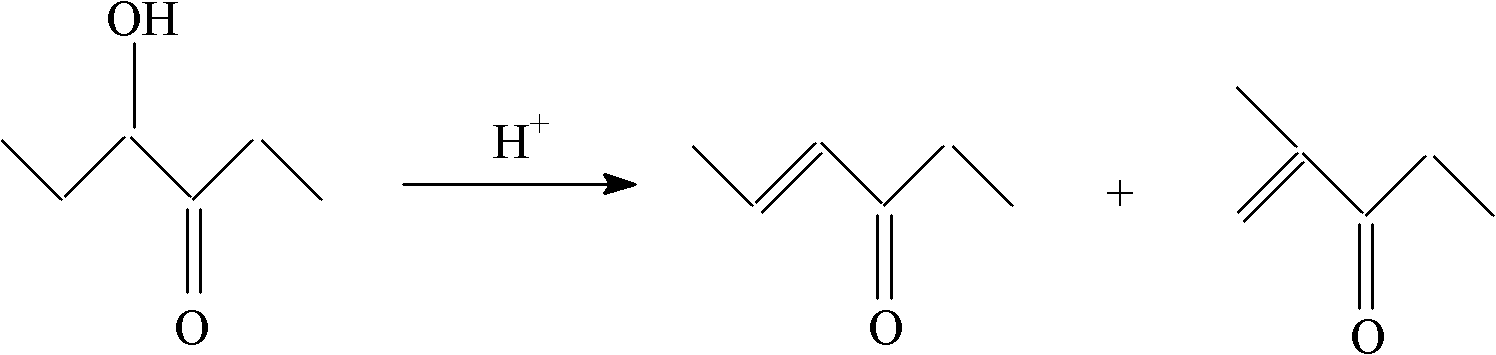

Method for preparing 4-hexene-3-ketone by catalytic dehydration of 4-hydroxyl-3-hexanone

A technology for catalytic dehydration and hexanone, which is applied to the preparation of carbon-based compounds, chemical instruments and methods, and the preparation of organic compounds. It can solve problems such as high reaction temperature, poor catalyst activity, and low space velocity, and achieve firm bonding and avoid Loss, long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

