Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31 results about "3-Hexanone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

3-Hexanone (ethyl propyl ketone) is an organic compound with the formula C₆H₁₂O. It is a ketone used as a solvent and as a chemical intermediate.

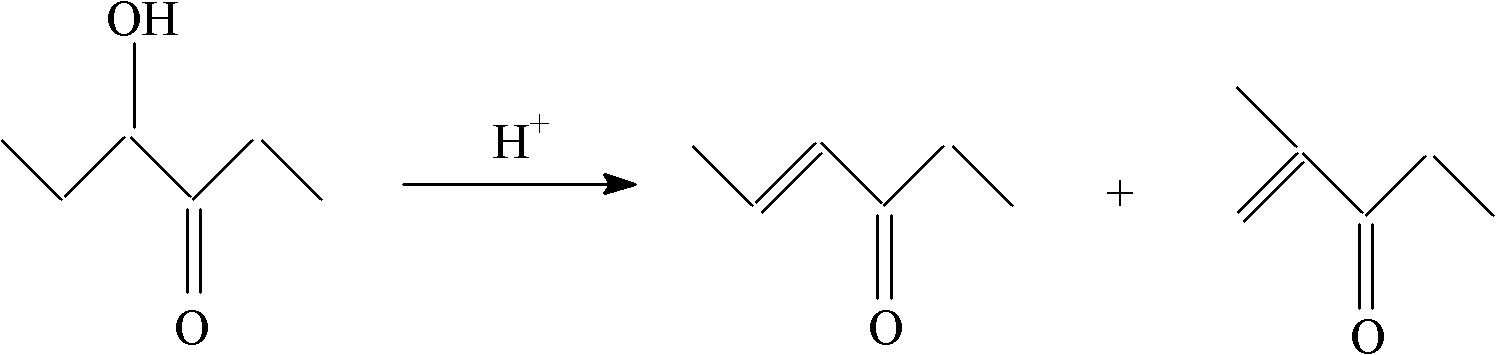

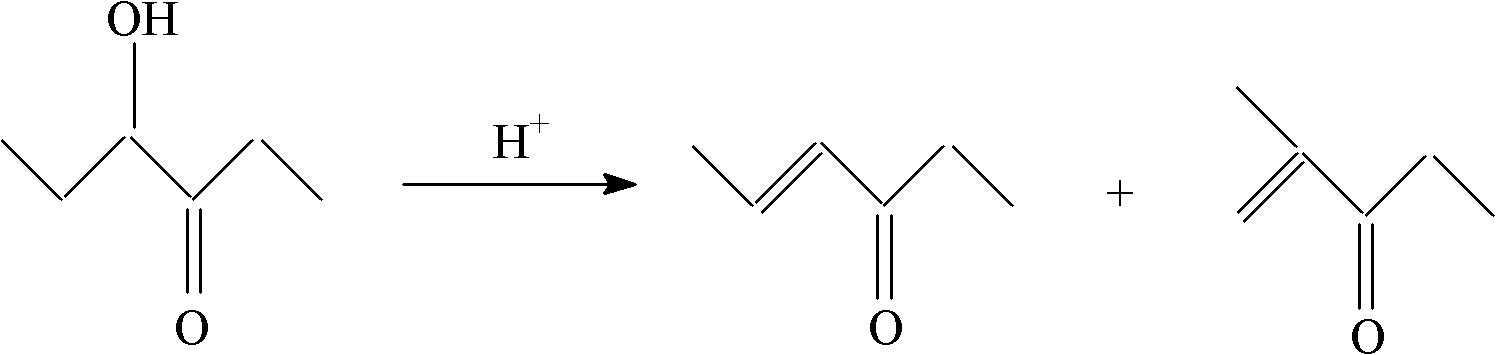

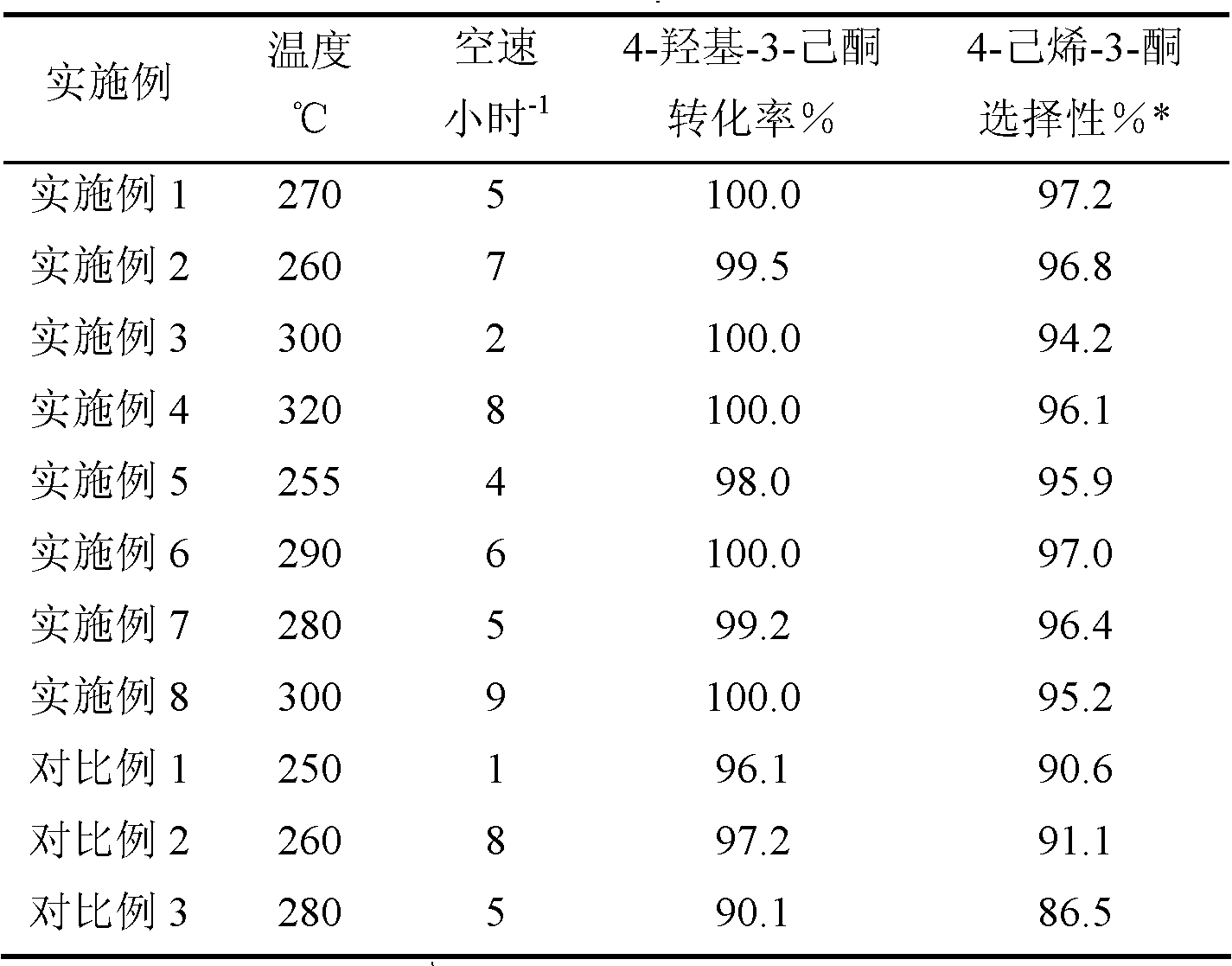

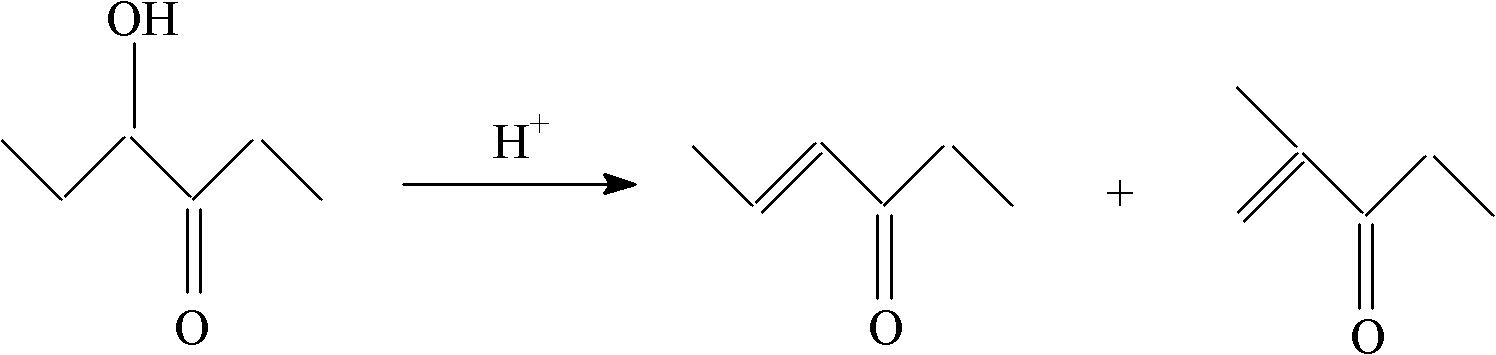

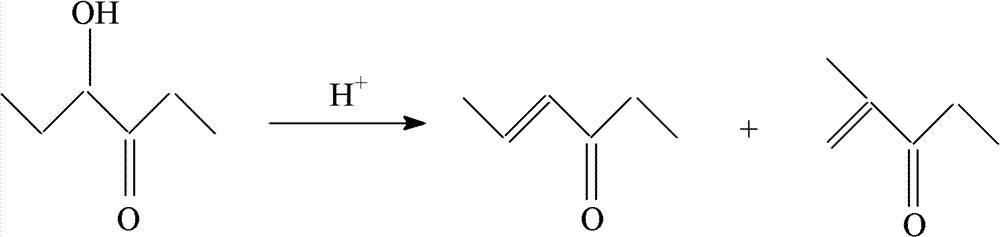

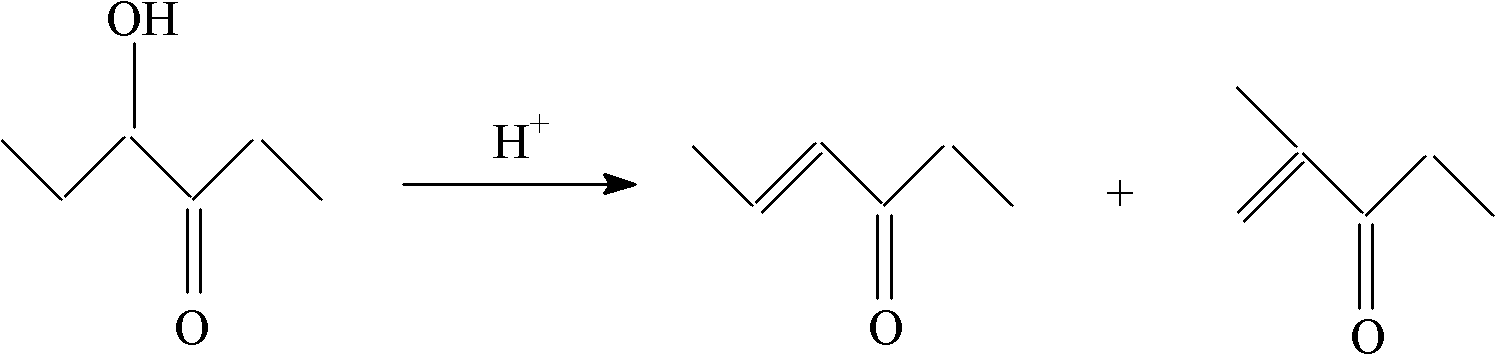

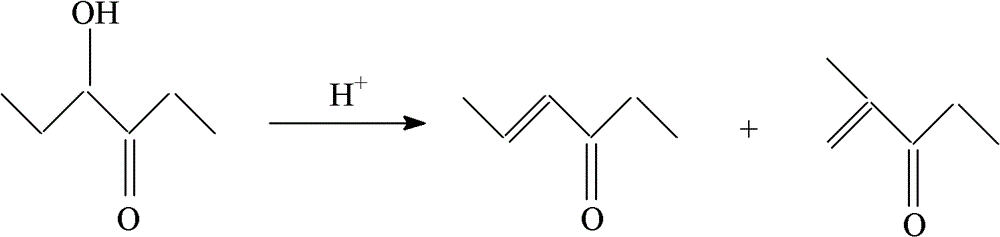

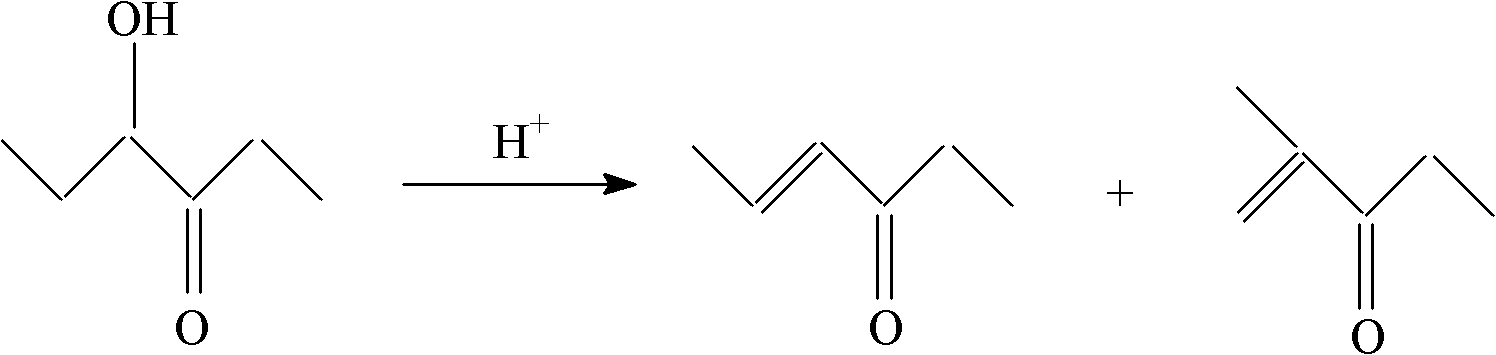

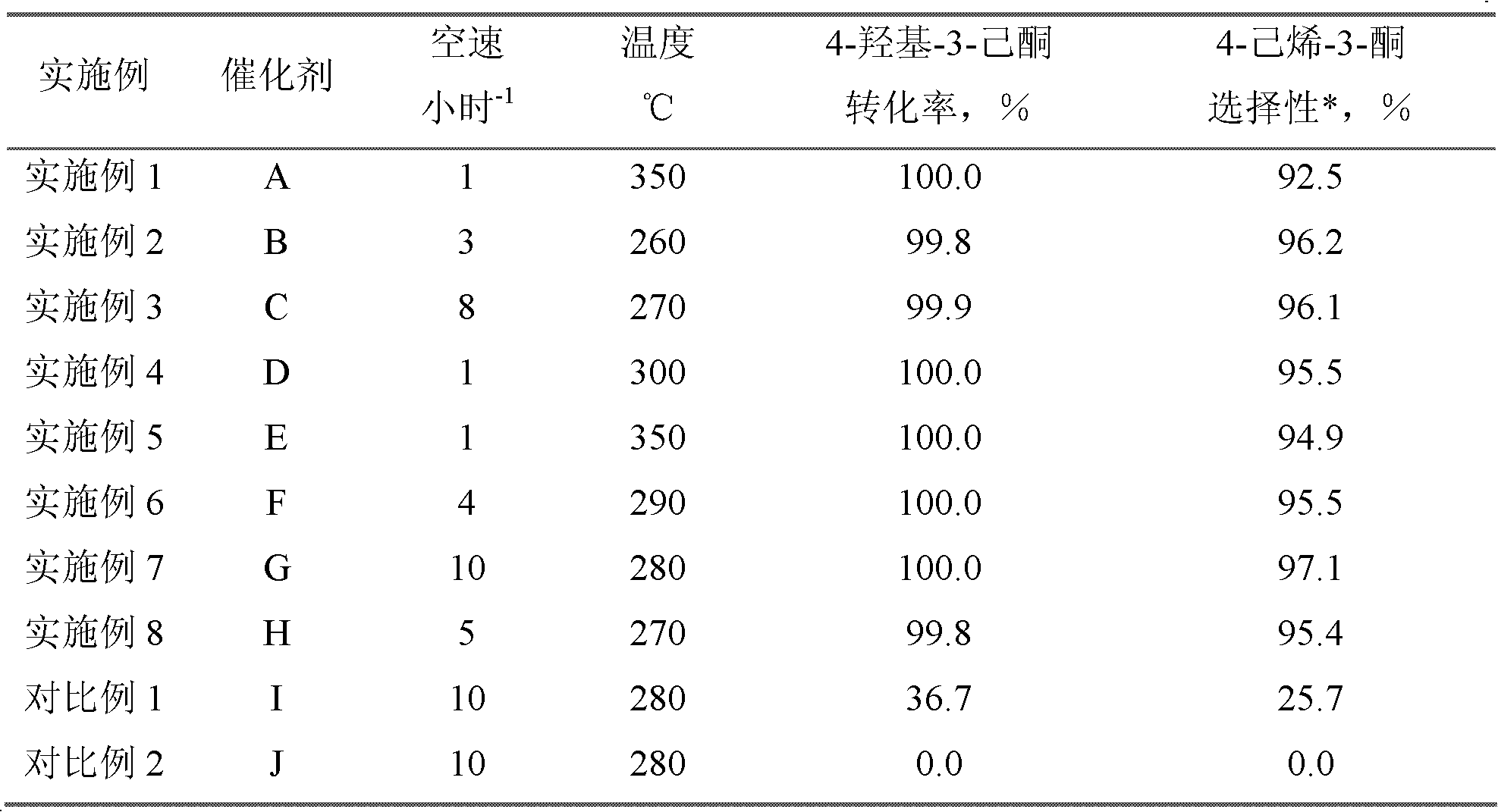

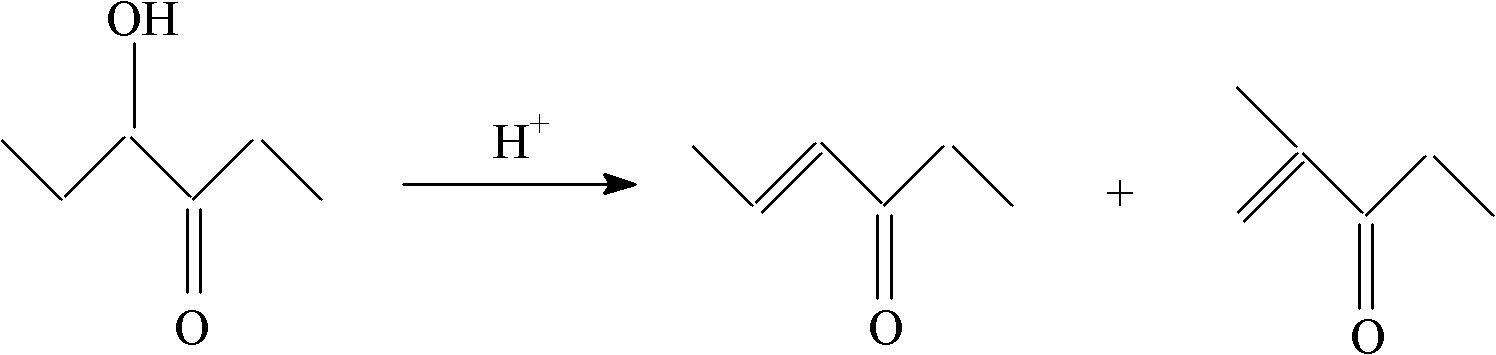

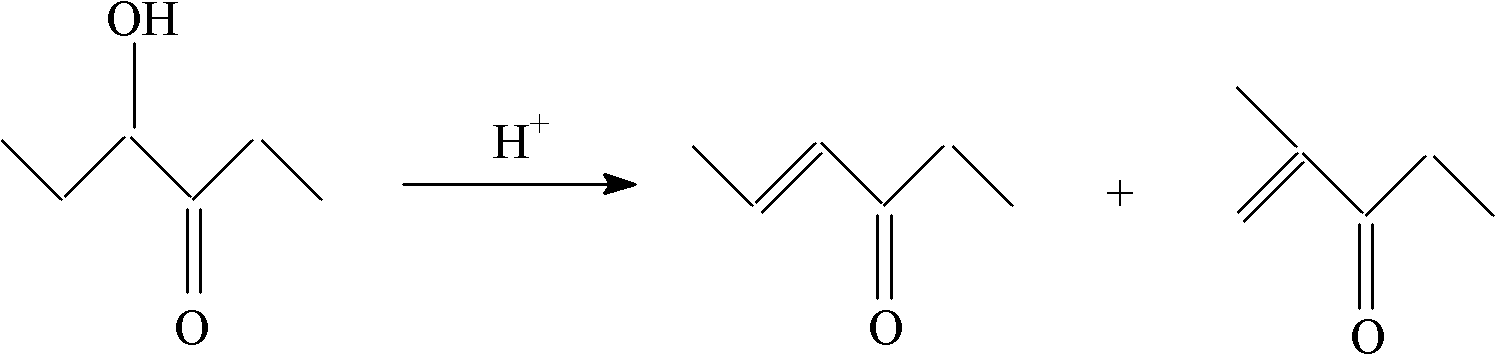

