Functional Alloy Resin

A chemical alloy and resin technology, which is applied in the field of chemical corrosion resistant functional resin new materials, can solve the problems of corrosion, cracking, and corrosion stress of refrigerator lining materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

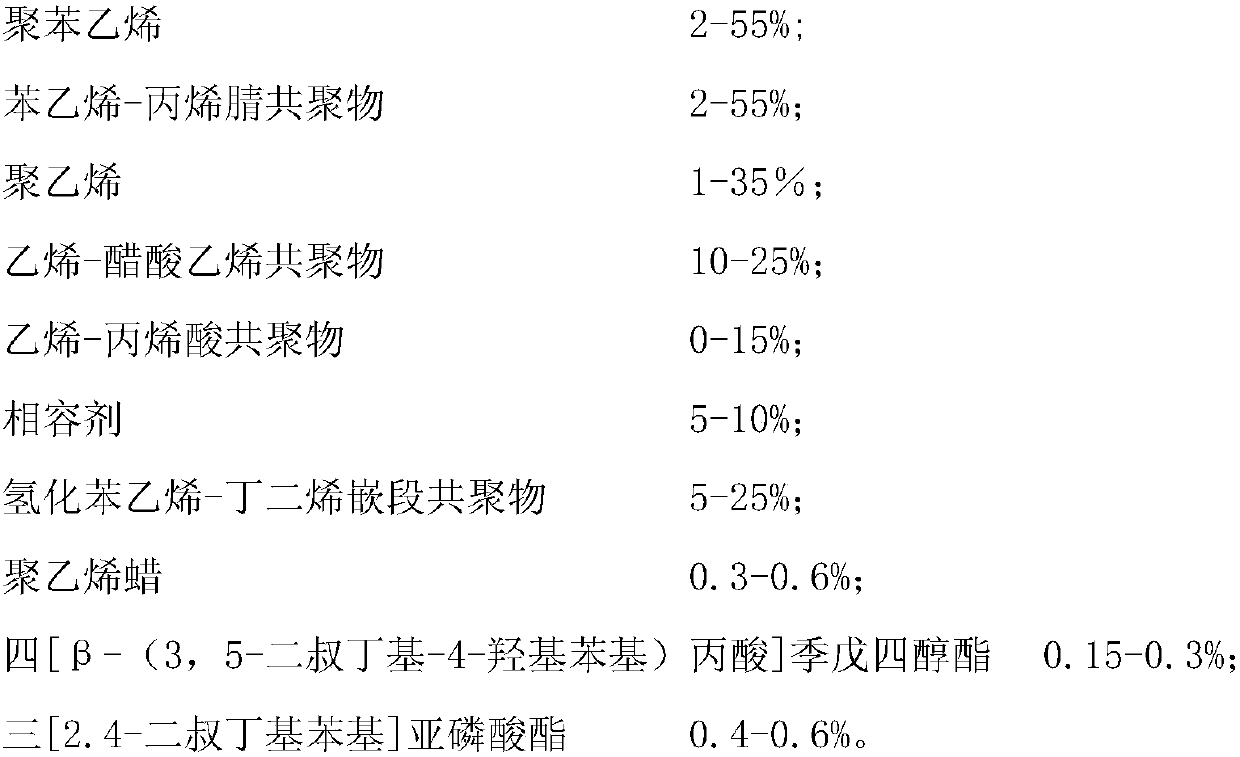

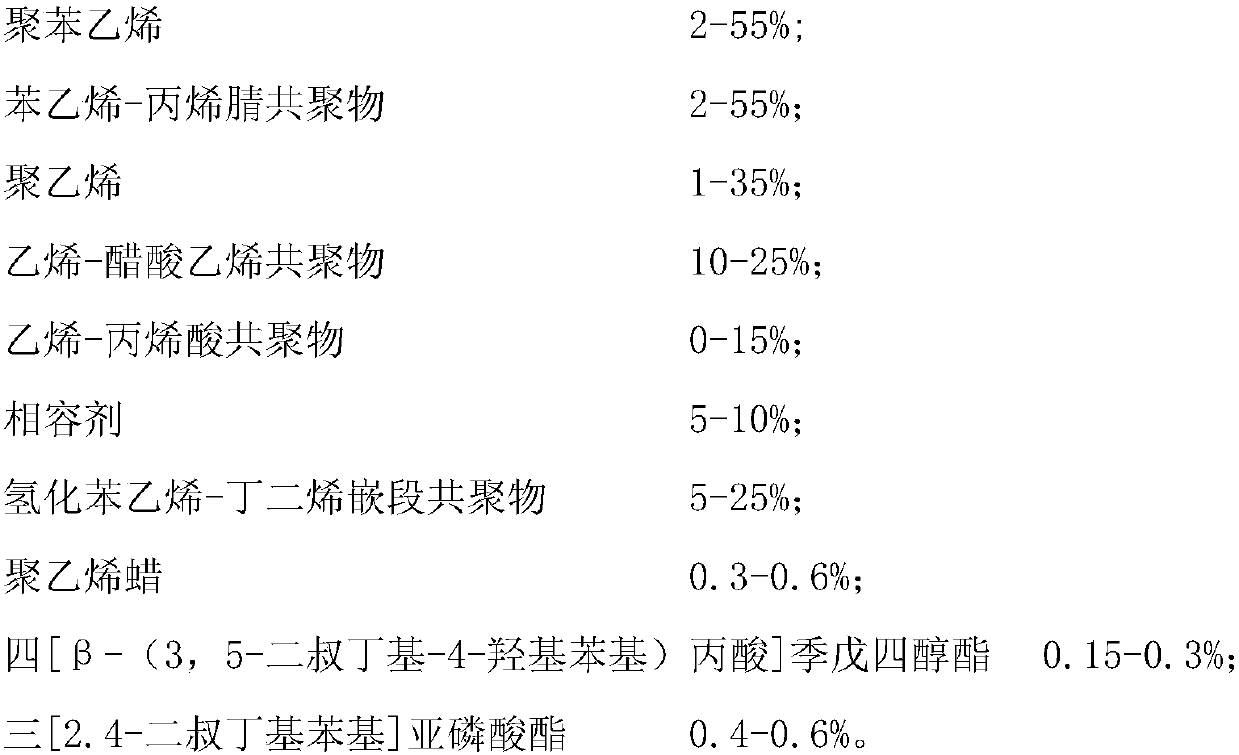

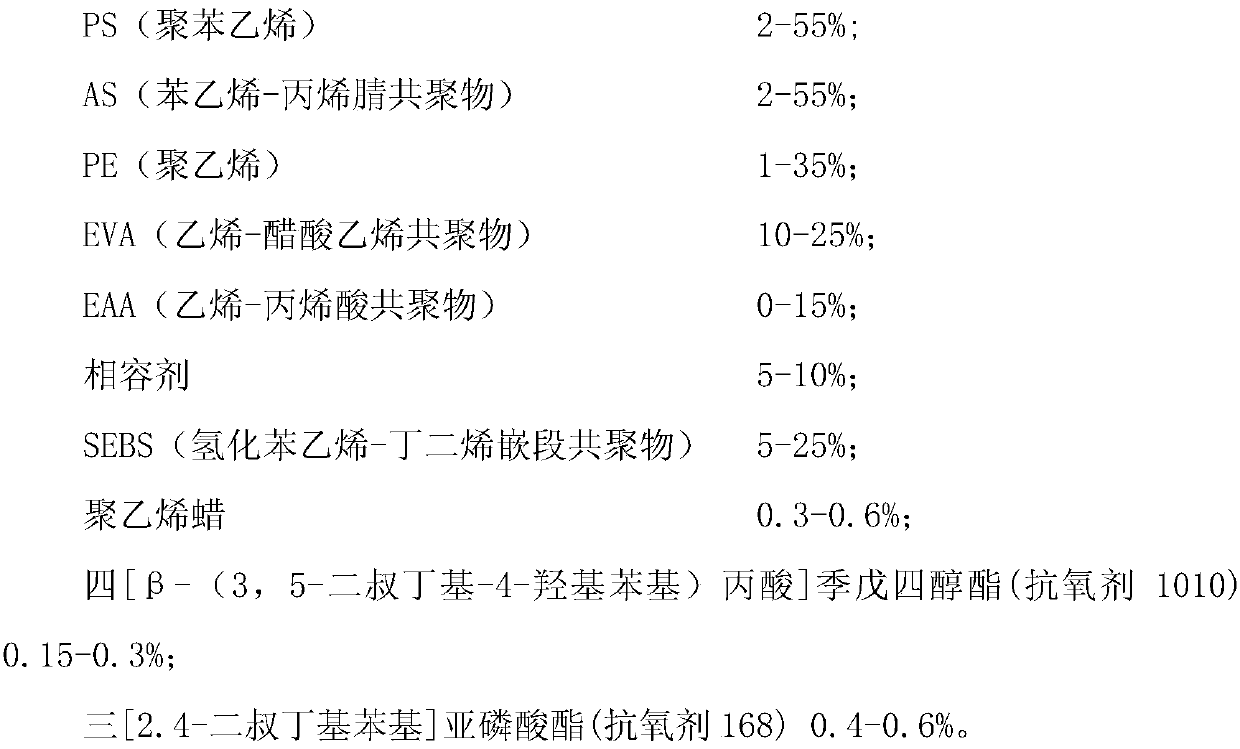

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the self-made compatibilizer is as follows: GMA (glycidyl methacrylate) 1%-5%, MAH (maleic anhydride also known as maleic anhydride) 0.5-1.5%, DMF (Dimethylformamide) 0.2-0.5%, DCP (dicumyl peroxide) 0.05-0.1%, PE (polyethylene) 70-85%, SEBS (hydrogenated styrene-butadiene block copolymer) 5 -15%, Antioxidant 1010 0.4%-0.6% is obtained by kneading and grafting with a twin-screw extruder, and the sum of the mass percentages of the various raw material components of the compatibilizer is equal to 100%. Among them, GMA and MAH are polar functional groups required by compatibilizer products, DMF mainly controls the crosslinking reaction in the grafting reaction process, DCP