Checkweigher for weighing slide way

A checkweigher and slideway technology, applied in the field of checkweigher, to achieve the effects of eliminating contact interference, reducing manufacturing costs, and reducing additional weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

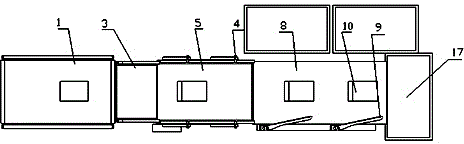

[0048] Such as Figure 1-2 As shown, a checkweigher for slideway weighing, which includes third Support frame 13 and the 4th support frame 14, be provided with load cell 6 on the 3rd support frame 13, be provided with the weighing slideway 5 that tilts to place on load cell 6; Be provided with on the 4th support frame 14 Rejecting platform and rejecting grading mechanism 9; Rejecting platform is placed below the discharge port of weighing slide 5; The included angle between the design force direction and the material sliding direction of the weighing slideway 5 is B, 0°<B<90° or 90°<B<180°. The rear end of the weighing slideway 5 is docked with the front end of the rejecting platform with a gap.

[0049] The weighing slideway 5 is an inclined rigid slideway with a smooth groove on the contact surface with the material, and the angle between the axis of the groove surface and the horizontal plane is A (0°

Embodiment 2

[0077] The similarities between this embodiment and Embodiment 1 will not be repeated, and the difference is that the rejecting platform is a common power belt. The ordinary power belt is used instead of the power belt rejecting and grading device that needs to be synchronously controlled.

[0078] like Figure 6-7 As shown, the rejecting and grading device 7 is replaced by a horizontal rejecting power belt, and a driving motor, a belt, a roller, and a power belt with an electrical control scheme without linear speed synchronous control requirements on the market are adopted (such as those produced by Shanghai Yingsheng Machinery Co., Ltd. belt conveyor), the total price is 2200 RMB, and the upper plane of the belt is placed 20mm below the weighing slideway 5. All machinery, installation and electric connection are also substantially the same, and weighing instrument 15 and electric control device 16 are also the same, and just electric control device 16 also will control the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com