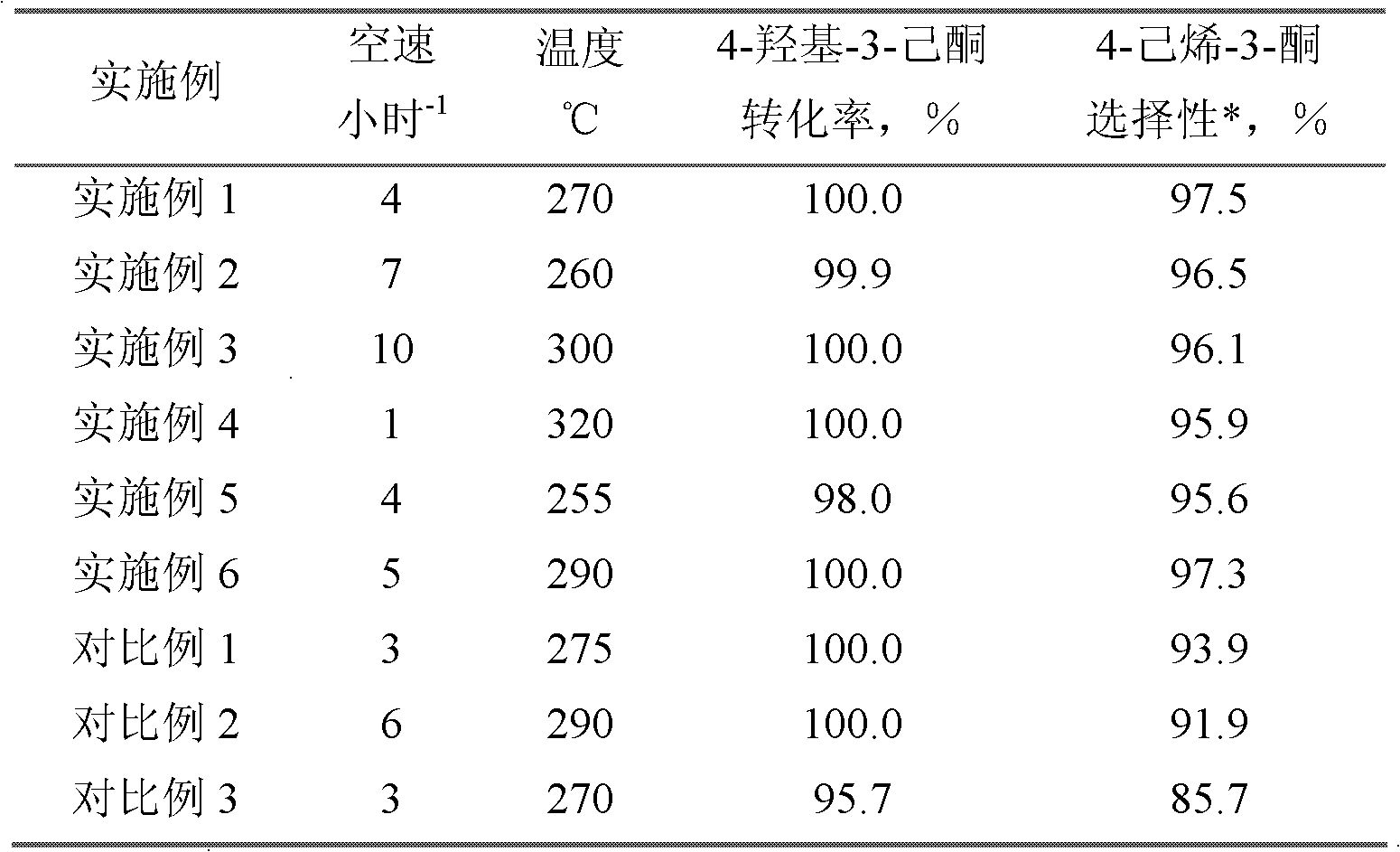

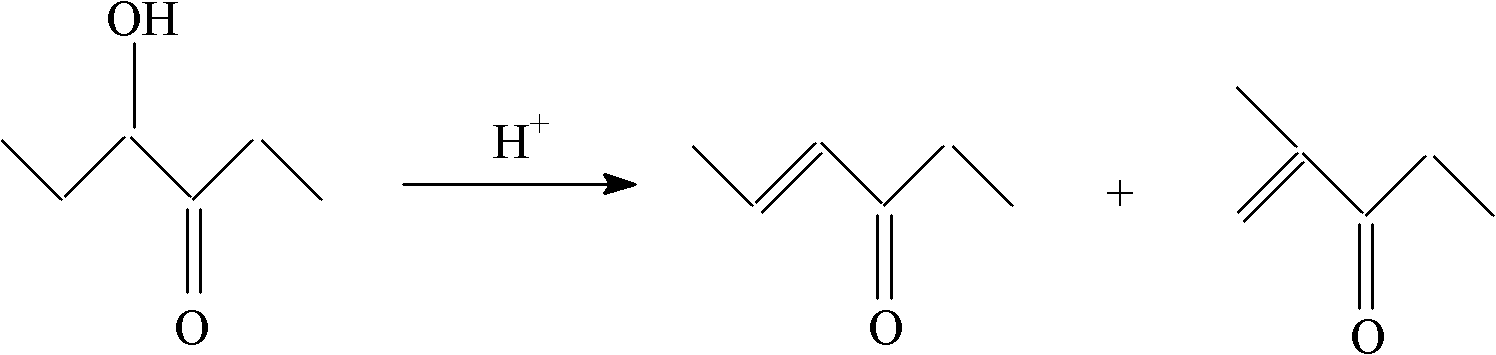

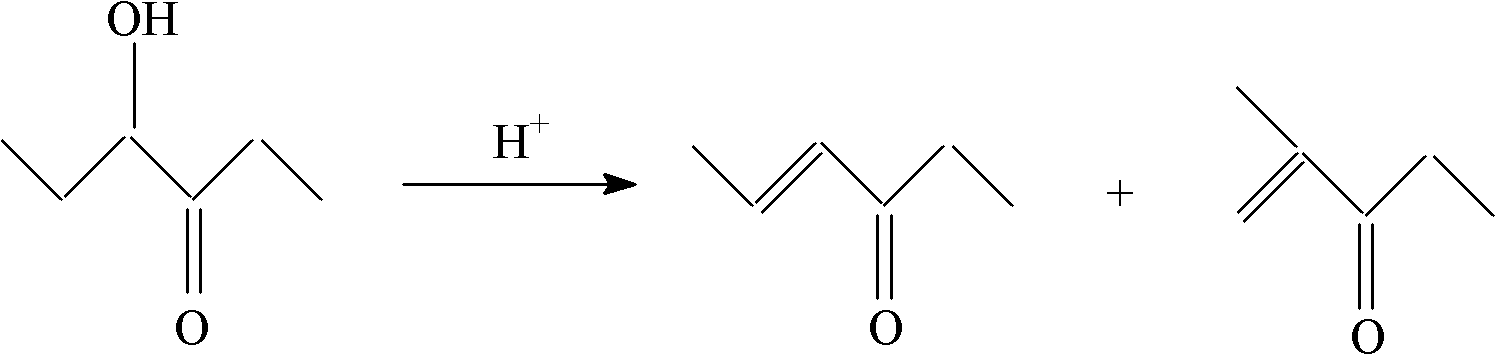

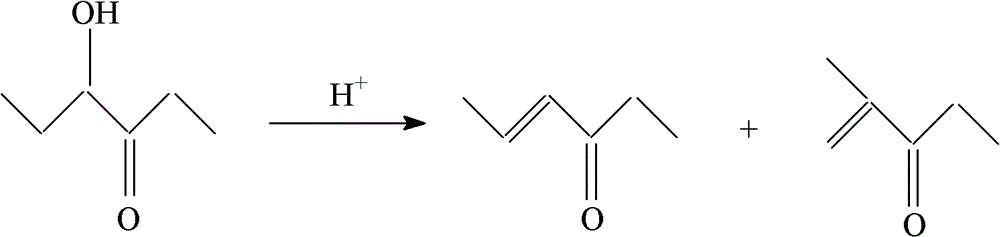

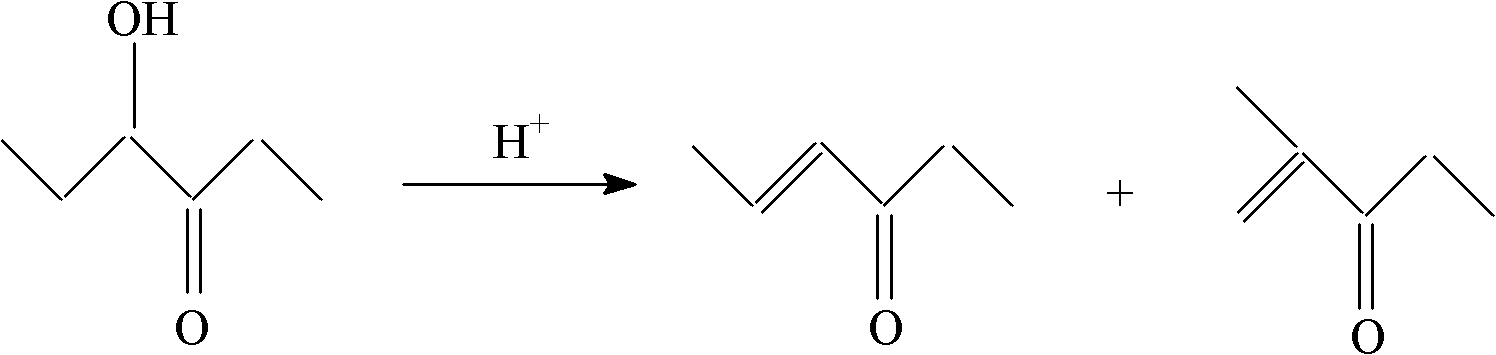

Method for catalyzing and dehydrating 4-hydroxy-3-hexanone

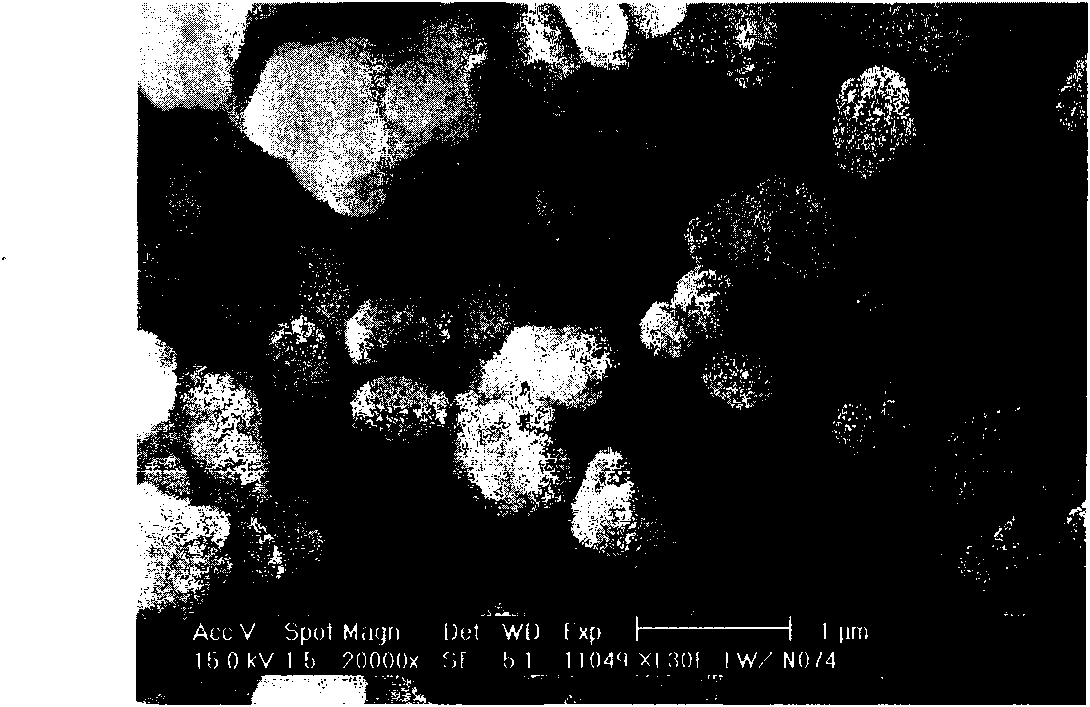

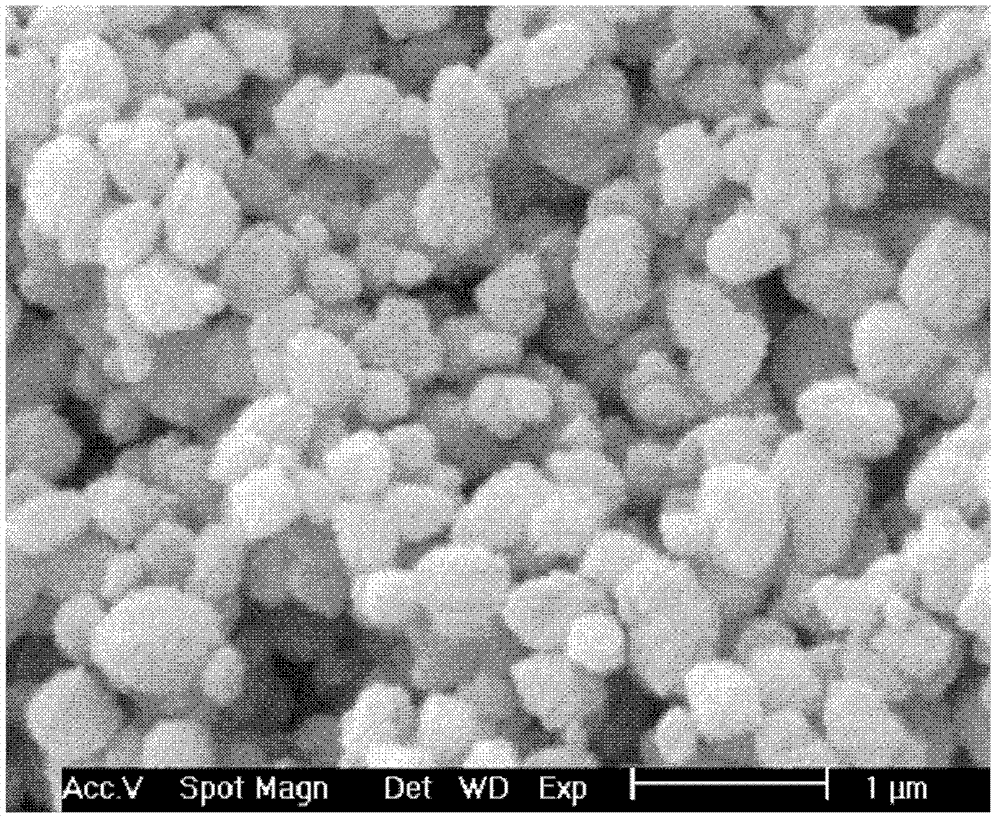

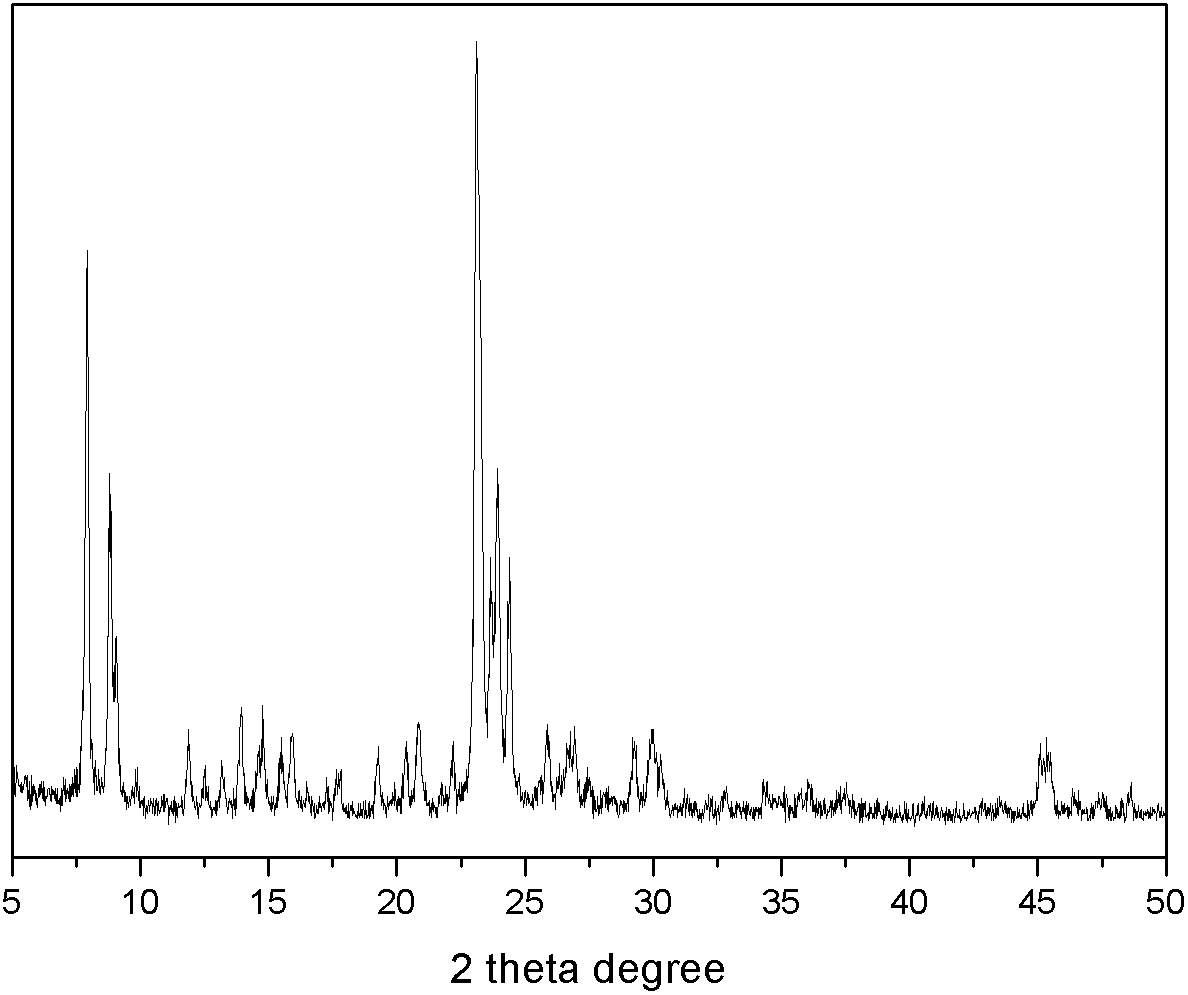

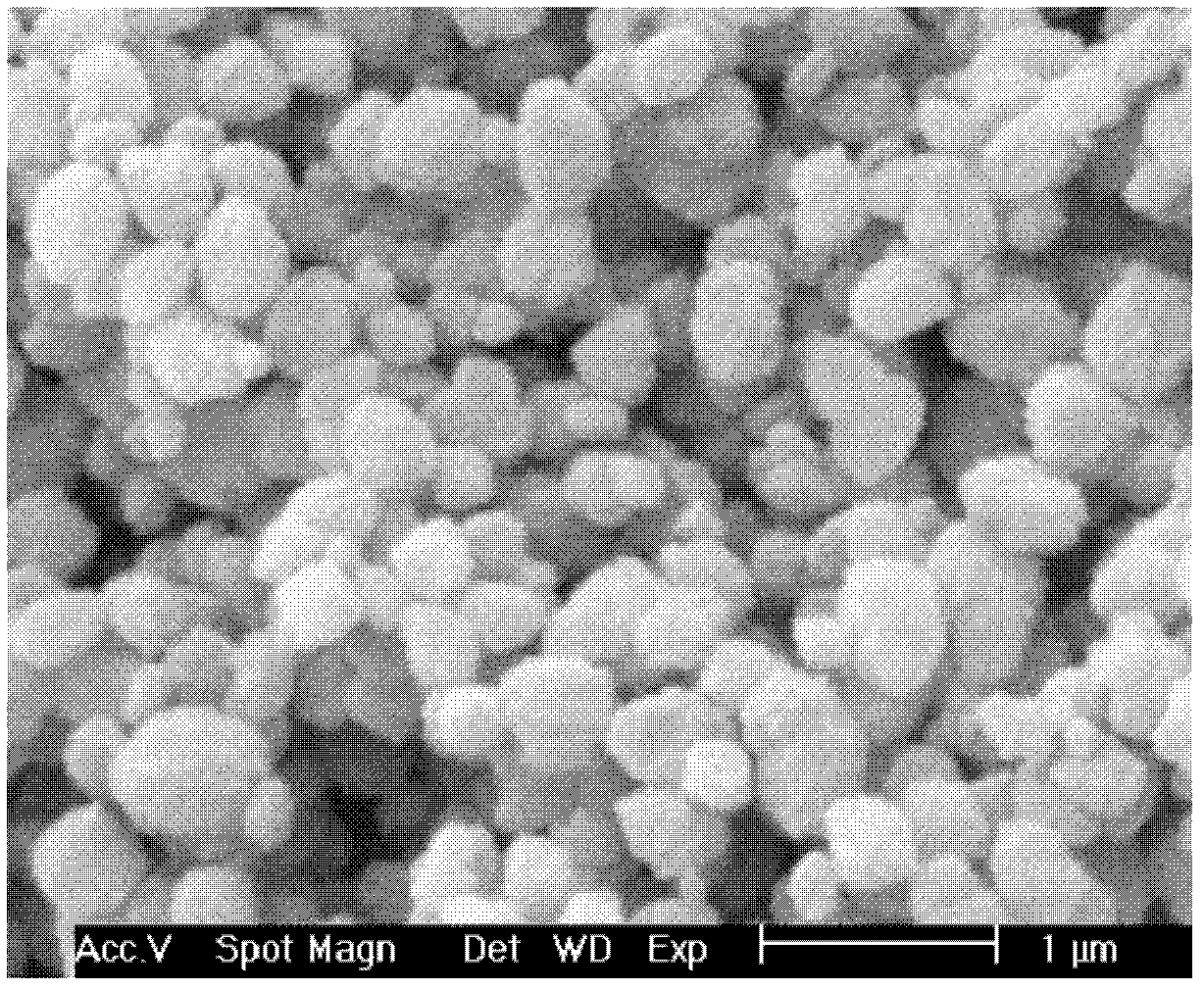

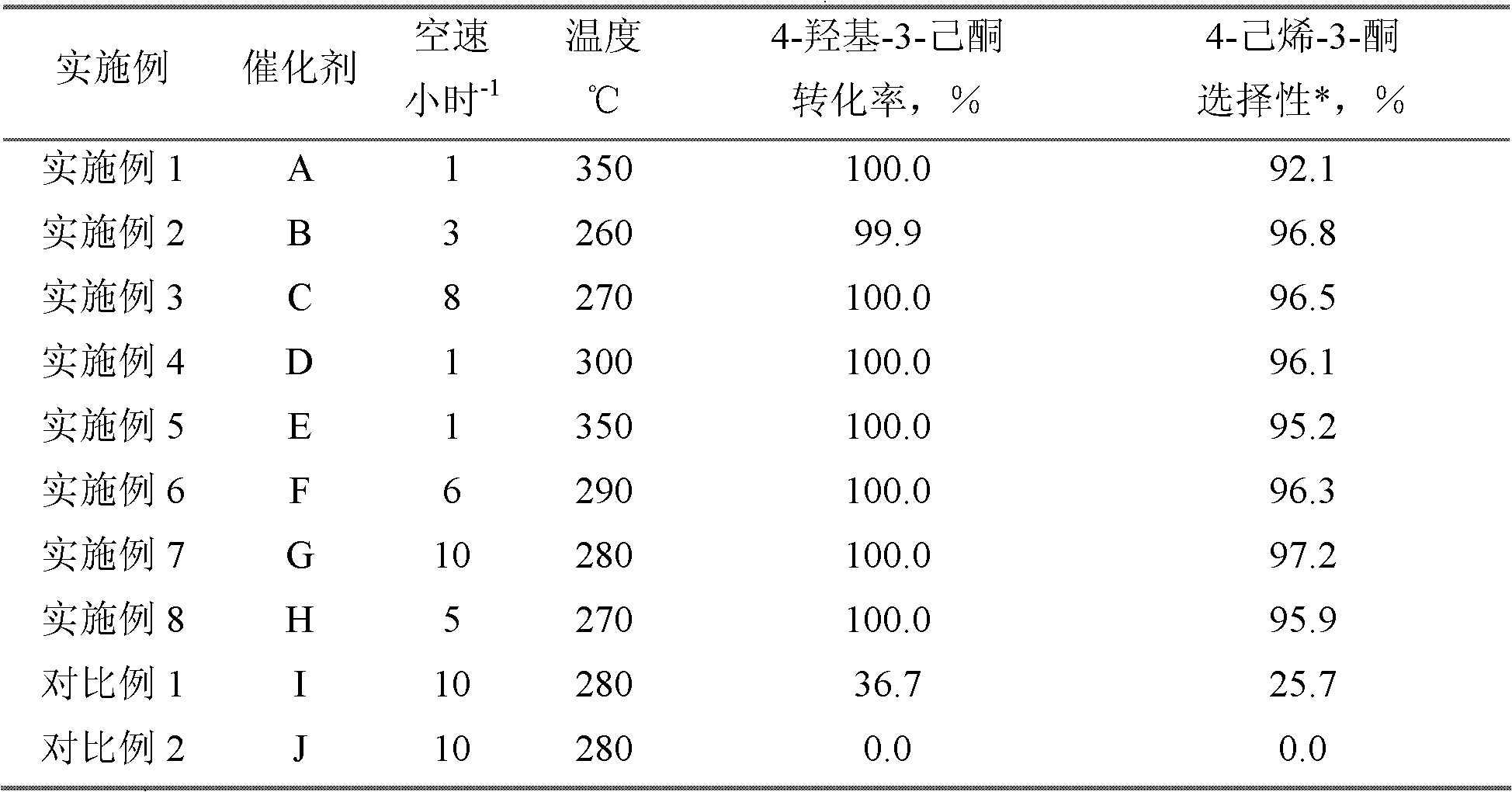

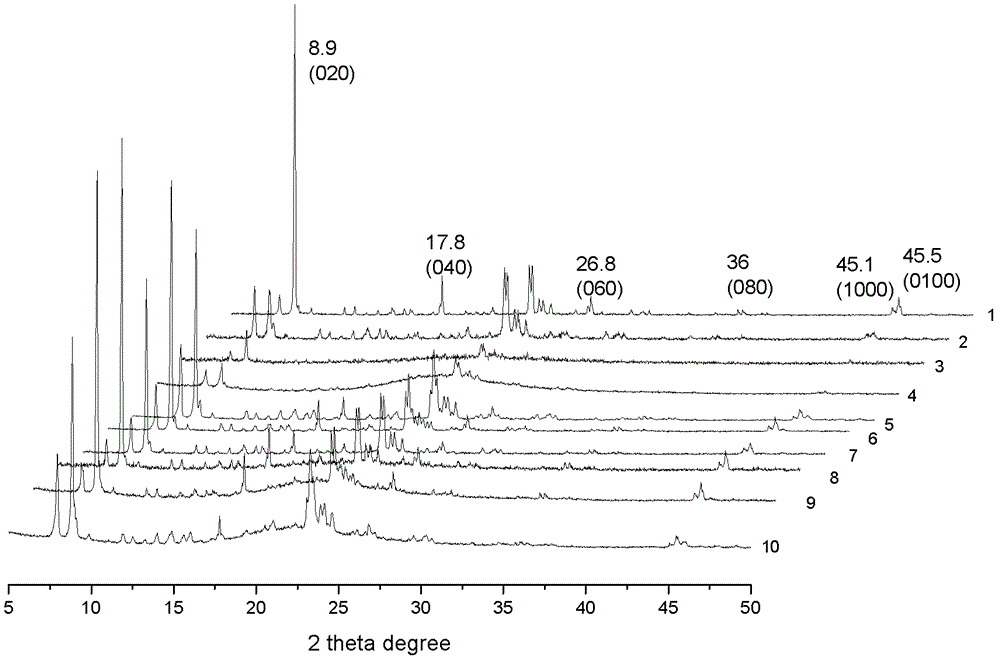

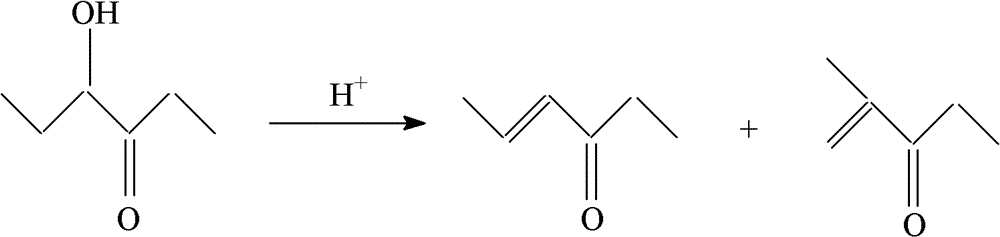

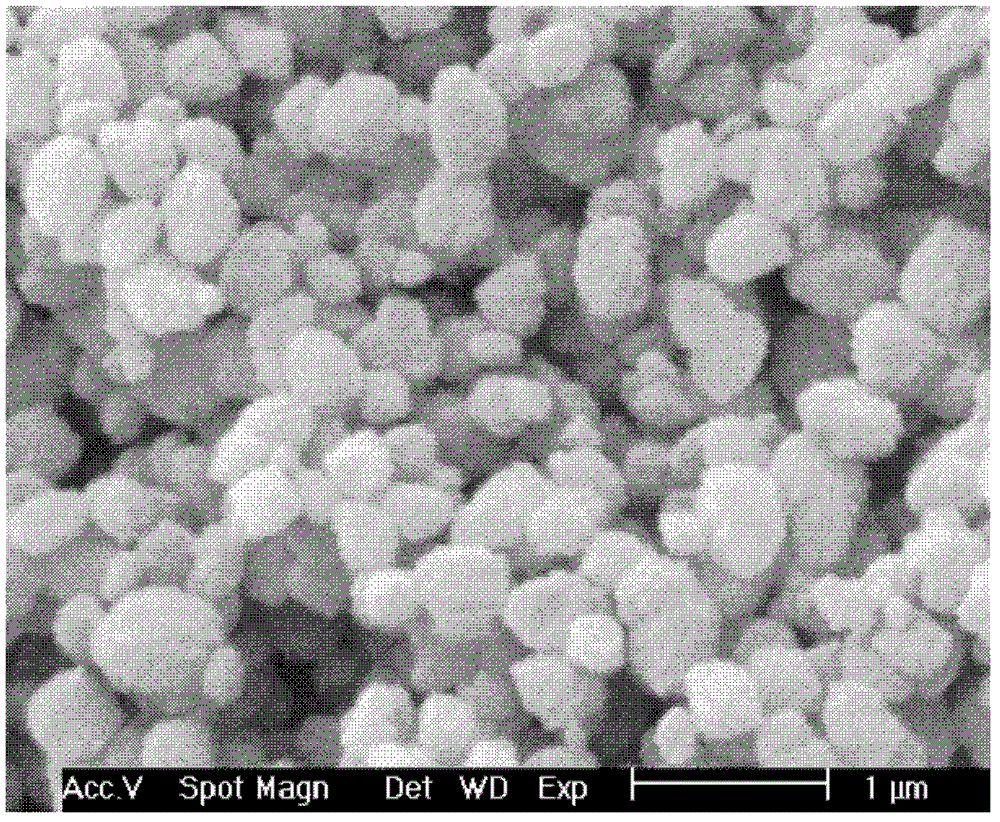

InactiveCN101941897AIncrease profitIncreased focus capacityMolecular sieve catalystsOrganic compound preparationMicrometerReaction temperature

