Material Flow Electronic Scale

An electronic scale and material technology, applied in the direction of continuous material flow weighing equipment, measuring devices, instruments, etc., to achieve the effects of eliminating the interference of weighing data, high resolution, and improving weighing accuracy

Active Publication Date: 2016-09-21

SHANDONG SETAQ INSTR

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

It effectively solves all the problems of the measuring unit of the current sorting scale

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

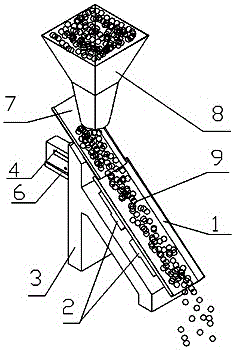

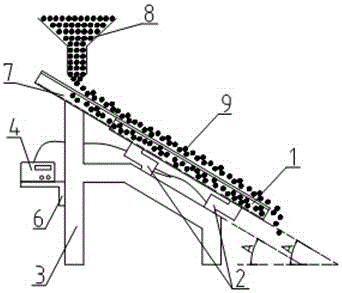

[0031] Such as Figure 1-2 Shown, a kind of material flow electronic scale, it comprises support frame 3 and at least one load cell 2 that is fixedly arranged on support frame 3, is fixedly provided with weighing chute 1 on load cell 2, weighs chute 1 The length direction and the horizontal plane form an angle A, 0°

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a material flow electronic scale which comprises a supporting frame and weighing sensors fixedly arranged on the supporting frame. A rigid weighing sliding chute is fixedly arranged on the weighing sensors. The material flow electronic scale is characterized in that an angle A is formed between the length direction of the rigid weighing sliding chute and the horizontal plane, and A is larger than zero and smaller than 90 degrees; a rigid material-smoothening sliding chute fixedly arranged on the supporting frame or a feeding device or an independent support is parallel and opposite to the weighing sliding chute at a close distance, does make contact with the weighing sliding chute and is slightly higher than the weighing sliding chute; the bearing ends of the weighing sensors are in rigid connection with the rigid weighing sliding chute, and the designed bearing stress direction of the weighing sensors is perpendicular to the length direction of the rigid weighing sliding chute; the material flow electronic scale is further provided with a weighing control instrument which is electrically connected with the weighing sensors.

Description

technical field [0001] The invention relates to a material flow electronic scale, which is suitable for the weight detection of continuous material flow on a production line. The material stream can be solid or liquid. Background technique [0002] All electronic weighing equipment (including: electronic scales) feel the weight of the object being weighed through sensors. Most electronic weighing devices use force sensors or load cells to measure the local gravity of objects. As we all know, the gravity of an object is perpendicular to the horizontal plane where the object is located. For a long time, when the force sensor or load cell is used, the installation method, force point and direction are strictly specified, so as not to affect the accuracy of the sensor. In order to reduce the component deviation of the sensor, almost all sensor manufacturers, weighing equipment manufacturers, textbooks, weighing industry standards and specifications, training materials, and eq...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01G11/04G01G11/08

Inventor 汤小牛刘久明

Owner SHANDONG SETAQ INSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com