Method for preparing 4-hexene-3-ketone by 4-hydroxy-3-hexanone hydration

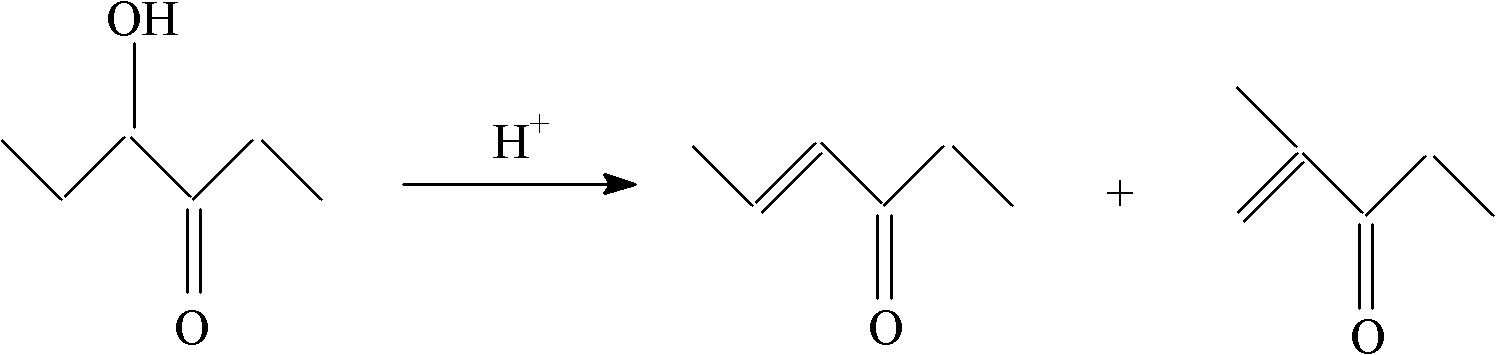

A technology of hexanone and hydroxyl, applied in the field of producing 4-hexen-3-one, which can solve the problems of poor catalyst activity, high reaction temperature, and low space velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

