Check-weigher

A checkweighing scale and weighing technology, applied in the field of checkweighing scales, can solve problems affecting weighing accuracy, affecting the freedom of weighing measurement units, affecting the weighing accuracy of checkweighing scales, economy, practicability, etc., to achieve additional Effects of weight reduction, reduced manufacturing cost, and elimination of impact disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

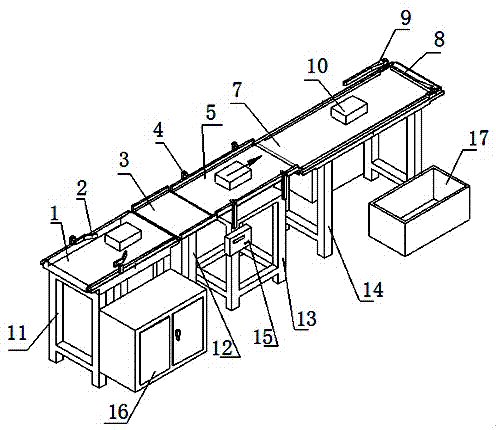

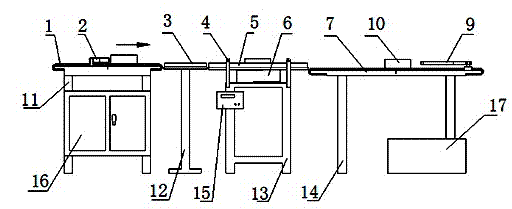

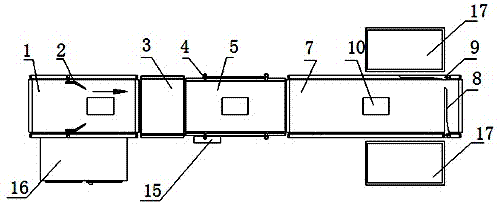

[0026] Such as Figure 1-3 Shown, a kind of checkweigher, it comprises feeding device 1 and the weighing chute 5 that arranges horizontally, is provided with weighing sensor 6 below weighing chute 5; The weighing control instrument 15; the weighing chute 5 is a rigid channel that is a smooth groove with a contact surface with the material, the axis of the groove is placed horizontally and is consistent with the running direction of the material. The loading and feeding device 1 is set on the first supporting frame 11 ; the weighing slideway 5 is set on the third supporting frame 13 ; Between the feeding device 1 and the weighing chute 5, a horizontally arranged chute 3 is arranged, and the chute 3 is arranged on the second support frame 12, and the chute 3 is lower than the feeding chute. into the device 1 and higher than the weighing chute 5. A photoelectric detection device 4 is arranged on the third support frame 13 ; a rejecting and classifying device 7 is also arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com