Checkweigher with material sending device

A checkweigher and weighing technology, applied in the direction of measuring devices, automatic feeding/discharging weighing equipment, instruments, etc., can solve the problem of insufficient distance between adjacent products, limit the scope of use of checkweighers, and affect conveyor line products Quality and other issues, to achieve the effect of weighing accuracy guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

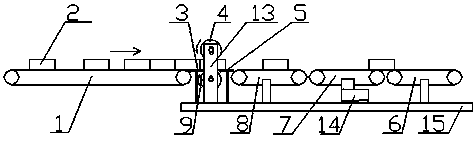

[0041] Embodiment 1: a kind of checkweigher with sending device, as figure 1 As shown, it includes a feeding unit, a weighing unit, and a rejecting unit 6 arranged sequentially from left to right, and also includes a control cabinet. The weighing unit is composed of an object moving platform and a load cell 14 connected thereto. The upper part of the object moving platform The surface is parallel to the upper surface of the feeding unit, the feeding unit is a feeding belt conveyor 8, the object moving platform is a weighing belt conveyor 7, and the weighing unit is connected with the frame 15 by a load cell 14, the feeding unit, The rejecting unit 6 is connected with the frame 15, the load cell 14 and the rejecting unit 6 are electrically connected with the control cabinet respectively, and the feeding belt conveyor 8 and the weighing belt conveyor 7 are also electrically connected with the control cabinet respectively. The left side of the left side is also provided with a ma...

Embodiment 2

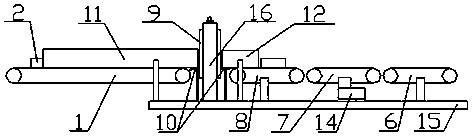

[0047] Embodiment 2: A checkweigher with a material sending device, the same as Embodiment 1 will not be repeated, as figure 2 with 3As shown, the difference is that the axes of the second roller shaft 4 and the first roller shaft 9 are perpendicular to the upper surface of the feeding unit, and the lengths of the second roller shaft 4 and the first roller shaft 9 are greater than the upper and lower thicknesses of the product 2, The roller shaft adjustment bracket is a vertical shaft adjustment bracket 16, and the vertical shaft adjustment bracket 16 includes two vertically opposite horizontal plates parallel to the upper surface of the feeding unit. The strip-shaped hole of the second roller shaft 4 is provided with a front guide rail 11 on the left side of the feeding device. The product channel formed by the front guide rail 11 and the product conveying line 1 includes a left channel and a right channel, and the left channel is a horn. Mouth-shaped groove-shaped passage,...

Embodiment 3

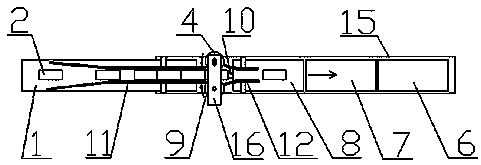

[0049] Embodiment 3: A checkweigher with a material sending device, the same as Embodiment 1 will not be repeated, the difference is that, as Figure 4 with 5 As shown, the feeding unit is the feeding slide 18, and the object moving platform is the weighing slide 17. The feeding slide 18 and the weighing slide 17 do not need to be electrically connected to the control cabinet. The feeding slide 18, the weighing slide 17, and the rejecting unit 6 Arranged obliquely from the upper left to the lower right, the bottom surface of the feeding slide 18 is parallel to the bottom surface of the weighing slide 17 and the inclination angle to the horizontal plane is α, 5°<α<55°, the feeding slide 18 can be a smooth flat plate, or It is a smooth flat-bottomed U-groove slightly wider than product 2. The bottom surface of the left end is bent downward to the left. Be provided with slide plate material guide mechanism 19, slide plate material guide mechanism 19 right end base plates stretch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com