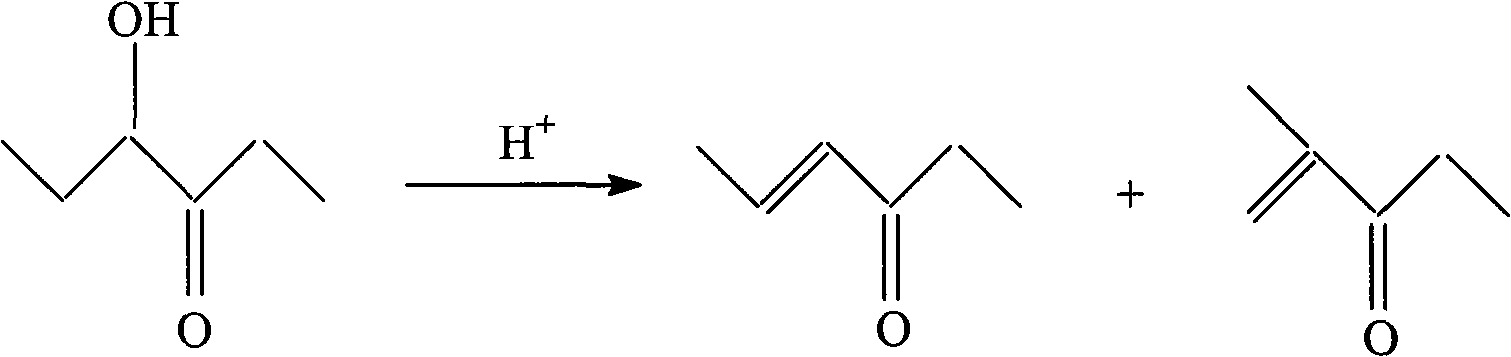

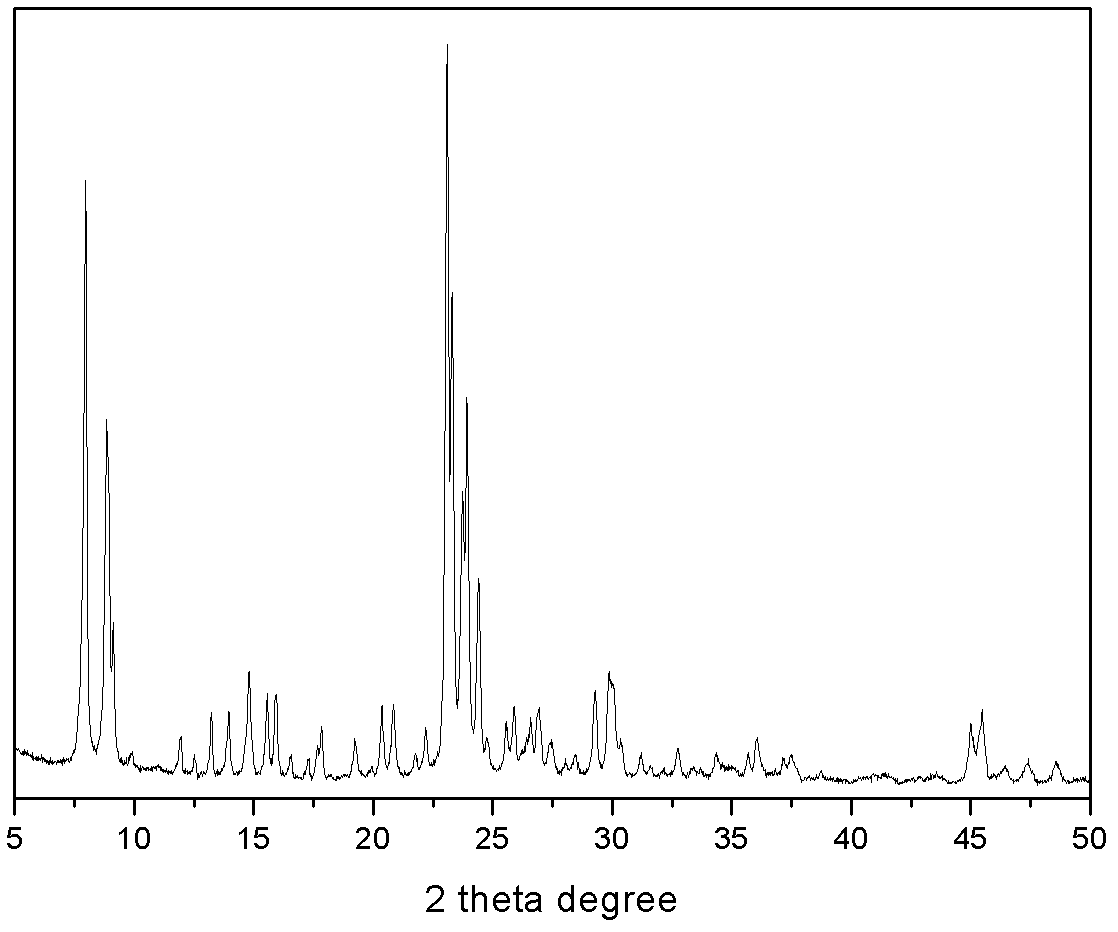

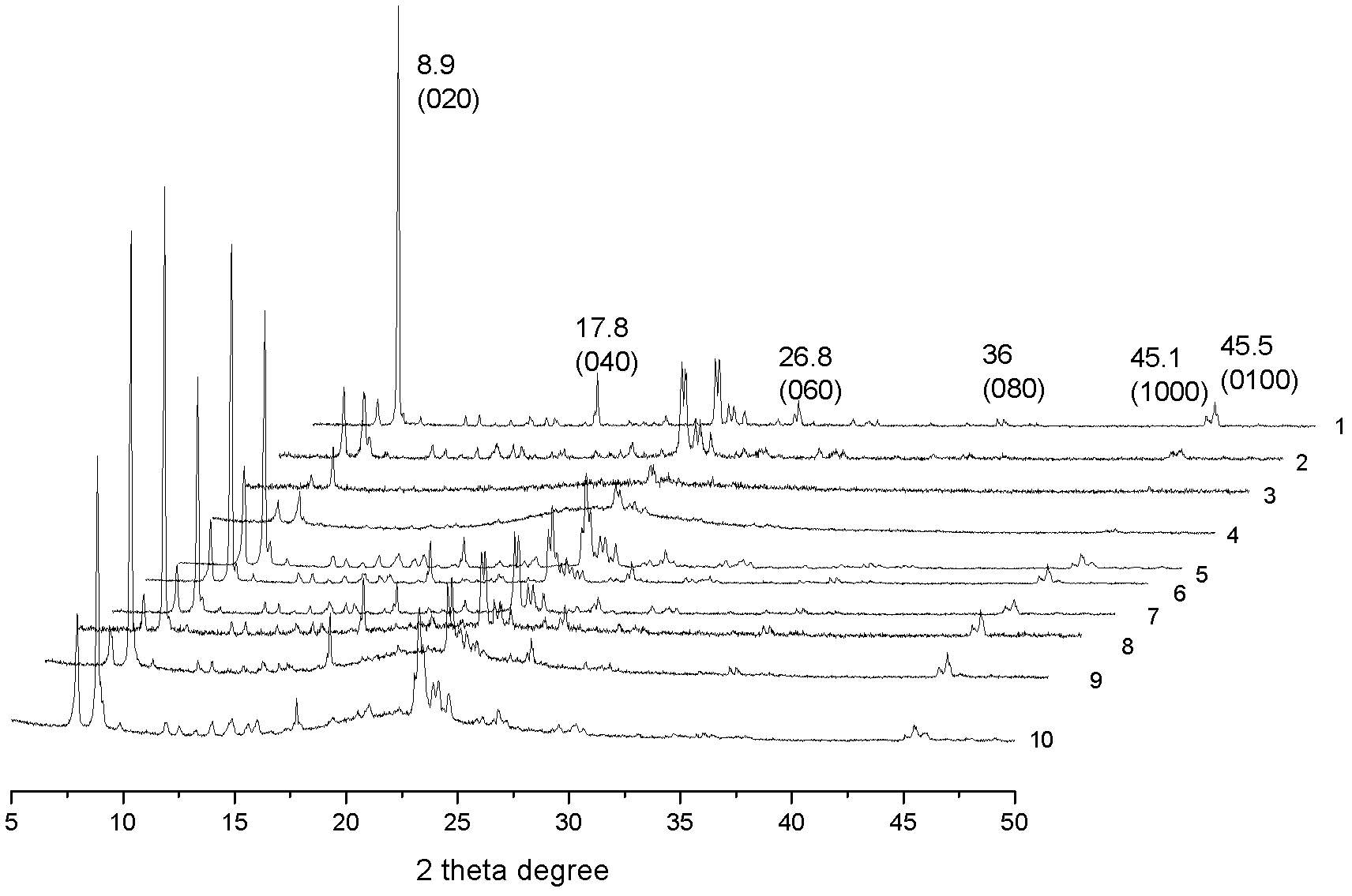

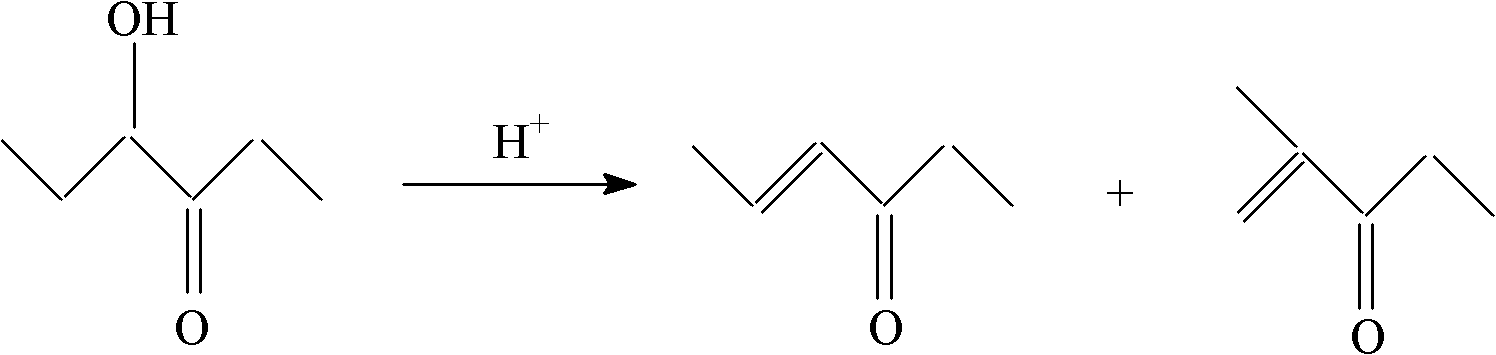

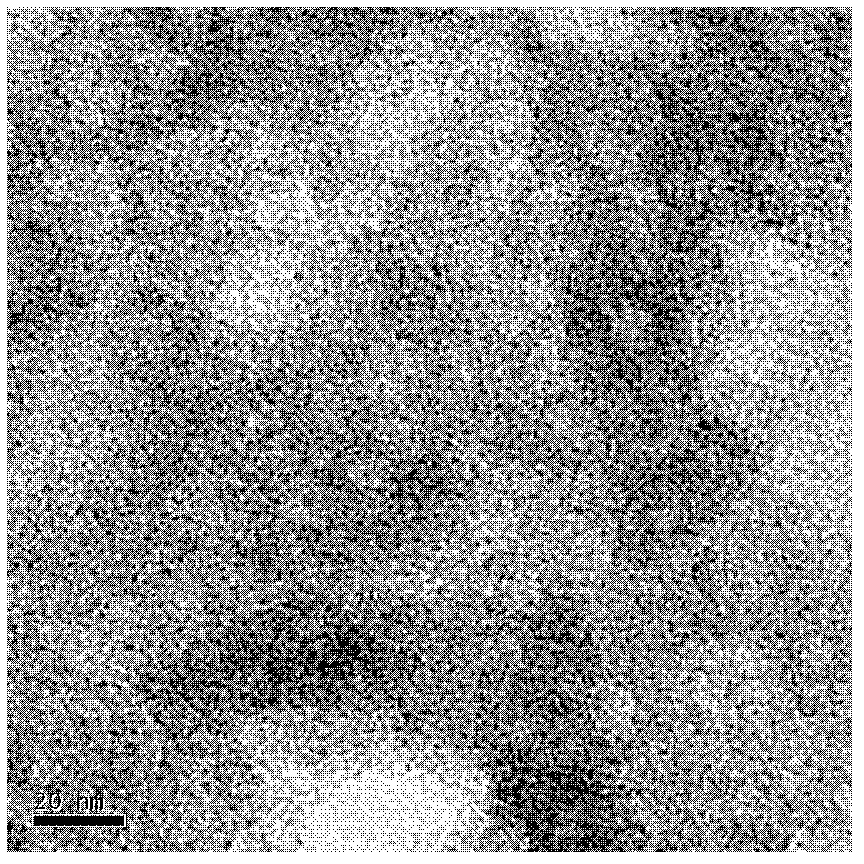

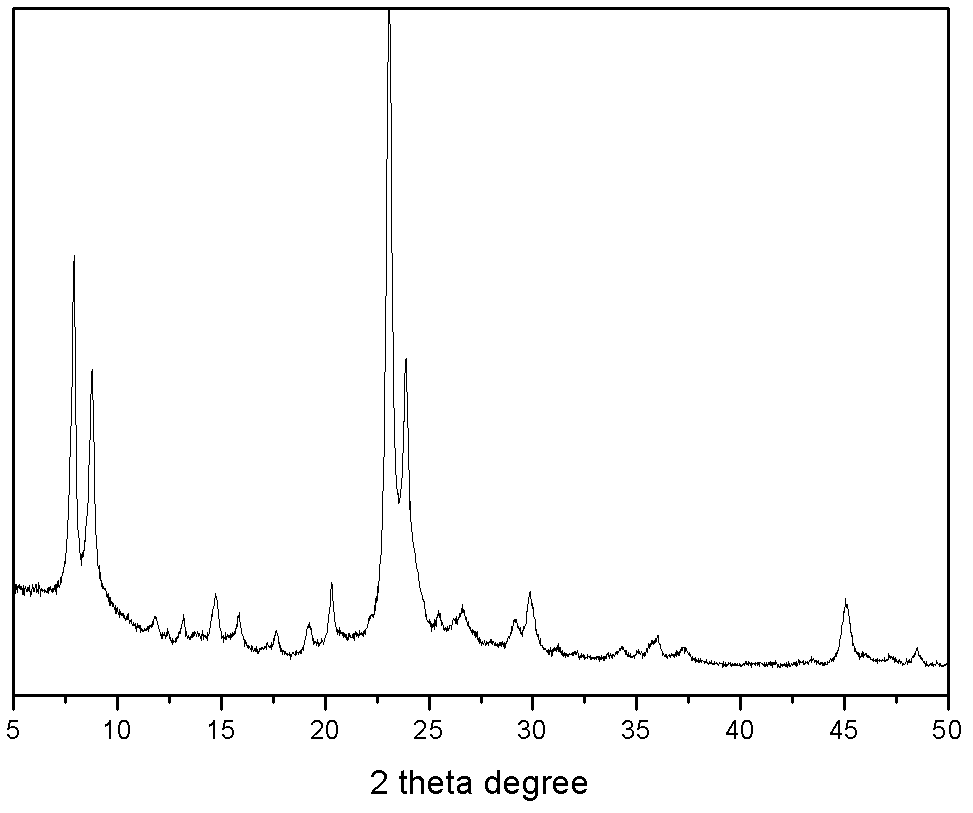

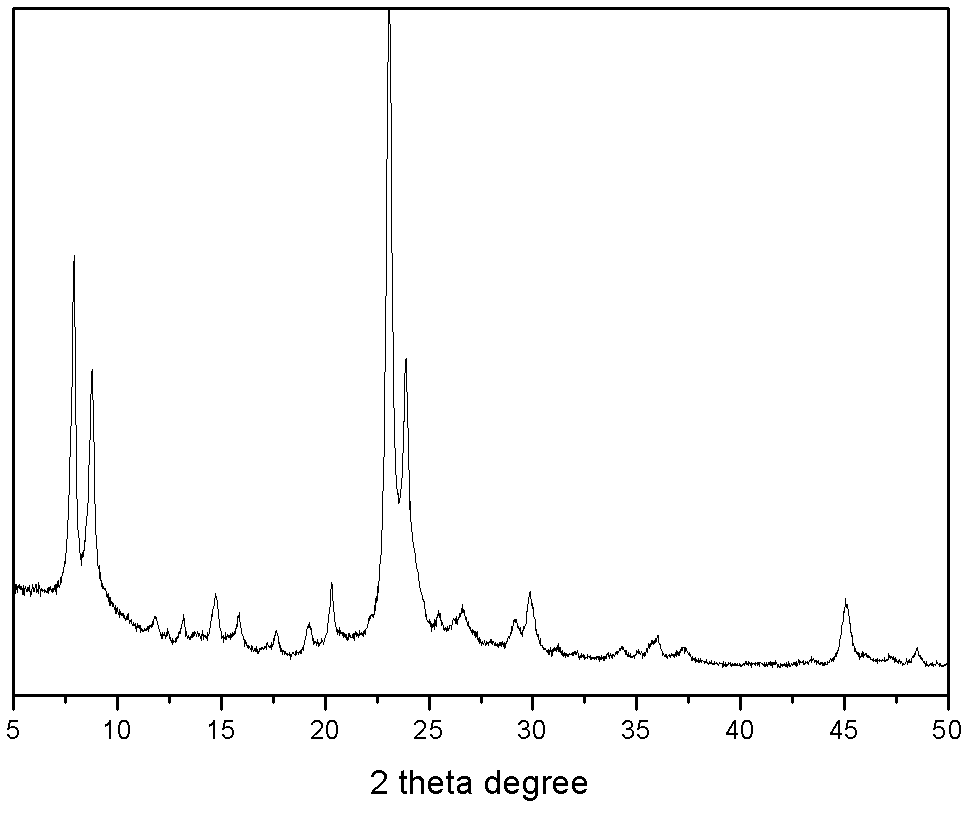

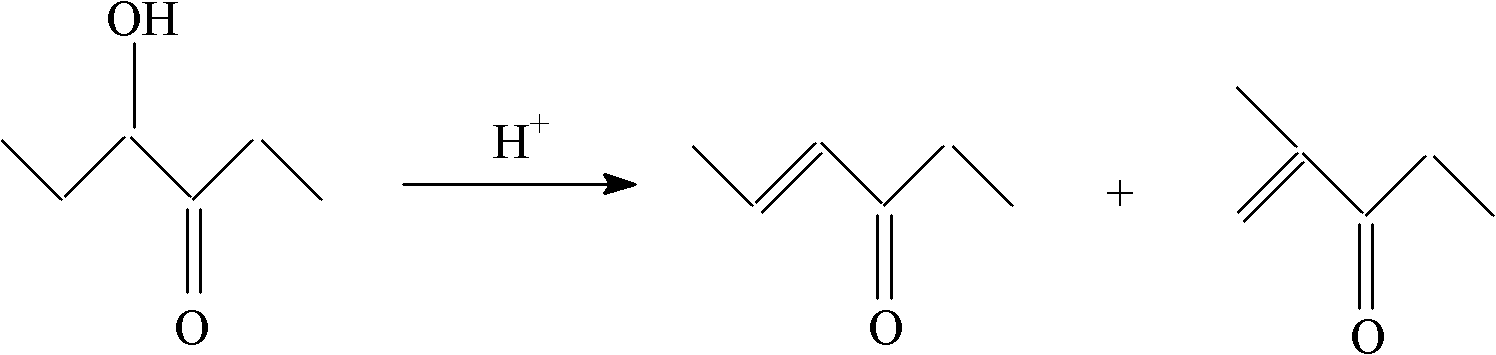

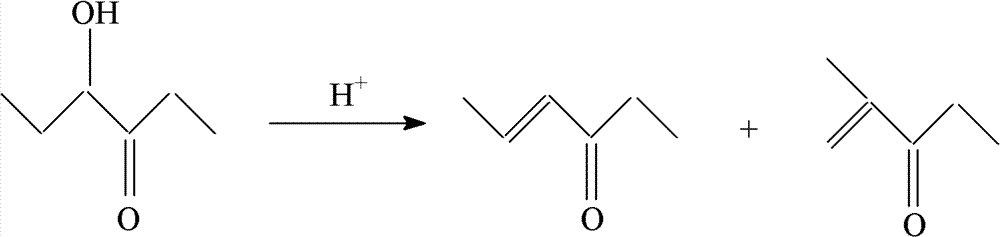

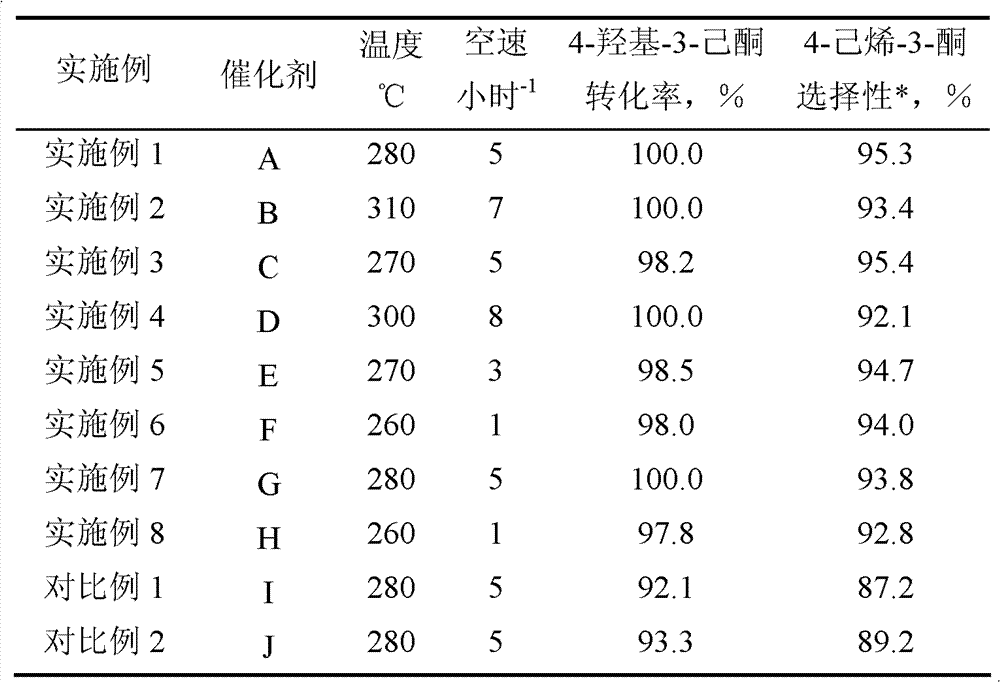

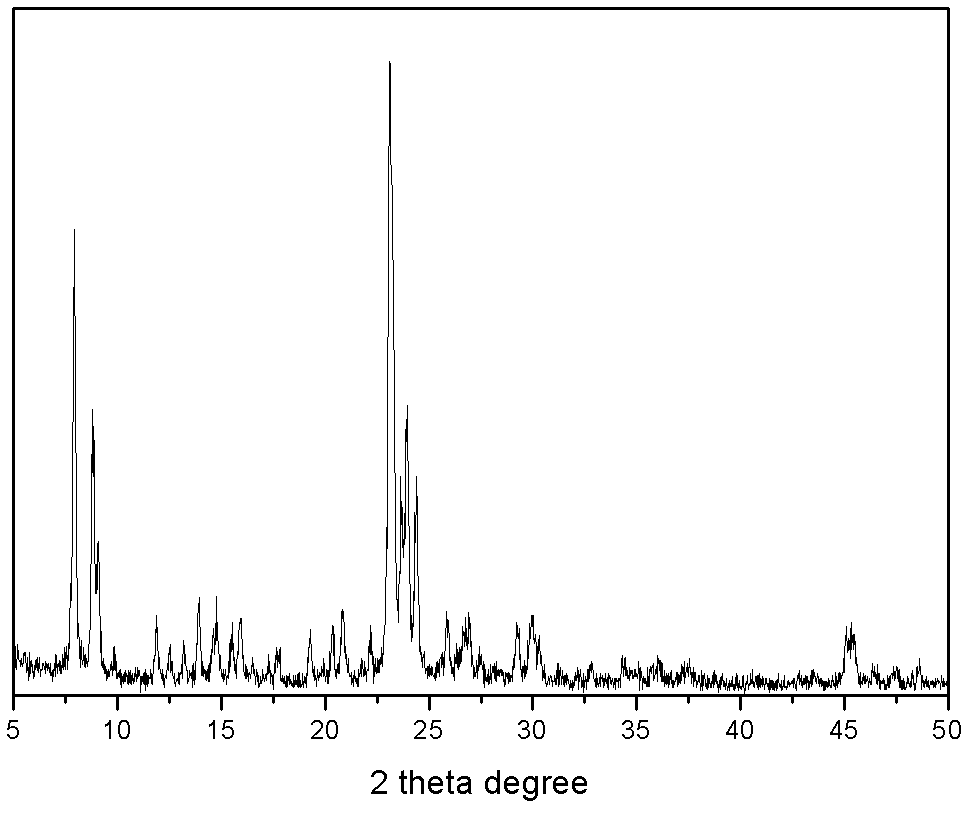

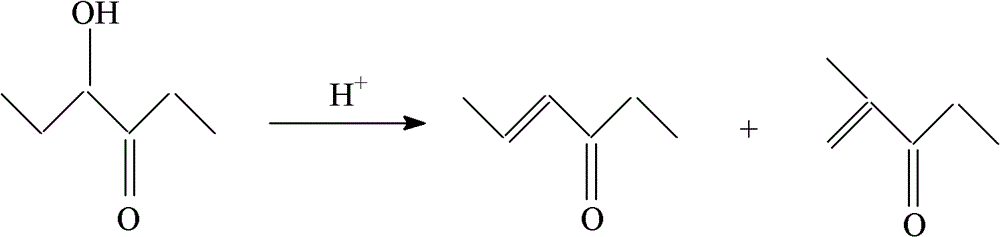

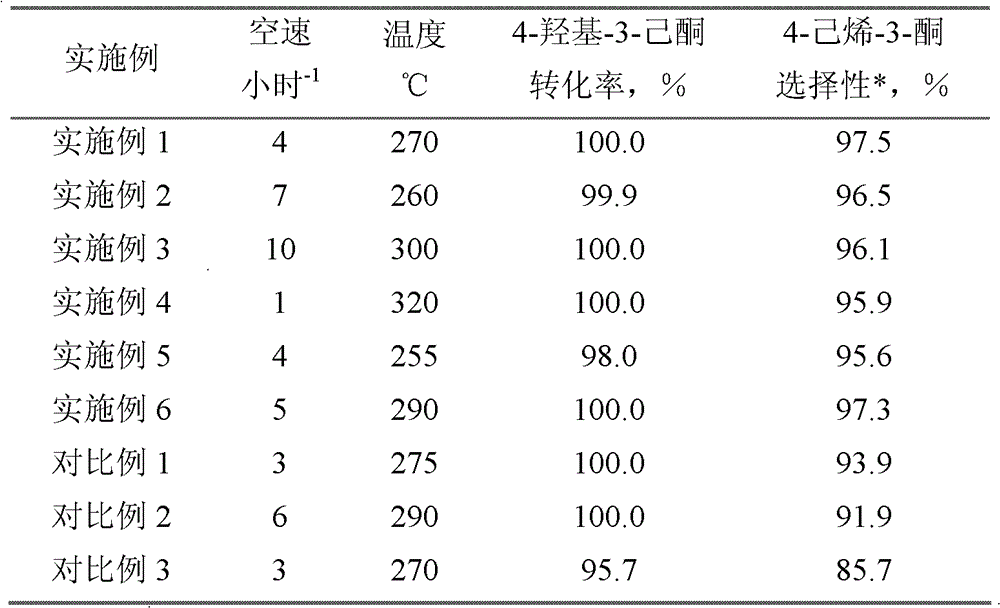

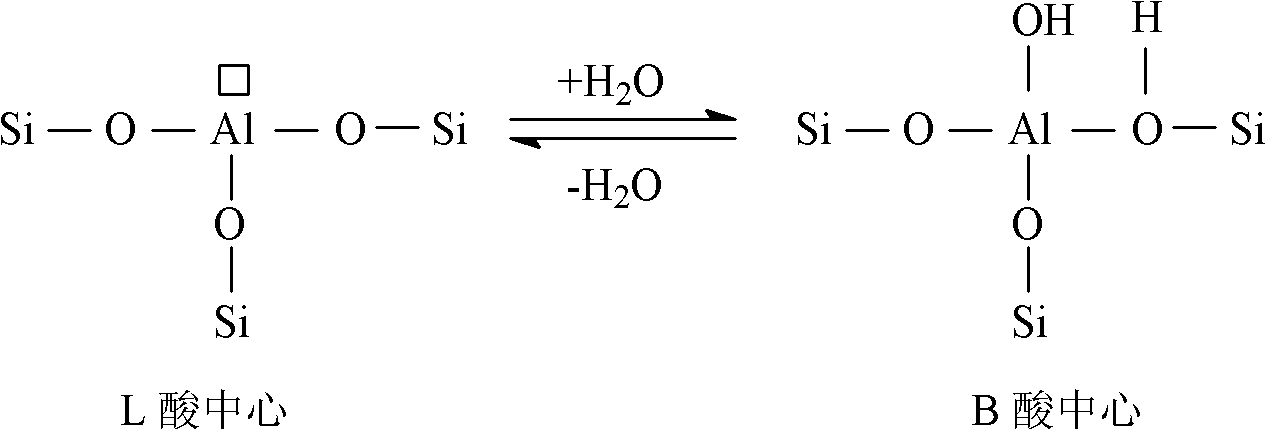

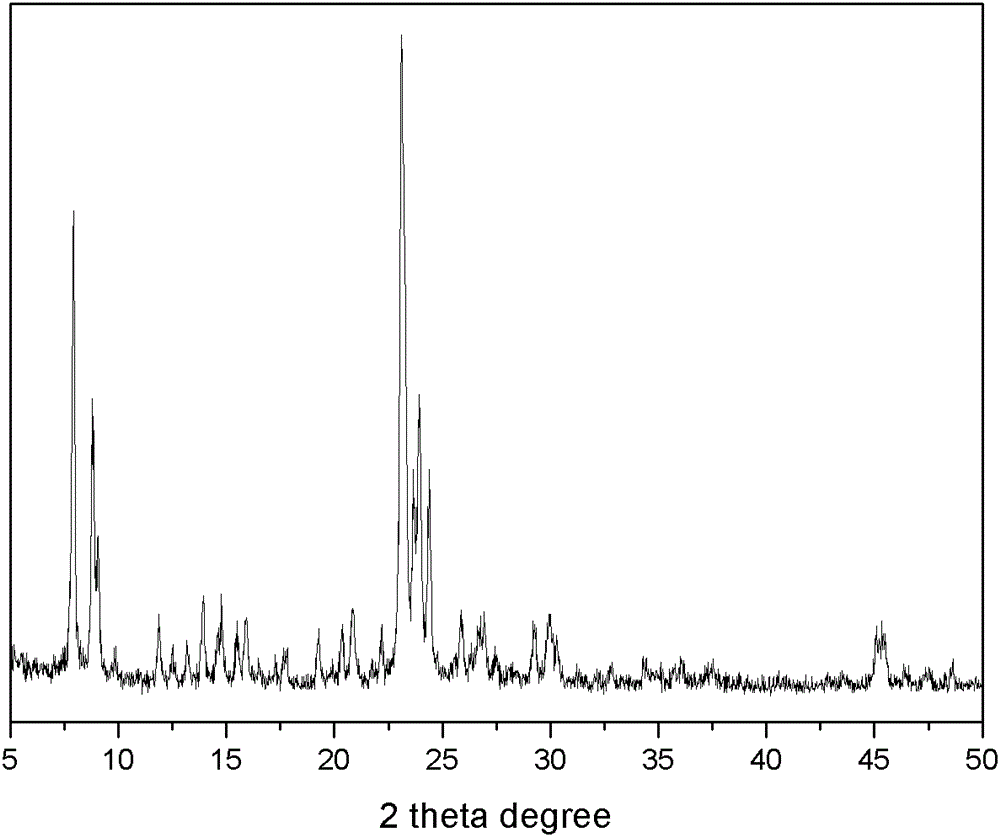

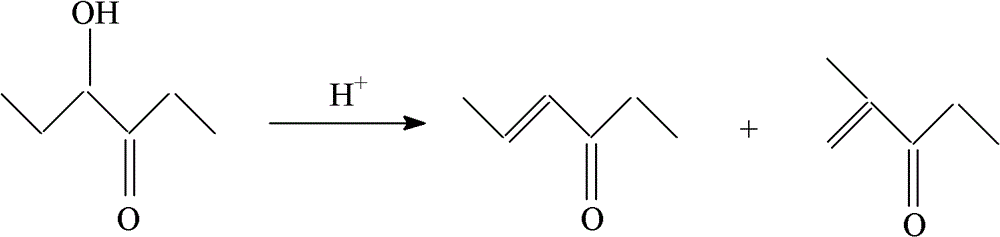

The invention relates to a method for catalyzing and dehydrating 4-hydroxy-3-hexanone, which mainly solves the problems of low catalyst activity, high reaction temperature and low airspeed in the prior art. In the method, the 4-hydroxy-3-hexanone is adopted as a raw material; the