A material-feeding device of a high-speed checkweigher

A checkweigher, high-speed technology, applied in the direction of conveyor control device, packaging, transportation and packaging, etc., can solve the problems of low production efficiency, low stability of bottle-shaped workpieces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

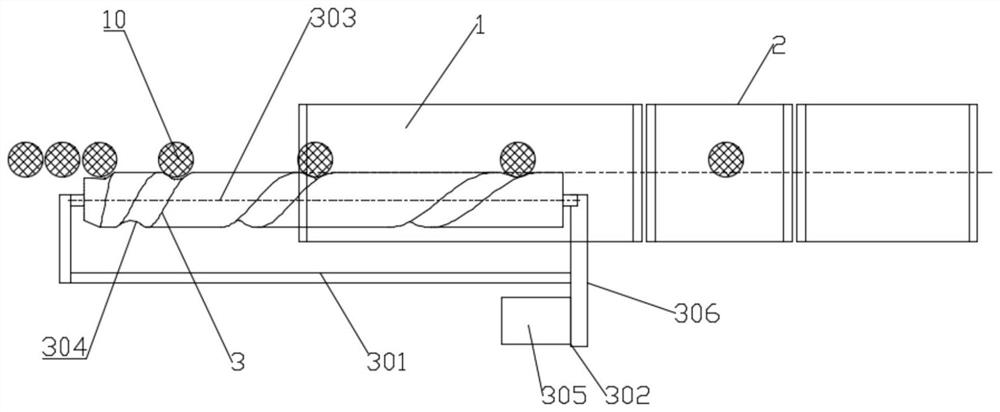

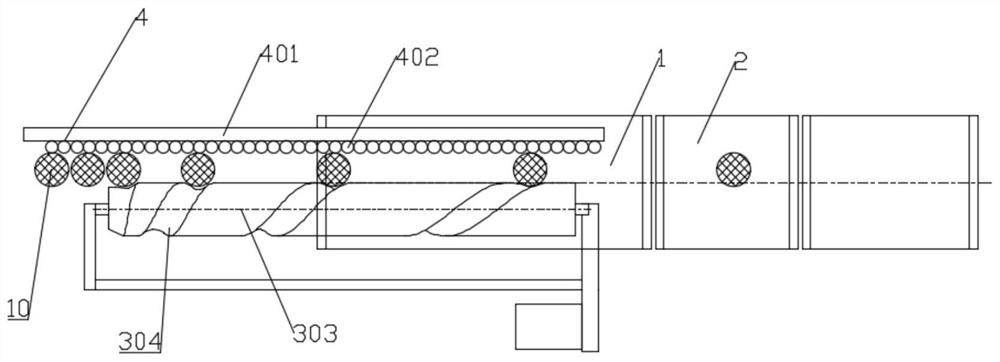

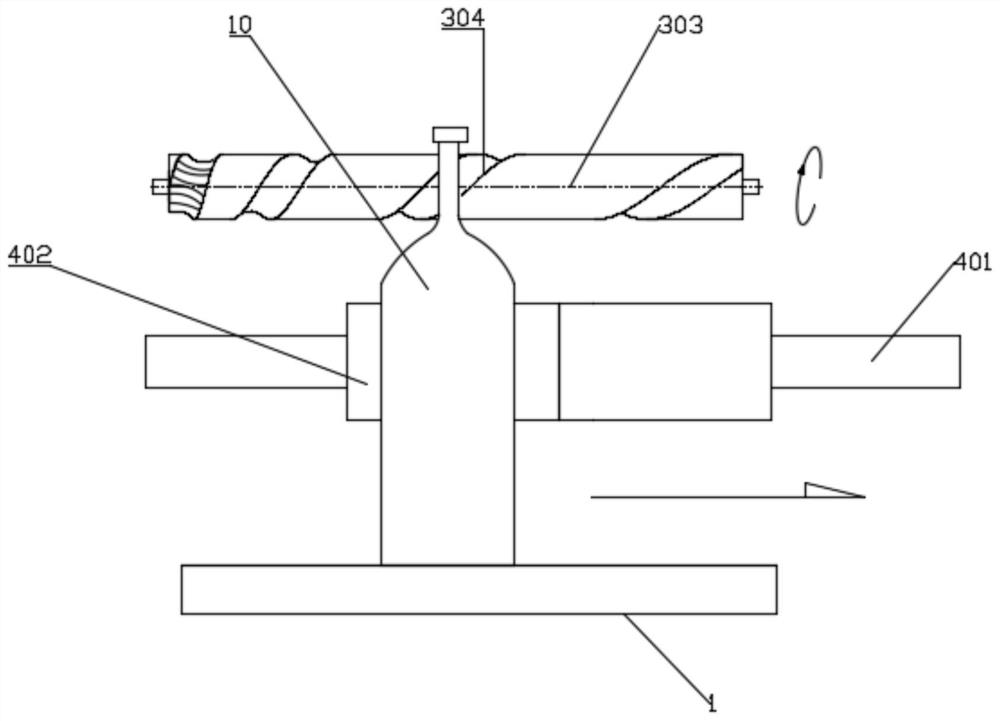

[0045] Such as figure 2 and image 3 As shown, the first clamping assembly 4 for limiting the side wall of the bottle-shaped workpiece 10 is provided parallel to the conveying direction of the front end conveyor 1 . Specifically: the first clamping assembly 4 includes a clamping support frame 401 , which is arranged parallel to the conveying direction of the front end conveyor 1 and distributed on one side of the conveying direction of the bottle-shaped workpiece 10 . It is used to prevent the bottle-shaped workpiece 10 from moving sideways and rotates with the screw rod 303 .

[0046] In order to reduce the friction between the bottle-shaped workpiece 10 and the clamping support frame 401, the clamping support frame 401 is provided with a conveying roller 402 set towards the conveying direction of the front end conveyor 1, and the sliding friction in contact between the two is changed into rolling friction , Reduce wear on the surface of the bottle-shaped workpiece 10.

...

Embodiment 2

[0049] Such as Figure 4 As shown, an indirect contact assembly 5 is movably connected to the variable-pitch helical groove 304. The indirect contact assembly 5 includes a wear-resistant limiting plate 501 for limiting the bottle-shaped workpiece 10. The wear-resistant limiting plate 501 can prevent the bottle-shaped workpiece from 10 rollovers. The wear-resistant limiting plate 501 is provided with a rolling clamp for clamping inside the variable-pitch helical groove 304 . The rolling clip can make the wear-resistant limiting plate 501 slide smoothly on the surface of the screw rod 303 .

[0050] Preferably, the rolling clamp is a universal wheel 502 , and the cross section of the variable-pitch helical groove 304 matches the universal wheel 502 .

[0051] The sidewalls at both ends of the wear-resistant limiting plate 501 are limited by the second clamping assembly 503, and the second clamping assembly 503 can prevent the wear-resistant limiting plate 501 from rotating dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com