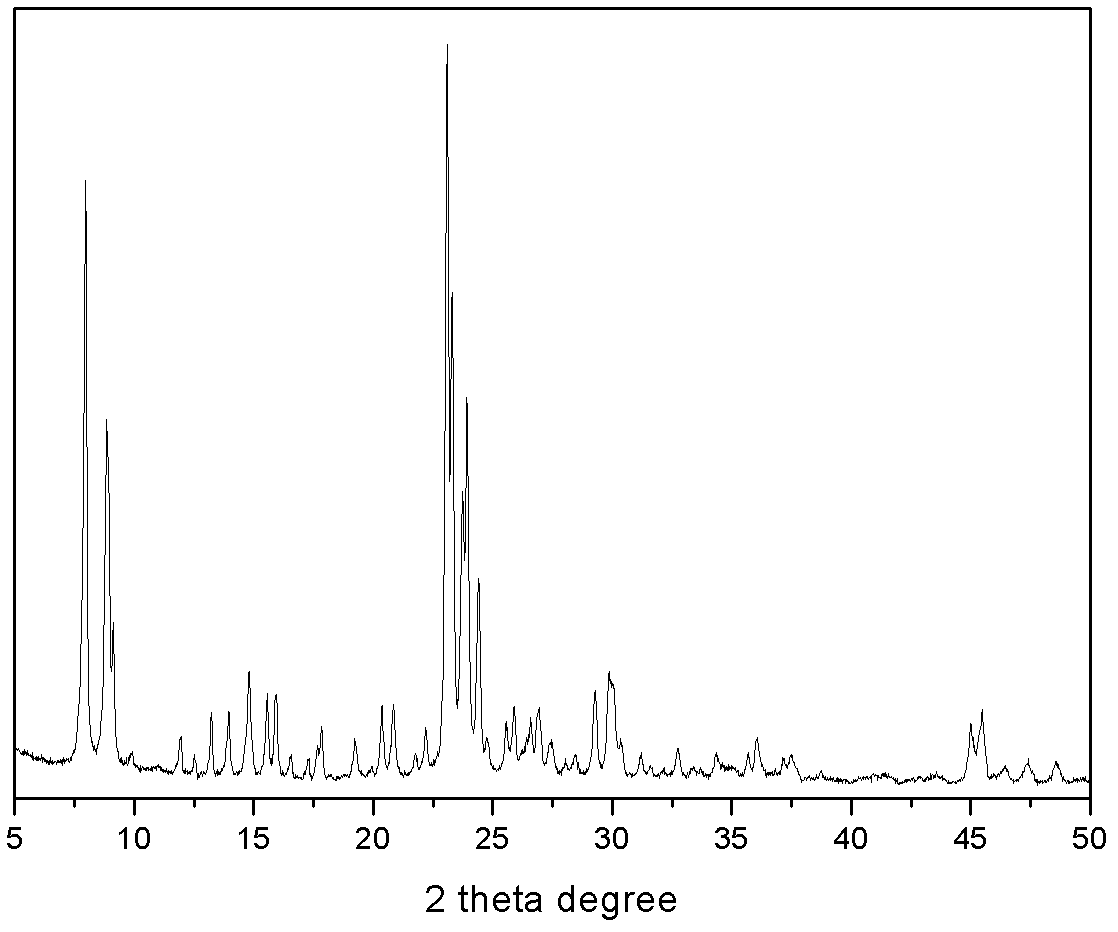

[0018] by SiO 2 : Al 2 o 3 :OH - :Cl - :H 2 O=1:0.017:0.2:0.1:30. Weigh each material, dissolve sodium aluminate in distilled water, add dropwise silica sol, stir for 1 hour, add dropwise sodium chloride aqueous solution, stir for 1 hour, add dropwise sodium hydroxide aqueous solution, and continue stirring for 5 hours. The resulting mixture was crystallized under hydrothermal conditions at 100°C for 10 hours, then crystallized under hydrothermal conditions at 170°C for 24 hours, washed, filtered and dried, then exchanged with ammonium, dried and calcined to obtain the catalyst. XRD spectrum see figure 1 , SEM photo see figure 2 .

[0019] The performance evaluation of the catalyst was carried out on a fixed-bed reaction device at normal pressure. A stainless steel reactor with an inner diameter of 10 mm was used. The loading amount of the catalyst was 10 ml, the reaction temperature was 350 °C, and the liquid space velocity was 1 hour. -1 , reacted under normal pres...

Embodiment 2

[0021] by SiO 2 : Al 2 o 3 :OH - :Cl - :H 2 O=1:0.01:0.25:0.2:41. Weigh each material, dissolve aluminum sulfate in distilled water, add dropwise silica sol, stir for 1 hour, add dropwise potassium chloride aqueous solution, stir for 1 hour, add dropwise potassium hydroxide aqueous solution, and continue stirring for 5 hours. The resulting mixture was crystallized under hydrothermal conditions of 90°C for 12 hours, and then crystallized under hydrothermal conditions of 180°C for 40 hours, washed, filtered, dried, exchanged with ammonium, dried, and roasted to obtain the catalyst. The grain size was 2.1 microns.

[0022] Catalyst performance evaluation is the same as [Example 1]. The reaction conditions and reaction results are shown in Table 1.

Embodiment 3

[0024] by SiO 2 : Al 2 o 3 :OH - :Cl - :H 2 O=1:0.03:0.28:0.4:60. Weigh each material, dissolve aluminum nitrate in distilled water, add dropwise silica sol, stir for 1 hour, add dropwise potassium chloride aqueous solution, stir for 1 hour, add dropwise potassium hydroxide aqueous solution, and continue stirring for 5 hours. The resulting mixture was crystallized under hydrothermal conditions of 80°C for 12 hours, and then crystallized under hydrothermal conditions of 150°C for 50 hours, washed, filtered and dried, then exchanged with ammonium, dried and calcined to obtain the catalyst. The grain size is 1.8 microns.

[0025] Catalyst performance evaluation is the same as [Example 1]. The reaction conditions and reaction results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com