reaction raw material and a catalyst contact to prepare 4-hydroxy-3-ketone under the condition that the reaction temperature is between 200 to 400 DEG C and the quality airspeed is 0.5 to 15 hours corresponding to 4-hydroxy-3-hexanone liquid; the technological scheme that the catalyst is HZSM-5 zeolite, the grain diameter of the zeolite is less than 5 micrometers and the molar ratio of SiO2 to Al2O3 is 1: 0.003 to 0.05 to solve the problem; and the method is suitable for industrial production for preparing the 4-hydroxy-3-ketone by the 4-hydroxy-3-hexanone.

Owner:SHANGHAI RES INST OF PETROCHEMICAL TECH SINOPEC

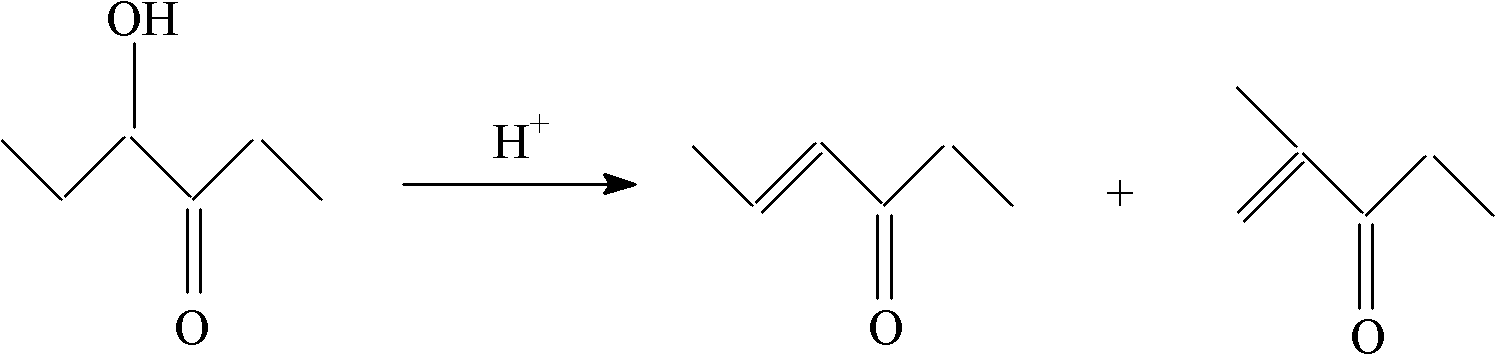

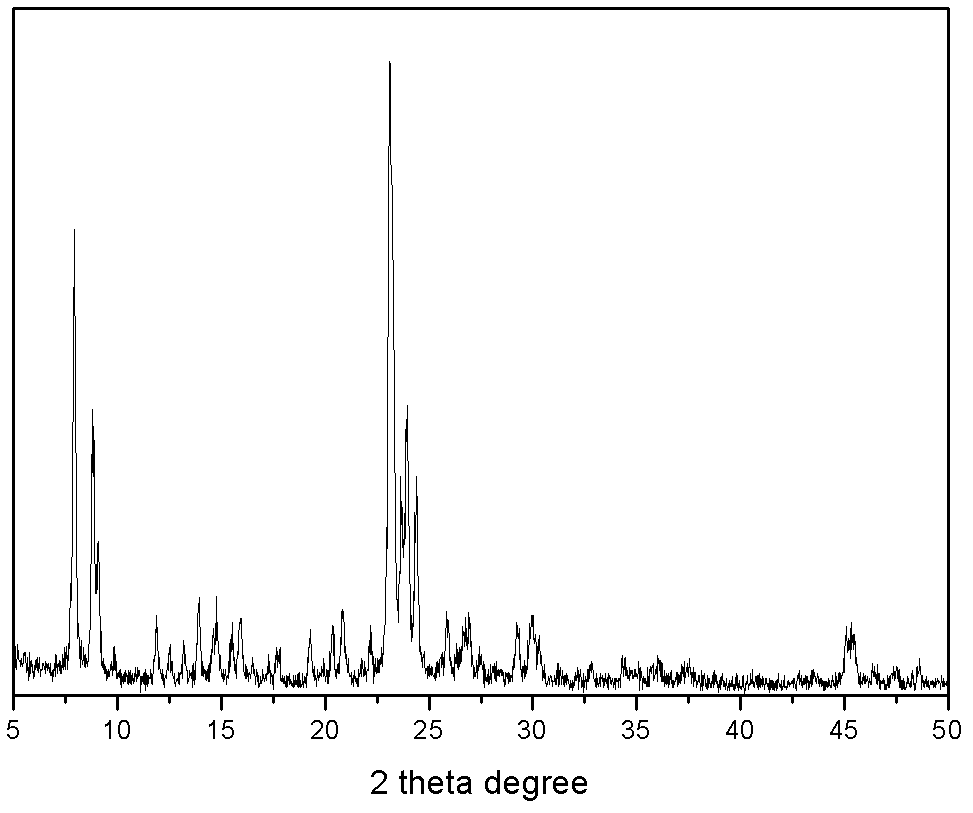

Method for preparing 4-hexene-3-ketone by 4-hydroxy-3-hexanone hydration

InactiveCN103030542AOvercoming the disadvantages of destructionImprove technical effectMolecular sieve catalystsOrganic compound preparationLow activityReaction temperature

