A kind of coating latex for preparing foam composite paper

A latex and coating technology, which is applied in the field of latex coating, can solve the problems of foam layer damage and dense foam points, etc., and achieve good printing effect and visual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

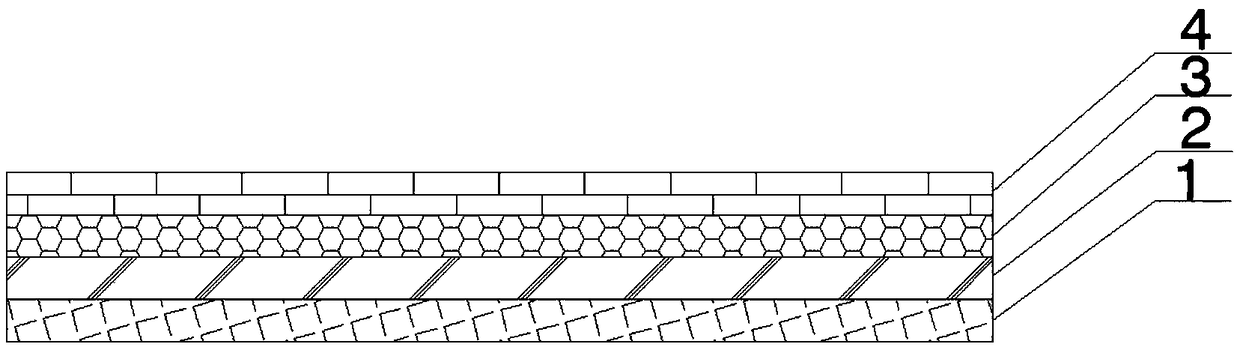

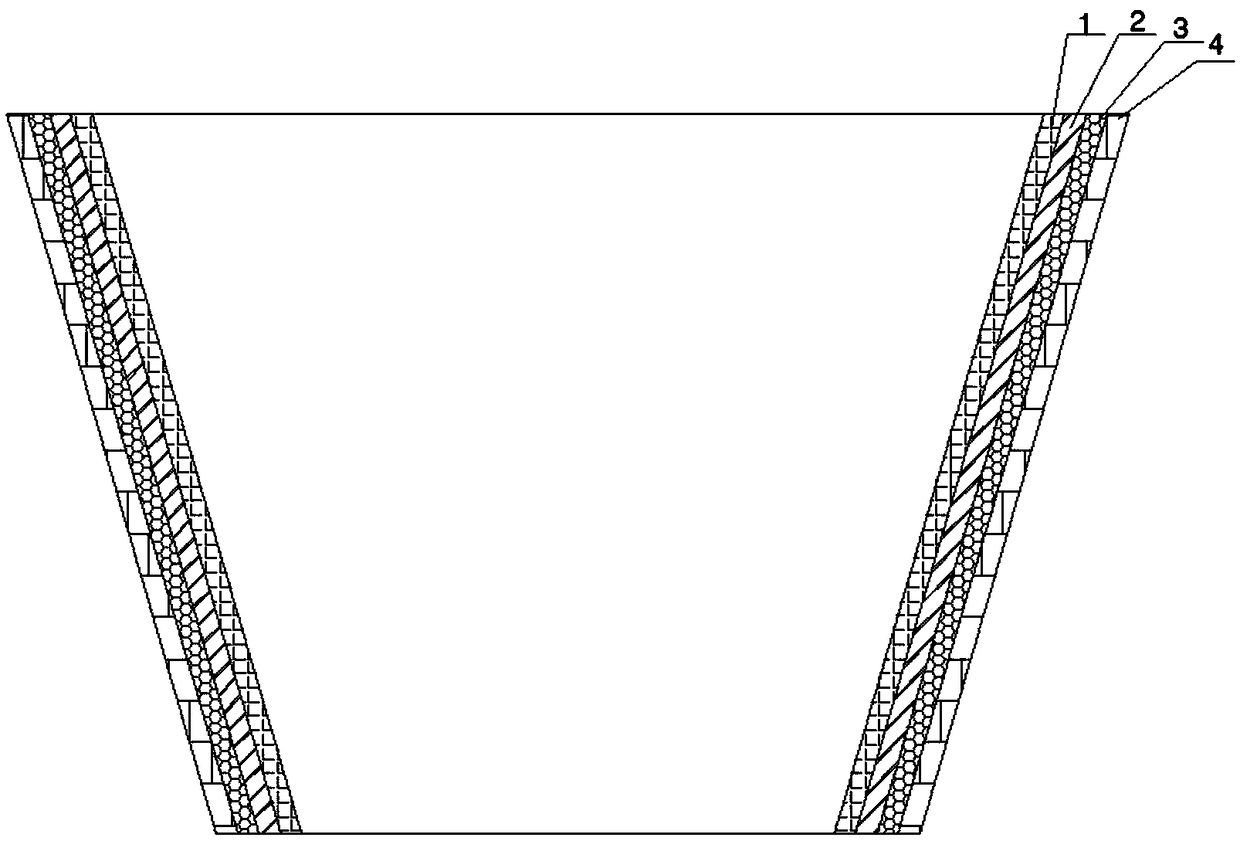

[0022] like figure 1 and figure 2 As shown, it is a new type of foam composite paper, including the first barrier layer 1 composed of medium-density polyethylene MDPE, the second layer of food-grade packaging paper layer 2, and the third layer composed of low-density polyethylene LDPE The foam layer 3, the fourth layer is a coating layer 4 made of coated latex, and the coating layer 4 is coated on the outside of the third foam layer 3 by using a gravure printing process. Wherein the coating layer 4 includes acrylate polymer (Henkel V-6859) 33%, defoamer 2%, titanium oxide (particle size 5-20 μm) 35%, deionized water 30%;