acts as an initiator in the reaction process, and PE\SEBS is mainly the main material of compatibilizer products , Antioxidant 1010 (tetra[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester) is to prevent the oxidative degradation of the main material during...

Embodiment 1

[0035] According to mass percentage, PS 55%, AS 5%, PE 14%, EVA 10%, the aforementioned self-made compatibilizer 5%, SEBS 10%, polyethylene wax 0.4%, antioxidant 1010 0.2%, antioxidant 168 0.4%.

[0036] Pour all into a high-speed mixer and stir for 5 minutes, and then put the above-mentioned components that have been uniformly stirred directly into a twin-screw extrusion granulator for extrusion and granulation.

[0037] This embodiment is suitable for the double-layer co-extrusion coating bottom layer of special materials for HIPS refrigerators. After blister foaming, LBA, FC-245fa, and cyclopentane multi-foaming agent are isolated from corroding HIPS materials. This coating is a protective film.

[0038] Its physical index: the melting index is 5-6g / 10min, and the tensile strength is greater than 26Mpa. The notched impact strength is greater than 200J / m, the heat distortion temperature is greater than 75°C, the elongation at break is greater than 120%, and the chemical co...

Embodiment 2

[0040] According to mass percentage, PS 5%, AS 55%, PE 2%, EVA 15%, the aforementioned self-made compatibilizer 5%, SEBS 17%, polyethylene wax 0.3%, antioxidant 1010 0.3%, antioxidant 168 0.4%.

[0041] Pour all into a high-speed mixer and stir for 5 minutes, and then put the above-mentioned components that have been uniformly stirred directly into a twin-screw extrusion granulator for extrusion and granulation.

[0042] This embodiment is suitable for double-layer co-extrusion lamination of ABS refrigerator liner boards, and the secondary formula material is a lamination co-extrusion film. The main purpose of this lamination film is to protect the ABS board from LBA, HFC-245fa, cyclopentane multiple Corrosion of the foaming agent, the thickness of the film accounts for 10% of the thickness of the entire plate.

[0043] Its physical indicators: melt index 2.5-3.5g / 10min, tensile strength greater than 32MPa, notched impact strength greater than 180J / m, heat forming temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com