw and the pressure bearing table are installed abovethe weighing sensor, after the weighing sensor assembly is subjected to impact force and the pressure bearing table deforms, and the pressure bearing table transmits pressure to the weighing sensor through the screw by means of deformation, so the weighing sensor is prevented from directly receiving impact force.

Owner:淮安市格洋浩瑞电子科技有限公司

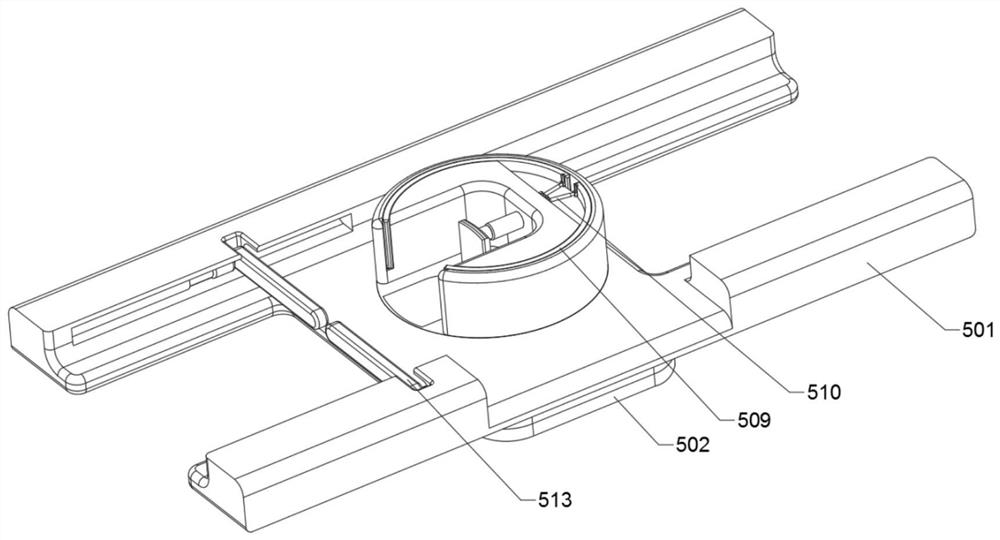

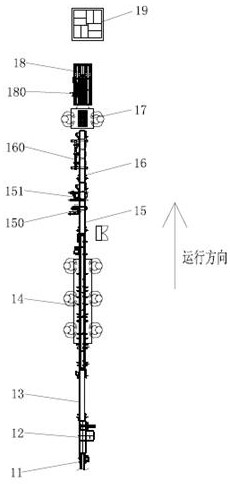

Checkweigher with material sending device

PendingCN109029653AGuaranteed weighing accuracyImprove applicabilityWeighing apparatus with automatic feed/dischargeEngineeringLoad cell

The invention relates to a checkweigher with a material sending device. The checkweigher comprises a material feeding unit and a weighing unit that are arranged in sequence from left to right, and further comprises a control cabinet, wherein the weighing unit comprises an object moving platform and a weighting sensor connected with the object moving platform, the upper surface of the object movingplatform is parallel to the upper surface of the material feeding unit, the weighing unit is connected with a rack through the weighing sensor, the material feeding unit is connected with the rack, the weighing sensor is electrically connected with the control cabinet, the material sending device is arranged at the left of the material feeding unit, the material sending device comprises a rolleradjustment support and a second roller and a first roller that are arranged on the roller adjustment support, the first roller and the second roller are opposite and are parallel, a plane in which axes of the first roller and the second roller is vertical to the upper surface of the material feeding unit, axes of the second roller and the first roller are vertical to a product moving direction onthe upper surface of the material feeding unit, at least one of the second roller and the first roller is connected with a rotating drive device, and the rotating drive device is electrically connected with the control cabinet.

Owner:SHANDONG SETAQ INSTR

Powder filling and packaging equipment for special-shaped plastic box and filling process of powder filling and packaging equipment

PendingCN114715494ASolve the mismatchFast packPackage sterilisationWrapper twisting/gatheringProduction lineIndustrial engineering

The invention discloses powder filling and packaging equipment for special-shaped plastic boxes and a filling process of the powder filling and packaging equipment. The powder filling and packaging equipment is provided with a material box UV sterilization machine, a special-shaped container multi-column horizontal filling machine, a material box side sealing machine, a weight checking scale, a material box labeling conveyor, a double-layer boxing conveyor, a code printing conveyor, a three-code-in-one conveyor, a boxing workbench, a box sealing machine and a stacking machine. The whole automatic filling and packaging production line can rapidly fill and package the special-shaped plastic boxes, the problem that a common production line is not matched is solved, and the filling and packaging efficiency is greatly improved due to full automation of the production line.

Owner:江苏永兴长和智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com