Automatic filling and inflating system of dry powder extinguisher

An automatic filling and inflation system technology, applied in fire rescue, transportation and packaging, conveyor objects, etc., can solve the problems of restricting production efficiency, short plate effect, inflatable air, etc., to improve efficiency and accuracy, Effects of improving reliability and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

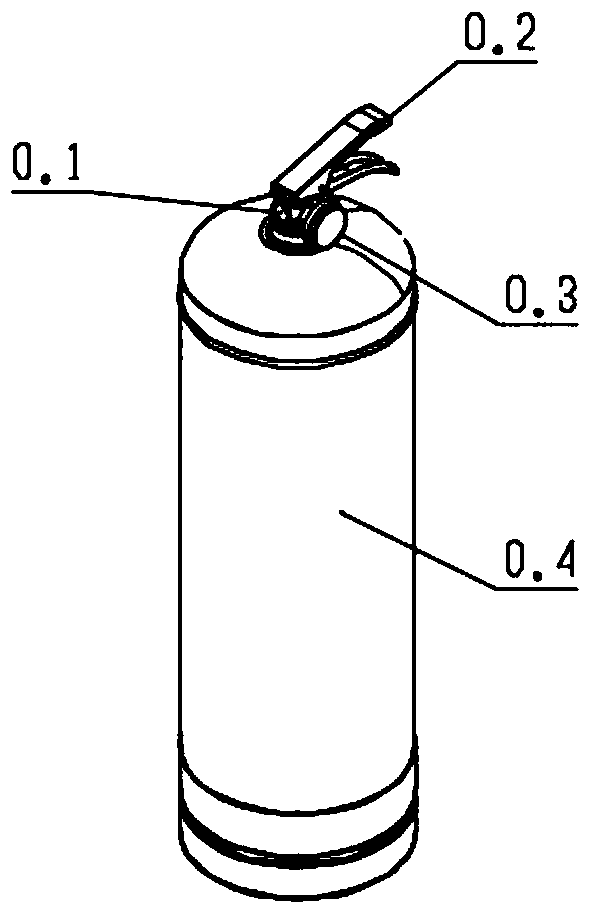

[0043] Dry powder fire extinguisher finished products such as figure 1 As shown, the fire extinguisher includes a fire extinguisher bottle 0.4, a handle 0.2 installed on the fire extinguisher bottle, a nozzle 0.1, and a pressure gauge 0.3.

