Check weigher

A technology for weighing scales and fixing flanges, which is used in the field of calibration scales and can solve the problems of connection technology defects and inability to be cleaned normally.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

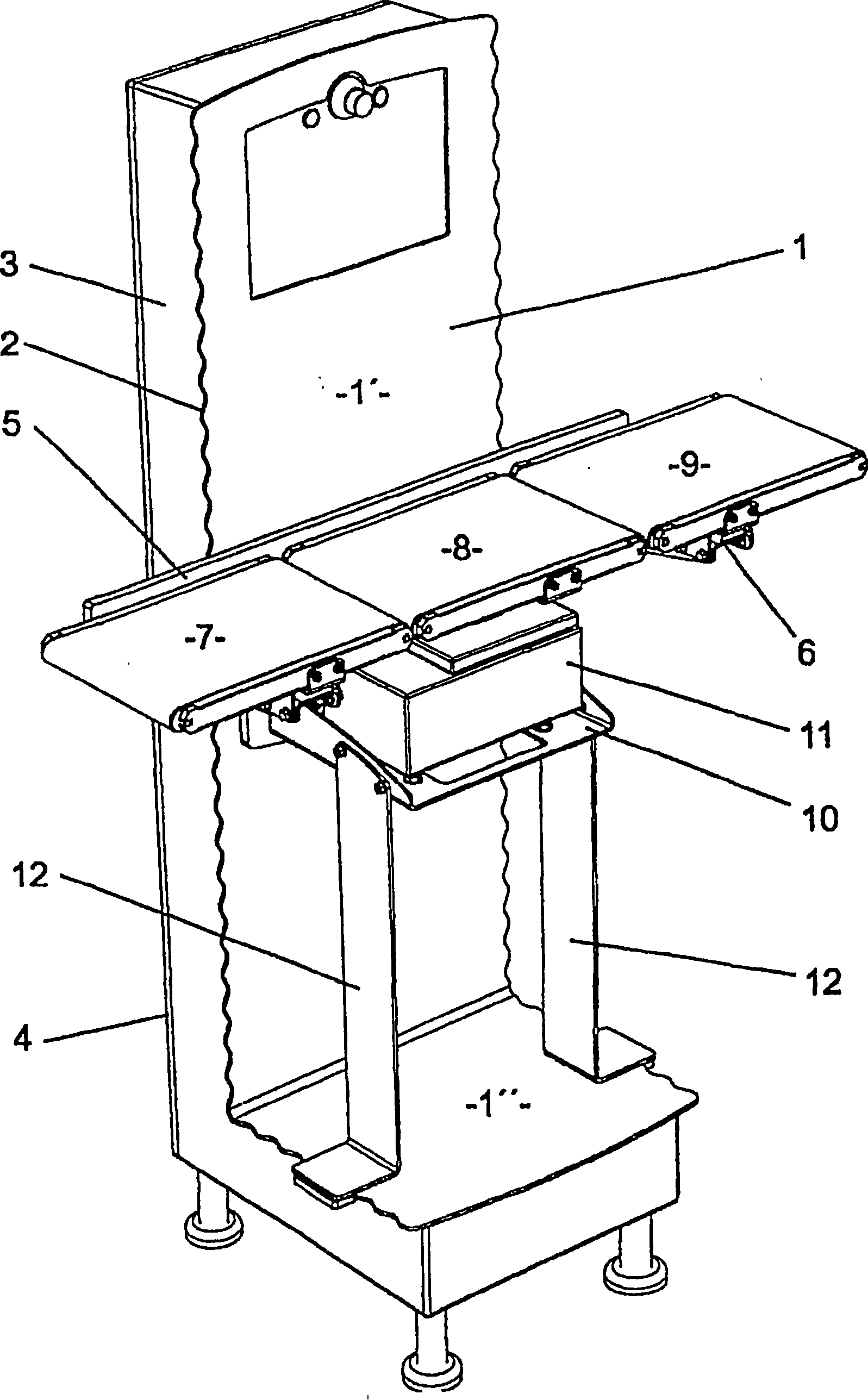

[0033] figure 1 An example of a check scale is shown. It consists of a fixed plate 1 with a fixed flange 2, preferably with vertical struts 1' and horizontal struts 1", detachably or inseparably connected to the fixed plate 1 a metal plate with a rear side door 4 Hollow body 3. The mounting plate 5 is fixed by means of fixing elements, not shown here, on the vertical struts 1' of the fixing plate 1 and carries two conveyor belt brackets 6 on which the conveyor belts 7 and 9 are fixed and Weighing cell bracket 10. The latter bracket holds a weighing cell 11 with a conveyor belt 8 and is optionally connected by a supporting strut 12 to the horizontal strut 1" of the fixed plate.

