Air-floating type automatic checkweigher

An automatic detection, air-floating technology, applied in continuous material flow weighing equipment, weighing equipment using fluid balance, measuring devices, etc., can solve self-vibration and electromagnetic radiation interference, increase the difficulty and cost of conveyor belt manufacturing , affecting the checkweighing accuracy of the automatic checkweigher, etc., to achieve the effect of improving the checkweighing accuracy and the structure is simple and compact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

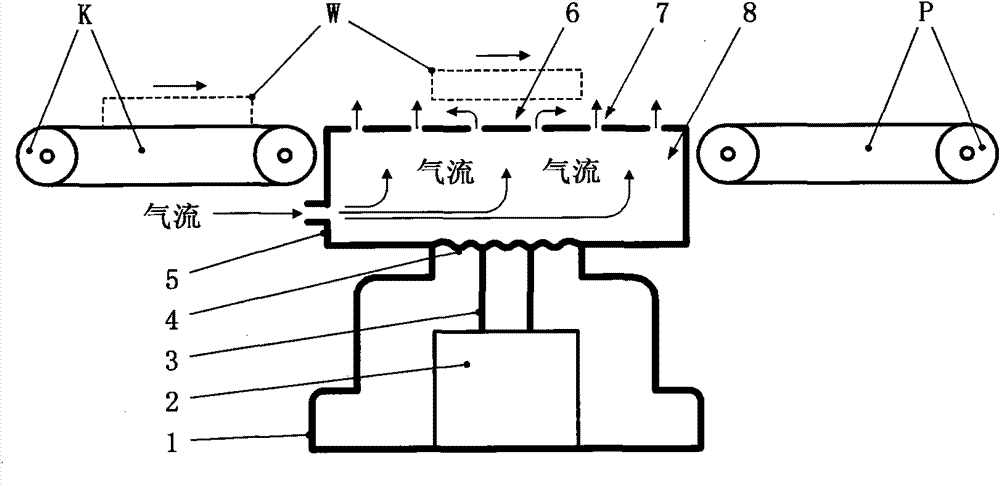

[0014] Packaging box W is an example of a commonly used square drug packaging box with a flat bottom. Its overall dimensions (length×width×height) are generally less than 140mm×100mm×40mm, and its weight is generally less than 300 grams. In order to facilitate the dynamic weighing of the packaging box W, in this embodiment, the overall dimensions (length×width×height) of the air-floating platform 5 are set to 280mm×120mm×60mm. The air flotation platform 5 is placed between the front conveyor belt K and the rear conveyor belt P, and the air flotation platform 5 is installed above the weighing platform 1. The upper part of the air flotation platform 5 is evenly distributed with 1265 airflow nozzles 7 with a diameter of 1 mm and a mutual distance of 5 mm. , the purpose is to make the compressed air spray upward through the air flow nozzle 7, thereby form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com