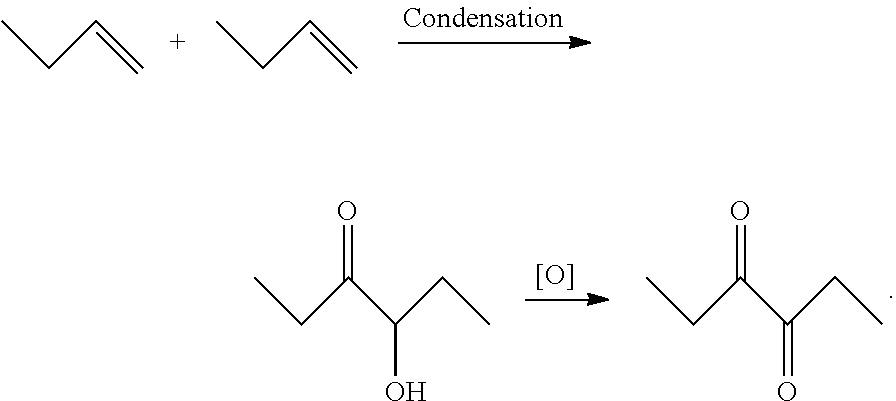

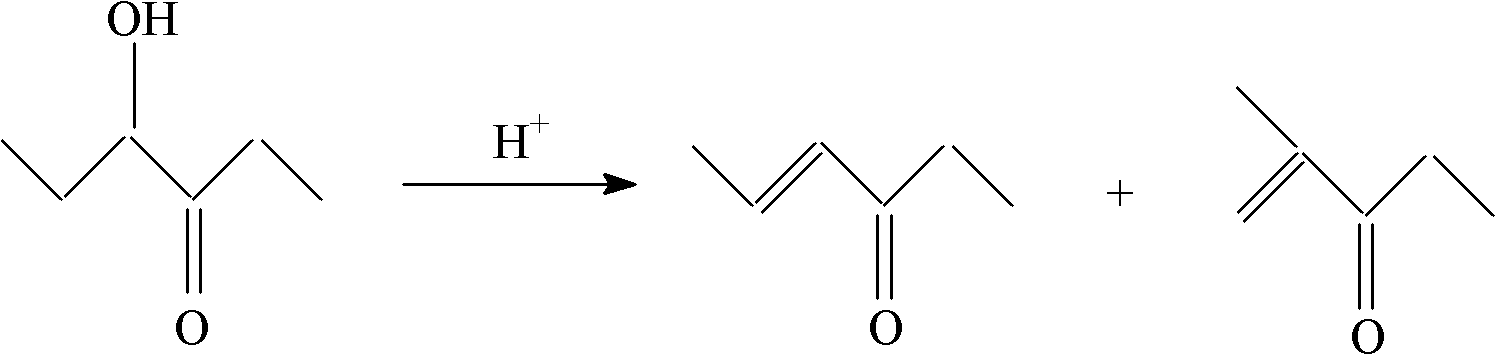

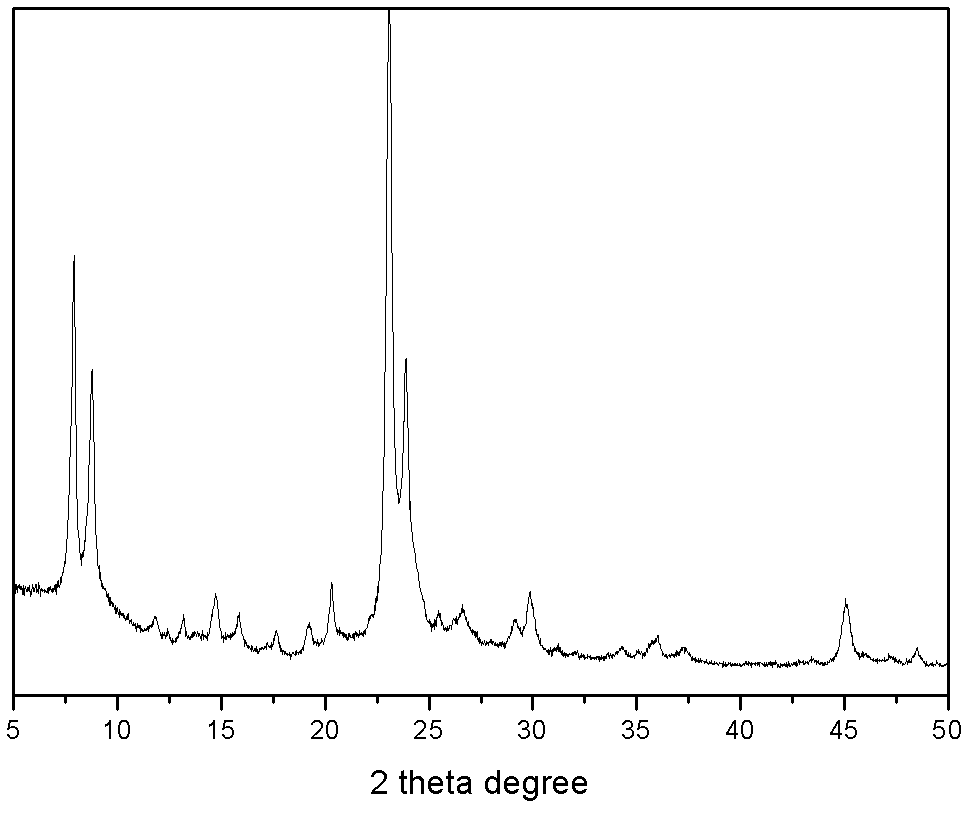

The invention relates to a method for preparing 4-hexene-3-ketone by 4-hydroxy-3-hexanone hydration, which mainly solves the problems of low activity of a catalyst, high reaction temperature, and low space velocity in the prior art. Aiming at well solving the problems, the method adopts the technical scheme that the 4-hydroxy-3-hexanone is used as a raw material, and the reaction raw material comes into contact with an ZSM-5 catalyst to generate the 4-hexene-3-ketone when the reaction temperature is 200 to 400 DEG C and the liquid weight hourly space velocity is 0.5 to 15 h<-1> relative to the 4-hydroxy-3-hexanone; and the ZSM-5 catalyst is prepared by the following method of mixing a silicon source, an aluminum source, an alkaline source, a salt source and water, wherein the reaction mixture has a molar ratio of SiO2:Al2O3:OH<->:Cl<->:H2O=1:0.0025-0.05:0.1-0.6:0.05-0.5:20-200; crystallizing the mixture for 2 to 24 hours at the temperature of 60 to 120 DEG C, and crystallizing for 2 to 72 h at the temperature of 140 to 200 DEG C; and carrying out separating, washing, drying, ammonium exchange and sintering on the product, so as to obtain the catalyst. The method can be used for the industrial production of the 4-hexene-3-ketone prepared by the 4-hydroxy-3-hexanone.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method of 4-hydroxy-3-hexanone catalysis and dehydration

InactiveCN103030548AIncrease acidityHigh acid strengthOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsLow activityHeteropoly acid

The invention relates to a method of 4-hydroxy-3-hexanone catalysis and dehydration, which mainly solves the problems of low activity of a catalyst, high reaction temperature, and low space velocity in the prior art. Aiming at well solving the problems, the method adopts the technical scheme that the 4-hydroxy-3-hexanone is used as a raw material, and the reaction raw material comes into contact with the catalyst to generate 4-hexene-3-ketone when the reaction temperature is 200 to 400 DEG C and the liquid weight hourly space velocity is 0.5 to 15 h<-1> relative to the 4-hydroxy-3-hexanone; and the catalyst is prepared by the following components in parts by weight: (a) 0.5 to 30 parts of heteropoly acid, and (b) 70 to 99.5 parts of alumina, wherein at least one of H3PMo12O40.nH2O, H4SiW12O40.nH2O or H3PW12O40.nH2O is adopted as the heteropoly acid, and n is 0 to 10. The method can be used for the industrial production of the 4-hexene-3-ketone prepared by the 4-hydroxy-3-hexanone.

Owner:CHINA PETROLEUM & CHEM CORP +1

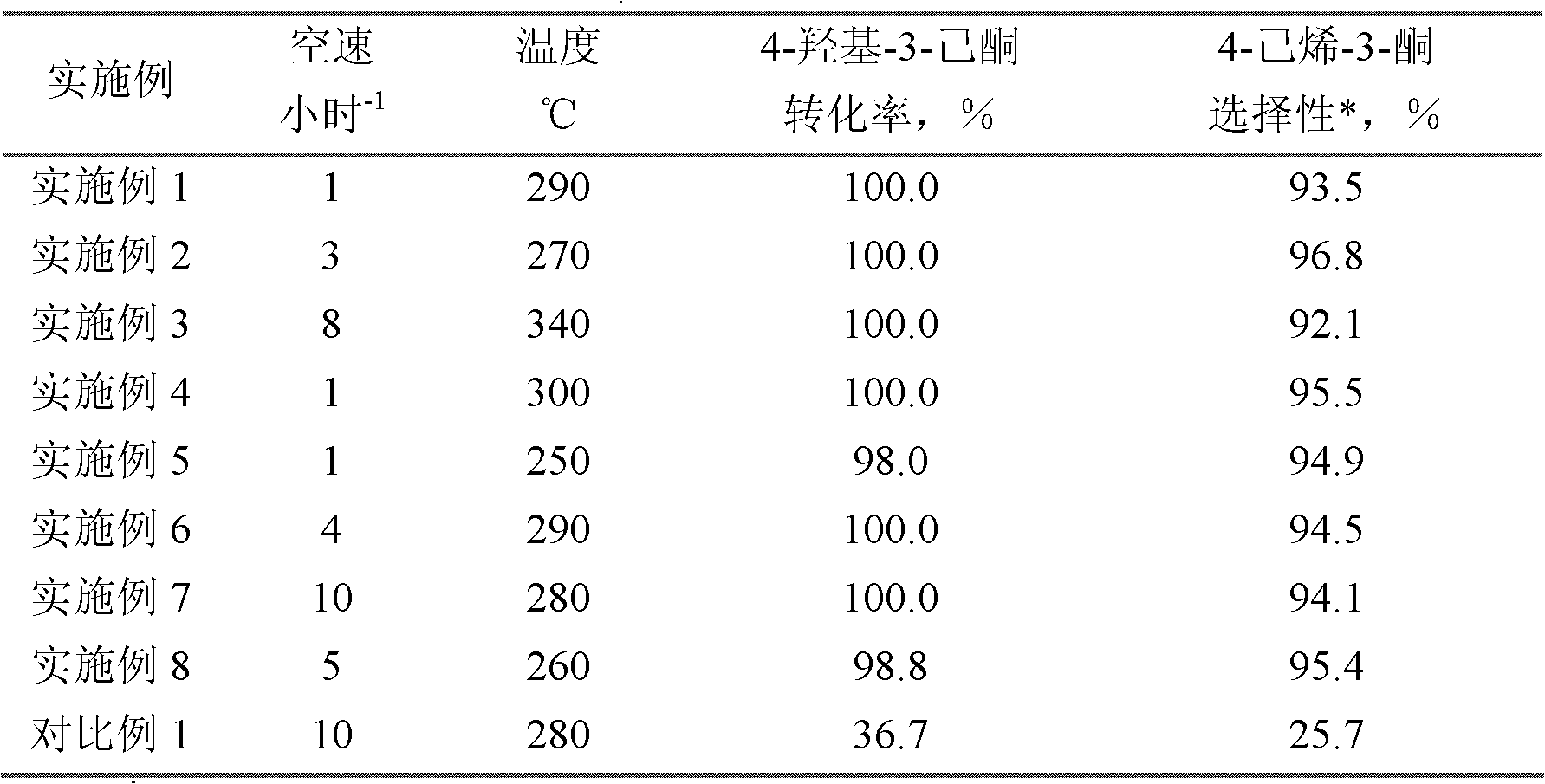

Method for preparing 4-hexene-3-ketone by carrying out dehydration on 4-hydroxy-3-hexanone

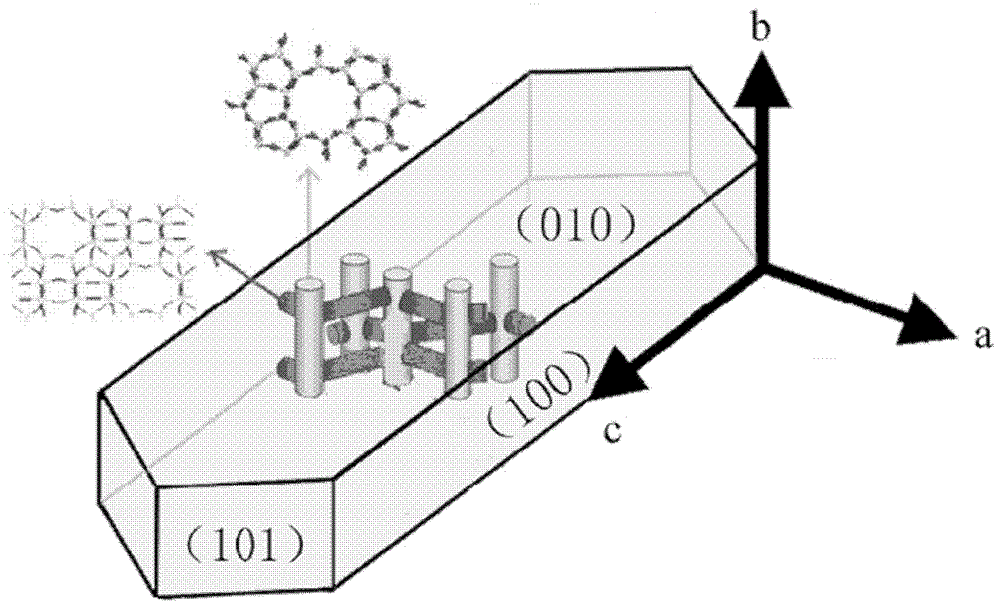

ActiveCN103030543AShort diffusion pathMolecular sieve catalystsOrganic compound preparationTetramethylammonium hydroxideReaction temperature

The invention relates to a method for preparing 4-hexene-3-ketone by carrying out dehydration on 4-hydroxy-3-hexanone, mainly aiming at solving the problems of low catalyst activity, high reaction temperature and slow space velocity in the prior art. The catalyst used by the method is prepared by the following steps of: mixing a silicon source, an aluminium source, template agent R1, template agent R2 and water, and adjusting the pH of the reaction mixture to be 8-14 with inorganic base; in the reaction mixture, controlling the molar ratio between Al2O3 and SiO2 to be 0.003-0.05, controlling the molar ratio of R1 to SiO2 to be 0.1-2, controlling the molar ratio of H2O to SiO2 to be 10-100 and controlling the molar ratio of R2 to SiO2 to be 0.05-2; and carrying out hydrothermal crystallization on the mixture for 1-10 days at the temperature of 100-250 DEG C to obtain the catalyst, wherein R1 comprises at least one selected from tetramethyl ammonium hydroxide, tetraethyl ammonium hydroxide, tetrapropyl ammonium hydroxide or tetrabutyl ammonium hydroxide, and R2 comprises at least one selected from beta-diketone, beta-diketone salt, oxalic acid, oxalate, catechol or 8-hydroxyquinoline. The technical scheme better solves the problems, and can be used in the industrial production of the 4-hexene-3-ketone prepared by the 4-hydroxy-3-hexanone.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production method of 4-hexene-3-one by catalyzed dehydration of 4-hydroxy-3-hexanone

InactiveCN103030541AHigh selectivityOrganic compound preparationCarbonyl compound preparationReaction temperatureKetone

The present invention relates to a production method of 4-hexene-3-one by catalyzed dehydration of 4-hydroxy-3-hexanone, and mainly solves the problem of low catalyst activity, high reaction temperature and low space velocity in the prior art. According to the invention, 4-hydroxy-3-hexanone is used as a raw material, and the reaction raw material is in contact with a catalyst to produce 4-hexen-3-one at the conditions of a reaction temperature of 200-450 DEG C and the airspeed of 0.5-15 hr-1 with respect to the mass of 4-hydroxy-3-hexanone liquid, wherein the catalyst is WO3 / ZrO2-SiO2 or MoO3 / ZrO2-SiO2, and the molar ratio of W or Mo:Zr:Si is (0.05-0 .3):1:(5-50). The technical solution solves the problem preferably. The method can be used in the industrial production of 4-hexen-3-one from 4-hydroxy-3-hexanone.

Owner:CHINA PETROLEUM & CHEM CORP +1

Synthesis Method of 3,4-hexanedione

InactiveUS20180334421A1Mild conditionsEasy to operateOrganic compound preparationPreparation by ozonolysisAcetic acidDistillation

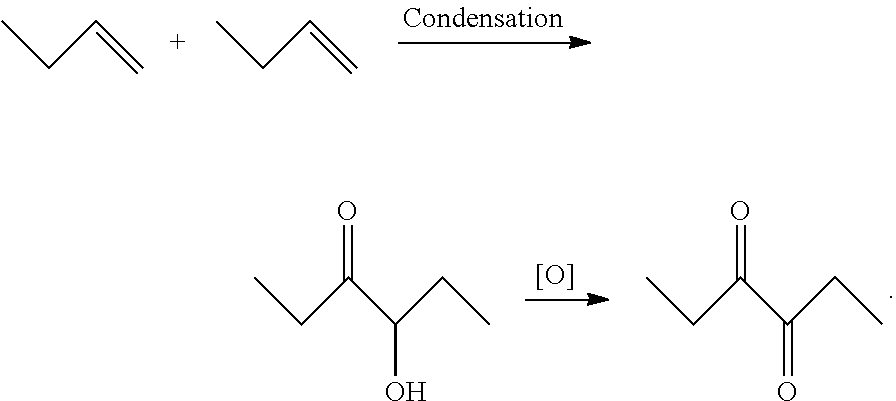

A synthesis method of 3,4-hexanedione comprises a step of 4-hydroxy-3-hexanonen oxidation, and in the step of 4-hydroxy-3-hexanonen oxidation, water is used as a catalyst, acetic acid is used as a cocatalyst, and ozone is used as an oxidizing agent to carry out an oxidation reaction on 4-hydroxy-3-hexanonen, and after the reaction, distillation under reduced pressure is carried out to obtain the 3,4-hexanedione. According to the synthesis method of 3,4-hexanedione in the invention, in the process of 4-hydroxy-3-hexanone oxidation, the 4-hydroxy-3-hexanone is placed in the water, the ozone is used for oxidation on the 4-hydroxy-3-hexanone, and the acetic acid is used as the cocatalyst, so that the entire oxidation reaction process is mild in conditions and simple to operate, no sewage is produced when the final product (3,4-hexanedione) is obtained, and the yield is greatly increased.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Method for producing 4-hexene-3-one by dehydration of 4-hydroxyl-3-hexanone

ActiveCN103121929AIncrease the effective surface areaEffective surface area reductionMolecular sieve catalystsOrganic compound preparationMolecular sieveReaction temperature

The invention relates to a method for producing 4-hexene-3-one by dehydration of 4-hydroxyl-3-hexanone and mainly solves the problem that catalysts are low in activity, high in reaction temperature and low in space velocity in the prior art. The 4-hydroxyl-3-hexanone is used as material to contact with catalyst at the reaction temperature of 200 DEG C-400 DEG C at weight hourly space velocity of 0.5-15 hours-1 relative to the 4-hydroxyl-3-hexanone so as to generate 4-hexene-3-one. The catalyst is molecular sieve ZSM-11 (zeolite socony mobil-11). The problem is solved well by the application of the technical scheme. The method is applicable to industrial production of 4-hexene-3-one by 4-hydroxyl-3-hexanone.

Owner:CHINA PETROLEUM & CHEM CORP +1

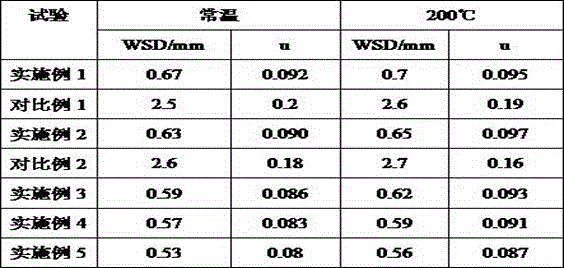

Heat-resisting anti-wear lubricating oil and preparation method thereof

InactiveCN106590838AGood heat and wear resistanceImprove the lubrication effectAdditivesThiamineHeat resistance

The invention discloses heat-resisting anti-wear lubricating oil. The lubricating oil is prepared from, by weight, 50-70 parts of base oil, 10-14 parts of allyl isothiocyanate, 6-10 parts of C thiamine pyrimidine, 4-8 parts of 3-thiophenecarboxaldehyde, 3-7 parts of 2-nitro-4-chlorophenol, 2-5 parts of 2-amino-6-chlorobenzothiazole, 9-13 parts of a perfluoroethylene propylene copolymer, 6-12 parts of fumaric acid resin, 10-13 parts of 2-methyl-2-propanethio, 10-20 parts of acetylsalicylic acid, 8-13 parts of diethylene glycol ether and 5-9 parts of 5-methyl-3-hexanone. The lubricating oil has both the good heat resistance and friction resistance by adopting various chemical substances for modifying the base oil.

Owner:苏州圣鑫莱新材料有限公司

Method of catalytic dehydration by 4-hydroxyl-3-hexanone

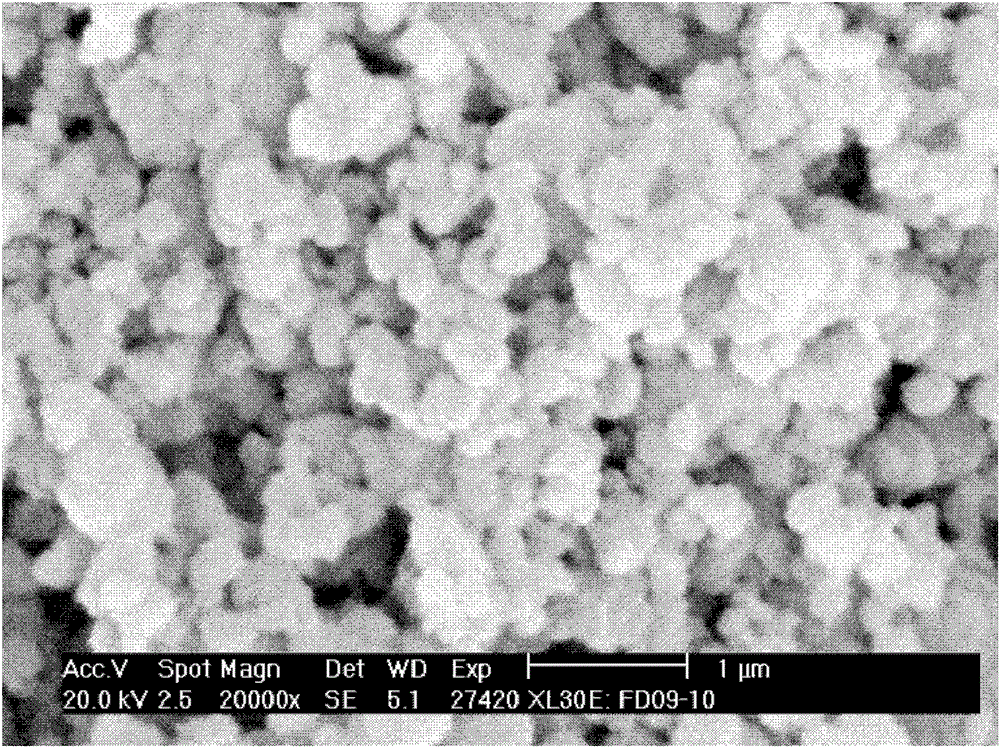

The invention relates to a method of catalytic dehydration by 4-hydroxyl-3-hexanone and mainly solves the problem that catalysts are low in activity, high in reaction temperature and low in space velocity in the prior art. The 4-hydroxyl-3-hexanone is used as material to contact with catalyst at the reaction temperature of 200 DEG C-400 DEG C at the weight hourly space velocity of 0.5-15 hours-1 relative to the 4-hydroxyl-3-hexanone so as to generate 4-hexene-3-one. The catalyst is molecular sieve ZSM-11(zeolite socony mobil-11) not larger than 5 micrometers in grain diameter. The problem is solved well by the application of the technical scheme. The method is applicable to industrial production of 4-hexene-3-one by catalytic dehydration of 4-hydroxyl-3-hexanone.