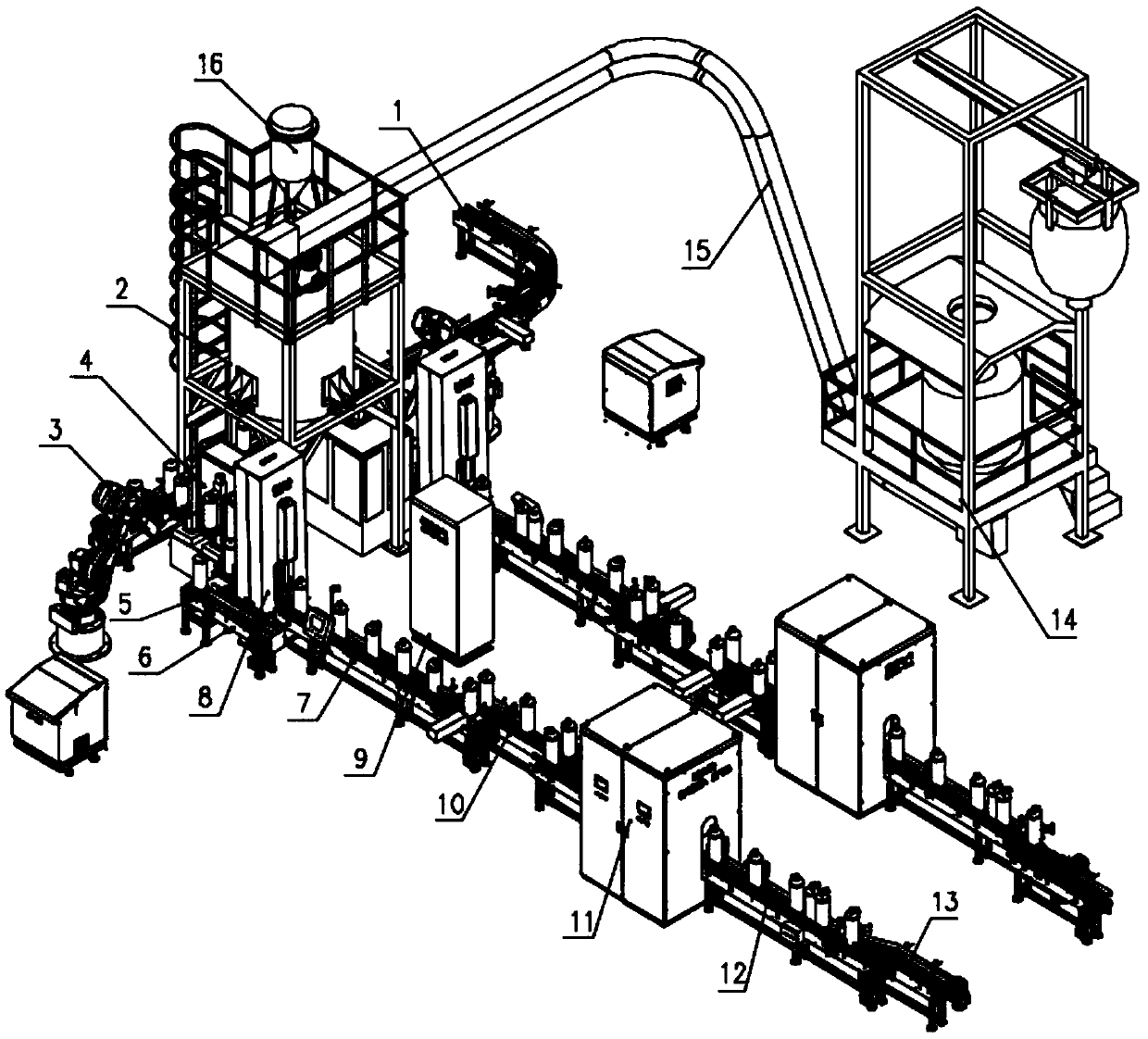

[0044] Such as figure 2 As shown, a kind of dry powder fire extinguisher automatic filling inflation system adopted in the present invention comprises:

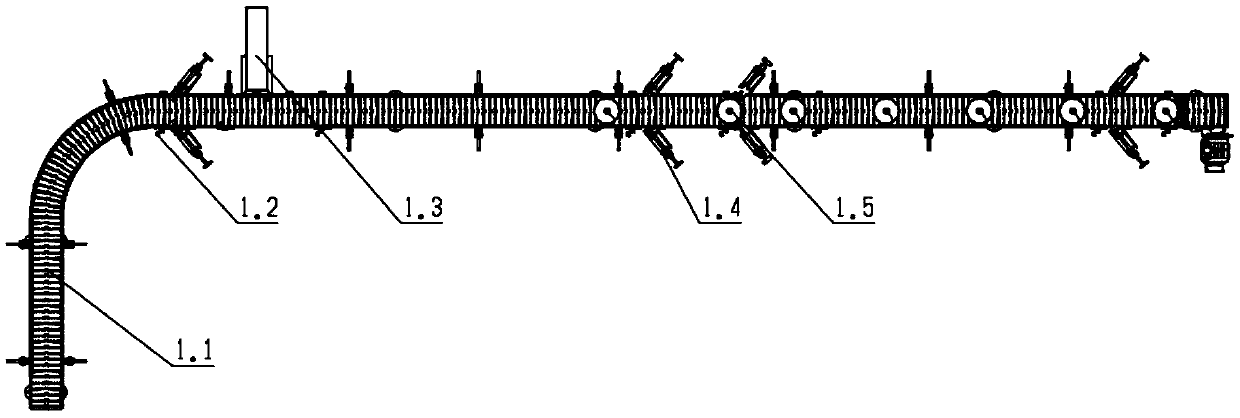

[0045] Bottle feeding device 1 for delivering fire extinguisher bottle 0.4 to filling machine 4, such as image 3 As shown, the bottle supply device 1 includes a transfer conveyor 1.1, and the transfer conveyor 1.1 is provided with multiple groups of bottle retaining mechanisms 1.4, a detection device 1.2 cooperating with each other, a bottle pushing mechanism 1.3, and a bottle fetching station 1.5; for storing dry powder The powder bin 2; the electric control cabine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com