Weighing sensor assembly and dynamic automatic weight checking scale comprising same

A technology of load cells and components, applied in the field of electronic scales, can solve the problems of lack of anti-collision protection and difficulty in replacement of load cell components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

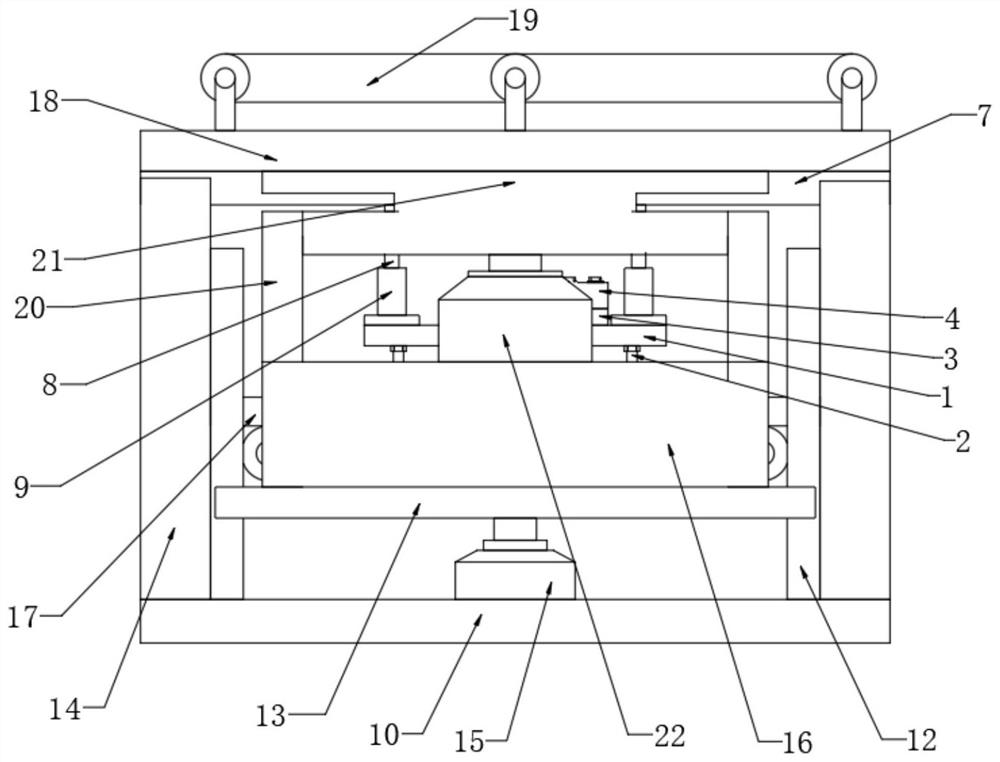

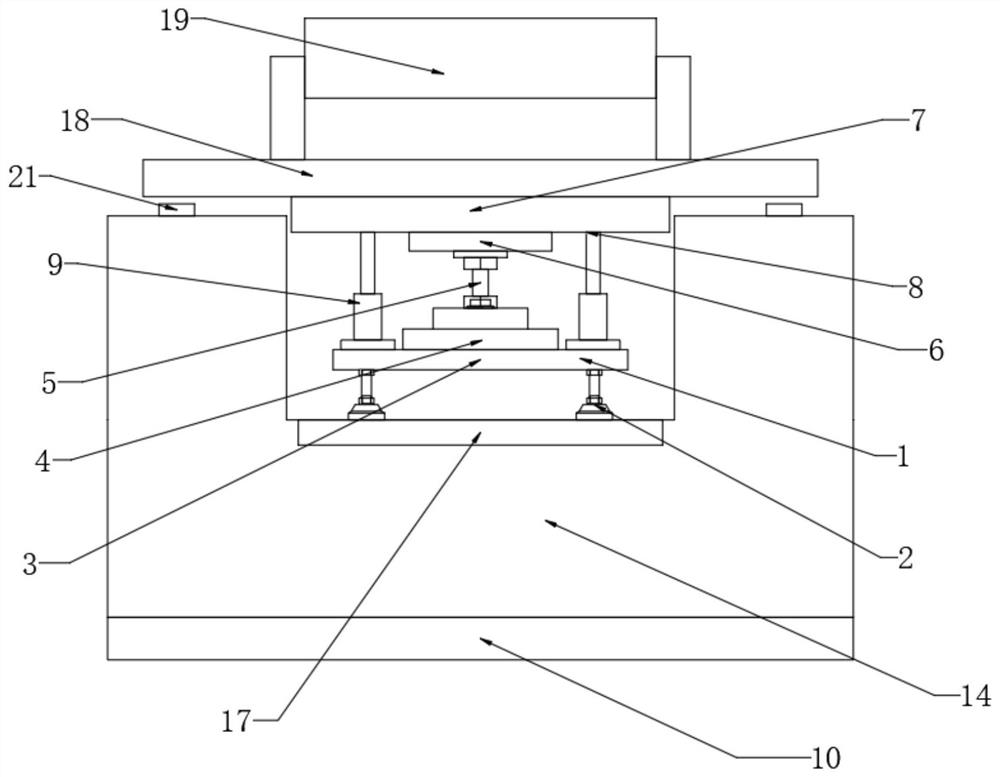

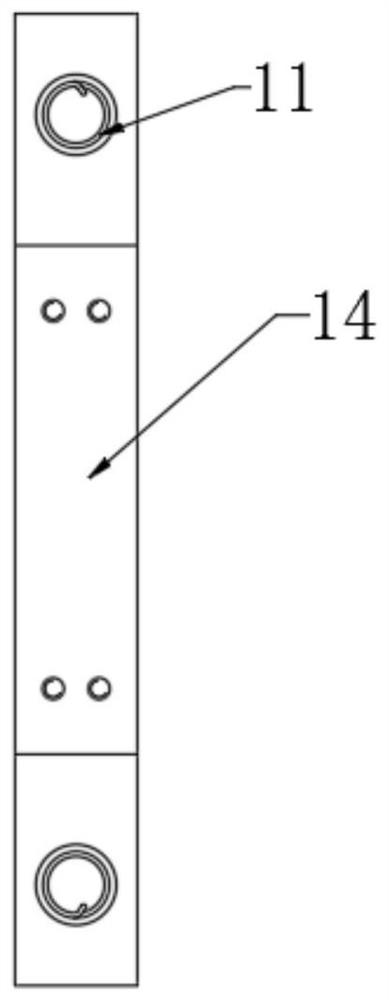

[0031] see Figure 1-9 , the present invention provides a technical solution: a load cell assembly, including a fixed platform 1, foot cups 3 are installed at the four corners below the fixed platform 1, a base 2 is installed above the fixed platform 1, and a base 2 is installed above the fixed platform 1. A load cell 4 is installed, the top left side of the load cell 4 is screwed with a screw 5, the upper side of the screw 5 is screwed with a pressure platform 6, and the outer sides of the upper and lower ends of the screw 5 are screwed with nuts. The pressure platform 6 is attached, the nut on the lower side is attached to the load cell 4, the weighing platform 7 is installed above the pressure platform 6, and the four corners below the weighing platform 7 are equipped with limit columns 8, and the fixed platform 1 Limiting sleeves 9 are installed at the four corners above, and the lower ends of the four limiting posts 8 are plugged into the inner cavities of the four limiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com