Owner:CHINA PETROLEUM & CHEM CORP +1

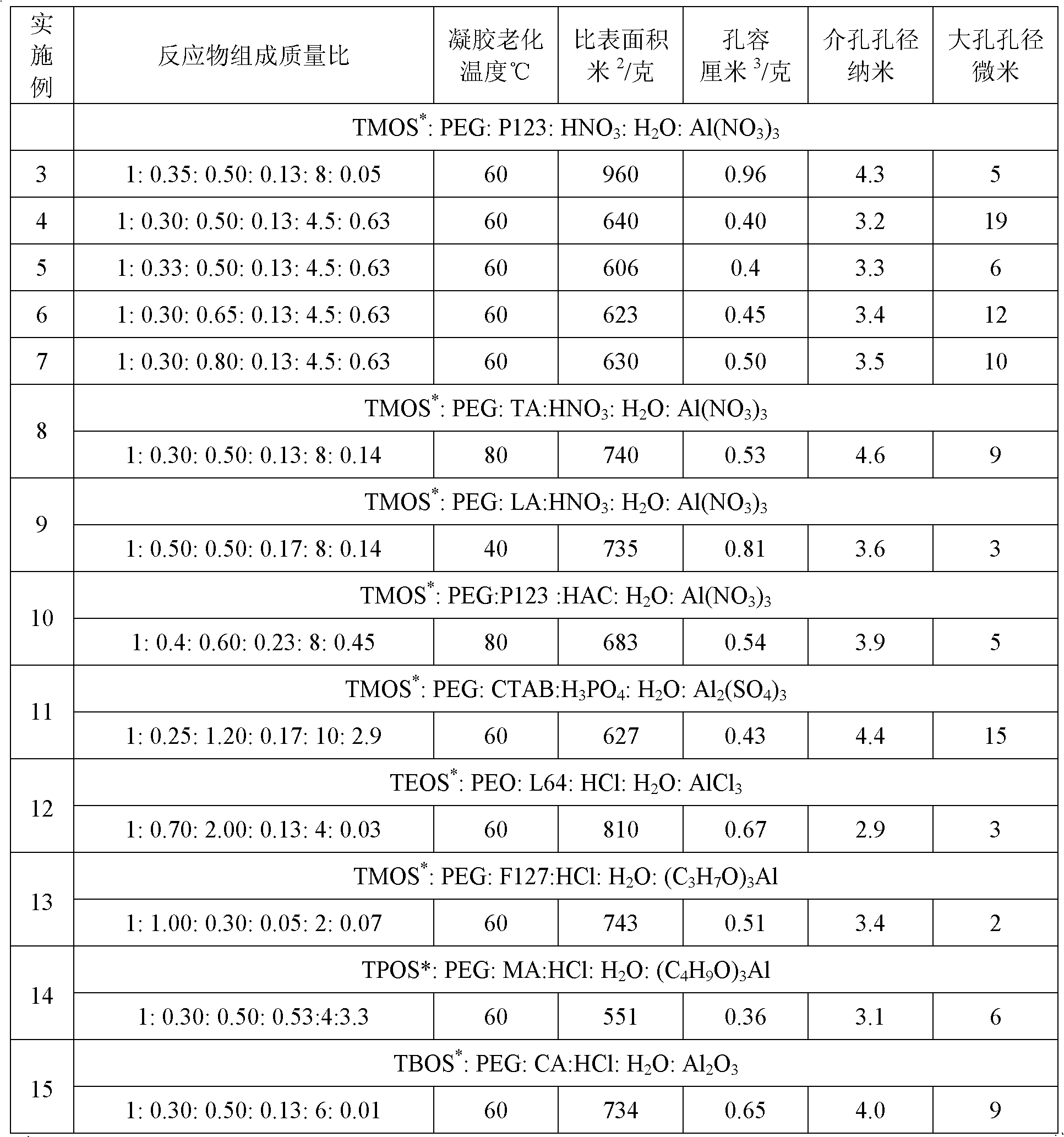

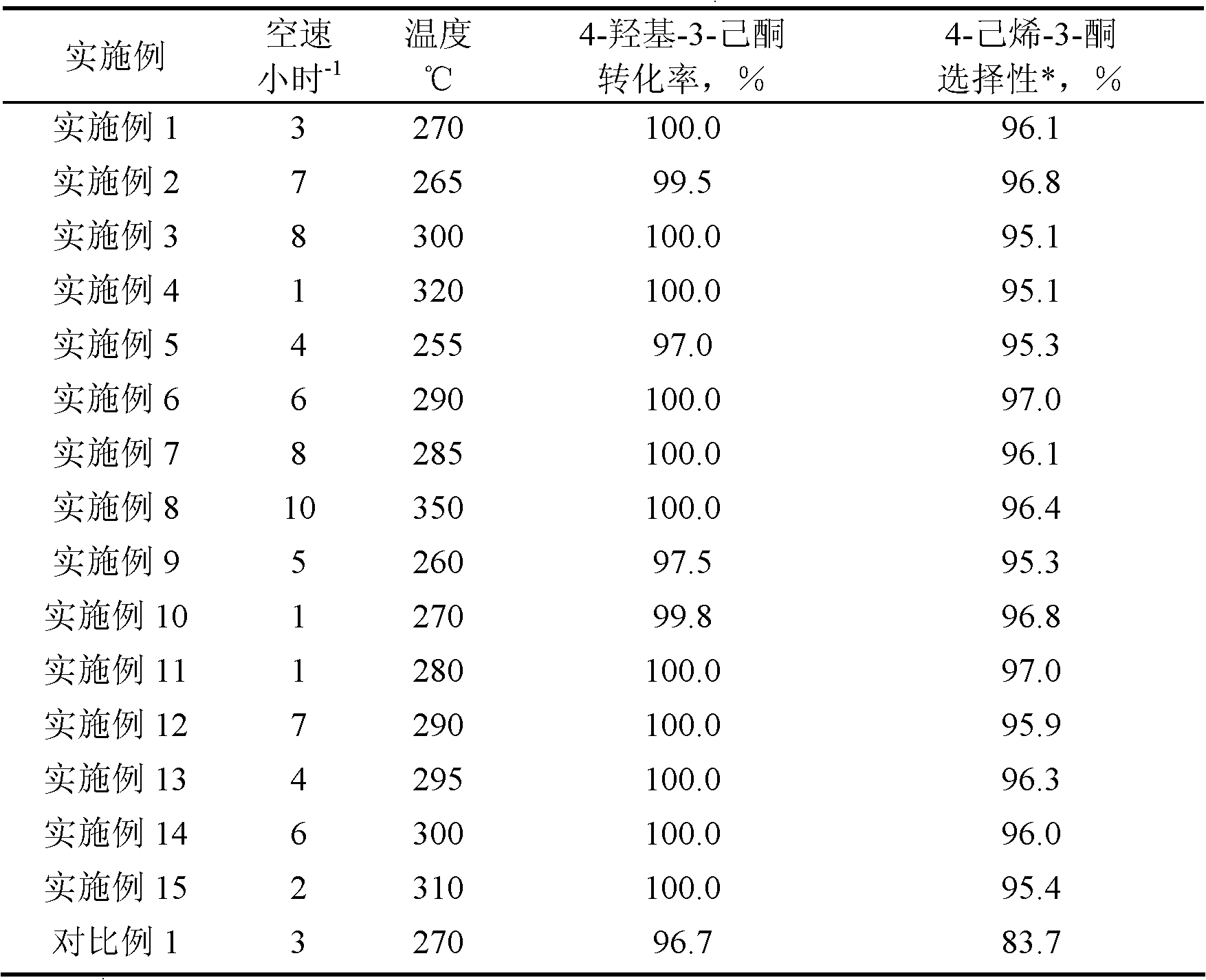

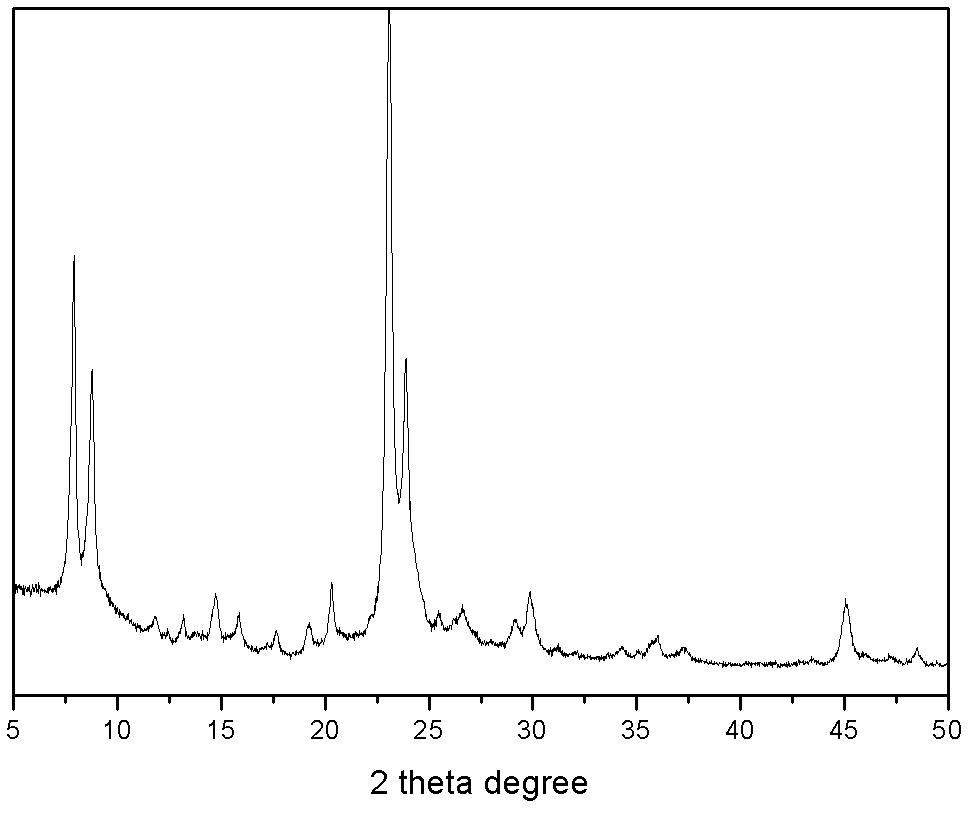

Method for preparing 4-hexene-3-ketone by 4-hydroxy-3-hexanone dehydration

InactiveCN103030545ALarge specific surface areaWell-developed pore structurePhysical/chemical process catalystsOrganic compound preparationLow activityReaction temperature

The invention relates to a method for preparing 4-hexene-3-ketone by 4-hydroxy-3-hexanone dehydration, which mainly solves the problems of low activity of a catalyst, high reaction temperature, and low space velocity in the prior art. Aiming at well solving the problems, the method adopts the technical scheme that the 4-hydroxy-3-hexanone is used as a raw material, and the reaction raw material comes into contact with the catalyst to generate the 4-hexene-3-ketone when the reaction temperature is 200 to 400 DEG C and the liquid weight hourly space velocity is 0.5 to 15 h<-1> relative to the 4-hydroxy-3-hexanone; and the catalyst is a mesoporous / macroporous silica and alumina oxide material with a composite pore structure The method can be used for the industrial production of the 4-hexene-3-ketone prepared by the 4-hydroxy-3-hexanone.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic dehydrating preparation method of 4-hexen-3-ketone by 4- hydroxy-3-hexanone

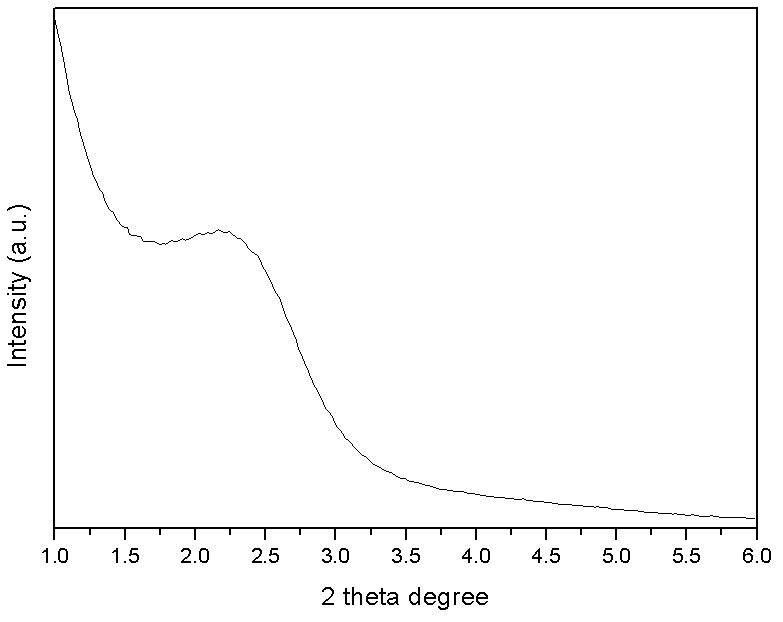

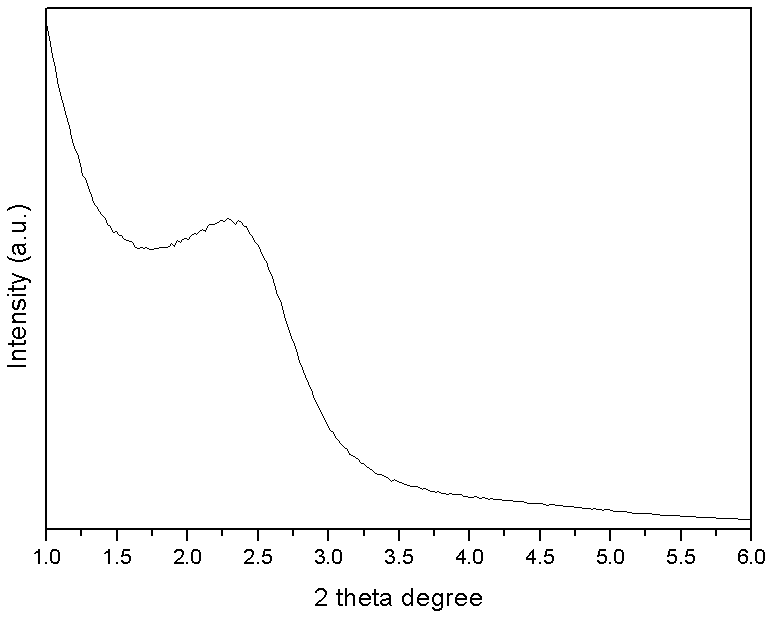

ActiveCN103121932BIncrease profitIncreased focus capacityMolecular sieve catalystsOrganic compound preparationReaction temperatureKetone

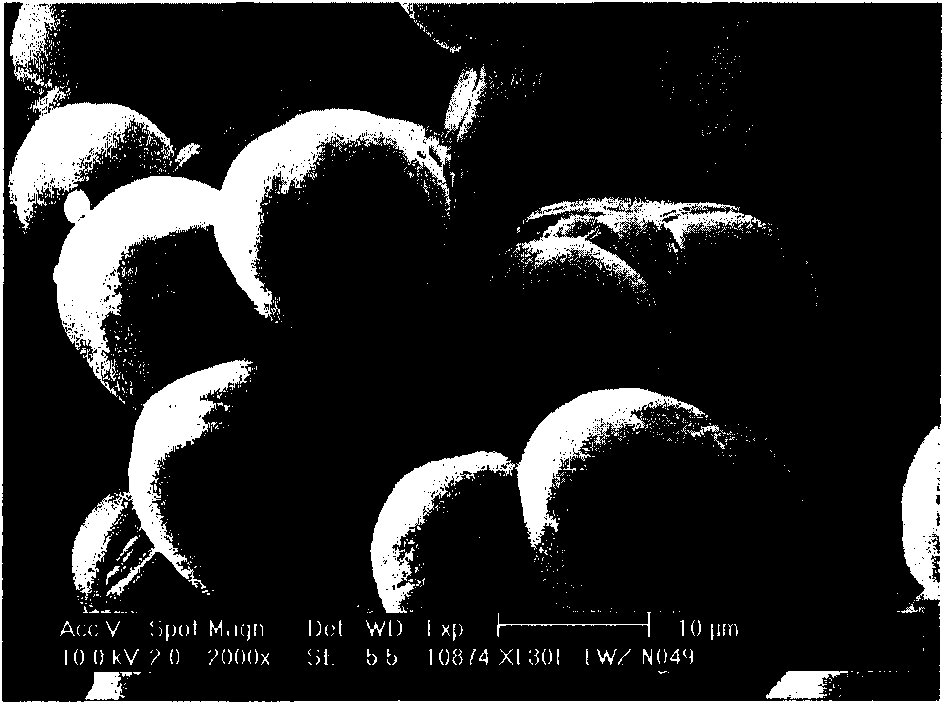

The invention relates to a catalytic dehydrating preparation method of 4-hexen-3-ketone by 4- hydroxy-3-hexanone and solves problems of low catalytic activity, high reaction temperature and low airspeed in the prior art. The 4- hydroxy-3-hexanone is adopted as a raw material, on conditions that reaction temperature ranges from 200 DEG C to 400 DEG C and the airspeed of 4- hydroxy-3-hexanone liquid quality is 0.5-15 hour -1, the raw material is contacted with a catalyst to form the 4-hexen-3-ketone. The grain diameter of the catalyst is < / = 5 micron, the catalyst is provided with zeolite ZSM-11 with mesopores and micropores, and the values of pore volumes of the mesopores and micropores of the zeolite ZSM-11 are 1.5-10. According to the technical scheme, the catalytic dehydrating preparation method solves the problems effectively and can be used in industrial production of 4-hexen-3-ketone by 4- hydroxy-3-hexanone.

Owner:CHINA PETROLEUM & CHEM CORP +1

4-hydroxyl-3-hexanone catalytic dehydration method

ActiveCN103121933AIncrease profitIncreased focus capacityMolecular sieve catalystsOrganic compound preparationLow activityReaction temperature

The invention relates to a 4-hydroxyl-3-hexanone catalytic dehydration method and mainly aims to solve the problems of a catalyst in the prior art, such as low activity, high reaction temperature and low space velocity. According to the technical scheme, 4-hydroxyl-3-hexanone serving as a raw material comes into contact with a catalyst to generate 4-hexylene-3-hexanone under the conditions that the reaction temperature ranges from 200 DEG C to 400 DEG C and the liquid mass space velocity relative to the 4-hydroxyl-3-hexanone is equal to 0.5-15h<-1>, wherein the used catalyst has the crystal grain diameter being at most 5mm, and has ZSM-5 zeolite with mesopores and micropores, and the ratio of the volume of the mesopores to the volume of the micropores in the ZSM-5 zeolite is equal to 1.5-10. The problems in the prior art can be well solved by adoption of the technical scheme. The 4-hydroxyl-3-hexanone catalytic dehydration method can be used for industrial production of 4-hexylene-3-hexanone prepared by using the 4-hydroxyl-3-hexanone.

Owner:CHINA PETROLEUM & CHEM CORP +1

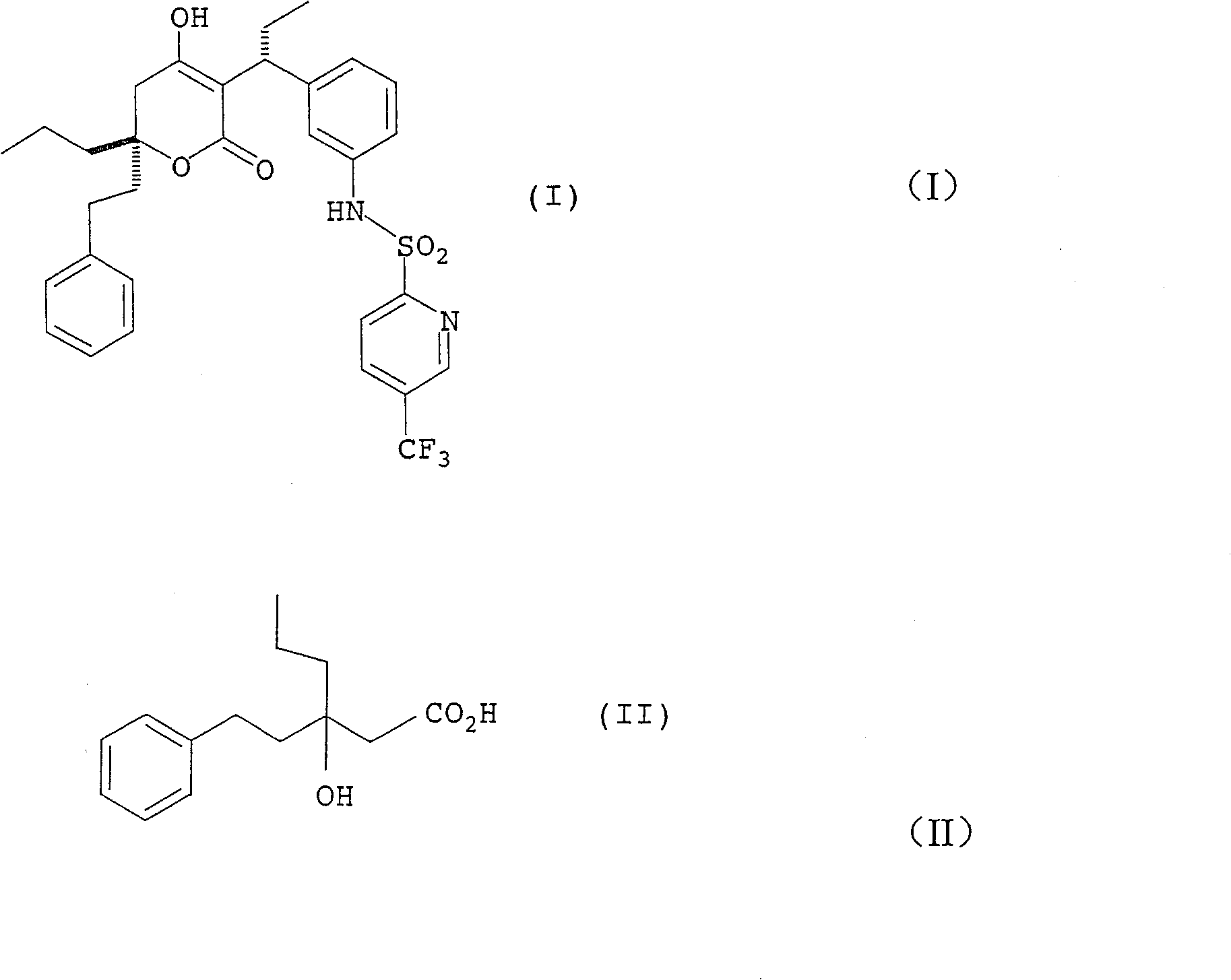

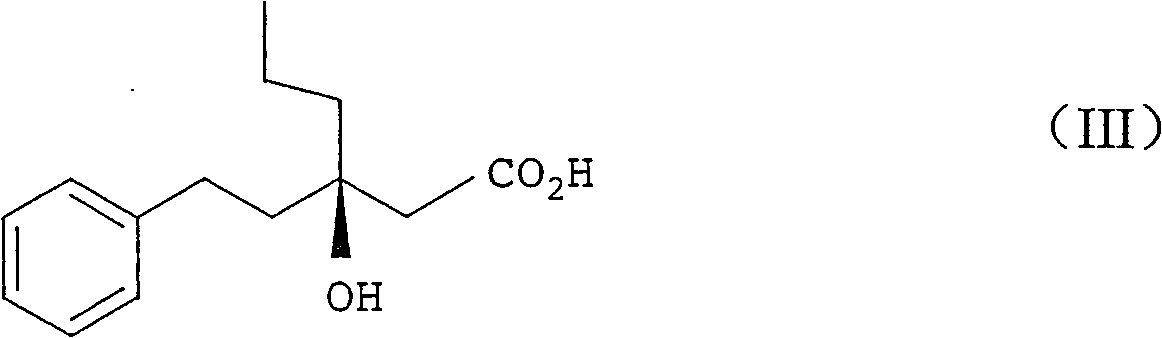

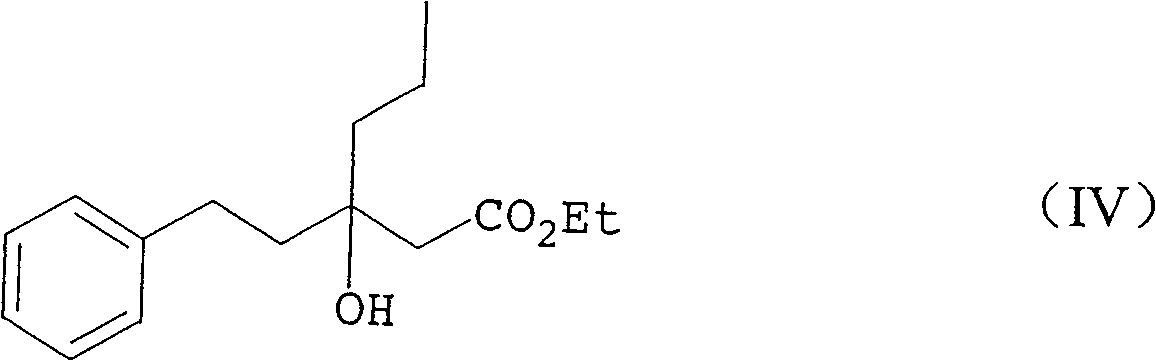

Production method of racemiation3-hydroxy-3- (2-phenylethyl) hexanoic acid C1-6 alkyl ester

InactiveCN100528828COrganic compound preparationCarboxylic acid esters preparationPhenyl groupHydroxy group

The present invention relates to a kind of production method of racemic 3-hydroxyl-3-(2-phenylethyl)hexanoic acid C1-6 alkyl ester, which comprises magnesium, haloacetate C1-6 alkyl ester and 1- Phenyl-3-hexanone reaction.