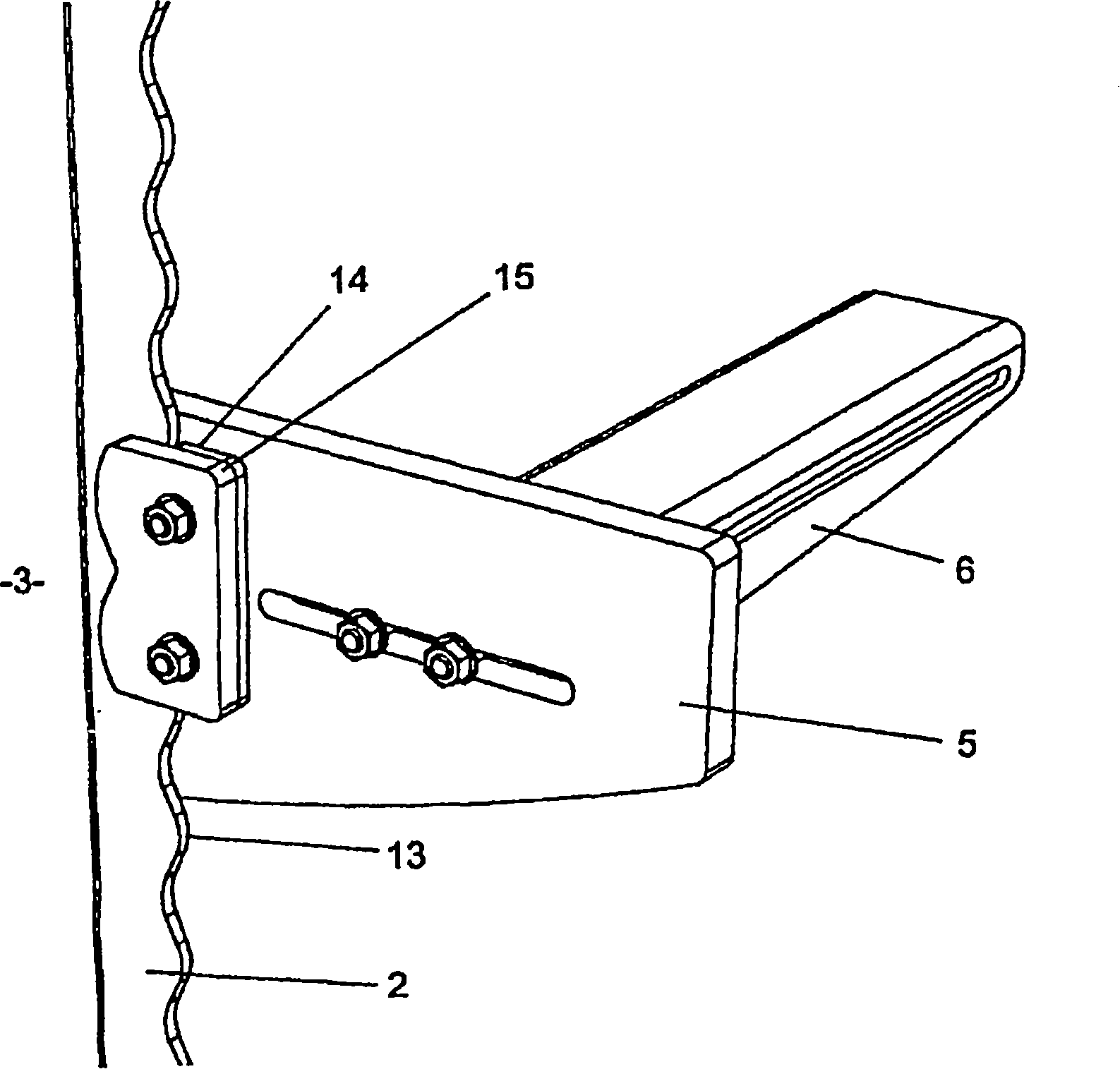

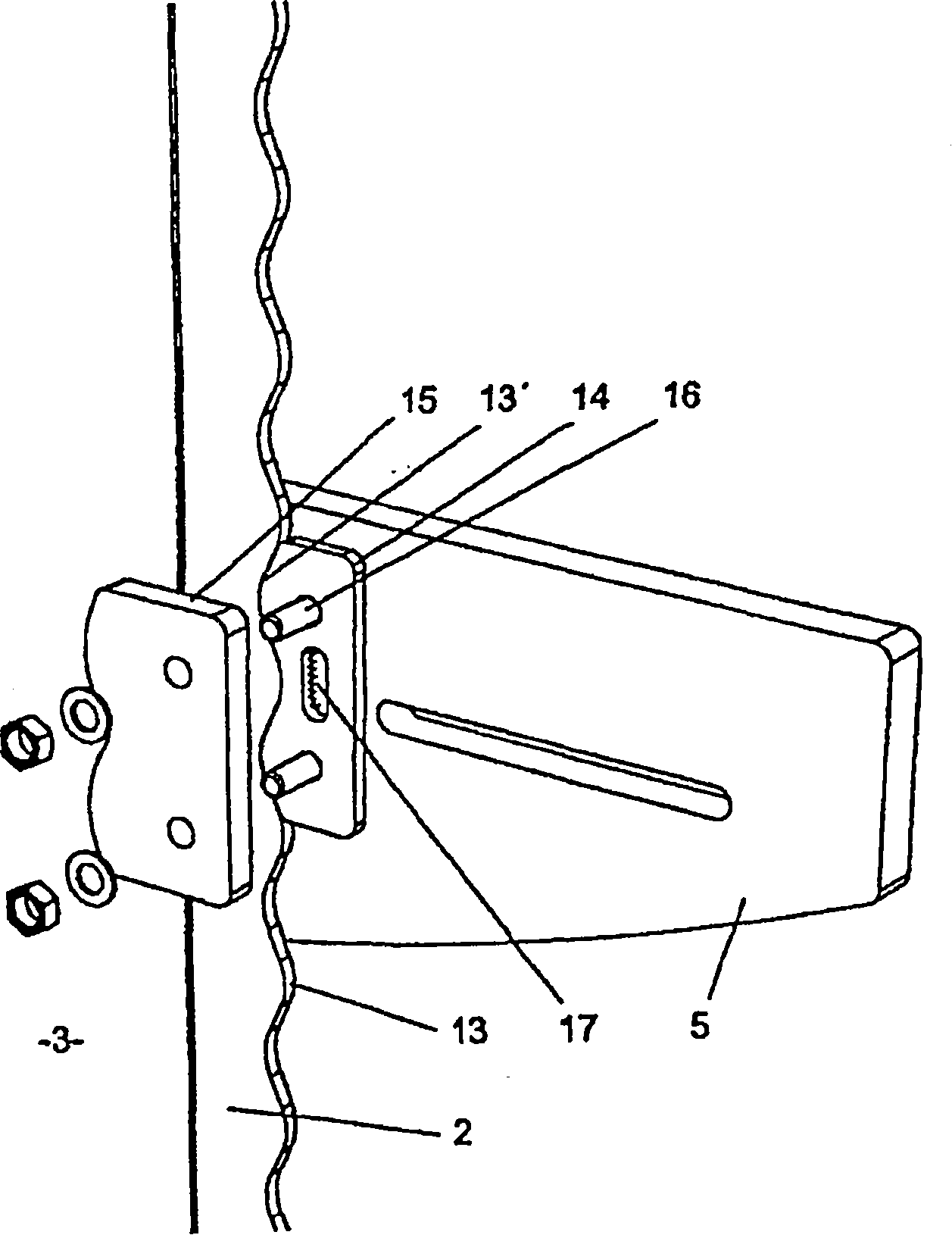

[0034] figure 2 The fixing of the mounting plate 5 and the fixing flange 2 and the arc surface 13 of the fixing flange 2 are shown in detail. This is achieved by the preferably non-detachable clamping plate 14 attached to the mounting plate 5 , whose curved surface 13 ′, not visible here, correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com