[0023] Above-mentioned coated latex is used for preparing foam composite paper:

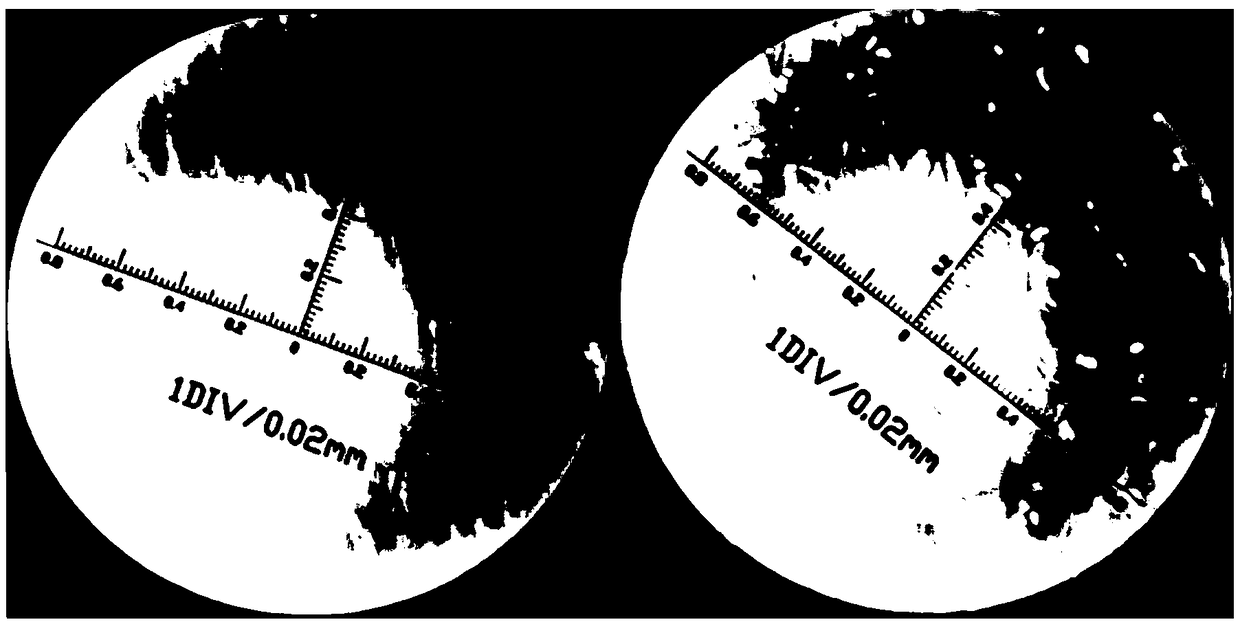

[0024] Its specific preparation method is: take foaming layer 3, food-grade packaging paper layer 2 and barrier layer 1 composition 40+250+20 grams / square meter of food-grade packaging laminating paper as the base material, and make 40 grams of the paper One layer of coatin...

Embodiment 2

[0026] like figure 1 and figure 2 As shown, it is a new type of foam composite paper, including the first barrier layer 1 composed of medium-density polyethylene MDPE, the second layer of food-grade packaging paper layer 2, and the third layer composed of low-density polyethylene LDPE The foam layer 3, the fourth layer is a coating layer 4 made of coated latex, and the coating layer 4 is coated on the outside of the third foam layer 3 by using a gravure printing process.

[0027] The specific preparation method is as follows: use 40+280+20 grams / square meter of food packaging coated paper composed of foaming layer 3, food-grade packaging paper layer 2 and barrier layer 1 as the base material, and foam 40 grams of the paper on the paper A coating layer is gravure printed on the layer, wherein the coating layer acrylate polymer (Henkel V-6859) 33%, defoamer 2%, titanium oxide (particle size 5-20 μm) 35%, deionized water 30% %, the printing speed is 100 m / min, the drying tempe...

Embodiment 3

[0029] like figure 1 and figure 2 As shown, it is a new type of foam composite paper, including the first barrier layer 1 composed of medium-density polyethylene MDPE, the second layer of food-grade packaging paper layer 2, and the third layer composed of low-density polyethylene LDPE The foam layer 3, the fourth layer is a coating layer 4 made of coated latex, and the coating layer 4 is coated on the outside of the third foam layer 3 by using a gravure printing process.

[0030] The specific preparation method is as follows: use 40+300+20 grams / square meter of food packaging coated paper composed of foaming layer 3, food-grade packaging paper layer 2 and barrier layer 1 as the substrate, and foam 40 grams of the paper on the paper. A coating layer is gravure printed on the layer, wherein the coating layer acrylate polymer (Henkel V-6859) 33%, defoamer 2%, titanium oxide (particle size 5-20 μm) 35%, deionized water 30% %, the printing speed is 100 m / min, the drying temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com