Owner:SUMITOMO CHEM CO LTD

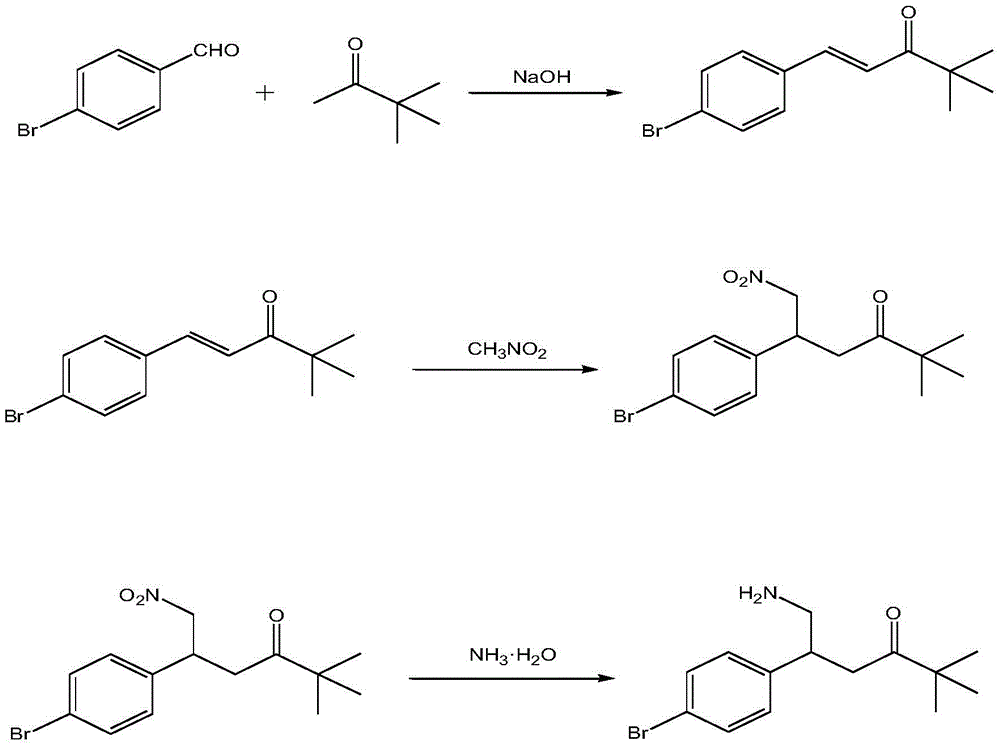

Synthesis method for 2,2-dimethyl-5-(4-bromophenyl)-6-amino-3-hexanone

InactiveCN105461578AOrganic compound preparationCarbonyl compound preparationCalcium hydroxideIce water

The invention relates to a synthesis method for a compound, in particular to a synthesis method for 2,2-dimethyl-5-(4-bromophenyl)-6-amino-3-hexanone. According to the method, pinacolone and sodium hydroxide serve as raw materials and react with bromobenzaldehyde, an ethanol solution is added dropwise, an ice-water bath is conducted on precipitate, the precipitate reacts with nitromethane, finally, ammonium hydroxide is added for ammoniation, drying is conducted after ice segregation, and 2,2-dimethyl-5-(4-bromophenyl)-6-amino-3-hexanone is obtained. According to the method, reaction conditions are mild, and the yield is high.

Owner:CHANGZHOU UNIV

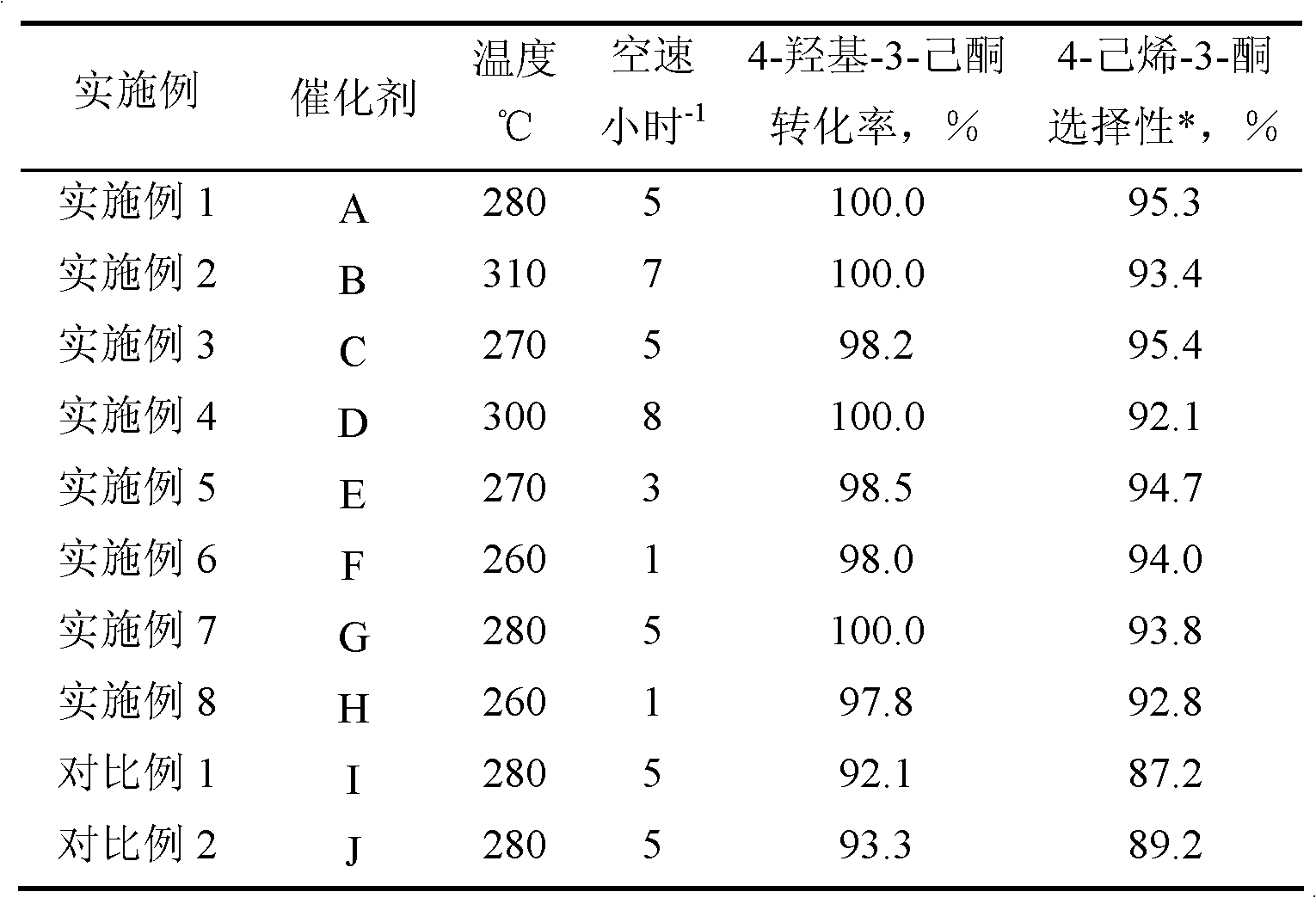

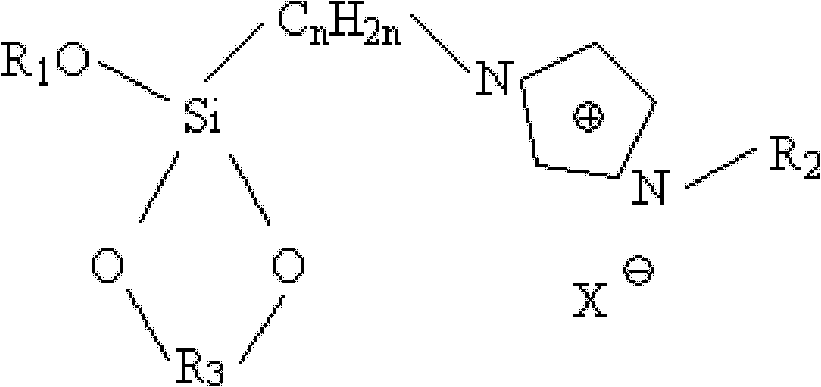

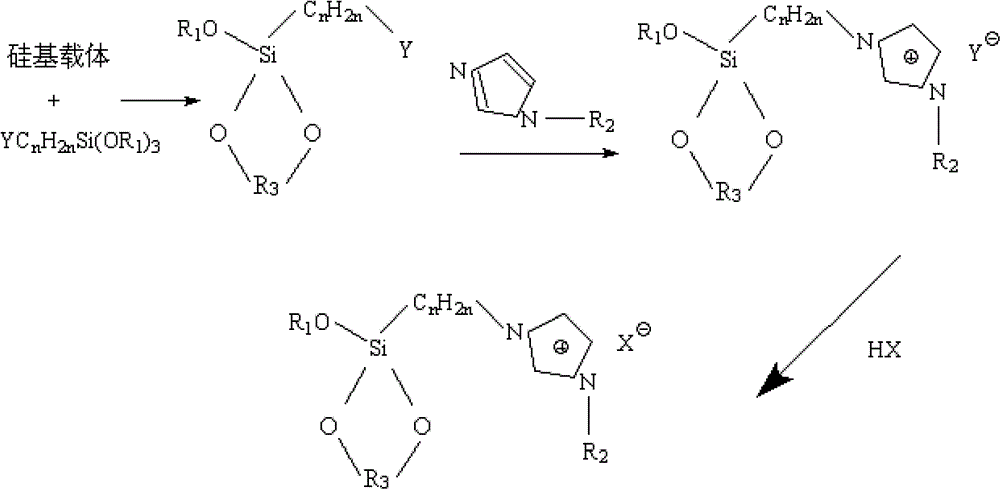

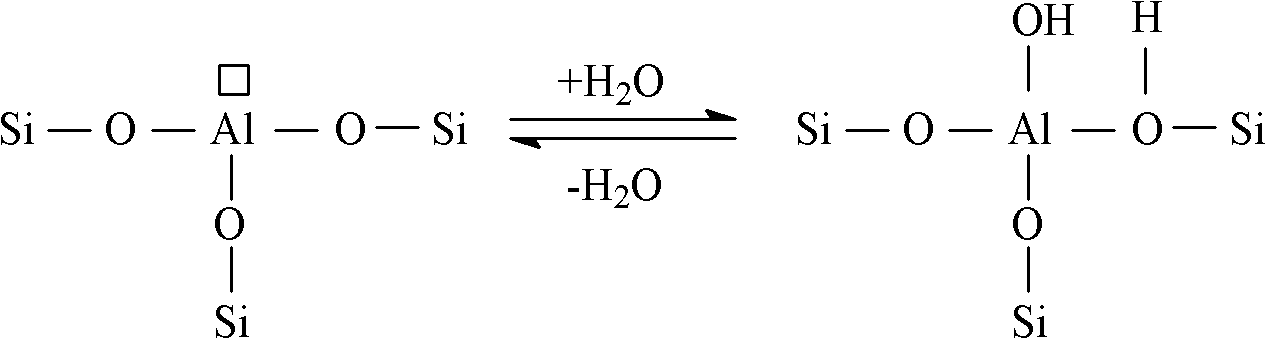

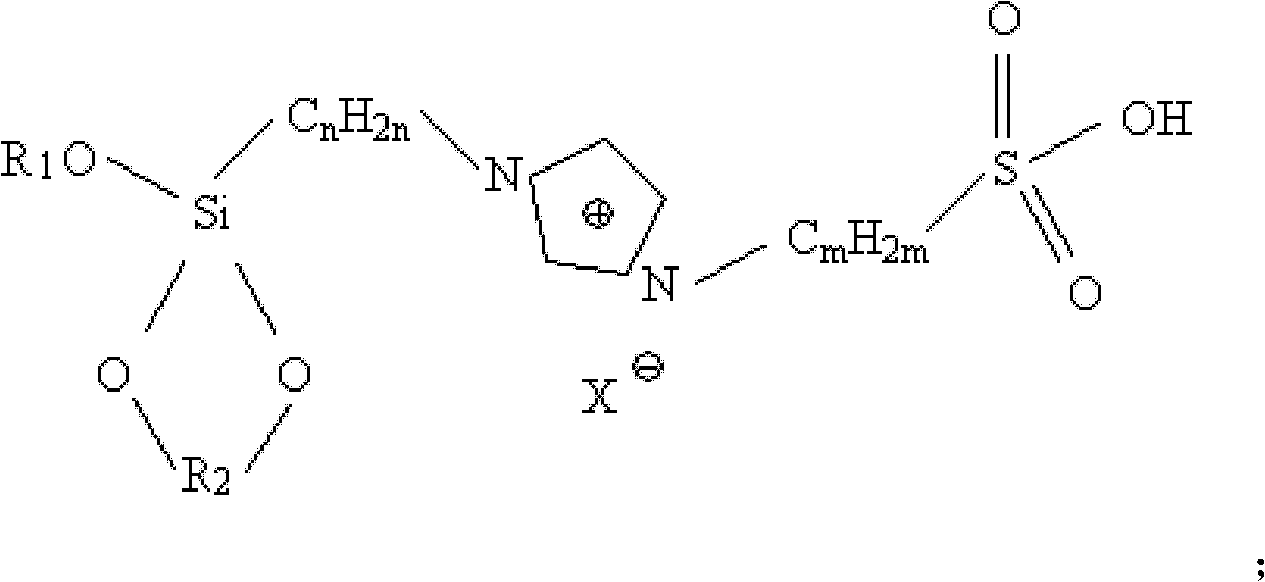

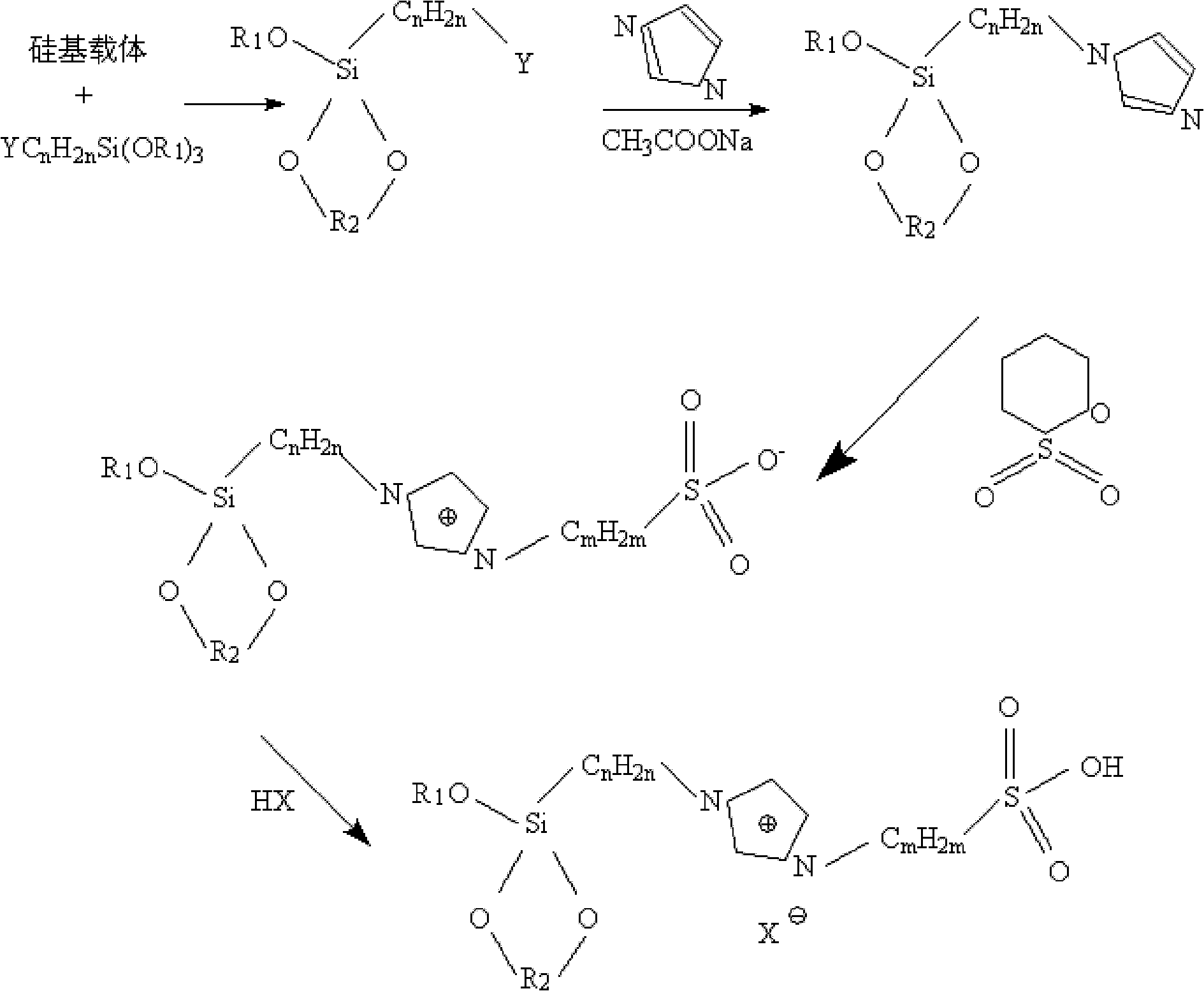

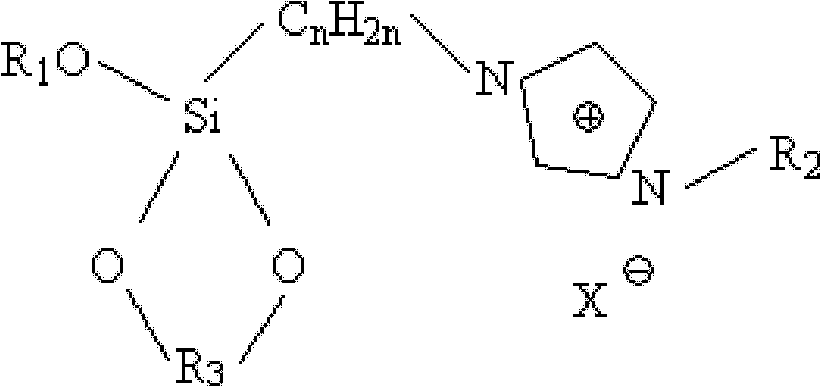

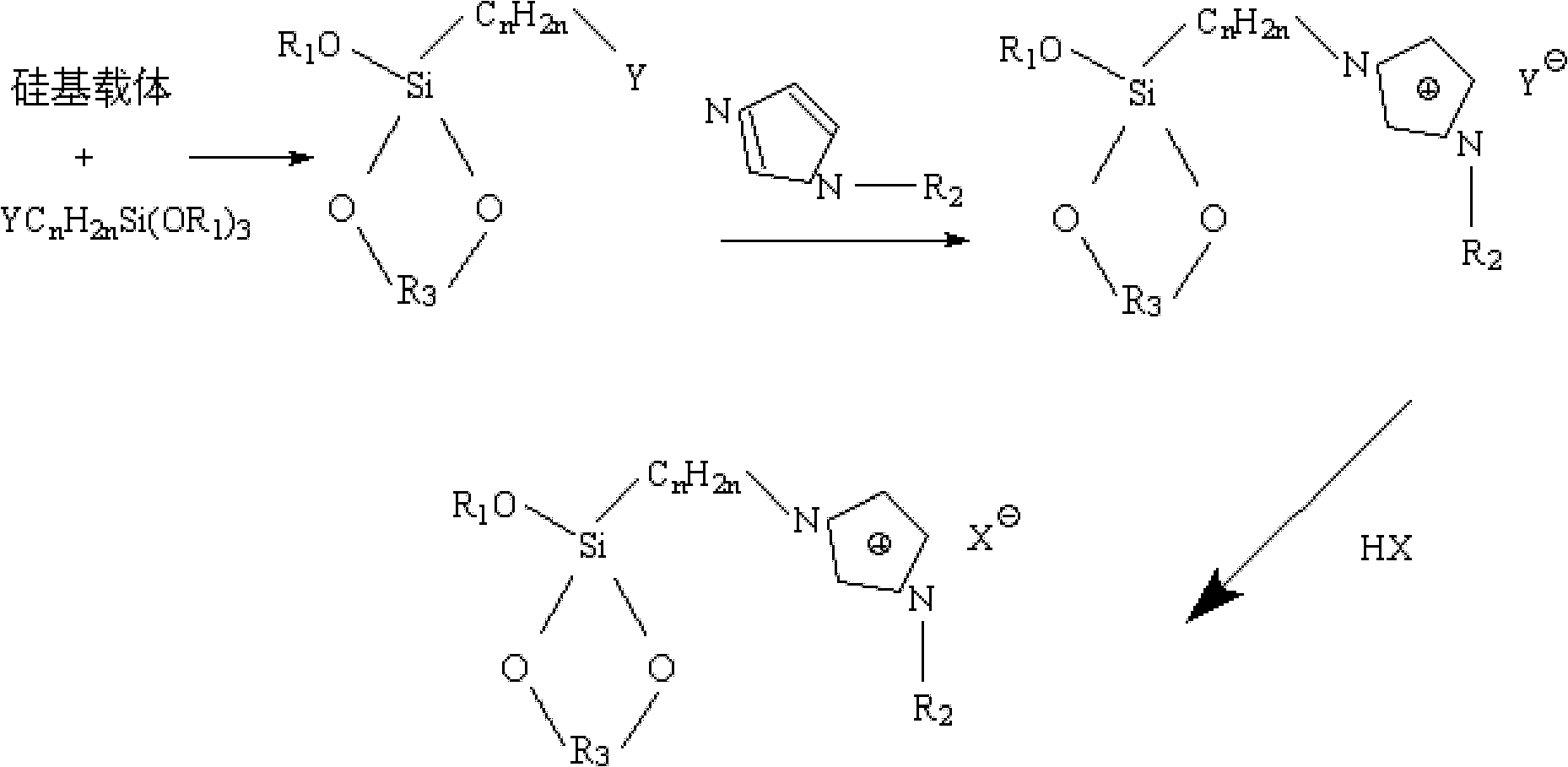

Method for catalytic dehydration of 4-hydroxy-3-hexanone

ActiveCN102875346BOrganic compound preparationCarbonyl compound preparationReaction temperatureKetone

The invention relates to a catalytic dehydration method of 4-hydroxyl-3-hexanone, mainly solving the problems of low catalyst activity, high reaction temperature, and low space velocity in the prior art. The method disclosed herein is characterized by using 4-hydroxyl-3-hexanone as a raw material, contacting the raw material with a catalyst to generate 4-hexene-3-ketone under the reaction conditions comprising a reaction temperature being 150-400 DEG C and a space velocity relative to the liquid mass of 4-hexene-3-ketone being 0.5-15h<-1>, wherein the catalyst is represented by the following structural formula. The method disclosed herein well solves the problems and can be applied in the industrial production of preparing 4-hexene-3-ketone from 4-hydroxyl-3-hexanone.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of 4-hexene-3-ketone by virtue of dehydration of 4-hydroxy-3-hexanone

ActiveCN103058838BIncrease profitIncreased focus capacityMolecular sieve catalystsOrganic compound preparationMolecular sieveReaction temperature

The invention relates to a preparation method of 4-hexene-3-ketone by virtue of dehydration of 4-hydroxy-3-hexanone, and the method is mainly used for solving the problems in the prior art that the catalyst activity is low, the reaction temperature is high and the space velocity is low. The technical scheme adopted by the invention is as follows: according to the preparation method, 4-hydroxy-3-hexanone which is used as a raw material, is contacted with a catalyst so as to generate 4-hexene-3-ketone under the condition that the reaction temperature is 200-400 DEG C, and the space velocity relative to the liquid weight of 4-hexene-3-ketone is 0.5-15h<-1>, wherein the catalyst comprises the following components in parts by weight: a), 40-95 parts of ZSM-11 molecular sieve with the silicon aluminum mole ratio (SiO2 / Al2O3) of 20-300 and the crystal particle diameter of equal to or less than 5 microns and b), 5-6 parts of binding agent, and the ZSM-11 molecular sieve is at least subjected to once acid pickling, so that the problems in the prior art are better solved, and the method can be used in the industrial production of 4-hexene-3-ketone prepared by utilizing 4-hydroxy-3-hexanone.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method of catalytic dehydration by 4-hydroxyl-3-hexanone

The invention relates to a method of catalytic dehydration by 4-hydroxyl-3-hexanone and mainly solves the problem that catalysts are low in activity, high in reaction temperature and low in space velocity in the prior art. The 4-hydroxyl-3-hexanone is used as material to contact with catalyst at the reaction temperature of 200 DEG C-400 DEG C at the weight hourly space velocity of 0.5-15 hours-1 relative to the 4-hydroxyl-3-hexanone so as to generate 4-hexene-3-one. The catalyst is molecular sieve ZSM-11(zeolite socony mobil-11) not larger than 5 micrometers in grain diameter. The problem is solved well by the application of the technical scheme. The method is applicable to industrial production of 4-hexene-3-one by catalytic dehydration of 4-hydroxyl-3-hexanone.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing 4-hexene-3-one by dehydration of 4-hydroxyl-3-hexanone

ActiveCN103121931BIncrease the effective surface areaEffective surface area reductionMolecular sieve catalystsOrganic compound preparationReaction temperatureKetone

The invention relates to a method for producing 4-hexene-3-one by dehydration of 4-hydroxyl-3-hexanone and mainly solves the problem that catalysts are low in activity, low in reaction temperature and low in space velocity in the prior art. The 4-hydroxyl-3-hexanone is used as material to contact with catalyst at the reaction temperature of 200 DEG C-400 DEG C at the weight hourly space velocity of 0.5-15 hours-1 relative to the 4-hydroxyl-3-hexanone so as to generate 4-hexene-3-one. The catalyst is adhesive-free ZSM-5 (zeolite socony mobil-5). The problem is solved well by the application of the technical scheme. The method is applicable to industrial production of 4-hexene-3-one by 4-hydroxyl-3-hexanone.

