A kind of thermosetting polyimide prepolymer and its preparation method and application

A polyimide and prepolymer technology, applied in the field of high-performance polymer materials, can solve problems such as inability to adapt to processing equipment, limit development and application, and narrow melt processing window, so as to improve solution stability and improve melt processing Window, Ease of Melt Processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

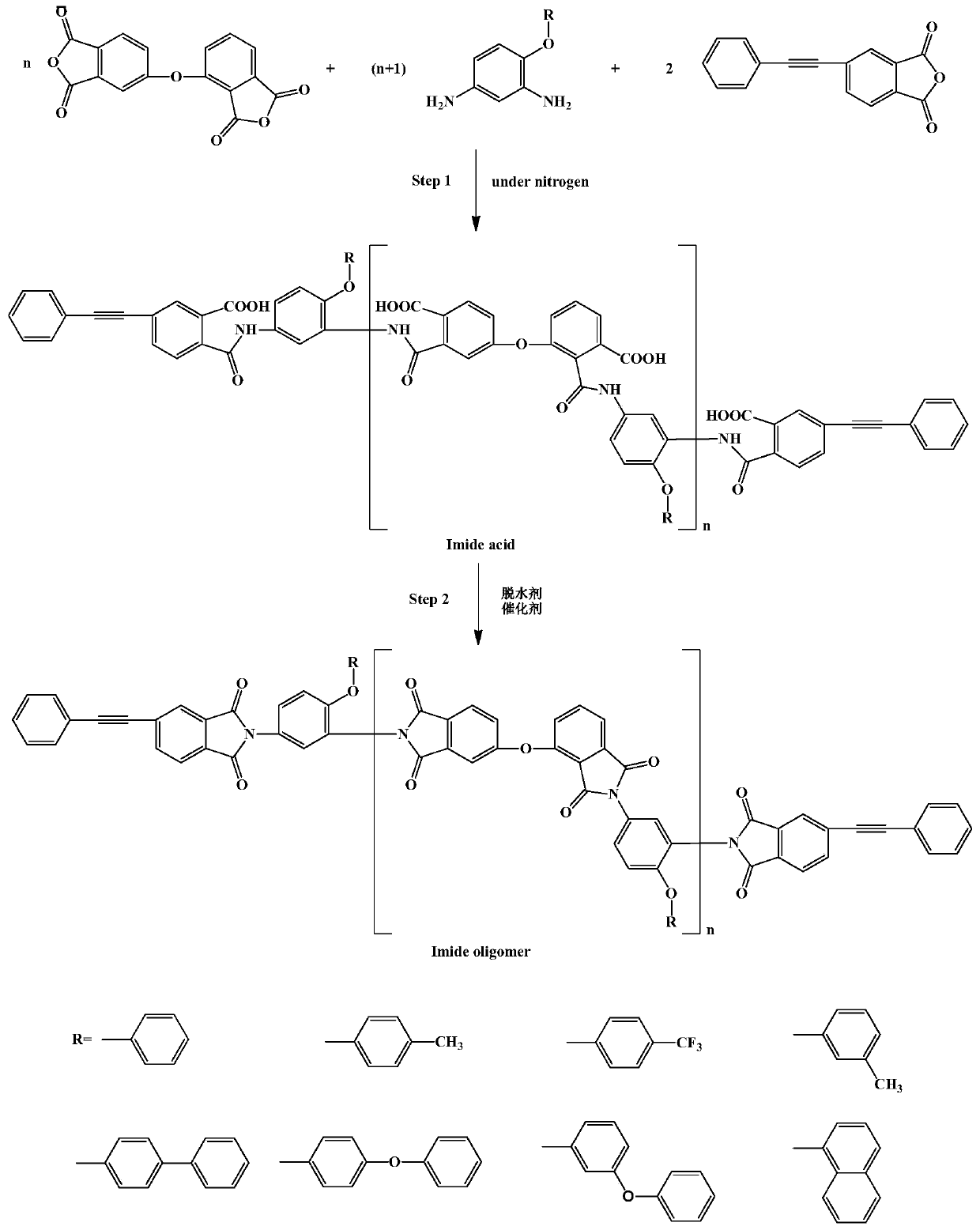

Method used

Image

Examples

Embodiment 1

[0031]Under nitrogen protection, add N-methylpyrrolidone (NMP, 20g) after vacuum distillation in a three-necked round-bottomed flask with mechanical stirring, then add 4-phenoxy m-phenylenediamine (0.04mol , 8g), after it was completely dissolved, accurately weighed 2,3,3',4'-diphenyl ether tetracarboxylic dianhydride (0.02mol, 6.2g) and 20gNMP, and the reaction temperature was reacted at room temperature for 6 hours Add end-capping agent 4-phenylacetylene phthalic anhydride (0.04mol, 9.92g) and NMP solvent, control the solid content of solution at 30wt%, continue to stir and react for 16 hours, then add triethylamine dropwise in the polyamic acid solution that generates Amine (0.12mol, 12.12g) and acetic anhydride (0.12mol, 12.24g) were reacted at room temperature for 6 hours, and finally the resulting solution was washed with 1000mL of distilled water for 3 times until the pH value of the filtered water was approximately equal to 7, while The obtained product was fully dried...

Embodiment 2

[0033] Under nitrogen protection, add N-methylpyrrolidone (NMP, 35g) after vacuum distillation in a three-necked round bottom flask with mechanical stirring, then add 4-phenoxy m-phenylenediamine (0.05mol , 10g), after it was completely dissolved, accurately weighed 2,3,3',4'-diphenyl ether tetracarboxylic dianhydride (0.04mol, 12.4g) and 35gNMP, and the reaction temperature was reacted at room temperature for 6 hours Add end-capping agent 4-phenylacetylene phthalic anhydride (0.02mol, 4.96g) and NMP solvent, control the solid content of solution at 30wt%, continue to stir and react for 16 hours, then add triethylamine dropwise in the polyamic acid solution that generates Amine (0.15mol, 15.15g) and acetic anhydride (0.15mol, 15.30g) were reacted at room temperature for 6 hours, and finally the resulting solution was washed with 1000mL of distilled water for 3 times until the pH value of the filtered water was approximately equal to 7, while The obtained product was fully drie...

Embodiment 3

[0035] Under the protection of nitrogen, in a three-necked round bottom flask with mechanical stirring, add N-methylpyrrolidone (NMP, 5g) after vacuum distillation, then add 4-phenoxy m-phenylenediamine (0.01mol , 2g), after it was completely dissolved, accurately weighed 2,3,3',4'-diphenyl ether tetracarboxylic dianhydride (0.009mol, 2.79g) and 5gNMP, and the reaction temperature was reacted at room temperature for 4 hours Add the end-capping agent 4-phenylacetylene phthalic anhydride (0.002mol, 0.496g) and the remaining NMP solvent, control the solid content of the solution at 20wt%, continue to stir and react for 20 hours, and then add it dropwise in the polyamic acid solution generated Triethylamine (0.02mol, 2.02g) and acetic anhydride (0.02mol, 2.04g) were reacted at room temperature for 12 hours, and finally the resulting solution was washed 4 times with 100mL of distilled water until the pH value of the filtered water was approximately equal to 7 At the same time, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com