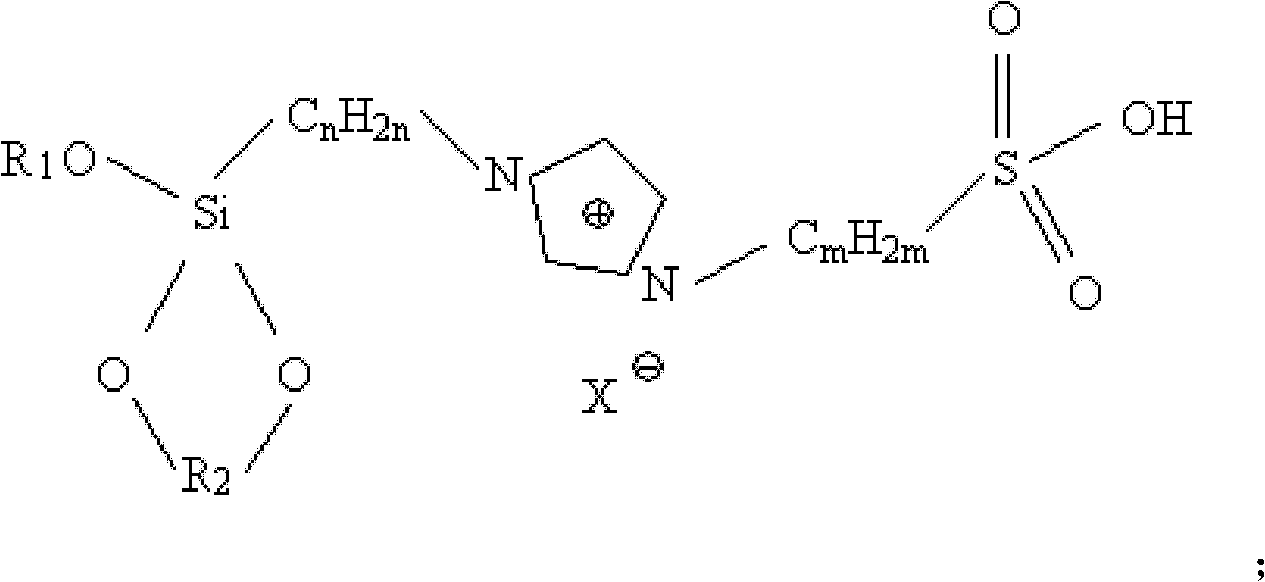

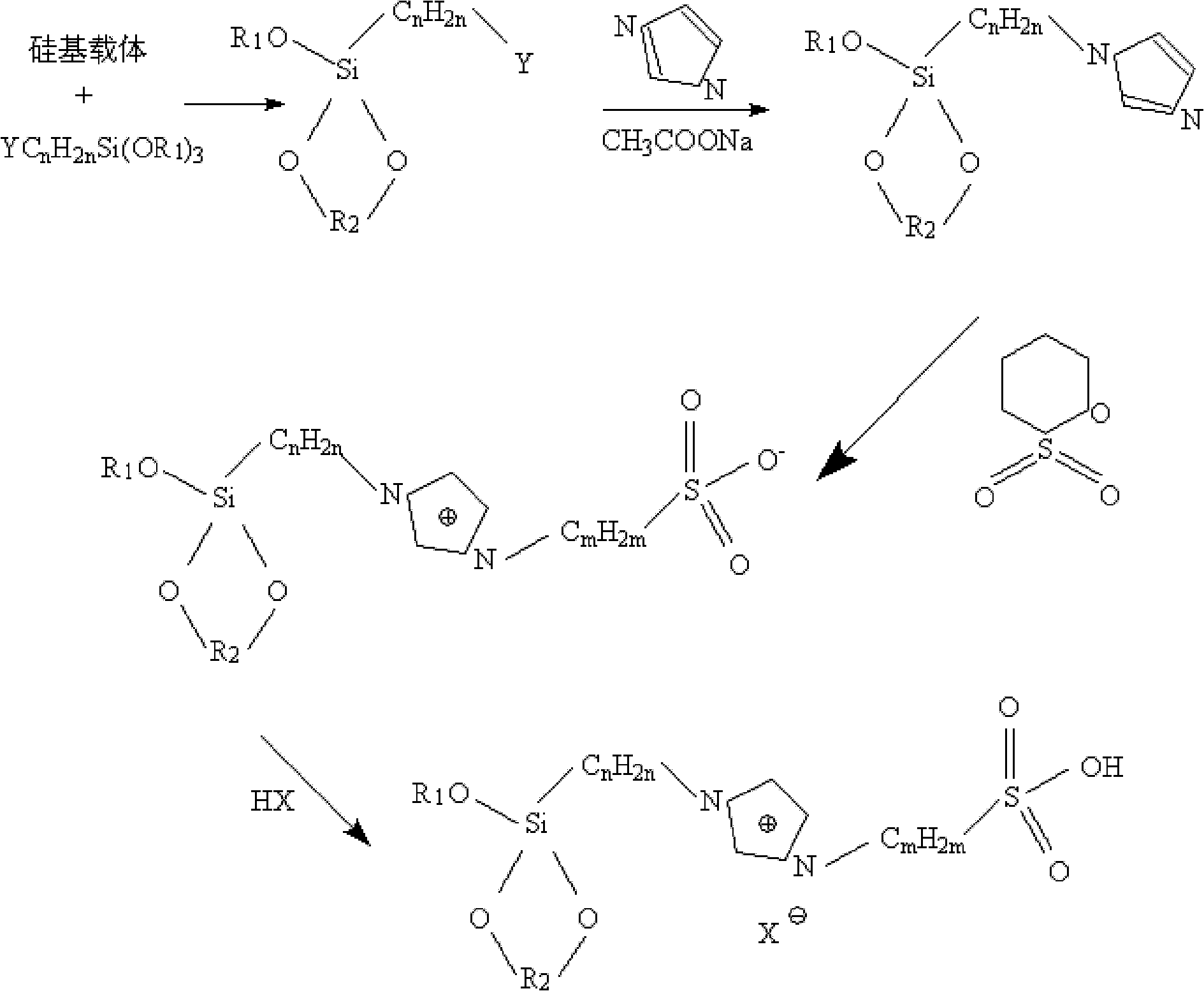

Embodiment 1

[0022] In the presence of toluene as an organic solvent, the silicon-based carrier SiO 2 with silylating reagent ClC 3 h 6 Si(OCH 3 ) 3 React at 80°C for 8 hours, filter, wash, and dry to obtain a silanized silicon-based carrier. Wherein, the weight ratio of the silylating agent to the silicon-based carrier is 2, and the weight ratio of the organic solvent to the silicon-based carrier is 5. In the presence of sodium ethoxide-ethanol saturated solution, the silanized silicon-based carrier was reacted with imidazole at 60° C. for 10 hours, filtered, washed and dried to obtain precursor I. The weight ratio of imidazole to silanized silicon-based support is 1 times. Precursor I was reacted with 1,4-butane sultone at 80°C for 5 hours, filtered, washed and dried to obtain Precursor II. The weight ratio of 1,4-butane sultone to precursor I was 7. Precursor II was reacted with sulfuric acid of the same amount at 50°C for 5 hours, filtered, washed, and dried to obtain catalyst A...

Embodiment 2

[0028] The performance evaluation of the catalyst was carried out on a fixed-bed reaction device under normal pressure. A stainless steel reactor with an inner diameter of 10 mm was used, and the loading amount of the catalyst was 10 ml, and the reaction was carried out under normal pressure. The reaction product was analyzed by HP 6890 gas chromatography, hydrogen flame detector, and HP-6 capillary column (60m×0.25mm×0.25μm). The experimental conditions and reaction results are shown in Table 1.

[0029] Table 1

[0030]

[0031] *: Contains isomers

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com