Owner:CHINA PETROLEUM & CHEM CORP +1

Synthesis method of 3,4-hexanedione

InactiveUS10160710B2Organic compound preparationPreparation by ozonolysisAcetic acidSynthesis methods

A synthesis method of 3,4-hexanedione comprises a step of 4-hydroxy-3-hexanonen oxidation, and in the step of 4-hydroxy-3-hexanonen oxidation, water is used as a catalyst, acetic acid is used as a cocatalyst, and ozone is used as an oxidizing agent to carry out an oxidation reaction on 4-hydroxy-3-hexanonen, and after the reaction, distillation under reduced pressure is carried out to obtain the 3,4-hexanedione. According to the synthesis method of 3,4-hexanedione in the invention, in the process of 4-hydroxy-3-hexanone oxidation, the 4-hydroxy-3-hexanone is placed in the water, the ozone is used for oxidation on the 4-hydroxy-3-hexanone, and the acetic acid is used as the cocatalyst, so that the entire oxidation reaction process is mild in conditions and simple to operate, no sewage is produced when the final product (3,4-hexanedione) is obtained, and the yield is greatly increased.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Method for producing 4-hexene-3-ketone by carrying out catalytic dehydration on 4-hydroxy-3-hexanone

InactiveCN103030546APhysical/chemical process catalystsOrganic compound preparationReaction temperatureKetone

The invention relates to a method for producing 4-hexene-3-ketone by carrying out catalytic dehydration on 4-hydroxy-3-hexanone, mainly aiming at solving the problems of low catalyst activity, high reaction temperature and slow space velocity in the prior art. The method takes the 4-hydroxy-3-hexanone as raw material, and can be used for producing the 4-hexene-3-ketone by enabling the reaction raw material to be contacted with catalyst under the conditions that the reaction temperature is 200-400 DEG C and the space velocity relative to the mass of the 4-hydroxy-3-hexanone liquid is 0.5-15h<-1>, wherein the catalyst comprises the components in parts by weight: a) 1-99 parts of SiO2 inner core, and b) 1-99 parts of Al2O3 surface coating. The technical scheme better solves the problems, and can be used in the industrial production of the 4-hexene-3-ketone prepared by the 4-hydroxy-3-hexanone.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method of 4-hydroxy-3-hexanone catalytic dehydration

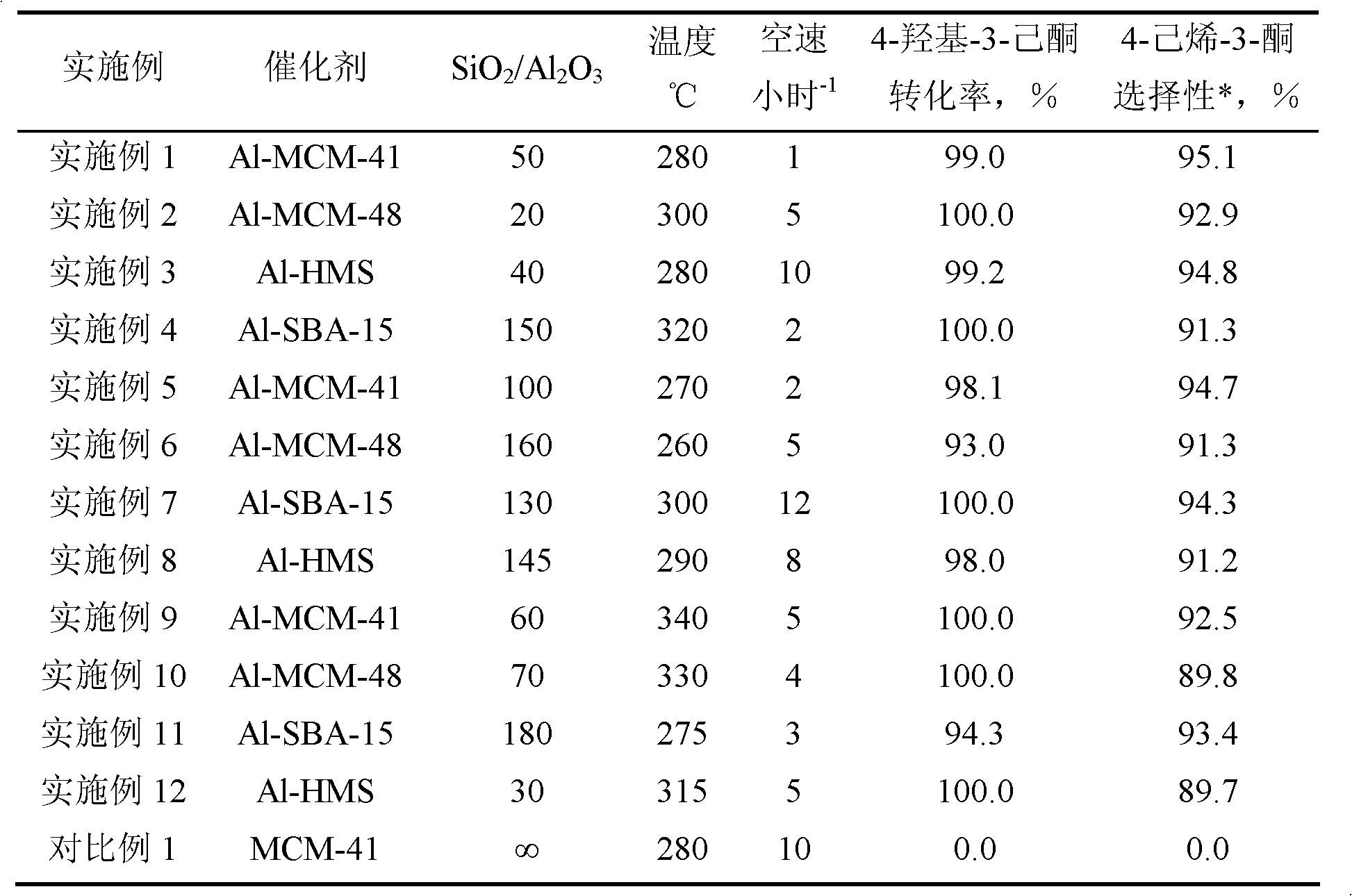

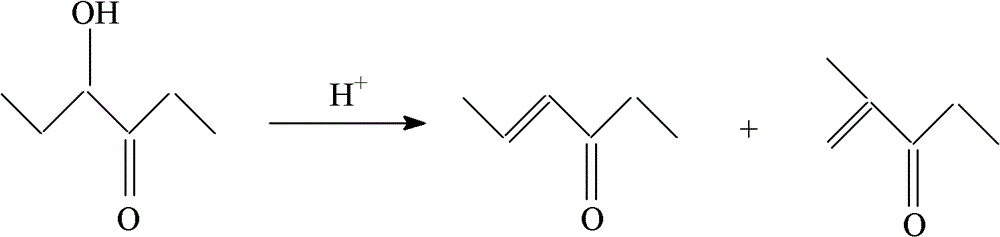

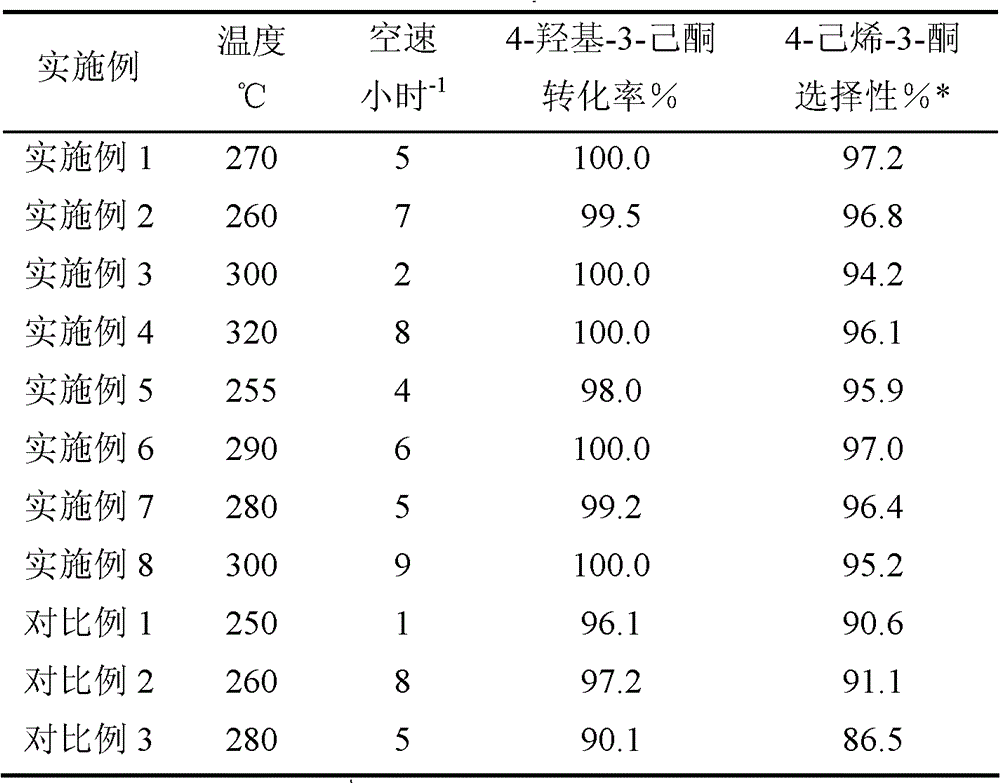

InactiveCN103030540AHigh activityRaise the reaction temperatureMolecular sieve catalystsOrganic compound preparationReaction temperatureKetone

The present invention relates to a method of 4-hydroxy-3-hexanone catalytic dehydration, and mainly solves the problem of low catalyst activity, high reaction temperature and low space velocity in the prior art. According to the invention, 4-hydroxy-3-hexanone is used as a raw material, and the reaction raw material is in contact with a catalyst to produce 4-hexen-3-one at the conditions of a reaction temperature of 200-400 DEG C and the space velocity of 0.5-15 hr-1 with respect to the mass of 4-hydroxy-3-hexanone liquid, wherein the catalyst is at least one selected from the group consisting of Al-MCM-41, Al-MCM-48, Al-SBA-15, Al-HMS, Al-MSU-1 or Al-MSU-2. The technical solution solves the problem preferably. The method can be used in the industrial production of 4-hexen-3-one from 4-hydroxy-3-hexanone.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing 4-hexene-3-one by dehydration of 4-hydroxyl-3-hexanone

ActiveCN103121929BIncrease the effective surface areaEffective surface area reductionMolecular sieve catalystsOrganic compound preparationMolecular sieveReaction temperature

The invention relates to a method for producing 4-hexene-3-one by dehydration of 4-hydroxyl-3-hexanone and mainly solves the problem that catalysts are low in activity, high in reaction temperature and low in space velocity in the prior art. The 4-hydroxyl-3-hexanone is used as material to contact with catalyst at the reaction temperature of 200 DEG C-400 DEG C at weight hourly space velocity of 0.5-15 hours-1 relative to the 4-hydroxyl-3-hexanone so as to generate 4-hexene-3-one. The catalyst is molecular sieve ZSM-11 (zeolite socony mobil-11). The problem is solved well by the application of the technical scheme. The method is applicable to industrial production of 4-hexene-3-one by 4-hydroxyl-3-hexanone.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing 4-hexene-3-one by dehydration of 4-hydroxyl-3-hexanone

ActiveCN103121931AIncrease the effective surface areaEffective surface area reductionMolecular sieve catalystsOrganic compound preparationReaction temperatureKetone

The invention relates to a method for producing 4-hexene-3-one by dehydration of 4-hydroxyl-3-hexanone and mainly solves the problem that catalysts are low in activity, low in reaction temperature and low in space velocity in the prior art. The 4-hydroxyl-3-hexanone is used as material to contact with catalyst at the reaction temperature of 200 DEG C-400 DEG C at the weight hourly space velocity of 0.5-15 hours-1 relative to the 4-hydroxyl-3-hexanone so as to generate 4-hexene-3-one. The catalyst is adhesive-free ZSM-5 (zeolite socony mobil-5). The problem is solved well by the application of the technical scheme. The method is applicable to industrial production of 4-hexene-3-one by 4-hydroxyl-3-hexanone.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing 4-hexene-3-ketone by catalytic dehydration of 4-hydroxyl-3-hexanone

ActiveCN102875345AAvoid churnImprove bindingOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsReaction temperatureKetone

The invention relates to a method for preparing 4-hexene-3-ketone by the catalytic dehydration of 4-hydroxyl-3-hexanone, mainly solving the problems of low catalyst activity, high reaction temperature, and low space velocity in the prior art. The method disclosed herein is characterized by using 4-hydroxyl-3-hexanone as a raw material, contacting the raw material with a catalyst to generate 4-hexene-3-ketone under the reaction conditions comprising a reaction temperature being 150-400 DEG C and a space velocity relative to the liquid mass of 4-hexene-3-hexanone being 0.5-15h<-1>, wherein the catalyst is represented by the following structural formula. The method disclosed herein well solves the problems and can be applied in the industrial production of preparing 4-hexene-3-ketone from 4-hydroxyl-3-hexanone.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing 4-hexene-3-ketone by carrying out catalytic dehydration on 4-hydroxy-3-hexanone

InactiveCN103030547AImprove technical effectMolecular sieve catalystsOrganic compound preparationReaction temperatureMCM-41

The invention relates to a method for preparing 4-hexene-3-ketone by carrying out catalytic dehydration on 4-hydroxy-3-hexanone, mainly aiming at solving the problems of low catalyst activity, high reaction temperature and slow space velocity in the prior art. The method takes the 4-hydroxy-3-hexanone as raw material, and can be used for producing the 4-hexene-3-ketone by enabling the reaction raw material to be contacted with catalyst under the conditions that the reaction temperature is 200-400 DEG C and the space velocity relative to the mass of the 4-hydroxy-3-hexanone liquid is 0.5-15h<-1>, wherein the catalyst comprises the components in parts by weight: a) 1-99 parts of pure silicon molecular sieve which is at least one selected from MCM-41, MCM-48, SBA-15, HMS, Silicate-1 or Silicate-2, and b) 1-99 parts of Al2O3 surface coating. The technical scheme better solves the problems, and can be used in the industrial production of the 4-hexene-3-ketone prepared by the 4-hydroxy-3-hexanone.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing 4-hexen-3-one by dehydration of 4-hydroxyl-3-hexanone

ActiveCN103030543BShort diffusion pathMolecular sieve catalystsOrganic compound preparationTetramethylammonium hydroxideReaction temperature

The invention relates to a method for preparing 4-hexene-3-ketone by carrying out dehydration on 4-hydroxy-3-hexanone, mainly aiming at solving the problems of low catalyst activity, high reaction temperature and slow space velocity in the prior art. The catalyst used by the method is prepared by the following steps of: mixing a silicon source, an aluminium source, template agent R1, template agent R2 and water, and adjusting the pH of the reaction mixture to be 8-14 with inorganic base; in the reaction mixture, controlling the molar ratio between Al2O3 and SiO2 to be 0.003-0.05, controlling the molar ratio of R1 to SiO2 to be 0.1-2, controlling the molar ratio of H2O to SiO2 to be 10-100 and controlling the molar ratio of R2 to SiO2 to be 0.05-2; and carrying out hydrothermal crystallization on the mixture for 1-10 days at the temperature of 100-250 DEG C to obtain the catalyst, wherein R1 comprises at least one selected from tetramethyl ammonium hydroxide, tetraethyl ammonium hydroxide, tetrapropyl ammonium hydroxide or tetrabutyl ammonium hydroxide, and R2 comprises at least one selected from beta-diketone, beta-diketone salt, oxalic acid, oxalate, catechol or 8-hydroxyquinoline. The technical scheme better solves the problems, and can be used in the industrial production of the 4-hexene-3-ketone prepared by the 4-hydroxy-3-hexanone.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic dehydration method of 4-hydroxy-3-hexanone

ActiveCN103121933BIncrease profitIncreased focus capacityMolecular sieve catalystsOrganic compound preparationLow activityReaction temperature

The invention relates to a 4-hydroxyl-3-hexanone catalytic dehydration method and mainly aims to solve the problems of a catalyst in the prior art, such as low activity, high reaction temperature and low space velocity. According to the technical scheme, 4-hydroxyl-3-hexanone serving as a raw material comes into contact with a catalyst to generate 4-hexylene-3-hexanone under the conditions that the reaction temperature ranges from 200 DEG C to 400 DEG C and the liquid mass space velocity relative to the 4-hydroxyl-3-hexanone is equal to 0.5-15h<-1>, wherein the used catalyst has the crystal grain diameter being at most 5mm, and has ZSM-5 zeolite with mesopores and micropores, and the ratio of the volume of the mesopores to the volume of the micropores in the ZSM-5 zeolite is equal to 1.5-10. The problems in the prior art can be well solved by adoption of the technical scheme. The 4-hydroxyl-3-hexanone catalytic dehydration method can be used for industrial production of 4-hexylene-3-hexanone prepared by using the 4-hydroxyl-3-hexanone.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of 4-hexene-3-ketone by virtue of dehydration of 4-hydroxy-3-hexanone

ActiveCN103058838AIncrease profitIncreased focus capacityMolecular sieve catalystsOrganic compound preparationMolecular sieveReaction temperature

The invention relates to a preparation method of 4-hexene-3-ketone by virtue of dehydration of 4-hydroxy-3-hexanone, and the method is mainly used for solving the problems in the prior art that the catalyst activity is low, the reaction temperature is high and the space velocity is low. The technical scheme adopted by the invention is as follows: according to the preparation method, 4-hydroxy-3-hexanone which is used as a raw material, is contacted with a catalyst so as to generate 4-hexene-3-ketone under the condition that the reaction temperature is 200-400 DEG C, and the space velocity relative to the liquid weight of 4-hexene-3-ketone is 0.5-15h<-1>, wherein the catalyst comprises the following components in parts by weight: a), 40-95 parts of ZSM-11 molecular sieve with the silicon aluminum mole ratio (SiO2 / Al2O3) of 20-300 and the crystal particle diameter of equal to or less than 5 microns and b), 5-6 parts of binding agent, and the ZSM-11 molecular sieve is at least subjected to once acid pickling, so that the problems in the prior art are better solved, and the method can be used in the industrial production of 4-hexene-3-ketone prepared by utilizing 4-hydroxy-3-hexanone.

Owner:CHINA PETROLEUM & CHEM CORP +1

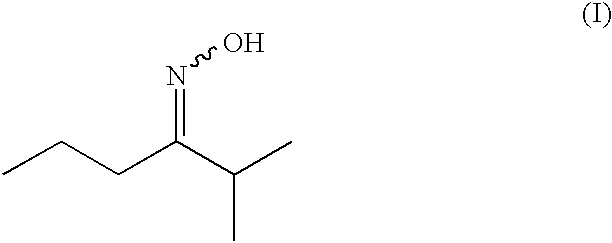

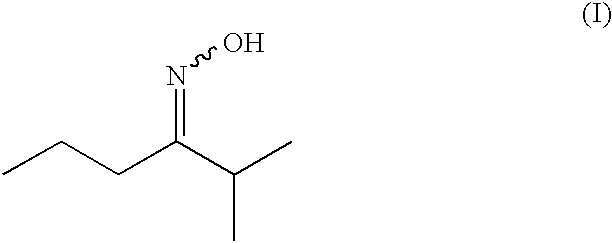

Oxime as perfuming ingredient

InactiveUS6872697B2Impart enhance modify odor propertyCosmetic preparationsToilet preparationsAdditive ingredientMethyl group

The present invention relates to the use as a perfuming ingredient of 2-methyl-3-hexanone-oxime of formula in which the wavy line represents a bond having a configuration of the type (Z) or (E) or a mixture of the two configurations.

Owner:FIRMENICH SA

Catalytic dehydration method of 4-hydroxyl-3-hexanone

ActiveCN102875346AAvoid churnImprove bindingOrganic compound preparationCarbonyl compound preparationReaction temperatureStructural formula

The invention relates to a catalytic dehydration method of 4-hydroxyl-3-hexanone, mainly solving the problems of low catalyst activity, high reaction temperature, and low space velocity in the prior art. The method disclosed herein is characterized by using 4-hydroxyl-3-hexanone as a raw material, contacting the raw material with a catalyst to generate 4-hexene-3-ketone under the reaction conditions comprising a reaction temperature being 150-400 DEG C and a space velocity relative to the liquid mass of 4-hexene-3-ketone being 0.5-15h<-1>, wherein the catalyst is represented by the following structural formula. The method disclosed herein well solves the problems and can be applied in the industrial production of preparing 4-hexene-3-ketone from 4-hydroxyl-3-hexanone.

Owner:CHINA PETROLEUM & CHEM CORP +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com